Page 1

User Manual

VX4101A

MultiPaqInstrument

071-0049-01

This document supports firmware version 2.0

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to the Safety Summary prior to

performing service.

Page 2

Copyright T ektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its suppliers and

are protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in T echnical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software – Restricted Rights clause at F AR 52.227-19, as applicable.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that this product will be free from defects in materials and workmanship for a period of three (3) years

from the date of shipment. If any such product proves defective during this warranty period, T ektronix, at its option, either

will repair the defective product without charge for parts and labor, or will provide a replacement in exchange for the

defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; or c) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time or

difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESSED OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUST OMER FOR BREACH OF THIS WARRANTY. TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

Getting Started

General Safety Summary xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VX4101A Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power-On Sequence 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Description 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuses 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IEEE-488 Address 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self-Test 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Options 1–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About the VXIplug&play Software 1–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Module in the Mainframe 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the VXIplug&play Software 1–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Powering-On the VX4101A 1–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYSFAIL* Operation 1–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Check 1–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational Check 1–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Checklist 1–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Basics

About Global and Instrument Commands 2–1. . . . . . . . . . . . . . . . . . . . . .

About Global Commands 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Instrument Commands 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VX4101A Operational Modes 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Synchronous Mode 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Asynchronous Mode 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Instrument Triggering 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trigger Sources 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VX4101A Trigger Architecture 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Fast Data Channel (FDC) Operation 2–13. . . . . . . . . . . . . . . . . . . . .

About FDC 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The FDC Process 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FDC Operation with the DMM and DAC 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FDC Example 2–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the VX4101A MultiPaqt Instrument 2–23. . . . . . . . . . . . . . . . . . . . .

Using Asynchronous Mode 2–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Counter 2–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What You Should Know About 2–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VX4101A MultiPaq Instrument User Manual

i

Page 6

Table of Contents

Measuring Frequency 2–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Time Interval 2–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Rise Time 2–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Time Interval with Delay 2–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Digital Input 2–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What You Should Know About 2–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming the Digital Input 2–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading Current Input 2–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading Points Using the External Handshake Feature 2–35. . . . . . . . . . . . . . . . . . . .

Using the Digital Output 2–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What You Should Know About 2–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outputing One 32-Bit Word 2–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outputing a Sequence 2–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Digital Multimeter 2–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What You Should Know About 2–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Making a DC Volt Measurement 2–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Making AC Volt Measurements 2–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Making a 2-Wire Resistance Measurement 2–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Making a Current Measurement 2–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Digital to Analog Converter (DAC) 2–47. . . . . . . . . . . . . . . . . . .

What You Should Know About 2–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generating Continuous and Multiple Waveforms 2–48. . . . . . . . . . . . . . . . . . . . . . . .

Generating Repetitive W aveforms 2–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading a Trace from the DAC in Binary 2–51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Sample Handshake Mechanism 2–52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming a Trace with a Numeric Array List 2–53. . . . . . . . . . . . . . . . . . . . . . . .

Using the Relay Drivers 2–55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Opening and Closing Relays 2–55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the SurePatht Modules 2–57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What You Should Know About 2–57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Closing a Relay 2–57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Syntax and Commands

ii

Command Syntax 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Protocol and Syntax 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCPI Commands for the VX4101A 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Summary 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ABORt Subsystem 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALibrate Subsystem 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTrument Subsystem 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OUTPut Subsystem 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SOURce Subsystem 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYST em Subsystem 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger Subsystem 3–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCPI Commands for the Counter 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Summary 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ARM Subsystem 3–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALCulate Subsystem 3–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALibrate Subsystem 3–58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VX4101A MultiPaq Instrument User Manual

Page 7

Table of Contents

CONFigure Subsystem 3–63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FETCh? Subsystem 3–73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INITiate Subsystem 3–77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INPut Subsystem 3–78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTrument Subsystem 3–89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MEASure? Subsystem 3–91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OUTPut Subsystem 3–100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

READ? Subsystem 3–102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SENSe Subsystem 3–102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SOURce Subsystem 3–109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST ATus Subsystem 3–110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST Subsystem 3–113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT Subsystem 3–114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCPI Commands for the Digital Input 3–115. . . . . . . . . . . . . . . . . . . . . . . . .

Command Summary 3–115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALibration Subsystem 3–119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONFigure Subsystem 3–120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FETCh? Subsystem 3–122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FORMat Subsystem 3–125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INITiate Subsystem 3–126. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTrument Subsystem 3–126. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MEASure Subsystem 3–128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

READ? Subsystem 3–130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SENSe Subsystem 3–131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST ATus? Subsystem 3–137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST Subsystem 3–138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger Subsystem 3–139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCPI Commands for the Digital Output 3–147. . . . . . . . . . . . . . . . . . . . . . . .

Command Summary 3–147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FORMat Subsystem 3–149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INITiate Subsystem 3–150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTrument Subsystem 3–152. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OUTPut Subsystem 3–153. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST ATus? Subsystem 3–155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST Subsystem 3–156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRACe Subsystem 3–157. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger Subsystem 3–163. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCPI Commands for the Digital to Analog Converter 3–169. . . . . . . . . . . .

Command Summary 3–169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALibrate Subsystem 3–171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FORMat Subsystem 3–172. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INITiate Subsystem 3–173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTrument Subsystem 3–174. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OUTPUT Subsystem 3–176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST ATus? Subsystem 3–178. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST Subsystem 3–179. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRACe Subsystem 3–180. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trigger Subsystem 3–188. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VXI:FDC Subsystem 3–193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCPI Commands for the Digital Multimeter 3–197. . . . . . . . . . . . . . . . . . . .

Command Summary 3–197. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VX4101A MultiPaq Instrument User Manual

iii

Page 8

Table of Contents

CALCulate Subsystem 3–202. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALibrate Subsystem 3–212. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONFigure Subsystem 3–218. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FETCh? Subsystem 3–221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INITiate Subsystem 3–223. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INPut Subsystem 3–224. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTrument Subsystem 3–225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MEASure? Subsystem 3–227. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST Subsystem 3–233. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

READ? Subsystem 3–234. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SENSe Subsystem 3–235. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST ATus? Subsystem 3–243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST Subsystem 3–245. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger Subsystem 3–246. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VXI:FDC Subsystem 3–251. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCPI Commands for the Relay Drivers 3–255. . . . . . . . . . . . . . . . . . . . . . . .

Command Summary 3–255. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ROUT e Subsystem 3–255. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST ATus? Subsystem 3–257. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCPI Commands for the SurePatht Modules 3–259. . . . . . . . . . . . . . . . . . . .

Command Summary 3–259. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INITiate Subsystem 3–261. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTrument Subsystem 3–262. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ROUT e Subsystem 3–264. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST ATus Subsystem 3–286. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST Subsystem 3–287. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIGger Subsystem 3–288. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IEEE-488.2 Common Commands 3–293. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*CLS 3–293. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*ESE 3–294. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*ESR 3–294. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*IDN? 3–295. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*OPC 3–296. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*RST 3–297. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*SRE 3–301. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*STB? 3–302. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*TRG 3–302. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*TST? 3–303. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*WAI 3–304. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status and Events

iv

Status and Event Reporting System 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

STATus and Event Commands 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATus 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATus : OPERation : ENABle 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATus : OPERation [:EVENt]? 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATus : OPERation : NTRansition 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATus : OPERation : PTRansition 4–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATus : QUEue : ENABle <numeric list> 4–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATus : QUEue [:NEXT]? 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATus : QUEStionable [:EVENt]? 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VX4101A MultiPaq Instrument User Manual

Page 9

Appendices

Table of Contents

STATus : QUEStionable : CONDition? 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATus : QUEStionable : ENABle 4–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATus : QUEStionable : NTRansition 4–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATus : QUEStionable : PTRansition 4–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Subsystem Example 4–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A: Specifications A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VX4101A General Characteristics A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Over Voltage Indication A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Universal Counter Specifications A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Multimeter (DMM) Specifications A–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Input and Output (Option 1D) A–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital to Analog Converter (DAC) (Option 1A) A–25. . . . . . . . . . . . . . . . . . . . . . . .

Relay Drivers (Option 1D) A–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SurePath Specifications A–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Certifications and Compliances A–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B: Input/Output Connections B–1. . . . . . . . . . . . . . . . . . . . . . . .

Appendix C: Instrument I/O Operation C–1. . . . . . . . . . . . . . . . . . . . . . . .

Configuration Registers C–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VMEbus Interrupt Level Selection C–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix D: Counter Architecture D–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix E: Obsolete Commands E–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Counter Commands E–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix F: Performance Verification Procedure F–1. . . . . . . . . . . . . . . .

Semi-Automated PVP Procedures F–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual PVP Procedures F–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix G: Calibration G–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration for the DMM G–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Mode Calibration Procedure G–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRMS AC (DC Coupled) Mode Calibrations G–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Resistance Mode Calibration Procedure G–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Mode Calibration Procedure G–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration for the Counter G–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration for the Digital to Analog Converter G–19. . . . . . . . . . . . . . . . . . . . . . . . .

DAC Calibration Procedure G–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration for the Digital Input G–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Input Calibration Procedure G–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix H: User Service H–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix I: Replaceable Parts I–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information I–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Parts List I–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary and Index

VX4101A MultiPaq Instrument User Manual

v

Page 10

Table of Contents

List of Figures

Figure 1–1: VX4101A VXIbus Connectors, Fuses, and

Switch Locations 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–2: VX4101A Front Panel 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–3: Module Installation 1–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–1: Typical FDC Process 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–1: VX4101A Standard Registers 4–2. . . . . . . . . . . . . . . . . . . . . .

Figure 4–2: Instrument Operational Status Registers 4–3. . . . . . . . . . . . .

Figure I–1: VX4101A Exploded View I–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure I–2: VX4101A Delay Line Cable Dress I–7. . . . . . . . . . . . . . . . . . .

vi

VX4101A MultiPaq Instrument User Manual

Page 11

List of Tables

Table of Contents

Table 1–1: VX4101A Performance Options 1–2. . . . . . . . . . . . . . . . . . . . .

Table 1–2: Standard Accessories 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–3: Optional Accessories 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–4: VX4101A Performance Options 1–13. . . . . . . . . . . . . . . . . . . . .

Table 1–5: Instrument-Specific Files 1–18. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–6: Commands Available at Power-On 1–22. . . . . . . . . . . . . . . . . .

Table 2–1: VX4101A Global Trigger Sources 2–9. . . . . . . . . . . . . . . . . . .

Table 2–2: VX4101A Counter-Specific Trigger Sources 2–10. . . . . . . . . . .

Table 2–3: VX4101A Fixed Trigger Sources for the DMM, DAC,

Digital Input and Digital Output 2–11. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–1: Commands Available at Power-On 3–21. . . . . . . . . . . . . . . . . .

Table 3–2: Trigger Resolution (in ms) 3–27. . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–3: Input Calibration Source Settings 3–60. . . . . . . . . . . . . . . . . . .

Table 3–4: Optimum Sensitivity Settings 3–84. . . . . . . . . . . . . . . . . . . . . . .

Table 3–5: Limits of Calibration Input 3–215. . . . . . . . . . . . . . . . . . . . . . . .

Table 3–6: Meaning of Returned String 3–221. . . . . . . . . . . . . . . . . . . . . . . .

Table 3–7: MEASure:VOLTage[DC]? and <Expected Value>

ranges 3–230. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–8: MEASure:VOLTage:AC? and <Expected Value>

ranges 3–230. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–9: MEASure:CURRent? and <expected value> ranges 3–231. . . .

Table 3–10: MEASure:RESistance? and MEASure:FRESistance

and <Expected Value> ranges 3–231. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–11: VX4101A Reset Values 3–297. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–12: Counter Front Panel Arm Reset Values 3–297. . . . . . . . . . . . .

Table 3–13: Counter Channels 1 & 2 Analog Front-End 3–297. . . . . . . . . .

Table 3–14: Counter Measurement Settings 3–298. . . . . . . . . . . . . . . . . . . .

Table 3–15: DMM Calibration Settings 3–298. . . . . . . . . . . . . . . . . . . . . . . .

Table 3–16: DMM Measurement Settings 3–298. . . . . . . . . . . . . . . . . . . . . .

Table 3–17: Digital Input Settings 3–299. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–18: Digital Output Settings 3–299. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–19: Digital to Analog Converter (DAC) Settings 3–300. . . . . . . . . .

Table 3–20: SurePath Settings 3–300. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–1: Instrument Operational Status Register 4–3. . . . . . . . . . . . . .

VX4101A MultiPaq Instrument User Manual

vii

Page 12

Table of Contents

Table 4–2: VX4101 A Operational Status Register 4–5. . . . . . . . . . . . . . .

Table 4–3: Status Byte Register 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–4: IEEE 488.2 Standard Event Status Register 4–6. . . . . . . . . . .

Table 4–5: Status Subsystem and Service Requests 4–20. . . . . . . . . . . . . .

Table A–1: VXI Instrument Characteristics A–1. . . . . . . . . . . . . . . . . . . . .

Table A–2: Power Supply Voltage and Current A–1. . . . . . . . . . . . . . . . . .

Table A–3: Environmental/Reliability Characteristics A–2. . . . . . . . . . . .

Table A–4: VX4101A-Specific Characteristics A–2. . . . . . . . . . . . . . . . . .

Table A–5: VX4101A-Specific Physical Characteristics A–3. . . . . . . . . . .

Table A–6: Universal Counter General Specifications A–4. . . . . . . . . . . .

Table A–7: Channel 1 and 2 Frequency A–4. . . . . . . . . . . . . . . . . . . . . . . .

Table A–8: Channel 1 and 2 Period A–5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–9: Channel 3 Frequency (Option 2C) A–5. . . . . . . . . . . . . . . . . .

Table A–10: Channel 3 Period (Option 2C) A–5. . . . . . . . . . . . . . . . . . . . .

Table A–11: Time Interval A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–12: Frequency Ratio A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–13: Channels 1 and 2 Totalizer A–6. . . . . . . . . . . . . . . . . . . . . . . .

Table A–14: Channels 1 and 2 Rise/Fall Time A–6. . . . . . . . . . . . . . . . . . .

Table A–15: Channels 1 and 2 Positive/Negative Pulse Width A–7. . . . .

Table A–16: Frequency Ratio 1/2,2/1,3/1,3/2,1/3,2/3 A–7. . . . . . . . . . . . . .

Table A–17: Voltages A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–18: Channels 1 and 2 Input Characteristics A–7. . . . . . . . . . . . .

Table A–19: Channel 3 Input Characteristics (Option 2C) A–8. . . . . . . .

Table A–20: Arm Characteristics A–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–21: Channel 1 and 2 Trigger Level A–9. . . . . . . . . . . . . . . . . . . .

Table A–22: Channels 1 and 2 Autotrigger A–9. . . . . . . . . . . . . . . . . . . . .

Table A–23: Front Panel Connectors A–9. . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–24: TimeBase Characteristics (Option 1T) A–10. . . . . . . . . . . . . .

Table A–25: Gate Input Trigger A–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–26: VXIBus TTLTRG Gate Input A–11. . . . . . . . . . . . . . . . . . . . .

Table A–27: Software Gate/Trigger A–11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–28: Gate Duration Modes A–11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–29: Measurement Throughput A–11. . . . . . . . . . . . . . . . . . . . . . .

Table A–30: Counter Specifications Terms A–12. . . . . . . . . . . . . . . . . . . . .

Table A–31: Aperture Specifications A–14. . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–32: Digits vs. Aperture A–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–33: Memory Capacity A–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–34: DC Voltage A–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

VX4101A MultiPaq Instrument User Manual

Page 13

Table of Contents

Table A–35: Accuracy Specifications for 2-Second Aperture A–14. . . . . .

Table A–36: Accuracy Specification for v 1 Millisecond Aperture A–15. .

Table A–37: DC Input Resistance A–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–38: DC Input Protection A–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–39: CMRR A–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–40: DC CMRR (0 to 400 Hz) A–16. . . . . . . . . . . . . . . . . . . . . . . . .

Table A–41: DC Normal Mode Rejection (50/60/400 Hz) A–16. . . . . . . . . .

Table A–42: DC ECMR (50/60/400 Hz) A–17. . . . . . . . . . . . . . . . . . . . . . . .

Table A–43: TRMS AC Voltage (DC Coupled and AC Coupled) A–17. . .

Table A–44: TRMS Accuracy Specifications –24-Hour A–17. . . . . . . . . . .

Table A–45: TRMS Accuracy–90 Day and 1 Year A–18. . . . . . . . . . . . . . .

Table A–46: TRMS Crest Factor A–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–47: TRMS Input Impedance A–18. . . . . . . . . . . . . . . . . . . . . . . . .

Table A–48: TRMS Input Protection – V+ to V–, V+ to Chassis, and

V– to Chassis A–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–49: TRMS CMRR (0 to 400 Hz) A–19. . . . . . . . . . . . . . . . . . . . . . .

Table A–50: Resistance (2-Wire and 4-Wire) A–19. . . . . . . . . . . . . . . . . . .

Table A–51: Resistance Accuracy Specifications for 2-Second

Aperture A–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–52: Resistance Accuracy Specifications for 1 Millisecond

Aperture A–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–53: Resistance Input Protection-All Ranges A–22. . . . . . . . . . . . .

Table A–54: DC Current A–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–55: DC Current Sense Resistance A–22. . . . . . . . . . . . . . . . . . . . .

Table A–56: DC Current Accuracy Specifications for 2-Second

Aperture A–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–57: DC Current Accuracy Specifications for 1 Millisecond

Aperture A–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–58: Digital Input Characteristics A–24. . . . . . . . . . . . . . . . . . . . . .

Table A–59: Digital Output Characteristics A–24. . . . . . . . . . . . . . . . . . . .

Table A–60: Digital to Analog Converter Characteristics A–25. . . . . . . . .

Table A–61: Relay Drivers Characteristics A–26. . . . . . . . . . . . . . . . . . . . .

Table A–62: Certifications and compliances A–27. . . . . . . . . . . . . . . . . . . .

Table B–1: Digital Multimeter (DMM) Input/Output Connections B–1.

Table B–2: 160-Pin Connector Pinouts B–2. . . . . . . . . . . . . . . . . . . . . . . . .

Table C–1: Register Definitions C–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table G–1: DAC Pin Connections G–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VX4101A MultiPaq Instrument User Manual

ix

Page 14

Table of Contents

x

VX4101A MultiPaq Instrument User Manual

Page 15

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

To Avoid Fire or

Personal Injury

Connect and Disconnect Properly . Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is indirectly grounded through the grounding

conductor of the mainframe power cord. To avoid electric shock, the grounding

conductor must be connected to earth ground. Before making connections to the

input or output terminals of the product, ensure that the product is properly

grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and marking on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry .

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

VX4101A MultiPaq Instrument User Manual

xi

Page 16

General Safety Summary

Symbols and Terms

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

WARNING

High Voltage

Protective Ground

(Earth) T erminal

CAUTION

Refer to Manual

Double

Insulated

xii

VX4101A MultiPaq Instrument User Manual

Page 17

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the main power by means

of the power cord or, if provided, the power switch.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

VX4101A MultiPaq Instrument User Manual

xiii

Page 18

Service Safety Summary

xiv

VX4101A MultiPaq Instrument User Manual

Page 19

Preface

This manual assumes you are familiar with the operation of VXIbus instruments

and with the purpose and function of this instrument.

Please read and follow all instructions for installation and configuration. Use the

Installation Checklist to ensure proper installation and to record your initial

settings.

The Operating Basics section gives a summary of VXIbus operation and

presents an overview of the operation of this instrument.

The Syntax and Commands section provides a summary of all the commands

followed by detailed descriptions of each command. Appendix E: Examples

contains example programs that demonstrate the programmable features of this

instrument.

The Status and Events section contains an explanation of the Status and Event

Reporting System and lists the system messages.

The Reference Guide contains a summary of all the SCPI instrument commands.

Conventions

The names of all switches, controls, and indicators appear in this manual exactly

as they appear on the instrument.

Specific conventions for programming are given in the sections Syntax and

Commands and Appendix E: Examples.

VX4101A MultiPaq Instrument User Manual

xv

Page 20

Preface

xvi

VX4101A MultiPaq Instrument User Manual

Page 21

Getting Started

Page 22

Page 23

Product Description

This section introduces the VX4101A MultiPaqtInstrument, and includes the

following information:

H The VX4101A description explains the key features, functionality, and

instruments included with the VX4101A

H The physical description shows the locations of the fuses and indicators

H The list of accessories describes the standard and optional accessories

H The VX4101A self-test outlines the self-diagnostic routines run on each

instrument

H Information about the logical IEEE-488 address of the VX4101A

H A description of the VXIplug&play software, including the soft front panels

and device drivers that you can use to control the VX4101A

VX4101A Description

Features

TheVX4101A MultiPaqtInstrument is a C-size single slot VXI module for use

in a mainframe conforming to the VXIbus specification. The VX4101A provides

powerful functionality in a small package, and includes the following instruments needed in a typical VXI system:

H Full function Universal Counter/Timer

H Digital Input and Output

H Full function Digital Multimeter (DMM)

H Digital to Analog Converter (DAC)

H Relay Drivers

H Scanner master function for the Tektronix SurePathtfamily of VXI relay

modules

All instruments included in the VX4101A are VXI message-based. Each

function is located at the same logical address, but can be accessed and used

separately. You can access the instruments sequentially in the same manner as

multiple instruments in a typical test system. They can be set up sequentially,

then triggered and operated concurrently, with local on-instrument processing

and memory for each function. To understand the principles of operation of the

VX4101A, see Operating Basics.

VX4101A MultiPaq Instrument User Manual

1–1

Page 24

Product Description

The VX4101A is programmed by issuing ASCII characters from the system

controller via the VXIbus commander and the VXIbus mainframe backplane.

Refer to the manual for the VXIbus device that will be the commander for details

on the operation of that device.

Instrument Control. You can control the instrument through either SCPI

commands or through VXIplug&play instrument drivers. The SCPI command

sets for each instrument conform to SCPI 1995 standards. The VXIplug&play

driver functions conform to 1997 standards as determined by the VXIplug&play

Alliance.

NOTE. SCPI permits a great deal of flexibility in the form in which you can enter

commands. Examples throughout this manual use various forms of the command

syntax to further illustrate these concepts.

Fast Data Channel. To maximize throughput, some of the the VX4101A

instruments support Fast Data Channel, a VXI Consortium standard protocol for

high speed block transfers of data. The VX4101A architecture implements FDC

V2.0 with a maximum of eight FDC channels per VXIbus module.

Performance Options

About the Universal

Counter

NOTE. The Digital Multimeter (DMM) and Digital to Analog Converter (DAC)

each use one FDC channel, which the VX4101A assigns at power-on.

Triggers. Each instrument in the VX4101A that supports triggering can trigger

any other instrument or the backplane TTL triggers.

You can enhance the performance of the VX4101A with the following options:

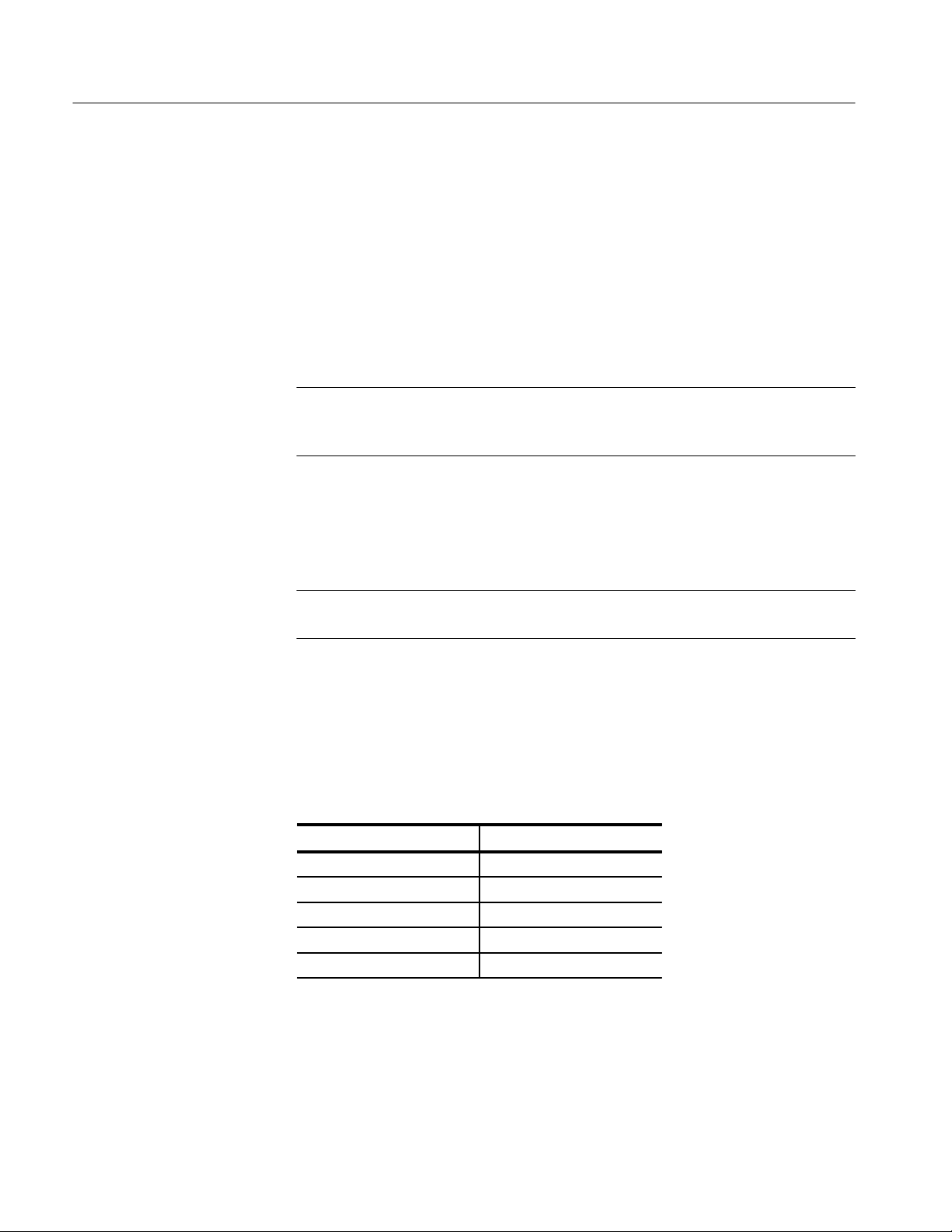

T able 1–1: VX4101A Performance Options

Description Option #

500 MHz Ch1 and Ch2 1C

3 GHz prescaler Ch3 2C

8 Ch DAC 1A

32 bit Digital I/O 1D

TCXO 1T

The Universal Counter in the VX4101A provides two input channels to make

frequency, period, rise and fall time, positive and negative pulse width, positive

and negative duty cycle, frequency ratio, totalizer, time interval, time interval

with delay by time or events, phase, and AC/DC voltage measurements.

1–2

VX4101A MultiPaq Instrument User Manual

Page 25

Product Description

Measurement gating comes from one of several sources, including VXI TTL

triggers, counter front panel arm, software triggers, periodic trigger, and another

VX4101A instrument, such as SurePathtrelay switched and settled. Other key

features of the Universal Counter are as follows:

H Frequency measurements with ten-digit resolution at 1 second aperture, with

a range of 1 mHz - 250 MHz

H The option 1C extends the maximum frequency beyond 500 MHz

H 250 ns resolution (1 ps with averaging)

H Input signal conditioning: x1, x10, x100 attenuation with 0.4 to 10.0 variable

gain and up to ±100 V offset depending on attenuation, DC or AC coupling,

and 50 W or 1 MW input (with automatic over-current protection for the

50 W mode)

For more information on Counter input operations, see Appendix D: Counter

Architecture.

H Optional 3 GHz channel 3 prescaler input with option 2C

About the Digital Input

and Output Modules

H Optional temperature controlled, oscillated or crystal Clock Source (TCXO)

with Option 1T

NOTE. You can also use the VXI backplane 10 MHz clock (CLK10) as the

Counter clock source.

Both the Digital Input and Digital Output instruments provide low-speed data

exchange with 32 bits of data. The Digital Input and Output share a single 32-bit

interface on the 160-pin connector. The frequency range for both input and

output is from 3.662 Hz to 48 kHz. The Digital Input and Output instruments

include the following features:

H External handshaking

H 4K × 32 bits memory

H Pattern matching available on the Digital Input

H Programmable input threshold and selectable output voltage

H Outputs can be repeated continuously or counted a specified number of times

The module self-tests perform full read, write, and verify tests on both shared

memory and read/write control registers. The SCPI TEST subsystem provides

programming capabilities for the self-test functions.

VX4101A MultiPaq Instrument User Manual

1–3

Page 26

Product Description

Digital Input. The Digital Input has a single programmable voltage threshold for

all 32 bits. The range of the input threshold voltage is from 0 volts to 20 volts.

The Digital Input has 8 K samples of digital input memory, 4 K samples each for

the pre-match pattern buffer and the post-match memory. You can query all

Digital Input settings.

Digital Output. Each of the 32 bits of digital output is programmable. Output

voltages can be set for 5 V, 12 V, or 24 V nominal operation. You can also use an

externally supplied voltage, if desired. You must set all digital output bits to the

same voltage setting. The output sample frequency range is from 3.662 Hz to

48 kHz, and applies to all 32 bits. The Digital Output has 4 K × 32 samples of

memory. You can repeat sample segments as either continuous, or with a

programmable count and repetition frequency, You can query all Digital Output

settings.

About the Digital

Multimeter (DMM)

The DMM has full function autoranging with 5 1/2 digit resolution. Measurements can be returned as single measurements, or as an array. Power cycle

averaging modes are available for 60 Hz and 50 Hz.

The device has autozero capability which minimize offset drift errors without

removing the customer input connections. The DMM has floating input isolation

of 300 VDC or AC

RMS

.

Ranges of operation are:

H Array measurements returned with up to 4096 measurements via the Fast

Data Channel Protocol.

H Over 500 programmable aperture times from 833 ms to 2 seconds

H DC voltage at 30 mV, 300 mV, 3 V, 30 V, and 300 V

H AC True RMS, either AC or DC coupled, at 30 mV

3 V

RMS

, 30 V

and 300 V

RMS

RMS

RMS

, 300 mV

RMS

,

H Four-wire or two-wire W measurement at ranges of 30 W, 300 W, 3 kW,

30 kW, 300 kW, 3 MW, 30 MW, and 300 MW

H DC Current at 150 mA and 1A

Acquisition triggering is provided from one of several sources, including VXI

TTL triggers, counter front panel arm, software triggers, periodic trigger, and

other VX4101A instrument triggers, such as the SurePathtrelay switched and

settled.

1–4

VX4101A MultiPaq Instrument User Manual

Page 27

Product Description

About the Digital to

Analog Converter

The Digital to Analog Converter (DAC) includes an eight-channel arbitrary

waveform generator. Waveform length can be generated with one to 1024 sample

points at sample rates from 3.662 to 15 kHz. Signals are generated on all eight

channels when the DAC is initiated. A default 0 VDC output will be set on

unused channels.

The VX4101A DAC includes the following features and functionality:

H Eight synchronized, 12-bit digital to analog channels synchronized to a

single programmable sample clock (3.662 Hz to 15 kHz)

H Amplitudes of –14 V to +14 V are supported with 8 mV resolution on each

channel

H Each channel is separately programmable to generate a different waveform

H Each channel has 1024 points of trace buffer memory available for waveform

synthesis

H Waveforms can be repeated either continuously or with a programmable

count and repetition frequency.

NOTE. Setting the sample rate, segment length, and repetition frequency the same

for one channel sets them for all channels.

About the Relay Drivers

About the SurePatht

Modules

The high-current relay drivers include the following:

H Eight lines of high-current outputs

H Open collector, 100 mA sink per output

The scanner master control enables you to use the VX4101A to control the

Tektronix SurePatht family of VXI relay modules, including the VX4320,

VX4330, VX4350, VX4351, and VX4380. Some of the features of the SurePatht family are as follows:

VX4320 1.3 GHz RF Multiplexor. This module is a single-wide VXIbus module

intended to switch RF and high-frequency digital signals. It is arranged as eight

1 × 4 coaxial switches with a 50 W characteristic impedance. Each 1 × 4 section

has five type SMB male snap-on subminiature coaxial connectors.

VX4330 120-Channel Scanner/Multiplexor. This module provides six 1 × 10 4-wire

multiplexor sections. Each of these six sections can be independently configured

under software control as two 1 × 10 2-wire multiplexor, a 1 × 20 2-wire

multiplexor, or as a 1 × 40 1-wire multiplexor. In addition, each section can be

VX4101A MultiPaq Instrument User Manual

1–5

Page 28

Product Description

programmed to connect it to the section above or below to produce a 1 × 60

4-wire multiplexor, a 1 × 120 2-wire multiplexor, or a 1 × 240 1-wire multiplexor.

VX4350 64-Channel SPST/SPDT Switching Module. This module provides 64

independent single-pole double-throw relays. A 0 W resistor is placed in series

with the common contact of each relay. This resistor may be replaced by a

resistor with a larger value to limit the current that flows through the relay in

order to protect the relay contacts. Pads are provided for optional metal oxide

varistors (MOVs). These varistors are connected from the common contact to the

normally closed contact, and from the common contact to the normally open

contact of each relay. Using the optional MOVs protects the relay contacts from

over voltage conditions encountered when switching electrical power to

inductive loads. The optional MOVs and current limiting resistors are user

installed, and are not available as factory options.

VX4351 40-Channel, 10 Amp, SPST Switch Module. This module contains 40 SPST

(form A) relays. Each relay may be controlled independently. The contacts of

each relay are connected to one of three 30-pin high current connectors which are

mounted on the module’s front panel. Circuitry is included on the VX4351 to

verify the control signals that are applied to each relay coil driver.

VX4380 256-Crosspoint Relay Matrix Module. This module provides four 4 × 16

2-wire matrix sections. Each section can be configured to connect either the four

rows or the sixteen columns to the section above or below it to produce up to a

16 × 16 2-wire matrix or a 4 × 64 2-wire matrix.

The VX4101A SurePathMaster provides serial I/O interface for control of

SurePath relay modules. It also monitors the power fuses of all SurePath

Relay modules, and provides a serial input interface to identify each module that

it controls.

NOTE. There is a query for the VX4101A which will return a list of the

SurePath family relay modules that the VX4101A SurePath Master detects in

the system.

1–6

VX4101A MultiPaq Instrument User Manual

Page 29

Power-On Sequence

Physical Description

Product Description

The power-on sequence of the VX4101A meets the timing requirements of the

VXIbus specification that communications may begin even if the instrument has

not completely initialized. At either power-on or a VXIbus reset, the VX4101A

initializes the VXIbus interface and all hardware and firmware necessary to begin

communication. For more information, see Powering On the VX4101A in

Installation.

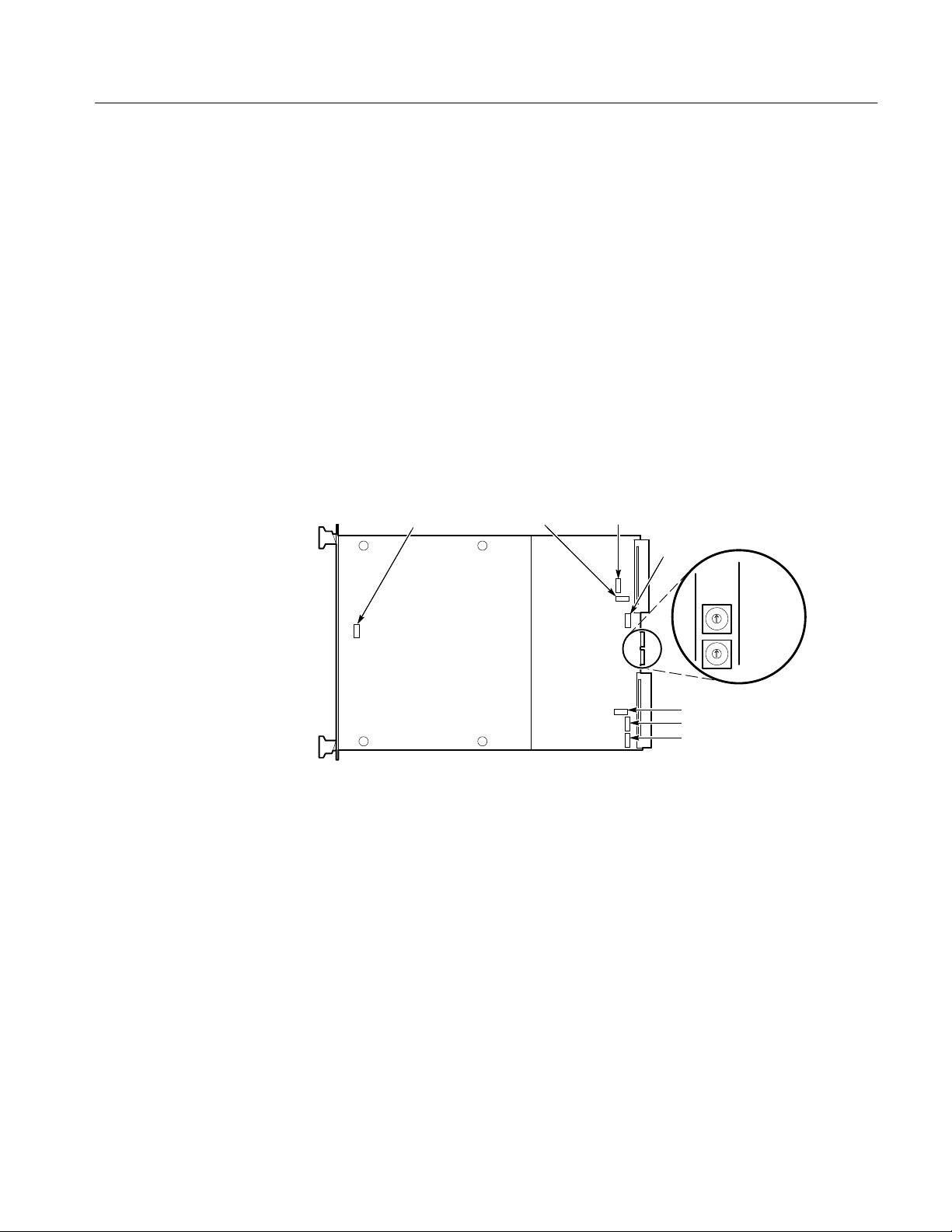

Figure 1–1 shows the VX4101A switches and fuses, and Figure 1–2 shows the

front panel.

Switches as viewed

F652 F651F01

from the rear of instrument

(labels are on the back shield)

F75

LOGICAL

ADDRS

HI

LO

F1351

F1352

F1451

Figure 1–1: VX4101A VXIbus Connectors, Fuses, and Switch Locations

VX4101A MultiPaq Instrument User Manual

1–7

Page 30

Product Description

Controls and Indicators

1–8

Figure 1–2: VX4101A Front Panel

The following logical address switches must be correctly set to ensure proper

operation. Refer to Figure 1–1 for their physical locations.

Logical Address Switches. The VX4101A supports VXI dynamic addressing. It is

shipped with the switches set to FF so that the Slot 0 will automatically assign

an address to the module.

Each functional module in a VXIbus System must be assigned a unique logical

address, from 1 to decimal 255 (hexadecimal FF).

VX4101A MultiPaq Instrument User Manual

Page 31

Product Description

NOTE. If you do not want to use dynamic addressing, align the desired switch

position with the arrow on the module shield.

The physical address of the instrument is on a 64 byte boundary. If the Logical

Address switch representing the most significant digit (LA-HI) of the logical

address is set to position X and the switch representing the least significant digit

(LA-LO) of the logical address is set to position Y, then the base physical

address of the module will be [(40

L.A. HI LO decimal hexadecimal

A

16

15

L.A. is the Logical Address

0

16

1

16

16

A

16

5

16

(64 * 10) + 49152 = 49792 (4016 * A16) + C00016 = C280

(64 * 21) + 49152 = 50496 (4016 * 1516) + C00016 = C540

× XY16) + C00016]. For example:

16

Base Physical Address

16

16

LEDs

Front Panel Connectors

The VX4101A has four LEDs visible on its front panel. These LEDs are labeled

as follows:

H Power LED – this LED is On if all six fuses for the six power buses are

intact. Any single fuse being blown results in the LED turning OFF

H Fail LED – this LED is normally OFF. During power-on or reset self-test,

the LED will be ON for the duration of the test. If the VX4101A detects a

failure during normal operation, the LED will come ON and the SYSFAIL

line on the backplane will be true

H Message LED – this LED flickers ON when the VX4101A is being

addressed on the VME backplane by its commander

H ERR LED – this LED is normally OFF. However, it may blink on and off to

indicate error conditions. The most common reason is a command syntax

error has been detected. Other error conditions that will cause the LED to

blink are discussed elsewhere in this manual. Sending the “SYSTem:ERRor?” query to the instrument will return the cause of the error. When all

errors in the queue have been retrieved, the error LED will return to the OFF

state

Refer to Appendix B:Input/Output Connections for more information.

VX4101A MultiPaq Instrument User Manual

1–9

Page 32

Product Description

Fuses

IEEE-488 Address

The VX4101A has 6 fuses that limit the amount of current that each module can

draw from the VXI backplane +5, -5.2, +24, -24, +12, and -12 V power pins.

These fuses protect the module in case of an accidental shorting of the power bus

or any other situation where excessive current might be drawn.

If any fuse opens, the module will assert SYSFAIL* on the VXIbus.

If the +5 V fuse opens, the VXIbus Resource Manager will be unable to assert

SYSFAIL INHIBIT to disable SYSFAIL*.

If any fuse opens, remove the fault before replacing the fuse. Replacement fuse

information is given in Appendix H: Replaceable Parts. Refer to the Separator

page, following page C-10, before performing any service to this product.

In order to use and program the VX4101A in an IEEE-488.2 environment, you

must know the IEEE-488 address of the module. Different manufacturers of

IEEE-488 interface devices have different algorithms for equating a logical

address with an IEEE-488 address. Consult the operating manual of the

IEEE-488 module being used.

Self-Test

VX4101A MultiPaqt

Instrument Self-Test

The VX4101A performs an interface self-test at power-on. This test ensures that

the VXIbus interface is fully functional and ready for communication with the

controller and that each instrument is initialized and ready for operation.

Built-In Test is provided by extensive self-tests which can be invoked via IEEE

488.2 and SCPI commands and queries.

The following are highlights of each test performed:

The self-test for the VX4101A MultiPaqtInstrument tests the following

components:

H CPU RAM

H CPU timers, including periodic trigger

H Internal CPU interrupts

H Software triggers

1–10

VX4101A MultiPaq Instrument User Manual

Page 33

Product Description

Counter Self-Test

Digital Input and Output

Self-Test

DMM Self-Test

The self-test for the Counter tests the following components:

H The two 4 Kb Counter measurement buffers.

H Logic registers

H The analog front end pre-amp offset, pre-amp inverter, and pre-amp gain

digital to analog converters (DACs).

H A 2.5 MHz signal is routed in through a test source and checked for

accuracy.

The self-test for the Digital Input and Digital Output includes a test of the Digital

Output hardware, as well as read/write/verify tests on shared memory and

read/write control registers.

The DMM self-test includes RAM testing, power supply and DMM reference

testing, amplifier and analog to digital converter testing, and control circuitry

testing. The self-test for the DMM tests the following components:

H The two 4 Kb DMM measurement buffers

H Logic registers

DAC Self-Test

Relay Drivers Self-Test

SurePatht Module

Self-Test

H Measurements of Ground are taken at the 30 mV DC range, 3 VDC range,

and 300 mV AC/DCV range

H The 2.75 V reference is tested in the 3 V range

The DAC performs the following self-test procedure:

H Read/write/verify test on shared memory

H Read/write/verify on all read/write control registers

There is no self-test for the Relay Drivers.

There is no automatic self-test for SurePath

query to test the control logic and data path for both the VX4101A and the

SurePathtcard in use. For more information on the TEST:ALL? query, see SCPI

Commands for the SurePath Modules in this manual

t modules. You use the TEST:ALL?

VX4101A MultiPaq Instrument User Manual

1–11

Page 34

Product Description

Accessories

T able 1–2: Standard Accessories

The following tables list the standard and optional accessories for the VX4101A:

Tektronix part

number

VX1784S 1 CONN HOODED; DE–9 FEMALE SOCKET TK2548

071–0049–XX 1 MANUAL,TECH:USERS,VX4101A TK2548 071–0049–XX

071–0051–XX 1 MANUAL,TECH:REFERENCE,VX4101A TK2548 071–0050–XX

063–2598–00 1 VXIplug&play 16-bit driver 063–2598–XX

063–2822–00 1 VXIplug&play 32-bit driver 063–2822–XX

Qty Name and description Mfr. Code

Mfr.

part number

T able 1–3: Optional Accessories

Tektronix part

number

VX1630 1 CABLE, ANALOG; 160 PIN CONN W/160 COND CBL

VX1630M 1 MOD KIT; VX4101 DMM MOD KIT FOR VX1630 CABLE, 3

VX1630S 1 160 PIN CON KIT; BAK SHL, PIN HOUSNG, 200 PINS

VX1729 1 CABLE,INTCON; COAX,VX1729;RFD,50 OHM,RG188,

VX1730 1 CABLE, ADAPTER; SMB SNAP ON PLUG TO PLUG

VX1760 1 SMA–BNC MALE; LE COAX CABLE, RFD50–OHM,

174–1428–00 1 CABLE ASSY:COAX,RFD,50 OHM,60.0L,SMA,STR,BOTH

012–0057–01 1 CA ASSY ,RF:COAXIAL,RFD,50 OHM,43 L,BNC,MALE 060D9 012–0057–01

003–1493–00 1 HAND TOOL:DISASSEMBLY TOOL FOR CRIMP & POKE

003–1494–00 1 HAND TOOL:HAND TOOL FOR LOOSE CRIMP & POKE

Qty Name and description Mfr. Code

TWISTED PAIRS, DE–9P MALE SUBMINIATURE, 24L

10 FT ,BNC,MALE X SMB,STR

1784S RG188, 10FT, BNC MALE–SMA, STR

060D9 174–1428–00

ENDS,MALE

6V439 471 555

CONT ACTS

6V439 014 374

CONT ACTS

Mfr. part number

1–12

VX4101A MultiPaq Instrument User Manual

Page 35

Performance Options

Product Description

You can purchase the following options to enhance performance of the

VX4101A:

T able 1–4: VX4101A Performance Options

Description Option Number

500 MHz Counter Channel One and

Channel Two

3 GHz Counter prescaler Channel

Three

Eight Channel DAC 1A

32 Bit Digital I/O with Eight Relay

Drivers

TCXO 1T

About the VXIplug&play Software

The VXIplug&play software included with the VX4101A consists of two

components:

H Device drivers

H Soft Front Panels (SFPs)

VXIplug&play device drivers enable you to operate the VX4101A under

program control.

The graphical user interfaces of the SFPs emulate the physical controls and

displays typically found on monolithic instruments. The instrument drivers call a

common set of I/O control functions that are independent of instrument types,

interface types, operating systems, programming languages, and networking

mechanisms.

1C

2C

1D

The installation program installs the VXIplug&play drivers for the framework

appropriate for your processing environment. The frameworks were developed as

established by the VXIplug&play Alliance. The possible frameworks are as

follows:

H WIN

H WINNT

H WIN95

VX4101A MultiPaq Instrument User Manual

1–13

Page 36

Product Description

Using the VXI plug&play

Software

Double clicking on the appropriate instrument icon launches the soft front panel

(SFP). The SFP displays a representation of the traditional controls and

indicators for an instrument. By selecting the appropriate controls on the SFP,

you can verify that the instrument has been correctly installed and is functional,

and perform almost all of the functions of the instrument. The SFP will:

H Control the instrument

H Display data

H Provide command line query and response (talk/listen)

H Provide error and event reporting

See Installation for instructions on installing and running the SFP and using the

C driver for program control. Detailed descriptions of the VXIplug&play drivers

are given in on-line Help and text files on the disk shipped with the instrument.

1–14

VX4101A MultiPaq Instrument User Manual

Page 37

Installation

This section contains the information you will need to install the VX4101A

MultiPaqtInstrument and its associated software, and to verify that the

instrument is functioning properly. This includes the following:

H Installing the VX4101A module in the mainframe

H Installing the VXIplug&play software

H Running a functional check

H Using the soft front panels (SFPs) included with the instrument

At the end of the section, you will find a checklist to summarize your installation

choices.

Installing the Module in the Mainframe

Installing the VX4101A in a Tektronix mainframe meets all instrument cooling

requirements.

Tools Required

Requirements and

Cautions

A slotted screwdriver set is required for proper installation.

The VX4101A is a C-size VXIbus instrument module and therefore can be

installed in any C- or D-size VXIbus mainframe slot other than Slot 0. To install

the module in a D-size mainframe, consult the operating manual for the

mainframe. Refer to Controls and Indicators for information on selecting and

setting the Logical Address switch of the module. This switch defines the

programming address of your module.

CAUTION. Note that there are two printed ejector handles on the card. To avoid

installing the card incorrectly, make sure the ejector marked “VX4101A” is at

the top. Installing it incorrectly may damage the DIN connectors on the module.

VX4101A MultiPaq Instrument User Manual

1–15

Page 38

Installation

NOTE. If the VX4101A is inserted in a slot with any empty slots to the left of the

module, the VME daisy-chain jumpers must be installed on the backplane in

order for the VXI Module to operate properly. Check the manual of the mainframe being used for instructions on jumper settings. If the jumpers are not

installed properly, there will be no interrupts and bus masters will not operate

properly. Jumpers are not necessary for auto-configuring backplane designs

such as those in Tektronix mainframes.

Module Installation

Procedure

Follow these steps to install the VX4101A:

CAUTION. The VX4101A Module is a piece of electronic equipment and therefore

has some susceptibility to electrostatic damage (ESD). ESD precautions must be

taken whenever the module is handled.

1. Record the revision levels, serial numbers (located on the label on the top

shield of the VX4101A), and switch settings on the Installation Checklist.

2. Verify that the switches are set to the correct values. Refer to Controls and

Indicators for more information on setting switches.

3. Make sure that the mainframe power is Off.

4. Insert the module into one of the instrument slots of the mainframe (see

Figure 1–3).

1–16

Figure 1–3: Module Installation

VX4101A MultiPaq Instrument User Manual

Page 39

CAUTION. Verify that the mainframe is able to provide adequate cooling and

power with this module installed. Refer to the mainframe Operating Manual for

instructions. If the mainframe cannot cool the unit adequately, the unit may not

operate properly and may be damaged.

Installing the VXIplug&play Software

Each VXIplug&play instrument includes either a 3 1/2 inch diskette or CD-

ROM storage media containing the SFPs and device drivers with which you can

control the instrument interactively. The SFPs are capable of controlling the

instrument immediately following a successful installation, without requiring a

specific application development environment. The soft front panels and the

supporting software were developed in conformance with the guidelines of the

VXIplug&play Systems Alliance.

All VXIplug&play products are classified within a particular framework, as

developed by the VXIplug&play Systems Alliance to categorize operating

systems, programming languages, and I/O software libraries. The framework

supported by the driver distributed with this VXI module is printed on the label

of the media.

Installation

About the Device Drivers

Installation Procedure

The source code as well as the dynamic link library (DLL) are distributed so that

you have the flexibility of using either of them in the end application.

The device driver distributed with the Tektronix VX4101A complies with all

current VXIplug&play requirements. The device driver uses VISA calls that are

portable across platforms and development environments. Tektronix uses only

the ANSI C implementation in instrument driver source code. No platform-specific libraries are included in the driver. The driver source code will compile

using MSVC, Borland, Symantec or Watcom compilers without having to use

foreign libraries, other than the VISA Dynamic Link Library (DLL). All driver

.DLL files are located in:

VXIPNP\<Framework>\BIN

Use the following procedure to install the VXIplug&play software:

1. Insert the media containing the driver files in the appropriate drive.

2. Locate the file Setup.exe, as follows:

H On a 3 1/2 inch floppy disk, the file is on disk 1

H On a CD-ROM, the file will be in the tkvx4101 directory

VX4101A MultiPaq Instrument User Manual

1–17

Page 40

Installation

3. Launch setup.exe as follows:

H In Windows or Windows NT/3.x, use the File menu and select Run.

Then, browse to find setup.exe or type the drive letter and program name

H In Windows 95 or or Windows NT/4.x, use Start and select Run. Browse

to locate setup.exe and click on OK

4. Follow the directions of the installation program.

Following installation, driver files (see list below) will be found in locations

defined by the VXIplug&play Alliance. Where required, modifications to your

autoexec.bat and system.ini files may be automatically completed.

Driver Files

The instrument driver for the VX4101A is distributed with a number of C source

code files, header files, dynamic link libraries and other supporting files. A

breakdown of the modules that the files control are as follows:

VX4101. This is the high level “controller” portion of the driver. This part of the

driver does the actual communication with the instrument. The tkvx4101.c or

tkvx4101.dll files have functions which perform VISA function calls. The other

modules, making up the total driver, call functions in the tkvx4101 to get system

configuration information and to communicate to each specific instrument.

Device-Specific Files. The files supporting the specific instruments are as follows: