Teledyne SofTA 300S ELSD Quick Start Manual

SofTA 300S ELSD

Quick Start Guide

Instruction Sheet 8-243109

May 2016

Overview

This quick start guide will take you through the steps

to successfully set up and use your SofTA 300S ELSD.

Please see the SofTA 300S ELSD User Manual for more

information regarding this product.

Connections

● Exhaust: The ELSD exhaust is a ½” O.D. stainless

steel tube. Use the supplied exhaust adaptor and

additional tubing to connect to a fume hood during operation.

● Communication: An output jack can be found on

the back of the ELSD for connection to a chart

recorder, computing integrator, or computerized data system. The maximum signal output is

1 V.

● Gas Connections: Connect a supply of clean, dry,

inert gas regulated to 65 psi to the

on the back of the unit. The internal gas regulator maintains the gas pressure at the factory set

value displayed on the front panel.

● Power Connection: The ELSD operates at either

120 V or 240 V, 50/60 Hz.

● Fluid Connections: Connect the outlet from your

HPLC injector to the inlet line on the front of the

unit. The length and volume between the injector outlet and the detector inlet should be kept

as short as possible to avoid unnecessary band

broadening.

● Thermo-Split Drain: Place the ¼” stainless steel

drain adapter, provided in the accessory kit, on

the drain port located on the front of the instrument. Direct the outlet of the tube to a collection vessel below the drain. Place the open end

of the flexible ¼” elastometric tubing in a suitable waste container, and trim the length as necessary. Watch the liquid level in the container

during operation and empty it when it is full

(especially when running the spray chamber at

sub-ambient temperature).

Location

All components of the system should be placed on a

sturdy table or bench in a room with a room temperature of 20 ± 5 °C. The detector is designed to fit

alongside an HPLC system. The detector must be placed

with at least 4” of clearance on the right and back of the

detector to allow for proper air flow through the

detector. Access to the back of the unit is required to

make the appropriate connections and provide for safe

removal of the power cord.

GAS INLET port

Operation

Instrument Controls

The ELSD is controlled via six touch-sensitive keys

on the front panel labeled PWR (power), A/Z (A/Z), ESC

(escape),

behind the front panel. The touch-sensitive keys are

activated by lightly placing a finger over the light representing the key. An audible beep is heard when the key

is activated. Touching the

parameters section to review operation conditions. If

there is a * at the upper right corner, touching ESC key

will bring up a screen to explain what’s wrong.

Menu

Touching the ENT key will bring up the MENU screen.

Start-up

▲ (up), ▼ (down) and ENT (enter) found

▲ or ▼ keys will circulate the

SC = Spray Chamber (setpoint: 10 °C to 60 °C; readout

range: -10.0 °C to 120.0 °C)

DT = Drift Tube (setpoint: 22°C to 120°C; readout

range: -10.0 °C to 120.0 °C)

OC = Optical Cell (setpoint: 22 °C to 70 °C; readout

range: -10.0 °C to 120.0 °C)

RST= Reset baseline to about 20 mV.

BLN = Baseline reading (5000.000 – 0.000 mV)

GAS = Gas (0.0 to 130.0 psi)

FLT or BFT = Baseline Filter (OFF, weight 1 to 10)

FS = Full Scale (1 V or 10 mV)

GAIN = Gain (Normal or Low)

CAL = Calibration (50% to 200%)

1. Make all connections (gas, liquid, power, communications, exhaust, and drain) as described

above. Do not turn on the gas supply yet.

2. Press the M

nostic tests. When the tests are complete, pressing the M

mode.

3. Confirm that the correct conditions are set by

touching the

parameters. If not

to display the M

keys to select set points. Touch M

key to accept the changes. The A

functions as an escape key, and abandons any

changes made.

4. Start your HPLC pump to deliver 1 mL/min

mobile phase to the detector. When you see liquid coming out of the drain port, the internal “p”

trap is filled with the mobile phase. (This may

ENU | Power key to begin self-diag-

ENU | Power key again will exit standby

▲ or ▼ keys to cycle through the

, touch the MENU | Power key

ENU screen. Touch the ▲ or ▼

ENU | Power

UTOZERO key

take up to 10 minutes.) Stop the pump at this

time.

5. Before conditions are met, a * blinks at the

upper right corner of the display and the green

light above Ready is not lit. Press the

ENU | Power key to display the error condition.

M

Allow up to 30 minutes for temperatures to reach

their set points and the electronics to stabilize.

6. Start the gas flow.

7. When the gas flow is stable, start the mobile

phase flow.

8. When the R

UTOZERO key to reset the baseline. Cycle

A

EADY light illuminates, press the

through the settings to BLN. This is the voltage

offset by the A

UTOZERO button. Record this value.

It is important to record this value for each set of

operating conditions. If the value is high (greater than

500 mV), the mobile phase is not being evaporated and

the detector temperatures should be modified. Monitor

your data system and ELSD signal for stability. The

signal should be stable within 2 mV. When stable, begin

your analysis.

Shut Down Procedure

Stop the flow of mobile phase to the system. Wait for

the pump pressure to return to zero. Select the E

TANDBY button from the HOME page or activate the

S

power key and follow the on screen directions. Allow the

standby timer to count down. In standby, the gas flow is

shut off and the laser and heaters are turned off.

NTER

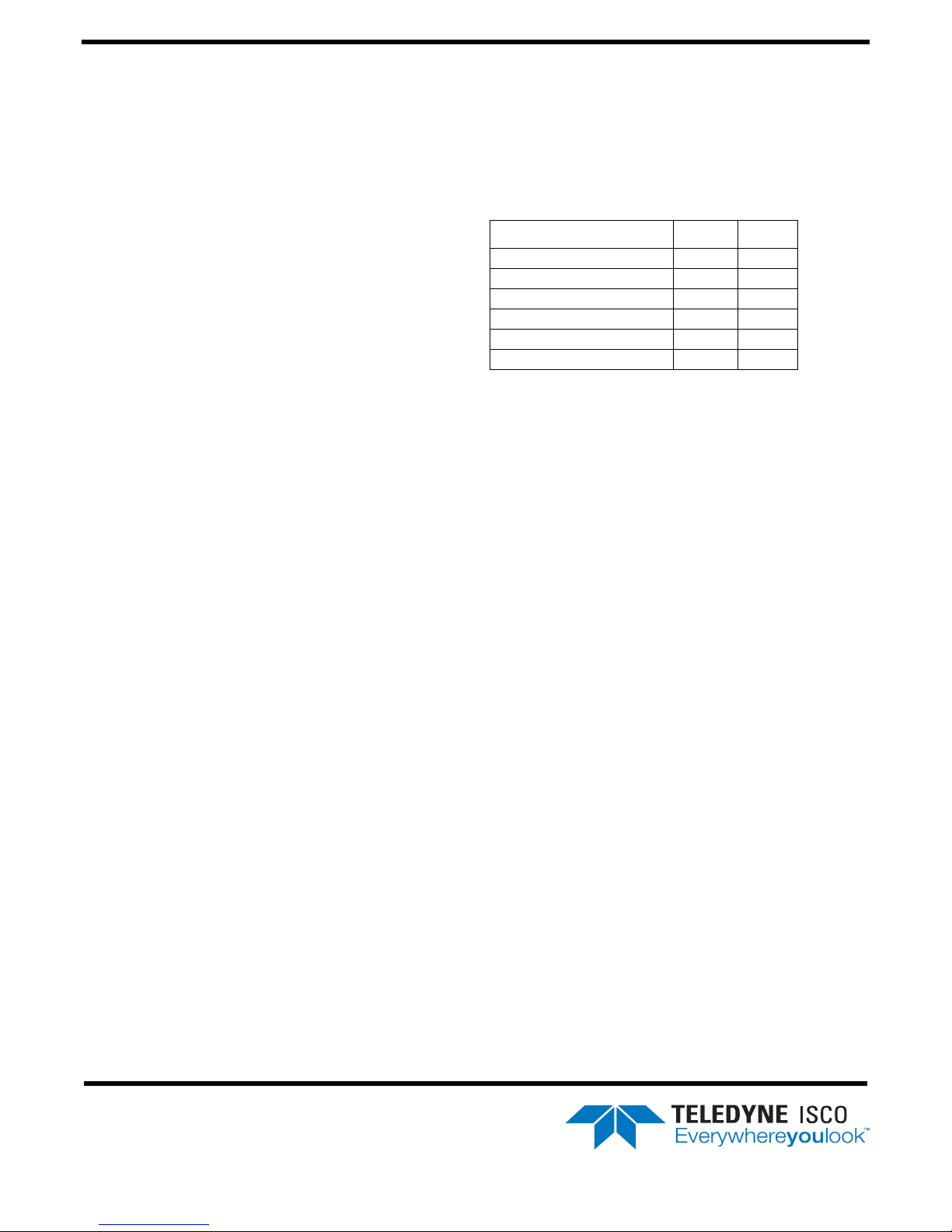

performance. The following table can provide a starting

point for some common mobile phases. Optimization for

the best signal-to-noise ratio will provide the best

sensitivity.

Solvent @ 1.0mL/min DT, °C SC, °C

90/10 Water/METHANOL 45 15

90/10 Methanol/WATER 65 50

50/50 Methanol/Water 60 30

Acetonitrile 60 50

Methanol 60 50

Water 45 10

Choosing Operating Conditions

The drift tube temperature and the Thermo-Split

spray chamber temperature are selected to provide the

maximum detector response with minimum baseline

noise. The temperatures are selected based on the solvent volatility and mobile phase flowrate. Some

experimentation will be required to optimize the ELSD.

When setting the ELSD temperatures for a new

method, select 25 °C for spray chamber temperature

and 55 °C for drift tube temperature. These temperatures should then be adjusted for the best

signal-to-noise ratio during method optimization. A

mobile phase that is highly organic and volatile will

require a moderately high drift tube temperature and an

ambient or elevated spray chamber temperature. Highly

aqueous or high boiling point organic mobile phases will

perform best at moderate drift tube temperatures and

sub-ambient spray chamber temperatures.

Each mobile phase can require a different set of operating conditions to achieve the best detector

Teledyne Isco

P.O. Box 82531, Lincoln, Nebraska, 68501 USA

Toll-free: (800) 775-2965 • Phone: (402) 464-0231 • Fax: (402) 465-3001

E-mail: IscoService@teledyne.com

Teledyne Isco is continually improving its products and reserves the right to change product

specifications, replacement parts, schematics, and instructions without notice.

Loading...

Loading...