TELEDYNE HASTINGS

INSTRUCTION MANUAL

HASTINGS 200 SERIESHASTINGS 200 SERIES

HASTINGS 200 SERIES

HASTINGS 200 SERIESHASTINGS 200 SERIES

FF

AST RESPONSEAST RESPONSE

F

AST RESPONSE

FF

AST RESPONSEAST RESPONSE

MASS FLOWMETERSMASS FLOWMETERS

MASS FLOWMETERS

MASS FLOWMETERSMASS FLOWMETERS

INSTRUCTION

INSTRUMENTS

126B - PAGE 1

Manual Print HistoryManual Print History

Manual Print History

Manual Print HistoryManual Print History

The print history shown below lists the printing dates of all revisions and addenda created for this

manual. The revision level letter increases alphabetically as the manual undergoes subsequent

updates. Addenda, which are released between revisions, contain important change information that

the user should incorporate immediately into the manual. Addenda are numbered sequentially .

When a new revision is created, all addenda associated with the previous revision of the manual are

incorporated into the new revision of the manual. Each new revision includes a revised copy of this

print history page.

Revision B (Document Number 126-082000) ............................................................ August 2000

Revision C (Document Number 126-082005)............................................................ August 2005

Visit www .teledyne-hi.com for WEEE disposal guidance.

Hastings Instruments reserves the right to change or modify the design of its equipment without

any obligation to provide notification of change or intent to change.

126B - PAGE 2

TABLE OF CONTENTS

SECTION 1.0 GENERAL INFORMATION..............................................................................................5

1.1 Features............................................................................................................... 5

1.2 Specifications ...................................................................................................... 5

1.3 Accessories .......................................................................................................... 6

1.3.1 Po w er Supplies................................................................................................. 6

1.3.2 Alarms.............................................................................................................. 6

1.3.3 Totalizer............................................................................................................ 6

1.3.4 4-20 mA Current Converter ............................................................................ 6

SECTION 2.0 INSTALLATION AND OPERATION ................................................................................. 7

2.1 Receiving Inspection ........................................................................................... 7

2.2 Po wer Requirements ........................................................................................... 7

2.3 Output Voltage .................................................................................................... 7

2.4 Mechanical Connections .................................................................................... 7

2.5 Electrical Connections ........................................................................................ 8

2.6 Operation ............................................................................................................ 8

2.6.1 Power Supply Operation.................................................................................. 8

2.6.2 Ambient Temperature....................................................................................... 8

2.6.3 Zero Check ...................................................................................................... 8

2.7 Range Changing.................................................................................................. 8

SECTION 3.0 THEORY OF OPERATION ............................................................................................. 9

3.1 Overall Functional Description........................................................................... 9

3.2 Sensor ................................................................................................................. 9

3.3 Electronics .......................................................................................................... 10

3.4 Shunt .................................................................................................................. 10

SECTION 4.0 MAINTENANCE ........................................................................................................... 13

4.1 Introduction........................................................................................................ 1 3

4.2 Authorized Maintenance..................................................................................... 13

4.3 Adjustments......................................................................................................... 13

4.3.1 Calibration Procedure...................................................................................... 1 3

4.3.2 Response Time Adjustments ............................................................................ 13

4.3.3 Miscellaneous Adjustments .............................................................................. 13

4.4 End Cap Removal............................................................................................... 1 4

4.5 Range Changes ................................................................................................... 14

126B - PAGE 3

4.6 Printed Circuit Board Replacement .................................................................... 15

4.7 Sensor Replacement............................................................................................ 15

4.8 Troubleshooting.................................................................................................. 1 5

SECTION 5.0 REPLACEMENT PARTS ................................................................................................ . 17

SECTION 6.0 WARRANTY AND REPAIR .............................................................................................. 19

SECTION 7.0 DIAGRAMS AND DRAWINGS ........................................................................................ 21

AssemblyDiagram,PC810FastReponse.............................................................................22

Schematic, PC-810 Fast Response .................................................................................23

HFM-200 Outline Drawng................................................................................................ 24

HFM-201 Outline Drawing....................................................................................... 25

HFM-200B Outline Drawing .................................................................................... 26

Laminar Flow Element Outline Drawing .................................................................. 27

126B - PAGE 4

1.0 GENERAL INFORMATION

Hastings Mass Flowmeters are designed to accurately measure mass flow without corrections or

compensations for gas pressure and temperature. Due to a linear electrical output signal, the flowmeters

are ideal for use with totalizers and recorders. Hastings Mass Flowmeters do not require any periodic

maintenance under normal operating conditions with clean gases. No damage will occur from the use of

moderate overpressures or overflows.

The standard flowmeter calibration is for air. Special calibrations for most other gases such as oxygen,

nitrogen, hydrogen, and carbon monoxide are available on special order, or by use of a gas multiplier.

These instruments are calibrated with air at the factory, then the output is adjusted using gas correction

factors.

1.1 Features1.1 Features

1.1 Features

1.1 Features1.1 Features

Hastings Fast Response HFM Flowmeters have response times of less than two seconds to 98% of

a 0-100% step change with less than 2% overshoot.

Fast Response HFM Flowmeters are available with a 15-pin “D” connector and are pin for pin

compatible with most other manufacturers’ thermal mass flowmeters with 20-pin connectors.

HFM Models incorporate a removable/replaceable sensor which virtually eliminates long down time

due to clogging, the most common cause of failure in the industry.

Each flowmeter has a shunt which can be quickly and easily adjusted in the field to different ranges,

however, recalibration is normally required.

A 100 micron filter is located upstream of the shunt and sensor to eliminate most of the larger impurities

in the system which tend to plug thermal mass flowmeters.

The Model HFM Flowmeter comes in 15 standard ranges from 0-10 SCCM to 0-500 SLPM. Special

ranges are available upon request.

Model HFM Flowmeters are constructed of 300 series stainless steel. Viton is standard for O-rings &

seals. Neoprene and Kalrez are available upon request, for use with corrosive gases.

1.2 Specifications1.2 Specifications

1.2 Specifications

1.2 Specifications1.2 Specifications

• Response Time .......................................................... (to 98% of 0-100% step change)Less than 2 seconds

• Accuracy & Linearity.................................................................................................................±1% (F.S.)

• Repeatability .......................................................................................................................... ±0.2% (F.S.)

• Std. Pressure Rating ......................................................................................................................500 psig

• High Pressure Option....................................................................... 1000 psig (proof tested to 1500 psig)

• Pressure Coefficient ........................................................................................... (0-500 psig N

• Leak Integrity................................................................................................................................10

• T emperature Coefficient of Span........................................................................................... <0.1% per

) 0.01%/psi

2

-9

sccs

o

C

• Pow er ........................................................................................................................ ±15 VDC @ ±50mA

• Flow Signal................................................................................................. 0-5.00 VDC (inherently linear)

• Wetted Material ............................................................................ 316 SS, Viton Seals, Gold/ Nickle Braze

• Connector ................................................................................................................... 15 pin D connector

• FittingsHFM-229, ............................................................................................................1/4" Swagelok

HFM-230, 1/2" Swagelok

TM

TM

• Weight (approx)HFM-229,............................................................................................................. 1.8 lbs.

HFM-230, 3.3 lbs.

126B - PAGE 5

1.3 1.3

1.3

1.3 1.3

AccessorAccessor

Accessor

AccessorAccessor

iesies

ies

iesies

1.3.1 P1.3.1 P

1.3.1 P

1.3.1 P1.3.1 P

Hastings’ P ower Supplies are designed as combination po wer supplies and digital readout monitors.

They can simultaneously power a combination of different Hastings Flow Instruments . The front panel

(9.47"H X 3.47"W) allows mounting of two units in a standard 19" rack. A terminal strip on the rear

panel provides the user with continuous analog outputs from all channels. All po wer supplies have a 3-1/

2 LCD display .

Models 200 and 400 Pow er Supplies can accommodate up to two or four Hastings Flow Instruments,

respectively , and the Model 40 is for use with flo wmeters only, powering up to 4 simultaneously . The

Model 40 also features user-adjustable gas conversion factors for direct reading when changing

gases. F or more information, request Product Bulletin No . 544.

1.3.2 1.3.2

1.3.2

1.3.2 1.3.2

The Model AL-1 Flow Alarm is available as an attachment suitable for use with any 0-5.00 VDC input

signal. Calibrated digital dial precision pots determine the low and high set points as a percent of full

scale. This permits use with any range flowmeter or other instrument having a 0-5.00 VDC linear

output signal. Control action is within 0.2% of scale. The AL-1 is available in the panel mount J

package.

1.3.3 1.3.3

1.3.3

1.3.3 1.3.3

The Hastings TR-1 Flow T otalizer integrates the 0-5.00 VDC signal generated by the flowmeter to give

a total flow reading. Count rates from 0-999 counts per minute are selectable b y internal setting. The

TR-1 is available in the panel mount J package.

oo

ww

er Supplieser Supplies

o

w

er Supplies

oo

ww

er Supplieser Supplies

AlarAlar

msms

Alar

ms

AlarAlar

msms

TT

otalizerotalizer

T

otalizer

TT

otalizerotalizer

1.3.4 4-20 mA Current Converter1.3.4 4-20 mA Current Converter

1.3.4 4-20 mA Current Converter

1.3.4 4-20 mA Current Converter1.3.4 4-20 mA Current Converter

The Hastings Model CC-420 Series Current Converter is an option available with Hastings Mass

Flowmeters. The CC-420 produces a 4-20 mA signal from the 0-5.00 VDC output of the flo wmeter.

The CC-420 is available in the panel mount J package.

126B - PAGE 6

2.0 INSTALLATION AND OPERATION

This section is designed to assist in getting a new flowmeter into operation as quickly and easily as

possible. Please read the following thoroughly before attempting to install the instrument.

2.1 Receiving Inspection:2.1 Receiving Inspection:

2.1 Receiving Inspection:

2.1 Receiving Inspection:2.1 Receiving Inspection:

Carefully unpack the Hastings Flowmeter and any accessories that arrive with it. Inspect it for any

obvious signs of damage due to shipment. Immediately advise the carrier who delivered the shipment if

any damage is suspected.

Compare each component shipped against the packing list. Ensure that all parts are present (i.e.

flowmeter, po wer supply, cables, etc.). Optional equipment or accessories will be listed separately on the

packing list (see Section 1.4 - Accessories). There may also be one or more OPT- options on the

packing list. These normally refer to special ranges or special gas calibrations. They may also refer to

special helium leak tests or high pressure tests, or special modifications such as high

temperature or special O-ring materials. In most cases these are not separate parts, but rather special

options or modifications built into the flowmeter or po wer supply .

2.2 P2.2 P

2.2 P

2.2 P2.2 P

All HFM Model Flowmeters require ±15 VDC @ ±50 mA max . The 15 VDC can va ry between 14.25

VDC and 15.75 VDC. The supply voltage should be regulated with no more than 50 mV ripple. Surge

suppressers are recommended to prevent power line spikes from feeding through to the instruments.

These power requirements are satisfied by the Hastings P ow er Supply described in Section 1.4 Accessories.

2.3 Output 2.3 Output

2.3 Output

2.3 Output 2.3 Output

The output of the flowmeter is a 0-5.00 VDC signal proportional to the flow rate. The output is sent to

the display and is available at terminals at the rear of the Hastings P ow er Supply . If a Hastings supply

is not being used, the output is available on pin 6 of the D connector. It is recommended that the load

resistance be no less than 2k Ohms.

2.4 Mechanical Connections:2.4 Mechanical Connections:

2.4 Mechanical Connections:

2.4 Mechanical Connections:2.4 Mechanical Connections:

The transducer may be oriented in any position, as long as the direction of gas flow through the

transducer follows the arrow marked on the bottom of the label. The preferred orientation is with the

inlet and outlet fittings in a horizontal plane with the connector pointing up.

The smallest passageway encountered on the Hastings HFM Flowmeter is .012" ID , therefore steps

should be taken to ensure proper filtering that

prevents blockage of these passageways.

oo

ww

er Requirements:er Requirements:

o

w

er Requirements:

oo

ww

er Requirements:er Requirements:

VV

oltage:oltage:

V

oltage:

VV

oltage:oltage:

There are two 8-32 threaded holes 1/4" deep in

the bottom of the transducer that can be used to

secure it to a mounting bracket, if desired.

The standard inlet and outlet fittings for the

HFM-229 Flowmeter are 1/4" Swagelok. For the

HFM-230, the fittings are 1/2"

Swagelok. Optional VCR and VCO fittings are

available from the factory . Viton O-rings are

standard with all fittings; Kalrez and

Neoprene O-rings are optional and can be

ordered from the factory.

126B - PAGE 7

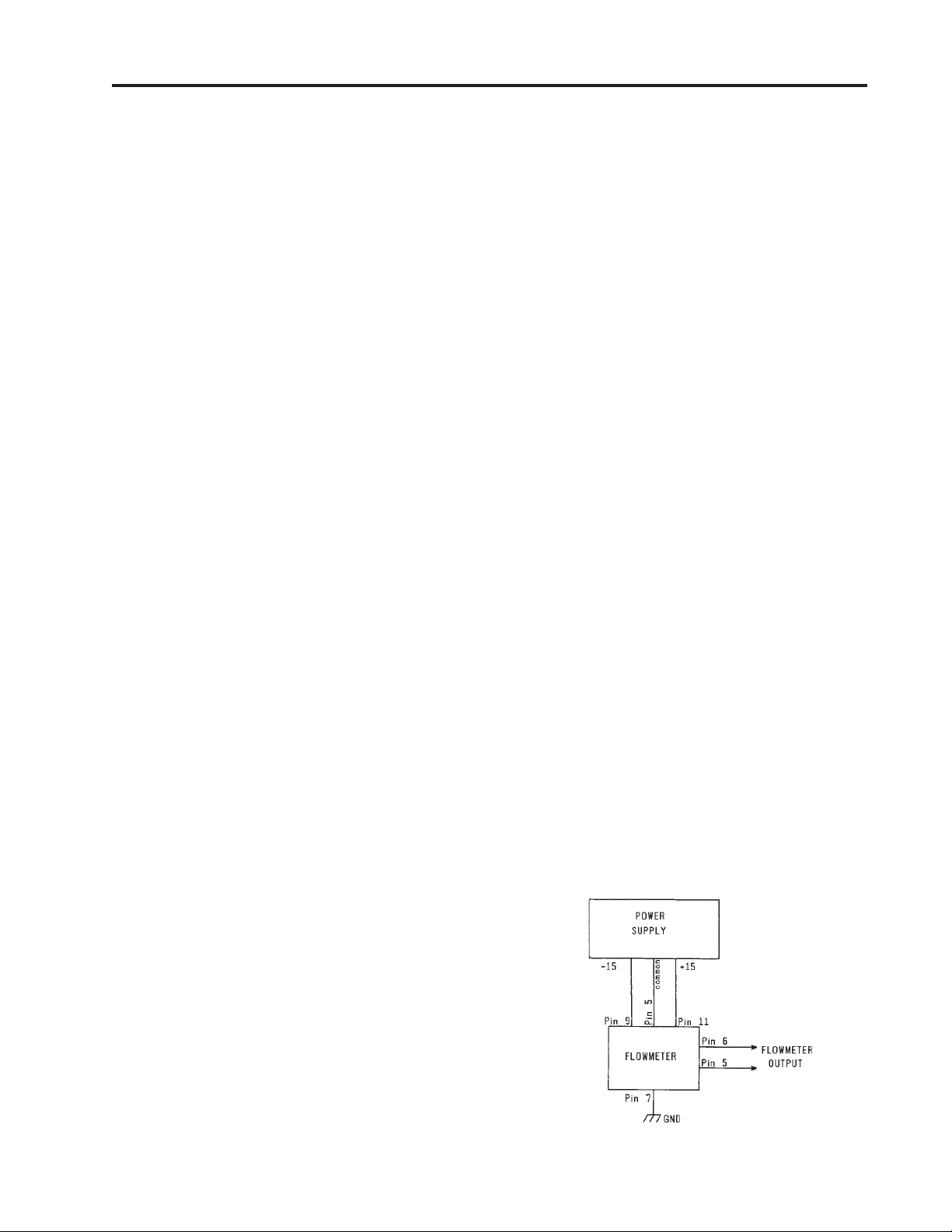

Fig.2.1Fig.2.1

Fig.2.1

Fig.2.1Fig.2.1

The standard inlet and outlet fittings for the HFM-229B Flowmeter are NPT thread in the size of the

pipe listed on the drawing on page 22, for sizes up to 3" laminar. On the 4", 6", and 8" laminars, flange

fittings are standard. Smooth tubulation is optional on all sizes.

It is suggested that all connections be checked for leaks after installation. This can be done by pressurizing the transducer (do not exceed 500 psig unless the transducer is specifically rated for higher pressures) and applying a diluted soap solution to the flow connections.

2.5 Electrical Connections:2.5 Electrical Connections:

2.5 Electrical Connections:

2.5 Electrical Connections:2.5 Electrical Connections:

If a power supply was purchased from Hastings Instruments, installation will consist of connecting the

cable, purchased separately from the po wer supply , from the rear of the supply to the top of the

flowmeter. If a Hastings supply was not purchased, follow the instructions below to connect up the

flowmeter.

The power supply used must be capable of supplying ±15VDC at ±50mA . These voltages must be

referenced to a common ground.

Refer to Fig. 2.1. Connect -15VDC to pin 9 and +15VDC to pin 11.

connected to the common connection at the power supply . Pin 7 is the case ground and it should be

connected to the cable shield if available, and to A C ground of the power supply . Pin 6 is the output

signal from the flowmeter. This output will be 0-5VDC, 5VDC being 100% of rated or full flow.

2.6 Operation:2.6 Operation:

2.6 Operation:

2.6 Operation:2.6 Operation:

2.6.1 P2.6.1 P

2.6.1 P

2.6.1 P2.6.1 P

Do not connect transducers while the power supply is energized. The display may read either percent of

full scale or actual flow rate, depending on the po wer supply purchased. To read flow rate, turn display

switch to desired channel.

2.6.2 2.6.2

2.6.2

2.6.2 2.6.2

In order to maintain the accuracy of the flowmeter with changes in ambient temperature, it is necessary

to keep the temperature of the transducer between 0oC and 50oC. Since some of the temperature shift

results in a slight zero offset, better results are obtained if the flowmeter is re-zeroed at the operating

temperature. The flowmeter calibration may change by a factor up to 0.1%/oC. Hastings Mass

Flowmeters are for GAS flow, so DO NOT let the temperature and/or pressure of the gas

reach a point that would cause the gas to change to a liquid state, or erroneous indications will result.

oo

ww

er Supply Operaer Supply Opera

o

w

er Supply Opera

oo

ww

er Supply Operaer Supply Opera

Ambient Ambient

Ambient

Ambient Ambient

TT

emperaempera

T

empera

TT

emperaempera

tureture

ture

tureture

tiontion

tion

tiontion

Pin 5 is common and must be

2.6.3 Zero Check2.6.3 Zero Check

2.6.3 Zero Check

2.6.3 Zero Check2.6.3 Zero Check

T urn the power supply “ON”. Allow the flo wmeter 10 minutes to warm up. Stop all flow through the

transducer and check electrical zero .

CAUTION: Do not assume that all metering valves will completely shut off flo w . Ev en a slight leakage

through a valve will cause an indication on the meter which will falsely appear to be a zero shift.

If necessary, adjust the “ZER O” potentiometer, located on the lower inlet side of the transducer, until

the meter indicates zero. This zero should be checked periodically during normal operation.

2.7 Range Changing:2.7 Range Changing:

2.7 Range Changing:

2.7 Range Changing:2.7 Range Changing:

The range of the flowmeter can be changed in the field if recalibration facilities are available. The

instructions to change the flow range can be found in Section 4.5. In order to change the range of a

Model HFM-230 Flowmeter, a new laminar flo w element must be purchased from the factory.

126B - PAGE 8

3.0 THEORY OF OPERATION

This section contains an overall functional description

of Model HFM Flowmeters. Detailed schematics and

parts lists can be found at the end of the manual in

Section 6.0. In this section and other sections

throughout this manual, when a power supply is

mentioned, it is assumed that the customer has a

Hastings Pow er Supply . These sections are not

applicable if another type of power supply is used.

3.1 Overall Functional Description3.1 Overall Functional Description

3.1 Overall Functional Description

3.1 Overall Functional Description3.1 Overall Functional Description

The HFM Flowmeter consists of a sensor, electronic

circuitry, and a shunt. The sensor measures the flow

rate from 0 to 10 sccm of the gas to be metered. The

shunt divides the flow such that the flow through the

sensor is a precise percentage of the flow through the

shunt. The flow through the sensor and the shunt is

always laminar. The circuit board amplifies the sensor

output to 5.00 VDC and sends it to the power supply

to display . All of these components working together

result in a fast, stable flowmeter.

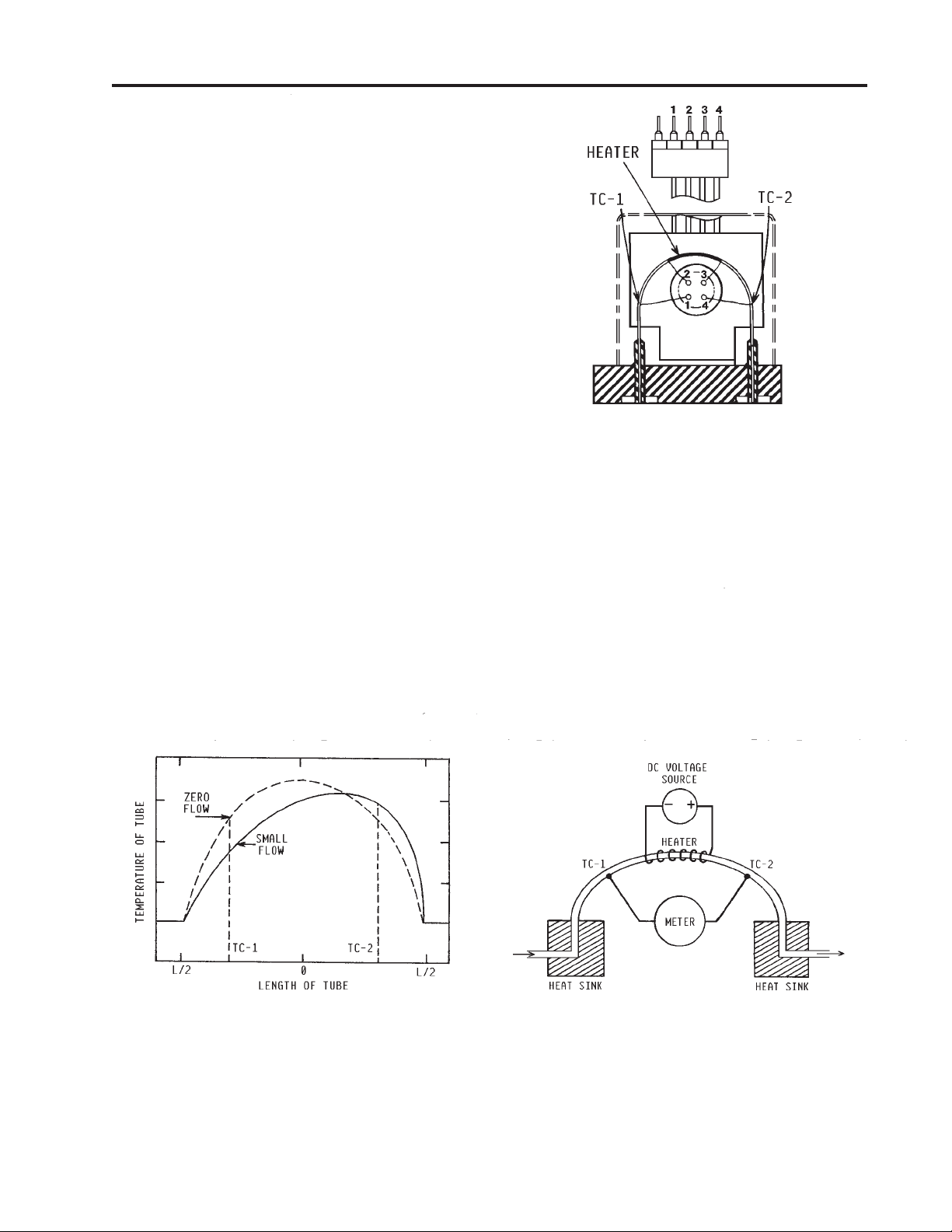

Fig.3.1Fig.3.1

Fig.3.1

Fig.3.1Fig.3.1

3.2 Sensor3.2 Sensor

3.2 Sensor

3.2 Sensor3.2 Sensor

The Hastings Model HFM Mass Flowmeter operates on a unique thermal electric principle

whereby a metallic capillary tube is heated uniformly by a resistance winding attached to the mid-

point of the capillary (see Figure 3.1). Thermocouples TC-1 and TC-2 are welded at equal distances

from the mid-point and develop equal outputs at zero flow.

When flow occurs through the tubing, heat is transferred from the tube to the gas on the inlet side, and

from the gas back to the tube on the outlet side creating an asymmetrical temperature distribution (see

Figure 3.2). The thermocouples sense this decrease and increase in the capillary tube temperature, and

produce a millivolt output signal proportional to that change.

Fig.3.2Fig.3.2

Fig.3.2

Fig.3.2Fig.3.2

126B - PAGE 9

Fig.3.3Fig.3.3

Fig.3.3

Fig.3.3Fig.3.3

For a constant power input, the differential thermocouple output is a function of the mass flow rate and

the heat capacity of the gas. Since the heat capacity of many gases is relatively constant over wide

ranges of temperature and pressure, the flowmeter may be calibrated directly in

gases. Changes in gas composition usually only require application of a simple multiplier to the air

calibration to account for the difference in heat capacity , and thus the flowmeter is capable of

measuring a wide variety of gases.

3.3 Electronics3.3 Electronics

3.3 Electronics

3.3 Electronics3.3 Electronics

The Fast Response Model HFM uses a thermal flow sensor to measure flow through a capillary tube,

which is a fixed percentage of the total flow through the instrument. This sensor develops an output

signal proportional to flow which is approximately 0.8 mv full scale magnitude (see Figure 3.3). This

signal is amplified by the meter circuitry until it is 0-5.00 VDC. This 5 volt output is sent back to the

power supply and to the flowmeter circuitry, if applicable. At the pow er supply the 5 volt output is sent

to the terminals on the back and to the decoding circuitry in the display which converts it to a 3-1/2

digit output.

mass units for those

Fig.3.4Fig.3.4

Fig.3.4

Fig.3.4Fig.3.4

The Fast Response Model HFM uses additional electronics to achieve fast response characteristics by

amplifying the rate ofchange of the input signal, and adding it to the amplified input signal. The electronics are adjusted to provide response times of less than two seconds to 98% of a 0-100% step change

with less than 2% overshoot. The electronics also maintain the ouput signal above 5.00 VDC when the

flowrate exceeds the full scale flow of the flowmeter.

NONO

TE:TE:

NO

TE:

The output signal will continue to increase above 5.00 VDC as the flow rate exceeds full scale flow,

NONO

TE:TE:

however , the output above 5.00 VDC is non-linear and should not be used for flo w measurement.

3.4 Shunt3.4 Shunt

3.4 Shunt

3.4 Shunt3.4 Shunt

Higher measurement of flow rates is achieved by dividing the flow with a fixed ratio shunting arrangement, as is illustrated in Figure 3.4. This is accomplished by placing the measuring capillary tube parallel

with one or more dimensionally similarchannels, called a laminar flo w element (LFE). Therefore, the

sensor only needs to heat the gas passing through the capillary tube resulting in low power requirements, while retaining all the mass measuring characteristics.

The HFM-229 has two possible shunts. The lo w range shunt consists of tubes inserted into a cylindrical

base. This shunt is adjustable for ranges from 0-10 sccm to 0-250 sccm (see Figure 3.5). The higher

range shunt consists of a corrugated stainless steel ribbon wound into a coil and fused. The higher range

shunt is adjustable from 0-0.3 slpm to 0-30 slpm ranges(Figure 3.6).

Fig.3.5Fig.3.5

Fig.3.5

Fig.3.5Fig.3.5

126B - PAGE 10

Fig.3.6Fig.3.6

Fig.3.6

Fig.3.6Fig.3.6

The HFM-230 uses a shunt which is acorrugated and fused shunt similar to the shunt used in the

lower flow range instruments (see Figure 3.7). This highest range shunt is adjustable from 0- 50 slpm

to 0-500 slpm.

The HFM-229B Series uses an external laminar flow element instead of an internal shunt, because the

necessary size for the element exceeds the body size of the flowmeter. This laminar flow element is

made of a corrugated and fused stainless steel ribbon similar to the one used in the

Model HFM-230.

Fig.3.7Fig.3.7

Fig.3.7

Fig.3.7Fig.3.7

126B - PAGE 11

126B - PAGE 12

4.0 MAINTENANCE

4.1 Introduction:4.1 Introduction:

4.1 Introduction:

4.1 Introduction:4.1 Introduction:

This section contains service and calibration information. Some portions of the instrument are delicate.

Use extreme care when servicing the flowmeter. The potentiometer positions and the electrical compo-

nents referred to in the troubleshooting section can be found in Section 6.0 on the electrical component

layout drawing.

4.2 4.2

AuthorAuthor

4.2

Author

4.2 4.2

AuthorAuthor

With proper care in installation and use, the flowmeter will require little or no maintenance. If mainte-

nance does become necessary, most of the instrument can be cleaned or repaired in the field. Some

procedures may require recalibration. Do not attempt these procedures unless facilities are available.

Entry into the sensor or tampering with the printed circuit board will void warranty . Do not perform

repairs on these assemblies while unit is still under warranty.

4.3 4.3

Adjustments:Adjustments:

4.3

Adjustments:

4.3 4.3

Adjustments:Adjustments:

4.3.1 Calibration Procedure4.3.1 Calibration Procedure

4.3.1 Calibration Procedure

4.3.1 Calibration Procedure4.3.1 Calibration Procedure

1.1.

1.

Connect power cable to D connector as specified in Section 2.5. Allo w instrument to warm up for

1.1.

30 minutes with all flow shut off.

2.2.

2.

Set ZERO potentiometer for 0.000 VDC output at pin 6 on the D connector or flow output pin on

2.2.

the rear of the Hastings Pow er Supply .

3.3.

3.

T urn on air supply to inlet of instrument. Adjust flow rate to 100% according to flo w reference.

3.3.

4.4.

4.

Adjust SPAN pot until the flo wmeter

4.4.

indicates full scale flow (5.000 VDC).

NOTE: P erform this step only if a

calibrated reference flowmeter is available.

ized Maintenance:ized Maintenance:

ized Maintenance:

ized Maintenance:ized Maintenance:

5. 5.

5. Record flowmeter and flow reference

5. 5.

outputs for flow rates of 20%, 40%, 60%,

80%, and 100%.

4.3.2 Response 4.3.2 Response

4.3.2 Response

4.3.2 Response 4.3.2 Response

Readjustments of the fast response

circuit should not be necessary unless

changes in the range or sensor have

been performed. The flowmeter should

be calibrated before setting the response

time.

IMPORTANT: Response time cannot

be tested with a simple shutoff valve.

Pressure builds up behind the valve, and when opened creates a surge flow in excess of the calibrated flow rate.

What must be used is a two-way valve or a fitting which can be quickly connected and provide a leak-free seal to

the flowmeter inlet. The reference flow is vented to atmosphere, and switches through the flowmeter when the

valve is operated or fitting is connected. The valve or fitting should be close coupled to the flo wmeter inlet to

reduce pneumatic time delays. The response pot is not accessible from the exterior of the flowmeter. The cover

must be removed to make any adjustments. See Fig. 4.1.

Using a voltmeter, strip chart recorder, or oscilloscope connected to the flow output voltage, switch flow through

the flowmeter and observe output voltage. Adjust response pot to increase or decrease response time. The

response pot is a single turn pot and a small pot adjustment produces a large response time change. Remove flow

from flowmeter and allow output voltage to reach zero volts. Repeat test until response time is set.

Time Time

Time

Time Time

AdjustmentsAdjustments

Adjustments

AdjustmentsAdjustments

Fig.4.1Fig.4.1

Fig.4.1

Fig.4.1Fig.4.1

4.3.34.3.3

4.3.3

4.3.34.3.3

Periodically , during normal operation, the ZER O should be checked and adjusted when required.

Miscellaneous Miscellaneous

Miscellaneous

Miscellaneous Miscellaneous

AdjustmentsAdjustments

Adjustments

AdjustmentsAdjustments

126B - PAGE 13

4.4 End Cap Removal4.4 End Cap Removal

4.4 End Cap Removal

4.4 End Cap Removal4.4 End Cap Removal

The end cap on the inlet side must be removed to gain access to the filter or shunt assembly. First shut

off the supply of gas to the instrument. Disconnect the Swagelok fitting on the inlet and outlet sides of

the instrument. Remove the four hex bolts holding the end cap to the instrument (see Figure 4.2).

Carefully remove the end cap, filter, wave spring and shunt, noting their order and proper orientation.

NOTE: The Model HFM-230 does not include a wave spring. The shunt can be severely damaged if

dropped. Examine the filter and shunt. If either is dirty or blocked, clean or replace as applicable.

Reassembly is the reverse of the removal procedure.

Fig.4.2Fig.4.2

Fig.4.2

Fig.4.2Fig.4.2

NO TE: When reinstalling the small range shunt, ensure that corrugated side is down.

4.5 Range Changes4.5 Range Changes

4.5 Range Changes

4.5 Range Changes4.5 Range Changes

Remove end cap and shunt assembly per Section 4.4 abov e. The 0-10 sccm to 0-300 sccm range

shunt has tubes, while the medium range shunt is built from a coil of corrugated stainless steel foil. The

medium range shunt has a disk assembly with two large, one medium, and one small hole. To change

ranges, the disc on the inlet of the shunt should be loosened, turned and retightened to expose the

number of holes or tubes as listed below for the range desired.

SIZESIZE

SIZE

SIZESIZE

SMALL .......................................... 0-10 sccm............................................................................... 0 tubes

........................................................ 0-30 sccm................................................................................ 1 tube

........................................................ 0-50 sccm...............................................................................2 tubes

........................................................ 0-100 sccm.............................................................................4 tubes

........................................................ 0-250 sccm...........................................................................10 tubes

MEDIUM....................................... 0-.3 slpm ...................................................................... smallest hole

........................................................ 0-1 slpm ........................................................................ medium hole

........................................................ 0-3 slpm .......................................................... 1 large and small hole

........................................................ 0-5 slpm ................................................................... both large holes

........................................................ 0-10 slpm ........................................................................ half-washer

........................................................ 0-30 slpm .................................................................washer removed

LARGE........................................... 0-50 slpm ................................................................................ 1 hole

........................................................ 0-100 slpm ............................................................................. 2 holes

........................................................ 0-150...............................................................................slpm3 holes

........................................................ 0-300................................................................ slpmwasher removed

........................................................ 0-500............................................................... slpm washer removed

NONO

TETE

NO

TE: These ranges are for Air a t Standard Temperature and Pressure.

NONO

TETE

RANGE RANGE

RANGE

RANGE RANGE

SHUNT SETUPSHUNT SETUP

SHUNT SETUP

SHUNT SETUPSHUNT SETUP

126B - PAGE 14

4.6 Printed Circuit Board4.6 Printed Circuit Board

4.6 Printed Circuit Board

4.6 Printed Circuit Board4.6 Printed Circuit Board

ReplacementReplacement

Replacement

ReplacementReplacement

In the unlikely event that the PC board

fails, it is easily removed from the instrument and replaced with a spare to minimize

instrument downtime. Replacement of the

PC board will require the instrument to be

recalibrated per Section 4.3.1.Unplug the

power cable from the top of the transducer.

Remove the two screws on the side of the

cover. Lift off the cover and unplug the

four-wire sensor plug noting the orientation

prior to removal.

holds the PC board to the sensor. T roubleshoot or replace as applicable. Installation is

the reverse of the above procedure.

Recalibrate if any components were

changed or if any potentiometers were

adjusted.

4.7 Sensor Replacement4.7 Sensor Replacement

4.7 Sensor Replacement

4.7 Sensor Replacement4.7 Sensor Replacement

Remove the screw that

Fig.4.3Fig.4.3

Fig.4.3

Fig.4.3Fig.4.3

If the sensor fails or becomes plugged it can be

Section 4.6 above. Remove the three bolts holding the sensor to the instrument base. Remove the

sensor from the base noting the two O-rings (Parker 2-005, V884-75) between the sensor and the base.

See Figure 4.3. If the sensor is plugged it can be cleaned by running a fine wire (approximately 0.008"

diameter) through the tube. If sensor needs replacement, obtain another from the factory and install it.

Ensure that O-rings are clean and intact. Install O-rings on seating surface, then carefully place sensor

over O-rings, and tighten do wn the three screws evenly . Replacement of sensor will require recalibration

per Section 4.3.1.

4.8 4.8

TT

4.8

4.8 4.8

SYMPTSYMPT

SYMPT

SYMPTSYMPT

CACA

CA

CACA

AA

CTION:CTION:

A

CTION: Turn off pow er supply for a few seconds, then turn back on. If this prov es ineffective,

AA

CTION:CTION:

disconnect the unit from the power supply . If power supply displa y does not return to zero, then a

regulator chip in the power supply is probably burned out.

Check supply voltages and replace faulty regulator. If display

returns to zero after disconnecting the power supply from the

unit there is a short in the unit to ground. Check capacitors C11

& C13 first.

SYMPTOM:SYMPTOM:

SYMPTOM: Output of unit is proportional to flow but

SYMPTOM:SYMPTOM:

extremely small and not correctable by span pot.

roubleshootingroubleshooting

T

roubleshooting

TT

roubleshootingroubleshooting

OM:OM:

OM: Output reads 40% of flow with no flow. Zero pot has no effect.

OM:OM:

USE:USE:

USE: Pow er supply locked up or shorted out.

USE:USE:

removed.

Remove the cover and the PC board per

CAUSE: CAUSE:

CAUSE: Sensor is not being heated.

CAUSE: CAUSE:

AA

CTION:CTION:

A

CTION: Unplug sensor from PC board (Fig. 4.3). Pins on sensor are

AA

CTION:CTION:

numbered from left to right. Begin counting with second pin from left (see Fig.

4.4). Check the resistance between pins 2 & 3 of the sensor. This will read between

2450 & 2550. Check the resistance between pins 1 & 4 of the sensor . This should

read approximately 2.3 ohms. If this reads open circuit, sensor was probably

plugged into PC board improperly and one of the thermocouples has been

destroyed. Replace sensor. Check the resistance between pin 2 and the base of the

sensor. This should be an open circuit. Repeat for pin 3 and the base. If resistance

readings are correct but sensor is not indicating flow, the sensor is probably plugged;

clean or replace as applicable.

126B - PAGE 15

Fig.4.4Fig.4.4

Fig.4.4

Fig.4.4Fig.4.4

SYMPTOM: SYMPTOM:

SYMPTOM: Sensor has proper resistance readings, but little or no output with flow .

SYMPTOM: SYMPTOM:

CAUSE:CAUSE:

CAUSE: Plugged sensor.

CAUSE:CAUSE:

AA

CTION:CTION:

A

CTION: Shut off gas supply and power supply. Remove cover and PC board from unit. Remove

AA

CTION:CTION:

sensor assembly and examine. If sensor has evidence of plugging, clean or replace as applicable.

SYMPTSYMPT

SYMPT

SYMPTSYMPT

OM:OM:

OM: Flowmeter reads other than 0.00 VDC with no flow , or there is a small flow when

OM:OM:

flowmeter reads 0.00 VDC.

CACA

USE:USE:

CA

USE: ZERO potentiometer is out of adjustment.

CACA

USE:USE:

AA

CTION:CTION:

A

CTION: Shut off all flow. Adjust ZER O potentiometer until output reads 0.00 VDC.

AA

CTION:CTION:

SYMPTOM:SYMPTOM:

SYMPTOM: Flowmeter out of calibration and non-linear.

SYMPTOM:SYMPTOM:

CAUSE:CAUSE:

CAUSE: Leaks in gas inlet or outlet fittings.

CAUSE:CAUSE:

AA

CTION:CTION:

A

CTION: Check all fittings for leaks by placing soap solution on all fittings between gas supply and

AA

CTION:CTION:

final destination of gas. Check flowmeter for leaks. Replace “O” rings if required or recalibrate as

necessary.

126B - PAGE 16

5.0 REPLACEMENT PARTS

The following is a list of the available replacement parts and their factory stock numbers. The HFM229, HFM-229B, HFM-200, HFM-200B, and the HFC-202 shunts and filter discs are interchangeable. The HFM-230, HFM-201, and the HFC-203 shunts and filter discs are also interchangeable. The

same sensor module is used on all of the above models.

STST

OCK NOOCK NO

ST

OCK NO

STST

OCK NOOCK NO

81-102L......... LO W RANGE SHUNT.....................................................10, 30, 50, 100, 250 SCCM

81-102H ........ MED RANGE SHUNT ....................................................... 0.3, 1, 3, 5, 10, 30 SLPM

81-102B......... HIGH RANGE SHUNT ............................................... 50, 100, 150, 300, 500 SLPM

65-140E......... LFE Model LS-2, 2.0" NPTM ................................................................. 0-750 SLPM

65-140G ........ LFE Model LS-3, 3.0" NPTM ............................................................... 0-1500 SLPM

65-140J .......... LFE Model LS-4F, 4.0" Flange............................................................... 0-3000 SLPM

65-140K ........LFE Model LS-6F, 6.0" Flange............................................................... 0-6000 SLPM

65-140L......... LFE Model LS-8F, 8.0" Flange............................................................ 0-15,000 SLPM

..

DESCRIPTIONDESCRIPTION

.

DESCRIPTION

..

DESCRIPTIONDESCRIPTION

AIR RANGEAIR RANGE

AIR RANGE

AIR RANGEAIR RANGE

39-02-003......SMALL FIL TER DISC................................................. HFM-229, HFM-229B, AND

39-02-002...... LARGE FIL TER DISC ...................................................... HFM-230 AND HFC-203

81-105 ........... SENSOR MODULE ...........................................................................ALL MODELS

65-595 ........... FAST RESPONSE HFM ELECTRONICS CARD ...................... D CONNECTOR

81-115 .....................................................................VITON O-RING KIT FOR HFM-200 and 200B

81-116 .....................................................................................VITON O-RING KIT FOR HFM-201

81-146 .............................................................. KALREZ

TM

O-RING KIT FOR HFM-200 and 200B

81-147 .............................................................................. KALREZTM O-RING KIT FOR HFM-201

81-150 ............................................................ NEOPRENE O-RING KIT FOR HFM-200 and 200B

81-151 ............................................................................ NEOPRENE O-RING KIT FOR HFM-201

NONO

TETE

NO

TE: Ranges listed are for same standard temperature and pressure.

NONO

TETE

To place an order or to obtain information concerning replacement parts, contact the factory or our

local manufacturer’s representativ e in your area. See below , or this manual’ s last page for the address or

phone number. When ordering, include the following information:

HFC-202

• Instrument model number

• Part description

• Hastings part number

126B - PAGE 17

126B - PAGE 18

6.0 Warranty and Repair

WW

arar

ranty Pranty P

W

ar

ranty P

WW

arar

ranty Pranty P

Hastings Instruments warrants this product for a period of one year from the date of shipment to

be free from defects in material and workmanship. This warranty does not apply to defects or

failures resulting from unauthorized modification, misuse or mishandling of the product. This

warranty does not apply to batteries or other expendable parts, nor to damage caused by leaking

batteries or any similar occurrence. This warranty does not apply to any instrument which has had

a tamper seal removed or broken.

This warranty is in lieu of all other warranties, expressed or implied, including any implied warranty

as to fitness for a particular use. Hastings Instruments shall not be liable for any indirect or consequential damages.

Hastings Instruments will, at its option, repair, replace or refund the selling price of the product if

Hastings Instruments determines, in good faith, that it is defective in materials or workmanship

during the warranty period. Defective instruments should be returned to Hastings Instruments

together with a written statement of the problem and a Return Material Authorization (RMA)

number. Please consult the factory for your RMA number before returning any product for repair.

olicolic

olic

olicolic

yy

y

yy

Non-WNon-W

Non-W

Non-WNon-W

Any product returned for a non-warranty repair must be accompanied by a purchase order, RMA

form and a written description of the problem with the instrument. If the repair cost is higher, you

will be contacted for authorization before we proceed with any repairs. If you then choose not to

have the product repaired, a minimum will be charged to cover the processing and inspection.

Please consult the factory for your RMA number before returning any product for repair.

arar

ranty Repair Pranty Repair P

ar

ranty Repair P

arar

ranty Repair Pranty Repair P

TELED YNE HASTINGS

804 NEWCOMBE AVENUE

HAMPTON, VIRGINIA 23669 U .S.A.

A TTENTION: REP AIR DEP AR TMENT

TELEPHONE (757) 723-6531

FA X (757) 723-3925

olicolic

olic

olicolic

yy

y

yy

1-800-950-2468

126B - PAGE 19

126B - PAGE 20

7.0 Diagrams and Drawings

126B - PAGE 21

PC-810 Assembly

(Information from Hastings drawing 30837 rev. F)

126B - PAGE 22

PC-810 Schematic

(Information from Hastings drawing 30837 rev. F)

126B - PAGE 23

126B - PAGE 24

126B - PAGE 25

126B - PAGE 26

126B - PAGE 27

126B - PAGE 28

Loading...

Loading...