Tennant 5100 Operator And Parts Manual

ENGLISH - ESPAÑOL - FRANÇAIS

5100

Battery Automatic Scrubber

Fregadora Automática Batería

Balayeuse Automatique De Batterie

Operator and Parts Manual

Manual De Operador

Y Lista De Repuestos

Model Part No.:

609139

609140 - Pac

SM15029

Opérateur Manuel et

Liste Des Piéces

www.tennantco.com

609372

Rev. 04 (04-2007)

*609372*

OPERATION

This manual is furnished with each new model.

It provides necessary operation and maintenance

instructions and an illustrated parts list.

Read this manual completely and understand the

machine before operating or servicing it.

When ordering replacement parts, use the illustrated

parts lists section in this manual. Before ordering parts

or supplies, be sure to have your machine model

number and serial number available. Parts and

supplies may be ordered by phone or mail from any

authorized parts and service center, distributor or from

any of the manufacturer’s subsidiaries.

This machine will provide excellent service. However,

the best results will be obtained at minimum costs if:

S The machine is operated with reasonable care.

S The machine is maintained regularly - per the

machine maintenance instructions provided.

S The machine is maintained with manufacturer

supplied or equivalent parts.

MACHINE DATA

Please fill out at time of installation for future reference.

Model No.-

Install. Date -

Serial No.-

PROTECT THE ENVIRONMENT

Please dispose of packaging materials,

old machine components such as

batteries, hazardous fluids such as

antifreeze and oil, in a safe

environmentally way according to your

local waste disposal regulations.

Always remember to recycle.

Tennant Company

PO Box 1452

Minneapolis, MN 55440

Phone: (800) 553--8033 or (763) 513--2850

www.nobles.com

Nobles, the Nobles logo and the Speed Scrub logo are registered United

States trademarks of Tennant Company.

Specifications and parts are subject to change without notice.

Copyright E1999, 2000, 2005, 2007 Tennant Company. All rights reserved.

Printed in U.S.A.

2

Speed Scrub 1701 Plus (04--07)

TABL E OF CONTENTS (ESPAÑOL....23) (FRANÇAIS....45)

OPERATION

SAFETY PRECAUTIONS 4....................

SAFETY LABELS 5...........................

MACHINE COMPONENTS 6...................

CONTROL PANEL SYMBOLS 6...............

MACHINE INSTALLATION 7...................

UNCRATING MACHINE 7..................

INSTALLING BATTERIES 7................

MACHINE SETUP 8..........................

ATTACHING SQUEEGEE ASSEMBLY 8.....

INSTALLING PAD DRIVER OR BRUSH 9....

REMOVING PAD DRIVER OR BRUSH 10.....

FILLING SOLUTION TANK 10...............

ADJUSTING CONTROL HANDLE HEIGHT 11.

MACHINE OPERATION 11.....................

PRE--OPERATION CHECKS 11..............

OPERATING MACHINE 1 1..................

OPERATING ES (OPTION) 12...............

WHILE OPERATING MACHINE 12...........

OPERATING ACCESSORY TOOLS

(OPTIONAL) 13............................

CIRCUIT BREAKERS 13....................

MACHINE ADJUSTMENTS 13..................

ADJUSTING SOLUTION FLOW 13...........

ADJUSTING PAD PRESSURE 14............

ADJUSTING SQUEEGEE LIFT CABLE 14....

DRAINING TANKS 14..........................

DRAINING RECOVERY TANK 14............

DRAINING SOLUTION TANK 15.............

BA TTER Y CHARGING 15......................

MACHINE MAINTENANCE 16..................

DAILY MAINTENANCE 16...................

WEEKLY MAINTENANCE 16................

MONTHLY MAINTENANCE 17...............

QUARTERLY MAINTENANCE 17............

BATTERY MAINTENANCE 17...............

TRANSPORTING MACHINE 18.................

STORING MACHINE 18........................

RECOMMENDED STOCK ITEMS 18.............

TROUBLE SHOOTING 19......................

SPECIFICATIONS 21..........................

MACHINE DIMENSIONS 22....................

ELECTRICAL DIAGRAMS 68...................

PARTS LIST 70...............................

REPLACEMENT BRUSHES AND PAD

DRIVER GROUP 70........................

SOLUTION TANK GROUP 72................

RECOVERY TANK GROUP 74...............

WHEEL GROUP 76........................

SCRUB HEAD GROUP 78..................

PLUMBING GROUP 80.....................

VACUUM MOTOR GROUP 82...............

SQUEEGEE GROUP 84

CONTROL HANDLE GROUP 86.............

CONTROL CONSOLE GROUP 87...........

BATTERY AND CHARGER GROUP 88.......

OPTIONS 90..................................

ES (EXTENDED SCRUB) KIT 90.............

WAND PUMP KIT 92.......................

HOUR METER AND LOW VOLTAGE

INTERRUPTER KITS 94....................

WET PICK--UP TOOL KIT 95................

DELUXE POWER WAND GROUP 96.........

POWER WAND GROUP 98.................

POWER WAND HOSE GROUP 100...........

QUICK CHANGE BATTERY KIT 77...........

BATTERY CONNECTOR MOUNT KIT 78.....

....................

Speed Scrub 1701 Plus (04--07)

3

OPERATION

SAFETY PRECAUTIONS

The following information signals potentially

dangerous conditions to the operator or

equipment:

This machine is intended for commercial use. It is

designed exclusively to scrub hard floors in an

indoor environment and is not constructed for any

other use. Use only recommended pads, brushes

and commercially approved floor cleaners

intended for machine application.

All operators must read, understand and practice

the following safety precautions.

The following warning alert symbol and the “FOR

SAFETY” heading are used throughout this manual as

indicated in their description:

WARNING: To warn of hazards or unsafe

practices which could result in severe personal

injury or death.

FOR SAFETY: To identify actions which must be

followed for safe operation of equipment.

Failure to follow these warnings may result in

personal injury, electrical shock, fire or explosion.

WARNING: Fire Or Explosion Hazard:

-- Never Use Flammable Liquids Or Operate

Machine in Or Near Flammable Liquids,

Vapors Or Combustible Dusts.

This machine is not equipped with explosion proof

motors. The electric motors will spark upon start

up and during operation which could cause a flash

fire or explosion if machine is used in an area

where flammable vapors/liquids or combustible

dusts are present.

-- Do Not Pick Up Flammable Materials Or

Reactive Metals.

-- Batteries Emit Hydrogen Gas. Keep Sparks

And Open Flame Away. Keep Battery

Compartment Open When Charging.

WARNING: Electrical Shock Hazard.

Disconnect Battery Cables Before Servicing

Machine.

WARNING: Spinning Brush. Keep Hands

Away. Turn Off Power Before Working On

Machine.

FOR SAFETY:

1. Do not operate machine:

-- With flammable liquids or near flammable

vapors as an explosion or flash fire may

occur.

-- Unless trained and authorized.

-- Unless operator manual is read and

understood.

-- If not in proper operating condition.

2. Before operating machine:

-- Make sure all safety devices are in place

and operate properly.

3. When using machine:

-- Go slow on inclines and slippery surfaces.

-- Wear non--slip shoes.

-- Reduce speed when turning.

-- Report machine damage or faulty

operation immediately.

-- Never allow children to play on or around.

-- Follow mixing and handling instructions

on chemical containers.

4. Before leaving or servicing machine:

-- Stop on level surface.

-- Turn machine off.

5. When servicing machine:

-- Avoid moving parts. Do not wear loose

jackets, shirts, or sleeves.

-- Disconnect battery connections before

working on machine.

-- Wear protective gloves and eye protection

when handling batteries or battery cables.

-- Avoid contact with battery acid.

-- Do not power spray or hose off machine.

Electrical malfunction may occur.

-- Use manufacturer supplied or approved

replacement parts.

-- All repairs must be performed by a

qualified service person.

-- Do not modify the machine from its

original design.

4

Speed Scrub 1701 Plus (06--05)

OPERATION

6. When transporting machine:

-- Turn machine off.

-- Do not lift machine when batteries are

installed.

-- Get assistance when lifting machine.

-- Use a recommended ramp when

loading/unloading on/off truck or trailer.

-- Use tie--down straps to secure machine to

truck or trailer.

-- Put scrub head in the lowered position.

SAFETY LABELS

The safety label appears on the machine in the location indicated. Replace label if it is missing or becomes damaged

or illegible.

WARNING LABEL -- LOCATED ON THE RECOVERY TANK COVER.

Speed Scrub 1701 Plus (04--07)

5

OPERATION

MACHINE COMPONENTS

2

7

6

5

4

1

3

17

18

22

38

21

23

25

8

9

16

24

26

13

10

1415

20

19

27

31

32

33

11

29

30

36

34

28

12

37

35

1. Key Switch

2. Power ON/OFF Indicator Light

3. Hour Meter (Opt.)

4. Main Circuit Breaker

5. Brush Circuit Breaker

6. Brush Release Button

7. Brush Pressure Meter

8. Battery Meter

9. Vacuum ON/OFF Switch

10. Solution ON/OFF Switch

11. Squeegee Lift Knob

12. Control Handle

13. Control Handle Height

Adjustment Knobs

CONTROL PANEL SYMBOLS

Main Power

Indicator Light

Key Switch

Vacuum

Switch

Solution

Switch

14. Wand Kit ON/OFF Switch (Opt.)

15. ES ON/OFF Switch (ES Model)

16. Pump On Light (ES Model)

17. Charger Plug

18. Recovery Tank Drain Hose

19. Solution Tank Drain Hose With

Level Indicator

20. Solution Fill Port Cover

21. Scrub Head Lift Pedal

22. Scrub Head Release Lift Pedal

23. Solution Flow Adjustment Knob

24. Squeegee Vacuum Hose

25. Squeegee Assembly

26. Squeegee Thumb Knobs

27. Wall Rollers

Brush Motor

35A Circuit Breaker

Main Power

20A Circuit Breaker

28. Brush Trigger

29. Recovery Tank Lid

30. Recovery Tank

31. Battery Compartment Hood

32. Scrub Head

33. Scrub Head Skirt

34. Transport Caster

35. Main Wheels

36. Wand Kit Solution Hose

Coupler (Opt.)

37. Solution Tank

38. Pad Pressure

Adjustment Knob

Battery Charge

Meter

Read Manual

Before Operating

6

Speed Scrubt 1701 (02--04)

MACHINE INSTALLATION

OPERATION

Squeegee assembly is packaged with machine.

Batteries, battery charger, brush, pad driver and pads

must be purchased separately. Consult an authorized

distributor for specific pads and brushes.

UNCRA TING MACHINE

Carefully check carton for signs of damage. Report

any damage at once to carrier.

Check Machine Contents to ensure package is

complete. Contact distributor for missing items.

Machine Contents:

1 -- Battery Cable #602871

1 -- Wire Asm. #6X24” Black #603208

2 -- 12VDC 130AH Batteries #130869 (included with

machine PAC)

1 -- Battery Charger, 24V/15A 120V #603553 (included

with machine PAC)

To uncrate your machine, remove shipping straps and

carefully lift or make a ramp to remove machine from

pallet. Do not roll machine off pallet, damage may

result.

FOR SAFETY: Get assistance when lifting

machine. Do not lift machine when batteries are

installed.

Raise scrub head to transport position before

maneuvering machine. Step down firmly on scrub

head lift pedal to raise (Figure 1).

NOTE: To prevent scrub head skirt damage, always

keep machine in transport position when pad driver is

not installed.

ATTENTION: The use of supplies other than those

recommended by manufacturer may cause

damage.

INSTALLING BATTERIES

WARNING: Fire Or Explosion Hazard.

Batteries Emit Hydrogen Gas. Keep Sparks And

Open Flame Away. Keep Battery Compartment

Open When Charging.

FOR SAFETY: When servicing machine, wear

protective gloves and eye protection when

handling batteries or battery cables. Avoid contact

with battery acid.

Battery Specifications:

Two 12 volt, deep cycle batteries. Consult with an

Authorized Distributor for specific batteries. Maximum

battery dimensions are 178mm (7 in.) W x 330mm

(13 in.) L x 254mm (10 in.) H.

1. Park machine on a level surface, turn off all

switches, and remove key.

2. Remove battery hood to access battery

compartment. Then remove metal battery tray and

loose battery cable from compartment.

3. Disconnect vacuum hose from recovery tank

snout. Carefully install bottom battery into

compartment with battery posts positioned

towards rear of machine (Figure 2).

FIG. 1

ATTENTION: Do not roll machine off pallet,

damage may occur.

A TTENTION: To prevent possible machine

damage, install batteries AFTER removing

machine from shipping pallet.

Speed Scrub 1701 Plus (04--07)

FIG. 2

ATTENTION: Do not drop battery into

compartment, battery and machine housing

damage may result. This damage is not covered

by warranty.

4. Connect red battery cable coming from machine to

positive (+) post of bottom battery. Then connect

black jumper cable to negative (--) post (Figure 4).

7

OPERATION

5. After connecting cables to bottom battery, carefully

hang metal battery tray on studs located above

bottom battery. Place top battery into tray with

posts positioned towards rear of machine. Secure

top battery with strap (Figure 3).

FIG. 3

6. Connect black battery cable coming from machine

to negative (--) post of top battery. Then connect

opposite end of black jumper cable to positive (+)

post (Figure 4).

(--)

Black

Cable

(+)

Jumper

Cable

TOP

BATTERY

8. After batteries are properly installed, turn on key

and vacuum switch and check battery meter

charge level. Charge if necessary (See BATTERY

CHARGING) (Figure 6).

FIG. 6

MACHINE SETUP

ATTACHING SQUEEGEE ASSEMBLY

1. Turn key to the off position.

FOR SAFETY: Before leaving or servicing

machine, stop on level surface and turn off

machine.

(--)

Jumper

Cable

FIG. 4

(+)

Red Cable

BOTTOM

BATTERY

7. Reconnect vacuum hose to recovery tank snout

as shown (Figure 5).

FIG. 5

2. Raise squeegee mount bracket by moving

squeegee lift knob to the left (Figure 7).

FIG. 7

3. Loosen two thumb knobs on squeegee assembly

and slide squeegee into slots on squeegee mount

bracket (Figure 8).

8

Speed Scrub 1701 Plus (02--04)

3. Turn key switch on (Figure 11).

OPERATION

FIG. 8

4. Tighten thumb knobs securely.

5. Connect vacuum hose from machine to squeegee

assembly (Figure 9).

FIG. 9

INSTALLING PAD DRIVER OR BRUSH

1. Select a recommended pad or brush that best

meets your cleaning needs.

NOTE: Consult an authorized distributor for

pad/brush recommendations.

2. Attach pad to pad driver before mounting driver to

motor hub. Secure pad with plastic centerlock ring

(Figure 10).

FIG. 11

4. Place the pad driver/brush on the floor in front of

the scrub head (Figure 12).

FIG. 12

5. Tilt the machine back on it’s rear wheels and

center the scrub head down over the pad

driver/brush (Figure 12).

6. IMPORTANT STEP: Release the brush lift pedal

from the transport position (Figure 13). Align the

motor hub down inside the pad driver/brush.

FIG. 10

Speed Scrub 1701 Plus (02--04)

FIG. 13

7. Pull the triggers to engage the pad driver/brush.

Make sure the front wheel is in the UP position

(Figure 14).

NOTE: When a pad driver/brush is not installed, make

sure to keep the machine in transport position to

prevent skirt damage.

9

OPERATION

FIG. 14

NOTE: Before installing pad driver or brush make sure

mounting surface is clean. A clean surface will ease

pad driver removal later.

REMOVING PAD DRIVER OR BRUSH

1. Raise scrub head to transport position. Step down

firmly on scrub head lift pedal to raise (Figure 15).

NOTE: To prevent scrub head skirt damage, always

keep machine in transport position when pad driver or

brush is not installed.

FILLING SOLUTION TANK

1. Transport machine to filling station. Raise

squeegee and scrub head when transporting.

2. Turn off key switch.

3. Remove solution tank fill port cover.

4. Fill solution tank with 28L (7.5 gal) of clean water,

60°C (140°F) maximum temperature. To fill with

bucket, use a bucket with a spout (Figure 17).

FIG. 15

2. Turn key switch on.

3. Tilt machine back on it’s rear wheels.

4. While pressing the “brush release button”, pull and

release the brush trigger quickly. The pad

driver/brush will automatically spin off motor hub.

If it doesn’t release, repeat step (Figure 16).

FIG. 16

FIG. 17

NOTE: If filling with a bucket be certain that bucket is

clean. This will prevent possible solution line clogs.

5. Add cleaning chemical. See proper dilution ratio

instructions on chemical container.

6. Replace solution tank fill port cover.

FOR SAFETY: When using machine, follow mixing

and handling instructions on chemical containers.

ATTENTION: Use only recommended detergents.

Machine damage due to improper detergent usage

will void the manufacturer’s warranty. Contact

your Sales Representative for detergent

recommendations.

WARNING: Fire Or Explosion Hazard. Never

Use Flammable Liquids Or Operate Machine in Or

Near Flammable Liquids, Vapors Or Combustible

Dusts.

7. If machine is equipped with ES (Extended Scrub)

Option, the recovery tank can be partially filled to

extend scrub time.

a. Remove recovery tank lid and fill tank with 13L

(3.5 gal) of clean water, 60°C (140°F)

maximum temperature. Close lid.

b. Make sure ES switch is turned on when

operating machine (Figure 18).

10

Speed Scrub 1701 Plus (02--04)

FIG. 18

c. The ES light will glow when the ES pump is

recycling.

ADJUSTING CONTROL HANDLE HEIGHT

The control handle has three height settings to

accommodate a comfortable operating height.

1. Locate two control handle height adjustments

knobs on handle (Figure 19).

2. Pull both knobs and raise or lower handle, release

knobs to lock (Figure 19).

OPERATION

S Check condition of squeegee blades.

OPERATING MACHINE

1. Release brush lift pedal from transport position by

stepping down on scrub head release pedal

(Figure 20).

FIG. 20

2. Lower squeegee assembly by moving squeegee

lift knob to the right (Figure 21).

FIG. 19

MACHINE OPERATION

FOR SAFETY: Do not operate machine unless

operator manual is read and understood.

PRE--OPERA TION CHECKS

S Sweep and dust mop floor to remove particles and

other debris.

S Check battery meter charge level to ensure

batteries are fully charged (See BATTERY

CHARGING).

S Check condition of pad or brush.

Speed Scrub 1701 Plus (06--05)

FIG. 21

FIG. 22

NOTE: The solution flow and brush will not start until

brush triggers are pulled.

4. Pull brush triggers and begin walking with

machine. The brush will propel the machine

forward allowing little effort maneuvering the

machine (Figure 23).

11

OPERATION

FIG. 23

NOTE: On rough surfaces it may be necessary to

reduce brush pressure.

5. Check the brush meter pressure when scrubbing.

Only operate machine in green zone. Never

operate machine in red zone (Figure 24).

NOTE: If brush pressure adjustment is required, see

MACHINE ADJUSTMENTS.

WARNING: Fire Or Explosion Hazard. Never

Use Flammable Liquids Or Operate Machine in Or

Near Flammable Liquids, Vapors Or Combustible

Dusts.

2. Turn on ES switch. During operation the ES pump

will automatically start recycling when ES pump on

light turns on (Figure 25).

FIG. 25

3. When finished scrubbing, drain and rinse solution

tank and clean ES filter (See DRAINING TANKS).

FIG. 24

ATTENTION: Do not operate machine with pad

pressure meter in red zone, circuit breakers will

trip and floor damage may occur.

6. To operate machine in reverse, simply pull the

machine backwards while pulling triggers.

7. To stop scrubbing, release brush triggers, turn off

all switches, and raise scrub head and squeegee.

OPERATING ES (OPTION)

ES Option extends scrubbing time by reusing

recovered water. The recovered water is filtered and

recycled back into the solution tank for reuse.

1. Fill recovery tank with 13L (3.5 gal) when filling

solution tank for operation.

WHILE OPERATING MACHINE

FOR SAFETY: When using machine, go slow on

inclines and slippery surfaces.

1. Observe amount of solution flow on floor. If

solution flow adjustment is needed, see MACHINE

ADJUSTMENTS.

2. Periodically check for foam buildup in recovery

tank (look through clear lid). If excessive foam is

developing, pour a recommended foam control

solution into recovery tank.

ATTENTION: Do not allow foam to enter the float

shut-off screen, vacuum motor damage will result.

Foam will not activate the float shut-off screen.

3. Always operate with caution when scrubbing

around walls or obstacles.

4. If squeegee leaves streaks, raise and wipe blades

with a cloth. Pre-sweep area to prevent streaking.

If squeegee adjustment is necessary, see

MACHINE ADJUSTMENTS.

5. Overlap each pass by 50mm (2 in).

6. Change or turn over pads when dirty.

7. Stay clear of floor obstructions, such as electrical

plates or grates, they will destroy pads.

8. During brief stops, you do not have to turn off any

switches, the brushes and solution flow will

automatically stop when triggers are released.

12

Speed Scrub 1701 Plus (06--05)

9. Periodically check battery meter discharge level.

When needle drops to the red zone, recharge

batteries.

ATTENTION: Do not operate machine with battery

meter in red zone, battery damage will result.

OPERATION

CIRCUIT BREAKERS

The machine is equipped with two circuit breakers to

protect machine from damage. The Main (20amp) and

Brush (35amp) circuit breakers.

WARNING: Fire Or Explosion Hazard. Do Not

Pick Up Flammable Materials Or Reactive Metals.

10. On last scrubbing pass, turn off solution switch

just prior to stopping machine. This will allow total

recovery pick up.

1 1. When solution tank runs dry , drain recovery tank

(See DRAINING TANKS).

OPERATING ACCESSORY TOOLS (OPTIONAL)

1. Attach accessory solution hose to quick coupler.

2. Disconnect squeegee hose from inlet tube and

replace with accessory vacuum hose.

3. Connect hoses to wand.

4. Turn on key, wand pump and vacuum switches

(Figure 26).

If a circuit breakers should trip during operation,

determine cause, allow motor to cool and then

manually reset breaker (See TROUBLE SHOOTING).

Brush motor circuit breakers will trip due to excessive

overload on pad. Reduce pad pressure or replace pad

if breaker trips. Circuit breakers are located on control

console (Figure 27).

FIG. 27

MACHINE ADJUSTMENTS

FIG. 26

5. Operate accessory tool as normal.

WARNING: Fire Or Explosion Hazard. Do Not

Pick Up Flammable Materials Or Reactive Metals.

FOR SAFETY: Before leaving or servicing

machine, stop on level surface and turn off

machine.

ADJUSTING SOLUTION FLOW

To increase or decrease the maximum solution flow,

turn adjustment knob. Adjustment knob is located near

brush lift pedal (Figure 28).

FIG. 28

Speed Scrub 1701 Plus (06--05)

13

OPERATION

ADJUSTING PAD PRESSURE

NOTE: On rough surfaces it may be necessary to

reduce brush pressure.

To adjust pad pressure, turn adjustment knob

clockwise to decrease or counterclockwise to increase

pad pressure. Adjustment knob is located below brush

lift pedal (Figure 29).

FIG. 29

ADJUSTING SQUEEGEE LIFT CABLE

To adjust squeegee lift cable, loosen lock nuts and

turn adjustment stem on squeegee cable. Retighten

lock nuts after adjusting (Figure 30).

DRAINING TANKS

When to drain recovery tank:

-- After each use.

-- Between solution tank fill ups.

-- When solution flow stops during operation.

-- When ball float screen is activated.

-- When squeegee starts trailing water.

NOTE: If using the ES recycling system, be certain to

drain and rinse both tanks after each use.

FOR SAFETY: Before leaving or servicing

machine, stop on level surface and turn off

machine.

DRAINING RECOVERY T ANK

ATTENTION: Do not allow foam to enter the float

shut-off screen, vacuum motor damage will result.

Foam will not activate the float shut-off screen.

1. Push machine to floor drain and turn off all

switches. Remove left side drain hose from holder,

position hose over drain, twist loose, and remove

drain hose cap (Figure 31).

FIG. 30

14

FIG. 31

NOTE: If using a bucket to drain machine, do not use

same bucket for filling solution tank. This will prevent

possible solution line clogs.

2. Open clear recovery tank lid and rinse tank, ball

float screen and ES filter if equipped. Remove and

rinse ball float screen and ES filter if they are

excessively dirty. Replace screen and filter

securely.

3. Replace drain hose cap securely when empty.

Speed Scrub 1701 Plus (06--05)

DRAINING SOLUTION TANK

To drain unused cleaning solution or recycled solution

from solution tank, follow steps below:

1. Remove clear drain hose from hose barb, position

hose over drain (Figure 32).

FIG. 32

2. Rinse out solution tank and solution flow system

with clean water to prevent clogging due to

chemical buildup.

3. Replace drain hose securely on hose barb when

empty.

OPERATION

1. Transport machine to a flat, dry surface in a well-ventilated area for charging.

2. Turn off all switches and key.

FOR SAFETY: Before leaving or servicing

machine, stop on level surface and turn off

machine.

3. Remove battery compartment hood.

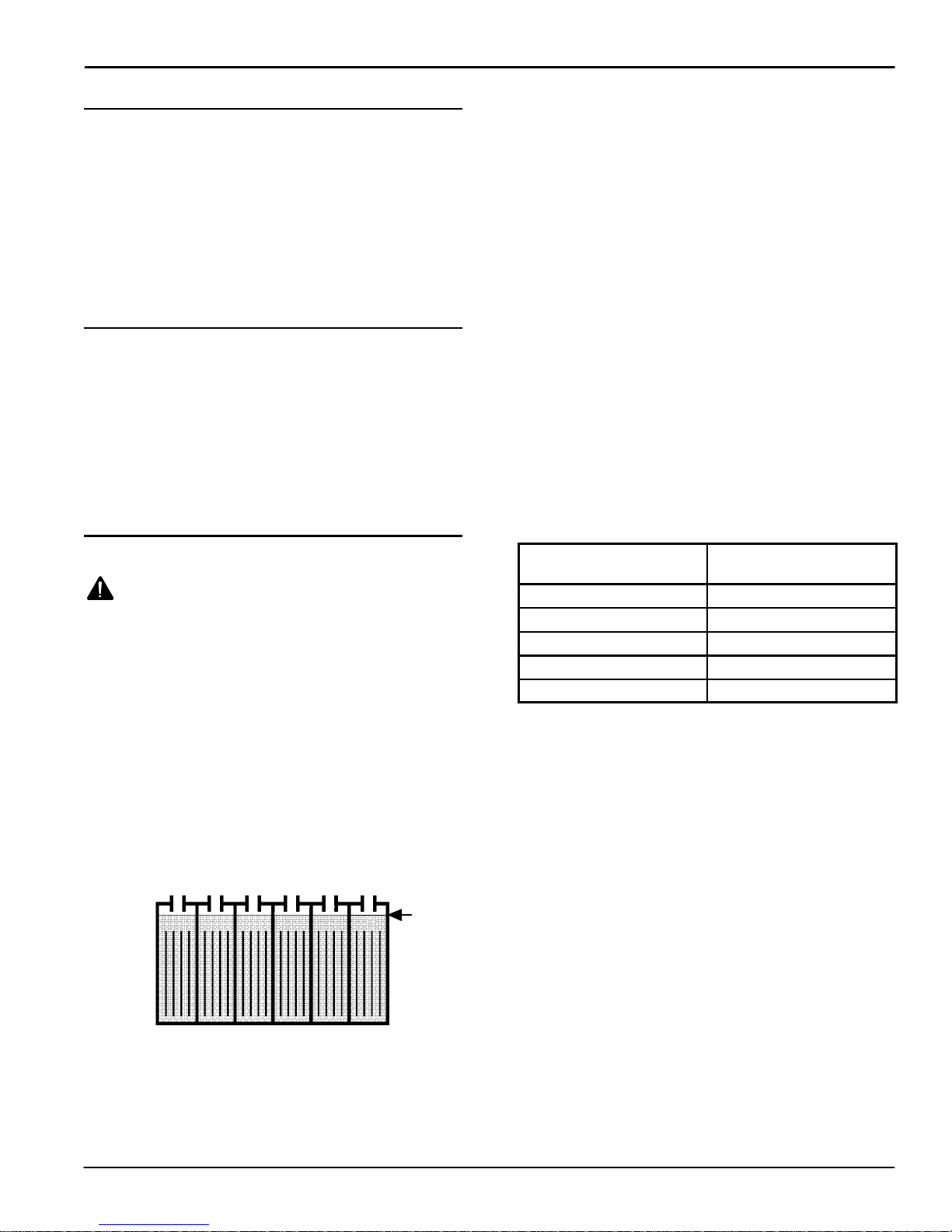

4. Before charging, check the fluid level (A) in each

battery cell. If the battery plates (B) are exposed,

add just enough distilled water to cover plates.

DO NOT OVERFILL. Overfilled batteries can

overflow during charging due to fluid expansion.

Replace cell caps before charging (Figure 33).

B

A

FIG. 33

5. With charger’s power supply cord unplugged,

connect charger to machine (Figure 34).

BATTERY CHARGING

NOTE: Recharge batteries ONLY after a total of 30

minutes of use or more. This will prolong battery life.

The following charging instructions are intended

for the 24V charger supplied with the machine.

Only use a charger with the following

specifications to prevent battery damage.

CHARGER SPECIFICATIONS:

S OUTPUT VOLTAGE - 24 VOLTS

S OUTPUT CURRENT - 25 AMPS MAXIMUM

S AUTOMATIC SHUTOFF CIRCUIT

S FOR DEEP CYCLE BATTERY CHARGING

NOTE: For optimum machine operation, keep

batteries charged at all times. Never let batteries set in

a discharge condition for lengthy periods.

WARNING: Fire Or Explosion Hazard.

Batteries Emit Hydrogen Gas. Keep Sparks And

Open Flame Away. Keep Battery Compartment

Open When Charging.

FOR SAFETY: When servicing machine, wear

protective gloves and eye protection when

handling batteries or battery cables. Avoid contact

with battery acid.

FIG. 34

NOTE: Once charger is connected to machine,

machine becomes inoperable.

6. Plug charger’s power supply cord into a grounded

wall outlet (Figure 35).

Grounded

3HoleOutlet

Ground Pin

FIG. 35

Speed Scrub 1701 Plus (06--05)

15

OPERATION

FOR SAFETY: Do not operate charger unless cord

is properly grounded.

WARNING: Fire Or Explosion Hazard.

Batteries Emit Hydrogen Gas. Keep Sparks And

Open Flame Away. Keep Battery Compartment

Open When Charging.

7. The charger will automatically begin charging and

shut off when fully charged.

8. After charger has turned off, unplug charger from

machine then disconnect charger from wall outlet.

9. After charging, recheck the battery fluid level (A) in

each battery cell. The level should be 1 cm (3/8 in)

from the bottom of sight tubes (B). Add distilled

water if needed. DO NOT OVERFILL (Figure 36).

B

FIG. 36

A

3. Open clear lid, remove and clean the ball float

screen. Replace screen securely (Figure 37).

FIG. 37

4. Open clear lid, remove and clean ES filter, if

equipped. Replace filter securely.

5. Raise squeegee and wipe it off with a dry cloth.

Store squeegee in the up position to prevent

squeegee damage.

6. Clean machine housing with a nonabrasive,

nonsolvent cleaner.

7. Recharge batteries if needed.

MACHINE MAINTENANCE

To keep machine in good working condition, simply

follow the daily, weekly and monthly maintenance

procedures.

FOR SAFETY: When leaving or servicing machine,

stop on level surface and turn off machine.

WARNING: Electrical Shock Hazard.

Disconnect Battery Cables Before Servicing

Machine.

ATTENTION: Contact an Authorized Service

Center for machine repairs. Machine repairs

performed by other than an authorized person will

void your warranty.

NOTE: If equipped with optional hour meter, record

machine hours when service was performed.

DAILY MAINTENANCE

(After Every Use)

1. Remove and clean pad or brush. Never use soiled

pads when cleaning. Replace pad when it

becomes worn or loaded with residue.

2. Drain and rinse both tanks thoroughly .

WEEKLY MAINTENANCE

(Every 20 Hours of Operation)

1. Flush out tanks and solution lines. Pour 750mL

(24 oz) of an acetic acid solution with 11.3L (3 gal)

of hot water into solution tank. Over a floor drain,

activate solution flow briefly to fill solution line.

Shut off power and let machine set over night.

Rinse with clean water afterwards.

2. Remove inline strainer filter and rinse out. Before

removing filter, be certain solution tank is empty.

Filter is located under machine at rear (Figure 38).

FIG. 38

3. Check fluid level in battery cells (See BATTERY

MAINTENANCE).

4. Clean battery tops to prevent corrosion (See

BATTERY MAINTENANCE).

5. Check for loose or corroded battery cables.

16

Speed Scrub 1701 Plus (06--05)

MONTHLY MAINTENANCE

(Every 80 Hours of Operation)

1. Lubricate wheel grease fittings with a water

resistant grease.

2. Lubricate all linkage pivot points with silicone

spray then coat with a water resistant grease to

maintain a smooth operation.

3. Check machine for water leaks and loose nuts and

bolts.

QUARTERLY MAINTENANCE

(Every 250 Hours of Operation)

Check motor(s) for carbon brush wear, replace

brushes if worn to a length of 10mm (0.38 in) or less.

Contact your Authorized Service Center for carbon

brush inspection.

FOR SAFETY: When servicing machine all repairs

must be performed by a qualified service person.

OPERATION

3. After charging batteries, measure the specific

gravity in each battery cell using a hydrometer

(Figure 40). This will determine the charge level

and condition of the batteries. If one or more of

the battery cells test lower than the other battery

cell (0.050 or more), the cell is damaged,

shortened, or is about to fail.

NOTE: Do not take reading immediately after adding

distilled water. The water and acid must be thoroughly

mixed in order for accurate reading.

FIG. 40

BA TTER Y MAINTENANCE

WARNING: Fire Or Explosion Hazard.

Batteries Emit Hydrogen Gas. Keep Sparks And

Open Flame Away. Keep Battery Compartment

Open When Charging.

FOR SAFETY: When servicing machine, wear

protective gloves and eye protection when

handling batteries or battery cables. Avoid contact

with battery acid.

1. Always follow proper charging instructions (See

BATTERY CHARGING).

2. Check fluid level (A) in each battery cell. The fluid

level should be 1 cm (3/8 in.) from the bottom of

sight tubes after charging. Add distilled water if

needed. DO NOT OVERFILL. Overfilled batteries

can overflow during charging due to fluid

expansion (Figure 39).

A

SPECIFIC GRAVITY

at 27°C(80°F)

1.265 100% CHARGED

1.223 75% CHARGED

1.185 50% CHARGED

1.148 25% CHARGED

1.110 DISCHARGED

BATTERY

CHARGE

NOTE: Add or subtract 0.004 gravity reading for each

6_C(10_F) above or below 27_C(80_F).

4. Keep battery tops and terminals clean and dry.

a. Mix a strong solution of baking soda and water

(Figure 41).

FIG. 39

Speed Scrub 1701 Plus (06--05)

FIG. 41

b. Brush solution sparingly over battery tops,

terminal and cable connectors.

NOTE: Do not allow baking soda solution to enter

battery cells.

17

OPERATION

c. Use wire brush to clean terminal post and

cable connections.

d. After cleaning, apply a coating of clear battery

post protectant to terminals and cable

connections.

5. Check for loose or worn cables. Replace if worn.

TRANSPORTING MACHINE

When transporting machine by use of trailer or truck,

be certain to follow tie--down procedures below:

FOR SAFETY: When using machine, go slow on

inclines and slippery surfaces.

1. Remove squeegee from machine and raise scrub

head. Leave pad or brush installed.

2. Load machine using a recommended loading

ramp.

3. Position front of machine up against front of trailer

or truck. Once machine is positioned, lower brush

head.

4. Place a block behind the wheels.

5. Place tie--down straps over top of machine and

secure straps to floor. It may be necessary to

install tie--down brackets to the floor of your trailer

or truck.

FOR SAFETY: When transporting machine, use a

recommended ramp when loading/unloading

into/off truck or trailer, use tie--down straps to

secure machine to truck or trailer.

STORING MACHINE

1. Before storing machine, be certain to rinse tanks

and drain machine of all water.

2. Store machine in a dry area with squeegee

removed and scrub head in the raised position.

3. Remove recovery tank lid to promote air

circulation.

ATTENTION: If storing machine in freezing

temperatures, be certain to drain machine of all

water. Damage due to freezing temperatures is not

covered by warranty.

WARNING: Do Not Use Outdoors. Do Not

Expose To Rain. Store Indoors.

RECOMMENDED STOCK ITEMS

Refer to Standard Parts section for recommended

stock items. Stock Items are clearly identified with a

bullet preceding the parts description. See example

below:

18

Speed Scrub 1701 Plus (02--04)

TROUBLE SHOOTING

PROBLEM CAUSE SOLUTION

No power, nothing runs. Faulty key switch. Contact Service Center.

Batteries need charging. See BATTERY CHARGING.

Faulty battery(s). Replace battery(s).

Loose battery cable. Tighten loose cable.

MAIN circuit breaker has tripped. Determine cause and reset circuit

breaker button.

Brush motor does not run. Faulty brush trigger switch. Contact Service Center.

Brush triggers not pulled. Pull brush triggers.

Brush circuit breaker has tripped. Clean or replace pad and reset brush

circuit breaker button.

Faulty brush motor or wiring. Contact Service Center.

Worn carbon brushes. Contact Service Center.

Faulty brush solenoid. Contact Service Center.

Vacuum motor does not run. Faulty vacuum switch. Contact Service Center.

Main circuit breaker has tripped. Remove obstruction and reset circuit

breaker button.

Faulty vacuum motor or wiring. Contact Service Center.

Worn carbon brushes. Contact Service Center.

Little or no solution flow. Solution switch is not activated. Turn on solution switch.

Solution line or solution tank filter is

clogged.

Solution valve or solenoid is clogged. Remove valve or solenoid and clean.

Faulty solution switch or solenoid. Contact Service Center.

Solution flow adjustment knob needs

adjusting.

ES Option: ES filter is clogged. Remove and clean ES filter.

ES Option: Faulty ES pump. Contact Service Center.

Short run time. Batteries not fully charged. Charge batteries.

Bad cell in one or more batteries. Replace battery.

Batteries need maintenance. See BATTERY MAINTENANCE.

Faulty charger. Repair or replace battery charger.

Remove hose and blow compressed

air through it. Flush solution tank after

each use.

Do not scratch inside of valve.

Turn solution flow adjustment knob to

desired setting.

OPERATION

Speed Scrub 1701 Plus (02--04)

19

OPERATION

TROUBLE SHOOTING -- continued

PROBLEM CAUSE SOLUTION

Poor water pick up. Recovery tank is full and ball float has

been activated.

Ball float screen inside recovery tank

is clogged.

Clogged squeegee. Clean squeegee.

Worn squeegee blades. Replace squeegee blades.

Loose squeegee thumbscrews. Tighten thumbscrews.

Vacuum hose connections are loose

or hose has a hole.

Clogged vacuum hose. Remove clogged debris.

Recovery tank inlet hole is obstructed. Empty recovery tank and tilt tank side-

Defective tank gasket. Replace gasket.

Loose drain hose plug. Tighten drain plug.

Recovery tank lid not in place. Properly position lid.

Loose vacuum motor. Contact Service Center.

Battery charge level is low. Charge batteries. Do not run machine

Empty recovery tank.

Remove screen and clean.

Push hose cuffs firmly on connections.

Replace hose if damaged.

ways to access inlet hole, remove obstruction.

when battery meter is in the red zone.

20

Speed Scrub 1701 Plus (02--04)

SPECIFICATIONS

OPERATION

MODEL

LENGTH 990 mm (39 in)

WIDTH 495 mm (19.5 in)

HEIGHT 914 mm (36 in)

WEIGHT 71Kg (158 lbs), 131Kg (290 lbs) with batteries

RECOVERY TANK CAPACITY 28.5L (7.5 gal)

SOLUTION TANK CAPACITY 28.5L (7.5 gal)

ES OPTION SOLUTION FILL CAPACITY 42.5L (11.25 gal)

DRIVE SYSTEM Brush driven

CLEANING RATE 1375m2per hour (14,800 sq. ft.)

CLEANING PATH WIDTH 430 mm (17 in)

PAD DIAMETER 430 mm (17 in)

PAD PRESSURE Variable 30--44Kg/65--95lbs

SQUEEGEE WIDTH 670 mm (26.5 in)

TOTAL POWER CONSUMPTION 35A nominal

BRUSH MOTOR .75 h.p., 165 rpm, 24V, 33A

VACUUM MOTOR .75 h.p., 2--stage 5.7”, 24V, 15A, 560W

WATER LIFT 1140 mm (45 in)

BATTERIES 2--12V, 130AH

RUN TIME PER CHARGE Up to 3 hours

DECIBEL RATING AT OPERATOR’S EAR, INDOORS ON TILE. 69.5dB(A)

Speed Scrub 1701 Plus

Speed Scrub 1701 Plus (02--04)

21

OPERATION

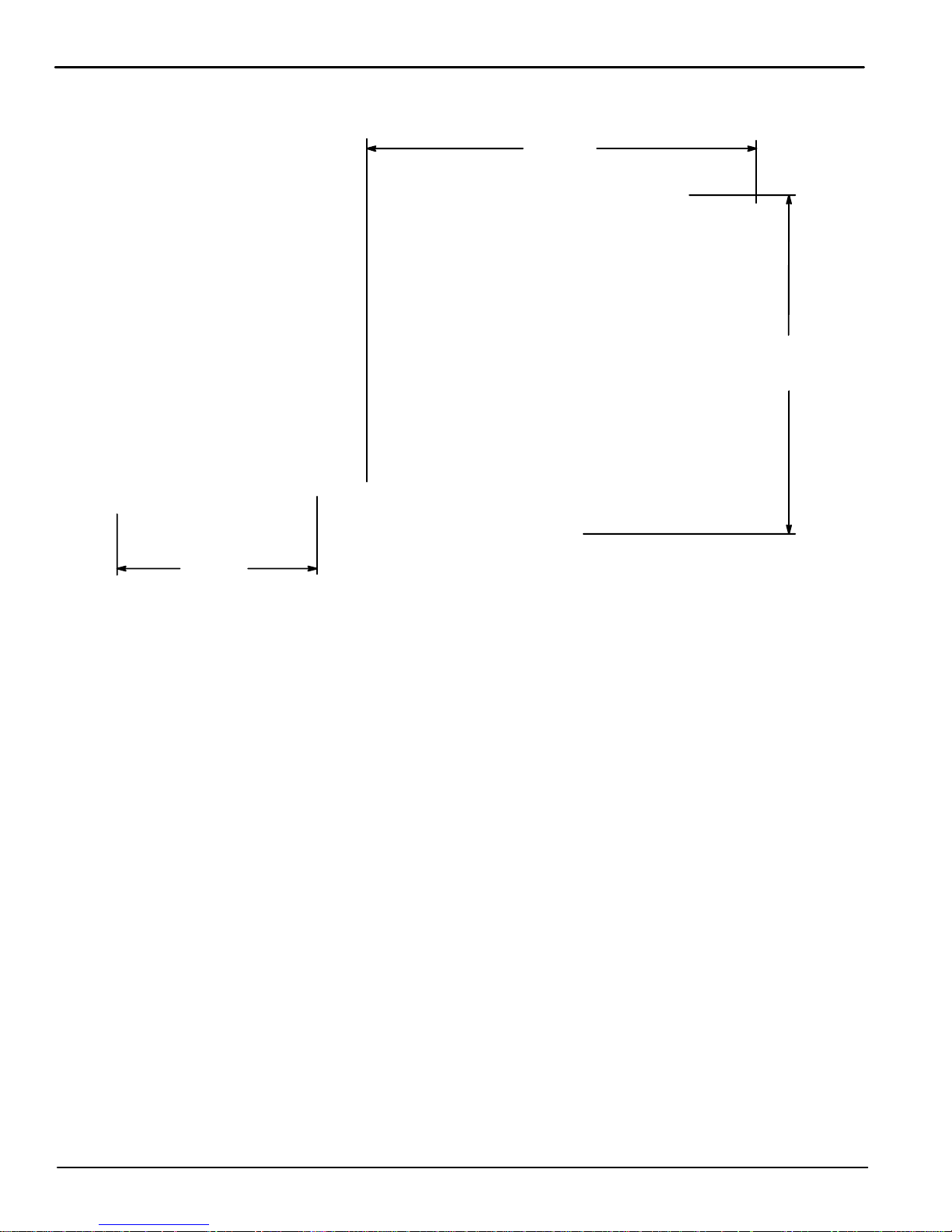

MACHINE DIMENSIONS

990 mm

(39 in)

914 mm

(36 in)

495 mm

(19.5 in)

22

Speed Scrub 1701 Plus (06--05)

Este manual se incluye en todos los modelos nuevos.

Proporciona la información necesaria para su

utilización y mantenimiento.

Lea todo el manual detenidamente para

comprender la máquina antes de utilizarla o

revisarla.

Use la Lista de Piezas incluida en este manual al

ordenar piezas de repuesto. Antes de ordenar piezas

o suministros, asegúrese de tener el número de

modelo y el número de serie de su máquina. Las

piezas y los suministros pueden ordenarse por

teléfono o por correo de cualquier centro autorizado

de piezas y servicios, distribuidor de piezas o de

cualquier subsidiaria del fabricante.

Esta máquina proporcionará un servicio excelente. Sin

embargo, los mejores resultados se obtienen a un

costo mínimo si:

S La máquina se opera con un cuidado razonable.

S La máquina se mantiene con regularidad, según las

instrucciones de mantenimiento provistas.

OPERACIÓN

DATOS DE LA MÁQUINA

Por favor complete al momento de la instalación para

referencia futura.

No. de Modelo-

Fechadeinstalación-

No. de Serie-

S La máquina se mantiene con las piezas provistas

por el fabricante o equivalentes.

PROTECCIÓN DEL MEDIO

AMBIENTE

Deseche el material de embalaje, los

componentes usados de la máquina

como las baterías y los líquidos

peligrosos como el anticongelante y el

aceite, de forma segura para el medio

ambiente, de acuerdo con las

normativas o disposiciones locales.

No olvide reciclar.

Speed Scrub 1701 Plus (04--07)

23

OPERACIÓN

INDICE

MEDIDAS DE SEGURIDAD 25..................

ADHESIVOS DE SEGURIDAD 26...............

COMPONENTES DE LA MÁQUINA 27...........

SÍMBOLOS DEL PANEL DE CONTROL 27......

INSTALACIÓN DE LA MÁQUINA 28............

DESEMBALADO DE LA MÁQUINA 28........

INSTALACIÓN DE LAS BATERÍAS 28........

PREPARACIÓN DE LA MÁQUINA 30............

FIJACIÓN DEL CONJUNTO DE LA

ESCOBILLA DE GOMA 30..................

INSTALACIÓN DEL IMPULSOR DE LA

ALMOHADILLA O DEL CEPILLO 30..........

EXTRACCIÓN DEL IMPULSOR DE LA

ALMOHADILLA O DEL CEPILLO 31..........

LLENADO DEL DEPÓSITO DE LA

DISOLUCIÓN 32...........................

AJUSTE DE LA ALTURA DEL MANDO DE

CONTROL 32..............................

OPERACIÓN DE LA MÁQUINA 33..............

PREOPERACIÓN 33.......................

FREGADO CON LA MÁQUINA 33............

OPERACIÓN DE LA OPCIÓN DE FREGADO

PROLONGADO 34.........................

AL OPERAR LA MÁQUINA 34...............

OPERACION DE LAS HERRAMIENTAS DE

ACCESORIOS (OPCIONAL) 35..............

CORTACIRCUITOS 35......................

AJUSTES DE LA MÁQUINA 36.................

AJUSTE DEL FLUJO DE LA DISOLUCIÓN 36.

AJUSTE DE LA PRESIÓN DE LA

ALMOHADILLA 36.........................

AJUSTE DEL CABLE DE ELEVACIÓN DE LA

ESCOBILLA DE GOMA 36..................

VACIADO DE LOS DEPÓSITOS 36..............

VACIADO DEL DEPÓSITO DE

RECUPERACIÓN 36.......................

VACIADO DEL DEPÓSITO DE LA

DISOLUCIÓN 37...........................

CARGA DE LA BATERÍA 37....................

MANTENIMIENTO DE LA MÁQUINA 38.........

MANTENIMIENTO DIARIO 39...............

MANTENIMIENTO SEMANAL 39.............

MANTENIMIENTO MENSUAL 39............

MANTENIMIENTO TRIMESTRAL 39.........

MANTENIMIENTO DE LA BATERÍA 40.......

TRANSPORTE DE LA MÁQUINA 41.............

ALMACENAMIENTO DE LA MÁQUINA 41.......

ARTICULOS RECOMENDADOS A TENER EN

EXISTENCIA 41...............................

LOCALIZACIÓN DE AVERÍAS 42...............

ESPECIFICACIONES 44.......................

DIMENSIONES DE LA MÁQUINA 45............

DIAGRAMAS ELECTRICAS 68.................

LISTA DE PIEZAS 70..........................

SUSTITUCIÓN DEL CONJUNTO DEL

IMPULSOR DE LA ALMOHADILLA Y

CEPILLOS 70..............................

GRUPE DEL DEPÓSITO DE DISOLUCIÓN 72.

CONJUNTO DESPOSITO RECUPERAR 74...

CONJUNTO DE LA RUEDA 76...............

GRUPO DEL CABEZAL DE FREGADO

DE DISCO 78..............................

GRUPO DE TUBERÍAS 80..................

CONJUNTO DEL MOTOR DE ASPIRACIÓN 82

CONJUNTO PALETA 84....................

MANIJA GRUPO 86........................

CONJUNTO CONSOLA DE CONTROLES 87..

CONJUNTO DE BATERÍA Y CARGADOR 88..

OPCIONES 90................................

CONJUNTO DEL SIST EMA ES 90...........

CONJUNTO DE LA BOMBA DEL TUBO 92....

CONTADOR DE HORAS Y CONJUNTO

DEL INTERRUPTOR DE BAJO VOLTAJE 94..

KIT DE HERRAMIENTA MOJADO 95.........

GRUPO DEL TUBO ELÉCTRICO DELUXE 96.

GRUPO DEL TUBO ELÉCTRICO 98..........

CONJUNTO DE LA MANGUERA DEL

TUBO ELÉCTRICO 100......................

24

Speed Scrub 1701 Plus (04--07)

MEDIDAS DE SEGURIDAD

OPERACIÓN

La siguiente información indica las condiciones

potencialmente peligrosas para el operario o

equipo:

Esta máquina está destinada al uso comercial.

Está diseñada exclusivamente para fregar suelos

en recintos cerrados y no debe utilizarse para

ningún otro uso. Utilice únicamente los cepillos,

almohadillas y limpiadores de suelos específicos

recomendados para máquinas disponibles en el

mercado.

Todos los operarios deben leer, comprender y

cumplir las siguientes medidas de seguridad.

A lo largo de todo el manual se utilizan los siguientes

símbolos de advertencia y encabezados “PARA SU

SEGURIDAD” descritos a continuación:

ADVERTENCIA: Advierte sobre riesgos o

prácticas inseguras que podrían provocar

lesiones personales graves o fatales.

PARA SU SEGURIDAD: Identifica las operaciones

que debe realizar para una utilización segura del

equipo.

El no cumplimiento de estas advertencias puede

causar lesiones personales, descargas eléctricas,

incendios y explosiones.

ADVERTENCIA: Peligro de incendio o

explosión:

-- Nunca utilice líquidos inflamables ni haga

funcionar la máquina en las proximidades de

líquidos, vapores o polvos inflamables.

Esta máquina no está equipada con motores a

prueba de explosión. Los motores eléctricos

emiten chispas al arrancar y durante el

funcionamiento lo que podría causar un fuego

explosivo o explosión si la máquina se usa en una

área donde están presentes vapores/líquidos

inflamables o polvos combustibles.

-- No recoja materiales inflamables ni metales

reactivos.

-- Las baterías emiten hidrógeno. Mantenga

chispasyllamasalejadasdelamáquina.

Mantenga el compartimento de la batería

abierto mientras realiza la operación de carga.

ADVERTENCIA: Peligro choque eléctrico.

Desconecte los cables de la batería antes de

realizar reparaciones en la máquina.

ADVERTENCIA: Cepillo giratorio. Mantenga

alejadas las manos. Apague la máquina antes de

trabajar en ella.

PARA SU SEGURIDAD:

1. No utilice la máquina:

-- Con líquidos inflamables o cerca de gases

inflamables, ya que podría provocar

explosiones o llamaradas.

-- Salvo que esté debidamente formado y

autorizado.

-- Salvo haber leído y comprendido el

manual del operario.

-- Si la máquina no funciona correctamente.

2. Antes de operar máquina:

-- Asegúrese de que todos los dispositivos

de seguridad se encuentren en su lugar y

funcionen correctamente.

3. Al utilizar la máquina:

-- Conduzca despacio en pendientes y

superficies resbaladizas.

-- Utilice calzado antideslizante.

-- Reduzca la velocidad al realizar giros.

-- Informe inmediatamente de las averías de

la máquina o si el funcionamiento no es

correcto.

-- No permita nunca que los niños jueguen

encima o alrededor de la máquina.

-- Siga las instrucciones de mezcla y

manipulación indicadas en los depósitos

para los productos químicos.

4. Antes de abandonar o revisar la máquina:

-- Deténgase en una superficie horizontal.

-- Apague la máquina.

5. Al revisar la máquina:

-- Evite las partes en movimiento. No utilice

chaquetas, camisas o mangas sueltas.

-- Desconecte las conexiones de la batería

antesdeempezaratrabajarenlamáquina.

-- Utilice guantes y gafas de protección al

trabajar con las baterías o sus cables.

-- Evite el contacto con el ácido de la batería.

-- No moje la máquina rociándola o

utilizando una manguera. Pueden

producirse fallos eléctricos.

-- Utilice repuestos suministrados o

aprobados por el fabricante.

-- Todas las reparaciones deben ser

realizadas por personal técnico

cualificado.

-- No modifique el diseño original de la

máquina.

Speed Scrub 1701 Plus (06--05)

25

OPERACIÓN

6. Al transportar la máquina:

-- Apague la máquina.

-- No levante la máquina con las baterías

instaladas.

-- Pida ayuda para levantar la máquina.

-- Utilice una rampa al cargar/descargar la

máquina en/de un camión o remolque.

-- Utilice las cintas para fijar la máquina al

camión o remolque.

-- Coloque el cabezal de fregado en la

posición bajada.

ADHESIVOS DE SEGURIDAD

La adhesivo de seguridad aparece en la máquina en la localización indicada. Sustituya el adhesivo si se ha

desprendido, o está deteriorado o son ilegible.

ETIQUETA DE ADVERTENCIA -- LOCALIZADA EN EL TANQUE DE RECUPERACION.

26

Speed Scrub 1701 Plus (04--07)

COMPONENTES DE LA MÁQUINA

OPERACIÓN

2

7

6

5

4

1

3

17

18

22

38

21

23

25

8

9

16

24

1415

26

1. Contacto para la llave

2. Indicador luminoso de

ENCENDIDO/APAGADO

3. Contador de horas (Opc.)

4. Cortacircuitos principal

5. Cortacircuitos del cepillo

6. Botón de liberación del cepillo

7. Indicador de la presión del

cepillo

8. Indicador del nivel de carga

de la baterías

9. Interruptor de ENCENDIDO/

APAGADO de la aspiración

10. Interruptor de ENCENDIDO/

APAGADO de la disolución

11. Mando de elevación de la

escobilla de goma

12. Mando de control

13. Botones de ajuste de la altura de

mando de control

11

29

30

13

10

20

19

27

31

32

36

33

34

14. Interruptor de ENCENDIDO/

APAGADO del tubo de

aspiración (Opc.)

15. Interruptor de ENCENDIDO/

APAGADO (Modelo ES)

16. Indicador luminoso de bomba

encendida (Modelo ES)

17. Enchufe del cargador

18. Manguera de vaciado del

depósito de recuperación

19. Manguera de Vaciado del

Depósito de Disolución con

Indicador de Nivel

20. Tapa del Orificio de Llenado de

la Disolución

21. Pedal de elevación del cabezal

de fregado

22. Pedal de liberación de la

elevación del cabezal de fregado

23.Botóndeajustedelflujodela

disolución

28

12

37

35

24. Manguera de aspiración de la

escobilla de goma

25. Conjunto de la escobilla de

goma

26. Palometa de la escobilla de goma

27. Rodillos de pared

28. Accionador del cepillo

29. Tapa del depósito de recuperación

30. Depósito de recuperación

31. Capó del compartimento

de la batería

32. Cabezal de fregado

33. Aleta del cabezal de fregado

34. Ruedecilla de transporte

35. Ruedas principales

36. Acoplador de la manguera de la

disolución del tubo de aspiración

Opc.

37. Depósito de la disolución

38.Botóndeajustedelapresiónde

la almohadilla

SÍMBOLOS DEL PANEL DE CONTROL

Indicador luminoso

de encedido

Contacto para

la llave

Speed Scrubt 1701 Plus (02--04)

Interruptor de

la aspiración

Interruptor de

la disolución

Motor del cepillo

Cortacircuitos de 35A

Cortacircuitos

de 20A

Nivel de carga

de la batería

Lea el Manual

antes de utilizar la

máquinaEncendido

27

OPERACIÓN

INSTALACIÓN DE LA MÁQUINA

DESEMBALADO DE LA MÁQUINA

Compruebe cuidadosamente si la caja de cartón

muestra daños. En caso de que así sea informe

inmediatamente al transportista.

Inspeccione el contenido de la máquina para

asegurarse que el envío está completo. Consultar con

el distribuidor por artículos faltantes.

Contenidos de la máquina:

1 -- Cable de batería #602871

1 -- Cable para las baterías #6X24pulg negro #603208

2 -- 12VDC 130AH Baterías #130869 (incluido con el

paquete de la máquina)

1 -- Cargador De Batería, 24V/15A 120V #603553

(incluido con el paquete de la máquina)

Para desempacar su máquina, extraiga las bandas

metálicas y eleve cuidadosamente o use una rampa

para extraer la máquina de la tarima. No ruede la

máquina fuera de la tarima ya que puede resultar en

daños.

PARA SU SEGURIDAD: Obtenga ayuda al alzar la

máquina. No levante la máquina con las baterías

instaladas.

Eleve el cabezal de fregado a la posición de

transporte antes de maniobrar con la máquina. Pise el

pedal de elevación del cabezal de fregado para elevar

dicho cabezal (Figura 1).

NOTA: Para evitar que la aleta del cabezal de fregado

se deteriore, mantenga la máquina siempre en la

posición de transporte cuando el impulsor de la

almohadilla no esté instalado.

ATENCIÓN: No retire la máquina del pallet

haciéndola rodar porque podría averiarla.

ATENCIÓN: La instalación de la batería debe

realizarse DESPUÉS de retirar la máquina del

pallet.

El conjunto de la escobilla de goma está embalado

con la máquina.

Las baterías, cargador, cepillo, impulsor de la

almohadilla y almohadillas deben adquirirse

separadamente. Consult an authorized distributor for

specific pads and brushes.

ATENCIÓN: La utilización de piezas diferentes a

las recomendadas por el fabricante puede

provocar averías.

INSTALACIÓN DE LAS BATERÍAS

ADVERTENCIA: Las baterías emiten

hidrógeno. Mantenga chispas y llamas alejadas de

la máquina. Mantenga el compartimento de la

batería abierto mientras realiza la operación de

carga.

PARA SU SEGURIDAD: Al prestar servicio a la

máquina, utilice guantes y gafas de protección al

trabajar con las baterías o sus cables. Evite el

contacto con el ácido de la batería.

Especificaciones de la batería:

Dos baterías de 12 voltios de ciclo profundo. Consulte

a un distribuidor autorizado sobre baterías

específicas. Las dimensiones máximas de la batería

son 17.8 cm ancho x 33 cm largo x 25.4 cm alto.

1. Estacione la máquina en una superficie plana,

apague todos los interruptores y retire la llave del

contacto.

2. Retire el capó de la batería para acceder al

compartimento de la batería. A continuación

extraiga la bandeja de metal de la batería y afloje

el cable de la batería del compartimento.

3. Desconecte la manguera de aspiración de la

boquilla del depósito de recuperación. Instale

cuidadosamente la primera batería en el

compartimento con los bornes de la batería

colocados como muestra la figura (Figura 2).

FIG. 1

28

Speed Scrub 1701 Plus (04--07)

OPERACIÓN

FIG. 2

A TENCIÓN: No deje caer la batería en el

compartimento, tanto la batería como su soporte

podrían deteriorarse. La garantía no cubre estos

daños.

4. Conecte el cable rojo de la batería procedente de

la máquina al borne positivo (+) de la batería

inferior. A continuación, conecte el cable del

puente negro al borne negativo (--) (Figura 4).

5. Después de conectar los cables al la batería

inferior, cuelgue cuidadosamente la bandeja de

metal de la batería sobre los pernos incluidos y

coloque la segunda batería en la bandeja con los

bornes en la posición que muestra la figura. Fije la

segunda batería con una cinta (Figura 3).

(--)

Negro

(--)

Puente

FIG. 4

(+)

Puente

(+)

Rojo

7. Conecte de nuevo la manguera de aspiración a la

boquilla del depósito de recuperación como se

muestra (Figura 5).

FIG. 3

6. Conecte el cable negro de la batería procedente

de la máquina al borne negativo (--) de la batería

superior. A continuación, conecte el otro extremo

del cable del puente negro el borne positivo (+)

(Figura 4).

FIG. 5

8. Una vez que todas las baterías estén

correctamente instaladas, gire la llave y arranque

la máquina, encienda el interruptor de la

aspiración y controle indicador del nivel de carga

de la batería. Cargue la batería en caso

necesario (Consulte el apartado de CARGA DE

LA BATERÍA) (Figura 6).

FIG. 6

Speed Scrub 1701 Plus (02--04)

29

OPERACIÓN

PREPARACIÓN DE LA MÁQUINA

FIJACIÓN DEL CONJUNTO DE LA ESCOBILLA DE

GOMA

1. Gire la llave hasta la posición de apagado.

PARA SU SEGURIDAD: Antes de dejar o prestar

servicio a la máquina, detenga la máquina sobre

una superficie nivelada y apague la máquina.

2. Eleve el soporte de montaje de la escobilla de

goma desplazando el botón de elevación de la

escobilla de goma a la izquierda (Figura 7).

FIG. 7

3. Afloje las dos palomets del conjunto de la

escobilla de goma y deslice dicha escobilla en las

ranuras del soporte de montaje de la escobilla de

goma (Figura 8).

5. Conecte la manguera de aspiración de la máquina

al conjunto de la escobilla de goma (Figura 9).

FIG. 9

INSTALACIÓN DEL IMPULSOR DE LA

ALMOHADILLA O DEL CEPILLO

1. Seleccione el cepillo o almohadilla recomendados

que mejor se adapte a sus necesidades.

NOTA: Consulte una distribuidor autorizada para las

recomendaciones de almohadilla/cepillo.

2. Fije la almohadilla al impulsor antes de instalar

dicho impulsor al cubo del motor. Fije la

almohadilla con el cierre central de plástico en

forma de anillo (Figura 10).

FIG. 8

4. Fije bien las palometas.

30

FIG. 10

3. Gire la llave hasta la posición de encendido

(Figura 11).

FIG. 11

Speed Scrub 1701 Plus (02--04)

Loading...

Loading...