Teledyne THCD-101 Instruction Manual

INSTRUCTION MANUAL

ISO 9001

CERTIFIED

www.teledyne-hi.com

THCD-101

Manual Print History

The print history shown below lists the printing dates of all revisions created for this manual. The revision level

letter increases alphabetically as the manual undergoes subsequent updates. Each new revision includes a

revised copy of this print history page.

Revision A (Document Number 181-122018) ................................................................................ December 2018

Visit www.teledyne-hi.com for WEEE disposal guidance.

Description of Symbols and Messages used in this manual

WARNING: indicates a hazardous situation, which, if not avoided, could result in death or

serious injury. Do not proceed beyond a WARNING notice until the indicated conditions are

fully understood.

CAUTION: indicates a hazardous situation, which if not avoided, could result in minor or

moderate injury. Do not proceed beyond a CAUTION notice until the indicated conditions are

fully understood and met.

NOTICE: calls attention to a procedure or practice that if not correctly performed or adhered

to, could result in equipment damage, loss of data, or inaccurate data.

NOTE: is used for tips and other digressions.

Hastings Instruments reserves the right to change or modify the design of its equipment without any obligation

181-122018_THCD-101 Instruction Manual Page 2 of 26

to provide notification of change or intent to change.

Table of Contents

1. GENERAL INFORMATION .................................................................................................... 5

FEATURES .................................................................................................................. 6

SPECIFICATIONS ............................................................................................................ 6

ACCESSORIES ............................................................................................................... 7

1.3.1. Power Supplies ................................................................................................... 7

1.3.2. Cables ............................................................................................................. 7

2. INSTALLATION AND SETUP ................................................................................................. 8

RECEIVING INSPECTION ..................................................................................................... 8

MECHANICAL CONNECTIONS ................................................................................................ 8

2.2.1. Mounting .......................................................................................................... 8

ELECTRICAL CONNECTIONS ................................................................................................. 9

2.3.1. Transducer socket Pinout – 15 Pin 'D' Connector ........................................................... 9

2.3.2. Interface Socket Pinout – 15 Pin HD 'D' Connector ...................................................... 10

2.3.3. USB Connector – USB Type-C ................................................................................ 10

2.3.4. Power Input Jack .............................................................................................. 10

3. OPERATION .................................................................................................................. 11

FEATURES ................................................................................................................ 11

3.1.1. Analog Input .................................................................................................... 11

3.1.2. Setpoint Control ............................................................................................... 11

3.1.3. User Rezero ..................................................................................................... 11

3.1.4. Adaptive Filtering ............................................................................................. 12

3.1.5. Analog Output ................................................................................................. 12

3.1.6. Alarm Relays ................................................................................................... 12

FRONT PANEL INTERFACE ................................................................................................ 12

4. REMOTE COMMUNICATIONS .............................................................................................. 16

WEBSERVER .............................................................................................................. 16

4.1.1. Main page ....................................................................................................... 16

4.1.2. Live data ........................................................................................................ 16

4.1.3. Channel Configuration page ................................................................................. 16

4.1.4. Control Configuration page ................................................................................. 17

SERIAL & TCP COMMUNICATION ..................................................................................... 17

4.2.1. Introduction .................................................................................................... 17

4.2.2. Command/Query format ..................................................................................... 18

4.2.3. Main commands ................................................................................................ 18

4.2.4. Communication commands .................................................................................. 20

4.2.5. Channel Setup commands .................................................................................... 20

4.2.6. Filtering commands ........................................................................................... 21

181-122018_THCD-101 Instruction Manual Page 3 of 26

Relay control commands ..................................................................................... 21

4.2.7.

4.2.8. Other commands .............................................................................................. 21

4.2.1. Command Set Summary ...................................................................................... 22

5. TROUBLESHOOTING ....................................................................................................... 24

AUTHORIZED MAINTENANCE .............................................................................................. 24

TROUBLESHOOTING ...................................................................................................... 24

5.2.1. Instrument Lists and Codes .................................................................................. 24

5.2.2. Possible Problems and Solutions............................................................................ 24

6. WARRANTY .................................................................................................................. 25

WARRANTY POLICY ....................................................................................................... 25

RETURN POLICY .......................................................................................................... 25

7. DRAWINGS ................................................................................................................... 26

181-122018_THCD-101 Instruction Manual Page 4 of 26

1. General Information

The THCD-101 is a multi-featured process display controller, capable of interfacing directly to a mass flow

meter, mass flow controller or another process transducer such as the HVG-2020 Vacuum Transducer. The

THCD-101 is a single channel unit which can be used to power a bipolar (±15Vdc @ 300mA) or unipolar (24Vdc @

400mA) device. The THCD-101 can display the output from a transducer that supplies voltage signals up to 10

VDC or 4 – 20 mA current signals. There is also an input that can be used for external command (setpoint)

control (+10Vdc full scale). Digital interfaces to the THCD-100 include USB (Serial Port Emulation) and

Ethernet.

Hastings vacuum instruments do not require any periodic maintenance under normal operating conditions with

clean gases. No damage will occur from the use of moderate overpressures (< 25 psig).

The following sections contain the steps needed to get a new power supply operating as quickly and easily as

possible. Please read the following thoroughly before attempting to install the instrument.

NOTICE: The instruments described in this manual may be available with multiple pin-outs.

Ensure that all electrical connections are correct.

NOTICE: The instruments described in this manual are designed for INDOOR use only.

NOTICE: The instruments described in this manual are designed for Class 2 installations in

accordance with IPC standards.

CAUTION: There are no operator serviceable parts or adjustments inside the product.

CAUTION: If this equipment is used in a manner other than that specified, the protection

provided by the equipment may be impaired.

181-122018_THCD-101 Instruction Manual Page 5 of 26

Features

± (0.02% Reading + 0.01% FS) Accuracy. The displayed valued is a highly accurate representation of the

analog input value.

0-5 Vdc, 0-10 Vdc Set Point Via Front Panel Or Digitally (USB/Ethernet). The desired control setpoint can be

set locally or via a remote computer.

Dual Programmable Alarms with Relays. The THCD-101 provides two double throw relays with 2A (@30 Vdc)

switching capacity and 220Vdc max switching voltage.

USB, Ethernet and Analog Output (Standard). The THCD-101 has multiple ways to provide the user with a

remote indication of the controlled parameter.

6 Digit Graphical Display. The display provided with THCD-101 can provide the user simultaneous indications

of the magnitude of the controlled parameter, unit of measure, valve over-ride status and alarm status.

Specifications

WARNING: Do not operate instruments exceeding the specifications listed below. Failure to

heed this warning could result in serious personal injury and/or damage to the equipment.

Display Range: 6-digit value including decimal point, 99999 max value

Analog Input -10.8 Vdc → +10.8 Vdc, Input Impedance > 100 kΩ

Measurement Accuracy: ±(0.02% Reading + 0.01% FS)

Setpoint Output 0 – 10 Vdc, Accuracy ±(0.03% Reading + 0.01% FS)

Operating Temperature: 5°C to 60°C

Humidity: max 90 %RH @ 50°C, non-condensing

Power Requirements: 24 VDC ±5%, 600 mA minimum

Class 2 power 150 VA max fused

NOTICE: Use of an underpowered or under-voltage supply could result in equipment damage.

CE Mark EN55011, EN61326, EN61010

RoHS Compliant YES

Weight (approx.): 0.44 lb. (0.2 kg)

Dual Alarm Relays: 2A (@30 Vdc) switching capacity and 220Vdc max switching voltage

Connectors: 2.1 x 5.5mm bayonet-style power jack (power)

15-pin “D” connector (Transducer connection)

15-pin high density “D” connector (Relay connections)

USB type-C (virtual COM port for serial communications)

RJ45 (Ethernet communications)

181-122018_THCD-101 Instruction Manual Page 6 of 26

Accessories

1.3.1. Power Supplies

Hastings offers power supplies that convert 100, 115 or 230VAC to the 24Vdc voltage required to

operate the THCD-101 and have a circular power plug that will mate with the power jack on the back

of the THCD-101. 24VDC power supply (P/N 12-01-169).

1.3.2. Cables

Hastings offers interface cables to connect the THCD-101 up to Hastings 200/300 series flow

instruments with the standard 15 pin D Connector or the 9 pin D connector used on the 24 Volt versions

as well as the HVG-2020 series of vacuum gauges

±15 Vdc Flow Instruments – 15 pin D connector (std H Pinout)

Stock# Length

65-431 18 inches

65-576 4 feet

65-149 8 feet

65-148 25 feet

65-160 50 feet

65-193 100 feet

65-576-SPECIAL Custom Length cable

±15 Vdc Flow Instruments – 15 pin D connector (U Pinout)

Stock# Length

65-791 8 feet

65-791-99 Custom Length cable

24 Vdc Flow Instruments (includes D300B series) –9 pin D connector

Stock# Length

CB-AF-8-24VM 8 feet

CB-AF-xxx-24VM Custom Length cable

IP-67 Digital Flow Instruments – 12 pin Circular connector

Stock# Length

CB-12PCF-8-AM 8 feet

CB-12PCF-XXX-AM Custom Length cable

HVG-2020 – 9 pin D connector

Stock# Length

CB-AF-8-HVG9M 8 feet

CB-AF-xxx-HVG9M Custom Length cable

Digital AVC – 15 pin High Density D connector

Stock# Length

CB-DAVC-8-AM 8 feet

CB-DAVC-XXX-AM Custom Length cable

More information about the power supplies and cables can be found on the Hastings web site:

http://www.teledyne-hi.com

181-122018_THCD-101 Instruction Manual Page 7 of 26

2. Installation and Setup

This section contains the necessary steps to assist in getting a new vacuum gauge into operation as quickly and

easily as possible. Please read the following thoroughly before attempting to install the instrument.

Receiving Inspection

Prior to opening, inspect for obvious signs of damage to the shipment. Immediately advise the carrier who

delivered the shipment if any damage is suspected. If the shipment has arrived intact, carefully unpack the

gauge and any accessories that have been ordered. Check each component shipped with the packing list.

Ensure that all parts are present (i.e. gauge, power supply, cables, etc.). Optional equipment or accessories

will be listed separately on the packing list.

Mechanical Connections

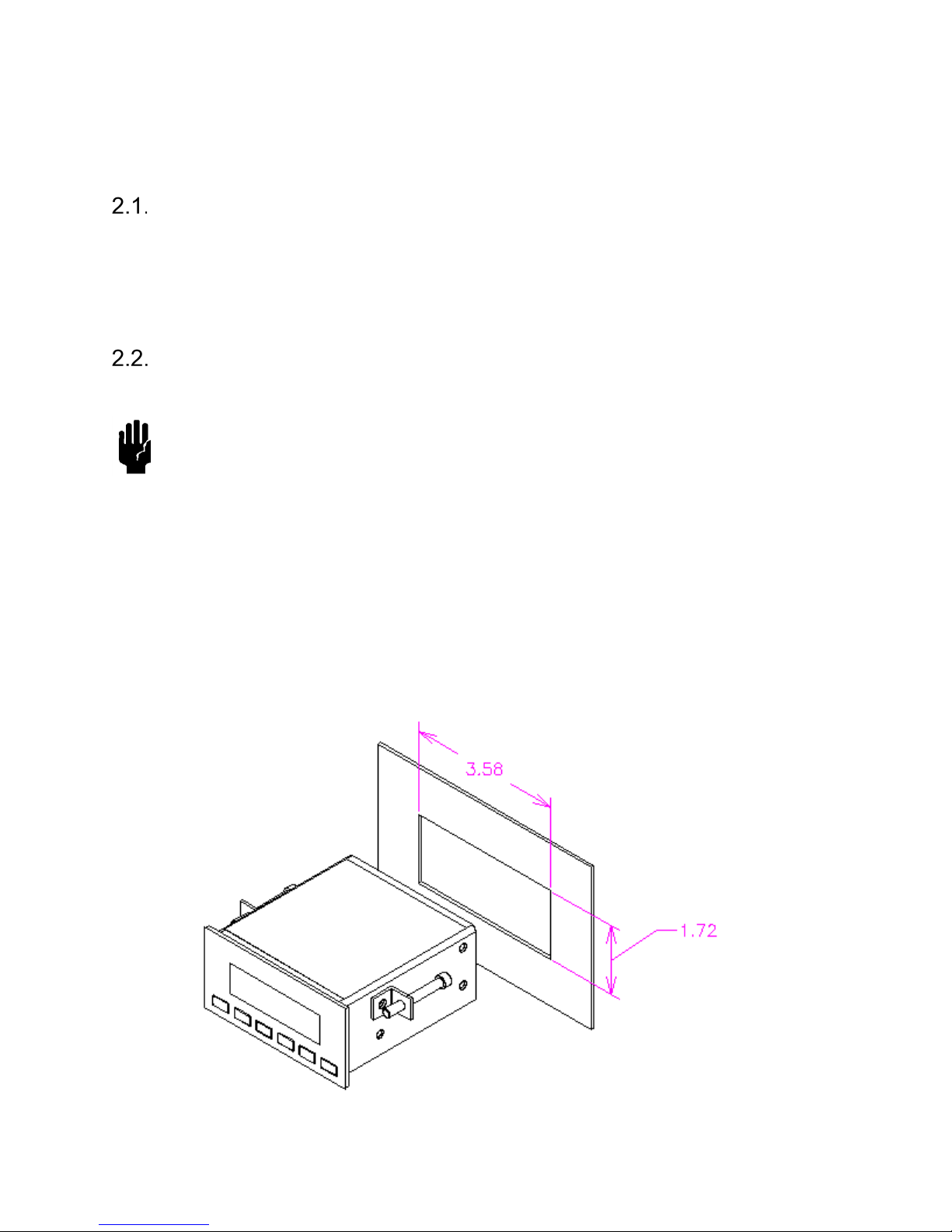

2.2.1. Mounting

NOTICE: The THCD-101 should be installed in a clean and careful manner. Take care not to drop the

product and avoid impacts to prevent damage.

The THCD-100 can be panel mounted, or used on a bench top and is a standard 96 x 48mm panel meter

enclosure. Note that the instrument must always be situated in such a way as to enable adequate air

circulation about the unit. If a transducer was supplied with the THCD-101, a suitable cable may have been

included.

A panel mount kit will have been supplied with the instrument. This consists of two screws (M3x6), two

brackets and two screws (50mm). Fit the M3x6 screws into the side of the unit into the diagonally opposed

holes. Do not tighten these screws, to allow the bracket to slide over the screw head. Thread locking adhesive

may be used but is not required, as these screws cannot rotate once the bracket is tightened. Insert the meter

into the panel. A cutout of 3.63” x 1.84” (92 x 45mm) is recommended. Slip the mounting bracket over the

screw head and tighten the 50mm screws. The unit should now be secure.

181-122018_THCD-101 Instruction Manual Page 8 of 26

Loading...

Loading...