Teledyne HFC-302, HFM-300 User Manual

TELEDYNE

HASTINGS

INSTRUMENTS

INSTRUCTION MANUAL

HFM-300 FLOW METER,

HFC-302 FLOW CONTROLLER

ISO 9001

CERTIFIED

Manual Print History

The print history shown below lists the printing dates of all revisions and addenda created for this

manual. The revision level letter increases alphabetically as the manual undergoes subsequent

updates. Addenda, which are released between revisions, contain important change information that

the user should incorporate immediately into the manual. Addenda are numbered sequentially. When a

new revision is created, all addenda associated with the previous revision of the manual are

incorporated into the new revision of the manual. Each new revision includes a revised copy of this

print history page.

Revision C (Document Number 151-032000) .................................................................March 2000

Revision D (Document Number 151-072000) .....................................................................July 2000

Revision E (Document Number 151-092002)............................................................September 2002

Revision F (Document Number 151-082005)................................................................. August 2005

Revision G (Document Number 151-032007) .................................................................March 2007

Revision H (Document Number 151-062008) .................................................................... June 2008

Revision J (Document Number 151-092008).............................................................September 2008

Revision K (Document Number 151-082009) ................................................................ August 2009

Revision L (Document Number 151-102009)............................................................... October 2009

Revision M (Document Number 151-082010)................................................................ August 2010

Visit www.teledyne-hi.com for WEEE disposal guidance.

CAUTION:

CAUTION:

CAUTION:

The instruments des cribed in this manual are available with multiple pin-outs.

Ensure that all electrical connections are correct.

The instruments des cribed in this manual are des igned for INDOOR use only.

The instruments described in this manual are designed for Class 2 installations

in accordance with IAW/IPC standards

Hastings Instruments reserves the right to change or modify the design of its equipment without

any obligation to provide notification of change or intent to change.

Manual: 151-082010 300-302 Series Page 2 of 31

Table of Contents

1. GENERAL INFORMATION............................................................................................................................................ 4

1.1. FEATURES.................................................................................................................................................................... 4

1.2. SPECIFICATIONS...........................................................................................................................................................5

1.3. OPTIONAL 4-20 MA CURRENT OUTPUT............................................................................................................................ 5

1.4. OTHER ACCESSORIES ......................................................................................................................................................6

1.4.1. Hastings Power supplies........................................................................................................................................6

1.4.2. Interconnecting Cables...........................................................................................................................................6

2. INSTALLATION AND OPERATION............................................................................................................................. 7

2.1. RECEIVING INSPECTION ............................................................................................................................................... 7

2.2. POWER REQUIREMENTS ............................................................................................................................................... 7

2.3. OUTPUT SIGNAL...........................................................................................................................................................7

2.4. MECHANICAL CONNECTIONS....................................................................................................................................... 8

2.4.1. Filtering..................................................................................................................................................................8

2.4.2. Mounting ................................................................................................................................................................ 8

2.4.3. Plumbing ................................................................................................................................................................ 8

2.5. ELECTRICAL CONNECTIONS......................................................................................................................................... 8

2.6. OPERATION.................................................................................................................................................................. 9

2.6.1. Operating Conditions.............................................................................................................................................9

2.6.2. Zero Check........................................................................................................................................................... 10

2.6.3. High Pressure Operation ..................................................................................................................................... 10

2.6.4. Blending of Gases.................................................................................................................................................11

2.7. OUTPUT FILTER ......................................................................................................................................................... 12

2.8. CONTROLLING OTHER PROCESS VARIABLES ............................................................................................................. 12

2.9. COMMAND INPUT....................................................................................................................................................... 13

2.10. VALVE-OVERRIDE CONTROL..................................................................................................................................... 13

2.11. GAIN POTENTIOMETER .............................................................................................................................................. 13

2.12. TEMPERATURE COEFFICIENTS ...................................................................................................................................14

3. THEORY OF OPERATION...........................................................................................................................................15

3.1. OVERALL FUNCTIONAL DESCRIPTION........................................................................................................................ 15

3.2. SENSOR DESCRIPTION................................................................................................................................................ 15

3.3. SENSOR THEORY........................................................................................................................................................ 15

3.4. BASE..........................................................................................................................................................................17

3.5. SHUNT DESCRIPTION.................................................................................................................................................. 17

3.6. SHUNT THEORY ......................................................................................................................................................... 17

3.7. CONTROL VALVE.......................................................................................................................................................21

3.8. ELECTRONIC CIRCUITRY............................................................................................................................................21

4. MAINTENANCE..............................................................................................................................................................22

4.1. TROUBLESHOOTING ................................................................................................................................................... 22

4.2. ADJUSTMENTS ........................................................................................................................................................... 23

4.2.1. Calibration Procedure ......................................................................................................................................... 23

4.3. END CAP REMOVAL................................................................................................................................................... 23

4.4. PRINTED CIRCUIT BOARD REPLACEMENT.................................................................................................................. 24

4.5. SENSOR REPLACEMENT ............................................................................................................................................. 24

5. GAS CONVERSION FACTORS.................................................................................................................................... 25

6. VOLUMETRIC VS MASS FLOW.................................................................................................................................27

7. DRAWINGS AND REFERENCES ................................................................................................................................ 28

8. WARRANTY....................................................................................................................................................................31

8.1. WARRANTY REPAIR POLICY ...................................................................................................................................... 31

8.2. NON-WARRANTY REPAIR POLICY .............................................................................................................................31

Manual: 151-082010 300-302 Series Page 3 of 31

1. General Information

The Teledyne Hastings HFM-300 is used to measure mass flow rates in gases. In addition to flow rate

measurement, the HFC-302 includes a proportional valve to accurately control gas flow. The Hastings mass flow

meter (HFM-300) and controller (HFC-302), hereafter referred to as the Hastings 300 series, are intrinsically

linear and are designed to accurately measure and control mass flow over the range of 0-5 sccm to 0-10 slm

with an accuracy of better than ±0.75% F.S. at 3σ from the mean (versions >10 slm are ±1.0% F.S.) . Hastings

mass flow instruments do not require any periodic maintenance under normal operating conditions with clean

gases. No damage will occur from the use of moderate overpressures (~500 psi/3.45MPa) or overflows.

Instruments are normally calibrated with the appropriate standard calibration gas (nitrogen) then a correction

factor is used to adjust the output for the intended gas. Calibrations for other gases, such as oxygen, helium and

argon, are available upon special order.

1.1. Features

• LINEAR BY DESIGN. The Hastings 300 series is intrinsically linear (no linearization circuitry is

employed). Should recalibration (a calibration standard is required) in the field be desired, the

customer needs to simply set the zero and span points. There will be no appreciable linearity change

of the instrument when the flowing gas is changed.

• NO FOLDOVER. The output signal is linear for very large over flows and is monotonically increasing

thereafter. The output signal will not come back on scale when flows an order of magnitude over the

full scale flow rate are measured. This means no false acceptable readings during leak testing.

• MODULAR SENSOR. The Hastings 300 series incorporates a removable/replaceable sensor module.

Field repairs to units can be achieved with a minimum of production line downtime.

• LARGE DIAMETER SENSOR TUBE. The Hastings 300 sensor is less likely to be clogged due to its large

internal diameter (0.026”/ 0.66mm). Clogging is the most common cause of failure in the industry.

• LOW ∆P. The Hastings 300 sensor requires a pressure of approximately 0.25 inches of water (62 Pa) at

a flow rate of 10 sccm. The low pressure drop across this instrument is ideal for leak detection

applications since the pneumatic settling times are proportional to the differential pressure.

• FAST SETTLING TIME. Changes in flow rate are detected in less than 250 milliseconds when using the

standard factory PC board settings.

• LOW TEMPERATURE DRIFT. The temperature coefficient of span for the Hastings 300 series is less

than 0.03% of full scale/°C from 15-50°C. The temperature coefficient of zero is less than 0.1 % of

reading/°C from 0-60°C.

• FIELD RANGEABLE. The Hastings 300 series is available in ranges from 0-5 sccm to 0-25 slpm. Each

flow meter has a shunt which can be quickly and easily exchanged in the field to select different

ranges. Calibration, however, is required.

• METAL SEALS. The Hastings 300 series is constructed of Stainless Steel. All internal seals are made

with Ni 200 gaskets, eliminating the permeation, degradation and outgassing problems of elastomer Orings.

• LOW SURFACE AREA. The shunt is designed to have minimal wetted surface area and no un-swept

volumes. This will minimize particle generation, trapping and retention. CURRENT LOOP. The 4-20

mA option gives the user the advantages of a current loop output to minimize environmental noise

pickup.

Manual: 151-082010 300-302 Series Page 4 of 31

1.2. Specifications

Accuracy .................................................................................... < ±0.75% full scale (F.S.) at 3σ

(±1.0% F.S. for >10 slm versions)

Repeatability .............................................................................±0.05% of reading + 0.02% F.S.

Maximum Pressure........................................................................................500 psi [3.45 MPa]

(With high pressure option) 1000 psi [6.9 MPa]

Pressure Coefficient .................................................. <0.01% of reading/psi [0.0015%/kPa] (N2)

See pressure section for higher pressure errors.

Operating Temperature ....................................................0-60°C in non-condensing environment

Temperature Coefficient (zero) .................................... Maximum ±0.1%F.S./°C (from 0 to 60°C)

Temperature Coefficient (span) ..................................Maximum ±300 ppm/°C (from 15 to 50 °C)

Maximum ±450 ppm/°C (from 0 to 60 °C)

Leak Integrity ...............................................................................................<1x10-9 std. cc/s.

Flow Ranges .................................................................. 0-5 sccm to 0-25* slpm. (N2 Equivalent)

Standard Output ........................................................................... 0-5 VDC. (load min 2k Ohms)

Optional Output ............................................................................ 4 -20 mA. (load < 600 Ohms)

Power Requirements..................................................................... ±(15) VDC @ 55 mA (meters)

± (15) VDC @ 150 mA (controller)

Class 2 power 150VA max

Wetted Materials ................................................................................ stainless steel, nickel 200

Attitude Sensitivity of zero ..............................................< ±0.7% F.S. for 90° without re-zeroing

{N2 at 19.7 psia (135 KPa)}

Weight ............................................................................................................ 1.93 lb [0.88 kg]

Electrical Connector............................................................................... 15 pin subminiature “D”

Fitting Options................... ¼” Swagelok®, 1/8” Swagelok®, VCR®, VCO®, 9/16”-18 Female thread

Face Seal to Face Seal Length................................................................ 1.88”(47.75 mm) VCR®

(Specifications may vary for instruments with ranges greater than 10 slpm)

1.3. Optional 4-20 mA Current Output

An option to the standard 0-5 VDC output is the 4-20 mA current output that is proportional to flow.

The 4 - 20 mA signal is produced from the 0 - 5 VDC output of the flow meter. The current loop output

is useful for remote applications where pickup noise could substantially affect the stability of the

voltage output.

The current loop signal replaces the voltage output on pin 6 of the “D” connector. The current loop

may be returned to either the signal common or the -15 VDC connection on the power supply. If the

current loop is returned to the signal common, the load must be between 0 and 600 ohm. If it is

returned to the -15VDC, the load must be between 600 and 1200 ohm. Failure to meet these

conditions will cause failure of the loop transmitter.

Manual: 151-082010 300-302 Series Page 5 of 31

The 4-20 mA I/O option can accept a current input. The 0-5 VDC command signal on pin 14 can be

replaced by a 4-20mA command signal. The loop presets an impedance of 75 ohms and is returned to

the power supply through the valve common.

1.4. Other Accessories

1.4.1. Hastings Power supplies

Hastings Power Pod power supply/display units are available in one and four channel versions. They

convert 100, 115 or 230VAC to the ±15 VDC required to operate the flow meter and provide a digital

indication of the flow rate. Interface terminals for the retransmission of the flow meter analog output

signal are located on the rear of the panel.

The Power Pod 100 and 400 models are built with controllers in mind but will work with meters as

well. The Model 40 is for flow meters only. Throughout this manual, when reference is made to a

power supply, it is assumed the customer is using a Hastings power supply. Hastings PowerPod-100 and

PowerPod-400 power supplies are CE marked, but the Model 40 does not meet CE standards at this

time. The Model 40 and PowerPod-100 are not compatible with 4–20 mA analog signals. With the

PowerPod 400, individual channels’ input signals, as well as their commands, become 4–20 mA

compatible when selected. The PowerPod-400 also sports a Totalizer feature. More information about

the Power Pods can be found on the Hastings web site. http://www.teledynehi.com/products/powerpod-series.htm

1.4.2. Interconnecting Cables

Cables are available from Hastings, in various lengths, to connect from the 15 pin "D" connector on the

back of the Power Pod directly to any of the 200 series and 300 series flow instruments (including

digital versions). More information about the available cables can be found in the Power Pod 400

bulletin on the Hastings web site. http://www.teledyne-hi.com/pdfs/bulletins.htm

Manual: 151-082010 300-302 Series Page 6 of 31

2. Installation and Operation

This section contains the steps necessary to assist in getting a new flow meter/controller into

operation as quickly and easily as possible. Please read the following thoroughly before attempting to

install the instrument.

2.1. Receiving Inspection

Carefully unpack the Hastings unit and any accessories that have also been ordered. Inspect for any

obvious signs of damage to the shipment. Immediately advise the carrier who delivered the shipment

if any damage is suspected. Check each component shipped with the packing list. Insure that all parts

are present (i.e., flow meter, power supply, cables, etc.). Optional equipment or accessories will be

listed separately on the packing list. There may also be one or more OPT-options on the packing list.

These normally refer to special ranges or special gas calibrations. They may also refer to special

helium leak tests, or high pressure tests. In most cases, these are not separate parts, rather, they are

special options or modifications built into the flow meter.

Quick Start

1. Insure flow circuit mechanical connections are leak free

2. Insure electrical connections are correct (see label).

3. Allow 30 min. to 1 hour for warm-up.

4. Note the flow signal decays toward zero.

5. Run ~20% flow through instrument for 5 minutes.

6. Insure zero flow; wait 2 minutes, then zero the instrument.

7. Instrument is ready for operation

2.2. Power Requirements

The HFM-300 meter requires +15 VDC @ 55 mA, -15 VDC @50 mA for proper operation. The HFC-302

controller requires ±15 VDC @ 150mA. The supply voltage should be sufficiently regulated to no more

than 50 mV ripple. The supply voltage can vary from 14.0 to 16.0 VDC. Surge suppressors are

recommended to prevent power spikes reaching the instrument. The Hastings power supply described

in Section 1.4.2 satisfies these power requirements.

2.3. Output Signal

The standard output of the flow meter is a 0-5 VDC signal proportional to the flow rate. In the

Hastings power supply the output is routed to the display, and is also available at the terminals on the

rear panel. If a Hastings supply is not used, the output is available on pin 6 of the “D” connector. It is

recommended that the load resistance be no less that 2kΩ. If the optional 4-20 mA output is used, the

load impedance must be selected in accordance with Section 1.3.

Manual: 151-082010 300-302 Series Page 7 of 31

2.4. Mechanical Connections

2.4.1. Filtering

The smallest of the internal passageways in the Hastings 300 is the diameter of the sensor tube, which

is 0.026”(0.66 mm), and the annular clearance for the 500 sccm shunt which is 0.006"(0.15 mm) (all

other flow ranges have larger passages), so the instrument requires adequate filtering of the gas supply

to prevent blockage or clogging of the tube.

2.4.2. Mounting

There are two mounting holes (#8-32 thread) in the bottom of the transducer that can be used to

secure it to a mounting bracket, if desired.

The flow meter may be mounted in any position as long as the direction of gas flow through the

instrument follows the arrow marked on the bottom of the flow meter case label. The preferred

orientation is with the inlet and outlet fittings in a horizontal plane.

As explained in the section on operating at high pressures, pressure can have a significant affect on

readings and accuracy. When considering mounting a flow meter in anything other than a horizontal

attitude, consideration must be given to the fact that the heater coil can now set up a circulating flow

through the sensor tube, thereby throwing the zero off. This condition worsens with denser gases or

with higher pressures. Whenever possible, install the instrument horizontally.

Always re-zero the instrument with zero flow, at its normal operating temperature and purged with its

intended gas at its normal operating pressure.

2.4.3. Plumbing

The standard inlet and outlet fittings for the Hastings 300 Series are VCR-4, VCO-4 or 1/4" Swagelok. It

is suggested that all connections be checked for leaks after installation. This can be done by

pressurizing the instrument (do not exceed 500 psig unless the flow meter is specifically rated for

higher pressures) and applying a diluted soap solution to the flow connections.

2.5. Electrical Connections

If a power supply from Hastings Instruments is used, installation consists of connecting the HFM300/302 series cable from the “D” connector on the rear of the power supply to the “D” connector on

the top of the flow meter /controller. The “H” pin-out requires cable AF-8-AM (grey molded

backshell). The “U” pin-out requires cable # 65-791 (black molded backshell).

If a different power supply is used, follow the instructions below when connecting the flow meter and

refer to either table 2.1 or 2.2 for the applicable pin-out. The power supply used must be bipolar and

capable of providing ±15 VDC at 55 mA for flow meter applications and ±15 VDC at 150 mA for

controllers. These voltages must be referenced to a common ground. One of the “common” pins must

be connected to the common terminal of the power supply. Case ground should be connected to the

AC ground locally. The cable shield (if available) should be connected to AC ground at the either the

power supply end, or the instrument end of the cable, not at both. Pin 6 is the output signal from the

flow meter. The standard output will be 0 to 5 VDC, where 5 VDC is 100% of the rated or full scale

flow.

The command (set point) input should be a 0-5 VDC signal (or 4-20mA if configured as such), and must

be free of spikes or other electrical noise, as these would generate false flow commands that the

controller would attempt to follow. The command signal should be referenced to signal common.

A valve override command is available to the flow controller. Connect the center pin of a single pole,

three-position switch (center off) to the override pin. Connect +15 VDC to one end of the three

position switch, and -15 VDC to the other end. The valve will be forced full open when +15 VDC is

supplied to the override pin, and full closed when -15 VDC is applied. When there is no connection to

the pin (the three-position switch is centered) the valve will be in auto control, and will obey the 0-5

VDC commands supplied to command (set-point) input.

Manual: 151-082010 300-302 Series Page 8 of 31

Fig. 2.1 Fig. 2.2

Figures 2.1/2.2, and Tables 2.1/2.2, show the 300/302 pin out.

Table 2.1

"U" Pin-Out

Pin # Pin #

1 Signal Common 1 Do not use

2 Do not use 2 Do not use

3 Do not use 3 Do not use

4 +15 VDC 4 Do not use

5 5 Signal Common

6 Output 0-5 VDC (4-20mA) 6 Output 0-5 VDC (4-20mA)

7 Signal Common 7 Case Ground

8 Case Ground 8 Valve Override

9 Valve Override 9 -15VDC

10 10 Do not use

11 -15VDC 11 +15VDC

12 External Input 12 Signal Common

13 Signal Common 13 External Input

14 Signal Common 14 Set Point 0-5 VDC (4-20mA)

15 Set Point 0-5 VDC (4-20mA) 15 Do not use

Table 2.2

"H" Pin-Out

2.6. Operation

The standard instrument output is a 0 - 5 VDC out and the signal is proportional to the flow i.e., 0

volts = zero flow and 5 volts = 100% of rated flow. The 4 - 20 mA option is also proportional to flow, 4

mA = zero flow and 20 mA = 100% of rated flow.

2.6.1. Operating Conditions

For proper operation, the combination of ambient temperature and gas temperature must be such that

the flow meter temperature remains between 0 and 60°C. (Most accurate measurement of flow will

be obtained if the flow meter is zeroed at operating temperature as temperature shifts result in some

zero offset.) The Hastings 300 series instrument is intended for use in non-condensing environments

only. Condensate or any other liquids which enter the flow meter may destroy its electronic

components.

Manual: 151-082010 300-302 Series Page 9 of 31

2.6.2. Zero Check

Turn the power supply on if not already energized. Allow for a 1 hour

warm-up. Stop all flow through the instrument and wait 2 minutes.

Caution: Do not assume that all metering valves completely shut off

the flow. Even a slight leakage will cause an indication on the meter

and an apparent zero shift. For the standard 0-5 VDC output, adjust

the zero potentiometer located on the inlet side of the flow meter

until the meter indicates zero (Fig 2.3). For the optional 4-20 mA

output, adjust the zero potentiometer so that the meter indicates

slightly more than 4 mA, i.e. 4.03 to 4.05 mA. This slight positive

adjustment ensures that the 4-20 mA current loop transmitter is not in

the cut-off region. The error induced by this adjustment is

approximately 0.3% of full scale. This zero should be checked

periodically during normal operation. Zero adjustment is required if

there is a change in ambient temperature, or vertical orientation of

Fig. 2.3

the flow meter /controller.

2.6.3. High Pressure Operation

When operating at high pressure, the increased density of gas will cause natural convection to flow

through the sensor tube if the instrument is not mounted in a level position. This natural convection

flow will be proportional to the system pressure. This will be seen as a shift in the zero flow output

that is directly proportional to the system pressure.

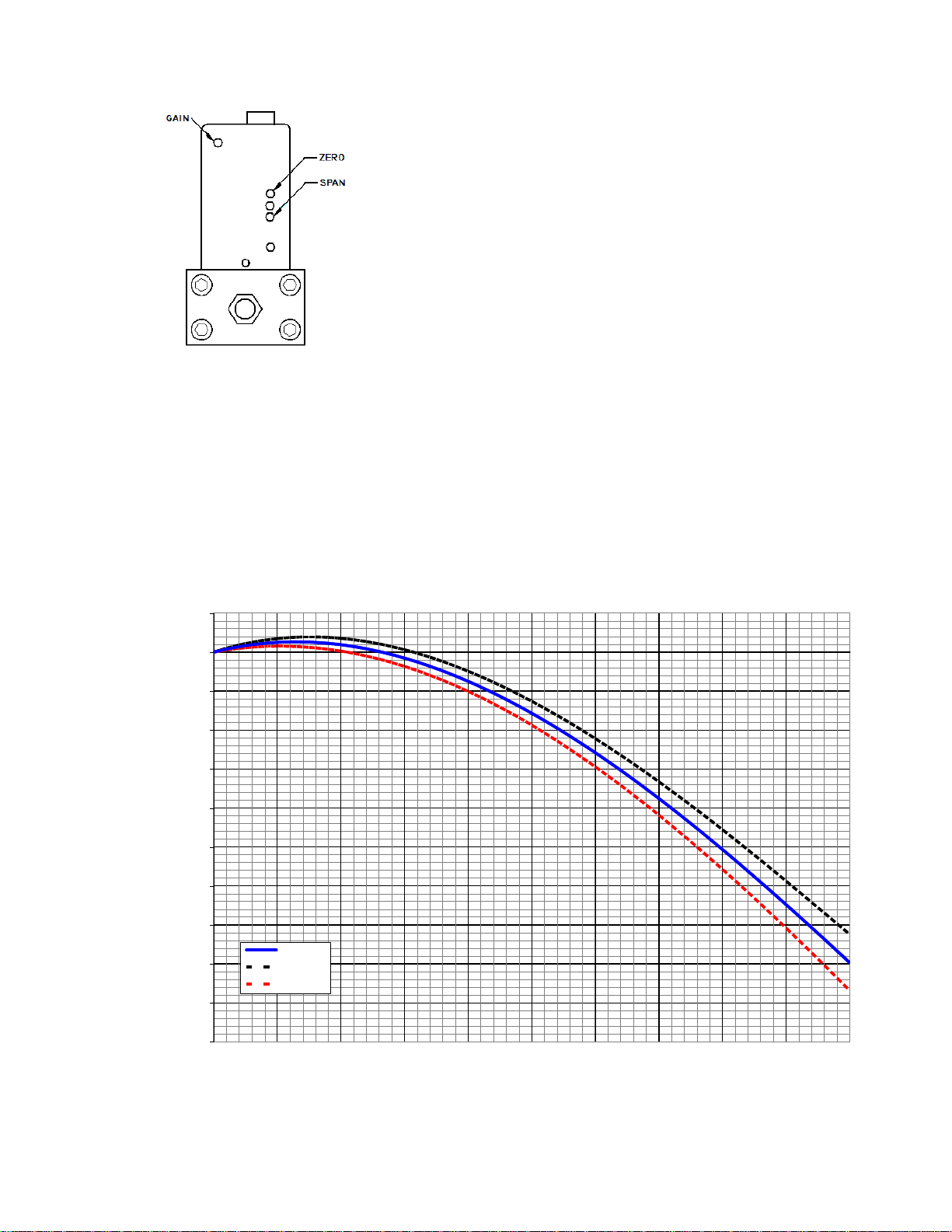

Fig. 2.4

2.0%

0.0%

-2.0%

-4.0%

-6.0%

-8.0%

-10.0%

-12.0%

Span Error (% reading)

-14.0%

-16.0%

-18.0%

Span Error vs Pressure

(0.026" Sensor Tube)

Mean error

max

min

-20.0%

0 100 200 300 400 500 600 700 800 900 1000

y = 9.8877E-11x33.4154E-07x - 28.3288E-05x +

Pressure(psig)

Manual: 151-082010 300-302 Series Page 10 of 31

Loading...

Loading...