Page 1

OPERATION MANUAL

MODEL T101

UV FLUORESCENCE H

Also supports operation of:

S ANALYZER

2

Model T102 Analyzer

(when used in conjunction with T102 Addendum, PN 07267)

© TELEDYNE ADVANCED POLLUTION INSTRUMENTATION

9480 CARROLL PARK DRIVE

SAN DIEGO, CA 92121-5201

USA

Toll-free Phone: 800-324-5190

Phone:

Fax:

Email:

Website:

Copyright 2011 - 2012 07266B DCN6845

Teledyne Advanced Pollution Instrumentation 08 June 2012

858-657-9800

858-657-9816

api-sales@teledyne.com

http://www.teledyne-api.com/

Page 2

Page 3

07266B DCN6485

ABOUT TELEDYNE ADVANCED POLLUTION INSTRUMENTATION (TAPI)

Teledyne Advanced Pollution Instrumentation (TAPI), a business unit of

Teledyne Instruments, Inc., is a worldwide market leader in the design and

manufacture of precision analytical instrumentation used for air quality

monitoring, continuous emissions monitoring, and specialty process monitoring

applications. Founded in San Diego, California, in 1988, TAPI introduced a

complete line of Air Quality Monitoring (AQM) instrumentation, which comply

with the United States Environmental Protection Administration (EPA) and

international requirements for the measurement of criteria pollutants, including

CO, SO

Since 1988 TAPI has combined state-of-the-art technology, proven measuring

principles, stringent quality assurance systems and world class after-sales support

to deliver the best products and customer satisfaction in the business.

For further information on our company, our complete range of products, and the

applications that they serve, please visit www.teledyne-api.com or contact

sales@teledyne-api.com.

, NOx and Ozone.

2

NOTICE OF COPYRIGHT

© 2011-2012 Teledyne Advanced Pollution Instrumentation. All rights reserved.

TRADEMARKS

All trademarks, registered trademarks, brand names or product names appearing

in this document are the property of their respective owners and are used herein

for identification purposes only.

i

Page 4

07266B DCN6485

This page intentionally left blank.

ii

Page 5

07266B DCN6485

SAFETY MESSAGES

Important safety messages are provided throughout this manual for the purpose of

avoiding personal injury or instrument damage. Please read these messages

carefully. Each safety message is associated with a safety alert symbol, and are

placed throughout this manual; the safety symbols are also located inside the

instrument. It is imperative that you pay close attention to these messages, the

descriptions of which are as follows:

WARNING: Electrical Shock Hazard

HAZARD: Strong oxidizer

GENERAL WARNING/CAUTION: Read the accompanying

message for specific information.

CAUTION: Hot Surface Warning

Do Not Touch: Touching some parts of the instrument

without protection or proper tools could result in damage to the

This instrument should only be used for the purpose and in the

manner described in this manual. If you use this instrument in a

manner other than that for which it was intended, unpredictable

behavior could ensue with possible hazardous consequences.

part(s) and/or the instrument.

Technician Symbol: All operations marked with this symbol

are to be performed by qualified maintenance personnel only.

Electrical Ground: This symbol inside the instrument marks

the central safety grounding point for the instrument.

CAUTION

NEVER use any gas analyzer to sample combustible gas(es)!

Note

For Technical Assistance regarding the use and maintenance of this instrument or any other

Teledyne API product, contact Teledyne API’s Technical Support Department:

Telephone: 800-324-5190

Email: sda_techsupport@teledyne.com

or access any of the service options on our website at http://www.teledyne-api.com/

iii

Page 6

07266B DCN6485

CONSIGNES DE SÉCURITÉ

Des consignes de sécurité importantes sont fournies tout au long du présent

manuel dans le but d’éviter des blessures corporelles ou d’endommager les

instruments. Veuillez lire attentivement ces consignes. Chaque consigne de

sécurité est représentée par un pictogramme d’alerte de sécurité; ces

pictogrammes se retrouvent dans ce manuel et à l’intérieur des instruments. Les

symboles correspondent aux consignes suivantes :

AVERTISSEMENT : Risque de choc électrique

DANGER : Oxydant puissant

AVERTISSEMENT GÉNÉRAL / MISE EN GARDE : Lire la consigne

complémentaire pour des renseignements spécifiques

MISE EN GARDE : Surface chaude

Ne pas toucher : Toucher à certaines parties de l’instrument sans

protection ou sans les outils appropriés pourrait entraîner des

dommages aux pièces ou à l’instrument.

Pictogramme « technicien » : Toutes les opérations portant ce

symbole doivent être effectuées uniquement par du personnel de

maintenance qualifié.

Mise à la terre : Ce symbole à l’intérieur de l’instrument détermine le

point central de la mise à la terre sécuritaire de l’instrument.

MISE EN GARDE

Cet instrument doit être utilisé aux fins décrites et de la manière

décrite dans ce manuel. Si vous utilisez cet instrument d’une

autre manière que celle pour laquelle il a été prévu, l’instrument

pourrait se comporter de façon imprévisible et entraîner des

conséquences dangereuses.

NE JAMAIS utiliser un analyseur de gaz pour échantillonner des

gaz combustibles!

iv

Page 7

07266B DCN6485

WARRANTY

WARRANTY POLICY (02024 F)

Teledyne Advanced Pollution Instrumentation (TAPI), a business unit of Teledyne

Instruments, Inc., provides that:

Prior to shipment, TAPI equipment is thoroughly inspected and tested. Should

equipment failure occur, TAPI assures its customers that prompt service and support

will be available.

COVERAGE

After the warranty period and throughout the equipment lifetime, TAPI stands ready

to provide on-site or in-plant service at reasonable rates similar to those of other

manufacturers in the industry. All maintenance and the first level of field

troubleshooting are to be performed by the customer.

NON-TAPI MANUFACTURED EQUIPMENT

Equipment provided but not manufactured by TAPI is warranted and will be repaired

to the extent and according to the current terms and conditions of the respective

equipment manufacturer’s warranty.

Product Return

Failure to comply with proper anti-Electro-Static Discharge (ESD) handling and packing

instructions and Return Merchandise Authorization (RMA) procedures when returning

parts for repair or calibration may void your warranty. For anti-ESD handling and

packing instructions please refer to “Packing Components for Return to Teledyne API”

in the Primer on Electro-Static Discharge section of this manual, and for RMA

procedures please refer to our Website at http://www.teledyne-api.com

Customer Support > Return Authorization.

All units or components returned to Teledyne API should be properly packed for

handling and returned freight prepaid to the nearest designated Service Center.

After the repair, the equipment will be returned, freight prepaid.

The complete Terms and Conditions of Sale can be reviewed at

http://www.teledyne-api.com/terms_and_conditions.asp

CAUTION – Avoid Warranty Invalidation

under

v

Page 8

07266B DCN6485

This page intentionally left blank.

vi

Page 9

07266B DCN6485

ABOUT THIS MANUAL

This T101 operation manual, PN 07266, is comprised of multiple documents in PDF

format, as listed below.

Part No. Rev Name/Description

07266 B Model T101 Operation Manual (this manual)

05492 D Menu Trees and Software Documentation (inserted as Appendix A of this manual)

07347

05494 D Repair Questionnaire (inserted as Appendix C of this manual)

03956

04354

04181

04420

04693

04932

04468

06731

05803 B Schem, Gen5 Motherboard

06698 D Schem, LCD Tchscrn Interface

06882 B Schem, LVDS transmitter

1/19/2011

A

D

H

B

E

C

B

B

Spare Parts List (in Appendix B of this manual)

Documents included in Appendix D:

PCA, 03955, Relay Driver

PCA, 04003, Pressure Flow Sensor Board

PCA, 04180, PMT Preamp

PCA, 04120, UV Detector Preamp

PCA, 04692, UV Lamp Driver

PCA, Thermo-Electric Cooler Board

PCA, 04467, Analog Output Isolator

Schem, Auxiliary IO

NOTE

Please read this manual in its entirety before making any attempt to operate the instrument.

REVISION HISTORY

T101 Operation Manual 072660000

REV DATE DCN DESCRIPTION

B 2012 June 08 6845 Administrative updates.

A 2011 February 14 5970 Initial Release

vii

Page 10

07266B DCN6485

This page intentionally left blank.

viii

Page 11

07266B DCN6485

TABLE OF CONTENTS

1. INTRODUCTION ......................................................................................................................... 19

1.1. Features ..............................................................................................................................19

1.2. Options................................................................................................................................20

2. SPECIFICATIONS AND APPROVALS............................................................................................ 23

2.1. Specifications........................................................................................................................23

2.2. Approvals and Certifications....................................................................................................24

2.2.1. Safety ...........................................................................................................................24

2.2.2. EMC .............................................................................................................................. 24

2.2.3. Other Type Certifications.................................................................................................. 24

3. GETTING STARTED..................................................................................................................... 25

3.1. Unpacking and Initial Setup ....................................................................................................25

3.2. Instrument Layout................................................................................................................. 26

3.2.1. Front Panel ....................................................................................................................26

3.2.2. Rear Panel ..................................................................................................................... 30

3.2.3. Internal Chassis Layout....................................................................................................32

3.3. Electrical Connections ............................................................................................................ 33

3.3.1. Analog Inputs (Option 64) Connections .............................................................................. 33

3.3.2. Connecting the Analog Outputs .........................................................................................34

3.3.2.1. Current Loop Analog Outputs (Option 41) Setup............................................................35

3.3.3. Connecting the Status Outputs..........................................................................................36

3.3.4. Connecting the Control Inputs...........................................................................................37

3.3.5. Connecting the Communications Ports................................................................................39

3.3.5.1. Connecting the Serial Ports ........................................................................................39

3.3.5.2. Connecting to a LAN or the Internet ............................................................................ 39

3.3.5.3. Connecting to a Personal Computer (USB Option)..........................................................39

3.3.5.4. Connecting to a Multidrop Network (Option) ................................................................. 39

3.4. Pneumatic Connections .......................................................................................................... 39

3.4.1.1. Connections with Internal Valve Options Installed..........................................................45

3.5. Startup, Functional Checks, and Initial Calibration...................................................................... 50

3.5.1. Startup.......................................................................................................................... 50

3.5.2. Warm-Up....................................................................................................................... 50

3.5.3. Warning Messages .......................................................................................................... 50

3.5.4. Functional Check.............................................................................................................52

3.6. Initial Calibration...................................................................................................................53

3.6.1. Basic Calibration Procedure .............................................................................................. 53

3.6.2. Interferences for H2S Measurements.................................................................................. 56

4. OPERATING INSTRUCTIONS ...................................................................................................... 57

4.1. Overview of Operating Modes .................................................................................................. 57

4.2. Sample Mode........................................................................................................................ 58

4.2.1. Test Functions ................................................................................................................58

4.2.2. Warning Messages .......................................................................................................... 61

4.3. Calibration Mode ................................................................................................................... 62

4.3.1. Calibration Password Security ...........................................................................................62

4.4. Setup Mode ..........................................................................................................................64

4.4.1. Setup – CFG: Viewing the Analyzer’s Configuration Information............................................. 65

4.4.2. Setup – ACAL: Auto Calibration.........................................................................................66

ix

Page 12

TABLE OF CONTENTS Teledyne API – T101 Operation Manual

07266B DCN6485

4.4.3. Setup – DAS: Data Acquisition.......................................................................................... 66

4.4.4. Setup – Range: Analog Output Reporting Range Configuration...............................................66

4.4.4.1. Available Analog Output Signals..................................................................................66

4.4.4.2. Physical Range versus Analog Output Reporting Ranges .................................................67

4.4.4.3. Reporting Range Modes .............................................................................................68

4.4.4.4. Single Range Mode (SNGL) ........................................................................................ 69

4.4.4.5. Independent Range Mode (IND)..................................................................................70

4.4.4.6. Auto Range Mode (AUTO) .......................................................................................... 71

4.4.4.7. Range Units .............................................................................................................72

4.4.4.8. Dilution Ratio ........................................................................................................... 73

4.4.5. Setup – Pass: Password Protection .................................................................................... 74

4.4.6. SETUP – CLK: Setting the Internal Time-of-Day Clock .......................................................... 75

4.5. SETUP – VARS: Using the Internal Variables..............................................................................77

4.5.1. Setting the Gas Measurement Mode...................................................................................80

4.6. SETUP – DIAG: Using the Diagnostics Functions.........................................................................81

4.6.1. Signal I/O ...................................................................................................................... 83

4.6.2. Analog Output Step Test ..................................................................................................84

4.6.3. Analog I/O Configuration.................................................................................................. 85

4.6.3.1. Analog Output Signal Type and Range Span Selection ....................................................87

4.6.3.2. Analog Output Calibration Mode..................................................................................88

4.6.3.3. Manual Analog Output Calibration and Voltage Adjustment .............................................90

4.6.3.4. Analog Output Offset Adjustment................................................................................92

4.6.3.5. Current Loop Output Adjustment.................................................................................92

4.6.3.6. AIN Calibration.........................................................................................................95

4.6.3.7. Analog Inputs (XIN1…XIN8) Option Configuration.......................................................... 96

4.6.4. Optic Test ......................................................................................................................97

4.6.5. Electrical Test.................................................................................................................98

4.6.6. Lamp Calibration.............................................................................................................99

4.6.7. Pressure Calibration ...................................................................................................... 100

4.6.8. Flow Calibration ............................................................................................................ 101

4.6.9. Test Channel Output...................................................................................................... 102

4.7. SETUP – COMM: Setting Up the Analyser’s Communication Ports ................................................ 103

4.7.1. Instrument ID .............................................................................................................. 103

4.7.2. COM Port Default Settings .............................................................................................. 105

4.7.3. RS-232 COM Port Cable Connections................................................................................ 105

4.7.4. RS-485 Configuration ....................................................................................................107

4.7.5. DTE and DCE Communication ......................................................................................... 107

4.7.6. Ethernet Configuration................................................................................................... 107

4.7.6.1. Configuring the Ethernet Interface Using DHCP ........................................................... 107

4.7.6.2. Manually Configuring the Ethernet with Static IP Addresses .......................................... 109

4.7.6.3. Changing the Analyzer’s HOSTNAME.......................................................................... 112

4.7.7. USB Configuration......................................................................................................... 114

4.7.8. Multidrop RS-232 Set Up................................................................................................ 116

4.7.9. MODBUS Set Up ........................................................................................................... 119

4.7.10. COM Port Communication Modes ................................................................................... 121

4.7.11. COM Port Baud Rate .................................................................................................... 123

4.7.12. COM Port Testing ........................................................................................................ 124

4.8. Using the Data Acquisition System (DAS )............................................................................... 124

4.8.1. DAS Structure .............................................................................................................. 125

4.8.1.1. DAS Channels ........................................................................................................ 125

4.8.1.2. DAS Parameters ..................................................................................................... 126

4.8.1.3. DAS Configuration Limits ......................................................................................... 127

4.8.1.4. DAS Triggering Events............................................................................................. 127

4.8.2. Default DAS Channels.................................................................................................... 128

4.8.2.1. Viewing DAS Data and Settings................................................................................. 130

4.8.2.2. Editing DAS Data Channels ......................................................................................131

4.8.2.3. Trigger Events........................................................................................................ 133

4.8.2.4. Editing DAS Parameters........................................................................................... 134

4.8.2.5. Sample Period and Report Period .............................................................................. 135

4.8.2.6. Number of Records ................................................................................................. 137

4.8.2.7. RS-232 Report Function........................................................................................... 139

4.8.2.8. Compact Report ..................................................................................................... 139

x

Page 13

Teledyne API – T101 Operation Manual TABLE OF CONTENTS

07266B DCN6485

4.8.2.9. Starting Date ......................................................................................................... 139

4.8.2.10. Disabling/Enabling Data Channels ........................................................................... 140

4.8.2.11. HOLDOFF Feature .................................................................................................141

4.8.3. Remote DAS Configuration ............................................................................................. 142

5. REMOTE OPERATION................................................................................................................ 143

5.1.1. Remote Operation Using the External Digital I/O................................................................ 143

5.1.1.1. Status Outputs ....................................................................................................... 143

5.1.1.2. Control Inputs........................................................................................................ 145

5.1.2. Remote Operation Using the External Serial I/O.................................................................146

5.1.2.1. Terminal Operating Modes .......................................................................................146

5.1.2.2. Help Commands in Terminal Mode............................................................................. 147

5.1.2.3. Command Syntax ................................................................................................... 148

5.1.2.4. Data Types ............................................................................................................ 148

5.1.2.5. Status Reporting..................................................................................................... 149

5.1.2.6. General Message Format.......................................................................................... 150

5.1.2.7. Remote Access by Modem........................................................................................ 150

5.1.2.8. COM Port Password Security..................................................................................... 153

5.1.2.9. APICOM Remote Control Program.............................................................................. 153

5.1.3. Additional Communications Documentation....................................................................... 154

5.1.4. Using the T101 with a Hessen Protocol Network................................................................. 155

5.1.4.1. General Overview of Hessen Protocol......................................................................... 155

5.1.4.2. Hessen COMM Port Configuration .............................................................................. 155

5.1.4.3. Activating Hessen Protocol ....................................................................................... 156

5.1.4.4. Selecting a Hessen Protocol Type .............................................................................. 157

5.1.4.5. Setting The Hessen Protocol Response Mode............................................................... 157

5.1.4.6. Hessen Protocol Gas ID ........................................................................................... 159

5.1.4.7. Setting Hessen Protocol Status Flags ......................................................................... 160

6. CALIBRATION PROCEDURES.................................................................................................... 163

6.1. Calibration Preparations ....................................................................................................... 163

6.1.1. Required Equipment, Supplies, and Expendables ............................................................... 163

6.1.2. Zero Air....................................................................................................................... 164

6.1.3. Gas Standards.............................................................................................................. 164

6.1.4. Permeation Tubes ......................................................................................................... 164

6.1.5. Calibration Gas Traceability ............................................................................................165

6.1.6. Data Recording Devices ................................................................................................. 165

6.2. Manual Calibration............................................................................................................... 165

6.3. Manual Calibration Checks .................................................................................................... 169

6.4. Manual Calibration with Zero/Span Valves............................................................................... 170

6.5. Manual Calibration with IZS Option ........................................................................................ 173

6.6. Manual Calibration Checks with IZS or Zero/Span Valves .......................................................... 174

6.7. Manual Calibration in INDEPENDENT or AUTO Reporting Range Modes......................................... 177

6.7.1. Calibration With Remote Contact Closures ........................................................................ 177

6.8. Manual Calibration in Multigas Measurement Mode ................................................................... 178

6.9. Automatic Calibration/Checks (AutoCal).................................................................................. 179

6.9.1. Autocal of Instruments in INDEPENDENT or AUTO Reporting Range Modes ............................ 183

6.9.2. Autocal of Instruments in Multigas Measurement Mode ....................................................... 184

6.10. Calibration Quality ............................................................................................................. 185

7. EPA PROTOCOL CALIBRATION ................................................................................................. 187

7.1. Calibration Requirements...................................................................................................... 187

7.1.1. Calibration of Equipment................................................................................................ 187

7.1.2. Data Recording Device................................................................................................... 189

7.1.3. Recommended Standards for Establishing Traceability ........................................................ 189

7.1.4. EPA Calibration Using Permeation Tubes ........................................................................... 189

7.1.5. Calibration Frequency .................................................................................................... 190

7.1.6. Record Keeping ............................................................................................................ 190

7.1.7. Summary of Quality Assurance Checks............................................................................. 191

7.2. Level 1 Calibrations versus Level 2 Checks .............................................................................. 191

7.3. ZERO and SPAN Checks........................................................................................................ 193

7.3.1. Zero/Span Check Procedures .......................................................................................... 193

7.4. Precisions Calibration Procedures and Checks .......................................................................... 193

7.4.1. Precision Calibration ...................................................................................................... 194

7.4.2. Precision Check............................................................................................................. 194

xi

Page 14

TABLE OF CONTENTS Teledyne API – T101 Operation Manual

07266B DCN6485

7.5. Dynamic Multipoint Span Calibration ...................................................................................... 195

7.6. Special Calibration Requirements for Independent Range or Auto Range...................................... 196

7.7. References ......................................................................................................................... 196

8. INSTRUMENT MAINTENANCE................................................................................................... 197

8.1. Maintenance Schedule.......................................................................................................... 197

8.2. Predictive Diagnostics .......................................................................................................... 201

8.3. Maintenance Procedures....................................................................................................... 202

8.3.1. Changing the Sample Particulate Filter ............................................................................. 202

8.3.2. Changing the IZS Permeation Tube.................................................................................. 203

8.3.3. Maintaining the SO2 Scrubber .........................................................................................203

8.3.3.1. Predicting When the SO2 Scrubber Should Be Replaced. ............................................... 203

8.3.3.2. Checking the Function of the SO2 Scrubber................................................................. 204

8.3.3.3. Changing the SO2 Scrubber Material .......................................................................... 204

8.3.4. Changing the External Zero Air Scrubber .......................................................................... 205

8.3.5. Maintaining the H2S SO2 Converter .............................................................................. 206

8.3.5.1. Predicting When the Converter Catalyst Should Be Replaced. ........................................ 206

8.3.5.2. Checking the Efficiency of the H2S SO2 Converter..................................................... 206

8.3.5.3. Changing the H2S SO2 Converter Catalyst Material ................................................... 207

8.3.6. Checking for Light Leaks ................................................................................................ 209

8.3.7. Changing the Critical Flow Orifice .................................................................................... 209

9. TROUBLESHOOTING & SERVICE............................................................................................... 211

9.1. General Troubleshooting....................................................................................................... 211

9.1.1. Fault Diagnosis with Warning Messages............................................................................ 212

9.1.2. Fault Diagnosis with Test Functions.................................................................................. 216

9.1.3. Using the Diagnostic Signal I/O Function .......................................................................... 217

9.1.4. Status LEDs ................................................................................................................. 218

9.1.4.1. Motherboard Status Indicator (Watchdog) .................................................................. 219

9.1.4.2. CPU Status Indicator ............................................................................................... 219

9.1.4.3. Relay Board Status LEDs.......................................................................................... 219

9.2. Gas Flow Problems .............................................................................................................. 220

9.2.1. Zero or Low Sample Flow ............................................................................................... 221

9.2.2. High Flow..................................................................................................................... 221

9.3. Calibration Problems ............................................................................................................ 221

9.3.1. Negative Concentrations ................................................................................................ 221

9.3.2. No Response ................................................................................................................ 222

9.3.3. Unstable Zero and Span................................................................................................. 222

9.3.4. Inability to Span - No SPAN Button.................................................................................. 222

9.3.5. Inability to Zero - No ZERO Button .................................................................................. 223

9.3.6. Non-Linear Response..................................................................................................... 223

9.3.7. Discrepancy Between Analog Output and Display............................................................... 224

9.4. Other Performance Problems................................................................................................. 224

9.4.1. Excessive Noise ............................................................................................................ 224

9.4.2. Slow Response ............................................................................................................. 224

9.4.3. The Analyzer Doesn’t Appear on the LAN or Internet .......................................................... 225

9.5. Subsystem Checkout ........................................................................................................... 225

9.5.1. Detailed Pressure Leak Check ......................................................................................... 225

9.5.2. Performing a Sample Flow Check..................................................................................... 226

9.5.3. AC Power Configuration ................................................................................................. 226

9.5.4. DC Power Supply .......................................................................................................... 227

9.5.5. I2C Bus........................................................................................................................ 228

9.5.6. Touchscreen Interface ................................................................................................... 228

9.5.7. LCD Display Module....................................................................................................... 228

9.5.8. Relay Board ................................................................................................................. 228

9.5.9. Motherboard................................................................................................................. 229

9.5.9.1. A/D functions......................................................................................................... 229

9.5.9.2. Analog Output Voltages ........................................................................................... 229

9.5.9.3. Status Outputs ....................................................................................................... 230

9.5.9.4. Control Inputs........................................................................................................ 230

9.5.10. CPU........................................................................................................................... 230

9.5.11. RS-232 Communication................................................................................................ 231

9.5.11.1. General RS-232 Troubleshooting ............................................................................. 231

9.5.11.2. Modem or Terminal Operation................................................................................. 231

xii

Page 15

Teledyne API – T101 Operation Manual TABLE OF CONTENTS

07266B DCN6485

9.5.12. PMT Sensor ................................................................................................................ 232

9.5.13. PMT Preamplifier Board ................................................................................................ 232

9.5.14. PMT Temperature Control PCA....................................................................................... 232

9.5.15. High Voltage Power Supply ........................................................................................... 233

9.5.16. Pneumatic Sensor Assembly.......................................................................................... 233

9.5.16.1. Sample Pressure................................................................................................... 233

9.5.17. IZS Option ................................................................................................................. 233

9.5.18. Box Temperature ........................................................................................................ 234

9.5.19. PMT Temperature........................................................................................................ 234

9.6. Repair Procedures ............................................................................................................... 234

9.6.1. Disk-on-Module Replacement.......................................................................................... 234

9.6.2. Adjusting the UV Lamp (Peaking the Lamp) ...................................................................... 235

9.6.3. Replacing the UV Lamp .................................................................................................. 237

9.6.4. Factory Cal (PMT Sensor, Hardware Calibration) ................................................................ 238

9.7. Frequently Asked Questions (FAQs)........................................................................................ 240

9.8. Technical Assistance ............................................................................................................ 241

10. PRINCIPLES OF OPERATION.................................................................................................. 243

10.1. Measurement Principle ....................................................................................................... 243

10.1.1. H2S Conversion ........................................................................................................... 243

10.1.2. SO2 Ultraviolet Fluorescence ......................................................................................... 244

10.2. The UV Light Path.............................................................................................................. 247

10.2.1. UV Source Lamp ......................................................................................................... 247

10.2.2. The Reference Detector................................................................................................ 248

10.2.3. The PMT..................................................................................................................... 248

10.2.4. Optical Filters ............................................................................................................. 249

10.2.4.1. UV Source Optical Filter ......................................................................................... 249

10.2.4.2. PMT Optical Filter.................................................................................................. 249

10.2.5. Optical Lenses ............................................................................................................ 250

10.2.6. Measurement Interferences .......................................................................................... 251

10.2.6.1. Direct Interference................................................................................................ 251

10.2.6.2. UV Absorption by Ozone ........................................................................................ 252

10.2.6.3. Dilution ............................................................................................................... 252

10.2.6.4. Third Body Quenching............................................................................................252

10.2.6.5. Light Pollution ...................................................................................................... 252

10.3. Pneumatic Operation.......................................................................................................... 253

10.3.1. Sample Gas Flow......................................................................................................... 254

10.3.2. Multigas Measurement & H2S SO2 Switching Valve........................................................ 255

10.3.3. Flow Rate Control........................................................................................................ 255

10.3.3.1. Critical Flow Orifice ............................................................................................... 255

10.3.4. Sample Particulate Filter............................................................................................... 256

10.3.5. Hydrocarbon Scrubber (Kicker) ..................................................................................... 257

10.3.6. SO2 Scrubber.............................................................................................................. 257

10.3.7. Pneumatic Sensors ...................................................................................................... 258

10.3.7.1. Sample Pressure Sensor ........................................................................................ 258

10.3.7.2. Sample Flow Sensor.............................................................................................. 258

10.4. Electronic Operation........................................................................................................... 259

10.4.1. CPU........................................................................................................................... 261

10.4.1.1. Disk On Module (DOM) .......................................................................................... 261

10.4.1.2. Flash Chip............................................................................................................ 261

10.4.2. Sensor Module & Sample chamber ................................................................................. 262

10.4.3. Sample Chamber Heating Circuit ................................................................................... 262

10.4.4. Photo Multiplier Tube (PMT) .......................................................................................... 263

10.4.5. PMT Cooling System .................................................................................................... 264

10.4.5.1. Thermoelectric Cooler (TEC) ................................................................................... 264

10.4.5.2. TEC Control Board................................................................................................. 265

10.4.6. PMT Preamplifier ......................................................................................................... 265

10.4.7. Pneumatic Sensor Board............................................................................................... 267

10.4.8. Relay Board................................................................................................................ 267

10.4.8.1. Heater Control...................................................................................................... 267

10.4.8.2. Valve Control ....................................................................................................... 267

10.4.9. Status LEDs & Watch Dog Circuitry ................................................................................ 268

10.4.10. Motherboard ............................................................................................................. 269

xiii

Page 16

TABLE OF CONTENTS Teledyne API – T101 Operation Manual

07266B DCN6485

10.4.10.1. A to D Conversion ............................................................................................... 269

10.4.10.2. Sensor Inputs..................................................................................................... 269

10.4.10.3. Thermistor Interface............................................................................................ 270

10.4.11. Analog Outputs ......................................................................................................... 270

10.4.12. External Digital I/O.................................................................................................... 271

10.4.13. I2C Data Bus............................................................................................................. 271

10.4.14. Power up Circuit ........................................................................................................ 271

10.5. Power Supply/ Circuit Breaker ............................................................................................. 271

10.6. Front Panel/Display Interface .............................................................................................. 273

10.6.1. LVDS Transmitter Board............................................................................................... 273

10.6.2. Front Panel Interface PCA ............................................................................................. 273

10.7. Software Operation............................................................................................................ 274

10.7.1. Adaptive Filter ............................................................................................................ 274

10.7.2. Calibration - Slope and Offset........................................................................................ 275

10.7.3. Temperature and Pressure Compensation (TPC) Feature ................................................... 276

10.7.4. Internal Data Acquisition System (DAS )......................................................................... 276

11. A PRIMER ON ELECTRO-STATIC DISCHARGE.......................................................................... 277

11.1. How Static Charges are Created........................................................................................... 277

11.2. How Electro-Static Charges Cause Damage ........................................................................... 278

11.3. Common Myths About ESD Damage ..................................................................................... 279

11.4. Basic Principles of Static Control .......................................................................................... 280

11.4.1. General Rules ............................................................................................................. 280

11.4.2. Basic anti-ESD Procedures for Analyzer Repair and Maintenance ........................................ 282

11.4.2.1. Working at the Instrument Rack.............................................................................. 282

11.4.2.2. Working at an Anti-ESD Work Bench........................................................................ 282

11.4.2.3. Transferring Components from Rack to Bench and Back.............................................. 283

11.4.2.4. Opening Shipments from Teledyne API..................................................................... 283

11.4.2.5. Packing Components for Return to Teledyne API........................................................ 284

LIST OF APPENDICES

APPENDIX A - VERSION SPECIFIC SOFTWARE DOCUMENTATION

APPENDIX B - T101 SPARE PARTS LIST

APPENDIX C - REPAIR QUESTIONNAIRE - T101

APPENDIX D - ELECTRONIC SCHEMATICS

xiv

Page 17

Teledyne API – T101 Operation Manual TABLE OF CONTENTS

07266B DCN6485

LIST OF FIGURES

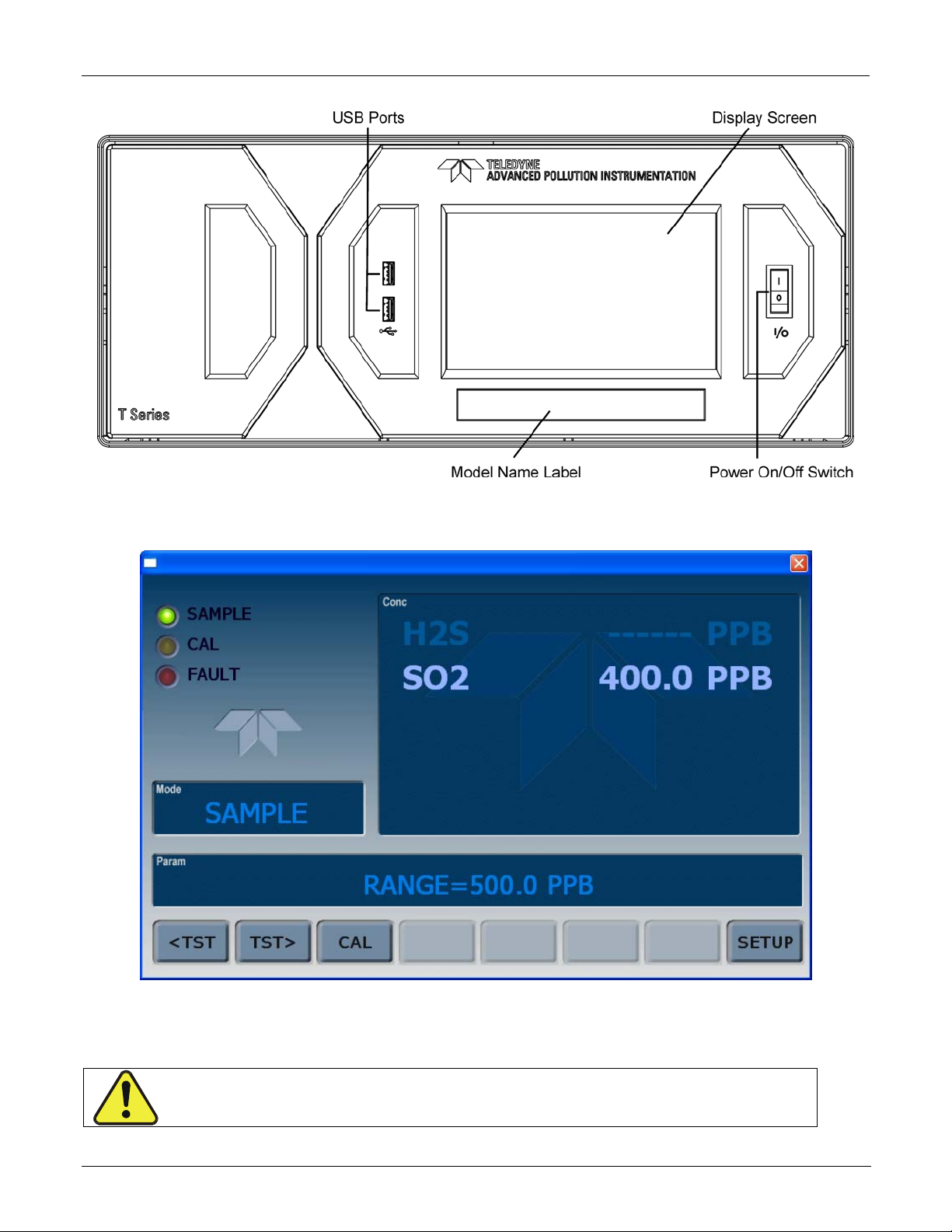

Figure 3-1. Front Panel Layout ........................................................................................... 27

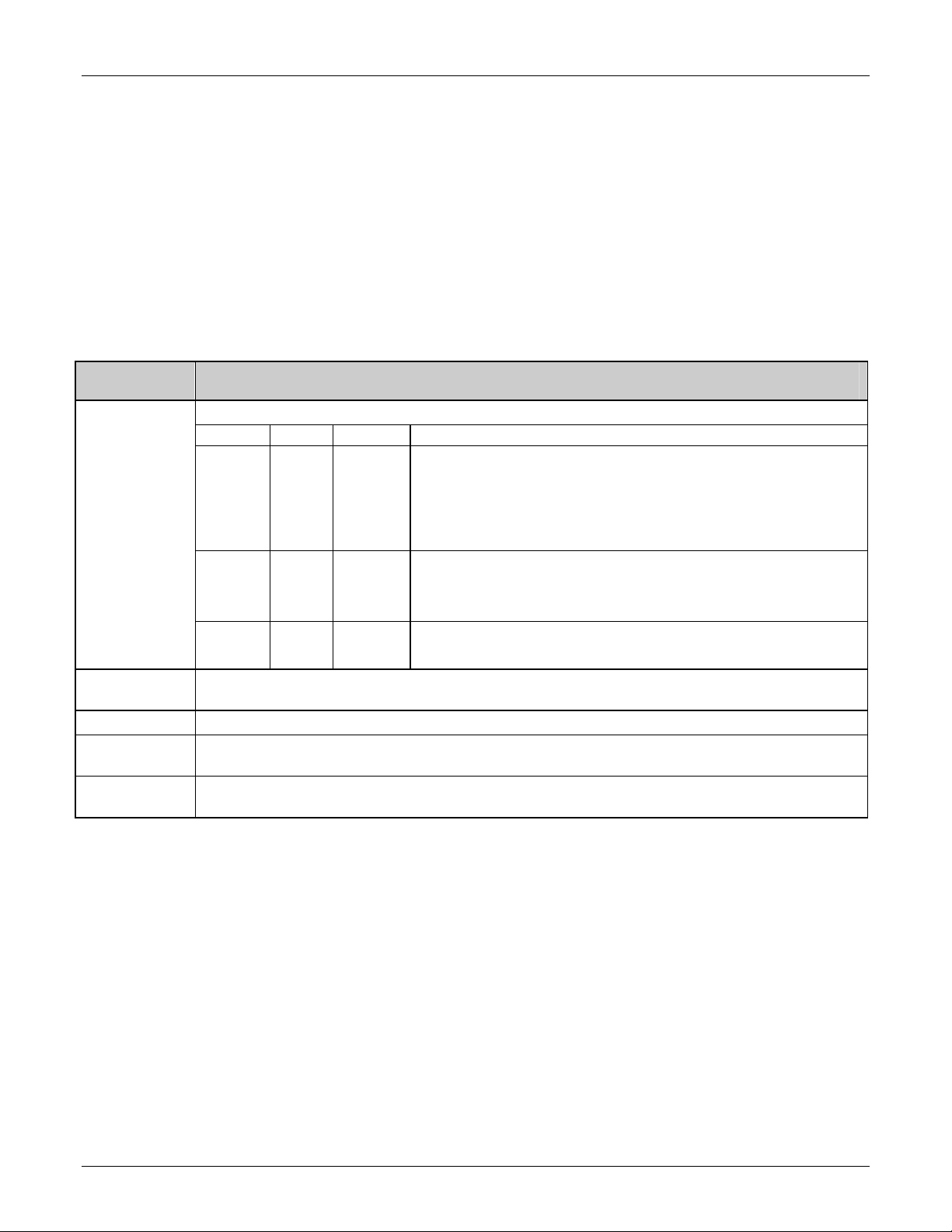

Figure 3-2. Display Screen and Touch Control ...................................................................... 27

Figure 3-3. Display/Touch Control Screen Mapped to Menu Charts.......................................... 29

Figure 3-4. Rear Panel Layout............................................................................................ 30

Figure 3-5. Internal Chassis Layout..................................................................................... 32

Figure 3-6. Analog In Connector......................................................................................... 33

Figure 3-7. Analog Output Connector .................................................................................. 34

Figure 3-8. Current Loop Option Installed on the Motherboard................................................ 35

Figure 3-9. Status Output Connector................................................................................... 36

Figure 3-10. Control Input Connector.................................................................................. 38

Figure 3-11. Pneumatic Connections, Basic Configuration Using Gas Dilution Calibrator .............. 40

Figure 3-12. Pneumatic Connections, Basic Configuration Using Bottled Span Gas ..................... 41

Figure 3-13. Pneumatic Diagram of the T101 Standard Configuration ...................................... 42

Figure 3-14. Basic Pneumatic Connections for Units with Valve Options.................................... 45

Figure 3-15. Pneumatic Diagram of the T101 With Z/S Option Installed ................................... 46

Figure 3-16. Pneumatic Diagram of the T101 with IZS Options Installed................................... 49

Figure 4-1. Viewing T101 TEST Functions ............................................................................ 60

Figure 4-2. Viewing and Clearing T101 WARNING Messages ................................................... 62

Figure 4-3. Analog Output Connectors Defined ..................................................................... 66

Figure 4-4. Setup for Calibrating Analog Outputs .................................................................. 91

Figure 4-5. Setup for Calibrating Current Outputs ................................................................. 93

Figure 4-6. DIAG – Analog Inputs (Option) Configuration Menu............................................... 96

Figure 4-7. Rear Panel Connector Pin-Outs for RS-232 Mode ................................................ 105

Figure 4-8. CPU Connector Pin-Outs for RS-232 Mode ......................................................... 106

Figure 4-9. Jumper and Cables for Multidrop Mode.............................................................. 117

Figure 4-10.Multidrop PCA Host/Analyzer Interconnect Diagram............................................ 118

Figure 4-11. Default DAS Channels Setup.......................................................................... 129

Figure 4-12. APICOM User Interface for Configuring the DAS ................................................ 142

Figure 5-1. Status Output Connector................................................................................. 144

Figure 5-2. Control Inputs with Local 5 V Power Supply ....................................................... 146

Figure 5-3.Control Inputs with External 5 V Power Supply .................................................... 146

Figure 5-4. APICOM Remote Control Program Interface ....................................................... 154

Figure 6-1. Setup for Manual Calibration without Z/S Valve or IZS Option .............................. 166

Figure 6-2. Setup for Manual Calibration with Z/S Valve Option Installed................................ 170

Figure 6-3. Setup for Manual Calibration Check with Z/S Valve or IZS Option.......................... 175

Figure 6-4. Typical Setup for Manual Calibratio in Multigas Measurement Mode ....................... 178

Figure 8-1. Sample Particulate Filter Assembly ................................................................... 202

Figure 8-2. Charcoal Canister Assembly............................................................................. 205

Figure 8-3. H2S - SO2 Converter Assembly........................................................................ 208

Figure 8-4. Critical Flow Orifice Assembly ......................................................................... 210

Figure 9-1. Viewing and Clearing Warning Messages ........................................................... 214

Figure 9-2. Example of Signal I/O Function ........................................................................ 218

Figure 9-3. CPU Status Indicator ...................................................................................... 219

Figure 9-4. Shutter Assembly........................................................................................... 236

Figure 9-5. Location of UV Reference Detector Potentiometer ............................................... 237

Figure 9-6. Pre-Amplifier Board Layout.............................................................................. 239

Figure 10-1. UV Absorption.............................................................................................. 245

Figure 10-2. UV Light Path .............................................................................................. 247

Figure 10-3. Source UV Lamp Construction ........................................................................ 248

Figure 10-4. Excitation Lamp UV Spectrum Before/After Filtration ......................................... 249

Figure 10-5. PMT Optical Filter Bandwidth.......................................................................... 250

Figure 10-6. Effects of Focusing Source UV in Sample Chamber ............................................ 250

Figure 10-7. T101 Gas Flow and Location of Critical Flow Orifice ........................................... 254

xv

Page 18

TABLE OF CONTENTS Teledyne API – T101 Operation Manual

07266B DCN6485

Figure 10-8. Typical Flow Control Assembly with Critical Flow Orifice ..................................... 256

Figure 10-9. T101 Hydrocarbon Scrubber (Kicker) .............................................................. 257

Figure 10-10. T101 Electronic Block Diagram ..................................................................... 259

Figure 10-11. T101 CPU Board ......................................................................................... 261

Figure 10-12. T101 Sample Chamber................................................................................ 262

Figure 10-13. PMT Assembly............................................................................................ 263

Figure 10-14. Basic PMT Design ....................................................................................... 264

Figure 10-15. PMT Cooling System ................................................................................... 265

Figure 10-16. PMT Preamp Block Diagram ......................................................................... 266

Figure 10-17. Relay Board Status LED Locations................................................................. 268

Figure 10-18. Power Distribution Block Diagram ................................................................. 272

Figure 10-19. Front Panel and Display Interface Block Diagram............................................. 273

Figure 10-20. Basic Software Operation............................................................................. 274

Figure 11-1. Triboelectric Charging ................................................................................... 277

Figure 11-2. Basic anti-ESD Work Station .......................................................................... 280

LIST OF TABLES

Table 1-1. Analyzer Options............................................................................................... 20

Table 2-1. Model T101 Basic Unit Specifications.................................................................... 23

Table 3-1. Display Screen and Touch Control Description ....................................................... 28

Table 3-2. Rear Panel Description....................................................................................... 31

Table 3-3. Analog Input Pin Assignments............................................................................. 34

Table 3-4. Analog Output Pin Assignmentss ......................................................................... 35

Table 3-5. Status Output Signals........................................................................................ 37

Table 3-6. Control Input Signals......................................................................................... 38

Table 3-7. Inlet / Outlet Connector Descriptions ................................................................... 40

Table 3-8. H2S – SO2 Switching Valve Operating States ......................................................... 42

Table 3-9. NIST-SRM's Available for Traceability of H2S & SO2 Calibration Gases ....................... 44

Table 3-10. Zero/Span Valve Operating States ..................................................................... 46

Table 3-11. IZS Valve Operating States............................................................................... 49

Table 3-12. Possible Warning Messages at Start-Up .............................................................. 51

Table 4-1. Analyzer Operating Modes .................................................................................. 57

Table 4-2. Test Functions Defined....................................................................................... 59

Table 4-3. List of Warning Messages ................................................................................... 61

Table 4-4. Primary Setup Mode Features and Functions ......................................................... 64

Table 4-5. Secondary Setup Mode Features and Functions ..................................................... 64

Table 4-6. Password Levels............................................................................................... 74

Table 4-7. Variable Names (VARS)...................................................................................... 77

Table 4-8. T101 Diagnostic (DIAG) Functions ....................................................................... 81

Table 4-9. DIAG - Analog I/O Functions............................................................................... 85

Table 4-10. Analog Output Voltage Ranges .......................................................................... 85

Table 4-11. Analog Output Current Loop Range .................................................................... 86

Table 4-12. Analog Output Pin Assignments ......................................................................... 86

Table 4-13. Voltage Tolerances for Analog Output Calibration ................................................. 90

xvi

Page 19

Teledyne API – T101 Operation Manual TABLE OF CONTENTS

07266B DCN6485

Table 4-14. Current Loop Output Calibration with Resistor ..................................................... 94

Table 4-15. Test Parameters Available for Analog Output A4 ................................................ 102

Table 4-16. Ethernet Status Indicators .............................................................................. 107

Table 4-17. LAN/Internet Default Configuration Properties ................................................... 109

Table 4-18. Internet Configuration Touchscreen Button Functions ......................................... 113

Table 4-19. COMM Port Communication Modes ................................................................... 121

Table 4-20. Front Panel LED Status Indicators for DAS ........................................................ 125

Table 4-21. DAS Data Channel Properties .......................................................................... 126

Table 4-22. DAS Data Parameter Functions........................................................................ 127

Table 5-1. Status Output Pin Assignments ......................................................................... 145

Table 5-2. Control Input Pin Assignments .......................................................................... 145

Table 5-3. Terminal Mode Software Commands .................................................................. 147

Table 5-4. Command Types ............................................................................................. 148

Table 5-5. Serial Interface Documents .............................................................................. 154

Table 5-6. Hessen RS-232 Communication Parameters........................................................ 155

Table 5-7. T101 Hessen Protocol Response Modes............................................................... 157

Table 5-8. Default Hessen Status Bit Assignments .............................................................. 160

Table 6-1. NIST-SRM's Available for Traceability of H2S and SO2 Calibration Gases ................. 165

Table 6-2. AutoCal Modes................................................................................................ 179

Table 6-3. AutoCal Attribute Setup Parameters................................................................... 180

Table 6-4. Example Auto-Cal Sequence ............................................................................. 181

Table 6-5. Example Auto-Cal Sequence ............................................................................. 185

Table 7-1. Activity Matrix for Calibration Equipment & Supplies............................................. 188

Table 7-2. Activity Matrix for Calibration Procedure ............................................................. 189

Table 7-3. Activity Matrix ................................................................................................ 191

Table 7-4. Definition of Level 1 and Level 2 Zero and Span Checks........................................ 192

Table 8-1 T101 Preventive Maintenance Schedule ............................................................... 199

Table 8-2 Predictive Uses for Test Functions....................................................................... 201

Table 9-1. Warning Messages - Indicated Failures............................................................... 214

Table 9-2. Test Functions - Possible Causes for Out-Of-Range Values .................................... 216

Table 9-3. Relay Board Status LEDs.................................................................................. 220

Table 9-4. DC Power Test Point and Wiring Color Code ........................................................ 227

Table 9-5. DC Power Supply Acceptable Levels ................................................................... 227

Table 9-6. Relay Board Control Devices ............................................................................. 229

Table 9-7. Analog Output Test Function - Nominal Values .................................................... 229

Table 9-8. Status Outputs Check Pin Out ........................................................................... 230

Table 9-9. Example of UV Lamp Power Supply Outputs........................................................ 237

xvii

Page 20

TABLE OF CONTENTS Teledyne API – T101 Operation Manual

07266B DCN6485

This page intentionally left blank.

xviii

Page 21

07266B DCN6485

1. INTRODUCTION

The Model T101 UV Fluorescence H2S Analyzer measures hydrogen sulfide in levels

commonly required for Ambient Air monitoring. The analyzer converts sulfur gases to

sulfur dioxide and measures the SO

1.1. FEATURES

Some features of the T101 include:

LCD Graphical User Interface with capacitive touch screen

concentrations using fluorescence technology.

2

Microprocessor controlled for versatility

Multi-tasking software allows viewing of test variables during operation

Bi-directional USB, RS-232, and 100BaseT Ethernet ports for remote

operation (optional RS-485)

Front panel USB ports for peripheral devices

Auto ranging, dual range and remote range selection

Built in self checks and diagnostic capabilities

Digital status outputs provide instrument condition

Auto Zero System

Adaptive signal filtering optimizes response time

Temperature & pressure compensation

Optional Calibration valves or permeation oven

User friendly operation and set up

Internal Zero Span

Internal Datalogger

Critical Orifices provide flow stability

19

Page 22

Introduction Teledyne API – T101 Operation Manual

07266B DCN6485

1.2. OPTIONS

The options available for your analyzer are presented in Table 1-1 with name, option

number, a description and/or comments, and if applicable, cross-references to technical

details in this manual, such as setup and calibration. To order these options or to learn

more about them, please contact the Sales department of Teledyne - Advanced Pollution

Instruments at:

TOLL-FREE: 800-324-5190

TEL: +1 858-657-9800

FAX: +1 858-657-9816

E-MAIL: apisales@teledyne.com

WEB SITE: http://www.teledyne-api.com/

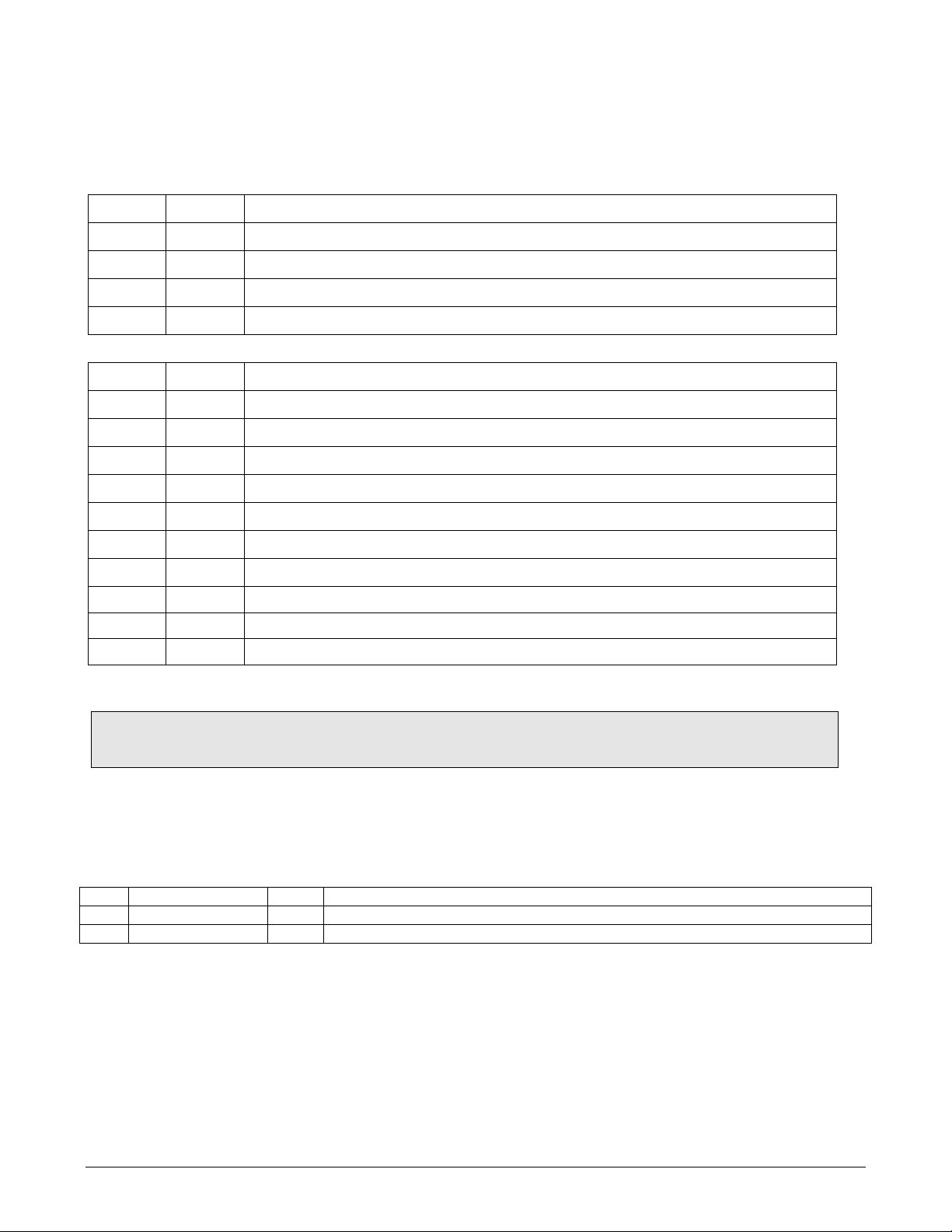

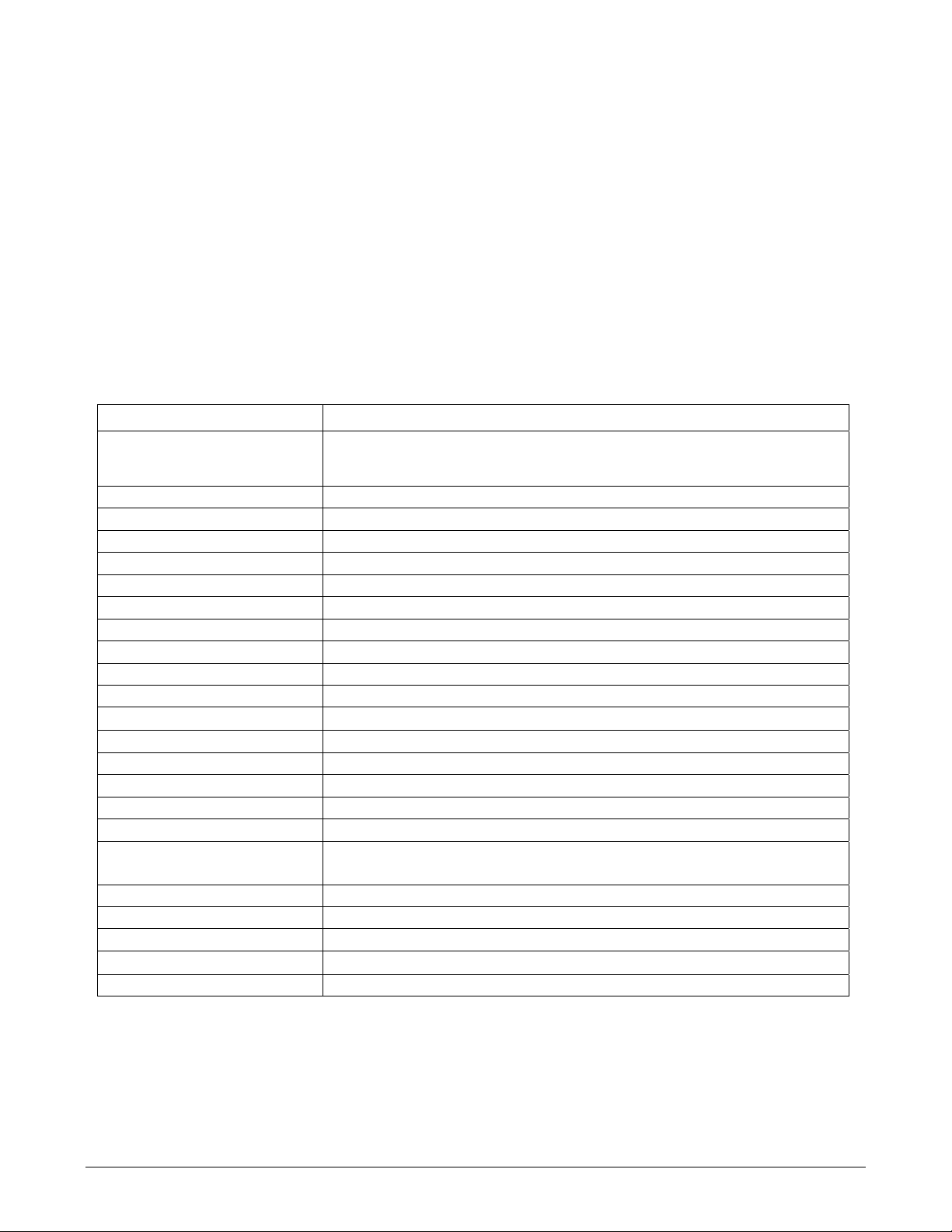

Table 1-1. Analyzer Options

Option

Pumps

Rack Mount

Kits

Carrying Strap/Handle Side-mounted strap for hand-carrying analyzer

29

Option

Number

Pumps meet all typical AC power supply standards while exhibiting

same pneumatic performance.

10A External Pump 100V - 120V @ 60 Hz

10B External Pump 220V - 240V @ 50 Hz

10C External Pump 220V - 240V @ 60 Hz

10D External Pump 100V – 12V @ 50 Hz

10E External Pump 100V @ 60 Hz

11A Pumpless (if one is standard either internal or external)

13 High Voltage Internal Pump 240V @ 50Hz

20A Rack mount brackets with 26 in. chassis slides

20B Rack mount brackets with 24 in. chassis slides

21 Rack mount brackets only (compatible with carrying strap, Option 29)

23 Rack mount for external pump pack (no slides)

Options for mounting the analyzer in standard 19” racks

Extends from “flat” position to accommodate hand for carrying.

Recesses to 9mm (3/8”) dimension for storage.

Can be used with rack mount brackets, Option 21.

Cannot be used with rack mount slides.

Description/Notes

20

CAUTION

GENERAL SAFETY HAZARD

A FULLY LOADED T101 WITH VALVE OPTIONS WEIGHS >20 KG (45

POUNDS).

To avoid personal injury we recommend that two persons lift and carry the

analyzer. Disconnect all cables and tubing from the analyzer before moving it.

Page 23

Teledyne API – T101 Operation Manual Introduction

07266B DCN6485

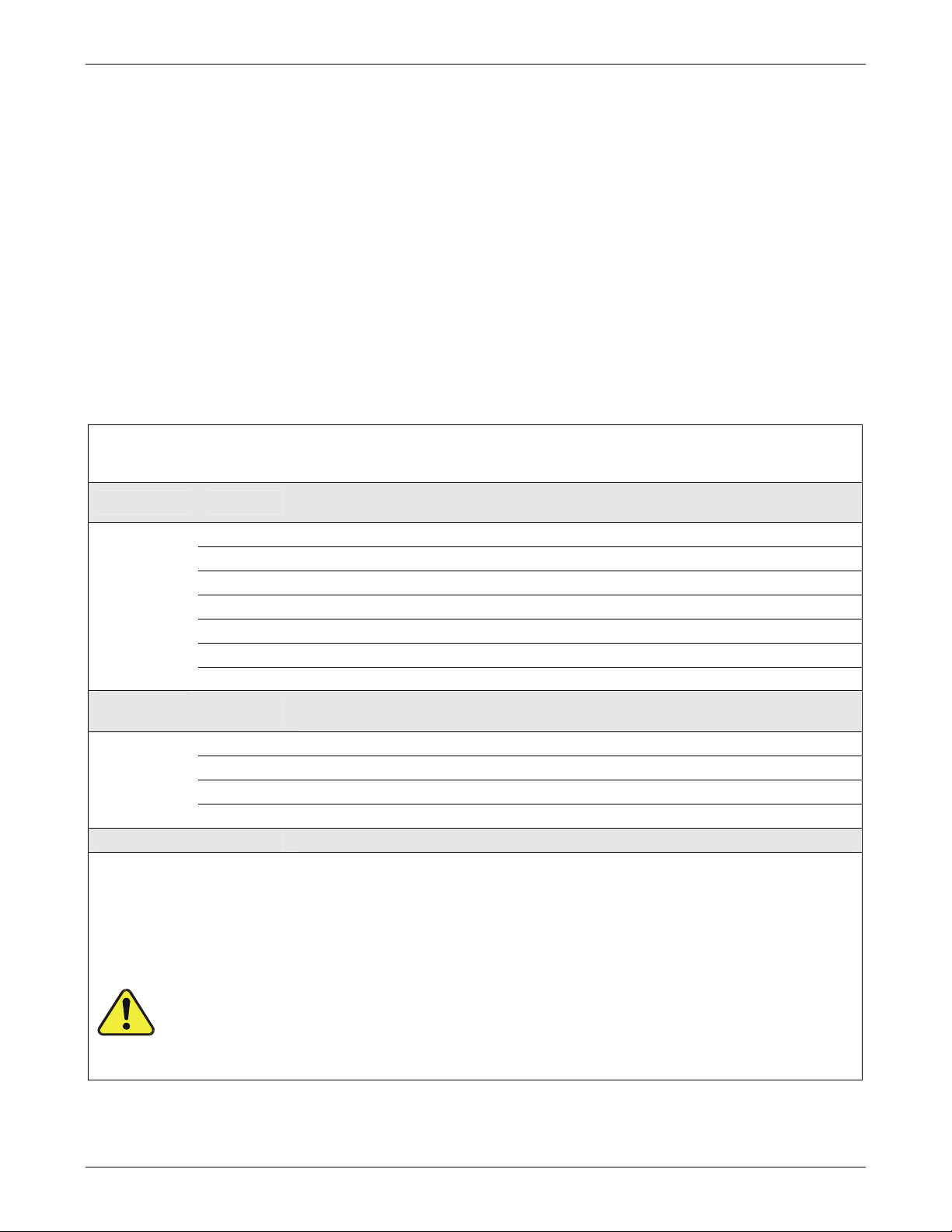

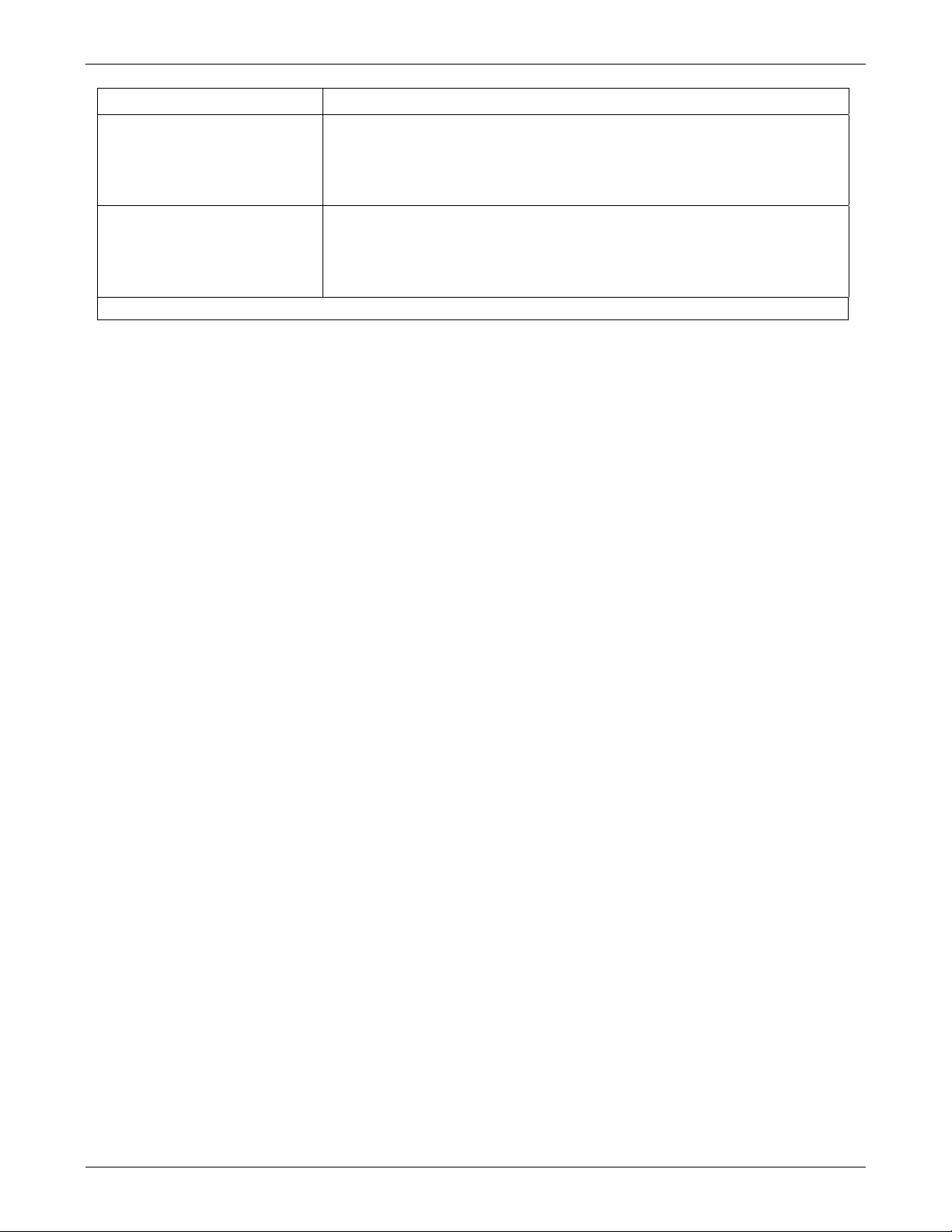

Option

Analog Inputs

64 Also can be used for logging these signals in the analyzer’s internal DAS

Current Loop Analog

Outputs

41

Parts Kits

NO Optical Filter Recommended for High NOX backgrounds.

47B Required for EN Certification.

Calibration Valves

Option

Number

Used for connecting external voltage signals from other instrumentation (such

as meteorological instruments).

Adds isolated, voltage-to-current conversion circuitry to the

analyzer’s analog outputs.

Isolated 0-20 or 4-20 mA current output (up to three can be retrofitted if not

installed at the factory)

42A

43

45 Spare Parts Kit includes spares parts for one unit.

50A Ambient Zero and Ambient Span

Expendables Kit with IZS includes the items needed to refurbish the

internal zero air scrubber (IZS) that is included.

Used to control the flow of calibration gases generated from external

sources, rather than manually switching the rear panel pneumatic

connections.

Description/Notes

50G Zero Scrubber and Internal Span Source (IZS)

H2 S Permeation Tubes

(uncertified) 52A 106 ng/min .08 -.12 ppm 0.76 lpm (nominal) ± 25%

(certified) 52E 76 ng/min .04 - .06 ppm 0.76 lpm ± 5%

Communication Cables

Type Description

60A RS-232

60B RS-232

60C Ethernet

60D USB

Concentration Alarm

Relay

61

Replacement tubes for the IZS option; identical size/shape; different

effusion rates.

Effusion Rate

(@ 50°C)

For remote serial, network and Internet communication with the

analyzer.

Shielded, straight-through DB-9F to DB-25M cable, about 1.8 m

long. Used to interface with older computers or code activated

switches with DB-25 serial connectors.

Shielded, straight-through DB-9F to DB-9F cable of about 1.8 m

length.

Patch cable, 2 meters long, used for Internet and LAN

communications.

Cable for direct connection between instrument (rear panel USB

port) and personal computer.

Issues warning when gas concentration exceeds limits set by user.

Four (4) “dry contact” relays on the rear panel of the instrument. This relay

option is different from and in addition to the “Contact Closures” that come

standard on all TAPI instruments.

Approximate

Concentration

Specified Flow Rate (of indicated perm

tube rate)

21

Page 24

Introduction Teledyne API – T101 Operation Manual

07266B DCN6485

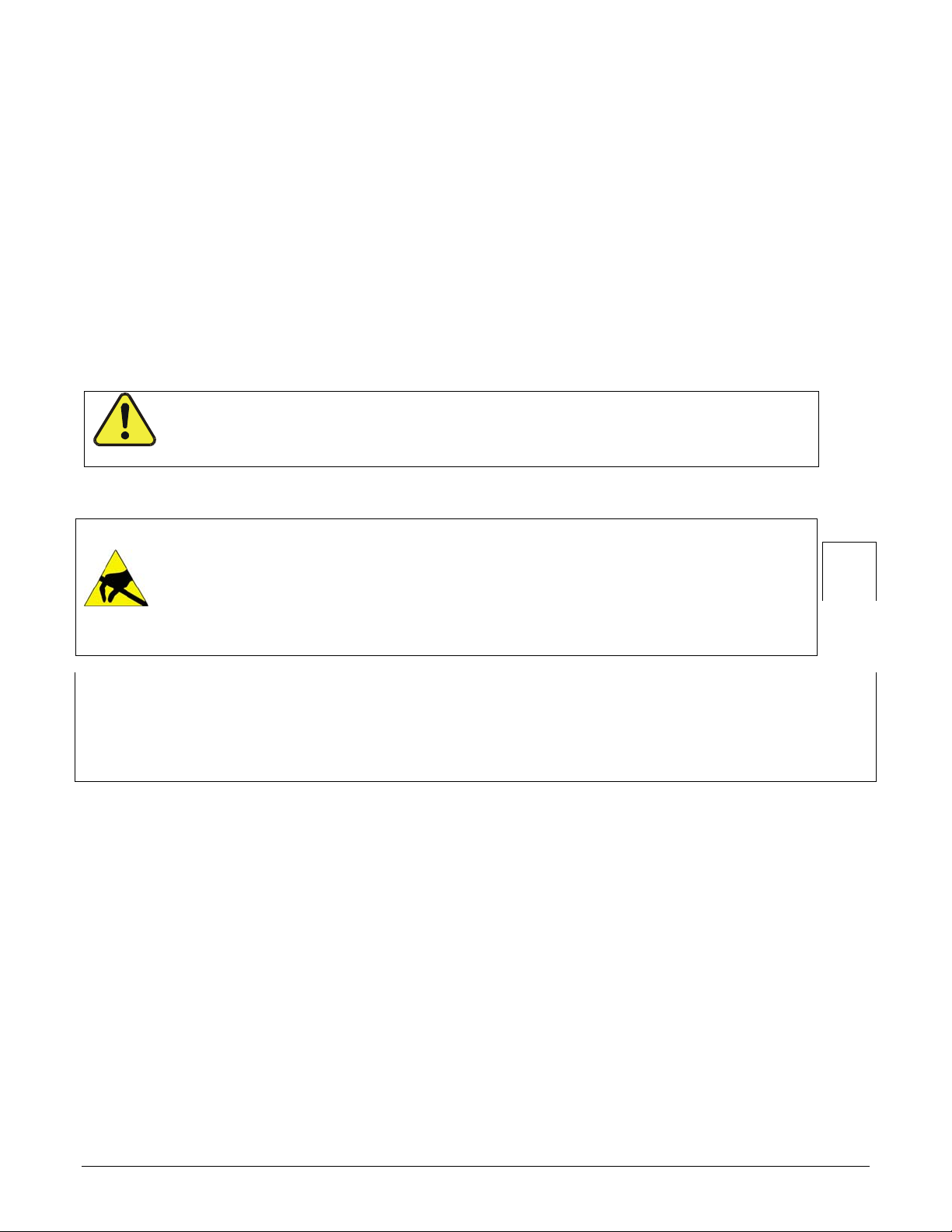

Option

RS-232 Multidrop

62

Special Features Built in features, software activated

N/A

N/A

N/A

Option

Number

Description/Notes

Enables communications between host computer and up to eight

analyzers.

Multidrop card seated on the analyzer’s CPU card.

Each instrument in the multidrop network requires this card and a

communications cable (Option 60B).

Maintenance Mode Switch, located inside the instrument, places the

analyzer in maintenance mode where it can continue sampling, yet ignore

calibration, diagnostic, and reset instrument commands. This feature is of

particular use for instruments connected to Multidrop or Hessen protocol

networks.

Call Technical Support for activation.

Second Language Switch activates an alternate set of display messages in

a language other than the instrument’s default language.

Call Technical Support for a specially programmed Disk on Module containing the

second language.

Dilution Ratio Option allows the user to compensate for diluted sample gas,

such as in continuous emission monitoring (CEM) where the quality of gas in a

smoke stack is being tested and the sampling method used to remove the gas

from the stack dilutes the gas.

Call Technical Support for activation.

22

Page 25

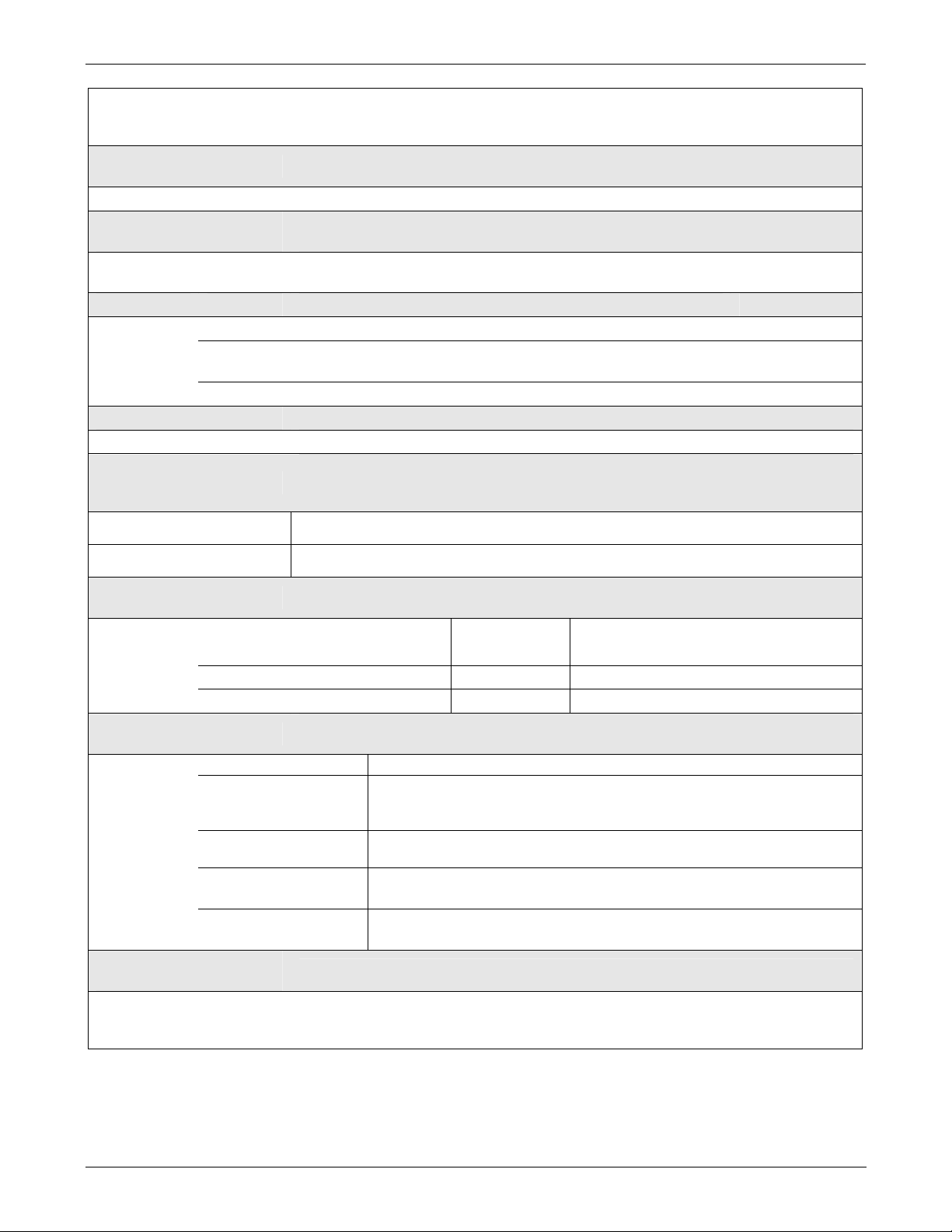

07266B DCN6485

2. SPECIFICATIONS AND APPROVALS

2.1. SPECIFICATIONS

Table 2-1. Model T101 Basic Unit Specifications

PARAMETER

Ranges H2S: Min 0-50 ppb Full scale; Max 0-10 ppm Full scale

SO

: Up to 0-20 ppm Full scale

2

(selectable, independent ranges and auto ranging supported)

Measurement Units ppb, ppm, µg/m3, mg/m3 (selectable)

Zero Noise1 <0.2 ppb (RMS)

Span Noise1 <0.5% of reading (RMS) above 50 ppb

Lower Detectable Limit2 0.4 ppb

Zero Drift (24 hours) <0.5 ppb

Span Drift (24 hours) <0.5% of full scale

Lag Time 20 seconds

Rise/Fall Time1 <120 seconds to 95%

Linearity 1% of full scale

Precision 0.5% of reading above 50 ppb

Sample Flow Rate

Temperature Coefficient < 0.1% per oC

Voltage Coefficient < 0.05% per V

Temperature Range 5-40oC

Humidity Range 0 - 95% RH, non-condensing

Dimensions H x W x D 7" x 17" x 23.5" (178 mm x 432 mm x 597 mm)

Weight, Analyzer

(Basic Configuration)

AC Power 100V-120V, 60 Hz (202W); 220V-240V, 50 Hz (200W)

Analog Output Ranges 10 V, 5V, 1V, 0.1V (selectable)

Analog Output Resolution 1 part in 4096 of selected full-scale voltage

Recorder Offset

Environmental Installation category (over-voltage category) II; Pollution degree 2

650 cm

41 lbs (18.3 kg)

45 lbs (20.5 kg) w/internal pump

±10%

3

/min ±10%

DESCRIPTION

23

Page 26

Specifications and Approvals Teledyne API – T101 Operation Manual

07266B DCN6485

PARAMETER

Standard I/O 1 Ethernet: 10/100Base-T

Optional I/O

For indoor use at altitudes ≤ 2000m only

2 RS-232 (300 – 115,200 baud)

2 USB device ports