Page 1

TELEDYNE

HASTINGS

INSTRUMENTS

INSTRUCTION MANUAL

HFM-I-401 AND HFM-I-405

INDUSTRIAL

FLOW METERS

ISO 9001

CERTIFIED

- i -

Page 2

Manual Print History

The print history shown below lists the printing dates of all revisions and addenda created for this

manual. The revision level letter increases alphabetically as the manual undergoes subsequent

updates. Addenda, which are released between revisions, contain important change information

that the user should incorporate immediately into the manual. Addenda are numbered

sequentially. When a new revision is created, all addenda associated with the previous revision of

the manual are incorporated into the new revision of the manual. Each new revision includes a

revised copy of this print history page.

Revision A (Document Number 171-042008).........................................................................March 2008

Revision B (Document Number 171-102008)...................................................................... October 2008

Revision C (Document Number 171-112008) ................................................................. November 2008

Revision D (Document Number 171-032009) ........................................................................March 2009

Revision E (Document Number 171-082010)........................................................................August 2010

Visit www.teledyne-hi.com for WEEE disposal guidance.

Description of Symbols and Messages used in this manual

WARNING

CAUTION

NOTE

This indicates a potential personnel hazard. It calls attention to a

procedure, practice, condition or the like, which, if not correctly

performed or adhered to, could result in injury to personnel.

This indicates a potential equipment hazard. It calls attention to

an operating procedure, practice, or the like, which, if not

correctly performed or adhered to, could result in damage to or

destruction of all or part of the product.

This indicates important information. It calls attention to a

procedure, practice, condition or the like, which is worthy of

special mention.

Teledyne Hastings Instruments reserves the right to change or modify the design of its equipment

without any obligation to provide notification of change or intent to change.

401-405 SERIES

- ii -

Page 3

Qui

ck

Sta

rt

Inst

ruc

tion

General Information

s

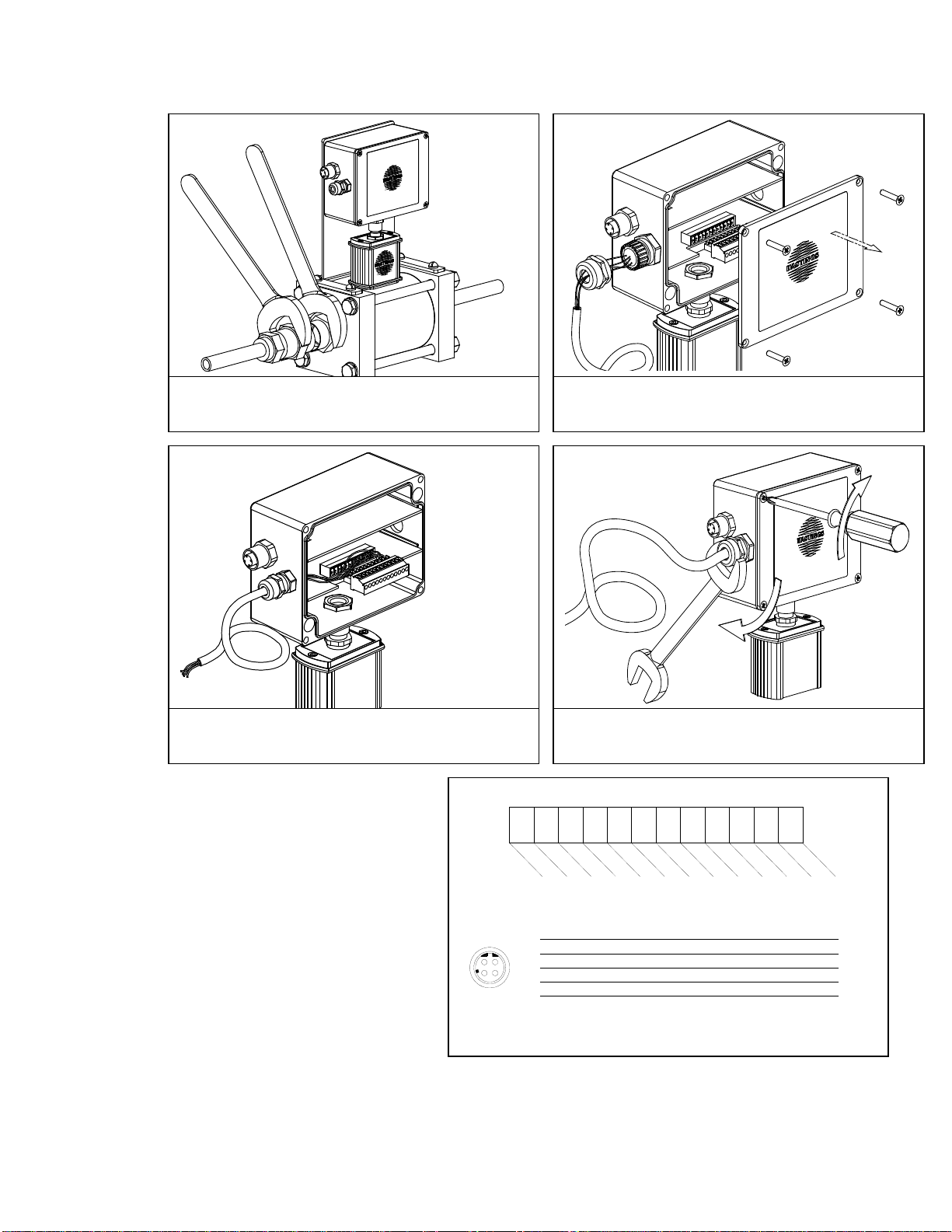

Connect dry, clean gas and ensure connections are

leak free.

Connect Cable for power and analog signal output.

Check that electrical connections are correct.

(See diagrams below)

Terminal Strip

Replace front cover and cable feed-through ensuring

gasket is seated and fasteners are secure.

112

A

ALARM

ALARM2

-

A

L

ARM1

O

A

A

I

N

-

DCOM

ZER

A

OU

I

N

+

T

+

OU

V

V

S

S

U

U

P

T

+

-

P

-

Digital Connector

12

3

4

PINS

SHIELD

1

2

3

4

RS232

GROUND

TRANSMIT

RECEIVE

UNUSED

UNUSED

RS485

GROUND

TX+ (A)

RX+ (A)

TX- (B)

RX- (B)

ETHERNET

GROUND

TD+

RD+

TDRD-

401-405 SERIES - iii -

Page 4

401-405 SERIES

- iv -

Page 5

401-405 SERIES - v -

Page 6

CAUTION

This instrument is available with multiple pin-outs.

Ensure electrical connections are correct.

CAUTION

NOTE

The 400-I series flow meters are designed for IEC

Installation/Over voltage Category II – single phase receptacle

connected loads.

The Hastings 400 Series flow meters are designed for

INDOOR and OUTDOOR operation.

CAUTION

CAUTION

In order to maintain the integrity of the Electrostatic Discharge

immunity both parts of the remote mounted version of the HFMI-400 instrument must be screwed to a well grounded structure.

In order to maintain the environmental integrity of the enclosure

the power/signal cable jacket must have a diameter of 0.12 -

0.35” (3 – 9 mm) for the cable gland or 0.25 - 0.275” (6.5 – 7

mm) for the circular connector. The nut on the cable gland must

be tightened down sufficiently to secure the cable. This cable

must be rated for at least 85°C.

401-405 SERIES

- vi -

Page 7

Table of Contents

GENERAL INFORMATION.....................................................................................................................................1

1. GENERAL INFORMATION ....................................................................................................................................1

1.1. OVERVIEW......................................................................................................................................................1

1.1.1. 400 Series Family..................................................................................................................................1

1.1.2. 400 Series Meters ..................................................................................................................................1

1.1.3. Measurement Approach.........................................................................................................................1

1.1.4. Additional Functions..............................................................................................................................1

1.2. SPECIFICATIONS .............................................................................................................................................2

INSTALLATION.........................................................................................................................................................4

2. INSTALLATION....................................................................................................................................................4

2.1. RECEIVING INSPECTION.................................................................................................................................. 4

2.2. ENVIRONMENTAL AND GAS REQUIREMENTS..................................................................................................4

2.3. MECHANICAL CONNECTIONS .........................................................................................................................4

2.4. MOUNTING THE ELECTRONICS REMOTELY .....................................................................................................5

2.5. ELECTRICAL CONNECTION .............................................................................................................................5

2.5.1. Power Supply.........................................................................................................................................6

2.5.2. Analog Output........................................................................................................................................6

2.5.2.1. Current Loop Output .........................................................................................................................6

2.5.2.2. Voltage output....................................................................................................................................9

2.6. DIGITAL CONNECTION....................................................................................................................................9

2.7. DIGITAL CONFIGURATION ..............................................................................................................................9

2.7.1. RS-232 ...................................................................................................................................................9

2.7.2. RS-485 .................................................................................................................................................10

2.7.3. Ethernet ...............................................................................................................................................10

2.8. ALARM OUTPUT CONNECTION .....................................................................................................................10

2.9. AUXILIARY INPUT CONNECTION ..................................................................................................................11

2.10. ROTARY GAS SELECTOR...........................................................................................................................12

2.11. ELECTRICAL REMOTE ZERO CONNECTION ...............................................................................................13

2.12. CHECK INSTALLATION PRIOR TO OPERATION...........................................................................................13

OPERATION.............................................................................................................................................................15

3. OPERATION ......................................................................................................................................................15

3.1. ENVIRONMENTAL AND GAS CONDITIONS .....................................................................................................15

3.2. INTERPRETING THE ANALOG OUTPUT ..........................................................................................................15

3.3. DIGITAL COMMUNICATIONS.........................................................................................................................15

3.3.1. Digitally Reported Flow Output..........................................................................................................16

3.3.2. Digitally Reported Analog Input..........................................................................................................16

3.4. ZEROING THE INSTRUMENT ..........................................................................................................................16

3.4.1. Preparing for a Zero Check.................................................................................................................16

3.4.2. Adjusting Zero .....................................................................................................................................17

3.5. OVER-RANGE................................................................................................................................................17

3.6. REVERSE FLOW ............................................................................................................................................18

3.7. HIGH PRESSURE OPERATION ........................................................................................................................18

3.7.1. Zero Shift .............................................................................................................................................19

3.7.2. Span Shift.............................................................................................................................................19

3.8. WARNINGS/ALARMS ....................................................................................................................................19

3.9. MULTI-GAS CALIBRATIONS..........................................................................................................................19

3.10. FLOW TOTALIZATION ...............................................................................................................................20

3.11. ADDITIONAL DIGITAL CAPABILITIES ........................................................................................................20

PARTS AND ACCESSORIES.................................................................................................................................21

4. PARTS & ACCESSORIES.....................................................................................................................................21

4.1. POWER POD – POWER & DISPLAY UNITS ......................................................................................................21

4.2. FITTINGS.......................................................................................................................................................22

4.3. CABLES ........................................................................................................................................................22

WARRANTY.............................................................................................................................................................23

401-405 SERIES - vii -

Page 8

WARRANTY......................................................................................................................................................23

5.

5.1. WARRANTY REPAIR POLICY.........................................................................................................................23

5.2. NON-WARRANTY REPAIR POLICY................................................................................................................23

APPENDICES............................................................................................................................................................24

6. APPENDICES .....................................................................................................................................................24

6.1. APPENDIX 1- VOLUMETRIC VERSUS MASS FLOW.........................................................................................24

6.2. APPENDIX 2 - GAS CONVERSION FACTORS...................................................................................................25

401-405 SERIES

- viii -

Page 9

1. General Information

1. General Information

1.1. Overview

1.1.1. 400 Series Family

The Hastings 400 Series is a family of flow instruments which is specifically designed to meet the needs

of the industrial gas flow market. The “I” family in the 400 Series features an IP-65 enclosure which

allows the use of the instrument in a wide variety of environments. The 400 I products consist of four

configurations: a flow meter, HFM-I-401, which has a nominal nitrogen full scale between 10 SLM and

300 SLM and a corresponding flow controller, the HFC-I-403; a larger flow meter, HFM-I-405, which

ranges from 100 SLM to 2500 SLM, and a corresponding flow controller, the HFC-I-407. These

instruments are configured in a convenient in-line flow-through design with standard fittings. Each

instrument in the series can be driven by either a +24 VDC power supply or a bipolar ±15 volt supply.

The electrical connection can be made via either a terminal strip located inside the enclosure or

optionally through an IP-65 compatible electrical connector. Also, these instruments include both

analog and digital communications capabilities.

1.1.2. 400 Series Meters

The Hastings HFM-I-401 and HFM-I-405 thermal mass flow meters are designed to provide very

accurate measurements over a wide range of flow rates and environmental conditions. The design is

such that no damage will occur from moderate overpressure or overflows and no maintenance is

required under normal operating conditions when using clean gases.

1.1.3. Measurement Approach

The instrument is based on mass flow sensing. This is accomplished by combining a high-speed thermal

transfer sensor with a parallel laminar flow shunt (see Figure 1-1). The flow through the meter is split

between the sensor and shunt in a constant ratio set by the full scale range. The thermal sensor consists

of a stainless steel tube with a heater at its center and two thermocouples symmetrically located

upstream and downstream of the heater. The ends of the sensor tube pass through an aluminum block

and into the stainless steel sensor base. With no flow in the tube the thermocouples report the same

elevated temperature; however a forward flow cools the upstream thermocouple relative to the

downstream. This temperature difference generates a voltage signal in the sensor which is digitized and

transferred to the main processor in the electronics enclosure. The processor uses this real-time

information and the sensor/shunt characteristics stored in non-volatile memory to calculate and report

the flow.

To ensure an inherently linear response to flow, both the thermal sensor and the shunt have been

engineered to overcome problems common to other flow meter designs. For example, nonlinearities and

performance variations often arise in typical flow meters due to pressure-related effects at the entrance

and exit areas of the laminar flow shunt. Hastings has designed the 400 Series meters such that the flowcritical splitting occurs at locations safely downstream from the entrance effects and well upstream from

the exit effects. This vastly improves the stability of the flow ratio between the sensor and shunt. The

result of this design feature is a better measurement when the specific gravity of the flowing medium

varies, for instance due to changes in pressure or gas type. Also, a common problem in typical flow

meters is a slow response to flow changes. To improve response time, some flow meter designs

introduce impurities such as silica gel. Alternatively, Hastings has designed the 400 Series sensor with

reduced thermal mass to improve the response time without exposing additional materials to the gas

stream.

1.1.4. Additional Functions

These instruments contain a number of functions in addition to reporting flow which include:

• Settable alarms and warnings with semiconductor switch outputs

401-405 SERIES - 1 -

Page 10

• A digitally reported status of alarms and warnings such as overflow/underflow

• A flow totalizer to track the amount of gas added to a system

• A digitizing channel for an auxiliary analog signal

• An internal curve fitting routine for “fine tuning” the base calibration

• An alternate calibration set of 8 different ranges/gases

1.2. Specifications

WARNING

Do not operate this instrument in excess of the specifications

listed below. Failure to heed this warning can result in serious

personal injury and/or damage to the equipment.

Performance

Full Scale Flow Ranges

)

(in N

2

Accuracy1

Optional: ± (0.5% reading + 0.2%FS) Optional: ± (0.5% reading + 0.2%FS)

Repeatability ± 0.1% of F.S. ± 0.1% of F.S.

Operating Temperature -20 to 70°C -20 to 70°C

Warm up time 30 min for optimum accuracy 30 min for optimum accuracy

2 min for ± 2% of full scale 2 min for ± 2% of full scale

Settling Time/Reponse

Time

Temperature Coefficient

of Zero

Temperature Coefficient

of Span

Operating Pressure Maximium

Optional: 1500 psig Optional: 1000 psig

Pressure Coefficient of

Span < 0.01%of reading /psi (N

Pressure Drop(N2@14.7

psia) < 1.1 psi at full scale flow < 5.1 psi at full scale flow

Attitude Sensitivity of

Zero < 2% of F.S. < 2% of F.S.

Electrical

Power Requirements

Analog Output

0-10 slm up to 0-350 slm 0-100 slm up to 0-2500 slm

Standard: ± 1% full scale Standard: ± 1% full scale

< 2.5 seconds (to within ± 2% of full scale) < 2.5 seconds (to within ± 2% of full scale)

< ±0.05% of Full Scale /°C < ±0.05% of Full Scale /°C

< ±0.16% of reading/°C < ±0.16% of reading/°C

Standard: 500 psig Standard: 500 psig

18-38 VDC, 3.5 watts(Ethernet) 2.5

watts(RS232/485)

Standard: 4 – 20 mA Standard: 4 – 20 mA

HFM-I-401 HFM-I-405

, 0-1000 psig) < 0.01%of reading /psi (N2, 0-1000 psig)

2

18-38 VDC, 3.5 watts(Ethernet) 2.5

watts(RS232/485)

Optional: 0-10 VDC, 0-20 mA, 0-5 VDC, 1-5 VDC Optional: 0-10 VDC, 0-20 mA, 0-5 VDC, 1-5 VDC

Digital Output

Optional: RS 485 Optional: RS 485

Optional: Ethernet Optional: Ethernet

Analog Connector

Optional: 12 pin Circular Connector Optional: 12 pin Circular Connector

Digital Connector 4 pin, D-coded M12 4 pin, D-coded M12

401-405 SERIES

- 2 -

Standard: RS 232 Standard: RS 232

Std: Terminal Block – M16 Cable Gland Std: Terminal Block – M16 Cable Gland

Page 11

Mechanical

Fittings

Standard: 1/2" Swagelok Standard: 1" Swagelok

Optional: ½" VCO®, ½" VCR®, ¾” Swagelok, Optional: 1" VCO®,1" VCR®, ¾” Swagelok, ,

10mm Swagelok, 3/8" male NPT, ½” male NPT 1" male NPT, ¾” male NPT, 1 5/16"-12 straight

12mm Swagelok, ¾"-16 SAE/MS straight thread thread

Leak Integrity < 1x10

-8

sccs He < 1x10

-8

sccs He

Wetted Materials 316L SS, Nickel 200, 302 SS, Viton® 316L SS, Nickel 200, 302 SS, Viton®

Weight (approx.) 12 lb (5.5 kg) 18 lb (8 kg)

®

is a trademark of DuPont Dow Elastomers, LLC.

Viton

®

Swagelok

, VCO®and VCR® are trademarks of the Swagelok Company.

401-405 SERIES - 3 -

Page 12

2. Installation

2. Installation

CAUTION

Many of the functions described in this section require removing

the enclosure front plate. Care must be taken when reinstalling

this plate to ensure that the sealing gasket is properly positioned

and the fasteners are secure to maintain an IP65 compliant seal.

2.1. Receiving Inspection

Your instrument has been manufactured, calibrated, and carefully packed so it is ready for operation.

However, please inspect all items for any obvious signs of damage due to shipment. Immediately advise

Teledyne Hastings and the carrier if any damage is suspected.

Use the packing slip as a check list to ensure all parts are present (e.g. flow meter, power supply, cables

etc.) and that the options are correctly configured (output, range, gas, connector).

If a return is necessary, obtain an RMA (Return Material Authorization) number from Teledyne

Hastings’ Customer Service Department at 1-800-950-2468 or hastings_instruments@teledyne.com

2.2. Environmental and Gas Requirements

• Use the following guidelines prior to installing the flow meter:

• Ensure that the temperature of all components and gas supply are between -20° and 70° C

• Ensure that the gas line is free of debris and contamination

• Ensure that the gas is dry and filtered (water and debris may clog the meter and/or affect its

performance)

.

• If corrosive gases are used, purge ambient (moist) air from the gas lines

2.3. Mechanical Connections

The meter can be mounted in any orientation unless using dense gases or pressures higher than 250 psig

in which case a “flow horizontal” orientation is required. The meter’s measured flow direction is

indicated by the arrow on the electronics enclosure.

A straight run of tubing upstream or downstream is not necessary for proper operation of the meter. The

flow meter incorporates elements that pre-condition the flow profile before the measurement region. So

for example, an elbow may be installed upstream from the flow meter entrance port without affecting

the flow performance.

Compression fittings should be connected and secured according to recommended procedures for that

fitting. Two wrenches should be used when tightening fittings (as shown in the Quick Start Guide on

page iii) to avoid subjecting the flow meter body to undue torque and related stress.

The fittings are not intended to support the weight of the meter. For mechanical structural support,

four mounting holes (#1/4-20 thread, 3/8” depth) are located in the bottom of the meter. The position

of these holes is documented on the outline drawing in Appendix 3 (Section 6.3).

Leak-check all fittings according to an established procedure appropriate for the facility.

401-405 SERIES

- 4 -

Page 13

2.4. Mounting the Electronics Remotely

CAUTION

The electronics enclosure can be separated

and relocated up to 30 feet away from the

flow meter base. This requires a cable which

is supplied with the instrument if ordered as

a cable mounted unit. Alternatively, a 2, 5,

or 10 meter cable can be purchased

separately. See section 4.2 for ordering

information and part numbers.

When remote mounting the electronics

enclosure, the support bracket can remain

attached to either the flow meter base or the

electronics. To separate the electronics

enclosure from the support bracket, remove

the two screws located on the back of the

support bracket. To separate the flow meter

base from the support bracket, remove the

four screws that mount the bracket to the top

of the flow meter base. Unscrew the

electrical connector between electronics enclosure and the flow meter base. Remove the electronics

enclosure from the flow meter base. Connect the female end

of the remote electronics cable to the flow meter base and

the male end to the electronics enclosure. The electronics

enclosure can be mounted remotely by using the two

threaded holes in the enclosure. The size and spacing of

these two holes are specified on the outline drawing in

Appendix 3 (Section 6.3). These holes may be used by

inserting fasteners from behind through a new mounting

bracket or they may be accessed from the front side by

temporarily removing the enclosure panel. This enables

mounting the enclosure to a wall or other solid structure.

Alternatively, if the instrument was originally configured as

a bracket mounted unit the bracket may be directly

mounted to a support structure. The bracket mounting

holes locations are the same as those for the flow meter base

mounting. (See the outline drawing in Appendix 3, Section

6.3.)

In order to maintain the integrity of the Electrostatic Discharge

immunity both parts of the remote mounted version of the HFMI-400 instrument must be screwed to a well grounded structure.

The ferrite that is shipped with the instrument must be installed

on the cable next to the electronics enclosure.

Figure 2-1 Accessing the terminal strip

Terminal Strip Pin-out

(Pins numbered right to left as

viewed from the front)

1 - Power Supply

2 + Power Supply

3- Flow Output

4+ Flow Output

5 + Auxiliary Input

6 - Auxiliary Input

7No Connection

8 Digital Common

9 Remote Zero

2.5. Electrical Connection

There are two electrical connectors on the Hastings 400-I

Series flow meters—an analog terminal strip (located

within the electronics enclosure) and a digital connector.

The analog connector provides for the power supply to

the meter along with analog signals and functions. As

such, its use is required for operation. The digital

connector is used for communications in either of RS232,

RS485, or Ethernet mode depending on the instrument’s

configuration. The digital connector does not have to be used if the meter is operated as an analogonly instrument.

10 Alarm 1

11 Alarm 2

12 Alarm Common

Figure 2-2 Electrical

connections for analog

inputs/outputs and power

401-405 SERIES - 5 -

Page 14

There are two possible connection methods to the analog terminal

strip. The standard method is by inserting a cable through the

supplied cable gland with an external jacket that meets the

specifications of the following caution note and tightening down the

cable gland nut securely to seal against the cable jacket.

There is also an optional sealed circular connector that may be ordered

with the instrument. If this connector is ordered the internal terminal

board will be connected to pins on the circular connector. This option

will be supplied with the mating connector (if a power cable was not

ordered with the instrument). This mating connector has pins that must

be soldered to wires (24 - 28 AWG) in a customer supplied cable that

meets the specifications in the caution note below. Other sealing collets for cable diameters other than

specified below can be ordered from Bulgin PX0482 (3 – 5 mm) or PX0483 (5 – 7 mm). Ensure that

the parts are installed on the cable assembly correctly before assembling. Installation and removal of the

outer housing may damage the latches and prevent the connector from making a leak-free seal.

In order to maintain the environmental integrity of the enclosure

CAUTION

the power/signal cable jacket must have a diameter of 0.12 -

0.35” (3 – 9 mm) for the cable gland or 0.25 - 0.275” (6.5 – 7

mm) for the circular connector. The nut on the cable gland must

be tightened down sufficiently to secure the cable. This cable

must be rated for at least 85°C.

2.5.1. Power Supply

Ensure that the power source meets the requirements detailed in the specifications section. Hastings

offers several power supply and readout products that meet these standards and are CE marked. If

multiple flow meters or other devices are sharing the same power supply, it must have sufficient

capability to provide the combined maximum current.

Power is delivered to the instrument through pins 1 and 2 of the analog terminal strip located within the

electronics enclosure (see Figure 2-1). As shown in the pin-out diagram Figure 2-2, the positive polarity

of the power supply is connected to pin 2 and the negative is connected to pin 1. (For a unipolar power

supply, pin 1 is power common and pin 2 is +24V. For a bipolar ±15V power supply, pin 1 is -15V and

pin 2 is + 15V.) To allow for inadvertent reversal of the power polarity, an internal diode bridge will

ensure that the proper polarity is applied to the internal circuitry. A green LED located next to the

terminal strip will illuminate when the meter is properly powered. The power supply inputs are

galvanically isolated from all other analog and digital circuitry.

2.5.2. Analog Output

The indicated flow output signal is found on pins 3 and 4 of the terminal strip as shown in Figure 2-2.

The negative output pin 3 is galvanically isolated from chasis ground and from the power supply input

common. The 400 Series meters can be configured to provide one of many available current and voltage

outputs; the standard 4 -20 mA or the optional 0 -20 mA, 0-5 Vdc, 1-5 Vdc, or 0-10 Vdc.

When the meter is configured with milliamp output it

cannot generate a signal that is below the zero current

value; therefore the 0-20 mA unit is limited in its ability

NOTE

to indicate a negative flow with the analog signal.

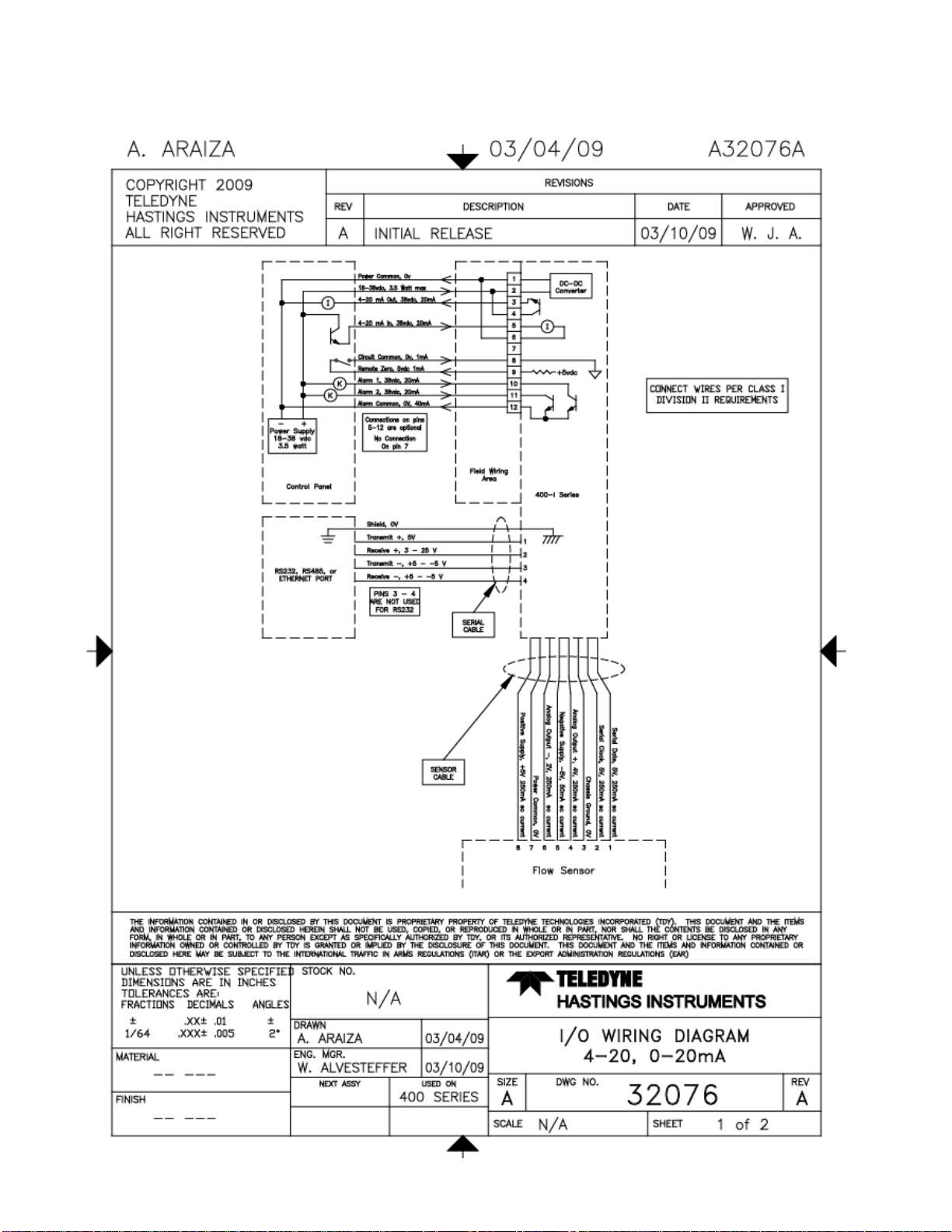

2.1.1.1. Current Loop Output

The standard instrument output is a 4 - 20 mA signal proportional to the measured flow (i.e. 4 mA =

zero flow and 20 mA = 100% FS). An optional current output of 0 – 20 mA (where 0 mA = zero flow

and 20 mA = 100% FS) may be selected at the time of ordering.

If either current loop output has been selected, the flow meter acts as a passive transmitter. It neither

sources nor sinks the current signal. The polarity of the loop must be such that pin 4 is at a higher

potential than pin 3 on the flow meter terminal strip. Loop power must be supplied with a potential in

401-405 SERIES

- 6 -

Page 15

the range of 5-28 Vdc from a source external to the flow meter. The loop supply can be the same supply

as that for the instrument power or it can be an isolated loop supply.

Figure 2-3 shows a typical setup using the same supply. This method requires a jumper from pin 2 to

pin 4 on the terminal strip while connecting pin 3 to a wire that carries this signal to the indicator (for

example, a process ammeter, data acquisition system, or PLC board). To complete the current loop,

another wire carries the return signal from the flow indicator back to the negative end of the input

supply.(Alternatively, the loop current can be measured on the “high potential side” by connecting the

indicator between the pins 2 and 4 while connecting pin 3 to pin 1.)

Figure 2-4 shows an arrangement using a separate loop supply which is isolated from the instrument

power supply.

401-405 SERIES - 7 -

Page 16

Figure 2-3 Wiring diagram showing the current loop supply powered by the instrument suppl

y

Figure 2-4 Wiring diagram showing the current loop powered by an external supply

401-405 SERIES

- 8 -

Page 17

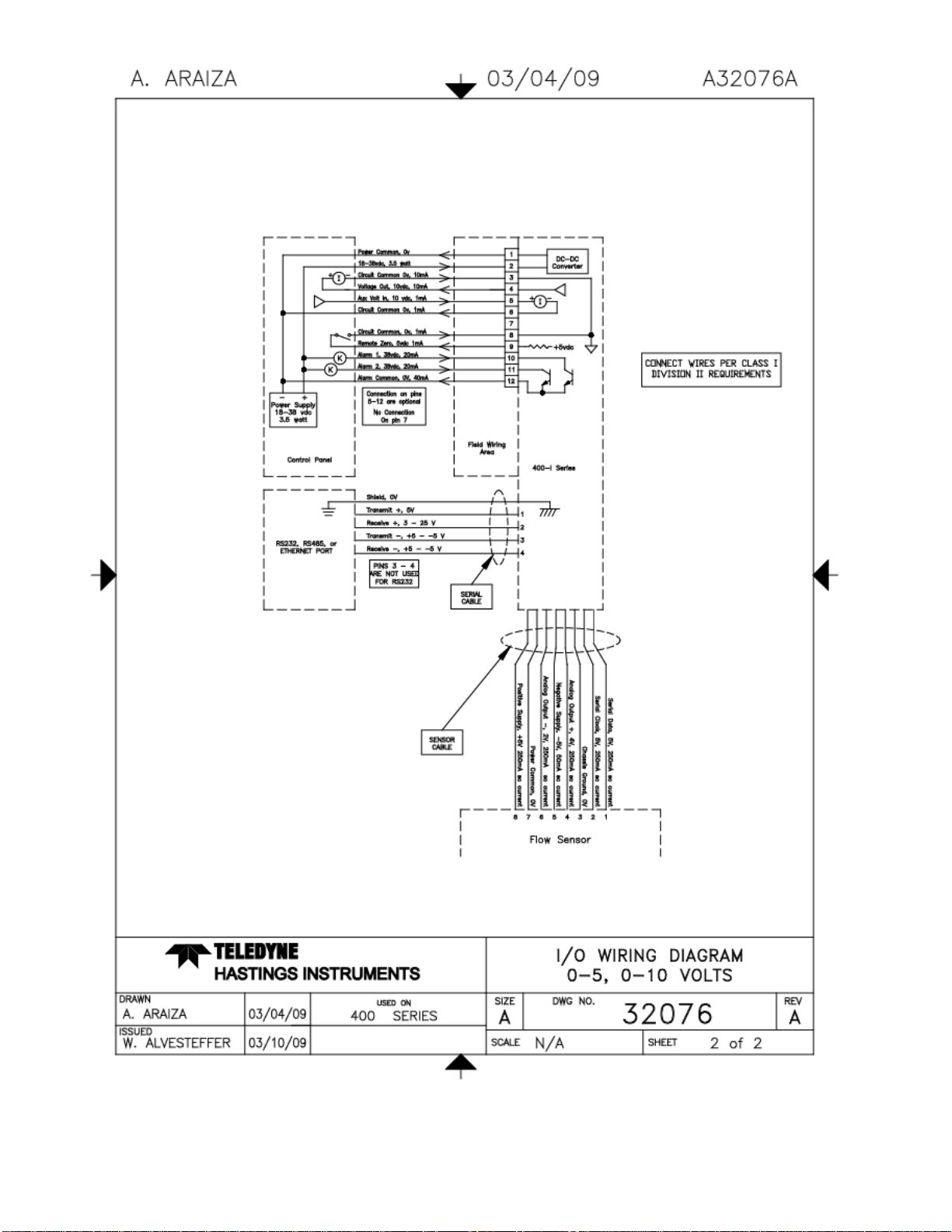

2.1.1.2. Voltage output

If the flow meter is configured for a voltage output, the signal will be available as a positive potential on

pin 4 relative to pin 3 of the terminal strip. Since these pins are galvanically isolated, the signal cannot

be read by an indicator between pin 4 and pin 1 of the terminal strip. Pin 3 must be used as the return

to properly read the output on pin 4. If an output that is referenced to power supply common is desired

then pins 3 and 1 must be connected. It is recommended that these signals be transmitted through

shielded cable, especially for installations where long cable runs are required or if the cable is located

near equipment that emits RF energy or uses large currents.

Note: When the meter is configured with a voltage output it cannot generate a signal that is more than a

few mV below the zero volt value; therefore the 0-5 volt and 0-10 volt units are limited in their ability to

indicate a negative flow with the analog signal.

2.6. Digital Connection

The digital signals are available on a sealed female D-coded M12 connector that is designed for use on

industrial Ethernet connections. There are many options for connecting to the M12. Hastings offers an

8 foot cable (stock# CB-RS232-M12) with a compatible male M12 connector to a 9-pin D connector

suitable for connecting the 400 I series instrument directly to the RS232 port on a PC. A cable to

convert USB to RS232 9-pin is available from Hastings (stock# CB-USB-RS232). Also, a 5 meter M12

male–male cable suitable for digital communications can be purchased from Hastings (stock# CBETHERNET-M12). Other length cables are available from Lumberg (#0985 342 100/5 M) or Phoenix.

Converters from the M12 connector to a standard modular Ethernet connector are available from

Hastings or from Lumberg (#0981 ENC 100). A compatible M12 connector suitable for field wiring

can be acquired from Harting (21 03 281 1405) or Mouser (617-21-03-281-1405).

The pin-out for the digital connector is shown in Figure 2-5.

PINS

SHIELD

12

34

Figure 2-5 Digital connector pin-out

1

2

3

4

RS232

GROUND

TRANSMIT

RECEIVE

UNUSED

UNUSED

RS485

GROUND

TX+ (A)

RX+ (A)

TX- (B)

RX- (B)

ETHERNET

GROUND

2.7. Digital Configuration

A Hastings 400-I Series flow meter is available with one

of three digital communications interfaces, RS232,

RS485, or Ethernet. Unless specified differently at the

time of ordering, the flow meter is configured for RS232

operation. For each interface, there are changes that can

be made to the configuration, either via software or

hardware settings. A brief overview of these is included

here. For more detailed information, consult the

Hastings 400 Series Software Manual.

TD+

RD+

TDRD-

Jumper

Enabled Disabled

1 RS485 RS232

2 Half Duplex Full Duplex

3 TX Terminated Unterminated

4 RX Terminated Unterminated

5 9600 Baud Software Selected

2.7.1. RS-232

The default configuration for the RS-232 interface is

19200 baud, 8 data bits, no–parity, one stop bit. The

6 Addr = 99 Software Selected

Figure 2-6 Functions for digital jumper field

baud rate is software selectable and can be overridden

by a hardware setting. Hardware settings for RS-232 and RS-485 are enacted on 12 pin jumper field

located on the left end of the top circuit board in the electronics enclosure. Only the state of jumpers 1,

2, and 5 affect the RS-232 operation. These jumpers are installed vertically over two pins when enabled

and are numbered from left to right. Jumper 1 must be disabled for RS-232; jumper 2 is used to select

401-405 SERIES - 9 -

Page 18

half or full duplex; and jumper 5 is enabled when a hardware override of the baud rate (forcing it to

9600) is desired. These functions are summarized in Figure 2-6.

2.7.2. RS-485

If RS485 is specified on the order, the flow meter is

set to the default values: address 61, unterminated Tx

and Rx lines. While the default address is 61, all

instruments will respond to an address of FF.

Hardware settings for RS-232 and RS-485 are

enacted on 12 pin jumper field located on the left end

of the top circuit board in the electronics enclosure.

Only the state of jumpers 1, 3, 4, and 6 affect the RS485 operation (see Figure 2-6). These jumpers are

installed vertically over two pins when enabled and

are numbered from left to right. Jumper 1 must be

enabled for RS-485. Enabling jumpers 3 and 4 effect

a 120 ohm resistance across the transmit and receive

signal pairs respectively. These should only be

enabled in the last instrument on a long buss.

Enabling jumper 6 forces the address to 99; this is

Figure 2-7 Web browser screen

sometimes used when initiating communications.

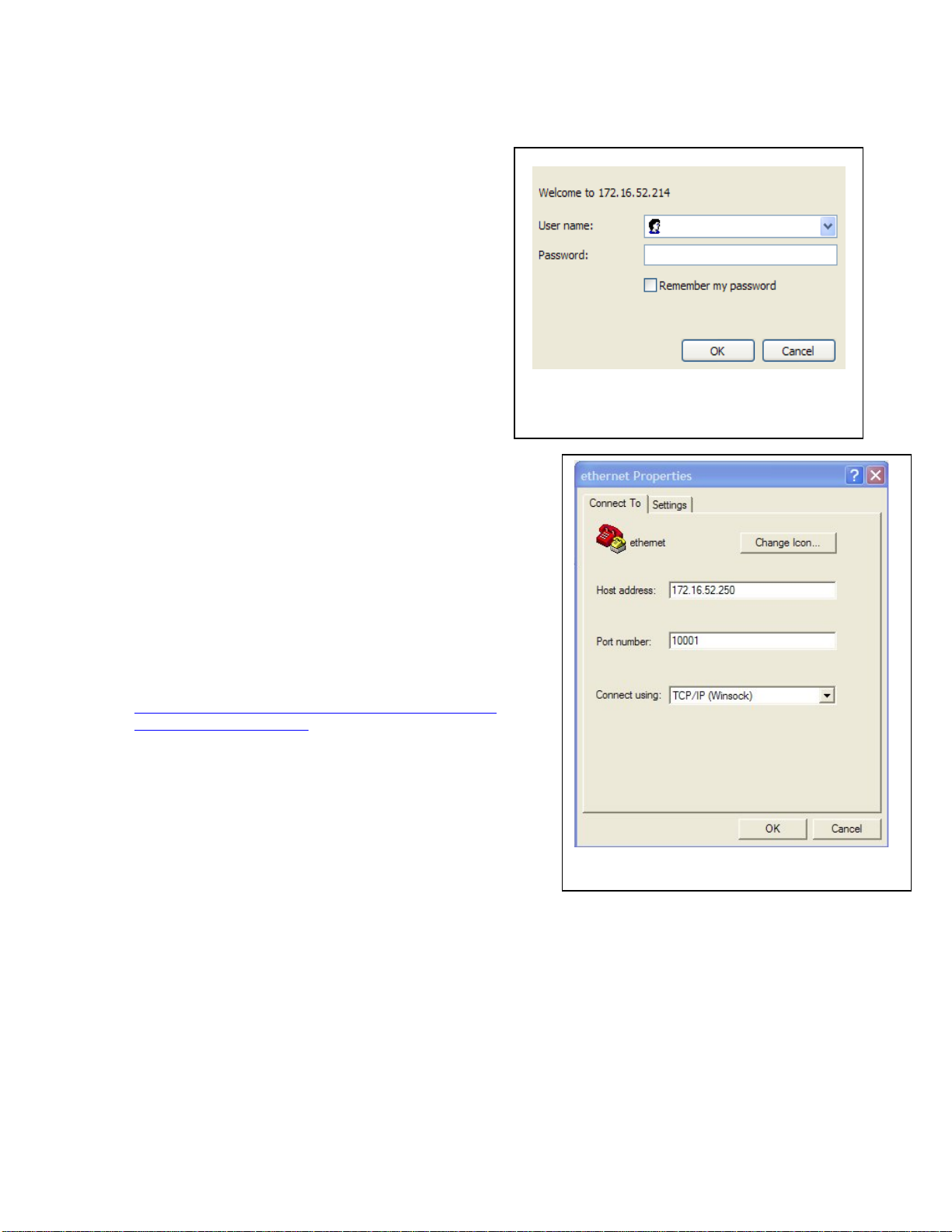

2.7.3. Ethernet

If Ethernet is specified on the order, the flow meter has IP

address 172.16.52.250 and communication port number

10001. There are no hardware settings required or available

to modify the configuration. This IP address can be changed

using a web browser to access the configuration of the

instrument by typing the IP address into the URL section of

the browser. Press OK to ignore the username/password

screen as shown in Figure 2-7. Select the new IP address

under the network section of the web page configuration

utility. If this address cannot be reached, the instrument can

be reconfigured by downloading and installing the Lantronix

Device Installer routine from:

http://www.lantronix.com/device-networking/utilitiestools/device-installer.html.

A standard web browser cannot be used to send and receive

messages (such as flow readings) from the main processor of

the flow meter. An Ethernet capable software program is

required to communicate with the meter’s processor.

Suitable examples of such programs are “Hyperterminal”

(typically installed as standard on PCs and shown in Figure

2-8) or custom Ethernet capable software such as LabView

For more information see the Software Manual.

2.8. Alarm Output Connection

The Hastings 400 Series flow meters include two software settable hardware alarms. Each is an opencollector transistor functioning as a semiconductor switch designed to conduct DC current when

activated. (See Figure 2-9.) These sink sufficient current to illuminate an external LED or to activate a

remote relay and can tolerate up to 70Vdc across the transistor. The alarm lines and the alarm common

are galvanically isolated from all other circuit components. The connections for Alarm 1, Alarm 2 and

Alarm Common are available as pins 10, 11, and 12 respectively on the analog terminal strip (see Quick

Start Guide on page iii).

401-405 SERIES

- 10 -

®

.

Figure 2-8 Example Hyperterminal window

Page 19

Since the alarms act as switches they do not produce

1

a voltage or current signal. However, they can be

used to generate a voltage signal on an Alarm Out

line. This is done by connecting a suitable pull-up

Alarm 1

resistor between an external voltage supply and the

desired alarm line while connecting Alarm Common

to the common of the power supply. When activated,

the alarm line voltage will be pulled toward the alarm

common line generating a sudden drop in the signal

Alarm 2

line voltage.

To use the alarm to illuminate an LED connect the

Alarm Common

positive terminal of the LED to a suitable power

supply and connect the other end to a current

limiting resistor. This resistor should be sized such

that the current is less than 20 mA when the entire

supply voltage is applied. Connect the other end of

Figure 2-9 Alarm circuit diagram

the resistor to Alarm 1 or Alarm 2. Connect Alarm

Common to the circuit common of the power supply. When activated, the alarm line is pulled toward

the alarm common generating sufficient current through the LED to cause it to illuminate.

Figure 2-10 shows an example of the LED circuit arrangement applied to Alarm 1 while Alarm 2 is

configured with a suitable pull-up resistor to provide a voltage output on an Alarm Out line.

Since the Alarm Common is a

shared contact, if both alarms

are being used independently

they must each be wired such

that the current passes

through the external signaling

Alarm

V +

device before reaching the

alarm line.

The alarm settings and

activation status are available

via software commands and

queries. The software

Alarm 2

Alarm Out

interprets an activated Alarm

1 as an “Alarm” condition,

while an activated Alarm2 is

interpreted as a “Warning”

Alarm

Common

V -

condition. The software

manual includes the detailed

descriptions for configuring

and interpreting the activation

of these alarms.

2.9. Auxiliary Input

Figure 2-10 Alarm circuit diagram for LED operation

Connection

The Hastings 400 Series flow meters provide an auxiliary analog input function. The flow meter can

read the analog value present between pins 5 and 6 on the terminal strip (as shown in Figure 2-2) and

make its value available via the digital interface. The accepted electrical input signal is the same as that

configured for the analog output signal (4 – 20 mA, 0 -20 mA, 0-5 Vdc, 1-5 Vdc, or 0-10 Vdc). Unlike

the analog output signal, which is isolated and capable operating at common mode offsets of over

1000V, the analog input signal cannot be galvanically isolated from ground potential.

401-405 SERIES - 11 -

Page 20

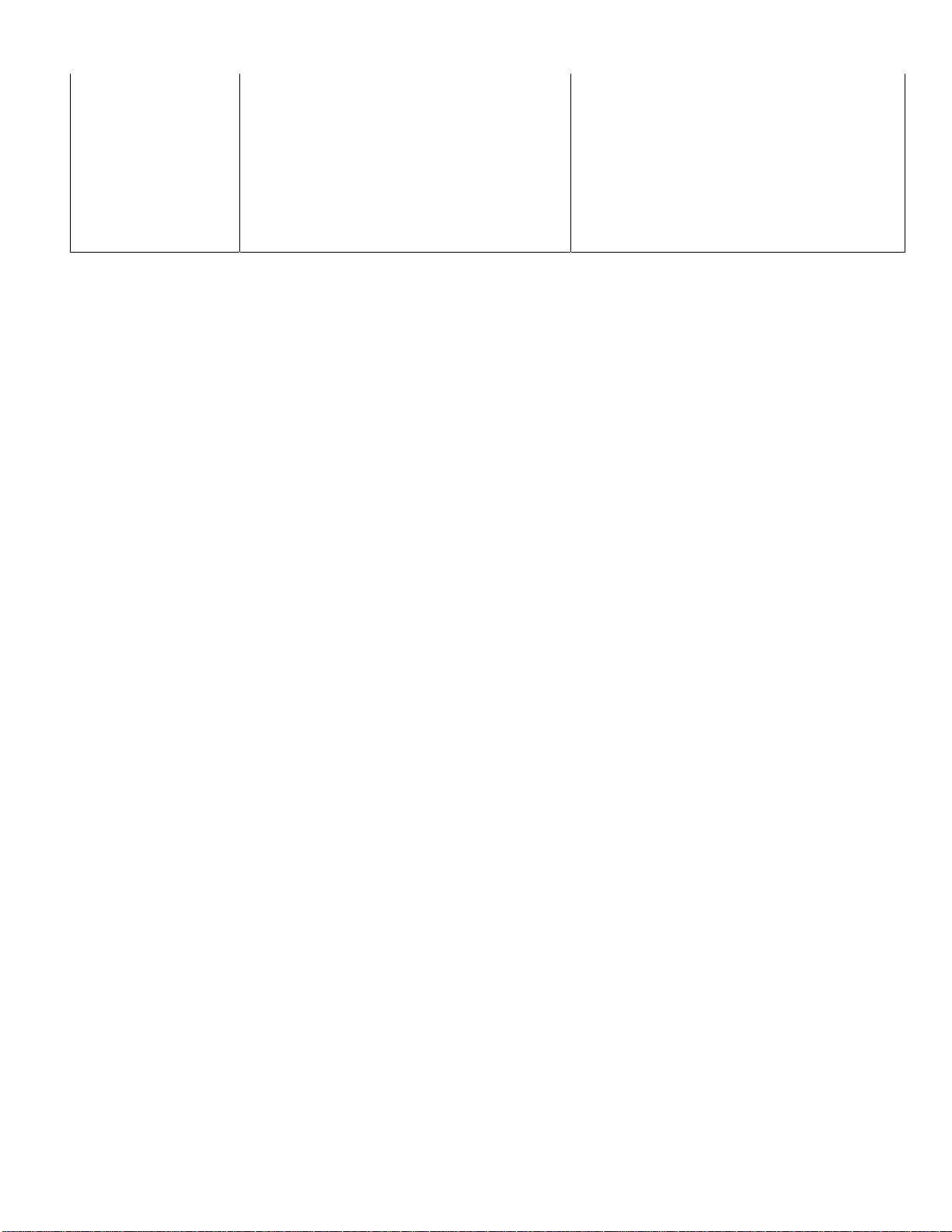

2.2. Rotary Gas Selector

The Hastings 400 Series flow meters can have up to eight different calibrations

stored internally. These are referred to as gas records. These records are used

to select different gases, but they can also be useful in other ways; for instance

reporting the flow in an alternate range, flow unit or reference temperature.

The records are referred to by their number label from #0 – #7.

The first six records will, by default, be setup for most common six gases as

shown in Figure 2-11. If a gas other than one of these six is specified on the

customer order it will be placed in record #6. If a second different gas is

selected, it will be placed in record #7. If multiple different gases or ranges are

specified they will replace some of the standard six gases.

Figure 2-11 Gas record table

The purchased calibration certificate is provided for the gas (or

gases) specified by the customer when ordering. This gas will be

indicated with an “X” on the Gas Label (diagram below) that is

located on the top of the 400 Series Mass flow meter’s electronics

enclosure. The remaining gas records will have a different full scale

value and an unverified calibration. The full scale range

can be calculated by using the Gas conversion factor or

GCF. A comprehensive list is found in Appendix 2 in

this manual.

Record# Gas

0 Nitrogen

1 Air

2 Helium

X

0

N

2

1

Air

2

He

3

H

2

4

5

6

7

S/N

Ar

(others use GCF)

O

2

X= cal report

generated

3 Hydrogen

4 Argon

5 Oxygen

6 Custom

7 Custom

Record# Gas

0 Nitrogen

1 Air

2 Helium

3 Hydrogen

4 Argon

5 Oxygen

6 Custom

7 Custom

Full Scale

Range

100 slm

100.15 slm

140 slm

100.38 slm

140.37 slm

97.95 slm

Not included if

not specified

Not included if

not specified

Example 1

To convert the calibration of a full scale range of 100 slm of Nitrogen to the other full scale ranges:

GCF

GCF

2

1

FSFS =

12

1. Calculate full scale value of Helium

Calibrated gas = Nitrogen (GCF

Full scale range (FS

Secondary gas (FS

) = 100 slm

1

) = Helium (GCF2 = 1.40)

2

= 1.000)

1

1.40/1 = 1.40, 1.40 x 100 = 140 slm of Helium

2. Calculate full scale value of Hydrogen

Calibrated gas = Nitrogen (GCF

Full scale range (FS

Secondary gas (FS

) = 100 slm

1

) = Hydrogen (GCF2 = 1.0038)

2

= 1.000)

1

1.0038/1 = 1.0038, 1.0038 x 100 = 100.38 slm of Hydrogen

401-405 SERIES

- 12 -

Page 21

Example 2- Changing the active gas record

Selecting the active gas record is accomplished in one of two ways:

1. Hardware setting

2. Software setting

Hardware:

The hardware setting is selected by accessing a rotary encoder on the upper PC board in the electronics

enclosure. When set to a number position from 0 to 7 it activates the corresponding gas record. If a

number greater than 7 is selected, then gas record control is passed to software.

Software:

See Section 3.9 Multi-Gas Calibrations and the software manual for more information about the

software control capabilities.

The software setting will override the hardware settings. If gas records are changed through the

software setting and the rotary encoder is not changed, the software setting will be active. However,

when the meter is powered down and subsequently powered up, the active setting will be based on the

rotary encoder setting.

2.10. Electrical Remote Zero Connection

The Hastings 400 Series allows the flow meter zeroing operation to be activated remotely using pins 8

and 9 of the analog terminal strip. (See Drawing in Quick Start Guide.) If these pins are connected

together, the meter initiates an internal routine that measures the current reading, stores it in

nonvolatile memory as a zero offset, and removes this value from all subsequent readings. When the pin

9 is electrically isolated the flow meter operates normally. The typical implementation of this type of

remote zeroing operation involves connecting a remote switch or relay to pins 8 and 9 of the terminal

strip. (For more about the zeroing operation, see Section 3.4)

2.11. Check Installation Prior to Operation

Before applying gas to the meter it is advisable to ensure that the mechanical and electrical connections

and digital communications (if applicable) are established and operating properly. This can be done by

following the guideline procedure below:

401-405 SERIES - 13 -

Page 22

401-405 SERIES

- 14 -

Page 23

3. Operation

3. Operation

The Hastings 400 Series flow meters are designed for operation with clean dry gas and in specified

environmental conditions (See Section 1.2). The properly installed meter measures and reports the

mass flow as an analog signal and, depending on the configuration and set up, as a digital response.

Other features can assist in the measurement operation and provide additional functions. The following

sections serves as a guide for correctly interpreting the analog and digital flow output, optimizing the

performance, and using the additional features of the instrument.

3.1. Environmental and Gas Conditions

For proper operation, the ambient and gas temperatures must be such that the flow meter remains

between -20 and 70°C. Optimal performance is achieved when the environment and gas temperatures

are equilibrated and stable. The 400 I series is intended for use with clean, non-condensing gases only.

Particles, contamination, condensate, or any other liquids which enter the flow meter body may

obstruct critical flow paths in the sensor or shunt, thus causing erroneous readings.

3.2. Interpreting the Analog Output

The analog output signal is proportional to mass flow rate. Each instrument is configured to provide

one of the available forms of analog output as described in Section 2.2. The signal read by an indicator

(for example, a process ammeter, data acquisition system, or PLC board) can be mapped to the

measured flow rate by applying the proper conversion equation selected from the table below.

Table 3-1 The Signal → Flow mapping equations

Analog Output Configuration Mapping Equation

4 -20 mA Flow = FS flow * (I

0 -20 mA Flow = FS flow * I

0 – 5 Vdc Flow = FS flow * V

0 – 10 Vdc Flow = FS flow * V

1 – 5 Vdc Flow = FS flow * (V

Alternatively an analog display meter can indicate the flow rate directly in the desired flow units by

setting the offset and scaling factors properly.

The flow meter is typically able to measure and report flow which slightly exceeds the full scale value.

Reverse or “negative” flows are indicated (to values up to 25% of full scale) by meters with 4-20 mA or

1-5 volt output. However, meters with 0-5 Volt, 0-10 volt or 0-20 mA output are limited in their ability

to indicate a negative flow with the analog signal since negative currents or voltages cannot be generated

by the meter’s circuitry.

– 4)/ 16

out

/ 20

out

/ 5

out

/ 10

out

-1)/ 4

out

3.3. Digital Communications

Many of the Hastings 400 Series flow meter’s operating parameters such as the flow measurement,

alarm settings, status, or gas type can be read or changed by digital communications. The digital

communications commands and protocols for each particular interface (RS-232, RS-485, and Ethernet)

are treated in detail in the Software Manual. However, the function and interpretation of flow output

and auxiliary input are also briefly presented here.

401-405 SERIES - 15 -

Page 24

3.3.1. Digitally Reported Flow Output

The flow rate can be read digitally by sending an ascii “F” command (preceded by the address for RS-

485). The instrument will respond with an ascii representation of the numerical value of the flow rate in

the units of flow specified on the nameplate label.

Example: A meter with RS-232 communications, calibrated for 500 slm FS N

2

Computer transmits: {F}

HFM flow meter replies: {137.5}

This is interpreted as 137.5 slm of nitrogen equivalent flow.

In most situations, the flow meter can measure beyond its range (i.e. a flow that exceeds the full scale or

a reverse flow) and report the value via the digital output. While the meter can perform beyond its

stated range, the accuracy of these values has not been verified during the calibration process. Flows

that exceed 160% of the nominal shunt range (S46 response) should not be relied upon. See the

software manual for further information.

3.3.2. Digitally Reported Analog Input

The flow meter can read the analog value present on pins 5 & 6 of the terminal strip (See Section 2.9).

This function is typically used to read the analog output from a nearby sensor such as a pressure sensor

or vacuum gauge. This value is spanned for the same range as the analog output signal; it reads volts for

flow meter configured for 0-5, 0-10 or 1-5 volt output and milliamps for a flow meter configured for 020 or 4-20 milliamp output. The value is accessed via the “S26” software query as shown below.

Example: A meter calibrated for 0-5 volt output and RS-232 communications.

Computer transmits: {S26}

HFM flow meter replies: {2.532}

This is interpreted as 2.532 volts.

3.4. Zeroing the Instrument

A proper zeroing of the flow meter is recommended after initial installation and warm-up. It is also

advisable to check the zero flow indication periodically during operation. Any uncertainty at zero flow is

an offset value which affects all subsequent flow readings. The frequency of these routine checks

depends on factors such as: the environmental conditions, the desired level of accuracy, and the desire

to measure low flow rates (relative to the meter full scale). To achieve the most precise flow readings,

the zeroing procedure is done while the meter is at the expected operating conditions including

temperature, line pressure, and gas type. This is especially true for cases where the flow meter is

operating at high pressure or with very dense gas.

3.4.1. Preparing for a Zero Check

Before checking or adjusting the meter’s zero, the following three requirements must be satisfied:

Warm-up – The instrument must be powered and in the operating environment for at least 30

minutes. Even though the meter will operate within a few minutes after power is applied, the entire

warm-up period is needed to establish a suitable zero reading.

No Flow – There must be an independent method to ensure that all flow through the instrument has

completely ceased before checking or adjusting the zero. Typically this is achieved by closing valve

downstream from the flow meter and waiting a sufficient time for any transient flow to decay. This is

especially critical for low flow units that have long piping lengths before or after the flow meter. In such

situations, it can require a significant settling time for the flow cease and enable a precise zero.

Stability – The flow meter must stabilize for at least 3 minutes at zero flow, especially following a high

flow or overflow condition. This will allow all parts of the sensor to come to thermal equilibrium

resulting in the best possible zero value.

401-405 SERIES

- 16 -

Page 25

3.4.2. Adjusting Zero

The pre-conditions required for a zero check must also be followed when making a zero adjustment.

The zero adjustment is a digitally controlled “reset” type operation. When commanded, the meter

initiates an internal routine that performs the following sequence: measure the current flow reading,

store it in nonvolatile memory as a zero offset, and remove this value from all subsequent readings.

If the instrument is inadvertently or improperly zeroed, for

example while flow is passing through the instrument, the flow

reading is subtracted from all future flow readings. This will

NOTE

This offset value can be accessed via the “S40” software query. The reported value is relative to an

internal, un-spanned sensor voltage. As an interpretation guideline, an offset that exceeds 0.15 volts

typically indicates that a faulty zero value is present.

There are three different methods to activate the zero reset function--manually, digitally, and

electrically.

Manually – With the electronics enclosure cover plate removed, a pushbutton switch on the upper

board is pressed.

CAUTION

produce large flow indication errors.

Accessing the manual zero pushbutton requires removing the

enclosure front plate. Care must be taken when reinstalling this

plate to ensure that the sealing gasket is properly positioned and

the fasteners are secure to maintain an IP65 compliant seal.

Digitally – A “ZRO” (“*[address]ZRO” for RS485) command is received properly by the flow meter’s

main processor.

Electrically – An external contact closure generates continuity between pins 8 and 9 of the terminal

strip.

3.4.2.3.5. Over-range

The thermal mass flow sensor heats a portion of the gas in order to measure the flow rate. As the flow

increases the heated tube is cooled and the slope of the sensor output versus the flow rate decreases.

The sensor linearization function corrects for this effect while the flow rate is within the normal

operating region. If the flow exceeds the normal operating region the digital flow indication will

continue to track this increase with a reduced accuracy. The analog flow will also indicate this overflow

condition until the circuitry reaches its limits (approximately 10 -25% over-range).

As the flow continues to increase above the normal operating region the sensor will be cooled

sufficiently that the output of the sensor will reach a peak value around 2 – 4 times the full scale flow

rate. If the flow continues to increase the sensor output will begin decreasing and the digital flow will

indicate a decreasing flow rate even though the flow is actually getting increasing. At approximately 3 –

7 times the full scale flow rate the sensor output will drop within range of the normal output and even

the analog output will record an on-scale flow rate when there is a very large over range flow rate.

401-405 SERIES - 17 -

Page 26

250%

)

200%

150%

100%

Indicated Flow (% Full Scale

Flow meter Output

Analog Out put

50%

0%

0% 100% 200% 300% 400% 500% 600%

Flow (% Full Scale)

Digital Output

3.4.2.3.6. Reverse Flow

If the flow through the flow

meter reverses and flow

begins to enter the exit of the

flow meter and leave through

the entrance of the flow meter

the flow meter will measure

this flow and report it digitally

with reduced accuracy. The

analog output will also

indicate this by either

generating a negative output

voltage or decreases the

current output below 4 mA,

depending on whether a

voltage or current output has

been selected.

3.7. High Pressure

Operation

When operating at high

pressure, the meter’s

performance can be affected

in two distinct and separate

ways—a zero shift and a span

(calibration) shift.

401-405 SERIES

- 18 -

8

7

6

5

4

3

2

Span Shift (% Reading)

1

0

-1

0 200 400 600 800 1000

Figure 3-1 The pressure effect on flow calibration (for nitrogen)

Pressure Ef f ect

Line Pressure (psig)

Page 27

3.7.1. Zero Shift

The zero offset can occur as the result of natural convection flow through the sensor tube if the

instrument is not mounted in a level orientation with flow horizontal. This natural convection effect

causes a zero shift proportional to the system pressure. The overall effect is more pronounced for gases

with higher density. Normally the shift is within the allowable zero offset range and can be removed by

activating the zero reset at the operating pressure.

3.7.2. Span Shift

The gas properties which form the basis for the flow measurement, such as viscosity and specific heat,

exhibit a slight dependence on the gas pressure. Fortunately, this pressure dependence is predictable

and can be corrected for in cases where it has an impact on accuracy (typically only significant for

pressures in excess of 100 psig). The graph shown in Figure 3-1 shows the expected span shift as a

function of pressure for nitrogen. This behavior is similar for most diatomic gases (O

this effect is insignificant for the monatomic gases (He, Ar, etc). This span shift must be considered and

accounted for as appropriate for accurate flow measurements at high pressure conditions.

, H2, etc), whereas

2

3.8. Warnings/Alarms

There are two alarm contacts on the terminal strip connector within the electronics enclosure (See

Section 2.8). These function as isolated semiconductor switches sharing a single, isolated common line.

In its normal state each switch is “open”; when an alarm is activated the switch is “closed”.

The meter’s processor can be configured via the digital interface to establish the internal condition for

activating each alarm. There are many choices for internal alarms and warnings including overflow,

underflow, or various instrument error conditions. Each alarm can also be given a selectable “wait

time”—a period for which it must remain in the alarm condition before the physical alarm is activated.

See the Software Manual for detailed alarm setting and configuration information.

3.9. Multi-gas Calibrations

The Hastings 400 Series flow meters can have up to eight different calibrations stored internally. These

are referred to as gas records. These records are typically used to represent different gases, but they can

also be useful in other ways; for instance reporting the flow in an alternate range, flow unit or reference

temperature. The records are referred to by their number label from #0 – #7. The first six records are,

by default, setup for the same range in the most common six gases as shown in Figure 2-11. If a gas

other than one of these six is specified on the customer order it will be placed in record #6. If a second

different gas is selected, it will be placed in record #7. If multiple different gases or ranges are specified

they will replace some of the standard six gases. Only the gas(es) specified on the order will be verified.

The other records will use nominal gas factors to approximate the gas sensitivity until an actual

calibration is performed to correct for individual instrument variations. Selecting the active gas record

can be done in one of two ways—a hardware setting or a software setting. The hardware setting is done

by accessing a rotary encoder on the upper PC board in the electronics enclosure. When set to a

number position from 0 to 7 it activates the corresponding gas record. When set to a number greater

than 7, the gas record control is passed to software. If the software setting mode is enabled, then the

“S6” digital command can be used to set the active gas record as shown in the example below.

Example: To first determine and then change the active gas record using RS-232,

Computer transmits: {S6}

HFM flow meter replies: {0}

This indicates that gas record #0 is currently active.

Computer transmits: {S6=4}

This changes the active gas record to #4.

See the Software Manual for further information including how to setup a new gas record and how to

reconfigure an existing gas record.

401-405 SERIES - 19 -

Page 28

CAUTION

NOTE

Accessing the rotary encoder requires removing the enclosure

front plate. Care must be taken when reinstalling this plate to

ensure that the sealing gasket is properly positioned and the

fasteners are secure to maintain an IP65 compliant seal.

The software command to change the active gas record will not

be executed unless the rotary encoder is set to a number greater

than 7. However, the software query will return the current active

gas record number even when it has been set by the hardware.

3.10. Flow Totalization

The Hastings 400 Series flow meters are capable of providing a value for the “total amount of gas” that

has passed through the flow meter since the last time the totalization function was reset. This value can

be used to determine for example, the amount of gas used to fill a chamber or drawn from a supply

vessel. To initialize the totalization function, reset the totalized flow value to zero using the S36 digital

command as shown in the example below. All subsequent flow readings are added over time and stored

as the totalized flow value. The totalized flow value can be read by querying the flow meter digitally as

in the example below. The totalized flow is reported in the flow units chosen for the active gas without

the time unit. For example, if the flow units are standard liters per minute, the totalized flow is reported

in standard liters; if flow units are standard cubic feet per hour, the totalized flow is reported in standard

cubic feet.

Example: For a 100 slm FS flow meter, to first reset/start the flow totalization function and then later read the

value using RS-232,

Computer transmits: {S36=0}

This resets the totalized value to zero and starts the totalization function. At some point later in time:

Computer transmits: {S36}

HFM flow meter replies: {45.7}

This is interpreted as a total gas amount of 45.7 standard liters has passed through the meter since the flow

totalizer was started.

3.11. Additional Digital Capabilities

The Hastings 400 series flow meters have a wide selection of other functions, operating parameters, and

values that can be reported and configured via digital communications such as the calibration date, the

instrument temperature, the number of hours that gas has been flowing, etc. See the Software Manual

for detailed information on these additional digital features.

401-405 SERIES

- 20 -

Page 29

4. Parts and Accessories

4. Parts & accessories

These are parts and accessories that are available by separate order from Teledyne Hastings Instruments.

4.1. Power Pod – Power & Display units

THPS-100 Singel Channel Power Supply

The Teledyne Hastings Instruments microprocessor based Power

Mass Flow Power Supply is a self-contained power supply and display for gas thermal

mass flow meters, pressure transducers or any device with a voltage output. The unit

features an automatically generated set point (0-5V or 0-10V), making it ideal for use

with thermal mass flow controllers and pressure controllers. Features include

4.5display, ±15 volt, 250mA transducer supply and an integrated +/- 15vdc @ 250ma

power supply is available providing a well regulated, short circuit and thermal overload

protected output, and CE compliance.

See the Teledyne Hastings Instruments Product Bulletin for the complete specification

on this product.

THPS-400 Four Channel Power Supply

The Teledyne Hastings Instruments Digital 4-Channel Power

rack profile for simple drop-in replacement of the existing Model 200 and 400 units,

or be used as a bench top unit.

The Power

fluorescent display (VFD). The display emulates a liquid crystal display in its

command structure but the VFD gives the unit a greater viewing angle than available

with most conventional LED or LCD displays.

The Power

count-up or count-down option; user selected filtering of readings; serial or Ethernet

communications.

The unit also offers a simultaneous display of all four channels or selective blanking of

unused channels, ratio control with analog outputs for stacking multiple power

supplies, and easy to follow menu driven calibration and setup.

The digital design of the Power

maximum display values corresponding to specific voltage or current inputs. One

advantage of this approach is that it negates the need to access hard to reach

transducers to re-zero them. Should the analog signal from the transducer change due

to a zero shift, the digital counts seen by the Power

either manually from the front panel or via serial communication with the unit.

Pod

-400 is equipped with a four line by twenty-character, vacuum

Pod

incorporates many features including an integrated totalizer with a

Pod

allows the user to set both the minimum and

Pod

can be changed to display zero

Pod

-100 Thermal

Pod

is featured in a half-

401-405 SERIES - 21 -

Page 30

4.1. Fittings

Fittings Hastings#

HFM-I-401

1/2" Swagelok Fittings 41-03-086

1/2" VCO Fittings 41-03-119

1/2" VCR Fittings 41-03-090

3/4" Swagelok Fitting 41-03-152

10 mm Swagelok 41-03-153

3/8" Male NPT 41-03-154

1/2" Male NPT 41-03-155

12 mm Swagelok 41-03-160

3/4-16 SAE/MS Straight Female (no fitting) N/A

HFM-I-405

1" Swagelok fitting 41-03-142

3/4" Swagelok 41-03-149

1" VCO Fitting 41-03-147

1" VCR fitting 41-03-148

1" Male NPT 41-03-150

3/4" Male NPT 41-03-151

1 5/16-12 Female SAE/MS straight thread (no fitting) N/A

4.2. Cables

Hastings

Description

Remote Electronics Cables

2 meter cable remote mounting cable CB-8P-M12-2MRA

5 meter remote mounting cable CB-8P-M12-5MRA

10 meter remote mounting cable CB-8P-M12-10MRA

401 Local Bracket - mount direct to sensor 14-03-002

405 Local Bracket - mount direct to sensor 14-03-001

Digital Communications

9 pin RS232 to 400 series M12 connector CB-RS232-M12

Digital M12 connector to M12 connector CB-ETHERNET-M12

USB to 9 pin RS232 connector CB-USB-RS232

RJ45 Ethernet to M12 Ethernet connector CB-RJ45-M12

Analog I/O

8 foot D connector to 8 bare leads

25 foot D connector to 8 bare leads

100 foot D connector to 8 bare leads

Stock#

CB-D15-Lead-8

CB-D15-Lead-25

CB-D15-Lead-100

401-405 SERIES

- 22 -

Page 31

5. WA R RAN T Y

5. Warranty

5.1. Warranty Repair Policy

Hastings Instruments warrants this product for a period of one year from the date of shipment to be free

from defects in material and workmanship. This warranty does not apply to defects or failures resulting

from unauthorized modification, misuse or mishandling of the product. This warranty does not apply to

batteries or other expendable parts, nor to damage caused by leaking batteries or any similar occurrence.

This warranty does not apply to any instrument which has had a tamper seal removed or broken.

This warranty is in lieu of all other warranties, expressed or implied, including any implied warranty as

to fitness for a particular use. Hastings Instruments shall not be liable for any indirect or consequential

damages.

Hastings Instruments, will, at its option, repair, replace or refund the selling price of the product if

Hastings Instruments determines, in good faith, that it is defective in materials or workmanship during

the warranty period. Defective instruments should be returned to Hastings Instruments, shipment

prepaid, together with a written statement of the problem and a Return Material Authorization (RMA)

number.

Please consult the factory for your RMA number before returning any product for repair. Collect freight

will not be accepted.

5.2. Non-Warranty Repair Policy

Any product returned for a non-warranty repair must be accompanied by a purchase order, RMA form

and a written description of the problem with the instrument. If the repair cost is higher, you will be

contacted for authorization before we proceed with any repairs. If you then choose not to have the

product repaired, a minimum will be charged to cover the processing and inspection. Please consult the

factory for your RMA number before returning any product repair.

TELEDYNE HASTINGS INSTRUMENTS

804 NEWCOMBE AVENUE

HAMPTON, VIRGINIA 23669 U.S.A.

ATTENTION: REPAIR DEPARTMENT

TELEPHONE (757) 723-6531

1-800-950-2468

FAX (757) 723-3925

E MAIL hastings_instruments@teledyne.com

INTERNET ADDRESS http://www.hastings-inst.com

Repair Forms may be obtained from the “Information Request” section of the

Hastings Instruments web site.

401-405 SERIES - 23 -

Page 32

6. Appendices

6. Appendices

6.1. Appendix 1- Volumetric versus Mass Flow

Mass flow measures just what it says, the mass or weight of the gas flowing through the instrument.

Mass flow (or weight per unit time) units are given in pounds per hour (lb/hour), kilograms per sec

(kg/sec) etc. When your specifications state units of flow to be in mass units, there is no reason to

reference a temperature or pressure. Mass does not change based on temperature or pressure.

However, if you need to see your results of gas flow in volumetric units, like liters per minute, cubic feet

per hour, etc. you must consider the fact that volume DOES change with temperature and pressure.

A mass flow meter measures MASS (grams) and then converts mass to volume. To do this the density

(grams/liter) of the gas must be known and this value changes with temperature and pressure.

When you heat a gas, the molecules have more energy and they move around faster, so when they

bounce off each other, they become more spread out, therefore the volume is different for the same

number of molecules.

Think about this:

The density of Air at 0° C is 1.29 g/liter

The density of Air at 25C is 1.19 g/liter

The difference is 0.1 g/liter. If you are measuring flows of 100 liters per minute, and you don’t use the

correct density factor then you will have an error of 10 g/minute!

Volume also changes with pressure. Think about a helium balloon with a volume of 1 liter. If you

could scuba dive with this balloon and the pressure on it increases. What do you think happens to the

weight of the helium? It stays the same. What would happen to the volume (1 liter)? It would shrink.

Why is the word standard included with the volume terms liters and cubic feet in mass flow

applications?

A mass flow meter measures mass …and we know we can convert to volume.

To use density we must pick one (or standard) temperature and pressure to use in our calculation.

When this calculation is done, the units are called standard liters per minute (SLM) or standard cubic

feet per minute (SCFM), etc because it is referenced to a standard temperature and pressure when the

volume is calculated.

1 Liter

0° C

0..179 grams/1

liter

401-405 SERIES

Using the example to the left, we can see a

standard liter can be defined differently. The

first balloon contains 0.179 grams of Helium at

0 ° C and 760 Torr (density of 0.179

grams/liter). Heat up that balloon to room

temperature and the volume increases, but the

mass has not changed – but the volume is not 1

liter anymore, it is 1.08 liters.

So to define a standard liter of Helium at 25 C,

we must extract only one liter from the second

balloon and that liter weighs only 0.175 grams.

If a mass flow meter is set up for STP at 0 C and

1.08 Liter 1 Liter

25 C

0.179 g/1.08

liters

- 24 -

25° C

0.164 grams

760 Torr, when it measures 0.179 grams of He,

it will give you results of 1 SLM.

If a second meter is set up for STP at 25 C and

760 Torr, when it measures 0.164 grams, it will

give results of 1 SLM.

Page 33

6.2. Appendix 2 - Gas Conversion Factors

The gas correction factors (GCF’s) presented in this manual were obtained by one of four methods.

The following table summarizes the different methods for determining GCF’s and will help identify for

which gases the highest degree of accuracy may be achieved when applying a correction factor.

1. Empirically determined

2. Calculated from virial coefficients of other investigator’s empirical data

3. From NIST tables

4. Calculated from specific heat data at 0° C at 1 atmosphere

The most accurate method is by direct measurement. Gases that are easily handled with safety such as

inert gases, gases common in the atmosphere or gases that are otherwise innocuous can be run through

a standard flow meter and the GCF determined empirically.

Many gases that have been investigated sufficiently by other researchers, can have their molar specific

heat (C’ p) calculated. The gas correction factor is then calculated using the following ratio:

GCF = C ’apN2

C’apGasX

GCF’s calculated in this manner have been found to agree with the empirically determined GCF’s

within a few tenths of a percent.

The National Institute of Standards[LH1] and Technology (NIST) maintains tables of thermodynamic