Teledyne GFC-7000E Instruction Manual

INSTRUCTION MANUAL

MODEL GFC7000E

CARBON DIOXIDE ANALYZER

© TELEDYNE ANALYTICAL INSTRUMENTS

16830 Chestnut St.

City of Industry, Ca. 91748

USA

Phone:

626-961-9221

Phone:

626-934-1500

Fax:

626-961-2538

Fax:

626-934-1651

04584

REV. A1

Copyright 2003 Teledyne Instruments Incorporated

02-August-2004

Model GFC7000E Instruction Manual GFC7000E Documentation

04584 Rev A1 i

SAFETY MESSAGES

Your safety and the safety of others is very important. We have provided many important safety

messages in this manual. Please read these messages carefully.

A safety message alerts you to potential hazards that could hurt you or others. Each safety

message is associated with a safety alert symbol. These symbols are found in the manual and

inside the instrument. The definition of these symbols is described below:

GENERAL SAFETY HAZARD: Refer to the instructions for

details on the specific hazard.

CAUTION: Hot Surface Warning

CAUTION: Electrical Shock Hazard

TECHNICIAN SYMBOL: All operations marked with this

symbol are to be performed by qualified maintenance

personnel only.

CAUTION

The analyzer should only be used for the purpose and in the manner described in this

manual. If you use the analyzer in a manner other than that for which it was intended,

unpredictable behavior could ensue with possible hazardous consequences.

NGFC7000E Documentation Model GFC7000E Instruction Manual

TABLE OF CONTENTS

SAFETY MESSAGES .................................................................................................................................I

TABLE OF CONTENTS............................................................................................................................ II

LIST OF APPENDICES .........................................................................................................................VII

LIST OF FIGURES ...............................................................................................................................VII

LIST OF TABLES................................................................................................................................ VIII

1. MGFC7000E DOCUMENTATION.......................................................................................................... 1

1.1. Using This Manual.......................................................................................................................... 1

2. SPECIFICATIONS, APPROVALS AND WARRANTY.............................................................................. 5

2.1. Specifications ................................................................................................................................ 5

2.2. CE Mark Compliance ...................................................................................................................... 6

2.3. Warranty ...................................................................................................................................... 6

3. GETTING STARTED ............................................................................................................................ 9

3.1. Unpacking and Initial Set Up........................................................................................................... 9

3.1.1. Electrical Connections.............................................................................................................11

3.1.2. Pneumatic Connections: .........................................................................................................15

3.1.2.1. Basic Pneumatic Connections............................................................................................15

3.1.2.2. Connections with Internal Valve Options Installed ..............................................................19

3.2. Initial Operation ...........................................................................................................................21

3.2.1. Startup .................................................................................................................................22

3.2.2. Warm Up...............................................................................................................................23

3.2.3. Warning Messages .................................................................................................................24

3.2.4. Functional Check....................................................................................................................25

3.3. Initial Calibration Procedure...........................................................................................................26

4. FREQUENTLY ASKED QUESTIONS ................................................................................................... 31

4.1. FAQ’s...........................................................................................................................................31

4.2. Glossary ......................................................................................................................................32

5. OPTIONAL HARDWARE AND SOFTWARE......................................................................................... 35

5.1. Rack Mount Kits (Options 20a, 20b & 21)........................................................................................35

5.2. Current Loop Analog Outputs (Option 41) .......................................................................................35

5.3. Expendable Kits (Options 42C, 42D and 43)....................................................................................36

5.4. Calibration Valves Options .............................................................................................................36

5.4.1. Zero/Span/Shutoff Valve (Option 50).......................................................................................36

5.4.2. Zero/Span/Shutoff with External CO2 Scrubber (Option 51) ......................................................38

5.4.3. Zero/Span Valve (Option 52) ..................................................................................................38

5.4.4. Zero/Span Valve with External CO2 Scrubber (Option 53) ..........................................................39

5.5. Communication Options ................................................................................................................39

5.5.1. RS232 Modem Cable (Option 60).............................................................................................39

5.5.2. RS-232 Multidrop (Option 62) .................................................................................................40

5.5.3. Ethernet (Option 63) ..............................................................................................................40

5.6. Additional Manuals........................................................................................................................40

5.6.1. Printed Manuals (Option 70) ...................................................................................................40

5.6.2. Manual on CD (Part number 045840200) .................................................................................41

5.7. Extended Warranty (Options 92 & 93) ............................................................................................41

5.8. Dilution Ratio Option (Option ??)....................................................................................................41

5.9. Maintenance Mode Switch (Option ??) ............................................................................................41

5.10. Second Language Switch (Option ??) ............................................................................................42

6. OPERATING INSTRUCTIONS ........................................................................................................... 43

6.1. Overview of Operating modes ........................................................................................................43

6.2. Sample Mode ...............................................................................................................................44

6.2.1. Test Functions .......................................................................................................................44

6.2.2. Warning Messages .................................................................................................................46

6.3. Calibration Mode...........................................................................................................................48

6.3.1. SETUP – PASS: Calibration Password Security ..........................................................................48

6.4. SETUP Mode.................................................................................................................................50

6.4.1. SETUP Mode Password Security...............................................................................................51

6.5. SETUP – CFG: Viewing the Analyzer’s Configuration Information .......................................................51

6.6. SETUP – CLK: Setting the Internal Time-of-Day Clock ......................................................................52

Model GFC7000E Instruction Manual GFC7000E Documentation

04584 Rev A1 iii

6.7. SETUP – RNGE: Analog Output Reporting Range Configuration .........................................................54

6.7.1. Physical Range versus Analog Output Reporting Ranges ............................................................54

6.7.2. Reporting Range Modes ..........................................................................................................55

6.7.3. Single Range mode (SNGL).....................................................................................................56

6.7.4. Dual Range Mode (DUAL) .......................................................................................................58

6.7.5. Auto Range Mode (AUTO) .......................................................................................................59

6.7.6. Range Units...........................................................................................................................60

6.7.7. Dilution Ratio.........................................................................................................................61

6.8. SETUP – VARS: Using the Internal Variables ...................................................................................62

6.9. SETUP – DIAG: Using the Diagnostics Functions ..............................................................................64

6.9.1. Accessing the Diagnostic Features ...........................................................................................65

6.9.2. Signal I/O .............................................................................................................................65

6.9.3. Analog Output Step Test.........................................................................................................66

6.9.4. Analog I/O Configuration ........................................................................................................67

6.9.4.1. Analog Output Signal Type and Range Span Selection ........................................................69

6.9.4.2. Analog Output Calibration Mode........................................................................................69

6.9.4.3. Manual Analog Output Calibration and Voltage Adjustment..................................................71

6.9.4.4. Current Loop Output Adjustment ......................................................................................73

6.9.4.5. AIN Calibration................................................................................................................75

6.9.5. Electric Test...........................................................................................................................75

6.9.6. Dark Calibration Test..............................................................................................................76

6.9.7. Pressure Calibration ...............................................................................................................76

6.9.8. Flow Calibration .....................................................................................................................78

6.9.9. Test Channel Output ..............................................................................................................79

6.10. SETUP – COMM: Using the Analyser’s Communication Ports............................................................80

6.10.1. Analyzer ID Code .................................................................................................................80

6.10.2. COMM Port Default Settings ..................................................................................................81

6.10.3. COMM Port Cable Connections ...............................................................................................82

6.10.4. RS-485 Configuration of COM2 ..............................................................................................82

6.10.5. DTE and DCE Communication................................................................................................83

6.10.6. COMM Port Communication Modes .........................................................................................83

6.10.7. COM Port Baud Rate .............................................................................................................86

6.10.8. COM Port Testing .................................................................................................................87

6.10.9. Ethernet Card Configuration ..................................................................................................87

6.10.9.1. Ethernet Card COM2 Communication Modes and Baud Rate...............................................88

6.10.9.2. Configuring the Ethernet Interface Option using DHCP ......................................................88

6.10.9.3. Manually Configuring the Network IP Addresses ...............................................................90

6.10.9.4. Changing the Analyzer’s HOSTNAME ...............................................................................92

6.11. SETUP – ALRM: Using the Gas Concentration Alarms......................................................................93

6.12. SETUP – DAS: Using the Data Acquisition System (iDAS) ...............................................................94

6.12.1. iDAS Structure.....................................................................................................................94

6.12.1.1. iDAS Channels...............................................................................................................95

6.12.1.2. iDAS Parameters ...........................................................................................................96

6.12.1.3. iDAS Triggering Events ..................................................................................................96

6.12.2. Default iDAS Channels..........................................................................................................97

6.12.2.1. Viewing iDAS Data and Settings....................................................................................101

6.12.2.2. Editing iDAS Data Channels ..........................................................................................102

6.12.2.3. Trigger Events.............................................................................................................103

6.12.2.4. Editing iDAS Parameters ..............................................................................................104

6.12.2.5. Sample Period and Report Period ..................................................................................105

6.12.2.6. Number of Records ......................................................................................................107

6.12.2.7. RS-232 Report Function ...............................................................................................108

6.12.2.8. Compact Report ..........................................................................................................109

6.12.2.9. Starting Date ..............................................................................................................109

6.12.2.10. Disabling/Enabling Data Channels ...............................................................................109

6.12.2.11. HOLDOFF Feature ......................................................................................................110

6.12.3. Remote iDAS Configuration .................................................................................................111

6.13. Remote Operation of the Analyzer ..............................................................................................113

6.13.1. Remote Operation Using the External Digital I/O...................................................................113

6.13.1.1. Status Outputs ............................................................................................................113

NGFC7000E Documentation Model GFC7000E Instruction Manual

6.13.1.2. Control Inputs.............................................................................................................114

6.13.2. Remote Operation Using the External Serial I/O....................................................................115

6.13.2.1. Terminal Operating Modes............................................................................................115

6.13.2.2. Help Commands in Terminal Mode ................................................................................116

6.13.2.3. Command Syntax ........................................................................................................116

6.13.2.4. Data Types .................................................................................................................117

6.13.2.5. Status Reporting .........................................................................................................118

6.13.2.6. Remote Access by Modem ............................................................................................118

6.13.2.7. COM Port Password Security.........................................................................................120

6.13.2.8. APICOM Remote Control Program .................................................................................120

6.13.3. Additional Communications Documentation ..........................................................................121

6.13.4. Using the MGFC7000E with a Hessen Protocol Network..........................................................121

6.13.4.1. General Overview of Hessen Protocol ............................................................................121

6.13.4.2. Hessen COMM Port Configuration ..................................................................................122

6.13.4.3. Activating Hessen Protocol ...........................................................................................122

6.13.4.4. Selecting a Hessen Protocol Type ..................................................................................123

6.13.4.5. Setting The Hessen Protocol Response Mode ..................................................................124

6.13.4.6. Hessen Protocol Gas ID................................................................................................124

6.13.4.7. Setting Hessen Protocol Status Flags.............................................................................125

6.13.4.8. Instrument ID Code.....................................................................................................126

7. CALIBRATION PROCEDURES ......................................................................................................... 129

7.1. Before Calibration .......................................................................................................................129

7.1.1. Zero Air and Span Gas .........................................................................................................129

7.1.2. Calibration Gas Traceability...................................................................................................130

7.1.3. Data Recording Devices ........................................................................................................130

7.2. Manual Calibration without Zero/Span Valves ................................................................................130

7.3. Manual Calibration Checks...........................................................................................................133

7.4. Manual Calibration with Zero/Span Valves.....................................................................................133

7.5. Manual Calibration Checks with Zero/Span Valves .........................................................................137

7.5.1. Zero/Span Calibration on Auto Range or Dual Ranges .............................................................137

7.5.2. Use of Zero/Span Valves with Remote Contact Closure............................................................138

7.6. Automatic Zero/Span Cal/Check (AutoCal) ....................................................................................139

7.6.1. AutoCal with Auto or Dual Reporting Ranges Modes Selected ...................................................142

7.7. Calibration Quality ......................................................................................................................142

8. EPA PROTOCOL CALIBRATION ...................................................................................................... 145

9. MAINTENANCE SCHEDULE & PROCEDURES................................................................................... 147

9.1. Maintenance Schedule.................................................................................................................147

9.2. Predicting Failures Using the Test Functions ..................................................................................150

9.3. Maintenance Procedures..............................................................................................................150

9.3.1. Replacing the Sample Particulate Filter ..................................................................................151

9.3.2. Rebuilding the Sample Pump.................................................................................................152

9.3.3. Performing Leak Checks .......................................................................................................152

9.3.3.1. Vacuum Leak Check and Pump Check .............................................................................152

9.3.3.2. Pressure Leak Check......................................................................................................152

9.3.4. Performing a Sample Flow Check...........................................................................................153

9.3.5. Cleaning the Optical Bench ...................................................................................................153

9.3.6. Cleaning Exterior Surfaces of the MGFC7000E ........................................................................153

10. THEORY OF OPERATION.............................................................................................................. 155

10.1. Measurement Method ................................................................................................................155

10.1.1. Beer’s Law.........................................................................................................................155

10.1.2. Measurement Fundamentals................................................................................................156

10.1.3. Gas Filter Correlation..........................................................................................................156

10.1.4. Ambient CO2 Interference Rejection.....................................................................................160

10.2. Pneumatic Operation.................................................................................................................160

10.2.1. Sample Gas Flow................................................................................................................161

10.2.1.1. Critical Flow Orifice ......................................................................................................161

10.2.1.2. Sample Pressure Sensor...............................................................................................162

10.2.1.3. Sample Flow Sensor ....................................................................................................162

10.2.1.4. Valve Options..............................................................................................................163

10.2.2. Purge Gas Pressure and Flow Control ...................................................................................163

10.3. Electronic Operation..................................................................................................................163

Model GFC7000E Instruction Manual GFC7000E Documentation

04584 Rev A1 v

10.3.1. Overview...........................................................................................................................163

10.3.2. CPU ..................................................................................................................................165

10.3.3. Optical Bench & GFC Wheel.................................................................................................165

10.3.3.1. Sample Gas and GFC Temperature Control ....................................................................165

10.3.3.2. IR Source ...................................................................................................................166

10.3.3.3. GFC Wheel..................................................................................................................166

10.3.3.4. IR Photo-Detector........................................................................................................167

10.3.4. Synchronous Demodulator (Sync/Demod) Assembly..............................................................167

10.3.4.1. Overview ....................................................................................................................167

10.3.4.2. Signal Synchronization and Demodulation......................................................................168

10.3.4.3. Phase Lock Warning.....................................................................................................169

10.3.4.4. Sync/Demod Status LED’s ............................................................................................169

10.3.4.5. Photo-Detector Temperature Control .............................................................................170

10.3.4.6. Dark Calibration Switch................................................................................................170

10.3.4.7. Electric Test Switch......................................................................................................170

10.3.5. Relay Board.......................................................................................................................170

10.3.5.1. Status LED’s ...............................................................................................................171

10.3.5.2. I

2

C Watch Dog Circuitry ..............................................................................................172

10.3.6. Mother Board.....................................................................................................................172

10.3.6.1. A to D Conversion........................................................................................................172

10.3.6.2. Sensor Inputs .............................................................................................................173

10.3.6.3. Thermistor Interface ....................................................................................................173

10.3.6.4. Analog Outputs ...........................................................................................................174

10.3.6.5. Internal Digital I/O ......................................................................................................174

10.3.6.6. External Digital I/O......................................................................................................175

10.3.7. I2C Data Bus......................................................................................................................175

10.3.8. Power Supply/ Circuit Breaker .............................................................................................175

10.4. Interface..................................................................................................................................176

10.4.1. Front Panel Interface ..........................................................................................................177

10.4.1.1. Analyzer Status LED’s ..................................................................................................178

10.4.1.2. Keyboard....................................................................................................................178

10.4.1.3. Display .......................................................................................................................178

10.4.1.4. Keyboard/Display Interface Electronics..........................................................................179

10.5. Software Operation ...................................................................................................................180

10.5.1. Adaptive Filter ...................................................................................................................181

10.5.2. Calibration - Slope and Offset..............................................................................................181

10.5.3. Measurement Algorithm......................................................................................................182

10.5.4. Temperature and Pressure Compensation.............................................................................182

10.5.5. Internal Data Acquisition System (iDAS) ..............................................................................182

11. TROUBLESHOOTING & REPAIR PROCEDURES............................................................................. 185

11.1. General Troubleshooting Hints ...................................................................................................185

11.1.1. Interpreting WARNING Messages.........................................................................................186

11.1.2. Fault Diagnosis with TEST Functions ....................................................................................188

11.1.3. Using the Diagnostic Signal I/O Function ..............................................................................190

11.1.4. Internal Electronic Status LED’s...........................................................................................191

11.1.4.1. CPU Status Indicator....................................................................................................191

11.1.4.2. Sync Demodulator Status LED’s ....................................................................................192

11.1.4.3. Relay Board Status LED’s .............................................................................................193

11.1.5. Gas Flow Problems .............................................................................................................194

11.1.6. Typical Sample Gas Flow Problems ......................................................................................195

11.1.6.1. Flow is Zero ................................................................................................................195

11.1.6.2. Low Flow ....................................................................................................................195

11.1.6.3. High Flow ...................................................................................................................196

11.1.6.4. Displayed Flow = “XXXX” .............................................................................................196

11.1.6.5. Actual Flow Does Not Match Displayed Flow ...................................................................196

11.1.6.6. Sample Pump..............................................................................................................196

11.1.7. Poor or Stopped Flow of Purge Gas ......................................................................................196

11.2. Calibration Problems .................................................................................................................197

11.2.1. Miss-Calibrated ..................................................................................................................197

11.2.2. Non-Repeatable Zero and Span ...........................................................................................197

NGFC7000E Documentation Model GFC7000E Instruction Manual

11.2.3. Inability to Span – No SPAN Key..........................................................................................198

11.2.4. Inability to Zero – No ZERO Key ..........................................................................................198

11.3. Other Performance Problems......................................................................................................198

11.3.1. Temperature Problems........................................................................................................199

11.3.1.1. Box or Sample Temperature .........................................................................................199

11.3.1.2. Bench Temperature .....................................................................................................199

11.3.1.3. GFC Wheel Temperature ..............................................................................................200

11.3.1.4. IR Photo-Detector TEC Temperature..............................................................................200

11.3.2. Excessive Noise..................................................................................................................200

11.4. Subsystem Checkout.................................................................................................................201

11.4.1. AC Mains Configuration.......................................................................................................201

11.4.2. DC Power Supply ...............................................................................................................202

11.4.3. I2C Bus .............................................................................................................................202

11.4.4. Keyboard/Display Interface .................................................................................................203

11.4.5. Relay Board.......................................................................................................................203

11.4.6. Sensor Assembly................................................................................................................204

11.4.6.1. Sync/Demodulator Assembly ........................................................................................204

11.4.6.2. Opto Pickup Assembly..................................................................................................204

11.4.6.3. GFC Wheel Drive .........................................................................................................205

11.4.6.4. IR Source ...................................................................................................................205

11.4.6.5. Pressure/Flow Sensor Assembly....................................................................................205

11.4.7. Motherboard ......................................................................................................................206

11.4.7.1. A/D Functions .............................................................................................................206

11.4.7.2. Analog Outputs: Voltage ..............................................................................................206

11.4.7.3. Analog Outputs: Current Loop ......................................................................................207

11.4.7.4. Status Outputs ............................................................................................................207

11.4.7.5. Control Inputs – Remote Zero, Span .............................................................................208

11.4.8. CPU ..................................................................................................................................208

11.4.9. RS-232 Communications.....................................................................................................208

11.4.9.1. General RS-232 Troubleshooting...................................................................................208

11.4.9.2. Troubleshooting Analyzer/Modem or Terminal Operation .................................................209

11.5. Repair Procedures.....................................................................................................................209

11.5.1. Repairing Sample Flow Control Assembly .............................................................................209

11.5.2. Removing/Replacing the GFC Wheel.....................................................................................211

11.5.3. Disk-On-Chip Replacement Procedure ..................................................................................212

12. A PRIMER ON ELECTRO-STATIC DISCHARGE .............................................................................. 215

12.1. How Static Charges are Created .................................................................................................215

12.2. How Electro-Static Charges Cause Damage .................................................................................216

12.3. Common Myths About ESD Damage ...........................................................................................217

12.4. Basic Principles of Static Control.................................................................................................218

12.4.1. General Rules ....................................................................................................................218

12.4.2. Basic anti-ESD Procedures for Analyzer Repair and Maintenance.............................................220

12.4.2.1. Working at the Instrument Rack ...................................................................................220

12.4.2.2. Working at a Anti-ESD Work Bench. ..............................................................................220

12.4.2.3. Transferring Components from Rack To Bench and Back .................................................221

12.4.2.4. Opening Shipments from and Packing Components for Return to Teledyne Instruments

Customer Service. .....................................................................................................................222

Model GFC7000E Instruction Manual GFC7000E Documentation

04584 Rev A1 vii

LIST OF APPENDICES

APPENDIX A - VERSION SPECIFIC SOFTWARE DOCUMENTATION

APPENDIX A-1: MGFC7000E Software Menu Trees, Revision E.0

APPENDIX A-2: Setup Variables For Serial I/O, Revision E.0

APPENDIX A-3: Warnings and Test Functions, Revision E.0

APPENDIX A-4: MGFC7000E Signal I/O Definitions, Revision E.0

APPENDIX A-5: MGFC7000E iDAS Functions, Revision E.0

APPENDIX A-6: Terminal Command Designators, Revision E.0

APPENDIX B - GFC7000E SPARE PARTS LIST

APPENDIX C - REPAIR QUESTIONNAIRE - MGFC7000E

APPENDIX D - ELECTRONIC SCHEMATICS

LIST OF FIGURES

Figure 3-1: Removal of Shipping Screws ............................................................................10

Figure 3-2: Rear Panel Layout...........................................................................................12

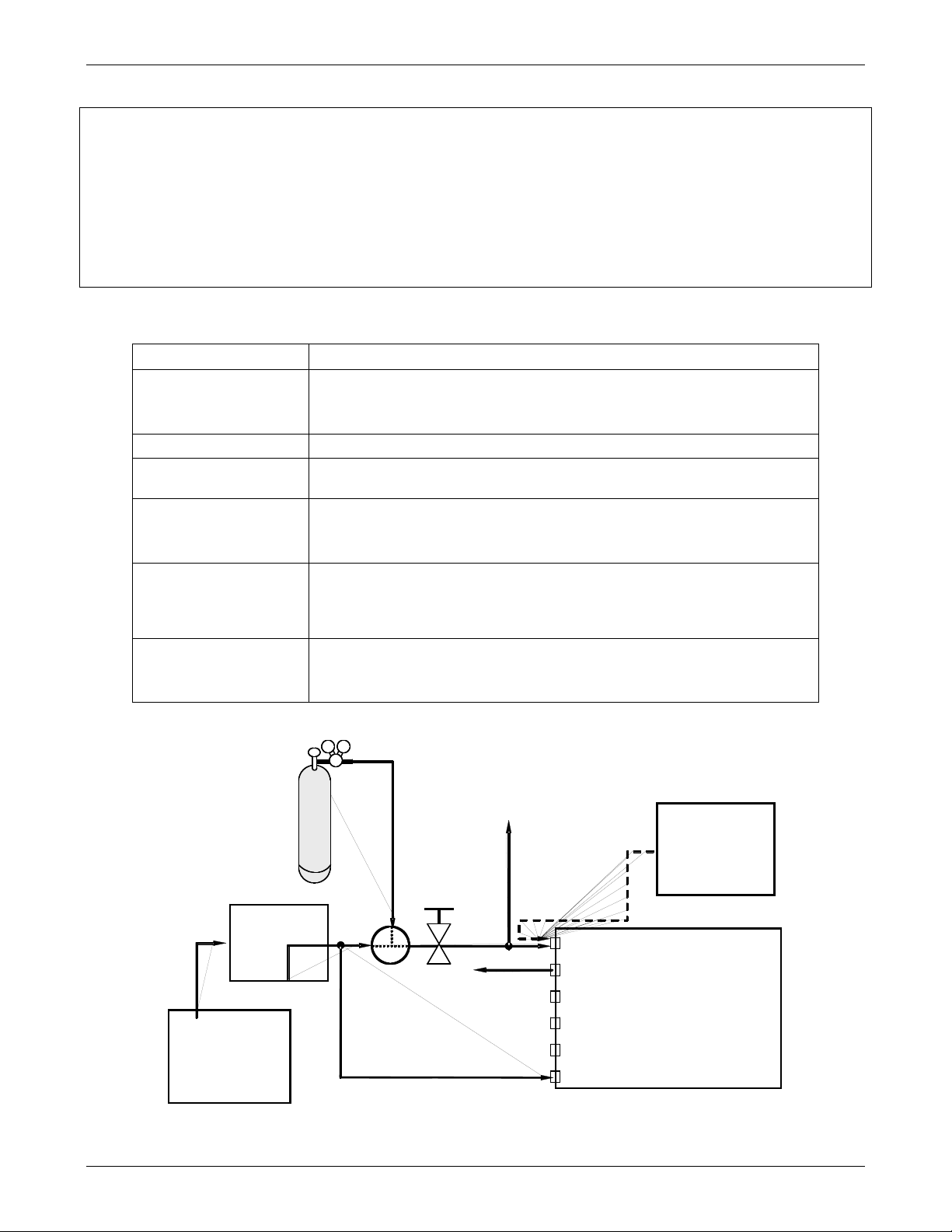

Figure 3-3: Pneumatic Connections–Basic Configuration–Using Bottled Span Gas .....................16

Figure 3-4: Pneumatic Connections–Basic Configuration–Using Gas Dilution Calibrator..............17

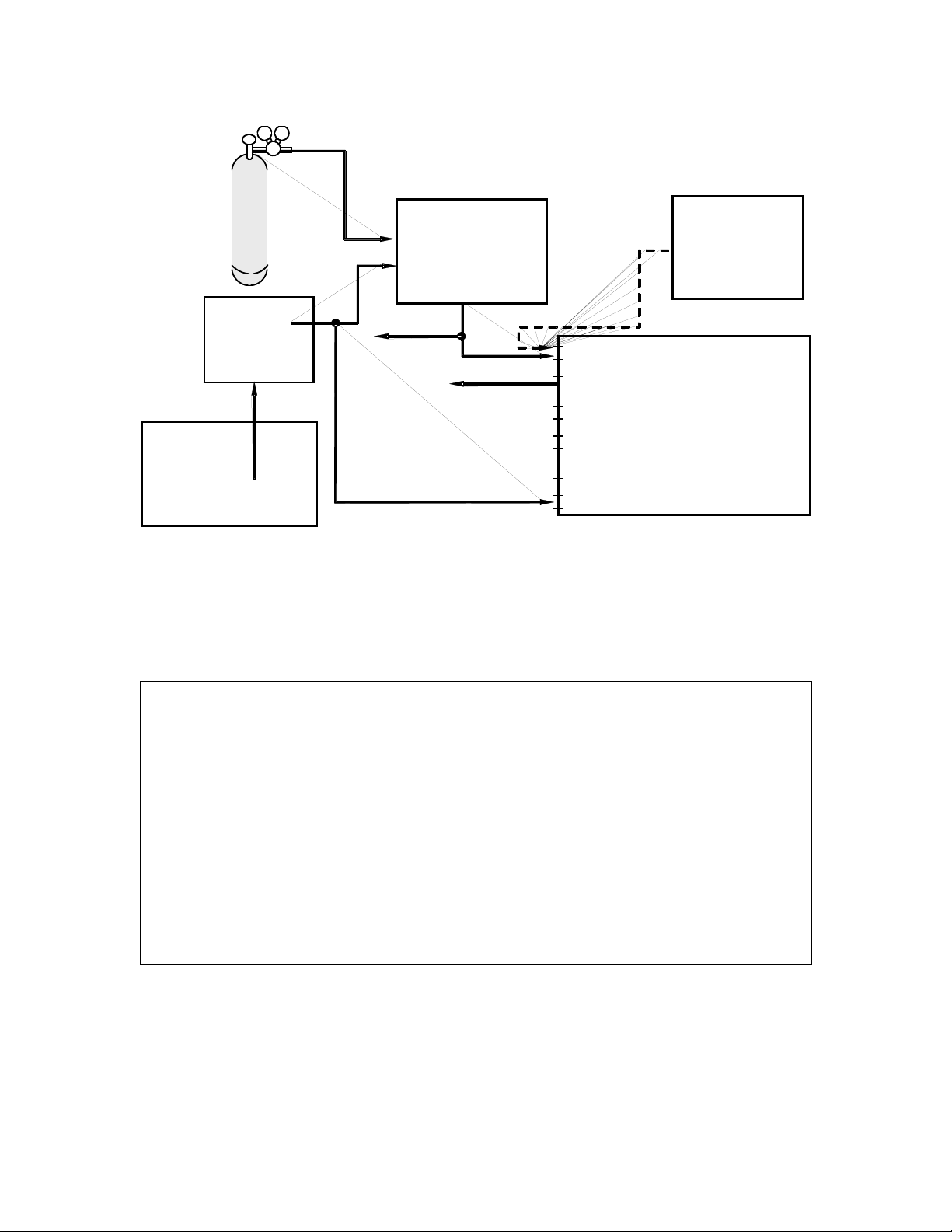

Figure 3-5: Pneumatic Connections–MGFC7000E with Zero/Span/Shutoff Valves (OPT 50).........19

Figure 3-6 Pneumatic Connections–MGFC7000E with Zero/Span/Shutoff Valves and External

Zero Air Scrubber (OPT 51) ............................................................................19

Figure 3-7: Pneumatic Connections–MGFC7000E with Zero/Span Valves (OPT 52)....................20

Figure 3-8: Pneumatic Connections–MGFC7000E with Zero/Span Valves with External Zero air

Scrubber (OPT 53) ........................................................................................20

Figure 3-9: Example of Pneumatic Set up for Multipoint Calibration of M360 ............................21

Figure 3-10: Front Panel Layout ..........................................................................................23

Figure 3-11: Assembly Layout ............................................................................................29

Figure 3-12: Optical Bench Layout.......................................................................................30

Figure 3-13: Internal Pneumatic Flow – Basic Configuration ....................................................30

Figure 5-1: Current Loop Option Installed on the Motherboard...............................................35

Figure 5-2: Internal Pneumatic Flow – Zero/Span/Shutoff Valves OPT 50 & 51.........................37

Figure 5-3: Internal Pneumatic Flow – Zero/Span OPT 52 & 53..............................................39

Figure 5-4: GFC7000E Ethernet Card and rear panel With Ethernet Installed ...........................40

Figure 6-1: Front Panel Display .........................................................................................43

Figure 6-2 Viewing MGFC7000E TEST Functions..................................................................46

Figure 6-3 Viewing and Clearing MGFC7000E WARNING Messages ........................................48

Figure 6-4: Analog Output Connector Pin Out......................................................................54

Figure 6-5: Setup for Calibrating Analog Voltage Outputs......................................................72

Figure 6-6: Setup for Calibrating Current Outputs................................................................73

Figure 6-7: Default iDAS Channels Setup............................................................................99

Figure 6-8: APICOM user interface for configuring the iDAS................................................. 111

Figure 6-9: iDAS Configuration Through a Terminal Emulation Program. ...............................112

Figure 6-10: Status Output Connector................................................................................ 113

Figure 6-11: Control Inputs ..............................................................................................115

Figure 6-12: APICOM Remote Control Program Interface ...................................................... 121

Figure 7-1: Pneumatic Connections–Basic Configuration–Using Bottled Span Gas ................... 130

Figure 7-2: Pneumatic Connections–Basic Configuration–Using Gas Dilution Calibrator............ 131

Figure 7-3: Pneumatic Connections–MGFC7000E with Zero/Span/Shutoff Valves (OPT 50)....... 134

Figure 7-4 Pneumatic Connections–MGFC7000E with Zero/Span/Shutoff Valves and External

Zero Air Scrubber (OPT 51) .......................................................................... 134

NGFC7000E Documentation Model GFC7000E Instruction Manual

Figure 7-5: Pneumatic Connections–MGFC7000E with Zero/Span Valves (OPT 52)..................134

Figure 7-6: Pneumatic Connections–MGFC7000E with Zero/Span Valves with External Zero air

Scrubber (OPT 53) ...................................................................................... 135

Figure 9-1: Sample Particulate Filter Assembly..................................................................151

Figure 10-1: Measurement Fundamentals........................................................................... 156

Figure 10-2: GFC Wheel................................................................................................... 157

Figure 10-3: Measurement Fundamentals with GFC Wheel ....................................................157

Figure 10-4: Affect of CO2 in the Sample on CO2 MEAS & CO2 REF ........................................ 158

Figure 10-5: Effects of Interfering Gas on CO2 MEAS & CO2 REF ........................................... 159

Figure 10-6: Chopped IR Signal ........................................................................................ 159

Figure 10-7: Internal Pneumatic Flow – Basic Configuration ..................................................161

Figure 10-8: Flow Control Assembly & Critical Flow Orifice ....................................................162

Figure 10-9: GFC7000E Electronic Block Diagram ................................................................ 164

Figure 10-10: GFC Light Mask............................................................................................. 166

Figure 10-11: Segment Sensor and M/R Sensor Output..........................................................167

Figure 10-12: GFC7000E Sync / Demod Block Diagram ..........................................................168

Figure 10-13: Sample & Hold Timing ...................................................................................169

Figure 10-14: Location of relay board Status LED’s ................................................................ 172

Figure 10-15: Power Distribution Block Diagram....................................................................176

Figure 10-16: Interface Block Diagram................................................................................. 177

Figure 10-17: MGFC7000E Front Panel Layout....................................................................... 177

Figure 10-18: Keyboard and Display Interface Block Diagram.................................................. 179

Figure 10-19: Basic Software Operation ............................................................................... 181

Figure 11-1: Viewing and Clearing Warning Messages .......................................................... 186

Figure 11-2: Example of Signal I/O Function....................................................................... 191

Figure 11-3: CPU Status Indicator ..................................................................................... 192

Figure 11-4: Sync/Demod Board Status LED Locations .........................................................193

Figure 11-5: Relay Board Status LEDs................................................................................ 193

Figure 11-6: Critical Flow Restrictor Assembly Disassembly................................................... 210

Figure 11-7: Opening the GFC Wheel Housing ..................................................................... 211

Figure 11-8: Removing the GFC Wheel................................................................................ 212

Figure 12-1: Triboelectric Charging.................................................................................... 215

Figure 12-2: Basic anti-ESD Work Station........................................................................... 218

Figure A-1: Basic Sample Display Menu.............................................................................225

Figure A-2: Sample Display Menu - Units with Z/S Valve or IZS Option installed ..................... 226

Figure A-3: Primary Setup Menu (Except iDAS) .................................................................. 227

Figure A-4: Primary Setup Menu (iDAS)............................................................................ 228

Figure A-5: Secondary Setup Menu (COMM & VARS) ........................................................... 229

Figure A-6: Secondary Setup Menu (COMM Menu with Ethernet Card) ...................................230

Figure A-7: Secondary Setup Menu (COMM Menu with HESSEN) ........................................... 231

Figure A-8: Secondary Setup Menu (DIAG) ........................................................................ 232

LIST OF TABLES

Table 2-1: Model GFC7000E Basic Unit Specifications ............................................................ 5

Table 3-1: GFC7000E Analog Output Pin Outs .....................................................................13

Table 3-2: GFC7000E Status Output Pin Outs......................................................................14

Table 3-3: GFC7000E Control Input Pin Outs.......................................................................15

Table 3-4: Model GFC7000E Rear Panel Pneumatic Connections.............................................16

Table 3-5: Front Panel Display During System Warm-Up.......................................................23

Table 3-6: Possible Warning Messages at Start-Up...............................................................24

Table 5-1: Zero/Span Valve Operating States for Options 50 & 51 .........................................36

Table 5-2: Zero/Span Valve Operating States for Options 52 & 53 .........................................38

Model GFC7000E Instruction Manual GFC7000E Documentation

04584 Rev A1 ix

Table 6-1: Analyzer Operating modes ................................................................................44

Table 6-2: Test Functions Defined .....................................................................................45

Table 6-3: List of Warning Messages..................................................................................47

Table 6-4: Primary Setup Mode Features and Functions........................................................50

Table 6-5: Secondary Setup Mode Features and Functions ....................................................50

Table 6-6: Variable Names (VARS) Revision B.3 ..................................................................62

Table 6-7: GFC7000E Diagnostic (DIAG) Functions ..............................................................64

Table 6-8: DIAG - Analog I/O Functions .............................................................................67

Table 6-9: Analog Output Voltage Ranges...........................................................................67

Table 6-10: Analog Output Current Loop Range.....................................................................68

Table 6-11: Analog Output Pin Assignments..........................................................................68

Table 6-12: Voltage Tolerances for Analog Output Calibration..................................................71

Table 6-13: Current Loop Output Calibration with Resistor ......................................................74

Table 6-14: Test Parameters Available for Analog Output A3 ...................................................79

Table 6-15: COM1 and COM2 DB-9 Pin Assignments ..............................................................83

Table 6-16: COMM Port Communication modes .....................................................................84

Table 6-17: Ethernet Status Indicators.................................................................................87

Table 6-18: LAN/Internet Configuration Properties.................................................................88

Table 6-19: Internet Configuration Keypad Functions .............................................................92

Table 6-20: CO2 Concentration Alarm Default Settings ...........................................................93

Table 6-21: Front Panel LED Status Indicators for iDAS ..........................................................94

Table 6-22: iDAS Data Channel Properties ............................................................................95

Table 6-23: iDAS Data Parameter Functions..........................................................................96

Table 6-24: Status Output Pin Assignments ........................................................................ 114

Table 6-25: Control Input Pin Assignments .........................................................................114

Table 6-26: Terminal Mode Software Commands ................................................................. 116

Table 6-27: Command Types ............................................................................................ 117

Table 6-28: Serial Interface Documents ............................................................................. 121

Table 6-29: RS-232 Communication Parameters for Hessen Protocol ...................................... 122

Table 6-30: Teledyne Instruments Hessen Protocol Response Modes ...................................... 124

Table 6-31: Default Hessen Status Bit Assignments ............................................................. 125

Table 7-1: AUTOCAL Modes ............................................................................................139

Table 7-2: AutoCal ATTRIBUTE Setup Parameters ..............................................................139

Table 7-3: Calibration Data Quality Evaluation...................................................................142

Table 9-1: GFC7000E Maintenance Schedule..................................................................... 148

Table 9-2: GFC7000E Test Function Record....................................................................... 149

Table 9-3: Predictive uses for Test Functions..................................................................... 150

Table 10-1: Sync/Demod Status LED Activity ...................................................................... 170

Table 10-2: Relay Board Status LED’s ................................................................................171

Table 10-3: Front Panel Status LED’s ................................................................................. 178

Table 11-1: Warning Messages - Indicated Failures.............................................................. 187

Table 11-2: Test Functions - Indicated Failures ...................................................................189

Table 11-3: Sync/Demod Board Status Failure Indications ....................................................192

Table 11-4: I

2

C Status LED Failure Indications .................................................................... 193

Table 11-5: Relay Board Status LED Failure Indications ........................................................ 194

Table 11-6: DC Power Test Point and Wiring Color Codes...................................................... 202

Table 11-7: DC Power Supply Acceptable Levels..................................................................202

Table 11-8: Relay Board Control Devices............................................................................ 203

Table 11-9: Opto Pickup Board Nominal Output Frequencies .................................................204

Table 11-10: Analog Output Test Function - Nominal Values Voltage Outputs ............................206

Table 11-11: Analog Output Test Function - Nominal Values Current Outputs ............................ 207

Table 11-12: Status Outputs Check ..................................................................................... 207

Table 12-1: Static Generation Voltages for Typical Activities.................................................. 216

Table 12-2: Sensitivity of Electronic Devices to Damage by ESD ............................................ 216

NGFC7000E Documentation Model GFC7000E Instruction Manual

Table A-1: GFC7000E Setup Variables, Revision E.0 ........................................................... 233

Table A-2: GFC7000E Warning Messages, Revision E.0 .......................................................240

Table A-3: GFC7000E Test Functions, Revision E.0............................................................. 241

Table A-4: GFC7000E Signal I/O Definitions, Revision E.0 ................................................... 242

Table A-5: GFC7000E DAS Trigger Events, Revision E.0...................................................... 245

Table A-6: GFC7000E iDAS Functions, Revision E.0............................................................246

Table A-7: Terminal Command Designators, Revision E.0 ...................................................247

Table D-1: List of Included Electronic Schematics .............................................................. 255

User Notes

Model GFC7000E Instruction Manual MGFC7000E Documentation

04584 Rev A1 1

1. MGFC7000E DOCUMENTATION

Thank you for purchasing the Model GFC7000E Gas Filter Correlation Carbon Dioxide Analyzer!

The documentation for this instrument is available in several different formats:

• Printed format, part number 045840100

• Electronic format on a CD-ROM, part number 045840200

The electronic manual is in Adobe® Systems Inc. “Portable Document Format”. The Adobe

®

Acrobat Reader® software, which is necessary to view these files, can be downloaded for free from

the internet at http://www.adobe.com/.

The electronic version of the manual has many advantages:

• Keyword and phrase search feature

• Figures, tables and internet addresses are linked so that clicking on the item will display

the associated feature or open the website.

• A list of chapters and sections as well as thumbnails of each page are displayed to the left

of the text.

• Entries in the table of contents are linked to the corresponding locations in the manual.

• Ability to print sections (or all) of the manual

Additional documentation for the Model GFC7000E CO2 Analyzer is available from Teledyne

Analytical Instruments’ website at http://www.teledyne-ai.com/manuals/

• APICOM software manual, part number 03945

• Multi-drop manual, part number 01842

• DAS Manual, part number 02837.

1.1. Using This Manual

This manual has the following data structures:

1.0 Table of Contents:

Outlines the contents of the manual in the order the information is presented. This is a good

overview of the topics covered in the manual. There is also a list of tables, a list of figures and a

list of appendices. In the electronic version of the manual, clicking on a any of these table entries

automatically views that section.

MGFC7000E Documentation Model GFC7000E Instruction Manual

2.0 Specifications and Warranty

This section contains a list of the analyzer’s performance specifications, a description of the

conditions and configuration under which EPA equivalency was approved and Teledyne

Instruments Incorporated’s warranty statement.

3.0 Getting Started:

A concise set of instructions for setting up, installing and running your analyzer for the first time.

4.0 FAQ:

Answers to the most frequently asked questions about operating the analyzer.

5.0 Optional Hardware & Software

A description of optional equipment to add functionality to your analyzer.

6.0 Operation Instructions

This section includes step by step instructions for operating the analyzer and using its various

features and functions.

7.0 Calibration Procedures

General information and step by step instructions for calibrating your analyzer.

8.0 EPA Protocol Calibration

Because CO2 is not declared a criteria air pollutant by the US EPA, EPA equivalency is not required

for this type of analyzer. Therefore no special calibration methods are needed to satisfy EPA

requirements.

9.0 Instrument Maintenance

Description of certain preventative maintenance procedures that should be regularly performed on

you instrument to keep it in good operating condition. This section also includes information on

using the iDAS to record diagnostic functions useful in predicting possible component failures

before they happen.

10.0 Theory of Operation

An in-depth look at the various principals by which your analyzer operates as well as a description

of how the various electronic, mechanical and pneumatic components of the instrument work and

interact with each other. A close reading of this section is invaluable for understanding the

instrument’s operation.

11.0 Troubleshooting Section:

This section includes pointers and instructions for diagnosing problems with the instrument, such

as excessive noise or drift, as well as instructions on performing repairs of the instrument’s major

subsystems.

Model GFC7000E Instruction Manual MGFC7000E Documentation

04584 Rev A1 3

Appendices:

For easier access and better updating, some information has been separated out of the manual

and placed in a series of appendices at the end of this manual. These include: software menu

trees, warning messages, definitions of iDAS & serial I/O variables, spare parts list, repair

questionnaire, interconnect listing and drawings, and electronic schematics.

NOTE

Throughout this manual, words printed in capital, bold letters, such as SETUP or ENTR

represent messages as they appear on the analyzer’s front panel display.

NOTE

The flowcharts in this manual contain typical representations of the analyzer’s display

during the various operations being described. These representations are not intended

to be exact and may differ slightly from the actual display of your instrument.

User Notes

Model GFC7000E Instruction Manual Specifications, Approvals and Warranty

04584 Rev A1 5

2. SPECIFICATIONS, APPROVALS AND

WARRANTY

2.1. Specifications

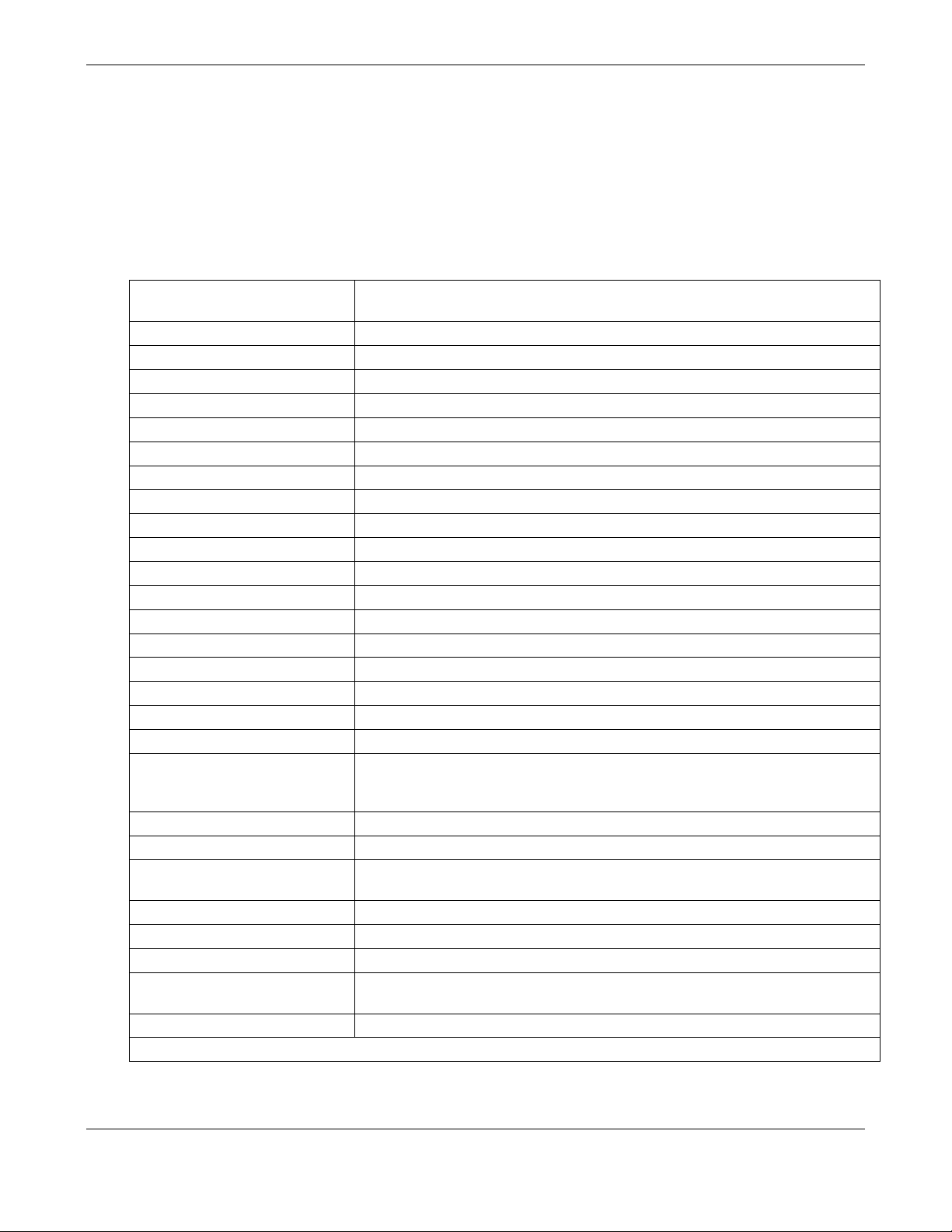

Table 2-1: Model GFC7000E Basic Unit Specifications

Min/Max Range

(Physical Analog Output)

In 1ppb increments from 50ppb to 2 000ppm, dual ranges or auto

ranging

Measurement Units

ppb, ppm, µg/m3, mg/m3, %(user selectable)

Zero Noise

< 0.1 ppm (RMS)

Span Noise

< 1% of reading (RMS)

Lower Detectable Limit1

< 0.2 ppm

1

Zero Drift (24 hours)

<0.25 ppm

1

Zero Drift (7 days)

<0.5 ppm

1

Span Drift (7 Days)

1% of reading above 50 PPM

1

Linearity

1% of full scale

Precision

0.5% of reading

Temperature Coefficient

< 0.1% of Full Scale per oC

Voltage Coefficient

< 0.05% of Full Scale per V

Lag Time

10 sec

Rise/Fall Time

95% in <60 sec

Sample Flow Rate

800cm3/min. ±10%

Temperature Range

5-40oC

Humidity Range

0 - 95% RH, non-condensing

Dimensions H x W x D

7" x 17" x 23.5" (178 mm x 432 mm x 597 mm)

Weight, Analyzer

38 lbs. (17 kg); add 1 lbs (0.5 kg) for IZS

AC Power Rating

100 V, 50/60 Hz (3.25A);

115 V, 60 Hz (3.0 A);

220 – 240 V, 50/60 Hz (2.5 A)

Environmental

Installation category (over-voltage category) II; Pollution degree 2

Analog Outputs

Three (3) Outputs

Analog Output Ranges

0.1V, 1 V, 5 V, 10 V, 2-20 or 4-20 mA isolated current loop.

All Ranges with 5% Under/Over Range

Analog Output Resolution

1 part in 4096 of selected full-scale voltage

Status Outputs

8 Status outputs - opto-isolated; including 2 alarm outputs

Control Inputs

6 Control Inputs, 3 defined, 3 spare

Serial I/O

One (1) RS-232; One (1) RS-485

Baud Rate : 300 – 115200: Optional Ethernet Interface

Certifications

CE: EN61010-1:90 + A1:92 + A2:95, EN61326 - Class A

1

At constant temperature and voltage.

Specifications, Approvals and Warranty Model GFC7000E Instruction Manual

2.2. CE Mark Compliance

Emissions Compliance

The Teledyne Instruments Model GFC7000E Gas Filter Correlation CO2 Analyzer was tested and

found to be fully compliant with:

EN61326 (1997 w/A1: 98) Class A, FCC Part 15 Subpart B Section 15.107 Class A, ICES-003

Class A (ANSI C63.4 1992) & AS/NZS 3548 (w/A1 & A2; 97) Class A.

Tested on 11-29-2001 at CKC Laboratories, Inc., Report Number CE01-249.

Safety Compliance

The Teledyne Instruments Model GFC7000E Gas Filter Correlation CO2 Analyzer was tested and

found to be fully compliant with:

IEC 61010-1:90 + A1:92 + A2:95,

Tested on 02-06-2002 at Nemko, Report Number 2002-012219.

2.3. Warranty

Warranty Policy (02024)

Prior to shipment, Teledyne Instruments Incorporated equipment is thoroughly inspected and

tested. Should equipment failure occur, Teledyne Instruments Incorporated assures its customers

that prompt service and support will be available.

Coverage

After the warranty period and throughout the equipment lifetime, Teledyne Instruments

Incorporated stands ready to provide on-site or in-plant service at reasonable rates similar to

those of other manufacturers in the industry. All maintenance and the first level of field

troubleshooting is to be performed by the customer.

Non-API Manufactured Equipment

Equipment provided but not manufactured by Teledyne Instruments Incorporated is warranted

and will be repaired to the extent and according to the current terms and conditions of the

respective equipment manufacturers warranty.

General

Teledyne Instruments Incorporated warrants each product manufactured by Teledyne Instruments

Incorporated to be free from defects in material and workmanship under normal use and service

for a period of one year from the date of delivery. All replacement parts and repairs are warranted

for 90 days after the purchase.

If a product fails to conform to its specifications within the warranty period, Teledyne Instruments

Incorporated shall correct such defect by, in Teledyne Instruments Incorporated’s discretion,

repairing or replacing such defective product or refunding the purchase price of such product.

Model GFC7000E Instruction Manual Specifications, Approvals and Warranty

04584 Rev A1 7

The warranties set forth in this section shall be of no force or effect with respect to any product:

(i) that has been altered or subjected to misuse, negligence or accident, or (ii) that has been used

in any manner other than in accordance with the instruction provided by TELEDYNE ANALYTICAL

INSTRUMENTS or (iii) not properly maintained.

THE WARRANTIES SET FORTH IN THIS SECTION AND THE REMEDIES THEREFORE ARE

EXCLUSIVE AND IN LIEU OF ANY IMPLIED WARRANTIES OF MERCHANTABILITY,

FITNESS FOR PARTICULAR PURPOSE OR OTHER WARRANTY OF QUALITY, WHETHER

EXPRESSED OR IMPLIED. THE REMEDIES SET FORTH IN THIS SECTION ARE THE

EXCLUSIVE REMEDIES FOR BREACH OF ANY WARRANTY CONTAINED HEREIN. Teledyne

Instruments Incorporated SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES ARISING OUT OF OR RELATED TO THIS AGREEMENT OF

TELEDYNE INSTRUMENTS INCORPORATED’S PERFORMANCE HEREUNDER, WHETHER

FOR BREACH OF WARRANTY OR OTHERWISE.

Terms and Conditions

All units or components returned to Teledyne Amnalytical Instruments should be properly packed

for handling and returned freight prepaid to the nearest designated Service Center. After the

repair, the equipment will be returned, freight prepaid.

User Notes

Model GFC7000E Instruction Manual Getting Started

04584 Rev A1 9

3. GETTING STARTED

3.1. Unpacking and Initial Set Up

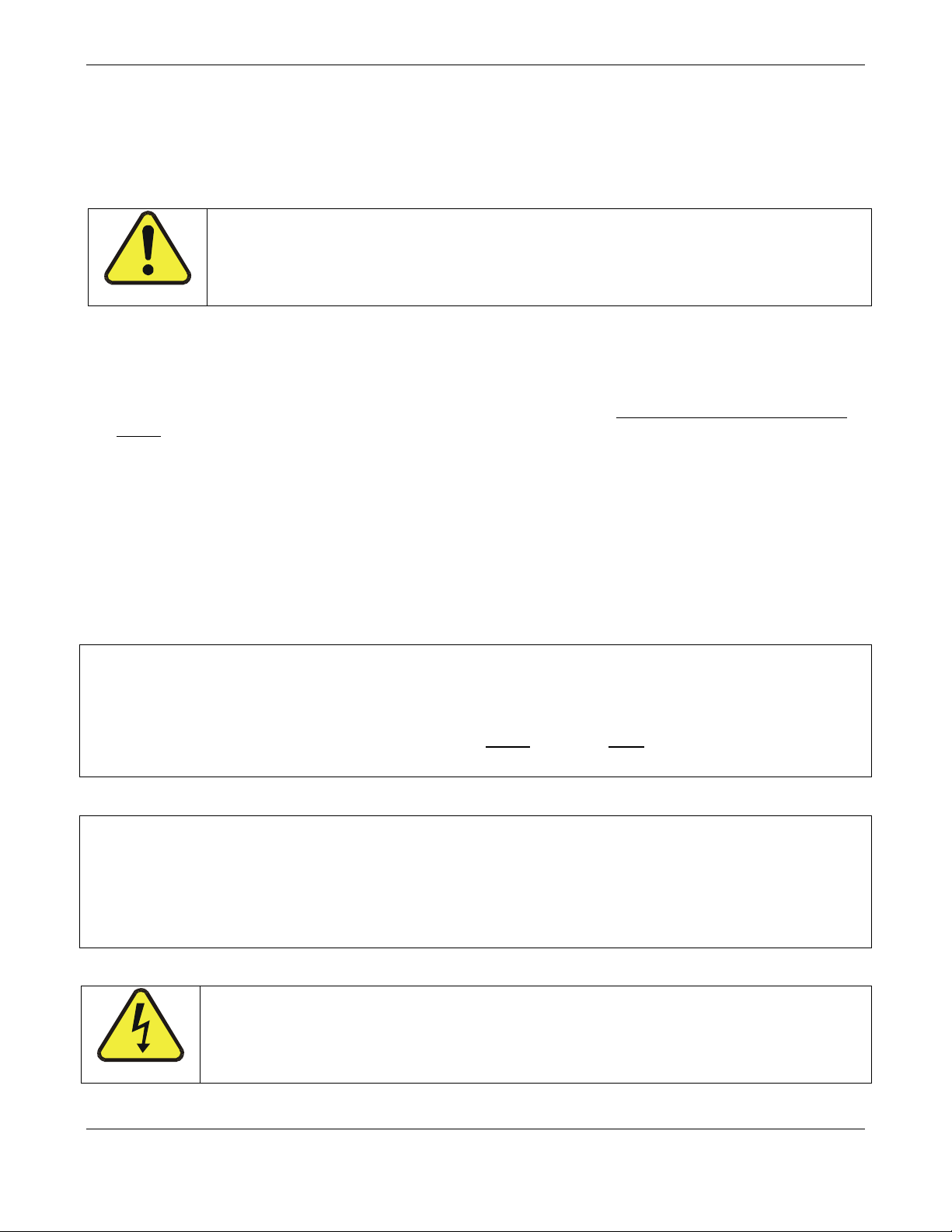

CAUTION

To avoid personal injury, always use two persons to lift and carry the

Model GFC7000E.

1. Verify that there is no apparent external shipping damage. If damage has occurred, please

advise the shipper first, then Teledyne Analytical Instruments.

2. Included with your analyzer is a printed record of the final performance characterization

performed on your instrument at the factory. This record, titled Final Test and Validation Data

Sheet (part number 04307) is an important quality assurance and calibration record for this

instrument. It should be placed in the quality records file for this instrument.

3. Carefully remove the top cover of the analyzer and check for internal shipping damage.

• Remove the set screw located in the top, center of the rear panel.

• Remove the four screws fastening the top cover to the unit (two per side).

• Lift the cover straight up. Do not slide backwards.

NOTE

Some versions of the GFC7000E CO2 Analyzer may have a spring loaded fastener at the

top center of the rear panel and as many as eight screws (four per side) fastening the

top cover to the chassis.

NOTE

Static sensitive parts are present on PCA (Printed Circuit Assemblies). Before touching

PCAs, touch a bare metal part of the chassis to discharge any electrostatic potentials or

connect a grounding strap to your wrist.

CAUTION

Never disconnect PCAs, wiring harnesses or electronic subassemblies

while under power.

Getting Started Model GFC7000E Instruction Manual

4. Inspect the interior of the instrument to make sure all circuit boards and other components

are in good shape and properly seated.

5. Check the connectors of the various internal wiring harnesses and pneumatic hoses to make

sure they are firmly and properly seated.

6. Verify that all of the optional hardware ordered with the unit has been installed. These are

listed on the paperwork accompanying the analyzer.

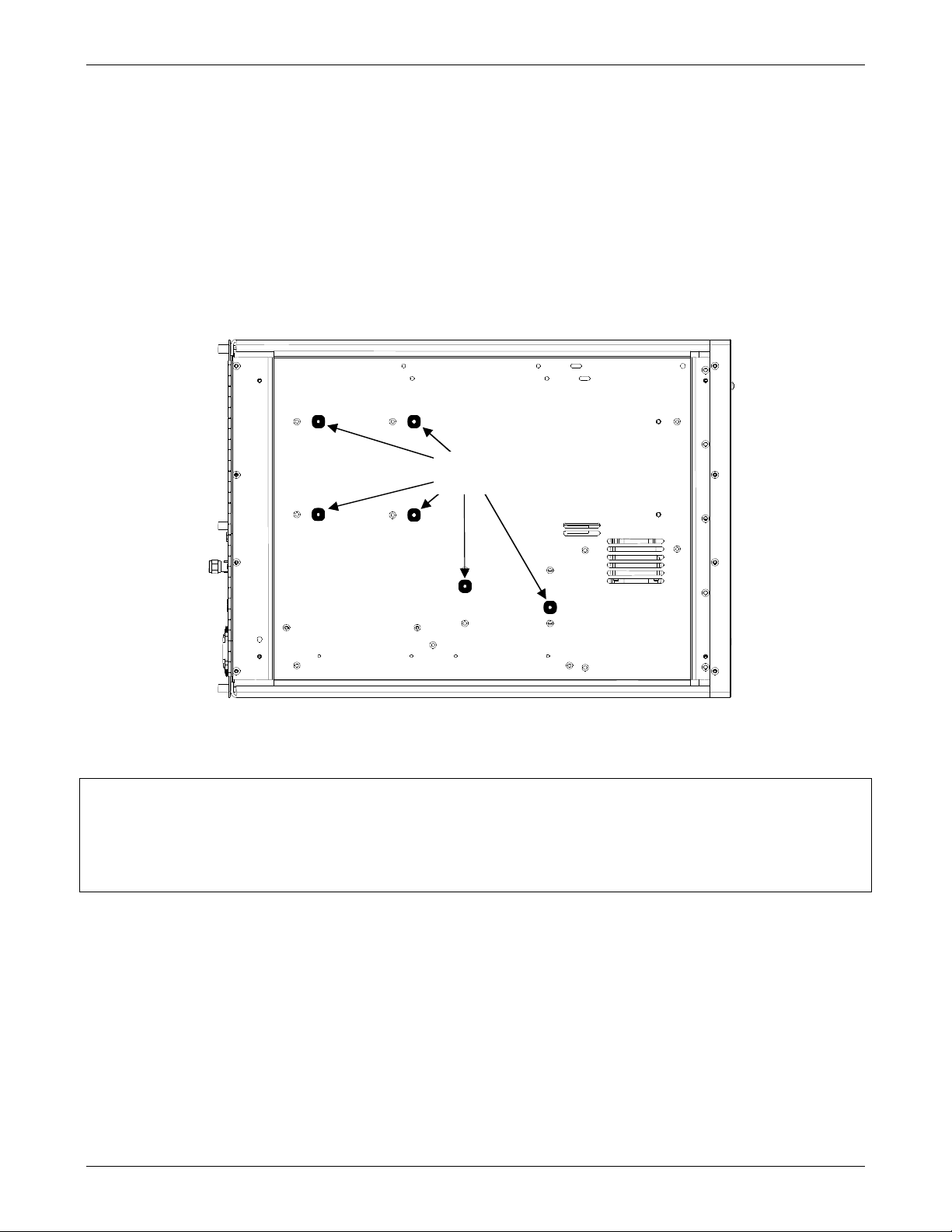

7. Once you have determined that no shipping damage exists, and the unit includes all expected

hardware options, remove all red colored shipping screws from the bottom of the chassis as

shown in Figure 3-1.

Shipping

Screws

Figure 3-1: Removal of Shipping Screws

NOTE

Save these shipping screws and re-install them whenever the unit is shipped to another

location.

Model GFC7000E Instruction Manual Getting Started

04584 Rev A1 11

8. VENTILATION CLEARANCE: Whether the analyzer is set up on a bench or installed into an

instrument rack, be sure to leave sufficient ventilation clearance.

AREA

MINIMUM REQUIRED CLEARANCE

Back of the instrument

4 in.

Sides of the instrument

1 in.

Above and below the instrument

1 in.

• Various rack mount kits are available for this analyzer. See Section 5.1 of this manual

for more information.

3.1.1. Electrical Connections

CAUTION

Check the voltage and frequency label on the rear panel of the

instrument (See Figure 3-2) for compatibility with the local

power before plugging the MGFC7000E into line power.

Do not plug in the power cord if the voltage or

frequency is incorrect.

CAUTION

Power connection must have functioning ground connection.

Do not defeat the ground wire on power plug.

CAUTION

Turn off analyzer power before disconnecting or

connecting electrical subassemblies.

Do not operate with cover off.

Getting Started Model GFC7000E Instruction Manual

Figure 3-2: Rear Panel Layout

9. Attach a strip chart recorder and/or data-logger to the appropriate analog output connections

on the rear panel of the analyzer.

ANALOG

A1 A2 A3 A4

1 2 3 4 5 6 7 8

When the instrument is in its default configuration, the A1 and A2 channels output a signal

that is proportional to the CO2 concentration of the sample gas. Either can be used for

connecting the analog output signal to a chart recorder or for interfacing with a datalogger.

The third analog output, labeled A3 is special. It can be set by the user (see Section

6.9.9) to output any one of the parameters accessible through the <TST TST> keys of the

units sample display.

The standard configuration for these outputs is mVDC. An optional current loop output is

available for each.

Output A4 is not used on the Model 306E.

Pin-outs for the analog output connector at the rear panel of the instrument are:

Model GFC7000E Instruction Manual Getting Started

04584 Rev A1 13

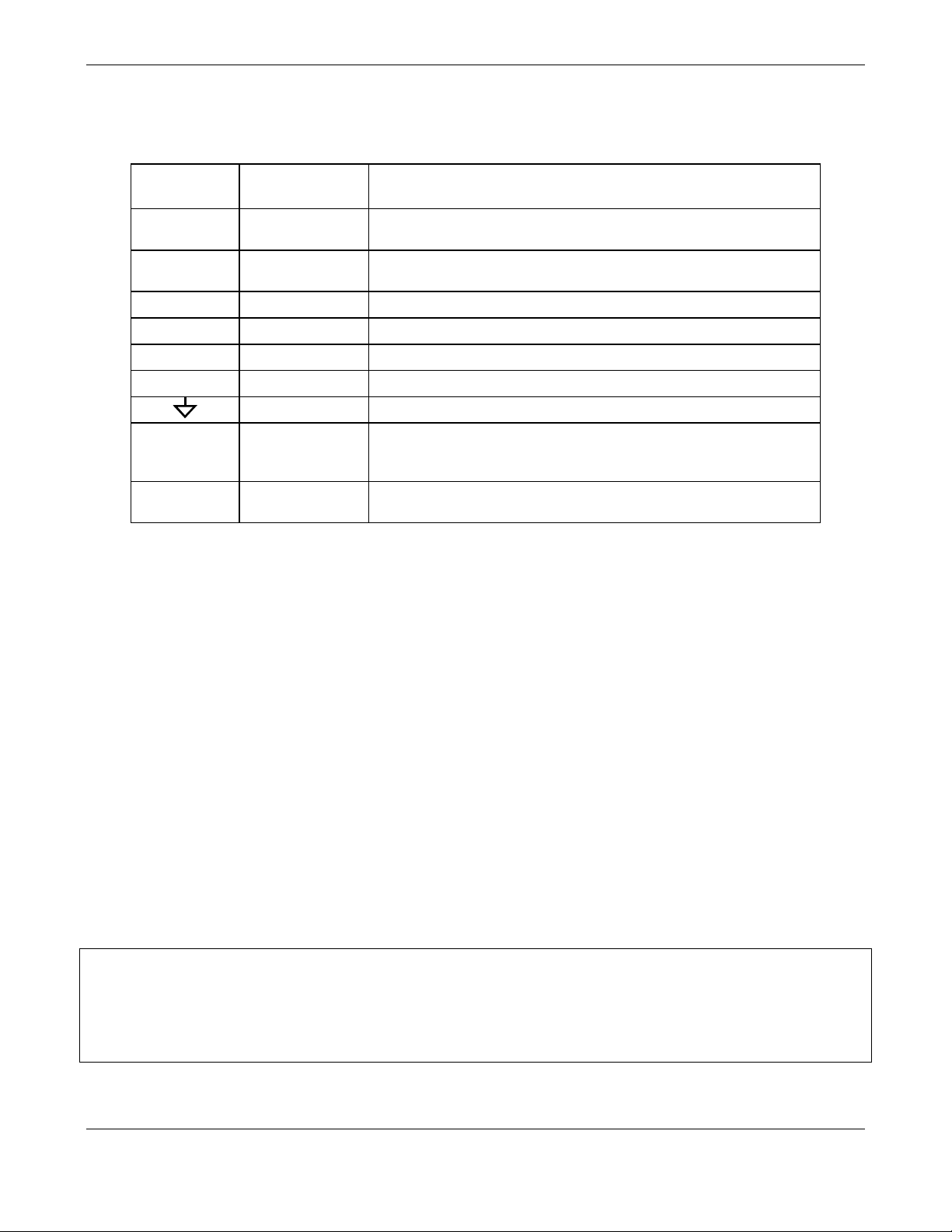

Table 3-1: GFC7000E Analog Output Pin Outs

Pin

Analog Output

VDC Signal

mADC Signal

1

V Out

I Out +

2A1Ground

I Out -

3

V Out

I Out +

4A2Ground

I Out -

5

V Out

I Out +

6A3Ground

I Out -

7

V Out

Not Available

8

A4 (Spare)

Ground

Not Available

• The default analog output voltage setting of the GFC7000E CO2 Analyzer is 0 – 5 VDC

with a range of 0 – 500 ppm.

• TO change these settings, see Sections 6.9.4 and 6.7 respectively.

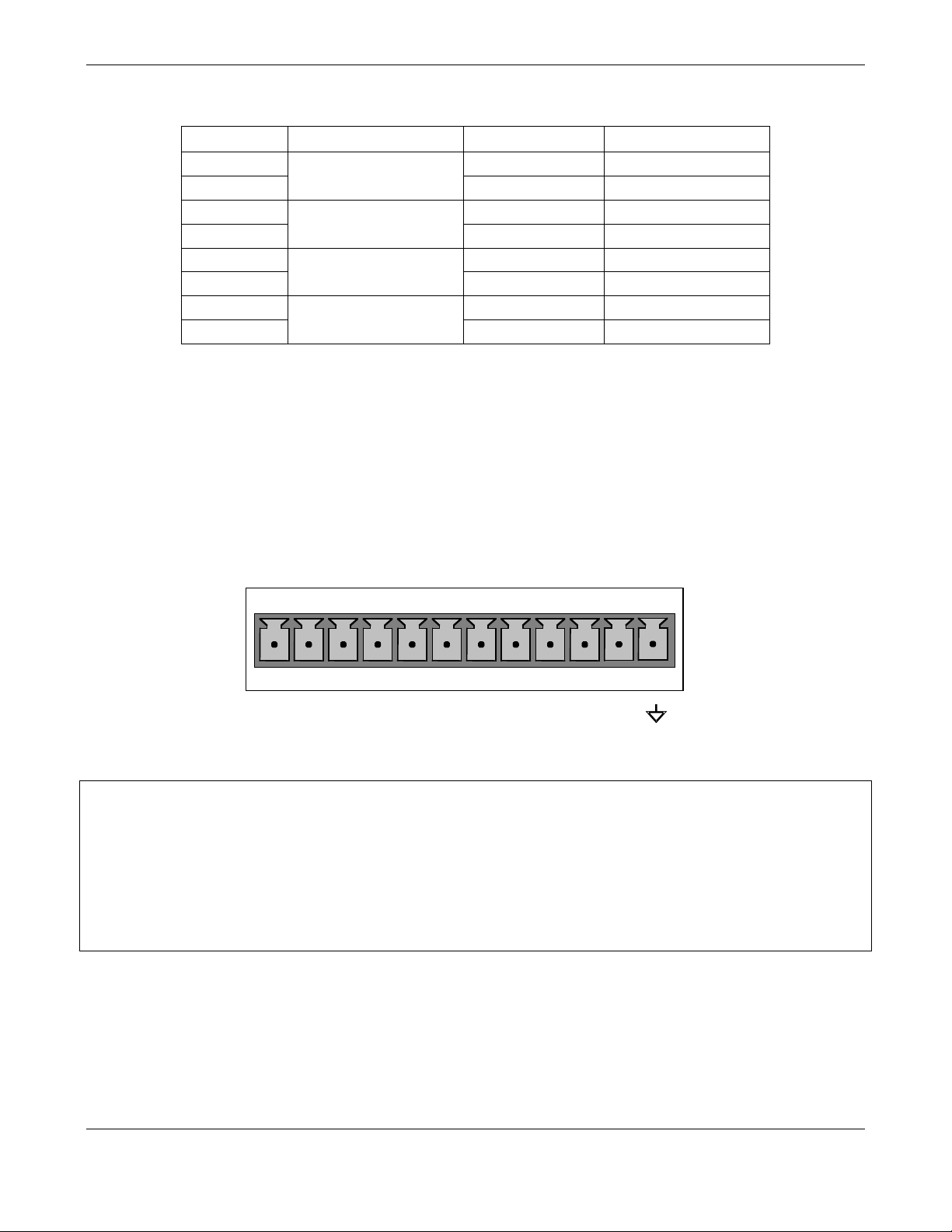

10. If you wish utilize the analyzer’s status outputs to interface with a device that accepts logic-

level digital inputs, such as programmable logic controllers (PLC’s) they are accessed via a 12pin connector on the analyzer’s rear panel labeled STATUS.

STATUS

1 2 3 4 5 6 7 8 D +

NOTE

Most PLC’s have internal provisions for limiting the current that the input will draw from

an external device. When connecting to a unit that does not have this feature, an

external dropping resistor must be used to limit the current through the transistor

output to less than 50mA. At 50mA, the transistor will drop approximately 1.2V from its

collector to emitter.

Getting Started Model GFC7000E Instruction Manual

The pin assignments for the status outputs can be found in the table below:

Table 3-2: GFC7000E Status Output Pin Outs

Output #

Status

Definition

Condition

1

SYSTEM OK

On if no faults are present.

2

CONC VALID

On if CO2 concentration measurement is valid.

If the CO2 concentration measurement is invalid, this bit is OFF.

3

HIGH RANGE

On if unit is in high range of DUAL or AUTO range modes.

4

ZERO CAL

On whenever the instruments ZERO point is being calibrated.

5

SPAN CAL

On whenever the instruments SPAN point is being calibrated.

6

DIAG MODE

On whenever the instrument is in DIAGNOSTIC mode.

7

ALARM1

On whenever the measured CO2 concentration is above the set

point for ALM1

8

ALARM2

On whenever the measured CO2 concentration is above the set

point for ALM2

D

EMITTER BUSS

The emitters of the transistors on pins 1-8 are bussed together.

+

DC POWER

+ 5 VDC

Digital Ground

The ground level from the analyzer’s internal DC power supplies.

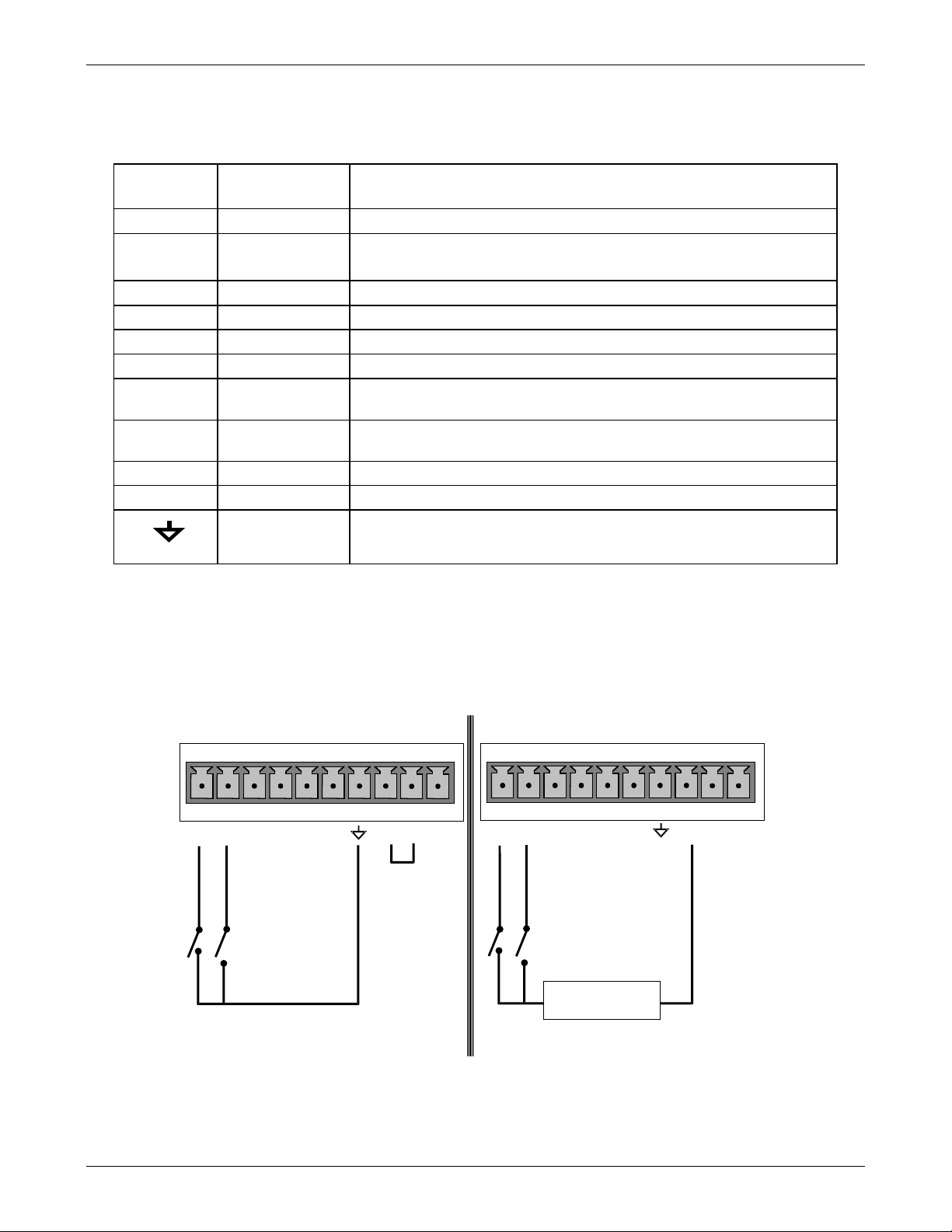

11. If you wish to use the analyzer’s to remotely activate the zero and span calibration modes,

several digital control inputs are provided via a 10-pin connector labeled CONTROL IN on the

analyzer’s rear panel. Two methods for energizing the inputs are provided below; the first

using the internal +5V available on the CONTROL IN connector and the second, if an external,

isolated supply is employed.

CONTROL IN

A B C D E F U +

S

P

A

N

Z

E

R

O

CONTROL IN

A B C D E F U +

-

+

5 VDC Power

Supply

S

P

A

N

Z

E

R

O

Local Power Connections

External Power Connections