Page 1

I

CIN-(RMS)

= 4A

0.5 x 0.5

= 2.0A

D =

V

OUT

V

IN

I

CIN-(RMS)

= I

LOAD

D(1 - D)

1 Introduction

The Texas Instruments LM20124 is a full featured buck switching regulator capable of driving up to 4A of

load current. The nominal 1 MHz switching frequency of the LM20124 reduces the size of the power stage

components while still allowing for highly efficient operation. The LM20124 is capable of converting an

input voltage between 2.95V and 5.5V down to an output voltage as low as 0.8V. Fault protection features

include cycle-by-cycle current limit, output power good, and output over-voltage protection. The dual

function soft-start/tracking pin can be used to control the startup response of the LM20124, and the

precision enable pin can be used to easily sequence the LM20124 in applications with sequencing

requirements. The LM20124 is available in a 16-pin HTSSOP package with an exposed pad for enhanced

thermal performance.

The LM20124 evaluation board has been designed to balance overall solution size with the efficiency of

the regulator. The evaluation board measures just under 1.3” × 1.1” on a two layer PCB, with all

components placed on the top layer. The power stage and compensation components of the LM20124

evaluation board have been optimized for an input voltage of 5V, but for testing purposes, the input can be

varied across the entire operating range. The output voltage of the evaluation board is nominally 1.2V, but

this voltage can be easily changed by replacing one of the feedback resistors (R

loop compensation of the LM20124 evaluation board has been designed to provide a stable solution over

the entire input and output voltage range with a reasonable transient response. The EN pin must be above

1.18V (typ) on the board to initiate switching. If the EN function is not necessary, the EN pin should be

externally tied to VIN.

User's Guide

SNVA252B–October 2007–Revised May 2013

AN-1654 LM20124 Evaluation Board

FB1

or R

). The control

FB2

2 Component Selection

This section provides a walk-through of the design process of the LM20124 evaluation board. Unless

otherwise indicated, all equations assume units of Amps (A) for current, Farads (F) for capacitance,

Henries (H) for inductance, and Volts (V) for voltages.

2.1 Input Capacitor

The required RMS current rating of the input capacitor for a buck regulator can be estimated by the

following equation:

The variable D refers to the duty cycle, and can be approximated by:

From this equation, it follows that the maximum I

the system operating at 50% duty cycle. Under this condition, the maximum I

Ceramic capacitors feature a very large I

for this application. A 100 µF X5R ceramic capacitor from Murata with a 5.4A I

necessary input capacitance for the evaluation board. For improved bypassing, a small 1 µF high

frequency capacitor is placed in parallel with the 100 µF bulk capacitor to filter high frequency noise

pulses on the supply.

All trademarks are the property of their respective owners.

CIN(RMS)

rating in a small footprint, making a ceramic capacitor ideal

RMS

requirement will occur at a full 4A load current with

CIN(RMS)

is given by:

rating provides the

RMS

(1)

(2)

(3)

SNVA252B–October 2007–Revised May 2013 AN-1654 LM20124 Evaluation Board

Submit Documentation Feedback

1

Copyright © 2007–2013, Texas Instruments Incorporated

Page 2

tSS =

CSS x 0.8

I

SS

'V

OUT

= 'I

p-p

x

R

ESR

+

1

8 x fSW x C

OUT

'I

p-p

=

(VIN - V

OUT

) x D

L x f

SW

Component Selection

2.2 AVIN Filter

An RC filter should be added to prevent any switching noise on PVIN from interfering with the internal

analog circuitry connected to AVIN. These can be seen on the schematic as components RFand CF.

There is a practical limit to the size of the resistor RFas the AVIN pin will draw a short 60mA burst of

current during startup, and if RFis too large the resulting voltage drop can trigger the UVLO comparator.

For the demo board a 1Ω resistor is used for RFensuring that UVLO will not be triggered after the part is

enabled. A recommended 1 µF CFcapacitor coupled with the 1Ω resistor provides roughly 16dB of

attenuation at the 1 MHz switching frequency.

2.3 Inductor

As per the datasheet recommendations, the inductor value should initially be chosen to give a peak to

peak ripple current equal to roughly 30% of the maximum output current. The peak to peak inductor ripple

current can be calculated by the equation:

Rearranging this equation and solving for the inductance reveals that for this application (VIN= 5V, V

1.2V, fSW= 1 MHz, and I

nearest standard inductor value, a final inductance of 1 µH is selected. This results in a peak-to-peak

ripple current of 912 mA and 1.122A when the converter is operating from 5V and 3.3V respectively. Once

an inductance value is calculated, an actual inductor needs to be selected based on a tradeoff between

physical size, efficiency, and current carrying capability. For the LM20124 evaluation board, a Coilcraft

MSS1038-102NL inductor offers a good balance between efficiency (6 mΩ DCR), size, and saturation

current rating (9A I

SAT

= 4A) the nominal inductance value is roughly 0.76 µH. Rounding up to the

OUT

rating).

www.ti.com

=

OUT

(4)

2.4 Output Capacitor

The value of the output capacitor in a buck regulator influences the voltage ripple that will be present on

the output voltage, as well as the large signal output voltage response to a load transient. Given the peakto-peak inductor current ripple (ΔI

2.5 C

The variable R

the ripple voltage on the output can be divided into two parts, one of which is attributed to the AC ripple

current flowing through the ESR of the output capacitor and another due to the AC ripple current actually

charging and discharging the output capacitor. The output capacitor also has an effect on the amount of

droop that is seen on the output voltage in response to a load transient event.

For the evaluation board, a Murata 100 µF ceramic capacitor is selected for the output capacitor to

provide good transient and DC performance in a relatively small package. From the technical

specifications of this capacitor, the ESR is roughly 2 mΩ, and the effective in-circuit capacitance is

approximately 55 µF (reduced from 100 µF due to the 1.2V DC bias). With these values, the peak to peak

voltage ripple on the output when operating from a 5V input can be calculated to be 3.9 mV.

SS

A soft-start capacitor can be used to control the startup time of the LM20124 voltage regulator. The startup

time of the regulator when using a soft-start capacitor can be estimated by the following equation:

For the LM20124, ISSis nominally 5 µA. For the evaluation board, the soft-start time has been designed to

be roughly 5 ms, resulting in a CSScapacitor value of 33 nF.

above refers to the ESR of the output capacitor. As can be seen in the above equation,

ESR

) the output voltage ripple can be approximated by the equation:

P-P

(5)

(6)

2

AN-1654 LM20124 Evaluation Board SNVA252B–October 2007–Revised May 2013

Copyright © 2007–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

R

FB1

= R

FB2

x

-1

V

OUT

0.8V

CC2 =

C

OUT

x R

ESR

R

C1

x

C

C1

C

OUT

I

OUT

V

OUT

+

18 x D

V

IN

-1

+

1-D

f

SW

x L

R

C1

=

www.ti.com

Component Selection

2.6 C

2.7 C

2.8 R

2.9 C

VCC

The C

capacitor is necessary to bypass an internal 2.7V subregulator. This capacitor should be sized

VCC

equal to or greater than 1 µF, but less than 10 µF. A value of 1 µF is sufficient for most applications..

C1

The capacitor CC1is used to set the crossover frequency of the LM20124 control loop. Since this board

was optimized to work well over the full input and output voltage range, the value of CC1was selected to

be 3.3 nF. Once the operating conditions for the device are known, the transient response can be

optimized by reducing the value of CC1and calculating the value for RC1as outlined in the next section.

C1

Once the value of CC1is known, resistor RC1is used to place a zero in the control loop to cancel the output

filter pole. This resistor can be sized according to the equation:

(7)

For stability purposes the device should be compensated for the maximum output current expected in the

application.

C2

A second compensation capacitor CC2can be used in some designs to provide a high frequency pole,

useful for cancelling a possible zero introduced by the ESR of the output capacitor. For the LM20124

evaluation board, the CC2footprint is unpopulated, as the low ESR ceramic capacitor used on the output

does not contribute a zero to the control loop before the crossover frequency. If the ceramic capacitor on

the evaluation board is replaced with a different capacitor having significant ESR, the required value of the

capacitor CC2can be estimated by the equation:

2.10 R

The resistors labeled R

set the output of the voltage regulator. Nominally, the output of the LM20124 evaluation board is set to

1.2V, giving resistor values of R

value of R

R

and R

FB1

does not need to be changed from its value of 10 kΩ.

FB2

FB2

and R

FB1

can be adjusted according to the equation:

FB1

create a voltage divider from V

FB2

= 4.99 kΩ and R

FB1

to the feedback pin that is used to

OUT

= 10 kΩ. If a different output voltage is required, the

FB2

(8)

(9)

SNVA252B–October 2007–Revised May 2013 AN-1654 LM20124 Evaluation Board

Submit Documentation Feedback

3

Copyright © 2007–2013, Texas Instruments Incorporated

Page 4

C

IN

PVIN

SW

AGND

FB

PGOOD

R

FB1

R

FB2

C

OUT

EN

C

SS

SS/TRK

AVIN

C

F

C

C1

COMP

R

C1

V

IN

LM20124

L

R

F

VCC

C

VCC

V

OUT

PGND

P

GOOD

R

PG

EN

C

C2

C

BYP

Evaluation Board Schematic

3 Evaluation Board Schematic

Figure 1. Evaluation Board Schematic

www.ti.com

4 Bill of Materials

Designator Description Part Number Manufacturer Qty

U1 Synchronous Buck Regulator LM20124 Texas Instruments 1

C

IN

C

BYP

C

OUT

L 1 µH, 6 mΩ MSS1038-102NL Coilcraft 1

R

F

C

F

C

VCC

R

PG

R

C1

C

C1

C

C2

C

SS

R

FB1

R

FB2

Test Points Test Points 160-1026-02-01-00 Cambion 7

4

AN-1654 LM20124 Evaluation Board SNVA252B–October 2007–Revised May 2013

100 µF, 1210, X5R, 6.3V GRM32ER60J107ME20 Murata 1

1 µF, 0603, X5R, 6.3V GRM188R60J105KA01 Murata 1

100 µF, 1210, X5R, 6.3V GRM32ER60J107ME20 Murata 1

1Ω, 0603 CRCW06031R0J-e3 Vishay-Dale 1

100 nF, 0603, X7R, 16V GRM188R71C104KA01 Murata 1

1 µF, 0603, X5R, 6.3V GRM188R60J105KA01 Murata 1

10 kΩ, 0603 CRCW06031002F-e3 Vishay-Dale 1

3.9 kΩ, 0603 CRCW06033901F-e3 Vishay-Dale 1

3.3 nF, 0603, X7R, 25V VJ0603Y332KXXA Vishay-Vitramon 1

OPEN OPEN N/A 0

33nF, 0603, X7R, 25V VJ0603Y333KXXA Vishay-Vitramon 1

4.99 kΩ, 0603 CRCW06034991F-e3 Vishay-Dale 1

10 kΩ, 0603 CRCW06031002F-e3 Vishay-Dale 1

Copyright © 2007–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

www.ti.com

5 Connection Descriptions

Terminal Silkscreen Description

VIN This terminal is the input voltage to the device. The device will operation over the input voltage

range of 2.95V to 5.5V. The absolute maximum voltage rating for this pin is 6V.

GND This terminal is the ground connection to the device. There are two different GND connections on

the PCB. One should be used for the input supply and the other for the load.

VOUT This terminal connects to the output voltage of the power supply and should be connected to the

load.

EN This terminal connects to the enable pin of the device. This terminal should be connected to VINor

driven externally. If driven externally, a voltage typically greater than 1.18V will enable the device.

The operating voltage for this pin should not exceed 5.5V. The absolute maximum voltage rating

on this pin is 6V.

SS/TRACK This terminal provides access to the SS/TRK pin of the device. Connections to this terminal are

not needed for most applications. The feedback pin of the device will track the voltage on the

SS/TRK pin if it is driven with an external voltage source that is below the 0.8V reference. The

voltage on this pin should not exceed 5.5V during normal operation. The absolute maximum

voltage rating on this pin is 6V.

PGOOD This terminal connects to the power good output of the device. There is a 10 kΩ pull-up resistor

from this pin to the input voltage. The voltage on this pin should not exceed 5.5V during normal

operation and has an absolute maximum voltage rating of 6V.

Connection Descriptions

SNVA252B–October 2007–Revised May 2013 AN-1654 LM20124 Evaluation Board

Submit Documentation Feedback

5

Copyright © 2007–2013, Texas Instruments Incorporated

Page 6

Performance Characteristics

6 Performance Characteristics

www.ti.com

Efficiency vs Load Line Regulation (I

0.5A to 4A Load Transient Response

Load Regulation (VIN= 5V) (200 µs/DIV)

LOAD

= 4A)

6

AN-1654 LM20124 Evaluation Board SNVA252B–October 2007–Revised May 2013

Startup Waveform

(2ms/DIV)

Copyright © 2007–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

www.ti.com

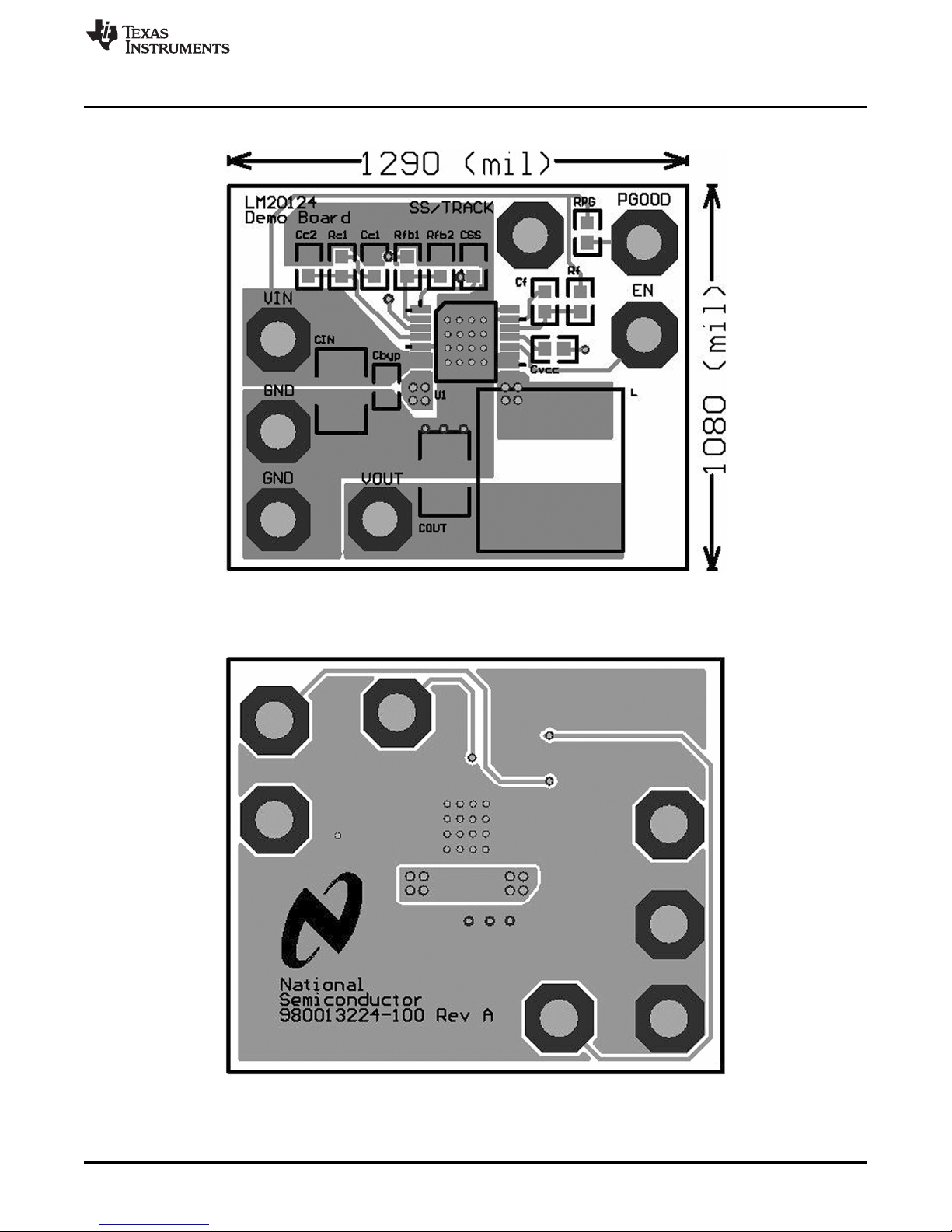

7 PCB Layout

PCB Layout

Figure 2. Top Layer

SNVA252B–October 2007–Revised May 2013 AN-1654 LM20124 Evaluation Board

Submit Documentation Feedback

Figure 3. Bottom Layer

7

Copyright © 2007–2013, Texas Instruments Incorporated

Page 8

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2013, Texas Instruments Incorporated

Loading...

Loading...