Page 1

Serial Data Debug Solutions

Operator's Manual

August, 2011

Page 2

LeCroy Corporation

700 Chestnut Ridge Road

Chestnut Ridge, NY, 10977-6499

Tel: (845) 578-6020, Fax: (845) 578 5985

Internet: www.lecroy.com

© 2011 by LeCroy Corporation. All rights reserved.

Unauthorized duplication of LeCroy documentation materials other than for internal sales and distribution purposes is strictly prohibited.

However, clients are encouraged to distribute and duplicate LeCroy documentation for their own internal educational purposes.

LeCroy and other product or brand names are trademarks or requested trademarks of their respective holders. Information in this publication

supersedes all earlier versions. Specifications are subject to change without notice.

919586 RevA

Page 3

919586 RevA

iii

TABLE OF CONTENTS

Serial Data Debug Solutions Introduction .................................................................. 9

Overview ...................................................................................................................... 9

Structure of This Manual ............................................................................................. 9

Assumptions ................................................................................................................ 9

Toolsets and Supported Protocols ............................................................................... 9

Compatibility.............................................................................................................. 10

Accessing and Using Supported Protocol Toolsets .................................................... 12

Accessing and Using Supported Protocol Toolsets Overview ................................... 12

The D and TD Toolsets ............................................................................................... 12

Technical Explanation of Serial Decode and Trigger ................................................. 12

Accessing The D and TD Supported Protocol Toolsets .............................................. 13

Using The D Supported Protocol Toolsets ................................................................. 14

Decode Toolset Features and Controls...................................................................... 18

Using The T Supported Protocol Toolsets ................................................................. 22

Accessing and Using The PROTObus MAG Supported Protocol Toolset ................... 23

Operator's Manual

Decode Output Operation Detail ............................................................................... 24

Decode Measurement Parameters via Measure Setup ............................................ 24

The ProtoSync Toolset ............................................................................................... 26

The ProtoSync Toolset Overview ............................................................................... 26

The CATC Protocol View ............................................................................................ 27

The CATC Bit Tracer View - PCI Express (PCIe) Only .................................................. 30

Oscilloscope and Protocol Analyzer - A Concurrent Analysis Example ..................... 30

Accessing and Using The Graphing Tools for Supported Protocols ........................... 32

Physical Layer Eye Diagram ....................................................................................... 32

Debug Examples ........................................................................................................ 32

Using the TD Packages: Characterize Embedded Controller Performance ............... 32

Isolating and Analyzing Serial Bus Activity................................................................. 37

Serial Pattern Encoding Schemes - 8b/10b ............................................................... 45

Serial Pattern Encoding Schemes Overview .............................................................. 45

8b/10b ....................................................................................................................... 45

Using the 8b/10b Option ........................................................................................... 45

Using the 8b/10b Option Overview ........................................................................... 45

8b/10b Decode Setup Detail...................................................................................... 45

Using 8b/10b Hi-Speed Serial Triggers on Zi Oscilloscopes ....................................... 47

Encoding Table Reference ......................................................................................... 50

8b/10b Decode Search .............................................................................................. 52

General Purpose Embedded Protocols ..................................................................... 53

General Purpose Embedded Protocols Overview ..................................................... 53

Page 4

Serial Data Debug Solutions

iv

919586 RevA

I2C ............................................................................................................................... 53

SPI .............................................................................................................................. 53

UART .......................................................................................................................... 53

RS-232 ........................................................................................................................ 53

Using the I2Cbus Option ............................................................................................ 53

Using the I2Cbus Option Overview............................................................................. 53

I2C Decode Setup Detail ............................................................................................. 54

Creating an I2Cbus Trigger Condition ......................................................................... 55

I2C Trigger Setup Detail .............................................................................................. 56

Using the SPIbus Option ............................................................................................ 58

Using the SPIbus Option Overview ............................................................................ 58

SPIbus Decode Setup Detail ....................................................................................... 59

Creating a SPIbus Trigger Condition .......................................................................... 60

SPIbus Trigger Setup Detail ........................................................................................ 61

Using the UART-RS232bus Options ........................................................................... 63

Using the UART-RS232bus Options Overview ........................................................... 63

UART-RS232bus Decode Setup Detail ....................................................................... 63

Creating a UART-RS232bus Trigger Condition ........................................................... 65

UART-RS232bus Trigger Setup Detail ........................................................................ 66

Automotive and Industrial Protocols ....................................................................... 68

Automotive and Industrial Protocols Overview ........................................................ 68

CAN ............................................................................................................................ 68

LIN .............................................................................................................................. 68

FlexRay ....................................................................................................................... 68

Using the CANbus Option .......................................................................................... 68

Using the CANbus Option Overview .......................................................................... 68

CANbus Decode Setup Detail ..................................................................................... 69

Creating a CANbus Trigger Condition ........................................................................ 70

CANbus Trigger Setup Detail ...................................................................................... 70

PROTObus MAG and CANbus TDM Toolset Differences ........................................... 72

Using the LINbus Option ............................................................................................ 73

Using the LINbus Option Overview ............................................................................ 73

LINbus Decode Right-Hand Dialog ............................................................................. 73

Creating a LINbus Trigger Condition .......................................................................... 74

LINbus Trigger Setup Detail ....................................................................................... 75

Using the FlexRaybus Option ..................................................................................... 77

Using the FlexRaybus Option Overview ..................................................................... 77

FlexRaybus Decode Setup Detail ............................................................................... 78

Creating a FlexRaybus Trigger Condition ................................................................... 79

Page 5

919586 RevA

v

FlexRaybus Trigger Setup Detail ................................................................................ 80

FlexRaybus Physical Layer and Eye Diagram Analysis ............................................... 83

FlexRaybus Measurement Parameter Setup ............................................................. 85

FlexRaybus Physical Layer Measurement Parameters .............................................. 86

Viewing FlexRaybus Physical Layer Measurements .................................................. 86

Serial Audio Protocol .............................................................................................. 87

Serial Audio Protocol Overview ................................................................................. 87

I2S ............................................................................................................................... 87

Using the Audiobus Option ........................................................................................ 87

Using the AudioBus Option Overview ....................................................................... 87

AudioBus Decode Setup Detail .................................................................................. 87

Creating an AudioBus Trigger Condition ................................................................... 91

AudioBus Trigger Setup Detail ................................................................................... 92

AudioBus Measure/Graph Setup Detail .................................................................... 96

Military and Avionic Protocols ................................................................................. 97

Military and Avionic Protocols Overview .................................................................. 97

Operator's Manual

ARINC 429 .................................................................................................................. 97

MIL-STD-1553 ............................................................................................................ 97

Using the ARINC 429 Option ...................................................................................... 97

Using the ARINC 429 Option Overview ..................................................................... 97

ARINC 429 Decode Setup Detail ................................................................................ 97

ARINC 429 Decode Trace Annotations .................................................................... 100

ARINC 429 Decode Table Column Details ................................................................ 101

ARINC 429 Decode Search ....................................................................................... 102

Using the MIL-STD-1553 Option .............................................................................. 102

Using the MIL-STD-1553 Option Overview .............................................................. 102

MIL-STD-1553 Decode Setup Detail ........................................................................ 103

MIL-STD-1553 Decode Trace Annotations ............................................................... 104

MIL-STD-1553 Decode Table Column Details .......................................................... 105

MIL-STD-1553 Decode Search ................................................................................. 106

Creating a MIL-STD-1553 Trigger Condition ............................................................ 106

MIL-STD-1553 Trigger Setup Detail ......................................................................... 107

Sub-Types, Setup Format, and Right-Hand Dialogs ................................................. 108

Handset, Cellular, and Mobile Computing Protocols ................................................ 118

Handset, Cellular, and Mobile Computing Protocols Overview .............................. 118

DigRF 3G .................................................................................................................. 118

DigRF 4G .................................................................................................................. 118

D-PHY (CSI-2/DSI) ..................................................................................................... 118

M-PHY ...................................................................................................................... 118

Page 6

Serial Data Debug Solutions

vi

919586 RevA

Using the DigRF 3G Option ...................................................................................... 118

Using the DigRF 3G Option Overview ...................................................................... 118

DigRF 3G Decode Setup Detail ................................................................................. 118

DigRF 3G Decode Trace Annotations ....................................................................... 120

DigRF 3G Decode Table Column Details .................................................................. 121

DigRF 3G Decode Search .......................................................................................... 122

Using the DigRF v4 Option ....................................................................................... 122

Using the DigRF v4 Option Overview ....................................................................... 122

DigRF v4 Decode Setup Detail ................................................................................. 123

DigRF v4 Decode Trace Annotations........................................................................ 125

DigRF v4 Decode Table Column Details ................................................................... 126

DigRF v4 Decode Search .......................................................................................... 127

Customizing WordName and Comment Definitions ............................................... 128

Using the MIPI D-PHY (CSI-2/DSI) Option ................................................................ 128

Using the MIPI D-PHY Decode Option Overview ..................................................... 128

MIPI D-PHY Decode Setup Detail ............................................................................. 128

MIPI D-PHY Decode Trace Annotations ................................................................... 130

MIPI D-PHY Decode Table Column Details .............................................................. 131

MIPI D-PHY Decode Search ...................................................................................... 132

MIPI D-PHY Physical Layer Measurement Parameters ............................................ 133

Using the MIPI M-PHY.............................................................................................. 145

Using the MIPI M-PHY Decode Option Overview .................................................... 145

MIPI M-PHY Decode Setup Detail ............................................................................ 145

MIPI M-PHY Decode Trace Annotations .................................................................. 146

MIPI M-PHY Decode Table Column Details ............................................................. 147

MIPI M-PHY Decode Search ..................................................................................... 148

MIPI M-PHY Physical Layer Measurement Parameters ........................................... 148

Storage, Peripherals, and Interconnect Protocols .................................................... 154

Storage, Peripherals, and Interconnect Protocols Overview .................................. 154

SAS ........................................................................................................................... 154

Fibre Channel ........................................................................................................... 154

SATA ......................................................................................................................... 154

PCIe .......................................................................................................................... 155

USB 2.0 ..................................................................................................................... 155

USB 3.0 ..................................................................................................................... 155

Using the SAS Option ............................................................................................... 155

Using the SAS Option Overview ............................................................................... 155

SAS Decode Setup Detail ......................................................................................... 155

SAS Decode Trace Annotations................................................................................ 157

Page 7

919586 RevA

vii

SAS Decode Table Column Details ........................................................................... 157

SAS Decode Search .................................................................................................. 158

Using the FibreChannel Option ............................................................................... 159

Using the FibreChannel Option Overview ............................................................... 159

FibreChannel Decode Setup Detail .......................................................................... 160

FibreChannel Decode Trace Annotations ................................................................ 161

FibreChannel Decode Table Column Details ........................................................... 162

FibreChannel Decode Search ................................................................................... 163

Using the PCIe Option .............................................................................................. 163

Using the PCIEbus Option Overview ........................................................................ 163

PCIEbus Decode Setup Detail .................................................................................. 164

PCIEbus Decode Trace Annotations......................................................................... 167

PCIEbus Decode Table Column Details .................................................................... 168

PCIEbus Decode Search ........................................................................................... 170

PCIEbus Decode Examples ....................................................................................... 171

Using the SATA Option ............................................................................................ 175

Operator's Manual

Using the SATA Option Overview ............................................................................ 175

SATA Decode Setup Detail ....................................................................................... 176

SATA Decode Trace Annotations ............................................................................. 177

SATA Decode Table Column Details ........................................................................ 178

SATA Decode Search ................................................................................................ 178

Creating a SATA Trigger Condition .......................................................................... 179

SATA Trigger Setup Detail ........................................................................................ 180

Using the USB2 Option ............................................................................................ 183

Using the USB2 Option Overview ............................................................................ 183

USB2 Decode Setup Detail ....................................................................................... 183

USB2 Decode Trace Annotations ............................................................................. 184

USB2 Decode Table Column Details ........................................................................ 185

USB2 Decode Search ................................................................................................ 186

Creating a USB2 Trigger Condition .......................................................................... 187

USB2 Trigger Setup Detail ........................................................................................ 188

Using the USB3 Option ............................................................................................ 191

Using the USB3 Option Overview ............................................................................ 191

USB3 Decode Setup Detail ....................................................................................... 191

USB3 Decode Trace Annotations ............................................................................. 192

USB3 Decode Table Column Details ........................................................................ 193

USB3 Decode Search ................................................................................................ 194

Troubleshooting Storage, Peripherals, and Interconnects Issues ........................... 195

Polarity Correction ................................................................................................... 195

Page 8

Serial Data Debug Solutions

viii

919586 RevA

Reference .............................................................................................................. 196

Dialog Area ............................................................................................................... 196

Touch Screen Controls ............................................................................................. 196

Specifications ........................................................................................................... 199

Contact LeCroy for Support ..................................................................................... 199

Index ..................................................................................................................... 201

Page 9

Operator's Manual

919586 RevA

9

Serial Data Debug Solutions Introduction

Overview

LeCroy's Serial Data Debug Solutions (SDDS) provide different Toolsets for analysis of the Supported Protocols.

Structure of This Manual

The documentation is structured in the following manner.

Introduction - This introduction explains the Toolsets.

Accessing Toolsets - Where you'll find the various toolsets on the interface/dialogs when the different

software options are enabled.

Using Toolsets - We then take you to the point of using the general parts of a given toolset - just up to the

point where protocol specific functions come into play.

Documentation for Each Supported Protocol - These remaining sections of the manual group the various

protocols into market-specific collections.

These collections include Encoding Schemes, General Purpose Embedded Protocols, Automotive and

Industrial Protocols, Audio Protocols, Military and Avionic Protocols, Handset and Cellular Protocols,

and Storage, Peripherals, and Interconnects.

Assumptions

A basic understanding of the various serial data standard physical and protocol layer specifications, and

knowledge of how these standards are used in embedded controllers is prerequisite. In addition, a basic

understanding of oscilloscope operation (specifically the LeCroy oscilloscope with which the serial trigger and

decode option is used) is required. Wherever practical or necessary, details on specific oscilloscope features

have been included in the material.

PLEASE NOTE THE FOLLOWING:

The Dialog Area (on page 196) topic covers essential input entry methods using standard LeCroy

oscilloscope interface controls and has been included in the Reference section at the end of this

documentation for convenience.

LeCroy has a policy of frequently updating software. While screen images in this manual may not exactly

match what is seen on your oscilloscope display, be assured that the functionality is nearly identical.

We are constantly expanding the coverage of serial data standards. Some capabilities covered in this

documentation may only be available with the latest version of our firmware at www.lecroy.com.

Many of the capabilities described require updated versions of the firmware. If you are experiencing

trouble with your software option, please try updating your firmware version to 6.4.0.x or higher.

Toolsets and Supported Protocols

Serial Data Debug Solution Toolsets are integrated into the oscilloscope – no external hardware is used. Serial

data signals are input to the oscilloscope through normal passive or active probes, such as LeCroy’s ZS Series of

high impedance active probes or ZD Series of differential probes, or through the use of cable inputs.

Serial Data Debug Solution Toolsets include the following:

Decode (D) - Both D and TD Toolsets greatly increase your ability to debug and analyze embedded

controllers using serial bus communications. Protocols having only the D Toolset only have Serial Decode

functionality. The D Toolset provides algorithms that interpret and annotate protocol signals and simplify

data viewing and analysis. Trigger and Decode (TD) - Protocols having the TD Toolset have both Serial

Trigger and Decode capabilities. In addition to the Decode capabilities described above, the TD Toolset

also recognizes serial data patterns to trigger the oscilloscope at a pre-determined time; other signals

coincident with the desired serial data pattern can also be captured simultaneously.

Page 10

Serial Data Debug Solutions

10

919586 RevA

PROTObus MAG - The PROTObus MAG Toolset equips certain protocols (I

FlexRay, DigRF 3G, and MIL-STD-1553) with decoders and a variety of data extraction, timing, and other

measurement and graphing functionality. It provides insight into the serial bus standards not provided by

any other analyzer or oscilloscope. The package includes five timing measurements, three bus utilization

measurements, and two tools for extracting the encoded digital data from a serial data message and

displaying it as an analog value or waveform representation. These are essential capabilities for engineers

who require more insight into serial data protocols under test and how they interact with other circuit

elements in embedded designs. This toolset is the basic building block upon which many other LeCroy

serial trigger and decoder options can then be added and significantly extending the trigger and decode

functionality of these other packages by providing tools for more complete and faster validation and

debugging of embedded designs. It provides the deepest level of insight possible.

ProtoSync - The ProtoSync toolset provides full protocol analysis for supported protocols. While using it

you can view decoded waveforms while also viewing both CATC Protocols and Bit Tracer Data

concurrently using a Packet Analysis View. Once a linkage is established and data is transferred between

your oscilloscope and the Protocol Analysis software, the programs work simultaneously; meaning,

actions executed either on the oscilloscope or in the Protocol Analysis software updates the other in real

time for extremely comprehensive protocol analysis.

There are some toolkits specifically designed for particular protocols. Physical (P) and Graph (G) toolsets exist

and are perfectly suited for FlexRay and I2S (Audiobus) protocols, respectively.

Measure (M) - Measure is a legacy toolset used for the CANbus TDM package. Measurement applications

have been improved and made part of the PROTObus MAG toolset. Measurement toolsets provide

controls for assigning measurement parameters to your protocol signal sources.

2

C, SPI, UART, RS-232, CAN, LIN,

PLEASE NOTE THE FOLLOWING:

Currently, the PROTObus MAG toolset handles most measurement instances for supported

protocols. However, the CANbus TDM option is handled and covered in a manner differently than

PROTObus MAG. The difference are explained in PROTObus MAG and CANbus TDM Toolset

Differences (on page 72)

The TDM Toolset can also support some Graphing capabilities as well. In this context, Measure

provides various protocol-specific timing or other measurement parameters and Graph provides

the ability to extract digital data from a message and display it either as a measurement parameter

value or as an analog waveform representation of the digitally encoded data.

Physical (P) - The Physical (P, or TDP) toolset supports Physical layer analysis capable of showing an eye

diagram with a mask on FlexRaybus, MIPI D-, and M-PHY signals.

Graph (G) - The Graph (G, or TDM/G) toolset provides additional tools on protocol signal source

measurement parameters rendering graphical representations of the signal (Histo, Trend, and Track), if

desired for I2S Audiobus signals.

Compatibility

The supported protocols are packaged and indicate specific toolsets as part of the name in the following

manner:

Supported Protocol Name+bus + a Toolset Suffix

Toolset suffixes are the names (many abbreviations) listed in the previous topic (D, TD, TDM). The following

table shows a list of supported protocols and their associated toolsets.

PLEASE NOTE THE FOLLOWING:

Contact LeCroy for more information about these Software Options by referring to the Contact LeCroy for

Support (on page 199) topic for more details.

Not all supported protocol software options are offered for each oscilloscope product line.

Page 11

Operator's Manual

919586 RevA

11

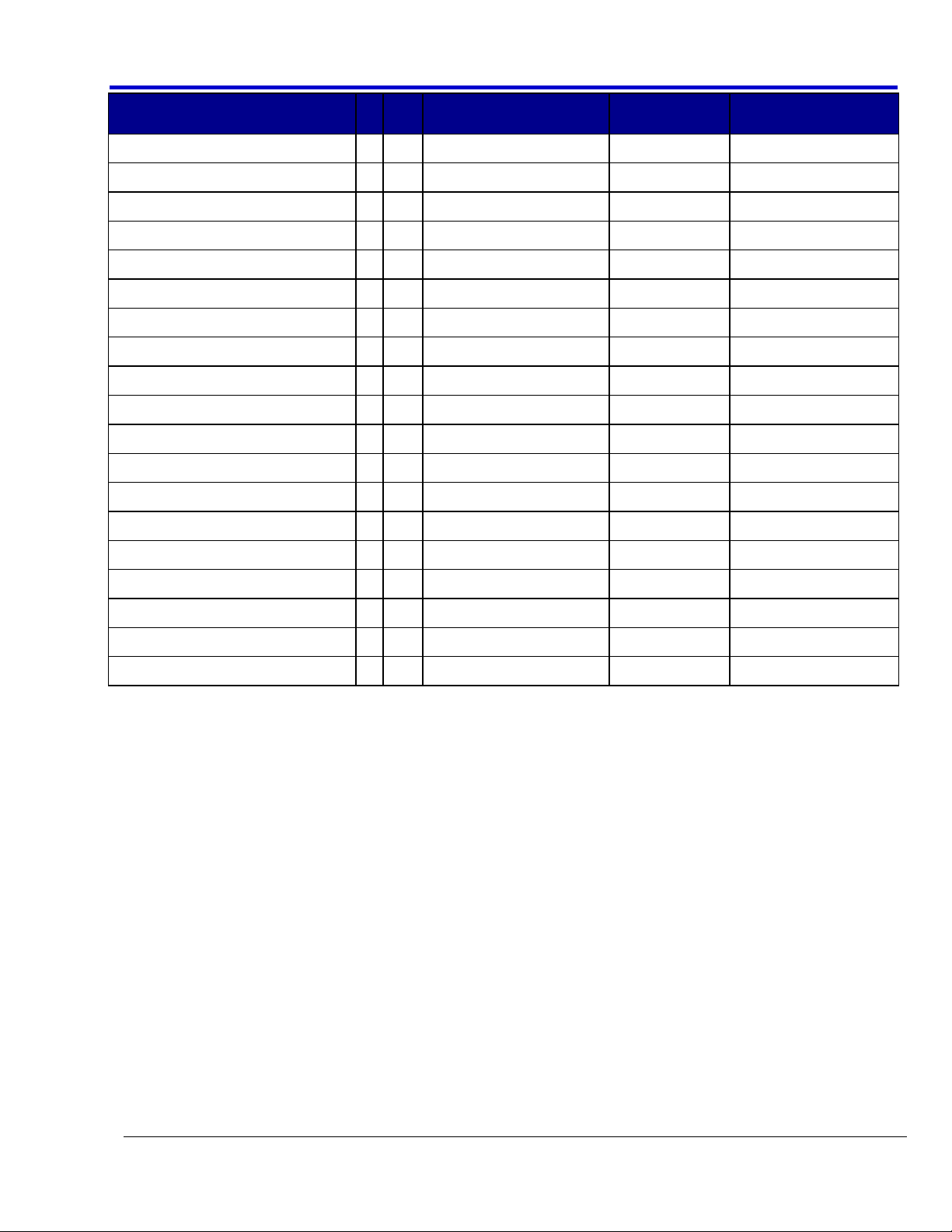

Protocol

D

TD

PROTObus MAG

ProtoSync

P, G, Toolsets*

I2C • • •

SPI • • •

UART, RS-232

•

• •

CAN • • •

LIN • • •

FlexRay

•

• •

P

I2S (Audiobus)

•

•

G

ARINC 429

•

MIL-STD-1553

•

• •

DigRF 3G

•

•

DigRF v4

•

•

MIPI D-PHY/CSI-2/DSI

•

P

MIPI M-PHY

•

P

SAS • •

FibreChannel

•

•

PCIe • • •

SATA • • •

USB 2.0

•

• •

USB 3.0

•

•

Table 3-1.*Physical (P) and Graph (G) Toolsets are specialized for both FlexRay and I2S Audiobus supported protocols.

Page 12

Serial Data Debug Solutions

12

919586 RevA

Accessing and Using Supported Protocol Toolsets

Accessing and Using Supported Protocol Toolsets Overview

LeCroy's various serial data debug solutions utilize advanced trigger circuitry and advanced software algorithms

to provide powerful capability for serial data triggering, decoding, and analysis. The various software options are

accessed in the user interfaces in different ways. Some options are provided with certain oscilloscope models;

others are purchased and installed.

PLEASE NOTE THE FOLLOWING:

This section of the manual is meant to provide an initial explanation as to how the different toolsets are

accessed and used with some technical explanations at the end of the section. The information is

provided in this fashion to illustrate the commonality among toolset usage across supported protocols.

Since each serial protocol is quite different, serial trigger conditions and other settings for supported

protocols are also different. Detailed information as to how a serial trigger conditions is set up for a

specific supported protocol is covered in corresponding sections of this manual for each option. Ask your

local LeCroy representative for more information about any Serial Data Debug Solution Protocols or

Toolkits using the Contact LeCroy for Support (on page 199) topic.

The D and TD Toolsets

Technical Explanation of Serial Decode and Trigger

SERIAL DECODE

Both the D and TD options contain powerful protocol decoding and annotation software algorithms. This

algorithm is used in all LeCroy serial decoders sold with oscilloscopes, and differs slightly for serial data signals

that have a clock embedded in data or a clock separate from data.

The software algorithm examines the embedded clock (see Serial Data Debug Solutions (on page 9) for

synchronous/asynchronous protocol details) for each message based on a default (or user set) vertical level.

Once the clock signal is extracted or known, the algorithm examines the corresponding data signal at a

predetermined vertical level to determine whether a data bit is high or low. The default vertical level is usually

set to 50% and is determined from a measurement of peak amplitude of the signals acquired by the

oscilloscope. It can also be set to an (absolute) voltage level, if desired. The algorithm intelligently applies a

hysteresis to the rising and falling edge of the serial data signal to minimize the chance of perturbations or

ringing on the edge affecting the data bit decoding.

After determining individual data bit values, a different algorithm performs a decoding of the serial data

message after separation of the underlying data bits into logical groups (Header/ID, Data Length Codes, Data,

CRC, Start Bits, Stop Bits, etc.) specific to the protocol. Once the clock signal is acquired and the decoding is

completed for a serial data message with separate clock and data lines, the oscilloscope channel showing the

capture clock signal can be turned OFF to reduce screen clutter.

Finally, another algorithm provides the appropriate color coding of the message, and displays the protocol

message data on the screen, as desired, overlaid on the source trace. Various compaction schemes are utilized

to show the data during a long acquisition (many hundreds or thousands of serial data messages) or a short

acquisition (one serial data message acquisition). In the case of the longest acquisition, only the most important

information is highlighted. In the case of the shortest acquisition, all information is displayed (Header/ID, Data

Length Codes, Data, CRC, Start Bits, Stop Bits, etc.) with additional highlighting of the complete message frame.

Page 13

Operator's Manual

919586 RevA

13

Note: Although the decoding algorithm is based on a clock extraction software algorithm using a vertical level,

the results returned are the same as those from a traditional protocol analyzer using sampling point-based

decode. In addition, the clock extraction technique allows partial decoding of messages in the event of physical

layer noise, in many cases, whereas a protocol analyzer usually cannot. This is a significant advantage for the

LeCroy software algorithm.

If the sampling rate (SR) is insufficient to resolve the signal adequately based on the bit rate (BR) setup or clock

frequency, the protocol decoding is turned OFF to protect the operator from incorrect data. The minimum SR:BR

ratio required is 4:1. It is suggested that you use a slightly higher SR:BR ratio if possible, and use significantly

higher SR:BR ratios if you want to also view perturbations or other anomalies on your serial data analog signal.

SERIAL TRIGGER

TD options for some supported protocols contain advanced serial data triggering. This serial data triggering is

implemented directly within the hardware of the oscilloscope acquisition system, and contains advanced

algorithms to protocol decode, recognize, and trigger on user-defined serial data patterns. This allows a

recognized serial data pattern to be used to trigger the oscilloscope at a pre-determined time, and other signals

coincident with the desired serial data pattern can be captured simultaneously.

Accessing The D and TD Supported Protocol Toolsets

These respective toolsets are accessed by locating the Serial Decode and Serial Trigger dialogs.

Note: Users approach the Trigger and Decode software options differently. Some use Decode first, and then

Trigger. In fact, LeCroy has a Link To Trigger feature used to specifically tie Decoded channels to Triggers.

Currently, the specific protocol content in this Serial Data Debug Solutions manual covers Decode, and then

Trigger tools. Still, the content is clearly titled so no matter what order you access Trigger and Decode

software, the functionality you're looking for is never far.

DECODERS

Decoders are all initially accessed by touching Analysis → Serial Decode from the menu bar.

Alternatively, you can also touch a Channel or Memory trace descriptor label showing its corresponding (channel

or memory) dialog, and then touch the Decode button listed shown on the lower part of the dialog. If a decode

table is already displayed, you can shortcut to the decode setup by touching the color-coded protocol name in

the upper-left corner of the decode table itself. See Protocol Results Table (on page 19) for more information.

Page 14

Serial Data Debug Solutions

14

919586 RevA

Some oscilloscope models also allow you to access the Serial Decode dialog the following ways:

Touch the grid display of a Channel, Memory, or Math trace and a pop-up dialog shows a Decode Setup...

shortcut if available on your instrument model. Touch this shortcut.

Press the Decode front panel button if available on your instrument model. The Serial Decode dialog is

then shown on the screen.

Use any of the aforementioned methods to access the main Serial Decode... dialog is shown.

TRIGGERS

Triggers are accessed by touching Trigger → Trigger Setup... from the menu bar. Alternatively, you can also

touch the Trigger trace descriptor label.

Note: Some oscilloscope models may also have a Trigger front panel button which shows the main Serial

Decode dialog when pressed.

Use your preferred method to access the main Trigger dialog.

Using The D Supported Protocol Toolsets

The main Serial Decode dialog acts as a summary page for your decode settings.

MAIN SERIAL DECODE DIALOG

There are four independent decoders. A user can operate up to four at a single time, although limitations may

occur with regard to how the numbers of channels are accommodated at one time. Practically speaking, if a user

decodes signals with a clock and data line (and perhaps also a chip select or other third line), then two

simultaneous decodes is the maximum number using the LeCroy oscilloscope analog channels. The addition of

the MS-250 or MS-500 Mixed Signal Oscilloscope options allow usage of digital lines for trigger and decoding,

which preserves analog channels for other uses. Contact your local LeCroy sales office for more information

about this option.

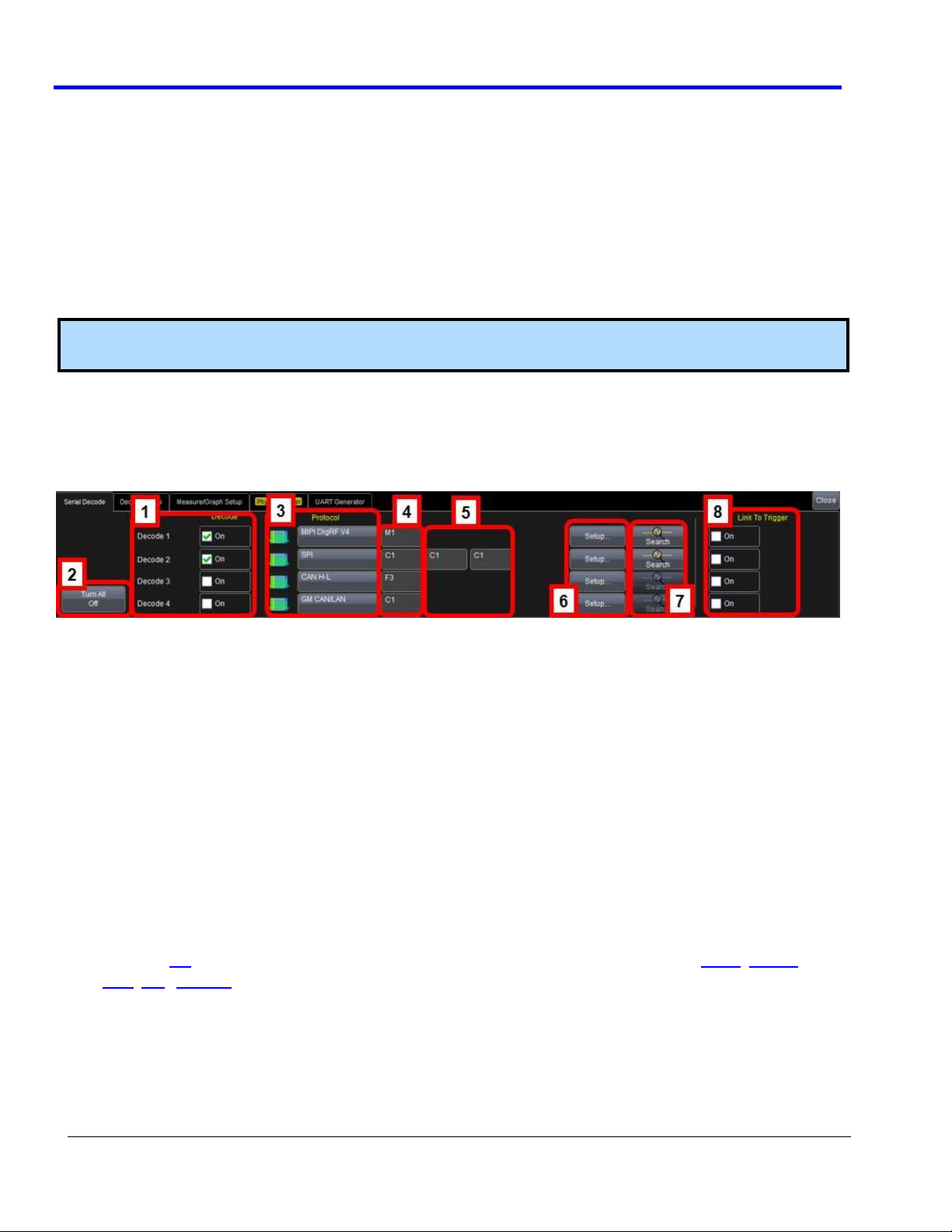

Numbered labels on this screen-shot correspond with the following explanations.

1. Decode - Mark or un-mark this checkbox to quickly enable or disable decoded signals.

2. Turn All Off - This button is provided for a convenient way to instantly disable all the decoded signals.

3. Protocol - Touch this field and select a desired protocol from the ones you have installed on your

instrument.

4. Source - Select which signal source to which you wish to apply your selected protocol.

5. Data and Clock Selection - These controls are available for certain protocols and provide pop-up channel

or source selections for the corresponding decode. Some protocols may require a third selection (for

instance, SPI also requires a Chip or Slave Selection). Asynchronous protocols, such as UART, RS-232,

CAN, LIN, FlexRay, and most high-speed serial data signals only require a single source.

6. Setup - Use this button to quickly access the corresponding detailed Decode Setup dialog for the

particular protocol selected.

7. Search - Use this button to quickly create a Zoom of the corresponding decoded signal. The right-hand

dialog of this Zoom provides search capabilities for the decode signal.

8. Link To Trigger - Mark or un-mark this checkbox to quickly tie the decoded signal to an additional Trigger

setup. This provides a faster, easier setup where the trigger is set similar as the decoder.

Page 15

Operator's Manual

919586 RevA

15

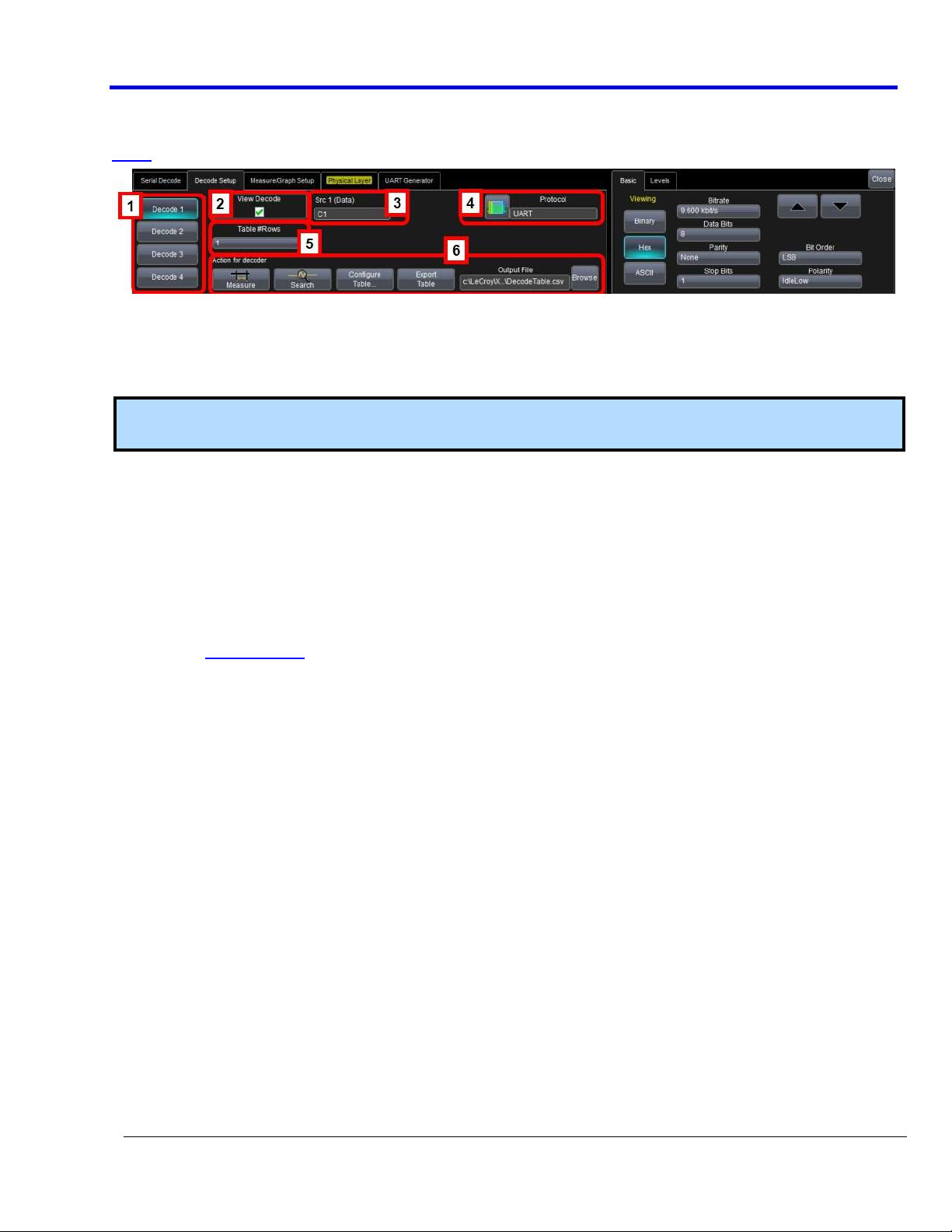

THE DECODE SETUP DIALOG

The Decode Setup dialog is where the details of a specific protocol decode is entered. It appears as follows (the

UART Decode Setup dialog is shown as an example):

This is a single tab with an indicator on the left side describing to which of the four decoders the setup

information pertains.

The left side of this dialog box is described here (the right side is explained in the protocol specific topics).

Numbered callouts correspond with the following explanations.

Note: DigRF 3 and 4G protocols are the only exceptions where a View I & Q button is available in place of

Measure in the Action for decoder section of the main Decode Setup dialog.

1. Decoder # Buttons - Indicates which of the four decoders to which the current information pertains.

2. View Decode Checkbox - Use this checkbox to turn decoding turned ON or OFF for the particular decoder.

Decoding ON provides a highlight of each message frame with color-coded highlighting and decoding of

the various protocol message portions.

PLEASE NOTE THE FOLLOWING:

If the View Decode checkbox is checked, the Table display is also shown. When the View Decode

checkbox is not marked the Table display is not shown.

When the Table is displayed, it appears similar to that shown previous (the example shown is for

MIL-STD-1553).

The first column heading (top left most cell of the table) bears the name of the corresponding

protocol. The cell's fill color matches the protocol color used on the grid display. Touching this

colorized, first column heading opens the Decode Setup dialog.

Touching the number cell (first cell) for each table row automatically sets up a Zoom for the

corresponding message position.

Page 16

Serial Data Debug Solutions

16

919586 RevA

Touching anywhere else on the table shows a pop-up with Off, Zoom, Setup..., Export, and

Measure... choices.

Decoding of an entire acquisition with very long acquisitions including thousands of messages

takes longer than shorter acquisitions.

3. Source Selection - Touch these selections to open a pop-up dialog where you can select sources for Data,

and (for some protocols) controls for Clock and other lines - for example Chip Select for SPI.

PLEASE NOTE THE FOLLOWING:

Source selection is dynamically linked to the Protocol selection, so the appearance and number of

sources to choose changes based on your selected Protocol.

Source can be a Channel (C1 – C4), a Memory Trace (M1 – M4), a Math Function (F1 – F4), or

digital lines (D1 - D36 on MS-250 or MS-500).

Use a Channel for a new, real-time acquisition.

Use a Memory for recalling saved data from a previous acquisition for further analysis. Refer to

your oscilloscope’s Save and Recall Waveforms topic for more details.

Use a Math Function to view decoded data on Sequence mode acquisitions. Sequence Mode is a

unique capability where you can utilize oscilloscope memory to capture events widely spaced in

time and then view them sequentially. Reference the chapter on Isolating and Analyzing Serial Bus

Activity for more information on setting the oscilloscope up in this mode.

4. Protocol Selection - Touch this selection to open a pop-up dialog box and choose a protocol decoder.

Depending on the decoder selected, the correct inputs (Clock, Data, and a third line, if required) are

shown to the left.

Page 17

Operator's Manual

919586 RevA

17

5. Table #Rows - Touch this option and provide a value (1-20) for the number of table rows for display. One

row of data is shown by default. If a value of 1 - 4 rows is provided, the scroll bar to the right of the table

is replaced with a pop-up scroll for more convenient use.

6. Action for Decoder Toolbar - Various buttons on this toolbar provide context-sensitive shortcuts for

decoding.

Search allows quick creation of a zoom trace and changes the dialog box to the zoom/search dialog

box.

Acquire long records of message data, and use Search to look through the record for a specific

message. When the message meeting the search criteria is found, the complete message is then

shown with the Zoom Trace. Use the arrow buttons to navigate forward and backward through the

messages. Unsuccessful searches are noted with a line of text.

Configure Table displays a pop-up dialog box specific to a particular protocol. The dialog contains

checkboxes for various columns in the table. Check or uncheck the checkboxes to show or hide

specific columns on the table.

Export Table exports the complete protocol table data to a .CSV file.

The Output File name and directory can be selected by the user using the controls to the right.

Click the Browse button to select a file.

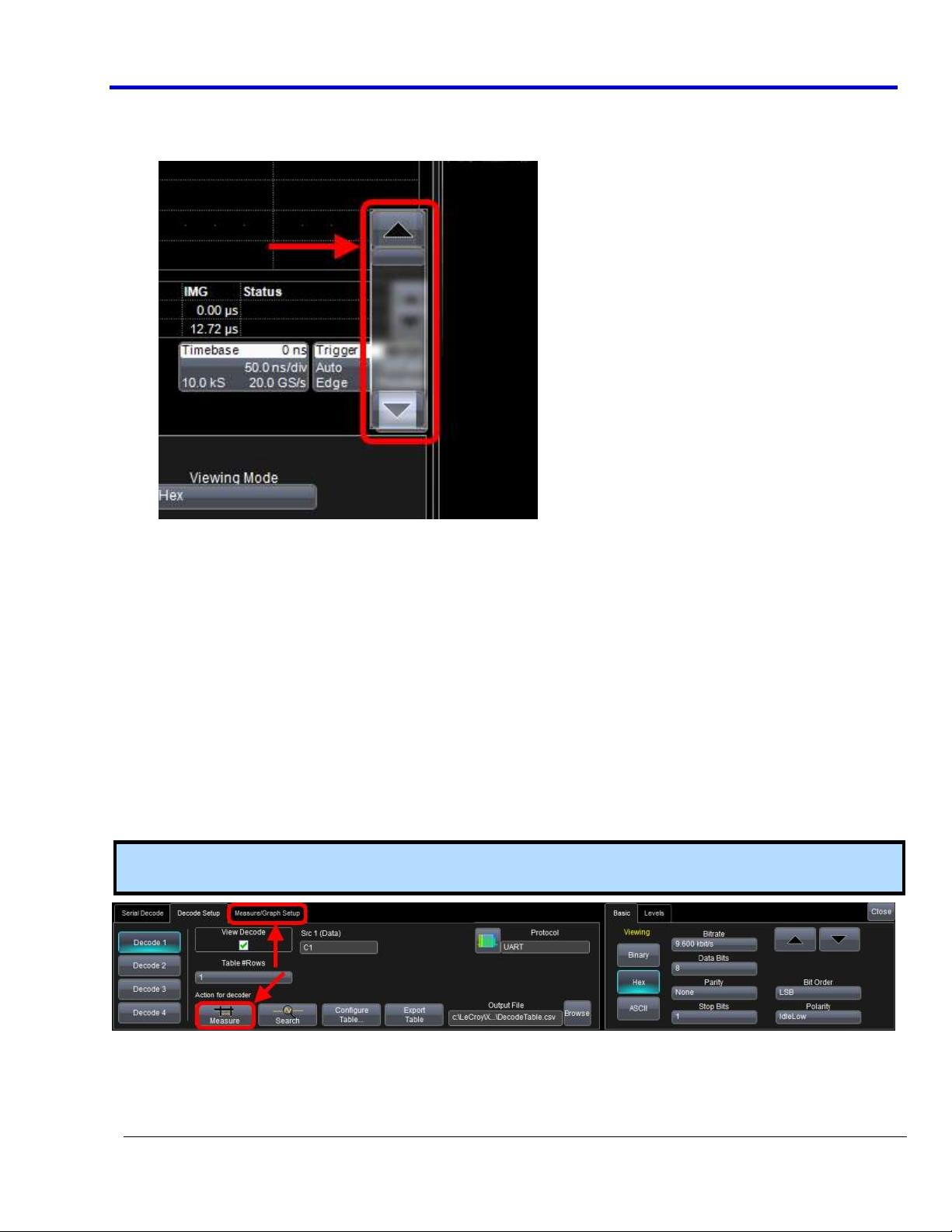

Note: If you have the PROTObus MAG toolkit option, those screens are easily accessed from the Decode Setup

screen by clicking either the Measure button or the Measure/Graph Setup... tab.

Page 18

Serial Data Debug Solutions

18

919586 RevA

Decode Toolset Features and Controls

DECODE TOOLSET FEATURES AND CONTROLS OVERVIEW

Data packets (or messages) on properly decoded signals for a given protocol can be easily viewed using Serial

Decode Trace Annotations (below), the Protocol Results Table (on page 19), and/or by Searching for Messages

(on page 21) (Types and Subtypes). These concurrent tools provide fast insight and perspective and are very

effective when used together.

PLEASE NOTE THE FOLLOWING:

Messages for most protocols are classified into Frames, Errors, Unknown or Grouped Primitives specific to

a given protocol. Sub Types then further classify each main message type into more protocol-specific

messages.

Protocol-specific topics may define a few messages while explaining how to access annotations, table

results, and search. Please refer to the corresponding protocol specification (maintained by groups

external to LeCroy). Links to these groups can be found in corresponding Overview content for each

market-specific collection.

LeCroy's market-specific collections of protocol solutions include Encoding Schemes, General Purpose

Embedded Protocols, Automotive and Industrial Protocols, Audio Protocols, Military and Avionic

Protocols, Handset and Cellular Protocols, and Storage, Peripherals, and Interconnects.

Specifications are subject to change without notice.

SERIAL DECODE TRACE ANNOTATIONS

When protocol signals are decoded and shown on the grid display area, highlighted overlays are shown to help

label specific data within the signal.

Information Shown Based on Annotation Rectangle Width

The information shown on a given annotation is affected by the rectangle width.

Annotations may include name, repetitions, and the contents of the details table display column, provided the

rectangle is wide enough. Sizes and information displayed are based on the following:

If an annotation rectangle is less than 10 pixels wide no annotation is shown.

Only the short form name is shown for annotation rectangles > 10 but < 100 pixels wide.

The long form name and repetition count are shown on annotation rectangles > 100 but < 500 pixels

wide.

Details are also shown on rectangles > 500 pixels.

Page 19

Operator's Manual

919586 RevA

19

PROTOCOL RESULTS TABLE

The protocol results table provides a quick and easy way to understand all of your protocol data as decoded by

the oscilloscope, even when messages are too compact to allow annotation on the display. In addition, the table

provides a quick and easy method to view decode results and quickly zoom to a specific message. Since the table

uses the decoded data (extracted as previously described) as its source, the View Table button (from the user

interfaces) is always checked and the table is shown by default as signals are decoded.

Note: All protocols with Decode (D) capability have a corresponding decode result table. Selecting a row on

the table creates a zoom of the specific row/message, regardless of protocol. Refer to Using The D Supported

Protocol Toolsets (on page 14) for more information about the View Table button and other information

about the protocol results table.

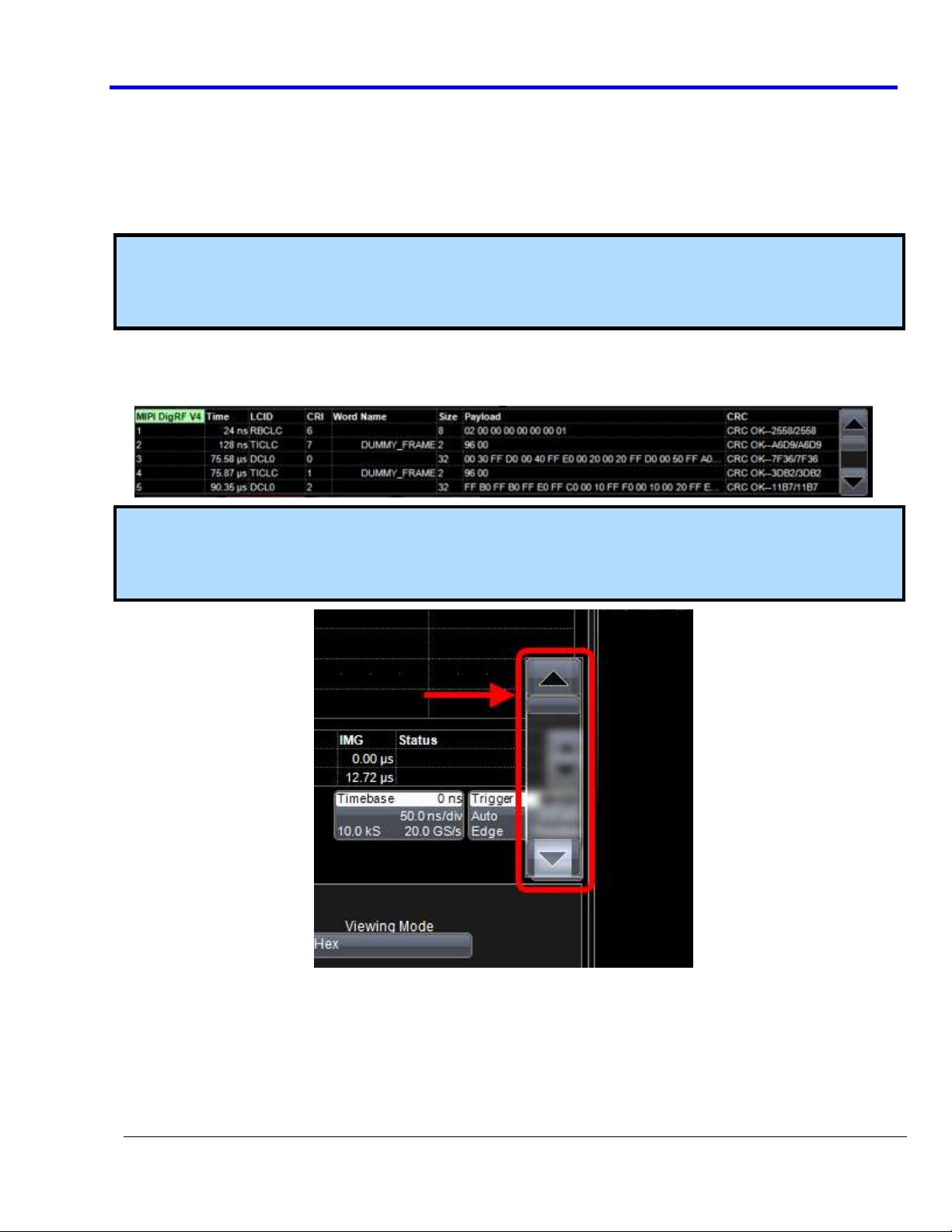

When displayed, the protocol results table appears under the waveform grid. The following protocol results

table is showing DigRF V4 data (each protocol's table looks different) and provides an example of what the table

looks like:

Note: If a value of only 1 - 4 rows is provided, oscilloscope models provide different solutions. Some replace

the vertical scroll bar to the right of the table with a pop-up scroll for more convenient use. Others turn the

vertical scroll bar yellow, indicating that the Adjust knob on the oscilloscope front panel can be used to

navigate table rows.

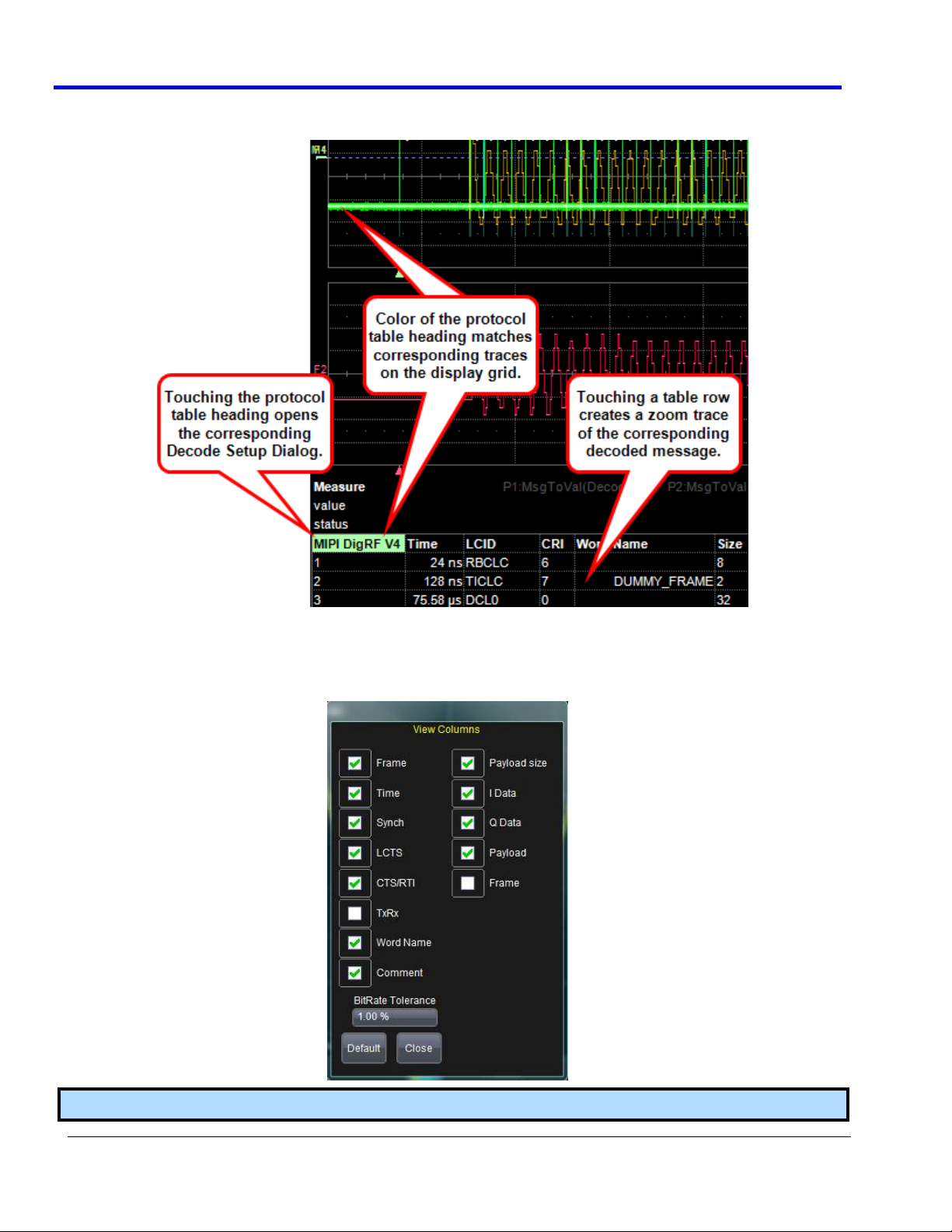

The first column heading (top left most cell of the table) bears the name of the corresponding protocol and the

cell's fill color matches the protocol color used on the grid display.

Page 20

Serial Data Debug Solutions

20

919586 RevA

Touching this colorized, first column heading opens the Decode Setup dialog. Touching any table row creates a

zoom trace of the corresponding decoded message.

The table is only shown if the View Table checkbox is marked on the Decode Setup Dialog and decoding has

occurred on the trace. Only one protocol table can be viewed at a time. As described in the previous section, the

protocol table can be configured or exported. Touching the Configure Table button on the Decode Setup Dialog

shows the View Columns pop-up similar to the following (they vary based on protocol):

Note: See Using The D Supported Protocol Toolsets (on page 14) for more information.

Page 21

Operator's Manual

919586 RevA

21

Checkboxes - Touch items to check the box and include them as table columns for a particular protocol.

BitRate Tolerance - Some protocols have a Bit Rate Tolerance setting. This can be set to any value from

0.01% to 10%. If the bit rate is outside the tolerance range set, then the calculated bit rate appears in red

text on the table.

Protocols with a wide variance of bit rates, such as I2C (which often has clock stretching) do not have this

feature.

Default - Press the Default button to reapply standard settings for a particular protocol.

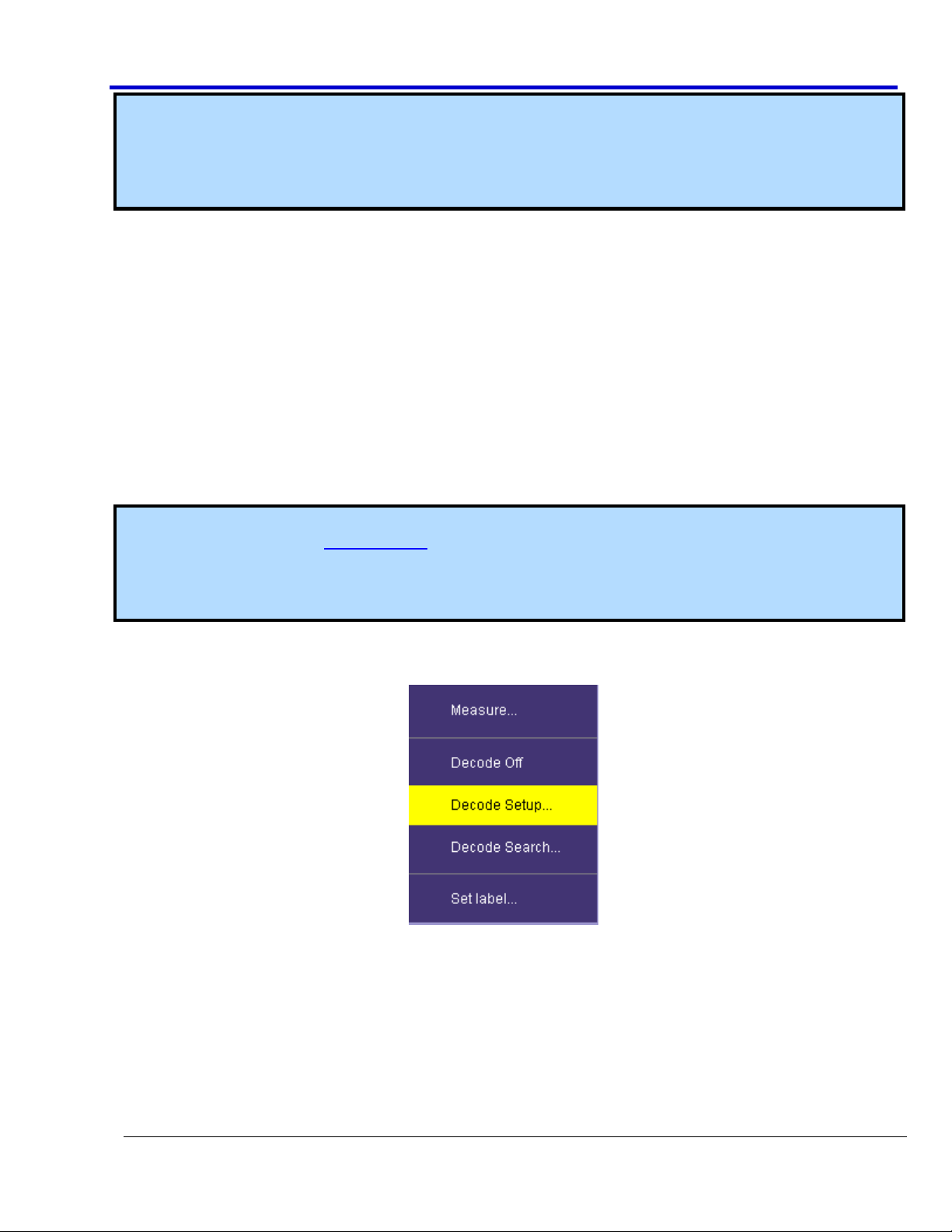

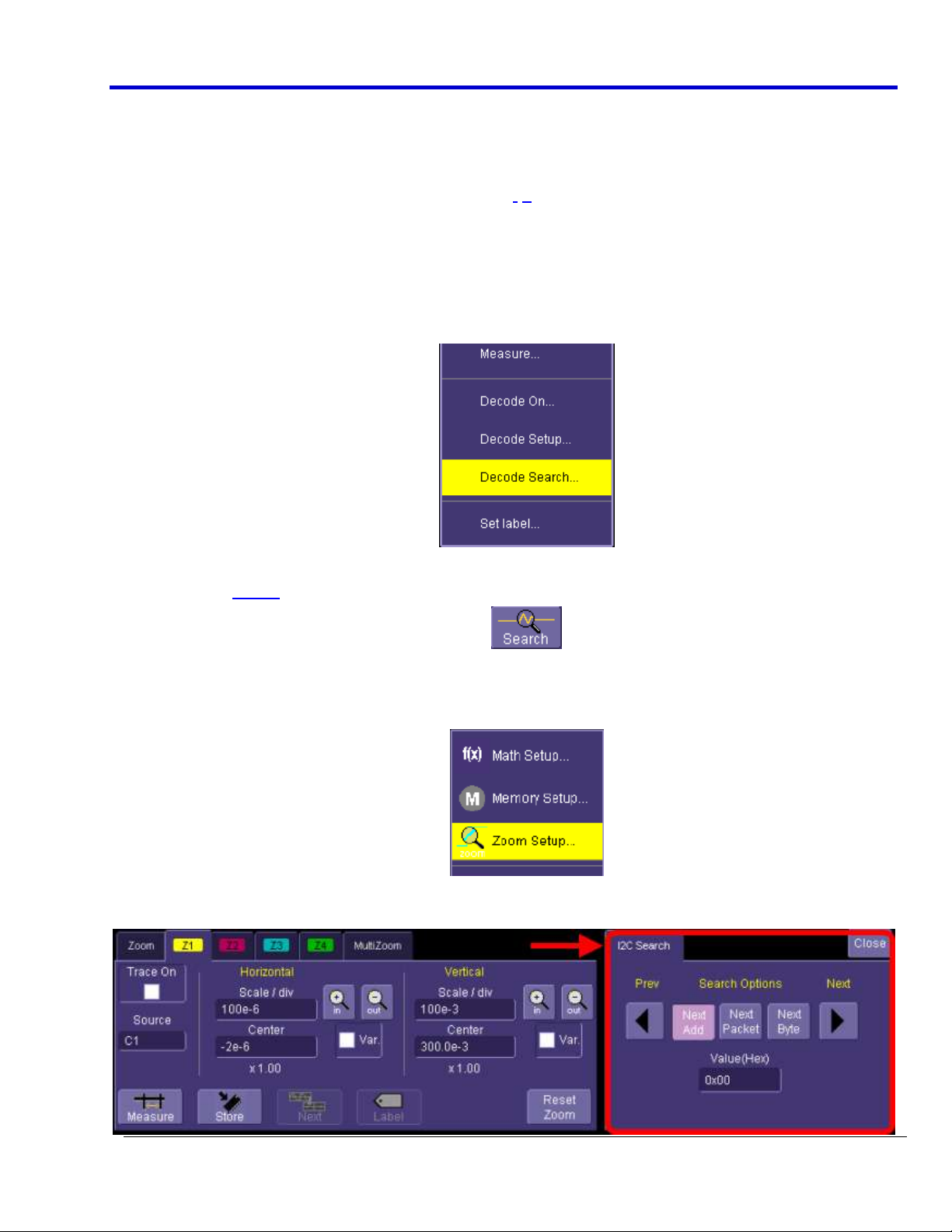

SEARCHING FOR MESSAGES

There are several ways to search for specific messages. The following are all valid ways to search messages.

Touch the decoded waveform. A pop-up dialog is shown where you can select Decode Search as follows:

OR

Touch the Search button in the Serial Decode Summary dialog box or the Decode Setup dialog box.

OR

Go to Math → Zoom Setup... from the Menu Bar to turn a Zoom ON, define its source, and search

directly.

Any of the aforementioned methods show the Zoom dialog box and a corresponding Search dialog box on the

right side.

Page 22

Serial Data Debug Solutions

22

919586 RevA

PLEASE NOTE THE FOLLOWING:

Search capabilities differ by protocol. For instance, SPI has no Address, so there is no capability to Search

by Address in SPI, while there is when searching under the I2C protocol.

Use the Search Options buttons to define the type of Search you want, enter a value in Hexadecimal

format, and use the left and right arrows to move your way from one message to the next.

When using search on a multi-data-lane protocol (PCIe), Z5 - Z8 zoom traces are used. Otherwise, single-

data-lane protocols use Z1 - Z4 zoom traces (based on the decoder assignment).

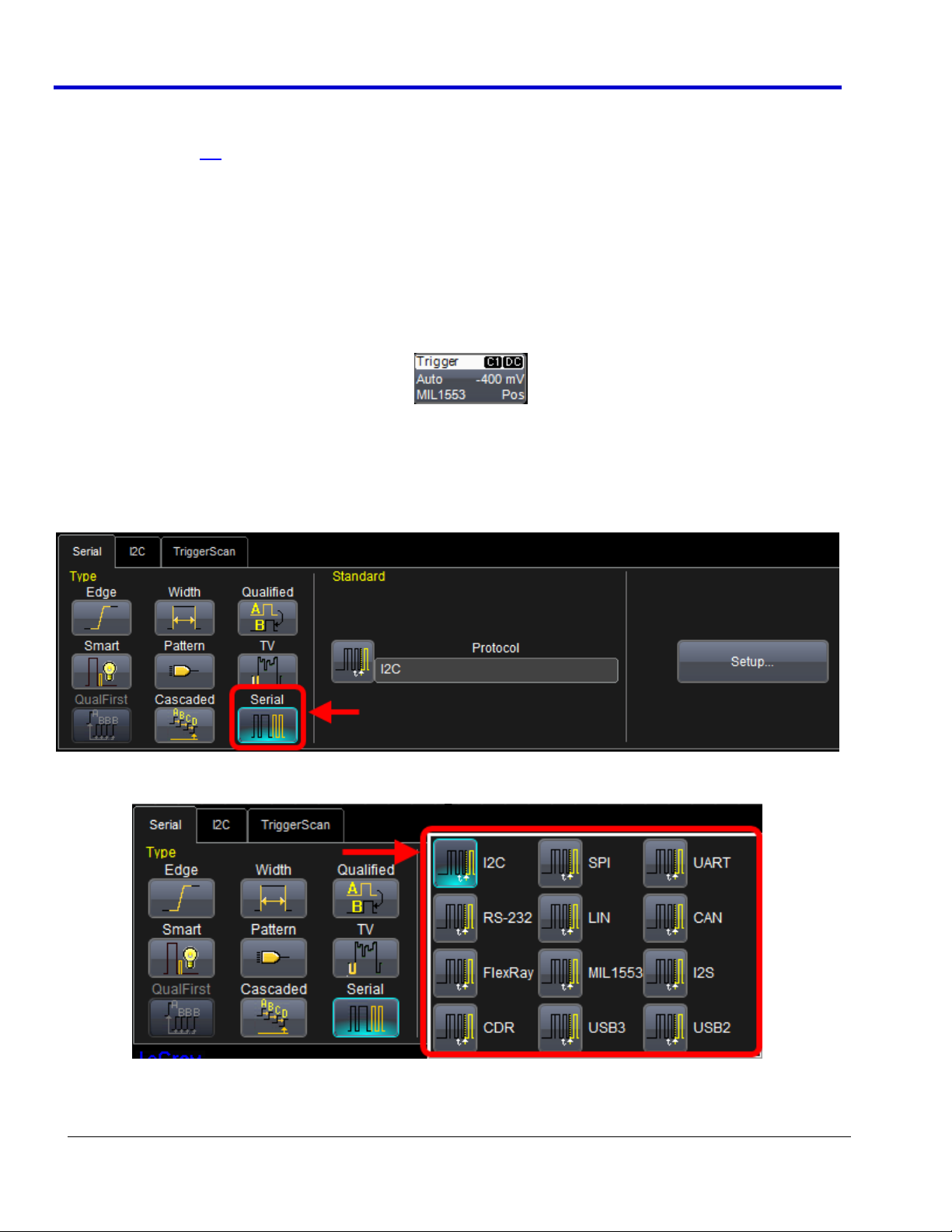

Using The T Supported Protocol Toolsets

When you acquire a LeCroy Serial Data Debug Solution equipped with a Serial Trigger, you access the specific

protocol trigger using one of the following methods:

Touch the Trigger Descriptor Box in the lower right hand corner of the oscilloscope display.

OR

Touch Trigger → Trigger Setup from the Menu Bar.

Some oscilloscope models may also have a Decode front panel button which shows the main Serial

Decode dialog when pressed.

Now, touch the Serial button on the Type section of the Trigger dialog.

Touch the Protocol field on the Standard section of the Trigger dialog and select your protocol from the choices

shown.

The focus then selects one tab to the right showing the selected Trigger Condition dialog reflecting the selected

protocol standard just selected.

Page 23

Operator's Manual

919586 RevA

23

PLEASE NOTE THE FOLLOWING:

Since each serial protocol is quite different, serial trigger conditions are also different. Detailed

information as to how a serial trigger conditions is set up for a specific protocol is covered in

corresponding protocol-specific sections of this manual.

Users approach Trigger and Decode software options differently. Some use Decode first, and then Trigger.

In fact, LeCroy has a Link To Trigger feature used to specifically tie Decoded channels to Triggers.

Currently, the protocol content in this Serial Trigger Decode and ProtoSync manual is covered in Decode,

and then Trigger order. Still, the topics are clearly covered so no matter what order you access Trigger

and Decode software, the functionality you're looking for is never far.

Accessing and Using The PROTObus MAG Supported Protocol Toolset

Certain protocol packages include the PROTObus MAG Serial Debug Toolset which provides capabilities for

making automated timing measurements using a set of provided measurement parameters. For instance, the

time between an analog signal and a corresponding serial data message can be measured with a user-definable

parameter, or an analog data value can be extracted from an embedded digital data signal or stream (digital-toanalog conversion) and displayed. Other protocol-specific measurements may also be included.

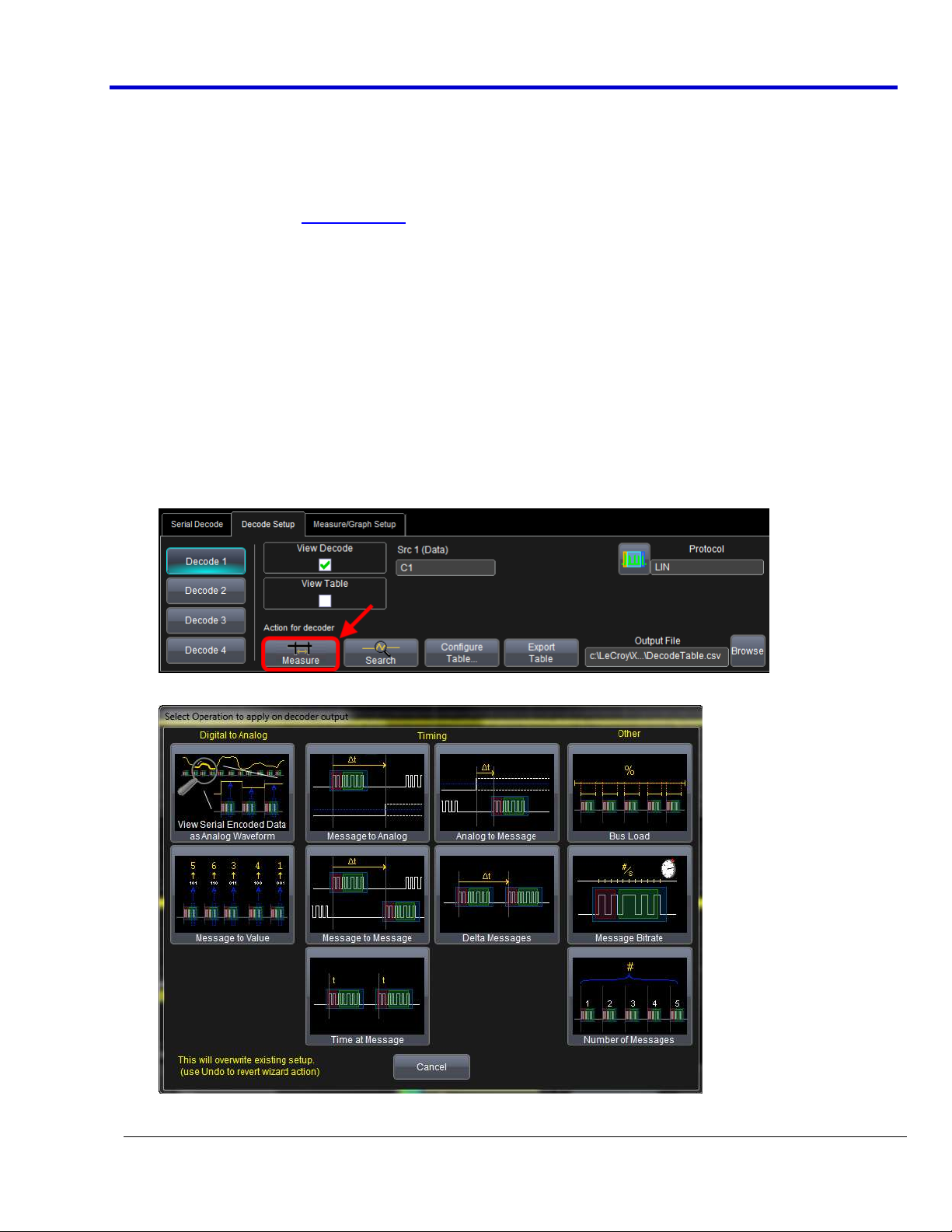

The PROTObus MAG toolset is accessed in the following manner:

1. Once you've accessed the Decode Setup dialog as explained in Accessing The D and TD Supported

Protocol Toolsets (on page 13), touch the Measure button for the desired Decode.

2. The Select operation to apply on decoder output pop-up is shown.

Page 24

Serial Data Debug Solutions

24

919586 RevA

The operations are organized in Digital to Analog, Timing, and Other columns on the pop-up for

convenience.

Choose the desired operation for your decode output by clicking the large icons on the pop-up.

Note: When accessing these parameters from the Measure button, the measurement source defaults to

DecodeX. Measurements also can be accessed using the standard Measure → Measure Setup... and Measure

dialogs. When accessed using the latter method, DecodeX has to be deliberately set as the source - instead of

the standard Signal, Math, Memory, or other trace (C1, F1, M1, etc.).

Decode Output Operation Detail

The following decode output operation explanations are organized into Digital to Analog, Timing, and Other

sections to coincide with the pop-up.

DIGITAL TO ANALOG DECODE OUTPUT OPERATIONS

View Serial Encoded Data as Analog Waveform - Automatically sets up a Message to Value parameter

and then tracks the assigned measurement. In doing so, a Digital-to-Analog Conversion (DAC) of the

embedded digital data is performed and the digital data is displayed as an analog waveform.

Message to Value - Extract and convert a specific portion of the data/payload in the message and display

it as an analog value.

TIMING DECODE OUTPUT OPERATIONS

MsgToAnalog (Message to Analog) - Computes the time difference from a protocol message to the

crossing of a threshold on an analog signal.

AnalogToMsg (Analog to Message) - Computes the time difference from the crossing of a threshold on an

analog signal to a protocol message.

MsgToMsg (Message to Message) - Computes the time difference from one protocol message to another

protocol message.

DeltaMsg (Delta Message) - Computes the time difference between two messages on a single decoded

line.

Time@Msg (Time at Message) - Time from trigger to each protocol message (meeting specified

conditions).

OTHER DECODE OUTPUT OPERATIONS

BusLoad - Computes the load of user-defined messages on the bus (as a percent).

MsgBitrate - Computes the bitrate of user-specified messages on decoded traces.

NumMessages (Number of Messages) - Computes the number of messages which match a user-specified

definition in decoded traces.

Decode Measurement Parameters via Measure Setup

TIP: You can also access these same Decode Measurement parameters from Measure → Measure Setup... on

the menu bar.

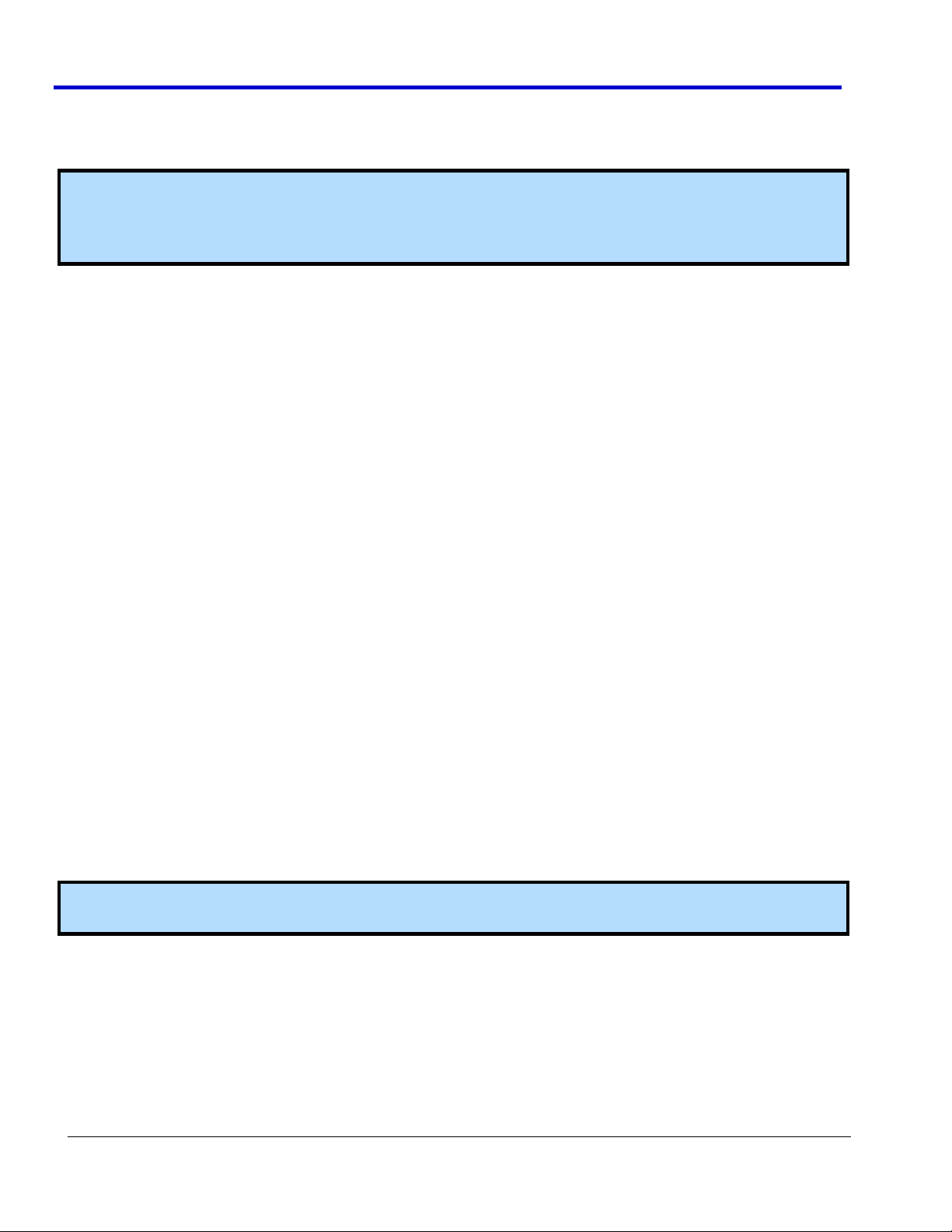

After selecting a given Px measurement from the main Measure dialog, additional settings can be made to the

corresponding dialog as follows:

Page 25

Operator's Manual

919586 RevA

25

PX DIALOG

Source

Select the source for you parameter measurement. The source for a measurement made on a decoded

waveform should be the DecodeX applied to the channel and not the Cx channel itself.

Measure

Click in this field to select the desired measurement from the pop-up.

Protocol measurements (where applicable) can also be selected as the source for histogram, trend, or track

functions.

Actions for Px

Histo - The Histogram displays a statistical distribution of a measurement parameter. Histogram is helpful

to understand the modality of a measurement parameter, and to debug the root cause of excessive

variation.

Note: After touching Histo, Trend, or Track buttons, a Math selection pop-up is shown to select which

Math trace in which you want the results to be placed.

Trend - The Trend statistical tool visualizes the evolution of a timing parameter over time in the form of a

line graph. The graph’s vertical axis is the value of the parameter; its horizontal axis is the order in which

values were acquired. Trend is typically used for a multi-shot acquisition. Trend is analogous to a chart

recorder.

Track - The Track displays a time-correlated accumulation of values for a single acquisition. Track can be

used to plot the digital-to-analog converted (DAC) values of serial data (using the Message to Value

parameter) and compare them to a corresponding analog signal, or observe changes in timing. Track is

typically used for a single-shot acquisition. A long acquisition with many parameter measurements

analyzed with Track could provide information about the modulation of the parameter.

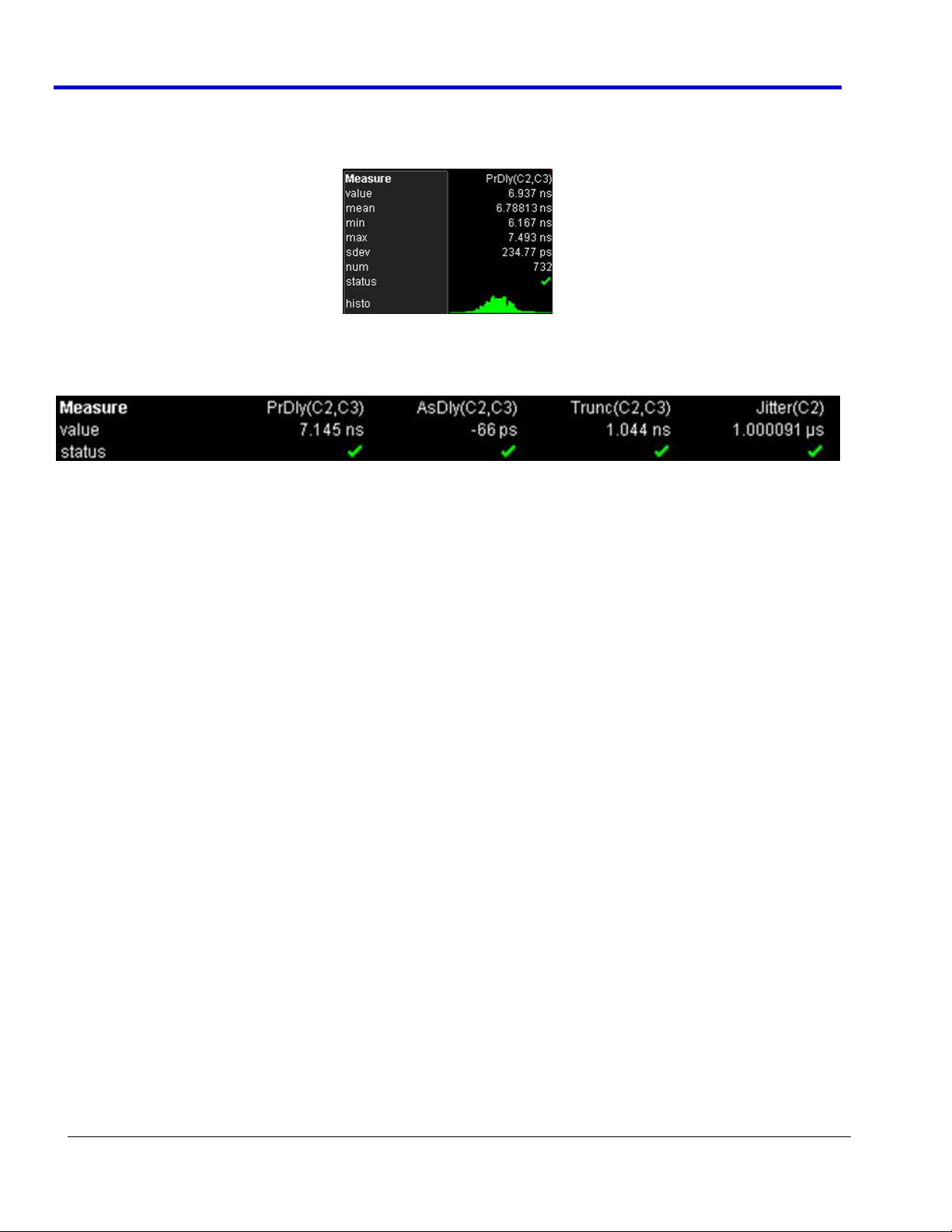

Now, on the main Measure dialog, additional settings can be made as follows:

MEASURE DIALOG

Statistics

Mark the On checkbox to add the statistics of your data to the lower grid display area (same area as displayed

data for the View and Load Table checkbox).

Page 26

Serial Data Debug Solutions

26

919586 RevA

Histicons

Mark the Histicons checkbox to show or hide this additional statistical information in your lower grid display

area. The information is graphically represented a Histicon directly beneath measurement values.

Show Table

Marking the Show Table checkbox displays table data along with measurement values on the lower portion of

the grid display.

The ProtoSync Toolset

The ProtoSync Toolset Overview

Using The Full ProtoSync and PE-B Protocol Analysis and BitTracer Displays

ProtoSync provides advanced protocol analysis tools simultaneous with physical layer waveform displays. The

protocol analysis software provided is a viewing, analyzing, and trace printing subset of the software provided

with LeCroy’s hardware protocol analyzer product families.

Using the ProtoSync Protocol Analysis (available for USB, SATA, SAS, FiberChannel, or PCI Express) or ProtoSyncBT Protocol Analysis and Bit Tracer display option (available for PCI Express only), signal data can be transferred

from the oscilloscope to LeCroy’s viewing and analysis subset of LeCroy’s Protocol Analysis or BitTracer software.

SENDING DATA TO PROTOSYNC

ProtoSync works together with various LeCroy serial decode options to provide more detailed views of the

protocol. ProtoSync and serial decoders supports USB2, USB3, SAS, SATA, FibreChannel, and PCI Express, and if

the following are present on the LeCroy oscilloscope, complete views are obtainable:

Storage, Peripherals, and Interconnect Protocols Overview (on page 154)

Serial decode option for USB2, USB3, SAS, SATA, FibreChannel, or PCI Express

ProtoSync or ProtoSync-BT option

LeCroy’s Protocol Analysis software for USB2/3 (Voyager), PCI Express (PE Tracer), or

SAS/SATA/FibreChannel (Sierra)

Then, when the serial datastream is decoded, both CATC Protocols (Protocol Analysis software) and Bit Tracer

Data (PCI Express only) may also be concurrently shown on a separate window or display. Automatic transfer

and linkage between the two programs makes this possible. Selection of packets or bytes on either the

oscilloscope or ProtoSync display updates the other in real time for extremely simultaneous and comprehensive

physical layer and protocol layer debug and analysis.

PLEASE NOTE THE FOLLOWING:

The -BT suffix for ProtoSync-BT indicates BitTracer view capability and is therefore only used for the

PCIEbus decode option.

Page 27

Operator's Manual

919586 RevA

27

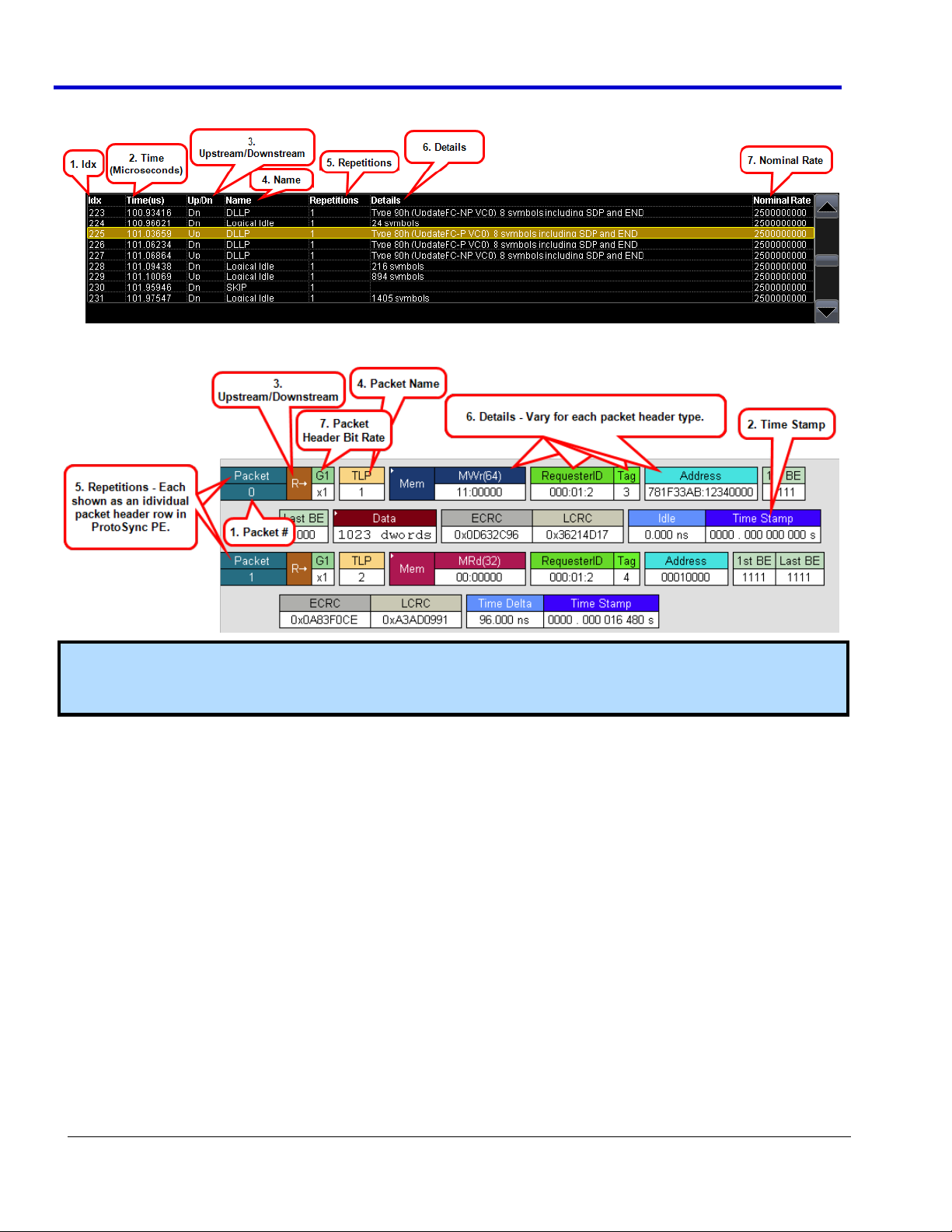

Label in the PCIEbus D Decode Annotation

Oscilloscope Table Display

Label in PETracer CATC Protocol View

1. Idx

2. Time (µs)

3. Up/Dn

4. Name

5. Repetitions - LeCroy shows one entry

in the table and indicates the number

of repetitions.

6. Details

7. Nominal Rate

1. Packet # - Actual numbers may vary from PCIEbus D decode

annotation table in the oscilloscope to PETracer protocol

packet view since repetitions are handled differently.

2. Time Stamp - Times are likely to differ (see subsequent

note).

3. Upstream (R→) or Downstream ( R← )

4. Packet Name

5. Repetitions - PETracer protocol packet view shows each

repetition as a packet header row in the display.

6. Details - Vary for each packet header type.

7. Packet Header Bit Rate

Respective protocols in the Storage, Peripherals, and Interconnects section of this manual show how

each protocol has their own Exporter right-hand dialog used for sending specific protocol data to

ProtoSync.

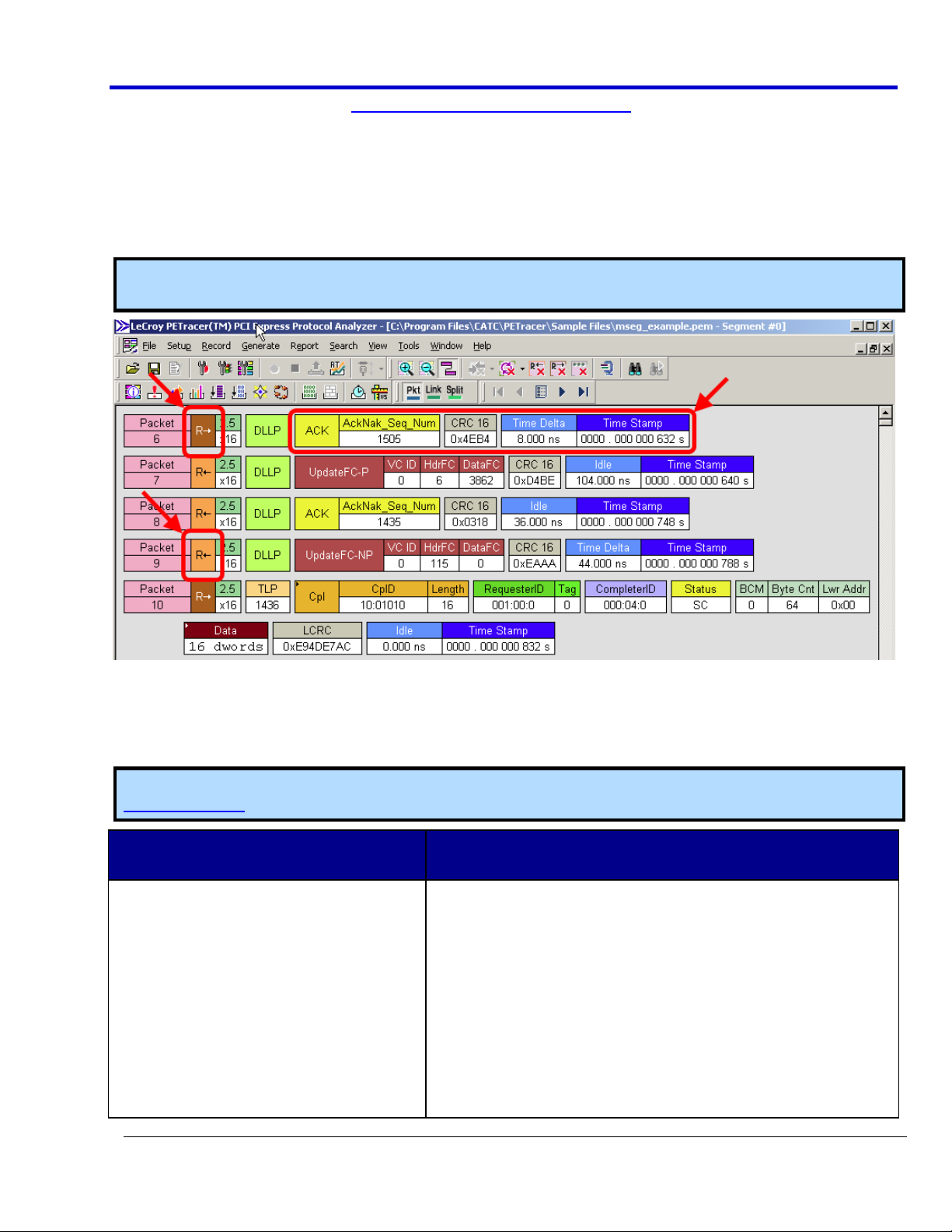

The CATC Protocol View

When ProtoSync is used to generate a protocol packet view of physical layer signals (in the screen-shots, using

the PCIe protocol), data packets are color-coded and shown as rows on the display. Transactions are even shown

as either upstream or downstream (shown here as R→ and R←, respectively for PCIEbus) .

Note: Viewing results look similar when using other Storage, Peripherals, and Interconnect Protocols. See

Storage, Peripherals, and Interconnect Protocols Overview (on page 154) for more information.

DECODED TABLE DATA CORRELATES TO CATC PROTOCOL DATA

While the Decode Annotation Table data is labeled and displayed differently than the CATC Protocol display,

correlation still exists between the two displays. The following table and screen-shots equates some of the

values for the PCIEbus option.

Note: Please refer to LeCroy Protocol Analyzer Software (Voyager, PE Tracer, or Sierra) user manuals at

www.lecroy.com for information regarding more specific usage when using specific supported protocols.

Page 28

Serial Data Debug Solutions

28

919586 RevA

OSCILLOSCOPE TABLE DISPLAY

PROTOSYNC PACKET VIEW

Note: Regarding Time (oscilloscope) and Time Stamp (protocol analyzer), Unless your oscilloscope trigger

delay is set to be the exact left edge of the display grid, the Protocol Analyzer Time Stamp values do not

correlate with the instrument.

Page 29

Operator's Manual

919586 RevA

29

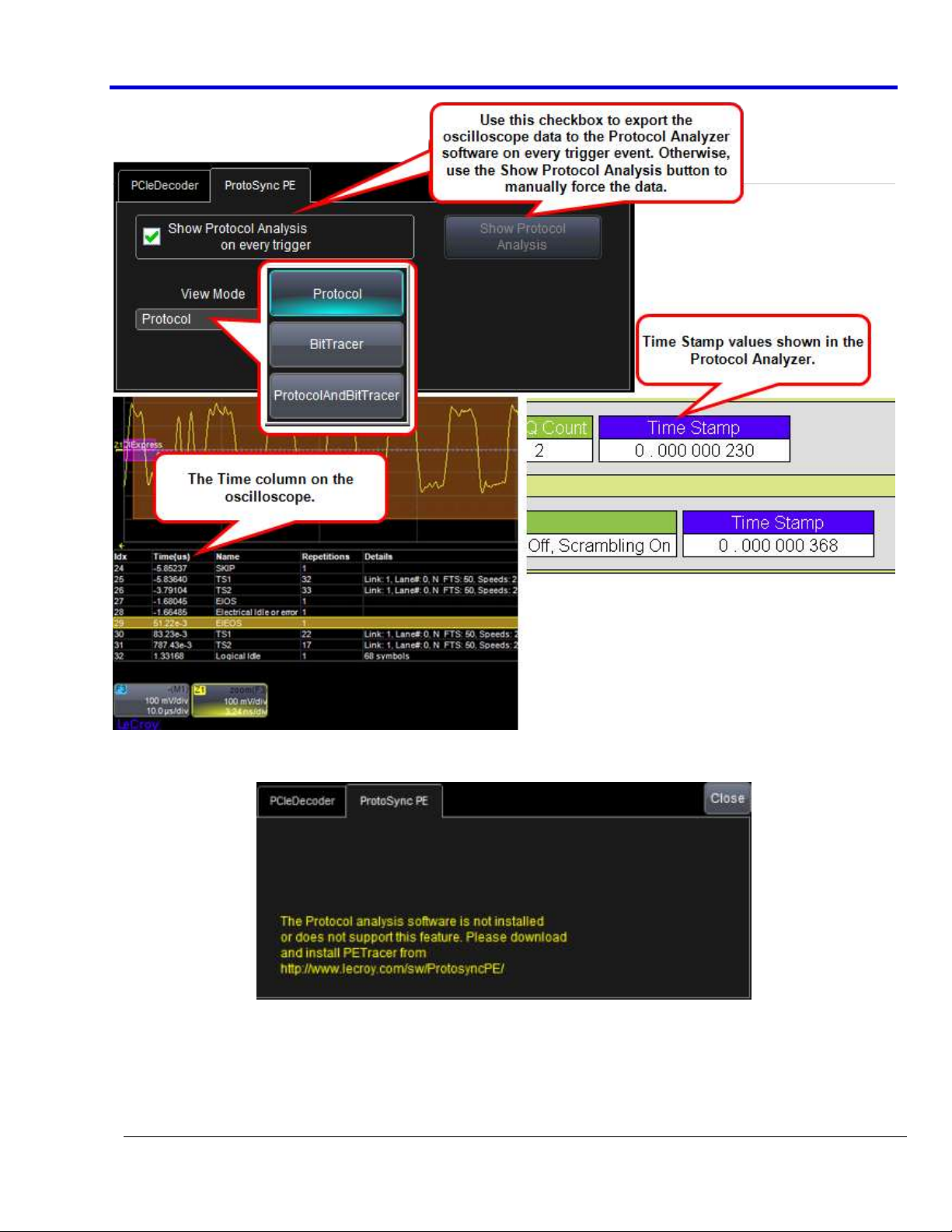

If you don't have the Protocol Analysis software installed, this particular dialog instead shows a notification

message in place of the controls used to send your oscilloscope data to the Protocol Analyzer.

PLEASE NOTE THE FOLLOWING:

In addition to the CATC Protocol View, the Protocol Analyzer also has Link and Split views for more a

more convenient display. The Link View is not to be confused with the Link Layer which is part of the

PCIEbus D decode option and decodes everything up to (but not including) the transaction layer packet

information.

Page 30

Serial Data Debug Solutions

30

919586 RevA

Please refer to LeCroy Protocol Analyzer Software user manuals at www.lecroy.com for information

regarding more specific usage for other Storage, Peripherals, and Interconnect Protocols. See Storage,

Peripherals, and Interconnect Protocols Overview (on page 154) for more information.

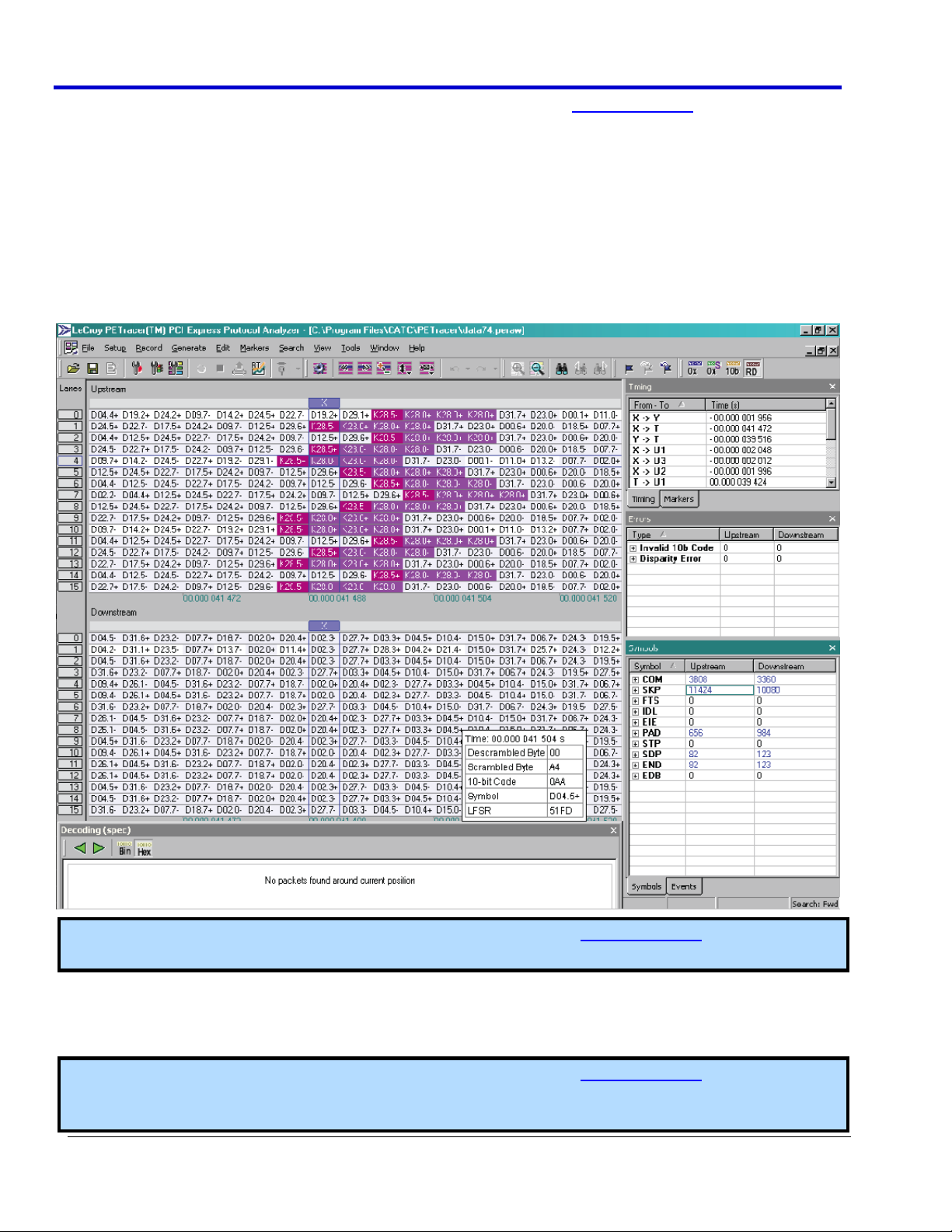

The CATC Bit Tracer View - PCI Express (PCIe) Only

Based on selections made on ProtoSync Right-Hand Dialogs (located on protocol decode dialogs), ProtoSync PEB may also be used to display a CATC Bit Tracer view. This view is ideally correlated with the LeCroy 8b/10b

Decode. See 8b/10b Decode Setup Detail (on page 45) for detailed steps to send 8b/10b Decode data to

ProtoSync.

The CATC Bit Tracer view shows the Hexadecimal form of each data bit of your transferred data. Oscilloscope

Decode and ProtoSync results look like the following:

Note: Please refer to LeCroy Protocol Analyzer Software user manuals at www.lecroy.com for information

regarding more specific usage.

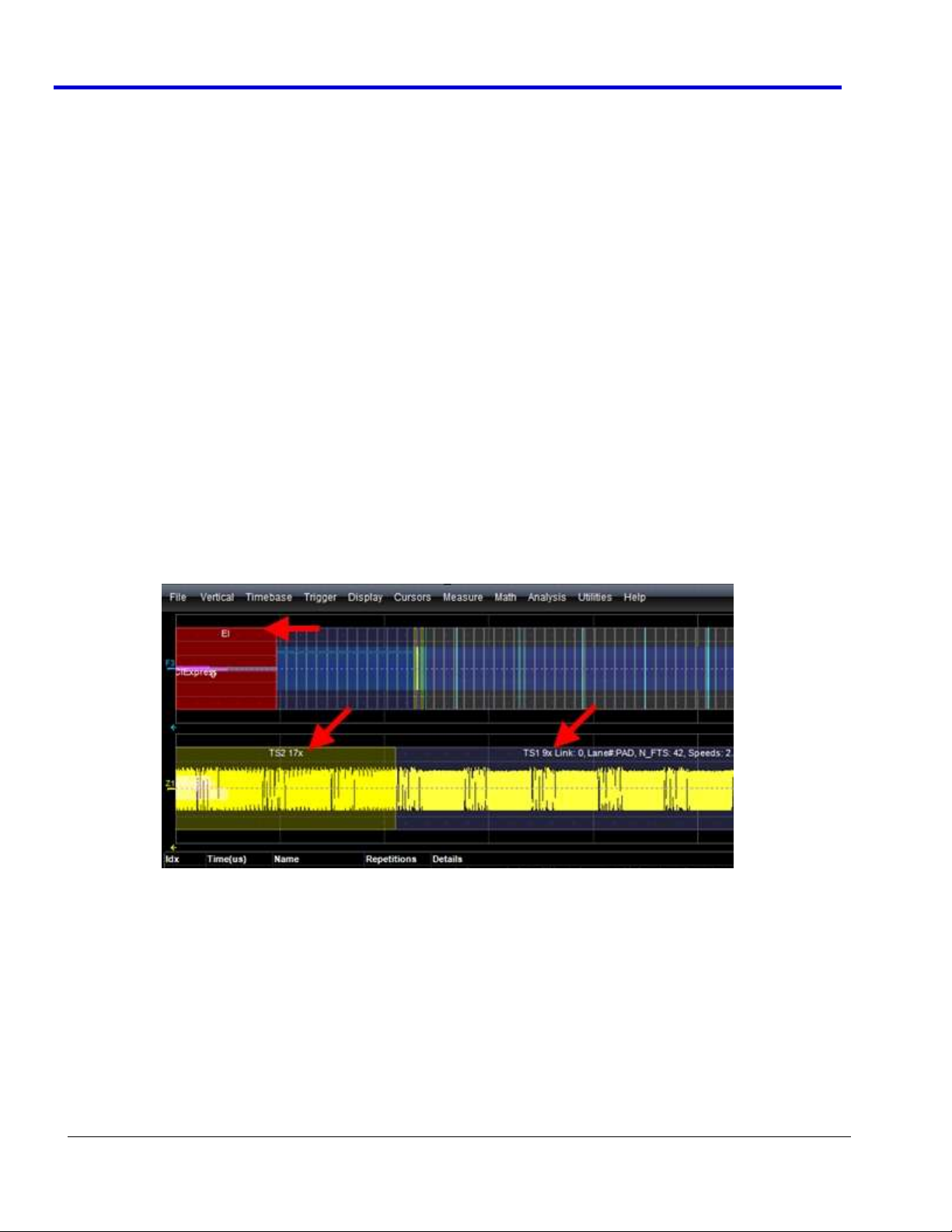

Oscilloscope and Protocol Analyzer - A Concurrent Analysis Example

This topic demonstrates the concurrent use of the Oscilloscope and Protocol Analyzer programs using PCIEbus

signals.

Note: Please refer to LeCroy Protocol Analyzer Software user manuals at www.lecroy.com for information

regarding more specific usage when using other supported protocols, see Storage, Peripherals, and

Interconnect Protocols Overview (on page 154).

Page 31

Operator's Manual

919586 RevA

31

The following screen-shot shows the oscilloscope Table display along with a corresponding CATC Protocol view.

Note: Yellow arrows indicate an indirect correlation between the fields (values may not be exactly the same,

but the fields correspond to one another), while Red arrows are exact correlations between the Table display

row and the ProtoSync PE packet data.

On the oscilloscope display, if a specific table entry is touched in the PCIEbus D decode annotation table, the

physical layer waveform and decode annotation view is zoomed to just that table entry (a new zoom waveform

is shown). If there are multiple channels (lanes), or if both transmit and receive lanes are displayed, and the

protocol packet information is not exactly synchronized in time between lanes, then the lane corresponding to

the table entry is precisely zoomed and the other channels/lanes are zoomed with the same ratio as the

selected table entry.

Page 32

Serial Data Debug Solutions

32

919586 RevA

If the appropriate selections are made in the ProtoSync right-hand dialog, then simultaneously with the

oscilloscope physical layer zoom, the Protocol Analysis viewing software is opened on the same or a second

monitor (depending on your setup) and the Protocol Analysis Packet and/or CATC Bit Tracer views locate the

packet or bytes corresponding to the selected oscilloscope PCIEbus D decode annotation table entry at the top

of the Protocol Analysis or Bit Tracer display. Conversely, if a protocol packet or byte is touched in the CATC

Protocol Analysis or Bit Tracer display, the PCIEbus D decode annotation zoom shows the physical layer

waveform corresponding to that packet or byte and simultaneously highlights the table entry. This makes it

possible to quickly and easily view both the physical layer waveform, data link layer (PCIEbus D decode

annotation), the transaction layer protocol packet (CATC Protocol Analysis View of ProtoSync) or Bit/Byte view

(CATC Bit Tracer view of ProtoSync-BT).

Accessing and Using The Graphing Tools for Supported Protocols

The AudioBus (I2S) TDG package contains capability to extract digital data from a serial data message and graph

it as an analog signal - effectively performing a digital-to-analog conversion. I2S (serial digital audio) encodes

multiple channel analog sound data as digital values in a streaming serial data message. By converting this digital

data back to an analog value and graphing it as an analog audio signal, errors in data conversion, or unexpected

glitches, clips or mutes are easily viewed.

Some packages contain capability to extract digital data from a serial data message and graph it as an analog

signal - effectively performing a digital-to-analog conversion. This can be helpful to intuitively understand the

digitally encoded data that is indecipherable in a serial data message or table display. For instance, CAN

commonly encodes sensor data digitally, and CANbus TDM allows this data to be viewed as an analog plot of the

digitally encoded data values for a specific sensor versus time. I2S (serial digital audio) encodes multiple channel

analog sound data as digital values in a streaming serial data message. By converting this digital data back to an

analog value and graphing it as an analog audio signal, errors in data conversion, or unexpected glitches, clips or

mutes are easily viewed.

AudioBus Decode Setup Detail (on page 87)

PLEASE NOTE THE FOLLOWING:

The Graph package included in I

PROTObus MAG toolkit.

Ask your local LeCroy representative for more information about the Accessing and Using The PROTObus

MAG Supported Protocol Toolset (on page 23) using the Contact LeCroy for Support (on page 199) topic.

2

S TDG protocol packages, provide unique functionality separate from the

Physical Layer Eye Diagram

The FlexRaybus package provides a display of the physical layer serial data signal in an eye diagram for quick and

easy determination of physical layer abnormalities at the bit level.

For more information refer to Using the FlexRaybus Option Overview (on page 77) and FlexRaybus Physical

Layer Measurement Parameters (on page 86).

Debug Examples

Using the TD Packages: Characterize Embedded Controller Performance

USING THE TD PACKAGES: CHARACTERIZING EMBEDDED CONTROLLER PERFORMANCE USING STANDARD OSCILLOSCOPE

TOOLS OVERVIEW

The standard oscilloscope contains a number of built-in tools, such as cursors, measurement parameters, and

statistical analyzers. They can be used to characterize performance for serial data signals (just as they are also

used to characterize performance on other signals). You may want to use cursors to make single-shot timing

measurements and measurement parameters when you need to accumulate statistical data over many different

acquisitions. Measurement parameters are also helpful to determine the underlying integrity of the serial data

physical signals.

Page 33

Operator's Manual

919586 RevA

33

All TD packages provide basic tools to characterize embedded controller performance. The tools can be used on

the decoded channels, memories, zooms, functions, etc. just like they are used on any un-decoded channels,

memories, zooms, functions, etc. You also can use normal Edge or SMART Triggers on an analog channel input to

trigger the oscilloscope when a certain analog signal occurs, and then measure to a particular serial data

message using the decoded info as your guide.

In general, some of these standard tools require a fair amount of manual setup. If the goal is to make many

hundreds or thousands of measurements, you might want to consider using functionality built into the

PROTObus MAG toolset.

Note: The following examples use CANbus messages; however, similar needs exist for other serial data signals,

and the included oscilloscope tools described in the following sections can be applied in the same way.

Take the following example of an analog signal creating a burst of CAN messages:

This data was acquired over a 500 ms duration. It is likely you want to understand whether the analog signal

input to your electronic control unit (ECU) is creating the desired CAN message output from the ECU. There are a

few ways this can be done as the following topics explain.

Page 34

Serial Data Debug Solutions

34

919586 RevA

CHARACTERIZATION USING CURSORS

Use horizontal cursors to mark locations on the waveform where the time measurement should be done, and

then read the cursor values to establish the measurement. Adjust the timebase or create zooms of the decoded

trace(s) as needed in order to view the signal with enough detail. This is a good method for single-shot / single

measurements.

CHARACTERIZATION USING MEASUREMENT PARAMETERS

Measurement parameters can be used to make basic signal integrity or timing measurements of serial data

signals.

Basic parameters, such as Amplitude, Rise, Fall, Overshoot, etc. are ideal for basic signal integrity checks, which

is often all that is required for low speed (~1 Mb/s) serial data signals. Timing parameters, such as Delay, Delta

Delay, Delta Time @ Level, etc., are ideal for measuring timing from trigger to other signals (such as from an I2C

or SPI Trigger to an analog signal). SDAII is ideal for performing standard-specific physical layer measurements

on high speed serial data signals, such as PCI Express. Delta Trig Time is ideal for measuring the time between

segments of a Sequence Mode acquisition.

Please see Isolating and Analyzing Serial Bus Activity topics for more information on Sequence mode.

Amplitude - Noise and overshoot resistant measurement of the amplitude of the signal (measurement

of amplitude from Top to Base).

Base - Value of the lowermost state in a bi-modal waveform, such as an I2C, SPI, or CAN Message.