Page 1

TELEDYNE

HASTINGS

INSTRUMENTS

INSTRUCTION MANUAL

HFM-301/305/306

FLOW METERS

HFC-303/307 FLOW

CONTROLLERS

ISO 9001

CERTIFIED

Page 2

Manual Print History

The print history shown below lists the printing dates of all revisions and addenda created for this

manual. The revision level letter increases alphabetically as the manual undergoes subsequent updates.

Addenda, which are released between revisions, contain important change information that the user

should incorporate immediately into the manual. Addenda are numbered sequentially. When a new

revision is created, all addenda associated with the previous revision of the manual are incorporated into

the new revision of the manual. Each new revision includes a revised copy of this print history page.

Revision F (Document Number 152-082002)................................................................. August 2002

Revision G (Document Number 152-102002) .............................................................. October 2002

Revision H (Document Number 152-082005) ................................................................ August 2005

Revision J (Document Number 152-042006)...................................................................March 2006

Revision K (Document Number 152-062008) ....................................................................June 2008

Revision L (Document Number 152-082008)................................................................. August 2008

Revision M (Document Number 152-082009)................................................................ August 2009

Revision N (Document Number 152-102009) .............................................................. October 2009

Revision P (Document Number 152-082010)................................................................. August 2010

Visit www.teledyne-hi.com for WEEE disposal guidance.

CAUTION:

CAUTION:

CAUTION:

The ins truments des cribed in this manual are av ailable with multiple pin- outs .

Ensure that all electrical connections are correct.

The ins truments described in this manual are designed for INDOO R us e only.

The instruments described in this manual are designed for Class 2 installations

in accordance with IAW/IPC standards

Hastings Instruments reserves the right to change or modify the design of its equipment without

any obligation to provide notification of change or intent to change.

Manual: 152-082010 301-305-306_303-307 Series Page 2 of 35

Page 3

Table of Contents

1. GENERAL INFORMATION............................................................................................................................................ 4

1.1. FEATURES.................................................................................................................................................................... 4

1.2. SPECIFICATIONS........................................................................................................................................................... 5

1.3. OPTIONAL 4-20 MA CURRENT OUTPUT .......................................................................................................................6

1.4. OTHER ACCESSORIES...................................................................................................................................................6

2. OPERATION...................................................................................................................................................................... 7

2.1. RECEIVING INSPECTION ............................................................................................................................................... 7

2.2. POWER REQUIREMENTS ...............................................................................................................................................7

2.3. OUTPUT SIGNAL...........................................................................................................................................................7

2.4. MECHANICAL CONNECTIONS....................................................................................................................................... 7

2.5. ELECTRICAL CONNECTIONS......................................................................................................................................... 8

2.6. 4 – 20 MA CONNECTIONS...........................................................................................................................................11

2.7. OPERATION................................................................................................................................................................ 12

2.8. RANGE CHANGING.....................................................................................................................................................16

2.9. OUTPUT FILTER ......................................................................................................................................................... 16

2.10. CONTROLLING OTHER PROCESS VARIABLES .............................................................................................................16

2.11. COMMAND INPUT.......................................................................................................................................................16

2.12. VALVE OVERRIDE CONTROL ..................................................................................................................................... 17

2.13. GAIN POTENTIOMETER .............................................................................................................................................. 17

2.14. TEMPERATURE COEFFICIENTS ................................................................................................................................... 18

3. THEORY AND FUNCTION........................................................................................................................................... 19

3.1. OVERALL FUNCTIONAL DESCRIPTION........................................................................................................................ 19

3.2. SENSOR DESCRIPTION................................................................................................................................................ 19

3.3. SENSOR THEORY........................................................................................................................................................ 19

3.4. BASE..........................................................................................................................................................................20

3.5. SHUNT DESCRIPTION..................................................................................................................................................21

3.6. SHUNT THEORY .........................................................................................................................................................21

3.7. CONTROL VALVE....................................................................................................................................................... 23

3.8. ELECTRONIC CIRCUITRY............................................................................................................................................ 24

3.9. INSTRUMENT PERFORMANCE .....................................................................................................................................24

4. MAINTENANCE..............................................................................................................................................................25

4.1. AUTHORIZED MAINTENANCE.....................................................................................................................................25

4.2. TROUBLESHOOTING ...................................................................................................................................................25

4.3. ADJUSTMENTS ........................................................................................................................................................... 26

4.4. END CAP REMOVAL................................................................................................................................................... 27

4.5. PRINTED CIRCUIT BOARD AND SENSOR REPLACEMENT............................................................................................. 28

5. OUTLINE DRAWINGS .................................................................................................................................................. 29

5.1. HFM-301...................................................................................................................................................................29

5.2. HFC-303 ................................................................................................................................................................... 29

5.3. HFM-305...................................................................................................................................................................30

5.4. HFM-306...................................................................................................................................................................30

5.5. HFC-307 ................................................................................................................................................................... 31

6. WARRANTY....................................................................................................................................................................32

6.1. WARRANTY REPAIR POLICY ......................................................................................................................................32

6.2. NON-WARRANTY REPAIR POLICY ............................................................................................................................. 32

7. APPENDIX ....................................................................................................................................................................... 33

7.1. APPENDIX 1- VOLUMETRIC VERSUS MASS FLOW.......................................................................................................33

7.2. APPENDIX 2 - GAS CONVERSION FACTORS ................................................................................................................ 34

Manual: 152-082010 301-305-306_303-307 Series Page 3 of 35

Page 4

1. General Information

The Hastings 300 Series high range mass flow meters are designed to accurately measure mass flow at a

range between 25 slm and 10000 slm. The Hastings 300 Series high range mass flow controllers are

designed to accurately measure and control mass flow at a range between 25 slm and 2500 slm. These

instruments are intrinsically linear and have an accuracy of better than ±1% F.S. (full scale).

Hastings mass flow instruments do not require any periodic maintenance under normal operating

conditions with clean gases. No damage will occur from the use of moderate overpressures (~500

psi/3.45MPa) or overflows. Instruments are normally calibrated with the appropriate standard calibration

gas (nitrogen) then a correction factor is used to adjust the output for the intended gas. Calibrations for

other gases, such as oxygen, helium and argon, are available upon special order.

1.1. Features

• LINEAR BY DESIGN. The HFM-301/305/306 and HFC-303/307 series is intrinsically linear (no

linearization circuitry is employed). Should recalibration (a calibration standard is required) in the

field be desired, the customer needs to simply set the zero and span points. There will be no

appreciable linearity change of the instrument when the flowing gas is changed.

• NO FOLD OVER. The output signal is linear for very large over flows and is monotonically increasing

thereafter. The output signal will not come back on scale when flows an order of magnitude over

the full scale flow rate are measured. This means no false acceptable readings during leak testing.

• MODULAR SENSOR. The HFM-301/305/306 and HFC-303/307 series incorporates a

removable/replaceable sensor module. Field repairs to units can be achieved with a minimum of

production line downtime. Calibration is required.

• FAST SETTLING TIME. Changes in flow rate are detected in less than 500 milli-seconds when using

the standard factory PC board settings. Controller response is typically < 2 seconds.

• LOW TEMPERATURE DRIFT. The temperature coefficient of span for the HFM-301/HFC-303 series is

less than 0.092% of full scale/°C from 0-60°C. The temperature coefficient of zero is less than 0.085

% of reading/°C from 0-60°C.

• FIELD RANGEABLE. The HFM-305 and HFC-307 are available in ranges from 1000 slm to 2500 slm.

The HFM-301 and HFC-303 are available from 25-1000 slm. Each flow meter has a shunt and

transducer which can be exchanged in the field to select different ranges. Calibration, however, is

required.

• CURRENT LOOP. The 4-20 mA option gives the user the advantages of a current loop output to

minimize environmental noise pickup.

Manual: 152-082010 301-305-306_303-307 Series Page 4 of 35

Page 5

1.2. Specifications

Accuracy..........................................................HFM-301/305 & HFC-303/307: ±1% full scale (F.S.)

...........................................................................................................HFM-306; ±3% full scale (F.S.)

Repeatability ................................................................................................................ ±0.07% of F.S.

Maximum pressure................................................................................................500 psi [3.45 MPa]

..............................................................................................................................300 psi (HFM-306)

Maximum pressure ................................................................................................1000 psi [6.9 MPa]

..................................................................... (with high pressure option on HFM-301/HFC303 only)

Pressure coefficient .................................................................................<0.026% of reading/psi (N2)

...............................................................................................See pressure section for pressure errors.

Operating temperature...........................................................0-60°C in non-condensing environment

Temperature coefficient (zero) .......................................................maximum ±0.085%/°C (0-60 0C)

Temperature coefficient (span) ................................................... maximum ±0.092%/°C (15-50 0C)

Leak integrity........................................................................................................... <1x10-9 std. cc/s.

Standard output................................................................................... 0-5 VDC (load min 2k Ohms)

Optional output ....................................................................................4 -20 mA. (load < 600 Ohms)

Power requirements ............................................................................±(15) VDC @ 55 mA (meters)

.....................................................................................................± (15) VDC @ 150 mA (controller)

................................................................................................................... Class 2 power 150VA max

Wetted materials ........................................................ 302/304 & 316 stainless steel, nickel 200, Viton

..................................................................................................................... Kalrez® (controller only)

Attitude sensitivity of zero .................................................. < ±0.25% F.S. for 90° without re-zeroing

..................................................................................................................{N2 at 19.7 psi (135 KPa)}

Attitude sensitivity of span...................................................................................< ±0.06% of reading

..................................................................................................................{N2 at 19.7 psi (135 KPa)}

Weight ...................................................................................................... HFM-301; 3.5 lbs. (1.6 kg)

................................................................................................................... HFC-303; 5.3 lbs. (2.4 kg)

.................................................................................................................. HFM-305; 8.0 lbs. (3.7 kg)

.............................................................................................................. HFM-306; 28.8 lbs. (13.2 kg)

............................................................................................................... HFC-307; 15.3 lbs. (6.94 kg)

Electrical connector ......................................................................................15 pin subminiature “D”

Fitting options..............................................HFM-301/HFC-303: 1/2” Swagelok®, 3/4” Swagelok®,

....................................................................................................................... 1/2”VCR®, 1/2”VCO®

................................................................... HFM-305/HFC-307: 1”Swagelok®, 1”VCR®, 1”VCO®

.......................................................... HFM-306: 1” Swagelok®, 1”VCR®, 1”VCO®, 2” Swagelok®

Manual: 152-082010 301-305-306_303-307 Series Page 5 of 35

Page 6

1.3. Optional 4-20 mA Current Output

An option to the standard 0 - 5 VDC output is the 4 - 20 mA current output that is proportional to flow.

The 4 - 20 mA signal is produced from the 0 - 5 VDC output of the flow meter. The current loop output is

useful for remote applications where pickup noise could substantially affect the stability of the voltage

output.

The current loop signal replaces the voltage output on pin 6 of the “D” connector. The load must be less

than 600Ω. Failure to meet this condition will cause failure of the loop transmitter.

1.4. Other Accessories

1.4.1. Hastings Power supplies

Hastings Power Pod power supply/display units are available in one and four channel versions. They

convert 100, 115 or 230VAC to the ±15 VDC required to operate the flow meter and provide a digital

indication of the flow rate. Interface terminals for the retransmission of the flow meter analog output

signal are located on the rear of the panel.

The Power Pod 100 and 400 models are built with controllers in mind but will work with meters as well.

The Model 40 is for flow meters only. Throughout this manual, when reference is made to a power

supply, it is assumed the customer is using a Hastings power supply. Hastings PowerPod-100 and

PowerPod-400 power supplies are CE marked, but the Model 40 does not meet CE standards at this time.

The Model 40 and PowerPod-100 are not compatible with 4–20 mA analog signals. With the PowerPod

400, individual channels’ input signals, as well as their commands, become 4–20 mA compatible when

selected. The PowerPod-400 also sports a Totalizer feature. More information about the Power Pods can

be found on the Hastings web site. http://www.teledyne-hi.com/products/powerpod-series.htm

1.4.2. Interconnecting Cables

Cables are available from Hastings, in various lengths, to connect from the 15 pin "D" connector on the

back of the Power Pod directly to any of the 200 series and 300 series flow instruments (including digital

versions). More information about the available cables can be found in the Power Pod 400 bulletin on

the Hastings web site. http://www.teledyne-hi.com/pdfs/bulletins.htm

The 300 series flow instruments normally come with the standard “H” pin-out connector. This type of

connector is supplied on the Hastings AF-8-AM series cables with grey backshells (such as #65-149). “U”

pin-out versions of the 300 series instruments require a different cable to connect to the power supply.

This cable is identifiable by black back-shells and is available as Hastings Instrument (#65-791)

Manual: 152-082010 301-305-306_303-307 Series Page 6 of 35

Page 7

2. Operation

This section contains the necessary steps to assist in getting a new flow meter/controller into operation

as quickly and easily as possible. Please read the following thoroughly before attempting to install the

instrument.

2.1. Receiving Inspection

Carefully unpack the Hastings 300 Series instrument and any accessories that have also been ordered.

Inspect for any obvious signs of damage to the shipment. Immediately advise the carrier who delivered

the shipment if any damage is suspected. Check each component shipped with the packing list. Insure

that all parts are present (i.e., flow meter, power supply, cables, etc.). Optional equipment or

accessories will be listed separately on the packing list. There may also be one or more OPT-options on

the packing list. These normally refer to special ranges or special gas calibrations. They may also refer

to special helium leak tests, or high pressure tests. In most cases, these are not separate parts, but

special options or modifications built into the flow meter.

1. Insure flow circuit mechanical connections are leak free.

2. Insure electrical connections are correct (See label).

3. Power up. (Allow 30 minutes to 1 hour warm-up for best accuracy.)

4. Note the flow signal decays toward zero.

5. Run ~20% flow (~ 1 VDC) through instrument for 5 minutes.

6. Insure zero flow; wait 2 minutes, then zero the instrument.

7. Instrument is ready for operation.

Quick Start

2.2. Power Requirements

The HFM-301/305/306 requires ±15 VDC @ 55 mA. The HFC-303/307 requires ±15VDC @ 150 mA for

proper operation. The supply voltage should be sufficiently regulated to no more than 50 mV ripple.

The supply voltage can vary from 14.0 to 16.0 VDC. Surge suppressors are recommended to prevent

power spikes reaching the instrument. The Hastings power supply described in Section Error! Reference

source not found. satisfies these power requirements.

2.3. Output Signal

The standard output of the flow meter is a 0 - 5 VDC signal proportional to the flow rate. In the Hastings

power supply the output is routed to the display and is also available at the terminals on the rear panel.

If a Hastings supply is not used, the output is available on pin 6 of the “D” connector. It is recommended

that the load resistance be no less that 2 kΩ. If the optional 4 - 20 mA output is used, the load

impedance must be less than 600 Ω.

2.4. Mechanical Connections

The flow meter may be mounted in any position as long as the direction of gas flow through the

instrument follows the arrow marked on the bottom of the flow meter case label. The preferred

orientation is with the inlet and outlet fittings in a horizontal plane. If operating with a dense gas (e.g.

Manual: 152-082010 301-305-306_303-307 Series Page 7 of 35

Page 8

sulfur hexafluoride) or at high pressures (> 250 psig) the instrument must be installed horizontally.

When mounted in a different orientation the instrument should be re-zeroed at zero flow with the

system pressurized to the expected operating pressure.

One of the smallest of the internal passageways in the 300 Series is the diameter of the sensor tube,

which can be 0.026” (0.66 mm), 0.017” (0.43mm), or 0.014” (0.36mm), so the instrument requires

adequate filtering of the gas supply to prevent blockage or clogging of the tube.

The pressure regulator and the plumbing upstream must be of sufficient size to minimize changes in the

upstream pressure. When switching from full flow to zero flow, the inlet pressure of instrument should

rise to no more that 30% above the inlet pressure at full flow. In general, high capacity regulators and

large internal diameter plumbing help to make the system more stable. The pressure drop between the

regulator and the instrument due to line resistance should be minimized.

There are two threaded holes located on the bottom of the base that can be used to secure it to a

mounting bracket, if desired. Other holes for special mounting can be added if desired.

The optional inlet and outlet fittings for the 301/303 are 0.5”, 0.75” Swagelok, 0.5” VCR and 0.5” VCO

fittings. The O-rings for the end cap are Viton (optional Kalrez, Neoprene or Buna-N). The HFM-305 and

HFC-307 are provided with 1” Swagelok, VCR or VCO fittings. The HFM-306 can have 1” or 2” Swagelok

fittings. It is suggested that all connections be checked for leaks after installation. This can be done by

pressurizing the instrument (do not exceed pressure rating of the instrument) and applying a diluted

soap solution to the flow connections.

2.5. Electrical Connections

DANGER: Care must be taken to avoid high voltages that may be present when dealing

with power supplies.

If a power supply from Hastings Instruments is used, installation consists of connecting the 300 Series

cable from the “D” connector on the rear of the power supply to the “D” connector on the top of the

flow meter/controller. The “H” pin-out requires cable AF-8-AM (grey molded back shell). The “U” pinout requires cable # 65-791 (black molded back shell).

If a different power supply is used, follow the instructions below when connecting the flow meter and

refer to either table 2.1 or 2.2 for the applicable pin-out. The power supply used must be bipolar and

capable of providing ±15 VDC at 55 mA for flow meter applications and ±15 VDC at 150 mA for

controllers. These voltages must be referenced to a common ground. One of the “common” pins of the

Hastings instrument must be connected to the common terminal of the power supply. Case ground of

the instrument should be connected to the AC ground locally. The cable shield (if available) should be

connected to AC ground at the either the power supply end, or the instrument end of the cable, not at

both. Pin 6 is the output signal from the flow meter. The standard output will be 0 to 5 VDC, where 5

VDC is 100% of the rated or full scale flow.

The command (set point) input should be a 0 - 5 VDC signal (or 4 - 20mA if configured as such), and must

be free of spikes or other electrical noise, as these would generate false flow commands that the

controller would attempt to follow. The command signal should be referenced to signal common.

A valve override command is available to the flow controller. Connect the center pin of a single pole,

three-position switch (center off) to the override pin. Connect +15 VDC to one end of the three position

switch, and -15 VDC to the other end. The valve will be forced full open when +15 VDC is supplied to the

override pin, and full closed when -15 VDC is applied. When there is no connection to the pin (the

three-position switch is centered) the valve will be in auto control, and will obey the 0 - 5 VDC

commands supplied to command (set-point) input.

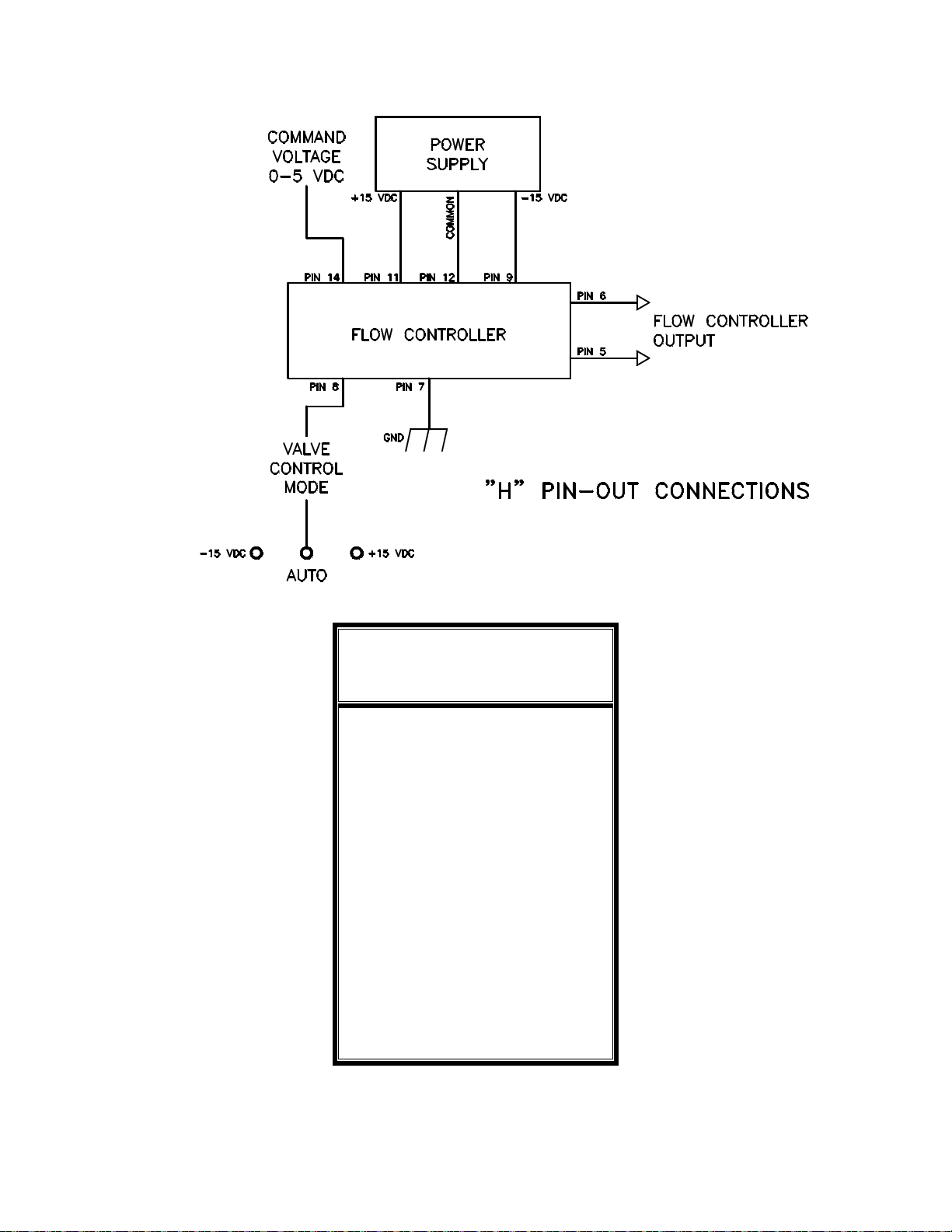

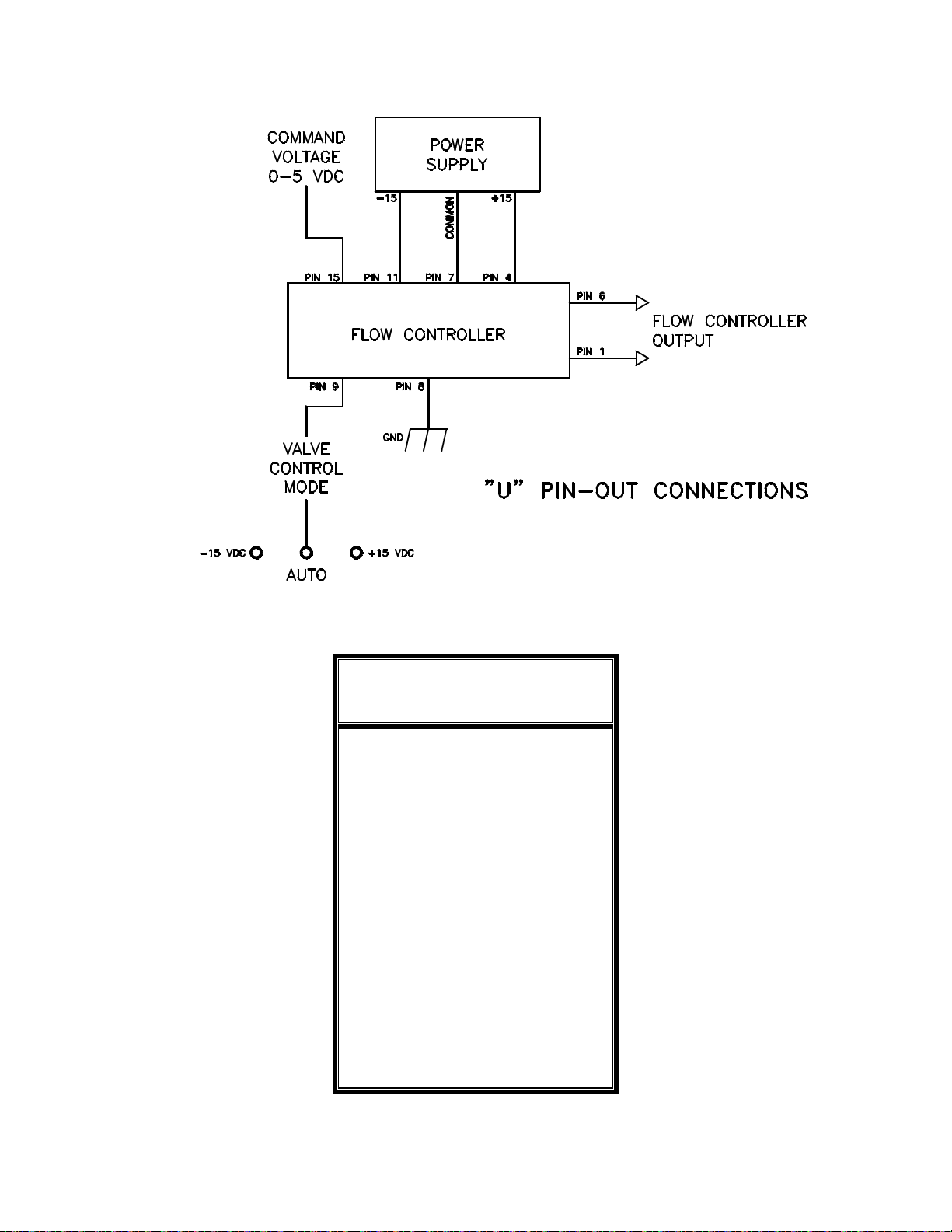

Figure 2-1 and Table 2-1 show the 300 Series “H” pin out.

Figure 2-2 and Table 2-2 show the 300 Series U” pin out.

Manual: 152-082010 301-305-306_303-307 Series Page 8 of 35

Page 9

Figure 2-1

Table 2-1

“H” Pin-out

Pin #

1 Do not use

2 Do not use

3 Do not use

4 Do not use

5 Signal Common

6 Output 0-5 VDC (4-20mA)

7 Case Ground

8 Valve Override

9 -15 VDC

10 Do not use

11 +15 VDC

12 Signal Common

13 External Input

14 Set Point 0-5 VDC (4-20mA)

15 Do not use

Manual: 152-082010 301-305-306_303-307 Series Page 9 of 35

Page 10

Figure 2-2

Table 2-2

“U” Pin-out

Pin #

1 Signal Common

2 Do not use

3 Do not use

4 +15 VDC

5

6 Output 0-5 VDC (4-20mA)

7 Signal Common

8 Case Ground

9 Valve Override

10

11 -15 VDC

12 External Input

13 Signal Common

14 Signal Common

15 Set Point 0-5 VDC (4-20mA)

Manual: 152-082010 301-305-306_303-307 Series Page 10 of 35

Page 11

2.6. 4 – 20 mA Connections

15 VD

C

Supply

The 300 Series flow meters have a 4 - 20 mA current output option available as an alternative to the

standard 0 - 5 VDC output. This current output is useful for remote applications where noise pick-up

could substantially affect the stability of the voltage output. The 4 - 20 mA signal is produced from the 0

- 5 VDC output of the flow meter and replaces the voltage output on pin 6 of the “D” connector. The

current is sourced by the flow controller and the metering circuit must sink the current, such that the

current loop is completed through power supply common connections. The load must be less than 600

Ohms. Failure to meet this condition will cause failure of the loop transmitter.

The 300 Series flow controllers have a 4 – 20 mA current input option available as an alternative to the

standard 0 – 5 VDC command input. The controller sinks the input current through a 77 Ohm load to

power supply common.

−+

Power

+

−

−

Common

+15 VDC

Ground

Hastings Flow controller

PLC or Analog I/O Card

0−600 Ohms

Power In

Analog Out

Analog In

Analog Return

Pin 7

Pin 11

Pin 9

Pin 5,12

Setpoint Input, Pin 14

Analog Output, Pin 6

−

77 Ohms

Figure 2-3

Manual: 152-082010 301-305-306_303-307 Series Page 11 of 35

Page 12

2.7. Operation

−+−

−+−

−−−

The standard instrument output is a 0 - 5 VDC and the signal is proportional to the flow i.e., 0 volts =

zero flow and 5 volts = 100% of rated flow. The 4 - 20 mA option is also proportional to flow, 4 mA =

zero flow and 20 mA = 100% of rated flow.

2.7.1. Operating Conditions

For proper operation, the combination of ambient temperature and gas temperature must be such that

the flow meter temperature remains between 0 and 60°C. Most accurate measurement of flow will be

obtained if the flow meter is zeroed at operating temperature as temperature shifts result in some zero

offset. The 300 Series is intended for use in non-condensing environments only. Condensate or any other

liquids which enter the flow meter may destroy its electronic components.

2.7.2. Zero Check

Turn the power supply on if not already energized. Allow for a 1 hour warm-up. Stop all flow through

the instrument and wait 2 minutes. Caution: Do not assume that all metering valves completely shut

off the flow. Even a slight leakage will cause an indication on the meter and an apparent zero shift. For

the standard 0 - 5 VDC output, adjust the zero potentiometer located on the lower inlet side of the flow

meter until the meter indicates zero. For the optional 4 - 20 mA output, adjust the zero potentiometer

so that the meter indicates slightly more than 4 mA, i.e. 4.03 to 4.05 mA. This slight positive

adjustment ensures that the 4 - 20 mA current loop transmitter is not in the cut-off region. The error

induced by this adjustment is approximately 0.3% of full scale. This zero should be checked periodically

during normal operation. Zero adjustment is required if there is a change in ambient temperature or

orientation of the flow meter/controller.

2.7.3. High Pressure Operation

If the instrument is not mounted in a level position when operating at high pressure, the increased

density of the gas will cause natural convection to flow through the sensor tube. This natural convection

flow will be proportional to the system pressure and will be seen as a shift in the zero flow output that is

directly proportional to the system pressure.

If the system pressure is higher than 250 psig (1.7 MPa) the pressure induced error in the span reading

becomes significant. The following charts show the mean error and the minimum/maximum expected span

errors induced by high pressures. This error can approach 4.5% at 400 psig. for 0.017” sensors. For accurate

high pressure measurements, this error must be corrected. Consult your packing list to determine if you have a

0.026”, 0.017” or 0.014” sensor. After determining the sensor tube ID, use one of the formulae below to

determine the expected mean error, expressed as a fraction of the reading.

2

=

26

17

14

Where P is the pressure in psig and Error is the fraction of the reading in error.

The flow reading can be corrected as follows:

Where the Indication is the indicated flow, Full Scale is the full scale reading and Error is the result of the

previous formula or read from charts below.

10*887.9(

-10

10*(1.533

-10

10*(-1.692

−

3

)

−=

3

)

+=

3

11

−

)

7

)

10*4154.3(

2

7

)

10*304.3(

2

7

)

10*776.1(

ErrorScaleFullIndicationCorrected *−=

5

10*3288.8(

4

10*8313.1(

5

10*929.1(

SensorPPPError

SensorPPPError

)"026.0(,)

SensorPPPError

)"017.0(,)

)"014.0(,)

CAUTION: The HFM-306 does not have a high pressure option and is only rated for a

maximum working pressure of 300 psig.

Manual: 152-082010 301-305-306_303-307 Series Page 12 of 35

Page 13

3%

2%

1%

0%

Span Error -vs- P ressure for 0.014" Sensors

-1%

Error shift (% re a ding)

-2%

-3%

0 100 200 300 400 500 600 700 800 900 1000

Mean

Max

Min

Pressure (psig)

Figure 2-4

Span Erro r - vs- Pressure for 0.017" Senso rs

5%

4%

3%

2%

1%

Error shift (% r eading)

0%

-1%

-2%

0 100 200 300 400 500 600 700 800 900 1000

Mean

Max

Min

Pressure (psig)

Figure 2-5

Manual: 152-082010 301-305-306_303-307 Series Page 13 of 35

Page 14

2.0%

0.0%

-2.0%

-4.0%

-6.0%

-8.0%

Span Error vs Pressure for 0.026" Sensor

-10.0%

Span Error (% reading)

-12.0%

-14.0%

-16.0%

-18.0%

-20.0%

0 100 200 300 400 500 600 700 800 900 1000

Pressure(psig)

Figure 2-6

Manual: 152-082010 301-305-306_303-307 Series Page 14 of 35

Page 15

1.0%

0.8%

0.6%

0.4%

0.2%

0.0%

Span Error vs Pressure

-0.2%

Span Error ( % reading)

-0.4%

-0.6%

-0.8%

-1.0%

0 50 100 150 200 250 300

M ean error

max

min

Pressure(psig)

Figure 2-7

2.7.4. Blending of Gases

In the blending of two gases, it is possible to maintain a fixed ratio of one gas to another. In this case,

the output of one flow controller is used as the reference voltage for the set point potentiometer of a

second flow controller. The set point potentiometer then provides a control signal that is proportional

to the output signal of the first flow controller, and hence controls the flow rate of the second gas as a

percentage of the flow rate of the first gas.

EXAMPLE: Flow controller A has 0 - 100 slm range with a 5.00 volt output at full scale. Flow

controller B has 0 - 10 slm range with a 5.00 volt output at full scale. If flow controller A is set at

80 slm, its output voltage would be 4.00 volts (80 slm/100 slm x 5.00 volts = 4.00 volts). If the

output signal from flow controller A is connected to the command potentiometer of flow controller

B, it then becomes a variable reference voltage for flow controller B proportional to the flow rate

of flow controller A.

If the set point potentiometer of flow controller B is set at 50% of full scale, and the reference

voltage from flow controller A is 4.00, then the command signal going to flow controller B would be

2.00 volts (4.00 volts x 50.0% = 2.00 volts). The flow of gas through flow controller B is then

controlled at 4 slm (2.00 volts/5.00 volts x 10 slm = 4 slm).

The ratio of the two gases is 20:1 (80 slm/4slm). The % mixture of gas A is 95.2 (80slm/84slm and

the % mixture of gas B is 4.8% (4 slm/84 slm).

Should the flow of flow controller A drop to 78 slm, flow controller B would drop to 3.9 slm, hence

maintaining the same ratio of the mixture. (78 slm/100slm x 5v = 3.90v x 50% = 1.95v; 1.95v/5.00v

x 10 slm = 3.9 slm; 78 slm: 3.9 slm = 20:1)

Manual: 152-082010 301-305-306_303-307 Series Page 15 of 35

Page 16

2.8. Range Changing

Changing the range of a flow controller can be done in the field, but calibration is required. It is

recommended however, that the unit be sent back to the factory along with the new range desired, gas

and operating parameters. Consult factory for more information.

2.9. Output Filter

The flow output signal may have noise superimposed on the

mean voltage levels. This noise may be due to high

turbulence in the flow stream that the fast sensor is

measuring or it could be electrical noise when the flow meter

has a high internal gain (i.e. 5 sccm full scale meter).

Varying levels of radio frequency noise or varying airflow over

the electronics cover can also induce noise.

Noise can be most pronounced when measuring the flow

output with a sampling analog/digital (A/D) converter. When

possible, program the system to take multiple samples and

average the readings to determine the flow rate.

If less overall system noise is desired, a jumper may be

installed over the pins of JP-1 on the flow measurement card.

See Figure 2-8. Covering the pins closest to the “D” connector

will activate a resistor-capacitor (RC) filter that has a time

constant of one second. This will change the settling time of

the indicated flow rate to approximately 4 seconds. Covering

the other two pins will change the response time to approx. 1

second. This adjustment will not affect the calibration of the

Figure 2-8

flow meter circuit or the actual flow response to change in

command signal (flow controllers). This will only slow down

the indicated response (output voltage/current).

2.10. Controlling Other Process Variables

Normally, a flow controller is setup to control the mass flow. The control loop will open and close the

valve as necessary to make the output from the flow measurement match the input on the command

line. Occasionally, gas is being added or removed from a system to control some other process variable.

This could be the system pressure, oxygen concentration, vacuum level or any other parameter which is

important to the process. If this process variable has a sensor that can supply an analog output signal

proportional to its value then the flow controller may be able to control this variable directly. This

analog output signal could be 0 - 5 Volts, 0 - 10 Volts (or 4 - 20 mA for units with 4 - 20 mA boards) or

any value in between.

On the CONTROLLER card there is a jumper (JP-1) that sets whether the control loop controls mass flow

or an external process variable. See Figure 2-9. If the jumper connects the top two pins, the loop

controls mass flow. If the jumper connects the bottom two pins, the loop controls an external process

variable. This process variable signal must be supplied on pin 13 of the D-connector (for H pin out units)

or pin 12 of the D-connector (for U pin out units) of the measurement card. When the controller is set

for external variable control it will open or close the valve as necessary to make the external process

variable signal match the command signal. The command signal may be 0 - 5 Volts, 0 - 10 Volts (4 - 20

mA for 4 - 20 mA input/output cards) or any value in between. If the process variable has a response

time that is much faster or slower than the flow meter signal it may be necessary to adjust the gain

potentiometer.

2.11. Command Input

The flow controller will operate normally with any command input signal between 0 - 10 Volts (4 - 20 mA

for units with 4 - 20 mA input/output cards). If the command signal exceeds ±14 volts it may damage the

circuit cards. During normal operation the control loop will open or close the valve to bring the output

Manual: 152-082010 301-305-306_303-307 Series Page 16 of 35

Page 17

of the flow meter signal to within ± 0.001 Volts of the command signal. The command signal will not

match the flow signal if there is insufficient gas pressure to generate the desired flow. If the command

signal exceeds 5 Volts the controller will continue to increase the flow until the output matches the

command signal. However, the flow output may not maintain the published accuracy values under these

conditions.

If the command signal is less than 1% of full scale (0.05 Volts or 4.16 mA) the valve override control

circuit will activate in the closed position. This will force the valve completely closed regardless of the

flow signal.

2.12. Valve Override Control

The valve override control line provides a method to override the loop controller and open or close the

valve regardless of the flow or command signals. During normal operation this line must be allowed to

float freely. This will allow the loop control to open and close the valve as it requires. If the valve

override line is forced high (> +5 Volts) the valve will be forced full open. If the valve overrides line is

forced negative (< -5 Volts) the valve will be forced closed.

2.13. Gain

Potentiometer

On the top left of the inlet side of the flow

controller there is a hole through which the gain

potentiometer is accessible. See Figure 2-9 and

Figure 4-2. This gain potentiometer affects the gain

of the closed loop controller. Normally this

potentiometer will be set at the factory for good

stable control. It may be necessary to adjust this

potentiometer in the field if the system varies

widely from the conditions under which the

controller was setup. Turning this gain

potentiometer clockwise will improve stability.

Turning the potentiometer counter-clockwise will

speed up the valve reaction time to changes in the

command signal.

Control Loop

Jumper

Gain

Potentiometer

Figure 2-9

Manual: 152-082010 301-305-306_303-307 Series Page 17 of 35

Page 18

2.14. Temperature Coefficients

As the temperature of the instrument changes from the calibration temperature, errors will be

introduced into the output of the instrument. The Temperature Coefficient of Zero describes the change

in the output that is seen at zero flow. This error is added in to the overall output signal regardless of

Span error -vs- Temperature

1.4%

1.2%

y = 5E- 06x2 - 9E-05x - 0.0007

1.0%

0.8%

0.6%

0.4%

Sp an Error (% of Point)

0.2%

0.0%

0 10203040506070

-0.2%

Temperature ( ° C)

Figure 2-10

flow, but can be eliminated by merely adjusting the zero potentiometer to read zero volts at zero flow

conditions. The Temperature Coefficient of Span describes the change in output after the zero error is

eliminated. This error cannot be eliminated, but can be compensated mathematically if necessary. The

curve pictured in Figure 2-10 shows the span error in percent of point as a function of temperature

assuming 23

0

C is the calibration temperature.

Manual: 152-082010 301-305-306_303-307 Series Page 18 of 35

Page 19

3. Theory and Function

3.1. Overall Functional Description

The 300 Series flow meters consist of a sensor, base, shunt, control valve (303/307) and electronic

circuitry. The sensor is configured to measure gas flow rate from 25-10000 slm, depending on the

customer’s desired overall flow rate. The shunt divides the overall gas flow such that the flow through

the sensor is a precise percentage of the flow through the shunt. The flow through both the sensor and

shunt is laminar. The control valve adjusts the flow so that the sensors measurement matches the setpoint input. The circuit board amplifies the sensor output from the two RTD’s (Resistive Temperature

Detectors) and provides an analog output of either 0 - 5 VDC or 4 - 20 mA.

3.2. Sensor Description

The sensor consists of two coils of resistance wire with a high temperature coefficient of resistance

(3500 ppm/

0.017”(0.43mm) or 0.026”(0.66mm) and 3.00” (7.62) cm length. These two identical resistance wire

coils are used to heat the gas stream and are symmetrically located upstream and downstream on the

sensor tube. Insulation surrounds the sensor tube and heater coils with no voids around the tube to

prevent any convection losses. The ends of this sensor tube pass through an aluminum block and into the

stainless steel sensor base. This aluminum block thermally shorts the ends of the sensor tube and

maintains them at ambient temperature.

There are two coils of resistance wire that are wound around the aluminum block. The coils are identical

to each other and are symmetrically spaced on the aluminum ambient block. These coils are wound

from the same spool of wire that is used for the sensor heater coils so they have the same resistivity and

the same temperature coefficient of resistance as the sensor heater coils. The number of turns is

controlled to have a resistance that is 10 times larger than the resistance of the heater coils. Thermal

grease fills any voids between the ambient temperature block and the sensor tube to ensure that the

ends of the sensor tube are thermally tied to the temperature of this aluminum block.

Aluminum has a very high thermal conductivity which ensures that both ends of the sensor tube and the

two coils wound around the ambient block will all be at the same temperature. This block is in good

thermal communication with the stainless steel base to ensure that the ambient block is at the same

temperature as the main instrument block and, therefore, the same temperature as the incoming gas

stream. This allows the coils wound on the aluminum block to sense the ambient gas temperature.

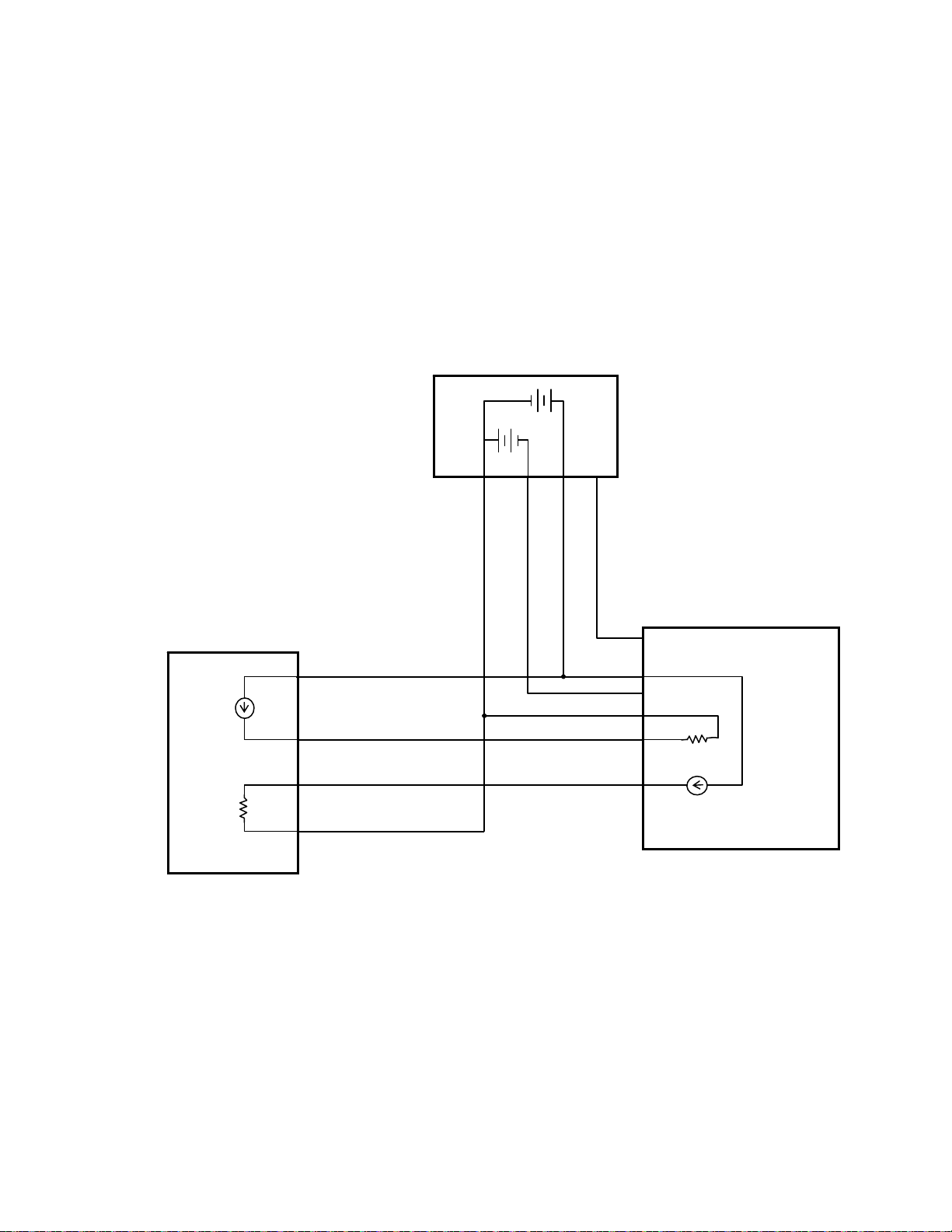

Two identical Wheatstone bridges are employed, as shown in Figure 3.2. Each bridge utilizes an ambient

temperature sensing coil and a heater coil. The heater coil and a constant value series resistor comprise

the first leg of the bridges. The second leg of each bridge contains the ambient sensing coil and two

constant value series resistors. These Wheatstone bridges keep each heater temperature at a fixed value

of ∆T = 48

the proper selection of the constant value bridge resistors.

o

C) wound around a stainless steel tube with internal diameter of 0.014”(0.36mm),

o

C above the ambient sensor temperature through the application of closed loop control and

3.3. Sensor Theory

The heat transferred by convection to or from a fluid is proportional to the mass flow of that fluid. Since

the constant differential temperature sensor has 2 heater coils symmetrically spaced on the sensor tube,

it is convenient to consider the upstream and downstream heat transfer modes separately. The electrical

power supplied to either of the heater coils will be converted to heat, which can be dissipated by

radiation, conduction, or convection. The radiation term is negligible due to the low temperatures used

by the sensor, and because the sensor construction preferentially favors the conductive and convective

heat transfer modes. The thermal energy of each heater will then be dissipated by conduction down the

stainless steel sensor tube, conduction to the insulating foam, plus the convection due to the mass flow

of the sensed gas.

Because great care is taken to wind the resistive heater coils symmetrically about the midpoint of the

tube, it is assumed that the heat conducted along the sensor tube from the upstream heater will be

equal to the heat conducted through the tube from the downstream heater. Similarly, the heat

Manual: 152-082010 301-305-306_303-307 Series Page 19 of 35

Page 20

(

conducted from the upstream and downstream coils to the foam insulation surrounding them is assumed

(

to be equal, based on the symmetry of the sensor construction.

Since the sensor tube inlet and outlet are linked by an aluminum ambient bar, the high thermal

conductivity of the bar provides a ‘thermal short’, constraining the ends of the sensor tube to be at

equal surface temperature. Moreover, the tube ends and the aluminum ambient bar have intimate

thermal communication with the main flow passageway prescribed by the main stainless steel flow meter

body. This further constrains each end of the sensor tube to be equal to the ambient gas temperature.

Further, since the length of each heater section is nearly 21 times greater than the inside tube diameter,

the mean gas temperature at the tubes axial midpoint is approximately equal to the tube surface

temperature at that point. Recall that the outside of the sensor tube is well insulated from the

surroundings; therefore the tube surface temperature at the axial midpoint is very close to the operating

temperature of the heater coils. The mean temperature of the gas stream is then approximately the

same as the heater temperature. Assuming the mean gas temperature is equal to the heater

temperature, it can be shown that the differential power is:

PP mCT T

−= −

The value of the constant pressure specific heat of a gas is virtually constant over small changes in

temperature. By maintaining both heaters at the same, constant temperature difference above the

ambient gas stream temperature, the difference in heater power is a function only of the mass flow

rate. Fluctuations in ambient gas temperature which cause errors in conventional mass flow sensors are

avoided; The resistance of the ambient sensing coil changes proportionally with the ambient

temperature fluctuations, causing the closed loop control to vary the bridge voltage such that the heater

resistance changes proportionally to the ambient temperature fluctuation.

The power supplied to each of the 2 heater coils is easily obtained by measuring the voltage across the

heater, shown as V2 on Figure 3.2, and the voltage across the fixed resistor R1. Since R1 is in series with

the heater RH they have the same current flowing through them. The electrical power supplied to a

given heater is then calculated:

With a constant differential temperature applied to each heater coil and no mass flow through the

sensor the difference in heater power will be zero. As the mass flow rate through the sensor tube is

increased, heat is transferred from the upstream heater to the gas stream. This heat loss from the

heater to the gas stream will force the upstream bridge control loop to apply more power to the

upstream heater so that the 48

ud pheaterambient

o

C constant differential temperature is maintained.

•

2

VVV

P

=

−

)

122

R

1

)

The gas stream will increase in temperature due to the heat it gains from the upstream heater. This

elevated gas stream temperature causes the heat transfer at the downstream heater to gain heat from

the gas stream. The heat gained from the gas stream forces the downstream bridge control loop to apply

less power to the downstream heater coil in order to maintain a constant differential temperature of 48

o

C.

The power difference at the RTD’s is a function of the mass flow rate and the specific heat of the gas.

Since the heat capacity of many gases is relatively constant over wide ranges of temperature and

pressure, the flow meter may be calibrated directly in mass units for those gases. Changes in gas

composition require application of a multiplication factor to the nitrogen calibration to account for the

difference in heat capacity.

3.4. Base

The 316 stainless steel base has a 2.0" by 2.0” (50.8 mm by 50.8 mm) cross-section and is 5.77"(146.6

mm) long on the HFC-303 and 4.32” (109.7 mm) long on the HFM-301. Lower flow (< 300 SLM) 301's are

0.2" shorter and lower flow 303's are 0.4" shorter. The base has an internal flow channel that is

Manual: 152-082010 301-305-306_303-307 Series Page 20 of 35

Page 21

1.75"(44.5 mm) diameter. The base and endcap seal is an O-ring gland configuration, which uses Viton

as a standard sealing material. The HFM-305/306 is made from a larger 3.0” by 3.0” (76.2 mm by 76.2

mm) cross section of 316 stainless steel and has a length of 5.3” (134.6 mm) while the 307 has a length

of 8” (203.2 mm). The 305/307 however has a larger 2.67” (67.8 mm) internal flow channel and knife

edge metal to metal seals on the end caps. Between the base and sensor module on the 300 Series is a

knife edge metal to metal seal. Gaskets made of nickel 200 are swaged between mating face seals

machined into the stainless steel parts. All seals are tested at the factory and have leak rates of less

-9

than 1x10

std. cc/s.

The HFM-306 base is much larger. The base/end cap seal is an O-ring gland configuration, which uses

Viton as a standard sealing material.

3.5. Shunt description

The flow rate of interest determines the size of the shunt required. As previously indicated, the

301/305 series can be configured from 25 to 2500 slm (303/307 controller from 25-2500 slm) using

various base, shunt and transducer combinations. The shunts employ a patented method of flow

division, which results in a more linear flow meter/controller; further calibration is more stable when

changing between measured gases.

The shunts are comprised of a 316 stainless steel cylindrical shell concentrically located in the base that

forms an annular flow channel of precise dimension. This flow channel creates laminar flow by the

inboard sensor taps. The cylindrical shell encases a corrugated matrix of flow channels which serve as a

shunt. The size and number of these channels is consistent with the sensor ∆P and flow range.

3.6. Shunt Theory

A flow divider for a thermal mass flow transducer usually consists of an inlet plenum, a flow restriction,

shunt and an outlet plenum. (See Figure 3-1). Since stability of the flow multiplier is desired to ensure a

stable instrument, there must be some matching between the linear volumetric flow versus pressure

drop of the sensor and the shape of the volumetric flow versus pressure drop of the shunt. Most

instruments employ Poiseuille’s law and use some sort of multi-passage device that creates laminar flow

between the upstream sensor inlet and the downstream outlet. This makes the volumetric flow versus

pressure drop curve primarily linear, but there are other effects which introduce higher order terms.

Most flow transducers are designed such that the outlet plenum has a smaller diameter than the inlet

plenum. This eases the insertion and containment of the shunt between the sensor inlet point and the

sensor outlet point. However there will be a pressure drop between the sensor inlet and outlet points

created by the change in flow passage diameter. Since the drop is a square function of the flow velocity

the differential pressure will be non-linear with respect to flow rate. Note also that the pressure drop is

a function of density.

The density will vary as a function of system

pressure and it will also vary when the gas

composition changes. This will cause the

magnitude of the pressure drop due to the area

change to be a function of system pressure and

gas composition.

Most of the shunts used contain or can be

approximated by many short capillary tubes in

parallel. We know that the equation for the

pressure drop across a capillary tube contains

terms that are proportional to the square of the

Figure 3-1

volumetric flow rate. These terms come from

the pressure drops associated with the sudden

c

ompression at the entrance and the sudden expansion at the exit of the capillary tube. The end effect

terms are a function of density which will cause the quadratic term to vary with system pressure and gas

composition. The absence of viscosity in the second term will cause a change in the relative magnitudes

of the two terms whenever the viscosity of the flowing gas changes.

Manual: 152-082010 301-305-306_303-307 Series Page 21 of 35

Page 22

μ

LQ

The end effects for a typical laminar flow element in air account for approximately 4% of the total

pressure drop. For hydrogen, however, which has a density that is about 14 times less than air and has a

viscosity that is much greater than air, the second term is completely negligible. For the heavier gasses

such as sulfur hexafluoride which has a density 5 times that of air the end effects will become 10% of the

total. These changes make it impossible to accurately calibrate an instrument on one gas and use it for

another gas.

The pressure drop is linear with respect to the volumetric flow rate between a point that is downstream

of the entrance area and another point further downstream but upstream of the exit region. For a

typical flow divider tube the entry length is approximately 0.16 cm. From this it can be seen that if the

sensor inlet pickup point is inside of the flow divider tube but downstream of the entrance length and if

the sensor outlet point is inside the flow divider tube but upstream of the exit point then the pressure

drop that drives the flow through the sensor would be linear with respect to volumetric flow rate. Since

the pressure drop across the sensor now increases linearly with the main flow rate and the sensor has a

linearly increasing flow with respect to pressure drop, there is now a flow through the sensor which is

directly proportional to the main flow through the flow divider, without the flow division errors that are

present when the sensor samples the flow completely upstream and downstream of the flow divider.

Unfortunately, a typical shunt has an internal diameter on the order of 0.3 mm. This is too small to

insert tap points into the tube. Also, the sample flow through the sensor is approximately 10 sccm while

the flow through a shunt is approximately 25 sccm. This means the sample flow would be affecting the

flow it was trying to measure. If the sensor tube is made large enough, and with enough flow through it

to insert the sensor taps at these positions, then the pressure drop would be too small to push the

necessary flow through the sensor tube.

128 8

ΔP

=+ +

4

π

D

2

ρ

Q

KK

()

24

π

D

ce

The solution is to use a different geometry for the flow tube. It must be large enough to allow the

sample points in the middle yet with passages thin enough to create the differential pressures required

for the sensor. An annular passage meets these requirements. All of the 400 I series shunts have an

annular passageway that passes between the outside of the main shunt body and the inside edge of the

base where the sensor taps are located.

Figure 3-2

The shunt must generate a pressure drop at the desired full scale flow which drives the proper flow

through the sensor tube to generate a full scale output from the sensor. Since the full scale flow of the

sensor is the same for all of the different full scale flows that may pass through the shunt, the geometry

must vary for the different full scale flows in order to generate the same pressured drop for all of them.

This is accomplished by adding more channels to main shunt body. As the full scale flow rate increases

the flow meter body must get larger to allow room for the increased number of bypass passageways that

are required.

Manual: 152-082010 301-305-306_303-307 Series Page 22 of 35

Page 23

3.7. Control Valve

The control valve is an “automatic metering solenoid” valve (see Figure 3-3). While most solenoid valves

operate in either the fully open or closed positions, the automatic metering solenoid valve is designed to

control flow. A spring is used to hold a magnetic plunger assembly tightly against an orifice, thereby

shutting off the flow. The magnetic plunger assembly is surrounded by a coil of magnet wire. When the

coil is energized the electric current passing through the wire coil produces a magnetic field which

attracts the plunger. The plunger assembly moves away from the orifice allowing the gas flow to pass

between the orifice and the plunger seat. The distance between the orifice and the plunger seat, and

thus the flow through the valve, is controlled by the amount of current supplied to the coil.

The valve seat is made of Kalrez (or equivalent) perflouroelastomer. The valve orifice is made from 316

stainless steel. The valve plunger and pole piece are made of nickel plated magnetic alloy (Hi-perm 49)

and the control springs are made of 302 stainless steel. The Diaphragm and all seals are as specified per

the customer order (Viton, Neoprene, Buna-N or Kalrez).

Figure 3-3

Manual: 152-082010 301-305-306_303-307 Series Page 23 of 35

Page 24

3.8. Electronic Circuitry

The 300 Series flow meters employs a thermal transfer principle (capillary tube described in section 3.2)

to measure the flow through the sensor which is proportional to the total flow through the instrument.

The sensor develops a differential voltage output signal proportional to flow, which is amplified to

produce 5 VDC at full scale flow. The amplified output can be measured on pins 6 and 1 of the external

“D” connector. If a Hastings power supply is employed, the 5 Volt output is also sent to the terminals on

the back and to the decoding circuitry in the display, which converts it to a numeric output. The

optional 4 - 20 mA analog output is available in lieu of an output voltage. The addition of a 4 - 20 mA

current loop transmitter on a secondary PC board (mounted parallel to the main pc board) is required to

provide this current loop. A jumper change is made on the secondary PC board to establish the selected

output mode.

3.9. Instrument Performance

The combination of these principles embodied in the 300 Series give inherently linear and highly

accurate output and the typical response time from zero to full flow is also quite good. The meter

settling time of a 1000 slm full scale flow meter is typically under 0.5 seconds. Flow controller response

is less than 2 seconds.

Manual: 152-082010 301-305-306_303-307 Series Page 24 of 35

Page 25

4. Maintenance

4.1. Authorized Maintenance

With proper care in installation and use, the flow meter will require little or no maintenance. If

maintenance does become necessary, most of the instrument can be cleaned or repaired in the field.

Some procedures may require recalibration. Do not attempt these procedures unless facilities are

available. Entry into the sensor or tampering with the printed circuit board will void warranty. Do not

perform repairs on these assemblies while the unit is still under warranty.

CAUTION: Some parts of the instrument are delicate and other parts are heavy enough

to cause an injury if dropped. Use extreme care when servicing the instrument. The

potentiometer positions and the electrical components referred to in the

troubleshooting section can be found in Section 4.3.

4.2. Troubleshooting

Symptom: Output reads strong indication of flow with no flow present. Zero pot has no effect.

Cause: Power shorted out.

Action: Turn the power supply off for a few seconds then turn it on again. If this is ineffective,

disconnect the power supply from the unit. Check that the power supply voltages are

correct. Incorrect voltages most likely signify a faulty regulator chip inside the supply.

If the power supply display returns to zero after the instrument has been disconnected

there may be a short from the unit to ground.

Symptom: 300 Series instrument output continues to indicate flow with no flow present, or

indicates ±14 volts. Power supply inputs are correct (see the above troubleshooting tip)

and zero pot has no effect.

Cause: Faulty IC chip(s) on the main PC board.

Action: Replace main PC board. (See Section 4.5)

Symptom: Output of flow meter is proportional to flow,

but extremely small and not correctable by span pot.

Cause: Sensor is not being heated.

5 6 7 8

4 3 2 1

Action: Shut off gas supply and disconnect the power to

the flow meter. Remove cover and PC board from unit.

Check the resistance from pins 1 to 2 and 3 to 4 of the

sensor module. Both sets of pins should read

approximately the same value between 1 and 2 k

nominal resistance. Also check that the resistance from

pins 5 to 6, and 7 to 8 are both nearly the same value

between 200 and 400

resistance values indicate that the sensor unit needs to

be replaced.

Ω. See Figure 4-1. Incorrect

Ω

Figure 4-1

Manual: 152-082010 301-305-306_303-307 Series Page 25 of 35

Page 26

Symptom: Sensor has proper resistance readings, but little or no output with flow.

Cause: Plugged sensor.

Action: Shut off gas supply and disconnect the power to the flow meter. Remove cover and PC

board from unit. Remove and inspect sensor. If sensor has evidence of clogging, clean

or replace as applicable.

Symptom: Flow meter reads other than 0.00 VDC with no flow or there is a small flow when the

flow meter reads 0.00 VDC.

Cause: Zero pot is out of adjustment.

Action: Shut off all flow. For the standard 0 – 5 VDC output, adjust the zero potentiometer (see

Section 4.3) located on the upper right inlet side of the flow meter until the meter

indicates zero. For the optional 4 - 20 mA output, adjust the zero potentiometer so that

the meter indicates slightly more than 4 mA, i.e. 4.03 to 4.05 mA. This slight positive

adjustment ensures that the 4 - 20 mA transmitter is not in its cut-off region. The error

induced by this adjustment is approximately 0.3% of full scale.

Symptom: Flow meter is out of calibration and non-linear.

Cause: Leaks in the gas inlet or outlet fittings.

Action: Check all fittings for leaks by placing soap solution on all fittings between gas supply and

final destination of gas. Check flow meter for leaks. Replace if required or recalibrate as

necessary.

Symptom: Little or no flow, even when the valve is in override OPEN.

Cause: Blocked orifice or incorrect pressure across the flow controller

Action: Verify that there is 10 to 15 psig pressure across the instrument. If the differential

pressure across the instrument is correct, the orifice may be obstructed. Remove all gas

pressure and shut off power supply. Remove the valve.

4.3. Adjustments

1. Connect power to “D” connector as specified in Section 2.5. Allow the instrument to warm up for at

least 30 minutes (60 minutes for best accuracy). Note the flow signal decays toward zero. Run ~20% of

flow range (~1 VDC) through instrument for 5 minutes.

2. Completely shut off the flow and wait for 2 minutes. For the standard 0 – 5 VDC output, adjust the

zero potentiometer located on the lower inlet side of the flow meter (see Figure 4-2) until the meter

indicates zero. For the optional 4 - 20 mA output, adjust the zero potentiometer so that the meter

indicates slightly more than 4 mA, i.e. 4.03 to 4.05 mA. This slight positive adjustment ensures that the

4 - 20 mA transmitter is not in its cut-off region. The error induced by this adjustment is approximately

0.3% of full scale.

3. Turn on gas supply to inlet of instrument and adjust the flow rate to the desired full scale flow as

indicated by a reference flow meter/controller. If the instrument to be calibrated is a controller, adjust

the flow rate by setting the command to 100% of full scale.

4. Perform this step only if a calibrated reference flow meter is available. Adjust Span pot (see Figure

4-2) until the indicated flow reads full scale (5.00 VDC or 20 mA) and the reference meter/controller

reads the desired full scale flow rate.

5. Record flow meter/controller and flow reference outputs for flow rates of 20%, 40%, 60%, 80% and

100% and make sure data are within ± 1% of full scale.

Manual: 152-082010 301-305-306_303-307 Series Page 26 of 35

Page 27

Control

Loop Gain

Zero

Span

PC

Board

Figure 4-2

4.4. End Cap Removal

The end cap on the inlet side must be removed to gain access to shunt assembly. First remove power

and shut off the supply of gas to the instrument. Disconnect the fittings on the inlet and outlet sides of

the transducer and remove it from the system plumbing. On both the HFM-301 and HFC-303, remove the

four Allen head screws holding the end cap to the instrument. Carefully remove the “O”-ring sealed end

cap and shunt, noting their order and the proper annular orientation of the shunt. The shunt position is

critical to the flow dynamics and can substantially affect the instrument linearity. The shunt can be

severely damaged if dropped. Examine the shunt. If damaged, dirty or blocked, clean and replace as

applicable. Reassemble in the reverse order of disassembly. Secure the endcap with 65 in lb. (7.3 N.m)

to 85 in lb (9.6 N-m) of torque on each high-tensile socket head cap screw. Use of a fastener other than

the one mentioned here may result in leakage at the seal. Recalibration of the 301/303 series

instrument is necessary.

For the HFM-305/307 remove the four 12 point bolts securing the endcap while carefully holding the

endcap in place. Carefully remove the metal gasket sealed endcap and shunt, noting their order and the

proper annular orientation of the shunt. The shunt position is critical to the flow dynamics and can

substantially affect the instrument linearity. The shunt can be severely damaged if dropped. Examine

the shunt. If damaged, dirty or blocked, clean and replace as applicable. Reassemble in the reverse

order of disassembly replacing the used metal gasket with a new one. Secure the endcap with 35 ft lb. (

47.5 N.m) to 40 ft lb. (54.3 N.m) of torque on each 12 pt bolt. Use of a fastener other than the one

mentioned here may result in leakage at the seal. Recalibration of the 305/307 series instrument is

necessary.

For the HFM-306, remove the six hex socket bolts from the inlet end cap. Remove the end cap and

ensure that the o-ring is not damaged. Remove the flow conditioning screen assembly and if damaged,

dirty or blocked, clean and replace as applicable. Carefully remove the flow straightener and shunt

assembly. If damaged, dirty or blocked, clean and replace as applicable. Reassemble in the reverse order

of disassembly. Recalibration of the HFM-306 instrument is necessary.

Manual: 152-082010 301-305-306_303-307 Series Page 27 of 35

Page 28

4.5. Printed Circuit Board and Sensor Replacement

NOTE: This instrument contains static sensitive PC boards. Maintain static protection when handling the

PC boards.

In the event that any of the PC boards fail, they are easily removed from the instrument and replaced

with a spare. It is recommended that the metering printed circuit board and sensor be replaced as a unit

because they are electronically matched to optimize response time. The sensor can also be removed

easily. This ease in disassembly and replacement substantially reduces instrument downtime.

1. Replacement of the 4 - 20 mA option PC board: Unplug the power cable from the instruments “D”

connector. Remove the fasteners and steel can. The 4 - 20 mA board is the PC board mounted by a

single screw. Remove the screw and lift off the 4 - 20 mA board. Be careful not to damage the main

board and 4 - 20 mA board connector.

2. Replacement of the main PC board: Unplug the power cable from the instruments “D” connector.

Remove the fasteners and steel can. Remove the 2 screws which fasten the main PC board to the sensor

module. Gently unplug the main board from the sensor (and from the 4 - 20 mA board, if present).

3. Replacement of the flow sensor: Remove the PC board(s) as described above. Remove the four (4)

Allen head cap screws that fasten the sensor to the main instrument base. Remove the sensor module

from the base, discarding the used nickel gaskets. New nickel gaskets are required for re-assembly.

To place an order or to obtain information concerning replacement parts, contact the factory

representative in your area. See section 6 in this manual for the address or phone number. When

ordering, include the following information: Instrument model number, part description and Hastings

part number.

Manual: 152-082010 301-305-306_303-307 Series Page 28 of 35

Page 29

5. Outline Drawings

5.1. HFM-301

5.2. HFC-303

Manual: 152-082010 301-305-306_303-307 Series Page 29 of 35

Page 30

5.3. HFM-305

5.4. HFM-306

Manual: 152-082010 301-305-306_303-307 Series Page 30 of 35

Page 31

5.5. HFC-307

Manual: 152-082010 301-305-306_303-307 Series Page 31 of 35

Page 32

6. WARRANTY

6.1. Warranty Repair Policy

Hastings Instruments warrants this product for a period of one year from the date of shipment to be free

from defects in material and workmanship. This warranty does not apply to defects or failures resulting

from unauthorized modification, misuse or mishandling of the product. This warranty does not apply to

batteries or other expendable parts, or to damage caused by leaking batteries or any similar occurrence.

This warranty does not apply to any instrument which has had a tamper seal removed or broken.

This warranty is in lieu of all other warranties, expressed or implied, including any implied warranty as

to fitness for a particular use. Hastings Instruments shall not be liable for any indirect or consequential

damages.

Hastings Instruments, will, at its option, repair, replace or refund the selling price of the product if

Hastings Instruments determines, in good faith, that it is defective in materials or workmanship during

the warranty period. Defective instruments should be returned to Hastings Instruments, shipment

prepaid, together with a written statement of the problem and a Return Material Authorization (RMA)

number.

Please consult the factory for your RMA number before returning any product for repair. Collect freight

will not be accepted.

6.2. Non-Warranty Repair Policy

Any product returned for a non-warranty repair must be accompanied by a purchase order, RMA form

and a written description of the problem with the instrument. If the repair cost is higher, you will be

contacted for authorization before we proceed with any repairs. If you then choose not to have the

product repaired, a minimum will be charged to cover the processing and inspection. Please consult the

factory for your RMA number before returning any product repair.

TELEDYNE HASTINGS INSTRUMENTS

804 NEWCOMBE AVENUE

HAMPTON, VIRGINIA 23669 U.S.A.

ATTENTION: REPAIR DEPARTMENT

TELEPHONE (757) 723-6531

TOLL FREE 1-800-950-2468

FAX (757) 723-3925

E MAIL hastings_instruments@teledyne.com

INTERNET ADDRESS http://www.teledyne-hi.com

Repair Forms may be obtained from the “Information Request” section of the Hastings Instruments web