Terex R190T-ROW Operation And Maintenance Manual

8/17/2016

Operation and Maintenance

Manual

R190T-ROW

SN 00461-Current

English

Not USA

Language:

Geographic Region:

Serial Number Range:

This manual is complements of

TrackLoaderParts.com

The world's best source for Terex parts.

Track Loader Parts 6543 Chupp Road Atlanta, Georgia 30058 USA (800)616-8156

CONTENTS

Introduction .................................................. 2

Safety ........................................................ 5

Technical Data.............................................. 29

Machine Description / Controls..................... 35

Operation ..................................................... 45

Transportation .............................................. 55

Maintenance ................................................ 61

California Proposition 65 .............................. 83

1

Page

The operator must read and understand all the instructions

in this manual before operating the RT-60/R160T/R190T.

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

1 INTRODUCTION

2

1.1 Product Identification (PIN)

The machine PIN is located on the identification plate, behind and to the left of

the operator seat.

Please state the model of the machine and PIN when making inquiries in regards

to parts, service, or warranty.

1.2 Introduction

Thank you for purchasing your RT-60/R160T/R190T Compact Track Loader.

We are confident that the machine you have chosen will provide excellent performance and efficient operation.

The information contained in this manual is intended to provide the operator with

all necessary information for the proper use of the machine.

It is imperative that this manual be provided to the end user at the time of purchase, prior to operation and kept with the machine at all times. If lost or damaged, contact your dealer immediately to obtain a replacement prior to resuming

operation.

The operator is responsible for the safe operation of the machine.

The operator must read, understand and obey the instructions in both this

and the AEM safety manual for skid steer and compact track loaders prior

to operating or performing maintenance or service on the machine.

Should you need clarification or further explanation of the topics in this manual,

please contact your dealer immediately for assistance.

Information describing special equipment or attachments and their operation are

not included in this manual.

This manual should be stored in the black plastic manual box located inside the

cab enclosure to protect it from the elements.

1.3 Safety Alert Symbol

The safety alert symbol is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

1 INTRODUCTION

3

1.4 Intended Use

The RT-60/R160T/R190T with bucket attachment is intended to be used solely for

work consistent with its design. Such work involves loosening, collecting, transporting, and distributing soil, rock, or similar materials as well as loading these

materials onto trucks, conveyors, or other methods of transport.

After installation of compatible (see section 4.10) special working attachments,

the equipment can be used for corresponding applications.

The operator must follow the operating instructions for any externally supplied

components or attachments.

Any use varying from that described here or any lack of adherence to the operating instructions, maintenance procedures, or replacement intervals described in

this manual shall be regarded as unintended or improper use. The supplier cannot

be held responsible for any damage resulting from improper use. This risk is

borne solely by the user.

1.5 Bulletin Compliance

It is very important to comply with all safety related bulletins. Bulletins are tied to

the most current owner on record. Therefore, it is important that any new owner

contact their local dealer to register the machine in their name. This will ensure

that they will be notified in the event of a safety related bulletin affecting their

machine.

1.6 Contacting the Manufacturer

If you have questions relating to ownership including, but not limited to: accident

reporting, current owner updates, product applications and safety, standards and

regulations compliance, product modifications, transfer of ownership, please

consult your local dealer as the first point of contact.

1.7 Copyright

This manual is intended for use by personnel responsible for operation, maintenance, repair, and supervision activities involving the machine described within.

This manual is copyrighted. It shall not, either in whole or in part, be reproduced,

transmitted, or used for the purpose of competition without our prior written consent.

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

1.8 Warranty

Your RT-60/R160T/R190T is warranted under the Compact Track Loader and

Utility Vehicle Standard Limited New Product Warranty (“Warranty”). A copy of the

Warranty certificate is available from your authorized RT-60/R160T/R190T

Distributor.

4

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

1 INTRODUCTION

2 SAFETY

5

2.1 Safety Alert System................................ 7

2.2 Graphical Symbols ................................. 8

2.3 Safety Signs (ISO)................................... 12

2.4 General Notes ........................................ 14

2.5 Personal Protection Equipment............... 15

2.6 Hazard Zone........................................... 15

2.7 Operation ............................................... 16

2.8 Stability.................................................. 17

2.9 Transport of Persons............................... 17

2.10 Fire Prevention ..................................... 18

2.11 Crush / Burn Avoidance........................ 19

2.12 Placing Into Operation .......................... 20

2.13 Starting the Machine............................ 20

2.14 Jobsite Safety ...................................... 21

2.15 Parking the Machine ............................ 22

2.16 Towing / Retrieving............................... 22

2.17 Transporting ......................................... 23

2.18 Maintenance ........................................ 24

2.19 Battery ................................................. 26

2.20 Hydraulic Lines / Hoses........................ 27

Page

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

6

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

This Page Intentionally Left Blank

2.1 Safety Alert System

Safety Alert Symbol

This symbol means: Attention! Be alert! Your safety

is involved!

The safety alert symbol is used to alert you to potential

personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or

death.

This symbol is used as an attention-getting device throughout this manual as well

as on decals and labels fixed to the machinery to assist in potential hazard recognition and prevention.

NOTICE indicates a property damage

message.

2 SAFETY

7

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

2 SAFETY

8

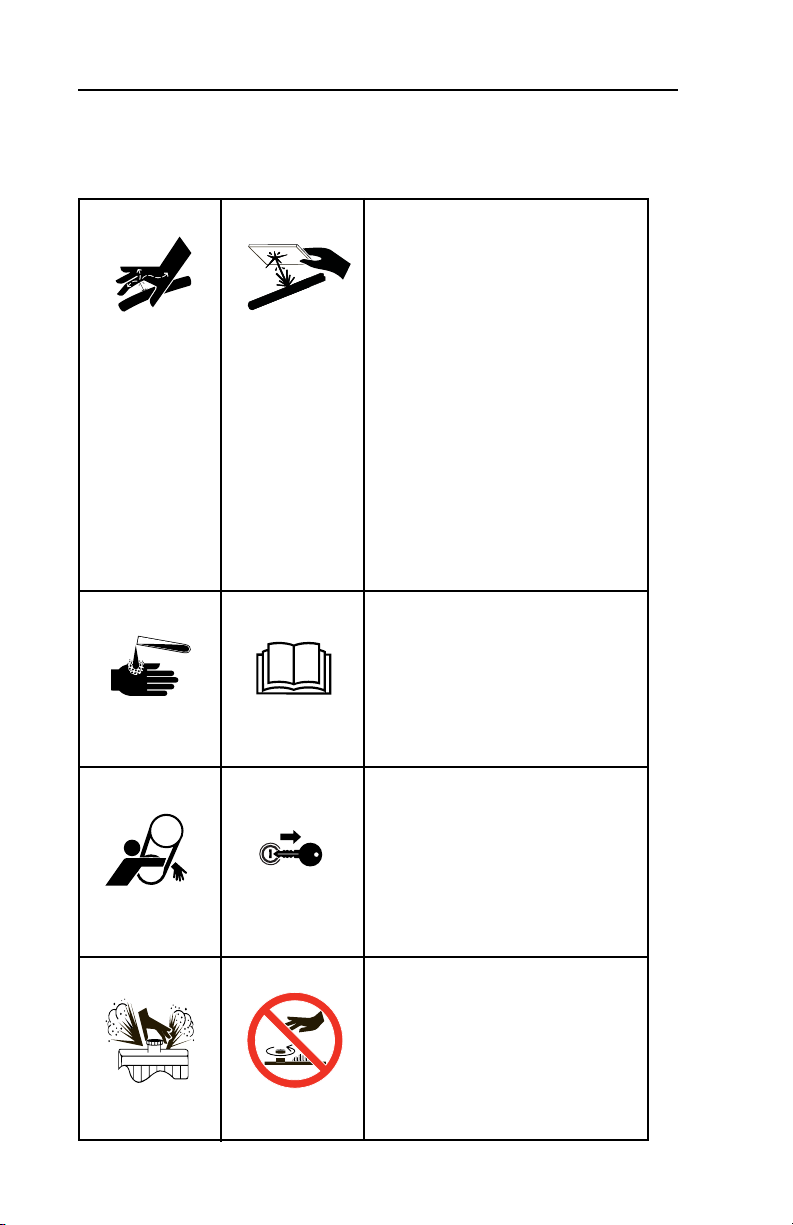

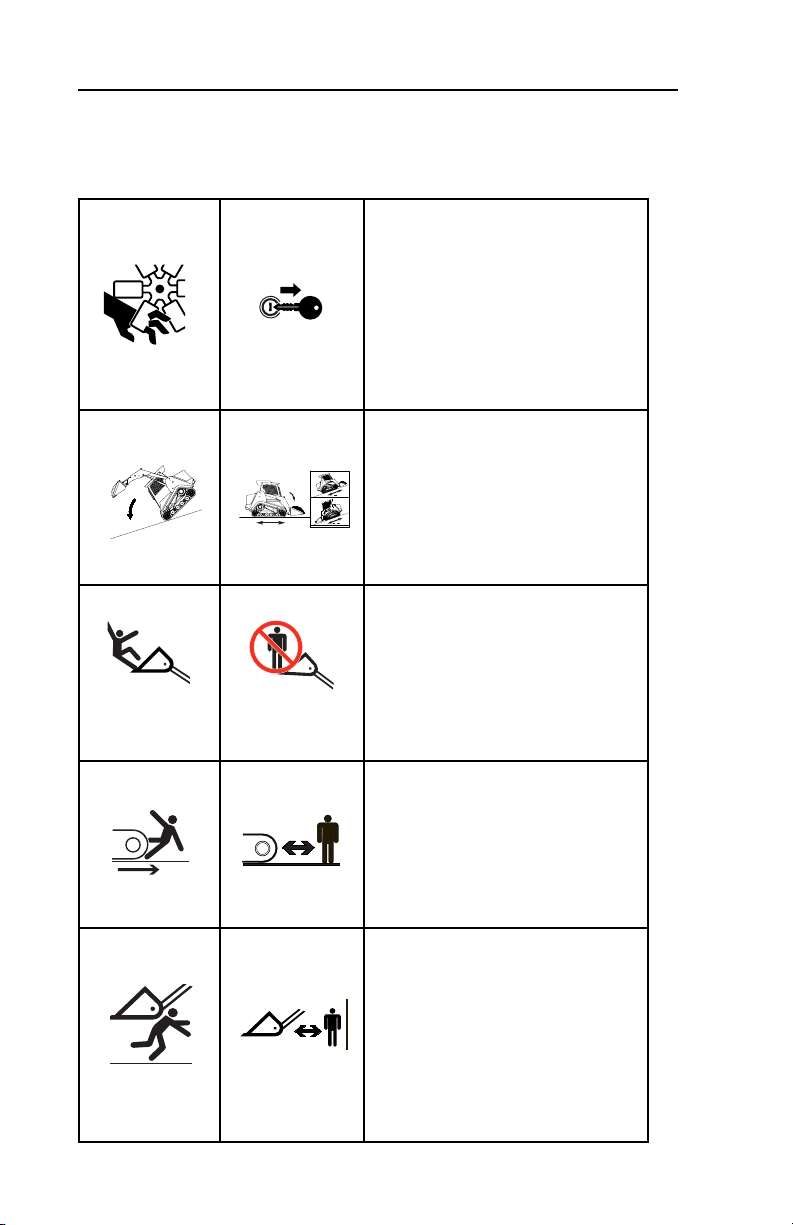

2.2 Graphical Symbols

Hazard Avoidance

Pictorial Pictorial Description

Hazard: Skin/Oil Injection

Avoidance:

• Relieve internal pressure before

disconnecting any line or fitting.

• Keep away from leaks or pinholes.

• Use cardboard to check for leaks.

Fluid injected into skin must be

surgically removed within a few

hours by a doctor familiar with this

type of injury or gangrene will

result.

Hazard: Corrosive

Avoidance: Read and understand

the operator’s manual.

Hazard: Entanglement

Avoidance: Stop machine and

remove key before servicing.

Hazard: Burn/Scald

Avoidance: Allow to cool before

opening.

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

2 SAFETY

9

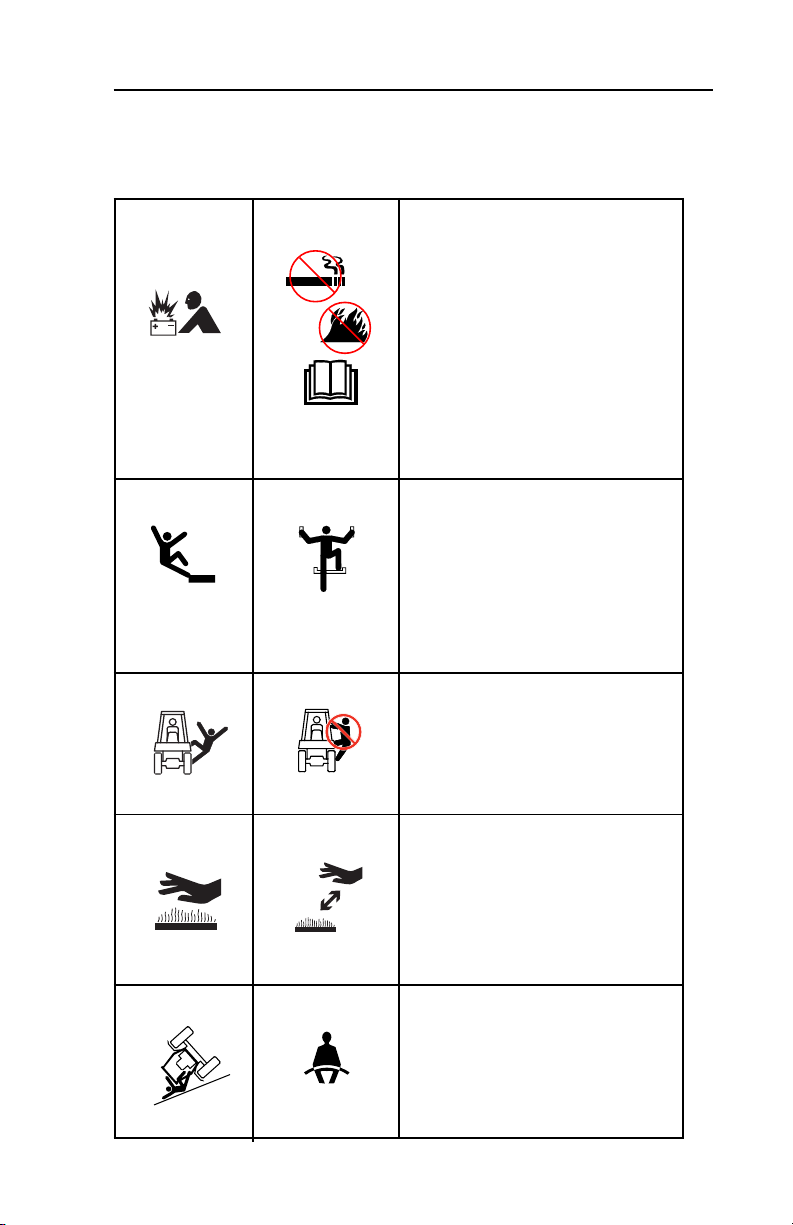

Hazard Avoidance

Pictorial Pictorial Description

Hazard: Explosion/Burn

Avoidance:

• Keep all flames/sparks away!

• No Smoking!

• Read and understand all

manuals.

Hazard: Fall

Avoidance: Use the provided

access system when entering or

exiting the machine.

Hazard: Fall

Avoidance: No Riders.

Hazard: Burn

Avoidance: Do not touch hot

surfaces.

Hazard: Crush

Avoidance: Fasten seat belt.

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

2 SAFETY

10

Hazard Avoidance

Pictorial Pictorial Description

Hazard: Entanglement

Avoidance: Stop machine and

remove key before servicing.

Hazard: Rollover / Ejection

Avoidance: Carry loads low, keep

heaviest end of machine uphill at

all times while operating on

inclines.

Hazard: Fall

Avoidance: Do not use the bucket

or attachment as a work platform.

Hazard: Crush

Avoidance: Stay clear of moving

machine.

Hazard: Crush

Avoidance: Keep clear of lift arms

and attachments.

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

2 SAFETY

11

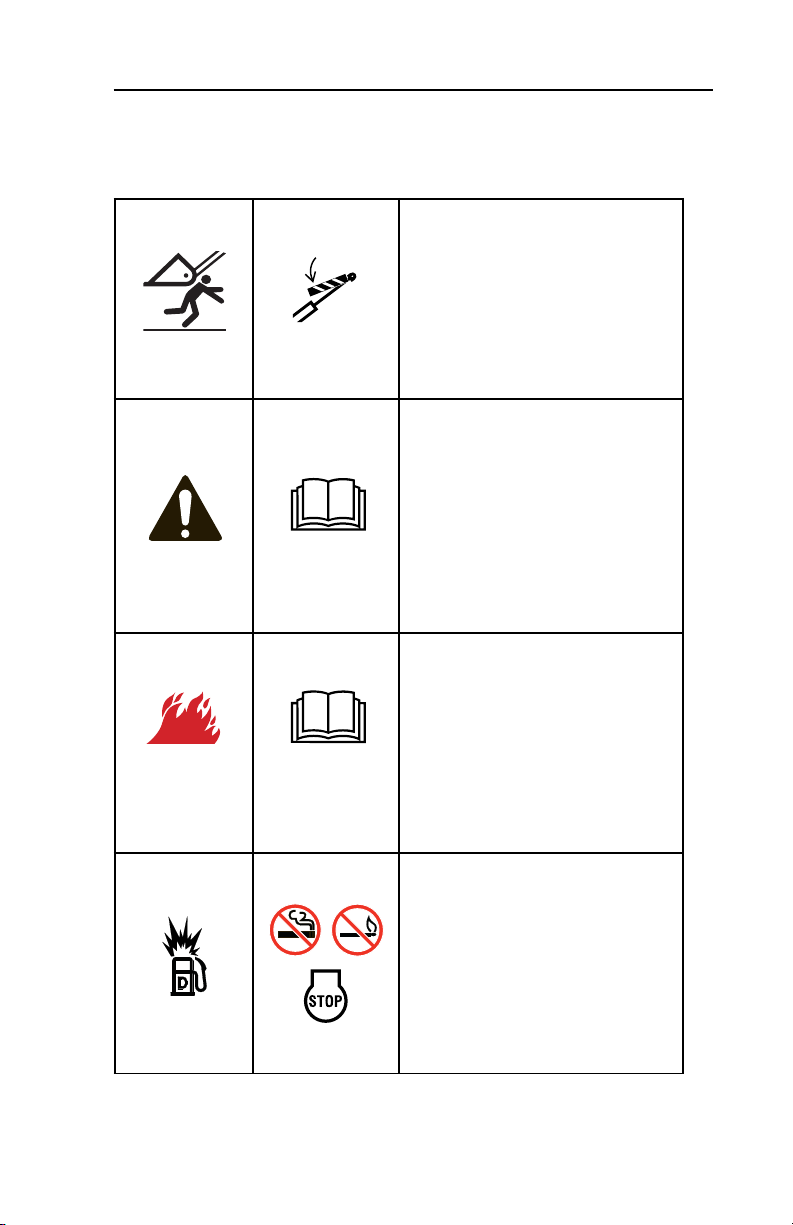

Hazard Avoidance

Pictorial Pictorial Description

Hazard: Crush

Avoidance: Install lift arm brace

before servicing.

Hazard: The safety alert symbol is

used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or

death.

Avoidance: Read and understand

the operator’s manual.

Hazard: Fire

Avoidance: Read and understand

the operator’s manual.

Hazard: Explosion / Burn

Avoidance: No smoking. Keep all

open flames and sparks away.

Stop engine before adding fuel.

7

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

2030-41

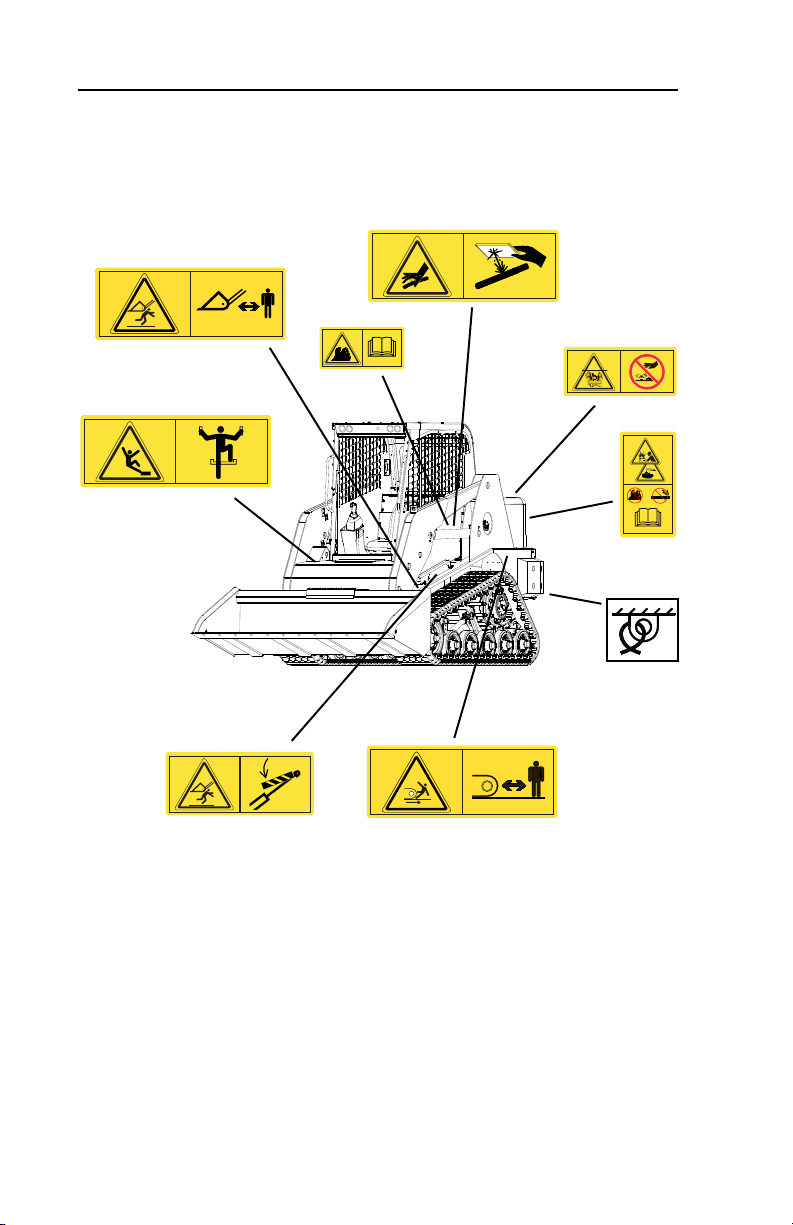

2.3 ANSI Safety Sign Location

The safety signs are located in/on the machine as indicated. (Descriptions of the

symbols are provided in section 2.2)

Key

1. Fall hazard

2. Crush hazard (lift arms)

3. Fire hazard (read manual, inside cab)

4. Skin (oil) injection hazard (outside of cab)

5. Burn hazard (engine compartment)

6. Explosion / burn hazard (read operator’s manual, engine compartment)

7. Tie down location

8. Crush hazard (run over)

9. Crush hazard (lift arm brace)

2 SAFETY

12

1

4

2

3

5

6

7

9

8

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

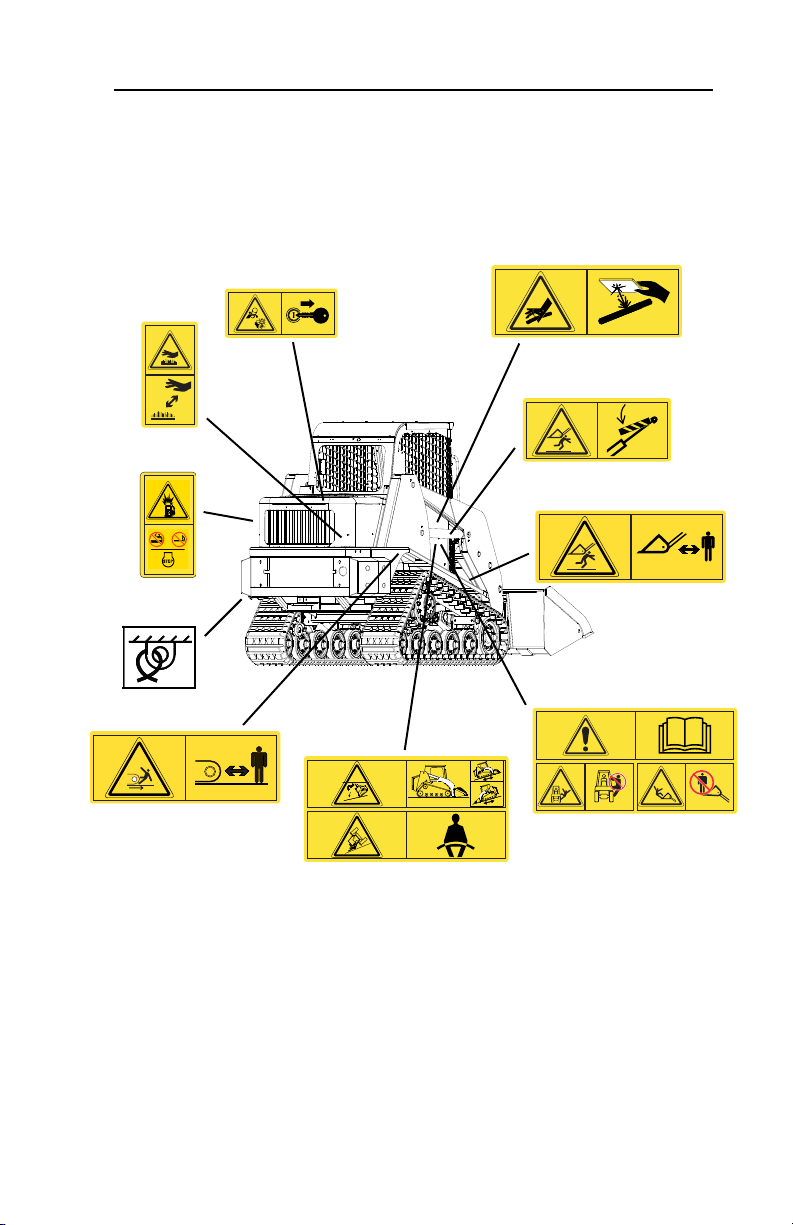

2030-553

2030-415

2030-427

2030-425

0404-599

2030-565

2030-417

2030-416

Note:

Safety signs are designed and fitted to the product to warn of possible dangers,

and MUST be replaced immediately if they become unreadable or lost. If the

product is repaired and parts have been replaced on which safety signs were

fixed, be sure new safety signs are fitted before the product is put into service.

Key (continued)

10. Burn hazard (engine compartment)

11. Belt/fan entanglement hazard (engine compartment)

12. Skin (oil) injection hazard (outside of cab)

13. Crush hazard (lift arm brace)

14. Crush Hazard (Lift arms)

15. Fall hazard / rollover Hazard / read operator’s manual (inside cab)

16. Crush / fall hazards (inside cab)

17. Crush (run over) hazard

18. Tie down location

19. Explosion / burn hazard (read operator’s manual)

2 SAFETY

13

10

11

12

14

15

16

17

18

13

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

19

0404-600

2030-553

2030-552

2030-417

0404-543

2030-415

2030-426

2030-416

2030-420

2.4 General Safety Notes

• It is the responsibility of the operator to be aware of his/her surroundings at

all times. Keep a safe distance from bystanders at all times during

operation. Always look in the direction of travel.

• Read and understand all safety signs, the operator’s manual and the AEM

safety manual for this type of equipment prior to operation.

• If safety signs are obstructed by dirt or debris, clean them using mild soap

and water prior to operation. DO NOT use solvent based cleaners, as they

may damage the safety sign material.

• If safety signs are damaged or illegible, replace them immediately, prior to

operation.

• Never jump off of the machine. Instead use the hand holds and step

designed for entering and exiting the machine. Face the machine and use

three points of contact (defined as: one foot and two hands, or one hand

and two feet) to ensure your safety.

• Ensure the access system (step and handholds) are clean prior to entering

or exiting the machine.

• Do not use any method of operation, inspection, or maintenance that may

impair safety.

• This machine is only to be used when properly equipped for the task to be

performed and when properly inspected and maintained to ensure safe

operation.

• The manufacturer’s instructions regarding operation, inspection, maintenance, repair and transportation must be followed.

• Never place the machine into operation without having first performed a

thorough walk-around inspection and making any necessary repairs or

adjustments.

• Safety devices on the machine shall not be deactivated or removed.

• Do not make any changes, additions or conversions to the machine that

could have a negative effect on safety without the manufacturer’s written

approval.

• It is the responsibility of the operator to communicate intentions for

work (machine movement) to anyone standing or working nearby, prior to

operation.

2 SAFETY

14

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

2.5 Personal Protection Equipment

The machine is designed to accommodate and protect an operator during operation from foreseeable injury when used as intended and when equipped prop-

erly for the task(s) being performed. Operators should not wear rings, scarves,

open jackets, and should ensure that all clothing is tightly secured. Long hair

should be restrained. Personal Protective Equipment (PPE) must be worn in the

absence of an enclosed cab. In this case PPE would include, but not be limited to,

safety glasses. The use of some attachments may require additional PPE, such as

hearing protection, hardhat, gloves, and steel-toed shoes. In some applications

high visibility/reflective jackets are required.

Personal protection equipment is also recommended when performing maintenance or service on a machine. Always wear appropriate protective equipment for

working conditions when working on or around the machine. Loose clothing

should not be worn and long hair should be restrained. Wear hard hats, protective

face/eyewear, safety shoes and any other equipment necessary to ensure your

safety and the safety of others around you as you work.

2.6 Hazard Zone

The hazard zone encompasses the area around the machine in which persons

may be injured by movements of the machine during operation, its attachments,

or by falling loads.

Do not position yourself or allow anyone else within this hazard zone during

machine operation. Keep a safe distance to ensure your safety while the machine

is in operation.

If someone enters the hazard zone, the operator must stop all work and give a

warning signal to the person who may be in danger to leave the hazard zone.

Work should not resume until all persons have vacated the hazard zone.

To minimize the possibility of a crushing hazard, a sufficient safety distance (min.

1.6 ft (0.5 m)) must be kept from solid objects, e. g. buildings, slopes, scaffolding,

other machines, etc. If that distance cannot be kept, fence off the area between

solid construction elements and the working range of the machine.

If conditions are such that the machine operator’s view of the driving and working

zone is restricted, he must be guided or the driving and working zone must be

secured by means of a solid barricade.

2 SAFETY

15

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

2.7 Operation

Earth moving machines are only to be operated and serviced by individuals who:

• are physically and mentally able to operate and / or service the

machine in a safe manner.

• have been instructed in the proper operation or maintenance of the

machine and have demonstrated competence in these areas.

• can be trusted to perform their assigned duties in a safe and reliable

manner.

• are of the legal minimum age for performing such duties.

It is the responsibility of the operator to:

• read, understand and obey the instructions in this manual and the AEM

safety manual for skid steer and compact track loaders.

• maintain a safe distance from bystanders at all times and always look in the

direction of travel.

• use the machine in accordance with its intended use (section 1.4).

• inspect the machine prior to operation and perform any necessary checks,

adjustments or repairs to ensure safe operation.

• familiarize him/herself with the local jobsite conditions and immediately

remedy any fault that may compromise safety.

• use the machine in accordance with the appropriate local jobsite

organization system to ensure safe coordination with other machines,

vehicles, and people on the jobsite.

Investigate any jobsite prior to operation to determine whether any special hazards exist. Take necessary measures to eliminate or reduce any hazard.

Do not operate the machine in unsafe conditions including, but not limited

to: in inclement weather (example: electrical storm), near overhead electric lines,

in enclosed areas without proper ventilation, in contaminated areas without necessary safety equipment and personnel.

Turning the key to the off position while the machine is in motion (as described

below) should be done only in an emergency. If done, the machine will stop

abruptly.

To stop all machine movement in case of emergency:

• Turn the ignition key to the off position (item 15, section 4.1).

2 SAFETY

16

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

2.8 Stability

The machine must always be operated with caution in order to maximize machine

stability and guard against the possibility of a rollover.

• Travel only at speeds appropriate for the local conditions.

• Do not exceed the operating capacity of the machine.

• Exercise extreme caution while operating on inclines.

• Avoid operation on steep inclines.

• Do not make sudden changes in direction, move slowly, and always carry

loads low to maximize machine stability.

• Always keep the heaviest end of the machine facing uphill when travelling

on an incline.

• When operating on any surface other than firm and level ground, use extra

caution. Decrease work speeds, limit load size and make any other

necessary adjustments to maximize your safety and that of others in the

work area.

2.9 Transporting Persons

• The machine must not be used to transport persons.

2 SAFETY

17

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

2.10 Fire Prevention

Compact Track loaders have components that operate at high temperatures. It is

important to observe all inspection, operation and maintenance guidelines to minimize the possibility of fire.

• Turn the engine off when refueling.

• When refueling or charging the battery, do not smoke or allow open flame

near the machine.

• Always start the engine according to the procedure in the operating

instructions.

• Inspect and clean the radiator/oil cooler, engine compartment, exhaust

system and other areas where there may be hot or rotating parts daily (or

as needed). In some work environments, flammable debris including but

not limited to: leaves, straw, wood particles (dust), and similar items can

accumulate in these areas and can lead to fire.

• Check the electrical system regularly. Have any faults such as loose

connections, burnt fuses, glow lamps and damaged wiring repaired by

professional personnel immediately.

• Regularly check all lines, hoses and threaded couplings for leaks and

damage. Repair leaks immediately and replace any defective parts. Oil leaks

can easily lead to a fire. NEVER use bare hands to check for hydraulic

leaks! Pressurized fluid (oil) can penetrate skin and cause gangrene. If

injection occurs, seek medical attention immediately!

• Do not use any starting aids containing ether to start diesel engines with

pre-heat systems! Use of starting aids of this nature can cause an

EXPLOSION!

• Familiarize yourself with the location of any fire extinguishers (if equipped)

in/on the machine and how to use them as well as local options for

reporting and fighting fires should one occur.

Fuel Handling Precautions

• Do not smoke or allow open flame near fueling operations.

• Always maintain control of the fuel filter nozzle when filling the tank.

• Do not fill the fuel tank to capacity, allow room for expansion.

• Clean up fuel spills immediately.

• Tighten the fuel tank cap securely. Should the cap become lost or damaged,

replace it immediately with the original manufacturer’s recommended

replacement cap to ensure proper venting and function.

• Never use fuel for cleaning purposes.

• Always use the correct fuel grade for the operating season.

2 SAFETY

18

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

2.11 Crush and Burn Avoidance

• Do not work under the lift arms unless they are resting safely on the ground

or supported by the lift arm brace.

• Keep your entire body inside the operator enclosure at all times during

operation. Never work with any part of your body protruding from the cab.

• Do not use any restraining devices such as cables or chains that are

damaged or do not have sufficient carrying capacity. Always wear safety

gloves when working with wire cables.

• In adverse conditions (high winds, uneven terrain, etc.), keep clear of (or

secure against unintended movement) raised or open hinged items (hoods,

doors, engine enclosure panels and similar).

• Never align holes with your fingers when working on the machine. Instead

use a suitable mandrel.

• Keep yourself and all objects that could be drawn into the fan at a safe

distance while the engine is running. The fan may deflect these objects

away or destroy them and would likely be damaged by the objects.

• The entire cooling system is hot and under pressure when it is at or near

operating temperature. Avoid touching parts that carry coolant to avoid the

possibility of burns.

• Allow the machine to cool thoroughly prior to touching or removing the

cooling system cap. Once cool, loosen the cover slowly to bleed off any

excess pressure.

• The engine and hydraulic oil are hot when at or near operating temperature.

Avoid skin contact with hot oil or parts carrying oil.

• Wear safety goggles and protective gloves when you are working with the

battery. Keep sparks and open flames away from the work area.

• Exhaust components are hot when at or near operating temperature. Allow

the machine to cool thoroughly prior to touching or performing service work

on exhaust components to avoid the possibility of burns.

2 SAFETY

19

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

2.12 Placing into Operation

• Every time before placing the machine into operation, perform a thorough

walk-around inspection of the machine.

• Check the machine for loose pins, cracks, tears, wear, leaks and deliberate

damage.

• Never place a damaged machine into operation.

• Make any necessary repairs immediately, prior to resuming operation.

• Inspect to make sure all warning signs are in place and legible, then close

and latch all hoods and covers.

• Make sure all windows (if equipped) are clean. Secure door and windows

against unintentional movements.

• If visibility is reduced by a lack of window or screen / lens clarity (yellowing,

scratches, damage, etc) replace affected components prior to operating.

• Make certain no one is working on or under the machine and warn any

persons standing nearby that the machine will be placed into operation.

• Prior to placing the machine into operation, adjust the driver’s seat, and

ventilation system settings (if equipped) so you can work in comfort

and safety.

2.13 Starting the Machine

• Before starting, check all indicator lamps and instruments to make certain

they are working properly.

• Start the engine in the manner described in the operating instructions.

• Only allow the engine to run in enclosed rooms if there is adequate

ventilation. If necessary, open doors and windows to ensure a proper supply

of fresh air.

• Bring the engine and hydraulic oil up to operating temperature. Low oil temperatures can cause the control system to respond sluggishly.

• Move the machine carefully to open ground and then check the functionality

of the lift arm and drive controls as well as the lighting equipment.

2 SAFETY

20

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

2.14 Jobsite Safety

• Before beginning work, become acquainted with any special features or

requirements of the jobsite. These may include, for example, obstructions

in the work area, the carrying capacity of the ground and requirements to

close the jobsite off from public traffic.

• Always maintain a safe distance from bystanders, overhanging features,

edges, embankments and unsafe surfaces.

• Be especially cautious if visibility is poor, light conditions are low or soil

conditions vary.

• Become acquainted with the location of supply lines at the jobsite and be

especially careful when working close to them. Consult appropriate local

authorities for necessary information regarding any such lines prior to

commencing work.

• Keep the machine at an adequate distance from overhead electrical lines.

When working in the vicinity of overhead electrical lines, do not come close

to the lines with the machine. Injury or death may result! If possible, have

the current turned off or line re-routed prior to beginning work.

• In the event electrical current jumps from a line to the machine, follow

these rules:

• do not perform any movements with the machine

• do not leave the cab

• warn persons outside not to approach or touch the machine

• have the current turned off immediately

• Always turn on the appropriate lighting when visibility is poor or light

conditions are low.

• Do not allow any passengers in or on the machine.

• Stay seated with the seat belt fastened while working.

• Report any operating faults immediately. Make sure any necessary repairs

are performed prior to resuming operation.

• Never leave the machine unattended with the engine running.

2 SAFETY

21

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

2.15 Parking the Machine

• Stop the machine only on an even and solid surface.

• Lower the lift arms to the frame stop and rest the bucket on the ground.

• Shut the machine down as described in section 5.13.

• Close the machine doors and windows (if equipped), remove the key to

secure the machine against unauthorized use.

2.16 Towing/Retrieving the Machine (see note below)

• Always observe the correct procedure as described in the operating

instructions.

• The machine should be towed only in exceptional cases, for example to

bring the machine away from an endangered place for repair.

• Check all trailing and drawing devices for their safety when pulling or

towing.

• Towing equipment such as ropes, etc., must be of the correct capacity and

must use at least two of the d-rings on the front or rear of the chassis.

• Pull the rope taut slowly and carefully. A sudden jerk can cause a sagging

rope or cable to tear or snap.

2 SAFETY

22

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

2.17 Transporting the Machine

• Use only suitable transport and lifting equipment with sufficient carrying

capacity.

• Load the machine on firm and level ground.

• Before driving onto the ramps, clean them and the machine tracks of any

materials that may cause slippage (snow, ice, water, mud, sludge, oil, etc.).

• Properly align the machine with the loading ramp.

• Have a guide give the machine operator any necessary signs to maximize

safety during loading.

• Back the machine carefully up the ramps and onto the transport vehicle.

Note: The heaviest end of the machine should remain uphill when operating on

an incline. Always back the machine onto the transport vehicle unless fitted with a

heavy attachment or loaded bucket.

• Before you leave the machine, relieve all residual pressure by making sure

all operating levers and switches are in their neutral positions. Remove the

ignition key.

• Secure the door, windows and hood on the machine.

• Secure the machine and any other items against slipping with chains, ropes

of the proper capacity.

• Before departure, investigate the route to be taken, especially in regard to

limits for width, height and weight.

• Pay close attention when driving under electrical lines, bridges, or through

tunnels.

• Use the same caution when unloading as for loading. Remove all

cables/chains. Start the engine as described in the operating instructions.

Carefully drive down the ramp from the transport vehicle using a guide if

necessary to direct movement.

• When lifting attachments or components, use caution. Attach straps or

chains securely and in such a way that they evenly distribute the weight of

the item to be lifted, ensuring a balanced load. Stay clear of expected travel

path.

2 SAFETY

23

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

2.18 Maintenance

• Do not perform any maintenance work or repair task that you do not

understand thoroughly.

• Park the machine on firm and level ground in a well lit and well ventilated

area suitable for performing service or maintenance work.

• Disconnect the battery and remove the ignition key from the ignition before

beginning work on a machine. Place a Do Not Operate tag across the

opening of the cab to alert any operator that maintenance is in progress.

• Do not work on or under any machine that is supported only by a hydraulic

jack or hoist. Always use mechanical supports to ensure that the machine

will not fall.

• Make sure the work area around the machine is safe and make yourself

aware of any hazardous conditions that may exist. If the engine needs to be

started inside an enclosure, make sure that the engine’s exhaust is properly

vented.

• Be sure all protective devices including guards and shields are properly

installed and functioning correctly before beginning any service task. If a

guard or shield must be removed to perform the maintenance work, use

extra caution.

• Always use the appropriate tools for the work to be performed. Tools should

be in good condition and you should understand how to use them properly

before performing any task.

• When replacing parts or fasteners, use parts of equivalent quality, grade

and/or size. Use original equipment components to ensure the proper form,

fit, and function of replacement parts.

• When performing maintenance work, always wear appropriate safety

clothing for the task to be performed. Some examples might include: safety

shoes, safety goggles and safety gloves.

• When performing service that requires the lift arms to be in the raised

position, always utilize the lift arm brace.

• If safety equipment needs to be dismantled to fit equipment or perform

maintenance or repairs, it must be reattached and tested immediately after

the maintenance and repair jobs are completed.

2 SAFETY

24

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

• Clean the machine prior to beginning work. Clean especially the connections

and screw couplings of oil, fuel and upkeep materials at the beginning of

the maintenance/repair job.

• Do not use flammable liquids to clean the machine.

• Perform tasks on the machine that involve welding or grinding only if

approved by the manufacturer. Clean the machine and the work area of dust

and any combustible materials before welding or grinding to avoid fire or

explosion.

• Before cleaning the machine with water jets (high pressure cleaner) or other

cleaning agents, cover or seal over all openings in which water or cleaning

agents should not penetrate for safety and/or functional reasons. Electrical

motors, switch panels and plug connections are especially subject to

damage. Before cleaning, inspect all fuel, engine oil and hydraulic oil lines

for leaks, loose connections, rubbed spots and damage. Repair or replace

any damaged components immediately.

• When working with oils, greases and other chemical substances, observe all

safety requirements that apply to the product in question.

• Ensure that fuels, lubricants and coolants as well as replaced parts are

disposed of in an environmentally proper manner.

• Proceed carefully when working with hot lubricants, coolants and fuels

(danger of burns and scalding).

Relieve Hydraulic System Pressure

Prior to attempting any hydraulic maintenance or repair, relieve hydraulic

system pressure by performing the following:

1. Remove any attachment, then shut the machine down as described in

section 5.13 of this manual.

Note: When lowering the lift arms, lower them to the frame stops (or onto

the lift arm brace if the lift arms are to remain up for service). Fully curl the

quick attach (or you can extend it to the ground if the loader is down), then

activate the float function (section 4.3.1 of this manual) momentarily to

ensure there is no pressure left in the lift arm circuit.

2. Turn the continuous auxiliary hydraulic switch off and ensure the

intermittent auxiliary switch is in it’s neutral resting position (section 4.7 of

this manual).

3. Make sure the drive and lift arm controls are in neutral positions (controls

are spring centered, resting position is neutral).

4. Relieve auxiliary hydraulic residual pressure (step 2 section 4.7 of this

manual).

2 SAFETY

25

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

Loading...

Loading...