Page 1

LMX248x Evaluatio n Boa rd

User's Guide

Revised – March 2014

SNAU137

Page 2

LMX248x

Evaluation Board Operating I nstructions

www.ti.com

2 SNAU137 LMX248x Evaluation Board User’s Guide Revised - March 2014

Copyright © 2014, Texas Instruments Incorporated

Page 3

www.ti.com

Table of Contents

EQUIPMENT ..................................................................................................................................................................................... 4

BASIC OPERATION ........................................................................................................................................................................... 5

LMX2485 BOARD INFORMATION .................................................................................................................................................... 7

PLL PHASE NOISE ..................................................................................................................................................................... 9

RF

PLL FRACTIONAL SPURS ......................................................................................................................................................... 11

RF

PLL LOCK TIME ...................................................................................................................................................................... 12

RF

PLL LOCK TIME ........................................................................................................................................................................ 14

IF

PLL PHASE NOISE ..................................................................................................................................................................... 15

IF

PLL SPURS ................................................................................................................................................................................ 16

IF

LMX2486

PLL PHASE NOISE ................................................................................................................................................................... 18

RF

PLL FRACTIONAL SPURS ......................................................................................................................................................... 20

RF

PLL LOCK TIME (WITH A SPECTURM ANALYZER) .................................................................................................................. 21

RF

PLL PHASE NOISE ..................................................................................................................................................................... 22

IF

PLL SPURS ................................................................................................................................................................................ 23

IF

PLL LOCK TIME ........................................................................................................................................................................ 24

IF

LMX2487

INDING A VCO ............................................................................................................................................................................ 25

F

EPLACING THE VCO W IT H A FOOTPRINT COMPATIBLE VCO ...................................................................................................... 26

R

APPENDIX A: SCHEMATICS ............................................................................................................................................................ 27

PPENDIX B: BUILD DIAGRAMS .................................................................................................................................................... 28

A

PPENDIX C: BIL L OF MATERIALS ................................................................................................................................................ 31

A

PPENDIX D: QUICK START FOR EVM COMMUNICATIONS ........................................................................................................... 34

A

BOARD INFORMATION .................................................................................................................................................. 17

BOARD INFORMATION .................................................................................................................................................. 25

Revised - March 2014 LMX248x Evaluation Board User’s Guide SNAU137 3

Copyright © 2014, Texas Instruments Incorporated

Page 4

www.ti.com

Equipment

Power Supply

The Power Supp ly should be a low noise power s upply. An Agilent 6623A Triple power supply with LC filters on the

output to reduce noise was used in creating these evaluation board instructions.

Signal Generator

The Signal Generator should be capable of frequencies and power level required for the part. A Rohde & Schwarz SML03

was used in creating these evaluation board instructions.

Phase Noise / Spectrum Analyzer

For measuring phase noise an Agilent E505 2A is recommended. An Agilent E4445A PSA Spectr um Analyzer with the

Phase Noise option is also usable although the architecture of the E5052A is superior for phase noise measurements. At

frequencies less than 100 MHz the local oscillator noise of the PSA is to o high and measurements will be of the loc al

oscillator, not the device under test.

Oscilloscope

The oscilloscope and probes should be capable of measuring the output frequencies of interest when evaluating this

board. The Agilent Infiniium DSO81204A was used in creating these evaluation board instructions.

4 SNAU137 LMX248x Evaluation Board User’s Guide Revised - March 2014

Copyright © 2014, Texas Instruments Incorporated

Page 5

www.ti.com

Basic Operation

1. Connect the signal generator output to the OSCin input of the board. For this ex ample we use a 10 MHz sin

signal at +5dBm power level.

2. Connect a low noise 3.3 V power supply to the Vcc connector located at the top left of the board.

3. Please see Appendix D for quick start on interfacing the board. Connect PC to the uWire header.

4. Start CodeLoader4.exe.

5. Click “Select Device” “PLL-Fractional” LMX248x depending on which chip is on your board.

Revised - March 2014 LMX248x Evaluation Board User’s Guide SNAU137 5

Copyright © 2014, Texas Instruments Incorporated

Page 6

www.ti.com

6. Select USB or LPT Communication Mode on the Port Setup tab as appropriate.

7. Click “CTRL + L” to load settings into device

6 SNAU137 LMX248x Evaluation Board User’s Guide Revised - March 2014

Copyright © 2014, Texas Instruments Incorporated

Page 7

RF LOOP FILTER

Theoretical ( NOT Measured ) Simulation

(Done with EasyPLL at http://www.ti.com/lsds/ti/wireless)

Pole Ratio

T3 /T1

VCO

CPoRF

2.7 nF

47 nF

820 Ω

270 pF

180 pF

3.9 KΩ 5.6 KΩ

Kφ

400 uA

Comparison

Frequency

Output

Frequency

2400 – 2480

MHz

PLL Supply

2.5 Volts

VCO Supply

3 Volts

Other Information

VCO Used

VARIL2450U

VCO Gain

55 MHz/Volt

VCO Input

Capacitance

www.ti.com

LMX2485 Board Information

TM

The LMX2485 Evaluation Board simplifies evaluat ion of the LMX2485 2.6 GHz/0.8 GHz PLLatinum

synthesizer. The board enables a ll performance measurements with no additional support circuitry. The evaluation

board consists of a LMX 2485 device, a RF VCO module and IF VCO & RF/IF loop fi lters built by discrete c omponents.

The SMA flange mount c onnector s are pr ovided f or ex ternal r ef erenc e inp ut, RF an d I F VCO outpu ts , and t he power and

grounding connection. A cable ass embly is bundled with the evaluation boar d f or c onnec ting to a PC throu gh t he parall el

printer port. By means of USB2ANY-uWire seria l port e mulation, the CodeLoader sof tware inclu ded c an be ru n o n a PC

to facilitate the LMX2485 internal register programming for the evaluation and measurement.

dual frequency

Phase Margin 48.3 deg

Loop Bandwidth 11.3 KHz

2400 – 2480 MHz to 1

Lock Time

KHz tolerance in

247 uS w/o Fastlock

Pole Ratio

Spur Gain

@ 200 KHz

40.2 %

T4/T3

36.3 %

-45.8 dB

Settings for Operation

10 MHz

22 pF

Revised - March 2014 LMX248x Evaluation Board User’s Guide SNAU137 7

Copyright © 2014, Texas Instruments Incorporated

Page 8

IF LOOP FILTER

Theoretical ( NOT Measured ) Simulation ( Done with EasyPLL at www.ti.com )

760 - 780 MHz

uS

VCO

CPoRF

1.8 nF

10 nF

8.2 KΩ

Open

Open

0 Ω 0 Ω

Settings for Operation

Kφ

4 mA

Comparison

Frequency

Output

Frequency

PLL Supply

2.5 Volts

VCO Supply

3 Volts

Other Information

VCO Used

VARIL191-773U

VCO Gain

18 MHz/Volt

VCO Input

Capacitance

www.ti.com

Phase Margin 47.1 deg Lock Time

MHz to 1 KHz

tolerance in 453

Loop Bandwidth 5.1 KHz

Spur Gain

@ 200 KHz

22.1 dB

50 kHz

760 - 780 MHz

100 pF

8 SNAU137 LMX248x Evaluation Board User’s Guide Revised - March 2014

Copyright © 2014, Texas Instruments Incorporated

Page 9

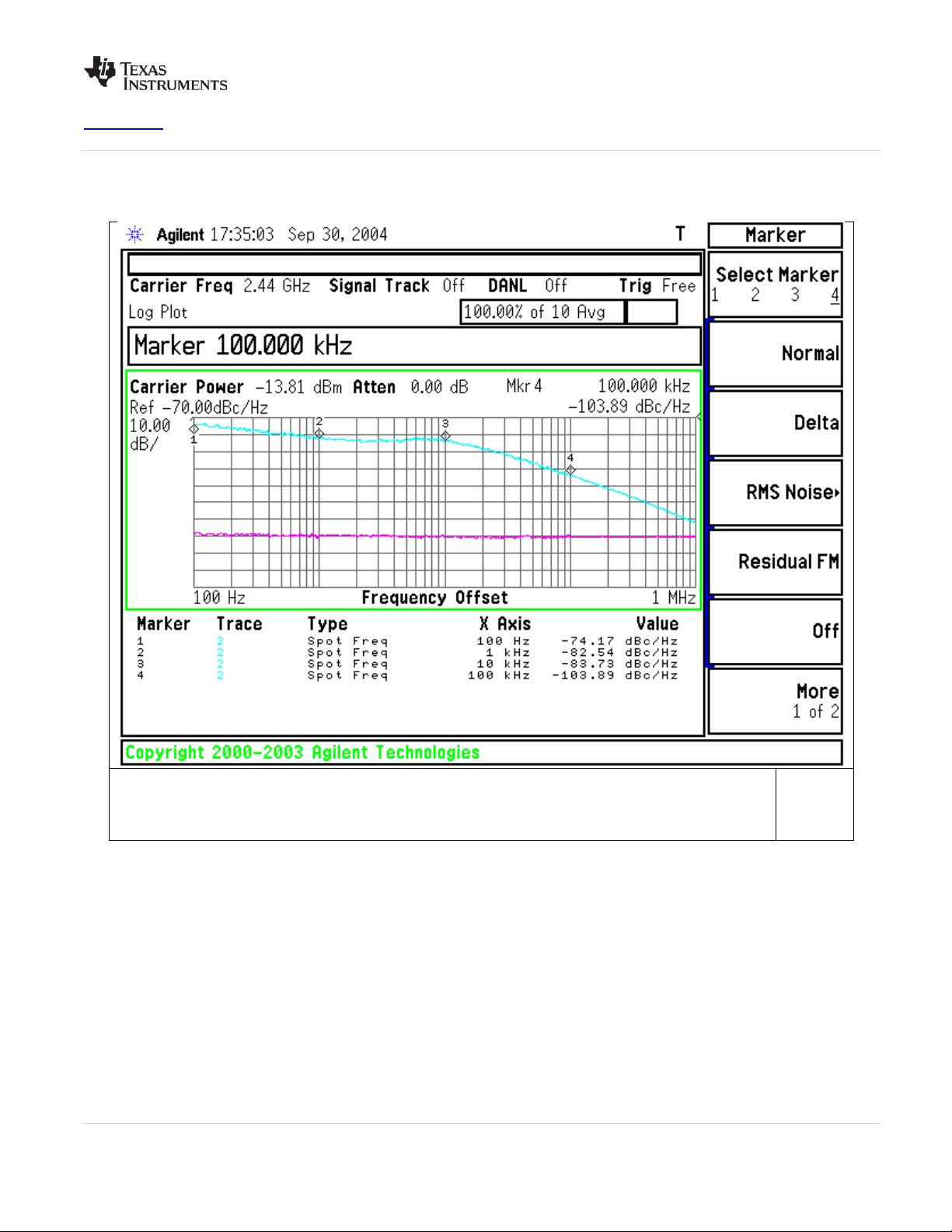

Loop Bandwidth is about 10 kHz. Note that the phase noise gradually improves as one goes farther

noise could still be degrading the in-band phase noise.

www.ti.com

RF PLL Phase Noise

from the carrier. Also note that this is done with 200 uA of current, and the true phase noise

capability of the part is not shown here bec ause the phase noise is worse, and the VCO phase

Revised - March 2014 LMX248x Evaluation Board User’s Guide SNAU137 9

Copyright © 2014, Texas Instruments Incorporated

Page 10

www.ti.com

For this plot, the charge pump was increased to 1600 uA. This improves the PLL phase noise performance and

lower current allows one to experiment with lower comparison frequencies like 2.5 MHz, 5 MHz, and 10 MHz.

also increases the loop bandwidth so the tr ue P LL performance can be seen. The reason that the origina l loop

filter was not designed for 1600 uA cur rent was that it makes the loop filter capacitors 8X larger and als o, the

10 SNAU137 LMX248x Evaluation Board User’s Guide Revised - March 2014

Copyright © 2014, Texas Instruments Incorporated

Page 11

www.ti.com

RF PLL Fractional Spurs

At 2400.2 MHz output frequency, the primary fr actional spur at 200 kHz is

-70.7 dBc, and the sub-fractional spur at 100 kHz is -69.5 dBc.

At 2440.2 MHz output f requency, the primary fr actional spur at 200 kHz is

-78.9 dBc, and the sub-fractional spur at 100 kHz is -72.9 dBc.

At 2480.2 MHz output f requency, the primary fr actional spur at 200 kHz is

-80.8 dBc, and the sub-fractional spur at 100 kHz is -73.4 dBc.

Revised - March 2014 LMX248x Evaluation Board User’s Guide SNAU137 11

Copyright © 2014, Texas Instruments Incorporated

Page 12

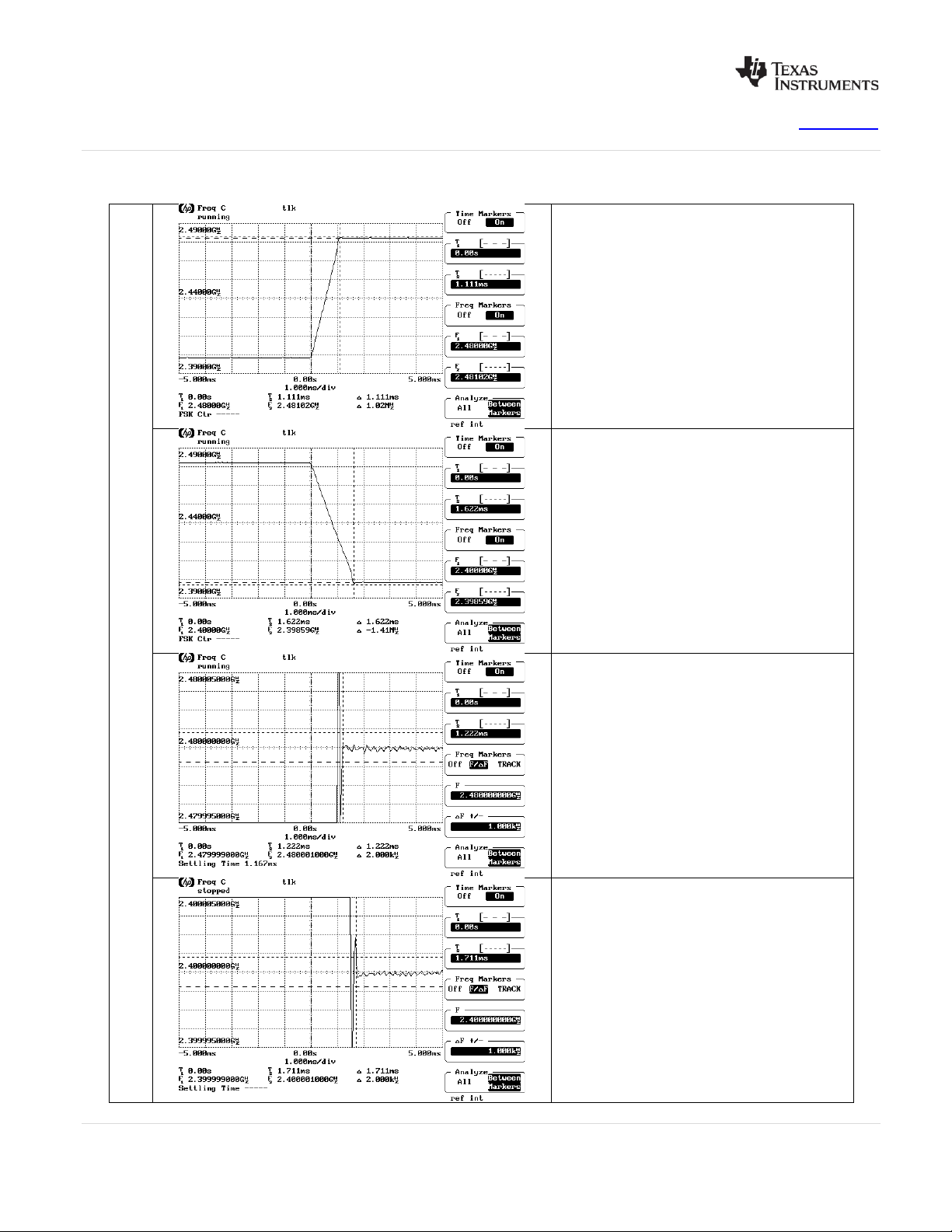

RF PLL Loc k Time

www.ti.com

Peak time withou t cycle slip

reduction is 1110 uS.

Peak time withou t cycle slip

reduction is 1622 uS.

No CSRC. RF_TOC=0

Positive lock time is 1220 uS

Negative Lo ck time i s 171 1 uS

12 SNAU137 LMX248x Evaluation Board User’s Guide Revised - March 2014

Copyright © 2014, Texas Instruments Incorporated

Page 13

www.ti.com

RF PLL Loc k Time

Peak time wi th cy cle slip r eduction

is 222 uS.

Peak time wi th cy cle slip r eduction

is 222 uS.

Positive lock time is 345 uS

Cycle Slip Reduction Enabled. RF_TOC=500

Negative Lo ck time i s 378 uS

Revised - March 2014 LMX248x Evaluation Board User’s Guide SNAU137 13

Copyright © 2014, Texas Instruments Incorporated

Page 14

IF PLL Lock Time

www.ti.com

Peak time is 97.8 uS

Peak Time is 133.3 u S

Positive Lo ck time is 510 u S

Negative Lock Ti me is 474 uS

14 SNAU137 LMX248x Evaluation Board User’s Guide Revised - March 2014

Copyright © 2014, Texas Instruments Incorporated

Page 15

www.ti.com

IF PLL Phase Noise

Revised - March 2014 LMX248x Evaluation Board User’s Guide SNAU137 15

Copyright © 2014, Texas Instruments Incorporated

Page 16

IF PLL Spurs

the loop bandwidth is wide relative to the

www.ti.com

Spurs at 50 kHz offset for an output frequency of

760 MHz are -97.5 dBc.

Note the cusping ef fect at 50 k Hz. This is because

comparison frequenc y. This is due to the discrete

sampling action of the phase detector.

Spurs at 50 kHz offset for an output frequency of

770 MHz are -81.7 dBc.

Spurs at 50 kHz offset for an output frequency of

780 MHz are -71.7 dBc.

16 SNAU137 LMX248x Evaluation Board User’s Guide Revised - March 2014

Copyright © 2014, Texas Instruments Incorporated

Page 17

RF Loop Filter

Phase Margin

46.5 deg

Pole Ratio T3

4.5 %

Loop Bandwidth

9.8 KHz

Pole Ratio

57.7 %

Theoretical Discrete

Lock Time

915 uS w/o CSR to 1

kHz

Roll-Off

@ 200 KHz

VCO

CPoRF

6.8 nF

220 nF

150 Ω

4.7 nF

15 nF

56 Ω 33

Ω

Kφ

8X (760 uA)

Comparison

Frequency

Output

Frequency

3200 – 3300

MHz

3.3 Volts from

regulator

VCO Supply

5.5 Volts

VCO Information

VCO Used

VARIL690-

KVCO

90 MHz/Volt

Input

Capacitance

IF Loop Filter

Theoretical

Time

Spur Gain

@ 50 KHz

VCO

CPoRF

680 pF

4.7 nF

4.7 KΩ

Open

0 Ω

Kφ

3.5 mA

Comparison

Frequency

Output

Frequency

2100 - 2200

MHz

3.3 Volts from

regulator

VCO Supply

5.5 volts

VCO Information

www.ti.com

LMX2486 Board Information

The LMX2486 Evaluation Board simplifies evaluat ion of the LMX2486 4.5 GHz/3.0 GHz PLLatinum

synthesizer. The board enables a ll performance measurements with no additional support circuitry. The evaluation

board consists of a LMX 2486 device, a RF VCO module and IF VCO & RF/IF loop fi lters built by discr ete components.

The SMA flange mount c onnector s are pr ovided f or ex ternal r ef erenc e inp ut, RF an d I F VCO outpu ts , and t he power and

grounding connection. A cable ass embly is bundled with the evaluation boar d f or c onnec ting to a PC thr ou gh the par allel

printer port. By means of USB2ANY-uWire serial port emulation, the CodeLoader software included can be run on a PC

to facilitate the LMX2486 internal register programming for the evaluation and measurement.

-42.7 dB

Settings for Operation

20 MHz

TM

dual frequency

Phase Margin 48.1 deg

Loop Bandwidth 16.8 KHz

PLL Supply

Discrete Lock

PLL Supply

22 pF

160 uS to 1 kHz

50.5 dB

Settings for Operation

200 kHz

Revised – March 2014 LMX248x Evaluation Board User’s Guide SNAU137 17

Copyright © 2014, Texas Instruments Incorporated

Page 18

VCO Used

VARIL190-

KVCO

80 MHz/Volt

Input

Capacitance

120 pF

RF PLL Phase Noise

Loop Bandwidth is about 10 k Hz. Note that the phase n oise graduall y improves as one goes f arther from the

carrier. This was taken with the IF PLL powered up and IF VCO connected.

www.ti.com

18 SNAU137 LMX248x Evaluation Board User’s Guide Revised – March 2014

Copyright © 2014, Texas Instruments Incorporated

Page 19

For this plot, the charge pump was increased to 16X and the other conditions were the same.

www.ti.com

Revised – March 2014 LMX248x Evaluation Board User’s Guide SNAU137 19

Copyright © 2014, Texas Instruments Incorporated

Page 20

www.ti.com

RF PLL Fractional Spurs

At 3200.2 MHz output fr equency, the primary

fractional spur at 200 kHz is

-80 dBc, and the sub-fractional spur at 100 kHz

is below the noise floor.

At 3240.2 MHz output fr equency, the primary

fractional spur at 200 kHz is

– 88 dBc and the sub-fractional spur at 100

kHz is below the noise floor.

At 3200.2 MHz output fr equency, the primary

fractional spur at 200 kH z is –82 dBc and the

sub-fractional spur is below the noise.

20 SNAU137 LMX248x Evaluation Board User’s Guide Revised – March 2014

Copyright © 2014, Texas Instruments Incorporated

Page 21

RF PLL Lock Time (With a Specturm Analyzer)

The first step is to tune the PLL to the

final frequency. On the spectrum

analyzer, set span to 0 Hz and the

dBm

of the spectrum analyzer can also be

the LE pulse, we measure the time it

takes to get and stay high enough in

increases to 2145 us. So cycle slip

it uses no external components and

requires no additional software

www.ti.com

frequency to the final frequenc y. Then

set the resolution bandwidth . If it is too

small, then it will make your lock time

look longer. If it is too large, frequency

resolution is lost. For this measurement,

30 kHz seems just about right. Now

adjust the sweep time to m atch the tim e

interval for the lock time measurement,

3 mS in this case. The power is –9.6

Now tune the PLL slight ly off fr equency.

If the PLL is tuned 10 kHz off frequency,

the output power drops to –11.1 dBm.

So when the output power is –11.1 dBm

or higher, we are theor etically within 10

kHz. If the PLL can not be tuned to fine

enough resolution, the cente r frequency

Cycle Slip Redu ctio n Enabl ed. R F_T OC= 25 00

offset.

Using the external trigger to trigger off

power to be about 720 u S to a 10 kHz

tolerance.

If the timeout counter is set to zero to

disable cycle slip reduction, the lock time

reduction is very worthwhile, considering

overhead, once the part is set up.

Revised – March 2014 LMX248x Evaluation Board User’s Guide SNAU137 21

Copyright © 2014, Texas Instruments Incorporated

Page 22

www.ti.com

IF PLL Phase Noise

The above plot was taken with the RF PLL powered down and IF VCO disconnected.

Above is the IF PLL phase noise with the RF PLL powered up.

22 SNAU137 LMX248x Evaluation Board User’s Guide Revised – March 2014

Copyright © 2014, Texas Instruments Incorporated

Page 23

IF PLL Spu rs

purs below the noise, but

www.ti.com

Fout = 2100 MHz

Not only are the s

they are actually improving the phase noise

near the offset of the spur!

This cusping effect is due to discrete s ampling

effects of the phase detector/charge pump that

occur if the loop band width is wide relative to

the comparison frequency.

Fout = 2150 MHz

Spurs at 200 kHz output frequency are

–82 dBc, although the noise is still being pulled

down due to this cusping effect.

Fout = 2200 MHz

Spurs at 200 kHz are not there and actually

reducing the noise due to discrete sampling

effects.

Revised – March 2014 LMX248x Evaluation Board User’s Guide SNAU137 23

Copyright © 2014, Texas Instruments Incorporated

Page 24

www.ti.com

IF PLL Lock T ime

Peak time is 73.3 uS. This peak time is

increased because the VCO tuning voltage is

approaching the rail of the c harge pump wh en

the PLL overshoots.

Peak Time is 37.8 uS

Positive Lock time is 253 uS

Negative Lock Time is 249 uS

24 SNAU137 LMX248x Evaluation Board User’s Guide Revised – March 2014

Copyright © 2014, Texas Instruments Incorporated

Page 25

Manufacturer

Part No.

Freq. Range (MHz)

Tuning Voltage

Universal Microwave

UMT-1051-I12

7150 - 7550

0.5 – 6.0

Universal Microwave

UMT-1050-I12

6800 - 6800

0.5 – 4.5

Spectrum Microwave

HVA103SM-22

6800 - 8000

0 - 20

Hittite

HMC532LP4

7100 - 7900

1 -13

www.ti.com

LMX2487 Board Information

Due to lack of availability for a VCO, there is no evaluation board avail able to evaluate the perform ance of the

LMX2487E. However, there are VCOs at higher frequency that are available in footprints that are not

compatible to this board that can be attached to it.

In order to demonstrate the perform ance of the LMX2487E, one can take the LMX2487 ev aluation board and

modify it for use with an external VCO. If the VCO is one that has a footprint that is the same or pinout

compatible, the best approach would be to rem ove the VCO from the ex isting LMX2487 evaluation board an d

replace the VCO. If the VCO is very different, it can be configured externally. Even though the LMX2487 is not

guaranteed to the sam e high f requenc y operatio n as the LMX2487 E, it is the same part, just tested to diff erent

specifications. The reason that the LMX2487E sells at a premium is that it requires a special test setup for high

frequency and the yields are a little lower. Therefore, even though the LMX2487 is being run above it’s

specified limits, it has a high probabilit y of working at these higher frequencies, the performance is just not

guaranteed.

Finding a VCO

Now this is the main problem. Many of the VCOs requi re higher tuning voltage or may have long lead tim es.

For VCOs that specify a higher tuning voltage than the LMX2487E can supply, there are two options. One is to

use an active filter and give the specified tuning voltage. Another solution is to use a pas sive traditional filt er

with the understanding that t he upper frequency range of the VCO wil l be less , s ince t he hi ghes t tun ing vo ltag e

can not be achieved.

Revised – March 2014 LMX248x Evaluation Board User’s Guide SNAU137 25

Copyright © 2014, Texas Instruments Incorporated

Page 26

www.ti.com

Replacing the VCO with a Footprint Compatible VCO

In order to replace the VCO, tak e component U2 an d replac e w ith the desired VCO. T he VCO m us t be of the

VARIL-T style footprint, which is used b y manufactures like Sirenza, Minicurcuits, Univer sal Microwave, and

Zcomm. However, it is suggested that if an LMX2487 board is being modified, the setup for that should be

verified. The dot signifies the tuning voltage.

26 SNAU137 LMX248x Evaluation Board User’s Guide Revised – March 2014

Copyright © 2014, Texas Instruments Incorporated

Page 27

www.ti.com

Appendix A: Schematics

LMX2487

Revised – March 2014 LMX248x Evaluation Board User’s Guide SNAU137 27

Copyright © 2014, Texas Instruments Incorporated

Page 28

Appendix B: Build Diagrams

LMX2485

www.ti.com

28 SNAU137 LMX248x Evaluation Board User’s Guide Revised – March 2014

Copyright © 2014, Texas Instruments Incorporated

Page 29

www.ti.com

LMX2486

Revised – March 2014 LMX248x Evaluation Board User’s Guide SNAU137 29

Copyright © 2014, Texas Instruments Incorporated

Page 30

LMX2487

www.ti.com

30 SNAU137 LMX248x Evaluation Board User’s Guide Revised – March 2014

Copyright © 2014, Texas Instruments Incorporated

Page 31

Manu-

facturer

Val-

ue

1 1 Texas Instruments

LMX2485SQACBPCB

er = 4.2

Top and Bottom Layers are 14 mil

Getek

n/a

2 4 SPC Technology

SPCS-6

Stand-Offs

Nylon

Place in 4 holds in edge of board

Place accross POWER_PLL (1-2, 3-4, 5-6, 7-8, 9-10,

and POWER_VCO (1-2, 3-4)

4 1 Com Con Connectors

HTSM3203-4G2

4-Pin

Header Plastic

POWER_VCO

5 1 Com Con Connectors

HTSM3203-12G2

12-Pin

Header Plastic

POWER_PLL

6 1 FCI Electronics

52601-S10-8

10-Pin

Header Plastic

uWire

Ftest/LD, IF_OUT, OSCin, RF_OUT, VccPLL,

VccVCO

C12, C13, C14, C15, C16, C17, C18, C19, C22, C23,

C27, C28, C30

10 1 Kemet

C0603C270J5GAC

270

pF

605

50 V

5%

C0G

C3_RF

11 1 Kemet

C0805C182J3GAC

1.8

nF

805

25 V

5%

C0G

C1_IF

12 1 Panasonic

ECHU1C103JX5

10

nF

805

16 V

5%

Film

C2_IF

13 1 Kemet

C0805C272J3GACTU

2.7

nF

603

C1_RF

14 2 Kemet

C0603C104K3RAC

100

nF

603

25 V

10%

X7R

C20, C21

15 1 Panasonic

ECHU1C473JB5

47

nF

1206

50 5 Film

C2pRF

16

11

Kemet

C0603C105K3PAC

1

uF

603

25 V

10%

X5R

C4, C5, C6, C7, C8, C9, C10, C11, C24, C25, C26

17 3 Kemet

T494A106K010AS

10

uF

1206

10 V

10%

Tantalum

C1, C2

18 3 Vishay

CRCW0603000ZRT1

0

ohm

0603

10 V

5%

Cermaic

R3_IF, R31

19 8 Vishay

CRCW0603100JRT1

10

ohm

0603

10 V

5%

Cermaic

R1, R4, R5, R6, R7, R8, R9, R10, R11

20 6 Vishay

CRCW0603180JRT1

18

ohm

0603

10 V

5%

Cermaic

R3, R27, R28, R29, R33, R34

21 1 Vishay

CRCW0603510FRT1

51

ohm

0603

10 V

1%

Cermaic

R32

22 1 Vishay

CRCW0603821JRT1

820

ohm

0603

10 V

5%

Cermaic

R2_RF

23 1 Vishay

CRCW0603392JRT1

3.9

Kohm

0603

10 V

5%

Cermaic

R3_RF

24 1 Vishay

CRCW0603562JRT1

5.6

Kohm

0603

10 V

5%

Cermaic

R4_RF

26 6 Vishay

CRCW0603103JRT1

10

Kohm

0603

10 V

5%

Cermaic

R13, R15, R17, R19, R21, R23

27 6 Vishay

CRCW0603123JRT1

12

Kohm

0603

10 V

5%

Cermaic

R12, R14, R16, R18, R20, R22

28 2 Steward

LI0603D301R-00

Inductor

nH

603

Ferrite

L1, L2

29 1 Texas Instruments

LMX2485

PLL

n/a

24P

3.6

n/a

Silicon

U1

2400 -

2480

31 1 VARIL

VCO191-773U

760-780

MHz U 3 V Can

U3

www.ti.com

LMX2485

Appendix C: Bill of Materials

Item Qty

-- C2_RF, C2pIF, C3, C3_IF, C29, C30p

0 25

3 8 Com Con Connectors CCIJ255G 2-Pin Shunt Plastic

7 6 Johnson Components 142-0701-851 Edge SMA Metal

8 13 Kemet C0603C470J5GAC 47 pF 603 50 V 5% C0G

9 1 Kemet C0603C180J5GAC 180 pF 604 50 V 5% C0G C4_RF

-- OSCin*, CPLR

-- R2, R2pRF, R3p, R24, R25, R26, R27p, R30, R33p

-- R100, R101, R102, R103, R104, R105, R106, C100, C101, C102

Part #

Unit Size Voltage Tolerance Material Designator

11-12)

25 1 Vishay CRCW0603822JRT1 8.2 Kohm 0603 10 V 5% Cermaic R2_IF

30 1 VARIL VCO191-2450U

MHz U 3 V Can U2

Revised – March 2014 LMX248x Evaluation Board User’s Guide SNAU137 31

Copyright © 2014, Texas Instruments Incorporated

Page 32

LMX2486

Item

Qty

Manufacturer

Part Number

Value

Unit

Size

Voltage

Tolerance

Material

Designator

C2pRF, C2_IF, C3_IF, C29, C100, C101

Ftest/LD, VccPLL

1 1 Texas Instruments

LMX2487SQAEBPCB

εr = 3.38

4 Layer board. Thickness is 62 mils.

Rogers 4003

n/a

4 1 Com Con Connectors

HTSM3203-4G2

4-Pin

Header Plastic

POWER_VCO

5 1 Com Con Connectors

HTSM3203-14G2

14-Pin

Header Plastic

POWER_PLL

6 1 FCI Electronics

52601-S10-8

10-Pin

Header Plastic

uWire

7 4 Johnson Components

142-0701-851

Edge SMA

Metal

IF_OUT, OSCin, RF_OUT, VccVCO

C19, C22, C23, C27, C28, C30, C33

9

1

Kemet

C0603C681J3GAC

680

pF

603

25 V

5%

C0G

C1_IF

10

1

Kemet

C0603C472J3RAC

4.7

nF

603

25 V

5%

X7R

C3_RF

11

1

Kemet

C0603C682J3RAC

6.8

nF

603

25 V

5%

X7R

C1_RF

12

1

Kemet

C1206C472J5GAC

4.7

nF

1206

50 V

5%

C0G

C2pIF

13

1

Kemet

C0603C153J3RAC

15

nF

603

25 V

5%

X7R

C4_RF

14

1

Kemet

C1206C103J3GAC

10

nF

1206

25 V

5%

C0G

C32

15

2

Kemet

C0603C104K3RAC

100

nF

603

25 V

10%

X7R

C20, C21

16

1

Kemet

C0805C224J4RAC

220

nF

805

16 V

5%

X7R

C2_RF

C3, C4, C5, C6, C7, C8, C9,

18

2

Kemet

C0805C106K8PAC

10

uF

805

10 V

10%

X5R

C1, C2

19 1 Vishay

CRCW0603000ZRT1

0

ohm

0603

10 V

5%

Cermaic

R3_IF

20 9 Vishay

CRCW0603100JRT1

10

ohm

0603

10 V

5%

Cermaic

R4, R5, R6, R7, R8, R9, R10, R11, R26

21 8 Vishay

CRCW0603180JRT1

18

ohm

0603

10 V

5%

Cermaic

R27, R28, R29, R30, R31, R32, L1, L2

22 1 Vishay

CRCW0603510FRT1

51

ohm

0603

10 V

1%

Cermaic

R2

23 1 Vishay

CRCW0603330FRT1

33

ohm

603

10 V

5%

Cermaic

R4_RF

24 1 Vishay

CRCW0603560FRT1

56

ohm

603

10 V

5%

Cermaic

R3_RF

25 1 Vishay

CRCW0603151JRT1

150

ohm

603

10 V

5%

Cermaic

R2_RF

26 1 Vishay

CRCW0603472JRT1

4.7

Kohm

0603

10 V

5%

Cermaic

R2_IF

27 5 Vishay

CRCW0603103JRT1

10

Kohm

0603

10 V

5%

Cermaic

R12, R14, R16, R18, R22

28 5 Vishay

CRCW0603123JRT1

12

Kohm

0603

10 V

5%

Cermaic

R13, R15, R17, R19, R23

29 1 Texas I nstruments

LMX2486SQ

PLL

n/a

24P

3.6 V

n/a

Silicon

U1

30 1 VARIL

VCO690-3300T

3120-3300

MHz T 5 V Can

U2

31 1 VARIL

VCO190-2200T

2100-2200

MHz T 5 V Can

U3

32 1 Texas I nstruments

LP3985IM5X-3.3

3.3

V

SOT23

3.3V Silicon

U4

www.ti.com

Revision

0 21

2 4 SPC Technolo gy SPCS-8 Stand-Offs Nylon Place in 4 holds in edge of board

3 9 Com Con Connectors CTIJ-255G 2-Pin Shunt Plastic

8 14 Kemet C0603C470J5GAC 47 pF 603 50 V 5% C0G

17 13 Kemet C0603C105K4PAC 1 uF 603 16 V 10% X5R

6/24/2005

Open

(No Component)

R1, R2pRF, R3, R20, R21, R24, R25, R27p

R30p, R100, R101, R102, R103

Place accross POWER_PLL

(1-2, 3-4, 5-6, 7-8, 9-10, 11-12, 13-14)

and POWER_VCO (1-2, 3-4)

C12, C13, C14, C15, C16, C17, C18,

C10, C11, C24, C25, C26, C31

32 SNAU137 LMX248x Evaluation Board User’s Guide Revised – March 2014

Copyright © 2014, Texas Instruments Incorporated

Page 33

Size

Voltage

Tolerance

Material

--

--

--

-1 1 Texas Instruments

LMX2487ESQACBPCB

er = 4.2

Top and Bottom Layers are 14 mil

Getek

n/a

2 4 SPC Technology

SPCS-6

Stand-Offs

Nylon

Place in 4 holds in edge of board

4 1 Com Con Connectors

HTSM3203-4G2

4-Pin

Header Plastic

POWER_VCO

5 1 Com Con Connectors

HTSM3203-12G2

12-Pin

Header Plastic

POWER_PLL

6 1 FCI Electronics

52601-S10-8

10-Pin

Header Plastic

uWire

7 6 Johnson Components

142-0701-851

Edge SMA

Metal

Ftest/LD, IF_OUT, OSCin, RF_OUT, VccPLL, VccVCO

8

13

Kemet

C0603C470J5GAC

47

pF

0603

50 V

5%

C0G

C12, C13, C14, C15, C16, C17, C18, C19, C22, C23, C27, C28, C30

9

1

Kemet

C0603C151J5GAC

150

pF

0603

50 V

5%

C0G

C4_RF

10

1

Kemet

C0603C181J5GAC

180

pF

0603

50 V

5%

C0G

C3_RF

11

1

Kemet

C0603C681J3GAC

680

pF

0603

25 V

5%

C0G

C1_IF

12

1

Kemet

C0805C472K3RAC

4.7

nF

0805

16 V

5%

X7R

C2_IF

13

1

Kemet

C0603C102J5GAC

1

nF

0603

25 V

5%

C0G

C1_RF

14

2

Kemet

C0603C104K3RAC

100

nF

0603

25 V

10%

X7R

C20, C21

15

1

Kemet

C0805C183K3RAC

18

nF

1206

16 V

20%

X7R

C2pRF

16

11

Kemet

C0603C105K3PAC

1

uF

0603

25 V

10%

X5R

C4, C5, C6, C7, C8, C9, C10, C11, C24, C25, C26

17

2

Kemet

T494A106K010AS

10

uF

1206

10 V

10%

Tantalum

C1, C2

18

2

Vishay

CRCW0603000ZRT1

0

ohm

0603

10 V

5%

Cermaic

R3_IF, R31

19

8

Vishay

CRCW0603100JRT1

10

ohm

0603

10 V

5%

Cermaic

R4, R5, R6, R7, R8, R9, R10, R11

20

6

Vishay

CRCW0603180JRT1

18

ohm

0603

10 V

5%

Cermaic

R3, R27, R28, R29, R33, R34

21

1

Vishay

CRCW0603510FRT1

51

ohm

0603

10 V

1%

Cermaic

R32

22

1

Vishay

CRCW0603272JRT1

2.7

Kohm

0603

10 V

5%

Cermaic

R2_RF

23

1

Vishay

CRCW0603472JRT1

4.7

Kohm

0603

10 V

5%

Cermaic

R3_RF

24

1

Vishay

CRCW0603682JRT1

6.8

Kohm

0603

10 V

5%

Cermaic

R4_RF

25

1

Vishay

CRCW0603472JRT1

4.7

Kohm

0603

10 V

5%

Cermaic

R2_IF

26

6

Vishay

CRCW0603103JRT1

10

Kohm

0603

10 V

5%

Cermaic

R13, R15, R17, R19, R21, R23

27

6

Vishay

CRCW0603123JRT1

12

Kohm

0603

10 V

5%

Cermaic

R12, R14, R16, R18, R20, R22

28 2 Steward

LI0603D301R-00

Inductor

nH

603

Ferrite

L1, L2

29

1

VARIL

MHz U 3 V Can

U2

30

1

VARIL

VCO191-773U

760-780

MHz U 3 V Can

U3

www.ti.com

LMX2487

# Qty Manufacturer Part # Value Unit

C2_RF, C2pIF, C3, C3_IF, C29, C30p

0 27

3 8 Com Con Connectors CCIJ255G 2-Pin Shunt Plastic

OSCin*, U1,CPLR

R1, R2, R2pRF, R3p, R24, R25, R26, R27p, R30, R33p

R100, R101, R102, R103, R104, R105, R106, C100, C101, C102

Designator

Place accross POWER_PLL (1-2, 3-4, 5-6, 7-8, 9-10, 11-12)

and POWER_VCO (1-2, 3-4)

Revised – March 2014 LMX248x Evaluation Board User’s Guide SNAU137 33

Copyright © 2014, Texas Instruments Incorporated

Page 34

www.ti.com

Appendix D: Q uick Start for EVM Communications

Codeloader is the software used to communicate with the EVM (Please download the latest version from

TI.com - http://www.ti.com/tool/codeloader

board. There are two options in communicating with the uWire interface from the computer.

OPTION 1

). This EVM can be control le d through the uWire interface on

Open Codeloader.exe Click “Select Device” Click “Port Setup” tab Click “LPT ” ( in Communication

Mode)

OPTION 2

34 SNAU137 LMX248x Evaluation Board Instructions Revised – March 2014

Copyright © 2014, Texas Instruments Incorporated

Page 35

Jumper Bank

Code Loader Configuration

A B C D E F G

H LMX2581

A4

B1

C2 E5

F1

G1

H1

BUFEN (pin 1), Trigger (pin 7)

LMX2541

A4 C3 E4

F1

G1

H1

CE (pin 1), Trigger (pin 10)

LMK0400x

A0 C3 E5

F1

G1

H1

GOE (pin 7)

LMK01000

A0 C1 E5

F1

G1

H1

GOE (pin 7)

LMK030xx

A0 C1 E5

F1

G1

H1

SYNC (pin 7)

LMK02000

A0 C1 E5

F1

G1

H1

SYNC (pin 7)

LMK0480x

A0

B2

C3 E5

F0

G0

H1

Status_CLKin1 (pin 3)

LMK04816/4906

A0

B2

C3 E5

F0

G0

H1

Status_CLKin1 (pin 3)

LMK01801

A0

B4

C5 E2

F0

G0

H1

Test (pin 3), SYNC0 (pin 10)

LMK0482x (prelease)

A0

B5

C3

D2

E4

F0

G0

H1

CLKin1_SEL (pin 6), Reset (pin 10)

LMX2531

A0 E5

F2

G1

H2

Trigger (pin 1)

LMX2485/7

A0 C1 E5

F2

G1

H0

ENOSC (pin 7), CE (pin 10)

LMK03200

A0 E5

F0

G0

H1

SYNC (pin 7)

LMK03806

A0 C1 E5

F0

G0

H1 LMK04100

A0 C1 E5

F1

G1

H1

www.ti.com

The Adapter Board

This table describes the pins configuration on the adapter board for each EVM board (See examples below table)

EVM

Example adapter configuration (LMK01801)

Open Codeloader.exe Click “Select Device” Click “Port Setup” Tab Click “USB” (in Communication

Mode)

*Remember to also make modifications in “Pin Configuration” Section according to Table above

Revised – March 2014 LMX248x Evaluation Board Instructions SNAU137 35

Copyright © 2014, Texas Instruments Incorporated

Page 36

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2014, Texas Instruments Incorporated

Page 37

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Texas Instruments:

LMX2487E-EVM LMX2485E-EVAL/NOPB

Loading...

Loading...