Page 1

Operator's

Manual

SDAII Software

Page 2

Serial Data Analysis II Software Operator's Manual

© 2013 Teledyne LeCroy, Inc. All rights reserved.

Unauthorized duplication of Teledyne LeCroy documentation materials other than for internal sales and distribution purposes is strictly prohibited. However, clients are encouraged to distribute and duplicate Teledyne LeCroy documentation

for their own internal educational purposes.

Serial Data Analysis II and Teledyne LeCroy are registered trademarks of Teledyne LeCroy, Inc. Windows is a registered

trademark of Microsoft Corporation. Other product or brand names are trademarks or requested trademarks of their

respective holders. Information in this publication supersedes all earlier versions. Specifications are subject to change

without notice.

922968 Rev A

May 2013

Page 3

Operator's Manual

TABLE OF CONTENTS

SDAII Overview 2

Key Features 2

Serial Data Analysis II Dialog 2

Setting Up SDAII 3

Quick View 4

Setting Up Quick View 5

Signal Inputs 6

Set Up Signal 6

Serial Data Inputs 7

Signal Types 7

Crossing Levels 7

Reference Clock 9

Set Up Reference Clock 9

Reference Clock Inputs 10

Crossing Level 10

Clock Timing 10

Clock Recovery 11

Set Up Clock Recovery 11

Bit Rate 11

Reference Clock 11

PLL Setup 12

Clock Recovery Theory 14

Eye Measurements 17

Eye Measure Dialog 17

Set Up Eye Diagram 17

Eye Modes 18

Mask Testing 19

Eye Diagram Configuration Dialog 19

Eye Parameters Dialog 21

Eye Measurement Parameters 21

Eye Analysis Theory 24

Jitter Measurements 26

Set Up Jitter Measurements 26

Jitter Filter 28

Pattern Analysis 29

Jitter Track 30

Jitter Spectrum 31

Jitter Histogram Analysis 34

Jitter Parameters 35

922968 Rev A

1

Page 4

Serial Data Analysis II Software

SDAII Overview

The new Serial Data Analyzer (SDAII) provides comprehensive measurement capabilities for evaluating

serial digital signals. SDAII operates by processing a long signal acquisition. All jitter measurements and

displays are based on times of successive edges for the signal only - nothing is relative to the trigger. As a

result, they are not affected by trigger jitter. Acquisitions should be long enough to include at least 100,

000 UI of the signal under test (500,000 UI or more is optimal). It may be desirable to acquire longer records to see low frequency jitter.

Note: Acquisitions can be up to the full available memory depth of the instrument and may take considerable time to process.

The SDAII processes include clock recovery, eye pattern measurement, and jitter measurement. These

operations are performed on the same data record.

Key Features

l SDAII provides two types of measurements: eye pattern testing and comprehensive jitter anal-

ysis (including random and deterministic jitter separation, and direct measurement of periodic

jitter, DDj, and DCD).

l Many plot types for jitter and eye diagram analysis, including eye diagram, IsoBER, DDj Plot, dig-

ital pattern, DDj Histogram, jitter track, PLL track, jitter spectrum (with peak annotation), spectrum threshold, Pj Inverse FFT, jitter histogram, CDF, bathtub and Normalized Q-scale fit.

l Filtered jitter processes the time interval error trend versus time with a user-selectable band-pass

filter. This feature allows applying filters in addition to the high-pass filtering effect of the clock

recovery PLL, which is required for some serial data specifications.

l IsoBER displays the extrapolated lines of constant Bit Error Ratio down to the BER of interest on an

eye diagram.

l Quick View provides a shortcut displaying the eye diagram, TIE track, bathtub curve, jitter his-

togram, NQ-scale cursors, and jitter spectrum all on the screen at the same time.

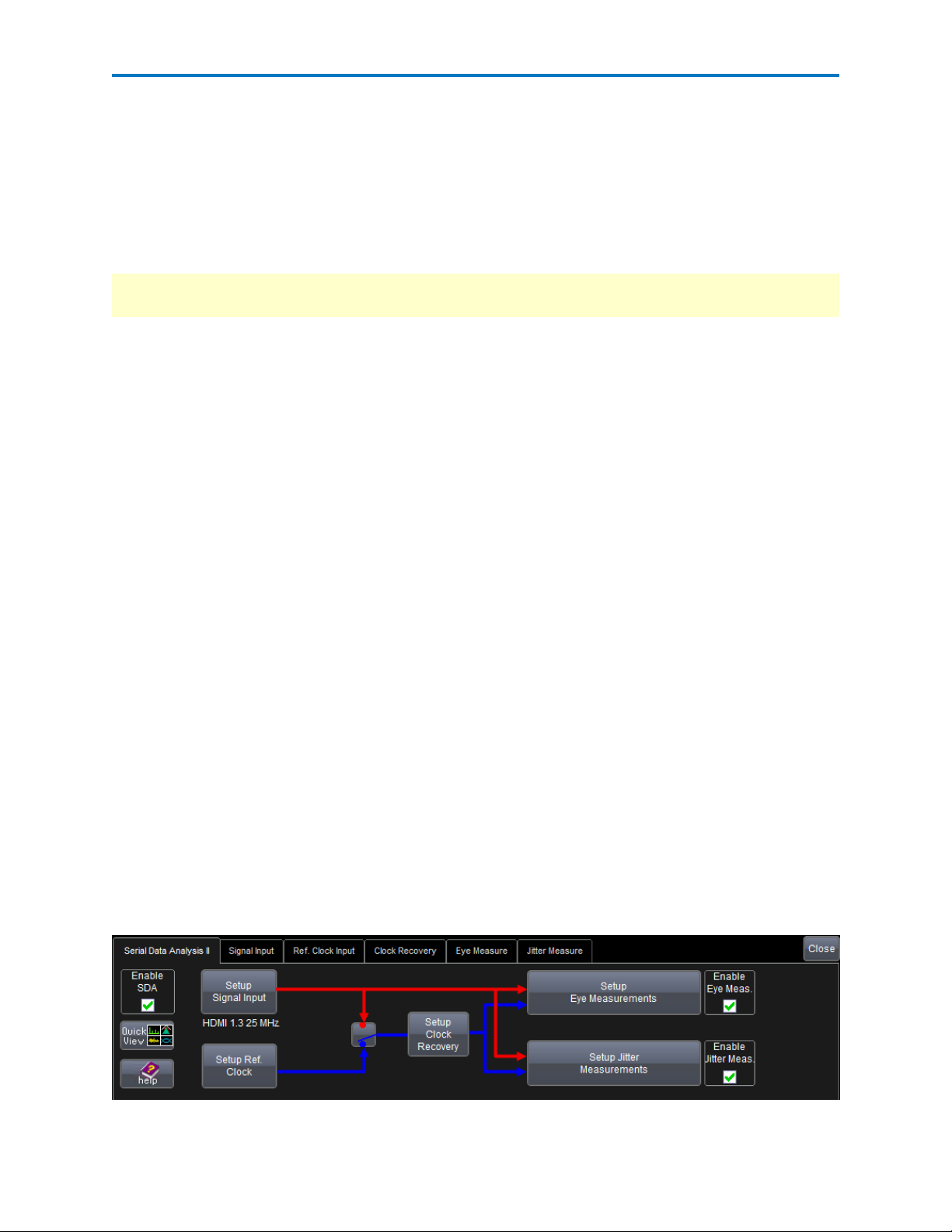

Serial Data Analysis II Dialog

Access the SDAII dialog by choosing Analysis → Serial Data.

The Serial Data Analysis II dialog shows the overall flow for viewing and analyzing serial data. Each block

in the flow diagram is a button that, when touched, displays its corresponding dialog.

The multiplexer switch button (on the Setup Clock Recovery button's respective dialog) allows you to

select clock recovery from the input data signal or, in the down position, a separate explicit clock signal.

Touch the multiplexer switch button to change the state.

2

922968 Rev A

Page 5

Operator's Manual

Setting Up SDAII

Use the following steps to start your SDAII setup.

1. If you haven't done so already, touch Analysis → Serial Data on the menu bar.

2. On the Serial Data Analysis II dialog, place a checkmark in the Enable SDA box.

3. Touch the Setup Signal Inputs button to configure your signal input sources, crossing levels, and signal type.

Note: Touch the Quick View button to quickly set up and view your serial data.

4. If you are recovering clock data from the data signal (the default selection), make sure the clock

recovery input multiplexer switch is in the up position (clock recovery via the red path).

When the switch is in the up position, the Setup Ref. Clock button is disabled (grayed out).

5. Touch the Setup Clock Recovery button and define clock recovery settings, such as Bit Rate and PLL

settings.

OR

If you are using an explicit reference clock, click the clock recovery multiplexer switch button so that

the switch is in the down position.

6. The Setup Reference Clock Inputs button is then enabled. Click this button and set up your reference

clock inputs.

7. On the far right of the Serial Data Analysis II dialog, place a checkmark in the Enable Eye Meas. box

and click the Setup Eye Measurements button (showing its respective dialog) to define eye measurement settings.

8. On the far right of the Serial Data Analysis II dialog, place a checkmark in the Enable Jitter Meas.

box and click the Setup Jitter Measurements button (showing its respective dialog) to define jitter

measurement settings. The Jitter Measure dialog opens displaying another flow diagram.

922968 Rev A

3

Page 6

Serial Data Analysis II Software

Quick View

The SDAIIQuick View shows the eye diagram, TIE track, bathtub curve, jitter histogram, NQ-scale, and

jitter spectrum (with peaks annotated) in a single, summarized view.

SDAII Quick View

You must specify only the input signal for analysis. You can also specify the crossing level.

4

922968 Rev A

Page 7

Operator's Manual

Setting Up Quick View

Follow these steps to set up Quick View.

1. If you haven't done so already, touch Analysis → Serial Data on the menu bar or touch the Serial

Data Analyzer button on the Quick Access toolbar.

2. On the Serial Data Analysis II dialog, touch the Quick View button. The Signal Input(s) to be

Analyzed pop-up window opens.

3. On the Serial Data Input(s) section, if you are using a differential probe, touch the 1 Input (or Diff.

Probe) button. Now, touch inside the Data field below the 1 Input (or Diff. Probe) button and select

an input source from the Select Source pop-up window.

OR

If you are using two single-ended probes to calculate the differential signal, touch the Input1-Input2

button. Input2 is subtracted from Input1. Touch inside each Data field and select a source for each

Select Source pop-up window.

4. Increase the sampling rate of the signal by touching inside the Upsample by data entry field and

entering the upsample factor . at the bottom of the screen.

5. In the Crossing Level section, if you want to set an absolute crossing level, touch inside the Level is

field and choose Absolute from the pop-up menu. Then, touch inside the Abs Level data entry field

and enter the voltage level at which the signal timing is measured at the bottom of the window.

OR

If you want to use a relative level set to the selected percentage on each acquisition, touch inside the

Level is field and choose Percent from the pop-up menu. Then, touch inside the Percent Level data

entry field and enter the percentage . at the bottom of the window.

Note: You can touch the Find Level button to automatically find the level. The level is found by locating the midpoint between the highest and lowest signal levels in the current acquisition.

6. Click OK to view the summary all on one screen.

922968 Rev A

5

Page 8

Serial Data Analysis II Software

Signal Inputs

Set Up Signal

On the Serial Data Analysis II dialog, touch the Setup Signal Input button to access the Signal Input

dialog.

Serial Data Input(s) section (1) lets you define the serial data input(s). If you are using a differential probe

or if your signal is connected by one coaxial cable, you can select 1 Input (or Diff. Probe) and specify the

input source in the Input1 box. If you are using two single-ended probes or two coaxial cables, you can

select Input1-Input2 and specify the input sources to use when calculating the differential signal. For

more information, see Serial Data Inputs.

Crossing Level section (2) lets you to set the voltage level at which the signal timing is measured. The

crossing level is set separately for the data and clock signals (if an external clock is selected) and can either

be an absolute voltage or a percentage of the signal amplitude via the relative selection. You can also configure a hysteresis level, and between positive, negative and both edge types for when the "Clock" Signal

Type is selected. The Crossing Level section on this dialog is for the data signal. For more information, see

Crossing Levels.

Signal Type section (3) lets you choose a standard signal type. The signal type you choose automatically

sets the nominal bit rate for the selected standard, and populates the Mask Type selector in the Eye

dialog. For more information, see Signal Types.

Noise Settings includes settings that are used by the vertical noise measurements toolkit. Settings

include the Sample Phase, which determines where in the unit interval the sample is taken for the noise

measurement. Also, see How to Order SDAIII-CompleteLinQ Capabilities for information on which prod-

ucts include the vertical noise analysis capabilities.

NOTE:

l Many of the measurements in SDAIIrequire both a high sampling rate and long memory to com-

pute jitter and vertical noise accurately.

l Lower sampling rates can result in less accurate jitter measurements, and short record lengths can

give incomplete eye patterns or jitter and noise displays that diverge.

l For best results, acquire waveforms with at least 100,000 unit intervals, and of >100 iterations of

the pattern. See Jitter Pattern Analysis.

6

922968 Rev A

Page 9

Operator's Manual

Serial Data Inputs

There are several scenarios for the configuration of the SeriaData Input(s) section.

If you are using a differential probe or if your signal is connected by one coaxial cable, use the 1 Input (or

Diff. Probe) button and select the input source.

If you have a differential signal transmitted on two two coaxial cables or two single-ended probes., use

the Input1-Input2 button and select the input channels used.

NOTE:There is no need to configure a math function to calculate the difference between to inputs. Doing

so adds additional computational steps, and unnecessarily uses RAM.

Lastly, any math function, memory trace, etc. can be used as an input, as well as any input channel.

When in Input1-Input2 mode, and when using traces that may have been the result of other processing

steps, be sure that both traces have the same record length and sample rate.

You can choose to upsample rate in the Serial Data Inputs dialog by a factor of two in order to provide a

higher sample density for analysis. In SDAII this was typically done to facilitate formation of eye diagrams

without gaps for bit rates integrally related to the sampling rate (for example, 20 GS/s is exactly eight

times 2.5 Gb/s), and especially for relatively short acquisitions. This, however, unnecessarily slowed

down the analysis process. When needing to upsample to remove gaps in the eye use the upsample control in the Eye Diagram dialog.

Signal Types

The signal type defines the compliance masks and bit rate for the selected standard.

When you touch the Signal Type field, a pop-up table of standard signal types is shown. Touch the

desired signal type to populate the Signal Type field. The list of signal types is taken from the SDAMask

Database. As new serial data standards are invented, masks are added to the database.

When choosing Custom from the Signal Type pop-up menu, always enter a bit rate in the Nominal Rate

entry box. Using an incorrect Nominal Rate can lead to incorrect equalizer results, since this value is used

by several of the equalizers that are available the oscilloscope includes Eye Doctor II functionality. The

Custom selection does not specify any eye masks, and the Mask Type selector in the Eye dialog will be

greyed out.

Crossing Levels

The Crossing level section of the Signal Input dialog determines the voltage level where the arrival time

of each edge of the signal is measured. The crossing level is set separately for the data and clock (if an

external clock is selected).. The Crossing Level on this dialog is for the data. Setting the crossing level to a

value that is not optimal can result in higher than expected deterministic jitter, since the error in the timing of the edges will be different for rising and falling edges.

The Level Type can be either absolute or relative.

The Absolute crossing level can be set directly in volts (or watts for an optical signal) , or you can click the

Find Level button to automatically find the level. The level is found by locating the midpoint between the

highest and lowest signal levels in the current acquisition. When you select the Absolute crossing level,

the crossing time used by both the jitter and eye pattern measurements is determined as the time at

which the signal level crosses the specified threshold. When Relative level is selected, the level is auto-

922968 Rev A

7

Page 10

Serial Data Analysis II Software

matically set on each acquisition. The value set is the selected percentage of the signal amplitude (which

equals base - top).

The Slope selector determines which edges are measured when "Clock" is selected in the Signal Type

selector in the Signal dialog.. The choices for slope are Pos(itive), Neg(ative) or Both Select the choice

that corresponds to the edge type that is used for clocking of the data in your device, or that is of interest in your analysis. For example, if you only latch data on positive edges, select Pos. If you clock on

both edges, you can select Pos or Neg rather than both in order to understand how the edge type affects

the jitter measurement.

The Hysteresis entry box sets the hysteresis level to use for edge detection, in units of vertical divisions.

The hysteresis is the vertical amount that the signal is required to travel beyond the crossing level to

allow detection of a crossing in the opposite direction. Incorporating hysteresis in the edge detection

algorithm prevents the software from finding false edges that would otherwise be detected due to noise

or other small glitches in the signal. The default value is 500mdiv, or 1/2 a division. When the input signals are properly scaled (i.e. to fill approximately 90% of the grid, vertically, this level of hysteresis should

be sufficient. When dealing with signals that result in closed eyes, a smaller value for hystersis may be

required.

More information about how the SDAanalysis software determines the edge timing using the crossing

level can be found in the Clock Recovery Theory section

NOTE: The Relative setting can potentially remove jitter by tracking slow level shifts between acquisitions, if this is not desired, use the Absolute level setting.

8

922968 Rev A

Page 11

Operator's Manual

Reference Clock

Set Up Reference Clock

An accurate reference clock is central to the measurements performed by SDAII. When the clock is recovered from data, the clock is defined from the locations of the data's crossing points in time. When a reference clock is used, the clock is defined from the locations of the reference clock's crossing points.

Starting with zero, the clock edges are computed at specific time intervals relative to each other.

Example: A 2.5 GHz clock has edges separated in time by 400 ps. Making a 2.5 GHz clock from a 100 MHz

reference clock requires setting the Multiplier to 25.

Follow these steps to define the crossing points.

1. Touch Analysis → Serial Data on the menu bar.

2. On the Serial Data Analysis IIdialog, make sure the multiplex switch next to Clock Recovery is in the

down position to select Reference Clock, then touch the Setup Ref Clock button.

3. Under Reference Clock Inputs, touch the Clock+ Only button, then touch the Clock Ref+ box and

select an input source from the Select Source pop-up window.

OR

Touch the Clock+ and Clock- button, then touch the Clock Ref+ and Clock Ref- boxes and select a

source for each from the Select Source pop-up window.

4. If you want to increase the sampling rate of the signal, touch inside the Upsample by data entry field

and enter the upsample factor.

5. To set an absolute crossing level, touch inside the Level field and choose Absolute from the pop-up

menu. Then, touch inside the Abs Level data entry field and enter the voltage level at which the signal timing is measured using either the keypad or the slider bar at the bottom of the screen.

OR

To use a relative level set to the selected percentage on each acquisition, touch inside the Level is

field and choose Percent from the pop-up menu. Then, touch inside the Percent Level data entry

field and enter the percentage at the bottom of the screen.

NOTE: Alternatively, touch Find Level to automatically find the level. The level is found by locating

the midpoint between the highest and lowest signal levels in the current acquisition.

6. Determine clock timing by touching the Clock Slope field and choose Positive, Negative, or Both.

922968 Rev A

9

Page 12

Serial Data Analysis II Software

Reference Clock Inputs

The Reference Clock Input(s) section in the Ref. Clock Input dialog lets you define the clock input(s). You

can choose Clock+ Only or Clock+ and Clock- .You can also define the upsample rate (when increasing

the sampling rate of the clock signal).

Crossing Level

The Crossing level section of the Reference Clock Inputs dialog lets you set the voltage level where tim-

ing is measured for the reference clock. The crossing level is set separately for the data and clock (the controls on this dialog are for the clock) and can be either absolute or relative.

You can either set the Absolute crossing level in volts (or watts for an optical signal) directly, or you click

the Find Level button to automatically find the level. The level is found by locating the midpoint between

the highest and lowest clock levels in the current acquisition. When you select the Absolute crossing

level, the crossing time used by both the jitter and eye pattern measurements is determined as the time

at which the clock level crosses the specified threshold. The Relative level is automatically set to the

selected percentage on each acquisition.

Clock Timing

The Clock Timing section of the Ref. Clock Input dialog lets you define a clock slope setting. A clock signal

goes through one complete cycle during each bit interval. The edge timing can be measured relative to

the rising slope, falling slope, or both slopes, of the clock by means of the Clock Slope setting.

10

922968 Rev A

Page 13

Operator's Manual

Clock Recovery

Set Up Clock Recovery

An accurate reference clock is central to any jitter measurement, including all the measurements performed by SDAIII-CompleteLinQ. The recovered clock is defined by the times at which the specified signal

(either data or reference clock) crosses the specified threshold. Starting with zero, the clock edges are

computed at specific time intervals relative to each other. A 2.5 GHz clock, for example, will have edges

separated in time by 400 ps.

On the Serial Data Analysis II dialog, touch the Setup Clock Recovery button to access the Clock Recov-

ery dialog.

Data or Bit Rate section - Lets you define a custom expected bit rate, or you can click the Find Rate Now

button to automatically find the bit rate from the signal. If you do neither, this field remains set to the

standard's nominal bit rate. For more information, see Bit Rate.

Reference Clock section - Enables positioning of the clock edges relative to the data signal. It shifts the

clock signal relative to the data signal. For convenience, it duplicates controls found elsewhere: the Use

Explicit Clock Ref checkbox (serving the same function as the multiplexer switch on the SDAII dialog) and

Multiplier field (also found on the Ref. Clock dialog). For more information, see Reference Clock.

PLL Setup... section - Sets the type and bandwidth of the digital PLL used in SDAII measurements. The

PLL bandwidth limits the response of the recovered clock to high rate variations in the data rate. For

example,depending on the type of PLL, a PLL bandwidth of 5 MHz will allow the recovered clock to track

frequency variations below approximately half this rate, thereby removing their effect from jitter and eye

pattern measurements. Configure this section to match the behavior of the receiver's PLL.

Bit Rate

The Data or Bit Rate section of the Clock Recovery dialog lets you define a custom expected bit rate or

find the bit rate from the signal.

Reference Clock

The Reference Clocksection on the Clock Recovery dialog allows you to shift the clock edges relative to

the data signal.

922968 Rev A

11

Page 14

Serial Data Analysis II Software

This section duplicates controls found elsewhere: the Use Explicit Clock Ref checkbox (serving the same

function as the multiplexer switch on the SDAII dialog) and the Multiplier field (also found on the Ref

Clock dialog).

PLL Setup

The PLL Setup section of the Clock Recoverydialog contains the controls to set the type and bandwidth

of the digital PLL used in all SDAII measurements. The PLL bandwidth limits the response of the recovered

clock to high rate variations in the data rate. Configure this section to match the behavior of your receiver's PLL.

Example: A PLL bandwidth of 5 MHz allows the recovered clock to track frequency variations below

approximately half the frequency, therefore removing the effect from jitter and eye pattern measurements. The software PLL implemented in SDAII allows you to choose among several types of PLL.

The selected PLL is applied to either the data stream under test or the selected clock source (if a Reference Clock is in use) when the PLL On control is checked. The PLL recovers a reference clock from the

selected source, which is used by all subsequent SDAII measurements.

PLLTypes

FC GOLDEN

FC Golden is the default selection and implements the golden PLL as defined in the Fibrechannel specification. By default, the golden PLL is set to a cutoff frequency of 1/1667 times the bit rate of the signal

under test. This ratio can be adjusted from 1/10 to 1/1e6.

Make the following settings for the FC Golden PLL on the Golden PLL dialog at the far right of the screen:

l Touch inside the Cutoff Divisorfield and enter a value using the pop-up keypad. The default value

of 1667 is the industry standard for a Golden PLL and equals the ratio of the Bit Rate to the PLL Cutoff frequency.

The PLL cutoff divisor is the value by which the bit rate is divided to compute the cutoff frequency

for the loop bandwidth of the clock recovery operation for sequential eye pattern, jitter, and bit

error rate functions. This control is variable from 10 to 1,000. A low PLL cutoff divisor means the

PLL tracks and, therefore, attenuates jitter at higher frequencies.The default value of 1667 causes

the clock recovery to operate as a golden PLL, as defined in the Fibrechannel specification.

l The PLL Cutoff frequency control reads the frequency corresponding to the Cutoff Divisor. Alter-

natively, the PLL Cutoff frequency may be provided and the nearest cutoff divisor is then computed from the entry.

12

922968 Rev A

Page 15

Operator's Manual

PCI-EXPRESS

There are four PCI-Express selections that meet the following standards:

l PCI-Express Gen1

l PCI-Express Gen2 A

l PCI-Express Gen2 B

l PCI-Express Gen2 C

DVI

The DVI selection displays the DVIPLL dialog at the far right of the screen and follows the requirements

of the DVI (Digital Video Interactive) and HDMI (High Definition Multimedia Interface) specifications.

These specifications call out a clock recovery function having a single-pole PLL loop response with a cutoff

of 4 MHz.

FB-DIMM

The FB-DIMM selection applies a filter that replicates Fully-buffered DIMM.

USB

The USB selection applies a filter that meets the USB 3.0 SS requirements.

CUSTOM

The Custom selection shows the Custom PLL dialog on the far right of the screen and allows you to select

either a first or second order loop response. The first order response allows you to select a pole

frequency that sets the PLL cutoff, and a zero frequency that must be higher than the pole frequency

that limits the stop-band attenuation.

The second order PLL allows you to select the natural frequency and damping factor. The damping factor

determines the transient behavior of the phase locked loop and is variable from 2 to 0.5.

l A damping factor above 0.707 results in an under-damped response and the PLL is over-corrected

to a sudden change in frequency; however, reacts quicker to the change.

922968 Rev A

13

Page 16

Serial Data Analysis II Software

l A damping factor below 0.707 provides an under-damped response that reacts more slowly to sud-

den changes in frequency; however, does not over-correct.

The default value of 0.707 represents a critically damped response that provides the fastest reaction time

without over-correcting.

The second order PLL with a damping factor of 0.707 is specified in the serial ATA generation II document.

This type of PLL is also very useful for measuring signals with spread-spectrum clocking because it can

accurately track and remove the low-frequency clock spreading while allowing the signal jitter to be measured. The natural frequency is somewhat lower than the actual 3 dB cutoff frequency given by the equation:

The quantity is the damping factor, and is the natural frequency. For a damping factor of 0.707,

this relationship is fc= 2.06 fn. Settings for the Custom PLL: Touch inside the Poles field to select the

order of the PLL. The number of poles can be 1 or 2.

Clock Recovery Theory

Eye, jitter and vertical noise analysis all require a clock that defines the boundaries of each unit interval.

Additionally, the clock is used to determine the difference between actual and expected arrival times of

data edges (i.e., the time interval error, or TIE measurements). In many of today's high-speed serial standards, the clock is not a physical signal but is instead derived from the data signal via clock recovery hardware or software.

You may use a PLL as part of the clock recovery algorithm in order to best emulate the PLL in a receiver.

The recovered clock is defined by a list of times that correspond to expected edge arrival times.

The first step in creating a clock signal that is tracked by a PLL is to create a digital phase detector. This is

simply a software component that measures the location in time when a signal crosses a given threshold

value. Even given the maximum sampling rate available), interpolation is necessary in order to accurately

determine crossing times. Interpolation is automatically performed by SDAII. Interpolation is not performed on the entire waveform; rather, only the points surrounding the crossing level are interpolated. A

cubic interpolation is used, followed by a linear fit to the interpolated data to find the precise time that a

data signal edge traverses the crossing level (see figure below).

14

922968 Rev A

Page 17

Operator's Manual

SDA Edge Time Determination

Clock recovery implementation in the SDA is shown in the following figure. This algorithm generates time

values corresponding to a clock at the data rate. The computation follows variations in the data stream

being tested through the use of a feedback control loop correcting each period of the clock by adding a

portion of the error between the recovered clock edge and the nearest data edge.

Clock Recovery Implementation Usinga PLL

As shown in the previous image, the initial output and the output of the digital phase detector are set to

zero. The next time value output is equal to the nominal data rate. This value is fed back to the comparator on the far left which compares this time value to the measured time of the next data edge from

the digital phase detector. The difference is the error between the data rate and the recovered clock, and

can also incorporate the measurement of the number of UI's since the last edge(that is, the local transition density).This difference is filtered and added to the initial base period to then generate the corrected clock period. The filter controls the rate of this correction by scaling the amount of error fed back

to the clock period computation. The choice of filter in SDAII and SDAIII-CompleteLinQ includes a singlepole infinite impulse response (IIR) low-pass filter (the golden PLL, as defined by FibreChannel), a 1 pole 1

zero filter, and a 2 pole 1 zero filter. The equation of the golden PLL 1 pole filter is:

922968 Rev A

15

Page 18

Serial Data Analysis II Software

The value of ykis the correction value for the kthiteration of the computation and xkis the error

between the kthdata edge and the corresponding clock edge. Notice that the current correction factor is

equal to the weighted sum of the current error and all previous correction values. The multiplier value is

set to one in the SDA, and the value of n is the PLL cutoff divisor set from the Serial Data Analysis IIdialog.

The cutoff frequency is Fd/n, where Fd is the data rate. This filter is related to its analog counterpart

through a design process known as impulse invariance and is only valid for cutoff frequencies much less

than the data rate. For this reason, the minimum PLL cutoff divisor setting is 20 in the SDA.

The factor n determines the number of previous values of the correction value y used in the computation

of the current correction value. This is theoretically infinite; however, there is a practical limit to the

number of past values included.

16

922968 Rev A

Page 19

Operator's Manual

Eye Measurements

Eye Measure Dialog

The Eye Measure dialog is the principal tool for setting up Eye diagrams. Click the Setup Eye Measurements button on the Serial Data Analysis II dialog to access the Eye Measure dialog.

The Eye Modes section in the Eye Measure dialog lets you choose an eye mode, either Single Eye, Dual

Eye Trans/Non-trans, Dual Eye Gated, Dual Eye FSB.

The Masks section in the Eye Measure dialog lets you select different modes for the selected standard. A

standard may define different masks for different measurement types. The Mask Margin lets you define

how much to enlarge the mask, to make sure that your signal passes the mask plus margin.

Set Up Eye Diagram

Follow these steps to define the type, shape, and size of an Eye diagram.

1. Open the Eye Measurement dialog.

2. Place a checkmark in the Enable Eye Meas. checkbox to turn on eye measurements.

3. If you want to turn off the eye parameters display, touch the Turn Off Eye Params. button.

4. In the Eye Mode section, touch the Mode field and choose an eye mode from the pop-up menu.

5. Touch the Vertical Auto Fit checkbox if you want to scale the eye pattern. These controls are disabled (grayed out) if the mask is specified in absolute units (volts and seconds); that is, if the standard does not allow auto fit.

The vertical auto fit function sets the scaling of the eye pattern so that the one level is at the second

vertical division above center, and the zero level is at the second division below center. The Vertical

Auto fit checkbox is automatically checked or unchecked depending on the selected Signal Type.

Example: When an absolute mask like XAUI is selected, the Vertical Auto fit checkbox is unchecked;

however, it is checked for a normalized mask like FC1063.

Scaling for absolute mask signals is accomplished by setting the vertical scale of the input signal.

6. In the Mask section, touch the Mask Type field and choose a mask type from the pop-up menu.

922968 Rev A

17

Page 20

Serial Data Analysis II Software

7. Touch inside the X field and enter a value from 0 to 100%. As you enlarge the mask's margin, you

lengthen the horizontal dimension, bringing the mask closer to the crossing points of your eye diagram. This reduces the amount of jitter that can still pass the eye.

8. Touch inside the Y field and enter a value from 0 to 100%. As you enlarge the mask's Y margin, you

widen the vertical dimension, bringing the mask closer to the top and bottom of your eye diagram.

This reduces the amount of vertical eye closure that can still pass the eye.

9. Margin only center area checkbox - Check to have only the center hexagon or diamond expand

when the mask margin is set to a value other than 0%

Eye Modes

There are four eye modes you can choose when setting up an eye measurement:

Single Eye- This mode overlays all the UIs from all acquisitions.

Dual Eye Transition/Non-Transition - Divides the signal's UIs into two separate eyes: ones comprised of

UIs starting with a transition and one comprised of UIs without. The PCIe standard refers to these as Transition and Non-Transition eyes. This display mode is useful for those serial data standards using mask

testing for both types of eyes (PCI Express and FB-DIMM Point-to-Point).

Dual Eye Gated (Qualified) Eye Diagram - The Gated Eye Diagram mode uses a separate signal (the Gate

or qualifier) to create dual eye diagrams based on the polarity of the Gate.

Dual Eye FSB (Front Side Bus) - Operates similar to Sequential mode, but divides the results into two separate eyes based on which of a pair of signals occurred first. When Dual Eye FSB is selected, additional

fields are then shown.

18

922968 Rev A

Page 21

Operator's Manual

Mask Testing

Mask testing to either absolute or normalized masks can be performed with SDAIII-CompleteLinQ. You

can determine where the signal has violated the mask, how many failures have occurred, and determine

which particular UI is in violation.

When selecting a Signal Type on the Signal tab for a serial data standard, the Mask section of the Eye

Measure. Each standard has a set of required tests; some of the standards specify using a specific mask

template. Masks templates are stored in the database file EyeMaskProps.mdf, which can be edited via

the Mask Database Editor tool. A shortcut to launch this tool can be found in the LeCroy folder of the

Start menu.

Masks are either "absolute" or "normalized". Absolute masks specify specific voltage and time values.

When using absolute masks, the position of mask features will depend on the volts/div setting of the

mask. Normalized masks reference grid locations rather than absolute voltages.

You can also define how much to enlarge the mask in order to ensure your signal passes the mask plus

some additional margin.

Eye Diagram Configuration Dialog

The Eye Diagram right-hand dialog lets you configure how the eye diagram is displayed.

Show Eye - Displays the eye diagram(s).

Show Mask- Displays the mask template(s). If Custom or Clock is chosen for the Signal Type in the Signal

tab, then this checkbox is greyed out. (Users can create custom masks by defining a new signal type.)

Show IsoBER - Displays IsoBER, which provides a visual representation of the extrapolated eye diagram.

When you enable this, press Start IsoBER Scan.

922968 Rev A

19

Page 22

Serial Data Analysis II Software

Eye Saturation- Use the slider to increase or decrease eye saturation. The setting for saturation adjusts

the color grading or intensity. Slide to the left to reduce the threshold required to reach saturation.

Show Failures- Place a checkmark to show the mask failures. Mask failures are identified by contrasting

color spots which appear anywhere the data intersects the mask template. If Custom or Clock is chosen

for the Signal Type in the Signal tab, then this checkbox is greyed out.

Eye Style- You can choose the style you want to use to display the eye diagram. The selections are colorgraded or analog persistence. In color-graded persistence, pixels are given a color based on the pixel's relative population and the selected Eye Saturation. The color palette ranges from violet to red. When

analog persistence, is selected, the color used mimicks the relative intensity that would be seen on an

analog oscilloscope.

Start IsoBER Scan - Computes the IsoBER curves for values between the start and end BERs you specify.

The IsoBER curves display directly on the eye diagram itself.

IsoBERfrom/to/step - Select the range of BER values for which you would like to show contours in the

ISOBer plot.

Upsample- Increase from 1 to a higher number (e.g. 5) to fill in gaps in the eye diagram. Gaps can occur

when the bitrate is extremely close to a submultiple of the sampling rate, such that the sampling of the

waveform does not move throughout the entire unit interval. Gaps can also occur when using a record

length that does not sample a sufficiently large number of unit intervals. (Using record lengths of >= 1 million points is recommended in order to acquire tens of thousands, if not hundreds of thousands, of unit

intervals.)

20

Eye diagam with ISOBer superimposed

922968 Rev A

Page 23

Operator's Manual

Eye Parameters Dialog

The Eye Parameters right-hand dialog lets you choose which parameters you want to show on the

screen. You can also enter a slice width. The slice width is a percentage of the duration of a single bit (the

part of the pattern over which the extinction ratio is measured). Setting a percentage value indicates how

much of the central portion of the bit width to use.

Both the Jitter Measurements and the Eye Parameters can be on at the same time. They are shown separately on the table display. To turn off all eye parameter measurements, touch the "Turn off Eye

Params"button located on the left side of the adjacent Eye Diagram dialog.

Jitter Measurements and Eye Parameter display

Note: The oscilloscope's Measure table can also be displayed.

Eye Measurement Parameters

There are several important measurements are made on eye patterns. Many standards specify them as

part of required tests. Eye measurements mainly deal with amplitude and timing (outlined later in this

section). For information on setting up eye measurements, see Set Up Eye Diagram.

Eye Amplitude

Eye amplitude is a measure of the amplitude of the data signal. The measurement is made using the distribution of amplitude values in a region near the center of the eye (the "slice width")selected by the user

(normally 20% of the distance between the zero crossing times). The simple mean of the distribution

around the 0 level is subtracted from the mean of the distribution around the 1 level. This difference is

expressed in units of the signal amplitude (normally voltage). This measurement algorithm is best suited

to eye diagrams that are rendered from optical rather than electrical signals. In the presence of inter-symbol interference and/or equalization, it may not give reasonable results.

One Level

Simple mean of the 1 or high state of the eye within the selected slice width

Zero level

Simple mean of the 0 or low state of the eye within the selected slice width.

922968 Rev A

21

Page 24

Serial Data Analysis II Software

Eye Height

The eye height is a measure of the signal-to-noise ratio of a signal. The mean of the 0 level is subtracted

from the mean of the 1 level as in the eye amplitude measurement. This number is modified by subtracting three times the standard deviation of both the 1 and 0 levels. The measurement provides an indication of the eye opening and is made on the central region (normally 20%, user changeable) of the UI

(bit period). This measurement algorithm is best suited to eye diagrams that are rendered from optical

rather than electrical signals. In the presence of inter-symbol interference and/or equalization,it may not

give reasonable results.

Eye Width

This measurement gives an indication of the total jitter in the signal. The time between the crossing

points is computed by measuring the mean of the histograms at the two 0 crossings in the signal. Three

times the standard deviation of each distribution is subtracted from the difference between these two

means. This measurement algorithm is best suited to eye diagrams that are rendered from optical rather

than electrical signals. In the presence of inter-symbol interference and/or equalization, it may not give

reasonable results.

Extinction Ratio

This measurement, defined only for optical signals, is the ratio of the optical power when the laser is in

the ON state to that of the laser in the OFF state. Laser transmitters are never completely shut off since a

relatively long period of time is required to turn the laser back on (therefore limiting the rate at which the

laser can operate). The extinction ratio is the ratio of two power levels (one very near zero) and its accuracy is greatly affected by any offset in the input of the measurement system. Optical signals are measured using optical-to-electrical converters on the front end of the SDA. Any DC offset in the O/E must be

removed prior to measurement of the extinction ratio. This procedure is known as dark calibration. The

output of the O/E is measured with no signal attached (also referred to as being dark) and this value is

subtracted from all subsequent measurements.

Eye Crossing

Eye crossing is the point where the transitions from 0 to 1 and from 1 to 0 reach the same amplitude. This

is the point on the eye diagram where the rising and falling edges intersect. The eye crossing is expressed

as a percentage of the total eye amplitude. The eye crossing level is measured by finding the minimum

histogram width of a slice taken across the eye diagram in the horizontal direction (as the vertical displacement of this slice is varied).

Average Power

The average power is a measure of the mean value of the signal, derived from all levels contained within

the eye diagram. It can be viewed as the mean of a histogram of a vertical slice through the waveform

covering an entire bit interval. Unlike the eye amplitude measurement where the 1 and 0 histograms are

separated, the average power is the mean of both histograms combined. Depending on the data coding

used, the average power can be affected by the data pattern. A higher density of 1s, for example, results

in a higher average power. Most coding schemes are designed to maintain an even 1s density resulting in

an average power that is 50% of the overall eye amplitude.

Eye BER

Eye BER is an estimate of the bit error ratio is made from the eye diagram. It is derived from a measurement of the Q-factor, as described below.

22

922968 Rev A

Page 25

Operator's Manual

This measurement algorithm is best suited to eye diagrams that are rendered from optical rather than

electrical signals. In the presence of inter-symbol interference and/or equalization, it may not give reasonable results.

The Q factor is a measure of the overall signal-to-noise ratio of the data signal. It is computed by taking

the eye amplitude (the difference between the mean values of the 1 and 0 levels) and dividing it by the

sum of the noise values (standard deviations of the 1 and 0 levels).

All of these measurements are taken in the center (usually 20%) of the eye. Users can show the Q factor

via the Measure system.

Mask Hits

Number of samples where the signal impedes the mask.

Mask Out

Number of samples where the signal does not impeded the mask.

922968 Rev A

23

Page 26

Serial Data Analysis II Software

Eye Analysis Theory

Eye diagrams are persistence maps, where each pixel in the map takes on a color that indicates how

frequently a signal has passed through the time (within a UI) and voltage specified for that pixel. Theeye

diagram shows all values a digital signal takes on during a bit period. A bit period (or UI) is defined by the

data clock, so some sort of data clock is needed to measure the eye pattern.

Eye Diagram

Eye Diagramming in Older Oscilloscopes

The "traditional" method of generating an eye pattern that was used before oscilloscopes had the ability

to determine an eye from a single sweep involved building a persistance map over many sweeps. Signals

were acquired using the data clock as a trigger. One or more samples taken on each trigger were stored

in a persistence map with the vertical dimension equal to the signal level, with the horizontal position

equal to the sample position relative to the trigger. The eye pattern filled in after a large number of multiple occurrences of time and amplitude values (counted by incrementing counters in each x,y bin) for all

the data points collected. Users would typically put the trigger point "off screen", and build the persistance map until it showed sufficient data.

Timing jitter is indicated by the horizontal distribution of the points around the data crossings. The histogram of the bins around the crossing points provides the distribution of jitter amplitude. This traditional method, unfortunately, includes the oscilloscope's trigger jitter, with the consequence that the

jitter seen in the eye diagram was not just the jitter in the signal itself.

A recovered clock is used if there is no access to a data clock. In the traditional method, the recovered

clock is normally a hardware PLL designed to operate at specific data rates and with a cutoff frequency of

Fd/1667. A drawback of a hardware clock recovery circuit is that jitter associated with its trigger circuit

adds to the measured jitter by creating uncertainty in the horizontal positioning of the eye pattern samples. Another drawback is that the clock recovery PLL is not likely to be controllable, and may not meet

the exact requirements for a specific standard.

24

922968 Rev A

Page 27

Operator's Manual

Eye Patterns

SDAIImeasures eye patterns without using a trigger. This is done using the software clock recovery (discussed in Set Up Clock Recovery) to divide the data record into segments along the time values of the

clock. For the purpose of dividing the time line into segments, the time resolution is essentially infinite.

The samples occur at fixed intervals of 25 or 50 ps/pt (for 40 or 20 GS/s sampling rate). The samples are

positioned relative to the recovered clock edge times, and the segments delimited by the clock (the unit

intervals or bits) are overlayed by aligning the clock delimited boundaries.. A monochrome or color persistence display is used to show the distribution of the eye pattern data. Since the unit inteval are determined from the recovered clock and not from the oscilloscope's trigger position, this method does not

include jitter from any trigger circuit.

922968 Rev A

25

Page 28

Serial Data Analysis II Software

Jitter Measurements

Set Up Jitter Measurements

Touch the Setup Jitter Measurements button on the Serial Data Analysis II dialog to access the Jitter

Measure dialog. The SDAII jitter analysis follows a flow of events.

The main Jitter Measure dialog shows the basic flow of the jitter analysis through a simple block diagram

progressing from left to right. Each block in the diagram is also a button. Touching any of the buttons

opens its corresponding right hand dialog.

Jitter Measurements flow diagram dialog

SDAII jitter analysis techniques are described in the following topics. The main parts of this flow correspond to the block diagram on the main Jitter Measure dialog.

A comprehensive white paper describing how jitter is measured, SDAIII Jitter Calculation Methods, on

the Teledyne LeCroy website.

Enable Jitter Measure

If this checkbox is unchecked, it turns off all traces and parameters. However, the setup remains in effect.

When checked, the traces and parameters remain unchanged.

TIE Trend

NOTE:There is no block or button for TIE Trend on the dialog. However, the TIEtrend is calculated in the

background.

First, the TIE trend is calculated, which is the deviation of each edge from the ideal provided by the recovered clock. See Set Up Clock Recovery.

Jitter Filter

1. The TIE trend, which only has a sample for each edge in the input waveform, is converted to what we

call a track or TIETrack, which is uniformly sampled at every UI, by inserting interpolated samples for

each UI where there was no edge (virtual edge). The track is also given a time axis. The TIE can now be

filtered.

2. This step allows a bandpass filter be applied to the TIETrack. Use the Filter Mode to turn the function

On or Off. You can specify a Low Pass Cutoff, High Pass Cutoff, and a Transition Width.

3. Any Jitter filtered from the Jitter Track at this point is not passed on to any of the downstream analysis.

26

922968 Rev A

Page 29

Operator's Manual

Pattern Analysis

1. First the data pattern is found.

2. Then, a DDj analysis is performed on the TIE trend. The average TIE is calculated for each DDj class.

The DDj classes can be defined either by where the edge occurs in a repetitive pattern or by the N-bit

sequence occurring prior to the edge.

3. From this analysis, a list of DDj values and populations is created for each classification made from

step 1.

4. From this analysis, the following are calculated:

l DDj histogram

l DDj plot

l DDj parameter

l DCD (Duty Cycle Distortion ) parameter

l ISI parameters

5. The DDj is removed from each edge in the TIE Trend (according to their classification from step 1) to

create an RjBUj TIE Trend (RjBUjTrend), a TIE sequence (in which the DDj is removed, but still contains all the (Rj) Random jitter, and the (BUj) Bounded-Uncorrelated jitter). The most common case

of BUj is periodic jitter, where the period is unrelated to the data rate.

Jitter Track

1. In this step, the RjBUjTrend is converted to a track (RjBUjTrack) by inserting interpolated samples

into the RjBUj Trend for each UI where there was no edge, thereby yielding a uniformly sampled TIE

waveform with a sample for every UI and a time axis.

2. This function provides the capability to show/hide the RjBUjTrack, the TIETrack, and the PLLTrack.

The PLLTrack shows the jitter tracked out by the PLL compared to an ideal clock of frequency (found

by the Find Bit Rate function).

Jitter Spectrum

1. The spectral analysis step takes the FFT of the RjBUjTrack (DDj removed). Notice how the Jitter Spectrum is showing magnitude. Therefore, to get peak-to-peak jitter you must multiply by 2.

2. The background of the spectrum is estimated and integrated to get a spectrally derived Random

jitter, Rj(sp). If the jitter model selected in the Jitter Params dialog is Dual-Dirac Spectral, then this is

the Rj used in the jitter breakdown.

3. The peaks in the spectrum are identified and used for further periodic jitter analysis.

4. A version of the spectrum is created which only keeps the peaks above the threshold.

5. The inverse FFT (PjInvFFT) of the peaks only spectrum is created. The peak-to-peak Pj is measured

from this waveform.

Jitter Histogram

Update the TIE histogram and the Rj+BUj histogram with the values in the TIETrend and the RjBUjTrend,

respectively. For multiple input waveforms, the histogram continues to accumulate until the Clear

Sweeps Front Panel button is pressed.

922968 Rev A

27

Page 30

Serial Data Analysis II Software

Jitter Parameters

The fit extrapolation for the NQ-scale model can be shown on the histogram for the NQ-scale model.

The Rj+BUj jitter distribution with the analytical tail extrapolations is then convolved with the DDj distribution (found during the Pattern Analysis Step) to create the total jitter distribution. This is integrated

to give the jitter CDF. The jitter time at which the CDF crosses the point corresponding to the Bit error

rate of interest (usually 10-12) is calculated for each side of the distribution. The difference of those 2

values is Tj(BER).

The Dual-Dirac model is fit to the extrapolated CDF to yield the final Dj(d-d) and Rj in the case of the NQScale. For the Spectral technique, Rj is forced to Rj(sp) and Dj(d-d) is determined from the Dual-Dirac constraint.

The jitter parameters explained here are independent of the jitter model selected because they are determined before the final histogram analysis.

l ISI is the larger of the range (max-min) of the 2 subsets of the DDJ histogram for neg-

ative edges or positive edges.

l DCD is the difference in the means of the histograms for the positive and negative

edges.

l DDj is the range (max-min) of the DDj distribution for both positive and negative

edges (and includes the DCD effect).

l Pj is the peak-to-peak value of all the periodic jitter obtained from the IFFT of the

peaks.

Jitter Filter

You can optionally apply either a low-, high-, or band-pass filter to the TIE-vs.-time data measured on the

signal under test (configured on the Signal Input dialog of the Serial Data configuration screens). The filter

is applied as an FFT. Users can configure the low and high frequencies used, along with the slope of the

transitions in dB per octave determining the drop-off between the pass band and stop band(s).

The Jitter Filter right-hand dialog is accessed using the Jitter Configuration button on the Main Serial

Data dialog. Access the Serial Data dialog by selecting Analysis → Serial Data from the menu bar.

Filter State - Turns the Filter On or Off.

Filter Type - Use this control to choose Lowpass, Highpass, or Bandpass as desired.

dB per Octave - Use this control to specify the slope of the transition from the pass band to the stop

band.

28

922968 Rev A

Page 31

Operator's Manual

Cutoff Freq (1)- Shown when any filter type is selected.

Cutoff Freq (2) - Shown only when the Bandpass Filter Type is chosen.

Pattern Analysis

The DDj is measured by finding the average crossing time for each edge in the data pattern and comparing this to the nominal crossing time, based on the expected bit rate of the signal under test. This

measurement requires a repeating data pattern to operate. If the data pattern in the signal does not

repeat at least once in the acquired data record, the DDj parameter will indicate zero even though this

type of jitter is present. A graphical display of the DDj can be viewed by clicking the Show DDjPlot button

on the Pattern Analysis mini-dialog. This display shows the position error of the average crossing point

for each edge in the pattern. A digital representation of the pattern can also be displayed on the screen

by clicking the Show DigPatt button on the Pattern Analysis mini-dialog. Having the Digital Pattern and

the DDjPlot on the screen at the same time is useful to be able to identify exactly where in the pattern

DDj is found. Additionally, a histogram of all of the DDj values can be displayed by clicking on the Show

DDj Histogram button.

Another view that is available is theISI Plot. This plot shows an eye pattern consisting of the averaged

waveform trace from each pattern in the data stream of a specified length. This length can be adjusted

from 3 to 12 bits. This averaging removes the effects of random jitter in the signal. What is left is an eye

diagram with all noise and random jitter removed. All that remains is the Intersymbol Interference (ISI)

and the Duty Cycle Distortion (DCD). Additionally, a specific pattern can be selected to be highlighted on

the ISIPlot.

A repeating data pattern is not always present. In these cases an alternate method of measuring data

dependent jitter that does not rely on a repeating pattern can be used. In this alternate method, the

average TIE for is calculated for edges with similar patterns of preceding N bits. This method is turned on

by unchecking the Repeating Pattern check box.

Pattern Analysis Dialog

Show DDjPlot - Check this box to display the DDj Plot.

Show DigPatt - Check this box to display the Dig. Pattern.

Show DDj Histogram - Check this box to display the DDj Histogram.

Show ISIPlot - Check this box to display the ISIPlot.

Find Pattern - Touch to automatically find the pattern.

922968 Rev A

29

Page 32

Serial Data Analysis II Software

Length - Specify the length ..

Auto Clear - Check this box to automatically clear the selections.

Clear Sweeps - Click this button to clear sweeps.

Repeating Pattern - Check this box to repeat the pattern.

Min Patt. Reps. - Used to set the minimum number of repetitions of a pattern needed in the input wave-

form. A warning is shown if less than the minimum setting is provided.

Auto Find Pattern - Check this box to automatically find the pattern.

DDj Histo Edges - Allows the user to specify which edges are included in the DDj Histogram.The choices

are Positive, Negative or Both.

Pattern Dialog

Shift Pattern By - Allows the user to shift the Digital Pattern plot in multiples of UI.

Num Bits - Allows the user to select the number of bits to use in the creation of the ISIPlot.

ISIPlot Pattern Select - Allows the user to select a specific pattern to be highlighted in the ISIPlot.

Jitter Track

This dialog is used to display any of the three available jitter track results. If the box is checked, the Track

is plotted. All three jitter tracks plot jitter versus time. In order to zoom any of these plots, first touch or

click on the trace descriptor, and then touch or click on the zoom tab (on the mini dialog on the right side

of the screen).

Show RjBUjTrack - Plots the RjBUjTrack. This waveform is the TIETrack with the DDj removed, and with

values for "virtual edges"

30

922968 Rev A

Page 33

Operator's Manual

Show PLLTrack - Plots the jitter that the PLL is tracking out. This is relative to a ideal clock at the found bit

rate. PLLTrack waveform shows the behavior of the PLL to track out low frequency jitter in your signal. It

shows a waveform that includes, for each edge (real or virtual) in your signal, a measurement of the difference between (1) the expected arrival time of the edge, as determined by the PLL, and (2) the expected

arrival time of the edge if the PLL was not turned on.

Show TIETrack - Plots the TIETrack.

Jitter Spectrum

Touching the Jitter Spectrum button on the Jitter Measurement dialog displays the Jitter Spectrum

right-hand dialog.

Show RjBUjSpectrum - Checking this box displays the Rj BUj Spectrum. This plot displays the frequency

spectrum of the signal with the DDj removed.

Show Peak Threshold - Checking this box displays the threshold for the RjBUjSpectrum. Peaks higher

than this threshold are considered Pj and the remaining signal under the threshold is integrated to form

the Rj of the spectral method of jitter composition.

Show PjInv.FFT - Checking this box displays the Pj Inverse FFT. This plot is the inverse FFT of only the

points of the RjBUjSpectrum above the threshold. This allows you to view the peaks in the time domain

and is very useful for viewing time domain Pj effects.

Find Scale for Spectrum - Clicking this button automatically finds the optimal scale for viewing the RjBUjSpectrum.

Spect. Scale - Choose whether to view the RjBUjSpectrum on a linear or logarithmic scale.

Show Peaks - Checking this box displays the peaks of the RjBUjSpectrum. This annotates the points of

the RjBUjSpectrum above the threshold.

922968 Rev A

31

Page 34

Serial Data Analysis II Software

RjBUj Spectrum

When displaying the RjBUj Spectrum, the spectral analysis takes the FFT of the RjBUjTrack (DDj

removed). Note the Jitter Spectrum is showing magnitude; to get peak-to-peak jitter multiplied by 2.

RjBUj Spectrum Analysis

32

922968 Rev A

Page 35

Operator's Manual

Peak Threshold

Peak Threshold view enables you to know what peaks are viewed as Pj for downstream analysis.

Spectrum with Threshold and Peak Annotation

Pj Inv. FFT

The Pj Inverse FFT turns a complex frequency view of the peak information into a simple time domain

view of the users Pj (Periodic Jitter).

922968 Rev A

Pj Inverse FFT

33

Page 36

Serial Data Analysis II Software

Jitter Histogram Analysis

Two jitter histograms can be viewed in SDAII, the TIE histogram, which contains all sources of jitter, and

the Rj+BUj histogram, which has the DDj removed.

The integrated histogram or the CDF (cumulative distribution function) can also be viewed. The CDF can

also be displayed in the more standard representation of a bathtub curve. Zoom in on any of the plots

by touching the trace descriptor, and then selecting the zoom tab on the right side dialog. The following

picture shows the Histogram Analysis dialog.

Show Rj+BUj Histogram - Displays Rj+BUj Histogram. Vertical axis is in number of edges in a particular

jitter bin. Horizontal axis is the RjBUj jitter value. Scale is linear. Sometimes it's useful to use the log10

math function to get a log vertical scale to make it easier to view the tails.

Show TIE Histogram - Displays TIE Histogram. Vertical axis is in number of edges in a particular jitter bin.

Horizontal axis is the TIE jitter value. Scale is linear. Sometimes it's useful to use the log10 math function

to get a log vertical scale to make it easier to view the tails.

Show Q-Fit for RjBUj- Plots the histogram in the Q-Scale representation. In the Q-Scale representation,

Gaussian tails result in straight lines whose slope is equal to 1/Rj. Teledyne LeCroy uses a special Q-scale

which we call nQ-Scale or normalized Q-Scale. This allows for Gaussian distributions with variable populations or normalizations. Shown with the Q-scale transform is the best straight line fit (the thin white

line).

Show CDF - Plots the Cumulative Distribution Function for the extrapolated RjBUj histogram convolved

with the DDj histogram.

Show Bathtub - Plots the bathtub (same information as CDF, shown in bathtub format).

34

922968 Rev A

Page 37

Operator's Manual

Jitter Parameters

Touch the Jitter Parameters button on the Jitter Measurement dialog to display the Jitter

Parametersdialog and select the parameters to display on the readout table.

Dual-Dirac Spectral Rj+Dj CDFFit - If Spectral is selected, then spectral analysis is used to determine a

sigma value to fit the tails of RjBUjHist, and the positions of the right and left Gaussians, mu_left and

mu_right are obtained from a best fit. This technique gives the fastest convergence and is the right one

to use except in cases where crosstalk or other kinds of deterministic jitter exist that can masquerade as

random jitter. In those cases NQ-Scale should be used. In general if the 2 techniques are close, use the

spectral to take advantage of it's rapid convergence, if they differ by more than a little, then the assumptions of the spectral model are probably being stretched and it would be better to use the NQ-Scale.

Dual-Dirac NQ-Scale - If NQ-Scale is selected, then there are 3 free parameters that are fit to obtain each

tail Gaussian: (1) the mean or mu, (2) the sigma, and (3) the population. A separate Gaussian is fit for

both the left and right side of the distributions, so there are 6 parameters in all. Use this technique in

cases where deterministic jitter can masquerade as random jitter, such as when non-repetitive crosstalk

is present. If the NQ-scale is showing significantly less Rj than the Spectral method, the NQ-scale technique will give a more accurate measure because the Spectral method is probably misidentifying Dj as Rj.

Log10 BER - This control sets the BER at which the Tj is reported, 10^-12 by default.

Show Pj - The p-p value of all the periodic jitter obtained from the IFFT of the spectral Pj peaks.

Show DDj - The range (max-min) of the DDj distribution for both positive and negative edges (and

includes the DCD effect).

Show DCD - The difference in the means of the histograms for the positive and negative edges.

Show ISI - The larger of the range (max-min) of the 2 subsets of the DDJ histogram for negative edges or

positive edges.

Show Rate - Displays the Jitter Rate.

Turn Off All - Touch this button to turn off all jitter parameters.

922968 Rev A

35

Page 38

Loading...

Loading...