1-Feb-12

03-032-20123-00

www.teledynedalsa.com

Spyder3

SG-14 Camera User’s Manual

2 Spyder3 GigE Vision SG-14 Cameras User’s Manual

North America

605 McMurray Rd

Waterloo, ON N2V 2E9

Canada

Tel: 519 886 6000

Fax: 519 886 8023

www.teledynedalsa.com

sales.americas@teledynedalsa.com

support@teledynedalsa.com

Europe

Breslauer Str. 34

D-82194 Gröbenzell (Munich)

Germany

Tel: +49 - 8142 – 46770

Fax: +49 - 8142 – 467746

www. teledynedalsa.com

sales.europe@teledynedalsa.com

support@teledynedalsa.com

Asia Pacific

Ikebukuro East 13F

3-4-3 Higashi-Ikebukuro

Toshima-ku, Tokyo 170-0013

Japan

Tel: 81 3 5960 6353

Fax: 81 3 5960 6354 (fax)

www.teledynedalsa.com

sales.asia@teledynedalsa.com

support@teledynedalsa.com

© 2012 Teled yne DALSA Inc. All information provided in this manual is believed to be accurate and reliable. No responsibility is

assumed by Teledyne DALSA for its use. Teledyne DALSA reserves the right to make changes to this information without notice.

Reproduction of this manual in whole or in part, by any means, is prohibited without prior permission having been obtained from

Teled yne DALSA.

About Teledyne Technologies and Teledyne DALSA, Inc.

Teled yne Technologies is a leading provid er of sophisticated electronic subsystems, instrumentation and communication products,

en gin eered systems, aero sp a ce en gine s, and energy an d p ow er ge nera tio n systems. Teledyn e Techn ologies’ op erations ar e p rimar i ly

located in the United States, the United Kingdom and Mexico. For more information, visit Teled yne Tech nologies’ website a t

www.teledyne.com.

Teled yne DALSA, a Teledyne Technologies company, is an international leader in high performance digital imaging and

semiconductors with approximately 1,000 employees worldwide, headquartered in Waterloo, Ontario, Canad a. Established in 1980,

the company designs, develops, manufactures and markets digital imaging products and solutions, in addition to providing MEMS

products an d serv ices. For mo re information , visit Teled yne DA LSA’s w ebsite at w w w .teled ynedalsa.com.

Support

For further information not included in this manual, or for information on Teledyne DALSA’s extensive lin e of imag e sensing

products, please contact:

Industry Standards

Spyder GEV cameras are 100% compliant with the GigE Vision 1.0 specification. This specification defines

the communication interface protocol used by GigE Vision devices. For more information on these

requirements refer to the following site:

http:/ / www.machinevisiononline.org/ public/ articles/ details.cfm?id=2761

Spyder GEV cameras implement a superset of the GenICam ™ specification which defines device

capabilities. This description takes the form of an XML device description file respecting the syntax

defined by the GenApi module of the GenICam specification. For more information on these

requirements refer to the following site: www.genicam.org.

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 3

Contents

The Spyder3 SG-14 Cameras ________________________________________________________________________ 6

Camera Highlights ............................................................................................................................................................. 6

Camera Performance Specifications .................................................................................................................................. 7

Certifications ...................................................................................................................................................................... 10

Responsivity ....................................................................................................................................................................... 11

Mechanicals ........................................................................................................................................................................ 12

Mounting ......................................................................................................................................................... 13

Image Sensor ..................................................................................................................................................................... 14

Software and Hardware Setup .......................................................................................................................................... 15

Host System Requirements ............................................................................................................................. 15

Network Adapter Requirements ..................................................................................................................... 15

Ethernet Switch Requirements ........................................................................................................................ 15

Setup Steps: Overview ....................................................................................................................................................... 15

1. Install and Configure Ethernet Network Card ............................................................................................. 15

2. Connect Power, Ethernet and I/O Cables .................................................................................................... 16

3. Establish communicating with the camera .................................................................................................. 16

4. Check camera LED, settings and test pattern .............................................................................................. 16

5. Operate the Camera ................................................................................................................................... 16

Step 1. Ethernet Network Card: Install and Configure ...................................................................................................... 17

Install Network Card ....................................................................................................................................... 17

Configure Network Card ................................................................................................................................. 17

Step 2. Connect Power, Ethernet, and Trigger Cables ....................................................................................................... 20

Power Connector ............................................................................................................................................. 20

Ethernet Connector and Ethernet LED ............................................................................................................ 21

Status LED ....................................................................................................................................................... 21

GPIO Connector: External Input ..................................................................................................................... 22

GPIO Isolation................................................................................................................................................. 22

GPIO Configuration ........................................................................................................................................ 22

TTL Inputs and Outputs................................................................................................................................... 23

Step 3. Establish Communication with the Camera ........................................................................................................... 24

Power on the camera ...................................................................................................................................... 24

Connect to the camera .................................................................................................................................... 24

Check LED Status ............................................................................................................................................ 24

Software Interface ........................................................................................................................................... 24

Using Sapera CamExpert with Spyder3 Cameras .............................................................................................................. 25

CamExpert Panes ............................................................................................................................................ 26

Step 4. Camera Settings and Test Patterns ....................................................................................................................... 28

Review a Test Pattern Image .......................................................................................................................... 28

Camera Operation _______________________________________________________________________________ 29

Factory Settings ................................................................................................................................................................. 29

Check Camera and Sensor Information ............................................................................................................................. 30

Verify Temperature and Voltage ....................................................................................................................................... 30

Saving and Restoring Camera Settings ............................................................................................................................. 31

Teledyne DALSA 03-032-20123-00

4 Spyder3 GigE Vision SG-14 Cameras User’s Manual

Timing: Exposure and Synchronization ............................................................................................................................. 33

Timing ............................................................................................................................................................. 34

Exposure Controls .............................................................................................................................................................. 35

Set the Exposure Mode.................................................................................................................................... 35

Exposure Modes in Detail ............................................................................................................................... 36

Line Rate ........................................................................................................................................................................... 37

Exposure Time ................................................................................................................................................................... 38

Triggers.............................................................................................................................................................................. 38

Input / Output Control ....................................................................................................................................................... 39

Gain, Black Level, and Background .................................................................................................................................. 40

Image Size ......................................................................................................................................................................... 41

Pixel Format ...................................................................................................................................................................... 42

Sensitivity Mode ................................................................................................................................................................. 42

Sensor Direction Control .................................................................................................................................................... 42

Sensor Shift Direction ..................................................................................................................................... 43

Binning .............................................................................................................................................................................. 44

Resetting the Camera ........................................................................................................................................................ 44

Camera Calibration_______________________________________________________________________________ 45

Processing Chain Overview and Description ................................................................................................... 45

Analog Gain and Offset Adjustment .................................................................................................................................. 47

Calibrate the Camera to Remove Non-Uniformity (Flat Field Correction) ........................................................................ 49

Digital Signal Processing ................................................................................................................................ 51

Appendix A: Clear Dark Current ______________________________________________________________________ 55

Setting the Readout Mode .............................................................................................................................. 55

Appendix B: Sensitivity Mode ________________________________________________________________________ 62

Sensitivity Mode and Pixel Readout ............................................................................................................... 62

Appendix C: GPIO Control __________________________________________________________________________ 64

GPIO Getting Started: Beginner Mode .............................................................................................................................. 64

The GPIO Connector ........................................................................................................................................ 64

Configure GPIO Signal Levels ......................................................................................................................... 65

Examples: Setting the Camera Modes ............................................................................................................................... 66

Free Run Mode: Internal Line Trigger, Internal Direction Control, Internal frame trigger ........................... 66

Internal Line Trigger, External Direction Control, Internal frame trigger...................................................... 68

External Line Trigger, Internal Direction Control, Internal frame trigger...................................................... 69

External Line Trigger, External Direction Control from Rotary Encoder......................................................... 70

External Frame Trigger: Frame Start Trigger mode ..................................................................................... 72

Outputs .............................................................................................................................................................................. 75

Trigger Settings: GURU Mode ........................................................................................................................................... 77

Pulse Generator .............................................................................................................................................. 80

Rescaler ........................................................................................................................................................... 82

Counter ........................................................................................................................................................... 84

Input Debouncing ........................................................................................................................................... 85

Timestamp Counter ......................................................................................................................................... 86

Delayer ........................................................................................................................................................... 88

PLC Control ........................................................................................................................................................................ 88

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 5

The PLC Control Block ..................................................................................................................................... 89

GPIO Output Labels ........................................................................................................................................ 91

Signal Routing Block ......................................................................................................................................................... 93

How the Signal Routing Block Works ............................................................................................................. 94

How the Lookup Table Works ......................................................................................................................... 96

Appendix D: EMC Declaration ________________________________________________________________________ 97

Revision History _________________________________________________________________________________ 98

Index ________________________________________________________________________________________ 99

Teledyne DALSA 03-032-20123-00

6 Spyder3 GigE Vision SG-14 Cameras User’s Manual

The Spyder3 SG-14 Cameras

Camera Highlights

The Spyder3 SG-14 GigE Vision (GEV) are high sensitivity dual-line scan cameras. When operating in

high sensitivity (dual line scan) mode the Spyder3 GEV camera has 3x the responsivity of Teledyne

DALSA’s Sp yd er2 line scan cam era. Plus, the GigE Vision interface eliminates the need for a frame

grabber, resulting in significant system cost savings.

The Spyd er3 ca m eras ar e su pp orted by Teled yne DALSA Sap era™ softw are librar ies featu rin g

CamExpert for simplified camera set-up and configuration.

Features

Broadband responsivity up to 408 ±16 DN (nJ/ cm2) @ 10dB gain

1024, 2048, or 4096 x 2 pixels, 14 µm x 14 µm (1k and 2k) and 10 µm x 10 µm (4k) pixel pitch, 100 %

fill factor

High or low speed (40 or 80 MHz)

Up to 68 KHz line rates

Dynamic range up to 1400 : 1

Data transmission up to 100 meters

RoHS and CE compliant

GenICam-compliant

Programmable gain, offset, exposure time and line rate, trigger mode, test pattern output, and camera

diagnostics

Tall pixel, high sensitivity, or low sensitivity mode available

Flat-field correction—minimizes lens vignetting, non-uniform lighting, and sensor FPN and PRNU

Applications

FPD inspection

Pick and place

Container inspection

Wood / tile / steel inspection

100 % print inspection (lottery tickets, stamps, bank notes, pay checks)

Postal sorting

Glass bottle inspection

Industrial metrology

Food inspection

Web inspection

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 7

Model Number

Description

SG-14-01K40-00-R

1k resolution, 1 sensor tap, 40 MHz d ata rate, 36 kHz line rate, RoHS compliant.

SG-14-01K80-00-R

1k resolution, 2 sensor taps, 80 MHz data rate, 68 kHz line rate, RoHS compliant.

SG-14-02K40-00-R

2k resolution, 1 sensor tap, 40 MHz d ata rate, 18.5 kHz line rate, RoHS compliant.

SG-14-02K80-00-R

2k resolution, 2 sensor taps, 80 MHz data rate, 36 kHz line rate, RoHS compliant.

SG-14-04k80-00-R

4k resolution, 2 sensor taps, 80 MHz data rate, 18.5 kHz line rate, RoHS compliant.

Software

Product Number / Version Number

Sapera LT, including CamExpert GUI

application

Version 7.1 or later. Tested and recommended.

QuickCam

Version 2.0. Compliant.

Pleora Technologies Inc.’s Coyote

Compliant.

Third party software. E.g. CVB and NI.

Compatible. Drivers need to be provided by the third party.

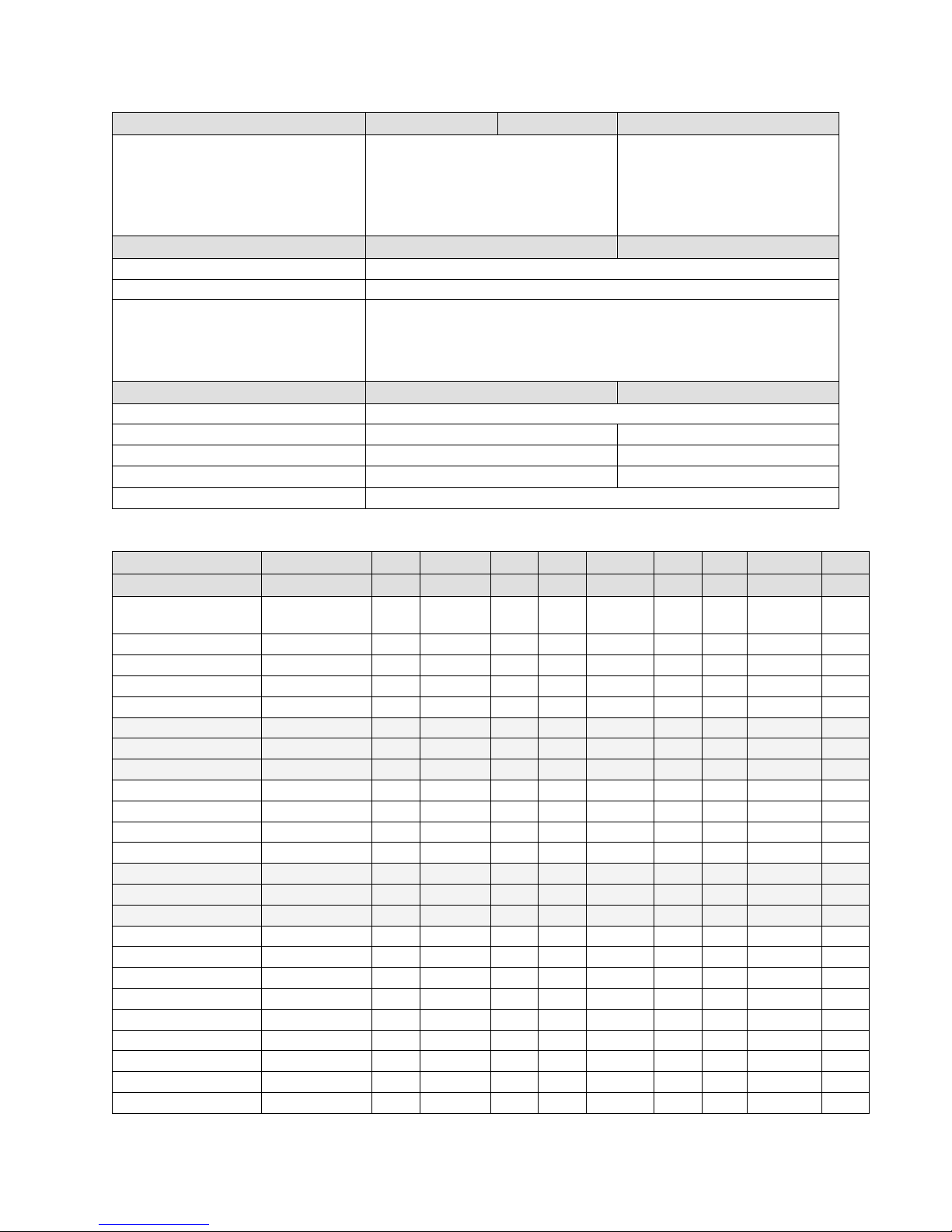

Feature / Specification

1k

2k

4k

Imager Format

dual line scan

dual line scan

dual line scan

Resolution

1024 x 2 pixels

2048 x 2 pixels

4096 x 2 pixels

Pixel Fill Factor

100 %

100 %

100 %

Pixel Size

14 µm x 14 µm

14 µm x 14 µm

10 µm x 10 µm

Output Format (# of taps)

1 or 2

depending on

model

1 or 2 depending

on model

2

Sensitivity Mode

High, low, or tall

pixel

High, low, or tall

pixel

High, low, or tall pixel

Antiblooming

100x

100x

100x

Gain Range

-10 dB to +10 dB

-10 dB to +10 dB

Not available. Calibrated at 0 dB.

Speed

1k

2k

4k

Minimum Internal Line Rate

300 Hz

300 Hz

300 Hz

Maximum Line Rate

80 MHz model

68 kHz

36 kHz

18.5 kHz

40 MHz model

36 kHz

18.5 kHz

NA

Data Rate

40 or 80 MHz

40 or 80 MHz

80 MHZ

Optical Interface

Back Focal Distance

6.56 ± 0.25 mm

Lens Mounts

M42 x 1, C and F (1k and 2k)

M58 x 0.75, F (4k)

Models

The Spyder3 SG-14 camera is available in the following configurations:

Table 1: Camera Models Overview

Table 2: Software

Camera Performance Specifications

Table 3: Camera Performance Specifications

Teledyne DALSA 03-032-20123-00

8 Spyder3 GigE Vision SG-14 Cameras User’s Manual

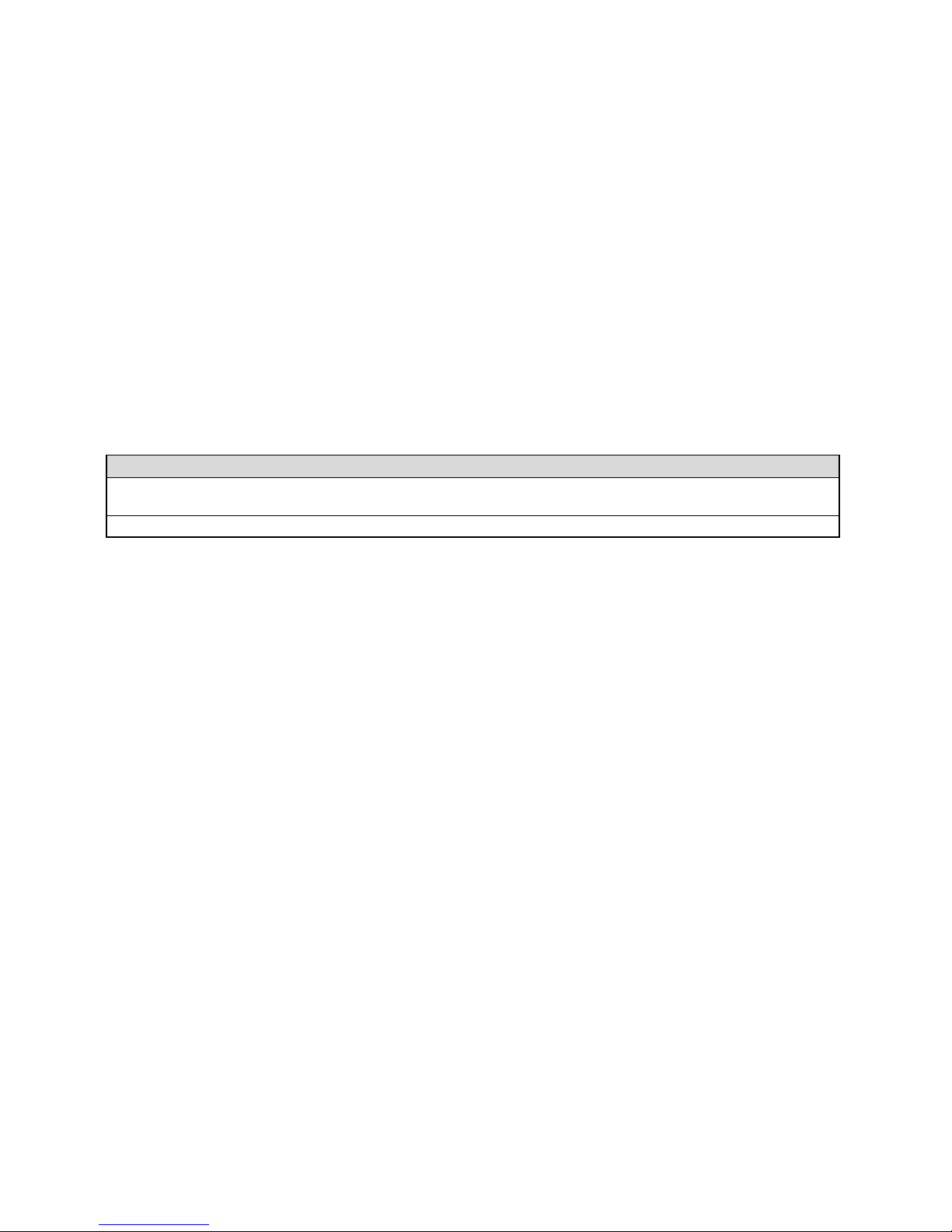

Feature / Specification

1k

2k

4k

Sensor Alignment

x

y

z

z

±50 µm

±50 µm

±0.25 mm

±0.2°

Mechanical Interface

1k and 2k

4k

Camera Size

72 mm x 60 mm x 65 mm, all models

Mass

< 300 g

Connectors

power connector

GigE connector

GPI/ O connector

6 pin male Hirose

RJ45

High density 15-pin dsub

Electrical Interface

Input Voltage

+12 V to +15 V

Power Dissipation

< 9 W

< 9 W (4k)

Operating Temperature

0 °C to 65 °C

Bit Wid th

8 or 12 bit, user selectable

Output Data Configuration

GigE Vision

Specifications

Unit

-10 dB

0 dB

+10 dB

Min

Typ

Max

Min

Typ

Max

Min

Typ

Max

Broadband

responsivity

DN/ (nJ/ cm²)

1k and 2k Dual line

652.8

2064

6528

1k and 2k Single line

326.4

1032

3264

4k Dual line

431

1363

4k Single line

216

682

Random noise rms

DN 1k and 2k

3

6.5 9.2

20.5 30

65

4k 10

24

Dynamic range

DN:DN

1k and 2k Dual line

500:1

1400:1

203:1

324:1

59:1

108:1

1k and 2k Single line

500:1

1400:1

203:1

324:1

59:1

108:1

4k Dual and Single

1225:1

387:1

FPN global

DN p-p

Uncorrected

52.8

169.6

536

Corrected

32

32

64

PRNU ECD

Uncorrected local

%

8.5

8.5

11.5

Uncorrected global

%

10

10

10

Corrected local

DN p-p

80

80

95

Corrected global

DN p-p

80

80

95

4k Dual and Single

Corrected local

DN p-p

32

32

Corrected global

DN p-p

80

80

Uncorrected local

%

9.5

9.5

Table 4: Camera Operating Specifications

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 9

Uncorrected

global

%

20

20

PRNU ECE

Uncorrected local

%

8.5

12

37

Uncorrected global

%

10

12

37

Corrected local

DN p-p

80

237

752

Corrected global

DN p-p

80

208

752

4k Dual and Single

Corrected local

DN p-p

237

237 Corrected global

DN p-p

237

237

Uncorrected local

%

9.5

9.5

Uncorrected global

%

20

20

SEE (calculated)

nJ/ cm²

1k and 2k Dual line

6.35

1.92

0.61 1k and 2k Single line

12.2

4.0

1.2

4k Dual line

9.2

2.9

4k Single line

18.0

5.7

NEE (calculated)

pJ/ cm²

Dual line

4.6

4.5

4.6

Single line

9.2

9.3

9.2

4k Dual line

7.0

8.1

4k Single line

14.0

16.1

Saturation output

amplitude

DN

3968±80

DC offset

DN

96

160

336

Teledyne DALSA 03-032-20123-00

10 Spyder3 GigE Vision SG-14 Cameras User’s Manual

Compliance

The CE Mark, FCC Part 15, and Industry Canada ICES-003 Evaluation of the DALSA Spyder GigE SG-14 cameras

meet the following requirements:

EN 55022 Class A, and EN 61326 Emissions Requirements, EN 55024, and EN 61326 Immunity to Disturbances

Test conditions unless otherwise noted:

12-bit values, Flat Field Correction (FFC) enabled.

CCD Pixel Rate: 40 MHz per sensor tap

Line Rate: 5000 Hz

Nominal Gain setting unless otherwise specified

Light Source: Broadband Quartz Halogen, 3250k, with 750 nm high-pass filter installed

Ambient test temperature 25 °C

Unless specified, all values are referenced at 12 bit

Exposure mode disabled.

Unless specified, dual line mode.

Note: PRNU measured at 50% SAT.

Certifications

Table 5: EMC Compliance Standards

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 11

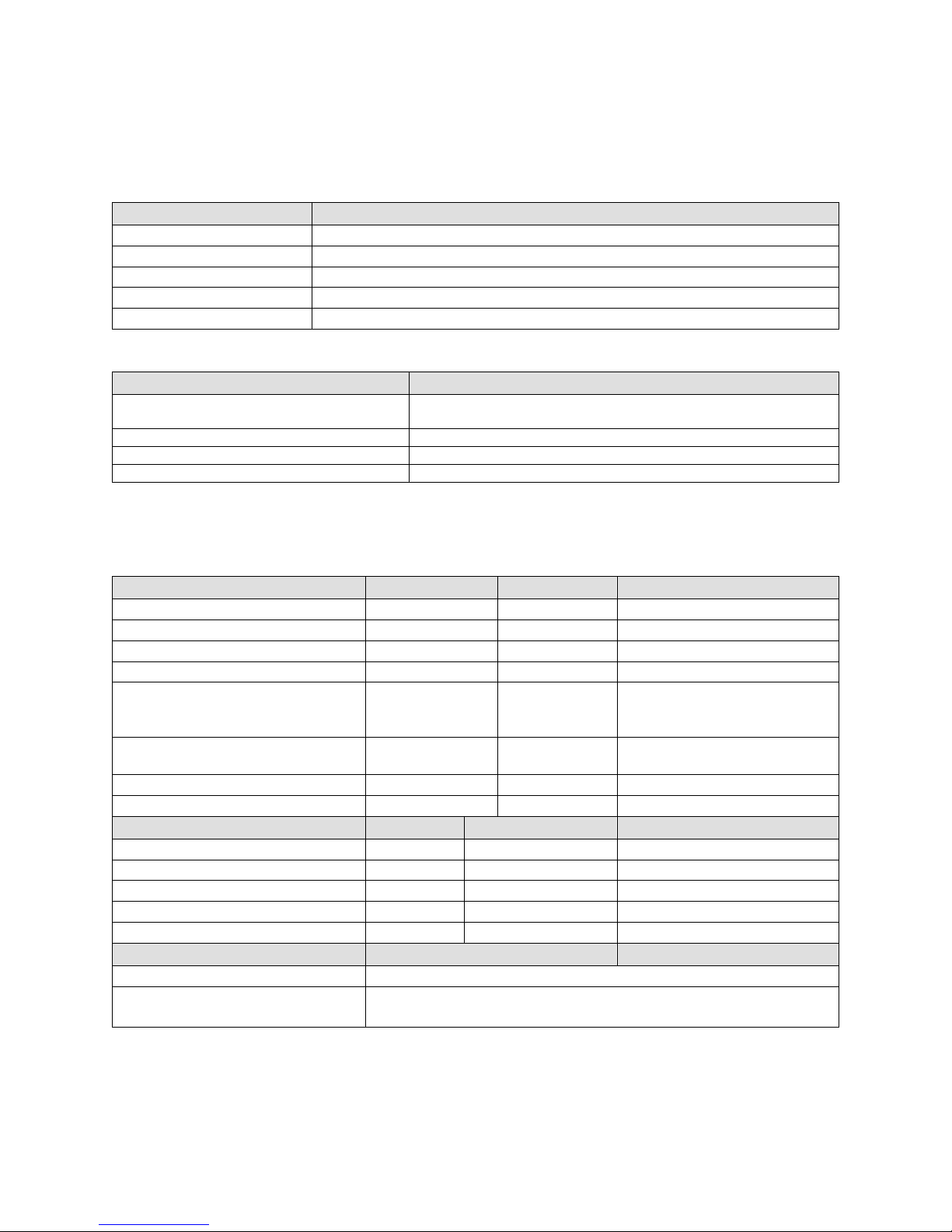

Spectral Responsivity @ 0 dB Gain

0

200

400

600

800

1000

1200

1400

1600

1800

2000

400

500

600

700

800

900

1000

1100

Wavelength (nm)

Low Sensitivity Mode

Hi Sensitivity Mode

12 bits DN/nJ/cm Responsivity

2

Responsivity

Figure 1: Spyder3 GigE Vision 1k and 2k Responsivity

Figure 2: Spyder3 GigE Vision 4k Responsivity

Teledyne DALSA 03-032-20123-00

12 Spyder3 GigE Vision SG-14 Cameras User’s Manual

Mechanicals

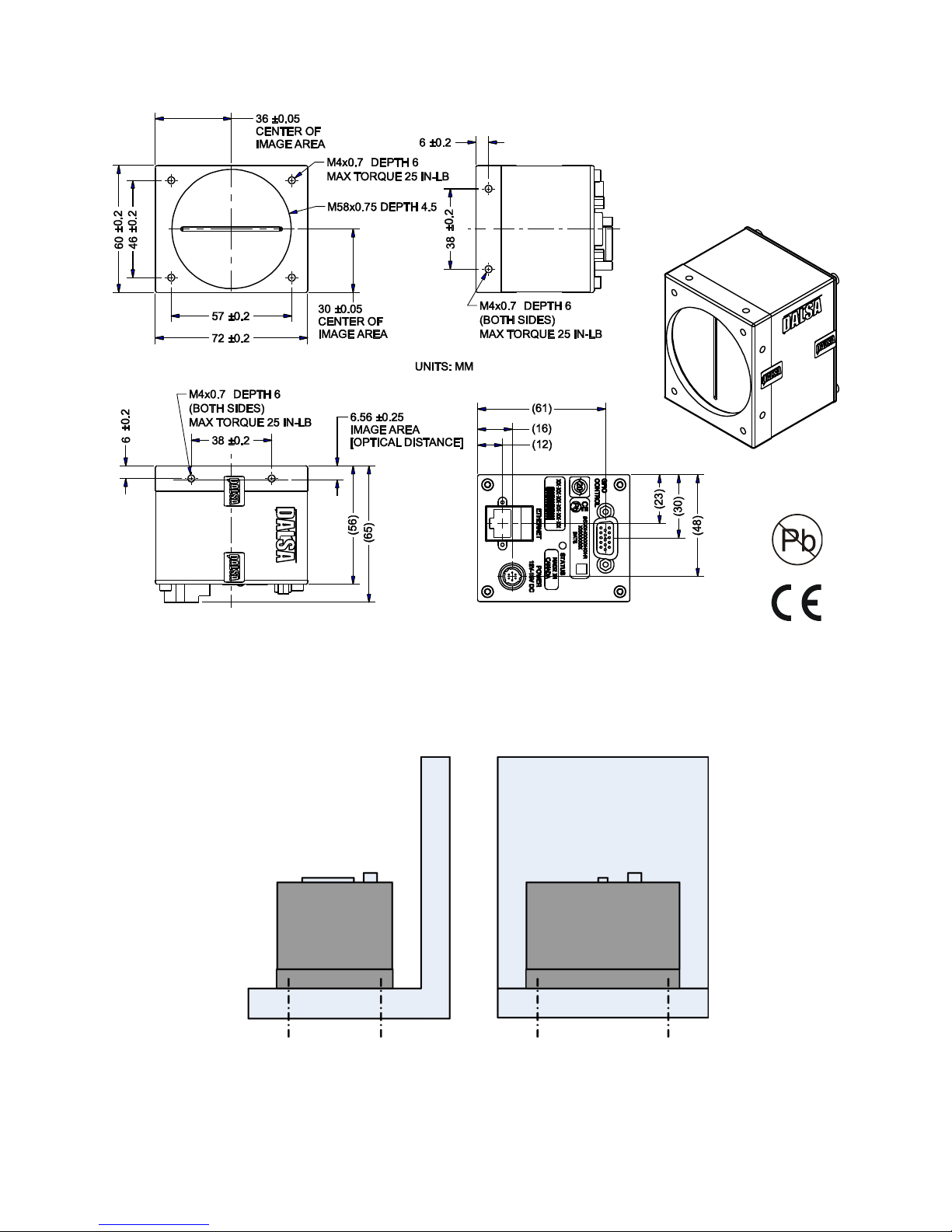

Figure 3: Spyder3 1k and 2k GigE Vision Mechanical

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 13

Figure 4: Spyder3 4k GigE Vision Mechanical

Mounting

Heat generated by the camera must be allowed to move away from the camera. Mount the camera on the

frontplate (using the provided mounting holes) with maximum contact to the area for best heat

dissipation.

Figure 5: Spyder3 Mounting Example

Teledyne DALSA 03-032-20123-00

14 Spyder3 GigE Vision SG-14 Cameras User’s Manual

Tap 2Tap 1

CCD Readout Shift Register

CCD Readout Shift Register

N

Pixels

N

Pixels

N

=1024, 2048, 4096

Pixel 1, 1

Tap 1

CCD Readout Shift Register

CCD Readout Shift Register

N

Pixels (14µm x 14µm)

N

Pixels (14µm x 14µm)

N

=1024, 2048

Pixel 1, 1

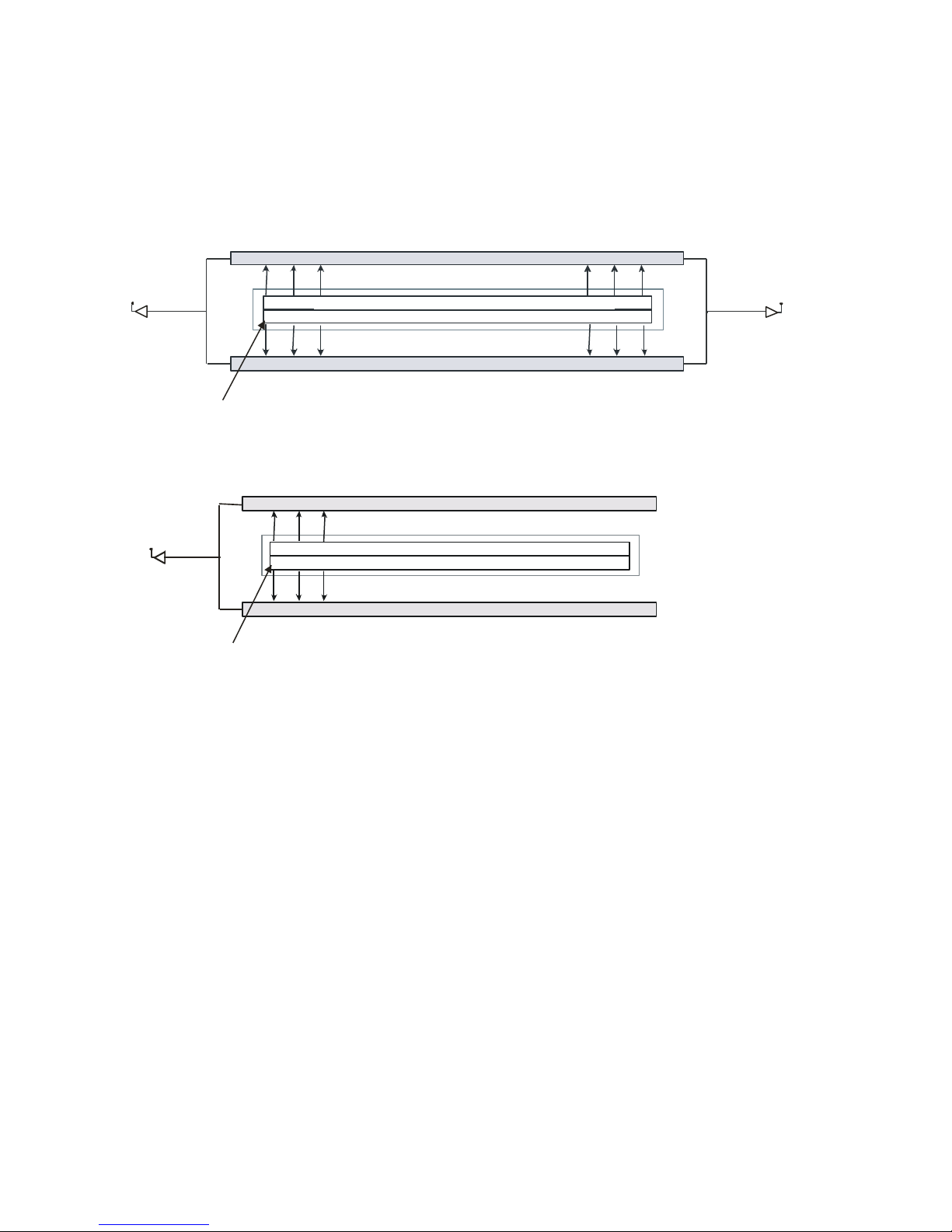

Image Sensor

The cam era u ses Teled yne D ALSA’s d u al line scan sensor. Th e camer a can be configured to read out in

either high or low sensitivity mode, tall pixel mode and forward or reverse shift direction.

Figure 6: 2 Tap Sensor Block Diagram

Figure 7: 1 Tap Sensor Block Diagram (1k and 2k only)

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 15

Software and Hardware Setup

Host System Requirements

To achieve best system performance, the following minimum requirements are recommended:

Operating system: Windows XP Professional, Windows Vista, Windows 7 (either 32-bit or 64-bit for

all) are supported.

Network Adapter Requirements

GigE network adapter (either PCI card or LOM): For high performance you must use a Intel

PRO/ 1000 MT ad apter.

The Spyder3 GEV camera works only with network adapters based on the Intel 82546, 82541, and 82540

network chips. The driver will also function with adapters based on the Intel 82544 chip, but these are not

recommended due to bugs in the chip that can cause control packets to be lost if sent while data is

streaming.

Ethernet Switch Requirements

When you require more than one device on the same network or a camera-to-PC separation of more than

100 metres, you can use an Ethernet switch. Since the Spyder3 GEV camera complies with the Internet

Protocol, the camera should work with all standard Ethernet switches. However, switches offer a range of

functions and performance grades, so care must be taken to choose the right switch for a particular

application.

Setup Steps: Overview

Take the following steps in order to setup and run your camera system. They are described briefly below

and in more detail in the following sections.

1. Install and Configure Ethernet Network Card

If your host computer does not have a Gigabit network adapter or equivalent (PCI bus Gigabit NIC)

already installed, then you need to install one.

For Gigabit performance we recommend the Intel PRO/ 1000 MT adapter, or equivalent. Follow the

manufactu rer’s installation instructions.

A GigE Vision compliant XML device description file is embedded within the cam era’s firmware

allowing GigE Vision compliant applications (e.g. Pleora`s Coyote, and SaperaLT) to recognize the

cam era’s cap abilities im mediately after connection. The Spyder3 camera was tested with and supports

SaperaLT which gives you access to the CamExpert GUI, a GigE Vision compliant application.

Software Installation

Install Sapera LT with CamExpert to control the Spyder3. You can access Sapera drivers, SDKs, and

demos from the following link: http:/ / www.teledynedalsa.com/ mv/ support/ driverSDKlist.aspx

Teledyne DALSA 03-032-20123-00

16 Spyder3 GigE Vision SG-14 Cameras User’s Manual

2. Connect Power, Ethernet and I/O Cables

Connect a power cable from the camera to a +12 VDC to +15 VDC power supply.

Connect the Ethernet cable from the camera to the computer Ethernet jack.

If using the external signals connect the external control cable to the camera.

3. Establish communicating with the camera

Start the GUI and establish communication with the camera.

4. Check camera LED, settings and test pattern

Ensure that the camera is operating properly by checking the LED, the current settings, and by acquiring

a test pattern.

5. Operate the Camera

At this point you will be ready to operate the camera in order to acquire and retrieve images, set camera

functions, and save settings.

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 17

Step 1. Ethernet Network Card: Install and

Configure

Install Network Card

The following network card has been tested and is recommended for use with this camera: Intel Pro/ 1000

MT Desktop Adapter (33-MHz, 32-bit PCI). Order Code: PWLA8391GT (single packs). Follow the

manufactu rer’s recom mend ations t o install this card in the host PC.

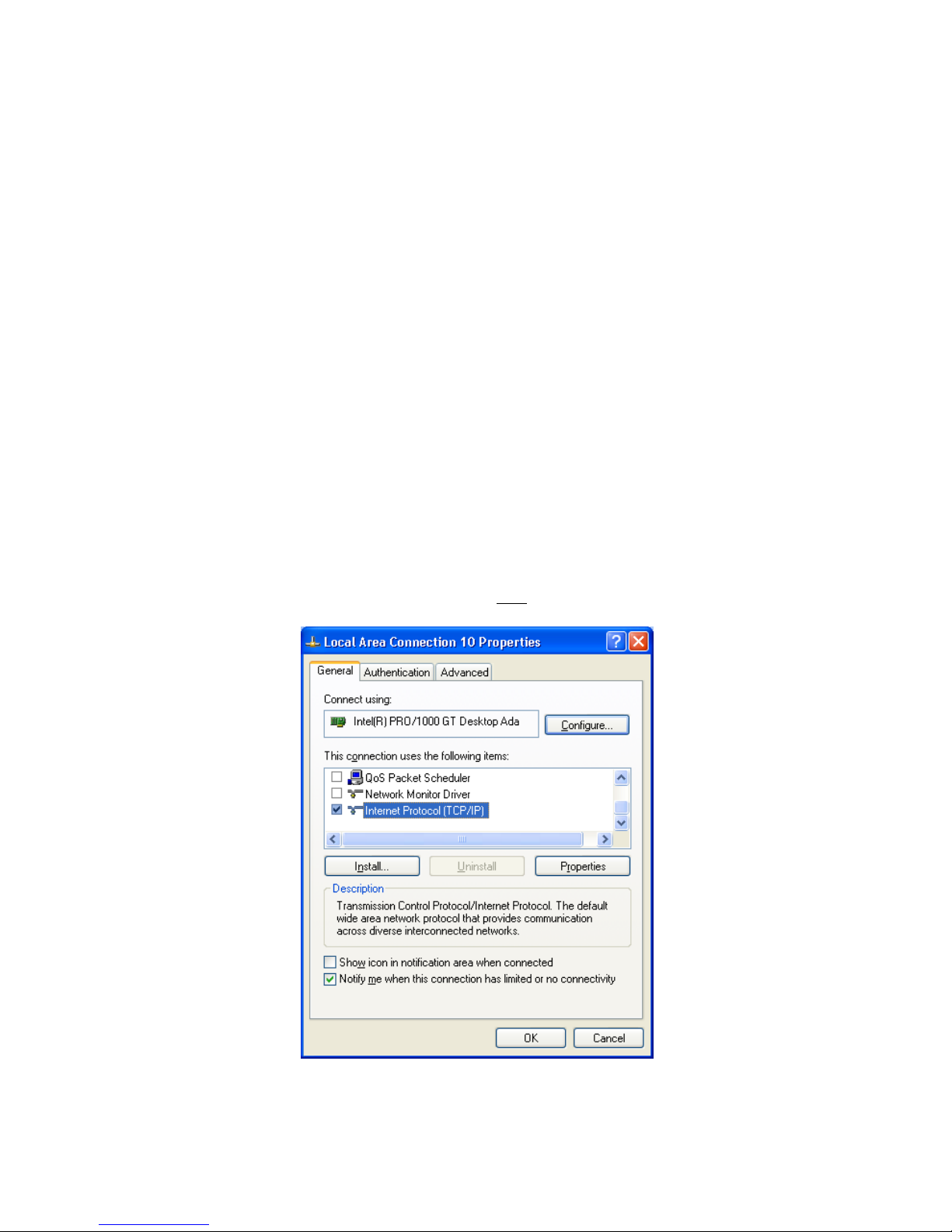

Configure Network Card

The configuration shown here uses the Windows XP operating system as the host platform.

The camera communicates using the Ethernet connection and employs the static IP address: 192.168.5.100

(default). A static address ensures the fastest operation. Alternatively, you can use a dynamic IP address.

To configure the network card from the host PC:

1. In the Start menu under ―Control Panel‖ select ―Netw ork Connections,‖ and configure the

network card as follows:

2. Select the installed network card and click on ―Ch ange settin gs of this con n ectio n .‖

3. Enable the ―Intern et Prot ocol (TCP/ IP)‖ option only.

4. With ―Internet Pr otocol (TCP/ IP)‖ selected , click on the ―Prop erties‖ bu tton .

Teledyne DALSA 03-032-20123-00

Figure 8. Internet Protocol

18 Spyder3 GigE Vision SG-14 Cameras User’s Manual

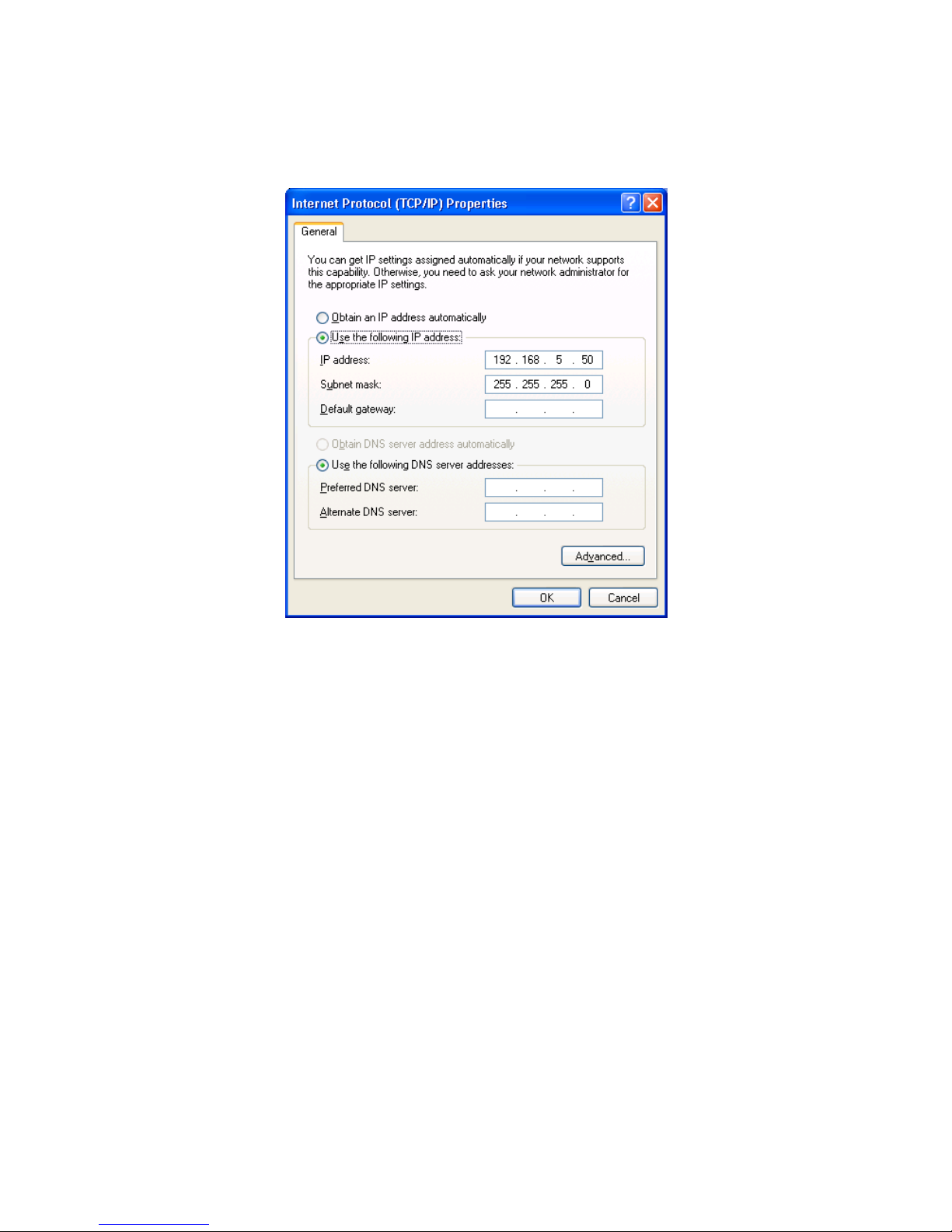

5. Select ―Use the follow in g IP add r ess‖ and set the IP address to an y address in this subnet other

than 192.168.5.100, which is used by the camera. In the example below, the address 192.168.5.50 is

used. Alternativ ely, select ―Obtain an IP ad d r ess au tom atically‖ to u se a d ynam ic add r ess.

6. Set subnet to: 255.255.255.0 an d click on ―OK.‖

Figure 9. IP Address

7. Click ―OK‖ t o save settin gs

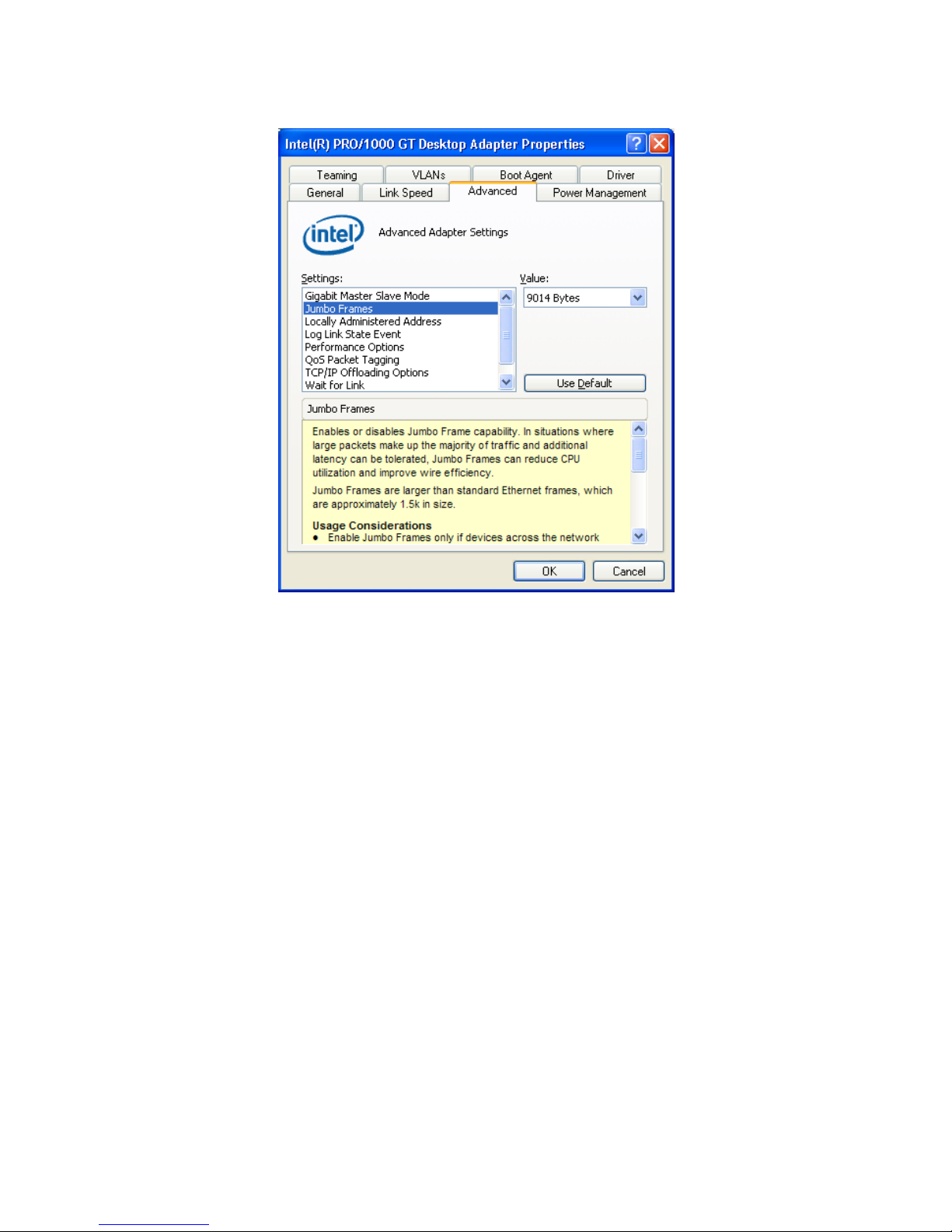

8. Click on ―C onfigure‖ button an d select ―A d van ced‖ ta b

9. Enable ―Jum bo Fram es‖ to greater th a n 9000 bytes. If your NIC does not support jumbo packets

the image transfer speed will be slower.

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 19

10. Click ―OK‖ to save settin gs

Figure 10. Jumbo Frames

Teledyne DALSA 03-032-20123-00

20 Spyder3 GigE Vision SG-14 Cameras User’s Manual

Pin

Description

1, 2, 3

Supply voltage—Min +12 VDC to Max +15 VDC

4, 5, 6

Ground

Hirose 6-pin Circular Male

5

4

6

2

3

1

Mating Part: HIROSE

HR10A-7P-6S

!

!

Step 2. Connect Power, Ethernet, and Trigger

Cables

WARNING! Grounding Instructions

Static electricity can damage electronic components. Please discharge any static electrical

charge by touching a grounded surface, such as the metal computer chassis, before performing

any hardware installation.

The use of cable types and lengths other than those specified may result in increased emission or

decreased immunity and performance of the camera.

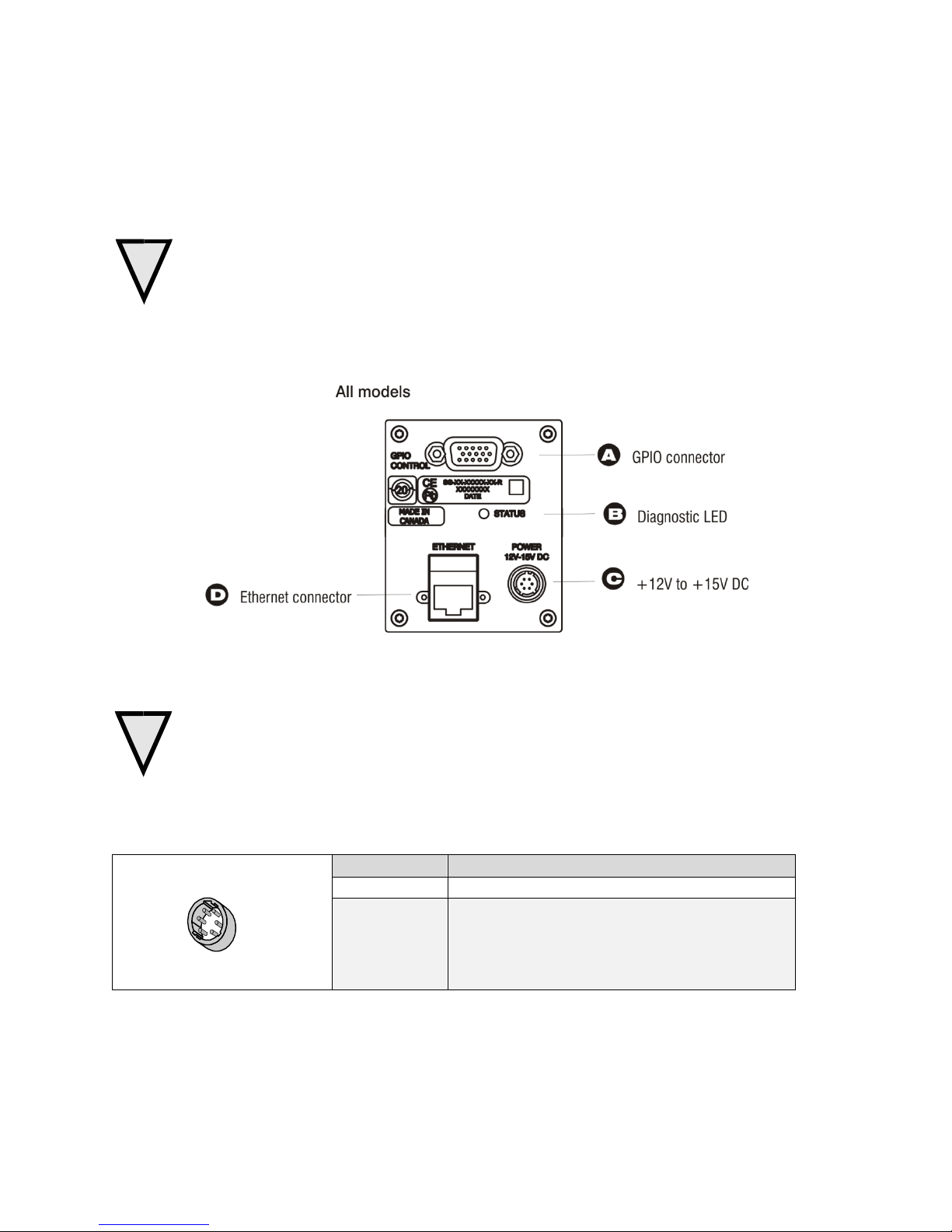

Figure 11: Input and Output, trigger, and Power Connectors

Power Connector

WARNING: It is extremely important that you apply the appropriate voltages to your camera.

Incorrect voltages may damage the camera. Input voltage requirement: +12 V to +15 V DC.

The camera requires a single 6-pin Hirose connector with a single voltage input +12 VDC to +15 VDC for

power. The camera meets all performance specifications using standard switching power supplies,

although well-regulated linear supplies provide optimum performance.

Table 6. Hirose 6-Pin Power Pinout

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 21

!

Priority

Color of Status LED

Meaning

1

Flashing Red

Fatal Error. For example, camera temperature is too high and

camera thermal shutdown has occurred.

2

Flashing Green

Camera initialization or executing a long command .

3

Solid Green

Camera is operational and functioning correctly.

Ethernet Connection

LED@ 1Gbps

Data Transmission LED

WARNING: When setting up the camera’s power supplies follow these guidelines:

Apply the appropriate voltages.

Protect the camera with a 2 amp slow-blow fuse between the power supply and the camera.

Do not use the shield on a multi-conductor cable for ground.

Keep leads as short as possible in order to reduce voltage drop.

Use high-quality linear supplies in order to minimize noise.

Note: If your power supply does not meet these requirements, then the camera performance specifications are not

guaranteed.

Ethernet Connector and Ethernet LED

The camera uses an RJ45 connector and a standard Cat 5 cable for Gigabit Ethernet signals and serial

communications. The device supports 10/ 100/ 1000 Mbit/ s speeds.

Note: Router connection not supported. Connection to a network switch for a single camera is supported.

Ethernet Connection LED

Steady ON indicates that an Ethernet connection is successfully established at 1Gbps.

Data Transmission LED

Steady ON indicates that the camera is ready for data transmission. Flashing indicates that the camera is

transmitting or receiving data.

EMC Compliance

In order to achieve EMC compliance, the Spyder3 camera requires the use of shielded CAT5e or CAT6

Ethernet cables.

Status LED

The camera is equipped with a red/ green LED used to display the status of the camera's operation. The

table below summarizes the operating states of the camera and the corresponding LED states.

When more than one condition is active, the LED indicates the condition with the highest priority. Error

and warning states are accompanied by corresponding messages that further describe the current camera

status.

Teledyne DALSA 03-032-20123-00

22 Spyder3 GigE Vision SG-14 Cameras User’s Manual

Pin

Signal

Description

GenICam Default

1

INPUT_ 0+

LVDS/TTL format (positive)

EXSYNC +

2

INPUT_0-

LVDS (negative)

EXSYNC -

3

INPUT_1+

LVDS/TTL format (positive)

FrameTrig +

4

INPUT_1-

LVDS (negative)

FrameTrig -

5

GND

6

INPUT_2+

LVDS/TTL format (positive)

Direction +

7

INPUT_2-

LVDS (negative)

Direction -

8

INPUT_3

TTL auxiliary input

9

OUTPUT_3

TTL auxiliary output

10

OUTPUT_2+

LVDS/TTL auxiliary output

11

OUTPUT_0+

LVDS/TTL auxiliary output

12

OUTPUT_0-

LVDS (negative)

13

OUTPUT_1+

LVDS/TTL auxiliary output

14

OUTPUT_1-

LVDS (negative)

15

OUTPUT_2-

LVDS (negative)

1

5

11

15

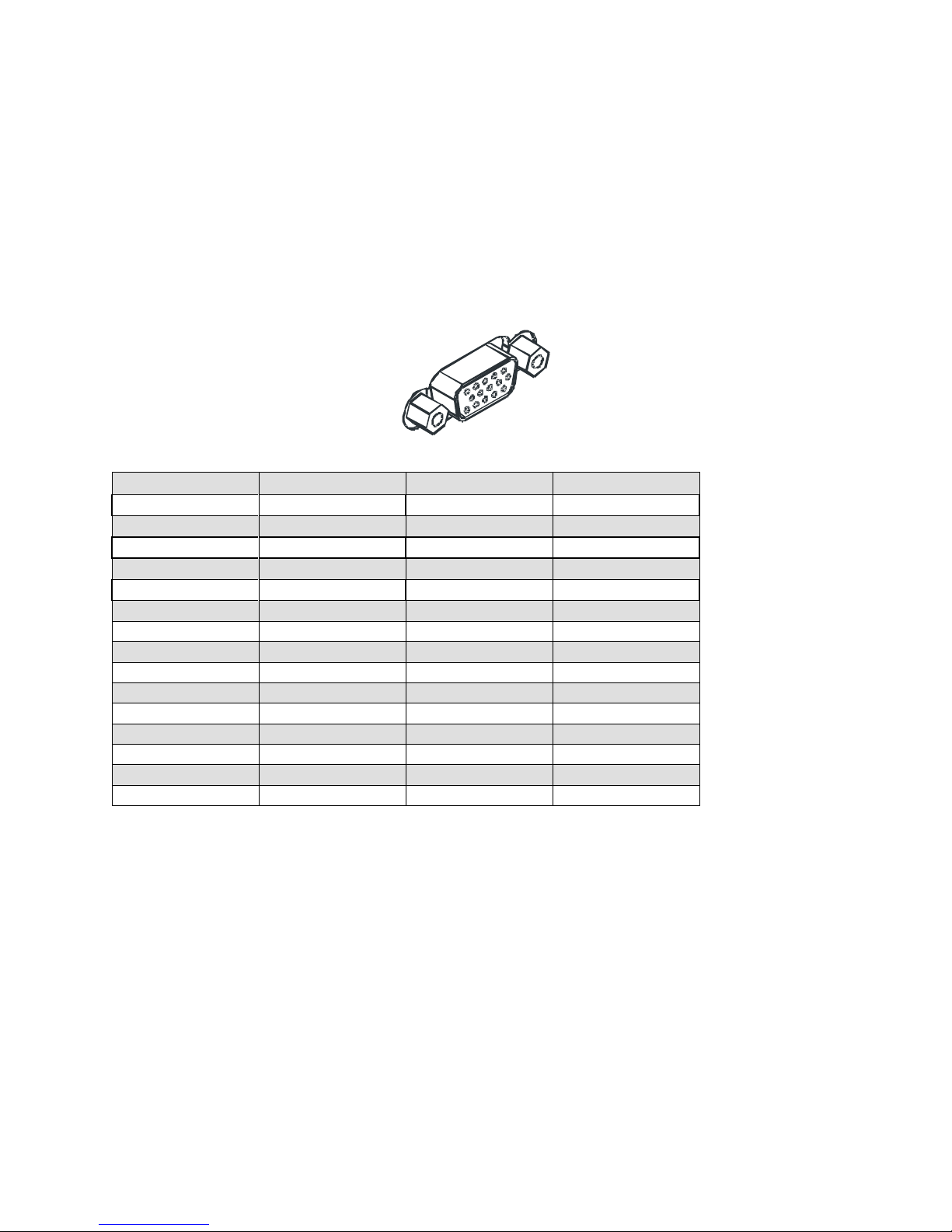

GPIO Connector: External Input

A single 15-pin general purpose input / output (GPIO) connector is used to receive or control external

signals. For example, the GPIO connector can be used to receive EXSYNC, PRIN (pixel reset), and

direction signals.

The GPIO connector is programmed through the GUI application. In CamExpert the relevant parameters

are located in the category Inputs Group.

Figure 12: GPIO Connector and Pin Numbers

Table 7: GPIO Connector Pinout

A schematic of the TTL input circuitry is shown in

Figure 13: TTL Input Schematic. The input signals are fed into the engine from external sources via the

GPIO connector.

GPIO Isolation

All of the GPIOs are isolated from the rest of the camera and the camera case. They are not isolated with

respect to each other and share a common return (ground) through pin 5 of the GPIO connector.

Note: The shell connection of the GPIO connector is not isolated and it should not be used as a return

(ground) for the GPIO signals. The shell connection is attached to the camera case.

GPIO Configuration

Refer to Appendix C: GPIO Control for a detailed description of the GPIO use-cases and configuration

options.

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 23

1000

3.3V

3.3V

TTL

100

ESD

Protection

5V

100

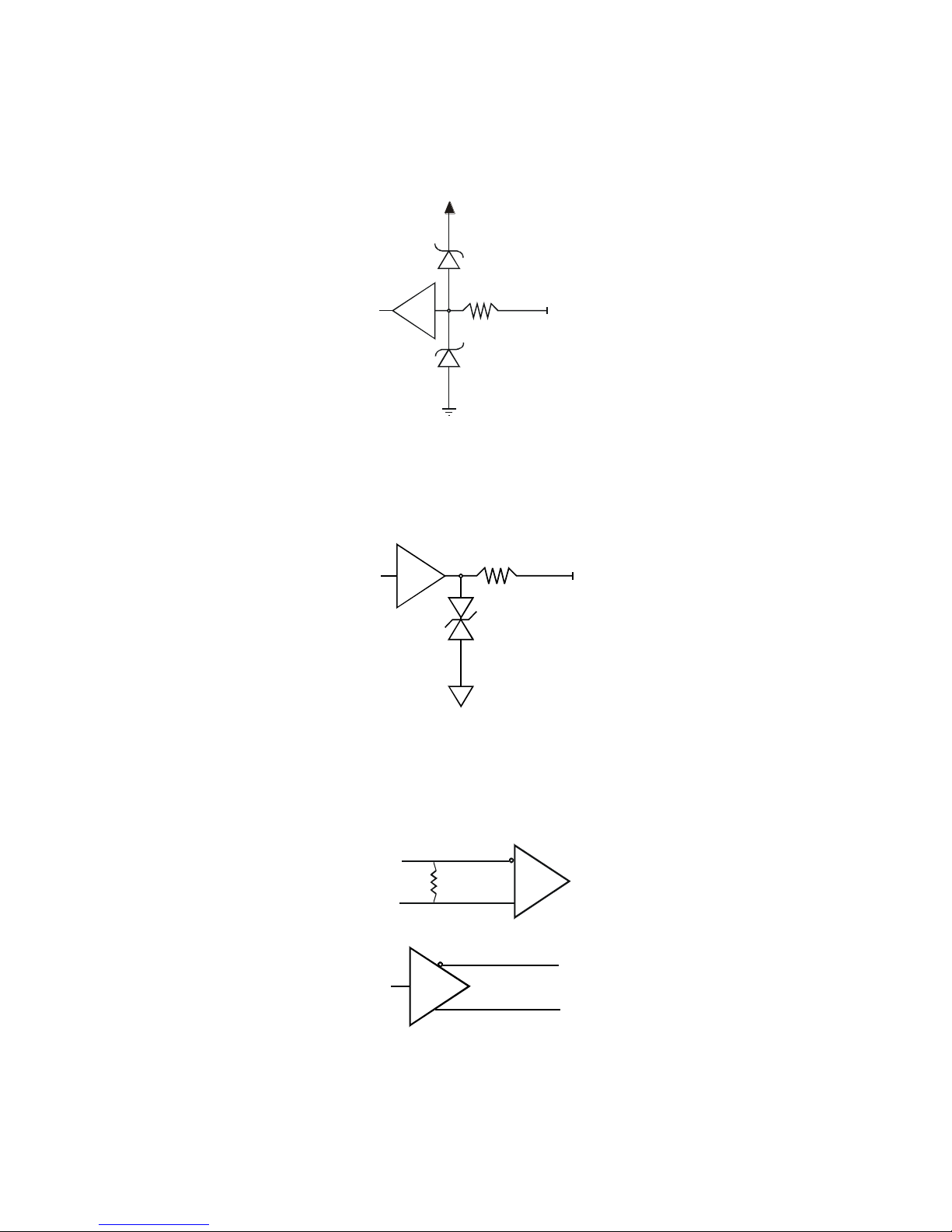

TTL Inputs and Outputs

Figure 13: TTL Input Schematic

Termination: 1000 Ω series

Input current: minimum 0 nA; maximum 2 mA

Input voltage: maximum of low 0.66 V; minimum of high 2.6 V

TTL inputs are maximum 5 V and 3.3 V logic tolerant

Figure 14: TTL Output Schematic

Termination: 100 Ω series

Output current: sink 50 mA; source 50 mA

Output voltage: maximum of low 0.55 V @ 32mA; minimum of high 3.8 V @ 32mA.

LVDS Inputs and Outputs (LVDS compliant)

Figure 15: LVDS Input

Figure 16Figure 17: LVDS Output

Teledyne DALSA 03-032-20123-00

24 Spyder3 GigE Vision SG-14 Cameras User’s Manual

Step 3. Establish Communication with the

Camera

Power on the camera

Turn on the cam era’s p ow er su pp ly . You may h ave to w ait u p to 60 second s w h ile the camera w arm s up

and prepares itself for operation.

Connect to the camera

1. Start a new Sapera CamExpert application (or equivalent GigE Vision compliant interface) by doubleclicking the desktop icon created during the softw are installation.

2. CamExpert will search for installed Sapera devices. In the Devices list area on the left side, the

connected Spyder camera will be shown.

3. Select the Spyder camera device by clicking on the camera user-defined name. By default the camera is

identified by its serial number.

Check LED Status

If the camera is operating correctly at this point, the diagnostic LED will flash for 10 seconds and then

turn solid green.

Software Interface

All the camera features can be controlled through the CamExpert interface. For example, under the

Sensor Control menu in the camera window you can control the frame rate and exposure times.

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 25

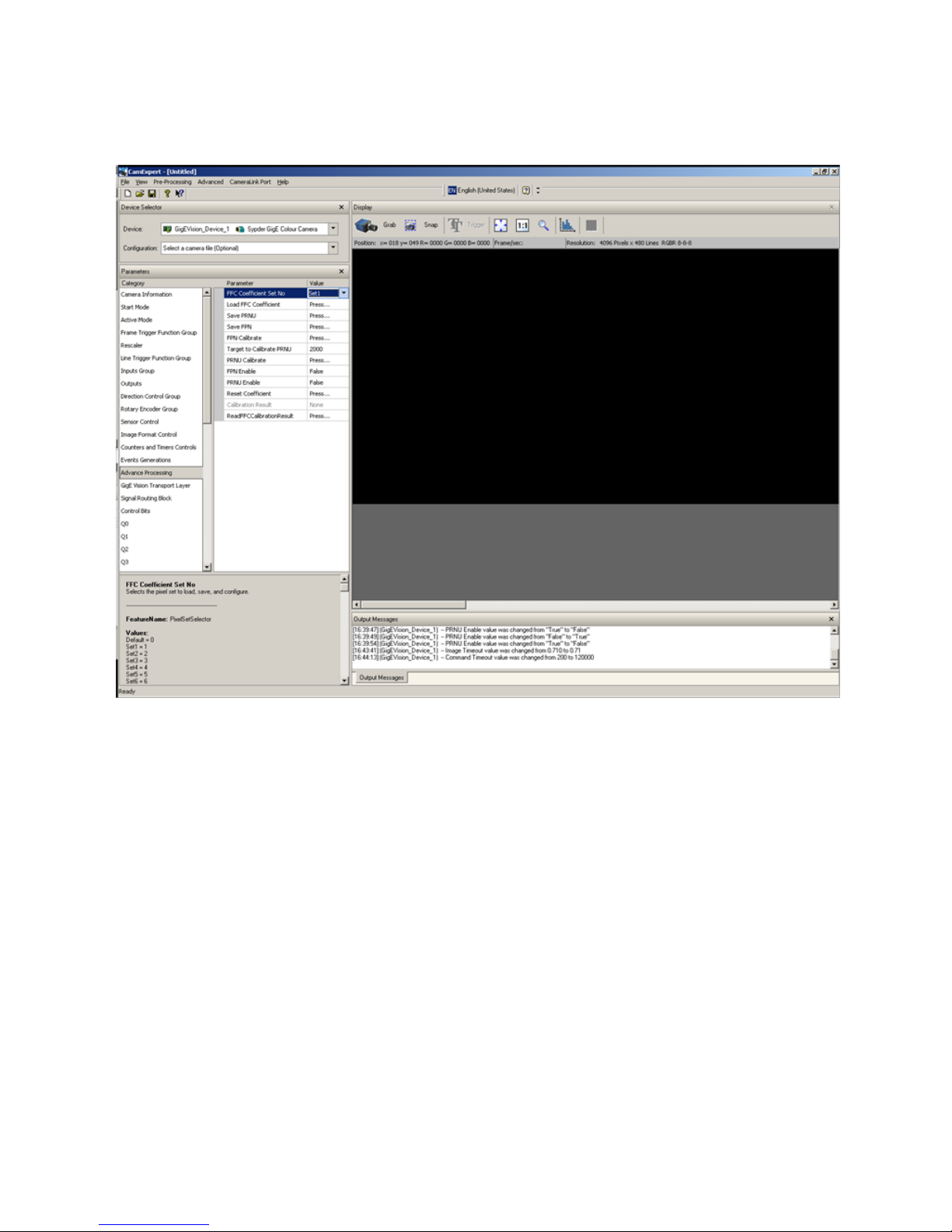

Using Sapera CamExpert with Spyder3 Cameras

CamExpert is the camera interfacing tool supported by the Sapera library. When used with a Spyder3

camera, CamExpert allows a user to test all Spyder3 operating modes. Additionally CamExpert saves the

Spyder3 user settings configuration to the camera or saves multiple configurations as individual camera

parameter files on the host system (*.ccf).

An important component of CamExpert is its live acquisition display window which allows immediate

verification of timing or control parameters without the need to run a separate acquisition program.

For context sensitive help, click on the button then click on a camera configuration parameter. A

short description of the configuration parameter will be shown in a popup. Click on the button to

open the help file for more descriptive information on CamExpert.

The central section of CamExpert provides access to the Spyder3 parameters. Note: The availability of the

parameters is dependent on the CamExpert user setting.

Teledyne DALSA 03-032-20123-00

26 Spyder3 GigE Vision SG-14 Cameras User’s Manual

CamExpert Panes

The CamExpert application uses 5 windows to simplify choosing and configuring camera files or

acquisition parameters for the installed device.

Device Selector pane: View and select from any installed Sapera acquisition device. Once a device is

selected CamExpert will only present acquisition parameters applicable to that device. Optionally

select a camera file included with the Sapera installation or saved by the user.

Parameters pane: Allows viewing or changing all acquisition parameters supported by the

acquisition device. CamExpert displays parameters only if those parameters are supported by the

installed device. This avoids confusion by eliminating parameter choices when they do not apply to

the hardware in use.

Display pane: Provides a live or single frame acquisition display. Frame buffer parameters are shown

in an information bar above the image window.

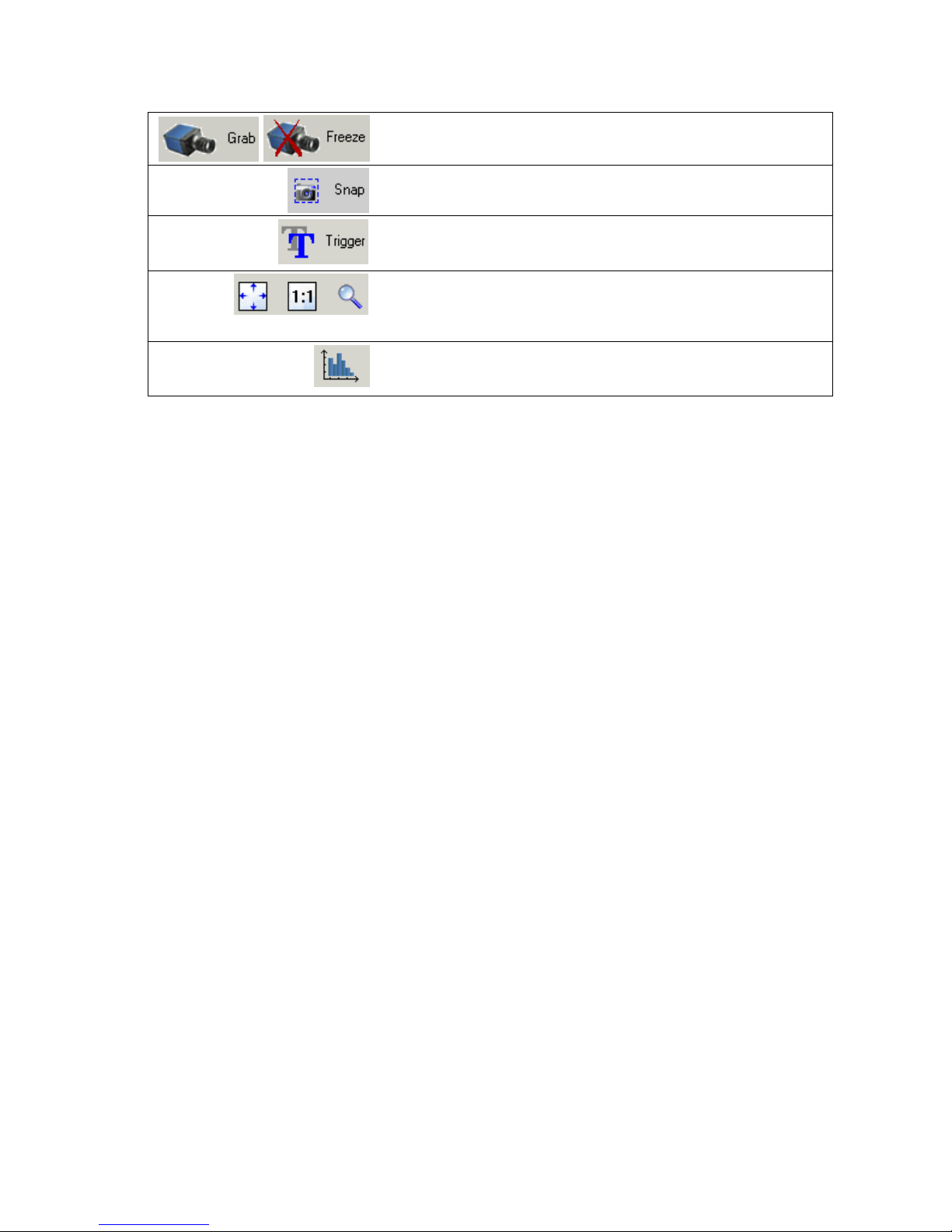

Control Buttons: The Display pane includes CamExpert control buttons. These are:

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 27

Acquisition control button:

Click once to start live grab, click again to stop.

Single frame grab:

Click to acquire one frame from device.

Software trigger button:

With the I/ O control parameters set to Trigger Enabled / Software

Trigger type, click to send a single software trigger command.

CamExpert display controls:

(these do not modify the frame buffer data)

Stretch image to fit, set image display to original size, or zoom the

image to any size and ratio.

Histogram / Profile tool:

Select to view a histogram or line/ column profile during live

acquisition.

Output Message pane: Displays messages from CamExpert or the device driver.

Teledyne DALSA 03-032-20123-00

28 Spyder3 GigE Vision SG-14 Cameras User’s Manual

Step 4. Camera Settings and Test Patterns

Review a Test Pattern Image

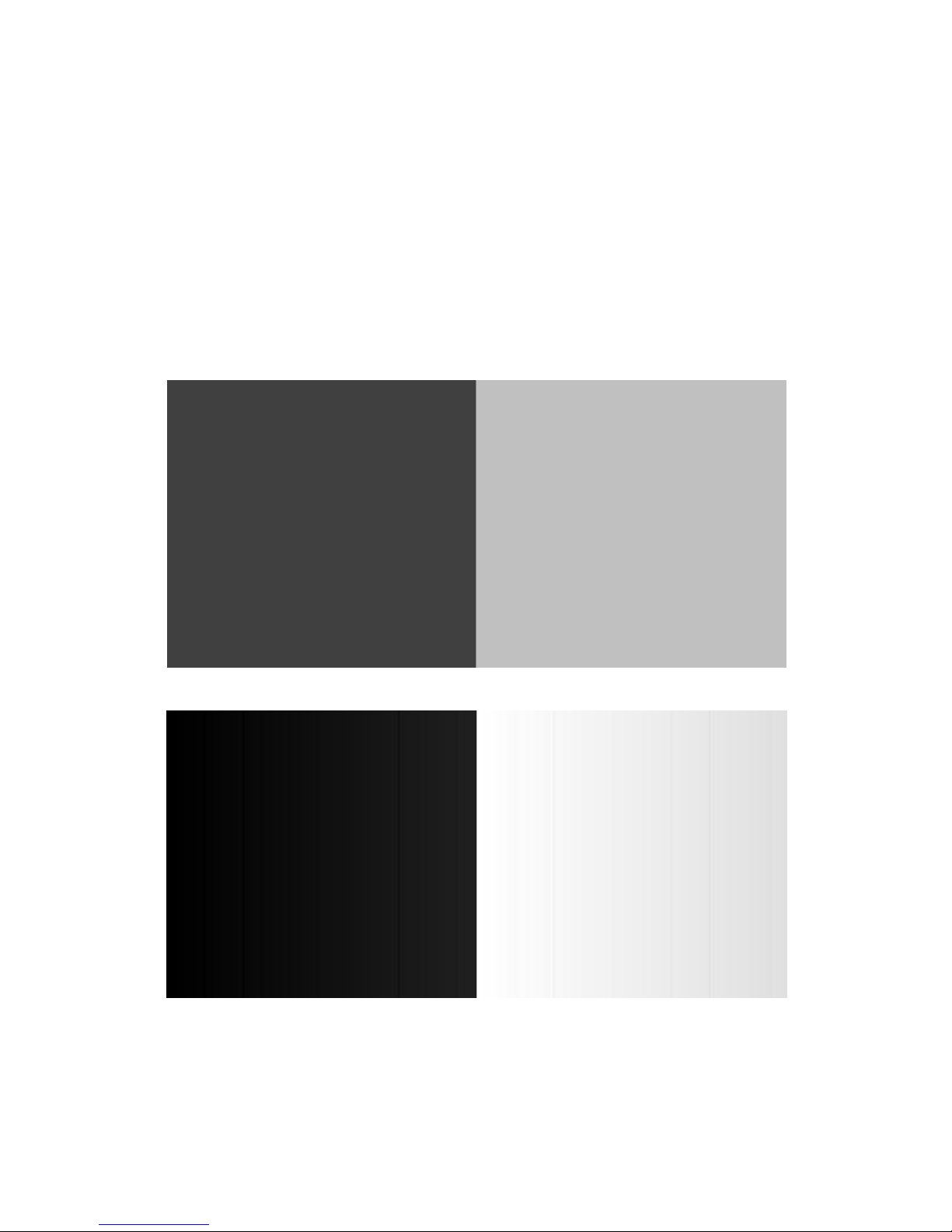

The camera is now ready to retrieve a test pattern. The Spyder3 cameras include a built-in test pattern

generator that can be used to confirm camera Ethernet connections without the need for a camera lens or

proper lighting. The test patterns are useful for verifying camera timing and connections, and to aid in

system trouble shooting.

Using CamExpert, select Image Format Control > Test Image Selector and choose one of the available

test images. Select live grab to see the pattern output. The following test patterns are available:

Figure 18. Grey horizontal step

Figure 19. Grey horizontal ramp

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 29

At this point you are ready to start operating the camera in order to acquire images, set camera functions,

and save settings.

Camera Operation

Factory Settings

The camera ships and powers up for the first time with the following factory settings:

High sensitivity mode

Forward CCD shift direction

8 bit, 2 tap

No binning

Exposure mode: internal sync & maximum exposure time

5, 000 Hz line rate

Factory calibrated analog gain and offset

Factory calibrated FPN and PRNU coefficients

Teledyne DALSA 03-032-20123-00

30 Spyder3 GigE Vision SG-14 Cameras User’s Manual

Camera Information

Parameter

Options

Manufacturer Name

Model Name

Manufacturer Info

Camera Version

Firmware Version

Camera serial ID number

Camera Temperature

Camera Voltage

User ID

Define a camera name up to 64 characters

Read temperature

In general, the temperature read is 15 C greater than the temperature at the front

plate. The temperature should not exceed 80 °C.

Read Camera input voltage

Click to read the voltage from the camera

Read Only Parameters

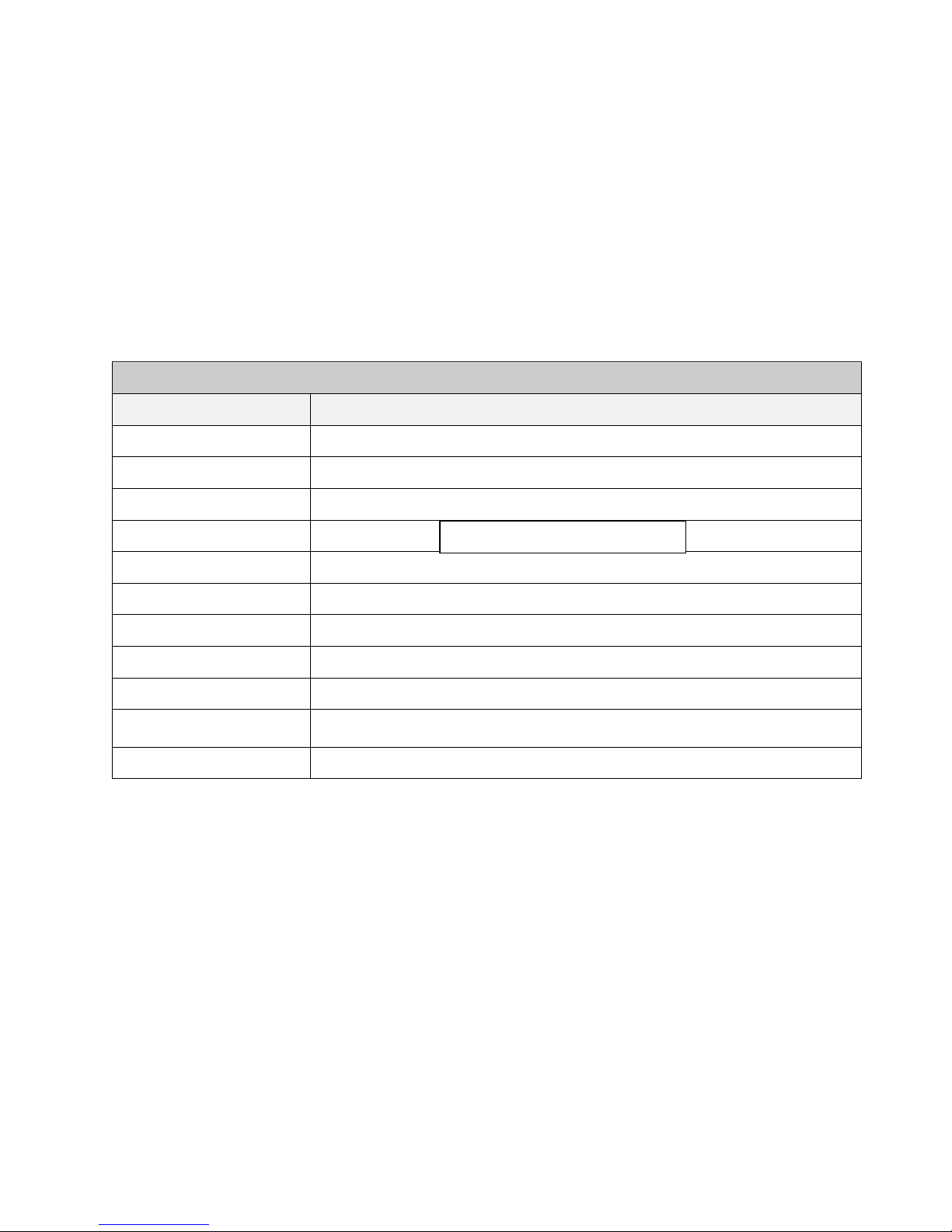

Check Camera and Sensor Information

Camera and sensor information can be retrieved via a controlling application—in the examples shown here,

CamExpert. Parameters such as camera model, firmware version, sensor characteristics, etc. are read to uniquely

identify the connected device.

The camera information parameters are grouped together as members of the Camera Information set.

GigE Vision Input Controls

Verify Temperature and Voltage

To determine the voltage and temperature at the camera, use the Read Voltage and Temperature feature

found in the Camera Information set.

The temperature returned is the internal chip case temperature in degrees Celsius. For proper operation,

this value should not exceed 80 °C. If the camera exceeds the designated temperature it will shut down

an d w ill not tu rn on u ntil th e camer a’s temp erature is 73 ºC or less. Use the reset camera function.

The voltage d isp layed is t h e cam er a’s inpu t volt age. N ote that the voltage measurement feature of the

camera provides only approximate results (typically within 10%). The measurement should not be used

to set the applied voltage to the camera, but only used as a test to isolate gross problems with the supply

voltage.

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 31

Camera Information

Parameter

Description

User Set Selector / Device Configuration

Selector

Selects the camera configuration set to load feature settings from or

save current feature settings to: factory (default) or user sets.

The Factory / Default set contains default camera feature settings.

User camera configuration sets contain feature settings previously

saved by the user.

User Set Load / Load GigE Configuration

Load the set specified by User Set Selector to the camera and make

it the active / current set.

User Set Save / Save Configuration

Save the current set as selected user set.

Saving and Restoring Camera Settings

The parameters used to select, load and save user sets are grouped together under the Camera

Information set of features.

GigE Vision Input Controls

Description of the Camera Settings

The camera operates in one of three settings:

1. Current session

2. User setting

3. Factory setting (Default, read-only)

The current settings can be saved (thereby becoming the user setting) using the User Set Save parameter.

A previously saved user setting (User Set 1) or the factory settings can be restored using the User Set

Selector and User Set Load parameters.

The relationship between these three settings is illustrated here and described below:

Figure 20. Relationship between the Camera Settings

Teledyne DALSA 03-032-20123-00

32 Spyder3 GigE Vision SG-14 Cameras User’s Manual

Current Session Active Setting

The active setting for the current session is the set of configurations that are operating while the camera is

currently running, including all unsaved changes you have made to the settings before saving them .

These active settings are stored in the camera’s volatile memory and will be lost and cannot be restored if

the camera resets or if the camera is powered down or loses power.

To save these settings for reuse the next time you power up or reset the camera, or to protect against

losing them in the case of power loss, you must save the current settings using the User Set Save

parameter. Once saved, the current settings become your User Set 1.

User Setting

The user setting is the saved set of camera configurations that you can customize, resave, and restore. By

default the user settings are shipped with the same settings as the factory set.

The command User Set Save saves the current settings to non-volatile memory as a User Set. The camera

automatically restores the last saved user settings when it resets and / or powers up.

To restore the last saved user settings, select the User Set parameter you want to restore and then select

the User Set Load parameter.

Factory (Default) Settings

The default setting is the camera settings that were shipped with the camera and which loaded during the

cam era’s first pow er -up. To load or restore the original factory settings, at any time, select the Default /

Factory Setting parameter and then select the User Set Load parameter.

Note: By default, the user settings are set to the factory settings.

Please note: the following features are not restored during a factory setting load / restore:

FFC Coefficients set number

Analog Gain selector

Blacklevel selector

Digital Offset selector

Background Subtract selector

Line selector

PRNU CalibrationTarget

Gain Calibration Target

Gain Calibration Selector

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 33

Line Trigger

Trigger Mode

The state of the line trigger. If OFF, then the line trigger is

internally generated. If ON, then triggered by an external

signal.

Trigger Source

The external source that causes a line trigger. The line

trigger is from the GPIO_PIN0. This feature is available

only when Line Trigger Mode is set to ON.

Trigger Activation

Determines the type of signal (high or low) that will cause

a line trigger. Line Trigger Mode must be ON.

External Line Trigger Frequency

Reads the external line trigger frequency. NOTE: The

camera cannot detect frequency less than 5 Hz and will

display 1 if it cannot detect a signal. This featur e is

available when the Line Trigger Mode is set o ON and

Sensor Direction Control is set to External.

Timing: Exposure and Synchronization

Image exposures are initiated by an event. The trigger event is either the camera's programmable internal

clock used in free running mode, an external input used for synchronizing exposures to external triggers,

or a programmed function call message by the controlling computer.

Trigger commands are available as members of the Sensor Control set.

GigE Vision Input Controls

The three trigger modes are described here:

Free running (trigger disabled)

The camera free-running mode has a programmable internal timer for line rate and a programmable

exposure period. Line rate is 0.1 fps to the maximum supported by the sensor. Exposures range from the

sensor minimum to a maximum also dependent on the current line rate. This always uses Synchronous

mode where exposure is aligned to the sensor horizontal line timing.

External trigger

Exposures are controlled by an external trigger signal. External signals are isolated by an opto-coupler

input with a time programmable debounce circuit. The following section provides information on

external trigger timing.

Software trigger

An exposure trigger is sent as a control command via the network connection. Software triggers can not

be considered time accurate due to network latency and sequential command jitter. But a software trigger

is more responsive than calling a single-line acquisition (Snap command) since the latter must validate

the acquisition parameters and modify on-board buffer allocation if the buffer size has changed since the

last acquisition.

Teledyne DALSA 03-032-20123-00

34 Spyder3 GigE Vision SG-14 Cameras User’s Manual

tLine Period

twSYNC_INTtwSYNC

tPR_INT

twPR_HIGH

twPR_LOWtPR

EXSYNC

PRIN

Internal Line Valid

tTRANSFER

tREADOUT

tOVERHEAD

Ethernet Latency to PC

Memory

Valid Data From

Diagramed

ExSync

tEthernet Latency

Units

Min.

Typ.

Max.

Notes

tLine_Period

μs

27.78

1000

1K 1 Tap

14.71

1000

1K 2 Tap

54.1 1000

2K 1 Tap

27.78

1000

2K 2 Tap

54.1 1000

4k 2 Tap

twSync

ns

100

twSYNC_INT

ns

100

(3000*)

For exposure mode 4 this value needs to be

>3000ns other w ise >100ns

tPR

ns 0

twPR_LOW

ns

3000

twPR_HIGH

ns

3000

tPR_INT

ns

3000

tREADOUT

Sensor Size

# Taps

Readout Time

1024

1

25600ns

1024

2

12800ns

2048

1

51200ns

2048

2

25600ns

4096

2

tOVERHEAD

Sensor Size

# Taps

Readout Time

1024

1

725ns

1024

2

450ns

2048

1

1400ns

2048

2

725ns

Timing

Table 8: Timing Parameter Table

Table 9: tReadout Values

Table 10: tOverhead Values

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 35

1. First set the camera mode using Exposure Mode and Line Trigger Mode commands.

2. Next, if using mode 2, 6, or 7 (see below ) use the commands Acquisition Line Rate Abs and/ or Exposure

Time Abs to set the line rate and exposure time.

Sensor Control

Exposure Mode

This feature is used to set the operation mode of the

Exposure (or shutter): Off, Timed, Trigger Width. If Off is

selected then the camera uses the maximum time according

to its line rate.

Line Trigger Group

Line Trigger Mode

The state of the line trigger. If the trigger is off, then the line

trigger is internally generated. Otherwise, the line trigger is

caused by an external signal. Modes: Off or On.

Programmable Line Rate Programmable Exposure Time

Mode

LineTriggerMode

ExposureMode

Description

A

Off (Internal)

Timed (Internal)

Yes

Yes

Internal line rate and exposure time.

Exposure mode enabled.

B

On (External)

Off (Internal)

No

No

Maximum exposure time. Exposure mode

disabled.

C

On (External)

TriggerWidth

(Internal)

No

No

Smart EXSYNC. Exposure mode enabled.

D

On (External)

Timed (Internal)

No

Yes

Fixed integration time. Exposure mode

enabled.

E

Off (Internal)

Off (Internal)

Yes

No

Internal line rate, maximum exposure

time. Exposure mode disabled.

Overhead Delay

Overhead_Delay can range from 5 to 6μs and depends on the internal operations of your computer.

Exposure Controls

The cam era can gr ab im ages in on e of sev en w ays. The cam era’s lin e rate (syn chronizat ion) can be

generated internally through the Acquisition Line Rate feature (a member of the Sensor Control set of

features) or set externally with an EXSYNC signal, depending on your mode of operation.

To select h ow you w an t the camer a’s line rat e to be generat ed:

GigE Vision Input Controls

Set the Exposure Mode

Sets th e camer a’s exp osure m od e allowin g you to control your sync, exposure time, and line rate

generation.

Note: When setting the camera to external signal modes EXSYNC must be supplied.

Teledyne DALSA 03-032-20123-00

36 Spyder3 GigE Vision SG-14 Cameras User’s Manual

Programmable Period ( command)ExposureTimeAbs

Line Period

Readout

CR Exposure Time

CR=Charge Reset

Line Period

Programmable Period

CR Exposure Time

Programmable Period ( command)AquisitionLineRateAbs

Readout

Programmable Period

Waiting Waiting

Line Period

Exposure Time

Line Period

Readout

Exposure Time

Falling Edge

Ignored During

Readout

Readout

Falling Edge

Ignored During

Readout

EXSYNC

Readout

EXSYNC

EXSYNC falling

edge ignored

during readout

Line Period

CR=Charge Reset

Readout

Line Period

EXSYNC falling

edge ignored

during readout

WaitingExposure Time

CR

Waiting

CR

Exposure Time

Exposure Modes in Detail

Mode A. Internally Programmable Line Rate and Exposure Time (Factory Setting): ExposureMode Timed and

LineTriggerMode Off (Internal)

Operates at a maximum line rate and exposure time.

When setting the line rate (using the AcquisitionLineRateAbs command), exposure time will be reduced, if

necessary, to accommodate the new line rate. The exposure time will always be set to the maximum time (line

period – line transfer time – pixel reset time) for that line rate when a new line rate requiring reduced exposure

time is entered.

When setting the exposure time (using the ExposureTimeAbs command), line time will be increased, if

necessary, to accommodate the exposure time. Under this condition, the line time will equal the exposure time

+ line transfer time.

Example 1: Exposure Time less than Line Period

Mode B. External Trigger with Maximum Exposure: ExposureMode Off and LineTriggerMode On (External)

Line rate is set by the period of the external trigger pulses. The falling edge of the external trigger marks the

beginning of the exposure.

Example 2: Line Rate is set by External Trigger Pulses.

Mode C. Smart EXSYNC, External Line Rate and Exposure Time: ExposureMode TriggerWidth and LineTriggerMode On

(External)

In this mode, EXSYNC sets both the line period and the exposure time. The rising edge of EXSYNC marks the

beginning of the exposure and the falling edge initiates readout.

Example 3: Trigger Period is Repetitive and Greater than Read Out Time.

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 37

Sensor Control

Parameter

Description

Line Rate (Hz)

Camera line rate, in Hz. 300 Hz min., 68000 Hz max.

Only available when the camera is in Internal Mode—

trigger is disabled (Trigger Mode off).

Line rates are in the following configurations:

1k 1 tap: 300-36000 Hz

1k 2 tap: 300-68000 Hz

2k 1 tap: 300-18500 Hz

2k 2 tap: 300-36000 Hz

4k 2 tap: 300-18500 Hz

Readout

EXSYNC

Line Period

CR=Charge Reset

Readout

Line Period

Programmable period

using commandExposureTimeAbs

Programmable period

using commandExposureTimeAbs

CR CR

Exposure Time Exposure Time

Waiting

Waiting

Exposure Time

Readout

Internal Sync set with

AquisitionLineRateAbs command

Line Period

Period

Exposure Time

Readout

Line Period

EXSYNC falling

edge ignored

during readout

EXSYNC falling

edge ignored

during readout

Mode D. External Line Rate and Internally Programmable Exposure Time: ExposureMode Timed and LineTriggerMode

On (External)

Figure 21: EXSYNC controls Line Period with Internally controlled Exposure Time

Mode E. Internally Programmable Line Rate, Maximum Exposure Time: ExposureMode Off and LineTriggerMode Off

(Internal)

In this mode, the line rate is set internally with a maximum exposure time.

Figure 22: Mode 7 Camera Timing

Line Rate

To set th e cam er a’s line r ate, u se the Line Rate feature found in the Sensor Control set. This feature is

only available while the camera is operating in Internal Imaging Mode (Trigger Mode off).

GigE Vision Input Controls

Teledyne DALSA 03-032-20123-00

38 Spyder3 GigE Vision SG-14 Cameras User’s Manual

Sensor Control

Parameter

Description

Exposure Mode

This feature is used to set the operation mode of the

Exposure (or shutter): Timed , Trigger Width, Off

(maximum, according to line rate).

Exposure Time

This feature is used to set the Exposure time (in

microseconds) when Exposure Mode is set to Timed. min 3,

max 3300 us.

Frame Trigger Function Group

The Frame Trigger Control section describes all features related to frame acquisition using trigger(s).

One or many Trigger(s) can be used to control the start of an Acquisition, of a Frame. It can also be

used to control the exposure duration at the beginning of a frame.

Parameter

Description

Trigger Overlap

Specify the type of trigger overlap permitted with the

previous frame. This defines when a valid trigger will be

accepted (or latched) for a new frame

Trigger Delay Raw

Specifies the delay in microseconds (μs) to apply after the

trigger reception before activating it

The delay of the selected trigger in 1 µs increments.

Frame Trigger Source

The line that triggers a frame trigger when Frame Start

Trigger Mode is On.

Frame Trigger Software Toggle

Trigger Software is a command that can be used by an

application to generate an internal trigger when Trigger

Source is set to Softw are. To generate a trigger, choose false

first then choose true.

Active Mode

Frame Active Trigger Activation

Specifies what type of signal (i.e. high, or low) causes a

variable length frame trigger.

Frame Active Trigger Mode

Specifies whether the external variable length frame trigger

is on or off. This trigger takes precedence over the

FrameStartTrigger.

Frame Active Delay

Enable the delayer.

Exposure Time

To set th e cam er a’s exp osure tim e, use the Exposure Time feature found in the Sensor Control set. This

feature is used to set the exposure time in µs. This feature is only available when the Exposure Mode is

set to Timed. The allowable range is from 3 µs to 3300 µs.

GigE Vision Input Controls

Triggers

GigE Vision Input Controls

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 39

Start Mode

Frame Start Trigger Mode

Specifies whether the external fixed length frame trigger is

on or off. If the FrameTriggerActiveMode is on then it takes

precedence.To turn On, please DeviceScanType to Linescan

(Start Mode).

Frame Start Trigger Activation

Specifies what type of signal(i.e. high, or low) causes a

fixed length frame trigger when Frame Start Trigger Mode

is On.

Frame Start Delay

Enable the delayer.

Line Trigger Function Group

The Line Trigger Control section describes all features related to line acquisition using trigger(s). One

or many Trigger(s) can be used to control the start of an Acquisition, of a Line. It can also be used to

control the exposure duration at the beginning of a line.

Parameter

Description

Line Trigger Mode

The state of the line trigger. If the trigger is off, then the line

trigger is internally generated otherwise it is caused by an

external signal

Line Trigger Source

The external line that causes a line trigger.The line trigger is

from GPIO_PIN0. This feature is available only when Line

Trigger Mode in set to On.

Line Trigger Activation

Specifies what type of signal(i.e. high, or low) causes a line

trigger if Line Trigger Mode is On.

External Line Trigger Frequency

Reads the external line trigger frequency. NOTE: The

camera cannot detect frequency less than 5 Hz and will

display 1 if it cannot detect a signal. This featuer is

available when the Line Trigger Mode is se to ON and

Sensor Direction Control is set to External

Read External Line Frequency

Read the external line trigger frequency and updates the

ExternalLineTriggerFrequency register. This feature is

available when the Line Trigger Mode is set to On.

Inputs Group

This group contains the features that allow the configuration of the camera physical input lines (pins)

Parameter

Description

Line Selector

This feature selects which physical line (or pin) of the external

device connector to configure. When a Line is selected, all the

other Line features will be applied to its associated I/O control

block and will condition the resulting input or output signal.

Line0-- Line Trigger, Line1-- Frame Trigger, Line2 -- Direction.

GigE Vision Input Controls

Input / Output Control

CamExpert groups the camera I / O Controls Parameters in either the Inputs group or the Outputs. These parameters

allow configuring the Spyder3 inputs and outputs for type of signal and signal polarity.

GigE Vision Input Controls

Teledyne DALSA 03-032-20123-00

40 Spyder3 GigE Vision SG-14 Cameras User’s Manual

If rotary encoder is used, Line0 -- Phase A , Line2 -- Phase B

Line Format

This feature returns or sets (if possible) the current electrical

format of the selected physical input Line: No connect, TTL,

LVDS

Line Connector Pin

Enumeration of the physical line (or pin) on the device connector.

This feature is not available when Line Format is set to Not

Connected and when Line Selector is set to a line smaller than

Line2

Line Function

Displays the line function

Line Debounce Factor

This feature control the minimum period of a input line transition

before detecting a signal transition.

Outputs Group

Parameter

Description

Output Selector

This feature selects which physical line (or pin) of the external

device connector to configure. When a Line is selected, all the

other Line features will be applied to its associated I / O control

block and will condition the resulting input or output signal.

Line0 outputs signals at PLC_Q0; Line1 outputs signals at

PLC_Q1; Line2 outputs signals at PLC_Q2; Line3 outputs signals

at PLC_Q3.

Output Format

This feature returns or sets (if possible) the current electrical format

of the selected physical output Line: No Connect, TTL, or LVDS

Analog Controls

Parameter

Description

Gain Selector

Select the channel to control the gain for

All digital channels of taps

Analog Gain (dB)

Set the gain as an amplification factor applied to the video

signal

-10 dB to +10 dB

Black Level Selector

Select which black level is controlled by the black level

parameters.

Gain, Black Level, and Background

The cameras provide gain and black level adjustments in the digital domain for the sensor. The gain and

black level controls can make small compensations to the acqu isition in situation s where lighting varies

and the lens iris cannot be easily adjusted. The user can evaluate gain and black level using CamExpert.

The parameters that control gain, black level, and background are grouped together in the Analog

Controls set.

Note th at calib r ating the gain can take u p to 10 second s. Ad just t h e GUI’s tim eou t valu es (in the

Advanced Processing set) accordingly.

A section describing camera calibration in detail is available later in this manual.

GigE Vision Input Controls

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 41

Black Level

Control the analog black level offset as an absolute physical

value.

Digital Gain (DN)

Sets the digital system gain control.

Digital Gain (dB)

Digital gain amplification in dB for a specified tap.

Digital Offset Selector

Tap selector. Select the tap to apply the digital offset.

Digital Offset (DN)

The digital offset enables the subtraction of the artificial

A/ D offset (the analog offset) so that application of the

PRNU coefficient does not result in artifacts at low light

levels due to the offset value.

Background Subtract Selector

Tap selector. Select which tap to apply the background

subtract.

Background Subtract (DN)

Used to increase image contrast after FPN and PRNU

calibration. Subtract a background value from the digitized

image data (in DN).

1K /2K Cameras

4K Cameras

Analog Gain

-10 dB to +10 dB

Calibrated 0 dB (default)

Not available in GigE

Calibrated -10 dB (default)

Digital Gain

4096 (0 dB)(default) to 65535 (> 20 dB)

4096 (0 dB) - 12953 (+10 dB)

(default)

Image Format Control

Parameter

Description

Maximum Image Width

This feature represents the maximum width (in pixels) of

the image after horizontal binning, decimation or any other

function changing the horizontal dimensions of the image.

Default width: size of the sensor.

Image Width

Current width of the image / area of interest (in pixels).

This value is dependent on the horizontal binning and

maximum width values.

Default size width: size of the sensor.

Image Height

Actual image height in active image pixels.

Default height: 480 pixels. Maximum height: 16, 383 pixels.

Image Offset

Image start position (in pixels). The horizontal offset from

the origin to the AOI (in pixels). Default offset: 0.

Table 11: Gain Range by Camera Model

Image Size

To set the height of the image, and therefore the number of lines to scan and transmit, use the parameters

grouped under the Image Format Control set.

GigE Vision Input Controls

Teledyne DALSA 03-032-20123-00

42 Spyder3 GigE Vision SG-14 Cameras User’s Manual

Image Flip Horizontal

This feature is used to flip horizontally the image sent by

the device. Default value: not flipped.

Image Format Control

Parameter

Description

Pixel Format

Mono 8

Mono 12

Image Format Control

Parameter

Description

Sensitivity Mode

High

Low

Tall

Direction Control

Parameter

Description

Sensor Scan Direction

When in high sensitivity mode, selects the forw ard or

reverse CCD shift direction or external direction control.

This accommodates object direction change on a web and

allows you to mount the camera "upside down"

Sensor Shift External Direction

The current sensor shift direction when the direction is

Pixel Format

Use the Pixel Format feature found in the Image Format Control set to select the format of the pixel to use

during image acquisition as either Mono 8 or Mono 12 bit depth.

GigE Vision Input Controls

Sensitivity Mode

To set the sensitivity mode use the Sensitivity Mode feature found as part of the Image Format Control

set. When using high sensitivity mode, the cameras responsivity increases. High sensitivity mode permits

much greater scanning speeds in low light. It can also allow for reduced lighting levels. The available

modes are: Low, High, and Tall.

More description and examples of the sensititivy mode can be found in the Appendix.

GigE Vision Input Controls

Sensor Direction Control

Found in the I / O Control > Direction Control set of features. Note: This feature is available when in

high sensitivity mode only.

Note: the Sensor Shift features are not available when the camera is in low or tall pixel sensitivity modes.

GigE Vision Input Controls

03-032-20123-00 Teledyne DALSA

Spyder3 GigE Vision SG-14 Cameras User’s Manual 43

externally controlled. This feature is only available wne

sensorScanDirection is set to External.

Read Sensor Shift Direction

Read current direction of the external signal that controls

the sensor shift direction. This feature is available only

when sensorScanDirection is set to External.

Sensor Shift Direction

When in high sensitivity mode, you can select either forward or reverse CCD shift direction. Selectable

direction acco m mod ates object d ir ection ch ange on a w eb and allow s you to m ount the cam era ― u p side

down‖.

Figure 23: Object Movement and Camera Direction Example using an Inverting Lens

Teledyne DALSA 03-032-20123-00

44 Spyder3 GigE Vision SG-14 Cameras User’s Manual

Image Format Control

Parameter

Description

Binning Horizontal

This feature represents the number of horizontal photo-sensitive cells that

must be combined (added) together.

Update the SensorWidth, Width and OffsetX registers when changing this

value.

Camera Information

Parameter

Description

Camera Reset

Reset the camera and put it in its power-up state (either with the default

factory settings or with saved user settings).

Binning

Binning is the combining of two or more image sensor pixels to form a new combined pixel prior to

readout or digitizing. A binned image using the same exposure settings as a non -binned image will show

an improved signal-to-noise ratio, reduced scanning times (due to lower spatial resolution) and save as a

smaller image file size compared with a non-binned image, at the expense of lower image resolution.

For this camera, the default binning value is 2 x 2, 4 physical pixels on the sensor are combined into one

image pixel. This operating mode is ideal for applications that require faster acquisition and processing

times and require greater signal collection.

The Binning Horizontal feature in the Image Format Control set represents the number of horizontal

pixels that will be combined (added) together.

GigE Vision Input Controls