Page 1

V

IN

Gnd

+V

O

A2

10kΩ

50Ω

50Ω

All resistors 30kΩ unless otherwise indicated.

V+

+Sense

–Sense

–V

O

A3

A1

10kΩ

Product

Folder

Sample &

Buy

Technical

Documents

Tools &

Software

Support &

Community

SBOS094B –JANUARY 1998–REVISED DECEMBER 2014

DRV13x Audio-Balanced Line Drivers

1 Features 3 Description

1

• Balanced Output

• Low Distortion: 0.0005% at f = 1 kHz

• Wide Output Swing: 17Vrms into 600 Ω

• High Capacitive Load Drive

• High Slew Rate: 15 V/µs

• Wide Supply Range: ±4.5 V to ±18 V

• Low Quiescent Current: ±5.2 mA

• 8-Pin DIP, SO-8, and SOL-16 Packages

• Companion to Audio Differential Line Receivers:

INA134 and INA137

• Improved Replacement for SSM2142

2 Applications

• Audio Differential Line Drivers

• Audio Mix Consoles

• Distribution Amplifiers

• Graphic and Parametric Equalizers

• Dynamic Range Processors

• Digital Effects Processors

• Telecom Systems

• Hi-Fi Equipment

• Industrial Instrumentation

The DRV134 and DRV135 are differential output

amplifiers that convert a single-ended input to a

balanced output pair. These balanced audio drivers

consist of high performance op amps with on-chip

precision resistors. They are fully specified for high

performance audio applications and have excellent ac

specifications, including low distortion (0.0005% at 1

kHz) and high slew rate (15 V/µs).

The on-chip resistors are laser-trimmed for accurate

gain and optimum output common-mode rejection.

Wide output voltage swing and high output drive

capability allow use in a wide variety of demanding

applications. They easily drive the large capacitive

loads associated with long audio cables. Used in

combination with the INA134 or INA137 differential

receivers, they offer a complete solution for

transmitting analog audio signals without degradation.

The DRV134 is available in 8-pin DIP and SOL-16

surface-mount packages. The DRV135 comes in a

space-saving SO-8 surface-mount package. Both are

specified for operation over the extended industrial

temperature range, –40°C to +85°C and operate from

–55°C to +125°C.

Device Information

PART NUMBER PACKAGE BODY SIZE (NOM)

DRV134 SOIC (16) 10.30 mm × 7.50 mm

DRV135 SOIC (8) 4.90 mm × 3.91 mm

(1) For all available packages, see the orderable addendum at

the end of the datasheet.

DRV134,DRV135

(1)

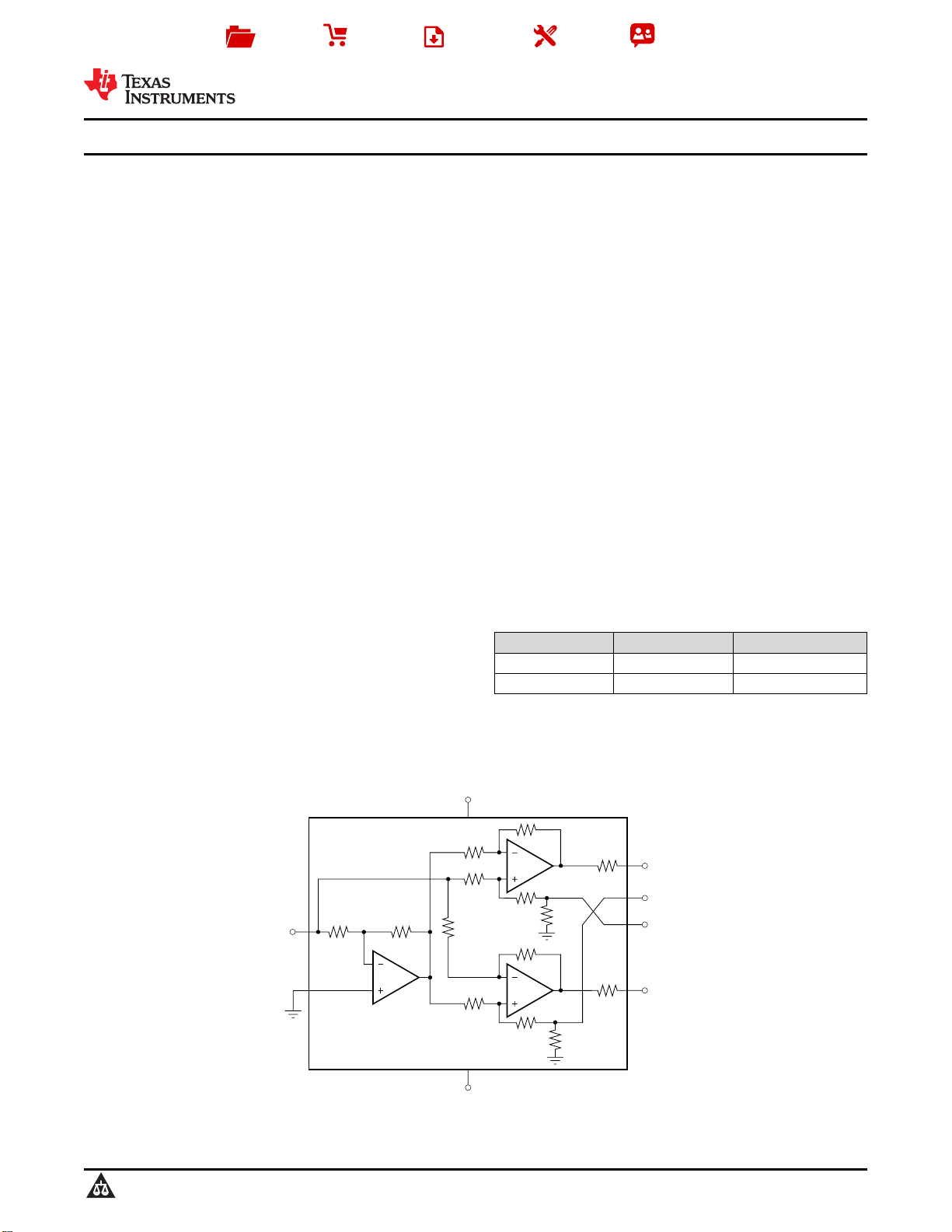

4 Simplified Schematic

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

Page 2

DRV134,DRV135

SBOS094B –JANUARY 1998–REVISED DECEMBER 2014

www.ti.com

Table of Contents

1 Features.................................................................. 1

2 Applications ........................................................... 1

3 Description ............................................................. 1

4 Simplified Schematic............................................. 1

5 Revision History..................................................... 2

6 Pin Configuration and Functions......................... 3

7 Specifications......................................................... 4

7.1 Absolute Maximum Ratings ...................................... 4

7.2 Handling Ratings....................................................... 4

7.3 Recommended Operating Conditions ...................... 4

7.4 Electrical Characteristics........................................... 5

7.5 Typical Characteristics.............................................. 6

8 Detailed Description ............................................ 11

8.1 Overview................................................................. 11

8.2 Functional Block Diagram ....................................... 11

8.3 Feature Description................................................. 11

8.4 Device Functional Modes........................................ 13

9 Application and Implementation........................ 15

9.1 Application Information............................................ 15

9.2 Typical Application ................................................. 15

10 Power Supply Recommendations..................... 17

11 Layout................................................................... 17

11.1 Layout Guidelines ................................................. 17

11.2 Layout Examples................................................... 18

11.3 Thermal Performance ........................................... 19

12 Device and Documentation Support................. 19

12.1 Documentation Support ........................................ 19

12.2 Related Links ........................................................ 19

12.3 Trademarks........................................................... 19

12.4 Electrostatic Discharge Caution............................ 19

12.5 Glossary................................................................ 19

13 Mechanical, Packaging, and Orderable

Information........................................................... 20

5 Revision History

Changes from Revision A (April 2007) to Revision B Page

• Added Handling Rating table, Feature Description section, Device Functional Modes, Application and

Implementation section, Power Supply Recommendations section, Layout section, Device and Documentation

Support section, and Mechanical, Packaging, and Orderable Information section ............................................................... 1

2 Submit Documentation Feedback Copyright © 1998–2014, Texas Instruments Incorporated

Product Folder Links: DRV134 DRV135

Page 3

Top View 8-Pin DIP/SO-8

Top View SOL-16

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

NC

NC

+V

O

+Sense

V+

V–

NC

NC

NC

NC

–V

O

–Sense

Gnd

V

IN

NC

NC

1

2

3

4

8

7

6

5

+V

O

+Sense

V+

V–

–V

O

–Sense

Gnd

V

IN

www.ti.com

SBOS094B –JANUARY 1998–REVISED DECEMBER 2014

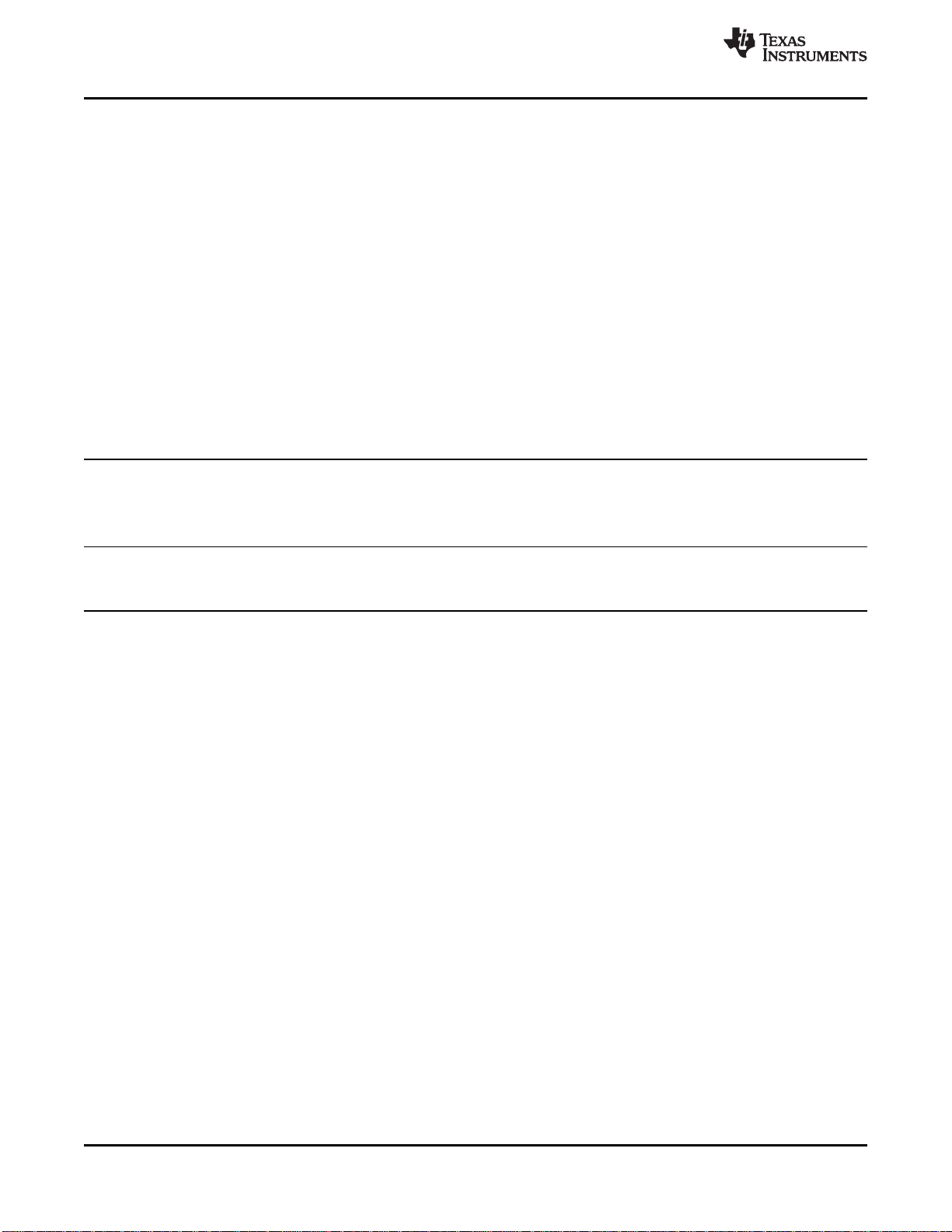

6 Pin Configuration and Functions

NOTE: NC - No internal connection

Pin Functions

PIN

NAME DIP-8 and SO-8 SOL-16

Gnd 3 5 – Ground

+Sense 7 13 I Sensing, non-inverting input

–Sense 2 4 I Sensing, inverting input

V+ 6 12 – Positive supply

V– 5 11 – Negative supply

V

–V

+V

IN

o

o

4 6 I Input

1 3 O Inverted, balanced differential output

8 14 O Balanced differential output

NC – 1,2,7,8,9,10,15,16 – These pins should be left unconnected

I/O DESCRIPTION

DRV134,DRV135

Copyright © 1998–2014, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Links: DRV134 DRV135

Page 4

DRV134,DRV135

SBOS094B –JANUARY 1998–REVISED DECEMBER 2014

www.ti.com

7 Specifications

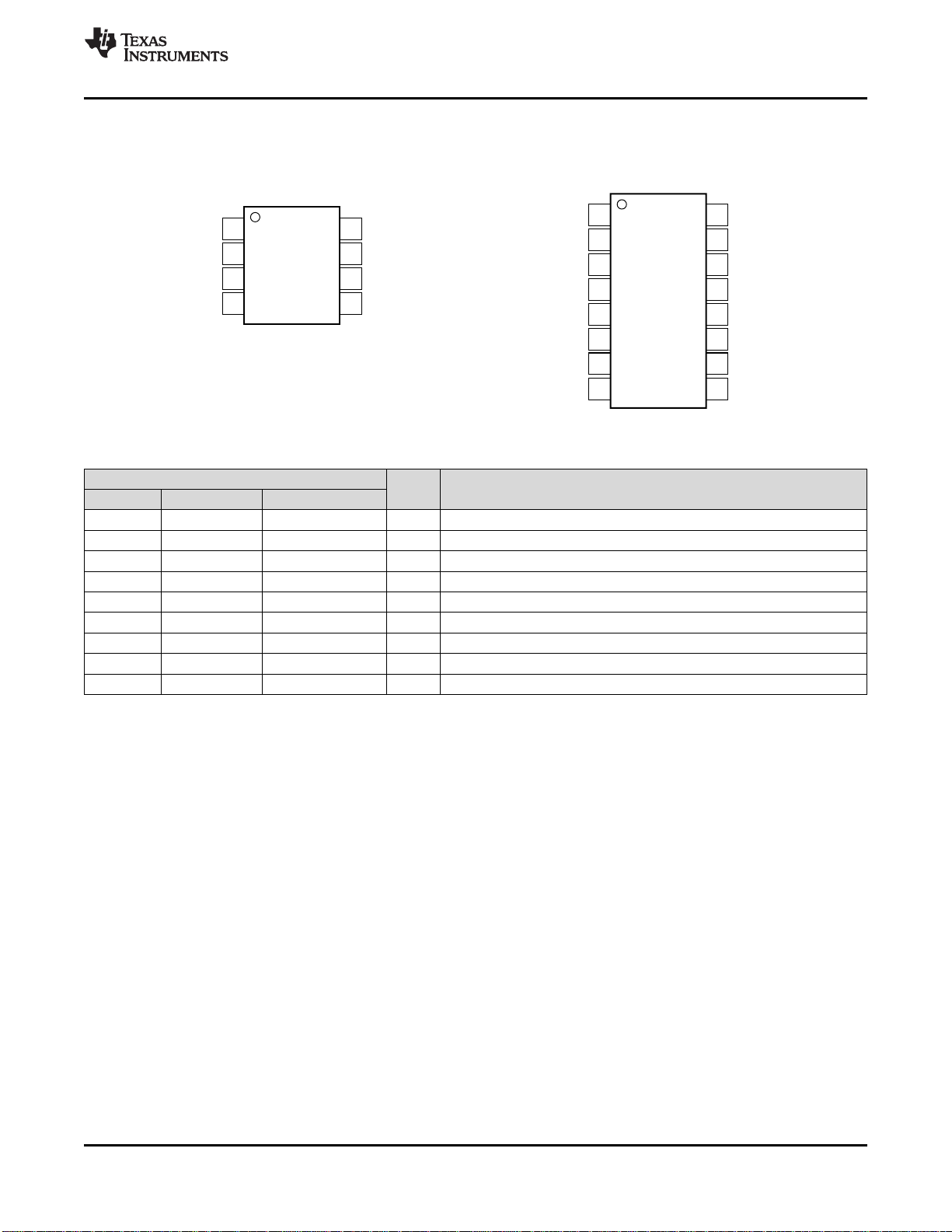

7.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)

Supply voltage, V+ to V– 40 V

Input voltage range V– V+

Output short-circuit (to ground) Continuous

Operating temperature –55 125 °C

Junction temperature 150 °C

(1) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions . Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

7.2 Handling Ratings

T

V

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(2) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

Storage temperature range –55 125 °C

stg

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001, all –2000 2000

(1)

Electrostatic discharge V

(ESD)

pins

Charged device model (CDM), per JEDEC specification –500 500

JESD22-C101, all pins

(2)

(1)

MIN MAX UNIT

MIN MAX UNIT

7.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN NOM MAX UNIT

T

T

V+ Positive supply 4.5 18 18 V

V– Negative supply –4.5 –18 –18 V

Specification temperature range –40 85 °C

spe

Operation temperature range –55 125 °C

A

4 Submit Documentation Feedback Copyright © 1998–2014, Texas Instruments Incorporated

Product Folder Links: DRV134 DRV135

Page 5

DRV134,DRV135

www.ti.com

SBOS094B –JANUARY 1998–REVISED DECEMBER 2014

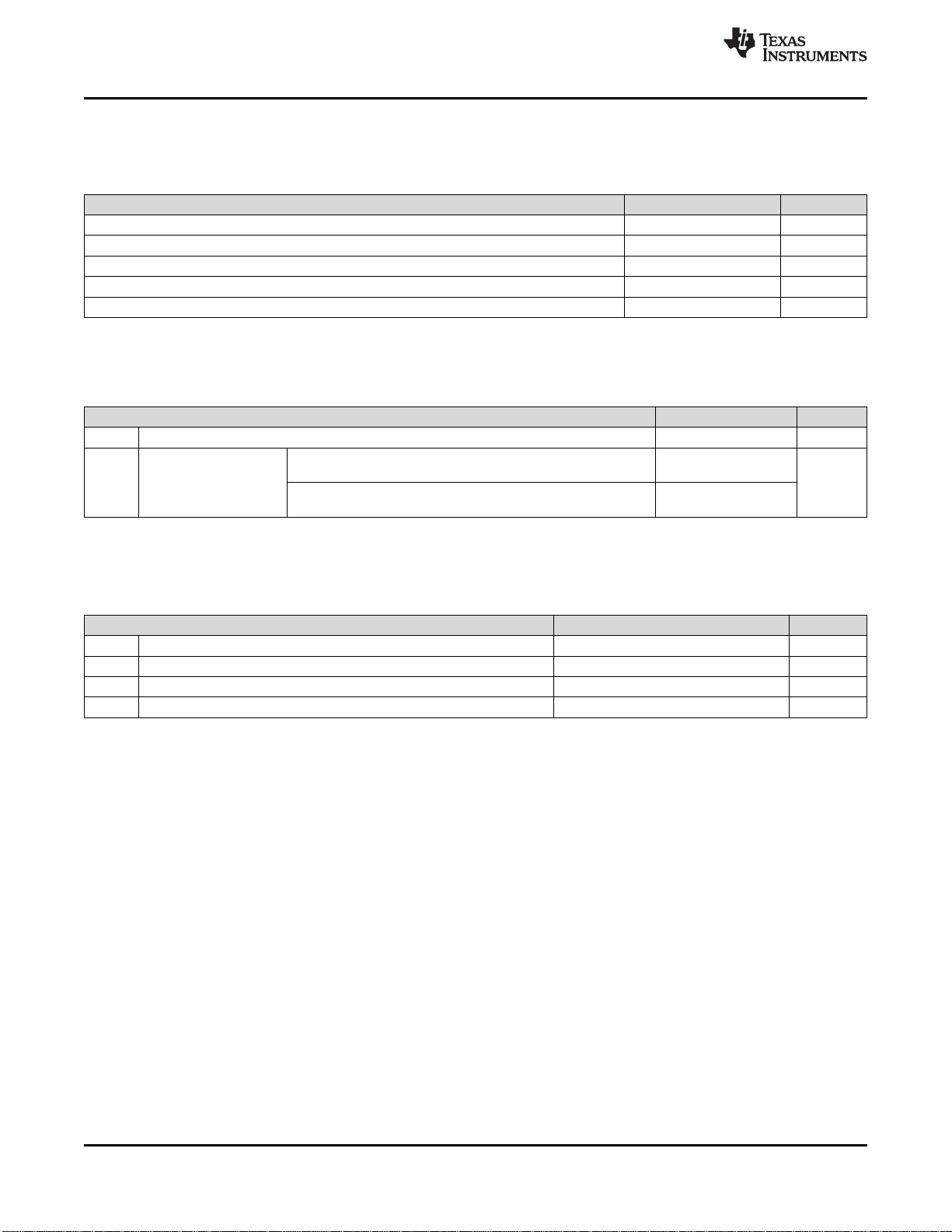

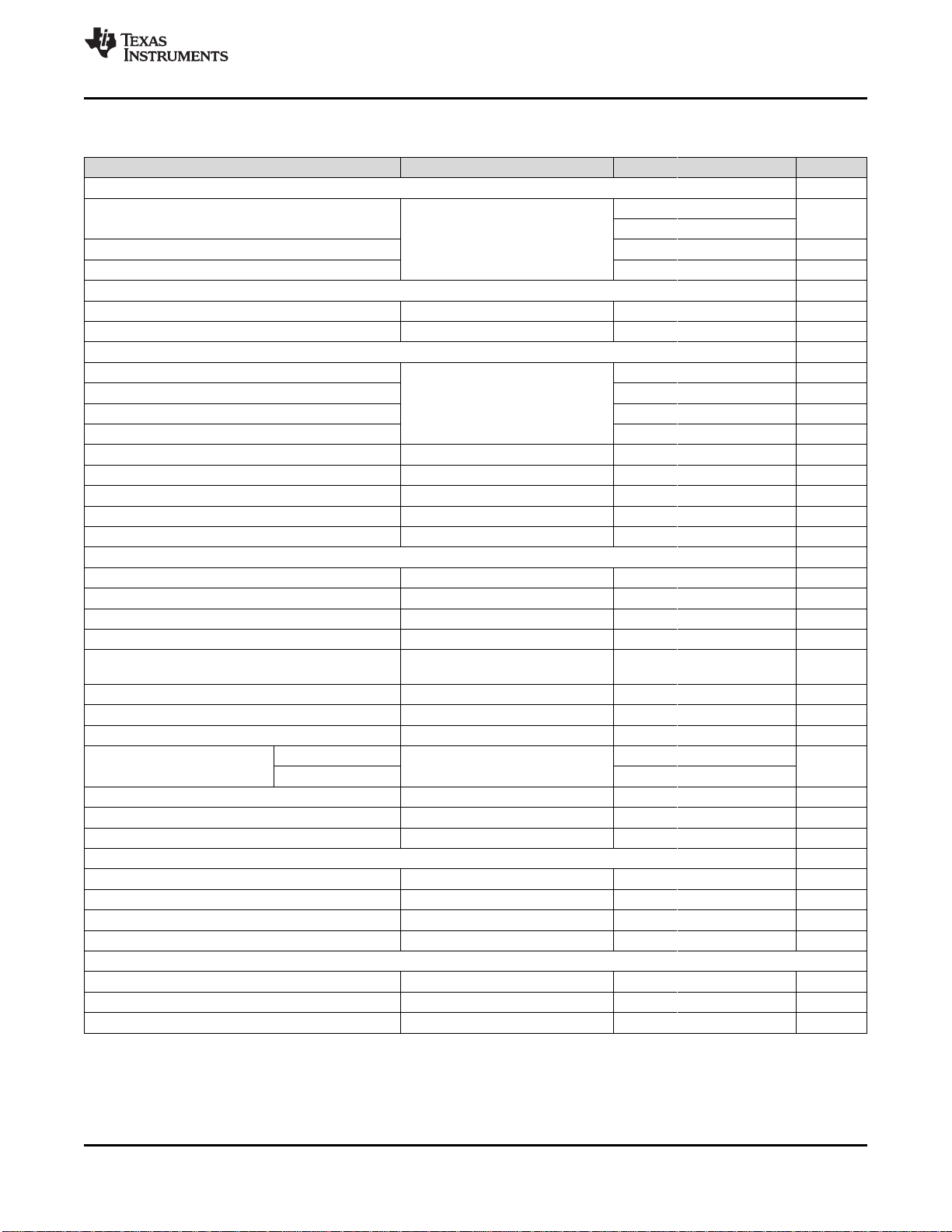

7.4 Electrical Characteristics

At TA= +25°C, VS= ±18 V, RL= 600 Ω differential connected between +VOand –VO, unless otherwise noted.

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

AUDIO PERFORMANCE

THD+N Total Harmonic Distortion + Noise 0.001%

(1)

RTO

RTO

Noise Floor –98 dBu

(1)

Headroom 27 dBu

INPUT

Z

IN

I

IN

Input Impedance

Input Current VIN= ±7.07 V –1000 ±700 1000 µA

(2)

GAIN

Differential

Initial 5.8 6 dB

Error –2% ±0.1% 2%

Error vs Temperature ±10 ppm/°C

Single-Ended VIN= ±5V

Initial 5.8 6 dB

Error –2% ±0.7% 2%

Error vs Temperature ±10 ppm/°C

Nonlinearity 0.0003 % of FS

OUTPUT

OCMR Common-Mode Rejection, f = 1kHz See Figure 25 46 68 dB

SBR Signal Balance Ratio, f = 1kHz See Figure 26 35 54 dB

Output Offset Voltage

(3)

V

OCM

Offset Voltage, Common-Mode VIN= 0 –250 ±50 250 mV

Offset Voltage, Common-Mode vs ±150 µV/°C

Temperature

(4)

V

OD

Offset Voltage, Differential VIN= 0 –10 ±1 10 mV

Offset Voltage, Differential vs Temperature ±5 µV/°C

PSRR Offset Voltage, Differential vs Power Supply VS= ±4.5V to ±18V 80 110 dB

Output Voltage Swing, No Load

Positive (V+) – 3 (V+) – 2.5

Negative (V–) + 2 (V–) + 1.5

Impedance 50 Ω

C

L

I

SC

Load Capacitance, Stable Operation CLTied to Ground (each output) 1 µF

Short-Circuit Current ±85 mA

FREQUENCY RESPONSE

Small-Signal Bandwidth 1.5 MHz

SR Slew Rate 15 V/µs

Settling Time: 0.01% V

Overload Recovery Output Overdriven 10% 3 µs

POWER SUPPLY

V

S

Rated Voltage ±18 V

Voltage Range ±4.5 ±18 V

I

Q

Quiescent Current IO= 0 –5.5 ±5.2 5.5 mA

(1) dBu = 20log (Vrms /0.7746); RTO = Referred-to-Output.

(2) Resistors are ratio matched but have ±20% absolute value.

(3) V

(4) VOD= (+VO) – (–VO).

= [(+VO) + (–VO)] / 2.

OCM

(5) Ensures linear operation. Includes common-mode offset.

f = 20Hz to 20kHz, VO= 10Vrms

f = 1kHz, VO= 10Vrms

0.0005%

20 kHz BW

THD+N < 1%

10 kΩ

[(+VO) – (–VO)]/V

IN

VIN= ±10V

(5)

= 10V Step 2.5 µs

OUT

V

Copyright © 1998–2014, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Links: DRV134 DRV135

Page 6

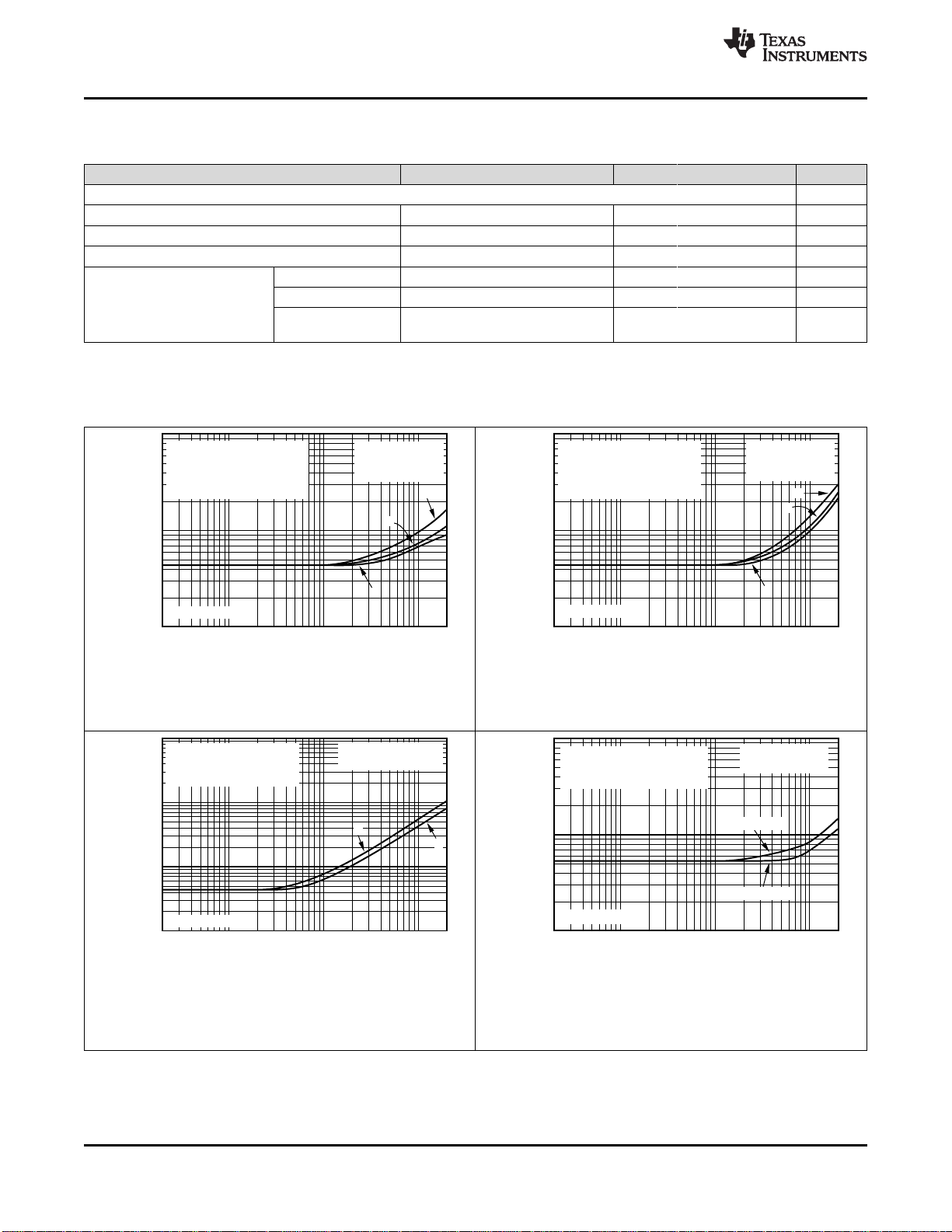

Frequency (Hz)

THD+N (%)

20 100 1k 10k 20k

0.1

0.01

0.001

0.0001

–VOor +VOGrounded

A: R

1

= 600Ω (250 ft cable)

B: R

1

= ∞ (no cable)

Single-Ended Mode

V

O

= 10Vrms

DRV134 Output

B

A

Frequency (Hz)

THD+N (%)

20 100 1k 10k 20k

0.01

0.001

0.0001

Differential Mode

V

O

= 10Vrms

See Figure 3 for Test Circuit

A: R

1

= R2= RL= ∞ (no load)

B: R

1

= R2= ∞ RL= 600Ω

INA137 Output

A (no cable)

B (500ft cable)

Frequency (Hz)

THD+N (%)

20 100 1k 10k 20k

C

0.01

0.001

0.0001

See Figure 3 for Test Circuit

A: R

1

= R2= RL= (no load)∞

B: R

1

= R2= 600Ω, RL= ∞

C: R

1

= R2= , R∞L= 600Ω

Differential Mode

V

O

= 10Vrms

No Cable

DRV134 Output

A

B

Frequency (Hz)

THD+N (%)

20 100 1k 10k 20k

0.01

0.001

0.0001

C

See Figure 3 for Test Circuit

A: R

1

= R2= RL= (no load)∞

B: R

1

= R2= 600Ω, RL= ∞

C: R

1

= R2= , R∞L= 600Ω

Differential Mode

V

O

= 10Vrms

500 ft cable

DRV134 Output

B

A

DRV134,DRV135

SBOS094B –JANUARY 1998–REVISED DECEMBER 2014

Electrical Characteristics (continued)

At TA= +25°C, VS= ±18 V, RL= 600 Ω differential connected between +VOand –VO, unless otherwise noted.

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

TEMPERATURE RANGE

Specification Range –40 85 °C

Operation Range –55 125 °C

Storage Range –55 125 °C

θ

JA

Thermal Resistance 8-Pin DIP 100 °C/W

SO-8 Surface mount 150 °C/W

SOL-16 Surface 80 °C/W

mount

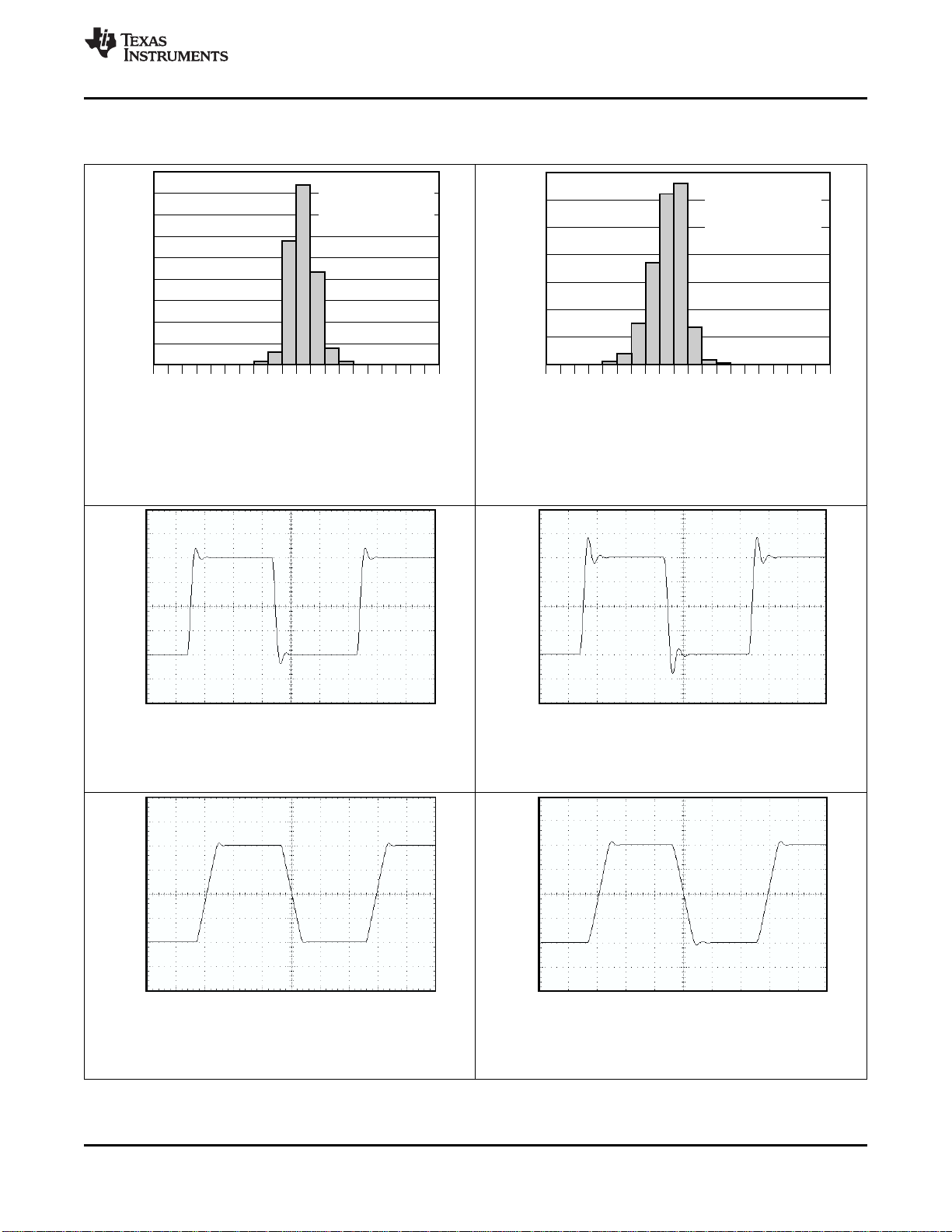

7.5 Typical Characteristics

At TA= 25°C, VS= ±18 V, RL= 600 Ω differential connected between +VOand –VO, unless otherwise noted.

www.ti.com

Figure 1. Total Harmonic Distortion + Noise vs Frequency Figure 2. Total Harmonic Distortion + Noise vs Frequency

Figure 3. Total Harmonic Distortion + Noise Figure 4. System Total Harmonic Distortion + Noise

6 Submit Documentation Feedback Copyright © 1998–2014, Texas Instruments Incorporated

vs Frequency vs Frequency

Product Folder Links: DRV134 DRV135

Page 7

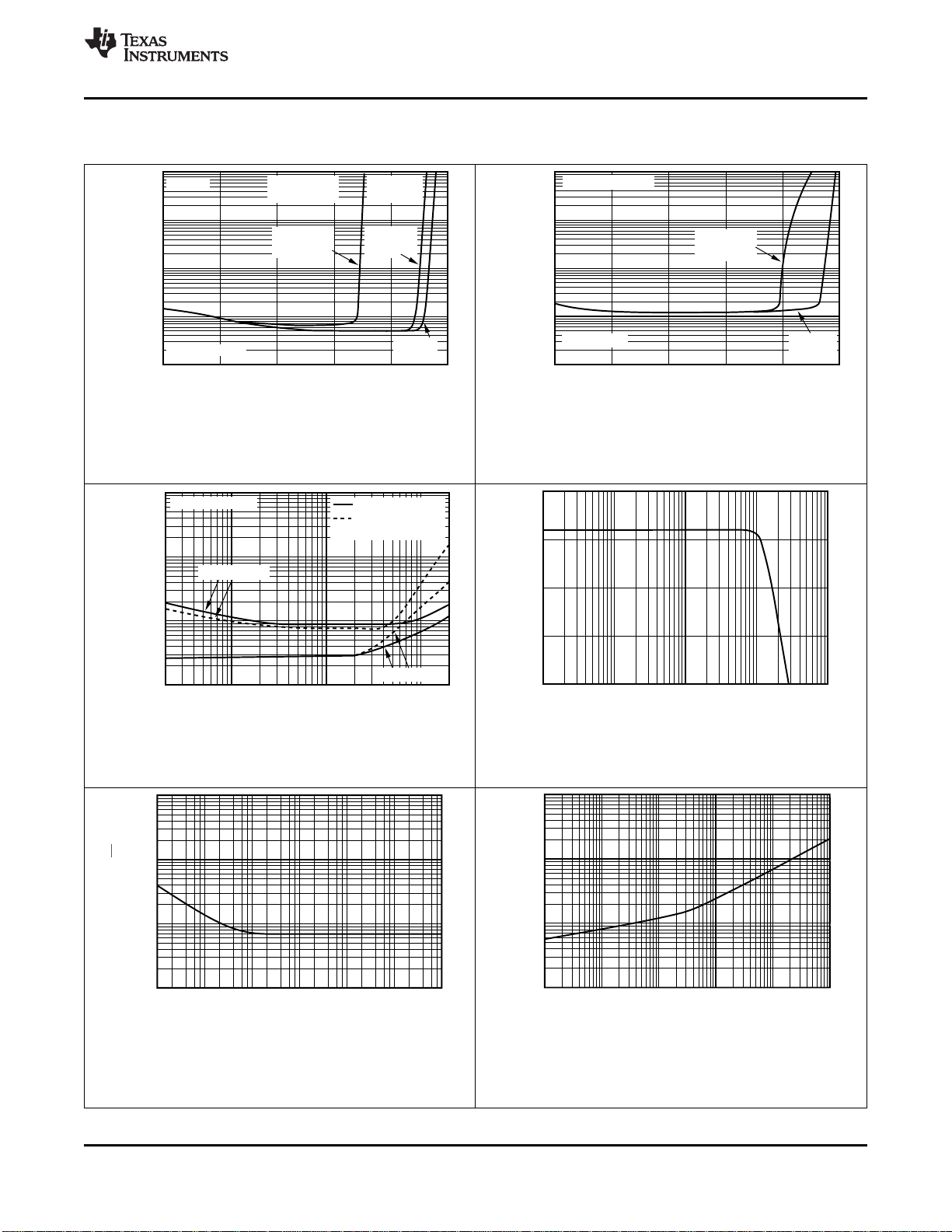

Frequency (Hz)

Voltage Noise (nV/√Hz)

1 10 100 1k 10k 100k 1M

10k

1k

100

10

Frequency (Hz)

Voltage Noise (µVrms)

1 10 100 1k 10k 100k

100

10

1

0.1

Frequency (Hz)

Amplitude (% of Fundamental)

20 100 1k 20k10k

0.01

0.001

0.0001

0.00001

Differential Mode

2nd Harmonic

3rd Harmonic

No Cable, RL= ∞

500 ft Cable,

R

L

= 600Ω

Frequency (Hz)

Voltage Gain (dB)

1k 10k 100k 10M1M

10

5

0

–5

–10

Output Amplitude (dBu)

THD+N (%)

5 10 15 20 3025

1

0.1

0.01

0.001

0.0001

No Cable

R

L

= ∞

500 ft Cable

R

L

= 600Ω

Single-Ended

Mode

f = 1kHz

DRV134 Output

Differential

Mode

500 ft Cable

R

L

= 600Ω

Output Amplitude (dBu)

DIM (%)

5 10 15 20 3025

1

0.1

0.01

0.001

0.0001

Differential Mode

No Cable

R

L

= ∞

500 ft Cable

R

L

= 600Ω

BW = 30kHz

www.ti.com

SBOS094B –JANUARY 1998–REVISED DECEMBER 2014

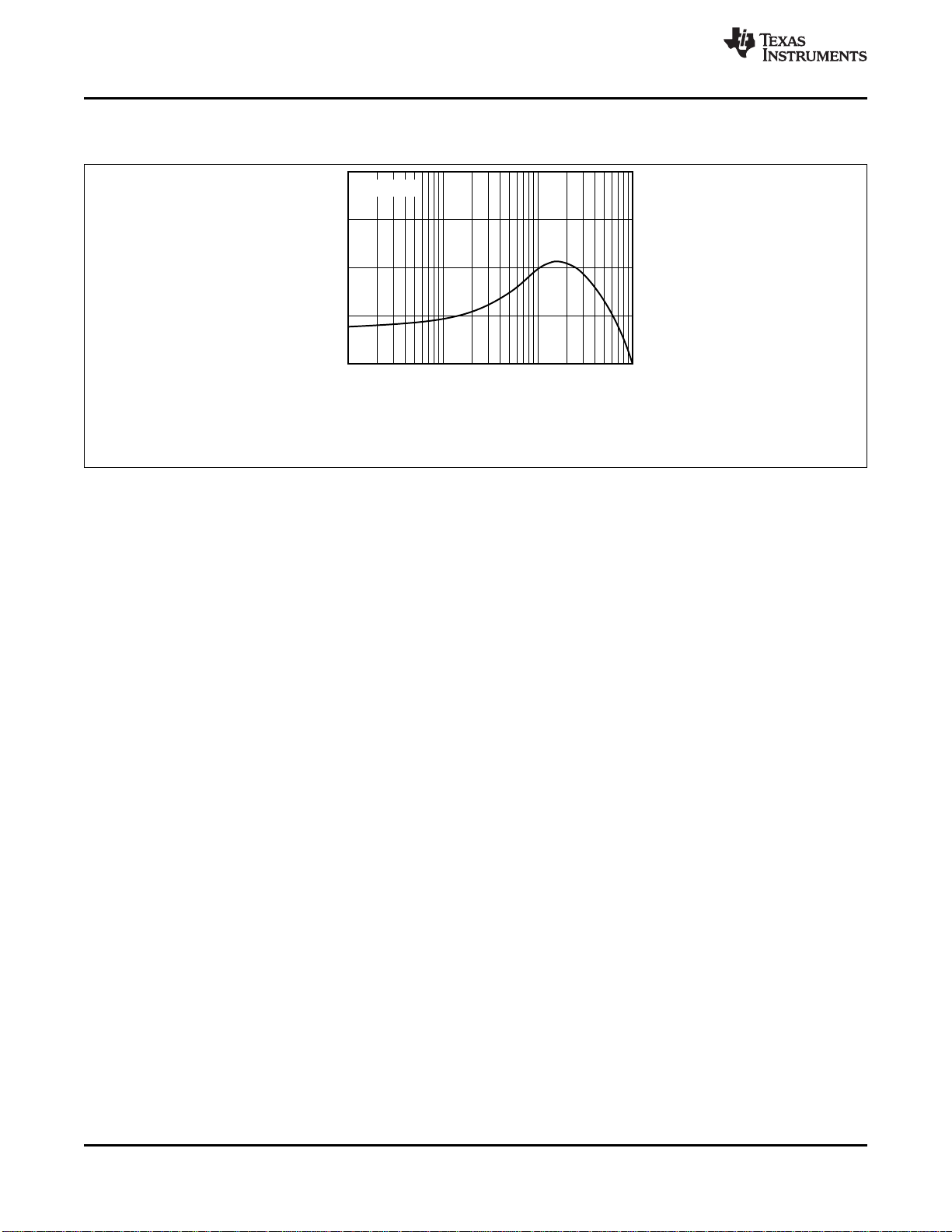

Typical Characteristics (continued)

At TA= 25°C, VS= ±18 V, RL= 600 Ω differential connected between +VOand –VO, unless otherwise noted.

Figure 5. Headroom – Total Harmonic Distortion + Noise Figure 6. Dim Intermodulation Distortion

vs Output Amplitude vs Output Amplitude

DRV134,DRV135

Figure 7. Harmonic Distortion Products vs Frequency Figure 8. Gain vs Frequency

Copyright © 1998–2014, Texas Instruments Incorporated Submit Documentation Feedback 7

Figure 9. Output Voltage Noise Spectral Density Figure 10. Output Voltage Noise

vs Frequency vs Noise Bandwidth

Product Folder Links: DRV134 DRV135

Page 8

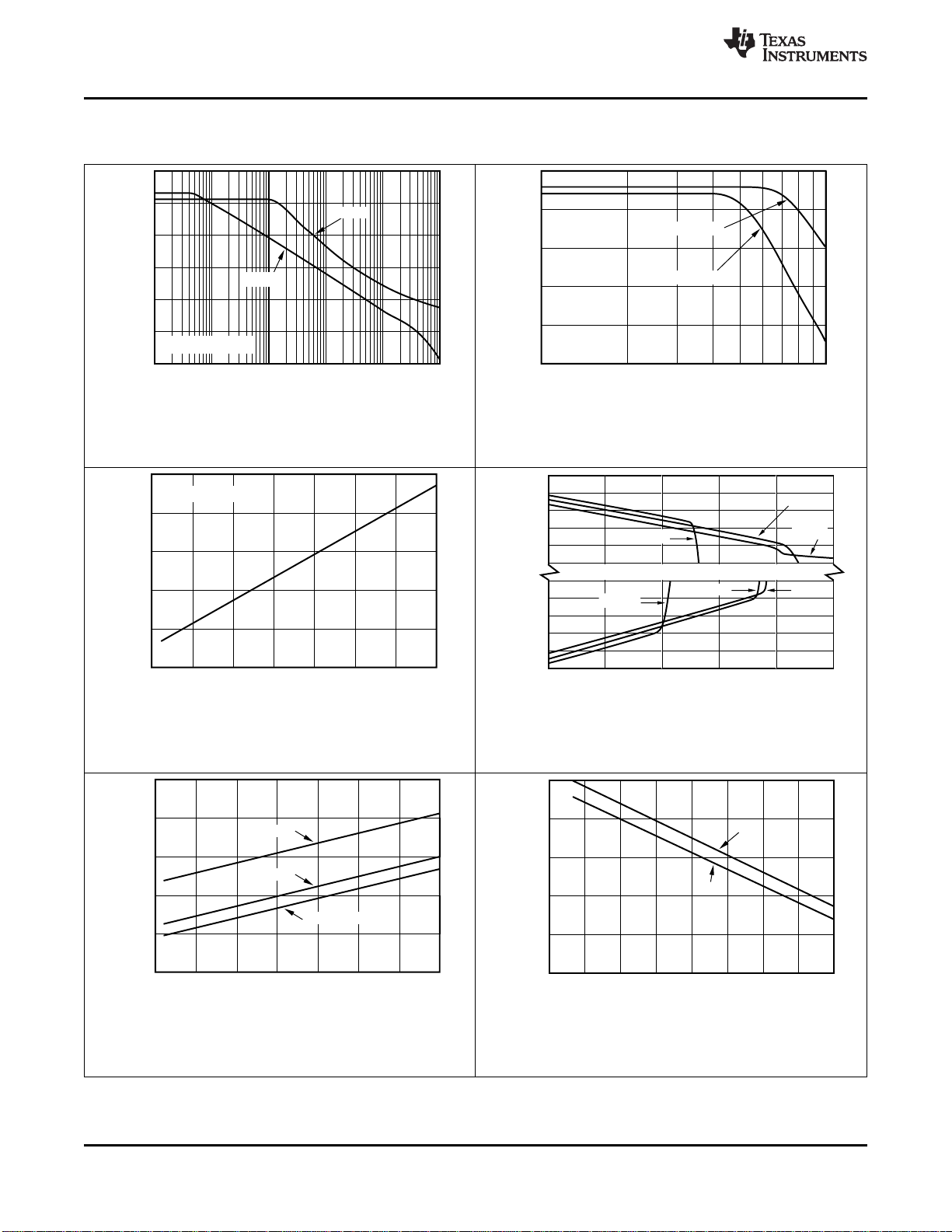

Supply Voltage (V)

Quiescent Current (mA)

±4 ±18±16±14±12±10±8±6

±5.6

±5.4

±5.2

±5

±4.8

±4.6

T = –55°C

T = +25°C

T = +125°C

Temperature ( °C)

Short-Circuit Current (mA)

–75 –50 –25 0 25 50 75 125100

±120

±100

±80

±60

±40

±20

+I

SC

–I

SC

Output Current (mA)

Output Voltage Swing (V)

0 ±20 ±40 ±60 ±80 ±100

18

16

14

12

10

8

–8

–10

–12

–14

–16

–18

–55°C

+25°C

+125°C

+125°C

+25°C –55°C

Supply Voltage (V)

Differential Output Voltage (Vrms)

±4 ±6 ±8 ±10 ±12 ±14 ±16 ±18

20

16

12

8

4

0

THD+N ≤ 0.1%

Frequency (Hz)

Power Supply Rejection (dB)

10 100 1k 1M100k10k

120

100

80

60

40

20

0

+PSRR

–PSRR

VS= ±4.5V to ±18V

Frequency (Hz)

Output Voltage Swing (Vrms)

10k 20k 100k80k50k

20

16

12

8

4

0

0.1% Distortion

0.01% Distortion

R

L

= 600Ω

Diff Mode

DRV134,DRV135

SBOS094B –JANUARY 1998–REVISED DECEMBER 2014

Typical Characteristics (continued)

At TA= 25°C, VS= ±18 V, RL= 600 Ω differential connected between +VOand –VO, unless otherwise noted.

Figure 11. Power Supply Rejection vs Frequency Figure 12. Maximum Output Voltage Swing vs Frequency

www.ti.com

Figure 13. Output Voltage Swing vs Supply Voltage

8 Submit Documentation Feedback Copyright © 1998–2014, Texas Instruments Incorporated

Figure 15. Quiescent Current vs Supply Voltage Figure 16. Short-Circuit Current vs Temperature

Figure 14. Output Voltage Swing vs Output Current

Product Folder Links: DRV134 DRV135

Page 9

2µs/div

5V/div

2µs/div

5V/div

2µs/div

50mV/div

2µs/div

50mV/div

Percent of Units (%)

Common-Mode Offset Voltage (mV)

–

250

–

225

–

200

–

175

–

150

–

125

–

100

–

75

–

50

–

25

0

25

50

75

100

125

150

175

200

225

250

35

30

25

20

15

10

5

0

Typical production

distribution of packaged

units. All package types

included.

Percent of Units (%)

Differential Offset Voltage (mV)

–

10

–9

–8

–7

–6

–5

–4

–3

–2

–1

0

1

2

3

4

5

6

7

8

9

10

45

40

35

30

25

20

15

10

5

0

Typical production

distribution of packaged

units. All package types

included.

www.ti.com

SBOS094B –JANUARY 1998–REVISED DECEMBER 2014

Typical Characteristics (continued)

At TA= 25°C, VS= ±18 V, RL= 600 Ω differential connected between +VOand –VO, unless otherwise noted.

DRV134,DRV135

Figure 17. Differential Offset Voltage

Production Distribution

Figure 18. Common-Mode Offset Voltage

Production Distribution

CL= 100 pF CL= 1000 pF

Figure 19. Small-Signal Step Response Figure 20. Small-Signal Step Response

Copyright © 1998–2014, Texas Instruments Incorporated Submit Documentation Feedback 9

CL= 100 pF

Figure 21. Large-Signal Step Response

CL= 1000 pF

Figure 22. Large-Signal Step Response

Product Folder Links: DRV134 DRV135

Page 10

Load Capacitance (pF)

Overshoot (%)

10 1k100 10k

40

30

20

10

0

100mV Step

DRV134,DRV135

SBOS094B –JANUARY 1998–REVISED DECEMBER 2014

Typical Characteristics (continued)

At TA= 25°C, VS= ±18 V, RL= 600 Ω differential connected between +VOand –VO, unless otherwise noted.

Figure 23. Small-Signal Step Overshoot vs Load Capacitance

www.ti.com

10 Submit Documentation Feedback Copyright © 1998–2014, Texas Instruments Incorporated

Product Folder Links: DRV134 DRV135

Page 11

V

IN

Gnd

+V

O

A2

10kΩ

50Ω

50Ω

All resistors 30kΩ unless otherwise indicated.

+Sense

–Sense

–V

O

G = +6dB

V+

(12)6

A3

A1

10kΩ

1µF

V–

DRV134

DRV135

5 (11)

1µF

4

(6)

3

(5)

8

(14)

7

(13)

2

(4)

1

(3)

DRV134,DRV135

www.ti.com

SBOS094B –JANUARY 1998–REVISED DECEMBER 2014

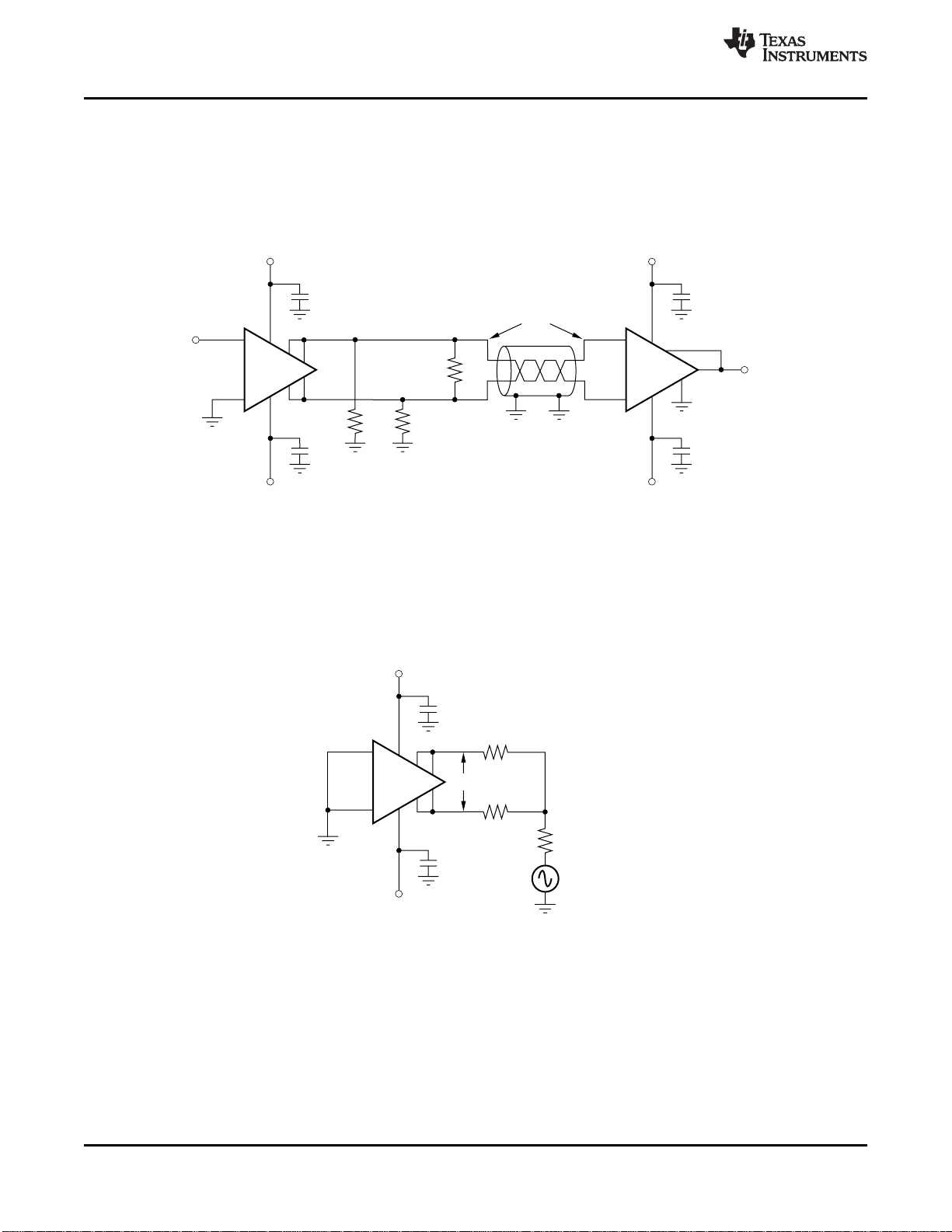

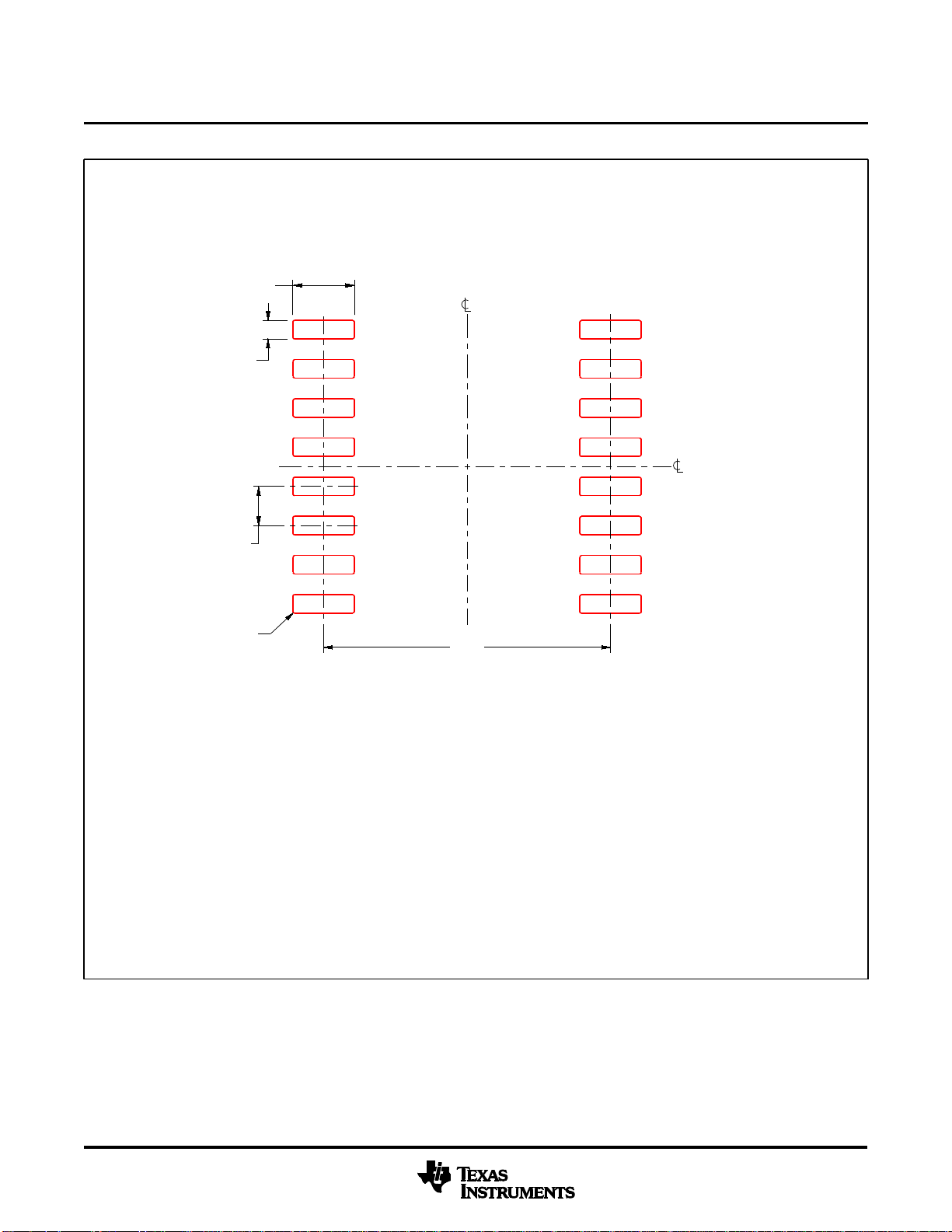

8 Detailed Description

8.1 Overview

The DRV134 and DRV135 consist of an input inverter driving a cross- coupled differential output stage with 50 Ω

series output resistors. Characterized by low differential-mode output impedance (50 Ω) and high common-mode

output impedance (1.6 kΩ), the DRV134 and DRV135 are ideal for audio applications.

Excellent internal design and layout techniques provide low signal distortion, high output level (27 dBu), and a

low noise floor (–98 dBu). Laser trimming of thin film resistors assures excellent output common-mode rejection

(OCMR) and signal balance ratio (SBR). In addition, low dc voltage offset reduces errors and minimizes load

currents.

The Functional Block Diagram section shows a detailed block diagram of the DRV134 and DRV135.

8.2 Functional Block Diagram

8.3 Feature Description

OCM

errors have virtually no effect on performance.

8.3.1 Audio Performance

The DRV134 and DRV135 were designed for enhanced ac performance. Very low distortion, low noise, and wide

bandwidth provide superior performance in high quality audio applications. Laser-trimmed matched resistors

provide optimum output common-mode rejection (typically 68dB), especially when compared to circuits

implemented with op amps and discrete precision resistors. In addition, high slew rate (15 V/μs) and fast settling

time (2.5 μs to 0.01%) ensure excellent dynamic response.

The DRV134 and DRV135 have excellent distortion characteristics. As shown in the distortion data provided in

the Typical Characteristics section, THD+Noise is below 0.003% throughout the audio frequency range under

various output conditions. Both differential and single-ended modes of operation are shown. In addition, the

optional 10μF blocking capacitors used to minimize V

Measurements were taken with an Audio Precision System One (with the internal 80 kHz noise filter) using the

THD test circuit shown in Figure 24.

Copyright © 1998–2014, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Links: DRV134 DRV135

Page 12

600Ω

V

CM

= 10Vp-p

300Ω

(1)

300Ω

(1)

V

IN

Gnd

+V

O

V

OD

–V

O

DRV134

1µF

+18V

6

8

1

7

2

1µF

–18V

5

4

3

R

1

R

2

R

L

V

OUT

INA137

1µF

V

IN

+V

O

–In

+In

–V

O

+18V

7

2

3

6

1

5

1µF

–18V

4

DRV134

1µF

+18V

6

8

1

7

2

1µF

–18V

5

4

3

Test Point

or

DRV134,DRV135

SBOS094B –JANUARY 1998–REVISED DECEMBER 2014

www.ti.com

Feature Description (continued)

Up to approximately 10 kHz, distortion is below the measurement limit of commonly used test equipment.

Furthermore, distortion remains relatively constant over the wide output voltage swing range (approximately 2.5

V from the positive supply and 1.5 V from the negative supply). A special output stage topology yields a design

with minimum distortion variation from lot-to-lot and unit-to-unit. Furthermore, the small and large signal transient

response curves demonstrate the stability under load of the DRV134 and DRV135.

Figure 24. Distortion Test Circuit

8.3.2 Output Common-Mode Rejection

Output common-mode rejection (OCMR) is defined as the change in differential output voltage due to a change

in output common-mode voltage. When measuring OCMR, VINis grounded and a common-mode voltage, VCM,

is applied to the output as shown in Figure 25. Ideally no differential mode signal (VOD) should appear.

However, a small mode-conversion effect causes an error signal whose magnitude is quantified by OCMR.

Figure 25. Output Common-Mode Rejection Test Circuit

8.3.3 Signal Balance Ratio

Signal balance ratio (SBR) measures the symmetry of the output signals under loaded conditions. To measure

SBR an input signal is applied and the outputs are summed as shown in Figure 26. V

each output ideally is exactly equal and opposite. However, an error signal results from any imbalance in the

outputs. This error is quantified by SBR. The impedances of the DRV134 and DRV135’s output stages are

closely matched by laser trimming to minimize SBR errors. In an application, SBR also depends on the balance

of the load network.

12 Submit Documentation Feedback Copyright © 1998–2014, Texas Instruments Incorporated

Product Folder Links: DRV134 DRV135

should be zero since

OUT

Page 13

V

IN

Gnd

+V

O

A2

10kΩ

50Ω

50Ω

All resistors 30kΩ unless otherwise indicated.

+Sense

–Sense

–V

O

G = +6dB

V+

(12)6

A3

A1

10kΩ

1µF

V–

DRV134

DRV135

5 (11)

1µF

4

(6)

3

(5)

8

(14)

7

(13)

2

(4)

1

(3)

600Ω

300Ω

(1)

300Ω

(1)

V

OUT

V

IN

= 10Vp-p

+V

O

O

–V

DRV134

1µF

+18V

6

8

1

7

2

1µF

–18V

Gnd

5

4

3

DRV134,DRV135

www.ti.com

SBOS094B –JANUARY 1998–REVISED DECEMBER 2014

Feature Description (continued)

Figure 26. Signal Balance Ratio Test Circuit

8.4 Device Functional Modes

8.4.1 Differential-Output Mode

In differential-output mode, the DRV134 (and DRV135 in SO-8 package) converts a single-ended, groundreferenced input to a floating differential output with +6 dB gain (G = 2). Figure 27 shows the basic connections

required for operation in differential-output mode.

Normally, +VOis connected to +Sense, –VOis connected to –Sense, and the outputs are taken from these

junctions as shown in Figure 27.

Copyright © 1998–2014, Texas Instruments Incorporated Submit Documentation Feedback 13

Figure 27. Basic Connections for Differential-Output Mode

Product Folder Links: DRV134 DRV135

Page 14

600Ω

V

OUT

= 2V

IN

V

IN

V+

DRV134

8

1

7

2

G = +6dB

4

5

6

3

DRV134,DRV135

SBOS094B –JANUARY 1998–REVISED DECEMBER 2014

www.ti.com

Device Functional Modes (continued)

8.4.2 Single-Ended Mode

The DRV134 can be operated in single-ended mode without degrading output drive capability. Single-ended

operation requires that the unused side of the output pair be grounded (both the VOand Sense pins) to a low

impedance return path. Gain remains +6 dB. Grounding the negative outputs as shown in Figure 28 results in a

non-inverted output signal (G = +2) while grounding the positive outputs gives an inverted output signal (G = –2).

Figure 28. Typical Single-Ended Application

For best rejection of line noise and hum differential mode operation is recommended. However, single-ended

performance is adequate for many applications. In general single ended performance is comparable to

differential mode (see THD+N typical performance curves), but the common mode and noise rejection inherent in

balanced-pair systems is lost.

14 Submit Documentation Feedback Copyright © 1998–2014, Texas Instruments Incorporated

Product Folder Links: DRV134 DRV135

Page 15

V

IN

Gnd

A2

10kΩ

50Ω

50Ω

All resistors 30kΩ unless otherwise indicated.

INA134 (G = 1): VO= 2V

IN

INA137 (G = 1/2): VO= V

IN

A3

A1

10kΩ

DRV134

DRV135

4

3

8

+V

O

–V

O

+V

O

–V

O

7

2

1

INA134, INA137

RECEIVER

DRIVER

BALANCED

CABLE PAIR

V

O

5

6

1

2

3

10µF

(1)

10µF

(1)

DRV134,DRV135

www.ti.com

SBOS094B –JANUARY 1998–REVISED DECEMBER 2014

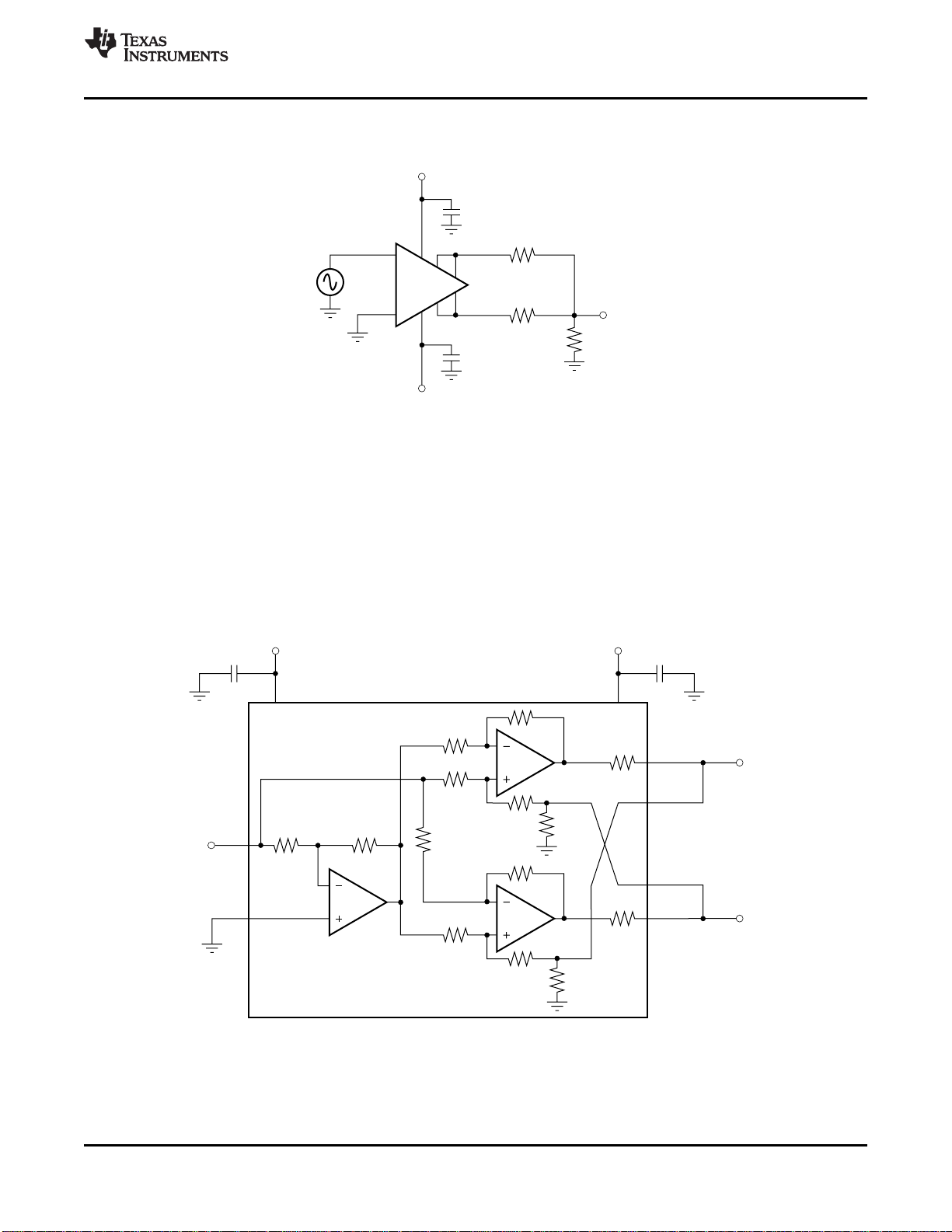

9 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

9.1 Application Information

Decoupling capacitors placed close to the device pins are strongly recommended in applications with noisy or

high impedance power supplies.

For best system performance, it is recommended that a high input-impedance difference amplifier be used as the

receiver. Used with the INA134 (G = 0 dB) or the INA137 (G = ±6 dB) differential line receivers, the DRV134

forms a complete solution for driving and receiving audio signals, replacing input and output coupling

transformers commonly used in professional audio systems (Figure 29). When used with the INA137 (G = –6 dB)

overall system gain is unity.

9.2 Typical Application

9.2.1 Cable Driving Application

The DRV134 is capable of driving large signals into 600-Ω loads over long cables. Low impedance shielded

audio cables such as the standard Belden 8451 or 9452 (or similar) are recommended, especially in applications

where long cable lengths are required.

For applications with large dc cable offset errors, a 10-µF electrolytic nonpolarized blocking capacitor at each

sense pin is recommended as shown in Figure 29.

Figure 29. Complete Audio Driver and Receiver Circuit

9.2.1.1 Design Requirements

Consider a design with the goal of differentially transmitting a single ended signal of up to 22.2 dBu through 500

ft of cable with no load at the receiving side. The signal at the end of the cable should have no more than 0.002

percent of total harmonic distortion plus noise (THD+N) at 10 kHz and less than 0.0005 percent of THD+N for

frequencies between 20 Hz and 1 kHz.

The system is required to put out a single ended signal 0 dB with respect to the input signal and accommodate

inputs with peak to RMS ratios of up to 1.5 for the maximum 22.2 dBu range established above.

Copyright © 1998–2014, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Links: DRV134 DRV135

Page 16

R

1

R

2

R

L

V

OUT

INA137

1µF

V

IN

+V

O

–In

+In

–V

O

+18V

7

2

3

6

1

5

1µF

–18V

4

DRV134

1µF

+18V

6

8

1

7

2

1µF

–18V

5

4

3

Test Point

or

PEAKPEAK_IN

V97.1498.95.1V

RMS

20

L

IN

V98.910775.0V

u

¸

¸

¹

·

¨

¨

©

§

¸

¹

·

¨

©

§

775.0

x

log20L

10u

DRV134,DRV135

SBOS094B –JANUARY 1998–REVISED DECEMBER 2014

www.ti.com

Typical Application (continued)

9.2.1.2 Detailed Design Procedure

The dBu is a common unit of measurement for input sensitivity and output level of professional audio equipment.

A 0 dBu signal dissipates 1 mW into a 600-Ω resistive load; therefore, a 0 dBu signal corresponds to

approximately 0.775 V

and the signal level in V

For this design, the single ended input signal of 22.2 dBu corresponds to 9.98 V

Given that the system must accommodate for 22.2 dBu signals with up to 1.5 of peak to RMS ratio, the

maximum peak input signal is 14.97 V

The DRV134 is chosen to convert the single ended input signal into a differential signal and the outputs of the

DRV134 will be connected to one end of the 500 ft cable. In order to prevent clipping and distortion of the input

signal, the power supply rails for the DRV134 are chosen as 3 V above and below the peak calculated in

Equation 3. The 3 V margin is derived from the output voltage swing specification given in the Electrical

Characteristics table. The supplies selected are 18 V for V+ and –18 V for V–.

Finally, the INA137 is used at the end of the 500 ft cable in order to convert the differential signal output of the

DRV134 into a single ended signal that is 0 dB with respect to the input signal.

Figure 30 shows the system diagram.

. Equation 1 shows the relationship between the signal level in dBu (denoted by Lu)

RMS

(denoted by x).

RMS

as shown in Equation 2.

RMS

as calculated in Equation 3.

PEAK

(1)

(2)

(3)

Figure 30. Diagram of System Based on DRV134 and INA137

16 Submit Documentation Feedback Copyright © 1998–2014, Texas Instruments Incorporated

Product Folder Links: DRV134 DRV135

Page 17

Frequency (Hz)

THD+N (%)

20 100 1k 10k 20k

0.01

0.001

0.0001

C

See Figure 3 for Test Circuit

A: R

1

= R2= RL= (no load)∞

B: R

1

= R2= 600Ω, RL= ∞

C: R

1

= R2= , R∞L= 600Ω

Differential Mode

V

O

= 10Vrms

500 ft cable

DRV134 Output

B

A

www.ti.com

SBOS094B –JANUARY 1998–REVISED DECEMBER 2014

Typical Application (continued)

9.2.1.3 Application Curve

Figure 31 shows the performance obtained with the system depicted in Figure 30.

Figure 31. Measured Performance of a System Based on DRV134

10 Power Supply Recommendations

DRV134,DRV135

The DRV134 and DRV135 are designed to operate from an input voltage supply range between ±4.5 V and ±18

V. This input supply should be well regulated. If the input supply is located more than a few inches from the

DRV134 or DRV135 additional bulk capacitance may be required in addition to the ceramic bypass capacitors.

11 Layout

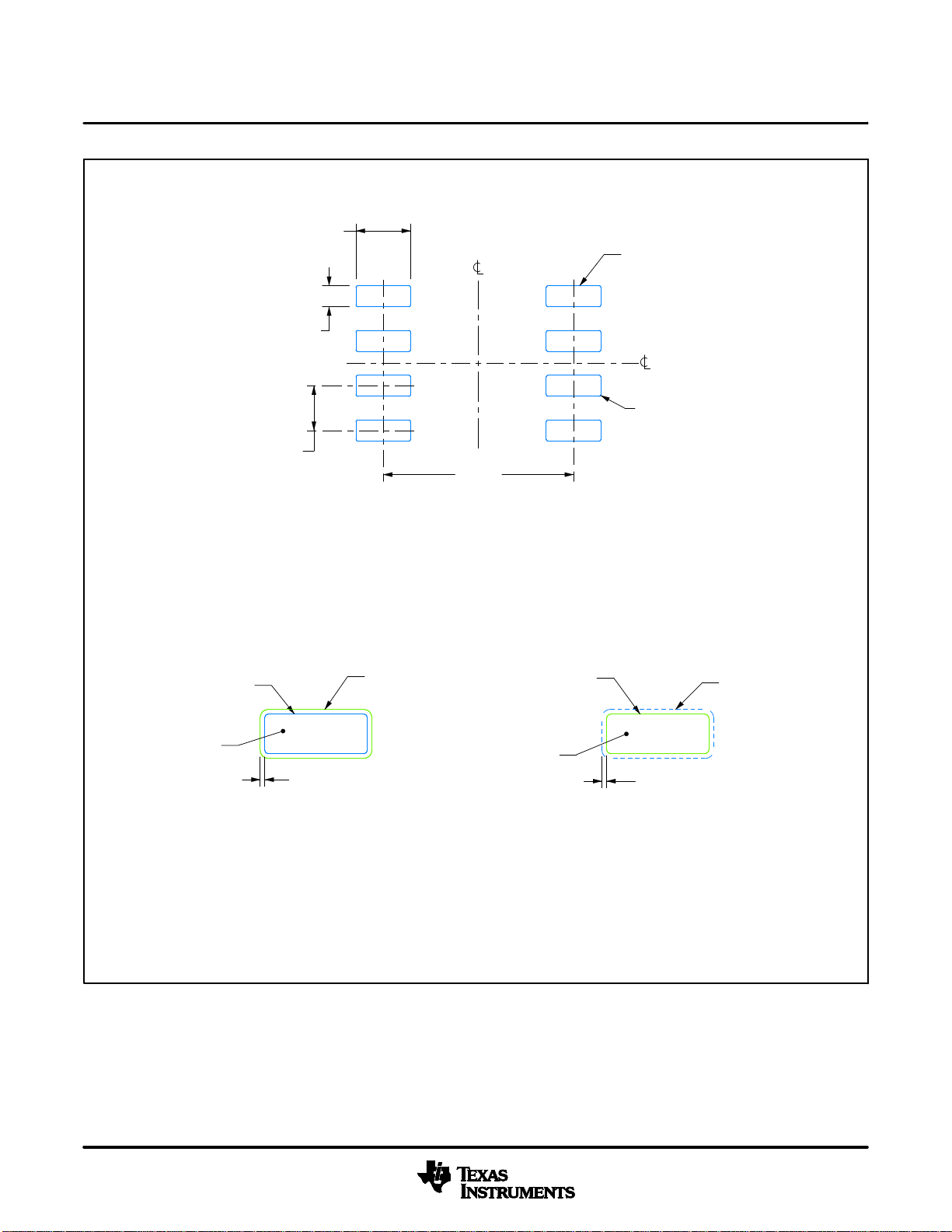

11.1 Layout Guidelines

A driver/receiver balanced-pair (such as the DRV134 and INA137) rejects the voltage differences between the

grounds at each end of the cable, which can be caused by ground currents, supply variations, etc. In addition to

proper bypassing (as shown in Figure 32 and Figure 33), the suggestions below should be followed to achieve

optimal OCMR and noise rejection.

• The DRV134 input should be driven by a low impedance source such as an op amp or buffer.

• As is the case for any single-ended system, the source’s common should be connected as close as possible

to the DRV134’s ground. Any ground offset errors in the source will degrade system performance.

• Symmetry on the outputs should be maintained.

• Shielded twisted-pair cable is recommended for all applications. Physical balance in signal wiring should be

maintained. Capacitive differences due to varying wire lengths may result in unequal noise pickup between

the pair and degrade OCMR. Follow industry practices for proper system grounding of the cables.

Copyright © 1998–2014, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Links: DRV134 DRV135

Page 18

DRV135

-Vo

+Vo

+Sense

V-

-Sense

1

8

Top View

LEGEND

TOP layer:

copper pour & traces

PCB

via to ground plane

V

IN

V+

1 µF

SMD

0603

4

5

1 µF

SMD

0603

Gnd

DRV134

NC

-Vo

NC

+Vo

+Sense

V-

NC

-Sense

1

16

Top View

LEGEND

TOP layer:

copper pour & traces

PCB

via to ground plane

V

IN

NC

V+

NC

NC

NC

NC

1 µF

SMD

0603

8

9

1 µF

SMD

0603

Gnd

DRV134,DRV135

SBOS094B –JANUARY 1998–REVISED DECEMBER 2014

11.2 Layout Examples

www.ti.com

18 Submit Documentation Feedback Copyright © 1998–2014, Texas Instruments Incorporated

Figure 32. DRV134 Layout Example

Figure 33. DRV135 Layout Example

Product Folder Links: DRV134 DRV135

Page 19

DRV134,DRV135

www.ti.com

SBOS094B –JANUARY 1998–REVISED DECEMBER 2014

11.3 Thermal Performance

The DRV134 and DRV135 have robust output drive capability and excellent performance over temperature. In

most applications there is no significant difference between the DIP, SOL-16, and SO-8 packages. However, for

applications with extreme temperature and load conditions, the SOL-16 (DRV134UA) or DIP (DRV134PA)

packages are recommended. Under these conditions, such as loads greater than 600 Ω or very long cables,

performance may be degraded in the SO-8 (DRV135UA) package.

12 Device and Documentation Support

12.1 Documentation Support

12.1.1 Related Documentation

For related documentation see the following:

• Audio Differential Line Receivers 0dB (G = 1), INA134

• Audio Differential Line Receivers ±6dB (G = 1/2 or 2), INA137

12.2 Related Links

The table below lists quick access links. Categories include technical documents, support and community

resources, tools and software, and quick access to sample or buy.

Table 1. Related Links

PARTS PRODUCT FOLDER SAMPLE & BUY

DRV134 Click here Click here Click here Click here Click here

DRV135 Click here Click here Click here Click here Click here

TECHNICAL TOOLS & SUPPORT &

DOCUMENTS SOFTWARE COMMUNITY

12.3 Trademarks

All trademarks are the property of their respective owners.

12.4 Electrostatic Discharge Caution

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

12.5 Glossary

SLYZ022 — TI Glossary.

This glossary lists and explains terms, acronyms, and definitions.

Copyright © 1998–2014, Texas Instruments Incorporated Submit Documentation Feedback 19

Product Folder Links: DRV134 DRV135

Page 20

DRV134,DRV135

SBOS094B –JANUARY 1998–REVISED DECEMBER 2014

www.ti.com

13 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

20 Submit Documentation Feedback Copyright © 1998–2014, Texas Instruments Incorporated

Product Folder Links: DRV134 DRV135

Page 21

PACKAGE OPTION ADDENDUM

www.ti.com

PACKAGING INFORMATION

Orderable Device Status

DRV134PA ACTIVE PDIP P 8 50 Green (RoHS

DRV134PAG4 ACTIVE PDIP P 8 50 Green (RoHS

DRV134UA ACTIVE SOIC DW 16 40 Green (RoHS

DRV134UA/1K ACTIVE SOIC DW 16 1000 Green (RoHS

DRV134UAE4 ACTIVE SOIC DW 16 40 Green (RoHS

DRV135UA ACTIVE SOIC D 8 75 Green (RoHS

DRV135UA/2K5 ACTIVE SOIC D 8 2500 Green (RoHS

DRV135UA/2K5E4 ACTIVE SOIC D 8 2500 Green (RoHS

DRV135UAG4 ACTIVE SOIC D 8 75 Green (RoHS

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

Package Type Package

(1)

Drawing

Pins Package

Qty

Eco Plan

(2)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

Lead/Ball Finish

(6)

NIPDAU N / A for Pkg Type -55 to 125 DRV134PA

NIPDAU N / A for Pkg Type -55 to 125 DRV134PA

NIPDAU Level-3-260C-168 HR DRV134UA

NIPDAU Level-3-260C-168 HR DRV134UA

NIPDAU Level-3-260C-168 HR DRV134UA

NIPDAU Level-3-260C-168 HR -55 to 125 DRV

NIPDAU Level-3-260C-168 HR -55 to 125 DRV

NIPDAU Level-3-260C-168 HR -55 to 125 DRV

NIPDAU Level-3-260C-168 HR -55 to 125 DRV

MSL Peak Temp

(3)

Op Temp (°C) Device Marking

135UA

135UA

135UA

135UA

(4/5)

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of <=1000ppm threshold. Antimony trioxide based

flame retardants must also meet the <=1000ppm threshold requirement.

(3)

MSL, Peak Temp. - The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

6-Feb-2020

Samples

Addendum-Page 1

Page 22

PACKAGE OPTION ADDENDUM

www.ti.com

(4)

There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device.

(5)

Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation

of the previous line and the two combined represent the entire Device Marking for that device.

(6)

Lead/Ball Finish - Orderable Devices may have multiple material finish options. Finish options are separated by a vertical ruled line. Lead/Ball Finish values may wrap to two lines if the finish

value exceeds the maximum column width.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

6-Feb-2020

Addendum-Page 2

Page 23

PACKAGE MATERIALS INFORMATION

www.ti.com 10-Sep-2014

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

Type

DRV134UA/1K SOIC DW 16 1000 330.0 16.4 10.75 10.7 2.7 12.0 16.0 Q1

DRV135UA/2K5 SOIC D 8 2500 330.0 12.4 6.4 5.2 2.1 8.0 12.0 Q1

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

Page 24

PACKAGE MATERIALS INFORMATION

www.ti.com 10-Sep-2014

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

DRV134UA/1K SOIC DW 16 1000 367.0 367.0 38.0

DRV135UA/2K5 SOIC D 8 2500 367.0 367.0 35.0

Pack Materials-Page 2

Page 25

GENERIC PACKAGE VIEW

SOIC - 2.65 mm max heightDW 16

7.5 x 10.3, 1.27 mm pitch

This image is a representation of the package family, actual package may vary.

SMALL OUTLINE INTEGRATED CIRCUIT

Refer to the product data sheet for package details.

www.ti.com

4224780/A

Page 26

PACKAGE OUTLINE

A

10.5

10.1

NOTE 3

SCALE 1.500

10.63

TYP

9.97

PIN 1 ID

AREA

1

8

B

7.6

7.4

NOTE 4

16

9

14X 1.27

2X

8.89

0.51

16X

0.31

0.25 C A B

SOIC - 2.65 mm max heightDW0016A

SOIC

C

SEATING PLANE

0.1 C

2.65 MAX

0.33

TYP

0.10

SEE DETAIL A

GAGE PLANE

0 - 8

0.25

1.27

0.40

(1.4)

DETAIL A

TYPICAL

4220721/A 07/2016

NOTES:

1. All linear dimensions are in millimeters. Dimensions in parenthesis are for reference only. Dimensioning and tolerancing

per ASME Y14.5M.

2. This drawing is subject to change without notice.

3. This dimension does not include mold flash, protrusions, or gate burrs. Mold flash, protrusions, or gate burrs shall not

exceed 0.15 mm, per side.

4. This dimension does not include interlead flash. Interlead flash shall not exceed 0.25 mm, per side.

5. Reference JEDEC registration MS-013.

0.3

0.1

www.ti.com

Page 27

EXAMPLE BOARD LAYOUT

SOIC - 2.65 mm max heightDW0016A

SOIC

16X (2)

16X (0.6)

14X (1.27)

R0.05 TYP

SYMM

1

8

(9.3)

SEE

DETAILS

16

SYMM

9

LAND PATTERN EXAMPLE

SCALE:7X

METAL

0.07 MAX

ALL AROUND

NON SOLDER MASK

DEFINED

SOLDER MASK

OPENING

SOLDER MASK

OPENING

0.07 MIN

ALL AROUND

SOLDER MASK

DEFINED

SOLDER MASK DETAILS

NOTES: (continued)

6. Publication IPC-7351 may have alternate designs.

7. Solder mask tolerances between and around signal pads can vary based on board fabrication site.

METAL

4220721/A 07/2016

www.ti.com

Page 28

EXAMPLE STENCIL DESIGN

SOIC - 2.65 mm max heightDW0016A

SOIC

16X (2)

16X (0.6)

14X (1.27)

R0.05 TYP

SYMM

1

8

(9.3)

16

SYMM

9

SOLDER PASTE EXAMPLE

BASED ON 0.125 mm THICK STENCIL

NOTES: (continued)

8. Laser cutting apertures with trapezoidal walls and rounded corners may offer better paste release. IPC-7525 may have alternate

design recommendations.

9. Board assembly site may have different recommendations for stencil design.

SCALE:7X

4220721/A 07/2016

www.ti.com

Page 29

PACKAGE OUTLINE

A

.189-.197

[4.81-5.00]

NOTE 3

.228-.244 TYP

[5.80-6.19]

1

4

B .150-.157

[3.81-3.98]

PIN 1 ID AREA

NOTE 4

SCALE 2.800

6X .050

[1.27]

8

2X

.150

[3.81]

5

8X .012-.020

[0.31-0.51]

.010 [0.25] C A B

SOIC - 1.75 mm max heightD0008A

SMALL OUTLINE INTEGRATED CIRCUIT

C

SEATING PLANE

.004 [0.1] C

4X (0 -15 )

.069 MAX

[1.75]

.005-.010 TYP

[0.13-0.25]

4X (0 -15 )

SEE DETAIL A

.010

[0.25]

0 - 8

.016-.050

[0.41-1.27]

(.041)

[1.04]

DETAIL A

TYPICAL

.004-.010

[0.11-0.25]

4214825/C 02/2019

NOTES:

1. Linear dimensions are in inches [millimeters]. Dimensions in parenthesis are for reference only. Controlling dimensions are in inches.

Dimensioning and tolerancing per ASME Y14.5M.

2. This drawing is subject to change without notice.

3. This dimension does not include mold flash, protrusions, or gate burrs. Mold flash, protrusions, or gate burrs shall not

exceed .006 [0.15] per side.

4. This dimension does not include interlead flash.

5. Reference JEDEC registration MS-012, variation AA.

www.ti.com

Page 30

8X (.061 )

8X (.024)

6X (.050 )

[1.27]

[0.6]

[1.55]

SYMM

1

4

(.213)

[5.4]

LAND PATTERN EXAMPLE

EXPOSED METAL SHOWN

SCALE:8X

EXAMPLE BOARD LAYOUT

SOIC - 1.75 mm max heightD0008A

SMALL OUTLINE INTEGRATED CIRCUIT

SEE

DETAILS

8

SYMM

(R.002 ) TYP

5

[0.05]

EXPOSED

METAL

METAL

NON SOLDER MASK

SOLDER MASK

OPENING

.0028 MAX

[0.07]

ALL AROUND

DEFINED

SOLDER MASK

OPENING

EXPOSED

METAL

.0028 MIN

[0.07]

ALL AROUND

SOLDER MASK

DEFINED

SOLDER MASK DETAILS

NOTES: (continued)

6. Publication IPC-7351 may have alternate designs.

7. Solder mask tolerances between and around signal pads can vary based on board fabrication site.

METAL UNDER

SOLDER MASK

4214825/C 02/2019

www.ti.com

Page 31

8X (.061 )

8X (.024)

[0.6]

6X (.050 )

[1.27]

[1.55]

EXAMPLE STENCIL DESIGN

SOIC - 1.75 mm max heightD0008A

SMALL OUTLINE INTEGRATED CIRCUIT

SYMM

1

8

SYMM

(R.002 ) TYP

4

(.213)

[5.4]

5

[0.05]

BASED ON .005 INCH [0.125 MM] THICK STENCIL

NOTES: (continued)

8. Laser cutting apertures with trapezoidal walls and rounded corners may offer better paste release. IPC-7525 may have alternate

design recommendations.

9. Board assembly site may have different recommendations for stencil design.

SCALE:8X

4214825/C 02/2019

SOLDER PASTE EXAMPLE

www.ti.com

Page 32

Page 33

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you

permission to use these resources only for development of an application that uses the TI products described in the resource. Other

reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third

party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims,

damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on

ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable

warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2020, Texas Instruments Incorporated

Loading...

Loading...