Page 1

OAS

(bq24610)

OFB

(bq24617)

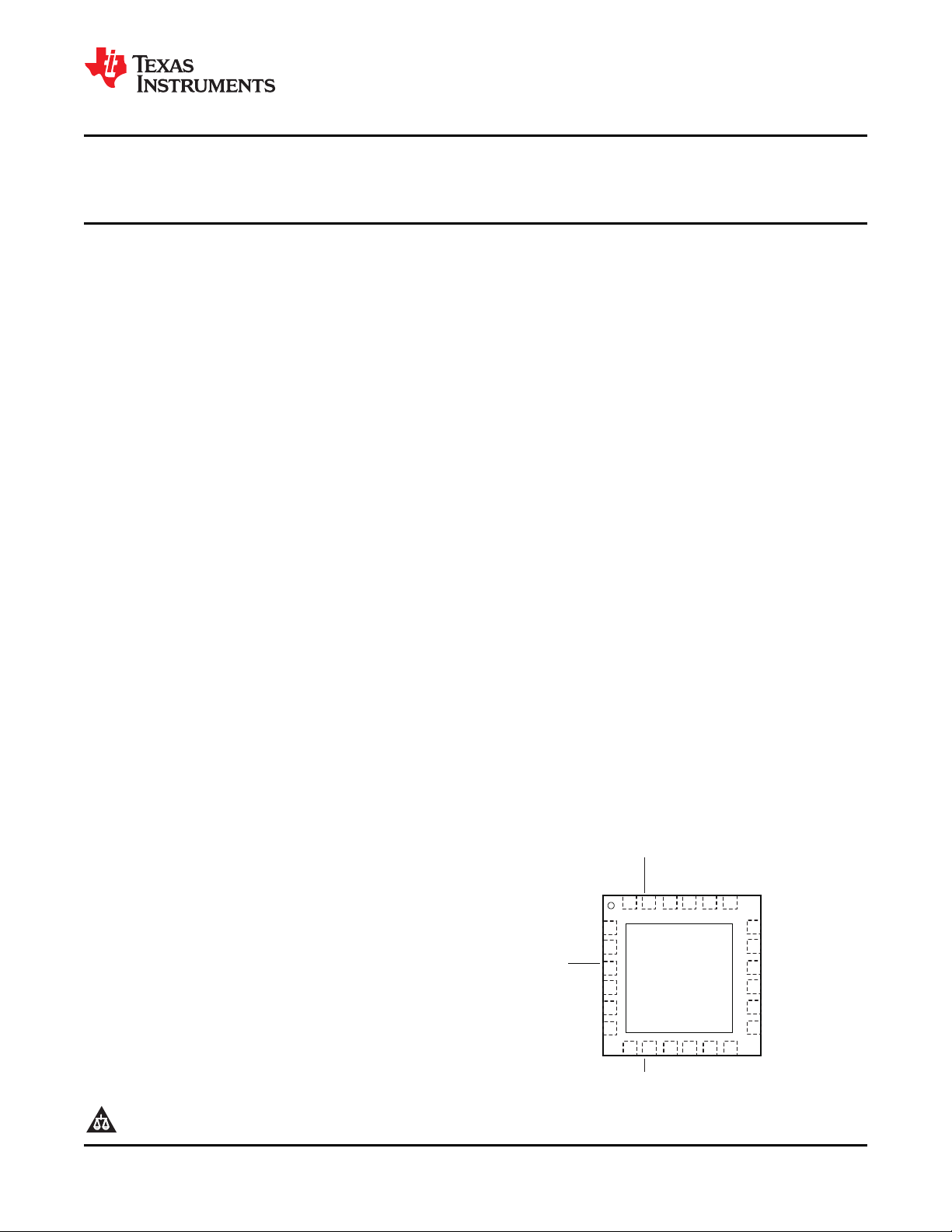

QFN-24

TOP VIEW

24 23 22 21 20 19

7 8 9 10 11 12

18

17

16

15

14

13

1

2

3

4

5

6

CE

ACN

ACP

ACDRV

STAT1

TS

SRN

SRP

ISET2

ACSET

GND

REGN

TTC

PG

STAT2

VREF

ISET1

VFB

VCC

BATDRV

BTST

HIDRV

PH

LODRV

bq24610

bq24617

www.ti.com

SLUS892 –DECEMBER 2009

Stand-Alone Synchronous Switch-Mode Li-Ion or Li-Polymer Battery Charger with System

1

FEATURES

Power Selector and Low I

Check for Samples: bq24610, bq24617

• 24-pin, 4×4-mm2QFN package

q

• 600 kHz NMOS-NMOS Synchronous Buck • Energy Star Low Quiescent Current I

Converter

• Stand-alone Charger Support for Li-Ion or

– < 15 µA Off-State Battery Discharge current

– < 1.5 mA Off-State Input Quiescent Current

Li-Polymer

• 5V–28V VCC Input Operating Range and APPLICATIONS Support 1-6 Battery Cells (bq24610)

• 5V–24V VCC Input Operating Range and

Support 1-5 Battery Cells (bq24617)

• Up to 10A Charge Current and Adapter Current

• High-Accuracy Voltage and Current Regulation

– ±0.5% Charge Voltage Accuracy

– ±3% Charge Current Accuracy

• Netbook, Mobile Internet Device and

Ultra-Mobile PC

• Personal Digital Assistants

• Handheld Terminals

• Industrial and Medical Equipment

• Portable Equipment

DESCRIPTION

– ±3% Adapter Current Accuracy

• Integration

– Automatic System Power Selection from

Adapter or Battery

– Internal Loop Compensation

– Internal Soft Start

– Dynamic Power Management

• Safety Protection

– Input Over-Voltage Protection

– Battery Thermistor Sense Hot/Cold Charge

Suspend

– Battery Detection

– Reverse Protection Input FET

– Programmable Safety Timer

– Charge Over-Current Protection

– Battery Short Protection

The bq24610/7 is highly integrated Li-ion or

Li-polymer switch-mode battery charge controller. It

offers a constant-frequency synchronous switching

PWM controller with high accuracy charge current

and voltage regulation, charge preconditioning,

termination, adapter current regulation and charge

status monitoring.

The bq24610/7 charges the battery in three phases:

preconditioning, constant current, and constant

voltage. Charge is terminated when the current

reaches a minimum user-selectable level. A

programmable charge timer provides a safety

backup. The bq24610/7 automatically restarts the

charge cycle if the battery voltage falls below an

internal threshold, and enters a low-quiescent current

sleep mode when the input voltage falls below the

battery voltage.

PACKAGE AND PIN-OUT

– Battery Over-Voltage Protection

– Thermal Shutdown

• Status Outputs

– Adapter Present

– Charger Operation Status

• Charge Enable Pin

• 6V Gate Drive for Synchronous Buck

Converter

• 30ns Driver Dead-time and 99.5% Max

Effective Duty Cycle

1

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2009, Texas Instruments Incorporated

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

q

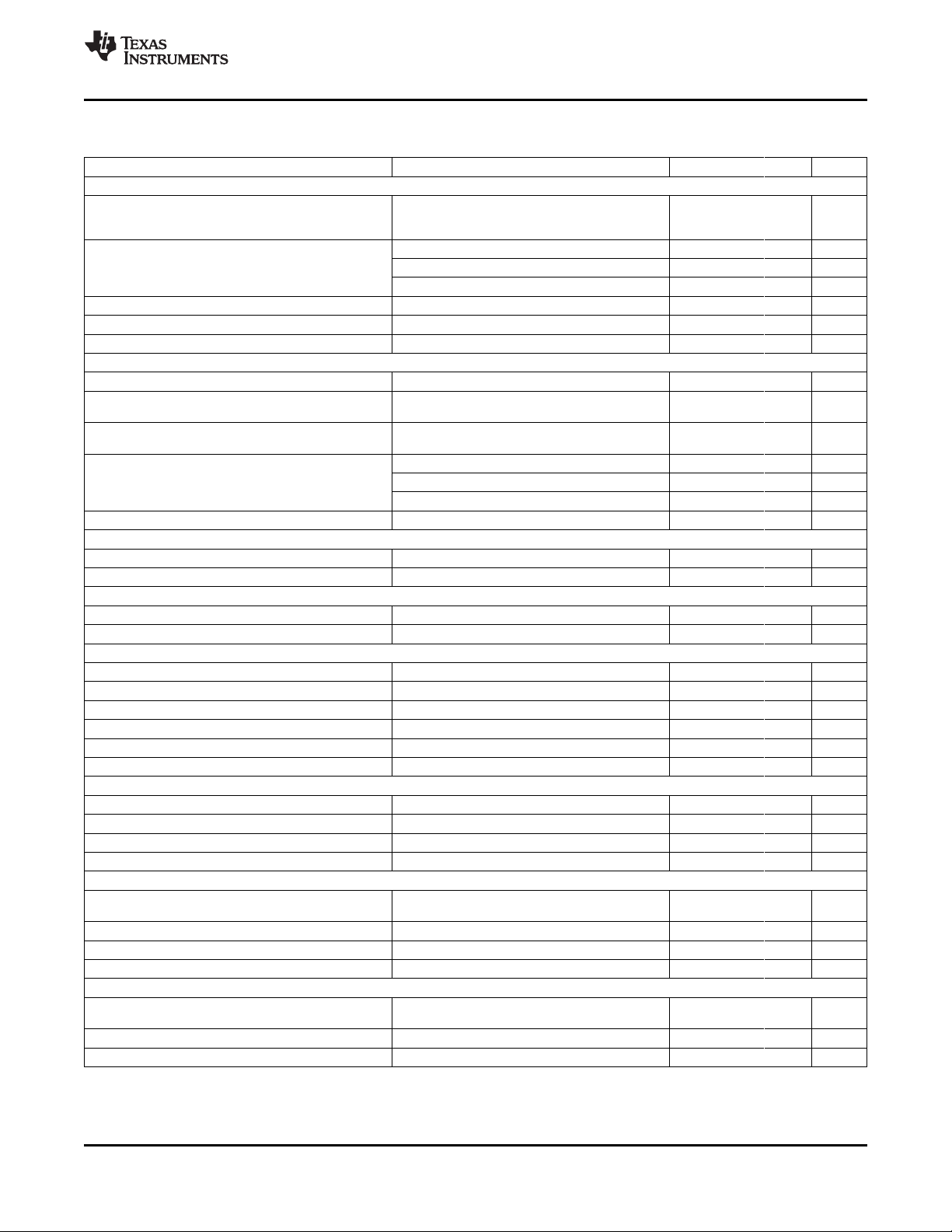

Page 2

RAC

0.010 W

Q1 (ACFET)

N

P

ACN

ACP

ISET2

ACSET

VREF

CE

VFB

TS

VCC

HIDRV

N

PH

BTST

REGN

LODRV

GND

SRP

SRN

P

PACK+

PACK-

SYSTEM

ADAPTER+

ADAPTER-

C4

0.1 µF

C2

0.1 µF

C3 C7

Q4

Q5

C6

L1

6.8µH*

D1

BAT54

C5

C10

0.1

µF

TTC

CTTC

VREF

STAT2

Pack

Thermistor

Sense

BATDRV

ACDRV

bq24610

bq24617

P

Q2 (ACFET)

Q3 (BATFET)

VREF

ISET1

STAT1

VBAT

R9

9.31kW

R10

430kW

R1

100

kW

PG

ADAPTER +

Cff

22 pF

0.1 µF

1µF

C8

10 µF

1 µF

1 µF

RSR

0.010

W

C11

0.1

µF

C12

10 µF*

C13

10 µF*

R2

500 kΩ

R1210kW

R1110

kW

R1310kW

R3

100 kW

R4

32.4 kW

R5

100 kW

R6

10kW

R7

100 kW

R8

22.1 kW

R14

100 kW

C14

0.1 mF

R15

100

kW

C15

0.1

µF

PwrPad

0.056 Fμ

R16

100

W

C1

0.1 Fμ

103AT

SI7617DN

SI7616DN

SIS412DN

SIS412DN

SI7617DN

C9

10 μF

R17

10Ω

R20

2Ω

C16

2.2μF

R18

1kΩ

R19

1kΩ

D2

D3

D4

bq24610

bq24617

SLUS892 –DECEMBER 2009

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

DESCRIPTION (CONTINUED)

The bq24610/7 controls external switches to prevent battery discharge back to the input, connect the adapter to

the system, and to connect the battery to the system using 6-V gate drives for better system efficiency. The

bq24610/7 features Dynamic Power Management (DPM). These features reduce battery charge current when

the input power limit is reached to avoid overloading the AC adapter when supplying the load and the battery

charger simultaneously. A highly-accurate current-sense amplifier enables precise measurement of input current

from the AC adapter to monitor the overall system power.

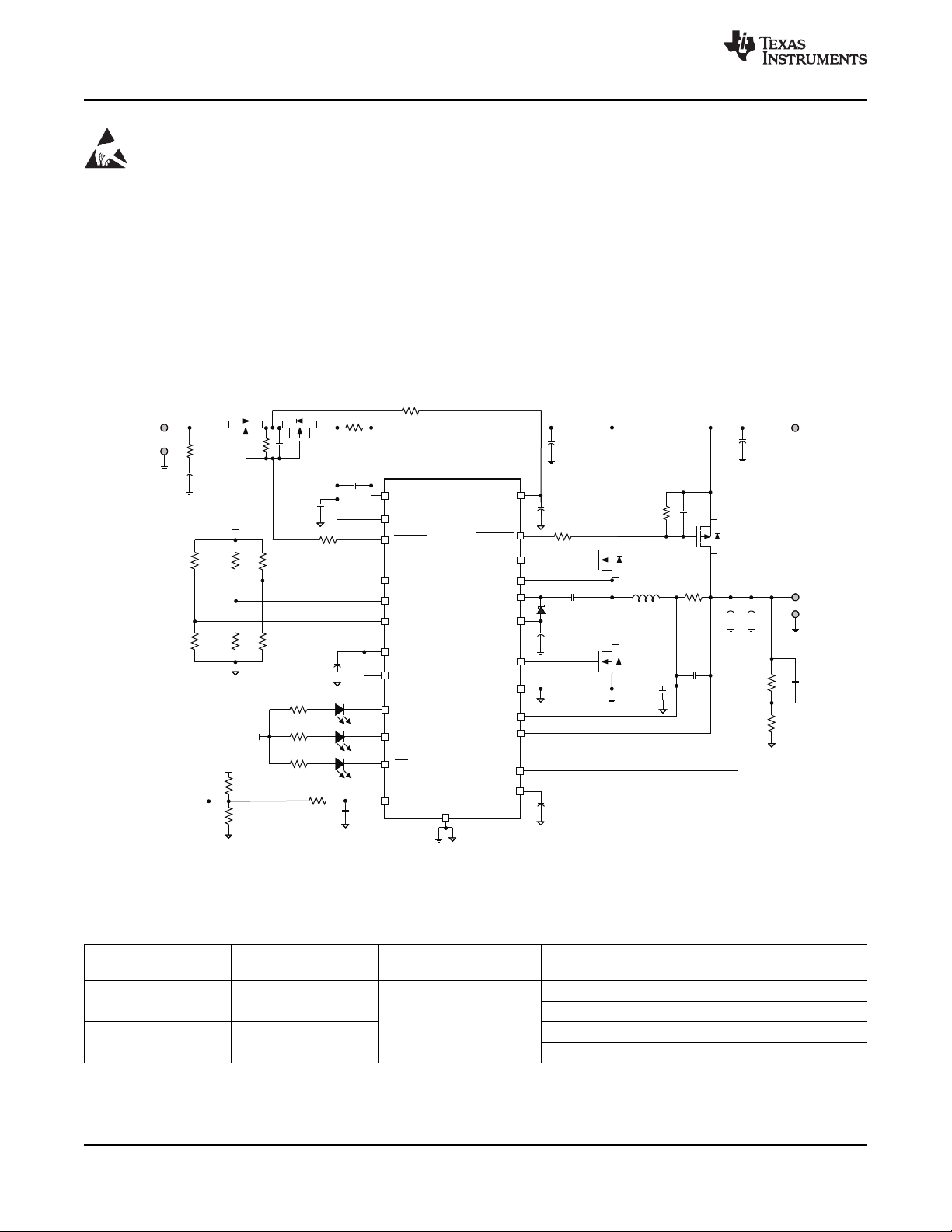

TYPICAL APPLICATION

www.ti.com

VIN=19V, 3-cell, I

adapter_limit

PART NUMBER IC MARKING PACKAGE QUANTITY

bq24610 OAS

2 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

bq24617 OFB

=4A, I

=3A, I

charge

Figure 1. Typical System Schematic

ORDERING INFORMATION

= I

pre-charge

=0.3A, 5 hour saftey timer

term

24-PIN 4×4 mm2QFN

Product Folder Link(s): bq24610 bq24617

ODERING NUMBER

(Tape andReel)

bq24610RGER 3000

bq24610RGET 250

bq24617RGER 3000

bq24617RGET 250

Page 3

bq24610

bq24617

www.ti.com

PACKAGE THERMAL DATA

PACKAGE θ

QFN – RGE

(1) This data is based on using the JEDEC High-K board and the exposed die pad is connected to a Cu pad on the board. This is

connected to the ground plane by a 2×2 via matrix. θJAhas 5% improvement by 3x3 via matrix.

(2) For the most current package and ordering information, see the Package Option Addendum at the end of this document, or see the TI

Web site at www.ti.com.

(1)(2)

JP

4°C/W 43°C/W 2.3 W 0.023 W/°C

θ

JA

TA= 25°C DERATING FACTOR

POWER RATING ABOVE TA= 25°C

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted)

VCC, ACP, ACN, SRP, SRN, BATDRV, ACDRV, CE, STAT1, STAT2, PG –0.3 to 33 V

PH –2 to 36 V

Voltage range

Maximum difference ACP–ACN, SRP–SRN –0.5 to 0.5 V

voltage

T

Junction temperature range –40 to 155 °C

J

T

Storage temperature range –55 to 155 °C

stg

(1) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltages are with respect to GND if not specified. Currents are positive into, negative out of the specified terminal. Consult Packaging

Section of the data book for thermal limitations and considerations of packages.

(3) Must have a series resistor between battery pack to VFB if Battery Pack voltage is expected to be greater than 16V. Usually the resistor

divider top resistor will take care of this.

VFB –0.3 to 16 V

REGN, LODRV, ACSET, TS, TTC –0.3 to 7 V

BTST, HIDRV with respect to GND –0.3 to 39 V

VREF, ISET1, ISET2 –0.3 to 3.6 V

(1) (2) (3)

SLUS892 –DECEMBER 2009

VALUE UNIT

RECOMMENDED OPERATING CONDITIONS

VALUE UNIT

VCC, ACP, ACN, SRP, SRN, BATDRV, ACDRV, CE, STAT1, STAT2, PG –0.3 to 28 V

PH –2 to 30 V

VFB –0.3 to 14 V

Voltage range REGN, LODRV, ACSET, TS, TTC –0.3 to 6.5 V

BTST, HIDRV with respect to GND –0.3 to 34 V

ISET1, ISET2 –0.3 to 3.3 V

VREF 3.3 V

Maximum difference ACP–ACN, SRP–SRN –0.2 to 0.2 V

voltage

T

Junction temperature range 0 to 125 °C

J

T

Storage temperature range –55 to 155 °C

stg

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Link(s): bq24610 bq24617

Page 4

bq24610

bq24617

SLUS892 –DECEMBER 2009

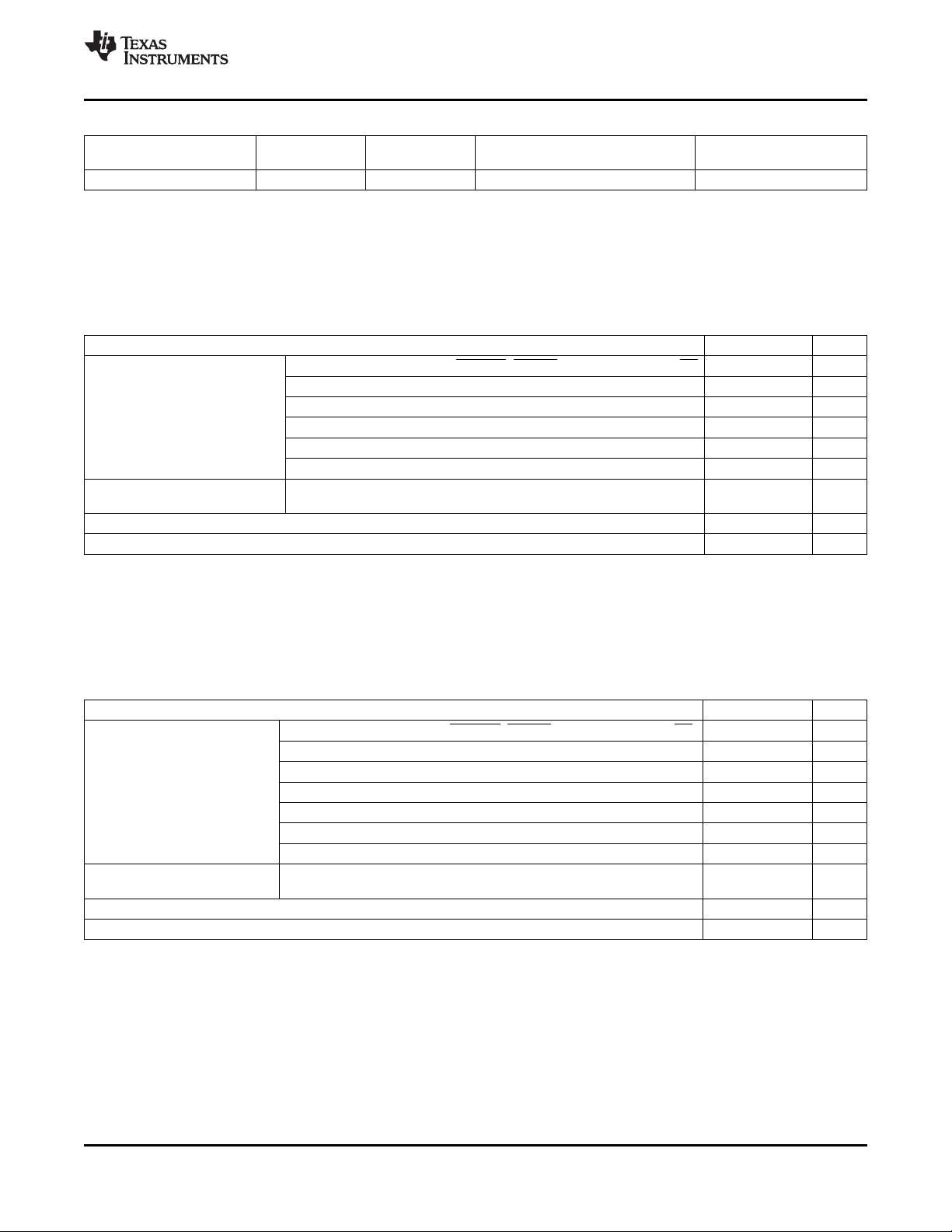

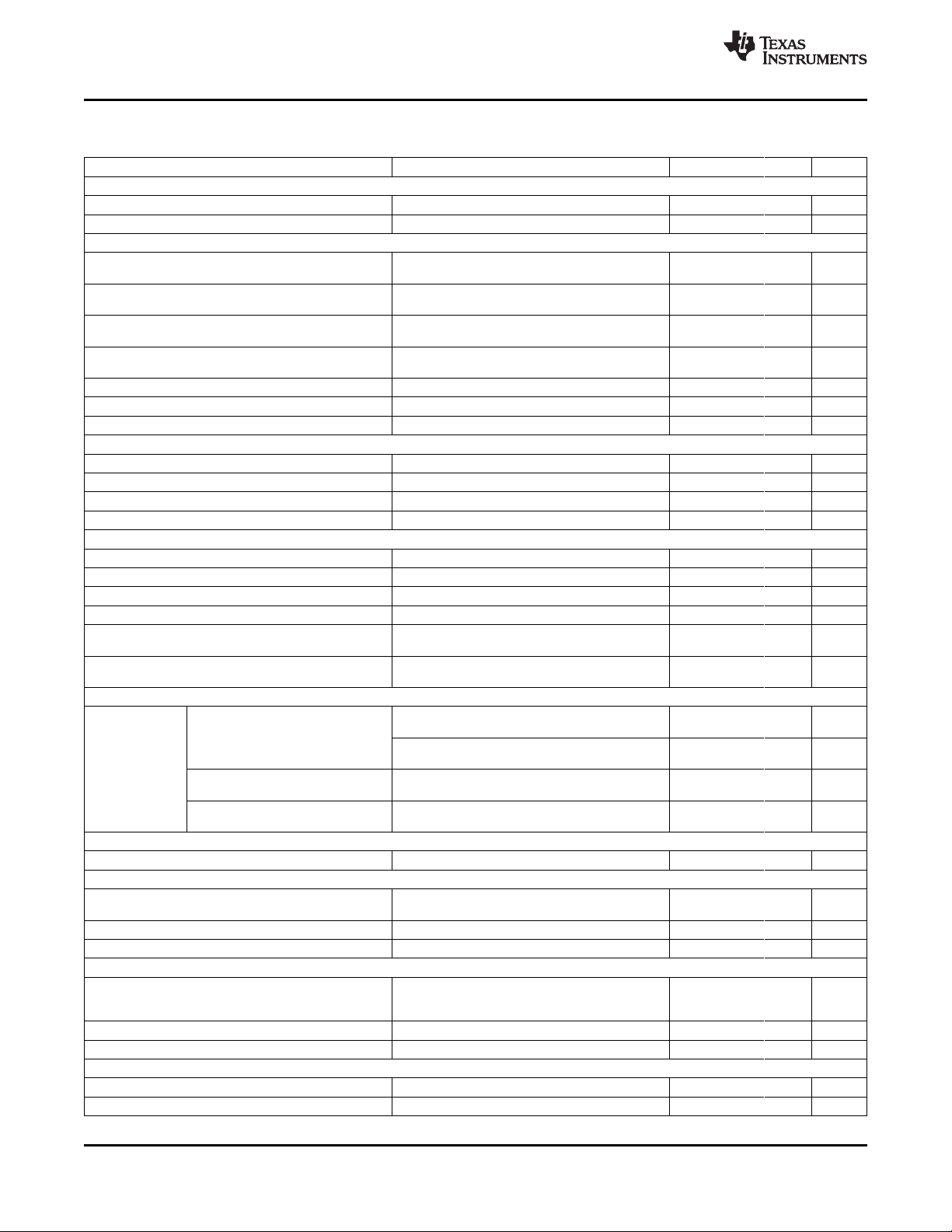

ELECTRICAL CHARACTERISTICS

5.0V ≤ V(VCC) ≤ 28V, 0°C < TJ< +125°C, typical values are at TA= 25°C, with respect to GND (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

OPERATING CONDITIONS

V

VCC_OP

QUIESCENT CURRENTS

I

BAT

I

AC

CHARGE VOLTAGE REGULATION

V

FB

I

VFB

CURRENT REGULATION – FAST CHARGE

V

ISET1

V

IREG_CHG

K

ISET1

I

ISET1

CURRENT REGULATION – PRECHARGE

V

ISET2

K

ISET2

I

ISET2

VCC input voltage operating range(610) 5.0 28.0

VCC input voltage operating range(617) 5.0 24.0

Total battery discharge current (sum of

currents into VCC, BTST, PH, ACP, V

ACN, SRP, SRN, VFB), VFB ≤2.1 V

Battery discharge current (sum of

currents into BTST, PH, SRP, SRN,

VFB), VFB ≤ 2.1 V

Adapter supply current (current into V

VCC,ACP,ACN pin) done

< V

> V

> V

> V

> V

> V

SRN

SRN

SRN

SRN

SRN

SRN

, V

, V

, V

, V

, V

, V

VCC

V

VCC

V

VCC

done

V

VCC

current)

VCC

V

VCC

Qg_total = 20 nC

> V

VCC

UVLO

> V

VCC

UVLO

> V

VCC

VCCLOW

> V

VCC

UVLO

VCC>VVCCLOW

VCC>VVCCLOW

(SLEEP) 15 μA

CE = LOW 5 µA

CE = HIGH, Charge

CE = LOW (IC quiescent

, CE = HIGH, charge

, CE = HIGH, Charging,

1 1.5

2 5 mA

25

Feedback regulation voltage 2.1 V

Charge voltage regulation accuracy

TJ= 0°C to 85°C –0.5% 0.5%

TJ= -40°C to 125°C –0.7% 0.7%

Leakage current into VFB pin VFB = 2.1 V 100 nA

ISET1 voltage range 2 V

SRP-SRN current sense voltage range V

Charge current set factor (amps of

charge current per volt on ISET1 pin)

Charge current regulation accuracy

Leakage current into ISET1 pin V

R

V

V

V

V

= V

IREG_CHG

= 10 mΩ 5 A/V

SENSE

IREG_CHG

IREG_CHG

IREG_CHG

IREG_CHG

= 2 V 100 nA

ISET1

– V

SRP

SRN

= 40 mV –3% 3%

= 20 mV –4% 4%

= 5 mV –25% 25%

= 1.5 mV (V

> 3.1V) –40% 40%

SRN

ISET2 voltage range 2 V

Precharge current set factor (amps of

precharge current per volt on ISET2 pin)

Precharge current regulation accuracy V

Leakage current into ISET2 pin V

R

= 10 mΩ 1 A/V

SENSE

V

IREG_PRECH

IREG_PRECH

V

IREG_PRECH

ISET2

= 20 mV –4% 4%

= 5 mV –25% 25%

= 1.5 mV (V

< 3.1V) –55% 55%

SRN

= 2V 100 nA

www.ti.com

5 µA

100 mV

V

4 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): bq24610 bq24617

Page 5

bq24610

bq24617

www.ti.com

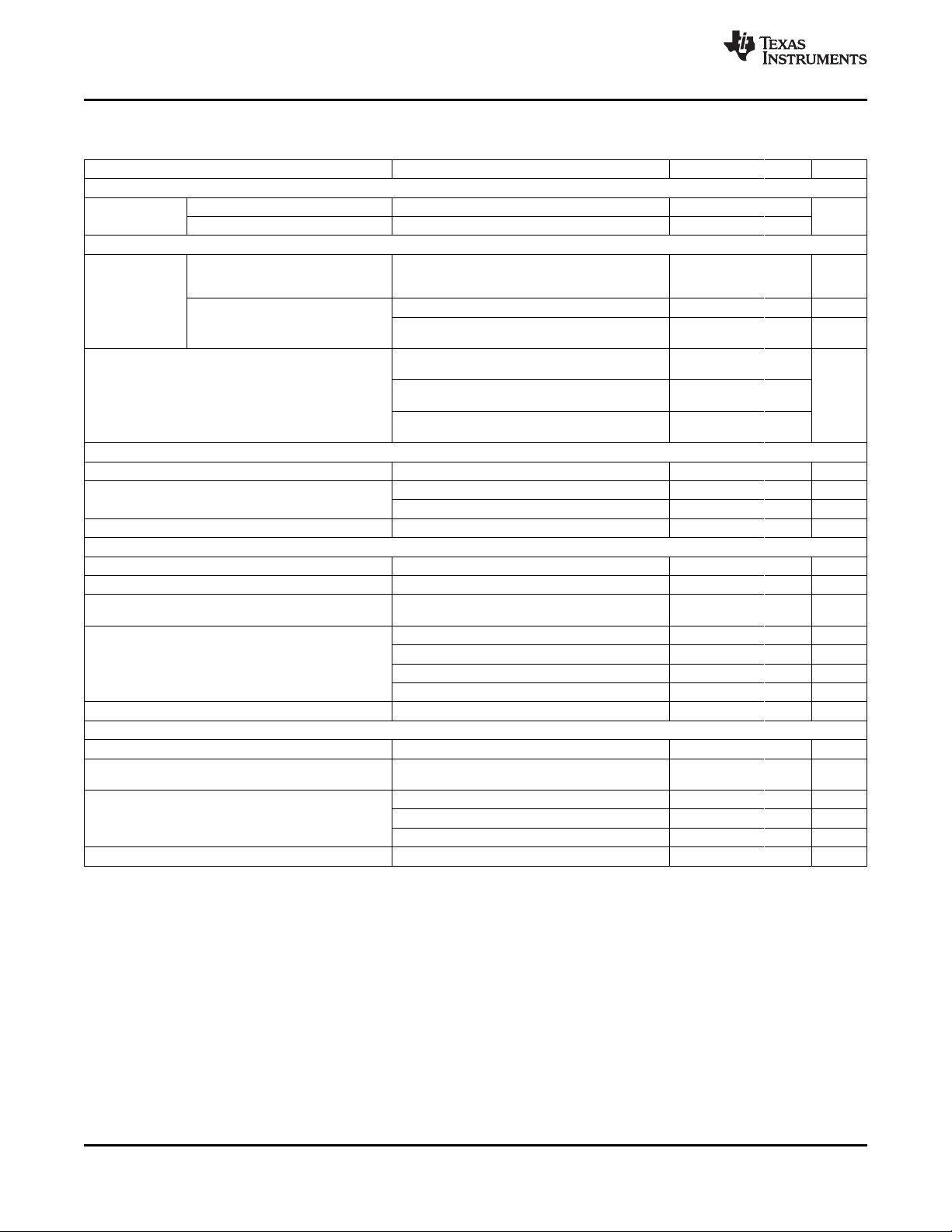

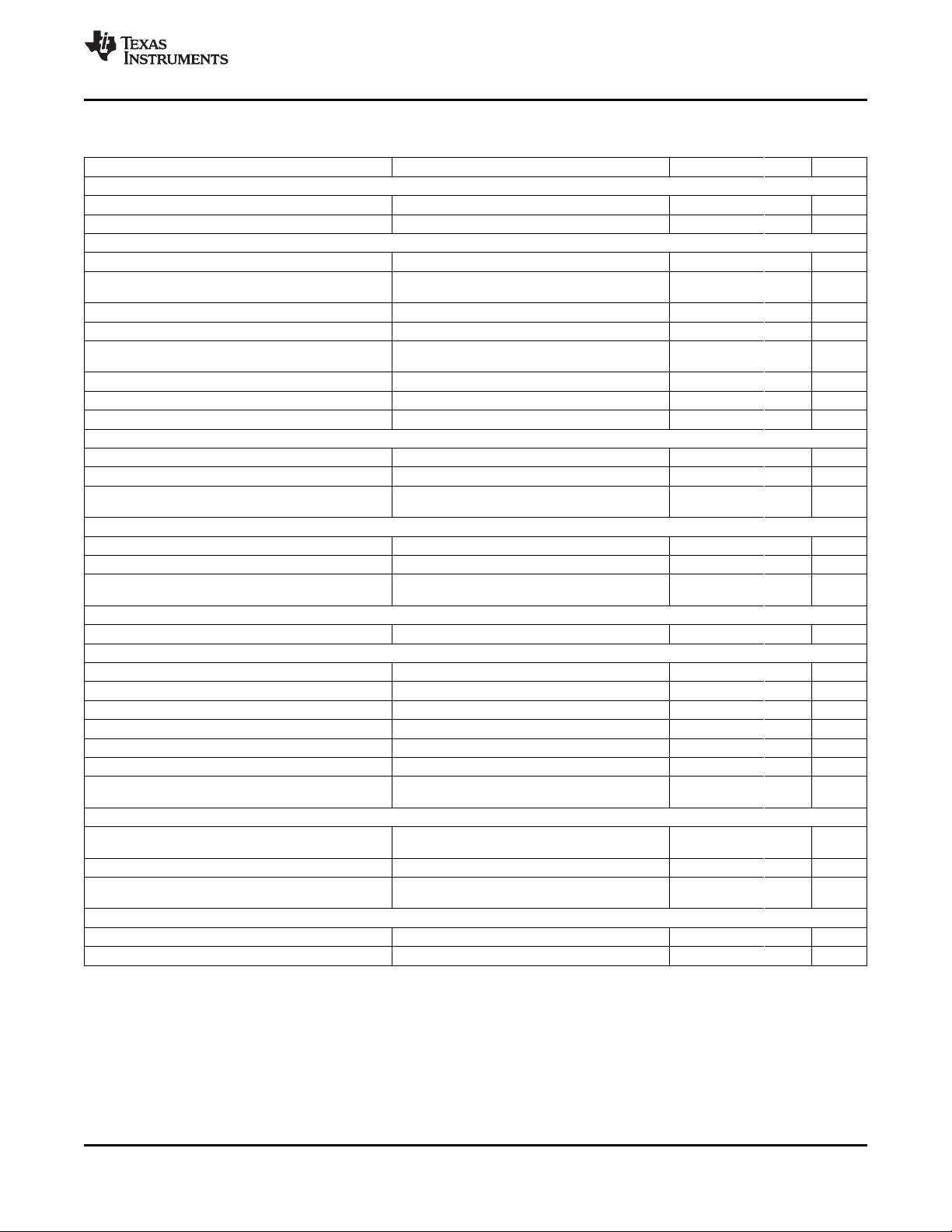

ELECTRICAL CHARACTERISTICS (continued)

5.0V ≤ V(VCC) ≤ 28V, 0°C < TJ< +125°C, typical values are at TA= 25°C, with respect to GND (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

CHARGE TERMINATION

K

TERM

t

QUAL

I

QUAL

INPUT CURRENT REGULATION

V

ACSET

V

IREG_DPM

K

ACSET

I

ACSET

I

ISET1

INPUT UNDER-VOLTAGE LOCK-OUT COMPARATOR (UVLO)

V

UVLO

V

UVLO_HYS

VCC LOWV COMPARATOR

SLEEP COMPARATOR (REVERSE DISCHARGING PROTECTION)

V

SLEEP _FALL

V

SLEEP_HYS

ACN / SRN COMPARATOR

V

ACN-SRN_FALL

V

ACN-SRN_HYS

BAT LOWV COMPARATOR

V

LOWV

V

LOWV_HYS

RECHARGE COMPARATOR

V

RECHG

Termination current set factor (Amps of

termination current per volt on ISET2 R

pin)

Termination current accuracy V

= 10 mΩ 1 A/V

SENSE

V

= 20 mV –4% 4%

ITERM

= 5 mV –25% 25%

ITERM

V

= 1.5 mV –45% 45%

ITERM

Deglitch time for termination (both edge) 100 ms

Termination qualification time V

BAT>VRECH

and I

CHG<ITERM

Termination qualification current Discharge current once termination is detected 2 mA

ACSET Voltage Range 2 V

ACP-ACN Current Sense Voltage

Range

Input current set factor (amps of input

current per volt on ACSET pin)

Input current regulation accuracy

leakage current in to ACSET pin

Leakage current in to ACSET pin V

V

R

V

V

V

= V

IREG_DPM

= 10 mΩ 5 A/V

SENSE

IREG_DPM

IREG_DPM

IREG_DPM

= 2 V 100 nA

ACSET

– V

ACP

ACN

= 40 mV –3% 3%

= 20 mV –4% 4%

= 5 mV –25% 25%

AC Under-voltage rising threshold Measure on VCC 3.65 3.85 4 V

AC Under-voltage hysteresis, falling 350 mV

Falling threshold, disable charge Measure on VCC 4.1 V

Rising threshold, resume charge 4.35 4.5 V

SLEEP falling threshold V

VCC

– V

to enter SLEEP 40 100 150 mV

SRN

SLEEP hysteresis 500 mV

SLEEP rising delay VCC falling below SRN, Delay to turn off ACFET 1 μs

SLEEP falling delay VCC rising above SRN, Delay to turn on ACFET 30 μs

SLEEP rising shutdown deglitch VCC falling below SRN, Delay to enter SLEEP mode 100 ms

SLEEP falling powerup deglitch VCC rising above SRN, Delay to exit SLEEP mode 30 ms

ACN to SRN falling threshold V

ACN

– V

to turn on BATFET 100 200 310 mV

SRN

ACN to SRN rising hysteresis 100 mV

ACN to SRN rising deglitch V

ACN to SRN falling deglitch V

Precharge to fastcharge transition

(LOWV threshold)

– V

– V

SRN

SRN

> V

ACN-SRN_RISE

< V

ACN-SRN_FALL

ACN

ACN

Measured on VFB pin, Rising 1.534 1.55 1.566 V

LOWV hysteresis 100 mV

LOWV rising deglitch VFB falling below V

LOWV falling deglitch VFB rising above V

Recharge threshold (with-respect-to

V

)

REG

Measured on VFB pin, Falling 35 50 65 mV

Recharge rising deglitch VFB decreasing below V

Recharge falling deglitch VFB decreasing above V

LOWV

LOWV

+ V

RECHG

RECHG

LOWV_HYS

SLUS892 –DECEMBER 2009

250 ms

100 mV

2 ms

50 μs

25 ms

25 ms

10 ms

10 ms

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Link(s): bq24610 bq24617

Page 6

bq24610

bq24617

SLUS892 –DECEMBER 2009

ELECTRICAL CHARACTERISTICS (continued)

5.0V ≤ V(VCC) ≤ 28V, 0°C < TJ< +125°C, typical values are at TA= 25°C, with respect to GND (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

BAT OVER-VOLTAGE COMPARATOR

V

OV_RISE

V

OV_FALL

INPUT OVER-VOLTAGE COMPARATOR (ACOV)

V

ACOV

V

ACOV_HYS

V

ACOV

V

ACOV_HYS

THERMAL SHUTDOWN COMPARATOR

T

SHUT

T

SHUT_HYS

THERMISTOR COMPARATOR

V

LTF

V

LTF_HYS

V

HTF

V

TCO

CHARGE OVER-CURRENT COMPARATOR (CYCLE-BY-CYCLE)

V

OC

CHARGE UNDER-CURRENT COMPARATOR (CYCLE-BY-CYCLE)

V

ISYNSET

BATTERY SHORTED COMPARATOR (BATSHORT)

V

BATSHT

V

BATSHT_HYS

V

BATSHT_DEG

LOW CHARGE CURRENT COMPARATOR

V

LC

V

LC_HYS

V

LC_DEG

VREF REGULATOR

V

VREF_REG

I

VREF_LIM

Over-voltage rising threshold As percentage of V

Over-voltage falling threshold As percentage of V

AC over-voltage rising threshold on

VCC (bq24610)

AC over-voltage falling hysteresis

(bq24610)

AC over-voltage rising threshold on

VCC (bq24617)

AC over-voltage falling

hysteresis(bq24617)

FB

FB

31.04 32 32.96 V

25.22 26 26.78 V

104%

102%

1 V

820 mV

AC over-voltage deglitch (both edge) Delay to changing the STAT pins 1 ms

AC over-voltage rising deglitch Delay to disable charge 1 ms

AC over-voltage falling deglitch Delay to resume charge 20 ms

Thermal shutdown rising temperature Temperature increasing 145 °C

Thermal shutdown hysteresis 15 °C

Thermal shutdown rising deglitch Temperature increasing 100 μs

Thermal shutdown falling deglitch Temperature decreasing 10 ms

Cold temperature rising threshold As Percentage to V

Rising hysteresis As Percentage to V

Hot temperature rising threshold As Percentage to V

Cut-off temperature rising threshold As Percentage to V

Deglitch time for temperature out of

range detection

Deglitch time for temperature in valid

range detection

VTS> V

VTS< V

LTF

LTF

, or VTS< V

– V

LTF_HYS

VREF

VREF

VREF

VREF

TCO

or VTS>V

, or VTS< V

TCO

HTF

, or VTS> V

HTF

Current rising, in non-synchronous mode, mesure on

Charge over-current falling threshold

V

Current rising, as percentage of V

synchronous mode, V

Charge over-current threshold floor 50 mV

Charge over-current threshold ceiling 180 mV

Minimum OCP threshold in synchronous mode,

measure on V

Maximum OCP threshold in synchronous mode,

measure on V

Charge under-current falling threshold Switch from SYNCH to NON-SYNCH, V

BAT Short falling threshold, forced

non-syn mode

V

, V

(SRP-SRN)

falling 2 V

SRP

< 2 V

SRP

(SRP-SRN)

(SRP-SRN)

SRP

, V

, V

> 2.2V

SRP

SRP

> 2.2V

> 2.2V

(IREG_CHG)

SRP

, in

> 2.2V 1 5 9 mV

72.5% 73.5% 74.5%

0.2% 0.4% 0.6%

36.2% 37% 37.8%

33.7% 34.4% 35.1%

400 ms

20 ms

45.5 mV

160%

BAT short rising hysteresis 200 mV

Deglitch on both edge 1 μs

Low charge current (average) falling

threshold to force into non-synchronous Measure on V

mode

(SRP-SRN)

1.25 mV

Low charge current rising hysteresis 1.25 mV

Deglitch on both edge 1 μs

VREF regulator voltage V

VREF current limit V

VCC

VREF

> V

, (0-35mA load) 3.267 3.3 3.333 V

UVLO

= 0V, V

VCC

> V

UVLO

35 mA

www.ti.com

6 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): bq24610 bq24617

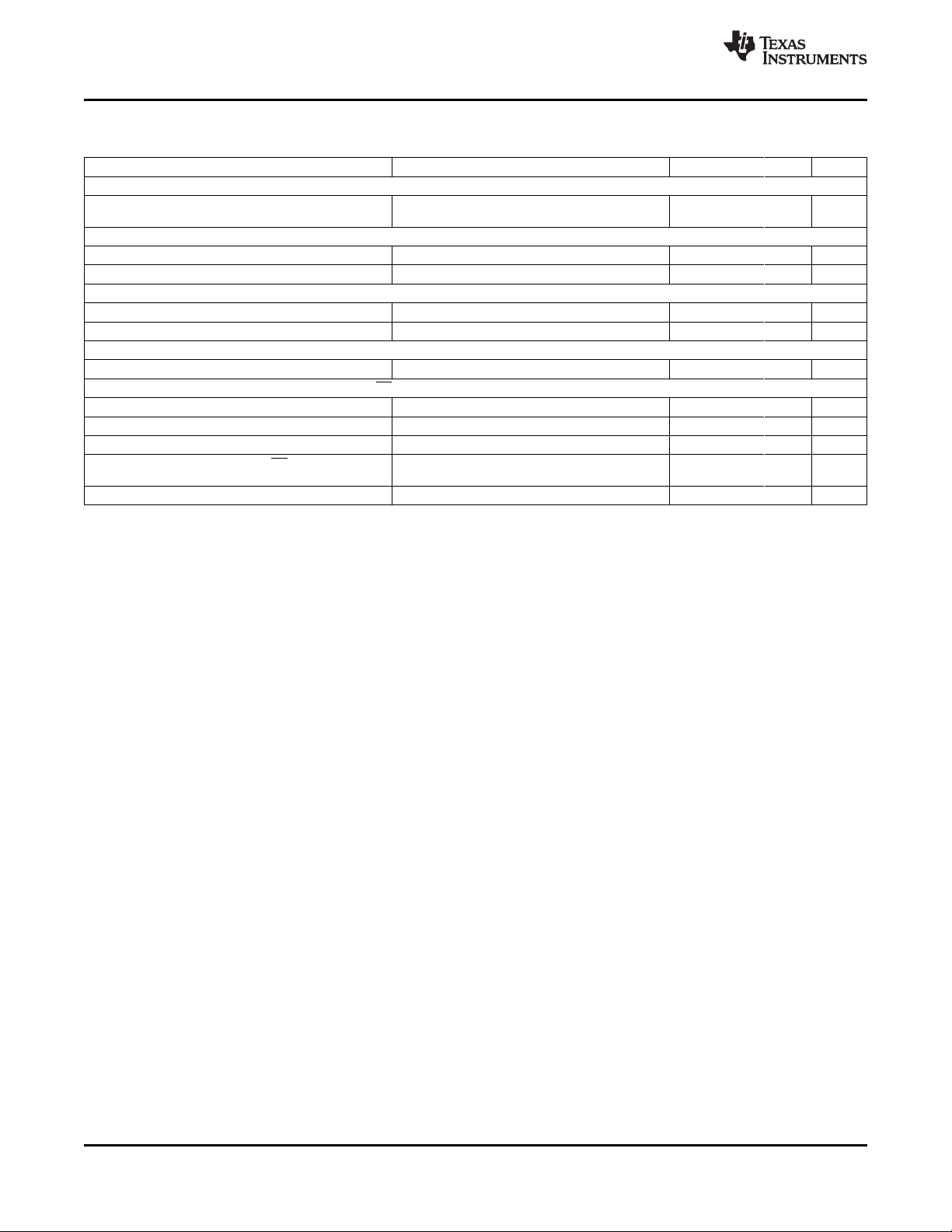

Page 7

bq24610

bq24617

www.ti.com

ELECTRICAL CHARACTERISTICS (continued)

5.0V ≤ V(VCC) ≤ 28V, 0°C < TJ< +125°C, typical values are at TA= 25°C, with respect to GND (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

REGN REGULATOR

V

REGN_REG

I

REGN_LIM

TTC INPUT AND SAFETY TIMER

T

PRECHG

T

CHARGE

K

TTC

BATTERY SWITCH (BATFET) DRIVER

R

DS_BAT_OFF

R

DS_BAT_ON

V

BATDRV_REG

AC SWITCH (ACFET) DRIVER

R

DS_AC_OFF

R

DS_AC_ON

V

ACDRV_REG

AC / BAT MOSFET DRIVERS TIMING

BATTERY DETECTION

t

WAKE

I

WAKE

t

DISCHARGE

I

DISCHARGE

I

FAULT

V

WAKE

V

DISCH

PWM HIGH SIDE DRIVER (HIDRV)

R

DS_HI_ON

R

DS_HI_OFF

V

BTST_REFRESH

PWM LOW SIDE DRIVER (LODRV)

R

DS_LO_ON

R

DS_LO_OFF

(1) Verified by design

REGN regulator voltage V

REGN current limit V

Precharge safety timer range

Fast charge saftey timer range, with +/-

10% accuracy

(1)

Fast charge timer accuracy

(1)

(1)

> 10V, CE = HIGH, (0-40mA load) 5.7 6.0 6.3 V

VCC

REGN

= 0V, V

VCC

> V

, CE = HIGH 40 mA

UVLO

Precharge time before fault occurs 1440 1800 2160 sec

Tchg = C

0.01 μF ≤ C

× K

TTC

TTC

≤ 0.11 μF –10% 10%

TTC

Timer multiplier 5.6 min/nF

V

below this threshold disables the safety timer and

TTC low threshold 0.4 V

TTC

termination

TTC oscillator high threshold 1.5 V

TTC oscillator low threshold 1 V

TTC source/sink current 45 50 55 μA

BATFET turn-off resistance V

BATFET turn-on resistance V

BATFET drive voltage 4.2 7 V

ACFET turn-off resistance V

ACFET turn-on resistance V

ACFET drive voltage 4.2 7 V

> 5V 150 Ω

ACN

> 5V 20 kΩ

ACN

V

BATDRV_REG

BATFET is on

VCC

VCC

V

ACDRV_REG

ACFET is on

= V

ACN

– V

BATDRV

when V

ACN

> 5V and

> 5V 30 Ω

> 5V 20 kΩ

= V

VCC

– V

ACDRV

when V

VCC

> 5V and

Driver dead time Dead time when switching between AC and BAT 10 μs

Wake time Max time charge is enabled 500 ms

Wake current R

= 10mΩ 50 125 200 mA

SENSE

Discharge time Max time discharge current is applied 1 sec

Discharge current 8 mA

Fault current after a timeout fault 2 mA

Wake threshold (with-respect-to V

Discharge threshold 1.55 V

High side driver (HSD) turn-on

resistance

High side driver turn-off resistance V

Bootstrap refresh comparator threshold

voltage

) Voltage on VFB to detect battery absent during Wake 50 mV

REG

Voltage on VFB to detect battery absent during

discharge

V

– VPH= 5.5 V 3.3 6 Ω

BTST

– VPH= 5.5 V 1 1.3 Ω

BTST

V

– VPHwhen low side refresh pulse is requested 4.0 4.2 V

BTST

Low side driver (LSD) turn-on resistance 4.1 7 Ω

Low side driver turn-off resistance 1 1.4 Ω

SLUS892 –DECEMBER 2009

1 10 Hr

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Link(s): bq24610 bq24617

Page 8

bq24610

bq24617

SLUS892 –DECEMBER 2009

ELECTRICAL CHARACTERISTICS (continued)

5.0V ≤ V(VCC) ≤ 28V, 0°C < TJ< +125°C, typical values are at TA= 25°C, with respect to GND (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

PWM DRIVERS TIMING

Driver dead time 30 ns

PWM OSCILLATOR

V

RAMP_HEIGHT

INTERNAL SOFT START (8 steps to regulation current ICHG)

CHARGER SECTION POWER-UP SEQUENCING

LOGIC IO PIN CHARACTERISTICS (CE, STAT1, STAT2, PG)

V

IN_LO

V

IN_HI

V

BIAS_CE

V

OUT_LO

I

OUT_HI

PWM ramp height As percentage of VCC 7 %

PWM switching frequency

Soft start steps 8 step

Soft start step time 1.6 ms

Charge-enable delay after power-up Delay from CE=1 to charger is allowed to turn on 1.5 s

CE input low threshold voltage 0.8 V

CE input high threshold voltage 2.1

CE input bias current V = 3.3V (CE has internal 1MΩ pulldown resistor) 6 μA

STAT1, STAT2, PG output low

saturation voltage

Leakage current V = 32 V 1.2 µA

(2)

(2) Verified by design

Dead time when switching between LSD and HSD, no

load at LSD and HSD

510 600 690 kHz

Sink Current = 5 mA 0.5 V

www.ti.com

8 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): bq24610 bq24617

Page 9

VCC

/PG

VREF

REGN

t − Time=4ms/div

5V/div

2V/div

10V/div

2V/div

t − Time=200ms/div

PH

LODRV

IBAT

CE

5V/div

5V/div

10V/div

2 A/div

t − Time=4ms/div

CE

PH

LODRV

IBAT

5V/div

5V/div

10V/div

2 A/div

t − Time=2 s/divμ

CE

PH

LODRV

IL

5V/div

5V/div

10V/div

2 A/div

www.ti.com

SLUS892 –DECEMBER 2009

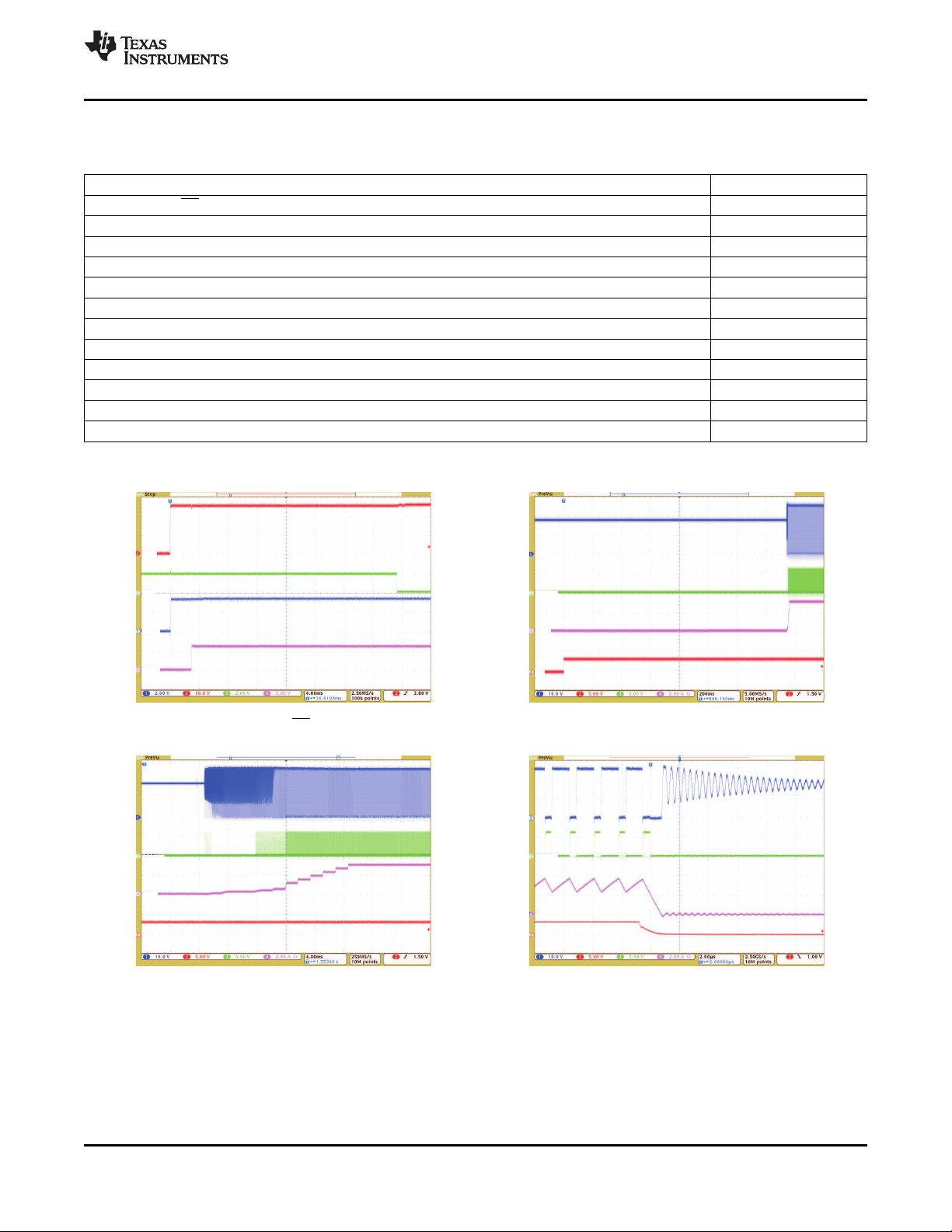

TYPICAL CHARACTERISTICS

Table 1. Table of Graphs

Figure

REF REGN and PG Power Up (CE=1) Figure 2

Charge Enable Figure 3

Current Soft-Start (CE=1) Figure 4

Charge Disable Figure 5

Continuous Conduction Mode Switching Waveforms Figure 6

Cycle-by-Cycle Synchronous to Nonsynchronous Figure 7

100% Duty and Refresh Pulse Figure 8

Transient System Load (DPM) Figure 9

Battery Insertion Figure 10

Battery to Ground Short Protection Figure 11

Battery to ground Short Transition Figure 12

Efficiency vs Output Current Figure 13

bq24610

bq24617

Figure 2. REF REGN and PG Power Up (CE=1) Figure 3. Charge Enable

Figure 4. Current Soft-Start (CE=1) Figure 5. Charge Disable

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Link(s): bq24610 bq24617

Page 10

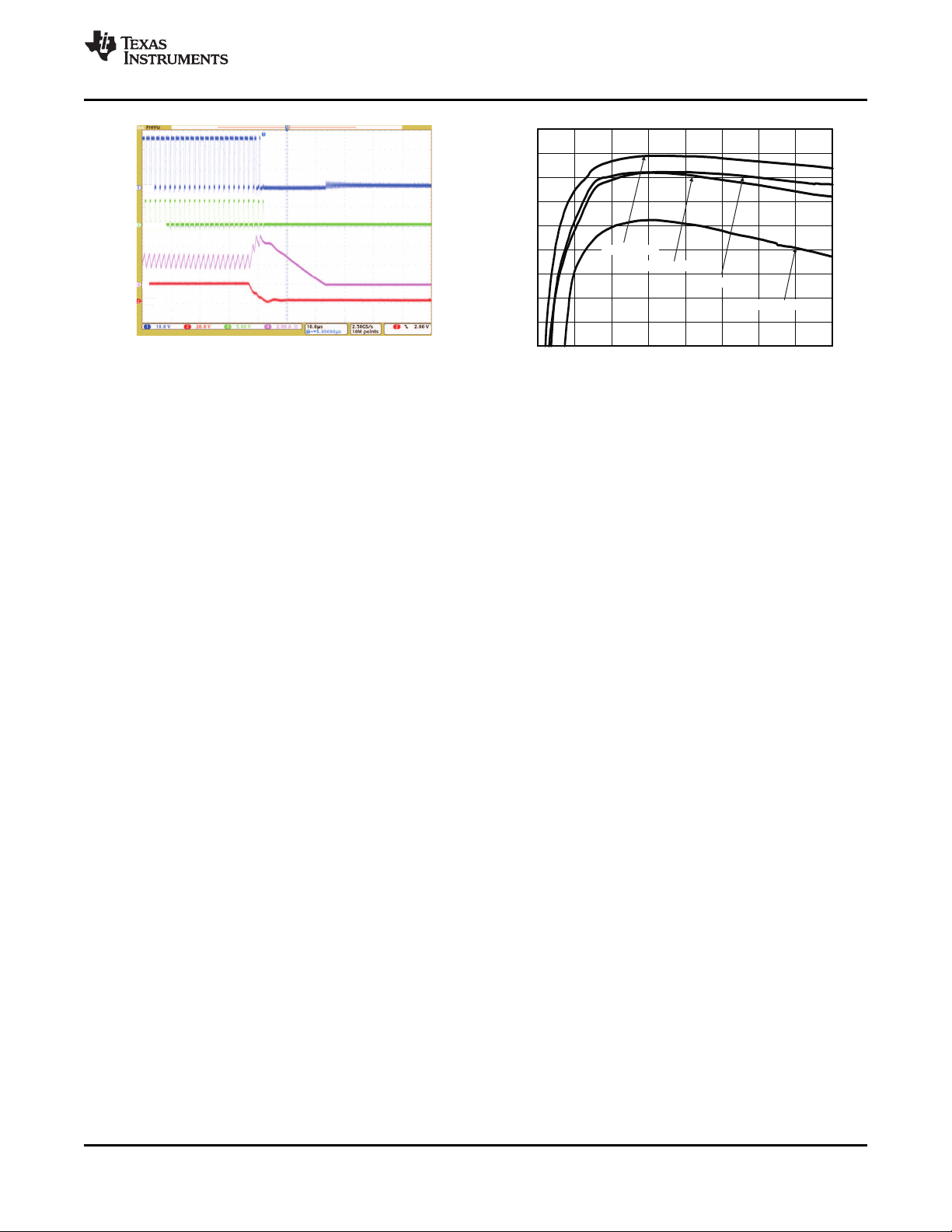

t − Time=100ns/div

HIDRV

PH

LODRV

IL

2 A/div

20V/div

20V/div

5V/div

t − Time=100ns/div

PH

LODRV

IL

1 A/div

5V/div

5V/div

t − Time=400ns/div

PH

LODRV

IL

0.5 A/div

10V/div

5V/div

t − Time=200 s/divμ

IIN

ISYS

IBAT

2 A/div

2 A/div

2 A/div

t − Time=200ms/div

PH

IL

VBAT

2 A/div

5V/div

10V/div

t − Time=4ms/div

PH

IL

VBAT

LODRV

20V/div

5V/div

10V/div

2 A/div

bq24610

bq24617

SLUS892 –DECEMBER 2009

Figure 6. Continuous Conduction Mode Switching Waveform Figure 7. Cycle-by-Cycle Synchronous to Nonsynchronous

www.ti.com

Figure 8. 100% Duty and Refresh Pulse Figure 9. Transient System Load (DPM)

Figure 10. Battery Insertion Figure 11. Battery to GND Short Protection

10 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): bq24610 bq24617

Page 11

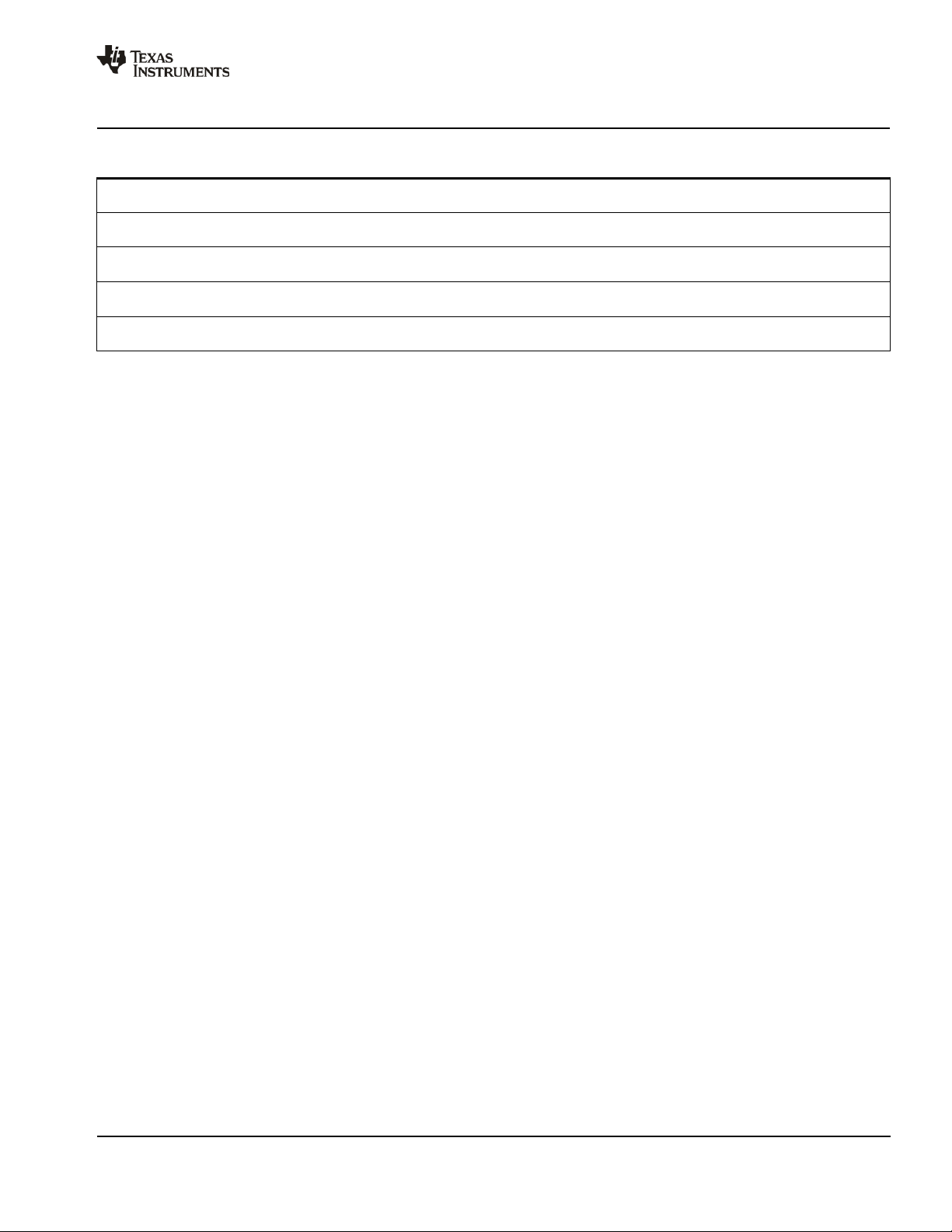

t − Time=10 s/divμ

PH

IL

VBAT

LODRV

20V/div

5V/div

10V/div

2 A/div

80

82

84

86

88

90

92

94

96

98

0 1 2 3

4

5

6

7

8

IBAT-OutputCurrent- A

Efficiency-%

12Vin,1cell

12Vin,2cell

20Vin,3cell

20Vin,4cell

www.ti.com

bq24610

bq24617

SLUS892 –DECEMBER 2009

Figure 12. Battery to GND Short Transition Figure 13. Efficiency vs Output Current

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Link(s): bq24610 bq24617

Page 12

bq24610

bq24617

SLUS892 –DECEMBER 2009

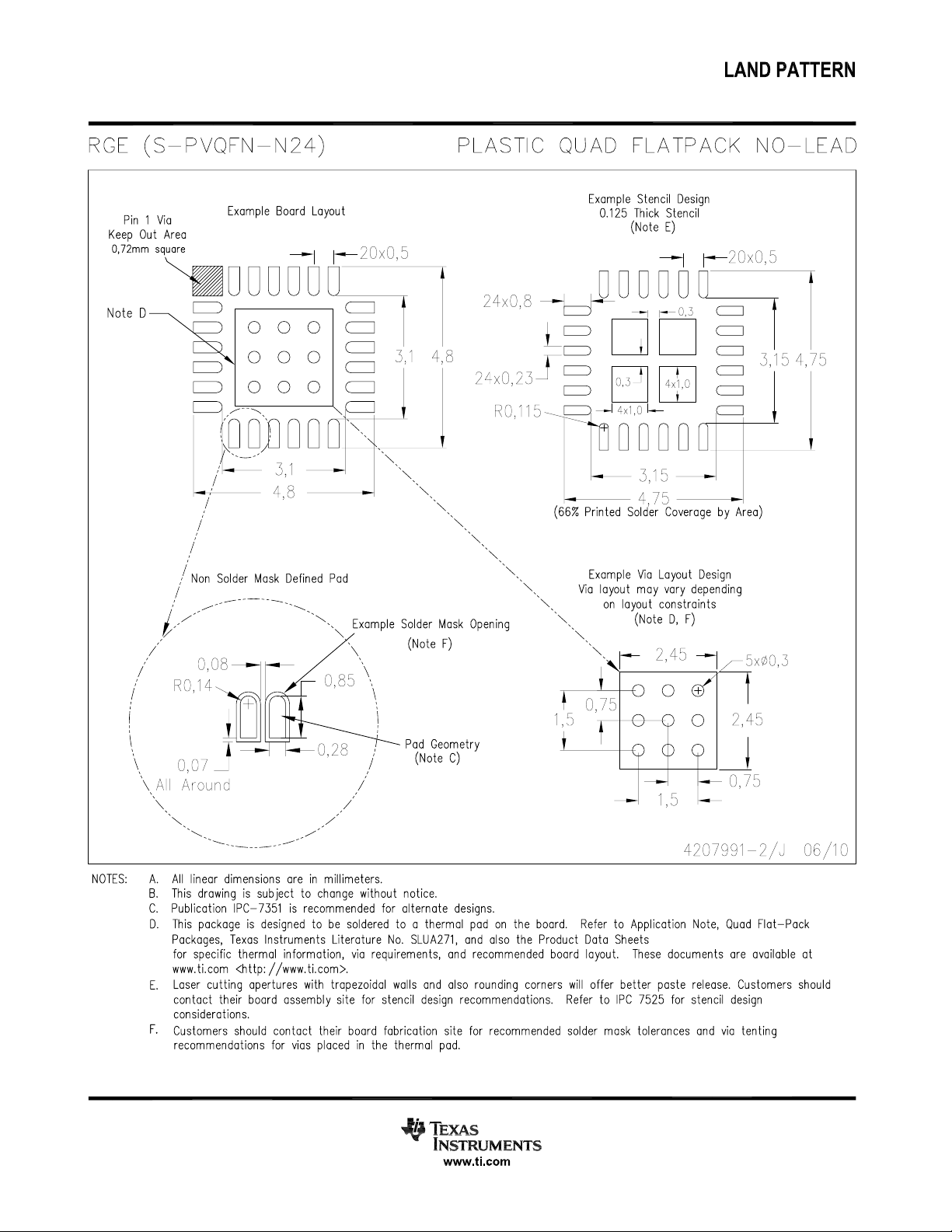

Pin Functions – 24-Pin QFN

PIN

NO. NAME

1 ACN Adapter current sense resistor, negative input. A 0.1-μF ceramic capacitor is placed from ACN to ACP to provide differential-mode

filtering. An optional 0.1-μF ceramic capacitor is placed from ACN pin to GND for common-mode filtering.

2 ACP Adapter current sense resistor, positive input. A 0.1-μF ceramic capacitor is placed from ACN to ACP to provide differential-mode

filtering. A 0.1-μF ceramic capacitor is placed from ACP pin to GND for common-mode filtering.

3 ACDRV AC adapter to system MOSFET driver output. Connect through a 1-kΩ resistor to the gate of the ACFET P-channel power MOSFET

and the reverse conduction blocking P-channel power MOSFET. The internal gate drive is asymmetrical, allowing a quick turn-off and

slow turn-on, in addition to the internal break-before-make logic with respect to BATDRV. If needed, an optional capacitor from gate to

source of the ACFET is used to slow down the ON and OFF times.

4 CE Charge-enable active-HIGH logic input. HI enables charge. LO disables charge. It has an internal 1MΩ pull-down resistor.

5 STAT1 Open-drain charge status pin to indicate various charger operation (See Table 3)

6 TS Temperature qualification voltage input for battery pack negative temperature coefficient thermistor. Program the hot and cold

temperature window with a resistor divider from VREF to TS to GND. (See Figure 18)

7 TTC SafetyTimer and termination control. Connect a capacitor from this node to GND to set the timer. When this input is LOW, the timer

and termination are disabled. When this input is HIGH, the timer is disabled but termination is allowed.

8 PG Open-drain power-good status output. Active LOW when IC has a valid VCC (not in UVLO or ACOV or SLEEP mode). Active HIGH

when IC has an invalid VCC. PGcan be used to drive a LED or communicate with a host processor.

9 STAT2 Open-drain charge status pin to indicate various charger operation (See Table 3)

10 VREF 3.3V regulated voltage output. Place a 1-μF ceramic capacitor from VREF to GND pin close to the IC. This voltage could be used for

programming of voltage and current regulation and for programming the TS threshold.

11 ISET1 Fast Charge current set input. The voltage of ISET1 pin programs the fast charge current regulation set-point.

12 VFB Output voltage analog feedback adjustment. Connect the output of a resistive voltage divider from the battery terminals to this node to

adjust the output battery regulation voltage.

13 SRN Charge current sense resistor, negative input. A 0.1-μF ceramic capacitor is placed from SRN to SRP to provide differential-mode

filtering. An optional 0.1-μF ceramic capacitor is placed from SRN pin to GND for common-mode filtering.

14 SRP Charge current sense resistor, positive input. A 0.1-μF ceramic capacitor is placed from SRN to SRP to provide differential-mode

filtering. A 0.1-μF ceramic capacitor is placed from SRP pin to GND for common-mode filtering.

15 ISET2 Pre-charge and termination current set input. The voltage of ISET2 pin programs the pre-charge current regulation set-point and

termination current trigger point.

16 ACSET Adapter current set input. The voltage of ACSET pin programs the input current regulation set-point during Dynamic Power

Management (DPM)

17 GND Low-current sensitive analog/digital ground. On PCB layout, connect with PowerPad underneath the IC.

18 REGN PWM low side driver positive 6V supply output. Connect a 1-μF ceramic capacitor from REGN to GND pin, close to the IC. Use for

low side driver and high-side driver bootstrap voltage by connecting a small signal Schottky diode from REGN to BTST.

19 LODRV PWM low side driver output. Connect to the gate of the low-side power MOSFET with a short trace.

20 PH PWM high side driver negative supply. Connect to the Phase switching node (junction of the low-side power MOSFET drain, high-side

power MOSFET source, and output inductor). Connect the 0.1-μF bootstrap capacitor from PH to BTST.

21 HIDRV PWM high side driver output. Connect to the gate of the high-side power MOSFET with a short trace.

22 BTST PWM high side driver positive supply. Connect to the Phase switching node (junction of the low-side power MOSFET drain, high-side

power MOSFET source, and output inductor). Connect the 0.1-μF bootstrap capacitor from SW to BTST.

23 BATDRV Battery to system MOSFET driver output. Gate drive for the battery to system load BAT PMOS power FET to isolate the system from

the battery to prevent current flow from the system to the battery, while allowing a low impedance path from battery to system.

Connect this pin through a 1-kΩ resistor to the gate of the input BAT P-channel MOSFET. Connect the source of the FET to the

system load voltage node. Connect the drain of the FET to the battery pack positive terminal. The internal gate drive is asymmetrical

to allow a quick turn-off and slow turn-on, in addition to the internal break-before-make logic with respect to ACDRV. If needed, an

optional capacitor from gate to source of the BATFET is used to slow down the ON and OFF times.

24 VCC IC power positive supply. Connect through a 10-Ω to the common-source (diode-OR) point: source of high-side P-channel MOSFET

and source of reverse-blocking power P-channel MOSFET. Place a 1-μF ceramic capacitor from VCC to GND pin close to the IC.

PowerPAD Exposed pad beneath the IC. Always solder PowerPAD to the board, and have vias on the PowerPAD plane star-connecting to GND

and ground plane for high-current power converter. It also serves as a thermal pad to dissipate the heat.

FUNCTION DESCRIPTION

www.ti.com

12 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): bq24610 bq24617

Page 13

VCC

ACDRV

BATDRV

BTST

HIDRV

PH

REGN

LODRV

GND

TS

bq24610/17

CE

ACP

ACN

VFB

SRP

6 VLDO

V(ACP-ACN)

+

-

V(SRP-SRN)

COMP

ERROR

AMPLIFIER

20µA

1V

2.1 V

IBAT_ REG

SRN

VCC

VCC-6 V

LDO

STATE

MACHINE

LOGIC

BATTERY

DETECTION

LOGIC

VCC

PH

4.2V

+

-

BTST REFRESH

SYSTEM

POWER

SELECTOR

LOGIC

CE

145 degC

ICTj

TSHUT

SRN+100 mV

VCC

SLEEP

LEVEL

SHIFTER

ACN

+

-

+

+

-

+

-

+

-

+

-

V(SRP-SRN)

CHG_OCP

+

-

160% XIBAT_REG

SYNCH

SRP-SRN

ISET1

ISET2

ACSET

IBAT_ REG

ISET1

ISET2

5 mV

20X

BAT

BAT_OVP

+

-

104% XVBAT_REG

LTF

+

-

HTF

VREF

TCO

+

-

+

-

SUSPEND

VCC

ACOV

+

-

V

ACOV

VREF

STAT 1

STAT1

20X

STAT 2

STAT2

3.3 V

LDO

VCC

VFB

LOWV

+

-

RCHRG

+

-

1.55V

+

-

2.05 V

VFB

RCHRG

TERM

+

-

V(SRP - SRN)

ISET2

TERM

TERMINATECHARGE

+

-

TTC

TTC

+

-

+

-

UVLO

V

UVLO

VCC

SLEEP

UVLO

VCC-6 V

VCC-6V

ACN-6V

ACN-6 V

LDO

ACN ACN-6 V

ACOV

PWM

CONTROL

LOGIC

+

-

PWM

+

-

+

-

+

-

PG

PG

+

-

CHARGE

20 µA

DISCHARGE

CHARGE

OR

DISCHARGE

8 mA

BAT_OVP

+

-

DISABLE

TMR/TERM

0.4 V

TTC

INTERNAL

REFERENCE

VREF

ACN-SRN

SRN+200 mV

+

-

ACN

Safety

Timer

TTC

FAULT

2 mA

FAULT

1M

CE

-

bq24610

bq24617

www.ti.com

BLOCK DIAGRAM

Figure 14. Functional Block Diagram for bq24610/7

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Link(s): bq24610 bq24617

SLUS892 –DECEMBER 2009

Page 14

VCC > SRN

No

IndicateSLEEP

SLEEP MODE

Yes

EnableVREFLDO &

ChipBias

Turnon

BATDRVFET

30msdelay

TurnoffBATFET

Turnon ACFET

Battery

present?

Yes

Initiatebattery

detectalgorithm

Indicatebattery

absent

No

Conditionsmet

forcharge?

No

IndicateNOT

CHARGING,

Suspendtimers

Yes

VFB < VLOWV Yes

Start 30 minute

prechargetimer

IndicateCharge-

In-Progress

Regulate

prechargecurrent

VFB < VLOWV

Precharge

timerexpired?

Yes

No

Yes

IndicateFAULT

FAULT

EnableI

FAULT

VFB > VRECH

StartFastcharge

timer

IndicateCharge-

In-Progress

Regulate

fastchargecurrent

Fastcharge

TimerExpired?

No Yes

VFB > VRECH

&

ICHG < ITERM

Yes

No

IndicateChargeIn

Progress

Turnoffcharge,

EnableI

DISCHG

for 1

second

VFB < VRECH

No

IndicateDONE

ChargeComplete

Yes

IndicateBATTERY

ABSENT

BatteryRemoved

Yes

POR

See EnablingandDisabling

ChargeSection

Conditionsmet

forcharge?

No

Yes

No

Conditionsmet

forcharge?

No

Yes

IndicateNOT

CHARGING,

Suspendtimers

No

No

bq24610

bq24617

SLUS892 –DECEMBER 2009

OPERATIONAL FLOWCHART

www.ti.com

Figure 15. Operational Flowchart

14 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): bq24610 bq24617

Page 15

V

LOWV

V

RECH

I

PRECH

& I

TERM

Precharge

Time

FastchargeSafetyTime

Precharge

Current

Regulation

Phase

FastchargeCurrent

RegulationPhase

FastchargeVoltage

RegulationPhase

Termination

Charge

Voltage

Charge

Current

RegulationCurrent

RegulationVoltage

R2

V = 2.1 V 1+ ,

BAT

R1

é ù

´

ê ú

ë û

ISET1

CHARGE

SR

V

I =

20 R´

www.ti.com

bq24610

bq24617

SLUS892 –DECEMBER 2009

DETAILED DESCRIPTION

Battery Voltage Regulation

The bq24610/7 uses a high accuracy voltage bandgap and regulator for the high charging voltage accuaracy.

The charge voltage is programmed via a resistor divider from the battery to ground, with the midpoint tied to the

VFB pin. The voltage at the VFB pin is regulated to 2.1V, giving the following equation for the regulation voltage:

where R2 is connected from VFB to the battery and R1 is connected from VFB to GND.

Battery Current Regulation

The ISET1 input sets the maximum fast charging current. Battery charge current is sensed by resistor R

connected between SRP and SRN. The full-scale differential voltage between SRP and SRN is 100mV. Thus, for

a 10mΩ sense resistor, the maximum charging current is 10A. The equation for charge current is:

V

voltage across RSRwith default value of 10mΩ. However, resistors of other values can also be used. A larger

sense resistor will give a larger sense voltage, a higher regulation accuracy; but, at the expense of higher

conduction loss.

Figure 16. Typical Charging Profile

, the input voltage range of ISET1 is between 0V and 2V. The SRP and SRN pins are used to sense

ISET1

(1)

SR

(2)

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Link(s): bq24610 bq24617

Page 16

ACSET

DPM

AC

V

I =

20 R´

ISET2

PRECHARGE

SR

V

I =

100 R´

ISET2

TERM

SR

V

I =

100 R´

CHARGE TTC TTC

t = C K´

bq24610

bq24617

SLUS892 –DECEMBER 2009

Input Adapter Current Regulation

The total input from an AC adapter or other DC sources is a function of the system supply current and the battery

charging current. System current normally fluctuates as portions of the systems are powered up or down. Without

Dynamic Power Management (DPM), the source must be able to supply the maximum system current and the

maximum charger input current simultaneously. By using DPM, the battery charger reduces the charging current

when the input current exceeds the input current limit set by ACSET. The current capability of the AC adaptor

can be lowered, reducing system cost.

Similar to setting battery regulation current, adaptor current is sensed by resistor RACconnected between ACP

and ACN. Its maximum value is set by ACSET using Equation 3:

V

, the input voltage range of ACSET is between 0 and 2V. The ACP and ACN pins are used to sense

ACSET

voltage across RACwith default value of 10mΩ. However, resistors of other values can also be used. A larger the

sense resistor will give a larger sense voltage, and a higher regulation accuracy; but, at the expense of higher

conduction loss.

Precharge

On power-up, if the battery voltage is below the V

the battery. This feature is intended to revive deeply discharged cells. If the V

30 minutes of initiating precharge, the charger turns off and a FAULT is indicated on the status pins.

V

, the precharge current is determined by the voltage on the ISET2 pin according to Equation 4.

ISET2

threshold, the bq24610/7 applies the precharge current to

LOWV

threshold is not reached within

LOWV

www.ti.com

(3)

(4)

Charge Termination, Recharge, and Safety Timer

The bq24610/7 monitors the charging current during the voltage regulation phase. When V

termination is detected while the voltage on the VFB pin is higher than the V

current is less than the I

threshold, as calculated in Equation 5:

TERM

threshold AND the charge

RECH

The input voltage of ISET2 is between 0 and 2V. The minimum precharge/termination current is clamped to be

around 125mA with default 10mΩ sensing resistor. As a safety backup, the bq24610/7 also provides a

programmable charge timer. The charge time is programmed by the capacitor connected between the TTC pin

and GND, and is given by Equation 6

where C

GND, and K

(range from 0.01µF to 0.11 µF to give 1-10hr safety time) is the capacitor connected from TTC pin to

TTC

is the constant multiplier (5.6min/nF).

TTC

A new charge cycle is initiated and safety timer is reset when one of the following conditions occur:

• The battery voltage falls below the recharge threshold

• A power-on-reset (POR) event occurs

• CE is toggled

The TTC pin may be taken LOW to disable termination and to disable the safety timer. If TTC is pulled to VREF,

the bq24610/7 will continue to allow termination but disable the safety timer. TTC taken low will reset the safety

timer. When ACOV, VCCLOWV and SLEEP mode resume normal, the safety timer will be reset.

TTC

is valid,

(5)

(6)

16 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): bq24610 bq24617

Page 17

bq24610

bq24617

www.ti.com

Power Up

The bq24610/7 uses a SLEEP comparator to determine the source of power on the VCC pin, since VCC can be

supplied either from the battery or the adapter. If the VCC voltage is greater than the SRN voltage, bq24610/7

will enable the ACFET and disable BATFET. If all other conditions are met for charging, bq24610/7 will then

attempt to charge the battery (See Enabling and Disabling Charging). If the SRN voltage is greater than VCC,

indicating that the battery is the power source, bq24610/7 enables the BATFET, and enters a low quiescent

current (<15μA) SLEEP mode to minimize current drain from the battery.

If VCC is below the UVLO threshold, the device is disabled, ACFET turns off and BATFET turns on.

Enable and Disable Charging

The following conditions have to be valid before charge is enabled:

• CE is HIGH

• The device is not in Under-Voltage-Lockout (UVLO) and not in VCCLOWV mode

• The device is not in SLEEP mode

• The VCC voltage is lower than the AC over-voltage threshold (VCC < V

• 30ms delay is complete after initial power-up

• The REGN LDO and VREF LDO voltages are at the correct levels

• Thermal Shut (TSHUT) is not valid

• TS fault is not detected

One of the following conditions will stop on-going charging:

• CE is LOW;

• Adapter is removed, causing the device to enter UVLO, VCCLOWV or SLEEP mode;

• Adapter is over voltage;

• The REGN or VREF LDOs are overloaded;

• TSHUT IC temperature threshold is reached (145°C on rising-edge with 15°C hysteresis).

• TS voltage goes out of range indicating the battery temperature is too hot or too cold.

• TTC safety timer out

ACOV

)

SLUS892 –DECEMBER 2009

System Power Selector

The bq24610/7 automatically switches adapter or battery power to the system load. The battery is connected to

the system by default during power up or during SLEEP mode. The battery is disconnected from the system and

then the adapter is connected to the system 30ms after exiting SLEEP. An automatic break-before-make logic

prevents shoot-through currents when the selectors switch.

The ACDRV is used to drive a pair of back-to-back p-channel power MOSFETs between adapter and ACP with

sources connected together and to VCC. The FET connected to adapter prevents reverse discharge from the

battery to the adapter when turned off. The p-channel FET with the drain connected to the adapter input provides

reverse battery discharge protection when off; and also minimizes system power dissipation, with its low-R

compared to a Schottky diode. The other p-channel FET connected to ACP separates battery from adapter, and

provides a limited dI/dt when connecting the adapter to the system by controlling the FET turn-on time. The

BATDRV controls a p-channel power MOSFET placed between BAT and system.

When adapter is not detected, the ACDRV is pulled to VCC to keep ACFET off, disconnecting the adapter from

system. BATDRV stays at ACN-6V to connect battery to system.

Approximately 30ms after the device comes out of SLEEP mode, the system begins to switch from battery to

adapter. The break-before-make logic keeps both ACFET and BATFET off for 10us before ACFET turns on. This

prevents shoot-through current or any large discharging current from going into the battery. The BATDRV is

pulled up to ACN and the ACDRV pin is set to VCC-6V by an internal regulator to turn on p-channel ACFET,

connecting the adapter to the system.

When the adapter is removed, the system waits until VCC drops back to within 200mV above SRN to switch from

adapter back to battery. The break-before-make logic still keeps 10μs dead time. The ACDRV is pulled up to

VCC and the BATDRV pin is set to ACN-6V by an internal regulator to turn on p-channel BATFET, connecting

the battery to the system.

DSON

,

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Link(s): bq24610 bq24617

Page 18

o

o o

1

=

2 L C

f

p

bq24610

bq24617

SLUS892 –DECEMBER 2009

Asymmetrical gate drive (fast turn-off and slow turn-on) for the ACDRV and BATDRV drivers provides fast

turn-off and slow turn-on of the ACFET and BATFET to help the break-before-make logic and to allow a soft-start

at turn-on of either FET. The soft-start time can be further increased, by putting a capacitor from gate to source

of the p-channel power MOSFETs.

Automatic Internal Soft-Start Charger Current

The charger automatically soft-starts the charger regulation current every time the charger goes into fast-charge

to ensure there is no overshoot or stress on the output capacitors or the power converter. The soft-start consists

of stepping-up the charge regulation current into 8 evenly divided steps up to the programmed charge current.

Each step lasts around 1.6ms, for a typical rise time of 12.8ms. No external components are needed for this

function.

Converter Operation

The synchronous buck PWM converter uses a fixed frequency voltage mode with feed-forward control scheme. A

type III compensation network allows using ceramic capacitors at the output of the converter. The compensation

input stage is connected internally between the feedback output (FBO) and the error amplifier input (EAI). The

feedback compensation stage is connected between the error amplifier input (EAI) and error amplifier output

(EAO). The LC output filter is selected to give a resonant frequency of 12kHz–17kHz for bq24610/7, where

resonant frequency, fo, is given by:

www.ti.com

(7)

An internal saw-tooth ramp is compared to the internal EAO error control signal to vary the duty-cycle of the

converter. The ramp height is 7% of the input adapter voltage making it always directly proportional to the input

adapter voltage. This cancels out any loop gain variation due to a change in input voltage, and simplifies the loop

compensation. The ramp is offset by 300mV in order to allow zero percent duty-cycle when the EAO signal is

below the ramp. The EAO signal is also allowed to exceed the saw-tooth ramp signal in order to get a 100%

duty-cycle PWM request. Internal gate drive logic allows achieving 99.5% duty-cycle while ensuring the

N-channel upper device always has enough voltage to stay fully on. If the BTST pin to PH pin voltage falls below

4.2V for more than 3 cycles, then the high-side n-channel power MOSFET is turned off and the low-side

n-channel power MOSFET is turned on to pull the PH node down and recharge the BTST capacitor. Then the

high-side driver returns to 100% duty-cycle operation until the (BTST-PH) voltage is detected to fall low again

due to leakage current discharging the BTST capacitor below the 4.2 V, and the reset pulse is reissued.

The fixed frequency oscillator keeps tight control of the switching frequency under all conditions of input voltage,

battery voltage, charge current, and temperature, simplifying output filter design and keeping it out of the audible

noise region. Also see Application Information for how to select inductor, capacitor and MOSFET.

Synchronous and Non-Synchronous Operation

The charger operates in synchronous mode when the SRP-SRN voltage is above 5mV (0.5A inductor current for

a 10mΩ sense resistor). During synchronous mode, the internal gate drive logic ensures there is

break-before-make complimentary switching to prevent shoot-through currents. During the 30ns dead time where

both FETs are off, the body-diode of the low-side power MOSFET conducts the inductor current. Having the

low-side FET turn-on keeps the power dissipation low, and allows safely charging at high currents. During

synchronous mode the inductor current is always flowing and converter operates in continuous conduction mode

(CCM), creating a fixed two-pole system.

The charger operates in non-synchronous mode when the SRP-SRN voltage is below 5mV (0.5A inductor

current for a 10mΩ sense resistor). The charger is forced into non-synchronous mode when battery voltage is

lower than 2V or when the average SRP-SRN voltage is lower than 1.25mV.

During non-synchronous operation, the body-diode of lower-side MOSFET can conduct the positive inductor

current after the high-side n-channel power MOSFET turns off. When the load current decreases and the

inductor current drops to zero, the body diode will be naturally turned off and the inductor current will become

discontinuous. This mode is called Discontinuous Conduction Mode (DCM). During DCM, the low-side n-channel

power MOSFET will turn-on for around 80ns when the bootstrap capacitor voltage drops below 4.2V, then the

low-side power MOSFET will turn-off and stay off until the beginning of the next cycle, where the high-side power

MOSFET is turned on again. The 80ns low-side MOSFET on-time is required to ensure the bootstrap capacitor is

18 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): bq24610 bq24617

Page 19

bq24610

bq24617

www.ti.com

always recharged and able to keep the high-side power MOSFET on during the next cycle. This is important for

battery chargers, where unlike regular dc-dc converters, there is a battery load that maintains a voltage and can

both source and sink current. The 80ns low-side pulse pulls the PH node (connection between high and low-side

MOSFET) down, allowing the bootstrap capacitor to recharge up to the REGN LDO value. After the 80ns, the

low-side MOSFET is kept off to prevent negative inductor current from occurring.

At very low currents during non-synchronous operation, there may be a small amount of negative inductor

current during the 80ns recharge pulse. The charge should be low enough to be absorbed by the input

capacitance. Whenever the converter goes into zero percent duty-cycle, the high-side MOSFET does not turn on,

and the low-side MOSFET does not turn on (only 80ns recharge pulse) either, and there is almost no discharge

from the battery.

During the DCM mode the loop response automatically changes and has a single pole system at which the pole

is proportional to the load current, because the converter does not sink current, and only the load provides a

current sink. This means at very low currents the loop response is slower, as there is less sinking current

available to discharge the output voltage.

Cycle-by-Cycle Charge Under Current Protection

If the SRP-SRN voltage decreases below 5mV (The charger is also forced into non-synchronous mode when the

average SRP-SRN voltage is lower than 1.25mV), the low side FET will be turned off for the remainder of the

switching cycle to prevent negative inductor current. During DCM, the low-side FET will only turn on for at around

80ns when the bootstrap capacitor voltage drops below 4.2V to provide refresh charge for the bootstrap

capacitor. This is important to prevent negative inductor current from causing a boost effect in which the input

voltage increases as power is transferred from the battery to the input capacitors and lead to an over-voltage

stress on the VCC node and potentially cause damage to the system.

SLUS892 –DECEMBER 2009

Input Over Voltage Protection (ACOV)

ACOV provides protection to prevent system damage due to high input voltage. Once the adapter voltage

reaches the ACOV threshold, charge is disabled and the system is switched to battery instead of adapter.

Input Under Voltage Lock Out (UVLO)

The system must have a minimum VCC voltage to allow proper operation. This VCC voltage could come from

either input adapter or battery, since a conduction path exists from the battery to VCC through the high side

NMOS body diode. When VCC is below the UVLO threshold, all circuits on the IC are disabled, and the gate

drive bias to ACFET and BATFET are disabled.

Battery Over-Voltage Protection

The converter will not allow the high-side FET to turn-on until the BAT voltage goes below 102% of the regulation

voltage. This allows one-cycle response to an over-voltage condition – such as occurs when the load is removed

or the battery is disconnected. An 8mA current sink from SRP to GND is on only during charge and allows

discharging the stored output inductor energy that is transferred to the output capacitors. BATOVP will also

suspend the safety timer.

Cycle-by-Cycle Charge Over-Current Protection

The charger has a secondary cycle-to-cycle over-current protection. It monitors the charge current, and prevents

the current from exceeding 160% of the programmed charge current. The high-side gate drive turns off when the

over-current is detected, and automatically resumes when the current falls below the over-current threshold.

Thermal Shutdown Protection

The QFN package has low thermal impedance, which provides good thermal conduction from the silicon to the

ambient, to keep junctions temperatures low. As added level of protection, the charger converter turns off and

self-protects whenever the junction temperature exceeds the TSHUT threshold of 145°C. The charger stays off

until the junction temperature falls below 130°C, then the charger will soft-start again if all other enable charge

conditions are valid. Thermal shutdown will also suspend the safety timer.

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 19

Product Folder Link(s): bq24610 bq24617

Page 20

CHARGESUSPENDED CHARGESUSPENDED

TEMPERATURERANGE

TOINITIATECHARGE

TEMPERATURERANGE

DURING A CHARGE

CYCLE

V

LTF

GND

V

TCO

GND

V

LTFH

VREF

VREF

CHARGESUSPENDED CHARGESUSPENDED

V

HTF

V

LTF

V

LTFH

VR EF COLD HO T

LTF HT F

VR EF VRE F

HOT COLD

HTF LTF

1 1

V RTH RTH

V V

RT2 =

V V

RTH 1 RT H 1

V V

æ ö

´ ´ ´ -

ç ÷

è ø

æ ö æ ö

´ - - ´ -

ç ÷ ç ÷

è ø è ø

VREF

LTF

COLD

V

1

V

RT1 =

1 1

+

RT2 RTH

-

VREF

TS

RT2

RT1

RTH

103AT

bq24610/7

bq24610

bq24617

SLUS892 –DECEMBER 2009

Temperature Qualification

The controller continuously monitors battery temperature by measuring the voltage between the TS pin and

GND. A negative temperature coefficient thermistor (NTC) and an external voltage divider typically develop this

voltage. The controller compares this voltage against its internal thresholds to determine if charging is allowed.

To initiate a charge cycle, the battery temperature must be within the V(LTF) to V(HTF) thresholds. If battery

temperature is outside of this range, the controller suspends charge and the safety timer and waits until the

battery temperature is within the V(LTF) to V(HTF) range. During the charge cycle the battery temperature must

be within the V(LTF) to V(TCO) thresholds. If battery temperature is outside of this range, the controller suspends

charge and waits until the battery temperature is within the V(LTF) to V(HTF) range. The controller suspends

charge by turning off the PWM charge FETs. Figure below summarizes the operation.

www.ti.com

Figure 17. TS pin, Thermistor Sense Thresholds

Assuming a 103AT NTC thermistor on the battery pack as shown in Figure 1, the value RT1 and RT2 can be

determined by using the following equations:

(8)

(9)

20 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Figure 18. TS Resistor Network

Product Folder Link(s): bq24610 bq24617

Page 21

www.ti.com

bq24610

bq24617

SLUS892 –DECEMBER 2009

For example, 103AT NTC thermistors are used to monitor the battery pack temperature. Select T

T

= 40ºC then we get RT2= 430kΩ, RT1= 9.31kΩ and T

HOT

CUT-OFF

is around 45ºC. A small RC filter is suggested

COLD

= 0ºC and

to use for system-level ESD protection.

Timer Fault Recovery

The bq24610/7 provides a recovery method to deal with timer fault conditions. The following summarizes this

method:

Condition 1: The battery voltage is above the recharge threshold and a timeout fault occurs.

Recovery Method: The timer fault will clear when the battery voltage falls below the recharge threshold, and

battery detection will begin. Taking CE low or a POR condition will also clear the fault.

Condition 2: The battery voltage is below the recharge threshold and a timeout fault occurs.

Recovery Method: Under this scenario, the bq24610/7 applies the I

current to the battery. This small

FAULT

current is used to detect a battery removal condition and remains on as long as the battery voltage stays below

the recharge threshold. If the battery voltage goes above the recharge threshold, the bq24610/7 disables the

fault current and executes the recovery method described in Condition 1. Taking CE low or a POR condition will

also clear the fault.

PG Output

The open drain PG(power good) output indicates whether the VCC voltage is valid or not. The open drain FET

turns on whenever bq24610/7 has a valid VCC input ( not in UVLO or ACOV or SLEEP mode). The PGpin can

be used to drive an LED or communicate to the host processor.

CE (Charge Enable)

The CE digital input is used to disable or enable the charge process. A high-level signal on this pin enables

charge, provided all the other conditions for charge are met (see Enabling and Disabling Charge). A high to low

transition on this pin also resets all timers and fault conditions. There is an internal 1MΩ pulldown resistor on the

CE pin, so if CE is floated the charge will not turn on.

Inductor, Capacitor, and Sense Resistor Selection Guidelines

The bq24610/7 provides internal loop compensation. With this scheme, best stability occurs when the LC

resonant frequency, fo, is approximately 12kHz–17kHz for bq24610/7.

The following table provides a summary of typical LC components for various charge currents:

Table 2. Typical Inductor, Capacitor, and Sense Resistor Values as a Function of Charge Current for

bq24610/7 (600 kHz Switching Frequency)

CHARGE CURRENT 2A 4A 6A 8A 10A

Output Inductor Lo 6.8 μH 6.8 μH 4.7 μH 3.3 μH 3.3 μH

Output Capacitor Co 20 μF 20 μF 30 μF 40 μF 40 μF

Sense Resistor 10 mΩ 10 mΩ 10 mΩ 10 mΩ 10 mΩ

Charge Status Outputs

The open-drain STAT1 and STAT2 outputs indicate various charger operations as shown in the table below.

These status pins can be used to drive LEDs or communicate with the host processor. Note that OFF indicates

that the open-drain transistor is turned off.

Table 3. STAT Pin Definition for bq24610/7

CHARGE STATE STAT1 STAT2

Charge in progress ON OFF

Charge complete OFF ON

Charge suspend, timer fault, over-voltage, sleep mode, battery absent OFF OFF

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 21

Product Folder Link(s): bq24610 bq24617

Page 22

PORorRECHARGE

Enable 125mA Charge,

Start 0.5stimer

VFB > V

RECH

No

BatteryPresent,

BeginCharge

0.5stimer

expired

Yes

No

Yes

Disable 125mA

Charge

Apply 8mA discharge

current, start 1stimer

VFB < V

LOWV

No

BatteryPresent,

BeginCharge

1stimer

expired

Yes

No

Yes

Disable 8mA

dischargecurrent

Thebatterydetectionroutinerunson

powerup, orifVFBfallsbelowVRECH

duetoremovingabatteryor

dischargingabattery

Battery Absent

bq24610

bq24617

SLUS892 –DECEMBER 2009

Battery Detection

For applications with removable battery packs, bq24610/7 provides a battery absent detection scheme to reliably

detect insertion or removal of battery packs.

www.ti.com

Figure 19. Battery Detection Flowchart

Once the device has powered up, an 8mA discharge current will be applied to the SRN terminal. If the battery

voltage falls below the LOWV threshold within 1 second, the discharge source is turned off, and the charger is

turned on at low charge current (125mA). If the battery voltage gets up above the recharge threshold within

500ms, there is no battery present and the cycle restarts. If either the 500ms or 1 second timer time out before

the respective thresholds are hit, a battery is detected and a charge cycle is initiated.

22 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): bq24610 bq24617

Page 23

V

RECH

V

LOWV

Battery

inserted

Batterynotdetected

t

WAKE

Batterydetected

t

LOWV_DEG

t

RECH_DEG

V

REG

( )V

WAKE

( )V

DISH

DISC H DISCH

MAX

2

1

I t

C =

R

0.5 1+

R

´

é ù

´

ê ú

ë û

MAX

8mA 1sec

C = = 2.7 mF

500k

0.5 1+

100k

´

é ù

´

ê ú

ë û

www.ti.com

bq24610

bq24617

SLUS892 –DECEMBER 2009

Figure 20. Battery Detect Timing Diagram

Care must be taken that the total output capacitance at the battery node is not so large that the discharge current

source cannot pull the voltage below the LOWV threshold during the 1 second discharge time. The maximum

output capacitance can be calculated as follows:

(10)

Where C

is the maximum output capacitance, I

MAX

is the discharge current, t

DISCH

is the discharge time, and

DISCH

R2and R1are the voltage feedback resistors from the battery to the VFB pin. The 0.5 factor is the difference

between the RECHARGE and the LOWV thresholds at the VFB pin.

Example

For a 3-cell Li+ charger, with R2 = 500k, R1 = 100k (giving 12.6V for voltage regulation), I

DISCH

= 8mA, t

DISCH

= 1

second,

(11)

Based on these calculations, no more than 2.7 mF should be allowed on the battery node for proper operation of

the battery detection circuit.

Component List for Typical System Circuit of Figure 1

PART DESIGNATOR QTY DESCRIPTION

Q1, Q2, Q3 3 P-channel MOSFET, –30 V,–35 A, PowerPAK 1212-8, Vishay-Siliconix, Si7617DN

Q4, Q5 2 N-channel MOSFET, 30 V, 12 A, PowerPAK 1212-8, Vishay-Siliconix, Sis412DN

D1 1 Diode, Dual Schottky, 30 V, 200 mA, SOT23, Fairchild, BAT54C

D2, D3, D4 3 LED Diode, Green, 2.1V, 20mA, LTST-C190GKT

RAC, R

SR

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 23

2 Sense Resistor, 10 mΩ, 2010, Vishay-Dale, WSL2010R0100F

Product Folder Link(s): bq24610 bq24617

Page 24

bq24610

bq24617

SLUS892 –DECEMBER 2009

PART DESIGNATOR QTY DESCRIPTION

L1 1 Inductor, 6.8 µH, 5.5A, Vishay-Dale IHLP2525CZ

C8, C9, C12, C13 4 Capacitor, Ceramic, 10 µF, 35 V, 20%, X7R

C4, C5 2 Capacitor, Ceramic, 1 µF, 16 V, 10%, X7R

C1, C3, C6, C11 4 Capacitor, Ceramic, 0.1 µF, 16 V, 10%, X7R

C2, C10 2 Capacitor, Ceramic, 0.1 µF, 50 V, 10%, X7R

C7 1 Capacitor, Ceramic, 1 µF, 50 V, 10%, X7R

C14, C15 (Optional) 2 Capacitor, Ceramic, 0.1 µF, 50 V, 10%, X7R

C16 1 Capacitor, Ceramic, 2.2 µF, 35V, 10%, X7R

C

ff

C

TTC

R1, R3, R5, R7 4 Resistor, Chip, 100 kΩ, 1/16W, 0.5%

R2 1 Resistor, Chip, 500 kΩ, 1/16W, 0.5%

R4 1 Resistor, Chip, 32.4 kΩ, 1/16W, 0.5%

R6 1 Resistor, Chip, 10 kΩ, 1/16W, 0.5%

R8 1 Resistor, Chip, 22.1 kΩ, 1/16W, 0.5%

R9 1 Resistor, Chip, 9.31 kΩ, 1/16W, 1%

R10 1 Resistor, Chip, 430 kΩ, 1/16W, 1%

R11, R12, R13, R18, R19 5 Resistor, Chip, 10 kΩ, 1/16W, 5%

R14, R15 (optional) 2 Resistor, Chip, 100 kΩ, 1/16W, 5%

R16 1 Resistor, Chip, 100 Ω, 1/16W, 5%

R17 1 Resistor, Chip, 10 Ω, 1/4W, 5%

R20 1 Resistor, Chip, 2 Ω, 1W, 5%

1 Capacitor, Ceramic, 22 pF, 25V, 10%, X7R

1 Capacitor, Ceramic, 0.056 µF, 16V, 5%, X7R

www.ti.com

24 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): bq24610 bq24617

Page 25

SAT CHG RIPPLE

I I + (1/2) I³

IN

RIPPLE

S

V D (1 D)

I =

f L

´ ´ -

´

CIN CHG

I = I D (1 D)´ ´ -

RIPPLE

COUT RIPPLE

I

I = 0.29 I

2 3

» ´

´

2

OUT

o

2

IN

s

V

1

V 1

V

8LC f

æ ö

D = -

ç ÷

ç ÷

è ø

bq24610

bq24617

www.ti.com

APPLICATION INFORMATION

Inductor Selection

The bq24610/7 has 600kHz switching frequency to allow the use of small inductor and capacitor values. Inductor

saturation current should be higher than the charging current (I

The inductor ripple current depends on input voltage (VIN), duty cycle (D=V

inductance (L):

The maximum inductor ripple current happens with D = 0.5 or close to 0.5. For example, the battery charging

voltage range is from 9V to 12.6V for 3-cell battery pack. For 20V adapter voltage, 10V battery voltage gives the

maximum inductor ripple current. Another example is 4-cell battery, the battery voltage range is from 12V to

16.8V, and 12V battery voltage gives the maximum inductor ripple current.

Usually inductor ripple is designed in the range of (20–40%) maximum charging current as a trade-off between

inductor size and efficiency for a practical design.

The bq24610/7 has cycle-by-cycle charge under current protection (UCP) by monitoring charging current sensing

resistor to prevent negative inductor current. The Typical UCP threshold is 5mV falling edge corresponding to

0.5A falling edge for a 10mΩ charging current sensing resistor.

) plus half the ripple current (I

CHG

OUT/VIN

), switching frequency (fs) and

SLUS892 –DECEMBER 2009

):

RIPPLE

(12)

(13)

Input Capacitor

Input capacitor should have enough ripple current rating to absorb input switching ripple current. The worst case

RMS ripple current is half of the charging current when duty cycle is 0.5. If the converter does not operate at

50% duty cycle, then the worst case capacitor RMS current I

occurs where the duty cycle is closest to 50%

CIN

and can be estimated by the following equation:

(14)

Low ESR ceramic capacitor such as X7R or X5R is preferred for input decoupling capacitor and should be

placed to the drain of the high side MOSFET and source of the low side MOSFET as close as possible. Voltage

rating of the capacitor must be higher than normal input voltage level. 25V rating or higher capacitor is preferred

for 20V input voltage. 10-20µF capacitance is suggested for typical of 3-4A charging current.

Output Capacitor

Output capacitor also should have enough ripple current rating to absorb output switching ripple current. The

output capacitor RMS current I

The output capacitor voltage ripple can be calculated as follows:

At certain input/output voltage and switching frequenccy, the voltage ripple can be reduced by increasing the

output filter LC.

The bq24610/7 has internal loop compensator. To get good loop stability, the resonant frequency of the output

inductor and output capacitor should be designed between 12 kHz and 17 kHz. The preferred ceramic capacitor

is 25V or higher rating, X7R or X5R for 4-cell application.

COUT

is given:

(15)

(16)

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 25

Product Folder Link(s): bq24610 bq24617

Page 26

top DS(on) G D bottom DS (on) G

FOM = R Q FOM = R Q´ ´

( )

2

top CHG DS(on) IN CHG on off S

1

P = D I R + V I t + t f

2

´ ´ ´ ´ ´ ´

SW SW

on off

on off

Q Q

t = , t =

I I

SW GD GS

1

Q = Q + Q2´

REG N plt p lt

on off

on off

V V V

I = , I =

R R

-

2

bottom C HG D S(on)

P = (1 D) I R- ´ ´

ICLoss_driver IN g_total s

P V Q f= × ×

bq24610

bq24617

SLUS892 –DECEMBER 2009

Power MOSFETs Selection

Two external N-channel MOSFETs are used for a synchronous switching battery charger. The gate drivers are

internally integrated into the IC with 6V of gate drive voltage. 30V or higher voltage rating MOSFETs are

preferred for 20V input voltage and 40V or higher rating MOSFETs are prefered for 20-28V input voltage.

Figure-of-merit (FOM) is usually used for selecting proper MOSFET based on a tradeoff between the conduction

loss and switching loss. For top side MOSFET, FOM is defined as the product of a MOSFET's on-resistance,

R

MOSFET's on-resistance, R

The lower the FOM value, the lower the total power loss. Usually lower R

package size.

The top-side MOSFET loss includes conduction loss and switching loss. It is a function of duty cycle

(D=V

(F), turn on time (ton) and turn off time (t

The first item represents the conduction loss. Usually MOSFET R

temperature rise. The second term represents the switching loss. The MOSFET turn-on and turn off times are

given by:

, and the gate-to-drain charge, QGD. For bottom side MOSFET, FOM is defined as the product of the

DS(ON)

OUT/VIN

), charging current (I

, and the total gate charge, QG.

DS(ON)

), MOSFET's on-resistance R

CHG

toff

):

has higher cost with the same

DS(ON)

), input voltage (VIN), switching frequency

DS(ON)

increases by 50% with 100ºC junction

DS(ON)

www.ti.com

(17)

(18)

(19)

where Qswis the switching charge, Ionis the turn-on gate driving current and Ioff is the turn-off gate driving

current. If the switching charge is not given in MOSFET datasheet, it can be estimated by gate-to-drain charge

(QGD) and gate-to-source charge (QGS):

(20)

Gate driving current total can be estimated by REGN voltage (V

turn-on gate resistance (Ron) and turn-off gate resistance R

) of the gate driver:

off

), MOSFET plateau voltage (V

REGN

), total

plt

(21)

The conduction loss of the bottom-side MOSFET is calculated with the following equation when it operates in

synchronous continuous conduction mode:

(22)

If the SRP-SRN voltage decreases below 5mV (The charger is also forced into non-synchronous mode when the

average SRP-SRN voltage is lower than 1.25mV), the low side FET will be turned off for the remainder of the

switching cycle to prevent negative inductor current.

As a result all the freewheeling current goes through the body-diode of the bottom-side MOSFET. The maximum

charging current in non-synchronous mode can be up to 0.9A (0.5A typ) for a 10mΩ charging current sensing

resistor considering IC tolerance. Choose the bottom-side MOSFET with either an internal Schottky or body