Page 1

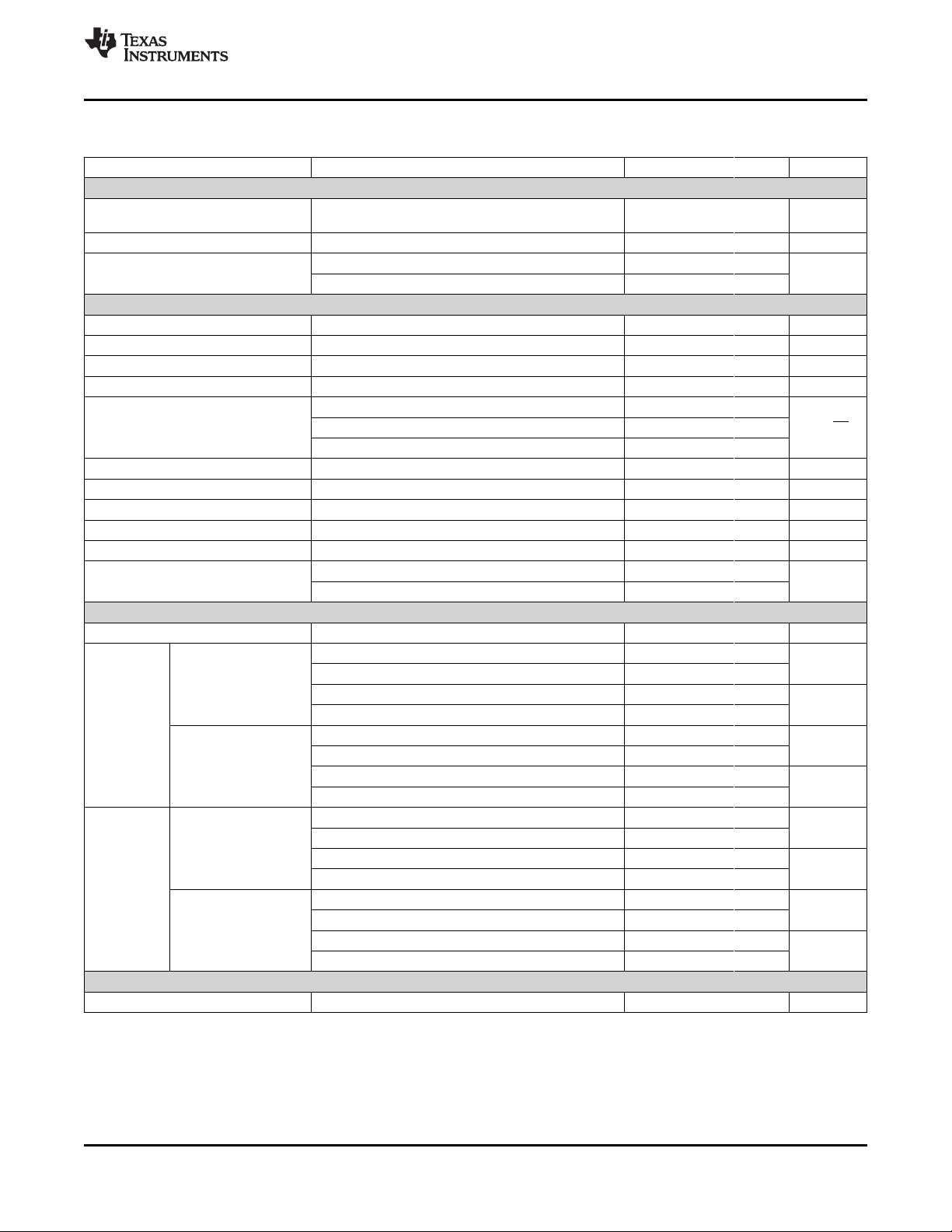

DAC756x

DAC816x

DAC856x

(12-Bit)

(14-Bit)

(16-Bit)

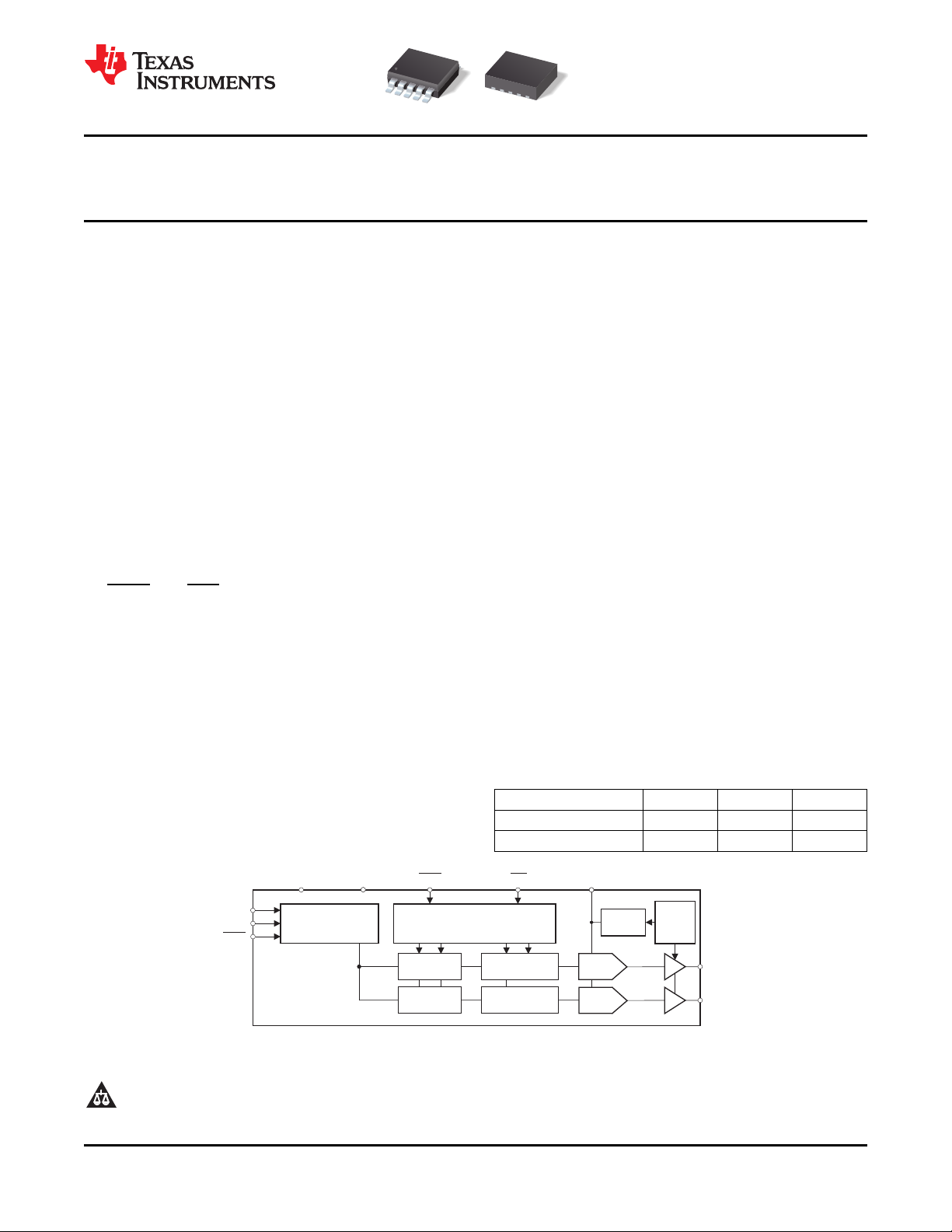

Data Buffer A

DAC Register A

Buffer Control Register Control

Control Logic

Power-

Down

Control

Logic

AV

DD

V

REFIN REFOUT

/V

CLRLDAC

2.5-V

Reference

Data Buffer B

DAC Register B

V B

OUT

V A

OUT

GND

DAC

DAC

Input Control Logic

SYNC

SCLK

D

IN

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

www.ti.com

SLAS719C –AUGUST 2010– REVISED JUNE 2011

DUAL 16-/14-/12-BIT, ULTRALOW-GLITCH, LOW-POWER, BUFFERED, VOLTAGE-OUTPUT

DAC WITH 2.5-V, 4-PPM/°C INTERNAL REFERENCE IN SMALL 3-MM × 3-MM QFN

Check for Samples: DAC8562, DAC8563, DAC8162, DAC8163, DAC7562, DAC7563

1

FEATURES

23

• Relative Accuracy:

– DAC856x (16-Bit): 4 LSB INL

– DAC816x (14-Bit): 1 LSB INL

– DAC756x (12-Bit): 0.3 LSB INL

• Glitch Energy: 0.1 nV-s

• Bidirectional Reference: Input or 2.5-V Output

– Output Disabled by Default

– ±5-mV Initial Accuracy (Max)

– 4-ppm/°C Temperature Drift (Typ)

– 10-ppm/°C Temperature Drift (Max)

– 20-mA Sink/Source Capability

• Power-On Reset to Zero Scale or Mid-Scale

• Low-Power: 4 mW (Typ, 5-V AVDD, Including

Internal Reference Current)

• Wide Power-Supply Range: 2.7 V to 5.5 V

• 50-MHz SPI With Schmitt-Triggered Inputs

• LDAC and CLR Functions

• Output Buffer With Rail-to-Rail Operation

• Packages: QFN-10 (3x3 mm), MSOP-10

• Temperature Range: –40°C to 125°C

APPLICATIONS

• Portable Instrumentation

• Bipolar Outputs (reference design)

• PLC Analog Output Module (reference design)

• Closed-Loop Servo Control

• Voltage Controlled Oscillator Tuning

• Data Acquisition Systems

• Programmable Gain and Offset Adjustment

DESCRIPTION

The DAC856x, DAC816x, and DAC756x are

low-power, voltage-output, dual-channel, 16-, 14-,

and 12-bit digital-to-analog converters (DACs),

respectively. These devices include a 2.5-V,

4-ppm/°C internal reference, giving a full-scale output

voltage range of 2.5 V or 5 V. The internal reference

has an initial accuracy of ±5 mV and can source or

sink up to 20 mA at the V

REFIN/VREFOUT

These devices are monotonic, providing excellent

linearity and minimizing undesired code-to-code

transient voltages (glitch). They use a versatile

three-wire serial interface that operates at clock rates

up to 50 MHz. The interface is compatible with

standard SPI™, QSPI™, Microwire™, and digital

signal processor (DSP) interfaces. The DACxx62

devices incorporate a power-on-reset circuit that

ensures the DAC output powers up at zero scale until

a valid code is written to the device, whereas the

DACxx63s similarly power up at mid-scale. These

devices contain a power-down feature that reduces

current consumption to typically 10 nA at 5 V. The

low power consumption, internal reference, and small

footprint make these devices ideal for portable,

battery-operated equipment.

The DACxx62 devices are drop-in and

function-compatible with each other, as are the

DACxx63s. The entire family is available in MSOP-10

and QFN-10 packages.

Table 1. RELATED DEVICES

16-BIT 14-BIT 12-BIT

Reset to zero DAC8562 DAC8162 DAC7562

Reset to mid-scale DAC8563 DAC8163 DAC7563

pin.

1

2SPI, QSPI are trademarks of Motorola, Inc.

3Microwire is a trademark of National Semiconductor.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Copyright © 2010–2011, Texas Instruments Incorporated

Page 2

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

SLAS719C –AUGUST 2010– REVISED JUNE 2011

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

www.ti.com

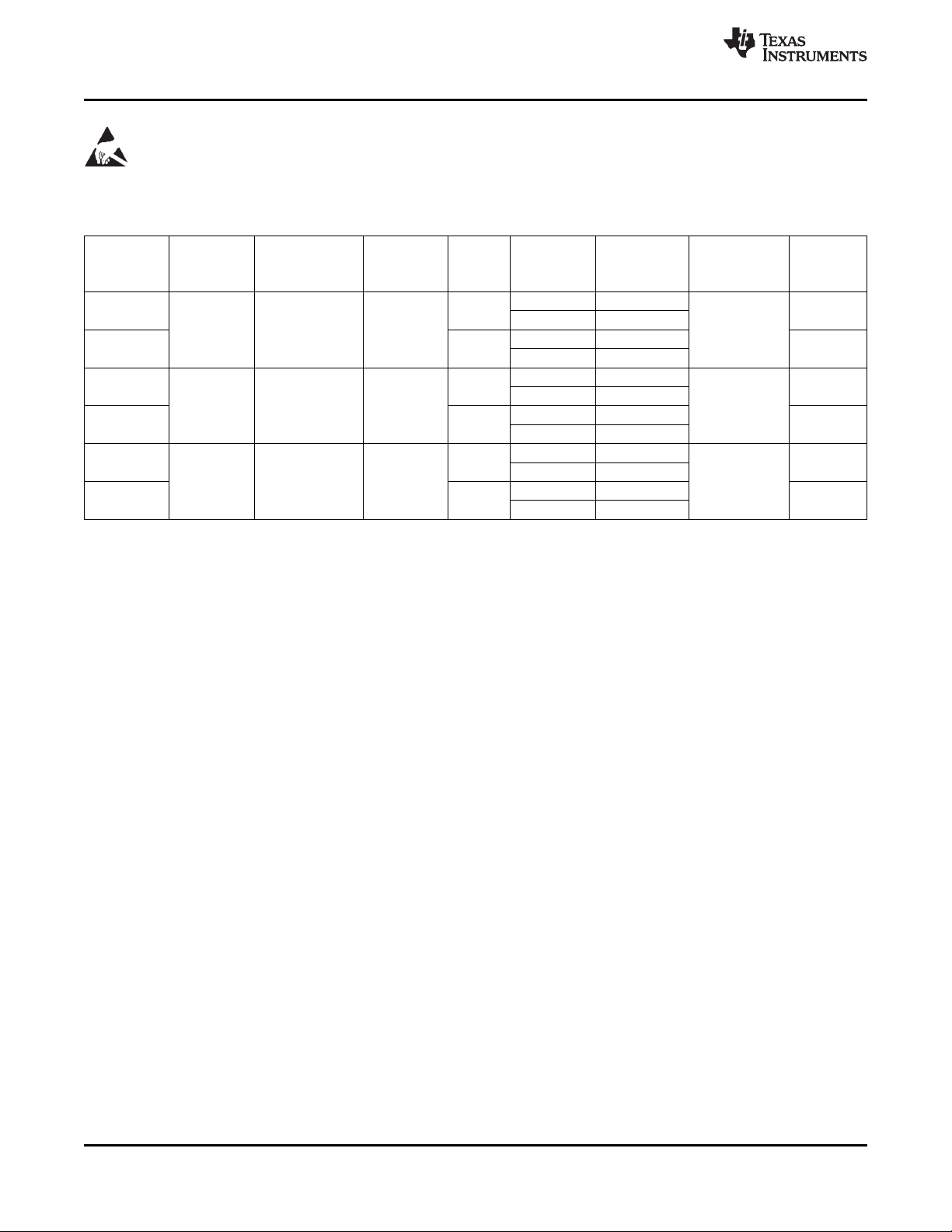

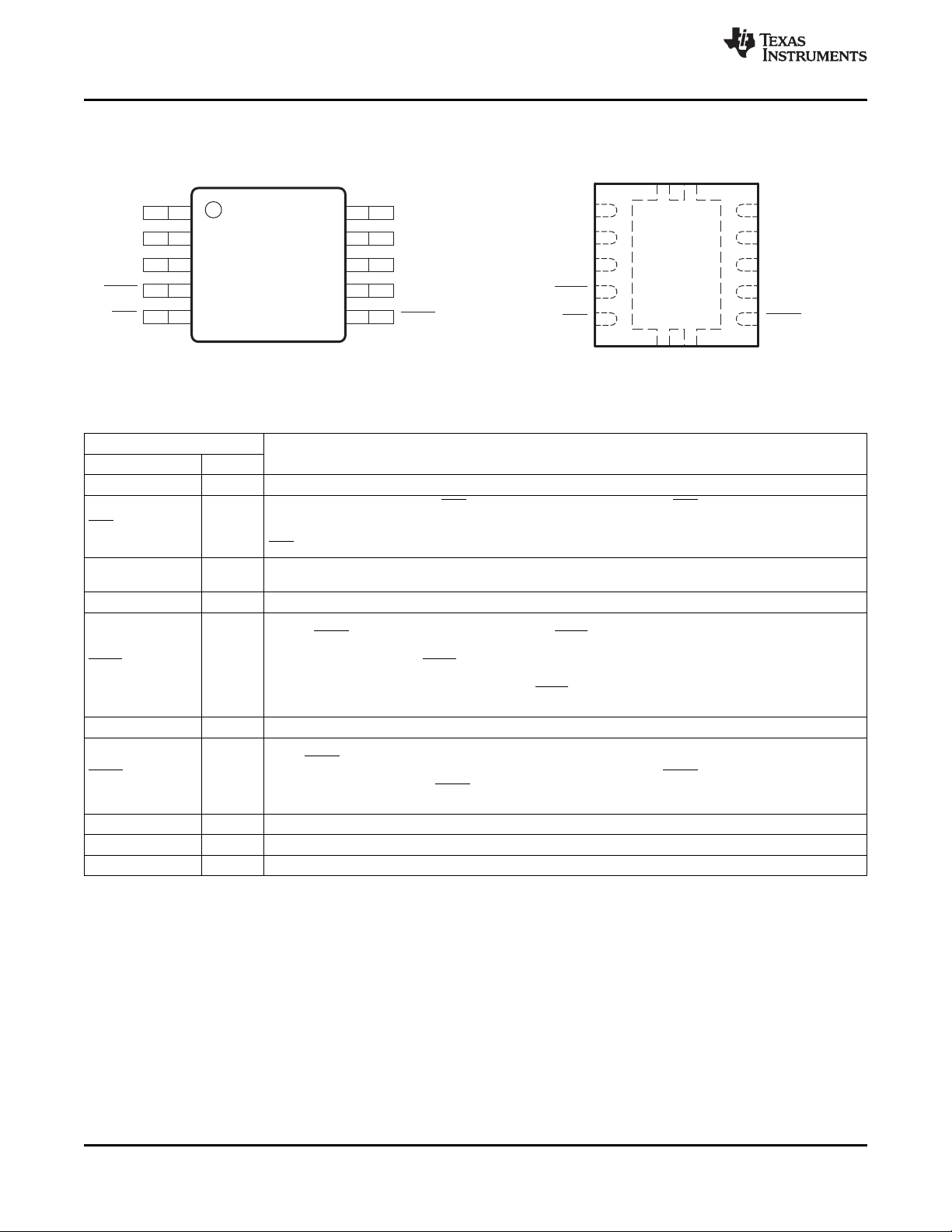

DEVICE INFORMATION

MAXIMUM MAXIMUM MAXIMUM

PRODUCT TEMPER-

DAC8562 Zero 8562

DAC8563 Mid-scale 8563

DAC8162 Zero 8162

DAC8163 Mid-scale 8163

DAC7562 Zero 7562

DAC7563 Mid-scale 7563

RELATIVE DIFFERENTIAL REFERENCE RESET PACKAGE- PACKAGE PACKAGE

ACCURACY NONLINEARITY DRIFT TO LEAD DESIGNATOR MARKING

(LSB) (LSB) (ppm/°C)

±12 ±1 10 –40°C to 125°C

±3 ±0.5 10 –40°C to 125°C

±0.75 ±0.25 10 –40°C to 125°C

(1)

SPECIFIED

ATURE RANGE

QFN-10 DSC

MSOP-10 DGS

QFN-10 DSC

MSOP-10 DGS

QFN-10 DSC

MSOP-10 DGS

QFN-10 DSC

MSOP-10 DGS

QFN-10 DSC

MSOP-10 DGS

QFN-10 DSC

MSOP-10 DGS

(1) For the most current package and ordering information, see the Package Option Addendum at the end of this data sheet, or see the TI

Web site at www.ti.com.

2 Copyright © 2010–2011, Texas Instruments Incorporated

Page 3

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

www.ti.com

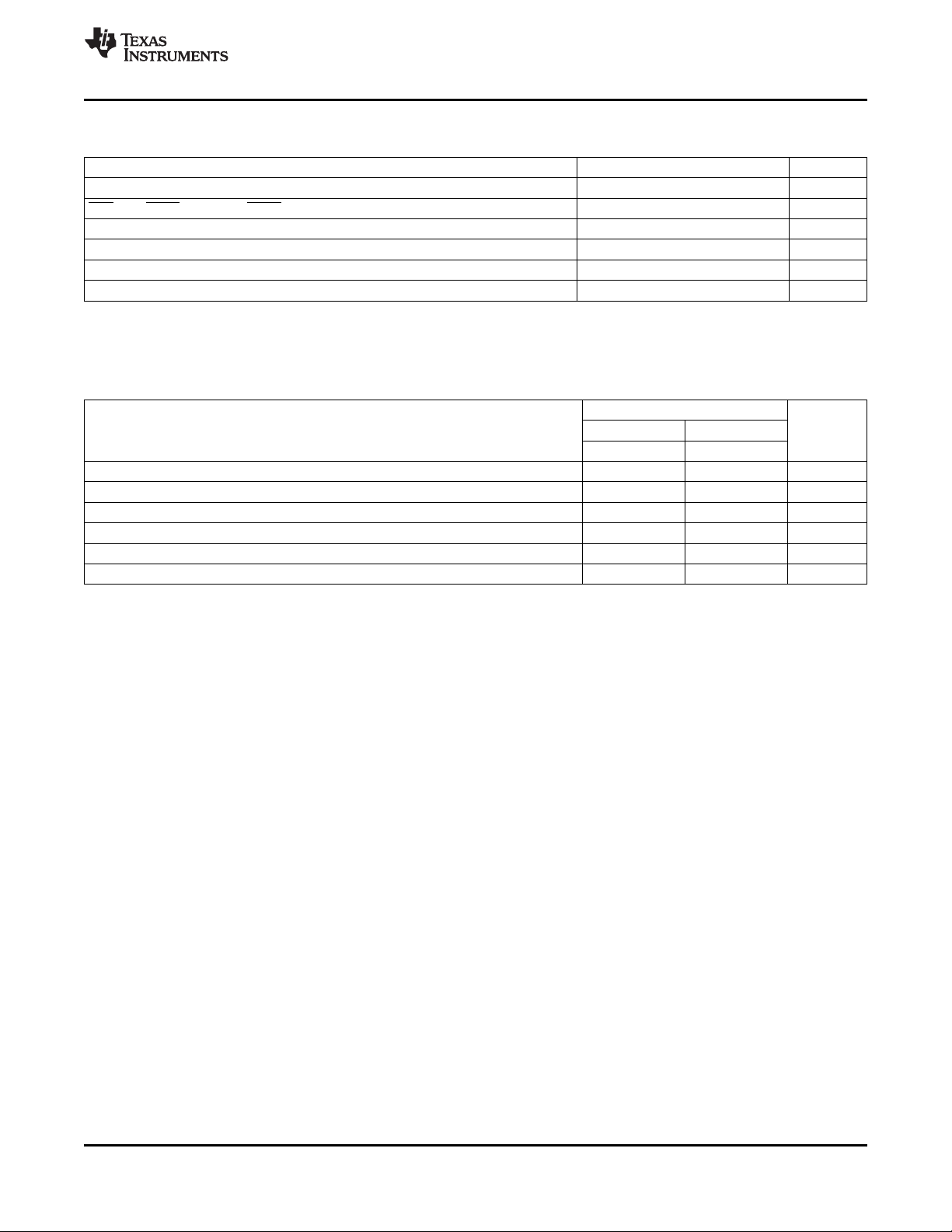

ABSOLUTE MAXIMUM RATINGS

(1)

Over operating free-air temperature range (unless otherwise noted).

AVDDto GND –0.3 to 6 V

CLR, DIN, LDAC, SCLK and SYNC input voltage to GND –0.3 to AVDD+ 0.3 V

V

to GND –0.3 to AVDD+ 0.3 V

OUT

V

REFIN/VREFOUT

to GND –0.3 to AVDD+ 0.3 V

Operating temperature range –40 to 125 °C

Junction temperature, maximum (T

) 150 °C

J max

(1) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under Recommended Operating

Conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

THERMAL INFORMATION

THERMAL METRIC DSC DGS UNIT

θ

θ

θ

ψ

ψ

θ

JA

JCtop

JB

JT

JB

JCbot

Junction-to-ambient thermal resistance

Junction-to-case (top) thermal resistance

Junction-to-board thermal resistance

Junction-to-top characterization parameter

Junction-to-board characterization parameter

Junction-to-case (bottom) thermal resistance

(1) The junction-to-ambient thermal resistance under natural convection is obtained in a simulation on a JEDEC-standard, high-K board, as

specified in JESD51-7, in an environment described in JESD51-2a.

(2) The junction-to-case (top) thermal resistance is obtained by simulating a cold plate test on the package top. No specific

JEDEC-standard test exists, but a close description can be found in the ANSI SEMI standard G30-88.

(3) The junction-to-board thermal resistance is obtained by simulating in an environment with a ring cold plate fixture to control the PCB

temperature, as described in JESD51-8.

(4) The junction-to-top characterization parameter, ψJT, estimates the junction temperature of a device in a real system and is extracted

from the simulation data for obtaining θJA, using a procedure described in JESD51-2a (sections 6 and 7).

(5) The junction-to-board characterization parameter, ψJB, estimates the junction temperature of a device in a real system and is extracted

from the simulation data for obtaining θJA, using a procedure described in JESD51-2a (sections 6 and 7).

(6) The junction-to-case (bottom) thermal resistance is obtained by simulating a cold plate test on the exposed (power) pad. No specific

JEDEC standard test exists, but a close description can be found in the ANSI SEMI standard G30-88.

(1)

(2)

(3)

(4)

(5)

(6)

SLAS719C –AUGUST 2010– REVISED JUNE 2011

VALUE UNIT

DAC856x, DAC816x, DAC756x

10 PINS 10 PINS

62.8 173.8 °C/W

44.3 48.5 °C/W

26.5 79.9 °C/W

0.4 1.7 °C/W

25.5 68.4 °C/W

46.2 N/A °C/W

Copyright © 2010–2011, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 4

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

SLAS719C –AUGUST 2010– REVISED JUNE 2011

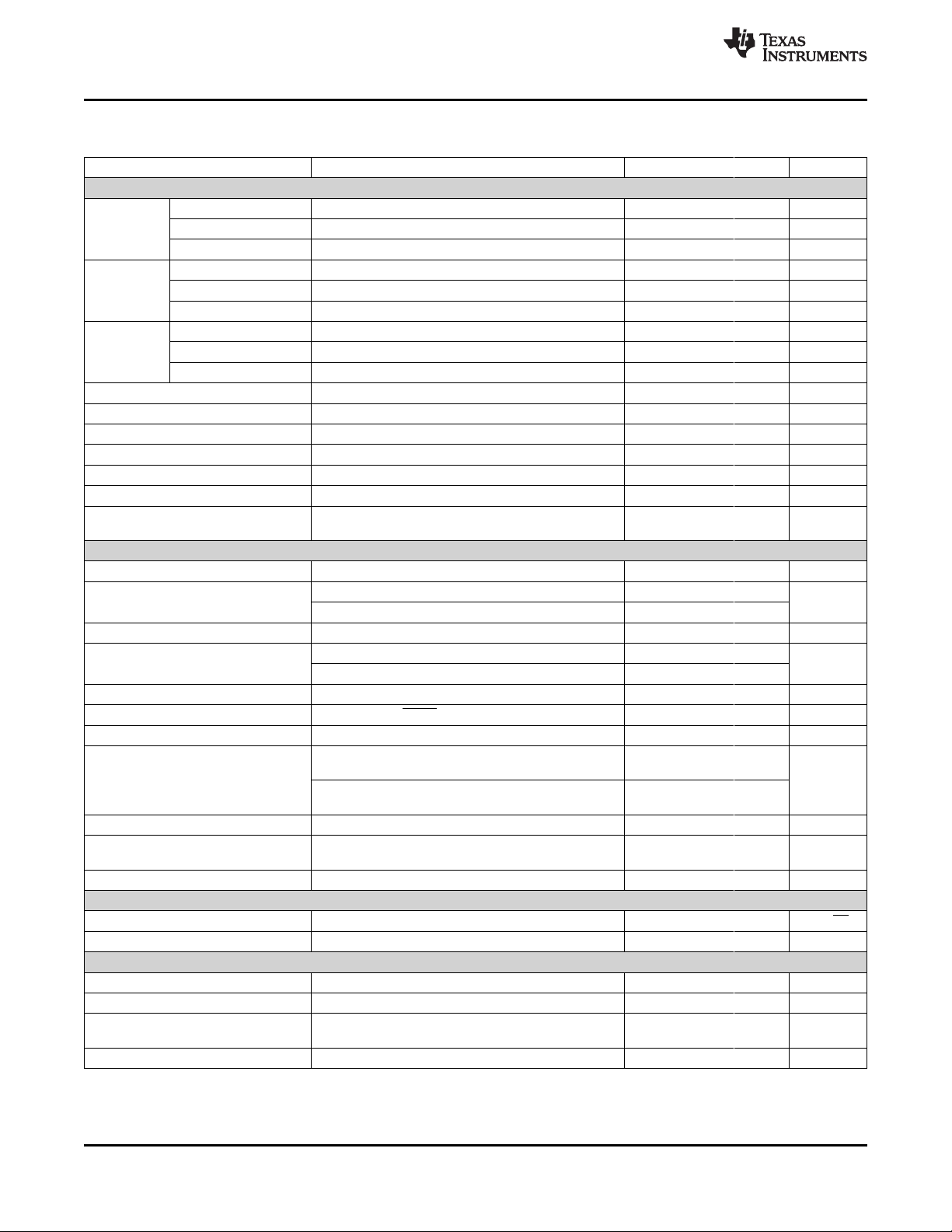

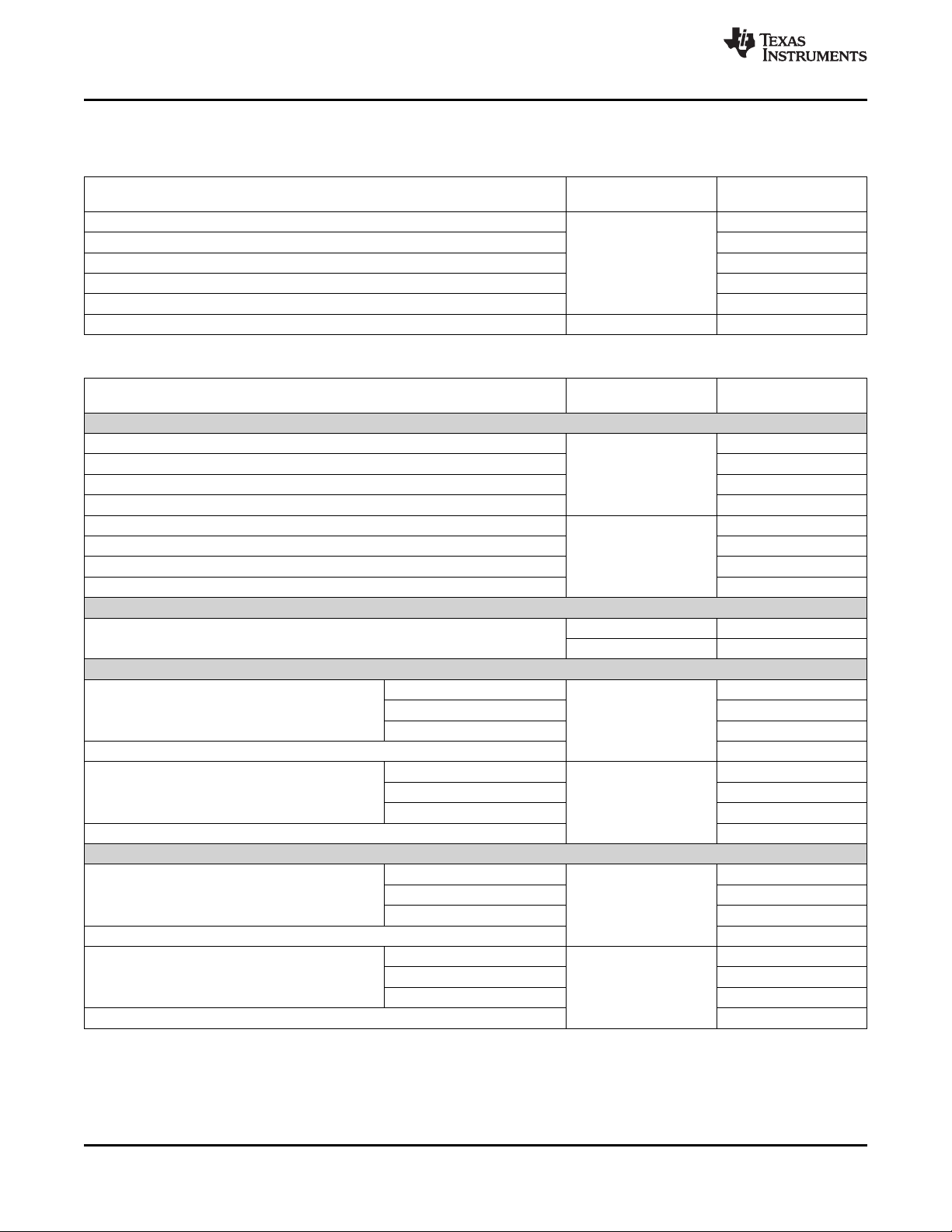

ELECTRICAL CHARACTERISTICS

At AVDD= 2.7 V to 5.5 V and TA= –40°C to 125°C (unless otherwise noted).

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

STATIC PERFORMANCE

Resolution 16 Bits

DAC856x Relative accuracy Using line passing through codes 512 and 65,024 ±4 ±12 LSB

Differential nonlinearity 16-bit monotonic ±0.2 ±1 LSB

Resolution 14 Bits

DAC816x Relative accuracy Using line passing through codes 128 and 16,256 ±1 ±3 LSB

Differential nonlinearity 14-bit monotonic ±0.1 ±0.5 LSB

Resolution 12 Bits

DAC756x Relative accuracy Using line passing through codes 32 and 4,064 ±0.3 ±0.75 LSB

Differential nonlinearity 12-bit monotonic ±0.05 ±0.25 LSB

Offset error Extrapolated from two-point line

Offset error drift ±2 µV/°C

Full-scale error DAC register loaded with all 1s ±0.03 ±0.2 % FSR

Zero-code error DAC register loaded with all 0s 1 4 mV

Zero-code error drift ±2 µV/°C

Gain error Extrapolated from two-point line

Gain temperature coefficient ±1

OUTPUT CHARACTERISTICS

Output voltage range 0 AV

Output voltage settling time

Slew rate Measured between 20% - 80% of a full-scale transition 0.75 V/µs

Capacitive load stability nF

Code-change glitch impulse 1-LSB change around major carry 0.1 nV-s

Digital feedthrough SCLK toggling, SYNC high 0.1 nV-s

Power-on glitch impulse RL= 2 kΩ, CL= 470 pF, AVDD= 5.5 V 40 mV

Channel-to-channel dc crosstalk µV

DC output impedance At mid-scale input 5 Ω

Short-circuit current 40 mA

Power-up time, including settling time Coming out of power-down mode 50 µs

AC PERFORMANCE

DAC output noise density TA= 25°C, at mid-scale input, f

DAC output noise TA= 25°C, at mid-scale input, 0.1 Hz to 10 Hz 2.6 µV

LOGIC INPUTS

(2)

Input pin Leakage current –1 ±0.1 1 µA

Logic input LOW voltage VINL 0 0.8 V

Logic input HIGH voltage VINH AV

Pin capacitance 3 pF

(1) 16-bit: codes 512 and 65,024; 14-bit: codes 128 and 16,256; 12-bit: codes 32 and 4,064

(2) Specified by design or characterization

(3) Transition time between 1/4 scale and 3/4 scale including settling to within ±0.024% FSR

(1)

(1)

, unloaded ±1 ±4 mV

(1)

, unloaded ±0.01 ±0.15 % FSR

(2)

(3)

DACs unloaded 7

RL= 1 MΩ 10

RL= ∞ 1

RL= 2 kΩ 3

Full-scale swing on adjacent channel,

External reference

Full-scale swing on adjacent channel,

Internal reference

5

15

DAC outputs at full-scale, DAC outputs shorted to

GND

(2)

= 1 kHz 90 nV/√Hz

OUT

0.7 ×

AV

DD

DD

DD

www.ti.com

ppm

FSR/°C

V

µs

V

PP

4 Submit Documentation Feedback Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 5

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

www.ti.com

ELECTRICAL CHARACTERISTICS (continued)

At AVDD= 2.7 V to 5.5 V and TA= –40°C to 125°C (unless otherwise noted).

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

REFERENCE

External reference current 15 µA

V

reference input range 0 AV

REFIN

Reference input impedance kΩ

External V

disabled), all channels active using gain = 1

Internal reference disabled, gain = 1 170

Internal reference disabled, gain = 2 85

REFERENCE OUTPUT

Output voltage TA= 25°C 2.495 2.5 2.505 V

Initial accuracy TA= 25°C –5 ±0.1 5 mV

Output voltage temperature drift

(4)

Output voltage noise f = 0.1 Hz to 10 Hz 12 µV

TA= 25°C, f = 1 kHz, CL= 0 µF 250

Output voltage noise density

(high-frequency noise)

TA= 25°C, f = 1 MHz, CL= 0 µF 30 nV/√Hz

TA= 25°C, f = 1 MHz, CL= 4.7 µF 10

Load regulation, sourcing

Load regulation, sinking

Output current load capability

(5)

(5)

(6)

TA= 25°C 20 µV/mA

TA= 25°C 185 µV/mA

Line regulation TA= 25°C 50 µV/V

Long-term stability/drift (aging)

Thermal hysteresis

(5)

POWER REQUIREMENTS

(5)

TA= 25°C, time = 0 to 1900 hours 100 ppm

First cycle 200

Additional cycles 50

(7)

Power supply voltage 2.7 5.5 V

Normal mode, internal reference off 0.25 0.5

AVDD= 3.6 V to 5.5 V

I

DD

AVDD= 2.7 V to 3.6 V

Normal mode, internal reference on 0.8 1.3

Power-down modes

Power-down modes

Normal mode, internal reference off 0.2 0.4

Normal mode, internal reference on 0.73 1.3

Power-down modes

Power-down modes

Normal mode, internal reference off 0.9 2.75

AVDD= 3.6 V to 5.5 V

Power

dissipation

AVDD= 2.7 V to 3.6 V

Normal mode, internal reference on 2.9 7.15

Power-down modes

Power-down modes

Normal mode, internal reference off 0.54 1.44

Normal mode, internal reference on 1.97 4.68

Power-down modes

Power-down modes

TEMPERATURE RANGE

Specified performance –40 125 °C

(4) Internal reference output voltage temperature drift is characterized from –40°C to 125°C.

(5) Explained in more detail in the Application Information section of this data sheet.

(6) Specified by design or characterization

(7) Input code = mid-scale, no load, VINH = AVDD, and VINL = GND

(8) Temperature range –40°C to 105°C

(9) Temperature range –40°C to 125°C

= 2.5 V (when internal reference is

REF

(8)

(9)

(8)

(9)

(8)

(9)

(8)

(9)

SLAS719C –AUGUST 2010– REVISED JUNE 2011

DD

4 10 ppm/°C

±20 mA

ppm

mA

0.01 1

0.01 3

mA

0.008 1

0.008 3

mW

0.04 5.5

0.04 16.5

µW

mW

0.02 3.6

0.02 10.8

µW

V

PP

µA

µA

Copyright © 2010–2011, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 6

V A

OUT

V B

OUT

GND

LDAC

CLR

1

2

3

4

5

6

7

8

9

10

SYNC

SYNC

SCLK

SCLK

D

IN

D

IN

AV

DD

AV

DD

V /V

REFIN REFOUT

V /V

REFIN REFOUT

1

2

3

4

5

6

7

8

9

10

V A

OUT

V B

OUT

GND

LDAC

CLR

DGS

(Top View)

DSC

(Top View)

MSOP Package QFN Package

Thermal Pad

(1)

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

SLAS719C –AUGUST 2010– REVISED JUNE 2011

PIN CONFIGURATIONS

(1) It is recommended to connect the thermal pad to the ground plane for better thermal dissipation.

Table 2. PIN DESCRIPTIONS

PIN

NAME NO.

AV

DD

9 Power-supply input, 2.7 V to 5.5 V

Asynchronous clear input. The CLR input is falling-edge sensitive. When CLR is activated, zero scale

CLR 5

(DACxx62) or mid-scale (DACxx63) is loaded to all input and DAC registers. This sets the DAC output

voltages accordingly. The part exits clear code mode on the 24thfalling edge of the next write to the part. If

CLR is activated during a write sequence, the write is aborted.

D

IN

Serial data input. Data are clocked into the 24-bit input shift register on each falling edge of the serial clock

8

input. Schmitt-trigger logic input

GND 3 Ground reference point for all circuitry on the device

In synchronous mode, data are updated with the falling edge of the 24thSCLK cycle, which follows a falling

edge of SYNC. For such synchronous updates, the LDAC pin is not required, and it must be connected to

GND permanently or asserted and held low before sending commands to the device.

LDAC 4 In asynchronous mode, the LDAC pin is used as a negative edge-triggered timing signal for simultaneous

DAC updates. Multiple single-channel commands can be written in order to set different channel buffers to

desired values and then make a falling edge on LDAC pin to simultaneously update the DAC output

registers.

SCLK 7 Serial clock input. Data can be transferred at rates up to 50 MHz. Schmitt-trigger logic input

Level-triggered control input (active-low). This input is the frame synchronization signal for the input data.

When SYNC goes low, it enables the input shift register, and data are sampled on subsequent falling clock

SYNC 6 edges. The DAC output updates following the 24thclock falling edge. If SYNC is taken high before the 23

clock edge, the rising edge of SYNC acts as an interrupt, and the write sequence is ignored by the

DAC756x/DAC816x/DAC856x. Schmitt-trigger logic input

V

A 1 Analog output voltage from DAC-A

OUT

V

B 2 Analog output voltage from DAC-B

OUT

V

REFIN

/ V

REFOUT

10 Bidirectional voltage reference pin. If internal reference is used, 2.5-V output.

DESCRIPTION

www.ti.com

rd

6 Submit Documentation Feedback Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 7

SCLK

SYNC

DIN

VOUT

DB23

DB0

LDAC

(1)

LDAC

(2)

CLR

t

2

t

7

t

6

t

9

t

10

t

8

t

4

t

5

t

3

t

1

t

12

t

13

t

14

t

11

www.ti.com

TIMING DIAGRAM

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

SLAS719C –AUGUST 2010– REVISED JUNE 2011

(1) Asynchronous LDAC update mode. For more information, see the LDAC Functionality section.

(2) Synchronous LDAC update mode; LDAC remains low. For more information, see the LDAC Functionality section.

Figure 1. Serial Write Operation

TIMING REQUIREMENTS

At AVDD= 2.7 V to 5.5 V and over –40°C to 125°C (unless otherwise noted).

t

1

(3)

t

2

t

3

t

4

t

5

t

6

t

7

t

8

t

9

t

10

t

11

t

12

t

13

t

14

(1) All input signals are specified with tR= tF= 3 ns (10% to 90% of AVDD) and timed from a voltage level of (VINL + VINH)/2.

(2) See the Serial Write Operation timing diagram (Figure 1).

(3) Maximum SCLK frequency is 50 MHz at AVDD= 2.7 V to 5.5 V.

SCLK falling edge to SYNC falling edge (for successful write operation) 10 ns

SCLK cycle time 20 ns

SYNC rising edge to 23rdSCLK falling edge (for successful SYNC interrupt) 13 ns

Minimum SYNC HIGH time 80 ns

SYNC to SCLK falling edge setup time 13 ns

SCLK LOW time 8 ns

SCLK HIGH time 8 ns

SCLK falling edge to SYNC rising edge 10 ns

Data setup time 6 ns

Data hold time 5 ns

SCLK falling edge to LDAC falling edge for asynchronous LDAC update mode 5 ns

LDAC pulse duration, LOW time 10 ns

CLR pulse duration, LOW time 80 ns

CLR falling edge to start of VOUT transition 100 ns

(1)(2)

PARAMETER UNIT

DAC756x/DAC816x/DAC856x

MIN TYP MAX

Copyright © 2010–2011, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 8

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

SLAS719C –AUGUST 2010– REVISED JUNE 2011

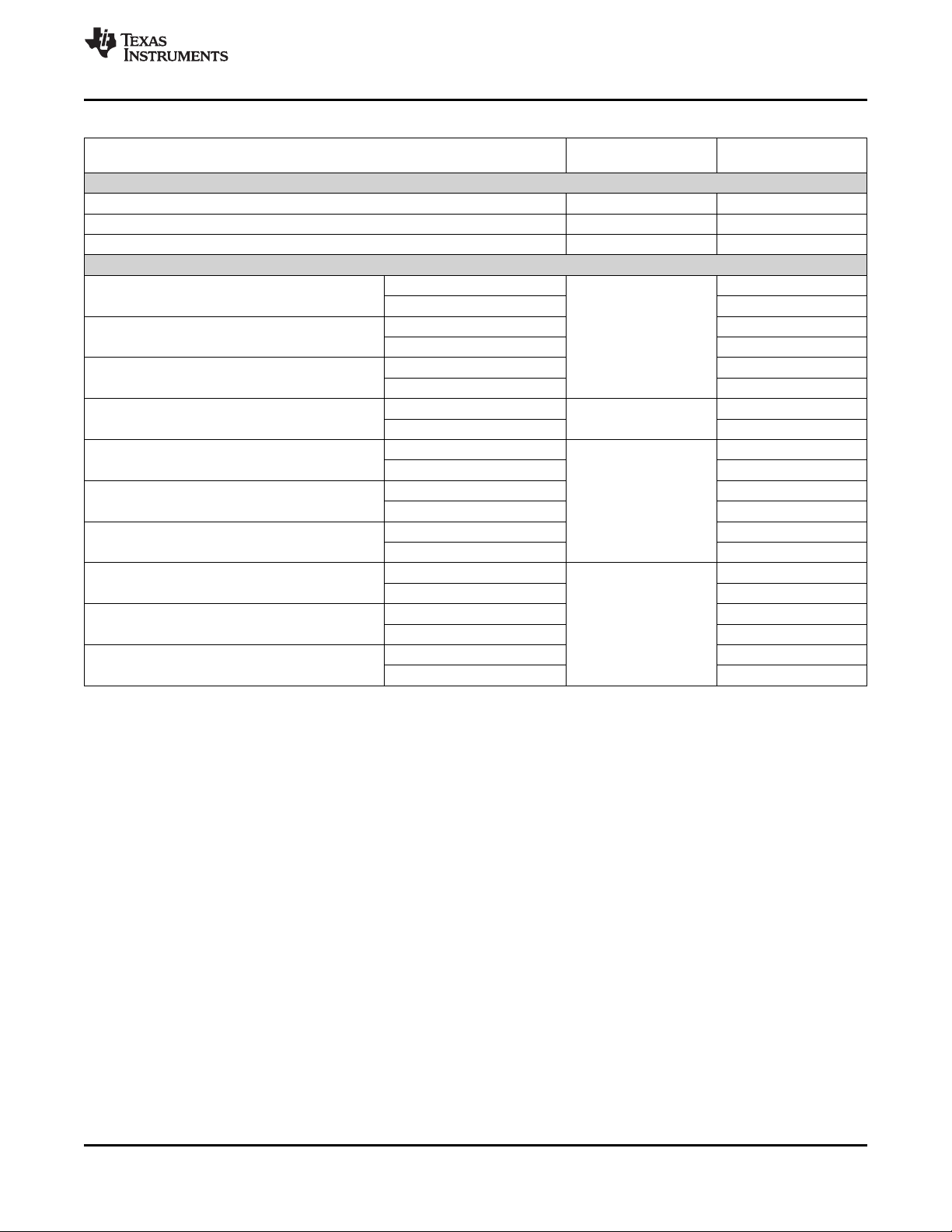

TABLES OF GRAPHS

Table 3. Typical Characteristics: Internal Reference Performance

MEASUREMENT FIGURE NUMBER

Internal Reference Voltage vs Temperature Figure 2

Internal Reference Voltage Temperature Drift Histogram Figure 3

Internal Reference Voltage vs Load Current 5.5 V Figure 4

Internal Reference Voltage vs Time Figure 5

Internal Reference Noise Density vs Frequency Figure 6

Internal Reference Voltage vs Supply Voltage 2.7 V – 5.5 V Figure 7

Table 4. Typical Characteristics: DAC Static Performance

MEASUREMENT FIGURE NUMBER

FULL-SCALE, GAIN, OFFSET AND ZERO-CODE ERRORS

Full-Scale Error vs Temperature Figure 16

Gain Error vs Temperature Figure 17

Offset Error vs Temperature Figure 18

Zero-Code Error vs Temperature Figure 19

Full-Scale Error vs Temperature Figure 63

Gain Error vs Temperature Figure 64

Offset Error vs Temperature Figure 65

Zero-Code Error vs Temperature Figure 66

LOAD REGULATION

DAC Output Voltage vs Load Current

DIFFERENTIAL NONLINEARITY ERROR

T = –40°C Figure 9

Differential Linearity Error vs Digital Input Code T = 25°C Figure 11

T = 125°C Figure 13

Differential Linearity Error vs Temperature Figure 15

T = –40°C Figure 56

Differential Linearity Error vs Digital Input Code T = 25°C Figure 58

T = 125°C Figure 60

Differential Linearity Error vs Temperature Figure 62

INTEGRAL NONLINEARITY ERROR (RELATIVE ACCURACY)

T = –40°C Figure 8

Linearity Error vs Digital Input Code T = 25°C Figure 10

T = 125°C Figure 12

Linearity Error vs Temperature Figure 14

T = –40°C Figure 55

Linearity Error vs Digital Input Code T = 25°C Figure 57

T = 125°C Figure 59

Linearity Error vs Temperature Figure 61

POWER-SUPPLY

VOLTAGE

POWER-SUPPLY

VOLTAGE

5.5 V

2.7 V

5.5 V Figure 30

2.7 V Figure 74

5.5 V

2.7 V

5.5 V

2.7 V

www.ti.com

8 Submit Documentation Feedback Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 9

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

www.ti.com

Table 4. Typical Characteristics: DAC Static Performance (continued)

MEASUREMENT FIGURE NUMBER

POWER-DOWN CURRENT

Power-Down Current vs Temperature 5.5 V Figure 28

Power-Down Current vs Power-Supply Voltage 2.7 V – 5.5 V Figure 29

Power-Down Current vs Temperature 2.7 V Figure 73

POWER-SUPPLY CURRENT

Power-Supply Current vs Temperature

Power-Supply Current vs Digital Input Code 5.5 V

Power-Supply Current Histogram

Power-Supply Current vs Power-Supply Voltage 2.7 V – 5.5 V

Power-Supply Current vs Temperature

Power-Supply Current vs Digital Input Code 3.6 V

Power-Supply Current Histogram

Power-Supply Current vs Temperature

Power-Supply Current vs Digital Input Code 2.7 V

Power-Supply Current Histogram

External V

Internal V

External V

Internal V

External V

Internal V

External V

Internal V

External V

Internal V

External V

Internal V

External V

Internal V

External V

Internal V

External V

Internal V

External V

Internal V

REF

REF

REF

REF

REF

REF

REF

REF

REF

REF

REF

REF

REF

REF

REF

REF

REF

REF

REF

REF

SLAS719C –AUGUST 2010– REVISED JUNE 2011

POWER-SUPPLY

VOLTAGE

Figure 20

Figure 21

Figure 22

Figure 23

Figure 24

Figure 25

Figure 26

Figure 27

Figure 49

Figure 50

Figure 51

Figure 52

Figure 53

Figure 54

Figure 67

Figure 68

Figure 69

Figure 70

Figure 71

Figure 72

Copyright © 2010–2011, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 10

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

SLAS719C –AUGUST 2010– REVISED JUNE 2011

Table 5. Typical Characteristics: DAC Dynamic Performance

MEASUREMENT FIGURE NUMBER

CHANNEL-TO-CHANNEL CROSSTALK

Channel-to-Channel Crosstalk 5.5 V

CLOCK FEEDTHROUGH

Clock Feedthrough 500 kHz, Midscale

GLITCH ENERGY

Glitch Energy, 1-LSB Step

Glitch Energy, 4-LSB Step 5.5 V

Glitch Energy, 16-LSB Step

Glitch Energy, 1-LSB Step

Glitch Energy, 4-LSB Step 2.7 V

Glitch Energy, 16-LSB Step

NOISE

DAC Output Noise Density vs

Frequency

DAC Output Noise 0.1 Hz to 10 Hz External V

POWER-ON GLITCH

Power-on Glitch

SETTLING TIME

Full-Scale Settling Time

Half-Scale Settling Time

Full-Scale Settling Time

Half-Scale Settling Time

5-V Rising Edge Figure 43

5-V Falling Edge Figure 44

Rising Edge, Code 7FFFh to 8000h Figure 37

Falling Edge, Code 8000h to 7FFFh Figure 38

Rising Edge, Code 7FFCh to 8000h Figure 39

Falling Edge, Code 8000h to 7FFCh Figure 40

Rising Edge, Code 7FF0h to 8000h Figure 41

Falling Edge, Code 8000h to 7FF0h Figure 42

Rising Edge, Code 7FFFh to 8000h Figure 79

Falling Edge, Code 8000h to 7FFFh Figure 80

Rising Edge, Code 7FFCh to 8000h Figure 81

Falling Edge, Code 8000h to 7FFCh Figure 82

Rising Edge, Code 7FF0h to 8000h Figure 83

Falling Edge, Code 8000h to 7FF0h Figure 84

External V

Internal V

Reset to Zero Scale Figure 35

Reset to Midscale Figure 36

Reset to Zero Scale Figure 85

Reset to Midscale Figure 86

Rising Edge, Code 0h to FFFFh Figure 31

Falling Edge, Code FFFFh to 0h Figure 32

Rising Edge, Code 4000h to C000h Figure 33

Falling Edge, Code C000h to 4000h Figure 34

Rising Edge, Code 0h to FFFFh Figure 75

Falling Edge, Code FFFFh to 0h Figure 76

Rising Edge, Code 4000h to C000h Figure 77

Falling Edge, Code C000h to 4000h Figure 78

REF

REF

REF

POWER-SUPPLY

VOLTAGE

5.5 V Figure 48

2.7 V Figure 87

5.5 V Figure 46

5.5 V

2.7 V

5.5 V

2.7 V

www.ti.com

Figure 45

Figure 47

10 Submit Documentation Feedback Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 11

2.495

2.496

2.497

2.498

2.499

2.500

2.501

2.502

2.503

2.504

2.505

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

V

REFOUT

(V)

60 units shown

(30 MSOP, 30 QFN−10)

Temperature Drift (ppm/ °C)

Population (%)

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

6.5

7.0

7.5

8.0

8.5

9.0

9.5

10.0

0

5

10

15

20

25

30

2.490

2.495

2.500

2.505

2.510

−20 −15 −10 −5 0 5 10 15 20

Load Current (mA)

V

REFOUT

(V)

0 250 500 750 1000 1250 1500

−400

−300

−200

−100

0

100

200

300

400

Elapsed Time (Hours)

Internal Reference Voltage Shift (ppm)

16 units shown (8 MSOP, 8 QFN−10)

Average shown in dashed line

0

50

100

150

200

250

300

350

400

10 100 1k 10k 100k 1M

Frequency (Hz)

Voltage Noise (nV/rt−Hz)

No Load

4.7 µF Load

2.495

2.496

2.497

2.498

2.499

2.500

2.501

2.502

2.503

2.504

2.505

2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5

AV

(V)

V

REFOUT

(V)

−40°C

+25°C

+125°C

www.ti.com

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

SLAS719C –AUGUST 2010– REVISED JUNE 2011

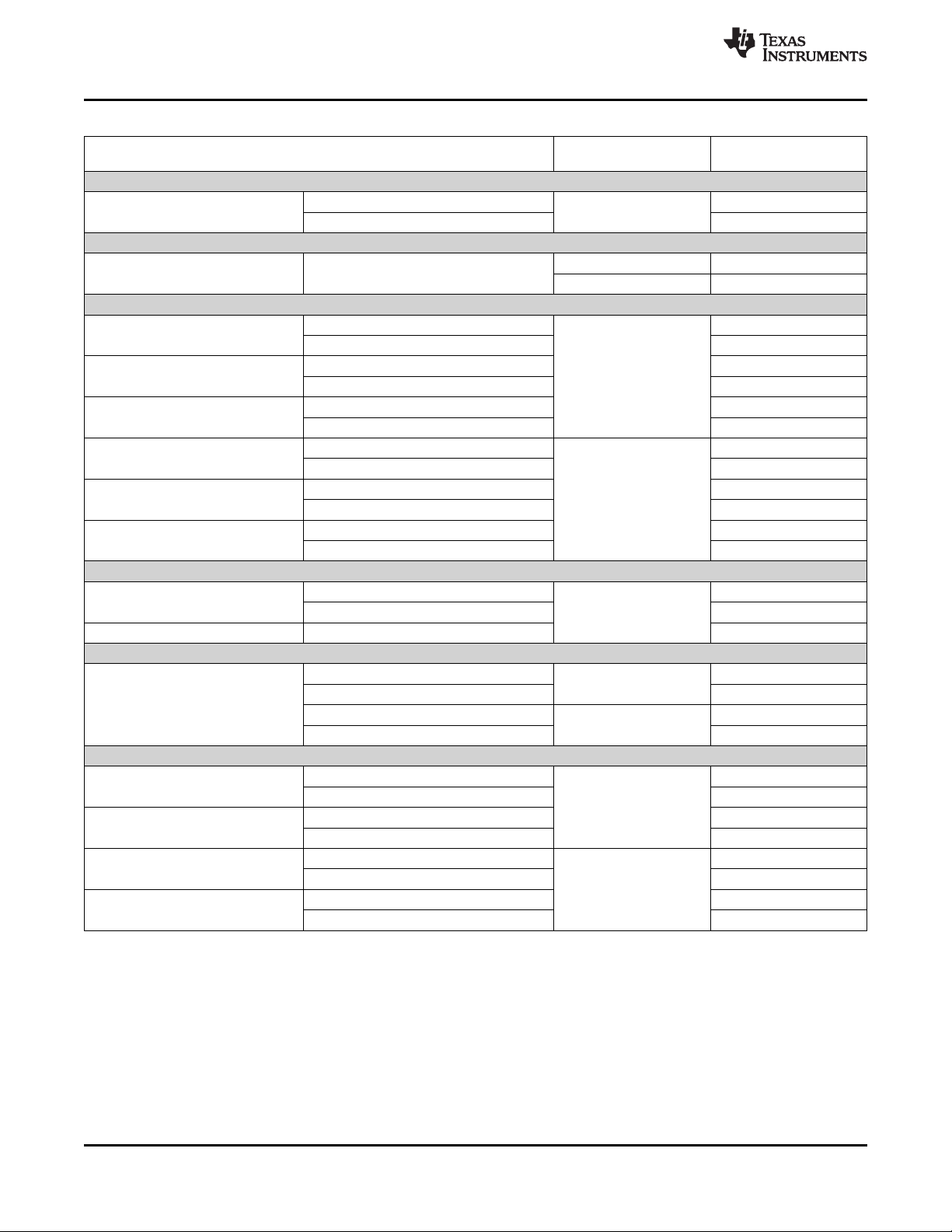

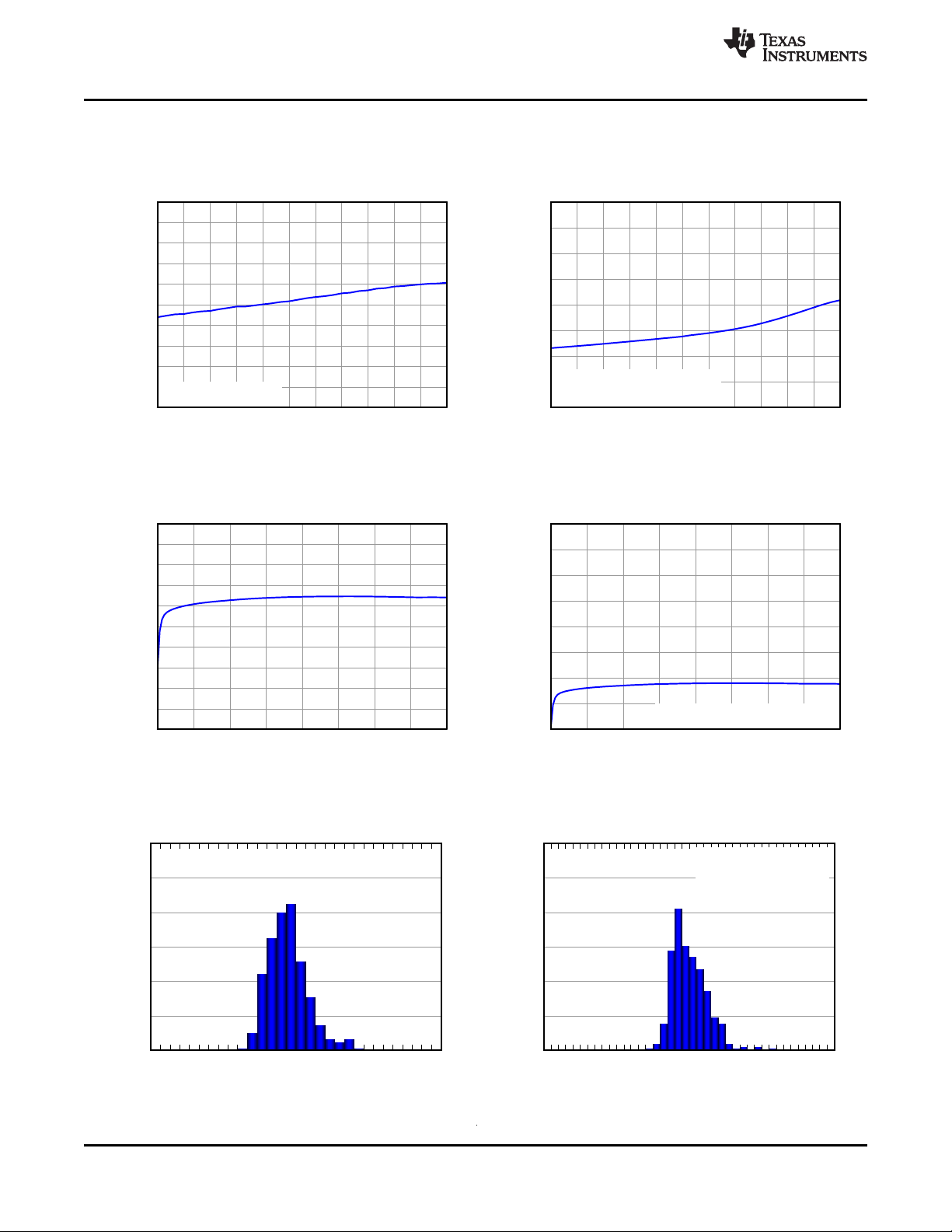

TYPICAL CHARACTERISTICS: Internal Reference

At TA= 25°C, AVDD= 5.5 V, gain = 2 and V

INTERNAL REFERENCE VOLTAGE INTERNAL REFERENCE VOLTAGE

vs TEMPERATURE TEMPERATURE DRIFT HISTOGRAM

Figure 2. Figure 3.

, unloaded unless otherwise noted.

REFOUT

INTERNAL REFERENCE VOLTAGE INTERNAL REFERENCE VOLTAGE

vs LOAD CURRENT vs TIME

Figure 4. Figure 5.

INTERNAL REFERENCE NOISE DENSITY INTERNAL REFERENCE VOLTAGE

vs FREQUENCY vs SUPPLY VOLTAGE

Copyright © 2010–2011, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Figure 6. Figure 7.

Page 12

−12

−9

−6

−3

0

3

6

9

12

0 8192 16384 24576 32768 40960 49152 57344 65536

Digital Input Code

INL Error (LSB)

Typical channel shown

−40°C

−1.0

−0.8

−0.6

−0.4

−0.2

0.0

0.2

0.4

0.6

0.8

1.0

0 8192 16384 24576 32768 40960 49152 57344 65536

Digital Input Code

DNL Error (LSB)

Typical channel shown

−40°C

−12

−9

−6

−3

0

3

6

9

12

0 8192 16384 24576 32768 40960 49152 57344 65536

Digital Input Code

INL Error (LSB)

Typical channel shown

25°C

−1.0

−0.8

−0.6

−0.4

−0.2

0.0

0.2

0.4

0.6

0.8

1.0

0 8192 16384 24576 32768 40960 49152 57344 65536

Digital Input Code

DNL Error (LSB)

Typical channel shown

25°C

−12

−9

−6

−3

0

3

6

9

12

0 8192 16384 24576 32768 40960 49152 57344 65536

Digital Input Code

INL Error (LSB)

Typical channel shown

125°C

−1.0

−0.8

−0.6

−0.4

−0.2

0.0

0.2

0.4

0.6

0.8

1.0

0 8192 16384 24576 32768 40960 49152 57344 65536

Digital Input Code

DNL Error (LSB)

Typical channel shown

125°C

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

SLAS719C –AUGUST 2010– REVISED JUNE 2011

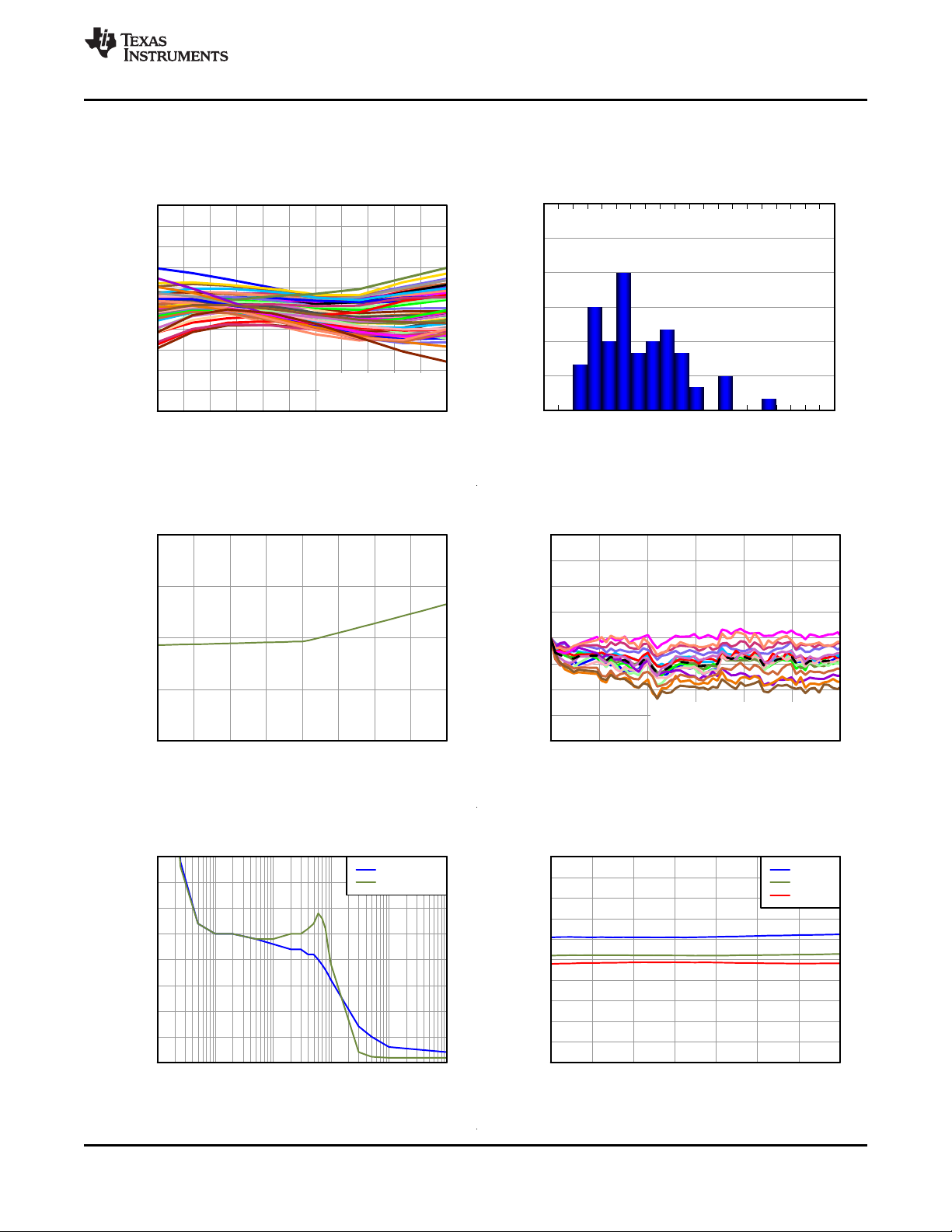

TYPICAL CHARACTERISTICS: DAC at AVDD= 5.5 V

At TA= 25°C, 5-V external reference used, gain = 1 and DAC output not loaded, unless otherwise noted.

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs DIGITAL INPUT CODE (–40°C) vs DIGITAL INPUT CODE (–40°C)

Figure 8. Figure 9.

www.ti.com

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs DIGITAL INPUT CODE (25°C) vs DIGITAL INPUT CODE (25°C)

Figure 10. Figure 11.

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs DIGITAL INPUT CODE (125°C) vs DIGITAL INPUT CODE (125°C)

12 Submit Documentation Feedback Copyright © 2010–2011, Texas Instruments Incorporated

Figure 12. Figure 13.

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 13

−12

−9

−6

−3

0

3

6

9

12

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

INL Error (LSB)

INL Max

INL Min

Typical channel shown

−1.0

−0.8

−0.6

−0.4

−0.2

0.0

0.2

0.4

0.6

0.8

1.0

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

DNL Error (LSB)

DNL Max

DNL Min

Typical channel shown

−0.20

−0.15

−0.10

−0.05

0.00

0.05

0.10

0.15

0.20

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

Full−Scale Error (%FSR)

Ch A

Ch B

−0.15

−0.10

−0.05

0.00

0.05

0.10

0.15

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

Gain Error (%FSR)

Ch A

Ch B

−4

−3

−2

−1

0

1

2

3

4

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

Offset Error (mV)

Ch A

Ch B

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

Zero−Code Error (mV)

Ch A

Ch B

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

www.ti.com

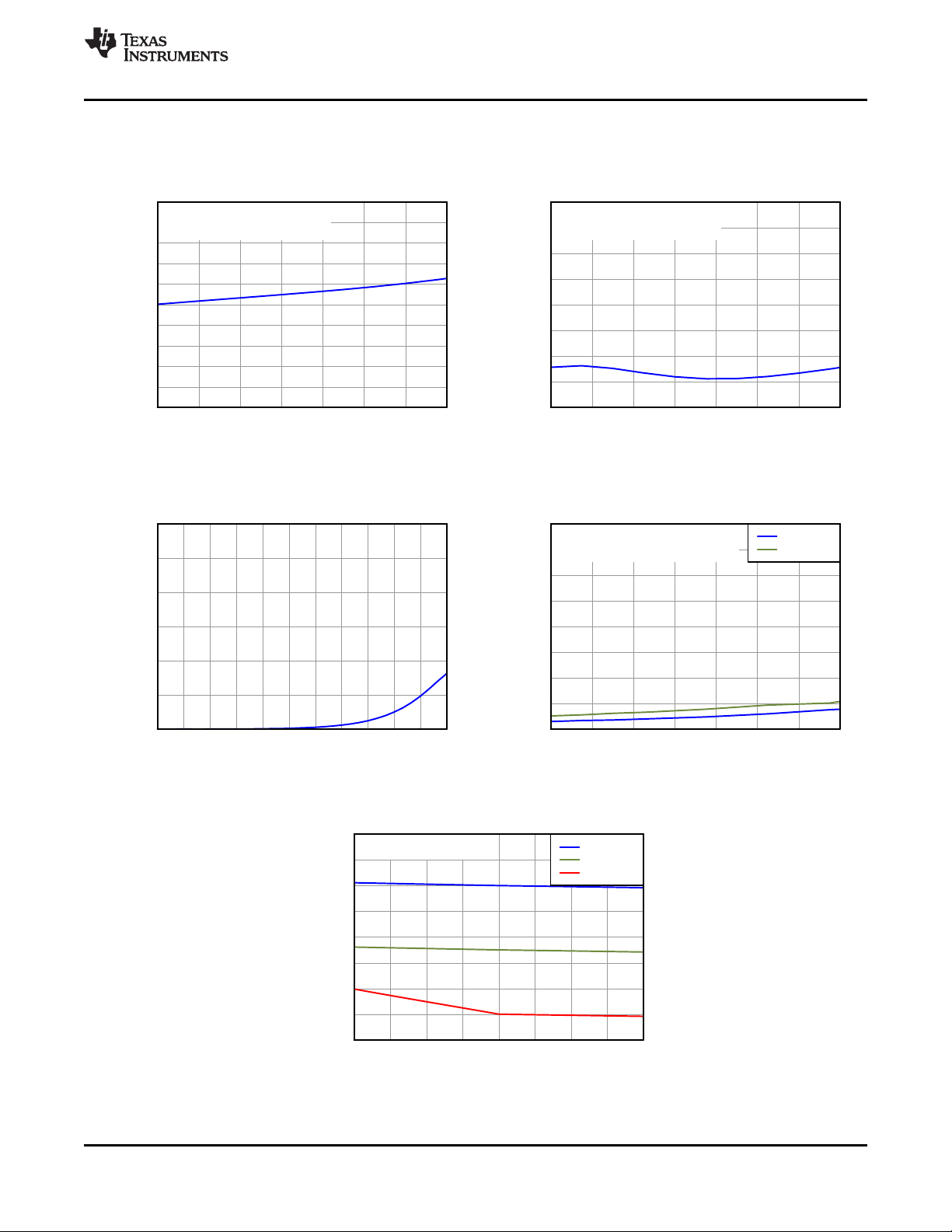

TYPICAL CHARACTERISTICS: DAC at AVDD= 5.5 V (continued)

At TA= 25°C, 5-V external reference used, gain = 1 and DAC output not loaded, unless otherwise noted.

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs TEMPERATURE vs TEMPERATURE

Figure 14. Figure 15.

SLAS719C –AUGUST 2010– REVISED JUNE 2011

FULL-SCALE ERROR GAIN ERROR

vs TEMPERATURE vs TEMPERATURE

Figure 16. Figure 17.

OFFSET ERROR ZERO-CODE ERROR

vs TEMPERATURE vs TEMPERATURE

Copyright © 2010–2011, Texas Instruments Incorporated Submit Documentation Feedback 13

Figure 18. Figure 19.

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 14

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

Power−Supply Current (mA)

DACs at midscale code

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

Power−Supply Current (mA)

Internal reference enabled

DACs at midscale code, Gain = 2

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0 8192 16384 24576 32768 40960 49152 57344 65536

Digital Input Code

Power−Supply Current (mA)

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

0 8192 16384 24576 32768 40960 49152 57344 65536

Digital Input Code

Power−Supply Current (mA)

Internal reference enabled, Gain = 2

Power Supply Current (mA)

Population (%)

0.15

0.17

0.19

0.21

0.23

0.25

0.27

0.29

0.31

0.33

0.35

0.37

0.39

0.41

0.43

0.45

0

5

10

15

20

25

30

Power Supply Current (mA)

Population (%)

0.30

0.35

0.40

0.45

0.50

0.55

0.60

0.65

0.70

0.75

0.80

0.85

0.90

0.95

1.00

1.05

1.10

1.15

1.20

1.25

1.30

0

5

10

15

20

25

30

Internal reference enabled

Gain = 2

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

SLAS719C –AUGUST 2010– REVISED JUNE 2011

TYPICAL CHARACTERISTICS: DAC at AVDD= 5.5 V (continued)

At TA= 25°C, 5-V external reference used, gain = 1 and DAC output not loaded, unless otherwise noted.

POWER-SUPPLY CURRENT POWER-SUPPLY CURRENT

vs TEMPERATURE vs TEMPERATURE

Figure 20. Figure 21.

www.ti.com

POWER-SUPPLY CURRENT POWER-SUPPLY CURRENT

vs DIGITAL INPUT CODE vs DIGITAL INPUT CODE

Figure 22. Figure 23.

POWER-SUPPLY CURRENT POWER-SUPPLY CURRENT

HISTOGRAM HISTOGRAM

14 Submit Documentation Feedback Copyright © 2010–2011, Texas Instruments Incorporated

Figure 24. Figure 25.

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 15

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5

AV

(V)

Power−Supply Current (mA)

V

REFIN

= 2.5 V

DACs at midscale code, Gain = 1

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5

AV

(V)

Power−Supply Current (mA)

Internal reference enabled

DACs at midscale code, Gain = 1

0.0

0.5

1.0

1.5

2.0

2.5

3.0

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

Power−Down Current (µA)

0.000

0.005

0.010

0.015

0.020

0.025

0.030

0.035

0.040

2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5

AV

(V)

Power−Down Current (µA)

IDD (µA)

I

REFIN

(µA)

Both channels and internal reference

in power−down mode; V

REFIN

= A

VDD

−1.0

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

−20 −15 −10 −5 0 5 10 15 20

I

(mA)

Output Voltage (V)

Full scale

Mid scale

Zero scale

Typical channel shown

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

www.ti.com

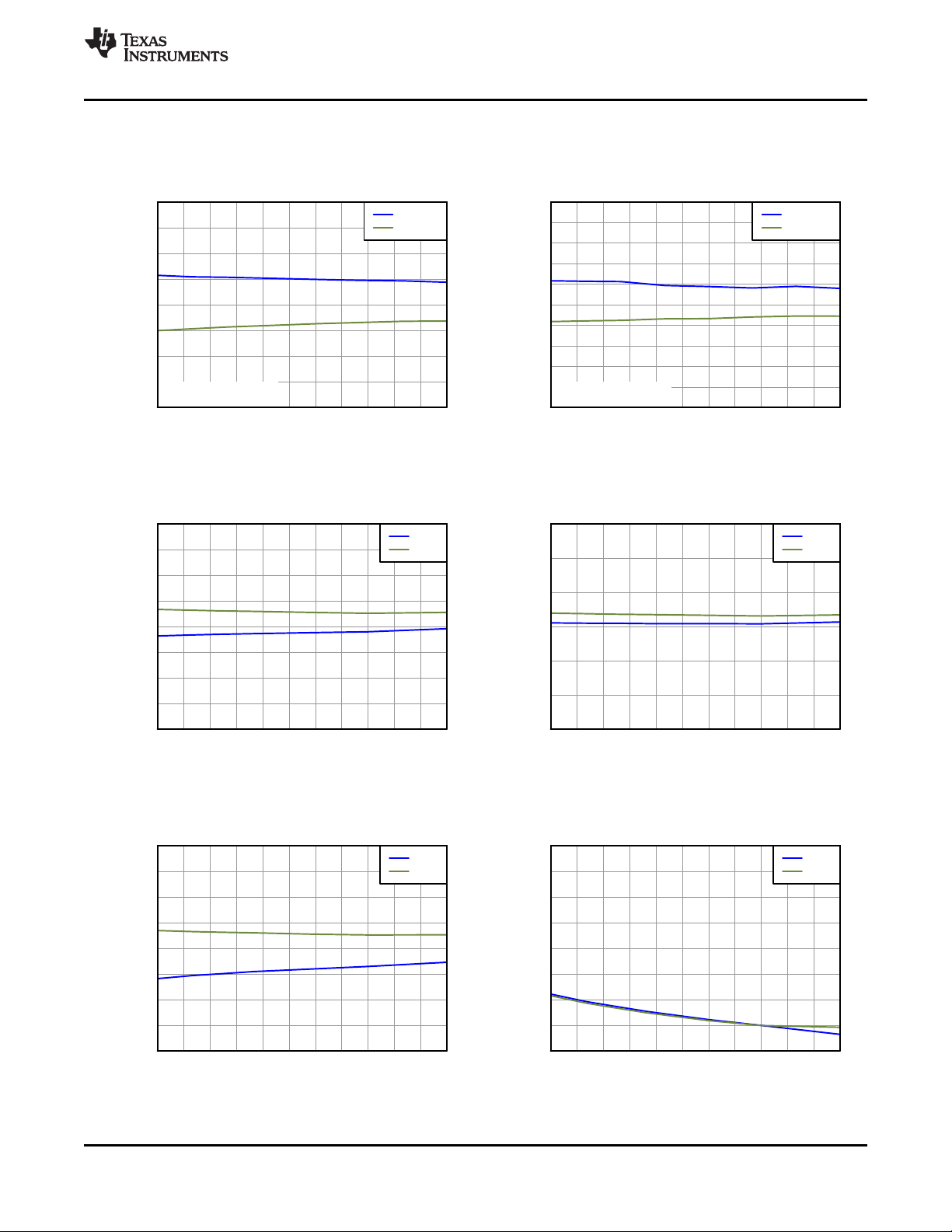

TYPICAL CHARACTERISTICS: DAC at AVDD= 5.5 V (continued)

At TA= 25°C, 5-V external reference used, gain = 1 and DAC output not loaded, unless otherwise noted.

POWER-SUPPLY CURRENT POWER-SUPPLY CURRENT

vs POWER-SUPPLY VOLTAGE vs POWER-SUPPLY VOLTAGE

Figure 26. Figure 27.

SLAS719C –AUGUST 2010– REVISED JUNE 2011

POWER-DOWN CURRENT POWER-DOWN CURRENT

vs TEMPERATURE vs POWER-SUPPLY VOLTAGE

Figure 28. Figure 29.

DAC OUTPUT VOLTAGE

vs LOAD CURRENT

Copyright © 2010–2011, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Figure 30.

Page 16

Time (5 s/div)μ

Trigger (5 V/div)LDAC

Large Signal V (2 V/div)

OUT

Small Signal Settling

(1.22 mV/div = 0.024% FSR)

From Code:

To Code:0hFFFFh

Time (5 s/div)μ

Trigger (5 V/div)LDAC

Large Signal V (2 V/div)

OUT

Small Signal Settling (1.22 mV/div = 0.024% FSR)

From Code: FFFF

To Code: 0hh

Time (5 s/div)μ

Trigger (5 V/div)LDAC

Large Signal V (2 V/div)

OUT

Small Signal Settling (1.22 mV/div = 0.024% FSR)

From Code:

To Code:

4000h

C000h

Time (5 s/div)μ

Trigger (5 V/div)LDAC

Large Signal V (2 V/div)

OUT

Small Signal Settling (1.22 mV/div = 0.024% FSR)

From Code: C000h

To Code: 4000h

Time (1 ms/div)

AV (2 V/div)

DD

V A (50 mV/div)

OUT

V shorted to

REFIN

AV

DD

V B (50 mV/div)

OUT

Time (1 ms/div)

AV (2 V/div)

DD

V A (1 V/div)

OUT

V shorted to

REFIN

AV

DD

V B (1 V/div)

OUT

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

SLAS719C –AUGUST 2010– REVISED JUNE 2011

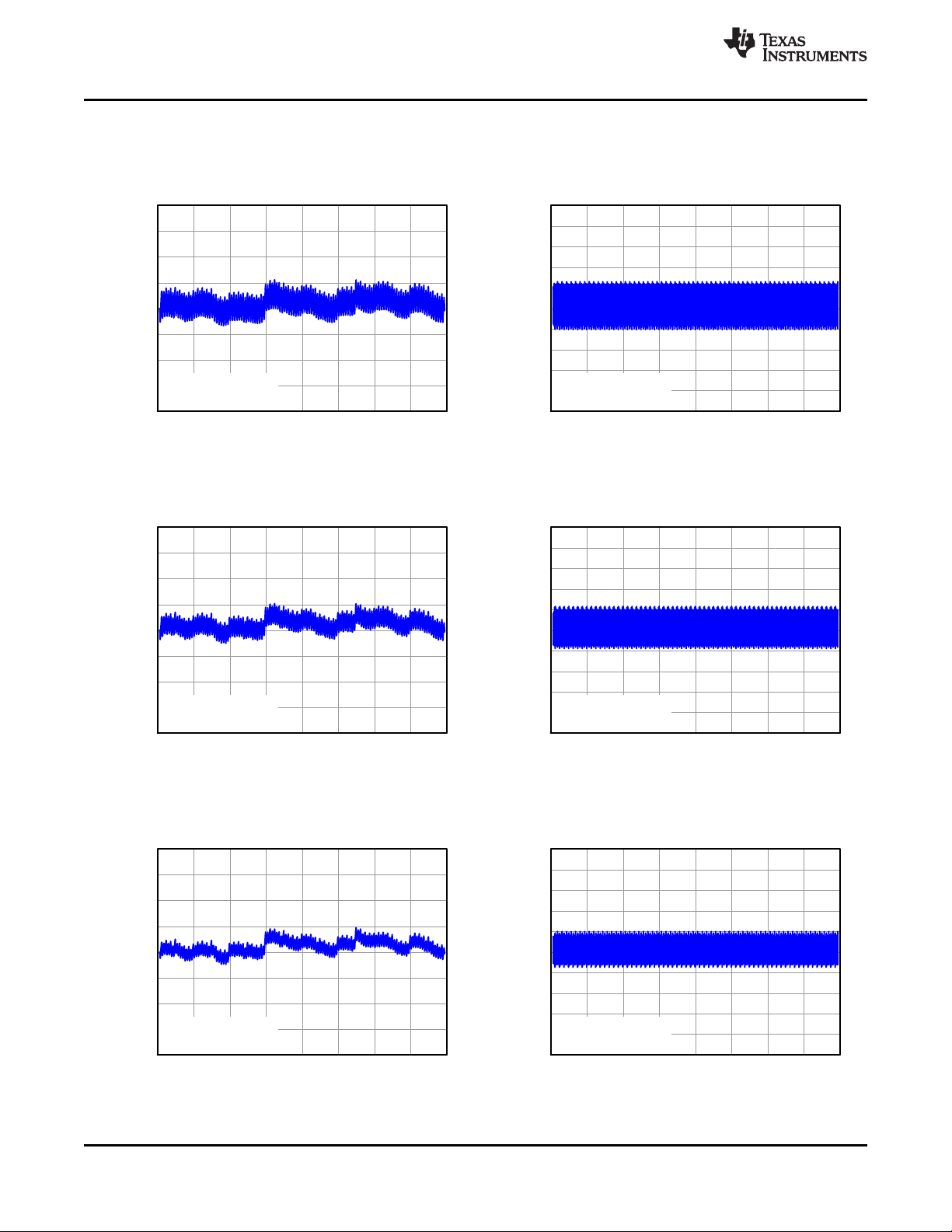

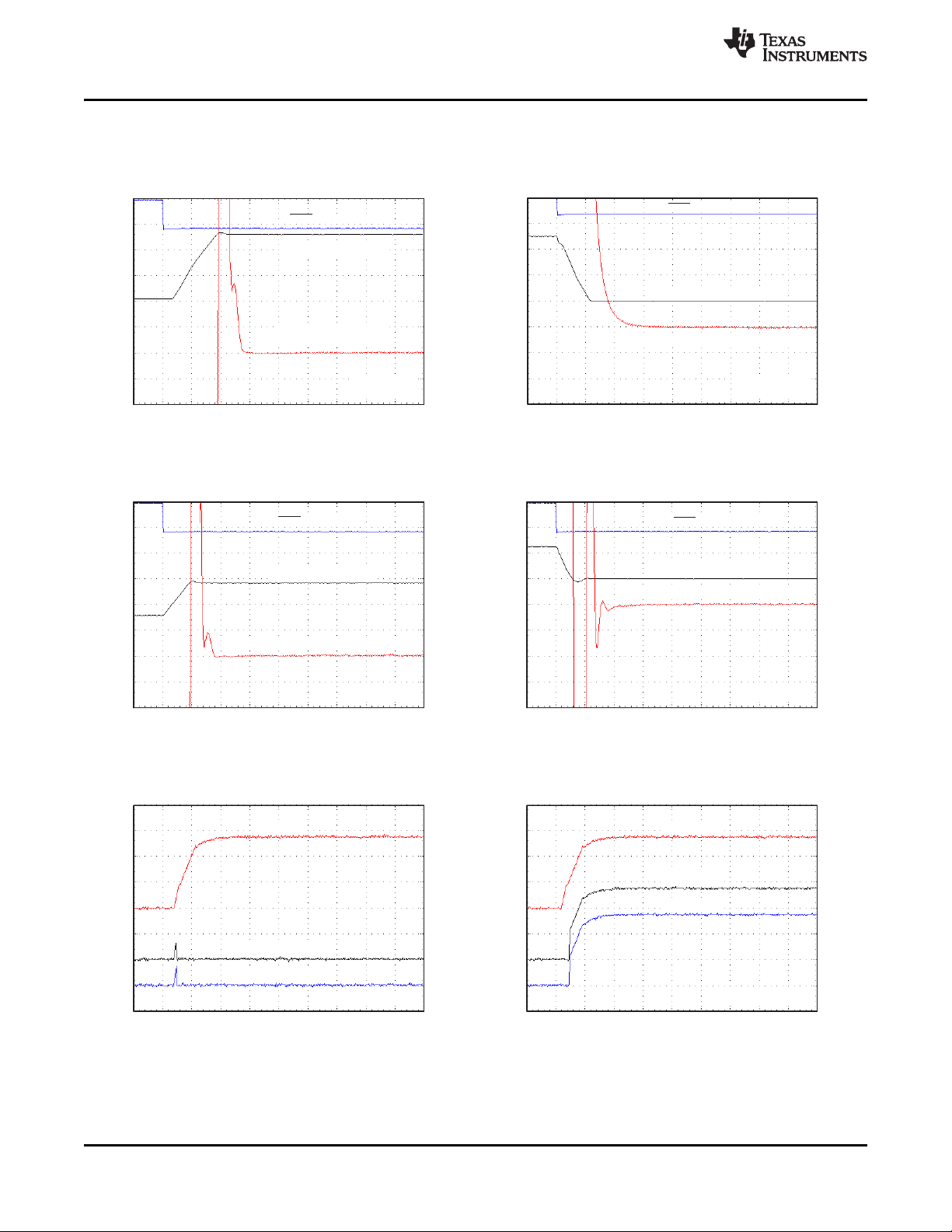

TYPICAL CHARACTERISTICS: DAC at AVDD= 5.5 V (continued)

At TA= 25°C, 5-V external reference used, gain = 1 and DAC output not loaded, unless otherwise noted.

FULL-SCALE SETTLING TIME: FULL-SCALE SETTLING TIME:

RISING EDGE FALLING EDGE

Figure 31. Figure 32.

HALF-SCALE SETTLING TIME: HALF-SCALE SETTLING TIME:

RISING EDGE FALLING EDGE

www.ti.com

Figure 33. Figure 34.

POWER-ON GLITCH POWER-ON GLITCH

RESET TO ZERO SCALE RESET TO MIDSCALE

16 Submit Documentation Feedback Copyright © 2010–2011, Texas Instruments Incorporated

Figure 35. Figure 36.

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 17

Time (5 s/div)μ

V (100 V/div)

OUT

μ

From Code: 7FFFh

To Code: 8000h

Trigger (5 V/div)LDAC

FeedthroughLDAC

Glitch Impulse 0.1 nV-s»

Time (5 s/div)μ

V (100 V/div)

OUT

μ

From Code:

To Code:

8000h

7FFFh

Trigger (5 V/div)LDAC

FeedthroughLDAC

Glitch Impulse 0.12 nV-s»

Time (5 s/div)μ

V (100 V/div)

OUT

μ

From Code: 7FFCh

To Code: 8000h

Trigger (5 V/div)LDAC

FeedthroughLDAC

Glitch Impulse 0.1 nV-s»

Time (5 s/div)μ

V (100 V/div)

OUT

μ

From Code:

To Code:

8000h

7FFCh

Trigger (5 V/div)LDAC

FeedthroughLDAC

Glitch Impulse 0.14 nV-s»

Time (5 s/div)μ

V (500 V/div)

OUT

μ

From Code: 7FF0h

To Code: 8000h

Trigger (5 V/div)LDAC

FeedthroughLDAC

Glitch Impulse 0.1 nV-s»

Time (5 s/div)μ

V (500 V/div)

OUT

μ

From Code:

To Code:

8000h

7FF0h

Trigger (5 V/div)LDAC

FeedthroughLDAC

Glitch Impulse 0.1 nV-s»

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

www.ti.com

TYPICAL CHARACTERISTICS: DAC at AVDD= 5.5 V (continued)

At TA= 25°C, 5-V external reference used, gain = 1 and DAC output not loaded, unless otherwise noted.

GLITCH ENERGY GLITCH ENERGY

RISING EDGE, 1-LSB STEP FALLING EDGE, 1-LSB STEP

Figure 37. Figure 38.

GLITCH ENERGY GLITCH ENERGY

RISING EDGE, 4-LSB STEP FALLING EDGE, 4-LSB STEP

SLAS719C –AUGUST 2010– REVISED JUNE 2011

Figure 39. Figure 40.

GLITCH ENERGY GLITCH ENERGY

RISING EDGE, 16-LSB STEP FALLING EDGE, 16-LSB STEP

Figure 41. Figure 42.

Copyright © 2010–2011, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 18

Time (5 s/div)μ

V B (1 V/div)

OUT

V A (500 V/div)

OUT

μ

V A at Midscale Code

Internal Reference Enabled

Gain = 2

OUT

Trigger (5 V/div)LDAC

Glitch Area (Between Cursors) = 1.6 nV-s

7.3 sμ

Time (5 s/div)μ

V B (1 V/div)

OUT

V A (500 V/div)

OUT

μ

V A at Midscale Code

Internal Reference Enabled

Gain = 2

OUT

Trigger (5 V/div)LDAC

Glitch Area (Between Cursors) = 2 nV-s

6.4 sμ

0

200

400

600

800

1000

1200

1400

10 100 1k 10k 100k

Frequency (Hz)

Voltage Noise (nV/rt−Hz)

Full Scale

Mid Scale

Zero Scale

Internal reference disabled

V

REFIN

= 5 V, Gain = 1

0

200

400

600

800

1000

1200

1400

10 100 1k 10k 100k

Frequency (Hz)

Voltage Noise (nV/rt−Hz)

Full Scale

Mid Scale

Zero Scale

Internal reference enabled

Gain = 2

V (1 V/div)

NOISE

μ

DAC = Midscale

2.5» μV

PP

Time (500 ns/div)

SCLK (5 V/div)

V (500 V/div)

OUT

μ

Clock Feedthrough Impulse 0.06 nV-s»

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

SLAS719C –AUGUST 2010– REVISED JUNE 2011

TYPICAL CHARACTERISTICS: DAC at AVDD= 5.5 V (continued)

At TA= 25°C, 5-V external reference used, gain = 1 and DAC output not loaded, unless otherwise noted.

CHANNEL-TO-CHANNEL CROSSTALK CHANNEL-TO-CHANNEL CROSSTALK

5-V RISING EDGE 5-V FALLING EDGE

Figure 43. Figure 44.

DAC OUTPUT NOISE DENSITY DAC OUTPUT NOISE DENSITY

vs FREQUENCY vs FREQUENCY

www.ti.com

18 Submit Documentation Feedback Copyright © 2010–2011, Texas Instruments Incorporated

DAC OUTPUT NOISE CLOCK FEEDTHROUGH

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Figure 45. Figure 46.

0.1 Hz TO 10 Hz 500 kHz, MIDSCALE

Figure 47. Figure 48.

Page 19

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

Power−Supply Current (mA)

DACs at midscale code

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

Power−Supply Current (mA)

Internal reference enabled

DACs at midscale code, Gain = 1

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0 8192 16384 24576 32768 40960 49152 57344 65536

Digital Input Code

Power−Supply Current (mA)

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

0 8192 16384 24576 32768 40960 49152 57344 65536

Digital Input Code

Power−Supply Current (mA)

Internal reference enabled, Gain = 1

Power Supply Current (mA)

Population (%)

0.10

0.12

0.14

0.16

0.18

0.20

0.22

0.24

0.26

0.28

0.30

0.32

0.34

0.36

0.38

0.40

0

5

10

15

20

25

30

Power Supply Current (mA)

Population (%)

0.30

0.35

0.40

0.45

0.50

0.55

0.60

0.65

0.70

0.75

0.80

0.85

0.90

0.95

1.00

1.05

1.10

1.15

1.20

1.25

1.30

0

5

10

15

20

25

30

Internal reference enabled

Gain = 1

www.ti.com

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

SLAS719C –AUGUST 2010– REVISED JUNE 2011

TYPICAL CHARACTERISTICS: DAC at AVDD= 3.6 V

At TA= 25°C, 3.3-V external reference used, gain = 1 and DAC output not loaded, unless otherwise noted.

POWER-SUPPLY CURRENT POWER-SUPPLY CURRENT

vs TEMPERATURE vs TEMPERATURE

Figure 49. Figure 50.

POWER-SUPPLY CURRENT POWER-SUPPLY CURRENT

vs DIGITAL INPUT CODE vs DIGITAL INPUT CODE

Figure 51. Figure 52.

POWER-SUPPLY CURRENT POWER-SUPPLY CURRENT

HISTOGRAM HISTOGRAM

Copyright © 2010–2011, Texas Instruments Incorporated Submit Documentation Feedback 19

Figure 53. Figure 54.

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 20

−12

−9

−6

−3

0

3

6

9

12

0 8192 16384 24576 32768 40960 49152 57344 65536

Digital Input Code

INL Error (LSB)

Typical channel shown

−40°C

−1.0

−0.8

−0.6

−0.4

−0.2

0.0

0.2

0.4

0.6

0.8

1.0

0 8192 16384 24576 32768 40960 49152 57344 65536

Digital Input Code

DNL Error (LSB)

Typical channel shown

−40°C

−12

−9

−6

−3

0

3

6

9

12

0 8192 16384 24576 32768 40960 49152 57344 65536

Digital Input Code

INL Error (LSB)

Typical channel shown

25°C

−1.0

−0.8

−0.6

−0.4

−0.2

0.0

0.2

0.4

0.6

0.8

1.0

0 8192 16384 24576 32768 40960 49152 57344 65536

Digital Input Code

DNL Error (LSB)

Typical channel shown

25°C

−12

−9

−6

−3

0

3

6

9

12

0 8192 16384 24576 32768 40960 49152 57344 65536

Digital Input Code

INL Error (LSB)

Typical channel shown

125°C

−1.0

−0.8

−0.6

−0.4

−0.2

0.0

0.2

0.4

0.6

0.8

1.0

0 8192 16384 24576 32768 40960 49152 57344 65536

Digital Input Code

DNL Error (LSB)

Typical channel shown

125°C

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

SLAS719C –AUGUST 2010– REVISED JUNE 2011

TYPICAL CHARACTERISTICS: DAC at AVDD= 2.7 V

At TA= 25°C, 2.5-V external reference used, gain = 1 and DAC output not loaded, unless otherwise noted.

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs DIGITAL INPUT CODE (–40°C) vs DIGITAL INPUT CODE (–40°C)

Figure 55. Figure 56.

www.ti.com

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs DIGITAL INPUT CODE (25°C) vs DIGITAL INPUT CODE (25°C)

Figure 57. Figure 58.

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs DIGITAL INPUT CODE (125°C) vs DIGITAL INPUT CODE (125°C)

20 Submit Documentation Feedback Copyright © 2010–2011, Texas Instruments Incorporated

Figure 59. Figure 60.

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 21

−12

−9

−6

−3

0

3

6

9

12

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

INL Error (LSB)

INL Max

INL Min

Typical channel shown

−1.0

−0.8

−0.6

−0.4

−0.2

0.0

0.2

0.4

0.6

0.8

1.0

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

DNL Error (LSB)

DNL Max

DNL Min

Typical channel shown

−0.20

−0.15

−0.10

−0.05

0.00

0.05

0.10

0.15

0.20

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

Full−Scale Error (%FSR)

Ch A

Ch B

−0.15

−0.10

−0.05

0.00

0.05

0.10

0.15

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

Gain Error (%FSR)

Ch A

Ch B

−4

−3

−2

−1

0

1

2

3

4

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

Offset Error (mV)

Ch A

Ch B

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

Zero−Code Error (mV)

Ch A

Ch B

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

www.ti.com

TYPICAL CHARACTERISTICS: DAC at AVDD= 2.7 V (continued)

At TA= 25°C, 2.5-V external reference used, gain = 1 and DAC output not loaded, unless otherwise noted.

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs TEMPERATURE vs TEMPERATURE

Figure 61. Figure 62.

SLAS719C –AUGUST 2010– REVISED JUNE 2011

FULL-SCALE ERROR GAIN ERROR

vs TEMPERATURE vs TEMPERATURE

Figure 63. Figure 64.

OFFSET ERROR ZERO-CODE ERROR

vs TEMPERATURE vs TEMPERATURE

Copyright © 2010–2011, Texas Instruments Incorporated Submit Documentation Feedback 21

Figure 65. Figure 66.

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 22

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

Power−Supply Current (mA)

DACs at midscale code

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

Power−Supply Current (mA)

Internal reference enabled

DACs at midscale code, Gain = 1

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0 8192 16384 24576 32768 40960 49152 57344 65536

Digital Input Code

Power−Supply Current (mA)

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

0 8192 16384 24576 32768 40960 49152 57344 65536

Digital Input Code

Power−Supply Current (mA)

Internal reference enabled, Gain = 1

Power Supply Current (mA)

Population (%)

0.10

0.12

0.14

0.16

0.18

0.20

0.22

0.24

0.26

0.28

0.30

0.32

0.34

0.36

0.38

0.40

0

5

10

15

20

25

30

Power Supply Current (mA)

Population (%)

0.30

0.35

0.40

0.45

0.50

0.55

0.60

0.65

0.70

0.75

0.80

0.85

0.90

0.95

1.00

1.05

1.10

1.15

1.20

1.25

1.30

0

5

10

15

20

25

30

Internal reference enabled

Gain = 1

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

SLAS719C –AUGUST 2010– REVISED JUNE 2011

TYPICAL CHARACTERISTICS: DAC at AVDD= 2.7 V (continued)

At TA= 25°C, 2.5-V external reference used, gain = 1 and DAC output not loaded, unless otherwise noted.

POWER-SUPPLY CURRENT POWER-SUPPLY CURRENT

vs TEMPERATURE vs TEMPERATURE

Figure 67. Figure 68.

www.ti.com

POWER-SUPPLY CURRENT POWER-SUPPLY CURRENT

vs DIGITAL INPUT CODE vs DIGITAL INPUT CODE

Figure 69. Figure 70.

POWER-SUPPLY CURRENT POWER-SUPPLY CURRENT

HISTOGRAM HISTOGRAM

22 Submit Documentation Feedback Copyright © 2010–2011, Texas Instruments Incorporated

Figure 71. Figure 72.

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 23

0.0

0.5

1.0

1.5

2.0

2.5

3.0

−40 −25 −10 5 20 35 50 65 80 95 110 125

Temperature (°C)

Power−Down Current (µA)

−1

0

1

2

3

4

−20 −15 −10 −5 0 5 10 15 20

I

(mA)

Output Voltage (V)

Full scale

Mid scale

Zero scale

Typical channel shown

Time (5 s/div)μ

Trigger (5 V/div)LDAC

Large Signal V (1 V/div)

OUT

Small Signal Settling (0.61 mV/div = 0.024% FSR)

From Code:

To Code:0hFFFFh

Time (5 s/div)μ

Trigger (5 V/div)LDAC

Large Signal V (1 V/div)

OUT

Small Signal Settling (0.61 mV/div = 0.024% FSR)

From Code: FFFF

To Code: 0hh

Time (5 s/div)μ

Trigger (5 V/div)LDAC

Large Signal V (1 V/div)

OUT

Small Signal Settling (0.61 mV/div = 0.024% FSR)

From Code:

To Code:

4000h

C000h

Time (5 s/div)μ

Trigger (5 V/div)LDAC

Large Signal V (1 V/div)

OUT

Small Signal Settling (0.61 mV/div = 0.024% FSR)

From Code: C000h

To Code: 4000h

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

www.ti.com

TYPICAL CHARACTERISTICS: DAC at AVDD= 2.7 V (continued)

At TA= 25°C, 2.5-V external reference used, gain = 1 and DAC output not loaded, unless otherwise noted.

POWER-DOWN CURRENT DAC OUTPUT VOLTAGE

vs TEMPERATURE vs LOAD CURRENT

Figure 73. Figure 74.

SLAS719C –AUGUST 2010– REVISED JUNE 2011

FULL-SCALE SETTLING TIME: FULL-SCALE SETTLING TIME:

RISING EDGE FALLING EDGE

Figure 75. Figure 76.

HALF-SCALE SETTLING TIME: HALF-SCALE SETTLING TIME:

RISING EDGE FALLING EDGE

Copyright © 2010–2011, Texas Instruments Incorporated Submit Documentation Feedback 23

Figure 77. Figure 78.

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 24

Time (5 s/div)μ

V (100 V/div)

OUT

μ

From Code: 7FFFh

To Code: 8000h

Trigger (5 V/div)LDAC

FeedthroughLDAC

Glitch Impulse 0.1 nV-s»

Time (5 s/div)μ

V (100 V/div)

OUT

μ

From Code:

To Code:

8000h

7FFFh

Trigger (5 V/div)LDAC

FeedthroughLDAC

Glitch Impulse 0.1 nV-s»

Time (5 s/div)μ

V (100 V/div)

OUT

μ

From Code: 7FFCh

To Code: 8000h

Trigger (5 V/div)LDAC

FeedthroughLDAC

Glitch Impulse 0.1 nV-s»

Time (5 s/div)μ

V (100 V/div)

OUT

μ

From Code:

To Code:

8000h

7FFCh

Trigger (5 V/div)LDAC

FeedthroughLDAC

Glitch Impulse 0.1 nV-s»

Time (5 s/div)μ

V (200 V/div)

OUT

μ

From Code: 7FF0h

To Code: 8000h

Trigger (5 V/div)LDAC

FeedthroughLDAC

Glitch Impulse 0.1 nV-s»

Time (5 s/div)μ

V (200 V/div)

OUT

μ

From Code:

To Code:

8000h

7FF0h

Trigger (5 V/div)LDAC

Glitch Impulse 0.1 nV-s»

FeedthroughLDAC

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

SLAS719C –AUGUST 2010– REVISED JUNE 2011

TYPICAL CHARACTERISTICS: DAC at AVDD= 2.7 V (continued)

At TA= 25°C, 2.5-V external reference used, gain = 1 and DAC output not loaded, unless otherwise noted.

GLITCH ENERGY GLITCH ENERGY

RISING EDGE, 1-LSB STEP FALLING EDGE, 1-LSB STEP

Figure 79. Figure 80.

GLITCH ENERGY GLITCH ENERGY

RISING EDGE, 4-LSB STEP FALLING EDGE, 4-LSB STEP

www.ti.com

Figure 81. Figure 82.

GLITCH ENERGY GLITCH ENERGY

RISING EDGE, 16-LSB STEP FALLING EDGE, 16-LSB STEP

Figure 83. Figure 84.

24 Submit Documentation Feedback Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 25

Time (1 ms/div)

AV (2 V/div)

DD

V A (50 mV/div)

OUT

V shorted to

REFIN

AV

DD

V B (50 mV/div)

OUT

Time (1 ms/div)

AV (2 V/div)

DD

V A (500 mV/div)

OUT

V shorted to

REFIN

AV

DD

V B (500 mV/div)

OUT

Time (500 ns/div)

SCLK (2 V/div)

V (500 V/div)

OUT

μ

Clock Feedthrough Impulse 0.02 nV-s»

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

www.ti.com

TYPICAL CHARACTERISTICS: DAC at AVDD= 2.7 V (continued)

At TA= 25°C, 2.5-V external reference used, gain = 1 and DAC output not loaded, unless otherwise noted.

POWER-ON GLITCH POWER-ON GLITCH

RESET TO ZERO SCALE RESET TO MIDSCALE

Figure 85. Figure 86.

CLOCK FEEDTHROUGH

500 kHz, MIDSCALE

SLAS719C –AUGUST 2010– REVISED JUNE 2011

Figure 87.

Copyright © 2010–2011, Texas Instruments Incorporated Submit Documentation Feedback 25

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 26

DAC

Gain

Register

Register

REF(+)

Resistor String

REF( )-

GND

V /

V

REFIN

REFOUT

V

OUT

150 kW 150 kW

D

IN

n

IN

O UT REF

n

D

V = V Gain

2

æ ö

´ ´

ç ÷

è ø

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

SLAS719C –AUGUST 2010– REVISED JUNE 2011

THEORY OF OPERATION

DIGITAL-TO-ANALOG CONVERTER (DAC)

The DAC756x, DAC816x, and DAC856x architecture consists of two string DACs, each followed by an output

buffer amplifier. The devices include an internal 2.5-V reference with 4-ppm/°C temperature drift performance.

Figure 88 shows a principal block diagram of the DAC architecture.

Figure 88. DAC Architecture

The input coding to the DAC756x, DAC816x, and DAC856x is straight binary, so the ideal output voltage is given

by Equation 1:

www.ti.com

where:

n = resolution in bits; either 12 (DAC756x), 14 (DAC816x) or 16 (DAC856x)

DIN= decimal equivalent of the binary code that is loaded to the DAC register. DINranges from 0 to 2n– 1.

V

= DAC reference voltage; either V

REF

REFOUT

from the internal 2.5-V reference or V

REFIN

aaa external reference.

Gain = 1 by default when internal reference is disabled (using external reference), and gain = 2 by default

aaa when using internal reference. Gain can also be manually set to either 1 or 2 using the gain register.

aaa See the GAIN REGISTERS section for more information.

(1)

from an

26 Submit Documentation Feedback Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 27

V

REFIN REFOUT

/V

R

R

R

R

V

REF

2

R

DIVIDER

ToOutput Amplifier

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

www.ti.com

Resistor String

The resistor string section is shown in Figure 89. It is simply a string of resistors, each of value R. The code

loaded into the DAC register determines at which node on the string the voltage is tapped off to be fed into the

output amplifier by closing one of the switches connecting the string to the amplifier. The resistor string

architecture guarantees monotonicity. The R

DIVIDER

switch is controlled by the gain registers (see the GAIN

REGISTERS section). Because the output amplifier has a gain of two, R

gain is set to one (default if internal reference is disabled), and is shorted when the DAC-n gain is set to two

(default if internal reference is enabled).

SLAS719C –AUGUST 2010– REVISED JUNE 2011

DIVIDER

is not shorted when the DAC-n

Figure 89. Resistor String

Output Amplifier

The output buffer amplifier is capable of generating rail-to-rail voltages on its output, giving a maximum output

range of 0 V to AVDD. It is capable of driving a load of 2 kΩ in parallel with 3 nF to GND. The typical slew rate is

0.75 V/µs, with a typical full-scale settling time of 14 µs as shown in Figure 31, Figure 32, Figure 75 and

Figure 76.

Copyright © 2010–2011, Texas Instruments Incorporated Submit Documentation Feedback 27

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 28

V /V

REFIN REFOUT

R

1

Q

2

Q

1

R

2

Reference

Enable

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

SLAS719C –AUGUST 2010– REVISED JUNE 2011

INTERNAL REFERENCE

The DAC756x, DAC816x, and DAC856x include a 2.5-V internal reference that is disabled by default. The

internal reference is externally available at the V

REFIN/VREFOUT

and can sink and source up to 20 mA.

A minimum 150-nF capacitor is recommended between the reference output and GND for noise filtering.

The internal reference of the DAC756x, DAC816x, and DAC856x is a bipolar transistor based precision bandgap

voltage reference. Figure 90 shows the basic bandgap topology. Transistors Q1and Q2are biased such that the

current density of Q1is greater than that of Q2. The difference of the two base-emitter voltages (V

a positive temperature coefficient and is forced across resistor R1. This voltage is amplified and added to the

base-emitter voltage of Q2, which has a negative temperature coefficient. The resulting output voltage is virtually

independent of temperature. The short-circuit current is limited by design to approximately 100 mA.

pin. The internal reference output voltage is 2.5 V

BE1

www.ti.com

– V

BE2

) has

Figure 90. Bandgap Reference Simplified Schematic

28 Submit Documentation Feedback Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 29

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

www.ti.com

POWER-ON RESET

Power-On Reset to Zero-scale

The DAC7562, DAC8162, and DAC8562 contain a power-on-reset circuit that controls the output voltage during

power up. All device registers are reset as shown in Table 6. At power up all DAC registers are filled with zeros

and the output voltages of all DAC channels are set to zero volts. Each DAC channel remains that way until a

valid load command is written to it. The power-on reset is useful in applications where it is important to know the

state of the output of each DAC while the device is in the process of powering up. No device pin should be

brought high before power is applied to the device. The internal reference is disabled by default and remains that

way until a valid reference-change command is executed.

Power-On Reset to Mid-scale

The DAC7563, DAC8163, and DAC8563 contain a power-on reset circuit that controls the output voltage during

power up. At power up, all DAC registers are reset to mid-scale code and the output voltages of all DAC

channels are set to V

it. The power-on reset is useful in applications where it is important to know the state of the output of each DAC

while the device is in the process of powering up. No device pin should be brought high before power is applied

to the device. The internal reference is powered off/down by default and remains that way until a valid

reference-change command is executed. If using an external reference, it is acceptable to power on the V

either at the same time as or after AVDDis applied.

/2 volts. Each DAC channel remains that way until a valid load command is written to

REFIN

SLAS719C –AUGUST 2010– REVISED JUNE 2011

REFIN

Table 6. DACxx62 and DACxx63 Power-On Reset Values

REGISTER DEFAULT SETTING

DAC and Input registers

LDAC registers LDAC pin enabled for both channels

Power-down registers DACs powered up

Internal reference register Internal reference disabled

Gain registers Gain = 1 for both channels

DACxx62 Zero-scale

DACxx63 Mid-scale

CLR FUNCTIONALITY

The edge-triggered CLR pin can be used to set the input and DAC registers immediately according to Table 7.

When the CLR pin receives a falling edge signal the clear mode is activated and changes the DAC output

voltages accordingly. The part exits clear mode on the 24thfalling edge of the next write to the part. If the CLR

pin receives a falling edge signal during a write sequence in normal operation, the clear mode is activated and

changes the input and DAC registers immediately according to Table 7.

Table 7. Clear Mode Reset Values

DEVICE DAC Output Entering Clear Mode

DAC8562, DAC8162, DAC7562 Zero-scale

DAC8563, DAC8163, DAC7563 Mid-scale

Copyright © 2010–2011, Texas Instruments Incorporated Submit Documentation Feedback 29

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 30

CLK

SYNC

D

IN

Valid Write Sequence:

Output/Mode Updates on the Falling Edge

24th Falling Edge 24th Falling Edge

DB23

DB0

DB23

DB0

Invalid/Interrupted Write Sequence:

Output/Mode Does Not Update on the Falling Edge

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

SLAS719C –AUGUST 2010– REVISED JUNE 2011

SERIAL INTERFACE

The DAC756x, DAC816x, and DAC856x have a 3-wire serial interface (SYNC, SCLK, and DIN; see the Pin

Descriptions) compatible with SPI, QSPI, and Microwire interface standards, as well as most DSPs. See the

Serial Write Operation timing diagram (Figure 1) for an example of a typical write sequence.

The DAC756x, DAC816x, or DAC856x input shift register is 24-bits wide, consisting of two don’t care bits (DB23

to DB22), three command bits (DB21 to DB19), three address bits (DB18 to DB16), and 16 data bits (DB15 to

DB0). The 16 data bits comprise the 16-, 14-, or 12-bit input code. All 24 bits of data are loaded into the DAC

under the control of the serial clock input, SCLK. DB23 (MSB) is the first bit that is loaded into the DAC shift

register. It is followed by the rest of the 24-bit word pattern, left-aligned. This configuration means that the first 24

bits of data are latched into the shift register, and any further clocking of data is ignored. When the DAC registers

are being written to, the DAC756x, DAC816x, and DAC856x receive all 24 bits of data, ignore DB23 and DB22,

and decode the next three bits (DB21 to DB19) in order to determine the DAC operating/control mode (see

Table 8 through Table 10). Bits DB18 to DB16 are used to address DAC channels. The next 16/14/12 bits of

data that follow are decoded by the DAC to determine the equivalent analog output. For more details on these

and other commands (such as write to LDAC register, power down DACs, etc.), see their respective sections.

The data format is straight binary, with all 0s corresponding to 0-V output and all 1s corresponding to full-scale

output. For all documentation purposes, the data format and representation used here is a true 16-bit pattern

(that is, FFFFh data word for full scale) that the DAC756x, DAC816x, and DAC856x require.

The write sequence begins by bringing the SYNC line low. Data from the DINline are clocked into the 24-bit shift

register on each falling edge of SCLK. The serial clock frequency can be as high as 50 MHz, making the

DAC756x, DAC816x, and DAC856x compatible with high-speed DSPs. On the 24thfalling edge of the serial

clock, the last data bit is clocked into the shift register and the shift register locks. Further clocking does not

change the shift register data.

After receiving the 24thfalling clock edge, the DAC756x, DAC816x, and DAC856x decode the three command

bits and three address bits and 16/14/12 data bits to perform the required function, without waiting for a SYNC

rising edge. After the 24thfalling edge of SCLK is received, the SYNC line may be kept low or brought high. In

either case, the minimum delay time from the 24thfalling SCLK edge to the next falling SYNC edge must be met

in order to begin the next cycle properly; see the Serial Write Operation timing diagram (Figure 1).

A rising edge of SYNC before the 24-bit sequence is complete resets the SPI interface; no data transfer occurs.

A new write sequence starts at the next falling edge of SYNC. To assure the lowest power consumption of the

device, care should be taken that the levels are as close to each rail as possible.

www.ti.com

SYNC Interrupt

In a normal write sequence, the SYNC line stays low for at least 24 falling edges of SCLK and the addressed

DAC register updates on the 24thfalling edge. However, if SYNC is brought high before the 23rdfalling edge, it

acts as an interrupt to the write sequence; the shift register resets and the write sequence is discarded. Neither

an update of the data buffer contents, DAC register contents, nor a change in the operating mode occurs (as

shown in Figure 91).

30 Submit Documentation Feedback Copyright © 2010–2011, Texas Instruments Incorporated

Figure 91. SYNC Interrupt Facility

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 31

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

www.ti.com

Input Shift Register

The input shift register (SR) of the DAC856x, DAC816x, and DAC756x is 24 bits wide (as shown in Table 8,

Table 9, and Table 10, respectively), and consists of two don’t care bits (DB23 to DB22), three command bits

(DB21 to DB19), three address bits (DB18 to DB16), and 16 data bits (DB15 to DB0). The 16 data bits comprise

the 16-, 14-, or 12-bit input code.

Table 8. DAC856x Data Input Register Format

(1)

X

DB23 DB0

(1) X' denotes don't care bits.

Command Address Data

X C2 C1 C0 A2 A1 A0 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Table 9. DAC816x Data Input Register Format

Command Address Data

X X C2 C1 C0 A2 A1 A0 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0 X X

DB23 DB0

Table 10. DAC756x Data Input Register Format

Command Address Data

X X C2 C1 C0 A2 A1 A0 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0 X X X X

DB23 DB0

SLAS719C –AUGUST 2010– REVISED JUNE 2011

The DAC856x, DAC816x, and DAC756x support a number of different load commands. The load commands are

summarized in Table 11 and Table 12, and fully exhausted in Table 13.

Table 11. Commands for the DAC856x, DAC816x, and DAC756x

C2 C1 C0

(DB21) (DB20) (DB19)

0 0 0 Write to input register n (Table 12)

0 0 1 Software LDAC, update DAC register n (Table 12)

0 1 0 Write to input register n (Table 12) and update all DAC registers

0 1 1 Write to input register n and update DAC register n (Table 12)

1 0 0 Set DAC power up/down mode

1 0 1 Software reset

1 1 0 Set LDAC registers

1 1 1 Enable/disable internal reference

Command

Table 12. Address Select for the DAC856x, DAC816x, and DAC756x

A2 A1 A0

(DB18) (DB17) (DB16)

0 0 0 DAC-A

0 0 1 DAC-B

0 1 0 Gain (only use with command 000)

0 1 1 Reserved

1 0 0 Reserved

1 0 1 Reserved

1 1 0 Reserved

1 1 1 DAC-A and DAC-B

Channel (n)

Copyright © 2010–2011, Texas Instruments Incorporated Submit Documentation Feedback 31

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 32

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

SLAS719C –AUGUST 2010– REVISED JUNE 2011

Table 13. Command Matrix for the DAC856x, DAC816x, and DAC756x

DB23-

DB22

(1)

X

X 0 1 0 0 0 1 16/14/12 bit DAC data Write to DAC-B input register and update all DACs

X 0 1 1 0 0 1 16/14/12 bit DAC data Write to DAC-B input register and update DAC-B

X 0 0 1 0 0 1 X Update DAC-B

X 0 0 0 0 1 0 X

X 1 0 0 X X 0 0 X 1 0 Power up DAC-B

X 1 0 0 X X 0 1 X 1 0 Power down DAC-B; 1 kΩ to GND

X 1 0 0 X X 1 0 X 1 0 Power down DAC-B; 100 kΩ to GND

X 1 0 0 X X 1 1 X 1 0 Power down DAC-B; Hi-Z

X 1 0 1 X X

X 1 1 0 X X

X 1 1 1 X X

(1) X' denotes don't care bits.

Command Address Data

C2 C1 C0 A2 A1 A0 DB5 DB4 DB1 DB0

0 0 0 16/14/12 bit DAC data Write to DAC-A input register

0 0 0 0 0 1 16/14/12 bit DAC data Write to DAC-B input register

1 1 1 16/14/12 bit DAC data Write to DAC-A and DAC-B input registers

0 0 0 16/14/12 bit DAC data Write to DAC-A input register and update all DACs

1 1 1 16/14/12 bit DAC data Write to DAC-A and DAC-B input register and update all DACs

0 0 0 16/14/12 bit DAC data Write to DAC-A input register and update DAC-A

1 1 1 16/14/12 bit DAC data Write to DAC-A and DAC-B input register and update all DACs

0 0 0 X Update DAC-A

1 1 1 X Update all DACs

DB15- DB3-

DB6 DB2

0 0 Gain: DAC-B gain = 2, DAC-A gain = 2 (default with internal V

0 1 Gain: DAC-B gain = 2, DAC-A gain = 1

1 0 Gain: DAC-B gain = 1, DAC-A gain = 2

1 1 Gain: DAC-B gain = 1, DAC-A gain = 1 (power-on default)

0 1 Power up DAC-A

1 1 Power up DAC-A and DAC-B

0 1 Power down DAC-A; 1 kΩ to GND

1 1 Power down DAC-A and DAC-B; 1 kΩ to GND

0 1 Power down DAC-A; 100 kΩ to GND

1 1 Power down DAC-A and DAC-B; 100 kΩ to GND

0 1 Power down DAC-A; Hi-Z

1 1 Power down DAC-A and DAC-B; Hi-Z

X 0 Reset DAC-A and DAC-B input register and update all DACs

X 1 Reset all registers and update all DACs (Power-on-reset update)

0 0 LDAC pin active for DAC-B and DAC-A

0 1 LDAC pin active for DAC-B; inactive for DAC-A

1 0 LDAC pin inactive for DAC-B; active for DAC-A

1 1 LDAC pin inactive for DAC-B and DAC-A

X 0 Disable internal reference and reset DACs to gain = 1

X 1 Enable Internal Reference & reset DACs to gain = 2

DESCRIPTION

www.ti.com

)

REF

32 Submit Documentation Feedback Copyright © 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): DAC8562 DAC8563 DAC8162 DAC8163 DAC7562 DAC7563

Page 33

IN

O UT REF

n

D

V = V Gain

2

æ ö

´ ´

ç ÷

è ø

DAC8562, DAC8563

DAC8162, DAC8163

DAC7562, DAC7563

www.ti.com

GAIN REGISTERS

The gain register controls the GAIN setting in the DAC transfer function: