Page 1

User Manual

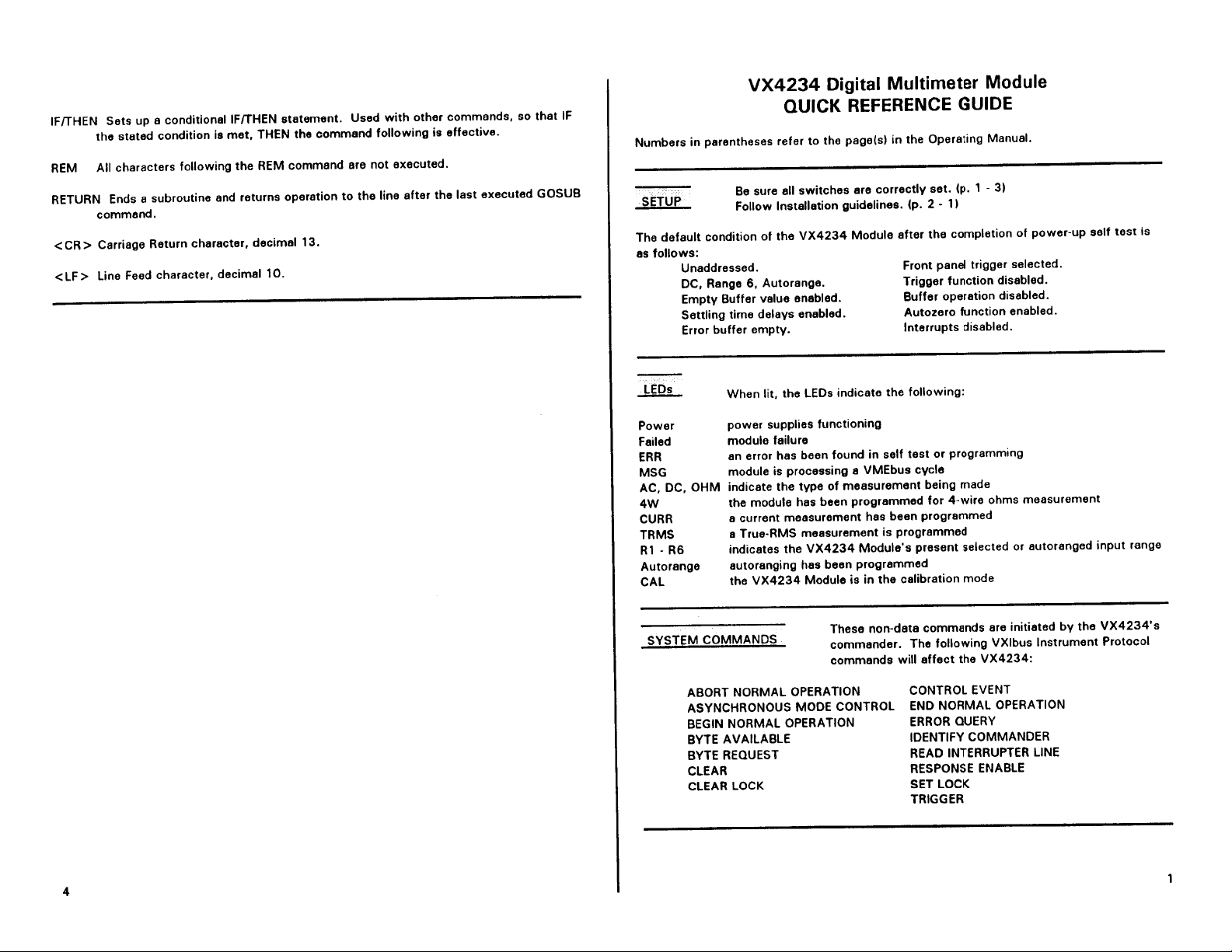

VX4234

Digital Multimeter Module

070-9139-02

This document applies for firmware version 1.00

and above.

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

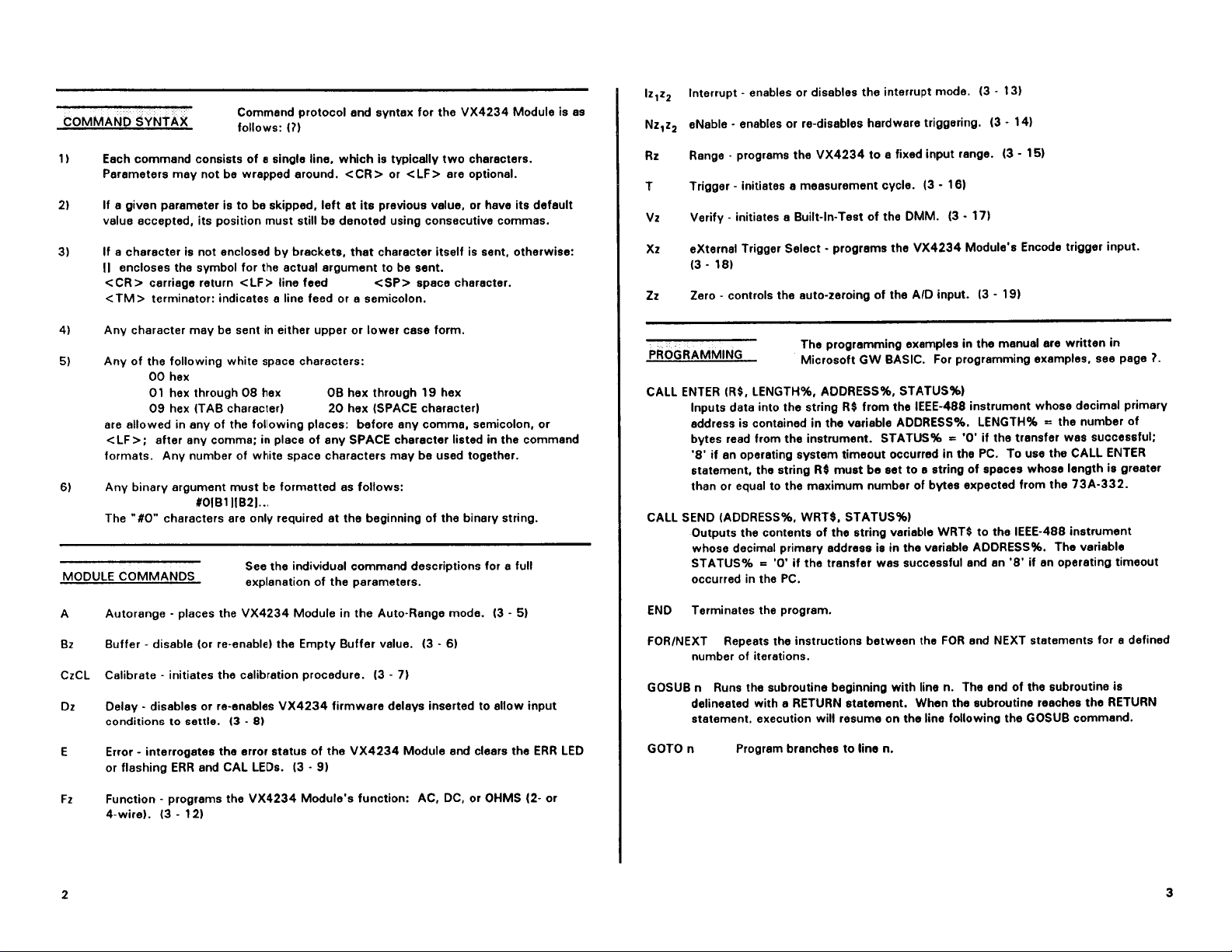

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

Injury Precautions

Avoid Electric Overload

Ground the Product

Do Not Operate Without

Covers

Use Proper Fuse

Do Not Operate in

Wet/Damp Conditions

Do Not Operate in

Explosive Atmosphere

Avoid Exposed Circuitry

To avoid electric shock or fire hazard, do not apply a voltage to a terminal that is

outside the range specified for that terminal.

This product is indirectly grounded through the grounding conductor of the

power cord. To avoid electric shock, the grounding conductor must be connected

to earth ground. Before making connections to the input or output terminals of

the product, ensure that the product is properly grounded.

To avoid electric shock or fire hazard, do not operate this product with covers or

panels removed.

To avoid fire hazard, use only the fuse type and rating specified for this product.

To avoid electric shock, do not operate this product in wet or damp conditions.

To avoid injury or fire hazard, do not operate this product in an explosive

atmosphere.

To avoid injury, remove jewelry such as rings, watches, and other metallic

objects. Do not touch exposed connections and components when power is

present.

Product Damage Precautions

Provide Proper Ventilation

VX4234

To prevent product overheating, provide proper ventilation.

iii

Page 8

General Safety Summary

Do Not Operate With

Suspected Failures

If you suspect there is damage to this product, have it inspected by qualified

service personnel.

Safety Terms and Symbols

Terms in This Manual

Terms on the Product

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

iv

VX4234

Page 9

General Safety Summary

Symbols on the Product

The following symbols may appear on the product:

DANGER

High Voltage

Protective Ground

(Earth) T erminal

ATTENTION

Refer to

Manual

Double

Insulated

VX4234

v

Page 10

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone

Disconnect Power

Use Care When Servicing

With Power On

Do not perform internal service or adjustments of this product unless another

person capable of rendering first aid and resuscitation is present.

To avoid electric shock, disconnect the main power by means of the power cord

or, if provided, the power switch.

Dangerous voltages or currents may exist in this product. Disconnect power,

remove battery (if applicable), and disconnect test leads before removing

protective panels, soldering, or replacing components.

To avoid electric shock, do not touch exposed connections.

VX4234

vii

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

DC Current:

200 A

2.0 mA

20 mA

200 mA

2.0 A

10.0 A

200 mV

2V

20 V

200 V

700 V

N/A

N/A

N/A

N/A

N/A

N/A

Range

15Hz-25Hz

25Hz-50Hz

50 Hz - 7.5 kHz

7.5 kHz - 12 kHz

12 kHz - 20 kHz

15Hz-25Hz

25Hz-50Hz

50 Hz - 7.5 kHz

7.5 kHz - 12 kHz

12 kHz - 20 kHz

15Hz-25Hz

25Hz-50Hz

50 Hz - 7.5 kHz

7.5 kHz - 12 kHz

12 kHz - 20 kHz

15Hz-25Hz

25Hz-50Hz

50 Hz - 7.5 kHz

7.5 kHz - 12 kHz

12 kHz - 20 kHz

15Hz-25Hz

25Hz-50Hz

** with input voltage greater than 10% of full scale.

0.08% + 300 nA

0.08% + 600 nA

0.08% + 6 A

0.12% + 60 A

0.08% + 600 A

0.12%+6mA

Maximum Value Overrange Value

1.25%+1mV

0.8%+1mV

0.6%+1mV

1.0%+1mV

1.5%+1mV

1.25%+6mV

0.8%+6mV

0.6%+6mV

1.0%+6mV

2.0%+6mV

1.25% +80 mV

0.8%+80mV

0.6%+80mV

1.6%+80mV

3.9%+80mV

1.25% + 0.8 V

0.8% + 0.8 V

0.6% + 0.8 V

1.6% + 0.8 V

3.9%+8V

1.25%+8V

0.8% + 0.8 V

0.008% + 30 nA

0.008% + 60 nA

0.013% + 0.6 A

0.033%+6 A

0.013% + 60 A

0.013% + 0.6 mA

0.008% + 9 V

0.008% + 60 V

0.008% + 8 mV**

0.008% + 6 mV**

0.008% + 60 mV**

Page 20

Range

200.00 mV

2.0000 V

20.000 V

200.00 V

700.0 V

Crest Factor:

AC Current:

2:1 for specified accuracy.

3:1 for additional -0.1% error.

7:1 for additional -1% error.

Range Maximum Value Overrange Value

2mA 15Hz-25Hz

25Hz-50Hz

50 Hz - 7.5 kHz

7.5 kHz - 12 kHz

12 kHz - 20 kHz

20 mA

200 mA

2A

10 A

15Hz-25Hz

25Hz-50Hz

50 Hz - 7.5 kHz

7.5 kHz - 12 kHz

12 kHz - 20 kHz

15Hz-25Hz

25Hz-50Hz

50 Hz - 7.5 kHz

7.5 kHz - 12 kHz

12 kHz - 20 kHz

15Hz-25Hz

25Hz-50Hz

50 Hz - 7.5 kHz

7.5 kHz - 12 kHz

12 kHz - 20 kHz

15Hz-25Hz

25Hz-50Hz

50 Hz - 7.5 kHz

7.5 kHz - 12 kHz

12 kHz - 20 kHz

1.87% + 15 A

1.2% + 15 A

0.9% + 15 A

1.5% + 15 A

2.25% + 15 A

1.87% + 150 A

1.2% + 150 A

0.9% + 150 A

1.5% + 150 A

2.25% + 150 A

1.87% + 1.5 mA

1.2% + 1.5 mA

0.9% + 1.5 mA

1.5% + 1.5 mA

2.25% + 1.5 mA

1.87% + 15 mA

1.2%+15mA

0.9%+15mA

1.5%+15mA

2.25% + 15 mA

1.87% + 90 mA

1.2%+90mA

0.9%+90mA

1.5%+90mA

3.00% + 90 mA

0.015% + 1.5 A

0.02% + 15 A

0.04% + 150 A**

0.02% + 1.5 mA**

0.02% + 9 mA**

VX4234

Page 21

Sensitivity 10 mA on 200 mA range.

Accuracy

(1 year at 23° C):

200 ohm

2 Kohm

20 Kohm

200 Kohm

2 Mohm

20 Mohm

Range Maximum Value Overrange Value

1mA

1mA

100 A

10 A

1 A

0.1 A

0.14% + 0.03 ohm

0.08% + 0.3 ohm

0.08%+3ohm

0.08% + 30 ohm

0.14% + 300 ohm

0.98% + 3000 ohm

not specified

not specified

not specified

not specified

not specified

not specified

A

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

Page 64

Page 65

Page 66

Page 67

Page 68

Page 69

Page 70

Page 71

Page 72

Appendix F: Performance Verification

This Performance Verification contains test sequences suitable for determining if

the VX4234 is functioning properly and meets the characteristics as warranted.

The following skills are required to perform this procedure:

Thorough knowledge of test instrument operation and proper measurement

techniques

Knowledge of VXIbus system components and command language

programming

Ability and facility to construct interconnections and fixtures as needed to

perform the procedure

General Information and Conventions

The following conventions apply throughout this procedure:

Each test sequence begins with a table, similar to the one below, which

provides information and requirements specific to that section. The item

number appearing after each piece of equipment refers to an entry in Table 1,

Required Test Equipment. Following the table, you will be given instructions

for interconnecting the VX4234 under-test and for checking the performance

parameters. Results may be recorded on a photocopy of the Test Record on

page A–24.

VX4234

Equipment

Requirements

Prerequisites All prerequisites listed on page A–22

This procedure assumes that you will be using a VX4521 Slot 0 Resource

Manager and a National Instruments PC-GPIB controller configuration as

described in Table 3. If you are using a different controller and software,

simply substitute the commands for that system to achieve the equivalent

results. In the test sequences, you will be instructed to issue Interface Bus

Interactive Control (ibic) commands to set up the VX4234 under-test and

other associated VXIbus test instruments. Please refer to the NI-488.2M

User Manual for additional information.

Commands to the VX4234 may be entered in upper or lower case. To avoid

confusion between alphanumeric characters, for example between a one (1)

Calibrator-Generator (item 1)

Coaxial Cable (item 2)

Dual Banana Connector, two (item 3)

A–21

Page 73

Appendix F: Performance Verification

Prerequisites

The verification sequences in this procedure are valid under the following

conditions:

The VX4234 module covers are in place and the module is installed in an

The VX4234 has passed the power-on self test

The VX4234 has been operating for a warm-up period of 10 minutes in an

and an “L” or a zero (0) and and the letter “o”, all commands in this

procedure are illustrated in the case which provides the greatest visual

distinction. However, when entering these commands you may use any

combination of upper and/or lower case.

approved VXIbus mainframe as described in Section 2 of the User Manual

ambient environment as specified in Section 1 of the User Manual

Equipment Required

This procedure uses traceable test equipment as specified in Table 1 to directly

check warranted characteristics. You may use instrumentation other than the

recommended example if it meets the minimum requirements.

T able 1: Required Test Equipment

Item Number and Description Minimum Requirements Example Purpose

1. Calibrator-Generator Variable DC Voltage to ± 700 V DC,

accuracy to 0.005%

Variable DC Current to 2.0 Amps,

accuracy to 0.005%

Variable True RMS to 700 V AC, 50 Hz

to 7500 Hz; accuracy to 0.005%

Variable Resistance to 10 M ,

accuracy to 0.005%

2. Coaxial BNC Cable

(two required)

3. Adapter, BNC female to dual

banana (four required)

4. 1 k , Resistor 1 k , Watt, 5% Tektronix part number

50 , 36 inch, male to male BNC

connectors

50 , BNC female to dual banana Tektronix part number

Fluke 5700A Calibrator Checking AC & DC Voltage,

DC Amps, and Resistance

accuracy .

Tektronix part number

012-0482-00

103-0090-00

315-0102-00

Interconnecting electrical

signals

Interconnecting electrical

signals

Checking CMRR

A–22

VX4234

Page 74

T able 1: Required Test Equipment (Cont.)

Item Number and Description PurposeExampleMinimum Requirements

Appendix F: Performance Verification

5. Adapter, BNC male to Dual

Binding post

6. Adapter, BNC female to

Clip Leads

50 , BNC male to Dual Binding post Tektronix part number

103-0035-00

50 , BNC female to dual Clip Leads Tektronix part number

013-0076-00

Interconnecting electrical

signals

Interconnecting electrical

signals

VX4234 Under-Test Configuration

The VX4234 under-test must be installed in an approved VXIbus system. At a

minimum, the system must contain the elements listed in Table 2.

T able 2: Elements of a Minimum VX4234 Under-Test System

Item Number and Description Minimum Requirements Example Purpose

1. VXIbus Mainframe One available slot (in addition to

the Slot 0 Resource Manager) for

the VX4234 under-test

2. Slot 0 Resource Manager Resource Mgr., Slot 0 Functions,

IEEE 488 GPIB Interface

3. VXIbus System Controller VXIbus-Talker/Listener/Controller 486 PC with National GPIB

Tektronix VX1410 IntelliFrame Provides power, cooling, and

backplane for VXIbus modules

VX4521 Slot 0 Resource Mgr. Provides Slot 0 Resource Mgr.

functions, and GPIB interface

Provides VXIbus command

PC2A & NI-488.2M software,

GPIB cable

and response interface

Test System Configuration

Test Record

VX4234

Table 3 describes the VXIbus system configuration assumed in this procedure. If

your configuration is different, please note that you will observe your device

names and addresses in test sequences. No secondary addressing is assumed.

Table 3: Test System Configuration Assumed

GPIB Device

Device

GPIB0 GPIB0 (PC card) NA 30

VX4521 VX4521 Slot 0 0D (hex) 13

VX4234 under-test VX4234 Slot 1 01 1

Name

VXI Slot

VXIbus Logical

Address

GPIB Primary

Address

Photocopy the Test Record which follows to record your results.

A–23

Page 75

Appendix F: Performance Verification

stem Configuration Response

T able 4: VX4234 Test Record

VX4234 Serial Number: Temperature and Relative Humidity:

Date of Last Calibration: Verification Performed by:

Certificate Number: Date of Verification:

VXIbus Interface Logical Address, IEEE Address, Slot No., MFG., Model, etc.

Sy

Extended Self Test Verification (S1) Passed Failed

DC Voltage Accuracy

20 mV Range ( R1 )

( 0.04% + 14 uV )

Calibrator +18.0000 mV +0.00000 mV –18.0000 mV

200 mV Range ( R2 )

( 0.04% + 40 uV )

2.0 V Range ( R3 )

( 0.03% + 0.3 mV )

20.0 V Range ( R4 )

( 0.04% + 6.0 mV )

Max. +.018021 . . +.000014 –.017979 . .

Measure

Min. +.017979 . . –.000014 –.018021 . .

Calibrator +180.000 mV +0.0000 mV –180.000 V

Max. +.18011 . . +.00004 . . –.17989 . .

Measure

Min. +.17989 . . –.00004 . . –.18011 . .

Calibrator +1.80000 V +0.0000 mV –1.80000 V

Max. +1.8008 . . +.0003 . . –1.7992 . .

Measure

Min. +1.7992 . . –.0003 . . –1.8008 . .

Calibrator +18.0000 V +0.0000 mV –18.0000 V

Max. +18.013 . . +.006 . . –17.987 . .

Measure

Min. +17.987 . . –.006 . . –18.013 . .

A–24

VX4234

Page 76

T able 4: VX4234 Test Record (Cont.)

Common Mode Rejectio

DC Voltage Accuracy

200.0 V Range ( R5 )

( 0.04% + 30 mV )

700.0 V Range ( R6 )

( 0.04% + 0.3 mV )

Normal Mode Rejection ≤ 73 dB @ 50/60 Hz

n ≤ 115 dB @ DC

Calibrator +180.000 V +0.0000 mV –180.000 V

Max. +180.10 . . +.03 . . –179.90 . .

Measure

Min. +179.90 . . –.03 . . –180.10 . .

Calibrator +630.000 V +0.0000 mV –630.000 V

Max. +630.3 . . +.0 . . –629.7 . .

Measure

Min. +629.7 . . –.0 . . –630.3 . .

Appendix F: Performance Verification

(1 kW unbalance)

DC Current Accuracy

200 mA Range ( R1 )

( 0.04% + 14 mA )

2.0 mA Range ( R2 )

( 0.04% + 40 mA )

20 mA Range ( R3 )

( 0.04% + 40 mA )

≤ 125 dB @ 50/60 Hz

Calibrator +180.000 mA +10.000 mA –180.000 mA

Max. +.00019407 . . +.00002400 –.00016592 . .

Measure

Min. +.00016592 . . –.00000400 –.00019407 . .

Calibrator +1.80000 mA +10.000 mA –1.80000 mA

Max. +.0018407 . . +.0000500 . . –.0017593 . .

Measure

Min. +.0017593 . . –.0000300 . . –.0018407 . .

Calibrator +18.0000 mA +10.000 mA –18.0000 mA

Max. +.018407 . . +.000050 . . –.017953 . .

Measure

Min. +.017953 . . –.000030 . . –.018407 . .

200 mA Range ( R4 )

( 0.04% + 40 mA )

VX4234

Calibrator +180.000 mA +10.000 mA –180.000 mA

Max. +.18011 . . +.00005 . . –.17989 . .

Measure

A–25

Page 77

Appendix F: Performance Verification

T able 4: VX4234 Test Record (Cont.)

DC Current Accuracy

Min. +.17989 . . –.00003 . . –.18011 . .

2.0 A Range ( R5 )

( 0.04% + 40 mA )

10.0 A Range ( R6 )

( 0.04% + 0.3 mA )

Calibrator +1.8000 A +10.000 mA –180.000 A

Max. +1.8008 . . +.0000 . . –1.8000 . .

Measure

Min. +1.8000 . . –.0000 . . –1.8008 . .

Calibrator +1.90000 A +10.000 mA –1.90000

Max. +1.901 . . +.000 . . –1.899 . .

Measure

Min. +1.899 . . –.000 . . –1.901 . .

AC RMS Voltage Accuracy Calibrator Maximum Measure Minimum

200 mV Range ( R2 )

( 0.6% + 1 mV )

2.0 V Range ( R3 )

( 0.6% + 6 mV )

20.0 V Range ( R4 )

( 0.6% + 80 mV )

200.0 V Range ( R5 )

( 0.6% + 30 mV )

700.0 V Range ( R6 )

( 0.6% + 8.0 V )

Resistance Accuracy Calibrator Maximum Measure Minimum

200 W Range (R1)

±( 0.14% Value + 0.015% FS)

2 kW Range (R1)

±( 0.08% Value + 0.015% FS

20 kW Range (R1)

±( 0.08% Value + 0.015% FS

200 kW Range (R1)

±( 0.08% Value + 0.015% FS

+180.000 mV (6 kHz) +.18208 . . +.17792 . .

+1.80000 V (6 kHz) +1.8168 . . +1.7832 . .

+18.0000 V (6 kHz) +18.188 . . +17.812 . .

+180.000 V (6 kHz) +181.88 . . +178.12 . .

+630.000 V (6 kHz) +641.8 . . +618.2 . .

100.000 +100.17 . . +99.83 . .

1000.00 +1001.1 . . +998.9 . .

10.0000 k +10011.0 . . +9989.0 . .

100.000 k +100110.0 . . +99890.0 . .

2 MW Range (R1)

±( 0.14% Value + 0.015% FS

20 MW Range (R1)

±( 0.17% Value + 0.015% FS

A–26

1.00000 M +1001700.0 . . +998300.0 . .

10.0000 M +10020000.0 . . +9980000.0 . .

VX4234

Page 78

Self Test

Appendix F: Performance Verification

The VX4234 includes a built-in self test function (BITE) which runs automatically each time the power is turned on and when the internal self-tests (V0 and

V1) are executed.

BITE uses internal routines and reference circuitry to confirm the instrument’s

capability to measure voltage, current, and resistance, and convert the measurement to a digital result. You may additionally execute the extended AC and DC

mid–scale tests with the V1 command.

NOTE. Because these tests verify operation up to the front panel, you must

disconnect all input signals before executing the extended verification.

In addition to BITE, the front panel indicator lights display the current status of

module power, module self test results (including the central processor), and the

assertion of SYSFAIL*. If the module loses any of its power voltages, the Failed

light will be on, the Power light will be off, and SYSFAIL* will be asserted.

Following a successful VXIbus system startup sequence, the green PWR light on

the VX4234 front panel indicates that the self test has passed and that the +5 V

power supply is operational.

NOTE. If you experience an error indication from the VX4234-under-test, or any

other VXIbus module, investigate and correct the problem before proceeding.

Common items to check are logical address conflicts (primary and secondary;

see Table 3), breaks in the VXIbus daisy chain signals, improper seating of a

module, loose GPIB cable, or loose or blown fuses.

Performance Verification Tests

This Performance Verification procedure may be executed in any order. You may

use any VXIbus system which meets the requirements described in Table 2,

however, the test sequences are structured for a system configuration as

described in Table 3.

NOTE. If at any time you do not observe the expected result, check the front panel

ERROR light. If it is on, perform error Queries (ibwrt ”e”<cr> ibrd 100<cr>)

until you receive a response of “99 . .”. Following a response of “99 . .”, the

front panel ERROR light should be off.

VX4234

A–27

Page 79

Appendix F: Performance Verification

VXIbus Interface

This sequence verifies that the VX4234 configures correctly and

communicates

properly with your system controller. It assumes a VXIbus system configuration

as specified in Table 3, and in particular, utilizes the VX4521 Resource Manager

“table” command for verification of the system configuration. If your VXIbus

system uses a different Resource Manager, you must substitute commands

specific to that Resource Manager-Controller to verify your system configuration.

Equipment

Requirements

Prerequisites All prerequisites listed on Page A–22

No test equipment required.

1. If you are using the VX4521 Slot 0 Resource Manager, send the TABLE

command to verify the system configuration. (If you are using a different

Controller, perform the equivalent function to confirm the responses shown

in Table 5.) Your configuration may not be identical, but the information

should be the same.

T able 5: VXIbus System Configuration

Command to Type Response to Verify

ibic

buffer 1

(Allows more comfortable viewing of responses)

ibfind VX4521

ibwrt "table"

ibrd 200 02 (Implies two modules in this system)

! LA 0, IEEE 13, Slot 0, MFG FFDh, MODEL VX4521,

PASS, , RM..

! LA 1, IEEE 01, Slot 1, MFG FFCh, MODEL VX4234,

PASS TRIGGER;LOCK;READ STB, MESG, 0, V1.3,

NORMAL ..

2. To verify overall module functionality, send the extended self-test (verifica-

tion) command and an Error query. Then confirm that the front panel

ERROR light is off and that there are no errors (code 99 indicates no errors).

ibfind VX4234

ibwrt "V1E" (Observe that the ERROR light is off)

and the tables and figures are thru numbered Arabic. ibrd 100

(Observe a response of: 99 . .)

A–28

VX4234

Page 80

Appendix F: Performance Verification

DC Voltage Accuracy

This sequence verifies the accuracy of the six DC voltage ranges.

Equipment

Requirements

Prerequisites All prerequisites listed on page A–22

Calibrator (item 1)

Coaxial Cable, one (item 2)

Dual Banana Connectors, two (item 3)

1. Set the Calibrator to +0.0000 mV DC .

2. Connect the Calibrator to the VX4234 Voltage Input using two Dual-Banana

connectors and a Coaxial cable.

3. Set the Calibrator to +18.0 mV DC.

4. With the following commands, set the VX4234 to DC volts and for the

20 mV range (Function 1, Range 1). Then perform an acquisition and verify

the response relative to the limits shown in the Test Record.

set VX4234

ibwrt "F1R1"

ibrd 100 (Observe: +.01800 ±0.0000212 VDC, see Table 6)

5. Set the Calibrator to –18.0 mV DC.

6. Re-acquire and verify the response to the limits shown in the Test Record:

ibrd 100 (Observe: –.01800 ±0.0000212 VDC, see Table 6)

7. Check the additional voltages listed in Table 6 . (Note that the first entry in

Table 6 is a repeat of steps 4 through 6 above .)

Table 6: DC Voltage Accuracy

Set Calibrator

+18.0000 mV DC

–18.0000 mV DC

(Steps 3 to 6 repeated for table

continuity)

+180.000 mV DC

–180.000 mV DC

+1.80000 VDC

–1.80000 VDC

Command To VX4234

ibwrt "F1R1"

ibrd 100

ibrd 100

ibwrt "R2"

ibrd 100

ibrd 100

ibwrt "R3"

ibrd 100

ibrd 100

Response to Verify

+.018021 . . to +.017979 . .

–.017979 . . to –.018021 . .

+.18011 . . to +.17989 . .

–.17989 . . to –.18011 . .

+1.8008 . . to +1.7992 . .

–1.7992 . . to –1.8008 . .

VX4234

A–29

Page 81

Appendix F: Performance Verification

Table 6: DC Voltage Accuracy (Cont.)

DC Common Mode

Rejection

Set Calibrator Response to Verify

+18.0000 VDC

Command To

ibwrt "R4"

ibrd 100

–18.0000 VDC

+180.000 VDC

ibrd 100

ibwrt "R5"

ibrd 100

–180.000 VDC

+630.00 VDC

ibrd 100

ibwrt "R6"

ibrd 100

–630.00 VDC

ibrd 100

VX4234

+18.013 . . to + 17.987 . .

–17.987 . . to –18.013 . .

+180.10 . . to +179.90 . .

–179.90 . . to –180.10 . .

+630.3 . . to +629.7 . .

–629.7 . . to –630.3 . .

8. Set the Calibrator to +0.0000 mV.

This sequence verifies the capability of the VX4234 to reject Common Mode

voltage when operating in the DC Voltage measurement mode.

Equipment

Requirements

Calibrator (item 1)

Coaxial Cable, one (item 2)

Dual Banana Connectors, two (item 3)

Binding Post Connector (item 5)

Clip Lead Connector (item 6)

1 k Resistor ( ¼ Watt, 5%)

A–30

Prerequisites All prerequisites listed on page A–22

1. Set the Calibrator to +0.0000 mV DC.

2. Connect the Calibrator to the VX4234 as follows:

a. Connect a BNC to Dual Banana connector to the Voltage input of the

VX4234.

b. Connect a BNC to Dual Binding post connector to the BNC to Dual

Banana connector on the VX4234.

c. Connect a 1 k resistor between the binding posts.

d. Connect a BNC to Dual Banana adapter to the calibrator then connect

one end of a coaxial cable to the Dual Banana adapter and the opposite

end of the coaxial cable to a BNC to Clip Lead adapter.

VX4234

Page 82

Appendix F: Performance Verification

e. Connect the red lead of the Clip Lead adapter to the red Dual Binding

post adapter on the VX4234 (one side of the resistor).

f. Connect the black lead of the Clip Lead adapter to the Chassis Ground

binding post of the VX4234.

3. Set the Calibrator to +100.0 VDC, and enable the output.

4. Using the following commands, set the VX4234 to read DC volts on the

20 mV range (Function 1, Range 1). Perform two acquisitions and verify the

second response to be ≤ 177.8 mV (Note: The first reading returned is stale

data).

set VX4234

ibwrt "F1R1"

ibrd 100 (Disregard this reading.)

ibrd 100 (Observe: ≤ [+/-].000018 . .)

DC Normal Mode

Rejection

5. Set the Calibrator to +100.0 V, 50 or 60 Hz. Perform two acquisitions and

verify the second response to be ≤ 56.8 mV

ibrd 100 (Disregard this reading.)

ibrd 100 (Observe: 3 [+/–].000056 . .)

6. Set the Calibrator to +0.0000 mV DC.

This sequence verifies the ability of the VX4234 to reject residual AC voltage

present on the input when operating in a DC Voltage mode.

Equipment

Requirements

Prerequisites All prerequisites listed on page A–22

Calibrator (item 1)

Coaxial Cable, one (item 2)

Dual Banana Connectors, two (item 3)

1. Set the Calibrator to +0.0000 mV DC.

2. Verify the VX4234-under-test 50/60 Hz reject switch (side panel) is in the

60 Hz position.

VX4234

3. Connect the Calibrator to the VX4234 Voltage Input using two Dual-Banana

connectors and a Coaxial cable.

4. Set the Calibrator to +10.0 V, 60 Hz and enable the output.

A–31

Page 83

Appendix F: Performance Verification

5. Using the following commands, set the VX4234 to read DC volts on the

6. Power down the VXI system, remove the VX4234-under-test and set the

7. Set the Calibrator to +10.0 V, 50 Hz.

8. Perform two acquisitions and verify the second response to be ≤ 2.24 mV.

20 mV range (Function 1, Range 1). Perform two acquisitions and verify the

second response to be ≤ 2.24 mV (Note: The first reading returned is stale

data).

set VX4234

ibwrt "F1R1"

ibrd 100 (Disregard this reading.)

ibrd 100 (Observe: 3 [+/–].002239 . .)

50/60 Hz reject switch to the 50 Hz position. Reinstall the VX4234

under-test and power-on the system.

DC Current Accuracy

ibrd 100 (Disregard this reading.)

ibrd 100 (Observe: 3 [+/–].002239 . .)

9. Set the Calibrator to +0.0000 mV DC.

10. Reset the VX4234-under-test 60 Hz reject switch to the AC power source

frequency being used by the VXI system.

This sequence verifies the accuracy of the six DC Current ranges.

Equipment

Requirements

Prerequisites All prerequisites listed on page A–22

Calibrator (item 1)

Coaxial Cable, one (item 2)

Dual Banana Connector, two (item 3)

1. Set the Calibrator to +0.0000 mV (If using the Fluke 5700A, press the clear

button twice).

2. Connect the Calibrator to the VX4234 Voltage input using two Dual-Banana

connectors and a Coaxial cable.

A–32

VX4234

Page 84

Appendix F: Performance Verification

3. Set the VX4234 to DC Current on the 200 mA range (Function 6. Range 1) .

set VX4234

ibwrt "F6R1"

4. Set the Calibrator to +180.000 mA.

5. Acquire a reading from the VX4234 and verify the response relative to the

limits shown in the Test Record (limits also shown in Table 7 and 8):

ibrd 100 (Observe; +.00018000 ±0.00001407A {table 7})

6. Set the Calibrator to –180.000 mA.

7. Acquire a reading from the VX4234 and verify the response to the limits

shown in the Test Record:

ibrd 100 (Observe: –.00018000 ±0.00001407 A {table 7})

8. Check the additional currents listed in Table 7 and 8. (Note that the first

entry in Table 7 is a repeat of steps 3 through 7 above.)

T able 7: DC Current Accuracy

Set Calibrator

+180.000 mA

–180.000 mA

Command to VX4234

ibwrt "F6R1"

ibrd 100

ibrd 100

Response to Verify

+.00019407 to +.00016593

–.00016593 to –.00019407

(Steps 3 to 7 repeated for

continuity)

+1.80000 mA

–1.80000 mA

+18.0000 mA

–18.0000 mA

+180.000 mA

–180.000 mA

ibwrt "R2"

ibrd 100

ibrd 100

ibwrt "R3"

ibrd 100

ibrd 100

ibwrt "R4"

ibrd 100

ibrd 100

+.0018407 to +.0017593

–.0017593 to –.0018407

+.018047 . . to +.017953 . .

–.017953 . . to –.018047 . .

+.18011 . . to + .17989 . .

–.17989 . . to –.18011 . .

9. Remove the Calibrator signal from the VX4234 “200 mA max” input and

connect to the “10 A max” input. Continue the DC Current checks as

directed in Table 8. (Be careful to reconnect the Calibrator cable in the

proper polarity. This will require rotating the dual banana connector 180

degrees.)

VX4234

A–33

Page 85

Appendix F: Performance Verification

T able 8: High Range DC Current Accuracy

AC Voltage Accuracy

Set Calibrator

+1.80000 A

–1.80000 A

+1.90000 A

–1.90000 A

Command to VX4234

ibwrt "R5"

ibrd 100

ibrd 100

ibwrt "R6"

ibrd 100

ibrd 100

Response to Verify

+1.8008 . . to +1.7992 . .

–1.7992 . . to –1.8008 . .

+1.901 . . to +1.899 . .

–1.899 . . to –1.901 . .

10. Set the Calibrator to +0.0000 mV.

This sequence verifies the accuracy of the five AC RMS voltage ranges.

Equipment

Requirements

Prerequisites All prerequisites listed on page A–22

Calibrator (item 1)

Dual Banana Connectors, two (item 3)

Coaxial cable, one (item 2)

1. Set the Calibrator to 180.000 mV and 6.0 kHz.

2. Connect the Calibrator to the VX4234 Voltage input using two Dual-Banana

connectors and a Coaxial cable.

3. Set the VX4234 to AC volts and the 200 mV range (Function 5, Range 2).

(Note: There is no Range 1 for AC). Acquire a reading from the VX4234 and

verify the response relative to the limits shown in the Test Record (limits are

also shown in Table 9):

set VX4234

ibwrt "F5R2" (Note: there is no R1 range for AC Volts)

ibrd 100 (Observe: +.18000 ±.00208, see Table 9)

4. Check the additional voltages as directed in Table 9 . (Note that the first

entry in Table 9 is a repeat of step 3 above.)

A–34

VX4234

Page 86

Table 9: AC RMS Voltage Accuracy

Appendix F: Performance Verification

Resistance Accuracy

Set Calibrator

+180.000 mV, 6.0 kHz

(Step 3 above repeated for

table continuity.)

+1.80000 V, 6.0 kHz

+18.0000 V, 6.0 kHz

+180.000 V, 6.0 kHz

+630.00 V , 1.0 kHz

Command to VX4234

ibwrt "F5R2"

ibrd 100

ibwrt "R3"

ibrd 100

ibwrt "R4"

ibrd 100

ibwrt "R5"

ibrd 100

ibwrt "R6"

ibrd 100

Response to Verify

+.18208 . . to +.17792 . .

+1.8168 . . to +1.7832 . .

+18.188 . . to + 17.812 . .

+181.88 . . to +178.12 . .

+641.8 . . to +618.2 . .

5. Set the Calibrator to +0.0000 mV DC.

This sequence verifies the accuracy of the six (6) Resistance ranges.

Equipment

Requirements

Calibrator (item 1)

Coaxial Cable, two (item 2)

Dual Banana Connectors, four (item 3)

Prerequisites All prerequisites listed on page A–22

1. Set the Calibrator to 100 .

2. Connect the Calibrator Hi/Lo Output to the top input (R+/R-) of the

VX4234 using two Dual-Banana connectors and a Coaxial cable.

3. Connect the Calibrator Hi/Lo Sense to the bottom input (R+/R-) of the

VX4234 using a second Coaxial cable and two Dual-Banana connectors.

4. Set the VX4234 to 4-Wire and the 200 range (Function 4, Range 1).

Acquire a reading from the VX4234 and verify the response relative to the

limits shown in the Test Record (the limits are also shown in Table 9):

set VX4234

ibwrt "F4R1"

ibrd 100 (Observe: +100.00 +0.170W, see Table 10)

VX4234

A–35

Page 87

Appendix F: Performance Verification

5. Check the additional resistance ranges listed in Table 10. (Note that the first

T able 10: Resistance Accuracy

Set Calibrator Command to VX4234 Response to Verify

+100.000

(Step 4 repeated for continuity)

+1000.00

+10.0000 k

+100.000 k

+1.00000 M

+10.0000 M

entry in Table 10 is a repeat of steps 4 above.)

ibwrt "F4R1"

ibrd 100

ibwrt "R2"

ibrd 100

ibwrt "R3"

ibrd 100

ibwrt "R4"

ibrd 100

ibwrt "R5"

ibrd 100

ibwrt "R6"

ibrd 100

+100.17 . . to +99.83 . .

+1001.1 . . to +998.9 . .

+10011.0 . . to +9989.0 . .

+100110.0 . . to + 99890.0 . .

+1001700.0 to +998300.0 . .

+10020000.0 to +9980000.0

This completes the VX4234 verification procedure.

A–36

VX4234

Page 88

WARNING

The following servicing instructions are for use only by qualified personnel. To

avoid injury, do not perform any servicing other than that stated in the operating

instructions unless you are qualified to do so. Refer to all Safety Summaries before

performing any service.

Page 89

37

Page 90

Appendix G

38

Page 91

Appendix G

39

Page 92

Appendix G

40

Loading...

Loading...