Texas Instruments BQ24650 Datasheet

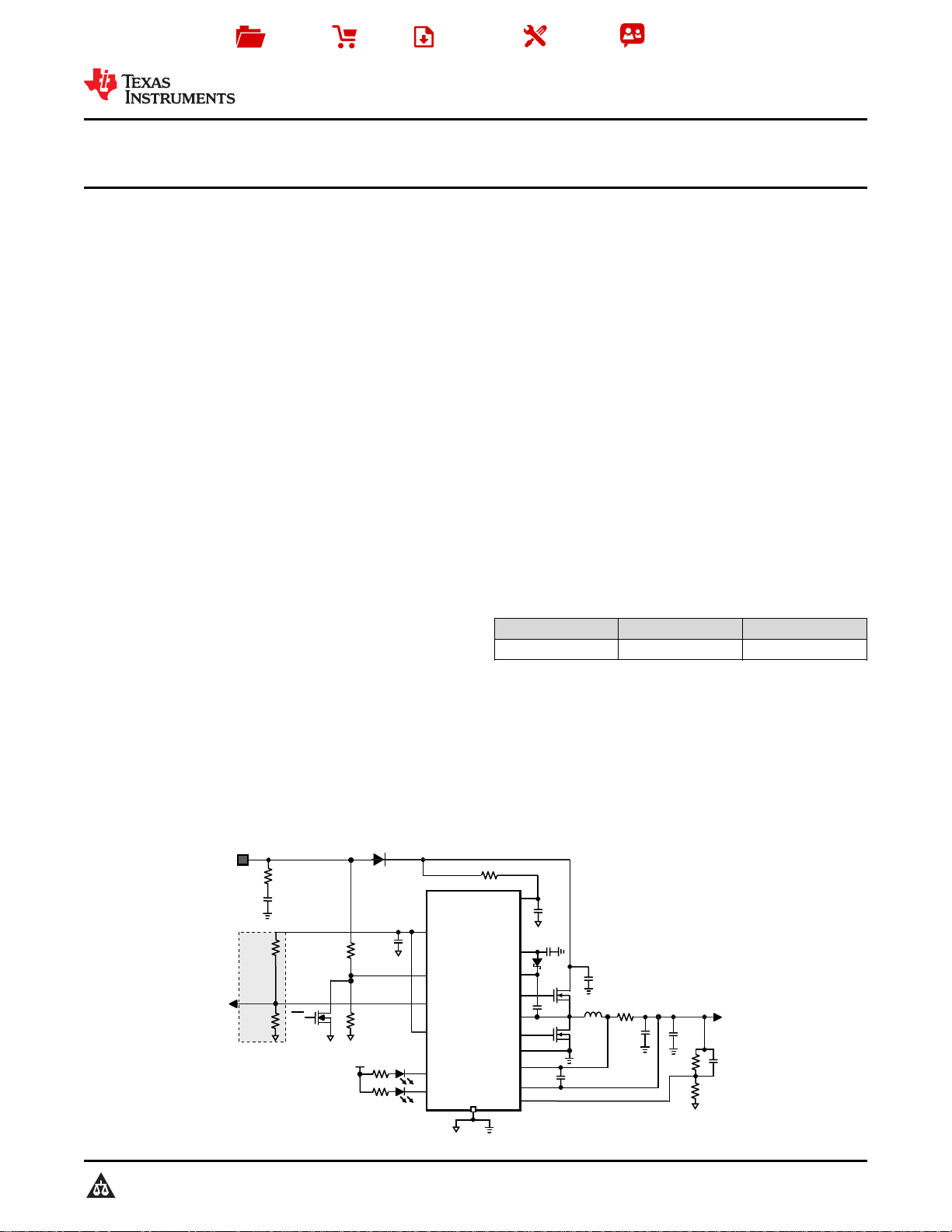

VCC

REGN

BTST

HIDRV

PH

LODRV

GND

SRP

SRN

VFB

VREF

MPPSET

TS

TERM_EN

STAT1

STAT2

Q2

L

C9

R

SR

BQ24650

C6

Q1

C1

Solar Cell

Half Panel

C8

Battery Pack

C7

C4

C3

C2

C10

R2

R1

R3

R4

R9

R10

Pack

Thermistor

R7

R8

VIN

R5

R6

CE

VIN

D3

D4

D2

C5

D1

Q3

Thermal

Pad

Product

Folder

Order

Now

Technical

Documents

Tools &

Software

Support &

Community

BQ24650

SLUSA75B –JULY 2010–REVISED JANUARY 2020

BQ24650 Stand-Alone Synchronous Buck Battery Charge Controller for Solar Power

With Maximum Power Point Tracking

1 Features

1

• Maximum Power Point Tracking (MPPT) capability

by input Voltage regulation

• Programmable MPPT setting

• 5-V to 28-V Input solar panel

• 600-kHz NMOS-NMOS Synchronous buck

controller

• Resistor programmable float voltage

• Accommodates Li-Ion/Polymer, LiFePO4, lead

acid chemistries

• Accuracy

– ±0.5% Charge voltage regulation

– ±3% Charge current regulation

– ±0.6% Input voltage regulation

• High Integration

– Internal loop compensation

– Internal digital soft start

• Safety

– Input overvoltage protection

– Battery temperature-sensing

– Battery absent detection

– Thermal shutdown

• Charge status outputs for LED or host processor

• Charge enable on MPPSET pin

• Automatic sleep mode for low power consumption

– < 15-μA OFF-state battery discharge current

• Small 3.5 × 3.5 mm216-pin QFN package

2 Applications

• Solar-powered applications

• Remote monitoring stations

• Portable handheld instruments

• 12-V to 24-V Automotive systems

• Current-limited power source

3 Description

The BQ24650 device is a highly integrated switchmode battery charge controller. It provides input

voltage regulation, which reduces charge current

when input voltage falls below a programmed level.

When the input is powered by a solar panel, the input

regulation loop lowers the charge current so that the

solar panel can provide maximum power output.

The BQ24650 offers a constant-frequency

synchronous PWM controller with high accuracy

current and voltage regulation, charge

preconditioning, charge termination, and charge

status monitoring.

Device Information

PART NUMBER PACKAGE BODY SIZE (NOM)

BQ24650 VQFN (16) 3.50 mm × 3.50 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

(1)

Typical Application

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

BQ24650

SLUSA75B –JULY 2010–REVISED JANUARY 2020

www.ti.com

Table of Contents

1 Features.................................................................. 1

2 Applications ........................................................... 1

3 Description ............................................................. 1

4 Revision History..................................................... 2

5 Description (continued)......................................... 3

6 Pin Configuration and Functions......................... 4

7 Specifications......................................................... 5

7.1 Absolute Maximum Ratings ...................................... 5

7.2 ESD Ratings.............................................................. 5

7.3 Recommended Operating Conditions....................... 5

7.4 Thermal Information.................................................. 6

7.5 Electrical Characteristics........................................... 6

7.6 Typical Characteristics............................................ 10

8 Detailed Description............................................ 12

8.1 Overview ................................................................. 12

8.2 Functional Block Diagram....................................... 12

8.3 Feature Description................................................. 12

8.4 Device Functional Modes........................................ 21

9 Application and Implementation ........................ 23

9.1 Application Information............................................ 23

9.2 Typical Application ................................................. 23

10 Power Supply Recommendations..................... 29

11 Layout................................................................... 29

11.1 Layout Guidelines ................................................. 29

11.2 Layout Example .................................................... 30

12 Device and Documentation Support ................. 31

12.1 Device Support...................................................... 31

12.2 Receiving Notification of Documentation Updates 31

12.3 Support Resources ............................................... 31

12.4 Trademarks........................................................... 31

12.5 Electrostatic Discharge Caution............................ 31

12.6 Glossary................................................................ 31

13 Mechanical, Packaging, and Orderable

Information........................................................... 31

4 Revision History

Changes from Revision A (April 2016) to Revision B Page

• Changed Title ........................................................................................................................................................................ 1

• Deleted Component Values from Typical Application on Page 1. ......................................................................................... 1

Changes from Original (July 2010) to Revision A Page

• Added ESD Ratings table, Feature Description section, Device Functional Modes, Application and Implementation

section, Power Supply Recommendations section, Layout section, Device and Documentation Support section, and

Mechanical, Packaging, and Orderable Information section.................................................................................................. 1

• Removed Ordering Information table .................................................................................................................................... 1

2

Submit Documentation Feedback Copyright © 2010–2020, Texas Instruments Incorporated

Product Folder Links: BQ24650

BQ24650

www.ti.com

SLUSA75B –JULY 2010–REVISED JANUARY 2020

5 Description (continued)

The BQ24650 charges the battery in three phases: pre-conditioning, constant current, and constant voltage.

Charge is terminated when the current reaches 1/10 of the fast charge rate. The pre-charge timer is fixed at 30

minutes. The BQ24650 automatically restarts the charge cycle if the battery voltage falls below an internal

threshold and enters a low quiescent current sleep mode when the input voltage falls below the battery voltage.

The BQ24650 supports a battery from 2.1 V to 26 V with VFB set to a 2.1-V feedback reference. The charge

current is programmed by selecting an appropriate sense resistor. The BQ24650 is available in a 16 -pin, 3.5 mm

× 3.5 mm2thin QFN package.

Product Folder Links: BQ24650

Submit Documentation FeedbackCopyright © 2010–2020, Texas Instruments Incorporated

3

ThermalPad

16 BTST5STAT2

1VCC 12 REGN

15 HIDRV6VREF

2MPPSET 11 GND

14 PH7TERM_EN

3STAT1 10 SRP

13 LODRV8VFB

4TS 9 SRN

BQ24650

SLUSA75B –JULY 2010–REVISED JANUARY 2020

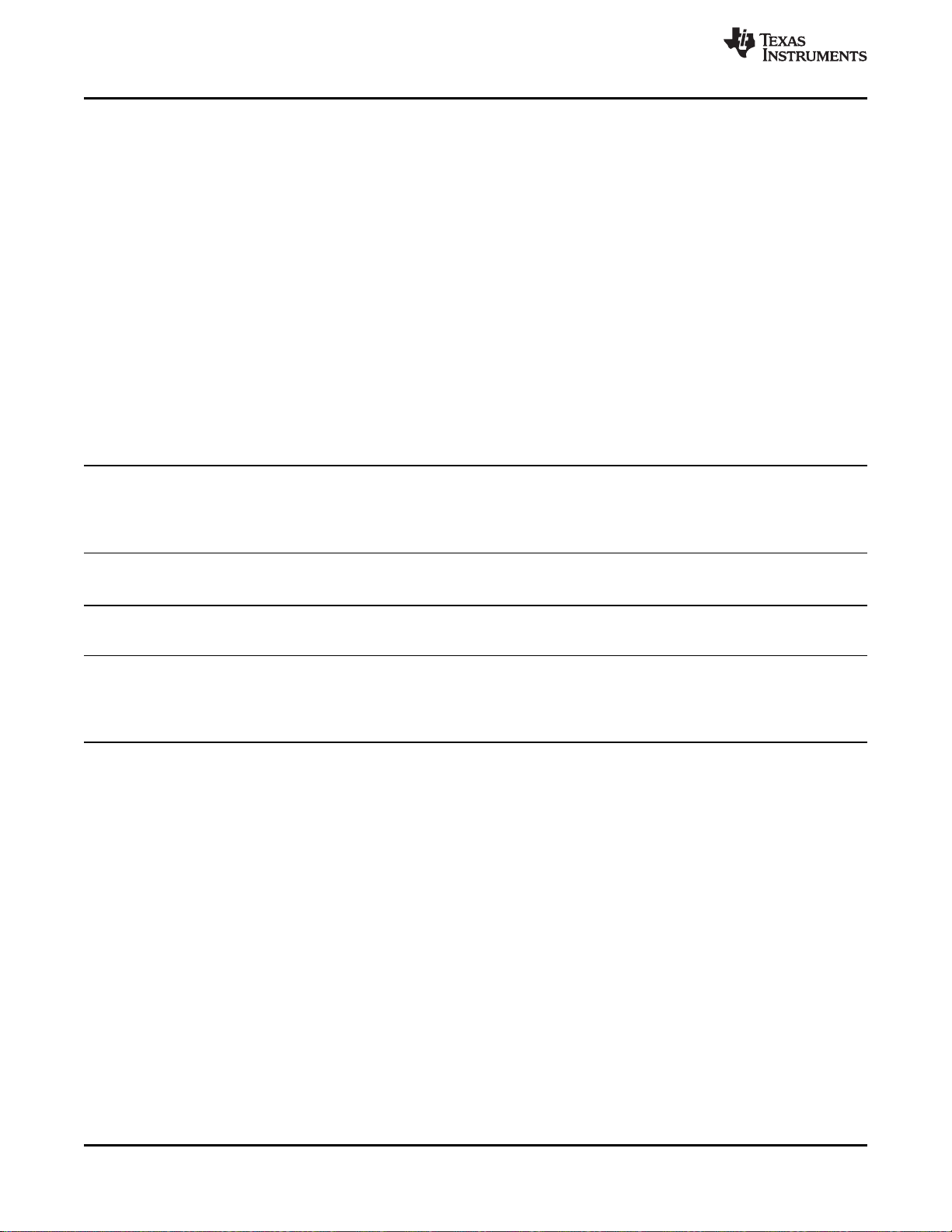

6 Pin Configuration and Functions

www.ti.com

RVA Package

16-Pin VQFN

Top View

PIN

NO. NAME

1 VCC P

2 MPPSET I

TYPE DESCRIPTION

IC power positive supply. Place a 1-μF ceramic capacitor from VCC to GND and place it as close as

possible to IC. Place a 10-Ω resistor from input side to VCC pin to filter the noise.

Input voltage set point. Use a voltage divider from input source to GND to set voltage on MPPSET to 1.2

V. To disable charge, pull MPPSET below 75 mV.

Open-drain charge status output to indicate various charger operation. Connect to the cathode of LED

3 STAT1 O

with 10 kΩ to the pullup rail. LOW or LED light up indicates charge in progress. Otherwise stays HI or

LED stays off. When any fault condition occurs, both STAT1 and STAT2 are HI, or both LEDs are off.

Temperature qualification voltage input. Connect to a negative temperature coefficient thermistor.

4 TS I

Program the hot and cold temperature window with a resistor divider from VREF to TS to GND. A 103AT2 thermister is recommended.

Open-drain charge status output to indicate various charger operation. Connect to the cathode of LED

5 STAT2 O

with 10 kΩ to the pullup rail. LOW or LED light up indicates charge is complete. Otherwise, stays HI or

LED stays off. When any fault condition occurs, both STAT1 and STAT2 are HI, or both LEDs are off.

6 VREF P

7 TERM_EN I

8 VFB I

3.3-V reference voltage output. Place a 1-μF ceramic capacitor from VREF to GND pin close to the IC.

This voltage could be used for programming voltage on TS and the pullup rail of STAT1 and STAT2.

Charge termination enable. Pull TERM_EN to GND to disable charge termination. Pull TERM_EN to

VREF to allow charge termination. TERM_EN must be terminated and cannot be left floating.

Charge voltage analog feedback adjustment. Connect the output of a resistor divider powered from the

battery terminals to this node to adjust the output battery voltage regulation.

Charge current sense resistor, negative input. A 0.1-μF ceramic capacitor is placed from SRN to SRP to

9 SRN I

10 SRP P/I

11 GND P

provide differential-mode filtering. An optional 0.1-μF ceramic capacitor is placed from SRN to GND for

common-mode filtering.

Charge current sense resistor, positive input. A 0.1-μF ceramic capacitor is placed from SRN to SRP to

provide differential-mode filtering. A 0.1-μF ceramic capacitor is placed from SRP to GND for commonmode filtering.

Power ground. Ground connection for high-current power converter node. On PCB layout, connect

directly to source of low-side power MOSFET, to ground connection of input and output capacitors of the

charger. Only connect to GND through the thermal pad underneath the IC.

Pin Functions

4

Submit Documentation Feedback Copyright © 2010–2020, Texas Instruments Incorporated

Product Folder Links: BQ24650

BQ24650

www.ti.com

SLUSA75B –JULY 2010–REVISED JANUARY 2020

Pin Functions (continued)

PIN

NO. NAME

12 REGN P

13 LODRV O

14 PH P

15 HIDRV O

16 BTST P PWM high-side driver positive supply. Connect the 0.1-µF bootstrap capacitor from PH to BTST.

—

Thermal

Pad

TYPE DESCRIPTION

PWM low-side driver positive 6-V supply output. Connect a 1-μF ceramic capacitor from REGN to GND,

close to the IC. Use to drive low-side driver and high-side driver bootstrap Schottky diode from REGN to

BTST.

PWM low-side driver output. Connect to the gate of the low-side N-channel power MOSFET with a short

trace.

Switching node, charge current output inductor connection. Connect the 0.1-μF bootstrap capacitor from

PH to BTST.

PWM high-side driver output. Connect to the gate of the high-side N-channel power MOSFET with a short

trace.

Exposed pad beneath the IC. The thermal pad must always be soldered to the board and have the vias

—

on the thermal pad plane star-connecting to GND and ground plane for high-current power converter. It

also serves as a thermal pad to dissipate heat.

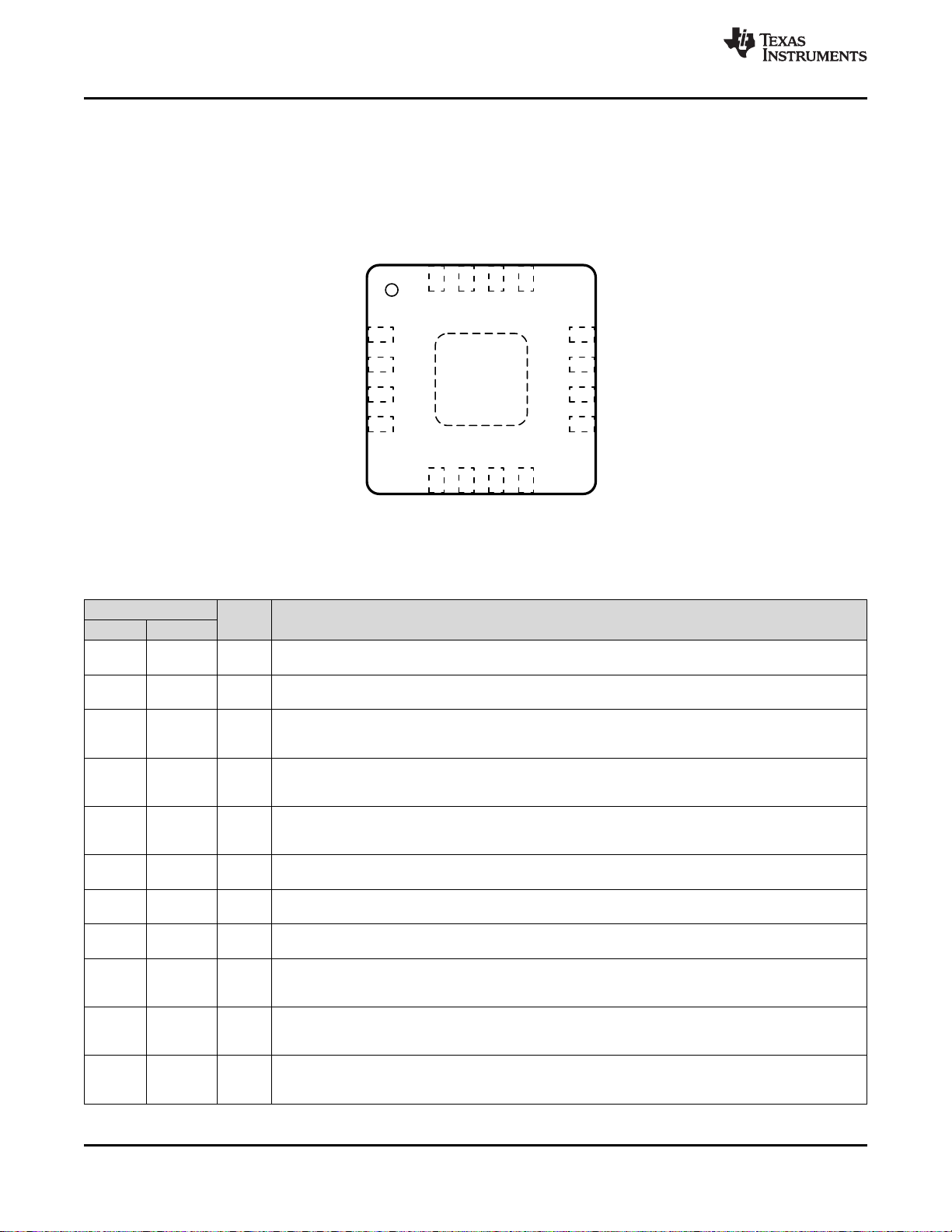

7 Specifications

7.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)

VCC, STAT1, STAT2, SRP, SRN –0.3 33

PH –2 36

Voltage (with respect to GND)

Maximum difference voltage SRP–SRN –0.5 0.5 V

Junction temperature, T

Storage temperature, T

(1) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under Recommended Operating

Conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltages are with respect to GND if not specified. Currents are positive into, negative out of the specified terminal. Consult Packaging

Section of the data book for thermal limitations and considerations of packages.

(3) Must have a series resistor between battery pack to VFB if battery pack voltage is expected to be greater than 16 V. Usually the resistor

divider top resistor takes care of this.

J

stg

VFB –0.3 16

REGN, LODRV, TS, MPPSET, TERM_EN –0.3 7

BTST, HIDRV with respect to GND –0.3 39

VREF –0.3 3.6

(1)(2)(3)

MIN MAX UNIT

V

–40 155 °C

–55 155 °C

7.2 ESD Ratings

V

(ESD)

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(2) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

Electrostatic discharge

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001

Charged-device model (CDM), per JEDEC specification JESD22-C101

(1)

(2)

7.3 Recommended Operating Conditions

MIN MAX UNIT

VCC, STAT1, STAT2, SRP, SRN –0.3 28

PH –2 30

Voltage range (with respect to

GND)

VFB –0.3 14

REGN, LODRV, TS, MPPSET, TERM_EN –0.3 6.5

BTST, HIDRV with respect to GND –0.3 34

VREF 3.3

Submit Documentation FeedbackCopyright © 2010–2020, Texas Instruments Incorporated

Product Folder Links: BQ24650

VALUE UNIT

±2000

±500

V

V

5

BQ24650

SLUSA75B –JULY 2010–REVISED JANUARY 2020

www.ti.com

Recommended Operating Conditions (continued)

MIN MAX UNIT

Maximum difference voltage SRP–SRN –0.2 0.2 V

Junction temperature, T

J

–40 125 °C

7.4 Thermal Information

BQ24650

THERMAL METRIC

R

θJA

R

θJC(top)

R

θJB

ψ

JT

ψ

JB

R

θJC(bot)

Junction-to-ambient thermal resistance

Junction-to-case (top) thermal resistance 81 °C/W

Junction-to-board thermal resistance 16 °C/W

Junction-to-top characterization parameter

Junction-to-board characterization parameter

Junction-to-case (bottom) thermal resistance 4 °C/W

(1) For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report, SPRA953.

(2) The junction-to-ambient thermal resistance under natural convection is obtained in a simulation on a JEDEC-standard, high-K board, as

specified in JESD51-7, in an environment described in JESD51-2a

(3) The junction-to-top characterization parameter, ψJT, estimates the junction temperature of a device in a real system and is extracted

from the simulation data for obtaining R

(4) The junction-to-board characterization parameter, ψJB, estimates the junction temperature of a device in a real system and is extracted

from the simulation data for obtaining R

, using a procedure described in JESD51-2a (sections 6 and 7).

θJA

, using a procedure described in JESD51-2a (sections 6 and 7).

θJA

(1)

UNITRVA (VQFN)

16 PINS

(2)

(3)

(4)

43.8 °C/W

0.6 °C/W

15.77 °C/W

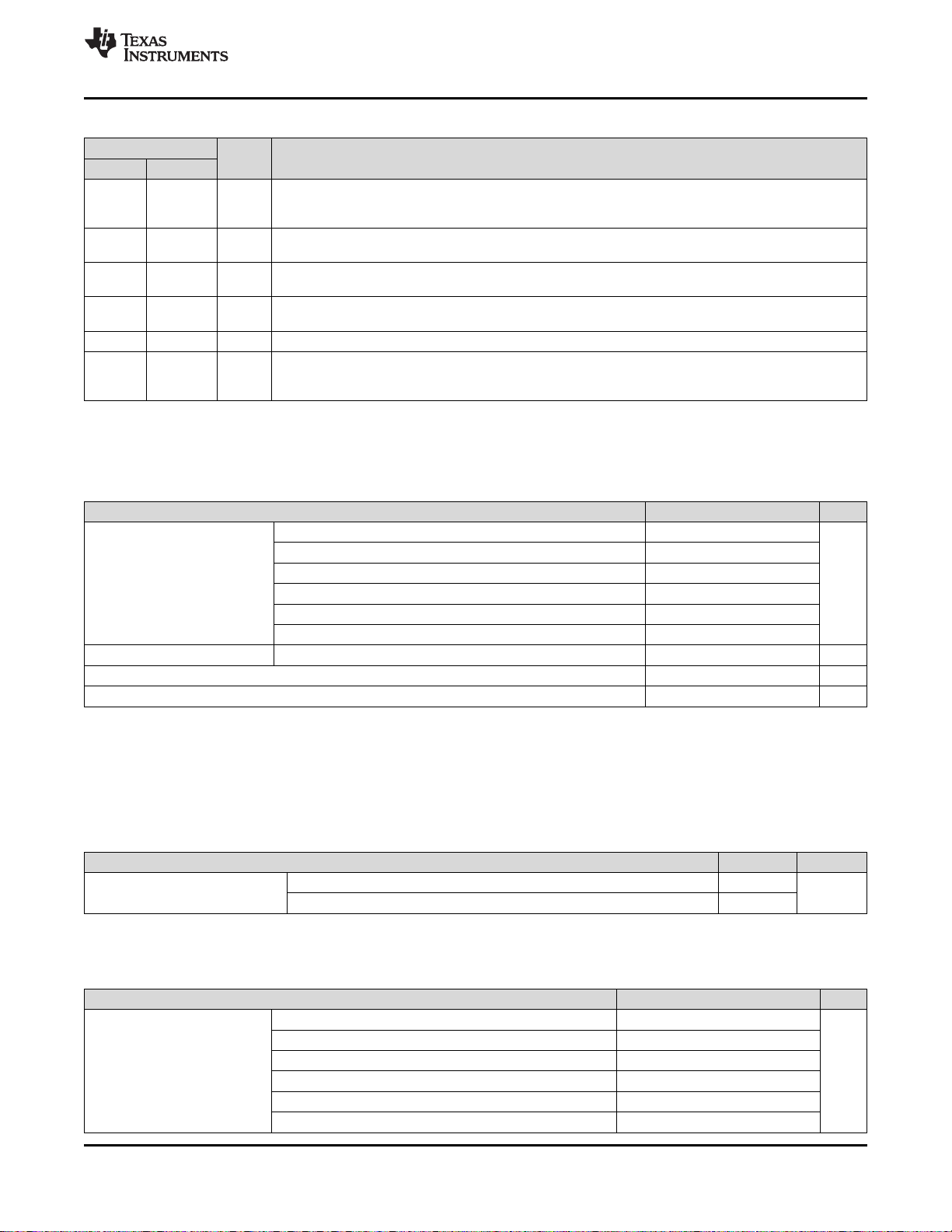

7.5 Electrical Characteristics

5 V ≤ V

OPERATING CONDITIONS

V

VCC_OP

QUIESCENT CURRENTS

I

BAT

I

AC

CHARGE VOLTAGE REGULATION

V

REG

I

VFB

CURRENT REGULATION – FAST CHARGE

V

IREG_CHG

CURRENT REGULATION – PRE-CHARGE

V

PRECHG

≤ 28 V, –40°C < TJ+ 125°C, typical values are at TA= 25°C, with respect to GND (unless otherwise noted)

VCC

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

VCC input voltage operating range 5 28 V

Total battery discharge current (sum of

currents into VCC, BTST, PH, SRP,

SRN, VFB), VFB ≤ 2.1V

Battery discharge current (sum of

currents into BTST, PH, SRP, SRN,

VFB), VFB ≤ 2.1V

Adapter supply current (sum of current

into VCC pin)

Feedback regulation voltage 2.1 V

Charge voltage regulation accuracy

Leakage current into VFB pin VFB = 2.1 V 100 nA

SRP-SRN current sense voltage range V

Charge current regulation accuracy V

Precharge current sense voltage

range

VCC < VBAT, VCC > V

VCC > VBAT, VCC > V

VCC > VBAT, VCC > V

CE = HIGH, Charge done

VCC > VBAT, VCC > V

VCC > VBAT, VCC > V

CE = HIGH, charge done

VCC > VBAT, VCC > V

CE = HIGH, Charging, Qg_total = 10 nC

(SLEEP) 15 µA

UVLO

, CE = LOW 5 µA

UVLO

VCCLOWV

UVLO

VCCLOWV

VCCLOWV

,

, CE = LOW 0.7 1 mA

,

2 3 mA

,

25 mA

[1]

TJ= 0°C to 85°C –0.5% 0.5%

TJ= –40°C to 125°C –0.7% 0.7%

= V

IREG_CHG

IREG_CHG

V

IREG_PRCHG

– V

SRP

SRN

= 40 mV –3% 3%

= V

– V

SRP

SRN

40 mV

4 mV

5 µA

6

Submit Documentation Feedback Copyright © 2010–2020, Texas Instruments Incorporated

Product Folder Links: BQ24650

www.ti.com

Electrical Characteristics (continued)

BQ24650

SLUSA75B –JULY 2010–REVISED JANUARY 2020

5 V ≤ V

≤ 28 V, –40°C < TJ+ 125°C, typical values are at TA= 25°C, with respect to GND (unless otherwise noted)

VCC

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Precharge current regulation accuracy V

IREG_PRECH

CHARGE TERMINATION

V

TERMCHG

Termination current sense voltage

range

Termination current accuracy V

V

ITERM

ITERM

Deglitch time for termination (both

edges)

t

QUAL

I

QUAL

Termination qualification time V

Termination qualification current

BAT

Discharge current once termination is

detected

INPUT VOLTAGE REGULATION

V

MPPSET

MPPSET regulation voltage 1.2 V

Input voltage regulation accuracy –0.6% 0.6%

I

MPPSET

V

MPPSET_CD

V

MPPSET_CE

Leakage current into MPPSET pin V

MPPSET

MPPSET shorted to disable charge 75 mV

MPPSET released to enable charge 175 mV

INPUT UNDERVOLTAGE LOCKOUT COMPARATOR (UVLO)

V

UVLO

V

UVLO_HYS

AC undervoltage rising threshold Measure on VCC 3.65 3.85 4 V

AC undervoltage hysteresis, falling 350 mV

VCC LOWV COMPARATOR

V

VCC LOWV_fall

V

VCC LOWV_rise

Falling threshold, disable charge Measure on VCC 4.1 V

Rising threshold, resume charge 4.35 V

SLEEP COMPARATOR (REVERSE DISCHARGING PROTECTION)

V

SLEEP _FALL

V

SLEEP_HYS

SLEEP falling threshold V

VCC

SLEEP hysteresis 500 mV

SLEEP rising shutdown deglitch VCC falling below SRN 100 ms

SLEEP falling powerup deglitch

VCC rising above SRN, Delay to exit

SLEEP mode

BAT LOWV COMPARATOR

V

LOWV

V

LOWV_HYS

Precharge to fast charge transition

(LOWV threshold)

Measure on VFB pin 1.54 1.55 1.56 V

LOWV hysteresis 100 mV

LOWV rising deglitch VFB falling below V

LOWV falling deglitch VFB rising above V

RECHARGE COMPARATOR

V

RECHG

Recharge threshold (with respect to

V

)

REG

Measure on VFB pin 35 50 65 mV

Recharge rising deglitch VFB decreasing below V

Recharge falling deglitch VFB increasing above V

BAT OVERVOLTAGE COMPARATOR

V

OV_RISE

V

OV_FALL

Overvoltage rising threshold As percentage of V

Overvoltage falling threshold As percentage of V

INPUT OVERVOLTAGE COMPARATOR (ACOV)

V

ACOV

V

ACOV_HYS

AC overvoltage rising threshold on

VCC

AC overvoltage falling hysteresis 1 V

AC overvoltage deglitch (both edges) Delay to changing the STAT pins 1 ms

AC overvoltage rising deglitch Delay to disable charge 1 ms

= 4 mV –25% 25%

= V

SRP

– V

SRN

4 mV

= 4 mV –25% 25%

100 ms

> V

RECH

and I

CHG

< I

TERM

250 ms

2 mA

= 7 V, TA= 0 – 85°C 1 µA

– V

to enter SLEEP 40 100 150 mV

SRN

30 ms

LOWV

LOWV

FB

FB

+ V

RECHG

RECHG

LOWV_HYS

25 ms

25 ms

10 ms

10 ms

104%

102%

31 32 33 V

Product Folder Links: BQ24650

Submit Documentation FeedbackCopyright © 2010–2020, Texas Instruments Incorporated

7

BQ24650

SLUSA75B –JULY 2010–REVISED JANUARY 2020

Electrical Characteristics (continued)

www.ti.com

5 V ≤ V

≤ 28 V, –40°C < TJ+ 125°C, typical values are at TA= 25°C, with respect to GND (unless otherwise noted)

VCC

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

AC overvoltage falling deglitch Delay to resume charge 20 ms

THERMAL SHUTDOWN COMPARATOR

T

SHUT

T

SHUT_HYS

Thermal shutdown rising temperature Temperature increasing 145 °C

Thermal shutdown hysteresis 15 °C

Thermal shutdown rising deglitch Temperature increasing 100 µs

Thermal shutdown falling deglitch Temperature decreasing 10 ms

THERMISTOR COMPARATOR

V

LTF

V

LTF_HYS

V

HTF

V

TCO

Cold temperature rising threshold

Rising hysteresis 0.2% 0.4% 0.6%

Hot temperature rising threshold 46.7% 47.5% 48.3%

As percentage to V

Cut-off temperature rising threshold 44.3% 45% 45.7%

Deglitch time for temperature out of

range detection

Deglitch time for temperature in valid

range detection

VTS< V

VTS< V

VTS> V

VTS> V

CHARGE OVERCURRENT COMPARATOR (CYCLE-BY-CYCLE)

V

OC

Charge overcurrent rising threshold

Current rising, in synchronous mode

measure (V

CHARGE UNDERCURRENT COMPARATOR (CYCLE-BY-CYCLE)

V

ISYNSET

Charge undercurrent falling threshold Switch from CCM to DCM, V

BATTERY-SHORTED COMPARATOR (BATSHORT)

V

BATSHT

V

BATSHT_HYS

t

BATSHT_DEG

BAT short falling threshold, forced

non-synchronous mode

V

SRP

BAT short rising hysteresis 200 mV

Deglitch on both edges 1 µs

LOW CHARGE CURRENT COMPARATOR

V

LC

V

LC_HYS

t

LC_DEG

Low charge current falling threshold Measure V

Low charge current rising hysteresis 1.25 mV

Deglitch on both edges 1 µs

VREF REGULATOR

V

VREF_REG

I

VREF_LIM

VREF regulator voltage V

VREF current limit V

VCC

VREF

REGN REGULATOR

V

REGN_REG

I

REGN_LIM

REGN regulator voltage V

REGN current limit

VCC

V

REGN

75 mV

BATTERY DETECTION

t

WAKE

I

WAKE

t

DISCHARGE

I

DISCHARGE

I

FAULT

I

QUAL

t

QUAL

V

WAKE

V

DISCH

Wake timer Max time charge is enabled 500 ms

Wake current R

SENSE

Discharge timer Max time discharge current is applied 1 sec

Discharge current 6 mA

Fault current after a timeout fault 2 mA

Termination qualification current 2 mA

Termination qualification time 250 ms

Wake threshold (with respect to V

Discharge threshold

Voltage on VFB to detect battery absent

)

REG

during wake

Voltage on VFB to detect battery absent

during discharge

72.5% 73.5% 74.5%

VREF

, or VTS< V

LTF

HTF

– V

LTF

HTF

SRP

LTF_HYS

– V

TCO

or VTS>V

)

SRN

, or

TCO

, or

400 ms

20 ms

80 mV

> 2.2V 1 5 9 mV

SRP

falling 2 V

(SRP-SRN)

> V

, 0 – 35 mA load 3.267 3.3 3.333 V

UVLO

= 0 V, V

VCC

> V

UVLO

1.25 mV

35 mA

> 10 V, MPPSET > 175 mV 5.7 6.0 6.3 V

= 0 V, V

VCC

> V

, MPPSET <

UVLO

40 mA

= 10 mΩ 50 125 200 mA

50 mV

1.55 V

8

Submit Documentation Feedback Copyright © 2010–2020, Texas Instruments Incorporated

Product Folder Links: BQ24650

www.ti.com

Electrical Characteristics (continued)

BQ24650

SLUSA75B –JULY 2010–REVISED JANUARY 2020

5 V ≤ V

≤ 28 V, –40°C < TJ+ 125°C, typical values are at TA= 25°C, with respect to GND (unless otherwise noted)

VCC

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

PWM HIGH-SIDE DRIVER (HIDRV)

R

DS_HI_ON

R

DS_HI_OFF

V

BTST_REFRESH

High-side driver (HSD) turnon

resistance

VBTST – VPH = 5.5 V 3.3 6 Ω

High-side driver turnoff resistance 1 1.4 Ω

Bootstrap refresh comparator

threshold Voltage

VBTST – VPH when low side refresh pulse

is requested

PWM LOW-SIDE DRIVER (LODRV)

R

DS_LO_ON

R

DS_LO_OFF

Low-side driver (LSD) turn-on

resistance

Low-side driver turn-off resistance 1 1.4 Ω

PWM DRIVERS TIMING

Driver dead-time

Dead time when switching between LSD

and HSD, No load at LSD and HSD

PWM OSCILLATOR

V

RAMP_HEIGHT

PWM ramp height As percentage of VCC 7%

PWM switching frequency 510 600 690 kHz

INTERNAL SOFT START (8 STEPS TO REGULATION CURRENT ICHG)

Soft-start steps 8 step

Soft-start step time 1.6 ms

CHARGER SECTION POWER-UP SEQUENCING

Charge-enable delay after power-up

Delay from MPPSET > 175 mV to charger

is allowed to turn on

LOGIC IO PIN CHARACTERISTICS (STAT1, STAT2, TERM_EN)

V

OUT_LOW

I

OUT_HI

V

IN_LOW

V

IN_HI

I

IN_BIAS

STAT1, STAT2 output low saturation

voltage

Sink current = 5 mA 0.5 V

Leakage current V = 32 V 1.2 µA

TERM_EN input low threshold voltage 0.4 V

TERM_EN input high threshold

voltage

TERM_EN bias current V

TERM_EN

= 0.5 V 60 µA

4.0 4.2 V

4.1 7 Ω

30 ns

1.5 s

1.6 V

Product Folder Links: BQ24650

Submit Documentation FeedbackCopyright © 2010–2020, Texas Instruments Incorporated

9

HIDRV

20V/div

LODRV

5V/div

PH

20V/div

IL

1A/div

200 ns/div

HIDRV

20V/div

LODRV

5V/div

PH

20V/div

IL

1A/div

100 ns/div

MPPSET

1V/div

LODRV

5V/div

PH

20V/div

IBAT

1A/div

10 s/divm

MPPSET

1V/div

LODRV

5V/div

PH

20V/div

IBAT

1A/div

4 ms/div

400 ms/div

MPPSET

1V/div

LODRV

5V/div

PH

20V/div

IBAT

1A/div

VCC

10V/div

VREF

2V/div

REGN

5V/div

STAT1

20V/div

800 s/divm

BQ24650

SLUSA75B –JULY 2010–REVISED JANUARY 2020

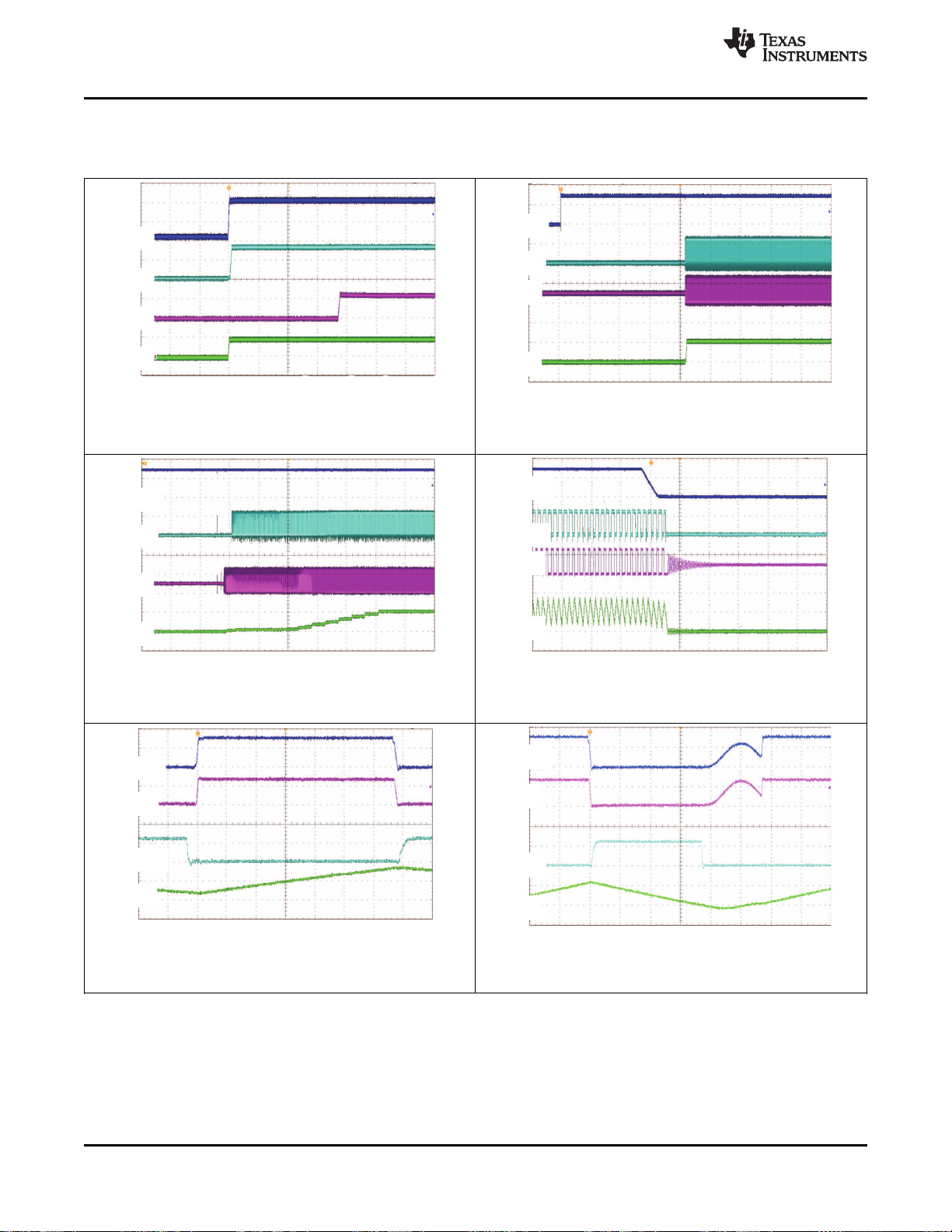

7.6 Typical Characteristics

VCC= 25 V, BQ24650 application circuit, TA= 25°C unless otherwise noted

www.ti.com

Figure 1. Power Up on V

CC

Figure 3. Charge Soft Start on MPPSET

Figure 2. Charge Start on MPPSET

Figure 4. Charge Stop on MPPSET

10

Figure 5. Switching in Continuous Conduction Mode

Figure 6. Switching in Discontinuous Conduction Mode

Submit Documentation Feedback Copyright © 2010–2020, Texas Instruments Incorporated

Product Folder Links: BQ24650

HIDRV

20V/div

LODRV

5V/div

PH

20V/div

IL

1A/div

400 s/divm

HIDRV

20V/div

LODRV

5V/div

PH

20V/div

IL

1A/div

100 ns/div

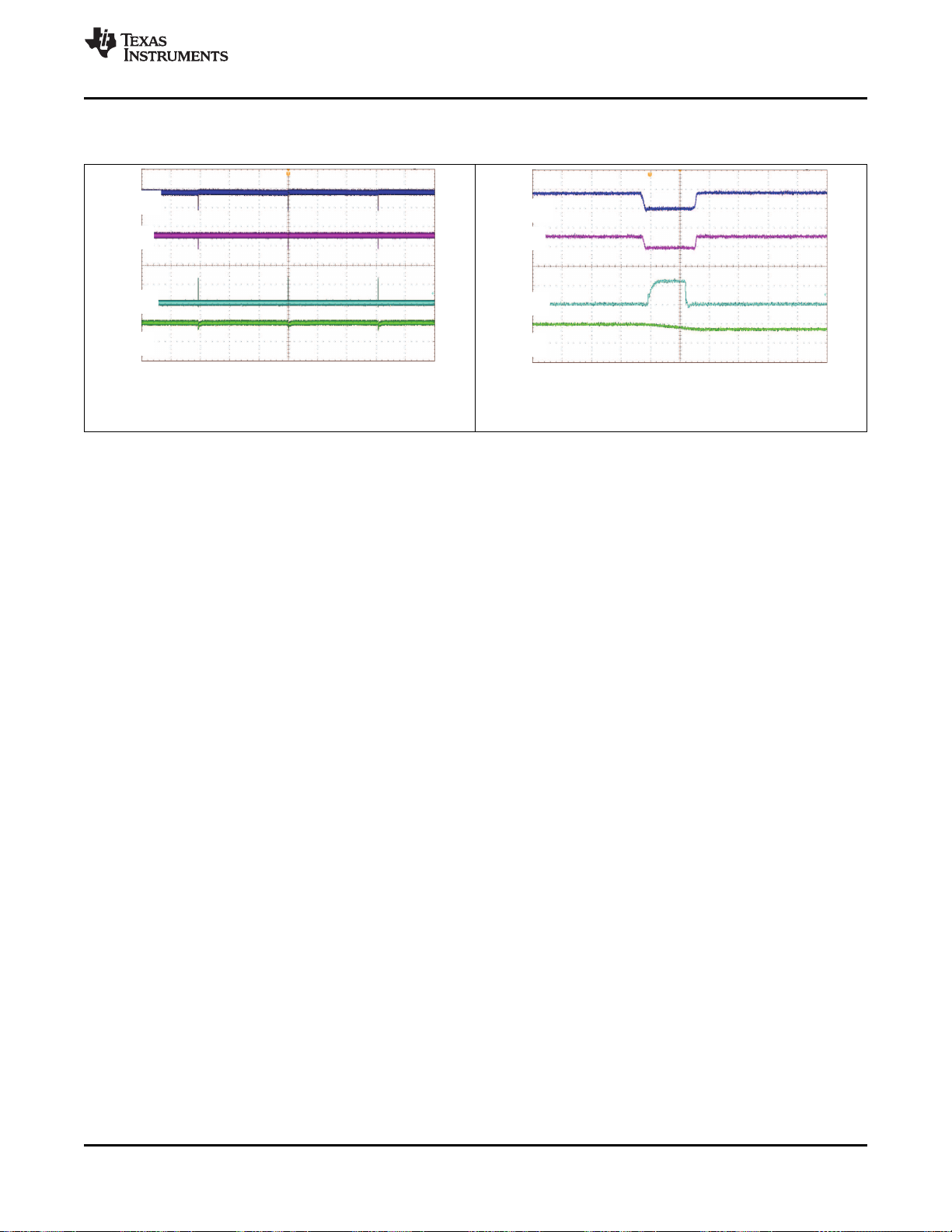

www.ti.com

Typical Characteristics (continued)

VCC= 25 V, BQ24650 application circuit, TA= 25°C unless otherwise noted

BQ24650

SLUSA75B –JULY 2010–REVISED JANUARY 2020

Figure 7. Switching at 100% Duty Cycle

Figure 8. Recharge the BTST-PH Capacitor

Product Folder Links: BQ24650

Submit Documentation FeedbackCopyright © 2010–2020, Texas Instruments Incorporated

11

VCC

BTST

HIDRV

PH

REGN

LODRV

GND

TS

VFB

SRP

6V LDO

V(SRP-SRN)

COMP

ERROR

AMPLIFIER

20 uA

1V

2.1 V

0.8V

SRN

STATE

MACHINE

LOGIC

BATTERY

DETECTION

LOGIC

VCC

PH

4V

+

_

BTST

REFRESH

CE

145 C°

IC Tj

TSHUT

SRN+100 mV

VCC

SLEEP

LEVEL

SHIFTER

+

-

+

-

+

-

+

-

+

-

V(SRP-SRN)

CHG_OCP

+

-

200% X IBAT_REG

SYNCH

SRP-SRN

IBAT_ REG

0.8V

0.8V

10

5

mV

20X

VFB

BAT_OVP

+

-

104% X 2.1V

LTF

+

-

HTF

VREF

TCO

+

-

+

-

SUSPEND

VCC

ACOV

+

-

32V

CE

VREF

STAT 1

STAT1

3.3V

LDO

VCC

VFB

LOWV

+

-

RCHRG

+

-

1.5V

+

-

2.05V

VFB

LOWV

RCHRG

TERM

+

-

V(SRP - SRN)

TERM

TERMINATE CHARGE

+

-

BQ24650

+

-

+

-

UVLO

V

UVLO

VCC

SLEEP

UVLO

PWM

CONTROL

LOGIC

+

-

PWM

+

-

+

-

+

-

STAT 2

+

-

CHARGE

20uA

DISCHARGE

CHARGE

8 mA

BAT_OVP

VOLTAGE

REFERENCE

VREF

0.8V

10

STAT2

30 Minute

Precharge

Timer

FAULT

FAULT

2 mA

DISCHARGE

MPPSET

1.2 V

+

-

175 mV

+

-

TERM_EN

FBO

EAI

EAO

Copyright © 2016, Texas Instruments Incorporated

BQ24650

SLUSA75B –JULY 2010–REVISED JANUARY 2020

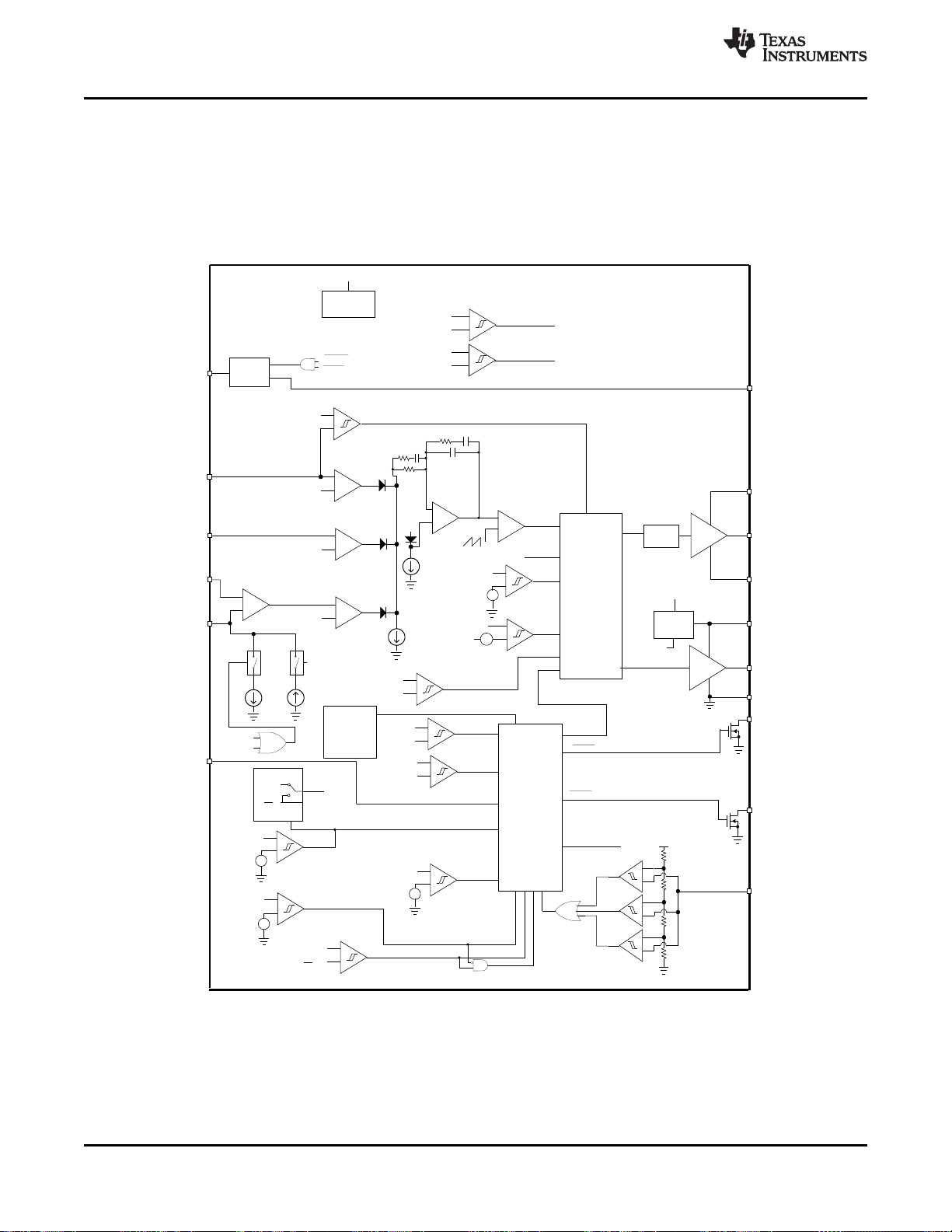

8 Detailed Description

8.1 Overview

The BQ24650 is a highly integrated solar input Li-ion or Li-polymer battery charge controller.

8.2 Functional Block Diagram

www.ti.com

8.3 Feature Description

8.3.1 Battery Voltage Regulation

The BQ24650 uses a high accuracy voltage regulator for the charging voltage. The charge voltage is

programmed through a resistor divider from the battery to ground, with the midpoint tied to the VFB pin. The

voltage at the VFB pin is regulated to 2.1 V, giving Equation 1 for the regulation voltage:

12

Submit Documentation Feedback Copyright © 2010–2020, Texas Instruments Incorporated

Product Folder Links: BQ24650

Loading...

Loading...