Teledyne THCD-100 User Manual

TELEDYNE

HASTINGS

INSTRUMENTS

INSTRUCTION MANUAL

THCD-100

CONFIGURABLE DISPLAY

ISO 9001

CERTIFIED

Manual Print History

The print history shown below lists the printing dates of all revisions and addenda created for this manual.

The revision level increases alphabetically as the manual undergoes subsequent updates. Addenda, which are

released between revisions, contain important change information that the user should incorporate

immediately into the manual. Addenda are numbered sequentially. When a new revision is created, all

addenda associated with the previous revision of the manual are incorporated into the new revision of the

manual. Each new revision includes a revised copy of this print history page.

Revision A (165-072011)....................................................................................................July 2011

Visit www.teledyne-hi.com for WEEE disposal guidance.

Please read this manual carefully before using the instrument.

Use of this equipment in a manner not specified in this

manual may impair the user’s protection.

Hastings Instruments reserves the right to change or modify the design of its equipment without

any obligation to provide notification of change or intent to change.

165-072011 THCD-100 Power Supply Page 2 of 28

Table of Contents

1. GENERAL INFORMATION............................................................................................................................................ 4

1.1. FEATURES.................................................................................................................................................................... 4

1.2. SPECIFICATIONS...........................................................................................................................................................4

2. INSTALLATION AND INTERCONNECTIONS........................................................................................................... 5

2.1. INSTALLATION .............................................................................................................................................................5

2.2. TRANSDUCER SOCKET PINOUT – 15 PIN 'D' TYPE.........................................................................................................5

2.3. INTERFACE SOCKET PIN OUT – MINIATURE 15 PIN 'D' TYPE ........................................................................................6

2.4. SERIAL INTERFACE SOCKET PINOUT – 9 PIN 'D' TYPE..................................................................................................6

2.5. POWER CONNECTION SOCKET ..................................................................................................................................... 7

2.6. PANEL MOUNTING ....................................................................................................................................................... 7

3. FEATURES......................................................................................................................................................................... 8

3.1. INTRODUCTION ............................................................................................................................................................8

3.2. ANALOG INPUTS ..........................................................................................................................................................8

3.3. ANALOG OUTPUTS.......................................................................................................................................................8

3.4. SETPOINT CONTROL.....................................................................................................................................................8

3.5. USER RE-ZERO.............................................................................................................................................................9

3.6. ADAPTIVE FILTERING .................................................................................................................................................. 9

4. FRONT PANEL OPERATION....................................................................................................................................... 11

4.1. INTRODUCTION ..........................................................................................................................................................11

4.2. COMMON SWITCH FUNCTIONS................................................................................................................................... 11

4.3. FRONT PANEL SCREENS............................................................................................................................................. 12

5. SERIAL COMMUNICATION........................................................................................................................................ 17

5.1. INTRODUCTION ..........................................................................................................................................................17

5.2. COMMAND/QUERY FORMAT...................................................................................................................................... 17

5.3. MAIN COMMANDS .....................................................................................................................................................18

5.4. SERIAL COMMANDS................................................................................................................................................... 20

5.5. CHANNEL SETUP COMMANDS.................................................................................................................................... 21

5.6. FILTERING COMMANDS.............................................................................................................................................. 21

5.7. RELAY CONTROL COMMANDS................................................................................................................................... 22

OTHER COMMANDS.................................................................................................................................................................. 23

6. SERVICE & CALIBRATION......................................................................................................................................... 24

6.1. SERVICE.....................................................................................................................................................................24

6.2. ANALOG INPUTS ........................................................................................................................................................24

6.3. CLEANING..................................................................................................................................................................24

6.4. END OF LIFE............................................................................................................................................................... 24

7. APPENDICES................................................................................................................................................................... 25

7.1. APPENDIX A............................................................................................................................................................... 25

7.2. APPENDIX B...............................................................................................................................................................26

7.3. APPENDIX C...............................................................................................................................................................27

8. WARRANTY .................................................................................................................................................................... 28

8.1. WARRANTY REPAIR POLICY ......................................................................................................................................28

8.2. NON-WARRANTY REPAIR POLICY ............................................................................................................................. 28

165-072011 THCD-100 Power Supply Page 3 of 28

1. GENERAL INFORMATION

The THCD-100 is a multi featured process display controller, capable of interfacing directly to a mass flow meter,

mass flow controller or another process transducer such as the THPS-760S Vacuum Transducer. The THCD-100 is

a single channel unit which can be used to power a bipolar (±15dc @ 250mA) device and/or display the output from

a transducer that supplies voltage signals up to 10 VDC. There is also an input that can be used for external

command (setpoint) control (+5v full scale). Digital interfaces to the THCD-100 include RS485 and RS232.

1.1. Features

16-bit Resolution

±0.2% Reading + 1 Digit Accuracy

0-5 Volt Set Point Via Front Panel Or Digitally (RS232/RS485)

Dual Programmable Alarms with Relays

RS232/485 and Analog Output (Standard)

CE Approved

1.2. Specifications

For a list of specifications, please see the PB-185_rev-0711_THCD-100 Power Supply.

165-072011 THCD-100 Power Supply Page 4 of 28

2. Installation and Interconnections

2.1. Installation

The THCD-100 can be panel mounted, or used on a bench top and is a standard 96 x 48mm panel meter

enclosure. Note that the instrument must always be situated in such a way as to enable adequate air

circulation about the unit. If a transducer was supplied with the THCD-100 a suitable cable may have been

included.

See Section 2.6 for a cut out detail for panel mounting.

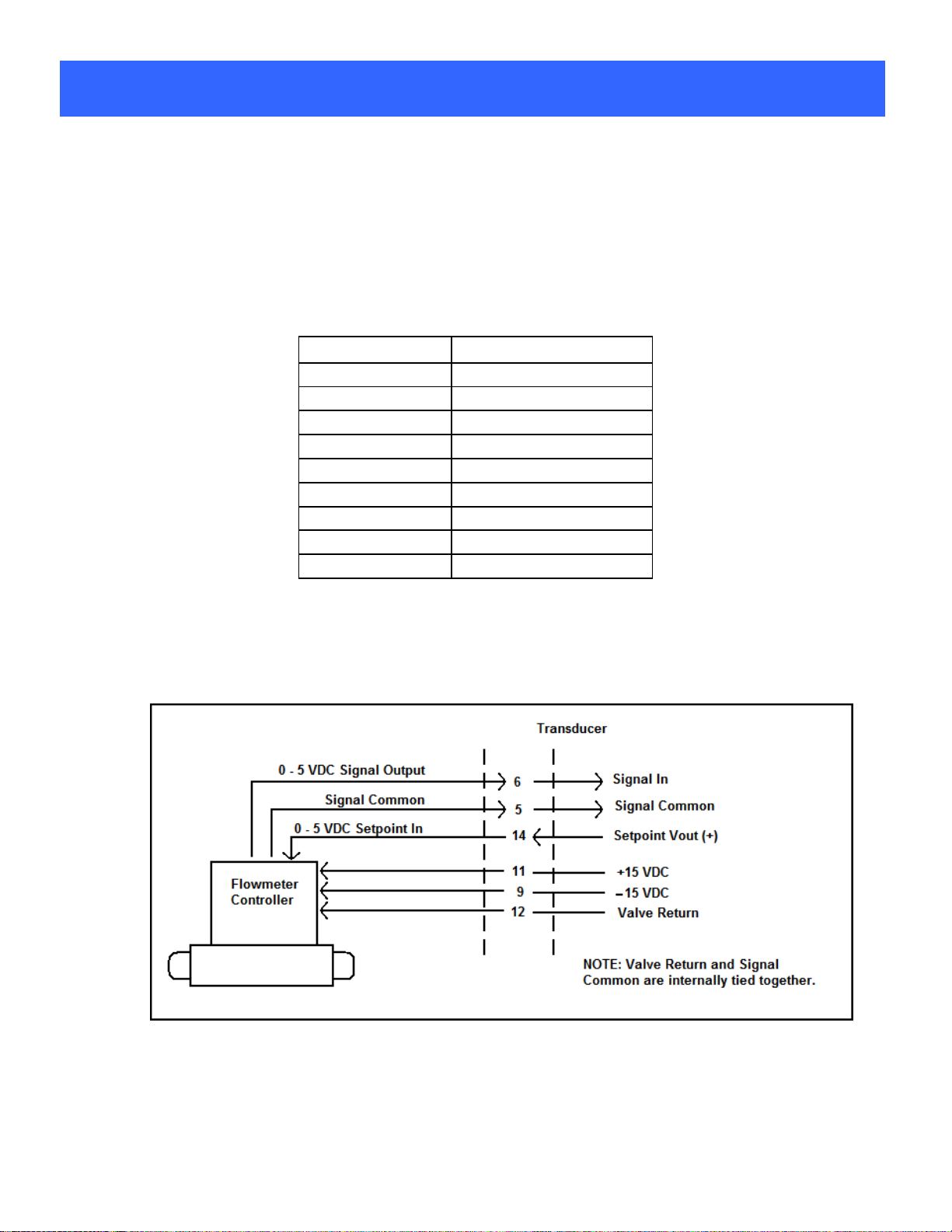

2.2. Transducer socket Pinout – 15 Pin 'D' Type

If the transducer is being powered from another source (e.g. a mains powered supply) it will only be

necessary to connect to the two signal pins. Note: The THCD-100 has a fully floating differential input. For

single ended use (i.e. transducers with differential output) join 0V (pin5) & Signal Return (pin12) at the

transducer. Ensure the common mode input range is not exceeded.

Pin Number Designation

5 Signal Common

6 Signal In (VDC)

7 Case Gnd

9 -15 VDC

11 +15 VDC

12 Valve Return

13 +24 VDC

14 Set Point Out (VDC)

All other pins Not Connected

165-072011 THCD-100 Power Supply Page 5 of 28

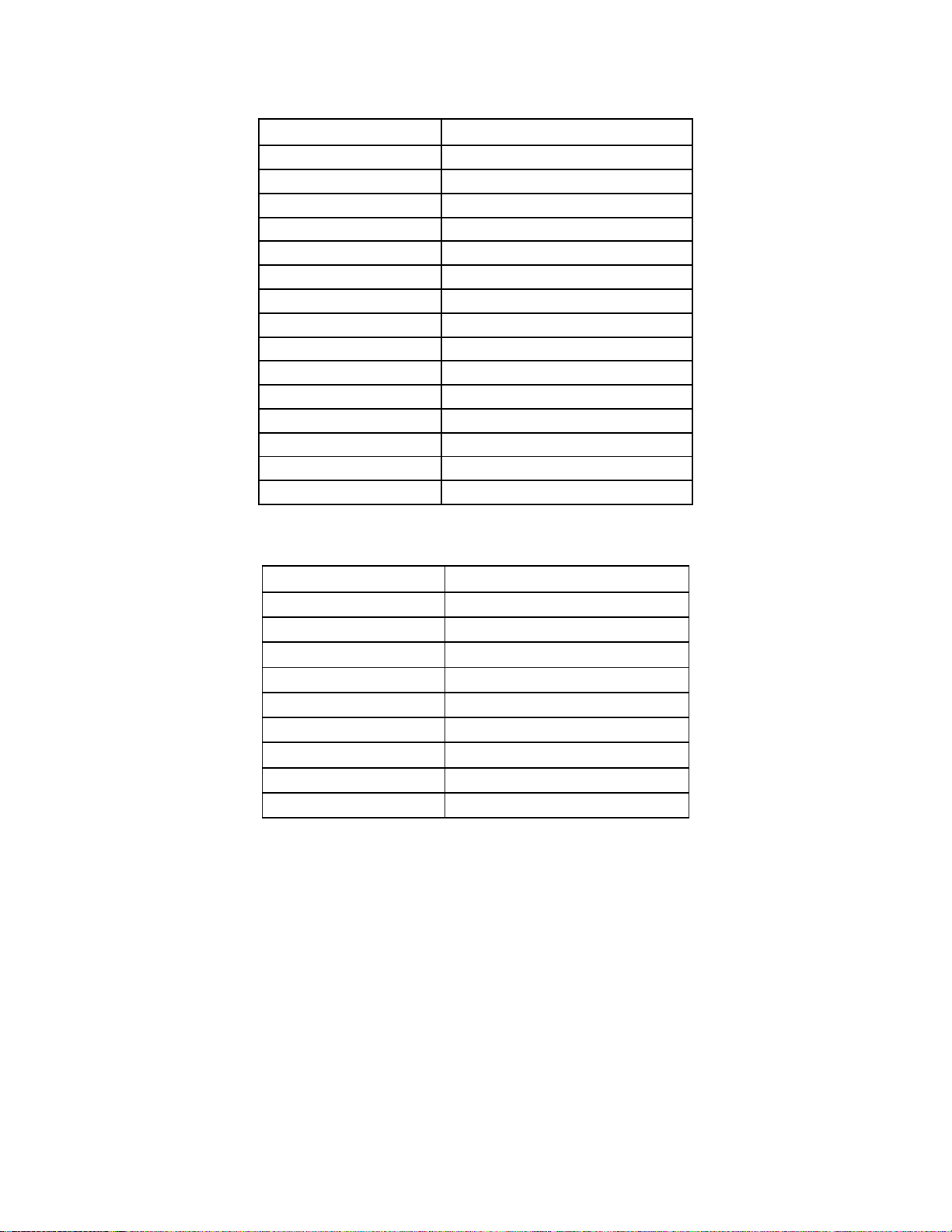

2.3. Interface Socket Pin out – Miniature 15 Pin 'D' Type

Pin Number Designation

1 Analog Output

2 Relay 2 Common

3 Relay 2 Normally Open contact

4 Relay 2 Normally Closed contact

5 0V (Signal Ground)

6 External Setpoint Return

7 N/C

8 External Setpoint

9 N/C

10 0V (Signal Ground)

11 TTL Input – Disable Menu

12 TTL Input – Disable Zero

13 Relay 1 Common

14 Relay 1 Normally Open contact

15 Relay 1 Normally Closed contact

2.4. Serial Interface

Socket Pinout – 9 Pin 'D' Type

1 2

Pin Number Designation

1 RS485 Tx +

2

3

4 RS485 Tx –

5

6 RS485 Rx +

7 RS485 Rx –

8 N/C

9 Common

1

For RS232 only, connect only the pins designated in bold font.

2

For RS485 only, connect only the pins designated in normal font.

See section 4 for instructions on changing the serial protocol.

RS232 Rx

RS232 Tx

Common

165-072011 THCD-100 Power Supply Page 6 of 28

2.5. Power Connection Socket

The THCD-100 requires a 24V, 500mA supply to operate. This must be a rectified and regulated direct

current supply, capable of 15W (recommended). Although the THCD-100 has an internal fuse and power

supply overload shutdown protection the supply to the THCD-100 should be protected by fuse or other

suitable electronic method. A standard 5.5mm diameter ‘dc power jack’ is required to connect to the

THCD-100. Connect the positive conductor to the center pin. Connect the negative (0V) conductor to the

outer of the jack.

For convenience, Hastings offers a compatible supply (12-01-169) that, when matched with the US (12-01-

160), Euro (12-01-164) or the UK (12-01-165) plug adapters, converts wall power to specified levels.

Cautions: Ensure correct power supply rating and polarity. Do not use

a partially assembled or faulty unit. Incorrect use of this equipment, or

use in a manner not specified may impair the user’s protection.

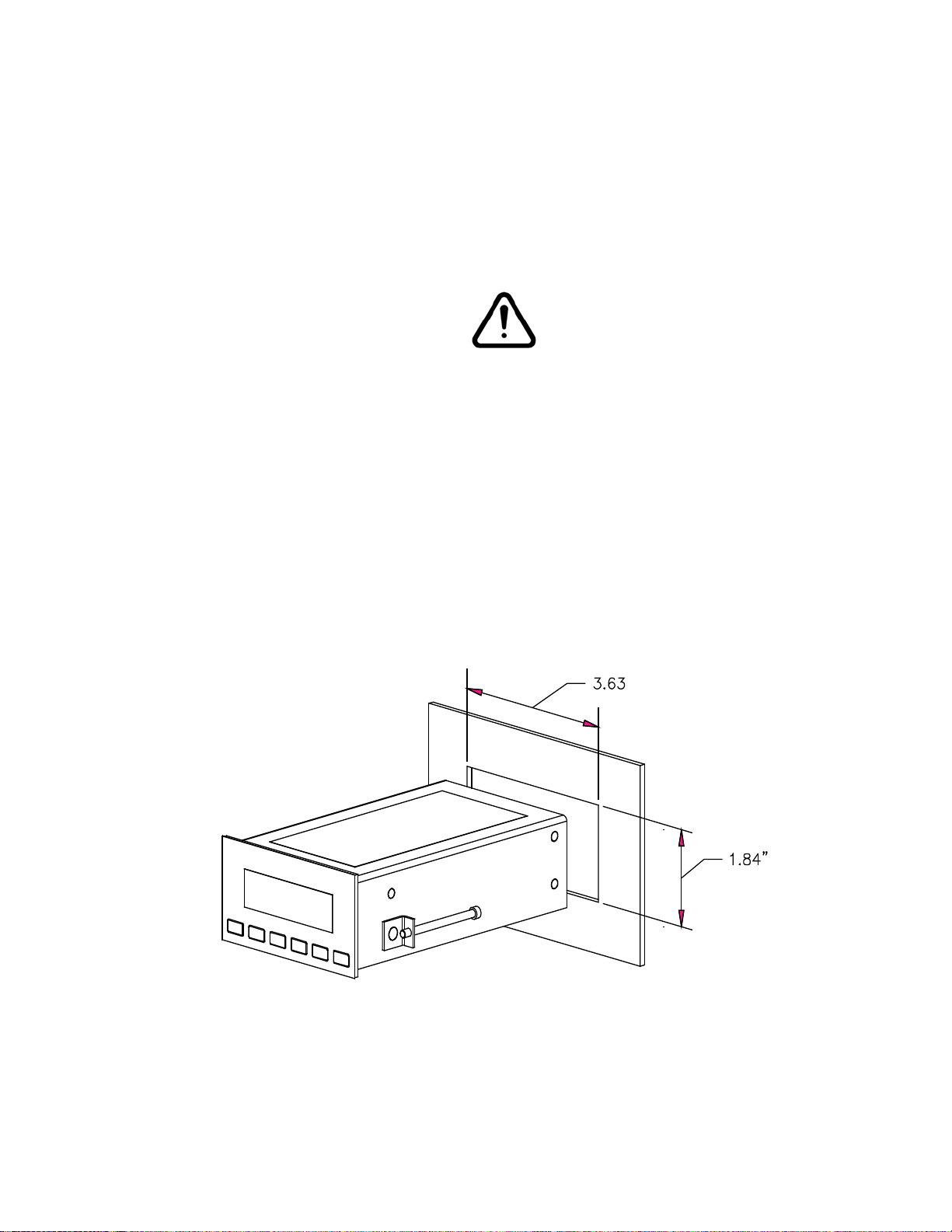

2.6. Panel Mounting

A panel mount kit will have been supplied with the instrument. This consists of: 2 screws (M3x6), 2 brackets

and 2 screws (50mm). Fit the M3x6 screws into the side of the unit into the diagonally opposed holes. Do

not tighten these screws, to allow the bracket to slide over the screw head. Thread locking adhesive may be

used but is not required as these screws cannot rotate once the bracket is tightened. Insert the meter into the

panel. A cutout of 3.63” x 1.84” (92 x 45mm) is recommended. Slip the mounting bracket over the screw

head and tighten the 50mm screws. The unit should now be secure.

165-072011 THCD-100 Power Supply Page 7 of 28

3. FEATURES

3.1. Introduction

This section describes the principles used in the THCD-100. It details the various settings for the inputs and

the outputs including setpoint control. It does not detail any servicing or calibration procedures.

3.2. Analog Inputs

The THCD-100 has two analog voltage input channels. The main input can be configured to accept any

input voltage from 0V to a full scale of up to 10V. This input is calibrated using a straight line fit method and

then can be displayed on the THCD with an applied range. The secondary input is used to accept an

external command setpoint and has a non-configurable full scale of 5V. This input is used when the setpoint

is set to slave source.

The main input channel has a number of associated setup parameters:

a)

Range

Each device attached to the THCD will be outputting a voltage that represents some form of units and

the range is used with the full scale to determine what the user sees on the screen for any input voltage.

Full Scale Voltage

b)

Each device attached to the THCD will have a full scale voltage which is the maximum voltage the

device should output under normal operating conditions. Typical values are 10V, 5V and 1V. The full

scale is used with the range to determine what the user sees on the screen for any input voltage. The

THCD will show the over range error (“RANGE!”) for any channel whose voltage input is more than

15% over the full scale voltage set for that channel.

Units String

c)

To inform the user of what units are being dealt with, each channel has an associated units string. This is

a free form text field (maximum 5 characters) that is displayed on the right side of the Main screen.

Example A device has a full scale voltage of 10V and a range of 100 mbar.

If the device now outputs 10V, the THCD-100 display will nominally show 100 (pending input

calibration). If the device outputs 5V, the THCD-100 will show 50, and so on.

3.3. Analog Outputs

There are two analog outputs on the THCD-100, both voltage outputs. One is for setpoint control with its

own set of setup parameters (see next section) and the other is a simple retransmission of the main input

voltage and has no user setup control. Typically this output can be used for data logging purposes or for

providing an external setpoint control to another THCD or similar instrument.

3.4. Setpoint Control

As mentioned above, there is one analog output that is used for command setpoint control that can be used

to operate a mass flow controller or similar. The setpoint command output always has a voltage full scale of

5V.

Example If the input channel is setup for a 100 slpm 5V full scale device, and the setpoint value is 10.0

165-072011 THCD-100 Power Supply Page 8 of 28

(assuming setpoint is in AUTO mode and not a slave source), then the output voltage of the setpoint would

be 0.5V.

The setpoint does have some configuration parameters that can be used to alter the function of the setpoint

control and they are detailed as follows:

Setpoint Mode

a)

The setpoint can be configured in one of three modes – AUTO, OPEN and CLOSED.

• In AUTO mode the setpoint output is dependant on the setpoint source and value

settings (see below).

• In OPEN mode the setpoint outputs a voltage greater than the full scale of the

device. Given that the setpoint command full scale is 5V, the output in this mode is 7V.

• In CLOSED mode the setpoint outputs a voltage less than the minimum output voltage

of most devices, the setpoint output voltage is –0.25V.

Setpoint Source

b)

The setpoint source dictates where the setpoint value comes from, assuming the mode is set to

AUTO (see above). This can be one of two possibilities – Internal or Slave.

• Internal source – the setpoint uses the value set internally via the ‘

communications.

• Slave source – in this case the setpoint uses a percentage of an externally produced value. The

percentage is set via the ‘▲’&‘▼’ switches and the external value comes from the secondary input

channel (as mentioned 5.2 in above)

3.5. User Re-zero

Over time it is possible that the input may ‘drift’ slightly due to various conditions (temperature changes,

etc.). As such it may be necessary for the channel to be re-zeroed by the user.

The user re-zero function is provided for this task. It simply takes the current reading (sampled and averaged

over 3 seconds) and uses that as an additional offset for the channel in question, subtracting the value from

all subsequent readings. Ensure any process value to be zeroed, is in fact truly zero before performing this

function. This would mean isolating flow devices or fully pumping a pressure device.

Note that the user re-zero via serial communications also provides the facility for clearing any user re-zero

value that may have already been set. This should be used before any input calibration is performed to

ensure that the calculated calibration points are not distorted by the user zero offset.

3.6. Adaptive Filtering

▲’& ‘▼’ switches or via external

The THCD-100 includes an adaptive averaging filter on the display and serial communication readings

output to aid in ‘smoothing out’ unwanted ‘noise’ on the displayed readings.

a)

Operational Band

The filter can be configured to only operate within a certain band, meaning that excursions between

subsequent readings that fall outside that band are shown as real (and not filtered) readings. The

band is configurable between 0.01% and 1.00% of the full scale range of the input channel. It can

also be set to OFF, which means that no filtering is performed (i.e. every reading is a ‘real’ one) and

can also be set to ON which means that filtering is always shown no matter how big of an excursion

occurs.

165-072011 THCD-100 Power Supply Page 9 of 28

Loading...

Loading...