Page 1

User's Guide

SLOU505–April 2018

DRV10974 Tuning Guide

The DRV10974 device is a three-phase sensorless motor driver with integrated power MOSFETs, which

provide drive-current capability up to 1 A continuous (rms). The device is specifically designed for lownoise, low external-component count, 12-V motor drive applications. The 180° commutation requires no

configuration beyond setting the peak current, the lead angle, and the acceleration profile, each of which

is configured by an external resistor.

This tuning guide covers quick tuning and comprehensive tuning. The quick tuning section covers how to

get the motor running quickly by inferring usable resistor values for the current, lead angle, and

acceleration profile. The comprehensive tuning section covers the methodology for tuning each resistor

value experimentally.

Contents

1 Bench Set Up................................................................................................................. 2

2 Quick Tuning ................................................................................................................. 2

3 Comprehensive Tuning ..................................................................................................... 2

3.1 Finding Closed-Loop Current and Coasting Time .............................................................. 3

3.2 Selecting CS Resistor.............................................................................................. 3

3.3 Selecting ADV Resistor............................................................................................ 4

3.4 Selecting RMP Resistor............................................................................................ 5

3.5 Example CS, ADV, and RMP Resistor Tuning ................................................................. 6

List of Figures

1 Example Peak Current in Closed Loop ................................................................................... 7

2 Example Coasting Time .................................................................................................... 7

3 Example Unsuccessful Steady-State, Stop, Start Test ................................................................. 9

4 Example Successful Steady-State, Stop, Start Test .................................................................... 9

List of Tables

1 Recommended Application Range for DRV10974 ...................................................................... 2

2 CS Resistor Table ........................................................................................................... 4

3 ADV Resistor Table ......................................................................................................... 4

4 RMP Resistor Values for t

5 RMP Resistor Table......................................................................................................... 6

6 Experimental Supply Current, Speed, and Speed/Current Ratio With Different Lead Times...................... 8

.............................................................................................. 5

coast

SLOU505–April 2018

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

DRV10974 Tuning Guide

1

Page 2

Bench Set Up

1 Bench Set Up

Before connecting a motor, read the Quick Start Guide section of the DRV10974 Evaluation Module

User's Guide. This will help set up the proper connections for the DRV10974 and DRV10974EVM.

2 Quick Tuning

The goal of quick tuning is to get the motor running quickly by inferring usable resistor values for the

current (CS pin), lead time (ADV pin), and acceleration profile (RMP pin).

If no information is known about the motor, the recommended the resistors should be as shown. Note that

these resistors are the default installed on the DRV10974EVM:

• RCS= 115 kΩ

– This sets the current limit to 1.4 A which is the second largest current limit.

• R

• R

If the motor fails to start up, reduce the CS value by one value, in accordance with the resistor selection in

Table 2, and repeat until the motor successfully starts up. The comprehensive resistor selection tables for

CS, ADV, and RMP are found in Table 2, Table 3, and Table 5, respectively.

If the user knows the target supply voltage (VCC) used in the application and the resistance of the motor,

either from the motor data sheet or by measuring the resistance between two phases (R

starting CS resistor value from Equation 2.

Using the current gathered from ICS, an appropriate RCScan be selected using Table 2.

If motor performance is satisfactory (for example, runs at target maximum and minimum speeds, succeeds

on start and stop tests, meets start up time requirements, and starts up reliably) then no further tuning is

needed. If the motor will not successfully start up, review Table 1 to make sure the motor is within the

application specifications that the DRV10974 can drive. In addition, use the comprehensive tuning section

to improve driving performance.

= 59 kΩ

ADV

– This sets the lead time to 400 µs, which is a lead time in the middle of the range of possible

settings.

= 7.32 kΩ

RMP

– This sets the second-order acceleration coefficient, the first-order acceleration coefficient, the

closed-loop acceleration and the closed-loop deceleration to 0.22 Hz/s2, 4.6 Hz/s, 2.7 s, and 44 s,

respectively.

– This is the slowest acceleration ramp rate.

PH-PH

www.ti.com

), obtain a

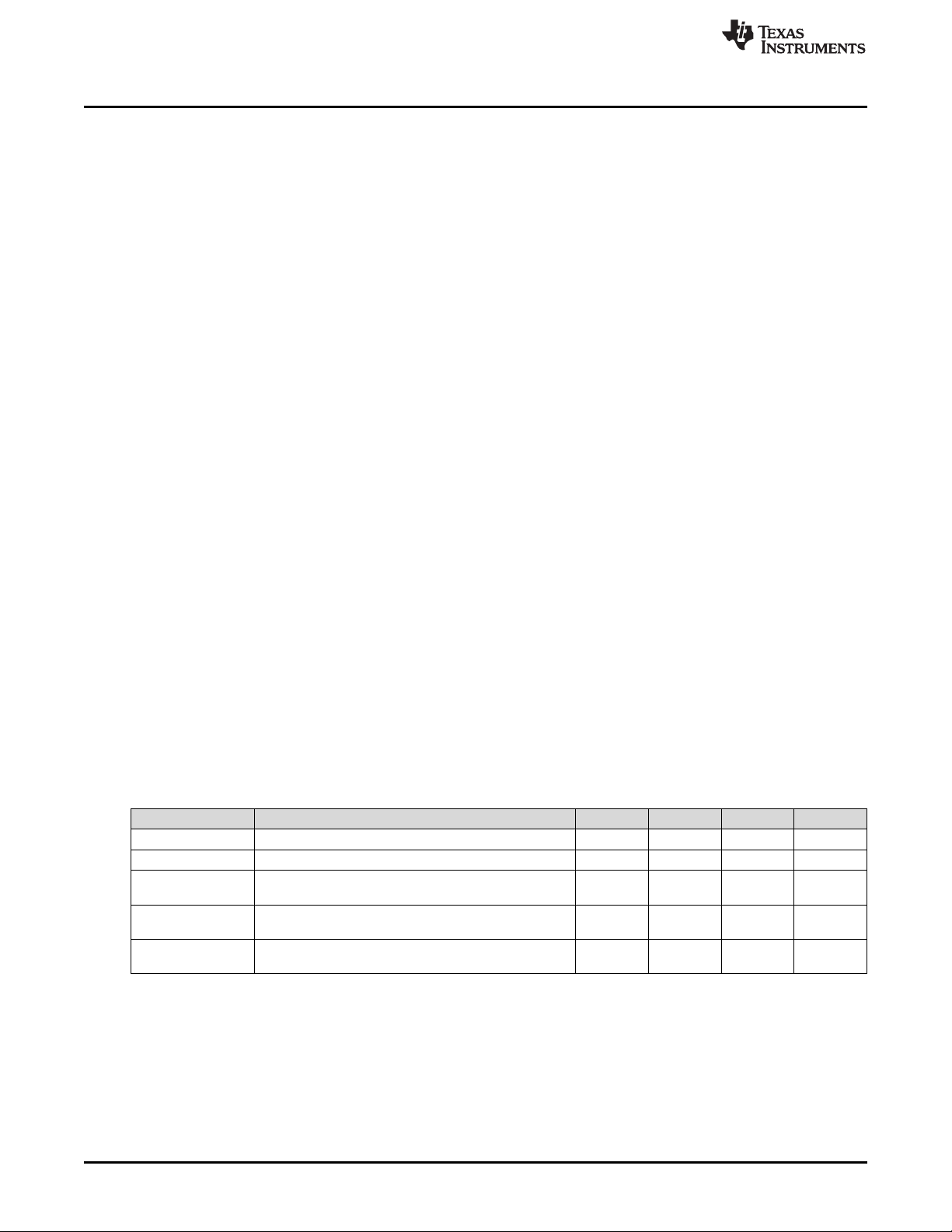

Table 1. Recommended Application Range for DRV10974

Parameter Description MIN TYP MAX Unit

Motor Voltage - 4.4 12 18 V

BEMF Constant (Kt) Phase to center tap. Measured while motor is coasting 5 150 mV/Hz

Motor Phase

Resistance

Motor Winding

Current

Absolute Maximum

Current

Phase to center Tap. Can be derived from dividing

phase-to-phase resistance by two.

During locked condition 2.5 A (Peak)

3 Comprehensive Tuning

The comprehensive tuning section covers the methodology for tuning each resistor value experimentally.

As a result, testing is required to find the optimal resistor value for the motor. This includes replacing the

resistors on the DRV10974 pins, as necessary. As a result, using a DRV10974EVM is highly recommend

for easily replacing resistors on the pins. For more information, see the DRV10974 Evaluation Module

User's Guide.

2

DRV10974 Tuning Guide

Copyright © 2018, Texas Instruments Incorporated

1 20 Ω

1 A (RMS)

SLOU505–April 2018

Submit Documentation Feedback

Page 3

www.ti.com

3.1 Finding Closed-Loop Current and Coasting Time

To choose the correct resistor values, the Closed-Loop Current (I

found.

1. Set ADV to 400 µs (59 kΩ), CS to 1.4 A (115 kΩ), RMP to the slowest setting (7.32 kΩ) which is

mentioned in the previous section. Note these are the default values on the EVM.

NOTE: If the user knows the target supply voltage (VCC) used in the application and the resistance of

the motor, either from the motor data sheet or by measuring the resistance between two

phases (R

), a starting CS resistor value can be obtained from Table 2 and Equation 2.

PH-PH

2. Apply power to the device to spin the motor to the maximum target speed.

3. If the motor fails to spin up reduce the current limit (CS) by one level. Repeat step 3 until the motor

successfully spins up.

4. Record the motor peak phase current during steady-state run (I

• This is used to determine the resistor on the CS pin

5. Provide a command of 0 and measure how long the motor takes to coast to a stop (t

• This is used to determine the resistor on the RMP pin

3.2 Selecting CS Resistor

The CS resistor controls the current limit during the open loop and align phase. Assuming I

captured in the previous section, use the closest value derived from Equation 1 to find an acceptable CS

resistor to set I

LIMIT

:

) and Coasting Time (t

PEAK

).

PEAK

Comprehensive Tuning

) must be

coast

).

coast

was

PEAK

(1)

NOTE: Large resistance motors may result in large I

values (that is, I

LIMIT

values that are larger

LIMIT

than in Table 2). As a result, use Equation 2 instead.

If the user knows the target supply voltage (VCC) used in the application and the resistance of the motor,

either from the motor data sheet or by measuring the resistance between two phases (R

), obtain an

PH-PH

accurate CS resistor value from Equation 2:

(2)

SLOU505–April 2018

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

DRV10974 Tuning Guide

3

Page 4

Comprehensive Tuning

Using the current gathered from ICS, select an appropriate RCSusing Table 2.

If the target RPM is slow, or the resistor given is larger than the value experimentally found in Section 3.1,

then the CS may have to be reduced until the motor can start up successfully.

3.3 Selecting ADV Resistor

The ADV pin controls the lead time that the DRV10974 will start driving the motor. The lead time attempts

to align the current applied through motor phases and the Back EMF voltage (BEMF) induced by the

permanent magnets on the rotor passing by the windings on the stator. If the current and the BEMF are

perfectly aligned, efficiency and start-up reliability are drastically increased.

However, tuning the lead time is very experimental and methodical. If the motor starts up reliability and

reaches the target RPM at 100%, then optimal tuning may not be needed.

To tune the lead time, start with the default lead time (400 µs) then:

Table 2. CS Resistor Table

R

(kΩ) I

(CS)

7.32 200

16.2 400

25.5 600

38.3 800

54.9 1000

80.6 1200

115 1400

182 1600 (1500 during align and startup)

(LIMIT)

(mA)

www.ti.com

1. Successfully run the motor at 100% speed

2. Record the current consumed by the power supply (ICC)

3. Record the frequency on the FG pin (fFG) which corresponds to the speed

4. Next, calculate the ratio of frequency (speed) over current (fFG/ ICC)

The highest ratio of frequency over current with the highest speed is the most efficient lead time. As a

result, decrease the lead time by one step (that is, lead time = 250 µs) by changing the ADV resistor and

repeat the process.

• If the ratio gets larger with the same speed after decreasing the lead time

– Keep decreasing the lead time until the ratio gets smaller

• If the ratio gets smaller with the same speed after decreasing the lead time

– Increase the lead time instead and see if the ratio gets larger

• If the speed significantly gets smaller after making the lead time larger

– Check previous values.

• Most applications fall within the 100 µs–400 µs range but the ratio and speed will show the best lead

time

• Once ADV is tuned for a specific motor, it does not need to be tuned again

Table 3. ADV Resistor Table

R

(kΩ) Lead Time (µs)

ADV

10.7 10

14.3 25

17.8 50

22.1 100

28 150

4

DRV10974 Tuning Guide

Copyright © 2018, Texas Instruments Incorporated

Submit Documentation Feedback

SLOU505–April 2018

Page 5

www.ti.com

3.4 Selecting RMP Resistor

The RMP resistor controls the acceleration profile used when driving the motor. The acceleration controls

how fast the motor accelerates during open loop using the first- and second-order acceleration coefficients

(ACCEL2 and ACCEL1, respectively), the closed-loop acceleration, and closed-loop deceleration.

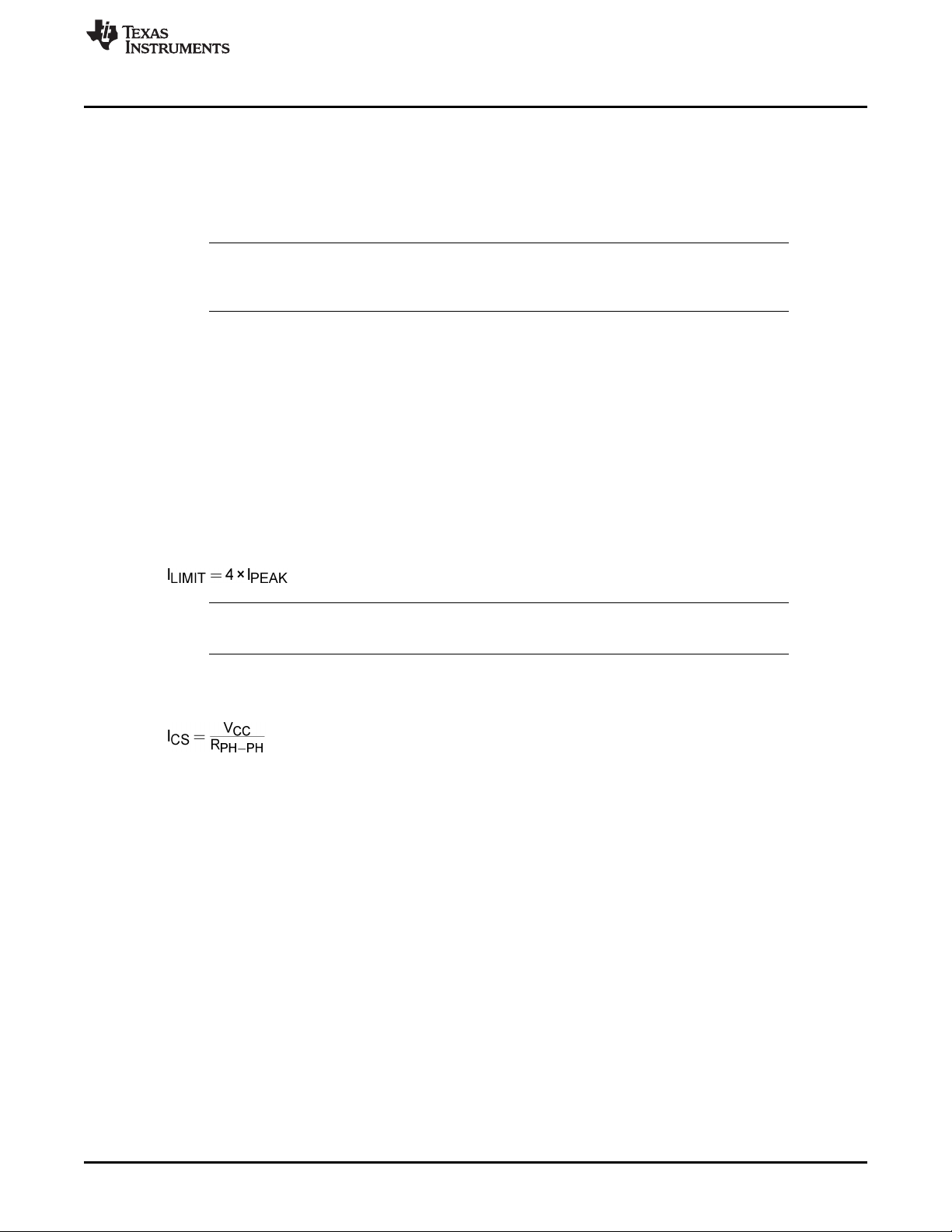

Assuming t

Table 4. Using the table, further tests are done to find the final RMP value:

was captured in the previous section, a table of recommended RMP resistors are given in

coast

Table 3. ADV Resistor Table (continued)

R

(kΩ) Lead Time (µs)

ADV

34 200

41.2 250

49.9 300

59 400

71.5 500

86.6 600

105 700

124 800

150 900

182 1000

Comprehensive Tuning

Table 4. RMP Resistor Values for t

t

(s) R

coast

t

< 11 41.2 27 75 0.2 11

coast

11 < t

t

coast

< 22 34 14 50 0.2 22

coast

> 22 22.1 7 25 0.2 44

(kΩ) ACCEL2 (Hz/s2) ACCEL1 (Hz/s) Closed-Loop

RMP

17.8 3.3 25 1 11

28 7 35 0.2 22

14.3 1.65 15 1 22

10.7 1.65 9.2 2.7 22

7.32 0.22 4.6 2.7 44

coast

Acceleration Slew Rate

(s)

Closed-Loop

Deceleration Slew Rate

(s)

To tune RMP:

1. Use Table 4 in combination with the measured t

to determine the range of RMP resistor values that

coast

should be used for this testing.

2. Start with the largest value RMP resistor in the range, which indicates the fastest start up in this range,

and conduct a few steady-state, stop, start tests.

• A steady-state, stop, start test refers to running the motor at a 100% for some time, giving a 0%

speed command to make the motor coast, and then giving a nonzero speed command before the

motor stops coasting. This will be the worst-case start up scenario for the motor

3. If the motor successfully and reliability started up after testing, then select the current value as the

RMP value.

4. If the motor did not successfully and reliability start up after testing, decrease the RMP resistor value in

the appropriate range and repeat the steady-state start, stop tests.

a. If every resistor in the current t

range does not work, use a lower t

coast

range and repeat the

coast

process.

b. In addition, reducing the CS value may help increase start up reliability.

SLOU505–April 2018

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

DRV10974 Tuning Guide

5

Page 6

Comprehensive Tuning

NOTE: Higher closed-loop acceleration variants are available for each setting in Table 4, consult

Table 5 for more information.

www.ti.com

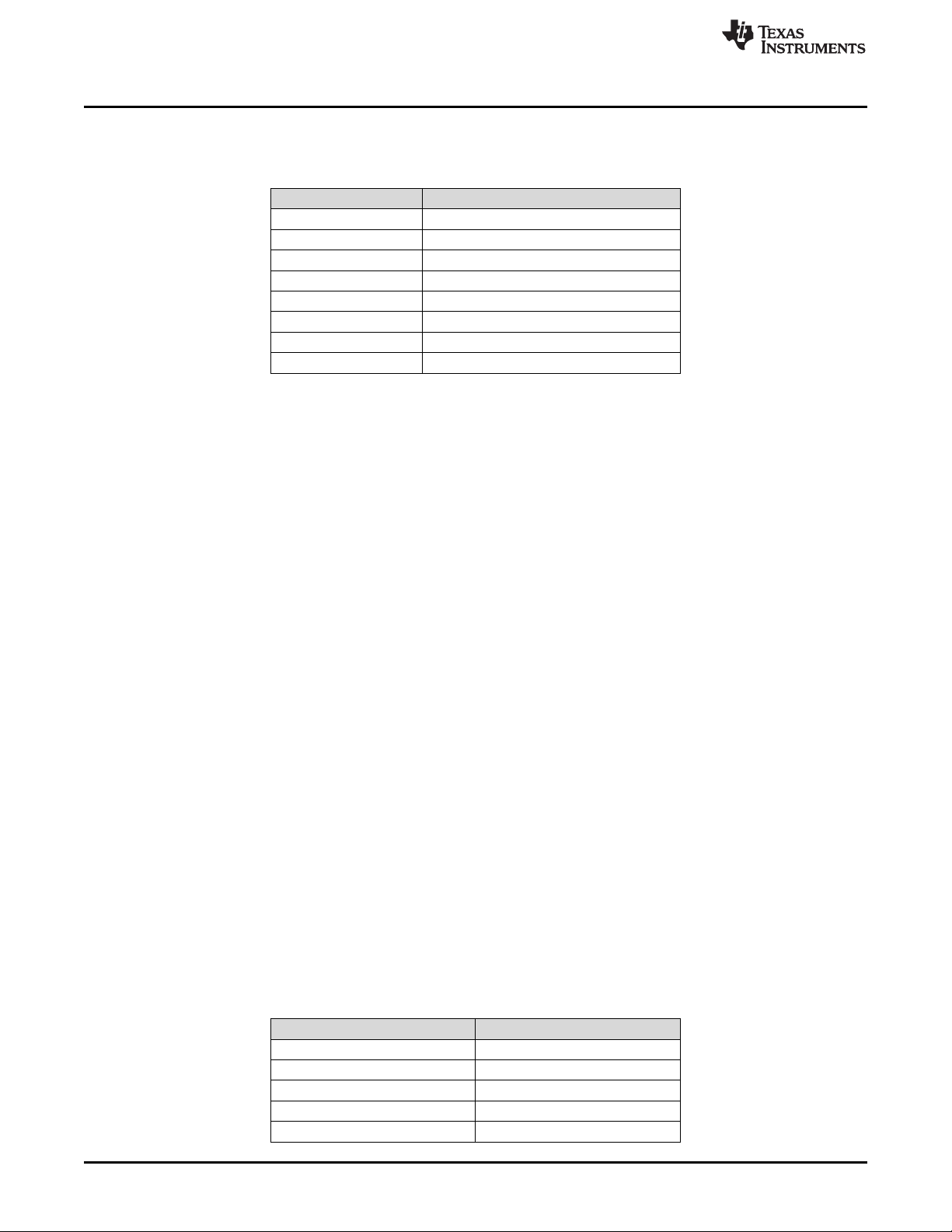

Table 5. RMP Resistor Table

RMP

Selection

0 7.32 0.22 4.6 2.7 44

1 10.7 1.65 9.2 2.7 22

2 14.3 1.65 15 1 22

3 17.8 3.3 25 1 11

4 22.1 7 25 0.2 44

5 28 7 35 0.2 22

6 34 14 50 0.2 22

7 41.2 27 75 0.2 11

8 49.9 27 75 5.4 11

9 59 14 50 8 22

10 71.5 7 35 11 22

11 86.6 7 25 22 44

12 105 3.3 25 5.4 11

13 124 1.65 15 8 22

14 150 1.65 9.2 11 22

15 182 0.22 4.2 22 44

R

(kΩ) ACCEL2 (Hz/s2) ACCEL1 (Hz/s) Closed-Loop

RMP

3.5 Example CS, ADV, and RMP Resistor Tuning

This section goes over an example scenario and the steps taken to tune each resistor for the CS, ADV,

and RMP settings.

An example motor application has the following parameters:

• VCC= 12 V

• Target RPM = 1500 RPM

• Motor Pole Pairs = 4 pairs

Acceleration Transition

Time (s)

Closed-Loop

Deceleration Transition

Time (s)

3.5.1 Example Closed-Loop Current and Coasting Time

While the motor was able to start up with the default resistor settings using the DRV10974EVM, some

optimization is needed. As a result, I

6

DRV10974 Tuning Guide

Copyright © 2018, Texas Instruments Incorporated

PEAK

and t

need to be measured.

coast

Submit Documentation Feedback

SLOU505–April 2018

Page 7

www.ti.com

Comprehensive Tuning

Figure 1. Example Peak Current in Closed Loop

As Figure 1 shows, the peak current can be roughly calculated as 375 mA. This is used when calculating

the CS resistor.

(3)

As Figure 2 shows, the DRV10974 stops driving the motor after driving it at 100% speed, and the coasting

time, t

SLOU505–April 2018

Submit Documentation Feedback

coast

= 11 s.

Figure 2. Example Coasting Time

Copyright © 2018, Texas Instruments Incorporated

DRV10974 Tuning Guide

7

Page 8

Comprehensive Tuning

3.5.2 Example CS Resistor Selection

Since I

= 325 mA and the motor will be used in a 12-V application, a CS resistor value is found using

PEAK

Equation 4:

Unfortunately, 1.5 A is not a valid current limit value according to CS Resistor Table 2. As a result, the

alternative method is used.

Using a DMM, the resistance between any of the 2 phases of a 3-Phase BLDC motor (R

determined to be 17 Ω. Using Equation 2, a general CS resistor value is chosen to be RCS= 25.5 kΩ,

corresponding 600 mA of current limiting according to Table 2.

By populating the resistor, the motor is still able to spin up reliably and enter closed loop.

3.5.3 Example ADV Resistor Selection

To find the correct ADV resistor, the highest ratio of speed over supply current (fFG/ ICC) with the highest

speed must be found. By creating Table 6, the ratio and speed can be easily visualized.

PH-PH

www.ti.com

(4)

) was

(5)

Table 6. Experimental Supply Current, Speed, and Speed/Current Ratio With Different Lead Times

Lead Time (µs) ICC(A) fFG(Hz) fFG/ ICC(Hz/A)

25 0.310 108.7 350.6

50 0.310 108.7 350.6

100 0.300 108.7 362.3

200 0.299 108.2 361.9

300 0.298 107.2 359.7

400 0.293 106.4 363.1

500 0.293 105.5 360.0

As Table 6 shows, the highest ratio with the highest speed corresponds to lead time = 100 µs. This

corresponds to the resistor value for R

While the 400 µs gave the highest ratio of speed over current, the actual speed (fFG) dropped 2% (108.7

Hz to 107.2 Hz). This makes 400 µs less optimal than 100 µs for the lead time.

3.5.4 Example RMP Resistor Selection

Since t

coast

= 11 s, t

falls between the 11 s and 22 s range in the RMP selection (R

coast

and 10.7 kΩ), the 34-kΩ resistor is populated and a steady-state, stop, start test is conducted. The 34-kΩ

resistor is used because it is the fastest RMP rate in this range.

= 22 kΩ in Table 3.

ADV

= 34, 28, 14.3,

RMP

8

DRV10974 Tuning Guide

Copyright © 2018, Texas Instruments Incorporated

Submit Documentation Feedback

SLOU505–April 2018

Page 9

www.ti.com

Comprehensive Tuning

Figure 3. Example Unsuccessful Steady-State, Stop, Start Test

As Figure 3 shows, the hand off from open loop to closed loop was unsuccessful and the DRV10974

stopped driving the motor for protection. Since this test was not successful, the next largest resistor (28

kΩ) was tested.

Figure 4. Example Successful Steady-State, Stop, Start Test

As Figure 4 shows, the hand off from open loop to closed loop was successful and the motor is driven to

100% speed. As a result, the resistor value is chosen to be R

open-loop acceleration, closed-loop acceleration, and closed-loop deceleration as shown in Table 5.

SLOU505–April 2018

Submit Documentation Feedback

= 28 kΩ. The corresponding settings for

RMP

Copyright © 2018, Texas Instruments Incorporated

DRV10974 Tuning Guide

9

Page 10

Comprehensive Tuning

3.5.5 Summary and Results

Using the tuning method, the following resistors were selected:

• RCS= 25.5 kΩ for a current limit of 600 mA

• R

• R

= 22 kΩ for a lead time of 100 µs

ADV

= 28 kΩ for a RMP code of 5

RMP

The RPM of the motor is calculated by using Equation 6:

Using the number of pole pairs and the speed from the lead time tuning for the ADV resistor, the RPM of

the motor is calculated to be above the target RPM of 1500 RPM.

www.ti.com

(6)

10

DRV10974 Tuning Guide

Copyright © 2018, Texas Instruments Incorporated

Submit Documentation Feedback

SLOU505–April 2018

Page 11

IMPORTANT NOTICE FOR TI DESIGN INFORMATION AND RESOURCES

Texas Instruments Incorporated (‘TI”) technical, application or other design advice, services or information, including, but not limited to,

reference designs and materials relating to evaluation modules, (collectively, “TI Resources”) are intended to assist designers who are

developing applications that incorporate TI products; by downloading, accessing or using any particular TI Resource in any way, you

(individually or, if you are acting on behalf of a company, your company) agree to use it solely for this purpose and subject to the terms of

this Notice.

TI’s provision of TI Resources does not expand or otherwise alter TI’s applicable published warranties or warranty disclaimers for TI

products, and no additional obligations or liabilities arise from TI providing such TI Resources. TI reserves the right to make corrections,

enhancements, improvements and other changes to its TI Resources.

You understand and agree that you remain responsible for using your independent analysis, evaluation and judgment in designing your

applications and that you have full and exclusive responsibility to assure the safety of your applications and compliance of your applications

(and of all TI products used in or for your applications) with all applicable regulations, laws and other applicable requirements. You

represent that, with respect to your applications, you have all the necessary expertise to create and implement safeguards that (1)

anticipate dangerous consequences of failures, (2) monitor failures and their consequences, and (3) lessen the likelihood of failures that

might cause harm and take appropriate actions. You agree that prior to using or distributing any applications that include TI products, you

will thoroughly test such applications and the functionality of such TI products as used in such applications. TI has not conducted any

testing other than that specifically described in the published documentation for a particular TI Resource.

You are authorized to use, copy and modify any individual TI Resource only in connection with the development of applications that include

the TI product(s) identified in such TI Resource. NO OTHER LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE TO

ANY OTHER TI INTELLECTUAL PROPERTY RIGHT, AND NO LICENSE TO ANY TECHNOLOGY OR INTELLECTUAL PROPERTY

RIGHT OF TI OR ANY THIRD PARTY IS GRANTED HEREIN, including but not limited to any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

regarding or referencing third-party products or services does not constitute a license to use such products or services, or a warranty or

endorsement thereof. Use of TI Resources may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

TI RESOURCES ARE PROVIDED “AS IS” AND WITH ALL FAULTS. TI DISCLAIMS ALL OTHER WARRANTIES OR

REPRESENTATIONS, EXPRESS OR IMPLIED, REGARDING TI RESOURCES OR USE THEREOF, INCLUDING BUT NOT LIMITED TO

ACCURACY OR COMPLETENESS, TITLE, ANY EPIDEMIC FAILURE WARRANTY AND ANY IMPLIED WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF ANY THIRD PARTY INTELLECTUAL

PROPERTY RIGHTS.

TI SHALL NOT BE LIABLE FOR AND SHALL NOT DEFEND OR INDEMNIFY YOU AGAINST ANY CLAIM, INCLUDING BUT NOT

LIMITED TO ANY INFRINGEMENT CLAIM THAT RELATES TO OR IS BASED ON ANY COMBINATION OF PRODUCTS EVEN IF

DESCRIBED IN TI RESOURCES OR OTHERWISE. IN NO EVENT SHALL TI BE LIABLE FOR ANY ACTUAL, DIRECT, SPECIAL,

COLLATERAL, INDIRECT, PUNITIVE, INCIDENTAL, CONSEQUENTIAL OR EXEMPLARY DAMAGES IN CONNECTION WITH OR

ARISING OUT OF TI RESOURCES OR USE THEREOF, AND REGARDLESS OF WHETHER TI HAS BEEN ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES.

You agree to fully indemnify TI and its representatives against any damages, costs, losses, and/or liabilities arising out of your noncompliance with the terms and provisions of this Notice.

This Notice applies to TI Resources. Additional terms apply to the use and purchase of certain types of materials, TI products and services.

These include; without limitation, TI’s standard terms for semiconductor products http://www.ti.com/sc/docs/stdterms.htm), evaluation

modules, and samples (http://www.ti.com/sc/docs/sampterms.htm).

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2018, Texas Instruments Incorporated

Loading...

Loading...