Page 1

Instructions

Rackmount (Option 1R) Kit

WCA200 and WCA200A Series

Portable Wireless Communication Analyzers

RSA200, RSA2000A and RSA3000A Series

Real-Time Spectrum Analyzers

075-1263-03

Warnin g

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

*P075126303*

075126303

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or

suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered tradema rks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, servic e, and technical support:

H In North America, call 1-800-833-9200.

H Worldwide, visit www.tektronix.com to find contacts in your area.

Page 3

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the mains power by means

of the power cord or, if provided, the power switch.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

Rackmount Instructions

i

Page 4

Service Safety Summary

Rackmount Instructions

ii

Page 5

General Information

This introduction describes the WCA Wireless Communication Analyzers and

RSA Real-Time Spectrum Analyzers Rack Adapter Kit, discusses its effects on

analyzer performance, and lists its clearance requirements. Please read these

topics before attempting to rackmount your analyzer.

The remainder of this document refers to the WCA Wireless Communication

Analyzers and RSA Real-Time Spectrum Analyzers generically as analyzers.

Products

WCA230A and WCA280A All serial numbers

WCA230 and WCA280 All serial numbers

RSA2203A and RSA2208A All serial numbers

RSA230 and RSA280 All serial numbers

RSA3303A and RSA3308A All serial numbers

RSA3408A All serial numbers

Rack-Adapter Kit Description

The rack adapter kit is a collection of parts that, once installed, configure the

analyzer for mounting in a standard 19-inch equipment rack.

NOTE. A standard equipment rack has rails with universal hole spacing. If you

use a rack with other than universal hole spacing, you may have to drill

additional mounting holes in the rack.

The dimensional drawing in Figure 3 on page 5 illustrates the rack-adapted

analyzer.

Warranted Characteristics

When the analyzer is installed according to the instructions in this document, the

rackmounted analyzer meets all warranted requirements except for those listed in

Environmental R equirements on page 2. Analyzers mounted using methods

other than those described in these instructions may cause the analyzer to not

meet its warranted requirements.

Rackmount Instructions

1

Page 6

General Information

Cooling air enters on the right side as shown in Figure 1. You must provide

adequate cool air to meet the exhaust temperature requirements.

Cool air inHot air out

Environmental

Requirements

Figure 1: Analyzer cooling

Refer to Specification in the user or service manual that applies to your analyzer

model for tables of the warranted characteristics.

The following environmental characteristics supercede those listed in the user or

service manual.

Characteristic Description

Temperature, operating

Inside rack cabinet +10 _Cto+40_C

Rackmount Instructions

2

Page 7

Clearance Requirements

The rack in which the rack adapted analyzer is mounted must provide the

following clearance requirements:

H A minimum of 264.5 mm (10.4 in) of vertical space.

H A minimum width of 441.6 mm (17.4 in) between the left- and right-front

H A minimum inside depth of at least 486.0 mm (19.1 in).

CAUTION. Adhering to these clearance requirements mounts the rack adapted

analyzer with sufficient for air circulation and accommodation of the power cord

and mounting hardware. Failure to provide these clearances can result in

overheating and can cause the analyzer to operate improperly and/or fail.

General Information

rails in the rack.

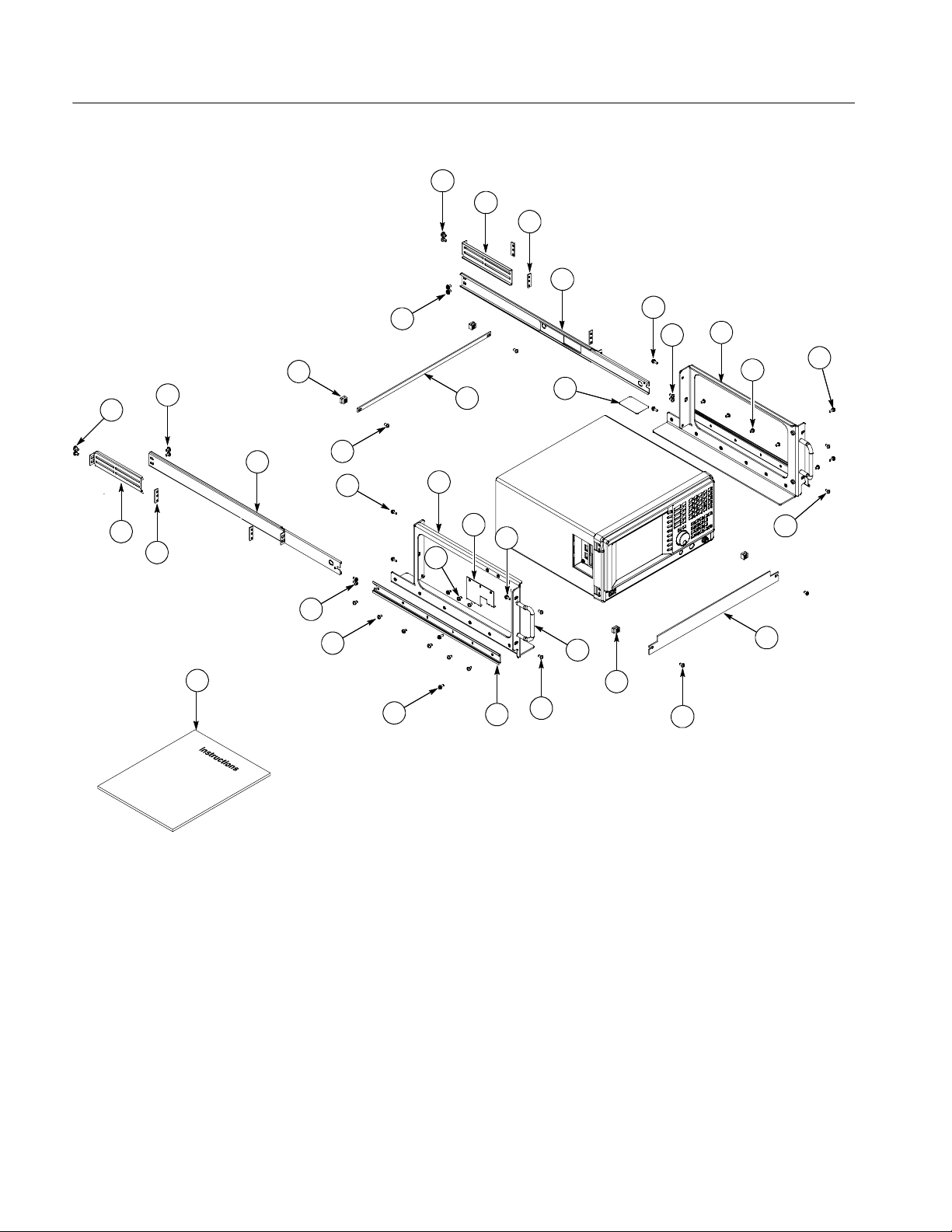

Kit Parts List

Figure 2 on

page 4

2-1 1 ea. 333-4538-01 PANEL, FRONT BLANK PANEL FOR RACK

2-2 1 ea. 407-5226-00 BRACKET HOLDING CABLE

2-3 1 ea. 407-5223-00 BRACKET SLIDE GUIDE LEFT

2-4 1 ea. 407-5224-00 BRACKET SLIDE GUIDE RIGHT

2-5 2 ea. 367-0525-00 HANDLE CARRYING

2-6 1 ea. 351-0313-01 GUIDERACKMOUNT

2-7 1 ea. 351-0241-01 SLIDE DWR EXT

2-8 2 ea. 407-5250-00 BRACKET, RAIL; EXTENDER REAR

2-9 8 ea. 211-A039-00 SCREW M4x14mm SEMS

2-10 15 ea. 212-0518-00 SCREW 10-32x0.312 inch, PNH

2-11 8 ea. 212-0509-00 SCREW 10-32x0.625 inch, PNH

2-12 4 ea. 212-0574-00 SCREW 10-32x0.438 inch FLH

2-13 12 ea. -- -- -- -- -- -- -- -- -- -- SCREW 10-32x0.354 inch, TRUSS

2-14 1 ea. 386-7496-00 PLATE, FRONT PANEL TOP, AL

Quantity Part number Description

Rackmount Instructions

2-15 8 ea. 220-0274-00 NUT, 10-32 STL, CLIP NUT

2-16 1 ea. 335-0391-00 MARKER, IDENT;SAFETY LABEL

2-17 1 ea. 075-1263-03 INSTRUCTION MANUAL, WCA2UP-1R

3

Page 8

General Information

13

8

7

7

13

15

9

13

4

10

1

11

9

11

13

15

13

7

8

7

17

11

9

13

10

9

14

3

2

12

10

6

16

5

11

Figure 2: Rackmount kit parts

4

Rackmount Instructions

Page 9

m

486.0 mm

(19.1 in)

General Information

441.6 mm

(17.4 in)

428.4 mm

(16.9 in)

536.8 mm

(21.1 in)

415.1 mm

(16.3 in)

235.0 mm

(9.3 in)

19.0 mm

(0.7 in)

22.6 mm

(0.9 in)

Figure 3: Instrument with rack adapter installed

264.5 mm

(10.4 in)

225.0 mm

(8.9 in)

450.0 mm

(17.7 in)

482.0 mm

(19.0 in)

146.0 m

(5.7 in)

482.6 mm

(19.0 in)

Rackmount Instructions

5

Page 10

General Information

Rackmount Instructions

6

Page 11

Installation Instructions

This section contains all procedures needed to rackmount the WCA or RSA

analyzer.

WARNING. To avoid personal injury, prevent the instrument from tipping or

dropping onto the installers. Two or more people should install this instrument

into the rack cabinet. Install the instrument so that the operator will be able to

access its rear panel connections without pushing on the instrument.

Equipment List

The following tools are required to attach the rack-adapter kit hardware, install

cabling hardware, and mount the rack-adapted analyzer into a standard equipment cabinet. All tools are standard tools that are readily available.

Required tools and equipment Description

Screwdriver handle Accepts Phillps-driver bits

#2 Phillips tip Phillips-driver bit for #2 size screw heads

Rackmount Instructions

7

Page 12

Installation Instructions

Strip the Analyzer for Conversion

Equipment Required: One #2 Phillips screwdriver.

NOTE. All parts removed from the analyzer in this procedure should be kept.

Some of those parts will be needed to perform this rack conversion and the

remainder will be needed if reconversion to a standard analyzer configuration is

desired at a later time.

Procedure:

1. Remove cables and rear cushions:

a. Disconnect all external cables and the power cord from the analyzer.

b. Remove the one screw securing the rear cushion over the cabinet to the

rear panel at each corner . Detach the cushions. See Figure 4.

Figure 4: Removing the rear cushions

Rackmount Instructions

8

Page 13

Installation Instructions

2. Remove the Front Cushions:

a. Remove the two screws securing the front cushion to the side panel at

each side. See Figure 5.

b. Lifting the front of the analyzer slightly, move the front cushion away.

Rackmount Instructions

Figure 5: Removing the front cushions

9

Page 14

Installation Instructions

Rackmount the Analyzer

This procedure describes how to assemble and install the slide-out tracks in the

equipment rack, and then how to install the analyzer into the rack.

Installing the Kit Hardware

M4X14 screws

(211-A039-00)

Left main bracket

Equipment Required: One #2 Phillips screwdriver.

1. Install the main brackets:

a. Install the right main bracket to the side and rear of the analyzer using

four M4 x 14 screws. See Figure 6.

b. Rotate the analyzer to face the left side and repeat step a to install the left

main bracket.

M4X14 screws

(211-A039-00)

Right main bracket

M4X14 screws

(211-A039-00)

Cable bracket

M4X14 screws

(211-A039-00)

Figure 6: Rackmount assembly

10

Rackmount Instructions

Page 15

Installation Instructions

2. Install the cable bracket:

a. If you use the USB and LAN connectors on the left side of the analyzer,

install the cable bracket to the left main bracket using three

10-32 screws. See Figure 7.

Cable bracket

Route the cables through

the cable bracket.

Figure 7: Installing the cable bracket

3. Apply the CAUTION label:

a. Remove the protective backing from the CAUTION label, and apply it

to the top center of the cabinet. See Figure 8 on page 12.

Rackmount Instructions

11

Page 16

Installation Instructions

CAUTION label

Front

Assembling the Slide-out

Tracks

Figure 8: Applying the CAUTION label on the cabinet (top view)

Equipment Required: One #2 Phillips screwdriver.

Procedure:

1. Identify the equipment rack right and left slide-out track assemblies by

finding the date code label on each assembly. The equipment rack left-side

assembly has a date code that ends with “LH”, for left hand. The equipment

rack right-side assembly has a date code ending with “RH”.

2. Measure the distance between the front and rear rail of the equipment rack.

3. Align the rear bracket to the right slide-out track as shown in

Figure 9 or Figure 10. Note that the rear bracket has multiple pairs of

mount-through holes. When aligning the bracket and track, be sure to select

a pair of holes that mount the rear bracket so that the flange-to-flange

distance matches the front rail to rear rail spacing of the rackmount rack just

measured in step 2.

4. Secure the rear bracket to the right slide-out track using two 10-32 screws

and a bar nut. Leave the screws loose so that you can adjust the overall

length of the slide-out track assembly in the rack.

12

5. Repeat steps 3 and 4 to assemble the left slide-out track assembly.

Rackmount Instructions

Page 17

Inside track

Installation Instructions

Stop latch

Rear bracket

Stop latch

Flat bar nut

Inner track

Stop latch hole

Front rack

Outer track

Rear rack

10-32 Panhead screws

Untapped hole

Flat bar nut

Flat bar nut

Untapped hole

10-32 Panhead screw

Figure 9: Assembling the slide-out tracks (for untapped rails)

Rackmount Instructions

13

Page 18

Installation Instructions

Inside track

Stop latch

Rear bracket

Stop latch

Flat bar nut

Inner track

Front rack

Stop latch hole

Outer track

Rear rack

10-32 Panhead screws

Tapped hole

Flat bar nut

Tapped hole

10-32 Panhead screw

Figure 10: Assembling the slide-out tracks (for tapped rails)

14

Rackmount Instructions

Page 19

Installation Instructions

Mounting the Slide-out

Tracks

1. Select a 1/2 inch spaced hole in the front rail.

2. Select the mounting method according to your rack type:

H To mount the slide-out tracks with their front and rear flanges outside of

the front and rear rails, use method A shown in Figure 11 when doing

step 3. This mounting method assumes tapped holes.

H To mount with front and rear flanges inside of rack rails, use mounting

method B shown in Figure 11. This mounting method assumes untapped

holes.

3. Using the method and hardware determined from step 2, secure the right

slide-out track assembly to the equipment rack front and rear rails. The

screws should be fully, but lightly, seated so that you can adjust the rack

later. See F igure 11.

4. Tighten the screws, applying 28 inch-lbs of torque, left loose in step 4 in

Assembling the Slide-out Tracks on page 12 to fix the front to rear flange

spacing of the slide-out track assembly.

5. Repeat steps 1 through 4 to mount the left slide-out track assembly.

Left slide-out track Left slide-out track

Bar nut

Left slide-out track

Left-front rail

10-32 Panhead

screw

Mounting Method A Mounting Method B

assembly

10-32 Flat head

Use flat head screws if the cabinet rails have countersunk

mounting holes; otherwise use panhead screws

Figure 11: Installation of slide-out track assemblies in the rack (top view)

screw

10-32 Panhead

screw

Rackmount Instructions

15

Page 20

Installation Instructions

Installing the Analyzer in

the Rack

Equipment Required: One #2 Phillips screwdriver.

Procedure: See Figure 12.

1. Install the analyzer:

a. Working from the front of the rack, slide out the inner track of each slide

guide until it stops at the catch.

b. Insert the left and right inner tracks into the tracks on the analyzer. Make

sure that the tracks on the analyzer slip inside the inner tracks.

c. Slide the analyzer backwards until it stops.

d. Push both stop latches, located on the outside of each track, and continue

to slide the analyzer all the way into the rack.

2. Level the rackmounted analyzer:

a. Tighten the four screws that were left loose at the rear of the rack when

you did step 3 in Mounting the Slide-out Tracks on page 15, then pull the

analyzer part way out of the rack.

b. Be sure the four screws that were left loose at the front of the rack are

loose enough to allow the slide guide assemblies to seek their normal

positions.

c. Retighten the four screws and push the analyzer all the way into the rack.

If the tracks do not slide smoothly, readjust the level using the method

just detailed.

d. When leveling is completed, tighten the four screws at the front of the

rack.

3. Secure the analyzer and make rear panel connections:

a. Secure the right and left main brackets to the front rails with four

10-32 screws. If the front rails have untapped holes, insert the four clip

nuts on the holes that you will use to secure the main brackets.

b. Secure the upper and lower blank panels to the front rails with four

10-32 screws. If the front rails have untapped holes, insert the four clip

nuts on the holes that you will use to secure the upper and lower blank

panels.

c. Install the power cord on the rear panel.

d. If necessary, connect cables on the rear panel.

16

Rackmount Instructions

Page 21

Clip nut (use if front

rails are not tapped)

Installation Instructions

Upper blank panel

Stop latch

Press the stop latch on each

side to slide the analyzer.

Figure 12: Installing the analyzer in the rack

Rackmount Instructions

10-32 screws

(211-0509-00)

Lower blank panel

10-32 screws

(211-0509-00)

17

Page 22

Installation Instructions

WARNING. After completing the installation procedure, the installers should

verify that the instrument and rack cabinet will not tip forward while the

instrument is in the extended position.

To avoid personal injury, operators should prevent the rackmounted instrument

from tipping forward onto them. Operators should verify that the rack does not

become unstable with the instrument fully extended. Do not leave the instrument

extended.

To remove the analyzer from the rack mount, slide it out until it stops at the

catches. Support the analyzer while you press in on the automatic latch on each

side. This action will free the analyzer to slide completely out of the rack.

Provide support while you slide the mainframe out of the rack.

g End of document g

18

Rackmount Instructions

Loading...

Loading...