Page 1

SJ1 SJ1

Connects SoftStart Capacitor

Connects Tracking

Resistors

AN-1573 LM2745-19A Demonstration Board

1 Introduction

This application notes describes the LM2745 printed circuit board (PCB) design and provides an example

typical application circuit. The LM2745 is a voltage mode PWM buck controller which implements

synchronous rectification. It provides a low cost, high power density, and efficient point of load solution. In

steady state operation the LM2745 is always synchronous, even at no load, thus simplifying the

compensation design. The LM2745 ensures a smooth and controlled start-up when the output is prebiased. The current limit protection does not require a current limit resistor in the power path, but is

achieved by sensing the voltage VDSacross the low side MOSFET. Though the control sections of the IC

are rated for 3 to 6V (VCC), the driver sections are designed to accept input supply rails (VIN) as high as

14V.

2 Specifics Of The Board

This demo board targets the fixed and mobile telecommunications, industrial electronics, and distributed

power markets. The demo board has a VINrange of 8V to 14V and a LDO regulator, the LP2937, powers

VCCby regulating a 5V output voltage. The LM2745 regulates to an output range of 1.2V to 3.3V at 19A

with a switching frequency of 300 kHz. Note, the demo board is optimized for the above parameters, thus

for additional design modifications refer to the Design Consideration section of the LM2745 data sheet.

The PCB is designed on four layers, the top and bottom layers are 2oz. copper and the two inner layers

are 1oz. copper. The board measures 2.19 in. x 1.03 in. x 0.41 in. (56 mm x 26.2 mm x 10.3 mm) (l, w, h)

on a FR4 laminate.

User's Guide

SNVA213A–May 2007–Revised May 2013

3 Feature Options

When the tracking feature of the LM2745 is required for use, remove the jumper that connects the softstart capacitor C10 and connect the resistor divider, on designators R13 and R14 (see Figure 1). The

Track terminal has been provided for your connecting convenience. The demo board is synchronize ready,

just connect an external clock to the SYNC terminal. Note: increasing the switching frequency results in a

lower inductor current ripple and input and output voltage ripple (if the component values are kept the

same). Monitor the MOSFET junction temperature since switching losses will increase, and do not exceed

the maximum junction temperature of the MOSFET. Refer to the MOSFET manufacturer datasheet for

maximum junction temperature specification and heat sinking guidelines.

Figure 1. Soft-Start and Tracking Jumper

All trademarks are the property of their respective owners.

SNVA213A–May 2007–Revised May 2013 AN-1573 LM2745-19A Demonstration Board

Submit Documentation Feedback

1

Copyright © 2007–2013, Texas Instruments Incorporated

Page 2

Specification Summary

4 Specification Summary

• Space saving footprint

• Wide ambient temperature range: -40 ºC to 65 ºC

• Input voltage range: 8V to 14V

• Adjustable output voltage: 1.2V to 3.3V

• No minimum load requirement

• Remote ON/OFF

• Power good signal

• Fixed switching frequency: 300 kHz

• Switching frequency synchronize range 250 kHz to 1 MHz

• Current Limit Protection

• Master power supply start-up tracking function

• Start-up with a pre-biased output load

• Adjustable soft-start

• Small size 2.19 in. x 1.03 in. x 0.41 in. (56 mm x 26.2 mm x 10.3 mm)

5 Performance Characteristics

Efficiency

www.ti.com

2

AN-1573 LM2745-19A Demonstration Board SNVA213A–May 2007–Revised May 2013

Figure 2. Efficiency vs. Load Current

V

= 3.3V, fSW= 300 kHz

OUT

Copyright © 2007–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

www.ti.com

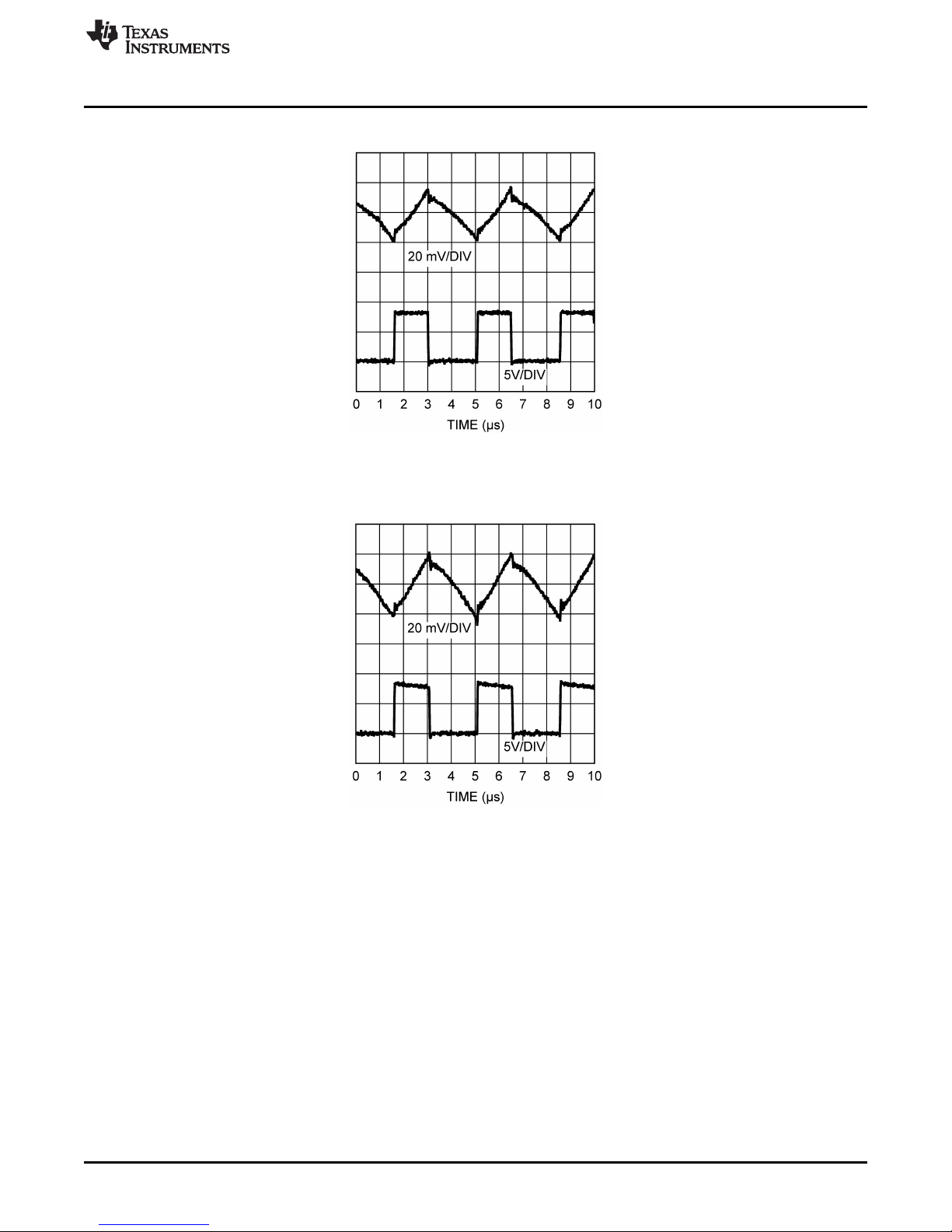

6 Switch Node Voltage and Output Voltage Ripple

Switch Node Voltage and Output Voltage Ripple

Figure 3. VIN= 8V, V

I

= 100 mA, fSW= 300 kHz

LOAD

OUT

20 MHz Bandwidth Limit

Figure 4. VIN= 8V, V

I

= 19A, fSW= 300 kHz

LOAD

OUT

20 MHz Bandwidth Limit

= 3.3V,

= 3.3V,

SNVA213A–May 2007–Revised May 2013 AN-1573 LM2745-19A Demonstration Board

Submit Documentation Feedback

3

Copyright © 2007–2013, Texas Instruments Incorporated

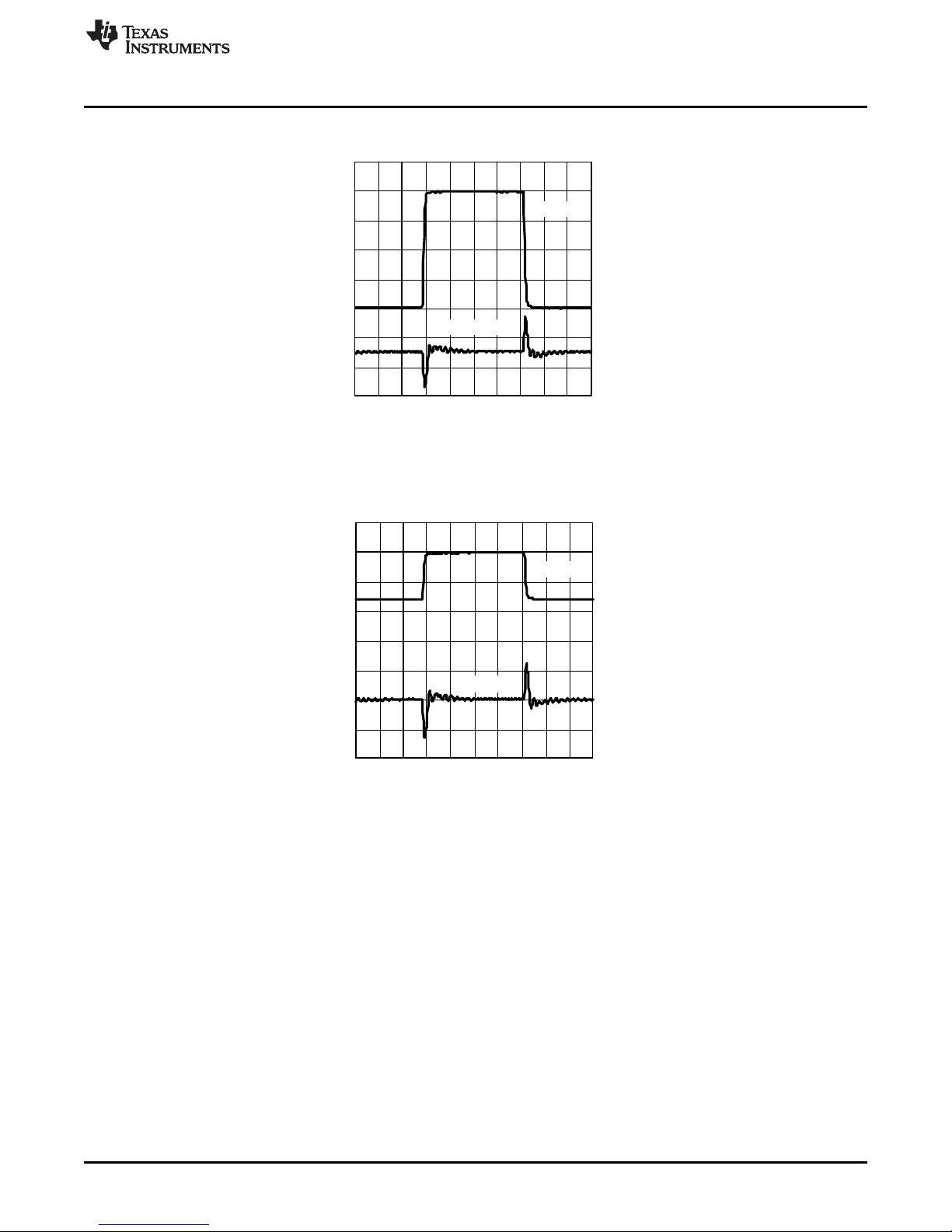

Page 4

Switch Node Voltage and Output Voltage Ripple

www.ti.com

Figure 5. VIN= 14V, V

I

= 100 mA, fSW= 300 kHz

LOAD

20 MHz Bandwidth Limit

Figure 6. VIN= 14V, V

I

= 19A, fSW= 300 kHz

LOAD

20 MHz Bandwidth Limit

OUT

OUT

= 3.3V,

= 3.3V,

4

AN-1573 LM2745-19A Demonstration Board SNVA213A–May 2007–Revised May 2013

Copyright © 2007–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

100 µs/DIV

50 mV/DIV

5A/DIV

100 µs/DIV

50 mV/DIV

2A/DIV

www.ti.com

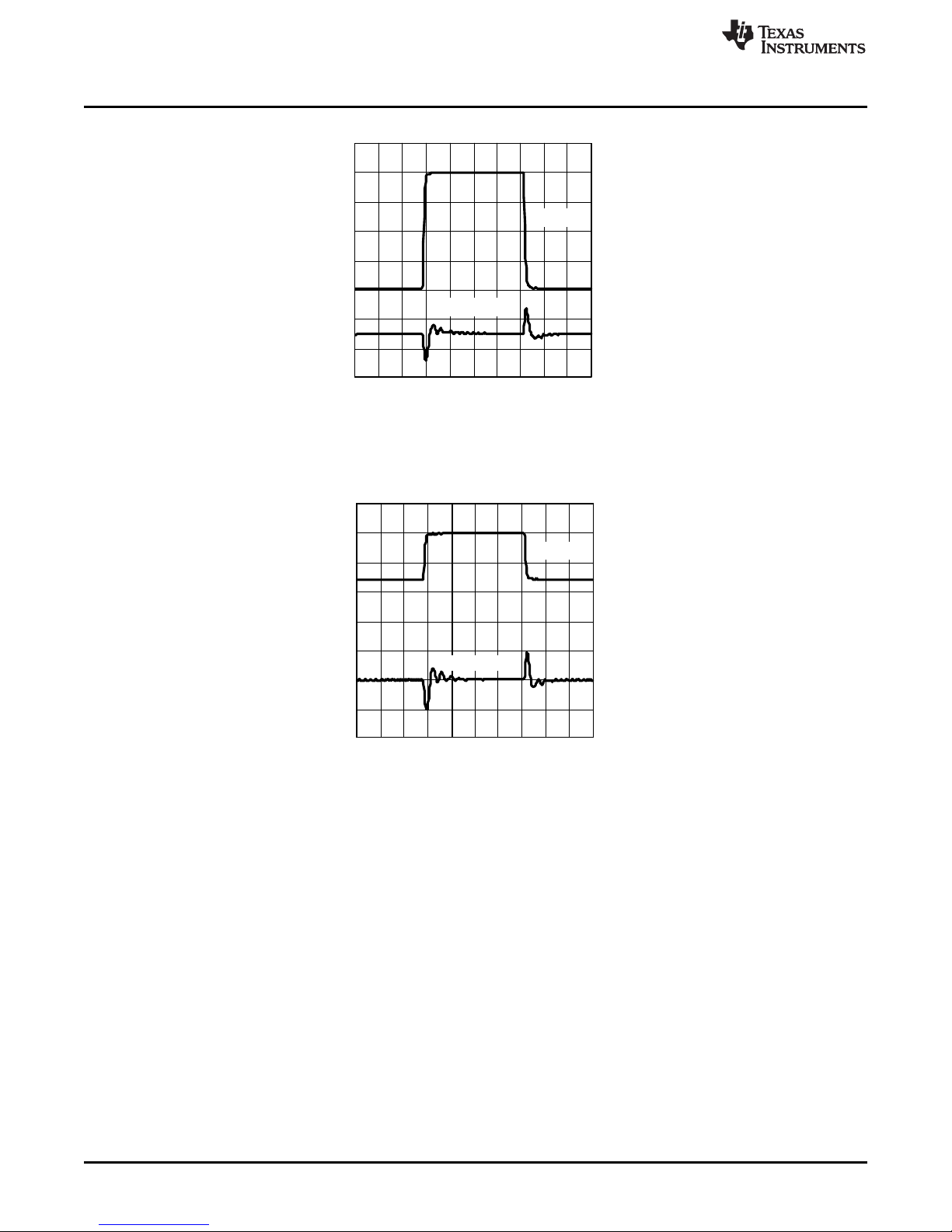

7 Load Transient Response

Load Transient Response

Figure 7. VIN= 14V, V

I

= 2A to 10A

LOAD

CH1: V

, CH2: I

OUT

Figure 8. VIN= 14V, V

I

= 11A to 19A

LOAD

CH1: V

, CH2: I

OUT

OUT

LOAD

OUT

LOAD

= 3.3V

= 3.3V

SNVA213A–May 2007–Revised May 2013 AN-1573 LM2745-19A Demonstration Board

Submit Documentation Feedback

5

Copyright © 2007–2013, Texas Instruments Incorporated

Page 6

100 µs/DIV

100 mV/DIV

5A/DIV

100 µs/DIV

100 mV/DIV

2A/DIV

Load Transient Response

www.ti.com

Figure 9. VIN= 8V, V

I

= 2A to 10A

LOAD

CH1: V

, CH2: I

OUT

Figure 10. VIN= 8V, V

I

= 11A to 19A

LOAD

CH1: V

, CH2: I

OUT

OUT

OUT

= 3.3V

LOAD

= 3.3V

LOAD

6

AN-1573 LM2745-19A Demonstration Board SNVA213A–May 2007–Revised May 2013

Copyright © 2007–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

www.ti.com

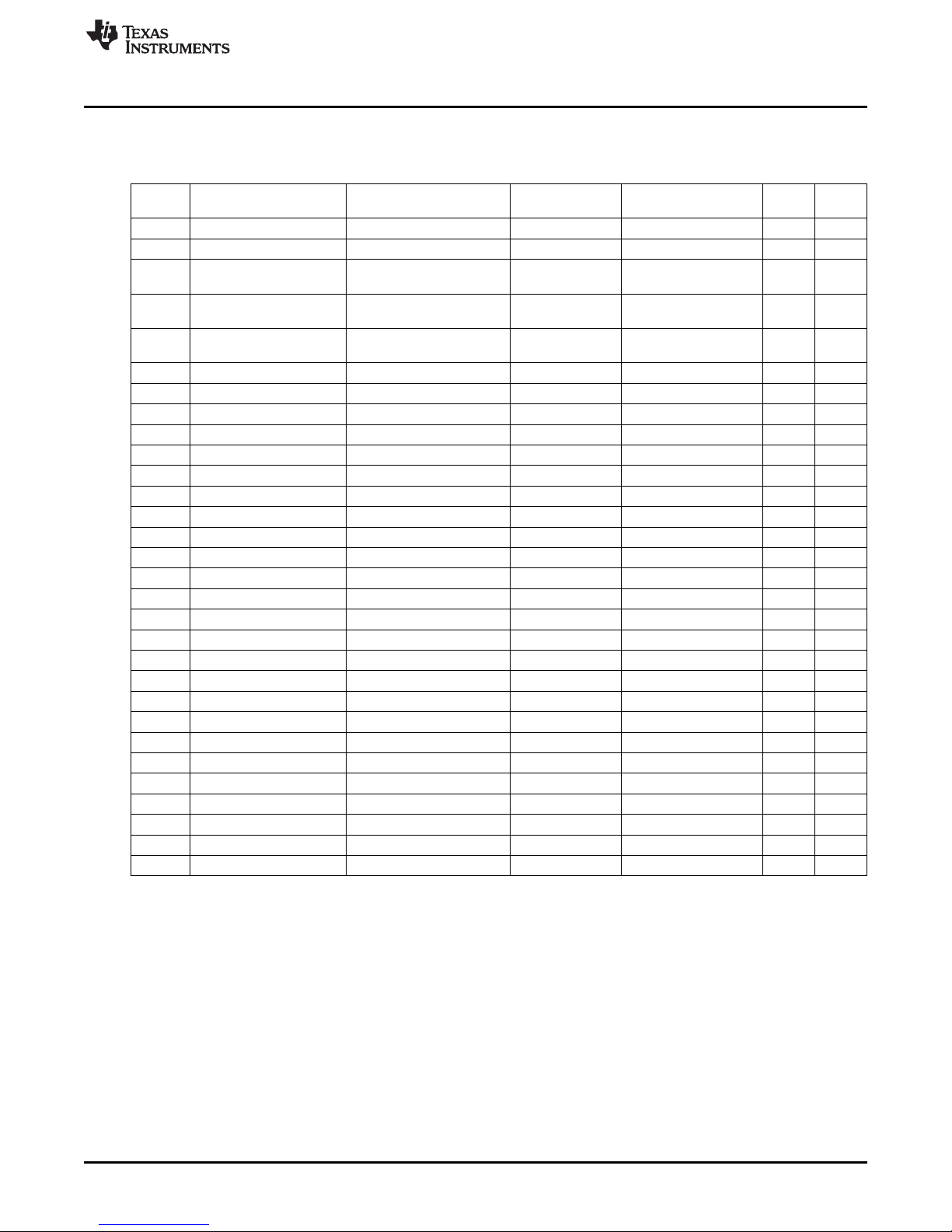

8 Bill of Materials

Table 1. Bill of Materials for LM2745 POL EVB (Vin: 8V to 14V, Vout:3.3V, 19A)

Locatio Part Number Type Size Parameters Qty Vendo

n r

U1 LM2745 Syn. Buck Controller TSSOP-14 Vin: 4.5V - 5.5V 1 NSC

U2 LM27937IMP-5.0 Linear Regulator 5V,500mA SOT-223 5V, 500mA 1 NSC

L1 SER2010-202ML Inductor 2uH, 27A, 0.852mohm 1 Coilcraf

Q1-2 IRF6633 N-MOSFET DirectFET-MP 20V, 16A, 4.1mohm, 2 Vishay

Q3 IRF6609 N-MOSFET DirectFET-MT 20V, 150A, 2mohm, 1 Vishay

D1 SL22-E3/2C Schottky Diode SMB 20V, 2A 1 Vishay

D2 MBRS0520 Schottky Diode SOD123 20V, 0.5A 1 Vishay

C1, 2 GRM32ER61C226KE20L Ceramic Capacitor 1210 22µF, 25V, X7R, 5% 2 Murata

C3, 11 GRM319R71H104KA01B Ceramic Capacitor 1206 100nF, 25V, X7R, 10% 2 Murata

C14 GRM319R71H474KA01B Ceramic Capacitor 1206 470nF, 25V, X7R, 10% 1 Murata

C9 GRM1885C1H1210JA01 Ceramic Capacitor 0603 120pF, 50V, C0G, 5% 1 Murata

C6 GRM188R71H222KA01 Ceramic Capacitor 0603 2.2nF, 50V, X7R, 10% 1 Murata

C7 GRM1885C1H101JA01 Ceramic Capacitor 0603 100pF, 50V, C0G, 5% 1 Murata

C8 GRM188R71H332KA01 Ceramic Capacitor 0603 3.3nF, 50V, X7R, 10% 1 Murata

C10 GRM188R71H153KA01 Ceramic Capacitor 0603 15nF, 50V, X7R, 10% 1 Murata

C12 GRM40X7R472K25 Ceramic Capacitor 0805 470nF, 25V, X7R, 10% 1 Murata

C13 12066D226MAT Ceramic Capacitor 1206 22µF, 6.3V, X5R, 20% 1 AVX

C4, 5 6SVPC220M OS-CON C6 220µF, 6.3V, 20% 2 Sanyo

R1,18 CRCW06030R00F Chip Resistor 0603 0ohm 2 Vishay

R2 CRCW06032151F Chip Resistor 0603 2.15k, 1% 1 Vishay

R3, R17 CRCW06031002F Chip Resistor 0603 10k, 1% 2 Vishay

R4 CRCW06032211F Chip Resistor 0603 2.21k, 1% 1 Vishay

R10, 11 CRCW06031003F Chip Resistor 0603 100k, 1% 2 Vishay

R5, 6, 8 CRCW06032R21F Chip Resistor 0603 2.21ohm, 1% 3 Vishay

R7, 9 CRCW06034702F Chip Resistor 0603 47k, 1% 2 Vishay

R12 CRCW06038451F Chip Resistor 0603 8.45k, 1% 1 Vishay

R15 CRCW06031821F Chip Resistor 0603 1.82k, 1% 1 Vishay

R16 CRCW060310R0F Chip Resistor 0603 10ohm, 1% 1 Vishay

- - F-Pin 8

- - Pin 90 deg., SIP, 6 way Pitch: 2.54mm 1

Bill of Materials

t

11nC

46nC

SNVA213A–May 2007–Revised May 2013 AN-1573 LM2745-19A Demonstration Board

Submit Documentation Feedback

7

Copyright © 2007–2013, Texas Instruments Incorporated

Page 8

R3

C8

R12

R15

C10

R10

C11

D2

C14

C2

L1

+

C9

R4

C5

R2

C6

R17

+

C4

C1

R11

Q1

R16

+

C3

VIN

Q3

HG

BOO

T

LG

PGND

FB

PWGD

FREQ/SYNC

SS/TRACK

SGND

EAO

PGND

LM2745

V

OUT

LM2937

V

IN

C13

V

OUT

GND

C12

D1

Q2

SD

R6

R5

R7

R8

R9

R18

U1

U2

C7

SYNC

R14

R13

TRACK

SJ2

PWGD

SD

TRIM

SENSE

SJ1

V

CC

I

SEN

PCB Layout

www.ti.com

9 PCB Layout

Figure 11. 300 kHz Demo Board Schematic

Figure 12. Top Silkscreen

8

AN-1573 LM2745-19A Demonstration Board SNVA213A–May 2007–Revised May 2013

Copyright © 2007–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

www.ti.com

PCB Layout

Figure 13. Top Copper Layer

Figure 14. Bottom Silkscreen

Figure 15. Bottom Copper Layer

SNVA213A–May 2007–Revised May 2013 AN-1573 LM2745-19A Demonstration Board

Submit Documentation Feedback

9

Copyright © 2007–2013, Texas Instruments Incorporated

Page 10

PCB Layout

www.ti.com

Figure 16. Internal Layer-1 (GND Copper)

Figure 17. Internal Layer-2 (GND Copper)

10

AN-1573 LM2745-19A Demonstration Board SNVA213A–May 2007–Revised May 2013

Copyright © 2007–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2013, Texas Instruments Incorporated

Page 12

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Texas Instruments:

LM2745-19AEVAL

Loading...

Loading...