Page 1

OMNi

800

electronic

data

terminals

MAINTENANCE

MODEL

MANUAL

TEXAS

NO.

Revised 1 June 1978

INSTRUMENTS

INCORPORATED

MANUAL

810 PRINTER

994386-9701 Rev. B

FOR

Page 2

The

information

inventions

employing

exclusive

No

copies

Texas

Instruments

Copyright

and/or

disclosed

the

materials,

property

of

the

herein

of

Texas

information

Incorporated.

1978

All

Rights

drawings

and

methods,

Instruments

by Texas

Reserved -

patents

or

drawings

set

forth

techniques

r----------------------..

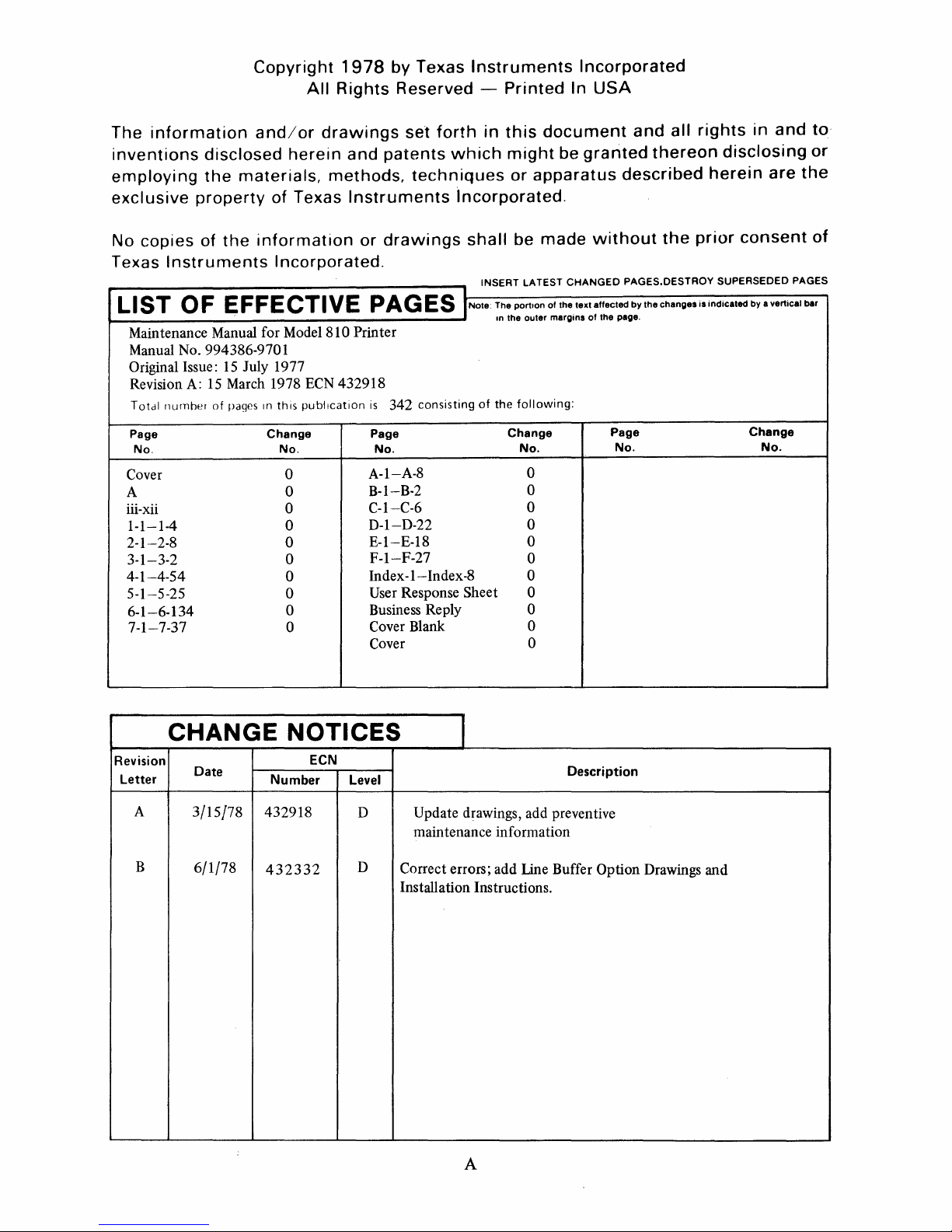

LIS T 0 F E F F E

Maintenance Manual for Model 810 Printer

Manual No. 994386-9701

Original Issue:

Revision

T

otdl

nurnher

A:

15

15

March 1978

of

pages

CT

July 1977

In

this

I V

EPA

ECN

432918

publication

G E S I Note: The portIon of the text affected

is

342

consisting

Instruments

Printed

in

this

document

which

might

or

apparatus

incorporated.

shall

be

made

INSERT LATEST

In the outer margins

of

the

following:

Incorporated

In

USA

and

be

granted

described

without

CHANGED

PAGES. DESTROY SUPERSEDED PAGES

by

of

the page.

all

thereon

the

the

changes

rights

in

and

disclosing

herein

prior

is

indicated by a vertical bar

are

consent

to

or

the

of

Page

No.

Cover

A

iii-xii

1-1-1-4

2-1--2-8 0

3-1-3-2

4-1-4-54

5-1-5-25 0

6-1-6-134

7-1-7-37

CHANGE

Revision

Letter

A

B

Date

3/15/78

6/1/78

Change

No.

0

0

0

0

0

0

0

0

NOTICES

ECN

Number

432918

432332

Page

No.

A-I-A-8

B-I-B-2

C-I-C-6

D-I-D-22

E-I-E-18

F-I-F-27

Index

-1-

Response Sheet 0

User

Business Reply

Cover

Blank

Cover

Level

D

D

Correct errors; add Line Buffer Option Drawings and

Installation Instructions.

Change

No.

0

0

0

0

0

0

Index·8 0

0

0

0

I

Description

Update drawings, add preventive

maintenance information

Page

No.

Change

No.

A

Page 3

This

manual

manufactured

provides operation, installation, 'and maintenance

by

Texas

sections:

Section I - describes

options

and

accessories.

Instruments

the

standard

PREFACE

Incorporated.

features

of

the

The

Model

information

manual

810

and

for

the

Model81 0 Printer

is organized into the following

lists specifications

and

available

Section II - presents installation instructions, including unpacking, interface cabling,

Section

Section

Section

Section

Section

preparation

III

- provides descriptions

help procedures, interface

IV - explains principles

V - describes maintenance, including troubleshooting, assembly removal

and

preventive maintenance.

VI - contains assembly drawings

VII - presents logic diagrams

and

testing.

of

the

control

information,

and

theory

and

and

electrical schematics.

panels

and

of

operation

and

indicators,

software commands.

of

the

associated parts lists.

operating

mechanism

instructions, self-

and

electronics.

and

replacement,

and

initial

iii

Page 4

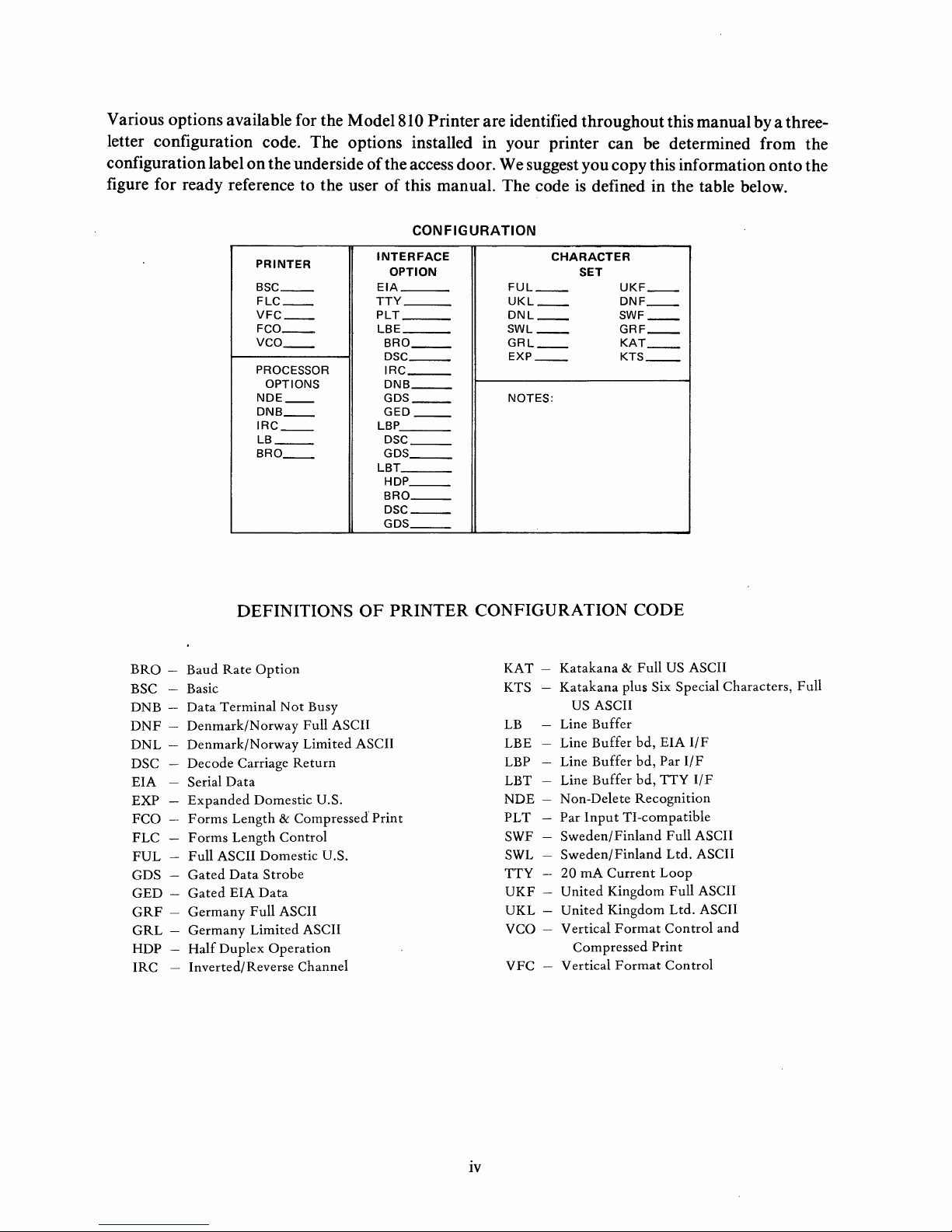

Various options available for the Model 810 Printer are identified throughout this manual by a threeletter configuration code. The options installed in your printer can be determined from the

on

configuration label

the underside

figure for ready reference to the user

PRINTER

__

BSC

FLC

__

VFC

__

FCO

__

VCO

__

PROCESSOR

OPTIONS

NDE

__

DNB

__

IRC

__

LB

__

BRO

__

of

the access door. We suggest you copy this information onto the

of

this manual. The code

is

defined in the table below.

CONFIGURATION

INTERFACE

OPTION

EIA

TTY

___

PLT

LBE

BRO

__

DSC

__

I

RC

___

DNB

__

GDS

__

GED

__

LBP

DSC

__

GDS

__

LBT

HDP

__

BRO

__

DSC

__

GDS

__

FUL

__

UKL

__

DNL

__

SWL

__

GRL

__

EXP

__

NOTES:

CHARACTER

SET

UKF

DNF

SWF

GRF

KAT

KTS

__

__

__

__

__

__

DEFINITIONS

BRa -Baud

-

BSC

DNB DNF -Denmark/Norway

DNL

DSC

EIA

EXP

FCO

FLC

FUL

GDS

GED

-

GRF

-

GRL

-

HDP

-

IRC

Rate

Option

Basic

Data

Terminal

Not

Denmark/Norway

Decode

Serial

Expanded

Forms

Forms

Full

Gated

Gated

Germany

Germany

Half

Carriage

Data

Domestic U.S.

Length & Compressed

Length

Control

ASCII Domestic U.S.

Data

Strobe

EIA

Data

Full

ASCII

Limited

Duplex

Operation

Inverted/Reverse Channel

Busy

Full ASCII

Limited

Return

ASCII

OF

PRINTER

ASCII

Print

CONFIGURATION

KAT KTS

LB

LBE

LBP

LBT

NDE PLT

SWF

SWL

TTY

UKF

UKL

VCO

VFC

Katakana & Full

Katakana

US ASCII

Buffer

Line

Buffer

Line

Line

Buffer

Line Buffer

Non-Delete

Par

Input

Sweden/Finland

Sweden/Finland

20

rnA

Current

United

United

Vertical

-

Kingdom

Kingdom

Format

Compressed

Vertical

-

Format

CODE

US

ASCII

plus Six Special Characters,

bd,

EIA

IfF

bd,

Par

l/F

bd,

TTY

I/F

Recognition

TI-compatible

Full

ASCII

Ltd.

ASCII

Loop

Full

ASCII

Ltd.

ASCII

Control

Print

Control

and

Full

iv

Page 5

TABLE OF CONTENTS

Paragraph Title

SECTION

1.1

1.2 Description

1.3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

............................................

Configuration

....

1.4 Modification Features

1.5

1.6

Optional Features

Accessories.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.

GENERAL

'.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.....................................

........................................

SECTION II. INSTALLATION

2.1

2.2 Space Requirements

2.3 Unpacking and Setting Up

Introduction

............................................

......................................

..................................

2.4 Cabling and Grounding Information

2.4.1 Serial Interface Cable

2.4.2 Parallel Interface Cable

2.4.3 TTY Interface Cable

2.5 Initial Preparation

2.5.1 Line Voltage Selection

2.5.2 Supplies Installation

2.5.3

Operational Checkout

....................................

...................................

.....................................

........................................

...................................

..................................

.................................

DESCRIPTION

............................

Page

..

1-1

1-3

..

1-3

1-3

1-4

..

1-4

2-1

2-1

2-1

2-2

2-3

2-5

2-5

2-6

2-6

2-7/2-8

2-7/2-8

SECTION III.

3.1

Introduction

3.2 Control Panel Controls and Indicators

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.2.6

3.2.7

Paper

Error

On

Out

Indicator

Line Switch and Indicator

Reset/Tab

Form

Align

Form

Align'"

Form

Feed/Set

3.2.8 Line Feed/ Line Feed Switch

OPERATION

AND

INTERFACE

............................................

..........................

Indicator

..............................

........................................

...............................

Switch

./Tab

......................................

/Tab

,Top

Set Switch

Clear Switch

of

Form

.............................

Switch

...........................

..........................

...............................

INFORMATION

'.......

3.2.9 Power Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Auxiliary Control Panel Controls and Indicators

3.3.1

Normal/Test/YFC

Switch (BSC,FLC,VFC,FCO,YCO)

3.3.2 Pencil Switches (BSC,FLC,YFC,FCO,YCO)

3.3.3 8

3.3.4

LPI

Form

Switch and Indicator (BSC,FLC,VFC)

Length

Rotary

Switch (FLC,FCO)

.....................

..............

.....................

.....................

.......................

..

3-1

3-2

3-2

3-2

3-2

3-3

3-3

3-3

3-3

3-3

3-3

3-3

3-5

3-5

3-5

3-5

v

Page 6

TABLE OF CONTENTS (Continued)

Paragraph

3.3.5

3.3.6

3.3.7

3.3.8

3.4

3.4.1

3.4.2

3.4.3

3.4.4

3.4.5

3.4.6

3.4.7

3.4.8

3.4.9

3.4.10

3.4.11

3.4.12

3.4.13

3.4.14

3.4.15

3.4.16

3.4.17

3.4.18

3.4.19

3.5

3.6

3.6.1

3.6.2

3.6.3

3.6.3.1

3.6.3.2

3.7

3.7.1

3.7.2

3.8

3.8.1

3.8.2

3.9

3.9.1

3.9.2

3.9.3

3.9.4

3.9.5 .

3.9.6

3.9.7

Title

VFC Switch (VFC,VCO)

Store/Recall

16.5

CPI/8

Switch (VFC,VCO)

LPI

Switch and Indicators (FCO,VCO)

Elapsed Time Indicator (Optional)

..................................

..............................

................

............................

Operating Procedures . . . . . . . . . . . . . ~ . . . . . . . . . . . . . . . . . . . . . .

Ribbon Installation (All Printers)

Paper

Loading (All Printers)

Turn-On Procedure ( All Printers)

Top

of

Form

Adjustment (All Printers)

Printhead Adjustment (All Printers)

Self-Test Diagnostic (All Printers)

Lines

Per

Inch Spacing (All Printers)

Characters

Baud Rate/ Parallel

Per

Inch Spacing (FCO, V CO)

Input

Selection (All Printers)

Parity Selection (All Printers)

Automatic Line Feed Override (All Printers)

............................

...............................

............................

.......................

..........................

.............

.........................

.....................

.................

..............................

....................

0 • • • • • • • • • • •

Automatic Perforation Skip Override (All Printers) . . . . . . . . . . . . . .

Vertical Tab Setting (All Printers)

Vertical Tab Clearing (All Printers)

Fixed Form Length Selection (FCO, FLC)

Programming

Storing Vertical

Recalling Vertical

Form

Format

Format

Length (FCO, FLC)

(VFC, VFO)

(VFC, VFO)

Turn-Off Procedure (All Printers)

Self-Help Procedures

Serial Interface

Baud Rate

..........................................

.....................................

........................................

...........................

..........................

.....................

......................

.........................

.......................

...........................

Signal Levels and Terminations . . . . . . . . . . . . . . . . . . . . . . . . . . .

Asynchronous

Timing

Parity

Parallel Interface (Optional)

Data

Format

...............................

...........................................

............................................

................................

Signal Levels and Terminations . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing

TTY Current Loop Interface (Optional)

.............................................

.........................

Signal Levels and Terminations . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing

Software (Remote Control)

Software Commands

Software

Software Horizontal

Software Line Width Setting

Software Vertical

Software Vertical

Software Vertical

..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.................................

..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Form

Length Setting

Tab

Setting

.............................

............................

..............................

Format

Format

Tab

Recall

Store

Setting

.........

-.

. . . . . . . . . . . . . . . .

............................

..

••

..

0 3-19

..

..

..

..

..

..

Page·

3-5

3-5

3-5

3-6

3-6

3-6

3-7

3-9

3-10

3-11

3-12

3-12

3-13

3-13

3-14

3-14

3-14

3-14

3-15

3-15

3-16

3-16

3-17

3-18

3-18

3-20

3-20

3-21

3-21

3-21

3-21

3-23

3-23

3-23

3-23

3-25

3-25

3-25

3-25

3-29

3-29

3-30

3-30

3-30

vi

Page 7

TABLE

OF

CONTENTS

(Continued)

Paragraph

4.1

4.2

4.2.1

4.2.1.1

4.2.1.2

4.2.1.3

4.2.1.4

4.2.1.5

4.2.2

4.2.3

4.2.4

4.2.4.1

4.2.4.2

4.2.5

4.2.6

4.2.7

4.3

4.3.1

4.3.2

4.3.2.1

4.3.2.2

4.3.2.3

4.3.2.4

4.3.2.5

4.3.3

4.3.3.1

4.3.3.2

4.3.3.3

4.3.4

4.3.4.1

4.3.4.2

4.3.4.3

4.3.4.4

4.3.4.5

4.3.4.6

4.3.4.7

4.3.4.8

4.3.5

4.3.5.1

4.3.5.2

4.3.5.3

Title

SECTION

General

Principles

Dot

...............................................

of

Operation

Matrix

Printhead

Printing Mechanism

Assembly

Carriage Drive

Paper

Ribbon

Dot

Electronic

Firmware

Printhead/

Printhead

Drive

.........................................

Drive

Matrix

Printing

Control

Program

Carriage Subsystem

Drive

Carriage Drive

Paper

Power

Fuses

Theory

Overview

Feed Subsystem

Supply

........................................

..............................................

of

Operation

...........................................

Processor Board

Microprocessor

Communications Interfaces

FIFO

Printhead

Software

Buffer

Carriage

..........................................

IV.

THEORY

OF

OPERATION

....................................

.............................

..................

.......................................

........................................

Mechanics

Subsystem

Overview

............................

...............................

...............................

..............................

......................................

.......................................

..................................

.....................................

......................................

System

................................

..............................

.......................................

Control

..............................

. . . . . . . . . . . . . . . .

Driver Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printhead

Carriage

Paper

Power

AC

+ 30 V de Supply

+5

V de Regulator

+8

SW

±12 Vdc

-75

Overvoltage Protection Circuit

Power

Current

Receiver Circuit

Transmitter Circuit

Auxiliary Parallel Interface

Driver Circuits

Motor

Feed

Supply

Power

Driver Circuit

Motor

Driver Circuits

........................................

Module

...................................

.....................................

....................................

...........................................

and

-5

Vdc Regulators

Vdc Supply

Good/Reset

Loop

Option

.....................................

...................................

Board

.....................................

....................................

...............................

............................

.........................

...........................

............................

...............................

'...............................

..

..

Page

4-1

4-1

4-1

4-2

4-2

4-3

4-4

4-4

4-6

4-8

4-8

4-9

4-9

4-11

4-12

4-14

4-14

4-14

4-16

4-16

4-18

4-18

4-18

4-22

4-29

4-29

4-32

4-36

4-42

4-43

4-44

4-44

4-47

4-48

4-49

4-49

4-50

4-52

4-52

4-53

4-53

vii

Page 8

TABLE

OF

CONTENTS (Continued)

Paragraph

5.1

General

SECTION

........................

Title

V.

MAINTENANCE

5.2 Preventive Maintenance 0 0 0 0 • 0 • 0 0 0 0 0 0 0

5.3

5.4 Removal and Replacement . 0 • 0 0

5.4.1

5.4.2 Battery (996351-0001)

5.4.3 AC

5.4.4 Motherboard

5.4.5

5.4.6

5.4.7

5.4.8

5.4.9 Ribbon Drive Assembly (994215)

5.4.10 Control Panel (994251)

5.4.11 Auxiliary Control

5.4.12 Carriage Drive

5.4.13 Wire Rope

5.4.14 Carriage and

5.4.15 Secondary Fuse 0

5.4.16 Power Line Fuse

5.5

5.5.1

5.6 Testing

Troubleshooting 0 0 0 0 0 0 0 • 0 0 0 0 0 0 0 • 0 • 0 • 0

••

0 • 0 • 0 0

Printed Circuit Boards 0 0 0 • 0

....

•• 0 •• 0 ••••

0 0 • 0 0 0 0 0 • 0 0 0 • 0

Power Module (994373-0001) Removal and Replacement

(994330-0001)

Fan

Assembly (996275)

Printhead (994258)

Paper

Paper

Drive

Motor

Tractor (996158-0001, 0002)

..........

Assembly (994183) 0

.............

..........

0"

0 0 0 0 0 • 0 0

0

o.

0"

•••••••

0 0 • 0

0

•••••••••••

•••

0 • 0 0

'0

Panel Assembly (994257) . 0 0

Motor

..

0 0 0 0 0

Paper

Assembly (994238)

•••

0

••••

0

••

0 • • • • • • • • • • • • • • • • • • • • •

Drive Assembly (994183)

•••••••••••

0

•• 0 •••••••••••

................................

Adjustments

Ribbon Guide

.......

............

...............

0

•••

0

••••••••

0

0

•••••

•••

0

0

••••

0

•• 0 ••••••••••••••

0 0 0 • 0 • 0

••

••

0

••

••••

• 0 0 • 0

0.'

......

•••••••

••

0 • 0 0 0 0 • 0

0 0 • 0 • 0

•••

0 • 0 • 0

0

•• 0 •••

0 • • • • • • • • • • • • • • • •

0 • 0

••••

0 • 0

••

0 0 0

0

••••••••••••

••

0

•••••

•••••

0

•••••••

0 0

•• 0 ••

0 0 0 0 0 0 0 0

•••••••••

0 0 • 0 0 • 0

••

0 • 0 • 0 0 • 0 0 0 0 • 0 0 5-14

0 • 0 • 0 • 0 0 • 0 • 0 0 0 0 • 0 5-15

••

0 • 0 • 0 0

0

••

0 • • • • • • • • •

0 • • • • • • • • • • • •

••

0 0 0 0

0 0 0 0 0 0 0 0

0 • 0 0 • 0 0 0 • o.

0

•• 0 ••

0

•••••••

••

••

0 0 0 0

0 • 0 • 0 0 0

..........

••

0 • • • • • •

0 • 0 0 0 0 0 • • •

••

0 0 0 • 0 5-10

0 • 0 0 0 0 0

••••

0 0 0 • 0 5-13

••

0 0 0 0 • 0 5-16

" • • • • • • • •

0 • 0

••

0 • • •

0

••

0 •

o.

o.

0

••

••

••

••

••

••

••

0 5-22

••

••

••

Page

5:-1

5-1

5-1

5-3

5-3

5-5

5-5

5-7

5-8

5-9

5-11

5-18

5-20

5-21

5-24

5-24

5-24

SECTION VI. ASSEMBLY DRAWINGS

SECTION VII. SCHEMATIC DIAGRAMS

APPENDIX

APPENDIX

APPENDIX

APPENDIX

APPENDIX

A.

CHARACTER

B.

ASCII CONTROL

C.

MODEL

OPTIONS,

D.

AND ACCESSORIES

TMS

E.

TMS

810

8080A

5501

AND

PRINTER

MICROPROCESSOR

I/O

APPENDIX F. INSTALLATION OF OPTIONAL KITS

ALPHABETICAL INDEX

viii

AND

LISTS OF MATERIAL

SET

DOT

MATRIX

CHARACTER

VERSIONS,

CONTROLLER

CODE

Page 9

LIST

OF

ILLUSTRATIONS

Figure

I-I Model 810

2-1

2-2

Printer Dimensions

Rear

2-3 Ground

2-4 Cable Options

2-5

3-1

3-2 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3

3-4

3-5

3-6 Asynchronous

3-7

4-1

4-2

4-3

4-4

4-5

4-6

Line Voltage Selection

Control Locations

Auxiliary Control Panels

Ribbon Installation

Paper

Parallel Interface Character Timing

Model 810 Printer Simplified Block Diagram

Model 810 Printer

Printing the Letter

Electronic Control Subsystem Block Diagram

Printhead/ Carriage Subsystem Block Diagram

Carriage

Printer

View

of

Jumper

Loading

Motor

........................................

........•..............................

Printer

Location

_..

.........•............................

...................................

. . . . . . . . . . • . . . . . . . . . • . . . . . . . . • . . . . . . . .

.....................................

........................................

...................................

.......................................

..........................................

Data

Format

Print

head Assembly

"E"

.....................................

Shaft Encoder Phase Relationship for

Left-to-Right Carriage Motion

4-7 Carriage Velocity Profiles Print Mode

4-8

4-9

4-10 Model 810 Printer Simplified Electronics Block Diagram

4-11

4-12

4-13

4-14 Carriage Speed Control Counter Timing Diagram

4-15

4-

16

4-17

4-18

4-19

4-20 Printhead Carriage State Diagram

4-21

4-22 Printhead Solenoid Current Pulse Profile

4-23

4-24

Paper

Drive System Block Diagram

Model 810 Printer Power Supply Block Diagram

Processor

FIFO

Carriage

Forming the Character

PC

Board, Detailed Block Diagram

Memory Write Cycle, Timing Diagram

Motor

Shaft Encoder State Diagram

"W"

Printhead Solenoid Timing Diagram

Normal

Printer Subroutine

Test Mode Flow

Print

Mode Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EI00

Accept States State Diagram

Chart

....................................

Driver Board Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printhead Power Driver Simplified Schematic

Printhead Carriage Driver Simplified Schematic

Title

................................

...........................

......................

..........................

......................

...........

.....•.......................

..........................

...........................

..................

....................

.....................

....................

..................

................................

...........................

..........

:.................

........................

..............

...................

~

.............

...............

. . . . . . .

. . . . .

..

..

..

..

..

..

Page

I-I

2-1

2-2

2-3

2-4

2-5

3-1

3-2

3-4

3-6

3-8

3-21

3-24

4-2

4-3

4-5

4-7

4-9

4-10

4-11

4-12

4-13

4-15

4-17

4-19

4-20

4-21

4-22

4-23

4-24

4-26

4-27

4-27

4-30

4-31

4-32

4-33

ix

Page 10

LIST OF ILLUSTRATIONS (Concluded)

Figure Title Page

4-25 Printhead Carriage Driver Circuit Forward Command

4-26

4-27

4-28

4-29

4-30

4-31

4~32

4-33 Power Supply Functional Block Diagram

4-34

4-35

4-36

4-37

4-38 ±12

4-39

4-40 Overvoltage Protection Circuit 0 0

4-41 Powergood/ Reset Signal Profiles 0

Print

head Carriage

Variable Reluctance,

Stepper

St~pper

Stepper

Paper

Stepper

Motor

Motor

Motor

Feed Stepper

Motor

Motor

Current Waveforms

Paper

Drive Circuit Simplified Diagram

Drive Circuit, Phase A 0 0 0 • 0 • 0

Circuit Waveforms

Motor

Line Feed Cycle . 0 0 0 0 0 0 0 • 0 0 0

Power Transformer Primary

30 Vdc Supply

+5

Vdc Regulator

+8

SW Line

Vdc and

-75

Vdc Supply . 0 0 • 0 • 0 • 0 • 0 0

o.

0 0 • 0

...

..

0 0

•• 0 ••

-5

Vdc Regulators

•••

0 0 0 • 0 0 0 0 • 0 0 • 0 0 0 • 0 0 0 0 • 0 0 0 0 • 0 0 0 0

.................

Feed Stepper

Motor

. 0 •

.....

••••

...

0

•••

0 0 • 0 ~ •••••••••••

Currents

Tap

0 0 0 0

0 • 0 0 0 0 0 • 0 • 0 0 0 0 0 0 • 0

................

••

o.

0 • 0 0 0 • 0 0

Arrangements 0 0 • 0 • 0 0 • 0 0

••

..

0

••

••

•••

•••

0 0 0 0 0

00

0 0 0 0 • 0

0 0

••

0 0 • 0 0 0 0 • 0

0 0 0 0 • 0 • 0 • 0 • 0 0 0

••

0 0 0 0 0 0 • 0 0 0 0

...

0 • 0 • 0 • 0 • 0 0 0

0

••

0 • 0 0 0 0

4-42 Powergood/ Reset Circuit Block Diagram 0 0 • 0 0 0 • 0

5-1

5-2 Electronics Cover Removal

5-3

5-4

5-5 Motherboard

5-6

5-7

5-8

Lubrication Points

...............

0

•••

0 0 • 0 • • • • • • • • • • • • • • • • •

................

Battery Replacement . 0 • 0

AC Power Module 0

....

Fan, Card Guide

0

and

Bracket 0 0

•• 0 •••••

••••••

•••

0 • 0

0 0

••••••

0 0

••••

0 0 0 0 0 0 0

•••

0

••

0 0

•••

0 • 0 • 0 0

0

•• 0 •••

•••

0 0

•• 0 •••

0 • 0 0

0 0

Printhead Being Removed 0 • • 0 0 • • • 0 0 0 • • • 0 • 0 0 • • 0 • • • • • 0 0 • • • 0 •

Paper

Drive

Motor

with Gear, Connector and Shaft

Removed . 0 • 0 • 0 • • • 0 • 0 0 0 0 • • 0 0 • 0 • 0 • 0 0 0 0 0 0 0 0 0 0 0 0 0 • 0 • • 0 0 5-10

5-9 Left

5-10

5-11

5-12

5-13 Control Panel Assembly 0

5-14

5-15

5-16 Idler Pulley 0 0 0 0 0 0 0 0 0 0 0 0 • 0

5-17

5-18

5-19 Paper-Out Switch 0 0

5-20 Secondary Fuse Area 0 0 0 • 0 0

5-21

5-22

Paper

Paper

Ribbon Drive Assembly 0 0 0 0 0 0 0

Ribbon Drive Assembly Removal

Auxiliary Control Panel 0

Carriage Drive

Wire Rope Detail

Carriage

Power Plug

Advance Bearing 0 0 0 0

Tractors Removal 0 0 0 0 • 0 0

•••••

•••

0

•••

Motor

and

Paper Drive Assembly 0 0 0

at

Rear

. 0

•••••

o.

00

• • 0 0 • • 0 • 0 0 0 0 • • 0 0 • 0 0 0 0 0 • • 0 0 0 0 0 0 0 • 0 • 0 5-19

••

0 0 • 0

•• 0 ••

••••••

of

Printer . 0 0 0 0 0 0 • 0 0 0

•••

0 • 0 0 0 0 • 0 0 • 0 0 0 0 0 0 0 0 0 0 0 0 0 • 0 5-12

••

0

•••

0 • 0 0 0 0 • 0 0 0 0 0

•••

0 0 • 0 0 0 0 0 0 • 0

o.

0

••

0 • 0 • 0 0 0

0 • 0

••

0 0 • 0 • 0

0 • 0 0 0

0

••

0 0 0 0 0 • 0 0 0 0

•••

0 0 0 • 0 • 0 0 0 0

••

0 0 0 0 0 • 0 0 0 0 0 0 0 0 0 0

0 0 • 0 0 0 0 • 0 0 • 0 0 0 0

••

••••••

0 0 • 0 0 0 0 0 0 0 0 0 0 • 0 0

•• 0 ••••

Test Barber Pole Printout 0 0 0 0 0 0 • 0 0 • 0 0 0 0 0 0 0 • 0 0 0

...............

00

0 ;

.• ' •••

0

•••

" • 0 0

0 0 0 • 0

••

••

•••

0 • 0

•••••

•• 0 ••••••

0 0

0 0 0

••

••••

•••

0

••••••••

••

0,

0

••••

•• 0 .....

0'0

•••••

•••••••

••

0 0 • 0 • 0 • 0 • 0 • 0

0 • 0

•••

•••••••

••••••••

•• 0 ••

•••

0 0

0

••

••

•• 0 ••

•••

0 • 0 • 0 • 0 • •

•••

0 • 0 • • • • •

0 0 • 0 0 • 0 • 0 0 0 0

0 0 0 ~ 0 0 0 0 0 •

••

•••

0

•••

••

0 0 0 0

4-34

0

••

4-35

0 •

oC

0 0 •

••

4-36

0 0

••

0 • 0 0 0 4-39

0 • • • •

0 • 0 • 0 0 0 • 0 4-44

0 0

••••

0 • 0 0 0

••

0 • 0 • 0 0 0

0 • 0 0 0 • 0

•••

".

•••

0 0

0 • 0

• •

••

4-40

••

4-41

0 0 4-43

0 0 4-45

••

0 4-46

0

••

4-46

0 • 0 4-47

••

4-48

0

••

4-48

••

4-49

••

4-50

••

4-51

4-51

5-1

0

•••••••

0

•••

0 • 0 • 0 0

•• 0 ••••

0 • 0 0 • 0

0 • 0 0 0 0 • 0 5-12

0 0 0 • 0 • 0

0 0 • 0 • 0

••••

0 0 0 0 0 0

0 • 0 • 0 0 0 5-22

0 • 0 • 0 •

•••••

0

•••

o.

o.

••

••

o.

o.

o.

o.

o.

o.

0 5-5

••

••

••

5-4

5-6

5-7

5-8

5-9

5-13

5-14

5-15

5-16

5-17

5-18

5-20

5-21

5-23

5-25

6-1

Model 810 Printer Major Assemblies

.•...

x

0 0 0

-.

0 0 0 0 0

••

0 0 0 0

••

0 0 0 0 • 0

6-3

Page 11

LIST OF TABLES

Table

I-I

Standard

Features

and

3-1 Self-Help Procedures

3-2 Software

3-3

4-1

4-2

Column

Printhead

Carriage

Commands

or

Line

'~n"

Subroutine

State

Maximum

(Microseconds)

4-3

5-1

5-2

C-l

C-2

C-3

C-4

Carriage

Failure Analysis

Option

List

Printer

Printer

Printer

Motion

Reference Speeds

Chart

PROM Part

of

Designations

Versions

Number

.......................................

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories

Title

Specifications 1-2

.....................................

......................................

Number

EI00

Conversion

Accept States

.........................

......................

Software Execution Times

.......................................

...........................

...................................

and Location

......................

. . . . . . . . . . . . . . . . . . . . . . . .

.

.............

.....................................

.

.

.

.

.

.

.

Page

3-19

3-26

3-28

4-25

4-28

4-28

5-2

5-26

C-I

C-2

C-3

C-5

xi/xii

Page 12

Page 13

SECTION I

1.1

INTRODUCTION

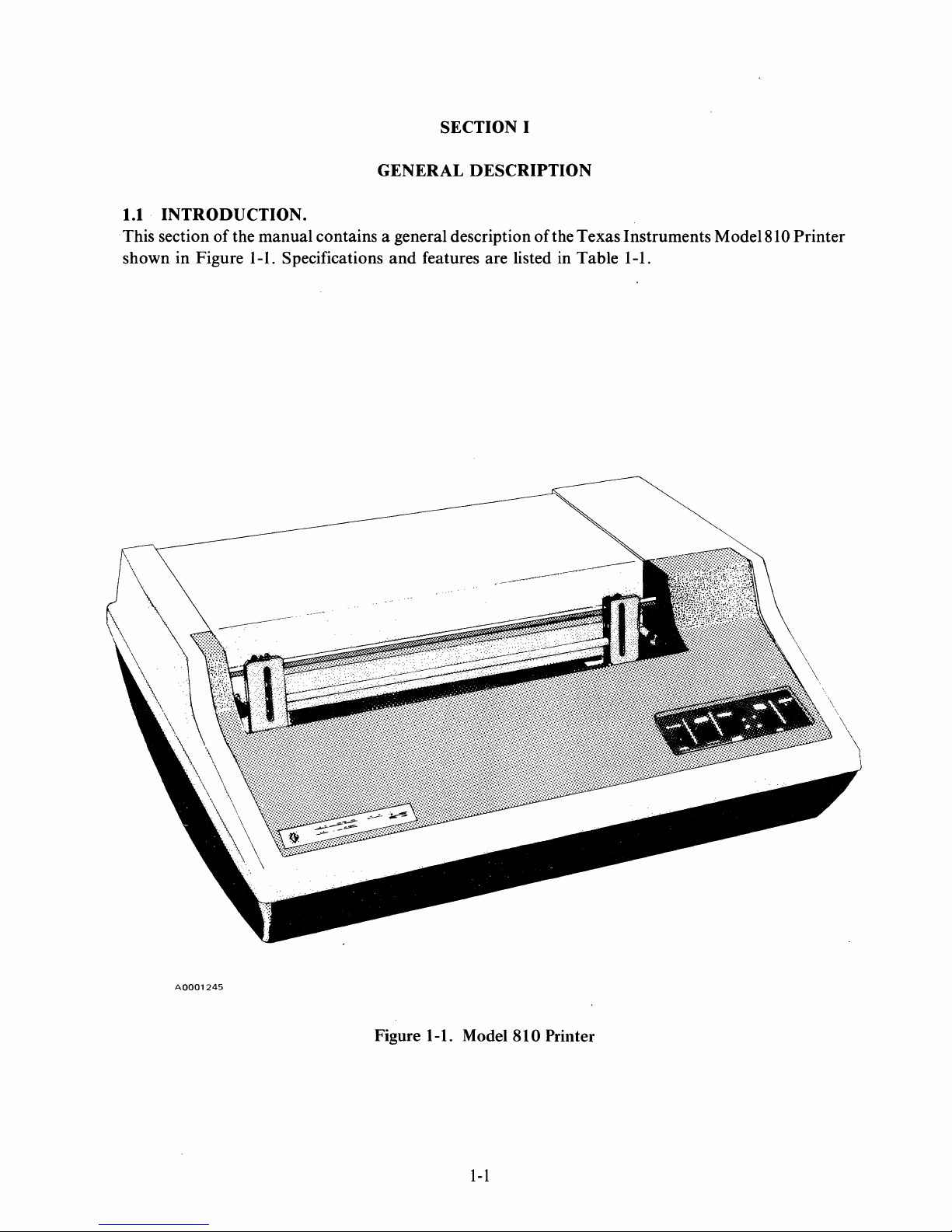

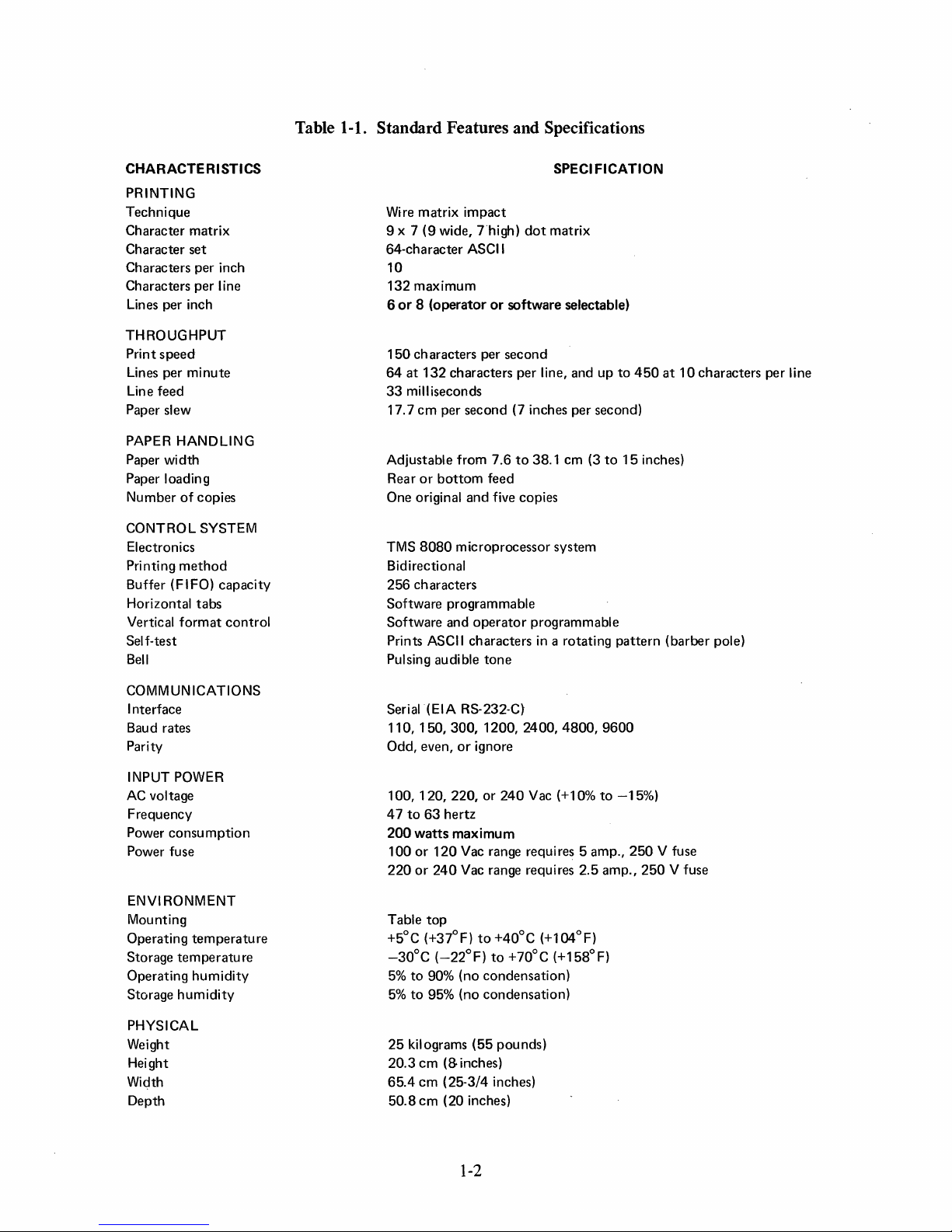

. This section

of

shown in Figure

GENERAL

DESCRIPTION

.

the manual contains a general description

1-1.

Specifications and features are listed in Table 1-1.

of

the Texas Instruments Model81 0 Printer

A0001245

Figure 1-1. Model

1-1

810

Printer

Page 14

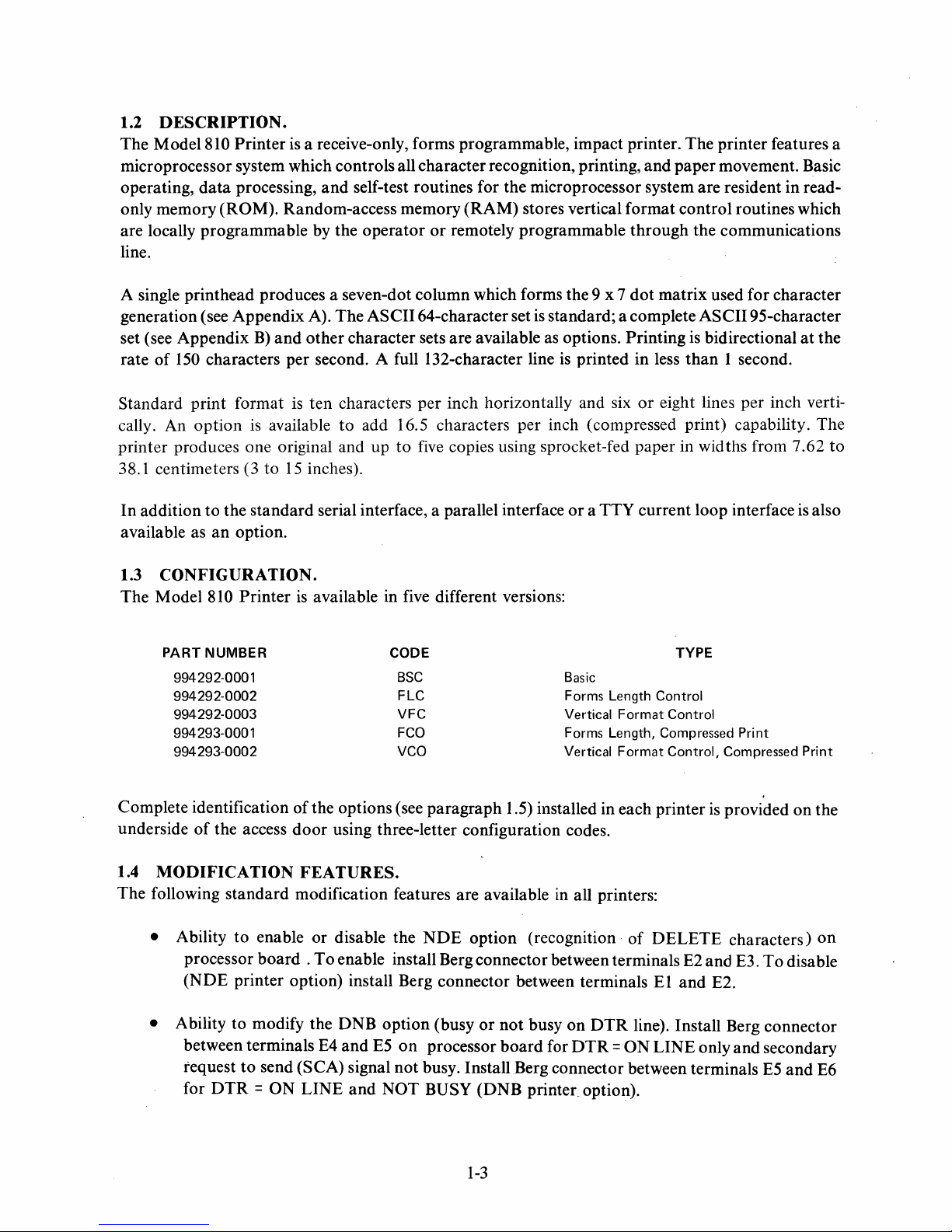

Table 1-1. Standard Features and Specifications

CHARACTERISTICS

PRINTING

Technique

Character matrix

Character set

Characters per inch

Characters per line

Lines per inch

THROUGHPUT

Print

speed

Lines per

Line feed

Paper slew

PAPER HANDLING

Paper width

Paper loading

Number

CONTROL SYSTEM

Electronics

Printing

Buffer (FIFO) capacity

Horizontal

Vertical

Self-test

Bell

minute

of

copies

method

tabs

format

control

SPECI

FICATION

Wire matrix

9 x 7

64-character ASCII

10

132

maximum

6

or 8 (operator

150

characters per

64

at

33

milliseconds

17.7

Adjustable from 7.6

Rear

One original

TMS

Bidirectional

256 characters

Software programmable

Software and

Prints ASCII characters in a rotating

Pulsing audible

impact

(9

wide,

Thigh)

132

characters per line, and up

cm

per second (7 inches per second)

or

bottom

and

8080

microprocessor system

operator

dot

matrix

or

software selectable)

second

to

38.1 cm (3

feed

five copies

programmable

tone

to

to

15

pattern

450

at

inches)

(barber pole)

10

characters per

Hne

COMMUNICATIONS

Interface

Baud rates

Parity

INPUT POWER

AC

voltage

Frequency

Power

consumption

Power fuse

ENVI RONMENT

Mounting

Operating

Storage

Operating

Storage

PHYSICAL

Weight

Height

Width

Depth

temperature

tem

peratu

humidity

humidity

re

Serial (EIA R5-232-C)

110,150,300,1200,2400,4800,9600

Odd, even,

100,120,220,

47

to

200

100

220

Table

+5°C (+37°F)

-30°C

5%

to

5%

to

25

kilograms

20.3

65.4

50.8

or

ignore

or

240

Vac (+10%

63

hertz

watts

maximum

or

120

Vac range requ ires 5 amp.,

or

240

Vac range requires 2.5 amp.,

top

to

+40°C

(-22°F)

90% (no condensation)

95% (no condensation)

cm

(8

cm

(25-3/4 inches)

cm

(20 inches)

to

(55

inches)

+70°C (+158°F)

pounds)

(+l04°F)

to

-15%)

250

250

V fuse

V fuse

1-2

Page 15

1.2

DESCRIPTION.

The Model 810 Printer

is

a receive-only, forms programmable, impact printer. The printer features a

microprocessor system which controls all character recognition, printing, and paper movement. Basic

operating,

data

processing,

and

self-test routines for the microprocessor system are resident in read-

only memory (ROM). Random-access memory (RAM) stores vertical format control routines which

or

are locally programmable by the operator

remotely programmable through the communications

line.

dot

A single printhead produces a seven-dot column which forms the 9 x 7

A).

generation (see Appendix

B)

set (see Appendix

of

150

rate

characters per second. A full 132-character line

and

Standard print format

is

cally. An option

available

printer produces one original and up

38.1 centimeters (3 to

In

addition to the standard serial interface, a parallel interface

available as

an

option.

15

The ASCII 64-character set

other character sets are available

is

ten characters per inch horizontally and six

to

add 16.5 characters per inch (compressed print) capability. The

to

five

copies using sprocket-fed paper in widths from 7.62

inches).

is

standard; a complete ASCII 95-character

as

options. Printing

is

printed in less

or

a TTY current loop interface

matrix used for character

is

bidirectional

than

1 second.

or

eight lines per inch verti-

at

is

the

to

also

1.3

CONFIGURATION.

The Model 810 Printer

PART NUMBER CODE TYPE

994292-0001

994292-0002

994292-0003

994293-0001

994293-0002

Complete identification

underside

1.4

of

the access

MODIFICATION

The following standard modification features are available

• Ability to enable or disable the

processor board .

(NDE

printer option) install Berg connector between terminals

• Ability to modify the DNB option (busy

between terminals E4 and

request

for

to

DTR = ON

is

available in five different versions:

BSC

FLC

VFC

FCO

VCO Vertical

of

the options (see paragraph 1.5) installed in each printer

door

using three-letter configuration codes.

Basic

Forms

Vertical

Forms

Length

Length,

FEATURES.

in

all printers:

NDE

option (recognition

To

enable install Berg connector between terminals E2 and E3.

or

not

busy

on

DTR

E5

on

processor

board

for

DTR = ON

send (SCA) signal not busy. Install Berg connector between terminals

LINE

and

NOT BUSY (DNB printec option).

Control

Format

Format

Compressed

of

DELETE

El

Control

Control,

is

and

Print

Compressed

provided on the

characters)

To

disable

E2.

line). Install Berg connector

LINE only and secondary

E5

and

Print

on

E6

1-3

Page 16

• Ability

tween terminals E8 and E9 (on processor board

to

modify the IRC option (reverse channel signal). Connect Berg connector be-

-0002 only) for asserted signal HIGH

(standard). Connect Berg connector between terminals E7 and E8 for asserted signal

(lRC printer).

. • Bell option. Disconnect R99 connection on Power Supply board

1.5 OPTIONAL FEATURES.

The following features (identified

by

configuration code in parentheses) are offered as options:

Full ASCII 95-character set (FUL)

to

disable bell.

LOW

European (DNF, DNL,

Texas Instruments-compatible

TTY

20-mA neutral current loop (TTY)

Selectable forms lengths

SWF,

(FCO

SWL,

UKF, or UKL) and

(PL T)

or

FLC)

Vertical Format Control, non-volatile eight-channel memory

(FCO

Compressed print 16.5 characters per inch

or

Elapsed Time Indicator

Line Buffer

Option Kit (See Appendix F for installation instructions).

1.6 ACCESSORIES.

The following items are available

as

accessories:

Paper Basket

other

VCO)

character sets

(VCO

or

VFC)

Floor Mounting Stand

Interface Cable (See cabling information in Section II for selection

1-4

of

cables.)

Page 17

SECTION

INSTALLATION

2.1

INTRODUCTION.

This section provides information for selecting the installation site, unpacking

printer,

2.2

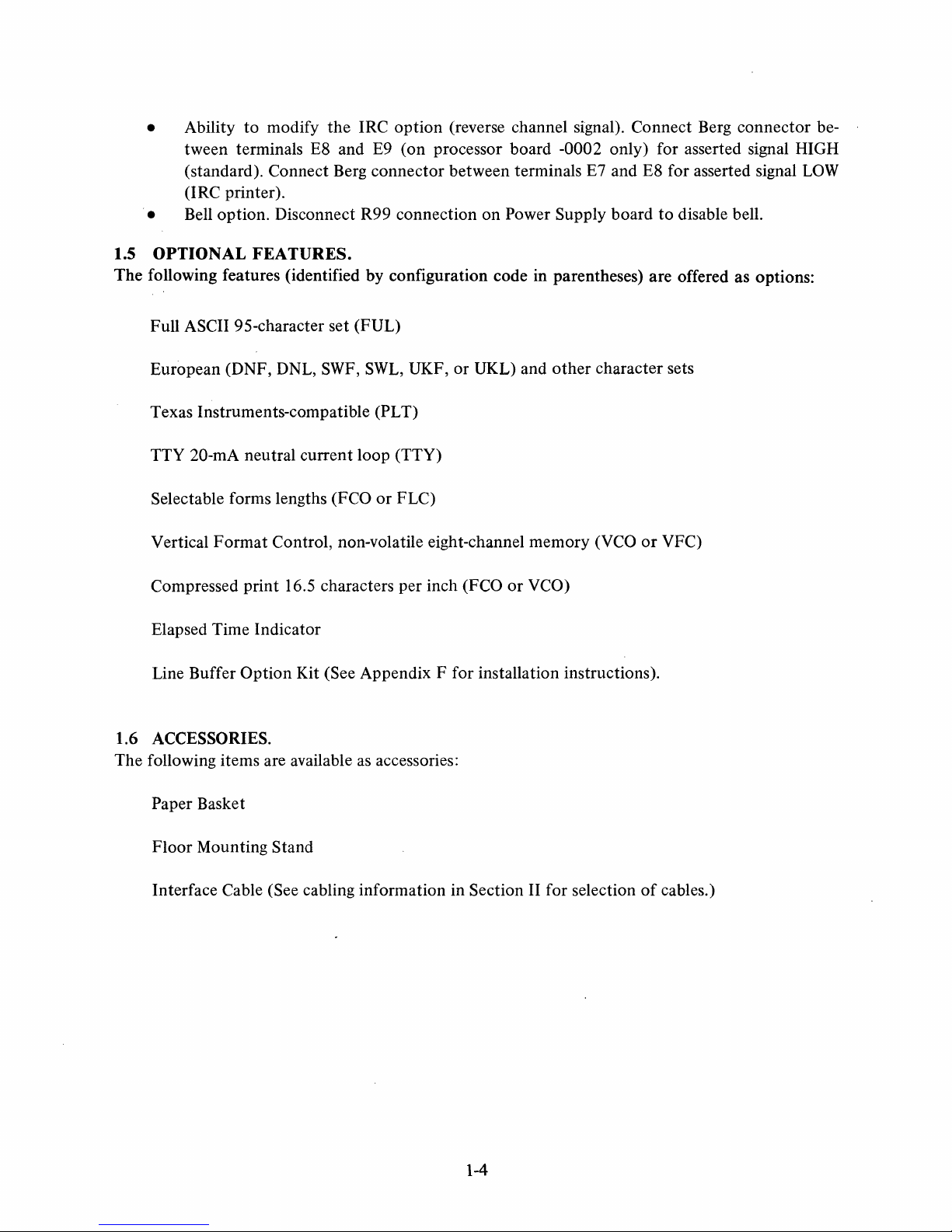

The printer occupies a flat surface area 65.4 centimeters (25.75 inches) wide by 58.4 centimeters (23

inches) deep including cable clearance of7.6 centimeters

dimensions. Space must be provided for adequate ventilation. Particular care must be taken to

prevent blocking the cooling fan intake and exhaust louvers

unobstructed paper feed

method

not used. The printer should be so located as

should not be placed in

Section I may be exceeded. A sturdy table capable

is

care must be taken

the printer

and

ensuring

SPACE

suitable if the optional floor mounting stands are

REQUIREMENTS.

of

holding the printed output must also be provided if the optional paper basket accessory

and

is

that

the printer

path

must be provided behind

an

environment where humidity, temperature,

to

ensure

not

that

subjected to any pressure which could deform it.

is

operating properly.

to

allow easy access

the paper chute underneath the printer does

II

(3

inches) . See Figure

(on

either side

or

below the printer for the paper supply. A

to

the

of

adequately supporting

not

used. Regardless

and

setting up the

2-1

for printer outline

of

the printer).

operator

or

other specifications listed in

controls. The printer

25

kilograms

of

the mounting selected,

not

bear any weight

(55

pounds)

An

is

of

I

~

65.4

(253/4

A0001246

UNPACKING

2.3

To

remove the printer from its 'shipping carton and place the printer in its normal operating location,

perform the following procedure.

I.

Examine shipping carton for apparent damage.

damage and follow local procedure for handling damaged shipments.

2.

Place shipping carton on floor and open top

3.

Remove loose items from shipping carton.

AND

CM

IN)

Figure 2-1. Printer Dimensions

SETTING

I

I I

UP.

\ J

u-

Z

M -

ci 00

N-

1

)

of

~

______

If

any damage

shipping carton.

50.8

CM

--------I.-t

(20

IN)

is

observed, note nature

of

2-1

Page 18

4. Using

printer

5. Remove styrofoam end caps.

an

assistant, grip printer close

from

shipping carton,

and

to

place

styrofoam end caps

.printer

on

table

or

(at

either end

of

printer), lift

optional floor mounting stand.

6. Remove two mechanism shipping snubbers

7.

Open

access door, remove styrofoam block covering printhead,

wrapped

8. Slide

freely

around

printhead

and

that

printhead.

from stop

wire rope is

to

not

stop

unstrung.

9. Close access door.

10.

(If

applicable) Install optional

AND

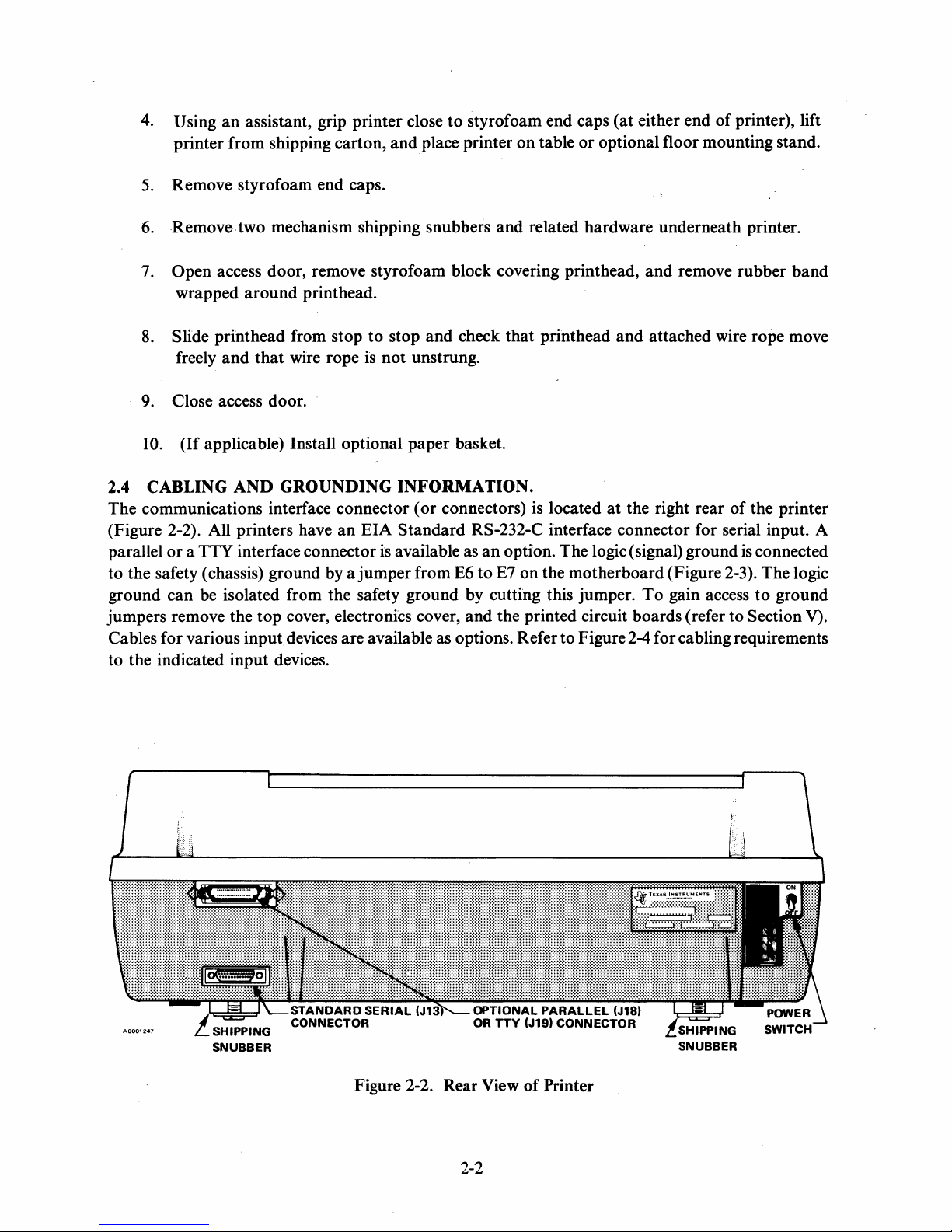

2.4 CABLING

The

communications interface connector

GROUNDING

(Figure 2-2). All printers have

parallel

to

ground

jumpers remove the

Cables for various

to the indicated

or a TTY

interface connector is available as

the safety (chassis) ground by a

can

be isolated from the safety

top

cover, electronics cover,

input

devices are available as options. Refer

input

devices.

an

EIA

jumper

paper

INFORMATION.

(or

Standard

from

ground

and

related hardware underneath printer.

and

remove

and

check

that

printhead

and

attached wire rope move

basket.

connectors) is located

at

the right rear

RS-232-C interface connector for serial input. A

an

option.

E6

to

E7

by cutting this jumper.

and

the printed circuit boards (refer

on

The

logic (signal) ground

the

motherboard

to

Figure 2-4 for cabling requirements

(Figure 2-3).

To

gain access

rubber

of

the printer

is

connected

The

to

ground

to

Section V).

band

logic

SNUBBER

Figure 2-2. Rear View

2-2

of

Printer

SNUBBER

Page 19

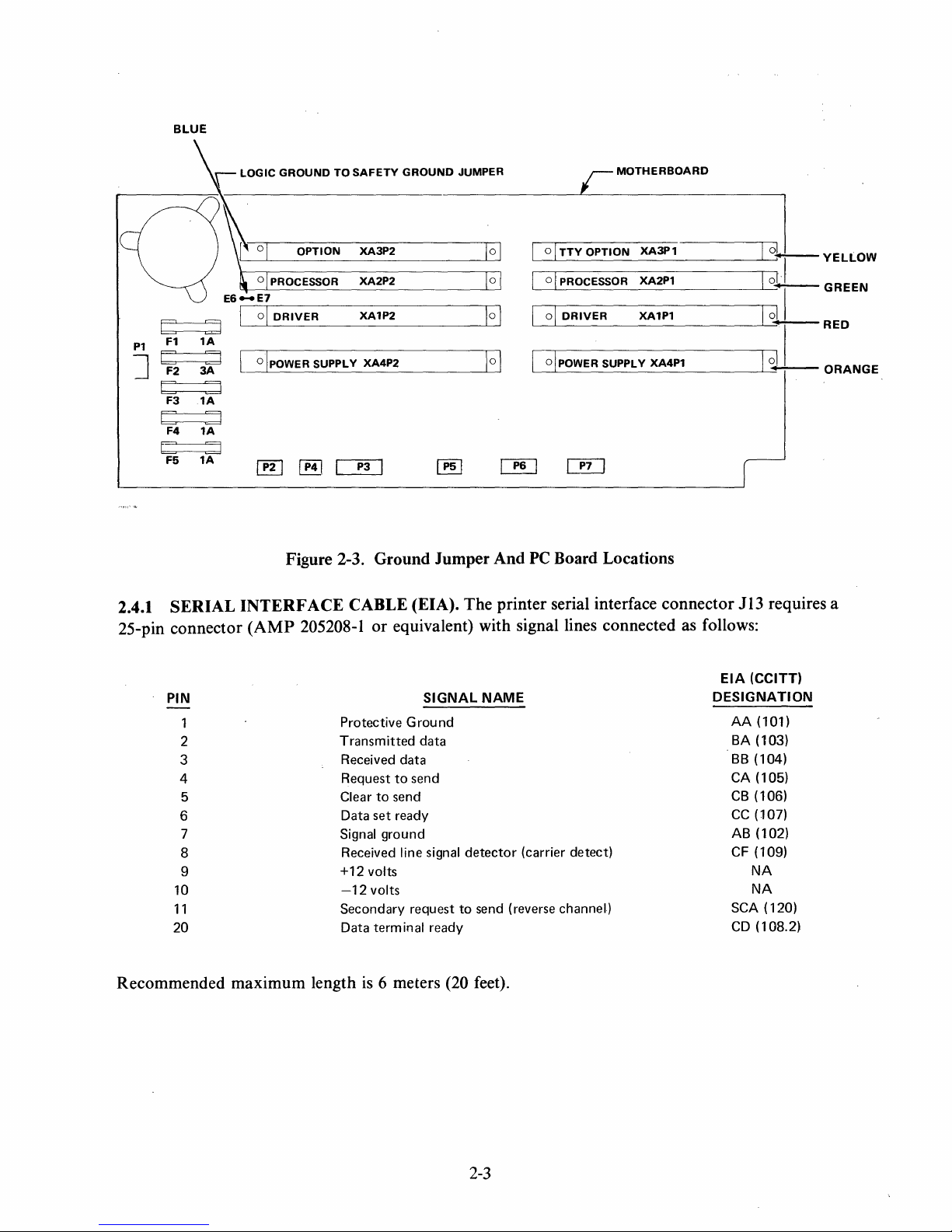

BLUE

r

LOGIC

GROUND

TO

SAFETY

GROUND

JUMPER

r=

MOTHERBOARD

b

d

1A

F1

P1

E

]

2.4.1

d

3A

F2

E

d

F3

1A

E d

F4

1A

b

d

1A

F5

SERIAL

25-pin connector

PIN

1

2

3

4

5

6

7 Signal

8

9

10

11

20

OPTION

o PROCESSOR

OjPOWER SUPPLY

[

[!!J

~

XA3P2

XA2P2

XA1P2

XA4P2

~

Figure 2-3. Ground Jumper And

INTERFACE

(AMP

205208-1 or equivalent) with signal lines connected as follows:

CABLE (EIA). The printer serial interface connector

SIGNAL

Protective Grou nd

Transmitted

Received

Request

Clear

Data

set

Received

+12

votts

-12

volts

Secondary

Data terminal ready

data

to

to

send

ready

ground

line signal

data

send

request

101

0

10 I

\01

[![]

~

NAME

detector

to

(carrier detect)

send (reverse channel)

0ITTY

.-----.---------rl---,0t-

OPTION

o I PROCESSOR

01

DRIVER

XA3P1

XA2P1

XA1P1

YELlOW

loT-GREEN

=========================I==~RED

~------------------~I---,~I

[ 0 \ POWER SUPPLY XA4P1

Q[J

PC

Board Locations

Jl3

requires a

ElA

(CCITT)

DESIGNATION

AA

(101)

BA

(103)

BB

(104)

CA (105)

CB

(106)

CC

(107)

AB

(102)

CF (109)

NA

NA

SCA (120)

CD

(108.2)

ORANGE

Recommended maximum length

is

6 meters (20 feet).

2-3

Page 20

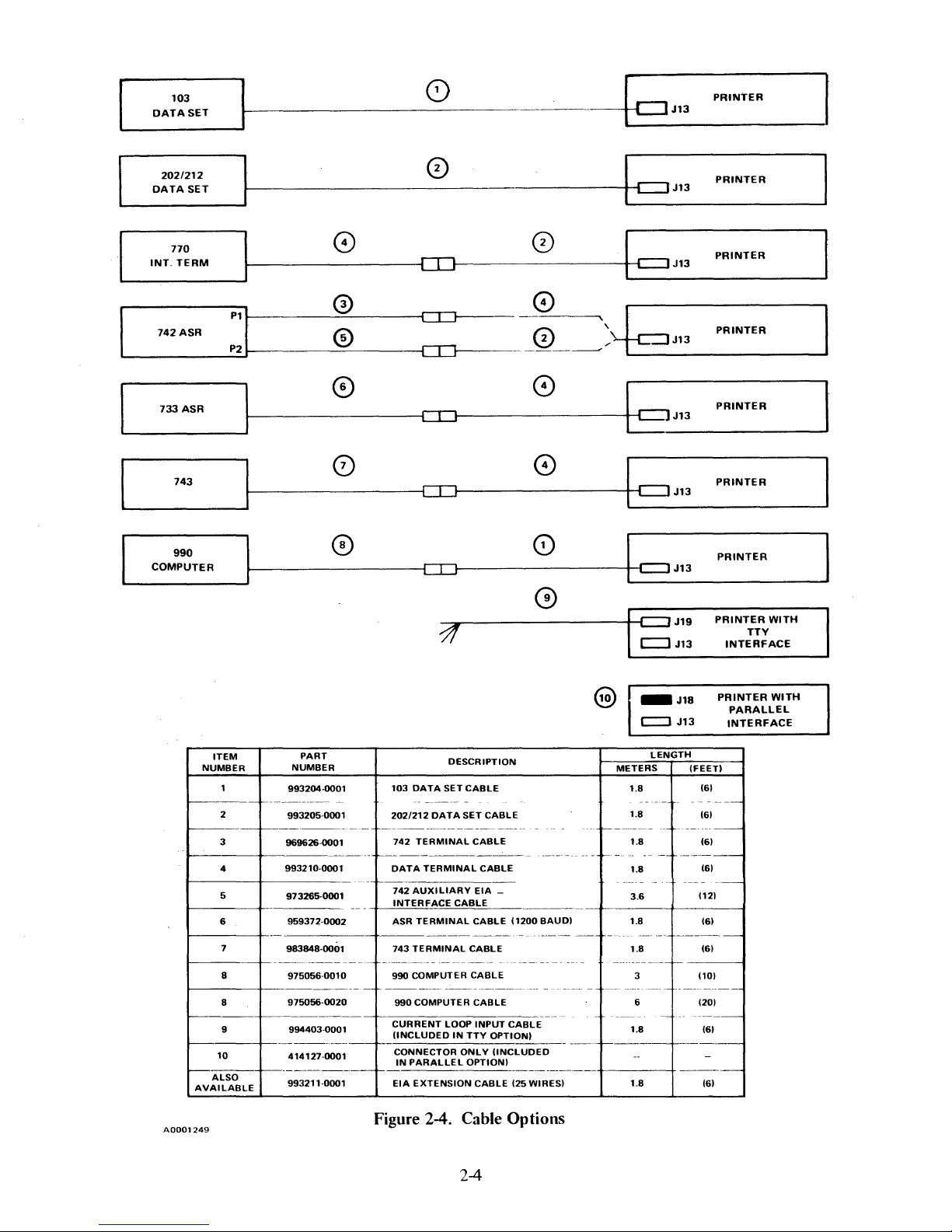

103

DATASET

0)

c:::J

PRINTER

J13

I

L

202/212

DATA

770

INT.

742

_____

733

COMPUTER

SET

TERM

ASR

ASR

743

990

0

c::::r

J13

~------------------~[][]------------------~~c::JJ13

o 0

r.;'\

.:!Jr-------\::..J-5----

:1

0

0

[][J------

CIJ

c::r::::J

CTI

CD

3!

---

r.:\

.

__

~_-----'".,'

0

0

0

0

~

"

L.

___

J1_3

_______

b?J13

c:::J

J13

c::::J

J13

c::::J

J19

c::J

J13

PRINTER

PRINTER

PRINTER

PRINTER

PRINTER

PRINTER

PRINTER

TTY

INTERFACE

~

WITH

ITEM

NUMBER

r--------

2

r-----------------------

3

~------+--------------

4

5

6

7

I-------+_

8

1---------+-----------

8

r---------

9

I---.----+---------------f------------------------r------------

10

I--------+------------f------------------------

ALSO

AVAILABLE

A0001249

PART

NUMBER

993204·0001

-------------

993205-000

969626-0001

993210-0001

---

1

--

-

973265-0001

959372-0002

983848-0001

--------------------

975056-0010

975056-0020

--------------1--------------

994403-0001

414127-0001

993211-0001

-

t-----------------

f-----------------

r----------

Figure 2-4. Cable Options

103

DATA

202/212

DATA

742

TERMINAL

DATA

TERMINAL

742

AUXILIARY

INTERFACE

ASR

TERMINAL

743

TERMINAL

-----------

990 COMPUTER

990

COMPUTER

CURRENT

(INCLUDED

CONNECTOR

IN

PARALLEL

EIA

EXTENSION

DESCRIPTION

SET

CABLE

SET

CABLE

CABLE

CABLE

EIA

CABLE

CABLE

CABLE

----------

CABLE

----------

CABLE

LOOP

INPUT

IN

TTY

OPTION)

ONLY

OPTION)

CABLE

_

(1200

-

------

CABLE

!INCLUDED

(25

WIRES)

BAUD)

------

----------

-

------

J13

~-

-------

--------

------t

-----------

------

(FEET)

(6)

-

(6)

(6)

(6)

(12)

(6)

(6)

(10)

------

(6)

(6)

PRINTER

----

-----

@

_J18

c:::::l

LENGTH

METERS

1.8

1.8

r-------------

1.8

f-----

----------

1.8

3.6

----

1.8

-

----

----

f-------

----

1.8

------

-----r--

3

---

6 (20)

1.8

1.8

WITH

PARALLEL

INTERFACE

2-4

Page 21

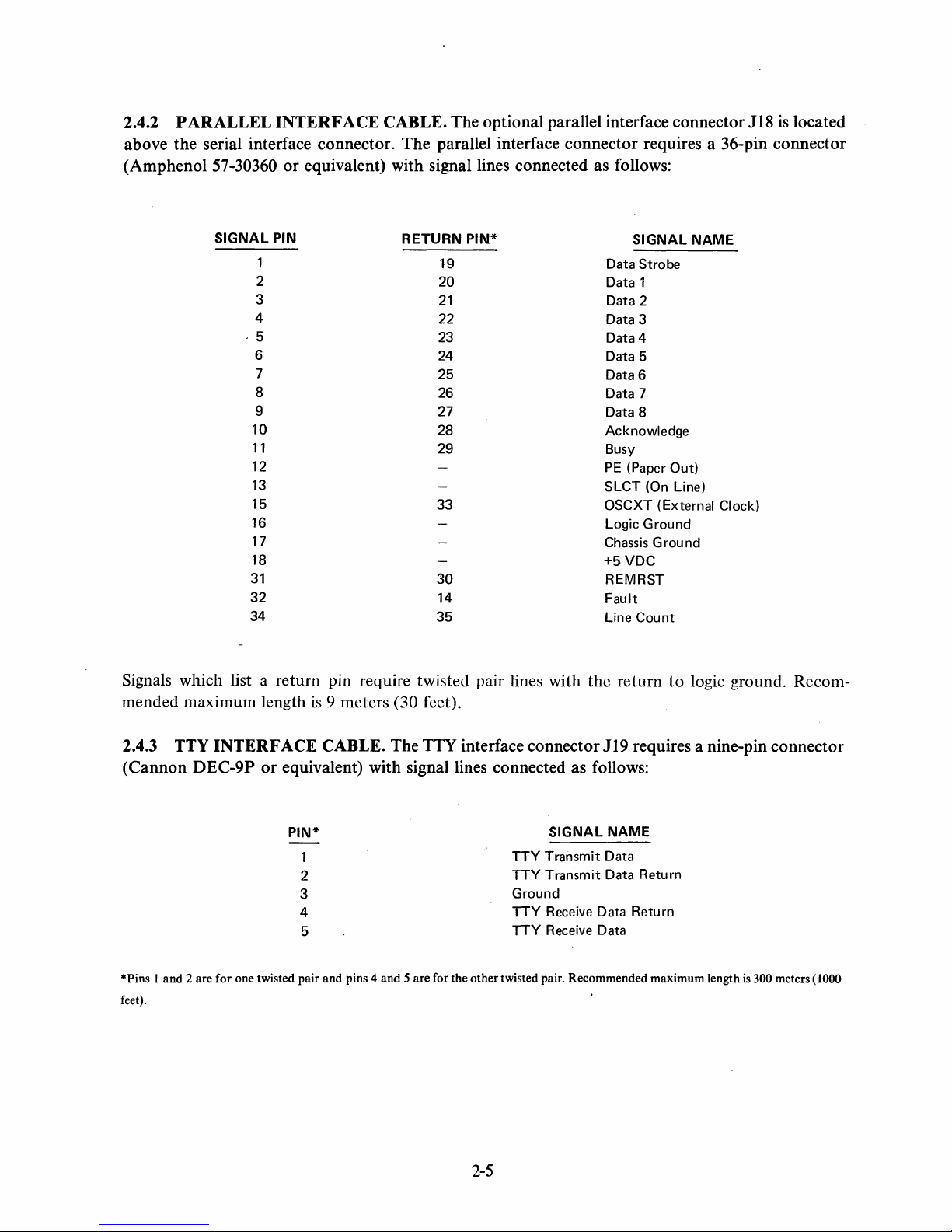

2.4.2 PARALLEL INTERFACE CABLE. The optional parallel interface connector 118

is

located

above the serial interface connector. The parallel interface connector requires a 36-pin connector

(Amphenol

57-30360 or equivalent) with signal lines connected as follows:

SIGNAL

-5

31

32

34

1

2

3

4

6

7

8

9

10

11

12

13

15

16

17

18

PIN

RETURN

19

20

21

22

23

24

25

26

27

28

29

33

30

14

35

PIN*

Signals which list a return pin require twisted pair lines with

is

mended maximum length

9 meters (30 feet).

SIGNAL

Data

Strobe

Data 1

Data 2

Data 3

Data 4

Data 5

Data 6

Data 7

Data 8

Acknowledge

Busy

PE

(Paper Out)

SLCT (On Line)

OSCXT (External Clock)

Logic

Ground

Chassis G rou nd

+5VDC

REMRST

Fault

Line

Count

the

return

NAME

to

logic ground. Recom-

2.4.3 TTY INTERFACE CABLE. The TTY interface connector 119 requires a nine-pin connector

or

(Cannon DEC-9P

*Pins I and 2 are for one twisted pair and pins 4 and 5 are for the other twisted pair. Recommended maximum length

feet).

equivalent) with signal lines connected as follows:

PIN*

2

3

4

5

SIGNAL

TTY

Transmit

TTY

Transmit

Ground

TTY Receive Data

TTY

Receive Data

NAME

Data

Data Return

Return

is

300 meters (1000

2-5

Page 22

2.5 INITIAL

In

addition

are required

PREPARATION.

to

the unpacking and setting up instructions, the procedures in the following paragraphs

to

ensure that the printer

is

ready for normal operation.

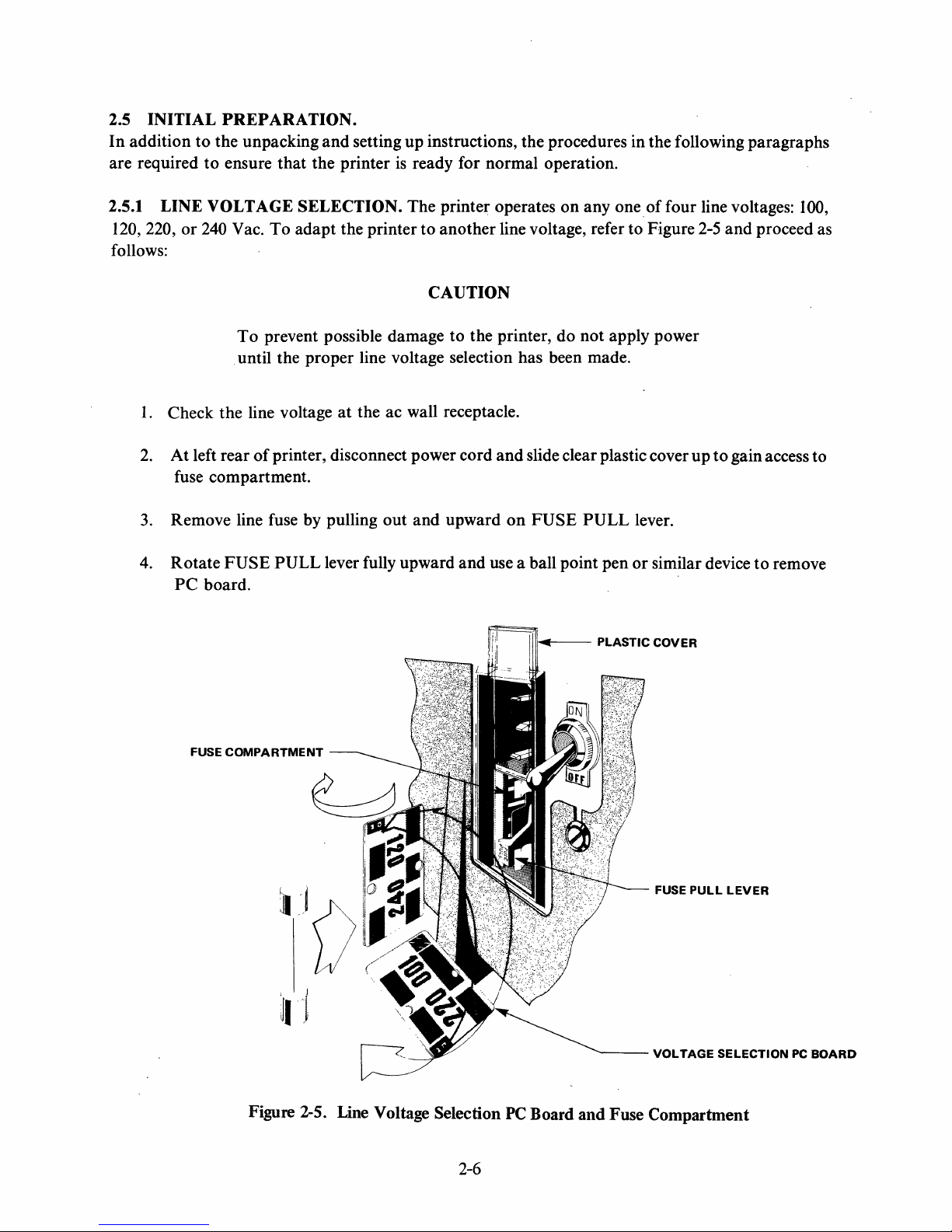

2.5.1 LINE VOLTAGE SELECTION. The printer operates on any one

120, 220,

or

240 Vac.

To

adapt the printer to another line voltage, refer to Figure 2-5

follows:

CAUTION

To

prevent possible damage to the printer, do not apply power

until the proper line voltage selection has been made.

1.

Check the line voltage

2.

At left rear

of

printer, disconnect power cord

at

the ac wall receptacle.

and

slide clear plastic cover

fuse compartment.

3.

Remove line fuse by pulling

4.

Rotate

PC

FUSE

board.

PULL

lever fully upward and use a ball point pen

out

and upward

on

FUSE

PULL

of

four line voltages: 100,

and

up

to

gain access to

lever.

or

similar device

proceed as

to

remove

COMPARTMENT

FUSE

)\),

'~I

III'-f---

PLASTIC

""'----

COVER

FUSE

PULL

VOLTAGE

LEVER

SELECTION

PC

BOARD

Figure 2-5. Line Voltage Selection

2-6

PC

Board and Fuse Compartment

Page 23

5.

Select operating voltage. (Line voltage must be within

6.

7.

Orient

Push

board

PC

board so

PC

board firmly into slot. (Only selected voltage marking should be visible after the

is

installed.)

that

selected voltage marking

CAUTION

To

prevent possible damage

to

the printer, be sure

fuse value for the voltage selected.

8.

Push

FUSE

PULL

lever down, select proper fuse, and place fuse in fuse holder.

is

+10%

at

to

-15%

of

top

and faces fuse area.

to

use proper

voltage selected.)

PC

VOLTAGE

SELECTED

100 or 120 volts

or 240 volts

220

9. Slide clear plastic cover down.

10.

2.5.2

Check that

11.

Connect power cord to receptacle and

SUPPLIES

ON/OFF

INSTALLATION.

paper loading procedures in

2.5.3

the following procedures in

OPERATIONAL CHECKOUT.

Section III.

Procedure

Turn

On

Procedure

Self-Test Diagnostic

(If

applicable) Programming

(If

applicable) Programming Vertical

Turn

Off Procedure

switch

is

To

Section III.

Form

FUSE TYPE

5.0 ampere, 250 V

ampere, 250 V

2.5

in

OFF

position.

to

power source.

TI

PART NUMBER

416434-0503

416434-0004

install the supplies, perform the ribbon installation and

To

provide

an

operational checkout

of

the printer, perform

Paragraph

Length

Format

Control

3.4.17

and

3.4.16

3.4.18

3.4.19

3.4.3

3.4.6

2-7/2-8

Page 24

Page 25

SECTION

III

OPERATION

3.1

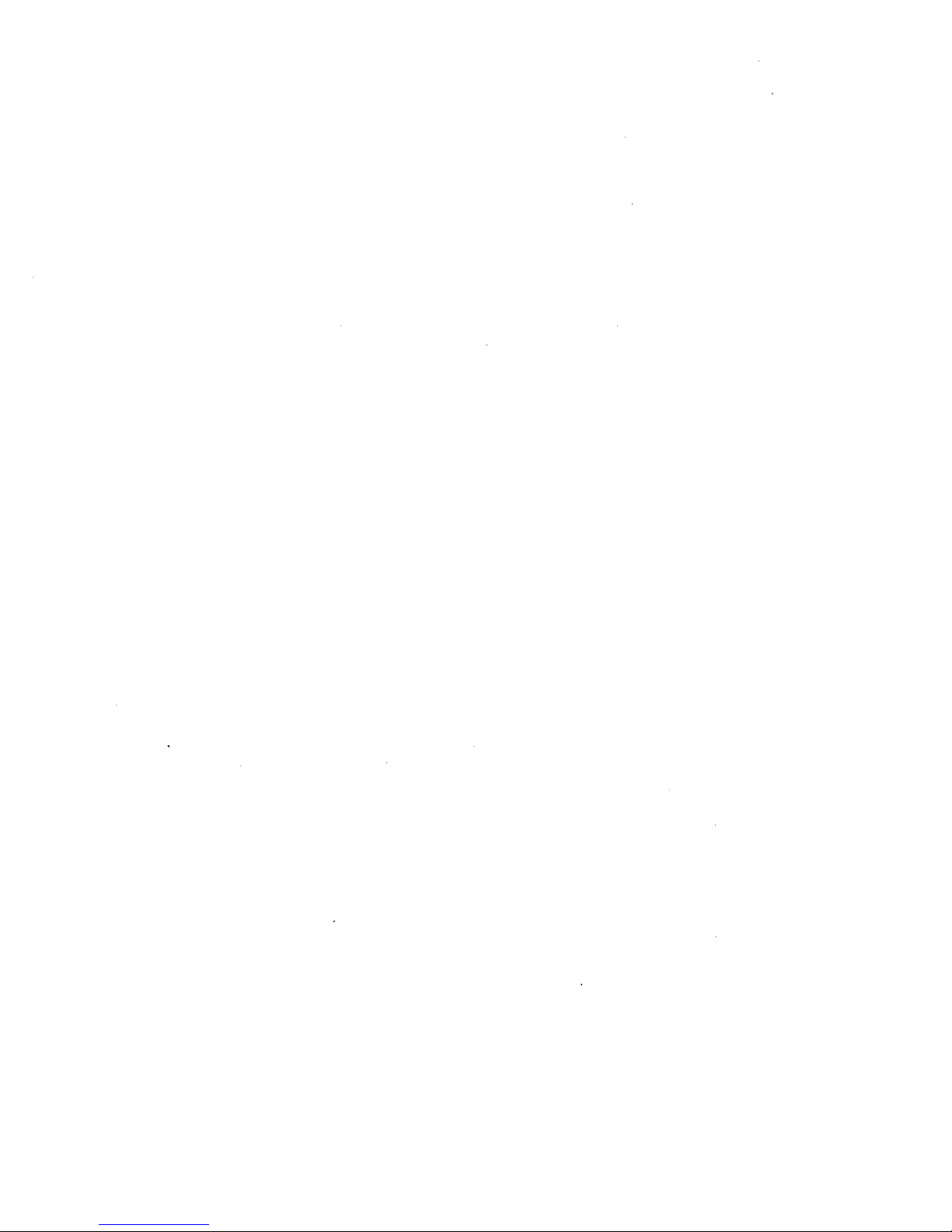

INTRODUCTION.

This section contains detailed information

AND

INTERFACE

on

INFORMATION

the printer controls

and

indicators,

information for the standard serial interface as well as for the optional parallel

General operating

and

indicators are located

access door) except for the power

operator control locations. The power

printer,

and

and

the printhead adjust lever

indicators which are most often used in normal operation are located

and

programming information is also provided. All operator available controls

on

the control panel

ON/OFF

POWER ON/OFF SWITCH

and

the auxiliary control panel (located under the

switch

ON/OFF

is

located under the right side

and

the print head adjust lever. See Figure

switch is located

on

the back left corner

of

the access door. These controls

on

and

signal interface

and

TTY interfaces.

3-1

of

the control panel.

for

the

COO01253

i.ttttttitit.t~~Si~Itt1~HrPRINTHEAD

E

AUXILIARY

CONTROL

PANEL

Figure 3-1. Con trol Locations

3-1

ADJUST

LEVER

CONTROLPANEL·

Page 26

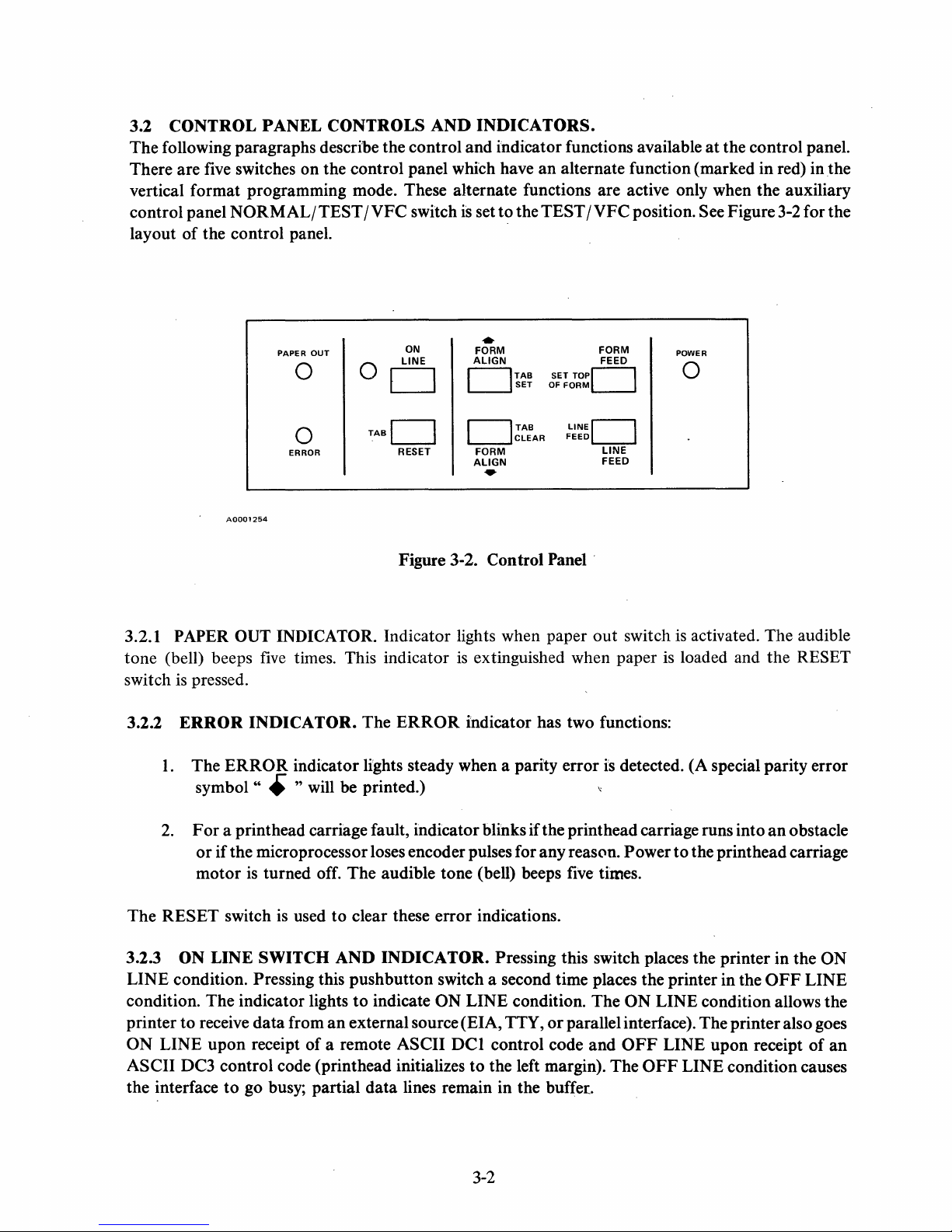

3.2 CONTROL PANEL CONTROLS

The following paragraphs describe the control and indicator functions available

five

There are

switches on the control panel which have an alternate function (marked in red) in

AND

INDICATORS.

at

the control panel.

the

vertical format programming mode. These alternate functions are active only when the auxiliary

control panel

of

layout

the control panel.

NORMAL/TEST

/VFC

switch

is

set to the TEST

/VFC

position. See Figure

3-2

for the

PAPER

0

0

ERROR

OUT

0

TABC]

ON

LINE

C]

RESET

..

FORM

ALIGN

C]TAB

C]TAB

FORM

ALIGN

SET

CLEAR

SET

OF

TOPC]

FORM

LINEC]

FEED

FORM

FEED

LINE

FEED

•

AOOO1254

Figure 3-2. Control

3.2.1 PAPER OUT INDICATOR. Indicator lights when paper out switch

tone (bell) beeps

switch

3.2.2

is

pressed.

ERROR

1.

The

symbol"

five

times. This indicator

INDICATOR. The

ERROR

indicator lights steady when a parity error

ERROR

is

extinguished when paper

indicator has two functions:

• " will be printed.) "

Panel'

is

detected. (A special parity error

POWER

0

is

activated. The audible

is

loaded and the RESET

2.

F or a printhead carriage fault, indicator blinks if the printhead carriage runs into

or

if the microprocessor loses encoder pulses for any reason. Power

is

turned off. The audible tone (bell) beeps five times.

is

used to clear these error indications.

The

RESET switch

3.2.3

ON LINE SWITCH AND INDICATOR. Pressing this switch places the printer in the ON

motor

LINE condition. Pressing this pushbutton switch a second time places the printer in the

condition. The indicator lights

printer to receive data from

ON LINE upon receipt of a remote ASCII

ASCII DC3 control code (printhead initializes to the left margin). The

to

the interface

go busy; partial data lines remain in the buffer.

to

the printhead carriage

to

indicate ON LINE condition. The ON LINE condition allows the

an

external source (EIA, TTY,

DCI

control code and

or

parallel interface). The printer also goes

OFF

LINE upon receipt of an

OFF

LINE condition causes

3-2

an

obstacle

OFF

LINE

Page 27

3.2.4

paper

clearing a carriage fault condition. The alternate TAB function

vertical format control mode. When active, pressing the switch advances the paper

tab

RESET

out

which has been set.

/T

AB

condition

SWITCH.

or

either

The

normal

of

the two error conditions. The printhead moves

RESET

function

of

this pushbutton switch clears the

of

this switch is active only in the

to

the left margin after

to

the next vertical

3.2.5

this pushbutton switch causes the paper

switch

accelerate

function

pushbutton switch sets a vertical

3.2.6

of

paper will continue

The alternate TAB

When active, pressing this pushbutton switch clears the vertical

3.2.7

pushbutton switch causes the paper

printed before paper motion occurs. This switch is active both off line and

TOP

active, pressing this pushbutton switch sets the top

FORM

3.2.8

moved up one line (twelve steps for six lines per inch

buffer

off line. The normal

FORM

is

FORMALIGN

this pushbutton switch causes the paper

FORM

OF

LENGTH

LINE

is

not

ALIGN

held down, three small steps will be taken

paper

of

FORM

movement. This switch is active

this switch

FEED/SET

function

FEED/LINE

empty, its contents will be printed before paper motion occurs. This switch

..

/TAB

is

active only in the vertical format control mode. When active, pressing this

..

/TABCLEARSWITCH.ThenormalFORMALIGN

to

move in 0.014 inch increments. This switch

CLEAR

switch setting.

and

function

TOP

of

this switch

FEED

alternate functions

SET

SWITCH.

to

move up 0.014 inches (refer

tab

at

the present line.

to

of

this switch is active only in the vertical format control mode.

OF

FORM

to

move to the top

SWITCH.

SWITCH.

is

active only in the vertical format control mode. When

Each time this pushbutton switch is pressed, the

of

The normal

and

both

off line

move 0.014 inches down.

The normal

of

the next form. Contents

of

form

and

nine steps for eight lines per inch).

this switch are the same.

FORM

then full line feeds will be executed

and

on

line. The alternate TAB

is

active both off line

tab

at

FORM

or

causes the microprocessor

ALIGN

to

paragraph 4.2.5).

If

the switch

the present line.

on

line. The alternate

..

..

is

FEED

function

of

the line buffer are

is

function

If

the

SET

function

held down,

and

on

line.

of

this

SET

to

read the

paper

If

the line

active'only

of

to

3.2.9

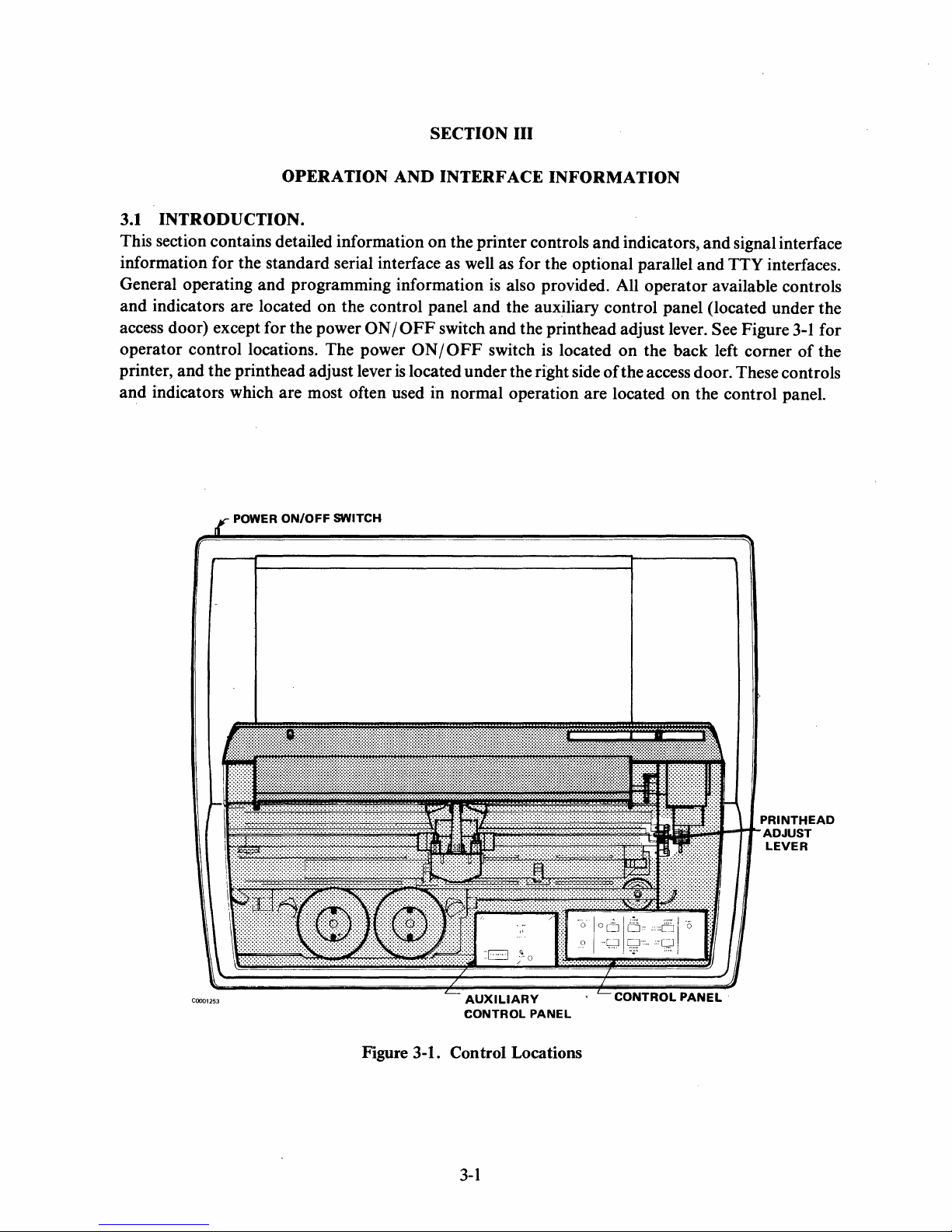

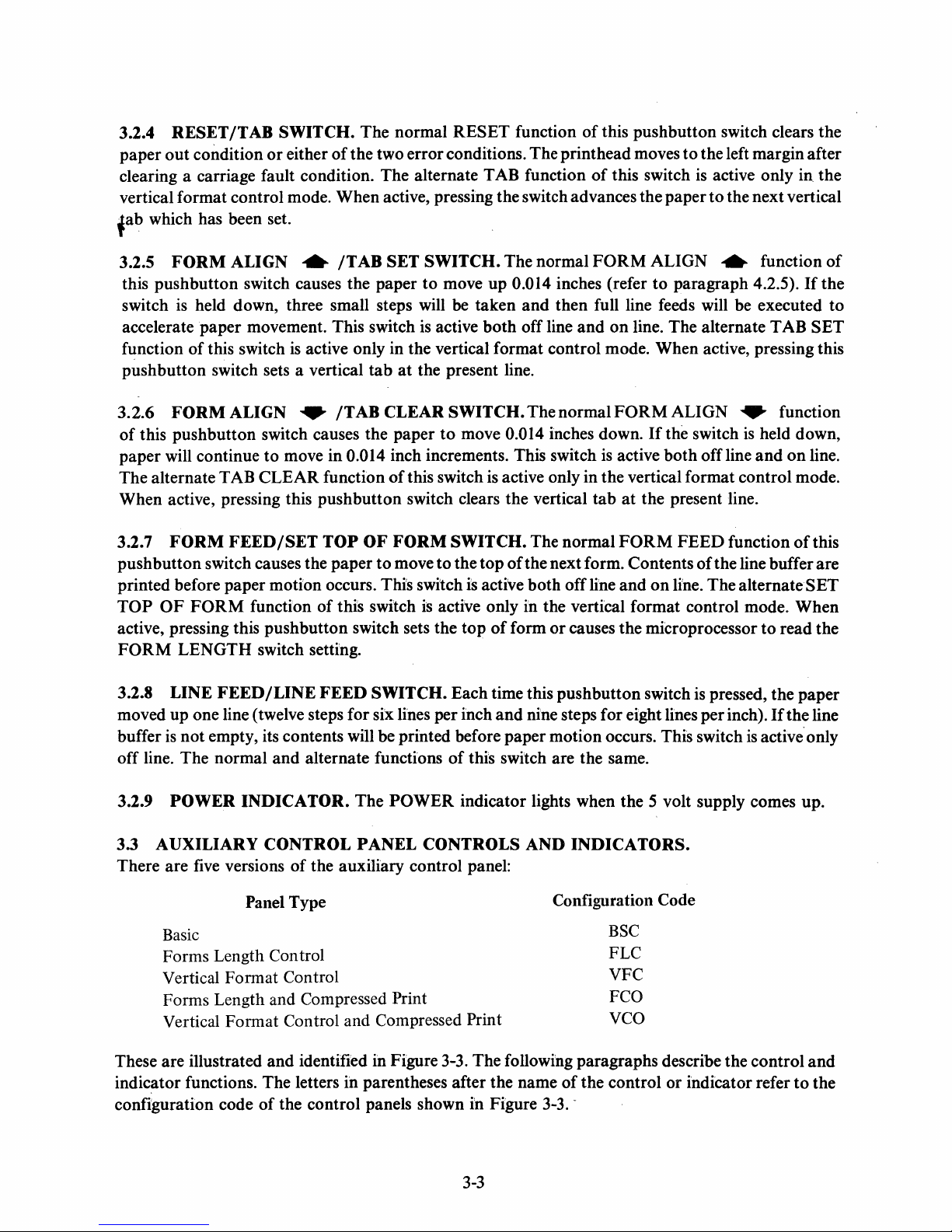

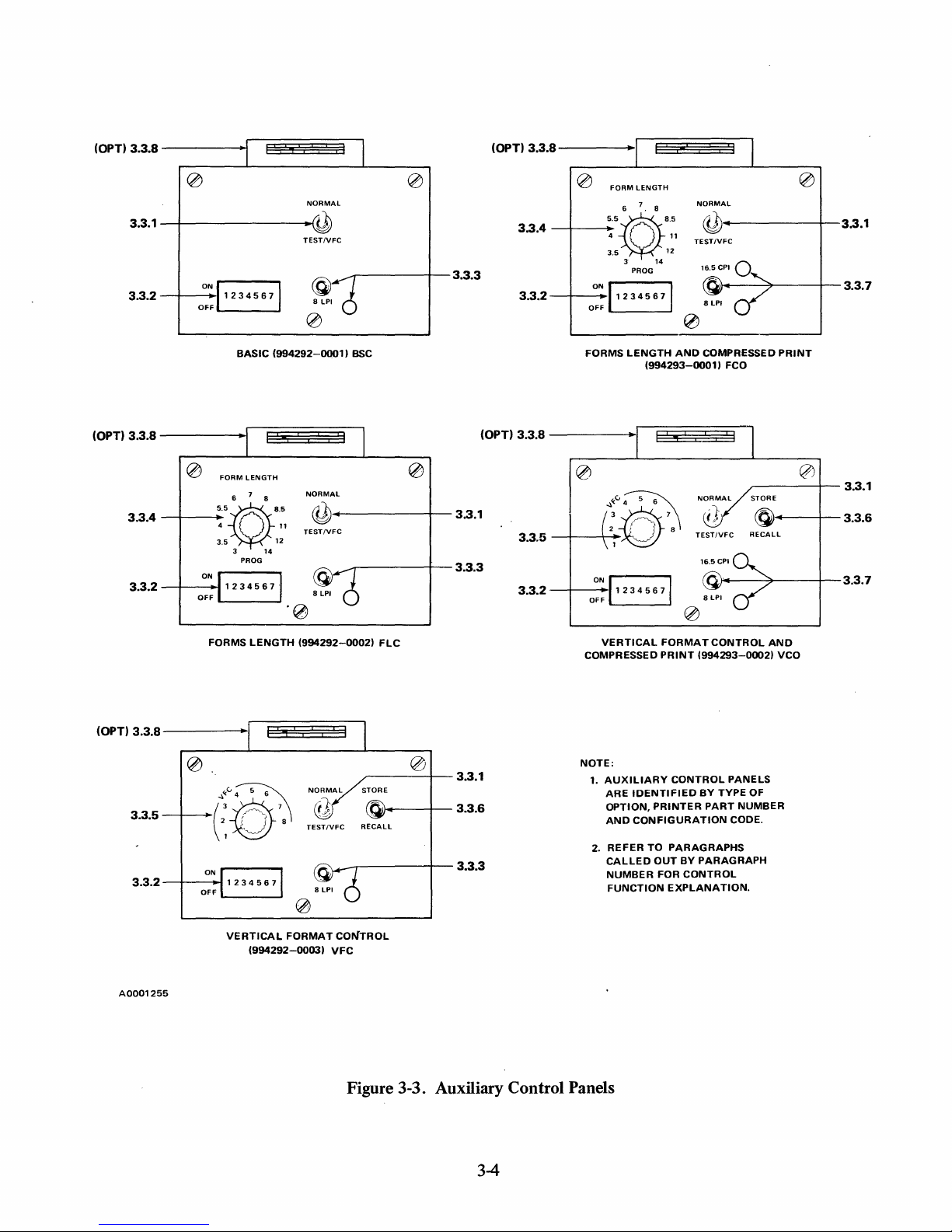

3.3

There are five versions

These are illustrated

indic~tor

configuration code

POWER

AUXILIARY

Basic

Forms Length Control

Vertical Format Control

Forms Length and Compressed

Vertical Format Control and Compressed Print

functions. The letters in parentheses after the name

INDICATOR.

CONTROL

of

the auxiliary control panel:

Panel Type

and

identified in Figure 3-3. The following paragraphs describe the control

of

the control panels shown in Figure 3-3. -

The

POWER

PANEL

Print

indicator lights when the 5 volt supply comes up.

CONTROLS

AND

INDICATORS.

Configuration Code

BSC

FLC

VFC

Fca

VCo

of

the control

3-3

or

indicator refer

to

and

the

Page 28

(OPT) 3.3.S

3.3.1

3.3.2

-----tl§~~§§§l

NORMAL

-+--------~~

_+--O-:N"J

1 2 3 4 5 6

BASIC

TESTIVFC

71

(994292-0001)

BSC

3.3.3

(OPT) 3.3.S

3.3.4

3.3.2

0

FORM

LENGTH

6 7 . 8

"~.'

4

3.5

3

PROG

0::

11

2

34

5 6

FORMS

LENGTH

(994293-0001)

14

NORMAL

,------+--3.3.1

cQ)

11

TESTIVFC

12

(OJ'~----7----+-

71

0

AND

COMPRESSED

FCO

3.3.7

PRINT

(OPT) 3.3.S

0

3.3.4

3.3.2

~

FORM

LENGTH

7

6

8

"~.'

4

3.5

ON

OFF

3

PROG

11

12

14

NORMAL

~

TESTIVFC

-------+-

-------+--

0

3.3.1

3.3.3

'0

FORMS

LENGTH

(OPT) 3.3.S

-----II§§~~~§)l

.:"v.v~

3.3.5--;-~(~~'.\

ON

3.3.2

-+-----l~

OFF

r------,

L--

__

--'

(994292-0002)

TESTIVFC

RECALL

.~....-----+-

He

,;-----+--

loJ~--+--

3.3.1

3.3.6

3.3.3

(OPT) 3.3.S

3.3.5

3.3.2

-----r~ES±i~~±2J~~l

NORMAL

_+-

__

~:~:10~

~

_-+---O-:N"

11

2 3 4 5 6

F

VERTICAL

COMPRESSED

NOTE:

1.

AUXILIARY

ARE

IDENTIFIED

OPTION,

AND

CONFIGURATION

2.

REFER

CALLED

NUMBER

FUNCTION

TO

TESTIVFC

71

FORMAT

PRINT

(994293-0002)

CONTROL

PRINTER

BY

PARAGRAPHS

OUT

BY

PARAGRAPH

FOR

CONTROL

EXPLANATION.

r------1--

STORE

~..---+--

RECALL

R.r.--'*---+--3.3.7

CONTROL

TYPE

PART

AND

VCO

PANELS

OF

NUMBER

CODE.

3.3.1

3.3.6

VERTICAL

A0001255

FORMAT

(994292-0003)

CONTROL

VFC

Figure 3-3. Auxiliary Control Panels

3-4

Page 29

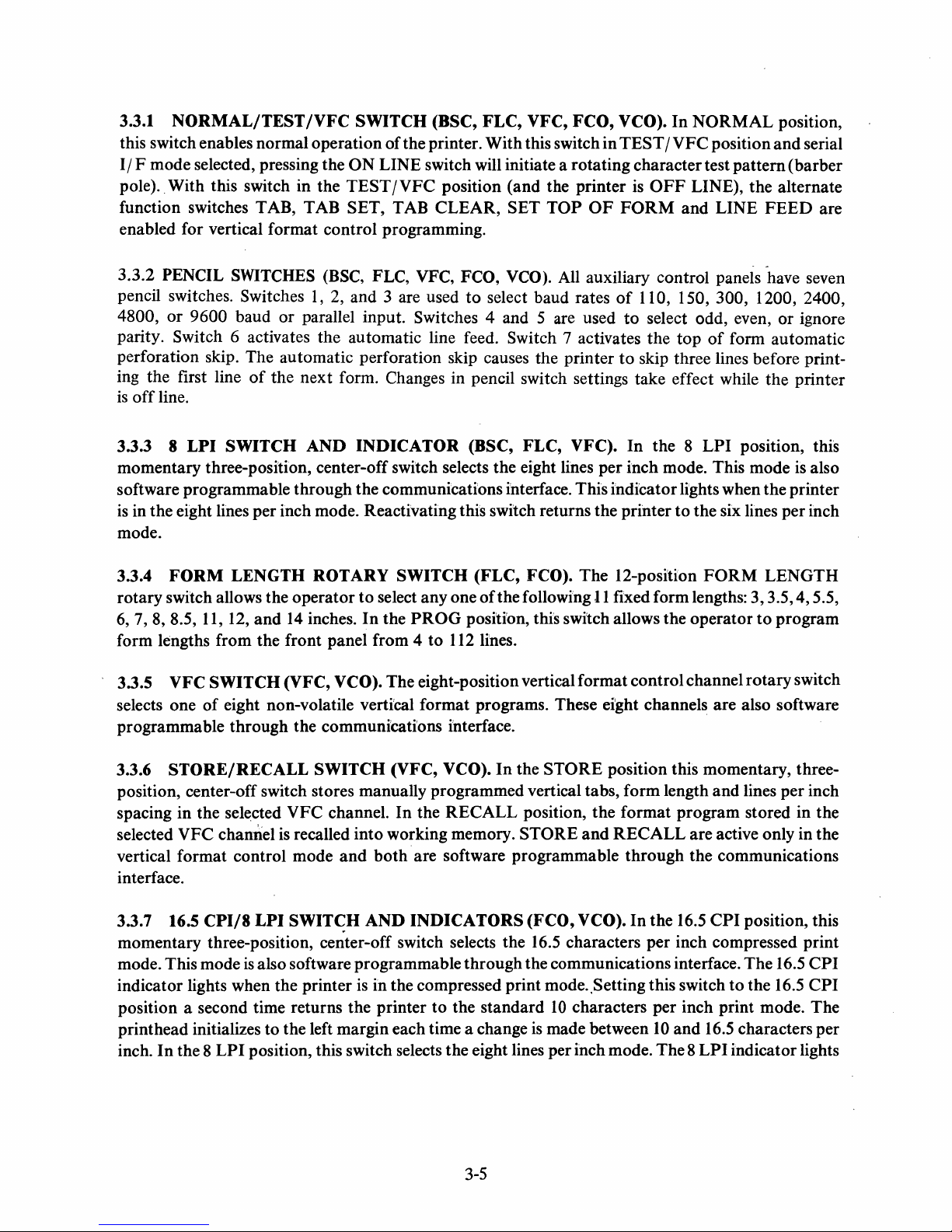

3.3.1

NORMAL/TEST

/VFC

SWITCH

(BSC,

FLC,

VFC,

FCO,

this switch enables normal operation of the printer. With this switch in

II F mode selected, pressing the

pole). With this switch in the

function switches TAB, TAB

ON

LINE switch will initiate a rotating character test

TEST

IVFC

SET, TAB CLEAR, SET

position (and the printer

TOP

OF

enabled for vertical format control programming.

VCO).

In

NORMAL

TEST / VFC

is

OFF

LINE), the alternate

FORM

and LINE

position,

position

and

pattem(barber

FEED

serial

are

PENCIL SWITCHES (BSC, FLC, VFC, FCO, VCO). All auxiliary control panels

3.3.2

1,

pencil switches. Switches

or

4800,

9600 baud

or

2, and 3 are used

parallel input. Switches 4 and 5 are used

to

select baud rates

of

110, 150, 300, 1200, 2400,

to

select odd, even,

parity. Switch 6 activates the automatic line feed. Switch 7 activates the

perforation skip. The automatic perforation skip causes the printer

of

ing the first line

is

off

line.

3.3.3 8

LPI

the next form. Changes in pencil switch settings take effect while the printer

SWITCH

AND

INDICATOR

(BSC, FLC, VFC).

to

skip three lines before print-

In

the 8

top

of

LPI

-have

seven

or

ignore

form automatic

position, this

momentary three-position, center-off switch selects the eight lines per inch mode. This mode is also

software programmable through the communications interface. This indicator lights when the printer

is

in the eight lines per inch mode. Reactivating this switch returns the printer

to

the six lines per inch

mode.

3.3.4

FORM

rotary switch allows the operator

6,

7, 8, 8.5,

form lengths from the front panel from 4

3.3.5 VFC

selects one

LENGTH

11,

12,

and

SWITCH

of

eight non-volatile vertical format programs. These eight channels are also software

ROTARY

14

inches.

to

In

select

the

SWITCH

anyone

PROG

to

112

(FLC, FCO). The 12-position

of

the following J 1 fixed form lengths:

FORM

position, this switch allows the operator

lines.

LENGTH

3,3.5,4,5.5,

to

program

(VFC, VCO). The eight-position vertical format control channel rotary switch

programmable through the communications interface.

3.3.6

STORE/RECALL

SWITCH

position, center-off switch stores manually programmed vertical tabs, form length and lines per inch

spacing in the selected VFC channel.

is

selected VFC channel

recalled into working memory. STORE

vertical format control mode

interface.

3.3.7 16.5

CPI/8

LPI

SWIT~H

momentary three-position, center-off switch selects the

mode. This mode

is

also software programmable through the communications interface. The 16.5

indicator lights when the printer

position a second time returns the printer

printhead initializes to the left margin each time a change

inch.

In

the 8

LPI

position, this switch selects the eight lines per inch mode.

(VFC, VCO).

In

the

RECALL

and

both

are software programmable through the communications

AND

INDICATORS

is

in the compressed print mode. ,Setting this switch

to

In

the

position, the format program stored in the

(FCO, VCO).

16.5

the standard

is

3-5

STORE

position this momentary, three-

and

RECALL

In

the

characters per inch compressed print

10

characters per inch print mode. The

made between

are active only in the

16.5

CPI

position, this

to

the 16.5

10

and

16.5

characters per

The 8 LPI

indicator lights

CPI

CPI

Page 30

when the printer

the communications interface. Setting this switch

printer

3.3.8

to

the six lines per inch mode.

ELAPSED

is

in the eight lines per inch mode. This mode

to

the 8

TIME

INDICATOR

(OPTIONAL). The optional elapsed time indicator shows

is

also software programmable through

LPI

position a second time returns the

accumulated ribbon motion time to 2000 hours.

3.3.9 BAUD RATE OPTION (BRO). This option

gives

you an additional baud rate family. See

Paragraph 3.4.9.

OPERATING

3.4

PROCEDURES.

Before the printer can be placed in service, the operator must determine the following:

1.

Printer configuration: BSC, FLC, VFC, FCO,

of

underside

the access door,

or

identify the printer from Figure 3-3 by the type

or

VCO. (See the configuration label

control panel installed.)

on

of

auxiliary

the

2. Baud rate

printers only)

3. Parity selection: odd, even,

Perform those procedures in the following paragraphs which apply

your printing requirements. The title

parentheses)

procedures;

or

procedures in paragraph

of

the received serial data,

is

to

to

which it applies.

if the

ERROR

3-5.

be received.

or

ignore.

of

If

the printer does

indicator lights;

or

whether parallel

data

(optional

to

your printer configuration and

on

PLC

orPLT

each paragraph identifies the printer configuration (in

not

perform as indicated in the following

or

if the audible tone (bell)

is

heard, consult the self-help

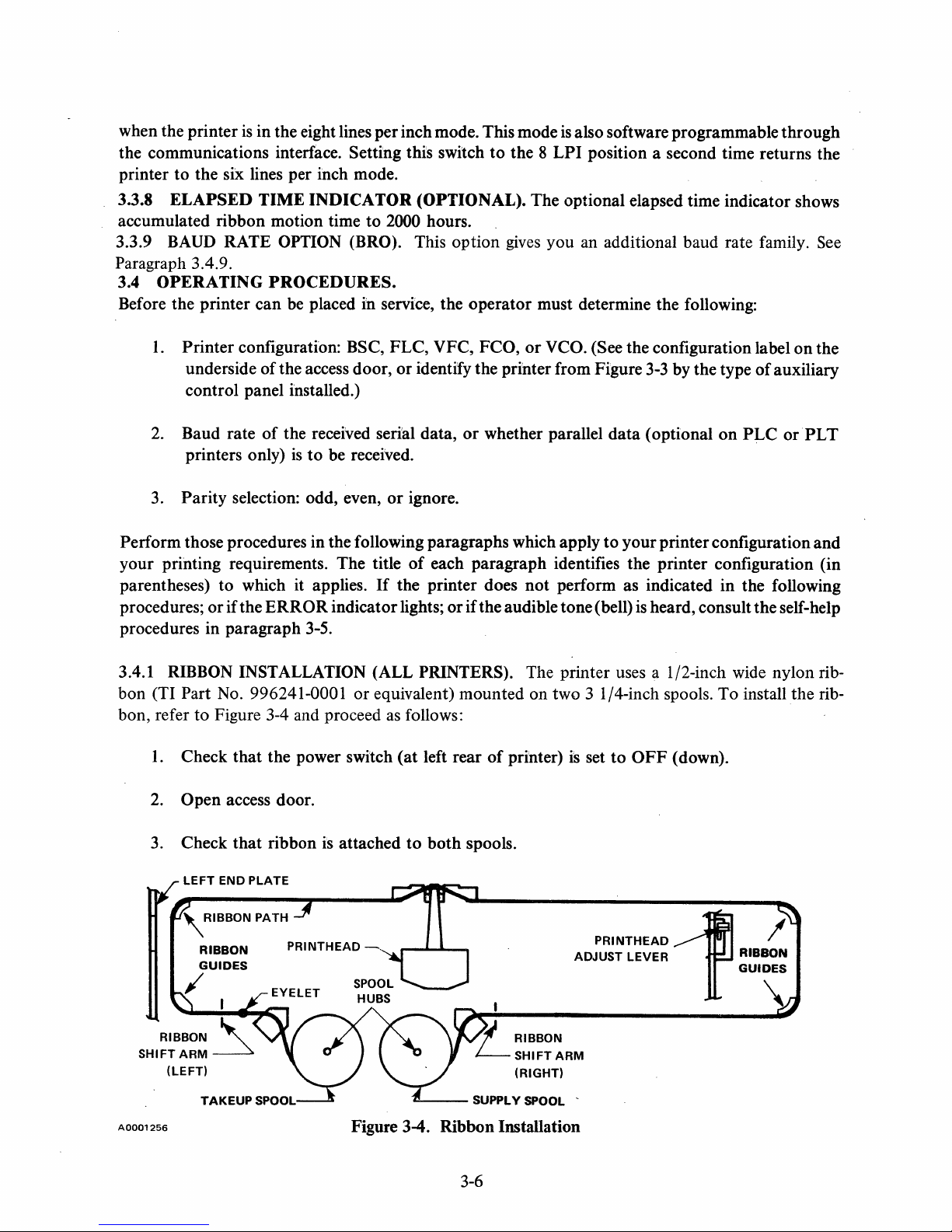

3.4.1 RIBBON INSTALLATION (ALL PRINTERS). The printer uses a 1/2-inch wide nylon ribbon (TI

bon, refer

Part No. 996241-0001 or equivalent) mounted on two 3 1/4-inch spools. To install the rib-

to

Figure 3-4 and proceed

1.

Check that the power switch

2. Open access door.

that

3. Check

LEFT

END PLATE

ribbon

is

attached

as

follows:

(at

to

left rear

both