Page 1

Genie™ TS Series

Camera User’s Manual

Genie TS Framework 1.00

GigE Vision Area Scan Camera

CA-GENM-TSM00

www.teledynedalsa.com

Page 2

© 2012 Teledyne DALSA

All information provided in this manual is believed to be accurate and reliable. No responsibility is assumed by

Teledyne DALSA for its use. Teledyne DALSA reserves the right to make changes to this information without

notice. Reproduction of this manual in whole or in part, by any means, is prohibited without prior permission having

been obtained from Teledyne DALSA.

Microsoft and Windows are registered trademarks of Microsoft Corporation in the United States and other

countries. Windows, Windows XP, Windows Vista, Windows 7 are trademarks of Microsoft Corporation.

All other trademarks or intellectual property mentioned herein belong to their respective owners.

Document Date: May 25, 2012

Document Number: CA-GENM-TSM00

*CA-GENM-TSM00*

About Teledyne DALSA

Teledyne DALSA is an international high performance semiconductor and electronics company that designs,

develops, manufactures, and markets digital imaging products and solutions, in addition to providing wafer foundry

services.

Teledyne DALSA Digital Imaging offers the widest range of machine vision components in the world. From

industry-leading image sensors through powerful and sophisticated cameras, frame grabbers, vision processors and

software to easy-to-use vision appliances and custom vision modules.

Page 3

Contents

GENIE TS SERIES OVERVIEW ...............................................................................................................5

DESCRIPTION ............................................................................................................................................5

Genie Application Advantages.......................................................................................................... 6

PART NUMBERS AND SOFTWARE REQUIREMENTS.....................................................................................7

GIGE VISION SAPERA APPLICATION DESCRIPTION ...................................................................................8

CAMERA SPECIFICATIONS OVERVIEW.......................................................................................................9

Certifications...................................................................................................................................10

Vibration and Shock Certifications................................................................................................. 10

GENIE TS SENSOR PERFORMANCE ..........................................................................................................11

DALSA DCK4131 Monochrome CMOS Sensor Specifications ......................................................11

Sensor Cosmetic Specifications: Teledyne DALSA DCK4131 Monochrome .................................12

Spectral Responsivity: Teledyne DALSA DCK4131 Monochrome.................................................13

Effective Quantum Efficiency: Teledyne DALSA DCK4131 Monochrome..................................... 13

CONNECTING THE GENIE TS CAMERA ...........................................................................................15

GIGE NETWORK ADAPTER OVERVIEW ................................................................................................... 15

PAUSE Frame Support...................................................................................................................15

CONNECT THE GENIE TS CAMERA ..........................................................................................................15

Connectors ...................................................................................................................................... 16

LED Indicators ...............................................................................................................................16

Network Status Indicators ....................................................................................................................... 16

Camera Status LED Indicator.................................................................................................................. 17

LED States on Power Up ........................................................................................................................ 17

Genie IP Configuration Sequence ..................................................................................................18

Supported Network Configurations......................................................................................................... 18

PREVENTING OPERATIONAL FAULTS DUE TO ESD..................................................................................18

USING GENIE TS WITH SAPERA API .................................................................................................19

NETWORK AND COMPUTER OVERVIEW...................................................................................................19

SAPERA LT LIBRARY WINDOWS INSTALLATION.....................................................................................20

GENIE TS FRAMEWORK INSTALLATION ..................................................................................................20

Procedure........................................................................................................................................20

Camera Firmware Updates ............................................................................................................20

Application Development Header Files..........................................................................................21

GigE Server Verification.................................................................................................................21

GigE Server Status..........................................................................................................................21

OPTIMIZING THE NETWORK ADAPTER USED WITH GENIE ....................................................................... 22

Running the Network Configuration Tool.......................................................................................22

QUICK TEST WITH CAMEXPERT ..............................................................................................................23

About the User-Defined Camera Name ..........................................................................................24

SILENT INSTALLATION OF GENIE FRAMEWORK.......................................................................................25

WINDOWS EMBEDDED 7 INSTALLATION .................................................................................................26

OPERATIONAL REFERENCE................................................................................................................27

USING CAMEXPERT WITH GENIE TS CAMERAS ......................................................................................27

CamExpert Panes............................................................................................................................27

CamExpert View Parameters Option.............................................................................................. 29

CAMERA INFORMATION CATEGORY........................................................................................................29

Genie_TS_Series GigE Vision Camera Contents 1

Page 4

Camera Information Feature Descriptions.....................................................................................30

SENSOR CONTROL CATEGORY ................................................................................................................32

Sensor Control Feature Descriptions .............................................................................................32

Gain and Black Level Control Details............................................................................................34

Exposure Controls Details..............................................................................................................34

Free-running Programmable Exposure.................................................................................................... 34

External Trigger Programmable Exposure .............................................................................................. 35

Synchronization Timing ..................................................................................................................36

Synchronous Mode.................................................................................................................................. 36

Reset Mode ............................................................................................................................................. 36

I/O CONTROL CATEGORY .......................................................................................................................37

I/O Control Feature Descriptions................................................................................................... 37

I/O Module Block Diagram..................................................................................................................... 41

Trigger Mode Details .............................................................................................................................. 41

Input Line Details.................................................................................................................................... 42

Output Line Details................................................................................................................................. 42

Output Open and Output Close Modes.................................................................................................... 42

COUNTER AND TIMER CONTROL CATEGORY ..........................................................................................43

Counter and Timer Control Feature Description ........................................................................... 43

Counter and Timer Group Block Diagram .............................................................................................. 46

Example: Counter Start Source = OFF.................................................................................................... 47

Example: Counter Start Source = CounterEnd (itself) ............................................................................ 47

Example: CounterStartSource = EVENT and Signal (Edge Base).......................................................... 48

Example: CounterStartSource = Signal (Level Base) Example 1 ........................................................... 48

Example: CounterStartSource = Line (Edge Base) Example 2 ............................................................... 49

ADVANCED PROCESSING CONTROL CATEGORY...................................................................................... 49

Advanced Processing Control Feature Descriptions......................................................................50

Lookup Table (LUT) Overview .......................................................................................................53

Sharpness Type Overview ...............................................................................................................54

Flat Field Correction and Defective Pixel Detection Overview ..................................................... 54

Correction Function Block Diagram ....................................................................................................... 54

Flat Field Correction Algorithm Description .......................................................................................... 55

Information on the Sapera Flat Field Coefficients File ........................................................................... 55

Important Factors about Flat Field Processing ........................................................................................ 56

Defective Pixel Replacement .................................................................................................................. 56

Defective Pixel Detection Algorithm Description................................................................................... 56

How to do a FFC Setup via Sapera CamExpert ............................................................................. 56

Set up Dark and Bright Acquisitions with the Histogram Tool............................................................... 56

Flat Field Correction Calibration Procedure ........................................................................................... 58

Using Flat Field Correction..................................................................................................................... 60

IMAGE FORMAT CONTROL CATEGORY....................................................................................................61

Image Format Control Feature Description................................................................................... 61

Width and Height Features for Partial Scan Control.....................................................................63

Vertical Cropping (Partial Scan) ............................................................................................................. 63

Maximum Frame Rate (fps) Examples (TS-M4096)............................................................................... 64

Maximum Frame Rate (fps) Examples (TS-M3500)............................................................................... 65

Maximum Frame Rate (fps) Examples (TS-M2500)............................................................................... 65

Horizontal Cropping (Partial Scan)......................................................................................................... 66

Binning............................................................................................................................................ 67

Horizontal Binning Constraints............................................................................................................... 67

Vertical Binning Constraints................................................................................................................... 67

Internal Test Image Generator .......................................................................................................68

METADATA CONTROL CATEGORY ..........................................................................................................69

Metadata Control Category Feature Descriptions .........................................................................69

ACQUISITION AND TRANSFER CONTROL CATEGORY...............................................................................70

Acquisition and Transfer Control Feature Descriptions ................................................................71

Acquisition Buffering.............................................................................................................................. 72

Start – End Command Requirements ...................................................................................................... 72

2 Contents Genie_TS_Series GigE Vision Camera

Page 5

Creating a Camera Configuration File in the Host.................................................................................. 72

EVENT CONTROL CATEGORY..................................................................................................................72

Event Control Feature Descriptions ...............................................................................................73

Basic Exposure Events Overview ........................................................................................................... 75

Events Associated with Triggered Synchronous Exposures.................................................................... 76

Events Associated with Triggered Multiple Frame Synchronous Exposures.......................................... 76

Events Associated with Triggered Reset Mode Exposures ..................................................................... 77

GIGE VISION TRANSPORT LAYER CONTROL CATEGORY ........................................................................77

GigE Vision Transport Layer Feature Descriptions.......................................................................78

GIGE VISION HOST CONTROL CATEGORY ..............................................................................................83

FILE ACCESS CONTROL CATEGORY ........................................................................................................83

File Access Control Feature Descriptions......................................................................................84

File Access via the CamExpert Tool ...............................................................................................85

NETWORK OVERVIEW & TOOLS.......................................................................................................87

GENIE IP CONFIGURATION MODE DETAILS ............................................................................................87

Link-Local Address (LLA)...............................................................................................................87

DHCP (Dynamic Host Configuration Protocol).............................................................................88

Persistent IP.................................................................................................................................... 89

TECHNICAL SPECIFICATIONS............................................................................................................ 91

GENIE TS MECHANICAL SPECIFICATIONS ...............................................................................................91

Nikon F Bayonet to M42x1 Adapter ...............................................................................................92

Genie TS Identification ...................................................................................................................93

Additional Notes on Genie TS Mechanical .....................................................................................93

SENSOR ALIGNMENT SPECIFICATION ......................................................................................................93

CONNECTORS..........................................................................................................................................94

25-pin Micro-D type Connector Details ......................................................................................... 94

Video Iris Connector Details ..........................................................................................................95

Iris Connector – Video Mode.................................................................................................................. 95

Iris Connector – DC Mode ...................................................................................................................... 95

Genie TS Input Signals Electrical Specifications............................................................................96

Genie TS Output Signals Electrical Specifications.........................................................................97

COMPUTER REQUIREMENTS FOR GENIE CAMERAS..................................................................................97

Host PC System............................................................................................................................... 97

Ethernet Switch Requirements ........................................................................................................98

IEEE 802.3x Pause Frame Flow Control................................................................................................. 98

Ethernet to Fiber-Optic Interface Requirements ............................................................................98

EC & FCC DECLARATION OF CONFORMITY ...........................................................................................99

ADDITIONAL REFERENCE INFORMATION...................................................................................101

LENS SELECTION OVERVIEW ................................................................................................................101

Lens Mount Types .........................................................................................................................101

Lens for the Genie TS with M42 or Nikon F-mount......................................................................101

Additional Lens Parameters (application specific).......................................................................102

OPTICAL CONSIDERATIONS...................................................................................................................102

Illumination................................................................................................................................... 102

Light Sources ................................................................................................................................102

Filters............................................................................................................................................103

Lens Modeling...............................................................................................................................103

Magnification and Resolution.......................................................................................................103

SENSOR HANDLING INSTRUCTIONS .......................................................................................................104

Electrostatic Discharge and the Sensor........................................................................................ 104

Protecting Against Dust, Oil and Scratches .................................................................................104

Cleaning the Sensor Window ........................................................................................................104

RUGGEDIZED RJ45 ETHERNET CABLES.................................................................................................105

Genie_TS_Series GigE Vision Camera Contents 3

Page 6

TROUBLESHOOTING............................................................................................................................107

OVERVIEW ............................................................................................................................................107

Problem Type Summary................................................................................................................107

Verifying Network Parameters......................................................................................................109

Before Contacting Technical Support ................................................................................................... 109

INSTALLATION ISSUES AND FUNCTIONAL PROBLEMS............................................................................109

The Windows XP Firewall Service Can Not Start ........................................................................109

DEVICE AVAILABLE WITH OPERATIONAL ISSUES.................................................................................. 110

Firmware Updates ........................................................................................................................110

Power Failure During a Firmware Update–Now What? .............................................................110

Cabling and Communication Issues .............................................................................................110

Acquisition Error without Timeout Messages...............................................................................111

No camera exposure when expected ..................................................................................................... 111

Camera is functional but frame rate is lower than expected.................................................................. 111

Camera acquisition is good but frame rate is lower than expected........................................................ 111

Camera is functional, frame rate is as expected, but image is black ..................................................... 112

Other Problems or Issues..............................................................................................................112

Random Invalid Trigger Events ............................................................................................................ 112

Minimum Sapera Version Required...................................................................................................... 112

CONTACT INFORMATION ..................................................................................................................113

SALES INFORMATION ............................................................................................................................113

TECHNICAL SUPPORT ............................................................................................................................114

GLOSSARY OF TERMS ......................................................................................................................... 115

INDEX........................................................................................................................................................119

4 Contents Genie_TS_Series GigE Vision Camera

Page 7

Genie TS Series Overview

Description

The Genie TS, a member of the Genie camera family, provides a new series of affordable easy to use digital cameras

specifically engineered for industrial imaging applications requiring embedded image processing and improved network

integration. Genie TS provides functions to increase dynamic range to ensure optimized image capture from a range of

lighting conditions. The TS series integrates features like motorized lens control, zoom and focus functionality, auto iris,

image compression, image transfer-on-demand, and both RS-485 and RS-232 ports.

Genie cameras combine standard gigabit Ethernet technology (GigE Vision 2.0 Compliant) with the Teledyne DALSA

Trigger-to-Image-Reliability framework to dependably capture and transfer images from the camera to the host PC. Genie

TS cameras are available in a number of models implementing different sensors and image resolutions, either in

monochrome or color versions.

Genie_TS_Series GigE Vision Camera Genie TS Series Overview 5

Page 8

Genie Application Advantages

Optimized, rugged design

GigE Vision 2.0 compliant (pending)

Gigabit Ethernet (GigE) interconnection to a computer via standard CAT5e or CAT6 cables

Supports connection to the host computer NIC through a GigE network switch

Available in multiple resolutions

High frame rates with high resolutions

High dynamic range with support for a Multi-slope function

Digital binning for increased sensitivity

Auto-Brightness (Auto-exposure, Auto-gain (AGC), Auto-iris)

Supports cycling multiple exposure times for sequential images. along with other parameters

Multiple lookup table pre-processing for monochrome cameras, single for color versions

Multiple real-time shading corrections available with image cycling (i.e. Flat Field processing)

Horizontal and Vertical Flip function

Smoothing / Sharpening image filtering

Supports several trigger modes for image capture control including motion detection

Supports JPG image compression with user controlled parameters

4 general purpose inputs with programmable threshold

4 general purpose outputs

Supports auto iris and motorized zoom and focus lens control

Native Trigger-to-Image Reliability design framework

Visual status LEDs on camera back plate

1µs internal timer or external events can timestamp images

Supported by Sapera™ LT software libraries

Supports Power Over Ethernet and auxiliary power input

Refer to the Operation Reference and Technical Specifications section of the manual for full details

6 Genie TS Series Overview Genie_TS_Series GigE Vision Camera

Page 9

Part Numbers and Software Requirements

This manual covers the Genie TS monochrome models summarized below. Color Genie TS models and other lens mount

adapters will be added as per availability. See "Camera Specifications" on page 9 for each Genie TS m

Camera Resolution Pixel size Max fps

TS-M4096 4096 x 3072 6.0 x 6.0 µm 12

TS-M3500 3520 x 2200 6.0 x 6.0 µm 19

TS-M2500 2560 x 2048 6.0 x 6.0 µm 29

Lens Mounts Product Number

M42 x 1mm treaded G2-GM10-T4095

M42 x 1mm treaded G2-GM10-T3505

M42 x 1mm treaded G2-GM10-T2505

Genie Accessories & Cables (sold separately) Order Number

Nikon F bayonet Adapter (see “Nikon F Bayonet to M42x1 Adapter” on page 92) G2-AM42-MOUNT4

Genie TS I/O and Power breakout cable (25-pin Micro-D type connector) G2-IOPC-MD25F

Optical filters such as NIR/UV blocking filers are available from Midwest Optical Systems.

Teledyne DALSA Software Platform

Genie TS Framework composed of the Sapera network Imaging Package, GeV Imaging Driver and latest

Genie TS Firmware. Required Microsoft Windows installation.

Sapera LT version 7.20 or later (for Windows)

includes Sapera Runtime and CamExpert

Provides everything you will need to develop imaging applications

Sapera documentation in compiled HTML help, and Adobe Acrobat® (PDF) formats.

Linux Package for Genie TS Contact Sales at Teledyne DALSA

Sapera Processing Imaging Development Library

(available for Windows or Linux - sold separately):

Included with Genie TS distribution

(via web download)

Available for download

http://www.teledynedalsa.com/mv/

Contact Sales at Teledyne DALSA

odel.

Third Party GigE Vision Software Platform Requirements

Support of GenICam GevApi version 2.0 General acquisition and control

Support of GenICam GevApi version 2.3 File access: firmware, LUT, FFC, configuration data, upload

Support of GenICam XML schema version 1.1

Support of GigE Vision 1.2 Includes Chunk Metadata support version 1.2

support of GigE Vision 2.0 Jpeg payload type including chunk support of version 2.0

GenICam™ support — XML camera description file Embedded within Genie

& download

Genie_TS_Series GigE Vision Camera Genie TS Series Overview 7

Page 10

GigE Vision Sapera Application Description

Genie cameras are 100% compliant with the GigE Vision 1.2 and 2.0 specification which defines

the communication interface protocol used by any GigE Vision device. The device description

and capabilities are contained in an XML file. For more information see:

http://www.machinevisiononline.org/public/articles/index.cfm

Genie cameras implement a superset of the GenICam™ specification which defines device

capabilities. This description takes the form of an XML device description file respecting the

syntax defined by the GenApi module of the GenICam™ specification. For more information see

www.genicam.org.

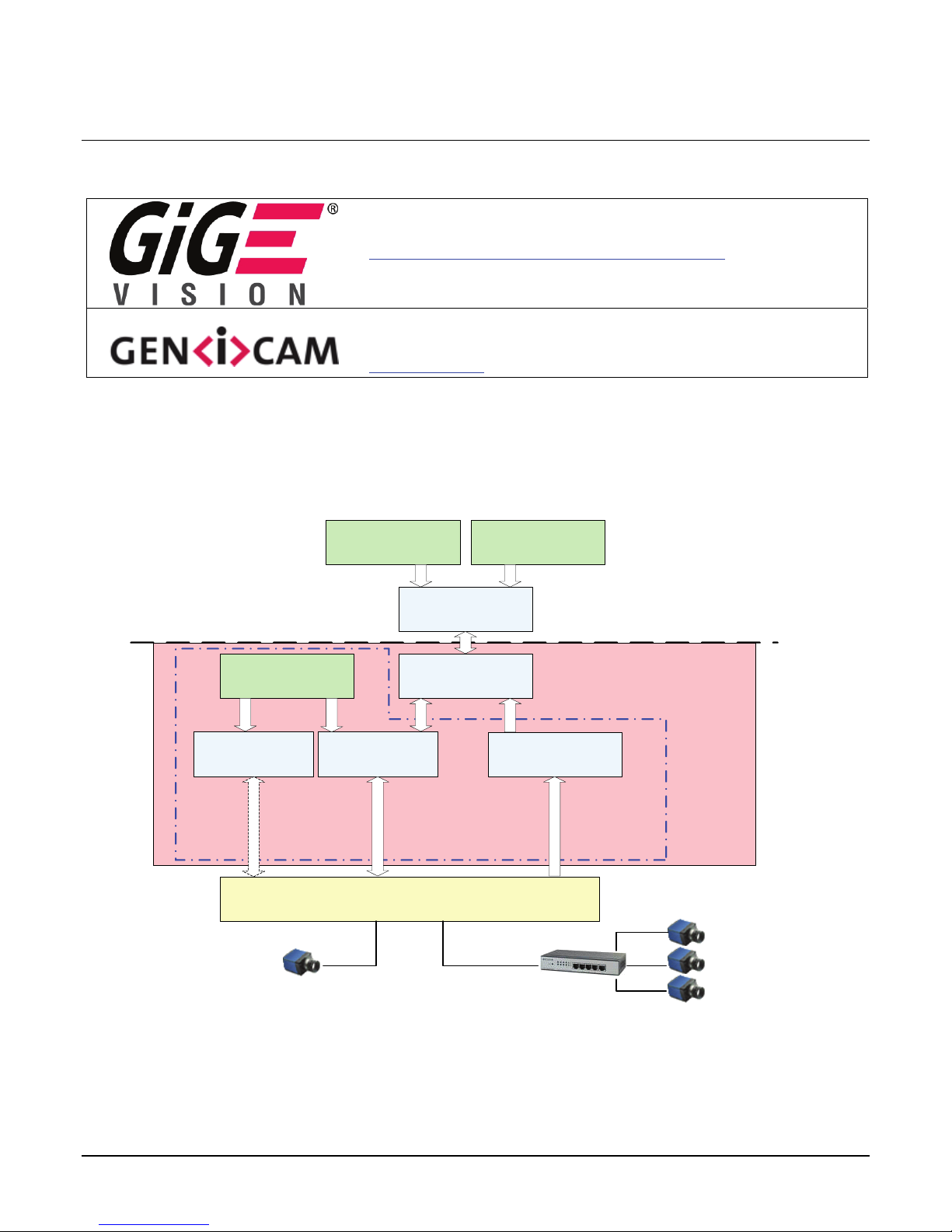

The Teledyne DALSA GigE Vision Module provides a license free development platform for Teledyne DALSA GigE

hardware or Sapera vision applications. Additionally supported are Sapera GigE Vision applications for third party hardware

with the purchase of a GigE Vision Module license, or the Sapera processing SDK with a valid license.

The GigE Vision Compliant XML device description file is embedded within Genie firmware allowing GigE Vision

Compliant applications access to Genie capabilities and controls immediately after connection.

User’s Sapera

Application

CamExpert

?cat=167

Sapera LT SDK

Sapera LT

Network

Configuration Tool

smart DHCP

Server

(optional)

GigE Server

GigE Vision

Module

Control

GVCP

GigE Vision

Control

Protocol

Images

Sapera Network

Imaging Driver

Ethernet Network Interface Card

single GigE Vision

Camera

Alternatively via a switch

Genie TS

Package

GVSP

GigE Vision

Stream

Protocol

Sapera

Network

Imaging

Module

To multiple GigE

Vision Cameras

8 Genie TS Series Overview Genie_TS_Series GigE Vision Camera

Page 11

Camera Specifications Overview

Camera Controls

Synchronization Modes Free running, External triggered, Software trigger through Ethernet

Exposure Modes Programmable in increments of 1µs

Trigger Inputs Opto-isolated, 2.4V to 24V typical, 16mA min.

Strobe Outputs

Features

Flat Field Correction 2 Factory FFC plus 2 User Defined FFC

3x3 Kernel Sharpening Filter 4 Predefined Selections

LUT Monochrome models: 4 LUT available

Binning Digitally based: Horizontal (2 and 4 pixel) and Vertical (2 and 4 line)

Gain Analog (analog gain steps are sensor dependent) and Digital gain up to 4x

Counter and Timer 1 Counter, and 1 Timer. User programmable, acquisition independent, with event generation.

Timestamp 1µs internal timer or external signal to timestamp images and events

Metadata Support Also know as Chunk Data Support in SFNC

Test image Internal generator with choice of static and shifting patterns, or user defined patterns uploaded with the file

User settings Select factory default or either of two user camera configurations

Onboard Memory

Minimum Reserved Data Buffer 256 MB

Reserved Packet Resend Buffer 24 MB default (user defined feature)

Total Memory 512 MB

Back Focal Distance

M42 x 1 mount

Nikon F bayonet mount

Mechanical Interface

Camera Size 49(H) x 49(W) x 54(L) in mm, see “Genie TS Mechanical Specifications” on page 91

Mass 196 g (no lens)

Power connector via 25-pin Micro-D connector, or RJ45 in PoE mode

Ethernet connector RJ45

Electrical Interface

Input Voltage +12 to +24 Volts DC (+20%/- 10%) at 0.6 Amp minimum

Power Dissipation < 6W

Operating Temperature -20 to 60°C

Relative Humidity 5% to 90% non-condensing (operating)

Output Data Configuration Gigabit Ethernet with PAUSE Frame support (as per IEEE 802.3x)

Data and Control GigE Vision compliant at 1000 or 100 Mbps

minimum 19µs

maximum is 16 seconds

Pulse controlled via Trigger pulse width.

Debounce range from 0 up to 255 µs

Trigger Delay from 0 to 2,000,000 µs

Output opto-isolated:

Aligned to the start of exposure with a programmable delay, duration and polarity

(using “start of exposure on output line source” feature)

access feature

12 mm

46.5 mm (34.5 mm for the F mount adapter plus 12 mm for the camera body)

Supports the Power Over Ethernet standard. (PoE Class 0 as per IEEE 802.3af)

Genie_TS_Series GigE Vision Camera Genie TS Series Overview 9

Page 12

Specifications for each available sensor follow this section.

Certifications

CE

FCC

RoHS

EN61000-4-2 : 2008 Electrostatic discharge immunity test

EN61000-4-3 : 2006 A1 : 2007 A2 : 2010 Radiated, radio-frequency, electromagnetic field immunity test

EN61000-4-4 : 2004 Electrical fast transient/burst immunity test

EN61000-4-5 : 2005 Surge immunity

EN61000-4-6 : 2008 Immunity to conducted disturbances, induced by radio-frequency fields

EN61000-4-8 : 2009 Power frequency magnetic field immunity

EN61000-4-11 : 2004 Voltage variations immunity

EN61000-6-2 : 2005 Electromagnetic immunity

EN61000-6-4: 2007 Electromagnetic emissions

CISPR 11: 2009 A1 : group 1 FCC, part 15, subpart B:2010 Limit: class A Conducted Emissions

CISPR 22 : 2008 Limit: class A LAN port Conducted Emissions

Part 15, class A

see "EC & FCC Declaration of Conformity" on page 99

Compliancy as per European directive 2004/105/EC

Vibration and Shock Certifications

Test (while operating) Test Levels Test Parameters

Random vibrations Level 1: 2 grms 60 min.

Level 2: 4 grms 45 min.

Level 3: 6 grms 30 min.

Shocks Level 1: 20 g / 11 ms

Level 2: 30 g / 11 ms

Level 3: 40 g / 60 ms

Frequency range: 5 to 2000 Hz

Directions: X, Y, and Z axes

Shape: half-sine

Number: 3 shocks (+) and 3 shocks (-)

Directions: ±X, ±Y, and ±Z axes

10 Genie TS Series Overview Genie_TS_Series GigE Vision Camera

Page 13

Genie TS Sensor Performance

The sensor description below provides a specification table and response graphics. The graph describes the sensor response

to different wavelengths of light (excluding lens and light source characteristics). Visible light spans wavelengths between

about 390 - 780 nanometers. Wavelengths below 390 nm are termed ultra-violet while those above 780 nm. are termed infrared.

DALSA DCK4131 Monochrome CMOS Sensor Specifications

Item / Feature Specification

Sensor Model Teledyne DALSA DCK4131 monochrome CMOS

Camera Models TS-M4096, TS-M3500, TS-M2500

Minimum Frame Rate (free-running) 0.1 fps (one frame every 10 seconds)

Maximum Frame Rate (free-running) Dependent on Genie TS model

Minimum Exposure 19 μs for any exposure mode

Maximum Exposure 16 s

Internal Trigger to Start of Exposure 106 μs

Horizontal Line Time 26.125 μs (TS-M4096), 22.925 μs (TS-M3500), 16.525 μs (TS-M2500)

Pixel Size 6.0µm x 6.0µm

Pixel Format User selectable 8-bit or 10-bit

Shutter Full frame electronic shutter

Sensor Gain Range Default Gain value = 1.0, Selectable Gain = 2.65 (will vary dependant on Black Level Offset setting)

Full Well Capacity 32ke (typical)

Output Dynamic Range † 60db (typical) with Factory FFC Active

Signal to Noise ratio †† 45db (typical)

DN Variation 50% saturation: typical +/-4%

Responsivity 16 DN/(nJ/cm2) @ 560 nm (typical)

† Dynamic Range Test Conditions

Analog Gain 1x

Exposure 1500µs

Factory FFC Active

Defective Pixel Detection Active with Threshold at 5%

Averaging 10 frames

†† SNR Test Conditions

Analog Gain 1x

Exposure 750µs

Factory FFC Active

Defective Pixel Detection Active with Threshold at 5%

Averaging 10 frames at 50% saturation

Genie_TS_Series GigE Vision Camera Genie TS Series Overview 11

Page 14

Sensor Cosmetic Specifications: Teledyne DALSA DCK4131 Monochrome

The following table lists the current cosmetic specifications for models TS-M4096, TS-M3500, and TS-M2500

Blemish Specifications Maximum Number of

Defects

Hot/Dead Pixel defects ††† Typical 0.015%

Max 0.05%

Spot defects none Grouping of more than 8 pixel defects within a sub-area of 3x3 pixels, to a

Clusters defects none Grouping of more than 5 single pixel defects in a 3x3 kernel.

Column defects none Vertical grouping of more than 10 contiguous pixel defects along a single column.

Row defects none Horizontal grouping of more than 10 contiguous pixel defects along a single row.

Note: All of the sensor cosmetic specifications are with factory flat-field correction (FFC) active and Dynamic Defective

Pixel Detection active. There are no pre-flat-field camera cosmetic specifications.

††† Test conditions

Factory FFC Active

Defective Pixel Detection OFF

Nominal light = illumination at 50% of saturation

Temperature of camera front plate is 45°C

Blemish Description

Any pixel that deviates by ±20% from the average of neighboring pixels at 50%

saturation including pixel stuck at 0 and maximum saturated value.

maximum spot size of 7x7 pixels.

12 Genie TS Series Overview Genie_TS_Series GigE Vision Camera

Page 15

Spectral Responsivity: Teledyne DALSA DCK4131 Monochrome

Spectral Responsivity

20.0

)

2

15.0

10.0

5.0

Responsivity (DN/nJ/cm

0.0

400 500 600 700 800 900 1000

Wavelength (nm)

Effective Quantum Efficiency: Teledyne DALSA DCK4131 Monochrome

The following quantum efficiency graph describes the fraction of photons at each wavelength that contribute charge to the

pixel.

Effective Spectral Quantum Efficiency

60.0%

50.0%

40.0%

30.0%

eff. QE [%]

20.0%

10.0%

0.0%

400 450 500 550 600 650 700 750 800 850 900

Genie_TS_Series GigE Vision Camera Genie TS Series Overview 13

Wavelength (nm)

Page 16

This Page Intentionally Left Blank

14 Genie TS Series Overview Genie_TS_Series GigE Vision Camera

Page 17

Connecting the Genie TS Camera

GigE Network Adapter Overview

If the computer to be used with the Genie camera does not have a Gigabit network adapter or second built in Gigabit NIC, a

Gigabit Network Interface adapter card (NIC) needs to be installed. Typically under Windows, the Gigabit NIC is recognized

automatically when Windows boots.

An example of a high performance NIC is the Intel PRO/1000 MT adapter. Review the NIC documentation concerning any

special driver required for your specific operating system. Install the PCI bus Gigabit NIC as described by the NIC

manufacture's documentation.

PAUSE Frame Support

The Genie TS supports the Gigabit Ethernet PAUSE Frame feature as per IEEE 802.3x. PAUSE Frame is the Ethernet flow

control mechanism that temporarily stops data transmission on the network. The PAUSE Frame feature can help a NIC that

doesn’t have enough buffering to handle full-speed reception. This requires the flow control option in the NIC property

settings must be enabled.

Note that this problem is not as common with advances in computer bus speeds and memory sizes. PAUSE Frame support is

typically required to manage network traffic within a switch when multiple cameras are simultaneously used.

Connect the Genie TS Camera

Connecting a Genie TS to a network system is independent to whether the Teledyne DALSA Sapera LT package or a third

party GigE Vision development package is used.

Before connecting power to the camera, test all power supplies. Power supplies must meet the requirements defined in

section "Genie TS Input Signals Electrical " on page 96. Apply power to the cam

Connect Genie to the host computer GigE network adapter or to the Ethernet switch via a CAT5e or CAT6 Ethernet

cable. Note: cable should not be less than 1 meter (3 feet) long or more than 100 meters (328 feet) long.

Once communication with the host computer is started the automatic IP configuration sequence will assign an LLA IP

address as described in section "Genie IP Configuration Sequence" on page 18, or a DHCP IP address if a DHCP server

s present on your network.

i

Check the diagnostic LED which will be initially red then switch to flashing blue while waiting for IP configuration. See

"Camera Status LED " on page 17 for Geni

The factory defaults for Genie is Persistent IP disabled and DHCP enabled with LLA always enabled as per the GigE

Vision specification. For additional information see "Genie IP Configuration Mode Details" on page 87. See the next

ion "Connectors" on page 16 for an overview of the Genie interfaces.

sect

e LED display descriptions.

era.

Genie_TS_Series GigE Vision Camera Connecting the Genie TS Camera 15

Page 18

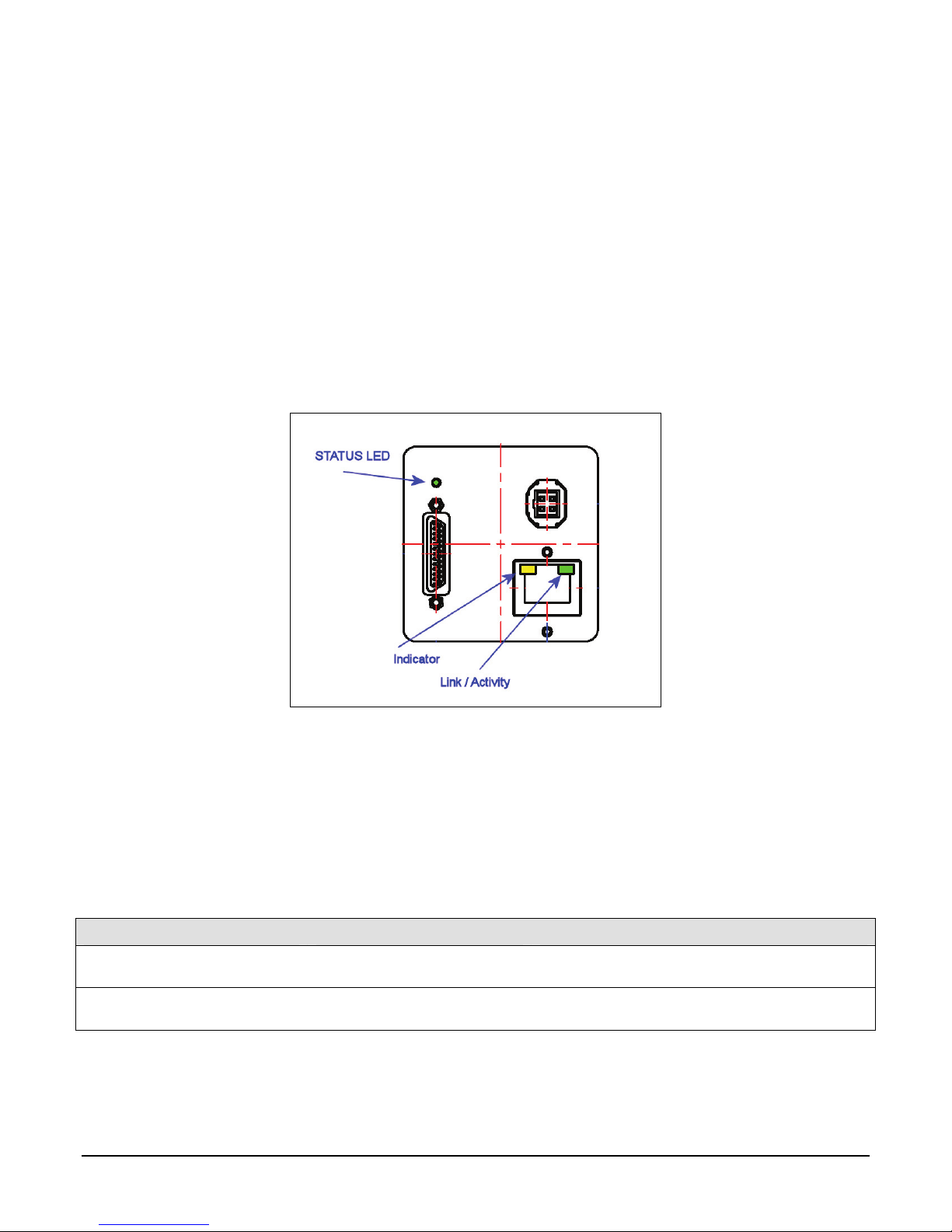

Connectors

The Genie has three connectors:

A single RJ45 Ethernet connector for control and video data transmitted to/from the host computer Gigabit NIC. The

Genie TS also supports Power Over Ethernet (PoE). See "Ruggedized RJ45 Ethernet Cables" on page 105 for secure

cables.

A Micro-D sub 25 co

Teledyne DALSA provides an optional breakout cable (part number G2-IOPC-MD25F). See “25-pin Micro-D type

onnector Details” on page 94 for connector pinout specifications.

C

A 4-pin auto-iris connector pinout compatible with common DC and video iris lens.

The following figure of the Genie back end shows connector and LED locations. See "Genie TS Mechanical Specifications"

on page 91 for det

ails on the Genie connectors and camera mounting dimensions.

nnector for camera power (or auxiliary power), plus trigger, strobe and general I/O signals.

Genie – Rear View

LED Indicators

The Genie has one multicolor LED to provide a simple visible indication of camera state and the RJ45 Ethernet connector

has two LEDs for network status conditions. These are described below.

Network Status Indicators

The Genie TS RJ45 Ethernet connector has two LEDS which display standardized information as follows:

Ethernet Connector LEDs Color Description

Left LED (Connection indicator)

Right LED (Link/Activity indicator)

Off No data is currently being transferred

Amber Connected to a network

Off Not Connected to a network

Green Blinking – There is activity on the port

16 Connecting the Genie TS Camera Genie_TS_Series GigE Vision Camera

Page 19

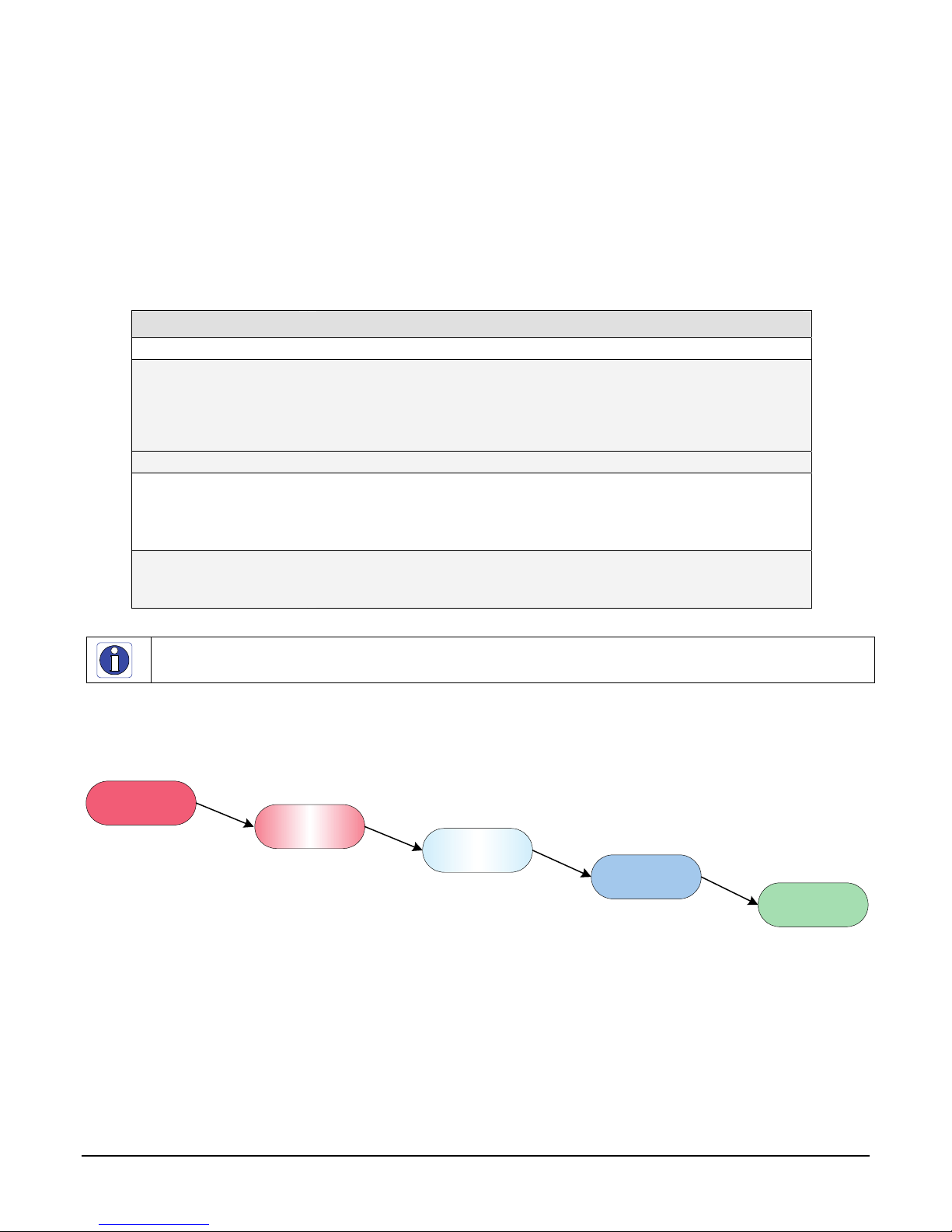

Camera Status LED Indicator

The camera is equipped with one LED to display the operational status of the camera. When more than one condition is

active, the LED color indicates the condition with the highest priority (such as an acquisition in progress has more priority

than a valid IP address assignment).

Once the Genie is connected to a network, the Status LED will turn to steady blue when the IP address is assigned. Only at

this time will it be possible by the GigE Server or any application to communicate with the camera. The following table

summarizes the LED states and corresponding camera status.

LED State Definition

LED is off No power to the camera

Steady Red Initial state on power up before flashing.

Slow Flashing Red Initialization sequence in progress

Steady Red + Flashing Blue Fatal Error. If the Genie TS does not reboot itself contact Technical Support.

Slow Flashing Blue Ethernet cable disconnected. The camera continuously attempts to assign itself an IP address.

Fast Flashing Blue File Access Feature is transferring data such as a firmware update, FCC or LUT transfer, etc.

Steady Blue IP address assigned;

Steady Green Application connected

Flashing Green Acquisition in progress. Flashing occurs on frame acquisition but does not exceed a rate of

Remains as steady Red only if there is a fatal error. Camera is not initialized **

** In general there is no serious problem with the Genie hardware.

Wait a few minutes for the Genie to reboot itself.

no application connected to the camera

100ms for faster frame rates.

Note: Even if the Genie has obtained an IP address, it might be on a different subnet than the NIC it is attached to. Therefore, if the Genie

LED is blue but an application can not see it, this indicates a network configuration problem. See the troubleshooting section in this manual.

LED States on Power Up

The following LED sequence occurs when the Genie is powered up connected to a network with installed Genie Framework

software.

Red

power connected

Flashing Red

initialization

Flashing Blue

waiting for IP

Blue

IP assigned

Green

application

connected

Genie_TS_Series GigE Vision Camera Connecting the Genie TS Camera 17

Page 20

Genie IP Configuration Sequence

The Genie IP (Internet Protocol) Configuration sequence to assign an IP address is executed automatically on camera powerup or when connected to a network. As a GigE Vision compliant device, Genie attempts to assign an IP address as follows.

For any GigE Vision device, the IP configuration protocol sequence is:

Persistent IP (if enabled)

DHCP (if a DHCP server is present such as the Teledyne DALSA Smart DHCP server)

Link-Local Address (always enabled)

The factory defaults for Genie is Persistent IP disabled and DHCP enabled with LLA always enabled as per the GigE Vision

specification. For additional information see "Genie IP Configuration Mode Details" on page 87.

Supported Network Configurations

The Genie obtains an IP address using the Link Local Address (LLA) or DHCP, by default. A LLA IP address is obtained in

about 6 seconds with Microsoft Vista/7 or in about 1 minute with Microsoft XP. If required, a persistent IP address can be

assigned (see "Running the Network Configuration Tool" on page 22).

Preferably, a DHCP server is present on the network, where the Genie issues a DHCP request for an IP address. The DHCP

hen provides the Genie an IP address. The Teledyne DALSA Network Configuration tool, installed with the Teledyne

server t

DALSA Network Imaging Package, provides a DHCP server which is easily enabled on the NIC used with the Genie TS

(refer to the Teledyne DALSA Network Imaging Package user's manual).

The LLA method, if used, automatically assigns the Genie with a randomly chosen address on the 169.254.xxx.xxx subnet.

After an address is chosen, the link-local process sends an ARP query with that IP onto the network to see if it is already in

use. If there is no response, the IP is assigned to the device, otherwise another IP is selected, and the ARP is repeated. Note

that LLA is unable to forward packets across routers.

Preventing Operational Faults due to ESD

Genie camera installations which do not protect against ESD (electrostatic discharge) may exhibit operational faults.

Problems such as random packet loss, random camera resets, and random loss of Ethernet connections, may all be solved by

proper ESD management.

The Genie camera when used with a simple power supply and Ethernet cable, is not properly connected to earth ground and

therefore is susceptible to ESD caused problems. An Ethernet cable has no ground connection and a power supply's 0 volt

return line is not necessarily connected to earth ground.

Teledyne DALSA has performed ESD testing on Genie cameras using an 8 kilovolt ESD generator without any indication of

operational faults. The two following methods, either individually or together will prevent ESD problems.

Method 1: Use a shielded power supply and/or Ethernet cable where the shield is connected to earth ground at the

supply end and to the Genie end. The Genie case is now properly connected to earth ground and can withstand ESD of 8

kilovolts, as tested by Teledyne DALSA.

Method 2: Mount the Genie camera on a metallic platform which has a good connection to earth ground.

18 Connecting the Genie TS Camera Genie_TS_Series GigE Vision Camera

Page 21

Using Genie TS with Sapera API

A Genie camera installation with Teledyne DALSA Sapera API generally follows the sequence described below. Detailed

installation instructions follow this overview.

Network and Computer Overview

Genie needs to connect to a computer with a GigE network adapter, either built in on the computer motherboard or

installed as a third party PCI adapter. See the previous section Connecting the Genie TS Camera.

Laptop computers with

especially when on battery power. Thorough testing is required with any laptop computer to determine the maximum

frame rate possible (refer to the Teledyne DALSA Network Imaging Package user's manual).

Genie also can connect through a Gigabit Ethernet switch. When using VLAN groups, the Genie and controlling

computer must be in the same group (refer to the Teledyne DALSA Network Imaging Package user's manual).

If Genie is to be used in a Sapera development environment, Sapera LT needs to be installed, either before or after the

Genie software package. If Genie will be used in a GigE Vision Compliant environment, Sapera or Sapera runtime is not

required and you need to follow the installation instructions of the third party package.

Install the Genie Framework software package if not using a third party GigE Vision compliant package. Also install

Sapera Run-time with CamExpert to control the Genie.

The Windows Firewall exceptions feature is automatically configured to allow the Sapera GigE Server to pass through

the firewall.

Computers with VPN software (virtual private network) may need to have the VPN driver disabled in the NIC

properties. This would be required only on the NIC used with the Genie. Testing by the user is required.

Once a Genie is connected, look at the small camera icon added to the Windows tray (next to the clock). Ensure the

Genie camera has been found (right click the icon and select Status) Note that in Windows 7, the icon remains hidden

until a camera is connected.

A new Genie installation may require a firmware update. The File Selector

the CamExpert procedure "File Access via the CamExpert Tool" on page 85 fo

Use CamExpert (installed either with Sapera or Sapera runtime) to test the installation of the Genie camera. Set the

Genie to internal test pattern. See "Internal Test Image Generator" on page 68.

Set

up the other components of the imaging system such as light sources, camera mounts, optics, encoders, trigger

sources, etc. Test with CamExpert.

built in GigE network adapters may still not be able to stream full frame rates from Genie,

feature is used to select a firmware file. See

r additional information.

Genie_TS_Series GigE Vision Camera Using Genie TS with Sapera API 19

Page 22

Sapera LT Library Windows Installation

Note: to install Sapera LT and the Genie device driver, logon to the workstation as an administrator or with an account that has

administrator privileges.

When Sapera application development is performed on the same computer that the Genie is connected to, the Sapera

Development Library (version 7.20 or later) must be installed. Else, Sapera LT SDK is not required to control the Genie

camera.

Download the Teledyne DALSA Sapera package or insert the Teledyne DALSA Sapera CD-ROM. Run the executable

file to start the installation.

The installation program will prompt you to reboot the computer.

Continue with the Genie TS Framework Installation described next.

Refer to Sapera LT User’s M

anual concerning application development with Sapera.

Genie TS Framework Installation

The Genie TS Framework software package and Sapera runtime provides all components required to control the Genie with

the supplied CamExpert tool. The Genie TS Framework includes the Network Imaging package (refer to the Teledyne

DALSA Network Imaging package manual).

Do not install the Network Imaging package if a third-party GigE Vision network driver is used and the user does not need

CamExpert.

Note: The Teledyne DALSA Sapera CamExpert tool (used throughout this manual to describe Genie TS GigE Vision features) is installed

with either the Sapera LT runtime or the Sapera LT development package. If Sapera application development is required, install Sapera

(7.20 or later) as described in the previous section.

Procedure

Download the Genie TS Framework package and install the Genie Framework Software which includes the Network

Imaging driver, and the Sapera GigE server.

The procedure will prompt for acceptance of the installation folder for the Genie files.

Optional: If the Teledyne DALSA Sapera LT SDK package is not used, click to install Sapera LT run-time only which

includes CamExpert. Follow the on screen prompts and reboot when the installation is complete.

Camera Firmware Updates

A Genie TS Framework installation includes the latest camera firmware file. The default folder and an example firmware file

is shown below. The user can upload new firmware using the File Access Control

[]:\Program Files\Teledyne DALSA\Genie TS\Firmwares\GenieTS_Mono-5M_8M_12M_STD-Firmware_3CA10.21.cbf

20 Using Genie TS with Sapera API Genie_TS_Series GigE Vision Camera

features as shown by CamExpert.

Page 23

Application Development Header Files

Teledyne DALSA provides header files for developers managing Genie TS LUT data and chunk payload data as supported

by GigE Vision 1.2. These files are installed by default in the folder [drv]:\Program Files\Teledyne DALSA\Genie

TS\Developer Support Files\.

These files are:

dalsa_genie_lut.h: Defines the structure for a user LUT data file.

dalsa_genie_chunk_payload.h: Used to capture the raw fields of the extended chunk metadata from the stream.

dalsa_genie_chunk_extract.h: This is passed the raw chunk data and fills in a data structure allowing access to the

metadata parameters.

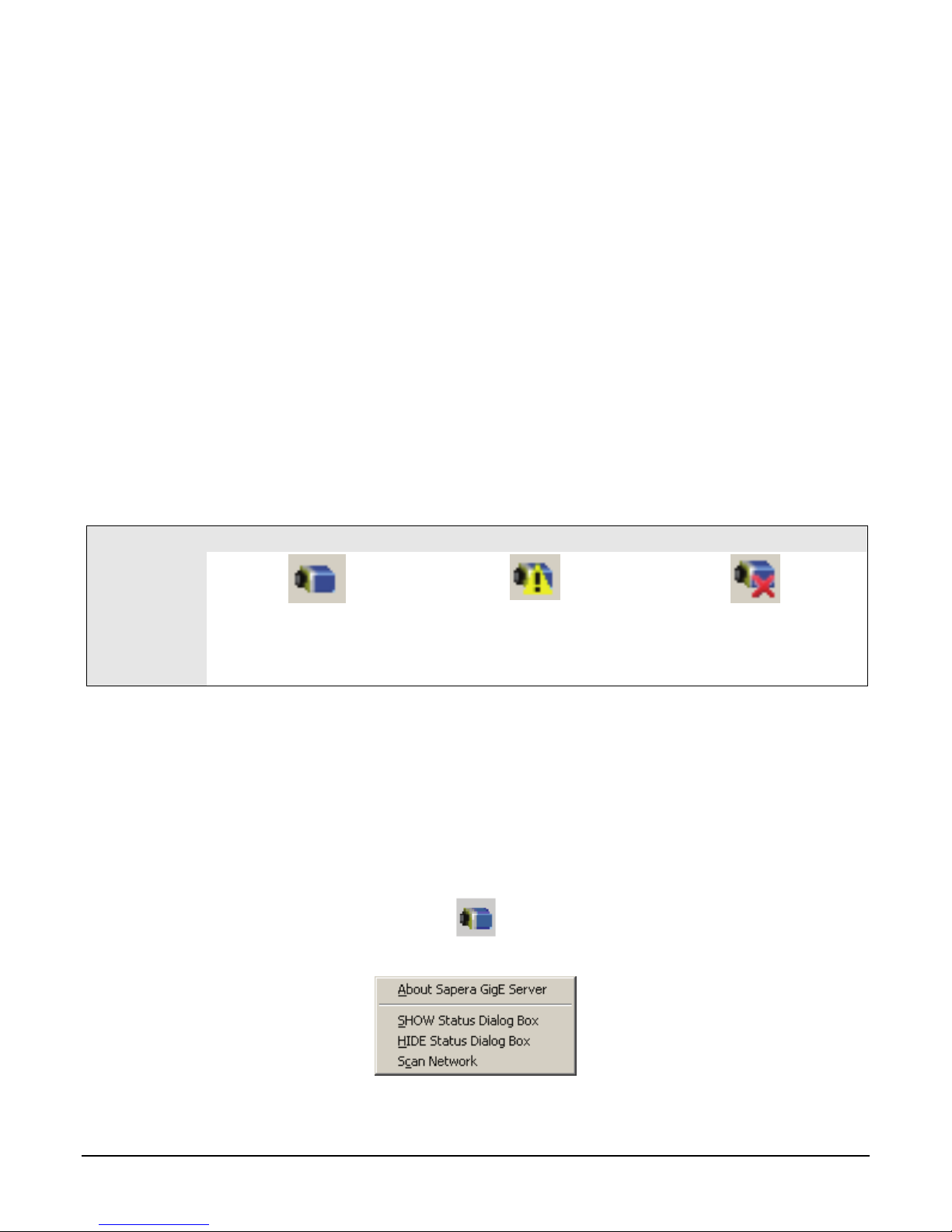

GigE Server Verification

After a successful Genie TS Framework package installation, the GigE Server icon is visible in the desktop taskbar tray area

(note that in Windows 7 the icon remains hidden until a camera is connected). After connecting a camera (see following

section), allow a few seconds for the GigE Server status to update. The Genie camera must be on the same subnet as the NIC

to be recognized by the GigE Server.

Device Available Device IP Error Device Not Available

GigE Server

Tray Icon:

The normal GigE server tray icon when

the Genie device is found. It will take a

few seconds for the GigE Server to

refresh its state after the Genie has

obtained an IP address.

The GigE server tray icon shows a

warning when a device is connected but

there is some type of IP error.

A red X will remain over the GigE server

tray icon when the Genie device is not

found. This indicates a major network

issue. Or in the simplest case, the Genie

is not connected.

If you place your mouse cursor on this icon, the GigE Server will display the number of GigE Vision devices found by your

PC. Right click the icon and select status to view information about those devices. See "Running the Network Configuration

" on page 22 and "Troubleshooting" on page 107for m

Tool

ore information.

GigE Server Status

Once the Genie is assigned an IP address (its Status LED is steady blue) the GigE server tray icon will not have a red X

through it, indicating that the Genie device was found. It might take a few seconds for the GigE Server to refresh its state

after the Genie has obtained an IP address.

Right-click the GigE Server tray icon to open the following menu.

Genie_TS_Series GigE Vision Camera Using Genie TS with Sapera API 21

Page 24

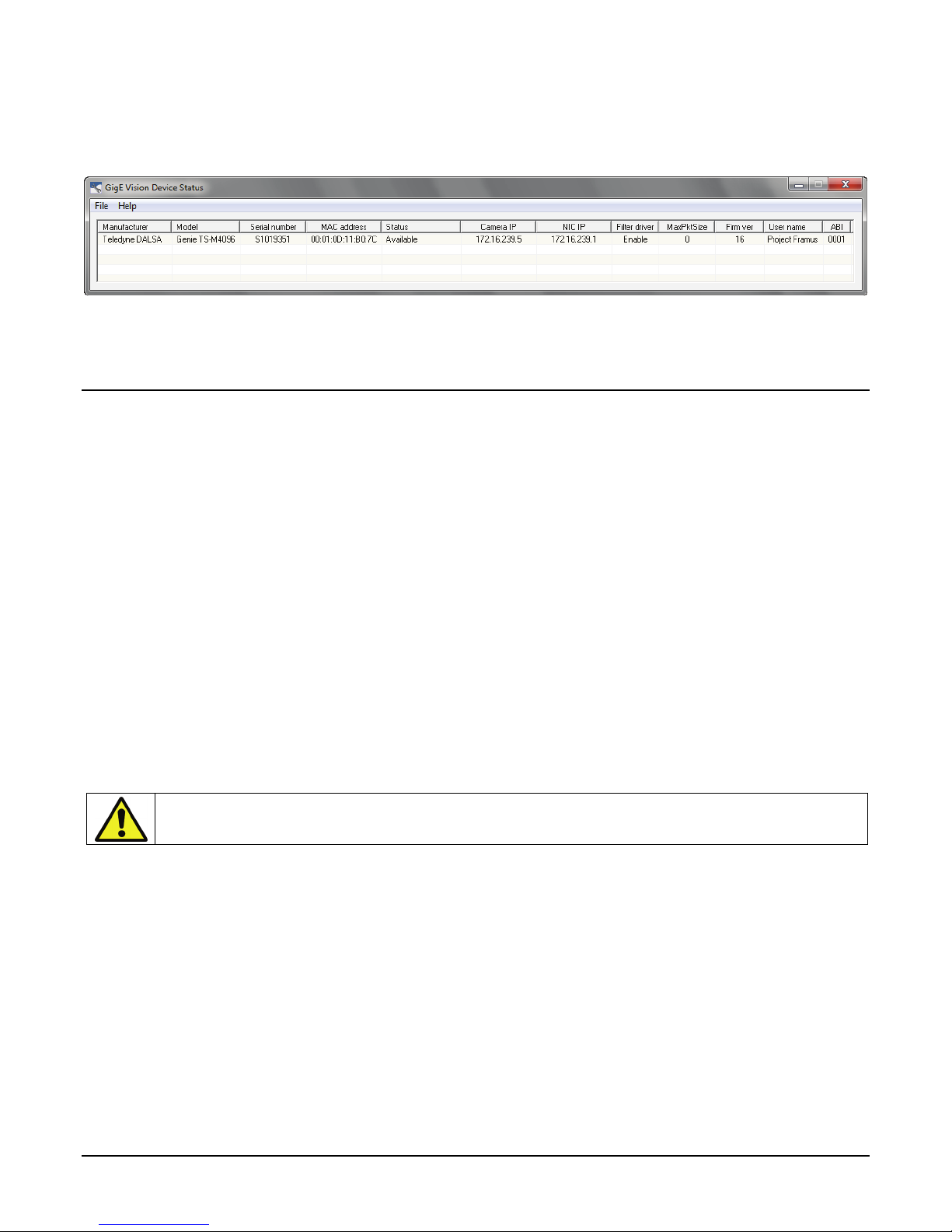

Click on Show Status to open a window listing all devices connected to the host system. Each GigE device is listed by name

along with important information such as the assigned IP address and device MAC address. The screen shot below shows a

connected Genie with no networking problems.

In the event that the device is physically connected, but the Sapera GigE Server icon is indicating that the connected device

is not recognized, click Scan Network to restart the discovery process. Note that the GigE server periodically scans the

network automatically to refresh its state. See "Troubleshooting" on page 107 for net

work problems.

Optimizing the Network Adapter used with Genie

Most Gigabit network interface controllers (NIC) allow user modifications to parameters such as Adapter Buffers and Jumbo

Frames. These should be optimized for use with the Genie during the installation. Refer to the Teledyne DALSA Network

Imaging package manual for optimization information.

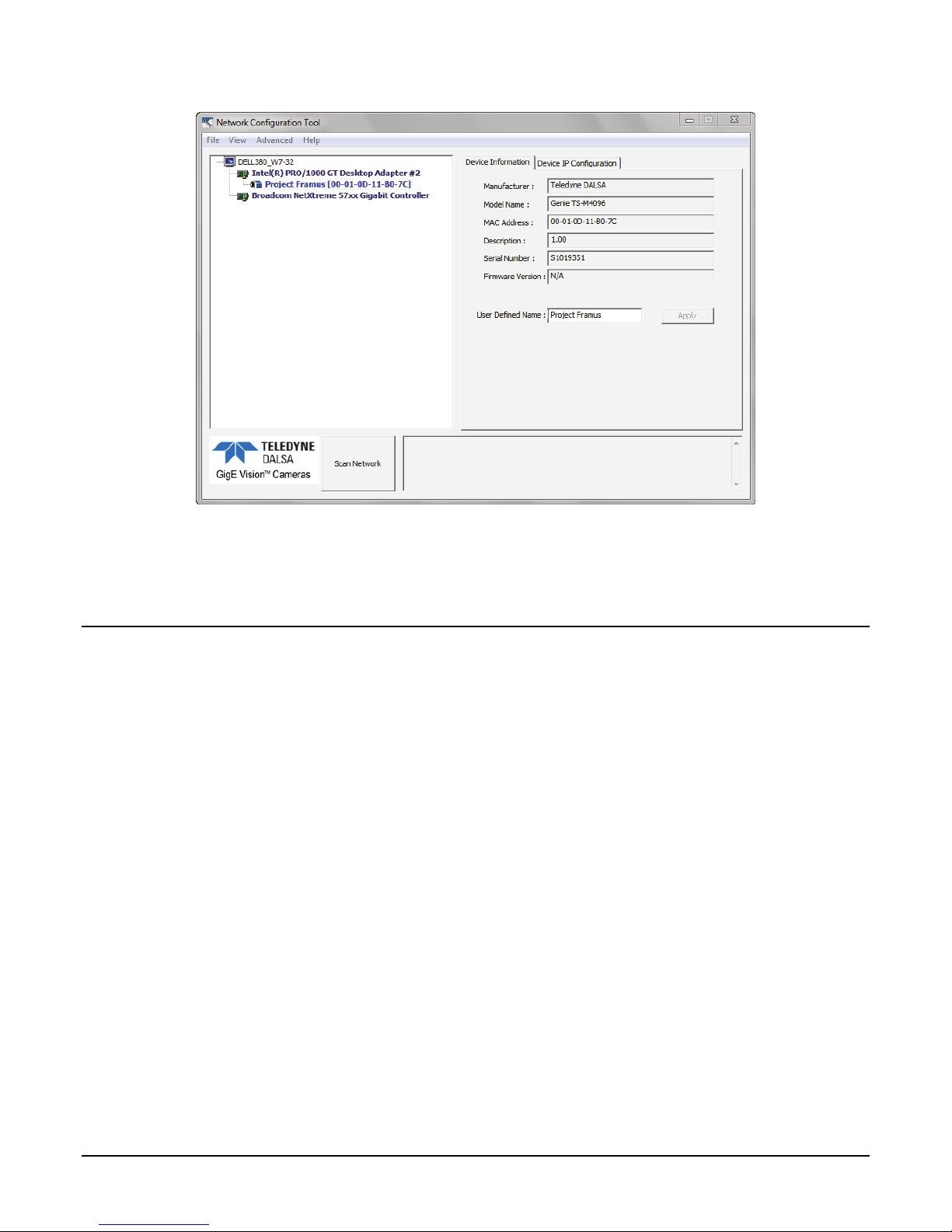

Running the Network Configuration Tool

The Network Configuration tool provides information and parameter adjustments for network adapters installed in the

system and any connected GigE Vision camera without use of any Windows Control Panel application. This tool allows you

to:

Activate the Network Imaging driver use for image acquisition on any NIC or disable the imaging driver for any

NIC not used with a GigE Vision camera.

Change the Auto Discovery Interval from the default of 15 seconds.

Verify that the GigE Server is in the Windows firewall exception list.

Configure the NIC and camera IP settings.

Assign a User-Defined name to a connected camera.

Assign a Persistent IP address to a camera instead of the default DHCP/LLA assigned address.

Easily Configure the NIC as a DHCP server for connected GigE Vision camera.

Important: Changes made with this tool may update Genie parameters stored in flash memory. Do not remove power from the Genie

camera for a minimum 10 seconds.

Refer to the Teledyne DALSA Network Imaging Module manual for more detailed information on using this tool. As shown

below, the Network Configuration tool can quickly verify and modify the network configuration of the imaging system.

22 Using Genie TS with Sapera API Genie_TS_Series GigE Vision Camera

Page 25

Run the tool from the Windows Start menu: Start•Programs•Teledyne DALSA Sapera Network Imaging Package•Dalsa

Network Configuration Tool. Verify the camera appears as a child of the NIC card it is connected to. By default the Genie

camera is identified by its serial number if no user-defined name has been assigned.

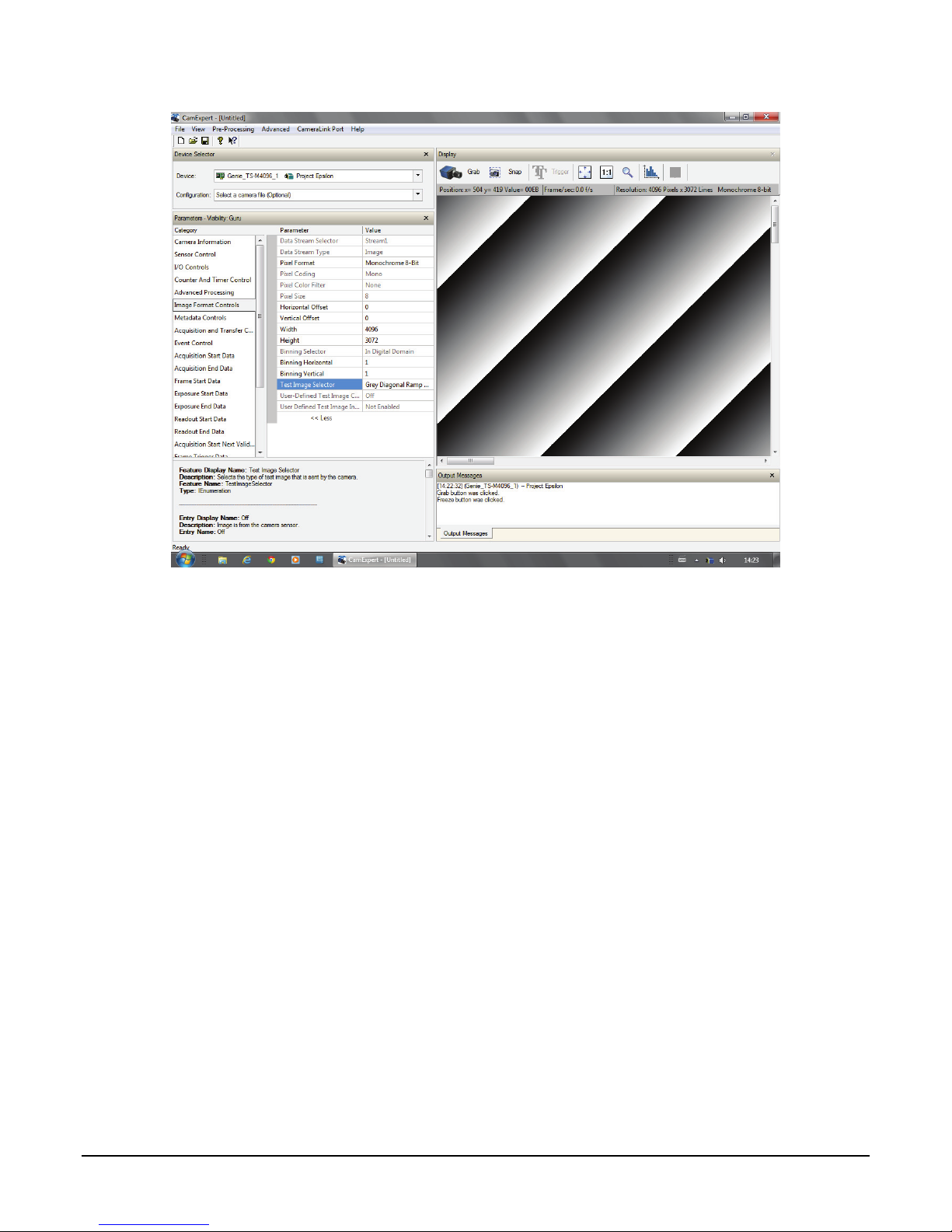

Quick Test with CamExpert

When the Genie TS camera is connected to a Gigabit network adapter on a host computer, testing the installation with

CamExpert is a straightforward procedure.

Start Sapera CamExpert by double clicking the desktop icon created during the Genie software installation.

CamExpert will search for installed Sapera devices. In the Device list area on the left side, the connected Genie camera

is shown or will be listed in a few seconds after CamExpert completes the automatic device search (device discovery).

Select the Genie camera device by clicking on the camera user-defined name. By default the Genie camera is identified

by its serial number. The Genie status LED will turn green, indicating the CamExpert application is now connected.

Click on the Grab button for live acquisition (the Genie default is Free Running mode). Focus and adjust the lens iris.

See "Operational Reference" on page 27 for inform

If the Genie has no lens, just select one of the internal test patterns available. All but one are static images to use with the

Snap or Grab function of CamExpert. The single “moving” test image is a shifting diagonal ramp pattern, which is

useful for testing network/computer bandwidth issues. The CamExpert feature selection and the grabbed pattern are

shown below.

Refer to the Teledyne DALSA Network Imaging package manual if error messages are shown in the Output Messages

pane. But first, increase the value of the Genie Interpacket Delay feature available from the GigE Vision Transport

Layer Category group in CamExpert. An increase from default may correct errors with NIC interfaces that do not have

adequate performance.

ation on CamExpert parameters with the Genie camera.

Genie_TS_Series GigE Vision Camera Using Genie TS with Sapera API 23

Page 26

About the User-Defined Camera Name

The Genie can be programmed with a user-defined name to aid identifying multiple cameras connected to the network. For

instance, on an inspection system with 4 cameras, the first camera might be labeled “top view”, the second “left view”, the

third “right view” and the last one “bottom view”. The factory default user name is set to match the camera serial number for

quick initial identification. Note that the factory programmed Genie TS serial number and MAC address are not user

changeable.

When using CamExpert, multiple Genie TS cameras on the network are seen as different "Genie_TS-xxxxx" devices as an

example. Non Teledyne DALSA cameras are labeled as “GigEVision Device”. Click on a device user name to select it for

control by CamExpert.

An imaging application uses any one of these attributes to identify a camera: its IP address, MAC address, serial number or

User Name. Some important considerations are listed below.

Do not use the camera's IP address as identification (unless it is a persistent IP) since it can change with each power

cycle.

A MAC address is unique to a single camera, therefore the control application is limited to the vision system with that

unique camera if it uses the camera's MAC address.

The User Name can be freely programmed to clearly represent the camera usage. This scheme is recommended for an

application to identify cameras. In this case, the vision system can be duplicated any number of times with cameras

identified by their function, not their serial numbers or MAC address.

24 Using Genie TS with Sapera API Genie_TS_Series GigE Vision Camera

Page 27

Silent Installation of Genie Framework

The Genie TS Framework installation can be integrated within a developer's installation procedure. The silent installation

mode allows the Genie Framework installation to proceed without the need for mouse clicks from a user.

Two steps are required:

Preparation of a response file to emulate a user.

Invoking the Genie Framework installer with command options to use the prepared response file.

Creating the Response File

An installer response file is created by performing a Genie Framework installation with the command line switch "-r". The

response file is automatically named setup.iss which is saved in the \windows folder. One simple method is to execute the

Framework installer from within a batch file. The batch file will have one command line.

As an example, using the possible executable file name for the Framework, the command line is:

"Genie_TS_1.00.00.0000 Release.exe" –r

Important: The executable name is enclosed in quotation marks. This is required because of the space characters in the Genie

Framework file name.

Running a Silent Mode Installation

A Genie Framework silent installation, whether done alone or within a larger software installation requires the Genie

Framework executable and the generated response file setup.iss.

Execute the Framework installer with the following command line:

"Genie_TS_1.00.00.0000 Release.exe" -s -f1".\setup.iss"

where in this example, the switch –f1".\setup.iss" specifies that the setup.iss file is in the same folder as the Framework

installer.

Genie_TS_Series GigE Vision Camera Using Genie TS with Sapera API 25

Page 28

Windows Embedded 7 Installation

Windows Embedded 7 is not officially supported by Teledyne DALSA due to the number of possible configurations.

However, Sapera LT and other Teledyne DALSA products should function properly on the Windows Embedded 7 platform

provided that the required components are installed.

Teledyne DALSA provides answer files (.xml) for use during Windows Embedded 7 installation that install all necessary

components for running Sapera LT 32-bit or 64-bit versions (SDK or Runtime), Sapera Processing 32-bit or 64-bit versions

(SDK or Runtime), Teledyne DALSA framegrabbers or Genie GigE Vision devices.

For each platform (32 or 64-bit), the answer file is provided:

SaperaGenie.xml: Configuration for Sapera LT, Sapera Processing and Teledyne DALSA Genie devices

These files are located in the following directories:

<Install Directory>\Sapera\Install\Win7_Embedded\Win32

<Install Directory>\Sapera\Install\Win7_Embedded\Win64

The OS footprint for these configurations is less than 1 GB. Alternatively, the Windows Thin Client configuration template

provided by Microsoft in the Windows Embedded 7 installation also provides the necessary dependencies for Sapera LT,

Teledyne DALSA framegrabbers and Genie devices (with an OS footprint of approximately 1.5 GB).

If you are installing other applications on the Windows Embedded 7 platform, it is recommended that you verify which

components are required, and if necessary, create a corresponding Answer File.

For more information on performing dependency analysis to enable your application on Windows Embedded 7, refer to the

Microsoft Windows Embedded 7 documentation.

26 Using Genie TS with Sapera API Genie_TS_Series GigE Vision Camera

Page 29

Operational Reference

Using CamExpert with Genie TS Cameras

The Sapera CamExpert tool is the interfacing tool for GigE Vision cameras, and is supported by the Sapera library and

hardware. When used with a Genie TS camera, CamExpert allows a user to test most of the operating modes. Additionally

CamExpert saves the Genie user settings configuration to the camera or saves multiple configurations as individual camera

parameter files on the host system (*.ccf).

An important component of CamExpert is its live acquisition display window which allows immediate verification of timing

or control parameters without the need to run a separate acquisition program.

Click on any parameter and a short description is displayed below the Category pane. The same context sensitive help is

available by clicking on the

help file for more descriptive information on CamExpert.

button then click on a camera configuration parameter. Click on the button to open the

CamExpert Panes

The various areas of the CamExpert tool are described in the summary figure below. GigE Vision device Categories and

Parameter features are displayed as per the device’s XML description file. The number of parameters shown is dependent on

the View mode selected (Beginner, Expert, Guru – see description below).

Genie_TS_Series GigE Vision Camera Operational Reference 27

Page 30

Device pane: View and select from any installed GigE Vision or Sapera acquisition device. After a device is selected

CamExpert will only present parameters applicable to that device.

Parameters pane: Allows viewing or changing all acquisition parameters supported by the acquisition device.

CamExpert displays parameters only if those parameters are supported by the installed device. This avoids confusion by

eliminating parameter choices when they do not apply to the hardware in use.

Display pane: Provides a live or single frame acquisition display. Frame buffer parameters are shown in an information

bar above the image window.

Control Buttons: The Display pane includes CamExpert control buttons. These are:

28 Operational Reference Genie_TS_Series GigE Vision Camera

Page 31

Acquisition control button:

Click once to start live grab, click again to stop.

Single frame grab:

Click to acquire one frame from device.

Software trigger button:

With the I/O control parameters set to Trigger Enabled / Software Trigger type, click to send a

single software trigger command.

CamExpert display controls:

(these do not modify the frame buffer data)

Stretch (or shrink) image to fit, set image display to original size, or zoom the image to any size

and ratio. Note that under certain combinations of image resolution, acquisition frame rate, and

host computer speed, the CamExpert screen display may not update completely due to the host

CPU running at near 100%. This does not affect the acquisition.

Histogram / Profile tool:

Select to view a histogram or line/column profile during live acquisition.

Output pane: Displays messages from CamExpert or the GigE Vision driver.

CamExpert View Parameters Option

All camera features have a Visibility attribute which defines its requirement or complexity. The states vary from Beginner

(features required for basic operation of the device) to Guru (optional features required only for complex operations).

CamExpert presents camera features based on their visibility attribute. CamExpert provides quick Visibility level selection

via controls below each Category Parameter list [ << Less More>> ]. The user can also choose the Visibility level from the

View · Parameters Options menu.

Camera Information Category

Camera information can be retrieved via a controlling application. Parameters such as camera model, firmware version, etc.

are read to uniquely identify the connected Genie device. These features are typically read-only. GigE Vision applications

retrieve this information to identify the camera along with its characteristics.

The Camera Information Category groups information specific to the individual GigE Vision camera. In this category the

number of features shown are identical whether the view is Beginner, Expert, or Guru.

Features listed in the description table but tagged as Invisible are usually for Teledyne DALSA or third party software

usage—not typically needed by end user applications.

Genie_TS_Series GigE Vision Camera Operational Reference 29

Page 32

Camera Information Feature Descriptions

The following table describes these parameters along with their view attribute and in which device version the feature was

introduced. Additionally the Device Version column will indicate which parameter is a member of the DALSA Features

Naming Convention (using the tag DFNC), verses the GenICam Standard Features Naming Convention (SFNC not shown).

The Device Version number represents the camera software functional group, not a firmware revision number. As Genie TS

capabilities evolve the device version tag will increase, therefore identifying the supported function package.

Display Name Feature Description Device Version

& View

Manufacturer Name DeviceVendorName Displays the device vendor name. (RO) 1.00

Model Name DeviceModelName Displays the device model name. (RO) 1.00

Device Version DeviceVersion Displays the device version. This tag will also highlight if

Manufacturer Info DeviceManufacturerInfo This feature provides extended manufacturer information

Firmware Version DeviceFirmwareVersion Displays the currently loaded firmware version number.

Serial Number DeviceID Displays the device’s factory set camera serial number.

MAC Address deviceMacAddress Displays the unique MAC (Media Access Control) address

Device User ID DeviceUserID Feature to store a user-programmable identifier of up to 15

Device Built-In Self Test deviceBIST Command to perform an internal test which will determine

Device Built-In Self Test

Status

Passed

Last firmware update failed

deviceBISTStatus Determine the status of the device using the ‘Built-In Self

Passed

FirmwareUpdateFailure

the firmware is a beta or custom design. (RO)

about the device. (RO)

Firmware files have a unique number and have the .cbf file

extension. (RO)

(RO)

of the Device. (RO)

characters. The default factory setting is the camera serial

number. (RW)

the device status. (W)

Test’. Possible return values are device-specific. (RO)

No failure detected.

Last firmware update failed.

Beginner

Beginner

1.00

Beginner

1.00

Beginner

1.00

Beginner

1.00

Beginner

1.00

DFNC

Beginner

1.00

Beginner

1.00

DFNC

Beginner

1.00

DFNC

Beginner

30 Operational Reference Genie_TS_Series GigE Vision Camera

Page 33

Device Reset DeviceReset Resets the device to its power up state. (W) 1.00

Power-up Configuration

Selector

Factory Setting

UserSet1

UserSet2

User Set Selector UserSetSelector Selects the camera configuration set to load feature settings

Factory Setting

UserSet 1

UserSet 2

Load Configuration UserSetLoad Loads the camera configuration set specified by the User

Save Configuration UserSetSave Saves the current camera configuration to the user set

Device Acquisition Type deviceAcquisitionType Displays the Device Acquisition Type of the product. (RO)

Sensor Sensor The device gets its data directly from a sensor.

DFNC Major Rev deviceDFNCVersionMajor Major revision of Dalsa Feature Naming Convention which

DFNC Minor Rev deviceDFNCVersionMinor Minor revision of Dalsa Feature Naming Convention which

SFNC Major Rev DeviceSFNCVersionMajor Major Version of the Standard Features Naming

SFNC Minor Rev DeviceSFNCVersionMinor Minor Version of the Standard Features Naming

SFNC SubMinor Rev DeviceSFNCVersionSubMinor SubMinor Version of the Standard Features Naming