Page 1

AM572x Industrial Development Kit (IDK)

Evaluation Module (EVM) Hardware

User's Guide

Literature Number: SPRUI64C

May 2017–Revised April 2018

Page 2

Contents

Preface ........................................................................................................................................ 5

1 Introduction......................................................................................................................... 6

1.1 Description ................................................................................................................ 6

1.2 System View .............................................................................................................. 7

2 Functional Description........................................................................................................ 11

2.1 Processor................................................................................................................ 12

2.2 Clocks.................................................................................................................... 12

2.3 Reset Signals ........................................................................................................... 12

3 Power Supplies .................................................................................................................. 13

3.1 Power Source ........................................................................................................... 13

3.2 TPS6590377 PMIC..................................................................................................... 13

3.3 AVS Control ............................................................................................................. 13

3.4 Other Power Supplies.................................................................................................. 13

4 Configuration/Setup............................................................................................................ 15

4.1 Boot Configuration...................................................................................................... 15

4.2 I2C Address Assignments ............................................................................................. 15

4.3 SEEPROM Header ..................................................................................................... 16

4.4 JTAG Emulation ........................................................................................................ 16

5 Memories Supported........................................................................................................... 17

5.1 DDR3L SDRAM......................................................................................................... 17

5.2 SPI NOR Flash.......................................................................................................... 17

5.3 Board Identity Memory................................................................................................. 17

5.4 SD/MMC ................................................................................................................. 17

5.5 eMMC NAND Flash .................................................................................................... 17

6 Ethernet Ports.................................................................................................................... 18

6.1 100Mb Ethernet Ports on PRU-ICSS ................................................................................ 18

6.2 Gigabit (1000Mb) Ethernet Ports..................................................................................... 18

7 USB Ports.......................................................................................................................... 19

7.1 Processor USB Port 1.................................................................................................. 19

7.2 Processor USB Port 2.................................................................................................. 19

7.3 FTDI USB Port .......................................................................................................... 19

8 PCIe.................................................................................................................................. 19

9 Video Input and Output....................................................................................................... 20

9.1 Camera................................................................................................................... 20

9.2 HDMI ..................................................................................................................... 20

9.3 LCD....................................................................................................................... 20

10 Industrial Interfaces............................................................................................................ 20

10.1 Profibus .................................................................................................................. 20

10.2 DCAN..................................................................................................................... 20

10.3 RS-485................................................................................................................... 20

11 User Interfaces................................................................................................................... 21

2

Table of Contents

Copyright © 2017–2018, Texas Instruments Incorporated

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Page 3

www.ti.com

11.1 Tri-color LEDs........................................................................................................... 21

11.2 Industrial Inputs ......................................................................................................... 21

11.3 Industrial Outputs / LEDs.............................................................................................. 21

12 Pin Use Description............................................................................................................ 21

12.1 Functional Interface Mapping ......................................................................................... 21

12.2 GPIO Pin Mapping...................................................................................................... 21

13 Board Connectors .............................................................................................................. 23

14 EVM Important Notice ......................................................................................................... 36

Appendix A Known Deficiencies in AM572x IDK EVM ..................................................................... 37

A.1 Power solution not sufficient for full PCIe plug-in card compliance............................................. 37

A.2 Early versions of the AM572x IDK EVM not installed with SOC devices rated for the full industrial

temperature range...................................................................................................... 37

A.3 AM572x IDK EVM does not support eMMC HS200 mode....................................................... 37

A.4 PCIe PERSTn line not in proper state at start-up................................................................. 37

A.5 EDIO connectors J4 and J7 should support real-time debugging for both PRU1 and PRU2............... 37

A.6 HDQ implementation not correct.................................................................................... 37

A.7 Removing the power plug and inserting it again while the power supply is energized may cause

damage .................................................................................................................. 37

A.8 Software shutdown of PMIC not operational ...................................................................... 38

A.9 PMIC implementation does not support required SOC shut-down sequence................................. 38

A.10 USB port providing UART console and XDS100 emulation not isolated from EVM board supplies ....... 38

A.11 Need 47-µf capacitor at camera header............................................................................ 38

A.12 Decoupling capacitors do not reflect AM572x PDN recommendations ........................................ 38

A.13 CCS System Reset fails ............................................................................................. 38

A.14 AM572x IDK EVM design contains 2 clamp circuits that may not be necessary ............................. 39

A.15 Crystal connected to osc0 needs to have 50 ppm or better long term accuracy ............................. 39

A.16 Software must program the CDCE913 for 0-pf load capacitance............................................... 39

A.17 Protection diode D2 should be rated for 5 V....................................................................... 39

A.18 PHY address LSB for U9 and U15 can be latched incorrectly .................................................. 39

A.19 3.3-V clamp circuit needs more margin ............................................................................ 39

A.20 Current PMIC does not provide the mandated power down sequence ........................................ 40

A.21 PMIC OSC16MCAP pin mistakenly grounded .................................................................... 40

Revision History.......................................................................................................................... 41

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Copyright © 2017–2018, Texas Instruments Incorporated

Contents

3

Page 4

www.ti.com

List of Figures

1 AM572x IDK EVM - Top View.............................................................................................. 7

2 AM572x IDK EVM - Bottom View.......................................................................................... 8

3 AM572x IDK EVM with LCD Display Assembly Attached - Top View ................................................ 9

4 AM572x IDK EVM with LCD Display Assembly Attached - Bottom View........................................... 10

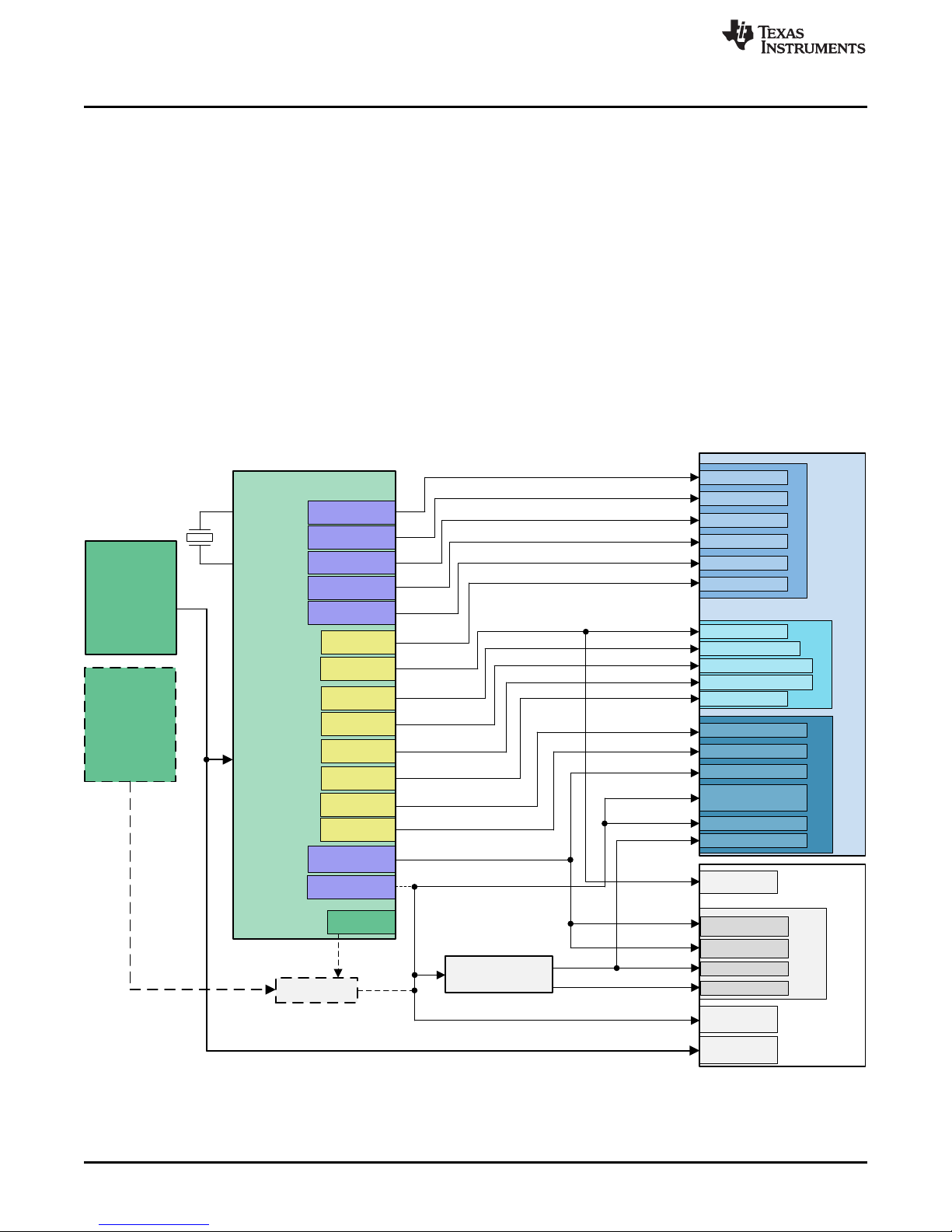

5 AM572x IDK EVM Block Diagram ....................................................................................... 11

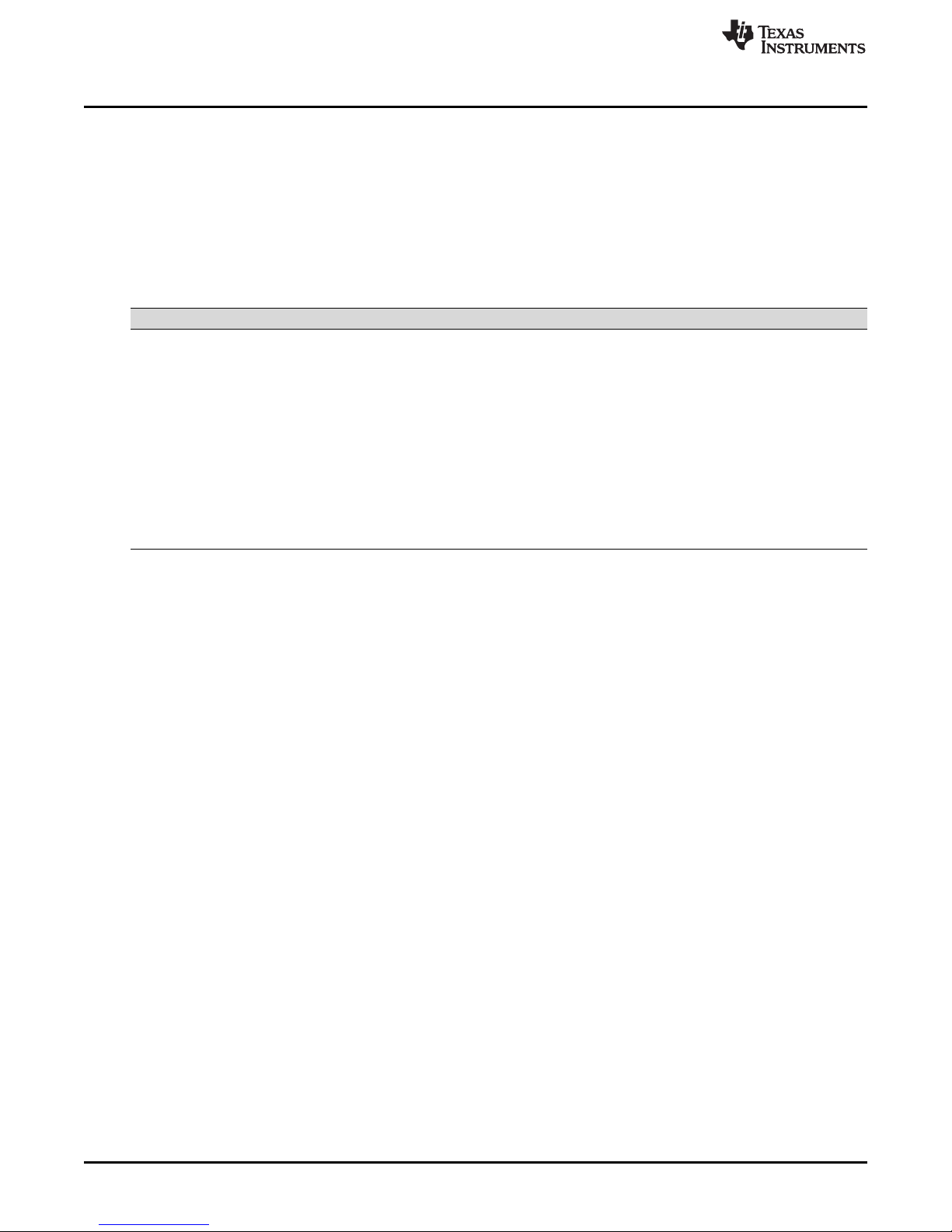

6 Connections from the TPS6590377 PMIC to the AM572x Processor............................................... 14

List of Tables

1 I2C1/IND_I2C ............................................................................................................... 15

2 I2C2/AM572X_HDMI_DDC ............................................................................................... 15

3 SEEPROM Header......................................................................................................... 16

4 PRU-ICSS Ethernet Ports................................................................................................. 18

5 GPIO Pin Mapping ......................................................................................................... 22

6 Expansion Connector - J21 ............................................................................................... 23

7 I/O Expansion Header Connector - J37................................................................................. 25

8 MicroSD Connector - J15 ................................................................................................. 26

9 Power Jack Connector - J1 ............................................................................................... 26

10 Power Terminal Block Connector - J2................................................................................... 26

11 PRU1ETH0 RJ45 Connector - J3........................................................................................ 27

12 PRU1ETH1 RJ45 Connector - J5........................................................................................ 27

13 PRU2ETH0 RJ45 Connector - J6........................................................................................ 28

14 PRU2ETH1 RJ45 Connector - J8........................................................................................ 28

15 PRU2ETH0 Test Header Connector - J7 ............................................................................... 29

16 PRU2ETH1 Test Header Connector - J4 ............................................................................... 29

17 Camera Connector - J9.................................................................................................... 29

18 GigE RJ45 Connector - J10............................................................................................... 30

19 GigE RJ45 Connector - J12............................................................................................... 30

20 LCD Module FFC Connector - J16....................................................................................... 31

21 Touchscreen Controller FFC Connector - J17 ......................................................................... 31

22 HDMI Standard A-type Connector - J24 ................................................................................ 32

23 MIPI-60 JTAG Connector - J18 .......................................................................................... 32

24 JTAG USB Micro-AB Connector - J19 .................................................................................. 34

25 USB Port 1 USB3.0 Standard A-type Connector - J23................................................................ 34

26 USB Port 2 USB2.1 Micro-AB Connector - J45 ........................................................................ 34

27 CAN Header Connector - J38 ............................................................................................ 35

28 Profibus DB9F Connector - J14.......................................................................................... 35

29 RS-485 Header Connector - J39......................................................................................... 35

30 PCIe Connector – J22..................................................................................................... 36

4

List of Figures

Copyright © 2017–2018, Texas Instruments Incorporated

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Page 5

About This Manual

This document describes the hardware architecture of the AM572x Industrial Development Kit (IDK)

Evaluation Module (EVM) (Part# TMDXIDK572x) that supports the Texas Instruments Sitara™ ARM

Cortex®-A15 AM572x processor family.

Glossary

TI Glossary —This glossary lists and explains terms, acronyms, and definitions.

Related Documentation From Texas Instruments

For product information, visit the Texas Instruments website at http://www.ti.com.

SPRABY8— AM572x GP EVM Power Simulations Application Report

SPRS953— AM572x Sitara Processors Silicon Revision 2.0 Data Manual

SPRZ429— AM572x Sitara Processors Silicon Errata. Describes the known exceptions to the functional

specifications for the device.

Preface

SPRUI64C–May 2017–Revised April 2018

Read This First

®

SPRUHZ6— AM572x Sitara Processors Technical Reference Manual. Details the integration, the

environment, the functional description, and the programming models for each peripheral and

subsystem in the device.

Community Resources

The following links connect to TI community resources. Linked contents are provided "AS IS" by the

respective contributors. They do not constitute TI specifications and do not necessarily reflect TI's views;

see TI's Terms of Use.

TI E2E™ Online Community— TI's Engineer-to-Engineer (E2E) Community. Created to foster

collaboration among engineers. At e2e.ti.com, you can ask questions, share knowledge, explore

ideas and help solve problems with fellow engineers.

TI Embedded Processors Wiki— Texas Instruments Embedded Processors Wiki. Established to help

developers get started with Embedded Processors from Texas Instruments and to foster innovation

and growth of general knowledge about the hardware and software surrounding these devices.

Trademarks

Sitara, E2E, Code Composer Studio, SmartReflex are trademarks of Texas Instruments.

ARM, Cortex are registered trademarks of ARM Limited.

Windows is a registered trademark of Microsoft Corporation.

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Copyright © 2017–2018, Texas Instruments Incorporated

Preface

5

Page 6

1 Introduction

This document describes the hardware architecture of the AM572x Industrial Development Kit (IDK)

Evaluation Module (EVM) (Part# TMDXIDK572x) that supports the Texas Instruments Sitara™ ARM

Cortex®-A15 AM572x processor family.

1.1 Description

The AM572x IDK is a standalone test, development, and evaluation module that enables developers to

write software and develop hardware for industrial control and industrial communications applications. It

has been equipped with a TI AM5728 processor and a defined set of features to allow you to experience

industrial communication solutions using various serial or Ethernet based interfaces. Using standard

interfaces, the AM572x IDK may interface to other processors or systems and act as a communication

gateway or controller. In addition, it can directly operate as a standard remote I/O system or a sensor

connected to an industrial communication network.

The AM572x IDK contains embedded emulation circuitry to quickly enable developers to begin using this

IDK. The embedded emulation logic allows emulation and debug using standard development tools such

as the Texas Instruments Code Composer Studio™ integrated development environment (IDE) by simply

connecting a USB cable to a Windows®-based computer.

The standard configuration for the AM572x IDK EVM provides the following Ethernet connectivity:

• Two Gigabit (1000Mb) metallic ports connected via PHY/RGMII to the on-chip Ethernet switch

• Two 100Mb metallic ports connected via PHY/MII to the PRU-ICSS subsystems

Reconfiguration through resistor removal and installation can provide an alternate Ethernet connectivity:

• Four 100Mb metallic ports connected via PHY/MII to the PRU-ICSS subsystems

Software support for the AM572x IDK EVM is provided within the Processor Software Development Kit

(SDK) package. This includes both Linux and RTOS support.

User's Guide

SPRUI64C–May 2017–Revised April 2018

AM572x Industrial Development Kit (IDK)

Evaluation Module (EVM) Hardware

®

6

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Hardware

Copyright © 2017–2018, Texas Instruments Incorporated

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Page 7

www.ti.com

1.2 System View

The system view of the AM572x IDK EVM consists of the main board and the camera board. There is also

an optional LCD panel and touch screen assembly that can be attached to the AM572x IDK EVM.

The top and the bottom views of the AM572x IDK EVM are provided in Figure 1 and Figure 2,

respectively.

The top and the bottom views of the AM572x IDK EVM with the optional LCD display assembly attached

are provided in Figure 3 and Figure 4, respectively.

Introduction

Figure 1. AM572x IDK EVM - Top View

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Copyright © 2017–2018, Texas Instruments Incorporated

Hardware

7

Page 8

Introduction

www.ti.com

Figure 2. AM572x IDK EVM - Bottom View

8

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Hardware

Copyright © 2017–2018, Texas Instruments Incorporated

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Page 9

www.ti.com

Introduction

Figure 3. AM572x IDK EVM with LCD Display Assembly Attached - Top View

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Copyright © 2017–2018, Texas Instruments Incorporated

Hardware

9

Page 10

Introduction

www.ti.com

Figure 4. AM572x IDK EVM with LCD Display Assembly Attached - Bottom View

10

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Hardware

Copyright © 2017–2018, Texas Instruments Incorporated

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Page 11

AM572x

DDR1

QSPI

RGMII0

MMC1

HDMI / I2C2

PCIe / I2C1

TLK105L

HDMI

PCIe x1

GbE

ICSS1

RJ45

MMC2

I2C

DDR3

1GB

QSPI

32MB

eMMC

16GB

uSD

EEPROM

USB2.0

MicroAB

PR2_MII0

I2C

USB2

UART

Camera

Header

VIN4B / I2C1

JTAG

JTAG

(60-pin)

ICs

TI ICs

Connectors

ISO1176T

Profibus

DB9

PRU UART

TLK105L

TPS6590377

PMIC

ICSS1

RJ45

TLK105L

ICSS0

RJ45

TLK105L

ICSS0

RJ45

KSZ9031

DDR3

1GB

w/ECC

PR2_MII1

PR1_MII1

(muxed

with

RGMII1)

ICSS Header

prx_mii0/1_txen/rxdv,

prx_edio_data_out + sync

Warm

RESET

INT

RGY LED ENET Status

GPIO

GPIO

RGMII1

GbE

KSZ9031

DCAN1

DDR2

USB1

USB3.0

Std A

FTDI

USB

SN65HVD78D

RS485

Header

UART2

Industrial Inputs &

Outputs/LEDs

SPI3 / I2C1

LCD &

Touch Panel

MIPI

Serializer

VOUT1/I2C1

ISO1050

TPD6E001

TPD4S012

TPD2EUSB30 &

TPD4E05U06

DCAN

Header

PR1_MII0

(muxed

with

RGMII0)

TPD12S016

www.ti.com

2 Functional Description

The AM572x IDK EVM is implemented on a single board with interface circuitry, memory ICs, and

connectors around the AM5728 processor. The board also contains power conversion circuitry to

efficiently create the needed power supply voltages from a single +5V input. As stated previously, this

EVM ships with a separate camera module that plugs in to the main board. An optional LCD panel and

touch screen assembly can be purchased separately and mounted on to the main board.

Figure 5 shows the functional block diagram of the AM572x IDK EVM.

Functional Description

Figure 5. AM572x IDK EVM Block Diagram

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Copyright © 2017–2018, Texas Instruments Incorporated

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Hardware

11

Page 12

Functional Description

2.1 Processor

The AM5728 processor is the central processing unit for this IDK EVM. The interface circuitry, memory

ICs, and connectors implemented on the board around the AM5728 processor provide development

support for the many industrial communication interfaces available on this platform. See the AM572x

Sitara Processors Silicon Revision 2.0 Data Manual (SPRS982) and the AM572x Sitara Processors

Technical Reference Manual (SPRUHZ6) for details about the processor.

The AM572x IDK EVM contains system configuration for the boot mode control inputs SYSBOOT[15..0].

These can be strapped using resistors. The default configuration will meet the needs of most developers.

Resistor reconfiguration is supported so that you can explore other boot configurations of the AM572x

processor. See Section 4 for more details.

2.2 Clocks

The main clock for the processor is derived from a 20-MHz crystal. An on-board oscillator in the AM572x

processor generates the base clock and the subsequent module clocks as needed within the AM572x

processor. The board design supports a crystal attached to the RTC block, but this is not needed since

RTC-only mode is not supported in this device.

2.3 Reset Signals

The AM572x processor contains 3 reset inputs and an output indicating a reset is in progress. The reset

pins are:

• PORz: PORz is a hard reset that resets everything including emulation logic. It also tri-states most

outputs.

• RESETn: RESETn is a device reset commonly driven by control logic or emulation.

• RTC_PORz: Separate PORz for the RTC module that must be driven at the same time as PORz.

(Note that PORz and RTC_PORz can only be directly connected as long as VDDSHV3 and VDDSHV5

are driven at the same voltage.)

• RSTOUTn: Output signal from SOC indicating that the device has entered reset. This is used to reset

other circuits that must be reset at the same time as the processor.

More details about the behavior of these reset pins within the AM572x processor can be found in the

AM572x Sitara Processors Silicon Revision 2.0 Data Manual (SPRS982). There are push buttons on the

IDK that can initiate either a RESETn or PORz input. SW1 can drive PORz active (low) and SW2 can

drive RESETn active (low).

There is a device erratum in all of the AM572x devices that prevents use of RESETn independent from

PORz. The workaround is to generate PORz whenever a device reset occurs even if it is from an internal

initiator. This is accomplished through cooperation with the PMIC paired with the AM572x device on the

IDK EVM. The RSTOUTn output from the AM572x device is connected to the NRESWARM input of the

PMIC. This initiates a re-start that drives RESET_OUT low and resets all voltages to their initial values.

Since RESET_OUT from the PMIC is connected to PORz in the AM572x device, a hard reset is forced on

the SOC that meets the needs of the erratum workaround.

The AM572x IDK EVM is started by pressing the start-up push button, SW3. The POWERHOLD input can

be connected to VRTC_OUT in customer designs to cause the board to power-on as soon as the main

supply is stable.

The configuration of the PMIC to provide RESET_OUT from the NRESWARM input creates an always-on

implementation. This always-on mode of operation prevents software shut-down of the IDK. Customer

designs should have power-good monitoring circuitry such as a TPS3808 connected to the main supply to

the PMIC that is connected to the PMIC RESET_IN. The TPS3808 can detect the main supply voltage

dropping and then trigger the PMIC to execute a controlled shut-down that meets the requirements in the

AM572x Sitara Processors Silicon Revision 2.0 Data Manual (SPRS982).

www.ti.com

12

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Hardware

Copyright © 2017–2018, Texas Instruments Incorporated

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Page 13

www.ti.com

3 Power Supplies

This section describes how the power supplies required for the design are generated.

3.1 Power Source

The AM572x IDK EVM uses an external 5V power supply. The 5V power input is converted into different

voltage levels to provide power inputs to the AM572x processor and other circuitry.

Early versions of the AM572x IDK EVM shipped with the GlobTek, Inc. external power supply with the part

number TR9CA6500LCP-N, model number GT-43008-3306-1.0-T3. This external power supply is rated for

an output voltage of +5VDC with an output current up to 6.5A. This external power supply contains

applicable regional product regulatory/safety certification requirements for most worldwide locations. If you

cannot use this supply, one with equivalent ratings that is approved for your location must be obtained.

The AM572x IDK EVM contains a right angle mounted power connector that accepts the +5VDC supply

input on the center pin with the outer shell as the common return. The power connector accepts a mating

plug with a 2.5mm ID and a 5.5mm OD.

Removing the power plug and inserting it again while the power supply is energized may damage the

AM572x IDK EVM and/or other devices attached to the board such as emulators that provide an alternate

path to ground. Removal of AC power from the external power supply is a safer method, if required.

It is recommended that the external power supply have the common return bonded to earth ground. If this

is not possible, a separate connection from the board ground to earth ground may need to be provided.

3.2 TPS6590377 PMIC

The power requirements of the processor are met by the TPS6590377 Power Management IC (PMIC).

The power sequencing requirements of the AM572x processor are also handled by the TPS6590377

PMIC. Figure 6 shows the supply connections from the TPS6590377 PMIC to the AM572x processor.

Refer to the AM572x Sitara Processors Silicon Revision 2.0 Data Manual (SPRS982) for more information

about the required supply voltages and supply sequencing. Also refer to the TPS659037 Power

Management Unit (PMU) for Processor Data Manual (SLIS165) and the TPS659037 User's Guide to

Power AM572x and AM571x User’s Guide (SLIU011) for details about its operation.

Note that the production version of the AM572x IDK EVM uses the TPS6590377 PMIC that supplies the

voltages needed for the latest silicon version of the AM5728 processor. Beta prototype IDK EVM units

used the TPS6590375 PMIC and Alpha prototype IDK EVM units used the TPS6590372 PMIC.

Power Supplies

3.3 AVS Control

The AM572x processor consumes most of its power in its core logic. Therefore, minimizing the voltage

supplied to this core logic can minimize power consumption. SmartReflex™ technology is used to provide

this optimized solution.

This core logic is separated into multiple segments that can each be controlled separately. In this way,

applications that need more performance in some processing blocks can operate at higher performance

levels by increasing the supply voltage, while other processing blocks that do not require the same level of

performance can operate at lower voltage thus further optimizing system power consumption.

The TPS6590377 PMIC is connected to the I2C1 on the AM5728 processor. This allows the application

software to individually control the AVS supply outputs. It also allows the application to control the voltage

generated by LDO1 that is used for the SDIO interface that operates at either 1.8V or 3.3V depending on

the operating mode.

3.4 Other Power Supplies

The AM572x IDK EVM contains 8 other power conversion devices that support the interface and memory

circuitry:

• TPS63010 Buck-Boost Converter: This converter generates 5.0V from the main supply input. It

supplies this voltage to the industrial interface circuits, the HDMI interface and to the USB master

ports.

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Copyright © 2017–2018, Texas Instruments Incorporated

Hardware

13

Page 14

5-V Input

Power

SMPS1, SMPS2

AVS (6 A max)

SMPS4, SMPS5

AVS (4 A max)

SMPS6

AVS (3 A max)

SMPS8

AVS (1 A max)

SMPS7

AVS (2 A max)

LDO9

(50 mA max)

LDOLN

(100 mA max)

LDO3

(200 mA max)

LDOVRTC

(25 mA max)

LDO1

(300 mA max)

LDOUSB

(100 mA max)

SMPS3

(3 A max)

PMIC

TPS659037

TPS51200

5 V

VDD_MPU

VDD_DSPEVE

VDD_GPU

VDD_IVAHD

VDD_CORE

VDD_RTC

VDDSHV8 (SDIO)

VDDA_USB3V3

VDD_DDR

Dual-Voltage Rails

(set to 3.3 V)

1V8

3V3

5V0

EMIF1

EMIF2

VTT

DDR

Other Domains

Processor

Core Domains

1.06 V

1.15 V

1.15 V

1.05 V

1.06 V

1.06 V

1.35 V or 1.5 V

1.35 V or 1.5 V

1.8 V

1.8 V

1.35 V or 1.5 V

1.8 V

3.3 V

3.3 V

1.8 V

0.675 V or 0.75 V

1.8 V

Peripherals

DDR_REF

SMPS9

(1 A max)

LDO2

(300 mA max)

VDDSHV5 (RTC I/O)

3.3 V

3.3 V

VREF

0.675 V or 0.75 V

VDD_1V8

VDDA_1V8 (PLLs)

1V8_PHY (USB/SATA)

VDDA_RTC

1.8-V Domains

1V8_PHY (HDMI/PCIe)

LDO4

(200 mA max)

OSC16MIN

OSC16MOUT

1.8 V

3.3V Input

Power

TPS22965

(Power Switch)

REGEN1

Power Supplies

• TPS61085 Boost Converter: This converter generates 12.0V from the main supply input. It supplies

voltage to the industrial interface circuits and the PCIe card connector.

• TPS51200 DDR Termination Voltage LDO (2 each): This LDO provides the push/pull termination

current required for the DDR3 memory interfaces. There is one implemented for each DDR3 EMIF.

• LP38693ADJ Low-Dropout Regulator: This LDO generates the 3.7V LCD bias voltage.

• TPS61081DRC LCD Backlight Generator: This Boost converter generates the LCD backlight supply.

• TPS71712 Low-Dropout Regulator: This LDO generates the 1.2V supply needed for the LCD driver

logic.

• TPS76650 Low-Dropout Regulator: This LDO generates the 5.0V supply needed for the Profibus

interface.

• R1Z-3.305HP Isolated DC-DC Supply: This converter generates 5.0V isolated from the primary

3.3V DC supply on board for the DCAN interface.

www.ti.com

Figure 6. Connections from the TPS6590377 PMIC to the AM572x Processor

14

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Hardware

Copyright © 2017–2018, Texas Instruments Incorporated

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Page 15

www.ti.com

4 Configuration/Setup

This section discusses the board configuration.

4.1 Boot Configuration

Various boot configurations can be set using the pull-up/pull-down resistor combinations provided on the

SYSBOOT[15..0] pins. Boot configuration pins are latched upon de-assertion of the PORz pin. Refer to

the AM572x Sitara Processors Silicon Revision 2.0 Data Manual (SPRS982) for more details. The

AM572x IDK EVM is configured by default to 0x8106 to enable UBOOT/Linux boot from the SDCARD.

The secondary boot device selected by this boot mode is QSPI1.

4.2 I2C Address Assignments

The AM572x IDK EVM contains multiple I2C buses connected to a master port on the processor. Each

bus contains one or more I2C slave devices that must have unique addresses to prevent contention.

Table 1 and Table 2 list the addresses of the I2C slave devices attached to buses I2C1 and I2C2,

respectively.

I2C Slave Device Address(es)

TPS590377 PMIC, U3 0x58, 0x59, 0x5A, 0x5B, 0x12

Camera Header, J9 Undefined

CDCE913 Ethernet Clock Generator A, U23 0x65

TPIC2810 Industrial Output Driver, U89 0x60

LCD Panel Driver TC358778, U73 0x0E

Touchscreen FPC Connector, J17 —

ID Memory SEEPROM, U33 0x50

PCIe Card Connector, J22 Undefined

Expansion Connector, J21 Undefined

Configuration/Setup

Table 1. I2C1/IND_I2C

CDCE913 Ethernet Clock Generator B, U25 0x65

NOTE: SCL/SDA names are swapped between the HDMI DDC port and I2C2 port on AM57xx

devices – I2C2 schematic connections to U25 must be reversed.

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Table 2. I2C2/AM572X_HDMI_DDC

I2C Slave Device Address(es)

HDMI Bridge, U46 —

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Copyright © 2017–2018, Texas Instruments Incorporated

Hardware

15

Page 16

Configuration/Setup

4.3 SEEPROM Header

Each of the AM572x IDK EVMs has a unique serial number. This serial number is printed on a sticker

attached to the IDK and it is programmed into a SEEPROM memory device connected to the AM5728

processor over the I2C bus. The SEEPROM also contains board details such as board type, version,

configuration, and so on. This information is stored in a structure at the beginning of the SEEPROM in a

known format that can be read by the application software. These values are all stored with the first

character or MSB stored at the lowest addressable location in each field. Table 3 lists all of the fields in

this header definition.

Name Size (bytes) Contents

Header 4 MSB 0xEE3355AA LSB

Board Name 8 Name for board in ASCII “AM572” = AM572x Industrial Development Kit EVM.

Version 4 Hardware version code for board in ASCII “1.3A” = revision 01.3A

Serial Number 12

Configuration Option 32 Codes to show the configuration setup on this board. Reserved.

Ethernet MAC

Address #0

Ethernet MAC

Address #5

Available 32696 Available user space for other non-volatile codes/data.

www.ti.com

Table 3. SEEPROM Header

Serial number of the board. This is a 12-character string that is: WWYY4P47nnnn, where

WW = 2 digit week of the year of production, YY = 2 digit year of production,

nnnn = incrementing board number.

6

6

Ethernet MAC Address #0 assigned to the AM572x IDK EVM. This is the first of a block of

addresses available for the Industrial Interface ports.

Ethernet MAC Address #5 assigned to the AM572x IDK EVM. This is the last of a block of

6 contiguous addresses available for the industrial interface ports.

4.4 JTAG Emulation

The AM572x IDK EVM supports embedded XDS100V2 USB Emulation through the USB Micro-AB

connector, J19, and the FTDI controller. This controller is not powered from the USB, thus the emulation

resets whenever the IDK is power cycled.

The AM572x IDK EVM also has a 60-pin MIPI connector to support high-performance external emulators

and, optionally, emulation trace. This emulation trace capability is not enabled by default.

16

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Hardware

Copyright © 2017–2018, Texas Instruments Incorporated

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Page 17

www.ti.com

5 Memories Supported

The AM572x IDK EVM supports on-board memories including DDR3L SDRAM, SPI NOR Flash, eMMC

NAND Flash, and I2C SEEPROM. It also supports a MicroSD card socket that can add memory storage.

5.1 DDR3L SDRAM

The AM572x IDK EVM design supports two banks of DDR3L SDRAM where each is attached to a

separate EMIF on the AM5728 processor. Each EMIF can support up to 2GB at speeds up to 1066MT/s.

Each EMIF on the IDK EVM contains two 4Gbit (256M × 16) SDRAMs for a total of 1GB of DDR3L

SDRAM memory on each EMIF. The part number for the DDR3L SDRAM memory used is

MT41K256M16HA-125 that contains timing for 1600MT/s operation. The package used is the 96-ball

TFBGA package. See the AM572x Sitara Processors Technical Reference Manual (SPRUHZ6) for

memory locations for this memory.

The first EMIF also contains an SDRAM attached to the ECC byte lane. Use of ECC on the DDR3L

interface is currently highly constrained by limitations in the AM572x devices. Refer to the AM574x Sitara

Processors Silicon Errata (SPRZ447) for more details.

5.2 SPI NOR Flash

The AM572x IDK EVM supports a 256Mbit (32MB) SPI Flash Memory from Spansion (S25FL256S) in a

16-pin SOIC package. It is connected to the QSPI port of the AM5728 device.

5.3 Board Identity Memory

Each of the AM572x IDK EVM boards contains a 256Kb (32KB) Serial EEPROM that contains boardspecific data. This data allows the application software to automatically detect the type of board that it is

running on and also to determine its version and, potentially, optional features. Other hardware specific

data can be stored on this memory device as well. The part number of the memory device is

CAT24C256WI-G in a SOIC-8 package. Refer to Section 4 for details on the data stored in this memory.

Memories Supported

5.4 SD/MMC

The SD/MMC connector on the AM572x IDK EVM is a MicroSD connector (part number SCHA5B0200).

This is a standard SD/MMC card type of connector. It is connected to the MMC1 port of the AM572x

processor that is optimized for this use. Refer to the AM572x Sitara Processors Silicon Revision 2.0 Data

Manual (SPRS982) and the AM572x Sitara Processors Technical Reference Manual (SPRUHZ6) for

supported card types and densities.

The SDWP input pin to the MMC1 port is connected to a 2-pin header, J44. The default state has the pin

pulled high. Shorting the header pulls the pin low. The polarity of this input is programmable; thus, the

hardware does not define whether a high or low level indicates Write Protest is active or not.

The transient protection implemented at the SDCARD connector is the TPD6E001.

5.5 eMMC NAND Flash

The MMC2 port on the AM572x processor supports eMMC memory devices, since it has 8 data lines. The

eMMC footprint is compliant with the JEDEC/MMC standard. Boards have been assembled and

successfully tested with the Kingston EMMC16G-S100 and the Micron MTFC16GAKAECN-2M WT. These

are 16GB eMMC NAND Flash memories that are standard version 5.0 compliant.

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Copyright © 2017–2018, Texas Instruments Incorporated

Hardware

17

Page 18

Ethernet Ports

6 Ethernet Ports

The AM572x IDK EVM supports up to four 100Mb Industrial Ethernet ports attached to the PRU-ICSS

subsystems and up to two Gigabit (1000Mb) Ethernet ports connected to the integrated Ethernet switch.

The final number of available ports depends on the configuration options. The default configuration

provides two 100Mb Industrial Ethernet ports and two Gigabit (1000Mb) Ethernet ports.

6.1 100Mb Ethernet Ports on PRU-ICSS

The AM572x IDK EVM contains four 100Mb Ethernet ports that each connect to an industrial

PHY/Transceiver (TLK105L), which then connect to RJ45 metallic connectors, with integrated magnetics,

J3, J5, J6, and J8. These Ethernet transceivers are connected to the PRU1 and PRU2 subsystems within

the AM5728 processor. Table 4 shows the mapping from the PRU-ICSS ports to the RJ45 connectors.

The COL functionality on the MII interface is not used. The TLK105L contains a feature that must be

enabled via software that provides rapid link status on the COL pin. Therefore, this pin is connected to the

RXLINK input to the PRU-ICSS ports for this purpose.

Test headers J4 and J7 are available to support real-time code development. The signals contained are

available for simplified probing.

The reset for the transceivers is driven low coincident with the PORz reset to the AM5728 processor. The

reset for each transceiver can also be driven low individually by separate GPIO signals from the

processor. A 25-MHz clock is provided into each of the TLK105L industrial transceivers.

Table 4. PRU-ICSS Ethernet Ports

www.ti.com

Connector PRU-ICSS Port MDIO Address Notes

J3 PRU1ETH0 0x0 on PRU1 Not available in default configuration. MII pins multiplexed with RGMII0.

J5 PRU1ETH1 0x1 on PRU1 Not available in default configuration. MII pins multiplexed with RGMII1.

J6 PRU2ETH0 0x0 on PRU2

J8 PRU2ETH1 0x1 on PRU2

6.2 Gigabit (1000Mb) Ethernet Ports

The AM572x IDK EVM contains two Gigabit (1000Mb) Ethernet PHY/Transceivers (KSZ9031RN)

interfaced to connectors J10 (RGMII0) and J12 (RGMII1). These Gigabit Ethernet transceivers are

connected over RGMII0 and RGMII1 to the Ethernet switch block within the AM5728 processor.

The resets for the transceivers are driven low coincident with the PORz reset to the AM5728 processor. A

25-MHz clock is provided into each of the KSZ9031RN Gigabit transceivers.

18

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Hardware

Copyright © 2017–2018, Texas Instruments Incorporated

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Page 19

www.ti.com

7 USB Ports

The AM572x IDK EVM contains three USB ports. Two ports are attached to the USB peripherals USB1

and USB2 on the AM572x processor. The third port provides both XDS100V2 JTAG emulation and UART

Console over the USB. This port simplifies the development environment for programmers using

computers that support this capability such as Windows®-based computers.

7.1 Processor USB Port 1

Processor port USB1 is implemented only as a USB host (master). It supports both USB2.1 (high speed)

and USB3.0 (super speed) data rates. The connector on the board, J23, is a USB3.0 Standard A-type

connector. The ESD devices implemented on this USB port are the TPD2EUSB30 for the DP and DM

lines and the TPD4E05U06 for the super-speed pairs.

Since processor USB port 1 supports host mode, it has the capability to drive 5.0V power on the VBUS

pin. The TPS2065D load switch is controlled by the USB1_DRVVBUS pin for this purpose.

7.2 Processor USB Port 2

Processor port USB2 is implemented as either USB host (master) or USB device (slave). It supports only

the USB2.1 (high speed and lower) data rates. The connector on the board, J45, is a USB2.1 Micro-AB

connector. The ESD device implemented on this USB port is the TPD4S012.

Since processor USB port 2 supports host mode, it has the capability to drive 5.0V power on the VBUS

pin. The TPS2051 load switch is controlled by the USB2_DRVVBUS pin for this purpose.

The USB2.1 standard defines different ranges of capacitance for the VBUS pin depending on whether it is

host or device. Since this port can do either, the AM572x IDK EVM provides the capability to meet either

requirement. The VBUS pin from the connector contains a 4.7µF capacitor that is appropriate for device

mode operation. When operating in host mode, 2-pin header J50 can be shorted to add 150µF of

additional capacitance to the VBUS pin. The shunt for this header is shown on the schematic as M2. It is

not installed on units when shipped as we expect this port to primarily be used in device mode.

USB Ports

7.3 FTDI USB Port

The FTDI bridge device provides both XDS100V2 JTAG emulation and UART Console over the USB. Its

USB connector is J19 and it is also a USB Micro-AB connector but it only operates in device (slave) mode

with the FTDI bridge device. The ESD device implemented on this USB port to the FTDI bridge is the

TPD2E001. Refer to Section 4.4 for more details on this functionality.

8 PCIe

The AM572x processors contain two lanes of peripheral component interconnect express (PCIe). These

can be implemented either as a single, dual-lane port or as two single-lane ports. The PCIe peripheral can

be configured to either be a Root Complex (master) or an Endpoint (slave). The AM572x IDK EVM only

implements one single-lane port as a Root Complex. The IDK EVM terminates this lane in a single-lane

PCIe female connector that accepts standard PCIe Endpoint cards.

A 2-pin header, J49, is available to provide the 3V3_AUX power separate from the primary 3V3 supply.

This is needed for some cards and PCIe driver configurations. The shunt, shown on the schematic as M1,

should be installed when the board is received since 3V3_AUX will be needed in most cases. Please refer

to the documentation for the card being installed to determine whether this shunt should remain installed.

The PERSTn reset for the connector is driven low coincident with the PORz reset to the AM5728

processor. The PERSTn reset to the connector can also be driven low by a GPIO signal from the

processor. This reset can also be blocked by a GPIO signal from the processor.

A 100-MHz clock is provided separately to both the PCIe peripheral and to the PCIe connector. These

clocks are buffered outputs from the same low-jitter source.

The AM572x IDK EVM is compatible with standard PCIe plug-in cards but not fully compliant with the

PCIe CEM standard. It does not support hot-plug and also does not provide sufficient current on the 3.3V

and 12V pins for all plug-in cards. It is currently limited to about 0.5A on each supply.

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Copyright © 2017–2018, Texas Instruments Incorporated

Hardware

19

Page 20

Video Input and Output

9 Video Input and Output

The AM572x processor family supports industrial video capture and display in addition to its industrial

communications capabilities. The AM572x IDK EVM contains a camera header for attaching a module

containing a camera sensor as well as support for an LCD panel display and HDMI video output.

9.1 Camera

The AM572x IDK EVM supports a camera daughterboard that attaches to a 24-pin (2 × 24) header, J9.

The custom-designed camera module from TI, previously designed for the AM437x IDK EVM, mounts on

this header. This header is connected to VIN4B on the AM5728 processor.

The 2Mp camera board contains the Darling Industrial camera module (part number DC-OVBD420AH).

The camera module contains the OmniVision OV2659 camera sensor. Please contact Omnivision for the

latest documentation on this sensor.

9.2 HDMI

The AM572x IDK EVM supports an HDMI connector driven from the HDMI port on the AM5728 processor.

The connector on the board, J24, is an HDMI Standard A-type connector. It is implemented with the

TPD12S016 HDMI companion chip. This companion chip provides I2C level shifting buffers, 5V load

switch, and multi-channel ESD protection.

9.3 LCD

The AM572x IDK EVM is available with an optional LCD panel that also has a capacitive touch overlay.

The video output driven for the LCD panel from the AM5728 processor is on VOUT1. A MIPI bridge device

from Toshiba, TC358778, is implemented to convert from the 24-bit RGB presented on the VOUT1 pins to

serial MIPI RGB streams. The LCD panel is shipped with FPC cables that plug into J16 for the MIPI video

and into J17 for the touchscreen controller. Both the MIPI bridge device and the touchscreen controller are

connected to the IND_I2C chain from processor port I2C1.

www.ti.com

10 Industrial Interfaces

There are additional industrial interfaces implemented on the AM572x IDK EVM to help showcase the

flexibility of the AM57xx line of processors.

10.1 Profibus

A compliant Profibus interface is implemented using the ISO1176T isolation device, transformer and

TPS76650 LDO regulator. This circuit terminates to a DB9F connector, J14. This Profibus interface is

driven by UART0 from the first PRU-ICSS block, PR1.

10.2 DCAN

The AM5728 processor contains two Controller Area Network (DCAN) interfaces. DCAN port 1 is routed

out to the ISO1050 isolation device and then to the 5-pin header, J38. The R1Z-3.305HP isolated DC-DC

supply provides an isolated 3.3V supply for this DCAN interface.

10.3 RS-485

The AM572x IDK EVM contains an RS-485 interface on 3-pin header, J39. This is enabled by the

SN65HVD78D Half-Duplex RS-485 Transceiver. The transceiver controls the half-duplex communication

and also provides high-voltage transient protection. This interface is attached to the SOC-level UART2

port for RX and TX data. The UART TX data line is monitored by PR2_PRU1, so that PRU code can

monitor TX activity and then control the DE and REn lines into the transceiver.

20

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Hardware

Copyright © 2017–2018, Texas Instruments Incorporated

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Page 21

www.ti.com

11 User Interfaces

The AM572x IDK EVM contains GPIO expanders that provide industrial inputs and outputs to support

development. The outputs contain LEDs for immediate feedback. There are also tri-color LEDs connected

to GPIOs to support development.

11.1 Tri-color LEDs

There are 6 tri-color LEDs connected to SOC GPIO pins that can be used to support development. There

is a separate GPIO assigned for each color: red, green, and yellow. Color mixing by turning on more than

one GPIO at a time will not provide the expected result since the separate colors have different intensities

due to the physics of the LED composition. Tri-color LEDs D16, D17, D18, and D19 are designated

Industrial LEDs. Tri-color LEDs D22 and D23 are designated Status LEDs.

11.2 Industrial Inputs

For industrial 24v digital inputs, an SN65HVS882 Digital-input Serializer for industrial digital inputs is used

to accept standard signals from the 30-pin (15 × 2) I/O Expansion Header, J37. The input values are

clocked into the SPI3 port of the AM5728 processor.

11.3 Industrial Outputs / LEDs

I2C to 8-bit LED driver TPIC2810 is used to drive the eight Industrial output LEDs D5 to D12. The I2C

interface is connected to the I2C1 port of the AM5728 processor along with the other devices on the

IND_I2C bus. The eight LED driver outputs are also driven to the I/O Expansion Header, J37. All the LEDs

are green in color.

User Interfaces

12 Pin Use Description

12.1 Functional Interface Mapping

Some signals of the AM5728 device are connected to a fixed device on the EVM where it cannot be

changed. However, some of the signals of the AM5728 device are connected to devices on the AM572x

IDK EVM based on the profile setting.

12.2 GPIO Pin Mapping

The developer can enable GPIO pins individually, as needed, as output, input, or both. Most of the

LVCMOS pins not currently allocated for other peripheral use can be defined as GPIO pins. Table 5 is a

compliment to the schematic and the recommended settings in the pinmux tool. Each of the defined GPIO

pins are listed along with the associated pin name and ball number and mode. The last column lists the

available physical pull-up (PU) or pull-down (PD) resistor attached or the recommended internal pull-up or

pull-down resistor defined in the pinmux file provided for the AM572x IDK EVM.

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM) Hardware

Copyright © 2017–2018, Texas Instruments Incorporated

21

Page 22

Pin Use Description

www.ti.com

Table 5. GPIO Pin Mapping

Pin Name GPIO # Pin # IDK Net Name / Function Direction

MCASP2_AXR4 GPIO1_4 D15 AM57XX_INDETHER_LED0_YEL Output EXT PD

MCASP2_AXR7 GPIO1_5 A17 AM57XX_INDETHER_LED1_YEL Output EXT PD

MCASP2_AXR6 GPIO2_29 B17 AM57XX_INDETHER_LED1_GRN Output EXT PD

VIN1A_D6 GPIO3_10 AG6 AM57XX_STATUSLED1_RED Output EXT PD

VIN1A_D7 GPIO3_11 AH4 AM57XX_STATUSLED0_GRN Output EXT PD

VIN1A_D8 GPIO3_12 AG4 AM57XX_STATUSLED0_YEL Output EXT PD

VIN1A_D10 GPIO3_14 AG3 TOUCH_INT Input INT PU

VIN1A_D12 GPIO3_16 AF2 GPIO_AM572X_USB2_ID Input/Output EXT PU

VIN1A_D13 GPIO3_17 AF6 AM57XX_INDETHER_LED3_GRN Output EXT PD

VIN1A_D14 GPIO3_18 AF3 AM57XX_INDETHER_LED3_YEL Output EXT PD

VIN1A_D15 GPIO3_19 AF4 AM57XX_GPIO_IND_LDn Output EXT PU

VIN1A_D17 GPIO3_21 AE3 GPIO_VPP_PWR_EN Output EXT PD

VIN1A_D18 GPIO3_22 AE5 GPIO_PCIE_RSTDRVn Output INT PD

VIN1A_D19 GPIO3_23 AE1 GPIO_PCIE_SWRSTn Output INT PU

VIN1A_D22 GPIO3_26 AD2 GPIO_USB2_VBUS_DET Input EXT PU

VIN2A_CLK0 GPIO3_28 E1 PRU1ETH0_INTn Input INT PU

VIN2A_DE0 GPIO3_29 G2 PRU1ETH1_INTn Input INT PU

VIN2A_FLD0 GPIO3_30 H7 PRU2ETH0_INTn Input INT PU

VIN2A_HSYNC0 GPIO3_31 G1 PRU2ETH1_INTn Input INT PU

VIN1A_D5 GPIO3_9 AH5 AM57XX_INDETHER_LED0_GRN Output EXT PD

VIN2A_VSYNC0 GPIO4_0 G6 AM57XX_STATUSLED0_RED Output EXT PD

VOUT1_FLD GPIO4_21 B11 eMMC_RSTn Output EXT PU

MCASP1_ACLKR GPIO5_0 B14 GB_ETH0_INTn Input EXT PU

MCASP1_FSR GPIO5_1 J14 GB_ETH1_INTn Input EXT PU

MCASP1_AXR2 GPIO5_4 G13 PCIE_CRDPRESENT Input EXT PU

MCASP1_AXR3 GPIO5_5 J11 PCIE_WAKEn Input EXT PU

MCASP1_AXR4 GPIO5_6 E12 GPIO_PRU1_ETH0_RESETn Output EXT PU

MCASP1_AXR5 GPIO5_7 F13 GPIO_PRU1_ETH1_RESETn Output EXT PU

MCASP1_AXR6 GPIO5_8 C12 GPIO_PRU2_ETH0_RESETn Output EXT PU

MCASP1_AXR7 GPIO5_9 D12 GPIO_PRU2_ETH1_RESETn Output EXT PU

GPIO6_14 GPIO6_14 E21 CAM_ENn Output PU/PD on camera

GPIO6_15 GPIO6_15 F20 GPIO_TOUCH_RESETn Output EXT PU

GPIO6_16 GPIO6_16 F21 PMIC_INT Input INT PU

XREF_CLK2 GPIO6_19 B26 AM57XX_INDETHER_LED0_RED Output EXT PD

MCASP2_AXR5 GPIO6_7 B16 AM57XX_INDETHER_LED1_RED Output EXT PD

SPI1_CS0 GPIO7_10 A24 AM57XX_INDETHER_LED2_YEL Output EXT PD

SPI1_CS1 GPIO7_11 A22 AM57XX_INDETHER_LED3_RED Output EXT PD

UART1_RXD GPIO7_22 B27 AM57XX_STATUSLED1_YEL Output EXT PD

UART1_TXD GPIO7_23 C26 AM57XX_STATUSLED1_GRN Output EXT PD

SPI1_SCLK GPIO7_7 A25 AM572X_HAPTICS_TRIG Output EXT PD

SPI1_D1 GPIO7_8 F16 AM57XX_INDETHER_LED2_GRN Output EXT PD

SPI1_D0 GPIO7_9 B25 AM57XX_INDETHER_LED2_RED Output EXT PD

Pull Up /

Pull Down

board

22

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Hardware

Copyright © 2017–2018, Texas Instruments Incorporated

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Page 23

www.ti.com

13 Board Connectors

This section shows the pin-outs for the connectors on the AM572x IDK EVM.

Pin Signal Name Secondary Signal Name

1 V3_3D —

2 V5_0D —

3 PR1_EDC_LATCH0 —

4 GPMC_CS0 —

5 PR1_EDC_SYNC0 —

6 GPMC_CS3 —

7 No Connect —

8 GPMC_ADVN_ALE —

9 No Connect AM57XX_PRU1ETH1_TXCLK

10 GPMC_OEN_REN —

11 No Connect AM57XX_PRU1ETH1_TXD3

12 GPMC_WEN —

13 PR2_EDC_LATCH0 AM57XX_PRU1ETH_MDCLK

14 GPMC_BEN0 —

15 PR2_EDC_LATCH1 PRU1ETH1_TXD1

16 GPMC_BEN1 —

17 PR2_EDC_SYNC0 PRU1ETH1_RXCLK

18 No Connect —

19 PR2_EDC_SYNC1 PRU1ETH1_RXD3

20 No Connect —

21 No Connect PRU1ETH1_RXD1

22 DGND —

23 No Connect PRU1ETH1_RXERR

24 SPI2_SCLK —

25 SYS_RESETn —

26 SPI2_DIN —

27 IND_I2C_SCL —

28 SPI2_DOUT —

29 IND_I2C_SDA —

30 SPI2_CS0n —

31 AM57XX_GPMC_AD0 —

32 AM57XX_GPMC_AD8 —

33 AM57XX_GPMC_AD1 —

34 AM57XX_GPMC_AD9 —

35 AM57XX_GPMC_AD2 —

36 AM57XX_GPMC_AD10 —

37 AM57XX_GPMC_AD3 —

38 AM57XX_GPMC_AD11 —

39 DGND —

40 DGND —

41 CAN1_RXDF —

42 AM57XX_GPMC_AD12 —

43 CAN1_TXDF —

44 AM57XX_GPMC_AD13 —

Board Connectors

Table 6. Expansion Connector - J21

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Copyright © 2017–2018, Texas Instruments Incorporated

Hardware

23

Page 24

Board Connectors

www.ti.com

Table 6. Expansion Connector - J21 (continued)

Pin Signal Name Secondary Signal Name

45 AM57XX_PR1_UART0_TXD —

46 AM57XX_GPMC_AD14 —

47 AM57XX_PR1_UART0_RXD —

48 AM57XX_GPMC_AD15 —

49 AM57XX_PR2_PROFI_TXEN —

50 HDQ —

51 AM57XX_GPMC_AD4 —

52 GPMC_WAIT0 —

53 AM57XX_GPMC_AD5 —

54 PR2_UART0_RXD —

55 AM57XX_GPMC_AD6 —

56 PR2_UART0_TXD —

57 AM57XX_GPMC_AD7 —

58 GPMC_CLK —

59 DGND —

60 DGND —

24

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Hardware

Copyright © 2017–2018, Texas Instruments Incorporated

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Page 25

www.ti.com

Board Connectors

Table 7. I/O Expansion Header Connector - J37

Pin Signal Name

1 INDUS_INPUT0

2 V12_0D

3 INDUS_INPUT1

4 V12_0D

5 INDUS_INPUT2

6 V12_0D

7 INDUS_INPUT3

8 V12_0D

9 INDUS_INPUT4

10 V12_0D

11 INDUS_INPUT5

12 V12_0D

13 INDUS_INPUT6

14 V12_0D

15 INDUS_INPUT7

16 V12_0D

17 DGND

18 No Connect

19 DRAIN0

20 DRAIN1

21 DRAIN2

22 DRAIN3

23 DRAIN4

24 DRAIN5

25 DRAIN6

26 DRAIN7

27 V5_0D

28 V5_0D

29 DGND

30 DGND

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Copyright © 2017–2018, Texas Instruments Incorporated

Hardware

25

Page 26

Board Connectors

www.ti.com

Table 8. MicroSD Connector - J15

Pin Pin Name Signal Name

1 DAT2 MMC_D2

2 DAT3 MMC_D3

3 CMD MMC_CMD

4 VDD V3_3D

5 CLOCK MMC_CLK

6 DGND VSS

7 DAT0 MMC_D0

8 DAT1 MMC_D1

9 GND DGND

10 CD MMC1_SDCD

11 GND3 DGND

12 GND4 DGND

13 GND5 DGND

14 GND6 DGND

15 GND7 DGND

16 GND8 DGND

Table 9. Power Jack Connector - J1

Pin Signal Name

1 VPWRIN_JCK

2 DGND

3 DGND

Table 10. Power Terminal Block Connector - J2

Pin Signal Name

1 VPWRIN_JCK

2 DGND

26

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Hardware

Copyright © 2017–2018, Texas Instruments Incorporated

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Page 27

www.ti.com

Board Connectors

Table 11. PRU1ETH0 RJ45 Connector - J3

Pin Pin Name Signal Name

1 RD+ PRU1ETHER0_RDP

2 RD- PRU1ETHER0_RDN

3 RCT V3_3D

4 TCT V3_3D

5 TD+ PRU1ETHER0_TDP

6 TD- PRU1ETHER0_TDN

7 N/C No connect

8 AC GND DGND

9 YEL LED Anode V3_3D

10 YEL LED Cathode RXLINK

11 GRN LED Anode V3_3D

12 GRN LED Cathode PRU1ETH0_LINKLED

SHLD1 Shield AGNDFRAME_PRU1ETH0

SHLD2 Shield AGNDFRAME_PRU1ETH0

Table 12. PRU1ETH1 RJ45 Connector - J5

Pin Pin Name Signal Name

1 RD+ PRU1ETHER1_RDP

2 RD- PRU1ETHER1_RDN

3 RCT V3_3D

4 TCT V3_3D

5 TD+ PRU1ETHER1_TDP

6 TD- PRU1ETHER1_TDN

7 N/C No connect

8 AC GND DGND

9 YEL LED Anode V3_3D

10 YEL LED Cathode RXLINK

11 GRN LED Anode V3_3D

12 GRN LED Cathode PRU1ETH1_LINKLED

SHLD1 Shield AGNDFRAME_PRU1ETH1

SHLD2 Shield AGNDFRAME_PRU1ETH1

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Copyright © 2017–2018, Texas Instruments Incorporated

Hardware

27

Page 28

Board Connectors

www.ti.com

Table 13. PRU2ETH0 RJ45 Connector - J6

Pin Pin Name Signal Name

1 RD+ PRU2ETHER0_RDP

2 RD- PRU2ETHER0_RDN

3 RCT V3_3D

4 TCT V3_3D

5 TD+ PRU2ETHER0_TDP

6 TD- PRU2ETHER0_TDN

7 N/C No connect

8 AC GND DGND

9 YEL LED Anode V3_3D

10 YEL LED Cathode RXLINK

11 GRN LED Anode V3_3D

12 GRN LED Cathode PRU2ETH0_LINKLED

SHLD1 Shield AGNDFRAME_PRU2ETH0

SHLD2 Shield AGNDFRAME_PRU2ETH0

Table 14. PRU2ETH1 RJ45 Connector - J8

Pin Pin Name Signal Name

1 RD+ PRU2ETHER1_RDP

2 RD- PRU2ETHER1_RDN

3 RCT V3_3D

4 TCT V3_3D

5 TD+ PRU2ETHER1_TDP

6 TD- PRU2ETHER1_TDN

7 N/C No connect

8 AC GND DGND

9 YEL LED Anode V3_3D

10 YEL LED Cathode RXLINK

11 GRN LED Anode V3_3D

12 GRN LED Cathode PRU2ETH1_LINKLED

SHLD1 Shield AGNDFRAME_PRU2ETH1

SHLD2 Shield AGNDFRAME_PRU2ETH1

28

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Hardware

Copyright © 2017–2018, Texas Instruments Incorporated

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Page 29

www.ti.com

Board Connectors

Table 15. PRU2ETH0 Test Header Connector - J7

Pin Signal Name Net Name

1 RT2_MII0_TXEN AM57XX_PRU2ETH0_TXEN

2 RT2_MII0_RXDV AM57XX_PRU2ETH0_RXDV

3 RT2_MII0_EDIO_DATA0 AM57XX_VIN2A_VSYNC0

4 RT2_MII0_EDIO_DATA1 AM57XX_PR1_UART0_TXD

5 DGND —

Table 16. PRU2ETH1 Test Header Connector - J4

Pin Signal Name Net Name

1 RT2_MII1_TXEN PRU2ETH1_TXEN

2 RT2_MII1_RXDV PRU2ETH1_RXDV

3 RT2_MII1_EDIO_DATA0 AM57XX_VIN2A_HSYNC0

4 RT2_MII1_EDIO_DATA1 AM57XX_VIN2A_DE0

5 DGND DGND

Table 17. Camera Connector - J9

Pin Pin Name Signal Name

1 Power VMAIN

2 CAM1_VSYNC DGND

3 CAM1_DATA0 AM572X_VIN4B_DATA0

4 CAM1_HSYNC AM572X_VIN4B_HSYNC

5 CAM1_DATA1 AM572X_VIN4B_DATA1

6 CAM1_DATA6 AM572X_VIN4B_DATA6

7 CAM1_DATA2 AM572X_VIN4B_DATA2

8 CAM1_DATA7 AM572X_VIN4B_DATA7

9 CAM1_PCLK AM572X_VIN4B_PCLK

10 No Connect —

11 GND DGND

12 GND DGND

13 CAM1_DATA3 AM572X_VIN4B_DATA3

14 No Connect —

15 CAM1_DATA4 AM572X_VIN4B_DATA4

16 CAM1_GIO0 PU to V3_3D

17 CAM1_WEN AM572X_VIN4B_DATA5

18 CAM1_GIO1 CAM_ENn

19 CAM1_DATA5 AM572X_VIN4B_DE

20 CAM1_FIELD AM572X_VIN4B_FLD

21 GND DGND

22 I2C_SCL IND_I2C_SCL

23 Clock 20.000 MHz Osc Out

24 I2C_SDA IND_I2C_SDA

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Copyright © 2017–2018, Texas Instruments Incorporated

Hardware

29

Page 30

Board Connectors

www.ti.com

Table 18. GigE RJ45 Connector - J10

Pin Pin Name Signal Name

1 CH-GND DGND

2 VCC No connect

3 MX3+ ETHER0_D3P

4 MX3- ETHER0_D3N

5 MX2+ ETHER0_D2P

6 MX2- ETHER0_D2N

7 MX1+ ETHER0_D1P

8 MX1- ETHER0_D1N

9 MX0+ ETHER0_D0P

10 MX0- ETHER0_D0N

11 RT GRN Anode PU to PHY0_LED_ACTn

12 RT YEL Anode DGND

13 LEFT GRN Anode DGND

14 LEFT YEL Anode PU to PHY0_LED_LINKn

SHLD1 Shield AGND_GBETH0

SHLD2 Shield AGND_GBETH0

Table 19. GigE RJ45 Connector - J12

Pin Pin Name Signal Name

1 CH-GND DGND

2 VCC No connect

3 MX3+ ETHER1_D3P

4 MX3- ETHER1_D3N

5 MX2+ ETHER1_D2P

6 MX2- ETHER1_D2N

7 MX1+ ETHER1_D1P

8 MX1- ETHER1_D1N

9 MX0+ ETHER1_D0P

10 MX0- ETHER1_D0N

11 RT GRN Anode PU to PHY1_LED_ACTn

12 RT YEL Anode DGND

13 LEFT GRN Anode DGND

14 LEFT YEL Anode PU to PHY1_LED_LINKn

SHLD1 Shield AGND_GBETH1

SHLD2 Shield AGND_GBETH1

30

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Hardware

Copyright © 2017–2018, Texas Instruments Incorporated

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Page 31

www.ti.com

Table 20. LCD Module FFC Connector - J16

Pin Pin Name Signal Name

1 — No Connect

2 — No Connect

3 VCC V3_7LCD

4 VCC V3_7LCD

5 VCC V3_7LCD

6 — No Connect

7 GND DGND

8 MIPI_LN3_N LCD_MIPI3N

9 MIPI_LN3_P LCD_MIPI3P

10 GND DGND

11 MIPI_LN2_N LCD_MIPI2N

12 MIPI_LN2_P LCD_MIPI2P

13 GND DGND

14 MIPI_LN1_N LCD_MIPI1N

15 MIPI_LN1_P LCD_MIPI1P

16 GND DGND

17 MIPI_LN0_N LCD_MIPI0N

18 MIPI_LN0_P LCD_MIPI0P

19 GND DGND

20 MIPI_CLK_N LCD_CLKN

21 MIPI_CLK_P LCD_CLKP

22 GND DGND

23 LED_CATHODE VLED24 LED_CATHODE VLED25 LED_CATHODE VLED26 LED_CATHODE VLED27 LED_CATHODE VLED28 LED_CATHODE VLED29 LED Anode Supply VLED+

30 LED Anode Supply VLED+

31 — No Connect

32 — No Connect

Board Connectors

Table 21. Touchscreen Controller FFC Connector - J17

Pin Pin Name Signal Name

1 SDA IND_I2C_SDA

2 SCL IND_I2C_SCL

3 TSC_RESETn GPIO_TOUCH_RESETn

4 TSC_INT TOUCH_INT

5 V+ V3_3D

6 GND DGND

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Copyright © 2017–2018, Texas Instruments Incorporated

Hardware

31

Page 32

Board Connectors

www.ti.com

Table 22. HDMI Standard A-type Connector - J24

Pin Pin Name Signal Name

1 DAT2+ HDMI_TX2+

2 DAT2_S DGND

3 DAT2- HDMI_TX24 DAT1+ HDMI_TX1+

5 DAT1_S DGND

6 DAT1- HDMI_TX17 DAT0+ HDMI_TX0+

8 DAT0_S DGND

9 DAT0- HDMI_TX010 CLK+ HDMI_CLK+

11 CLK_S DGND

12 CLK- HDMI_CLK13 CEC HDMICONN_CEC

14 NC No Connect

15 SCL HDMICONN_I2CSCL

16 SDA HDMICONN_I2CSDA

17 DDC/CEC GND DGND

18 +5V V5_0HDMICONN

19 HPLG HDMICONN_HPLG

MTG1 Sheild DGND

MTG2 Sheild DGND

MTG3 Sheild DGND

MTG4 Sheild DGND

Pin Pin Name Signal Name

1 VREF_DBG PU to V3_3D

2 TMS JTAG_TMS

3 TCK JTAG_TCK

4 TDO JTAG_TDO

5 TDI JTAG_TDI

6 RESETn EMU_RSTn

7 RTCK AM57XX_RTCK

8 TRSTPD JTAG_TRSTn

9 TRSTn No Connect

10 EXTE No Connect

11 EXTF No Connect

12 VREF_TR PU to V3_3D

13 TR_CLK0 EMU2

14 TR_CLK1 No Connect

15 TGT_DETECT DGND

16 GND DGND

17 TRD0.0 EMU3

18 TRD1.0 No Connect

32

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Hardware

Table 23. MIPI-60 JTAG Connector - J18

Copyright © 2017–2018, Texas Instruments Incorporated

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Page 33

www.ti.com

Board Connectors

Table 23. MIPI-60 JTAG Connector - J18 (continued)

Pin Pin Name Signal Name

19 TRD0.1 JTAG_EMU0

20 TRD1.1 No Connect

21 TRD0.2 JTAG_EMU1

22 TRD1.2 No Connect

23 TRD0.3 EMU4

24 TRD1.3 No Connect

25 TRD0.4 EMU5

26 TRD1.4 No Connect

27 TRD0.5 EMU6

28 TRD1.5 No Connect

29 TRD0.6 EMU7

30 TRD1.6 No Connect

31 TRD0.7 EMU8

32 TRD1.7 No Connect

33 TRD0.8 EMU9

34 TRD1.8 No Connect

35 TRD0.9 EMU10

36 TRD1.9 No Connect

37 TRD3.0 EMU11

38 TRD2.0 No Connect

39 TRD3.1 EMU12

40 TRD2.1 No Connect

41 TRD3.2 EMU13

42 TRD2.2 No Connect

43 TRD3.3 EMU14

44 TRD2.3 No Connect

45 TRD3.4 EMU15

46 TRD2.4 No Connect

47 TRD3.5 EMU16

48 TRD2.5 No Connect

49 TRD3.6 EMU17

50 TRD2.6 No Connect

51 TRD3.7 EMU18

52 TRD2.7 No Connect

53 TRD3.8 EMU19

54 TRD2.8 No Connect

55 TRD3.9 No Connect

56 TRD2.9 No Connect

57 GND DGND

58 GND DGND

59 TR_CLK3 No Connect

60 TR_CLK2 No Connect

61 GND DGND

62 GND DGND

63 GND DGND

64 GND DGND

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Copyright © 2017–2018, Texas Instruments Incorporated

Hardware

33

Page 34

Board Connectors

www.ti.com

Table 24. JTAG USB Micro-AB Connector - J19

Pin Pin Name Signal Name

1 VBUS VUSB_JTAG

2 DM EMU_USB_DM

3 DP EMU_USB_DP

4 ID No Connect

5 GND DGND

S1 S1 GNDUSBJ

S2 S2 GNDUSBJ

S3 S3 GNDUSBJ

S4 S4 GNDUSBJ

Table 25. USB Port 1 USB3.0 Standard A-type Connector - J23

Pin Pin Name Signal Name

1 VBUS VUSB_VBUS1

2 DM USB1_CONN_DM

3 DP USB1_CONN_DP

4 GND DGND

5 STDA_SSRX- USB1_3_0_STDA_SSRX-

6 STDA_SSRX+ USB1_3_0_STDA_SSRX+

7 GND_DRAIN DGND

8 STDA_SSTX- USB1_3_0_STDA_SSTX-

9 STDA_SSTX+ USB1_3_0_STDA_SSTX+

S1 S1 GNDUSB1

S2 S2 GNDUSB1

Table 26. USB Port 2 USB2.1 Micro-AB Connector - J45

Pin Pin Name Signal Name

1 VBUS VUSB_VBUS2

2 DM USB2_CONN_DM

3 DP USB2_CONN_DP

4 ID USB2_ID

5 GND DGND

S1 S1 GNDUSB2

S2 S2 GNDUSB2

S3 S3 GNDUSB2

S4 S4 GNDUSB2

34

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Hardware

Copyright © 2017–2018, Texas Instruments Incorporated

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Page 35

www.ti.com

Board Connectors

Table 27. CAN Header Connector - J38

Pin Signal Name

1 VCAN1

2 CAN1_H

3 CAN1_L

4 GND_CAN1

5 No Connect

Table 28. Profibus DB9F Connector - J14

Pin Signal Name

1 No Connect

2 No Connect

3 PROFIBUS_A

4 No Connect

5 GND_PROFI

6 VPROFI

7 No Connect

8 PROFIBUS_B

9 No Connect

Table 29. RS-485 Header Connector - J39

Pin Signal Name

1 RS485_A

2 RS485_B

3 DGND

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Copyright © 2017–2018, Texas Instruments Incorporated

Hardware

35

Page 36

EVM Important Notice

B10 +3.3V AUX V3_3AUX_PCIE

B11 WAKE# PCIE_WAKEn

B12 CLKREQ# No Connect

B13 Ground DGND

B14 HSOp(0) PCIECONN_PETp0

B15 HSOn(0) PCIECONN_PETn0

B16 Ground DGND

B17 PRSNT2# DGND

B18 Ground DGND

A10 +3.3V V3_3D

A11 PERST# PCIE_PERSTn

A12 Ground DGND

A13 REFCLK+ PCIE_REFCLKP

A14 REFCLK- PCIE_REFCLKN

A15 Ground DGND

A16 HSIp(0) PCIE_PERp0

A17 HSIn(0) PCIE_PERn0

A18 Ground DGND

www.ti.com

Table 30. PCIe Connector – J22

Pin Pin Nmae Signal Name

B1 +12 V V12_0D

B2 +12 V V12_0D

B3 +12 V V12_0D

B4 Ground DGND

B5 SMCLK PCIE_SMB_CLK

B6 SMDAT PCIE_SMB_DATA

B7 Ground DGND

B8 +3.3V V3_3D

B9 TRST# PCIE_TRSTn

A1 PRSNT1# PCIE_CRDPRESENT

A2 +12 V V12_0D

A3 +12 V V12_0D

A4 Ground DGND

A5 TCK PD to DGND

A6 TDI PU to V3_3D

A7 TDO TP20

A8 TMS PU to V3_3D

A9 +3.3V V3_3D

14 EVM Important Notice

Refer to the STANDARD TERMS AND CONDITIONS FOR EVALUATION MODULES (SSZZ027).

36

AM572x Industrial Development Kit (IDK) Evaluation Module (EVM)

Hardware

Copyright © 2017–2018, Texas Instruments Incorporated

SPRUI64C–May 2017–Revised April 2018

Submit Documentation Feedback

Page 37

Appendix A

SPRUI64C–May 2017–Revised April 2018

Known Deficiencies in AM572x IDK EVM

A.1 Power solution not sufficient for full PCIe plug-in card compliance

The AM572x IDK EVM supports compatibility to PCIe x1 plug-in cards. It is not compliant with the PCIe

Card Electro-Mechanical (CEM) specification. Specifically, the board does not provide the recommended

power per the CEM. It provides up to 0.5A of current on the 3.3V/3.3V_AUX input pins and up to 0.5A on

the 12V input pins. Also, the root complex design implemented does not support hot plug-in of cards.

A.2 Early versions of the AM572x IDK EVM not installed with SOC devices rated for the

full industrial temperature range

A.3 AM572x IDK EVM does not support eMMC HS200 mode

The interface voltage for the eMMC is fixed at 3.3V in all modes of operation. This prevents support of

HS200 which requires a transition to 1.8V. The AM572x IDK EVM does support this voltage shift for the

SDCARD attached to the MMC1 port. The MMC1 port is on VDDSHV8 supply that is attached to the

LDO1 PMIC output that supports this voltage shift for higher speed modes. The eMMC is attached to the

VDDSHV11 supply fixed at 3.3V. Board designs that require HS200 support for eMMC would need a

solution to transition from 3.3V to 1.8V under software control.

A.4 PCIe PERSTn line not in proper state at start-up

The board does not contain pull-up or pull-down resistors to allow this line to be pulled-high at start-up.

This can cause PCIe link training to fail. Future software releases need to properly control the GPIO

output pins to enable this correctly at start-up.

A.5 EDIO connectors J4 and J7 should support real-time debugging for both PRU1 and

PRU2

The pins chosen provide visibility to the PRU2 MII0 and MII1 ports and PRU1 EDIO ports.

A.6 HDQ implementation not correct