PRELIMINARY

LM3S617 Microcontroller

DATA SHEET

Copyright © 2007 Luminary Micro, Inc.DS-LM3S617-1972

Legal Disclaimers and Trademark Information

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH LUMINARY MICRO PRODUCTS. NO LICENSE, EXPRESS OR

IMPLIED, BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT

AS PROVIDED IN LUMINARY MICRO'S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, LUMINARY MICRO ASSUMES NO

LIABILITY WHATSOEVER,AND LUMINARYMICRO DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY,RELATING TO SALE AND/OR

USE OF LUMINARY MICRO'S PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

LUMINARY MICRO'S PRODUCTS ARE NOT INTENDED FOR USE IN MEDICAL, LIFE SAVING, OR LIFE-SUSTAINING APPLICATIONS.

Luminary Micro may make changes to specications and product descriptions at any time, without notice. Contact your local Luminary Micro sales ofce

or your distributor to obtain the latest specications before placing your product order.

Designers must not rely on the absence or characteristics of any features or instructions marked "reserved" or "undened." Luminary Micro reserves these

for future denition and shall have no responsibility whatsoever for conicts or incompatibilities arising from future changes to them.

Copyright © 2007 Luminary Micro, Inc. All rights reserved. Stellaris, Luminary Micro, and the Luminary Micro logo are registered trademarks of

Luminary Micro, Inc. or its subsidiaries in the United States and other countries. ARM and Thumb are registered trademarks and Cortex is a trademark

of ARM Limited. Other names and brands may be claimed as the property of others.

Luminary Micro, Inc.

108 Wild Basin, Suite 350

Austin, TX 78746

Main: +1-512-279-8800

Fax: +1-512-279-8879

http://www.luminarymicro.com

Preliminary

November 29, 20072

LM3S617 Microcontroller

Table of Contents

About This Document .................................................................................................................... 17

Audience .............................................................................................................................................. 17

About This Manual ................................................................................................................................ 17

Related Documents ............................................................................................................................... 17

Documentation Conventions .................................................................................................................. 17

1 Architectural Overview ...................................................................................................... 19

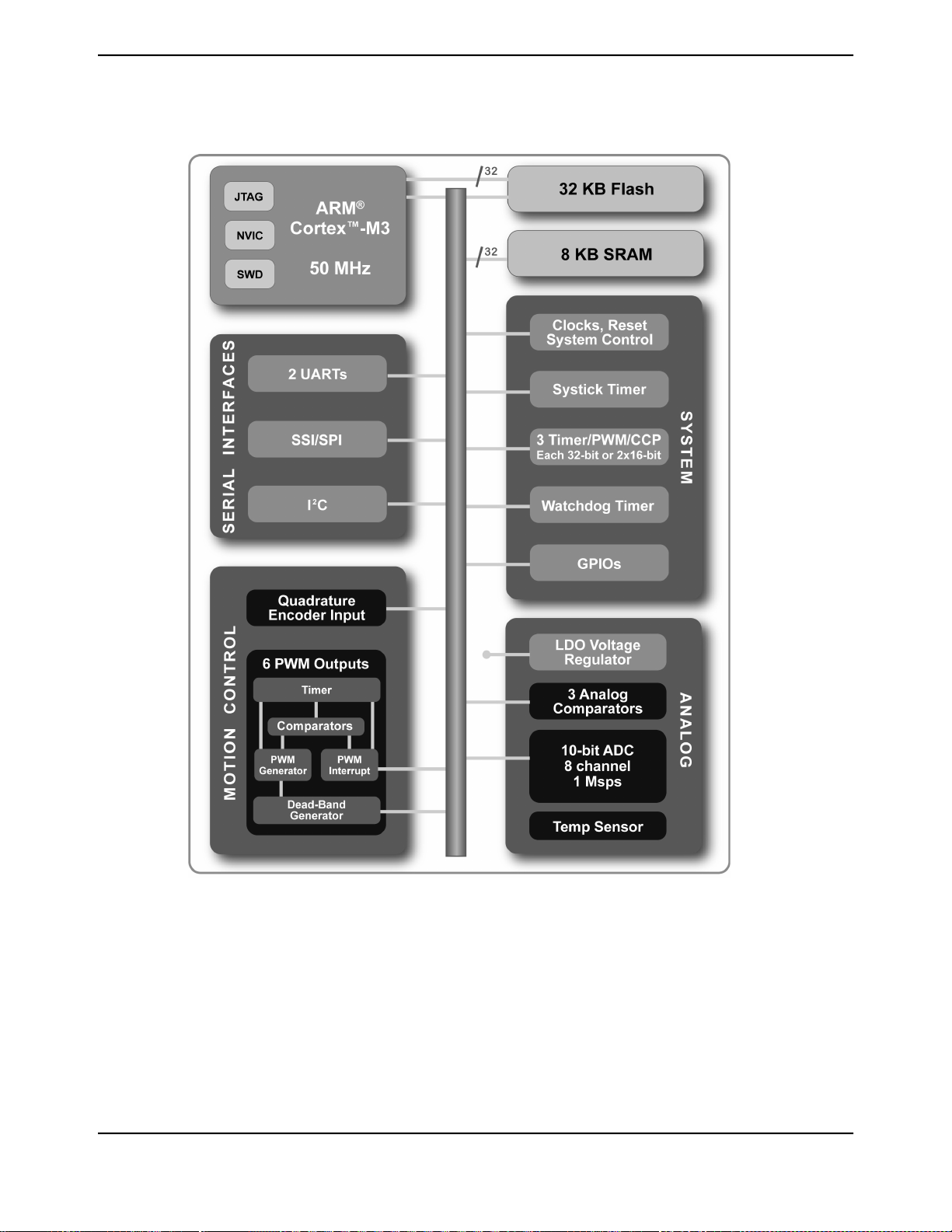

1.1 Product Features ...................................................................................................................... 19

1.2 Target Applications .................................................................................................................... 24

1.3 High-Level Block Diagram ......................................................................................................... 24

1.4 Functional Overview .................................................................................................................. 25

1.4.1 ARM Cortex™-M3 ..................................................................................................................... 26

1.4.2 Motor Control Peripherals .......................................................................................................... 26

1.4.3 Analog Peripherals .................................................................................................................... 27

1.4.4 Serial Communications Peripherals ............................................................................................ 28

1.4.5 System Peripherals ................................................................................................................... 28

1.4.6 Memory Peripherals .................................................................................................................. 29

1.4.7 Additional Features ................................................................................................................... 29

1.4.8 Hardware Details ...................................................................................................................... 30

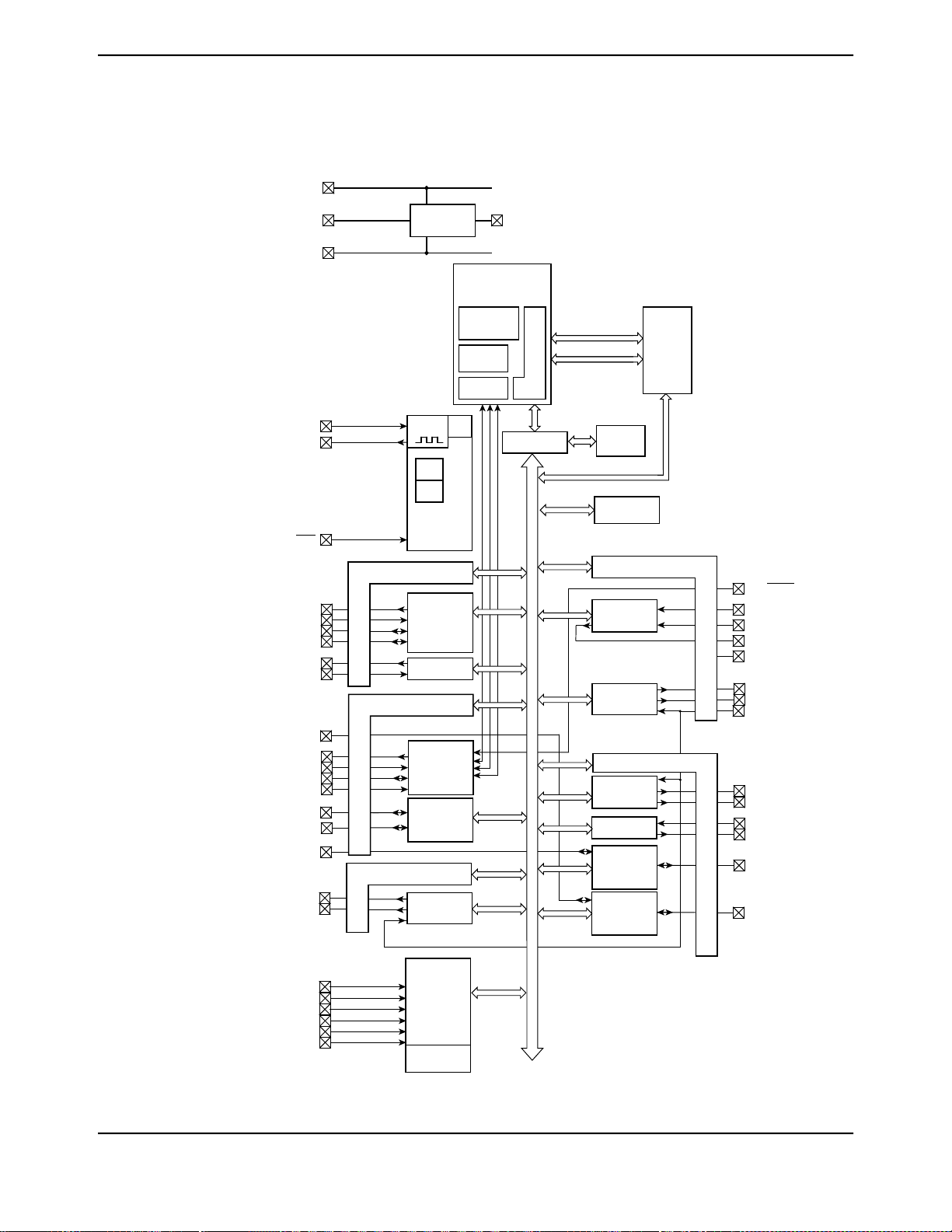

1.4.9 System Block Diagram .............................................................................................................. 31

2 ARM Cortex-M3 Processor Core ...................................................................................... 32

2.1 Block Diagram .......................................................................................................................... 33

2.2 Functional Description ............................................................................................................... 33

2.2.1 Serial Wire and JTAG Debug ..................................................................................................... 33

2.2.2 Embedded Trace Macrocell (ETM) ............................................................................................. 34

2.2.3 Trace Port Interface Unit (TPIU) ................................................................................................. 34

2.2.4 ROM Table ............................................................................................................................... 34

2.2.5 Memory Protection Unit (MPU) ................................................................................................... 34

2.2.6 Nested Vectored Interrupt Controller (NVIC) ................................................................................ 34

3 Memory Map ....................................................................................................................... 38

4 Interrupts ............................................................................................................................ 40

5 JTAG Interface .................................................................................................................... 42

5.1 Block Diagram .......................................................................................................................... 43

5.2 Functional Description ............................................................................................................... 43

5.2.1 JTAG Interface Pins .................................................................................................................. 44

5.2.2 JTAG TAP Controller ................................................................................................................. 45

5.2.3 Shift Registers .......................................................................................................................... 46

5.2.4 Operational Considerations ........................................................................................................ 46

5.3 Initialization and Configuration ................................................................................................... 47

5.4 Register Descriptions ................................................................................................................ 48

5.4.1 Instruction Register (IR) ............................................................................................................. 48

5.4.2 Data Registers .......................................................................................................................... 50

6 System Control ................................................................................................................... 52

6.1 Functional Description ............................................................................................................... 52

6.1.1 Device Identification .................................................................................................................. 52

Preliminary

3November 29, 2007

Table of Contents

6.1.2 Reset Control ............................................................................................................................ 52

6.1.3 Power Control ........................................................................................................................... 55

6.1.4 Clock Control ............................................................................................................................ 55

6.1.5 System Control ......................................................................................................................... 58

6.2 Initialization and Configuration ................................................................................................... 58

6.3 Register Map ............................................................................................................................ 59

6.4 Register Descriptions ................................................................................................................ 60

7 Internal Memory ............................................................................................................... 110

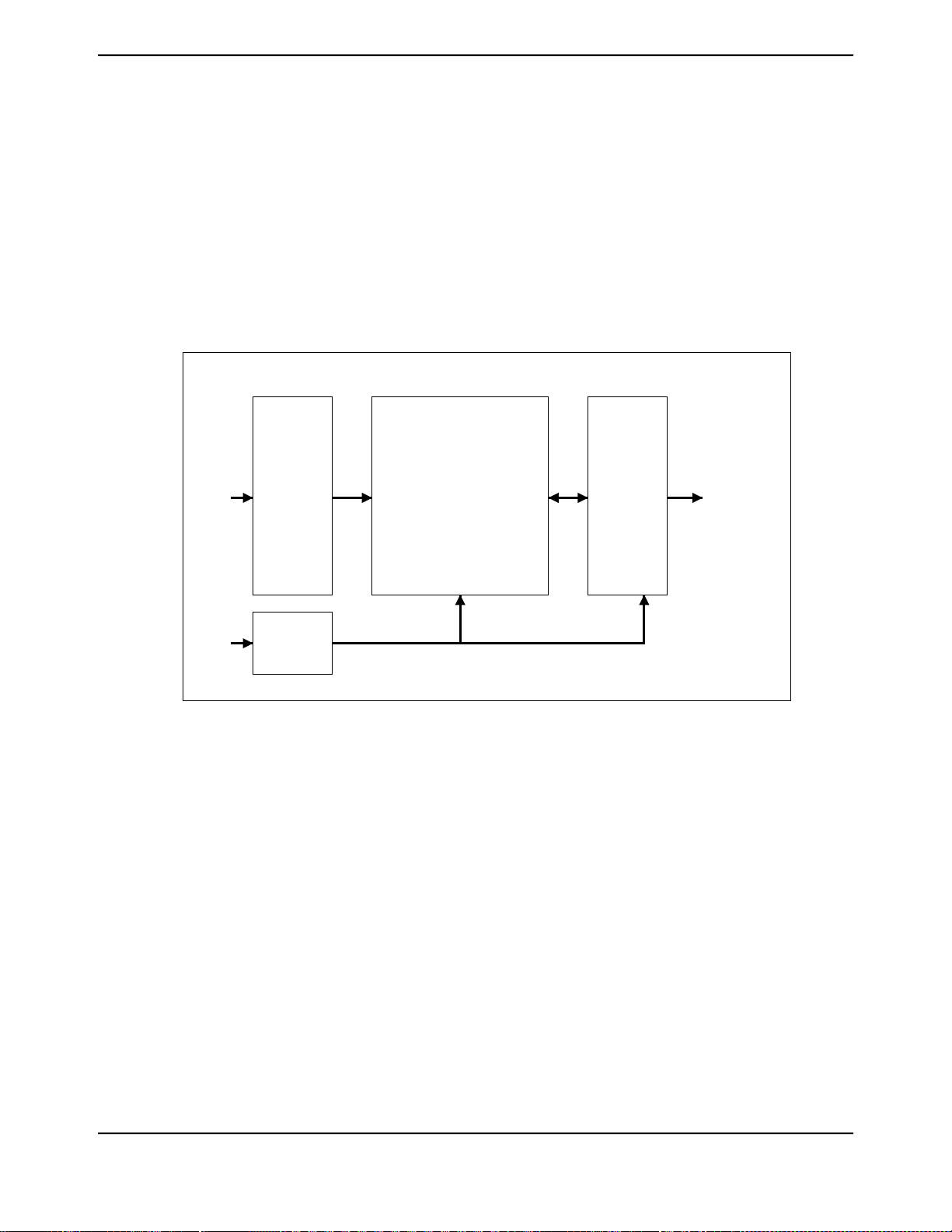

7.1 Block Diagram ........................................................................................................................ 110

7.2 Functional Description ............................................................................................................. 110

7.2.1 SRAM Memory ........................................................................................................................ 110

7.2.2 Flash Memory ......................................................................................................................... 111

7.3 Flash Memory Initialization and Configuration ........................................................................... 113

7.3.1 Changing Flash Protection Bits ................................................................................................ 113

7.3.2 Flash Programming ................................................................................................................. 114

7.4 Register Map .......................................................................................................................... 114

7.5 Flash Register Descriptions (Flash Control Offset) ..................................................................... 115

7.6 Flash Register Descriptions (System Control Offset) .................................................................. 122

8 General-Purpose Input/Outputs (GPIOs) ....................................................................... 126

8.1 Block Diagram ........................................................................................................................ 127

8.2 Functional Description ............................................................................................................. 127

8.2.1 Data Control ........................................................................................................................... 128

8.2.2 Interrupt Control ...................................................................................................................... 129

8.2.3 Mode Control .......................................................................................................................... 130

8.2.4 Pad Control ............................................................................................................................. 130

8.2.5 Identification ........................................................................................................................... 130

8.3 Initialization and Configuration ................................................................................................. 130

8.4 Register Map .......................................................................................................................... 131

8.5 Register Descriptions .............................................................................................................. 133

9 General-Purpose Timers ................................................................................................. 165

9.1 Block Diagram ........................................................................................................................ 165

9.2 Functional Description ............................................................................................................. 166

9.2.1 GPTM Reset Conditions .......................................................................................................... 166

9.2.2 32-Bit Timer Operating Modes .................................................................................................. 167

9.2.3 16-Bit Timer Operating Modes .................................................................................................. 168

9.3 Initialization and Configuration ................................................................................................. 172

9.3.1 32-Bit One-Shot/Periodic Timer Mode ....................................................................................... 172

9.3.2 32-Bit Real-Time Clock (RTC) Mode ......................................................................................... 173

9.3.3 16-Bit One-Shot/Periodic Timer Mode ....................................................................................... 173

9.3.4 16-Bit Input Edge Count Mode ................................................................................................. 174

9.3.5 16-Bit Input Edge Timing Mode ................................................................................................ 174

9.3.6 16-Bit PWM Mode ................................................................................................................... 175

9.4 Register Map .......................................................................................................................... 175

9.5 Register Descriptions .............................................................................................................. 176

10 Watchdog Timer ............................................................................................................... 201

10.1 Block Diagram ........................................................................................................................ 201

10.2 Functional Description ............................................................................................................. 201

Preliminary

November 29, 20074

LM3S617 Microcontroller

10.3 Initialization and Configuration ................................................................................................. 202

10.4 Register Map .......................................................................................................................... 202

10.5 Register Descriptions .............................................................................................................. 203

11 Analog-to-Digital Converter (ADC) ................................................................................. 224

11.1 Block Diagram ........................................................................................................................ 225

11.2 Functional Description ............................................................................................................. 225

11.2.1 Sample Sequencers ................................................................................................................ 225

11.2.2 Module Control ........................................................................................................................ 226

11.2.3 Hardware Sample Averaging Circuit ......................................................................................... 227

11.2.4 Analog-to-Digital Converter ...................................................................................................... 227

11.2.5 Test Modes ............................................................................................................................. 227

11.2.6 Internal Temperature Sensor .................................................................................................... 227

11.3 Initialization and Configuration ................................................................................................. 228

11.3.1 Module Initialization ................................................................................................................. 228

11.3.2 Sample Sequencer Configuration ............................................................................................. 228

11.4 Register Map .......................................................................................................................... 229

11.5 Register Descriptions .............................................................................................................. 230

12 Universal Asynchronous Receivers/Transmitters (UARTs) ......................................... 257

12.1 Block Diagram ........................................................................................................................ 258

12.2 Functional Description ............................................................................................................. 258

12.2.1 Transmit/Receive Logic ........................................................................................................... 258

12.2.2 Baud-Rate Generation ............................................................................................................. 259

12.2.3 Data Transmission .................................................................................................................. 260

12.2.4 FIFO Operation ....................................................................................................................... 260

12.2.5 Interrupts ................................................................................................................................ 260

12.2.6 Loopback Operation ................................................................................................................ 261

12.3 Initialization and Configuration ................................................................................................. 261

12.4 Register Map .......................................................................................................................... 262

12.5 Register Descriptions .............................................................................................................. 263

13 Synchronous Serial Interface (SSI) ................................................................................ 295

13.1 Block Diagram ........................................................................................................................ 295

13.2 Functional Description ............................................................................................................. 295

13.2.1 Bit Rate Generation ................................................................................................................. 296

13.2.2 FIFO Operation ....................................................................................................................... 296

13.2.3 Interrupts ................................................................................................................................ 296

13.2.4 Frame Formats ....................................................................................................................... 297

13.3 Initialization and Configuration ................................................................................................. 304

13.4 Register Map .......................................................................................................................... 305

13.5 Register Descriptions .............................................................................................................. 306

14 Analog Comparator ......................................................................................................... 332

14.1 Block Diagram ........................................................................................................................ 332

14.2 Functional Description ............................................................................................................. 332

14.2.1 Internal Reference Programming .............................................................................................. 333

14.3 Initialization and Configuration ................................................................................................. 334

14.4 Register Map .......................................................................................................................... 335

14.5 Register Descriptions .............................................................................................................. 335

Preliminary

5November 29, 2007

Table of Contents

15 Pulse Width Modulator (PWM) ........................................................................................ 343

15.1 Block Diagram ........................................................................................................................ 343

15.2 Functional Description ............................................................................................................. 343

15.2.1 PWM Timer ............................................................................................................................. 343

15.2.2 PWM Comparators .................................................................................................................. 344

15.2.3 PWM Signal Generator ............................................................................................................ 345

15.2.4 Dead-Band Generator ............................................................................................................. 346

15.2.5 Interrupt/ADC-Trigger Selector ................................................................................................. 346

15.2.6 Synchronization Methods ......................................................................................................... 346

15.2.7 Fault Conditions ...................................................................................................................... 347

15.2.8 Output Control Block ............................................................................................................... 347

15.3 Initialization and Configuration ................................................................................................. 347

15.4 Register Map .......................................................................................................................... 348

15.5 Register Descriptions .............................................................................................................. 350

16 Pin Diagram ...................................................................................................................... 379

17 Signal Tables .................................................................................................................... 380

18 Operating Characteristics ............................................................................................... 387

19 Electrical Characteristics ................................................................................................ 388

19.1 DC Characteristics .................................................................................................................. 388

19.1.1 Maximum Ratings ................................................................................................................... 388

19.1.2 Recommended DC Operating Conditions .................................................................................. 388

19.1.3 On-Chip Low Drop-Out (LDO) Regulator Characteristics ............................................................ 389

19.1.4 Power Specifications ............................................................................................................... 389

19.1.5 Flash Memory Characteristics .................................................................................................. 390

19.2 AC Characteristics ................................................................................................................... 390

19.2.1 Load Conditions ...................................................................................................................... 390

19.2.2 Clocks .................................................................................................................................... 390

19.2.3 Analog-to-Digital Converter ...................................................................................................... 391

19.2.4 Analog Comparator ................................................................................................................. 391

19.2.5 Synchronous Serial Interface (SSI) ........................................................................................... 392

19.2.6 JTAG and Boundary Scan ........................................................................................................ 393

19.2.7 General-Purpose I/O ............................................................................................................... 394

19.2.8 Reset ..................................................................................................................................... 395

20 Package Information ........................................................................................................ 398

A Serial Flash Loader .......................................................................................................... 400

A.1 Serial Flash Loader ................................................................................................................. 400

A.2 Interfaces ............................................................................................................................... 400

A.2.1 UART ..................................................................................................................................... 400

A.2.2 SSI ......................................................................................................................................... 400

A.3 Packet Handling ...................................................................................................................... 401

A.3.1 Packet Format ........................................................................................................................ 401

A.3.2 Sending Packets ..................................................................................................................... 401

A.3.3 Receiving Packets ................................................................................................................... 401

A.4 Commands ............................................................................................................................. 402

A.4.1 COMMAND_PING (0X20) ........................................................................................................ 402

A.4.2 COMMAND_GET_STATUS (0x23) ........................................................................................... 402

A.4.3 COMMAND_DOWNLOAD (0x21) ............................................................................................. 402

Preliminary

November 29, 20076

LM3S617 Microcontroller

A.4.4 COMMAND_SEND_DATA (0x24) ............................................................................................. 403

A.4.5 COMMAND_RUN (0x22) ......................................................................................................... 403

A.4.6 COMMAND_RESET (0x25) ..................................................................................................... 403

B Register Quick Reference ............................................................................................... 405

C Ordering and Contact Information ................................................................................. 420

C.1 Ordering Information ................................................................................................................ 420

C.2 Kits ......................................................................................................................................... 420

C.3 Company Information .............................................................................................................. 420

C.4 Support Information ................................................................................................................. 421

Preliminary

7November 29, 2007

Table of Contents

List of Figures

Figure 1-1. Stellaris®600 Series High-Level Block Diagram ................................................................ 25

Figure 1-2. LM3S617 Controller System-Level Block Diagram ............................................................. 31

Figure 2-1. CPU Block Diagram ......................................................................................................... 33

Figure 2-2. TPIU Block Diagram ........................................................................................................ 34

Figure 5-1. JTAG Module Block Diagram ............................................................................................ 43

Figure 5-2. Test Access Port State Machine ....................................................................................... 46

Figure 5-3. IDCODE Register Format ................................................................................................. 50

Figure 5-4. BYPASS Register Format ................................................................................................ 50

Figure 5-5. Boundary Scan Register Format ....................................................................................... 51

Figure 6-1. External Circuitry to Extend Reset .................................................................................... 53

Figure 6-2. Main Clock Tree .............................................................................................................. 56

Figure 7-1. Flash Block Diagram ...................................................................................................... 110

Figure 8-1. GPIO Module Block Diagram .......................................................................................... 127

Figure 8-2. GPIO Port Block Diagram ............................................................................................... 128

Figure 8-3. GPIODATA Write Example ............................................................................................. 129

Figure 8-4. GPIODATA Read Example ............................................................................................. 129

Figure 9-1. GPTM Module Block Diagram ........................................................................................ 166

Figure 9-2. 16-Bit Input Edge Count Mode Example .......................................................................... 170

Figure 9-3. 16-Bit Input Edge Time Mode Example ........................................................................... 171

Figure 9-4. 16-Bit PWM Mode Example ............................................................................................ 172

Figure 10-1. WDT Module Block Diagram .......................................................................................... 201

Figure 11-1. ADC Module Block Diagram ........................................................................................... 225

Figure 11-2. Internal Temperature Sensor Characteristic ..................................................................... 228

Figure 12-1. UART Module Block Diagram ......................................................................................... 258

Figure 12-2. UART Character Frame ................................................................................................. 259

Figure 13-1. SSI Module Block Diagram ............................................................................................. 295

Figure 13-2. TI Synchronous Serial Frame Format (Single Transfer) .................................................... 297

Figure 13-3. TI Synchronous Serial Frame Format (Continuous Transfer) ............................................ 298

Figure 13-4. Freescale SPI Format (Single Transfer) with SPO=0 and SPH=0 ...................................... 299

Figure 13-5. Freescale SPI Format (Continuous Transfer) with SPO=0 and SPH=0 .............................. 299

Figure 13-6. Freescale SPI Frame Format with SPO=0 and SPH=1 ..................................................... 300

Figure 13-7. Freescale SPI Frame Format (Single Transfer) with SPO=1 and SPH=0 ........................... 301

Figure 13-8. Freescale SPI Frame Format (Continuous Transfer) with SPO=1 and SPH=0 .................... 301

Figure 13-9. Freescale SPI Frame Format with SPO=1 and SPH=1 ..................................................... 302

Figure 13-10. MICROWIRE Frame Format (Single Frame) .................................................................... 303

Figure 13-11. MICROWIRE Frame Format (Continuous Transfer) ......................................................... 304

Figure 13-12. MICROWIRE Frame Format, SSIFss Input Setup and Hold Requirements ........................ 304

Figure 14-1. Analog Comparator Module Block Diagram ..................................................................... 332

Figure 14-2. Structure of Comparator Unit .......................................................................................... 333

Figure 14-3. Comparator Internal Reference Structure ........................................................................ 334

Figure 15-1. PWM Module Block Diagram .......................................................................................... 343

Figure 15-2. PWM Count-Down Mode ................................................................................................ 344

Figure 15-3. PWM Count-Up/Down Mode .......................................................................................... 345

Figure 15-4. PWM Generation Example In Count-Up/Down Mode ....................................................... 345

Figure 15-5. PWM Dead-Band Generator ........................................................................................... 346

Figure 16-1. Pin Connection Diagram ................................................................................................ 379

Preliminary

November 29, 20078

LM3S617 Microcontroller

Figure 19-1. Load Conditions ............................................................................................................ 390

Figure 19-2. SSI Timing for TI Frame Format (FRF=01), Single Transfer Timing Measurement .............. 392

Figure 19-3. SSI Timing for MICROWIRE Frame Format (FRF=10), Single Transfer ............................. 392

Figure 19-4. SSI Timing for SPI Frame Format (FRF=00), with SPH=1 ................................................. 393

Figure 19-5. JTAG Test Clock Input Timing ......................................................................................... 394

Figure 19-6. JTAG Test Access Port (TAP) Timing .............................................................................. 394

Figure 19-7. JTAG TRST Timing ........................................................................................................ 394

Figure 19-8. External Reset Timing (RST) .......................................................................................... 395

Figure 19-9. Power-On Reset Timing ................................................................................................. 396

Figure 19-10. Brown-Out Reset Timing ................................................................................................ 396

Figure 19-11. Software Reset Timing ................................................................................................... 396

Figure 19-12. Watchdog Reset Timing ................................................................................................. 397

Figure 19-13. LDO Reset Timing ......................................................................................................... 397

Figure 20-1. 48-Pin LQFP Package ................................................................................................... 398

Preliminary

9November 29, 2007

Table of Contents

List of Tables

Table 1. Documentation Conventions ............................................................................................ 17

Table 3-1. Memory Map ................................................................................................................... 38

Table 4-1. Exception Types .............................................................................................................. 40

Table 4-2. Interrupts ........................................................................................................................ 41

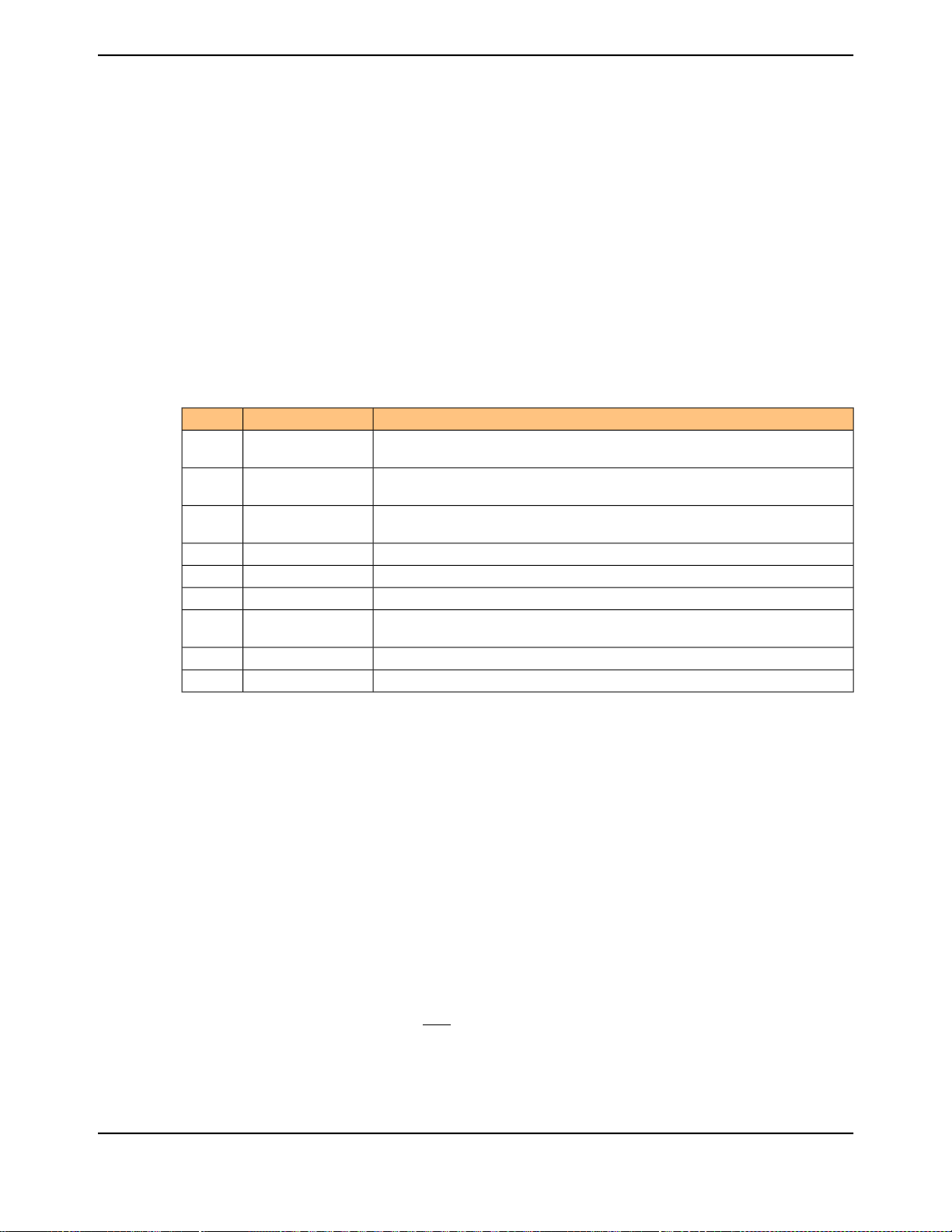

Table 5-1. JTAG Port Pins Reset State ............................................................................................. 44

Table 5-2. JTAG Instruction Register Commands ............................................................................... 48

Table 6-1. System Control Register Map ........................................................................................... 59

Table 6-2. PLL Mode Control ........................................................................................................... 74

Table 7-1. Flash Protection Policy Combinations ............................................................................. 112

Table 7-2. Flash Register Map ........................................................................................................ 115

Table 8-1. GPIO Pad Configuration Examples ................................................................................. 130

Table 8-2. GPIO Interrupt Configuration Example ............................................................................ 131

Table 8-3. GPIO Register Map ....................................................................................................... 132

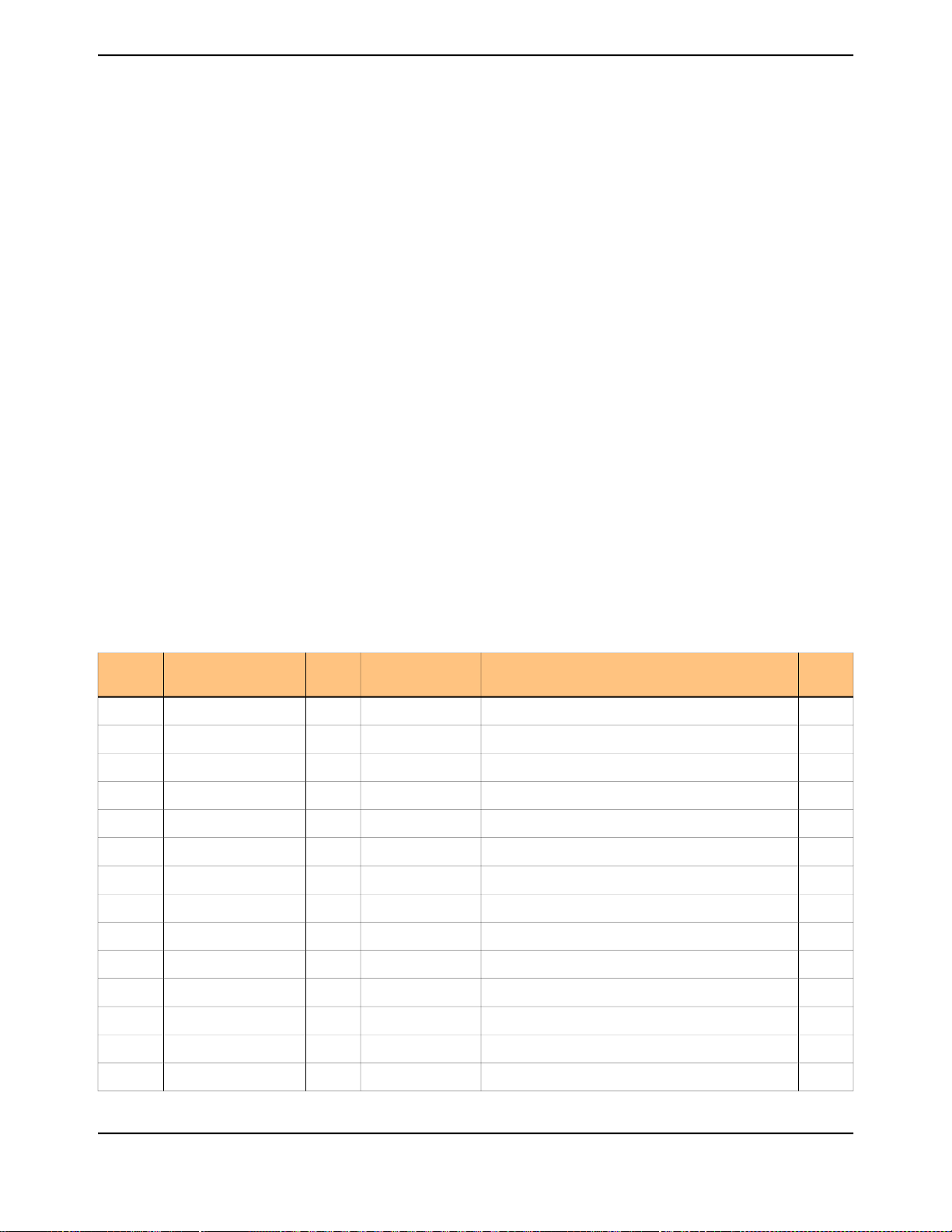

Table 9-1. Available CCP Pins ........................................................................................................ 166

Table 9-2. 16-Bit Timer With Prescaler Configurations ..................................................................... 169

Table 9-3. Timers Register Map ...................................................................................................... 175

Table 10-1. Watchdog Timer Register Map ........................................................................................ 202

Table 11-1. Samples and FIFO Depth of Sequencers ........................................................................ 225

Table 11-2. ADC Register Map ......................................................................................................... 229

Table 12-1. UART Register Map ....................................................................................................... 262

Table 13-1. SSI Register Map .......................................................................................................... 305

Table 14-1. Comparator 0 Operating Modes ...................................................................................... 333

Table 14-2. Internal Reference Voltage and ACREFCTL Field Values ................................................. 334

Table 14-3. Analog Comparators Register Map ................................................................................. 335

Table 15-1. PWM Register Map ........................................................................................................ 348

Table 17-1. Signals by Pin Number ................................................................................................... 380

Table 17-2. Signals by Signal Name ................................................................................................. 382

Table 17-3. Signals by Function, Except for GPIO ............................................................................. 384

Table 17-4. GPIO Pins and Alternate Functions ................................................................................. 385

Table 18-1. Temperature Characteristics ........................................................................................... 387

Table 18-2. Thermal Characteristics ................................................................................................. 387

Table 19-1. Maximum Ratings .......................................................................................................... 388

Table 19-2. Recommended DC Operating Conditions ........................................................................ 388

Table 19-3. LDO Regulator Characteristics ....................................................................................... 389

Table 19-4. Detailed Power Specifications ........................................................................................ 389

Table 19-5. Flash Memory Characteristics ........................................................................................ 390

Table 19-6. Phase Locked Loop (PLL) Characteristics ....................................................................... 390

Table 19-7. Clock Characteristics ..................................................................................................... 390

Table 19-8. ADC Characteristics ....................................................................................................... 391

Table 19-9. Analog Comparator Characteristics ................................................................................. 391

Table 19-10. Analog Comparator Voltage Reference Characteristics .................................................... 391

Table 19-11. SSI Characteristics ........................................................................................................ 392

Table 19-12. JTAG Characteristics ..................................................................................................... 393

Table 19-13. GPIO Characteristics ..................................................................................................... 395

Table 19-14. Reset Characteristics ..................................................................................................... 395

Table C-1. Part Ordering Information ............................................................................................... 420

Preliminary

November 29, 200710

LM3S617 Microcontroller

List of Registers

System Control .............................................................................................................................. 52

Register 1: Device Identification 0 (DID0), offset 0x000 ....................................................................... 61

Register 2: Power-On and Brown-Out Reset Control (PBORCTL), offset 0x030 .................................... 63

Register 3: LDO Power Control (LDOPCTL), offset 0x034 ................................................................... 64

Register 4: Raw Interrupt Status (RIS), offset 0x050 ........................................................................... 65

Register 5: Interrupt Mask Control (IMC), offset 0x054 ........................................................................ 66

Register 6: Masked Interrupt Status and Clear (MISC), offset 0x058 .................................................... 68

Register 7: Reset Cause (RESC), offset 0x05C .................................................................................. 69

Register 8: Run-Mode Clock Configuration (RCC), offset 0x060 .......................................................... 70

Register 9: XTAL to PLL Translation (PLLCFG), offset 0x064 .............................................................. 75

Register 10: Deep Sleep Clock Configuration (DSLPCLKCFG), offset 0x144 .......................................... 76

Register 11: Clock Verification Clear (CLKVCLR), offset 0x150 ............................................................. 77

Register 12: Allow Unregulated LDO to Reset the Part (LDOARST), offset 0x160 ................................... 78

Register 13: Device Identification 1 (DID1), offset 0x004 ....................................................................... 79

Register 14: Device Capabilities 0 (DC0), offset 0x008 ......................................................................... 81

Register 15: Device Capabilities 1 (DC1), offset 0x010 ......................................................................... 82

Register 16: Device Capabilities 2 (DC2), offset 0x014 ......................................................................... 84

Register 17: Device Capabilities 3 (DC3), offset 0x018 ......................................................................... 86

Register 18: Device Capabilities 4 (DC4), offset 0x01C ......................................................................... 88

Register 19: Run Mode Clock Gating Control Register 0 (RCGC0), offset 0x100 .................................... 89

Register 20: Sleep Mode Clock Gating Control Register 0 (SCGC0), offset 0x110 .................................. 91

Register 21: Deep Sleep Mode Clock Gating Control Register 0 (DCGC0), offset 0x120 ......................... 93

Register 22: Run Mode Clock Gating Control Register 1 (RCGC1), offset 0x104 .................................... 95

Register 23: Sleep Mode Clock Gating Control Register 1 (SCGC1), offset 0x114 .................................. 97

Register 24: Deep Sleep Mode Clock Gating Control Register 1 (DCGC1), offset 0x124 ......................... 99

Register 25: Run Mode Clock Gating Control Register 2 (RCGC2), offset 0x108 ................................... 101

Register 26: Sleep Mode Clock Gating Control Register 2 (SCGC2), offset 0x118 ................................. 103

Register 27: Deep Sleep Mode Clock Gating Control Register 2 (DCGC2), offset 0x128 ....................... 105

Register 28: Software Reset Control 0 (SRCR0), offset 0x040 ............................................................. 107

Register 29: Software Reset Control 1 (SRCR1), offset 0x044 ............................................................. 108

Register 30: Software Reset Control 2 (SRCR2), offset 0x048 ............................................................. 109

Internal Memory ........................................................................................................................... 110

Register 1: Flash Memory Address (FMA), offset 0x000 .................................................................... 116

Register 2: Flash Memory Data (FMD), offset 0x004 ......................................................................... 117

Register 3: Flash Memory Control (FMC), offset 0x008 ..................................................................... 118

Register 4: Flash Controller Raw Interrupt Status (FCRIS), offset 0x00C ............................................ 120

Register 5: Flash Controller Interrupt Mask (FCIM), offset 0x010 ........................................................ 121

Register 6: Flash Controller Masked Interrupt Status and Clear (FCMISC), offset 0x014 ..................... 122

Register 7: USec Reload (USECRL), offset 0x140 ............................................................................ 123

Register 8: Flash Memory Protection Read Enable (FMPRE), offset 0x130 ......................................... 124

Register 9: Flash Memory Protection Program Enable (FMPPE), offset 0x134 .................................... 125

General-Purpose Input/Outputs (GPIOs) ................................................................................... 126

Register 1: GPIO Data (GPIODATA), offset 0x000 ............................................................................ 134

Register 2: GPIO Direction (GPIODIR), offset 0x400 ......................................................................... 135

Register 3: GPIO Interrupt Sense (GPIOIS), offset 0x404 .................................................................. 136

Preliminary

11November 29, 2007

Table of Contents

Register 4: GPIO Interrupt Both Edges (GPIOIBE), offset 0x408 ........................................................ 137

Register 5: GPIO Interrupt Event (GPIOIEV), offset 0x40C ................................................................ 138

Register 6: GPIO Interrupt Mask (GPIOIM), offset 0x410 ................................................................... 139

Register 7: GPIO Raw Interrupt Status (GPIORIS), offset 0x414 ........................................................ 140

Register 8: GPIO Masked Interrupt Status (GPIOMIS), offset 0x418 ................................................... 141

Register 9: GPIO Interrupt Clear (GPIOICR), offset 0x41C ................................................................ 142

Register 10: GPIO Alternate Function Select (GPIOAFSEL), offset 0x420 ............................................ 143

Register 11: GPIO 2-mA Drive Select (GPIODR2R), offset 0x500 ........................................................ 145

Register 12: GPIO 4-mA Drive Select (GPIODR4R), offset 0x504 ........................................................ 146

Register 13: GPIO 8-mA Drive Select (GPIODR8R), offset 0x508 ........................................................ 147

Register 14: GPIO Open Drain Select (GPIOODR), offset 0x50C ......................................................... 148

Register 15: GPIO Pull-Up Select (GPIOPUR), offset 0x510 ................................................................ 149

Register 16: GPIO Pull-Down Select (GPIOPDR), offset 0x514 ........................................................... 150

Register 17: GPIO Slew Rate Control Select (GPIOSLR), offset 0x518 ................................................ 151

Register 18: GPIO Digital Enable (GPIODEN), offset 0x51C ................................................................ 152

Register 19: GPIO Peripheral Identification 4 (GPIOPeriphID4), offset 0xFD0 ....................................... 153

Register 20: GPIO Peripheral Identification 5 (GPIOPeriphID5), offset 0xFD4 ....................................... 154

Register 21: GPIO Peripheral Identification 6 (GPIOPeriphID6), offset 0xFD8 ....................................... 155

Register 22: GPIO Peripheral Identification 7 (GPIOPeriphID7), offset 0xFDC ...................................... 156

Register 23: GPIO Peripheral Identification 0 (GPIOPeriphID0), offset 0xFE0 ....................................... 157

Register 24: GPIO Peripheral Identification 1 (GPIOPeriphID1), offset 0xFE4 ....................................... 158

Register 25: GPIO Peripheral Identification 2 (GPIOPeriphID2), offset 0xFE8 ....................................... 159

Register 26: GPIO Peripheral Identification 3 (GPIOPeriphID3), offset 0xFEC ...................................... 160

Register 27: GPIO PrimeCell Identification 0 (GPIOPCellID0), offset 0xFF0 .......................................... 161

Register 28: GPIO PrimeCell Identification 1 (GPIOPCellID1), offset 0xFF4 .......................................... 162

Register 29: GPIO PrimeCell Identification 2 (GPIOPCellID2), offset 0xFF8 .......................................... 163

Register 30: GPIO PrimeCell Identification 3 (GPIOPCellID3), offset 0xFFC ......................................... 164

General-Purpose Timers ............................................................................................................. 165

Register 1: GPTM Configuration (GPTMCFG), offset 0x000 .............................................................. 177

Register 2: GPTM TimerA Mode (GPTMTAMR), offset 0x004 ............................................................ 178

Register 3: GPTM TimerB Mode (GPTMTBMR), offset 0x008 ............................................................ 180

Register 4: GPTM Control (GPTMCTL), offset 0x00C ........................................................................ 182

Register 5: GPTM Interrupt Mask (GPTMIMR), offset 0x018 .............................................................. 185

Register 6: GPTM Raw Interrupt Status (GPTMRIS), offset 0x01C ..................................................... 187

Register 7: GPTM Masked Interrupt Status (GPTMMIS), offset 0x020 ................................................ 188

Register 8: GPTM Interrupt Clear (GPTMICR), offset 0x024 .............................................................. 189

Register 9: GPTM TimerA Interval Load (GPTMTAILR), offset 0x028 ................................................. 191

Register 10: GPTM TimerB Interval Load (GPTMTBILR), offset 0x02C ................................................ 192

Register 11: GPTM TimerA Match (GPTMTAMATCHR), offset 0x030 ................................................... 193

Register 12: GPTM TimerB Match (GPTMTBMATCHR), offset 0x034 .................................................. 194

Register 13: GPTM TimerA Prescale (GPTMTAPR), offset 0x038 ........................................................ 195

Register 14: GPTM TimerB Prescale (GPTMTBPR), offset 0x03C ....................................................... 196

Register 15: GPTM TimerA Prescale Match (GPTMTAPMR), offset 0x040 ........................................... 197

Register 16: GPTM TimerB Prescale Match (GPTMTBPMR), offset 0x044 ........................................... 198

Register 17: GPTM TimerA (GPTMTAR), offset 0x048 ........................................................................ 199

Register 18: GPTM TimerB (GPTMTBR), offset 0x04C ....................................................................... 200

Watchdog Timer ........................................................................................................................... 201

Register 1: Watchdog Load (WDTLOAD), offset 0x000 ...................................................................... 204

Preliminary

November 29, 200712

LM3S617 Microcontroller

Register 2: Watchdog Value (WDTVALUE), offset 0x004 ................................................................... 205

Register 3: Watchdog Control (WDTCTL), offset 0x008 ..................................................................... 206

Register 4: Watchdog Interrupt Clear (WDTICR), offset 0x00C .......................................................... 207

Register 5: Watchdog Raw Interrupt Status (WDTRIS), offset 0x010 .................................................. 208

Register 6: Watchdog Masked Interrupt Status (WDTMIS), offset 0x014 ............................................. 209

Register 7: Watchdog Test (WDTTEST), offset 0x418 ....................................................................... 210

Register 8: Watchdog Lock (WDTLOCK), offset 0xC00 ..................................................................... 211

Register 9: Watchdog Peripheral Identification 4 (WDTPeriphID4), offset 0xFD0 ................................. 212

Register 10: Watchdog Peripheral Identification 5 (WDTPeriphID5), offset 0xFD4 ................................. 213

Register 11: Watchdog Peripheral Identification 6 (WDTPeriphID6), offset 0xFD8 ................................. 214

Register 12: Watchdog Peripheral Identification 7 (WDTPeriphID7), offset 0xFDC ................................ 215

Register 13: Watchdog Peripheral Identification 0 (WDTPeriphID0), offset 0xFE0 ................................. 216

Register 14: Watchdog Peripheral Identification 1 (WDTPeriphID1), offset 0xFE4 ................................. 217

Register 15: Watchdog Peripheral Identification 2 (WDTPeriphID2), offset 0xFE8 ................................. 218

Register 16: Watchdog Peripheral Identification 3 (WDTPeriphID3), offset 0xFEC ................................. 219

Register 17: Watchdog PrimeCell Identification 0 (WDTPCellID0), offset 0xFF0 .................................... 220

Register 18: Watchdog PrimeCell Identification 1 (WDTPCellID1), offset 0xFF4 .................................... 221

Register 19: Watchdog PrimeCell Identification 2 (WDTPCellID2), offset 0xFF8 .................................... 222

Register 20: Watchdog PrimeCell Identification 3 (WDTPCellID3 ), offset 0xFFC .................................. 223

Analog-to-Digital Converter (ADC) ............................................................................................. 224

Register 1: ADC Active Sample Sequencer (ADCACTSS), offset 0x000 ............................................. 231

Register 2: ADC Raw Interrupt Status (ADCRIS), offset 0x004 ........................................................... 232

Register 3: ADC Interrupt Mask (ADCIM), offset 0x008 ..................................................................... 233

Register 4: ADC Interrupt Status and Clear (ADCISC), offset 0x00C .................................................. 234

Register 5: ADC Overflow Status (ADCOSTAT), offset 0x010 ............................................................ 235

Register 6: ADC Event Multiplexer Select (ADCEMUX), offset 0x014 ................................................. 236

Register 7: ADC Underflow Status (ADCUSTAT), offset 0x018 ........................................................... 239

Register 8: ADC Sample Sequencer Priority (ADCSSPRI), offset 0x020 ............................................. 240

Register 9: ADC Processor Sample Sequence Initiate (ADCPSSI), offset 0x028 ................................. 241

Register 10: ADC Sample Averaging Control (ADCSAC), offset 0x030 ................................................. 242

Register 11: ADC Sample Sequence Input Multiplexer Select 0 (ADCSSMUX0), offset 0x040 ............... 243

Register 12: ADC Sample Sequence Control 0 (ADCSSCTL0), offset 0x044 ........................................ 245

Register 13: ADC Sample Sequence Result FIFO 0 (ADCSSFIFO0), offset 0x048 ................................ 248

Register 14: ADC Sample Sequence Result FIFO 1 (ADCSSFIFO1), offset 0x068 ................................ 248

Register 15: ADC Sample Sequence Result FIFO 2 (ADCSSFIFO2), offset 0x088 ................................ 248

Register 16: ADC Sample Sequence Result FIFO 3 (ADCSSFIFO3), offset 0x0A8 ............................... 248

Register 17: ADC Sample Sequence FIFO 0 Status (ADCSSFSTAT0), offset 0x04C ............................. 249

Register 18: ADC Sample Sequence FIFO 1 Status (ADCSSFSTAT1), offset 0x06C ............................. 249

Register 19: ADC Sample Sequence FIFO 2 Status (ADCSSFSTAT2), offset 0x08C ............................ 249

Register 20: ADC Sample Sequence FIFO 3 Status (ADCSSFSTAT3), offset 0x0AC ............................ 249

Register 21: ADC Sample Sequence Input Multiplexer Select 1 (ADCSSMUX1), offset 0x060 ............... 250

Register 22: ADC Sample Sequence Input Multiplexer Select 2 (ADCSSMUX2), offset 0x080 ............... 250

Register 23: ADC Sample Sequence Control 1 (ADCSSCTL1), offset 0x064 ........................................ 251

Register 24: ADC Sample Sequence Control 2 (ADCSSCTL2), offset 0x084 ........................................ 251

Register 25: ADC Sample Sequence Input Multiplexer Select 3 (ADCSSMUX3), offset 0x0A0 ............... 253

Register 26: ADC Sample Sequence Control 3 (ADCSSCTL3), offset 0x0A4 ........................................ 254

Register 27: ADC Test Mode Loopback (ADCTMLB), offset 0x100 ....................................................... 255

Preliminary

13November 29, 2007

Table of Contents

Universal Asynchronous Receivers/Transmitters (UARTs) ..................................................... 257

Register 1: UART Data (UARTDR), offset 0x000 ............................................................................... 264

Register 2: UART Receive Status/Error Clear (UARTRSR/UARTECR), offset 0x004 ........................... 266

Register 3: UART Flag (UARTFR), offset 0x018 ................................................................................ 268

Register 4: UART Integer Baud-Rate Divisor (UARTIBRD), offset 0x024 ............................................ 270

Register 5: UART Fractional Baud-Rate Divisor (UARTFBRD), offset 0x028 ....................................... 271

Register 6: UART Line Control (UARTLCRH), offset 0x02C ............................................................... 272

Register 7: UART Control (UARTCTL), offset 0x030 ......................................................................... 274

Register 8: UART Interrupt FIFO Level Select (UARTIFLS), offset 0x034 ........................................... 275

Register 9: UART Interrupt Mask (UARTIM), offset 0x038 ................................................................. 277

Register 10: UART Raw Interrupt Status (UARTRIS), offset 0x03C ...................................................... 279

Register 11: UART Masked Interrupt Status (UARTMIS), offset 0x040 ................................................. 280

Register 12: UART Interrupt Clear (UARTICR), offset 0x044 ............................................................... 281

Register 13: UART Peripheral Identification 4 (UARTPeriphID4), offset 0xFD0 ..................................... 283

Register 14: UART Peripheral Identification 5 (UARTPeriphID5), offset 0xFD4 ..................................... 284

Register 15: UART Peripheral Identification 6 (UARTPeriphID6), offset 0xFD8 ..................................... 285

Register 16: UART Peripheral Identification 7 (UARTPeriphID7), offset 0xFDC ..................................... 286

Register 17: UART Peripheral Identification 0 (UARTPeriphID0), offset 0xFE0 ...................................... 287

Register 18: UART Peripheral Identification 1 (UARTPeriphID1), offset 0xFE4 ...................................... 288

Register 19: UART Peripheral Identification 2 (UARTPeriphID2), offset 0xFE8 ...................................... 289

Register 20: UART Peripheral Identification 3 (UARTPeriphID3), offset 0xFEC ..................................... 290

Register 21: UART PrimeCell Identification 0 (UARTPCellID0), offset 0xFF0 ........................................ 291

Register 22: UART PrimeCell Identification 1 (UARTPCellID1), offset 0xFF4 ........................................ 292

Register 23: UART PrimeCell Identification 2 (UARTPCellID2), offset 0xFF8 ........................................ 293

Register 24: UART PrimeCell Identification 3 (UARTPCellID3), offset 0xFFC ........................................ 294

Synchronous Serial Interface (SSI) ............................................................................................ 295

Register 1: SSI Control 0 (SSICR0), offset 0x000 .............................................................................. 307

Register 2: SSI Control 1 (SSICR1), offset 0x004 .............................................................................. 309

Register 3: SSI Data (SSIDR), offset 0x008 ...................................................................................... 311

Register 4: SSI Status (SSISR), offset 0x00C ................................................................................... 312

Register 5: SSI Clock Prescale (SSICPSR), offset 0x010 .................................................................. 314

Register 6: SSI Interrupt Mask (SSIIM), offset 0x014 ......................................................................... 315

Register 7: SSI Raw Interrupt Status (SSIRIS), offset 0x018 .............................................................. 317

Register 8: SSI Masked Interrupt Status (SSIMIS), offset 0x01C ........................................................ 318

Register 9: SSI Interrupt Clear (SSIICR), offset 0x020 ....................................................................... 319

Register 10: SSI Peripheral Identification 4 (SSIPeriphID4), offset 0xFD0 ............................................. 320

Register 11: SSI Peripheral Identification 5 (SSIPeriphID5), offset 0xFD4 ............................................. 321

Register 12: SSI Peripheral Identification 6 (SSIPeriphID6), offset 0xFD8 ............................................. 322

Register 13: SSI Peripheral Identification 7 (SSIPeriphID7), offset 0xFDC ............................................ 323

Register 14: SSI Peripheral Identification 0 (SSIPeriphID0), offset 0xFE0 ............................................. 324

Register 15: SSI Peripheral Identification 1 (SSIPeriphID1), offset 0xFE4 ............................................. 325

Register 16: SSI Peripheral Identification 2 (SSIPeriphID2), offset 0xFE8 ............................................. 326

Register 17: SSI Peripheral Identification 3 (SSIPeriphID3), offset 0xFEC ............................................ 327

Register 18: SSI PrimeCell Identification 0 (SSIPCellID0), offset 0xFF0 ............................................... 328

Register 19: SSI PrimeCell Identification 1 (SSIPCellID1), offset 0xFF4 ............................................... 329

Register 20: SSI PrimeCell Identification 2 (SSIPCellID2), offset 0xFF8 ............................................... 330

Register 21: SSI PrimeCell Identification 3 (SSIPCellID3), offset 0xFFC ............................................... 331

Preliminary

November 29, 200714

LM3S617 Microcontroller

Analog Comparator ..................................................................................................................... 332

Register 1: Analog Comparator Masked Interrupt Status (ACMIS), offset 0x00 .................................... 336

Register 2: Analog Comparator Raw Interrupt Status (ACRIS), offset 0x04 ......................................... 337

Register 3: Analog Comparator Interrupt Enable (ACINTEN), offset 0x08 ........................................... 338

Register 4: Analog Comparator Reference Voltage Control (ACREFCTL), offset 0x10 ......................... 339

Register 5: Analog Comparator Status 0 (ACSTAT0), offset 0x20 ....................................................... 340

Register 6: Analog Comparator Control 0 (ACCTL0), offset 0x24 ....................................................... 341

Pulse Width Modulator (PWM) .................................................................................................... 343

Register 1: PWM Master Control (PWMCTL), offset 0x000 ................................................................ 351

Register 2: PWM Time Base Sync (PWMSYNC), offset 0x004 ........................................................... 352

Register 3: PWM Output Enable (PWMENABLE), offset 0x008 .......................................................... 353

Register 4: PWM Output Inversion (PWMINVERT), offset 0x00C ....................................................... 354

Register 5: PWM Output Fault (PWMFAULT), offset 0x010 ................................................................ 355

Register 6: PWM Interrupt Enable (PWMINTEN), offset 0x014 ........................................................... 356

Register 7: PWM Raw Interrupt Status (PWMRIS), offset 0x018 ........................................................ 357

Register 8: PWM Interrupt Status and Clear (PWMISC), offset 0x01C ................................................ 358

Register 9: PWM Status (PWMSTATUS), offset 0x020 ...................................................................... 359

Register 10: PWM0 Control (PWM0CTL), offset 0x040 ....................................................................... 360

Register 11: PWM1 Control (PWM1CTL), offset 0x080 ....................................................................... 360

Register 12: PWM2 Control (PWM2CTL), offset 0x0C0 ...................................................................... 360

Register 13: PWM0 Interrupt and Trigger Enable (PWM0INTEN), offset 0x044 .................................... 362

Register 14: PWM1 Interrupt and Trigger Enable (PWM1INTEN), offset 0x084 .................................... 362

Register 15: PWM2 Interrupt and Trigger Enable (PWM2INTEN), offset 0x0C4 .................................... 362

Register 16: PWM0 Raw Interrupt Status (PWM0RIS), offset 0x048 .................................................... 364

Register 17: PWM1 Raw Interrupt Status (PWM1RIS), offset 0x088 .................................................... 364

Register 18: PWM2 Raw Interrupt Status (PWM2RIS), offset 0x0C8 ................................................... 364

Register 19: PWM0 Interrupt Status and Clear (PWM0ISC), offset 0x04C ........................................... 365

Register 20: PWM1 Interrupt Status and Clear (PWM1ISC), offset 0x08C ........................................... 365

Register 21: PWM2 Interrupt Status and Clear (PWM2ISC), offset 0x0CC ........................................... 365

Register 22: PWM0 Load (PWM0LOAD), offset 0x050 ....................................................................... 366

Register 23: PWM1 Load (PWM1LOAD), offset 0x090 ....................................................................... 366

Register 24: PWM2 Load (PWM2LOAD), offset 0x0D0 ....................................................................... 366

Register 25: PWM0 Counter (PWM0COUNT), offset 0x054 ................................................................ 367

Register 26: PWM1 Counter (PWM1COUNT), offset 0x094 ................................................................ 367

Register 27: PWM2 Counter (PWM2COUNT), offset 0x0D4 ............................................................... 367

Register 28: PWM0 Compare A (PWM0CMPA), offset 0x058 ............................................................. 368

Register 29: PWM1 Compare A (PWM1CMPA), offset 0x098 ............................................................. 368

Register 30: PWM2 Compare A (PWM2CMPA), offset 0x0D8 ............................................................. 368

Register 31: PWM0 Compare B (PWM0CMPB), offset 0x05C ............................................................. 369

Register 32: PWM1 Compare B (PWM1CMPB), offset 0x09C ............................................................. 369

Register 33: PWM2 Compare B (PWM2CMPB), offset 0x0DC ............................................................ 369

Register 34: PWM0 Generator A Control (PWM0GENA), offset 0x060 ................................................ 370

Register 35: PWM1 Generator A Control (PWM1GENA), offset 0x0A0 ................................................ 370

Register 36: PWM2 Generator A Control (PWM2GENA), offset 0x0E0 ................................................ 370

Register 37: PWM0 Generator B Control (PWM0GENB), offset 0x064 ................................................ 373

Register 38: PWM1 Generator B Control (PWM1GENB), offset 0x0A4 ................................................ 373

Register 39: PWM2 Generator B Control (PWM2GENB), offset 0x0E4 ................................................ 373

Register 40: PWM0 Dead-Band Control (PWM0DBCTL), offset 0x068 ................................................ 376

Preliminary

15November 29, 2007

Table of Contents

Register 41: PWM1 Dead-Band Control (PWM1DBCTL), offset 0x0A8 ................................................. 376

Register 42: PWM2 Dead-Band Control (PWM2DBCTL), offset 0x0E8 ................................................ 376

Register 43: PWM0 Dead-Band Rising-Edge Delay (PWM0DBRISE), offset 0x06C ............................. 377

Register 44: PWM1 Dead-Band Rising-Edge Delay (PWM1DBRISE), offset 0x0AC ............................. 377

Register 45: PWM2 Dead-Band Rising-Edge Delay (PWM2DBRISE), offset 0x0EC ............................. 377

Register 46: PWM0 Dead-Band Falling-Edge-Delay (PWM0DBFALL), offset 0x070 ............................. 378

Register 47: PWM1 Dead-Band Falling-Edge-Delay (PWM1DBFALL), offset 0x0B0 ............................. 378

Register 48: PWM2 Dead-Band Falling-Edge-Delay (PWM2DBFALL), offset 0x0F0 ............................. 378

Preliminary

November 29, 200716

About This Document

This data sheet provides reference information for the LM3S617 microcontroller, describing the

functional blocks of the system-on-chip (SoC) device designed around the ARM® Cortex™-M3

core.

Audience

This manual is intended for system software developers, hardware designers, and application

developers.

About This Manual

This document is organized into sections that correspond to each major feature.

Related Documents

The following documents are referenced by the data sheet, and available on the documentation CD

or from the Luminary Micro web site at www.luminarymicro.com:

■

ARM® Cortex™-M3 Technical Reference Manual

LM3S617 Microcontroller

■

ARM® CoreSight Technical Reference Manual

■

ARM® v7-M Architecture Application Level Reference Manual

The following related documents are also referenced:

■

IEEE Standard 1149.1-Test Access Port and Boundary-Scan Architecture

This documentation list was current as of publication date. Please check the Luminary Micro web

site for additional documentation, including application notes and white papers.

Documentation Conventions

This document uses the conventions shown in Table 1 on page 17.

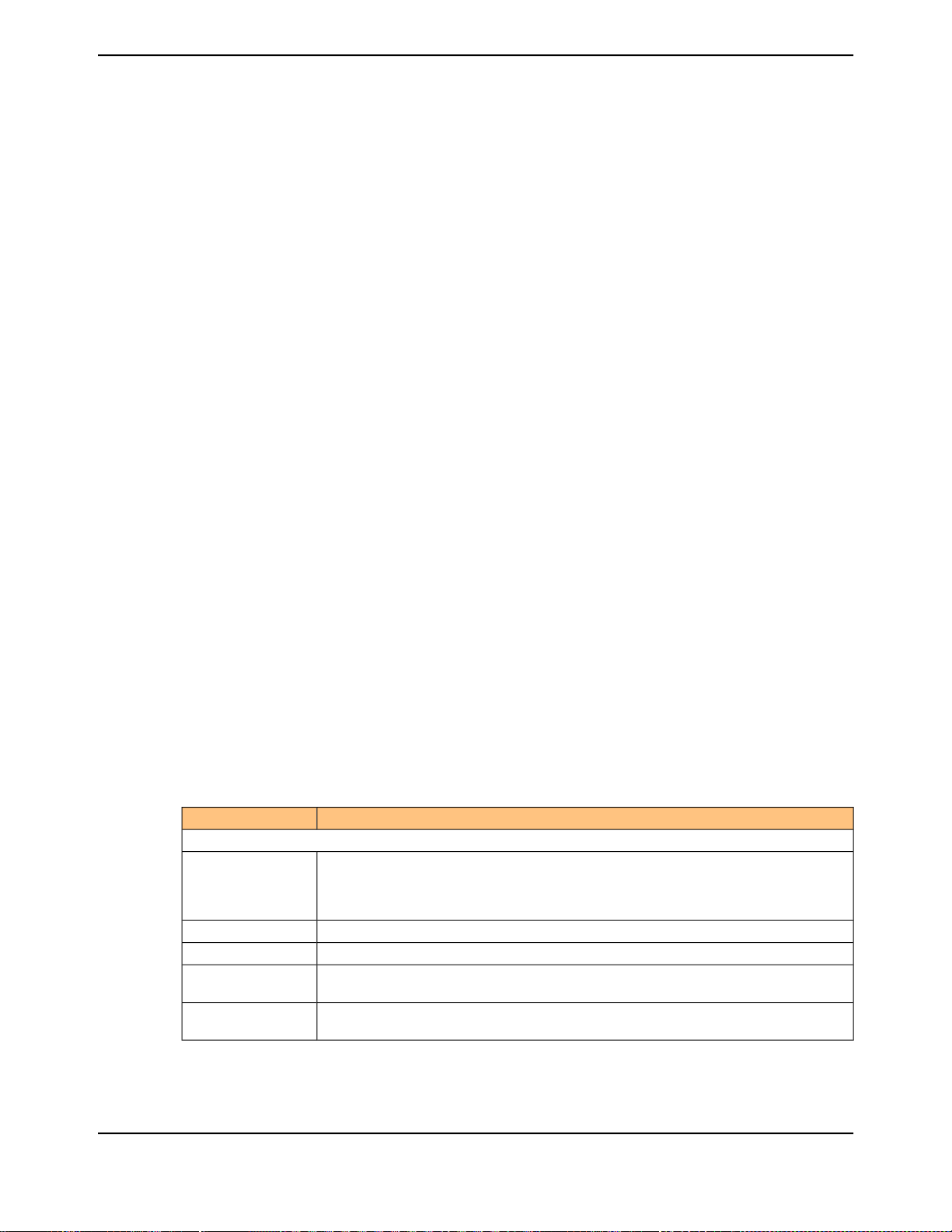

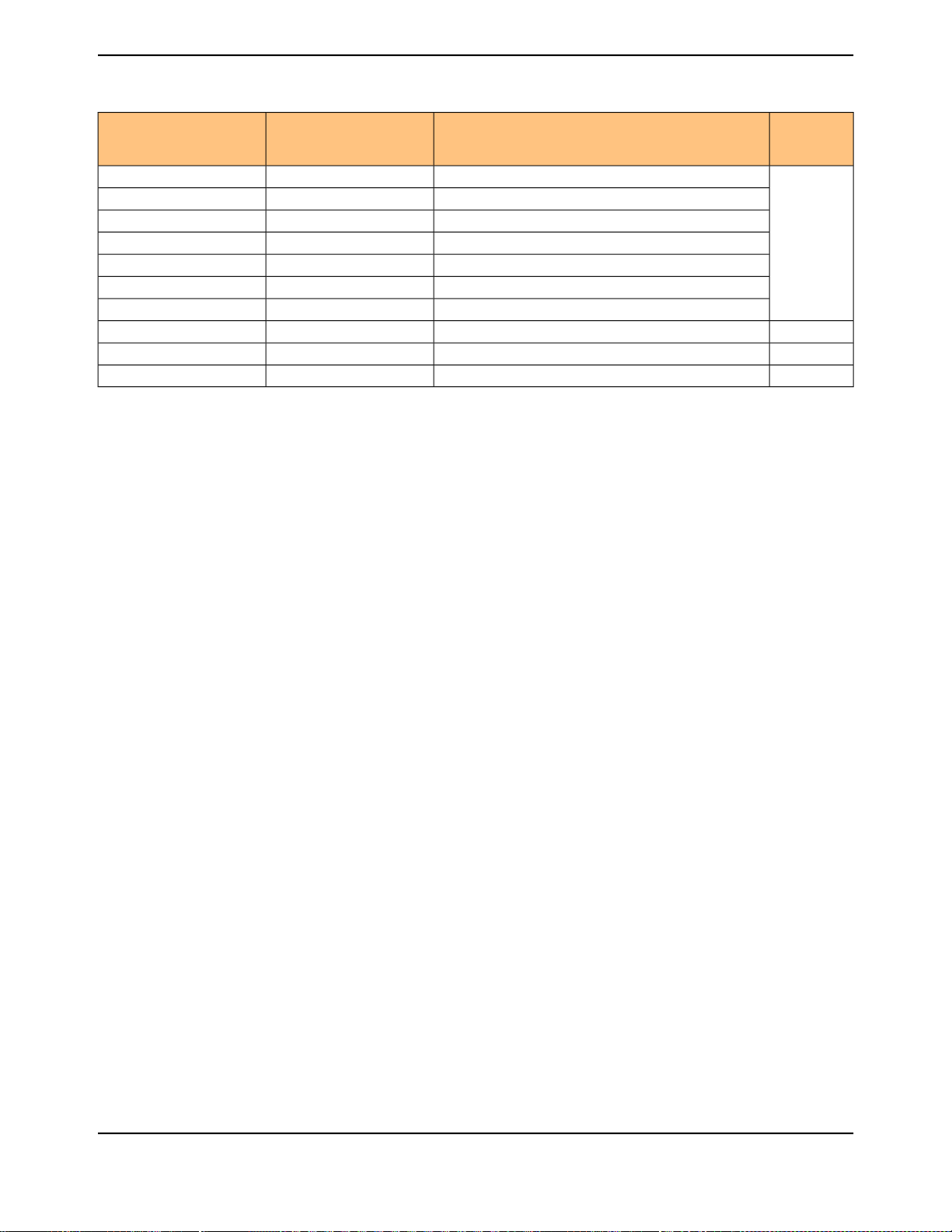

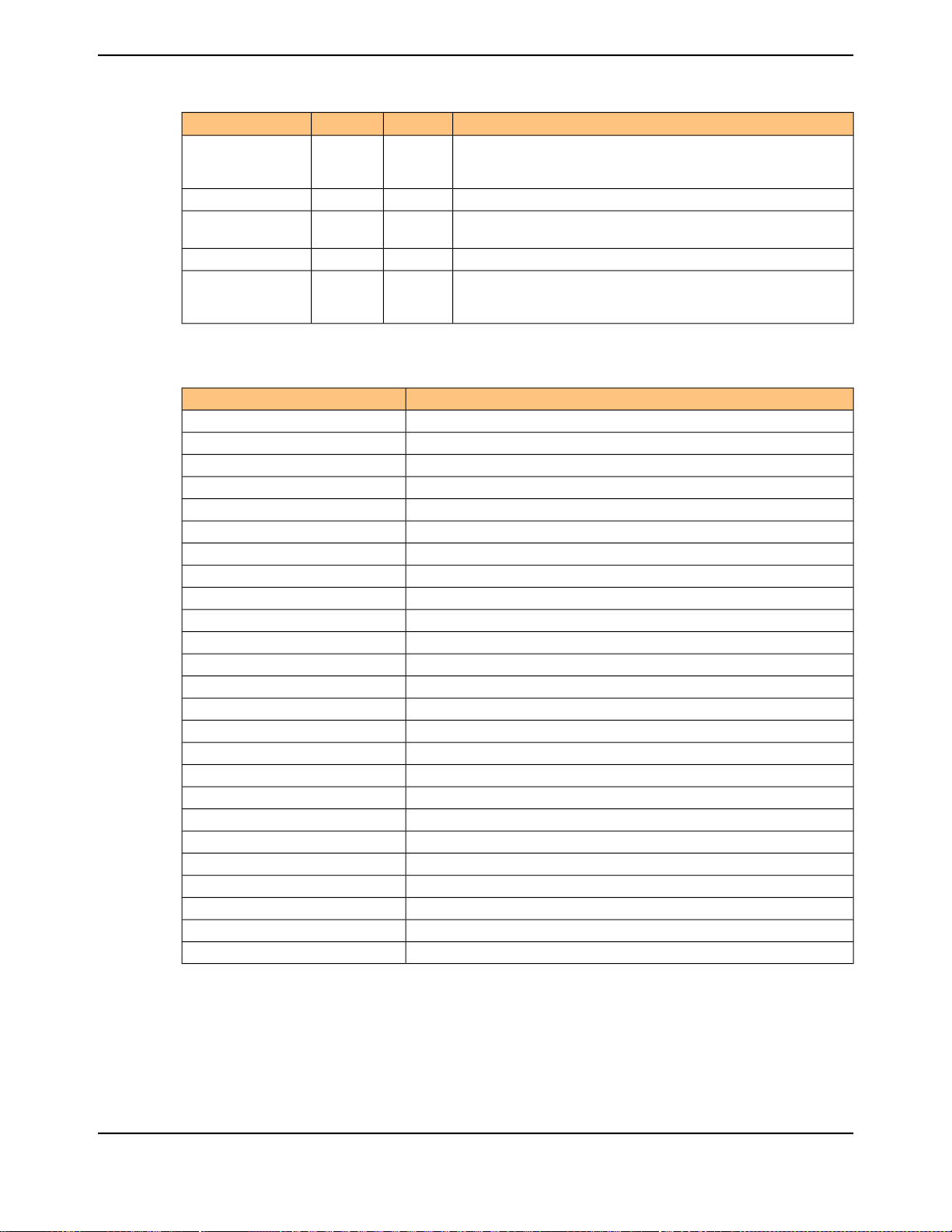

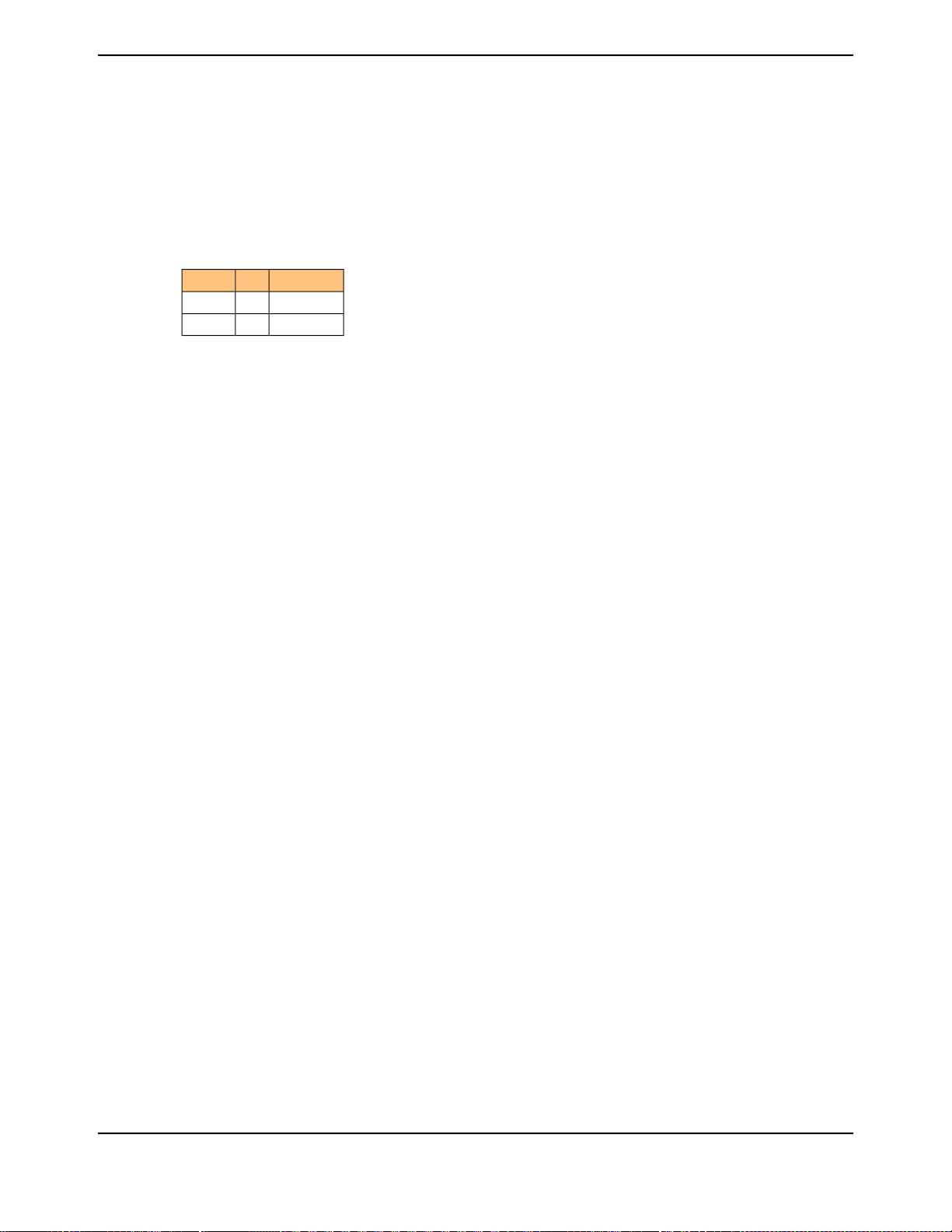

Table 1. Documentation Conventions

MeaningNotation

General Register Notation

REGISTER

offset 0xnnn

Register N

APB registers are indicated in uppercase bold. For example, PBORCTL is the Power-On and

Brown-Out Reset Control register. If a register name contains a lowercase n, it represents more

than one register. For example, SRCRn represents any (or all) of the three Software Reset Control

registers: SRCR0, SRCR1 , and SRCR2.

A single bit in a register.bit

Two or more consecutive and related bits.bit field

A hexadecimal increment to a register's address, relative to that module's base address as specified

in “Memory Map” on page 38.

Registers are numbered consecutively throughout the document to aid in referencing them. The

register number has no meaning to software.

Preliminary

17November 29, 2007

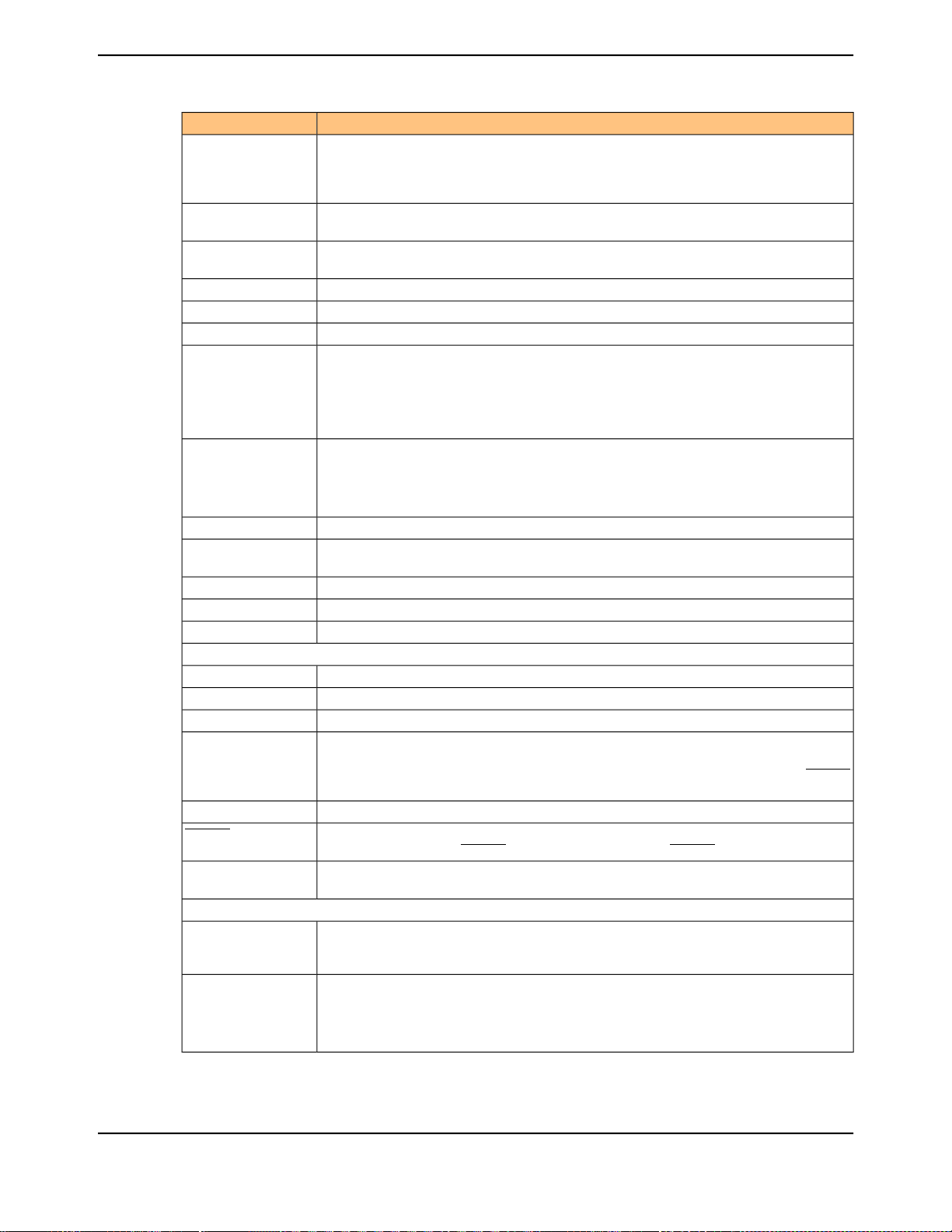

About This Document

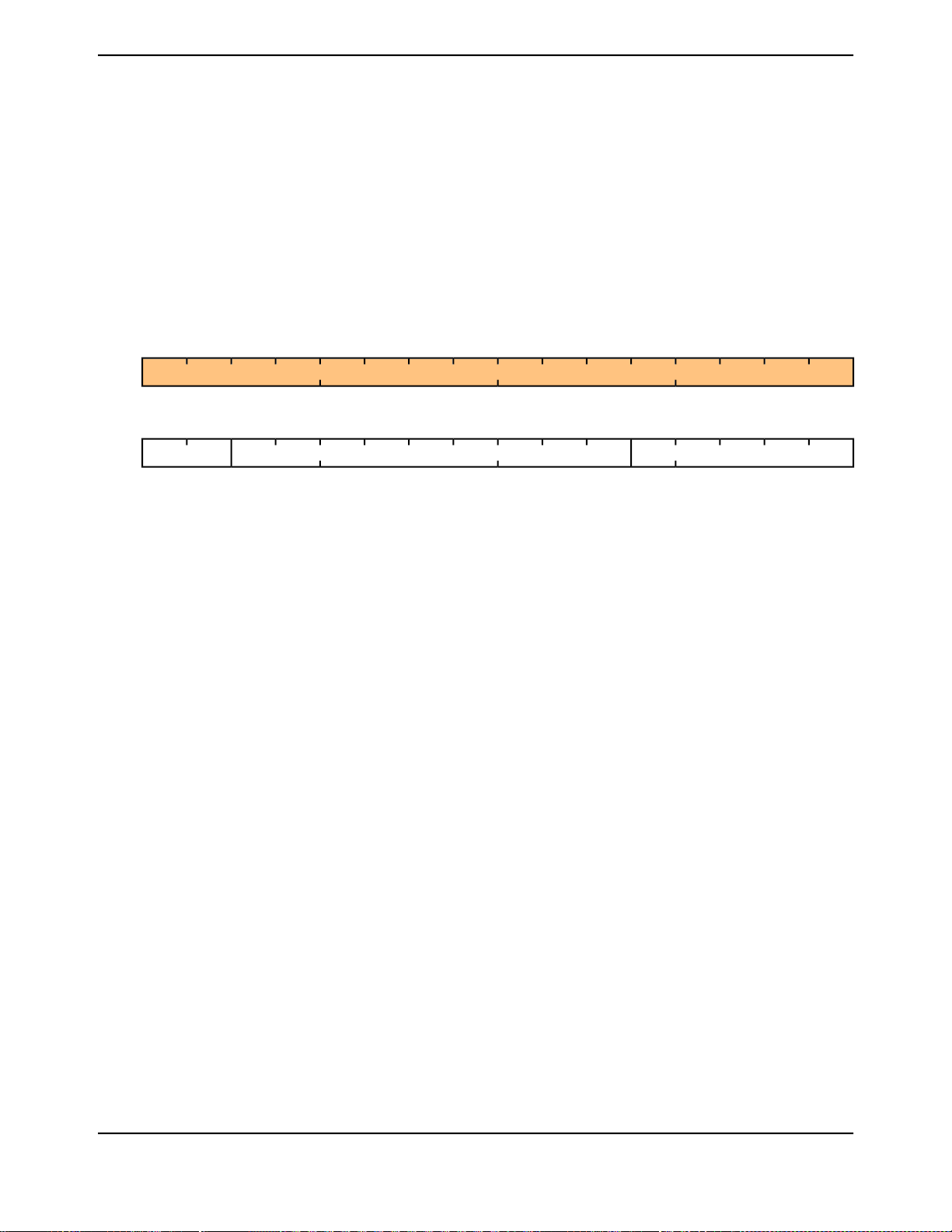

reserved

yy:xx

Register Bit/Field

Types

R/W1C

W1C

Reset Value

Pin/Signal Notation

assert a signal

SIGNAL

SIGNAL

Numbers

X

0x

MeaningNotation

Register bits marked reserved are reserved for future use. In most cases, reserved bits are set to

0; however, user software should not rely on the value of a reserved bit. To provide software

compatibility with future products, the value of a reserved bit should be preserved across a

read-modify-write operation.

The range of register bits inclusive from xx to yy. For example, 31:15 means bits 15 through 31 in

that register.

This value in the register bit diagram indicates whether software running on the controller can

change the value of the bit field.

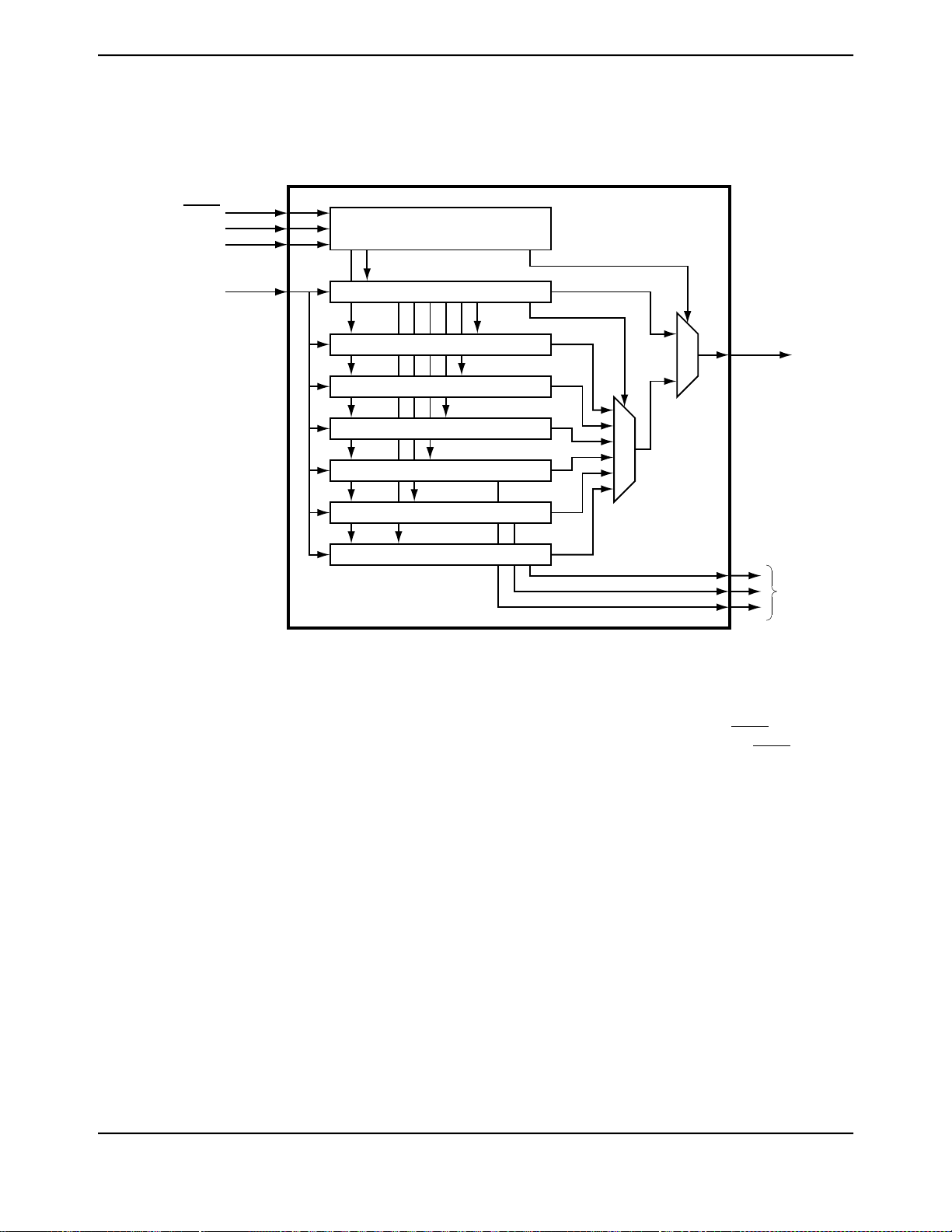

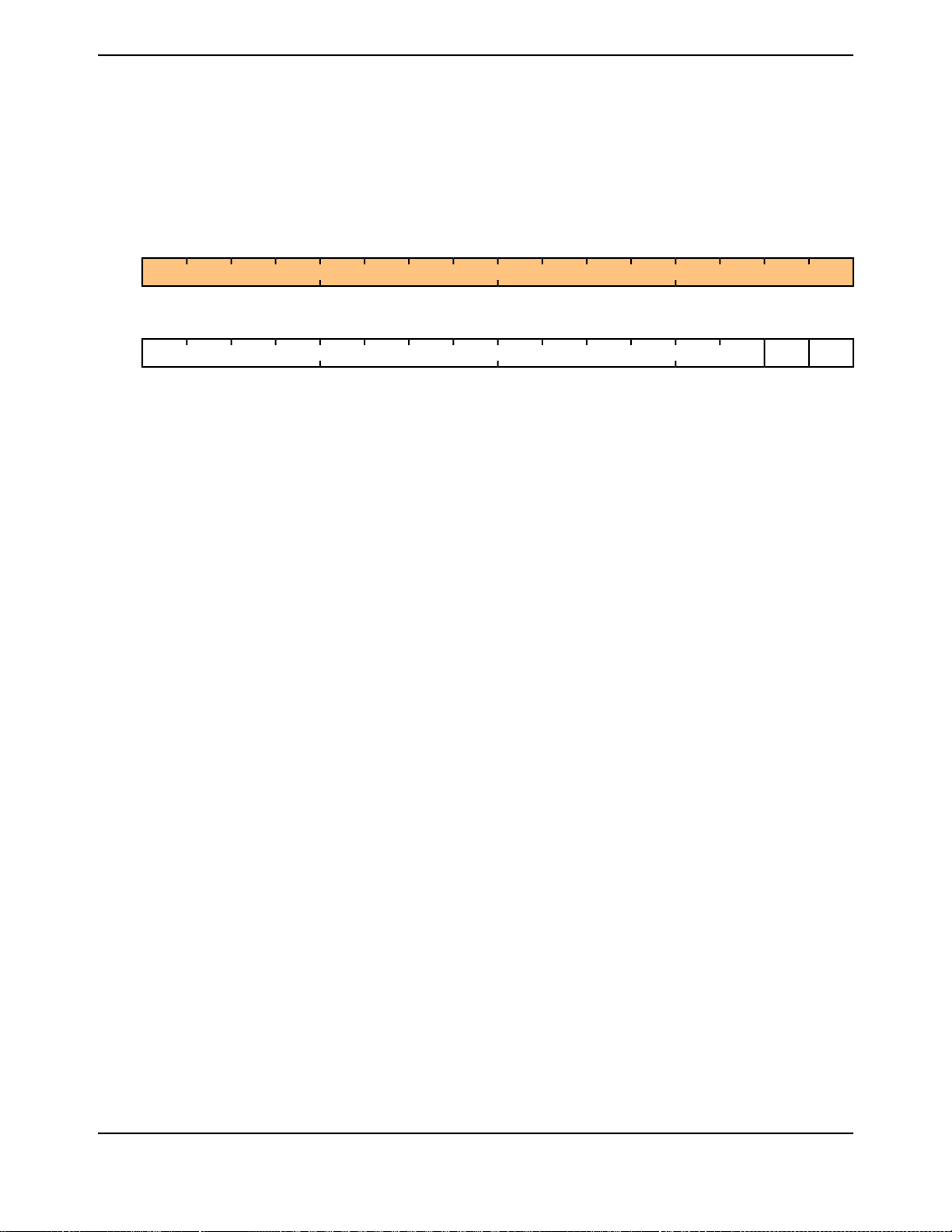

Software can read this field. The bit or field is cleared by hardware after reading the bit/field.RC