Page 1

Instruction Manual

VITS100

NTSC VITS Inserter

070-8333-02

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

Page 2

Copyright © T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of shipment. If a product proves defective during this warranty period, T ektronix,

at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Page 5

Service Assurance

If you have not already purchased Service Assurance for this product, you may do so at any time during the product’s

warranty period. Service Assurance provides Repair Protection and Calibration Services to meet your needs.

Repair Protection extends priority repair services beyond the product’s warranty period; you may purchase up to three

years of Repair Protection.

Calibration Services provide annual calibration of your product, standards compliance and required audit documentation,

recall assurance, and reminder notification of scheduled calibration. Coverage begins upon registration; you may purchase

up to five years of Calibration Services.

Service Assurance Advantages

H Priced well below the cost of a single repair or calibration

H Avoid delays for service by eliminating the need for separate purchase authorizations from your company

H Eliminates unexpected service expenses

For Information and Ordering

For more information or to order Service Assurance, contact your T ektronix representative and provide the information

below . Service Assurance may not be available in locations outside the United States of America.

Name VISA or Master Card number and expiration

Company date or purchase order number

Address Repair Protection (1,2, or 3 years)

City , State, Postal code Calibration Services (1,2,3,4, or 5 years)

Country Instrument model and serial number

Phone Instrument purchase date

Page 6

Page 7

Table of Contents

Getting Started

Operating Basics

Specifications

General Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VITS Inserter Functions 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories and Options 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Check and Installation 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Panel 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Insertion Options 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VITS Selection 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Control 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specification T ables 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Waveform Diagrams 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theory of Operation

Functional Description 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification

Incoming Inspection Test 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verification of T olerance Values 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verification Procedure 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedure

Static Discharge Precautions 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended T est Equipment 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedure 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance

Service Strategy 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ektronix Service Offerings 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Static Sensitive Components 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Board Jumpers 7–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VITS100 NTSC VITS Inserter Instruction Manual

i

Page 8

Table of Contents

Cleaning and Inspection 7–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Replacement Instructions 7–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics 7–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Electrical Parts

Parts Ordering Information 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Electrical Parts List 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams

A1 VITS Inserter Board (671-2132-05 & Up) 9–1. . . . . . . . . . . . . . . . . . . .

A1 VITS Inserter Board (671-2132-00 through -04) 9–23. . . . . . . . . . . . . .

Replaceable Mechanical Parts

Parts Ordering Information 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Mechanical Parts List 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix

Index

Appendix A: Options A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 1J A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 1M A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 2 A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

VITS100 NTSC VITS Inserter Instruction Manual

Page 9

List of Figures

Table of Contents

Figure 1–1: A setup for the functional check 1–3. . . . . . . . . . . . . . . . . . . .

Figure 1–2: A typical installation 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–1: The front panel 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–2: VITS100 NTSC VITS Inserter rear panel 2–2. . . . . . . . . . . .

Figure 2–3: VITS100 NTSC VITS Inserter source ID signal 2–4. . . . . . .

Figure 2–4: Location of VITS selection switches 2–6. . . . . . . . . . . . . . . . .

Figure 2–5: The VITS selection DIP switches 2–6. . . . . . . . . . . . . . . . . . . .

Figure 2–6: The REMOTE connector 2–8. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–1: 0% Black 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–2: 7.5% Black 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–3: 50% Gray 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–4: FCC Color Bars 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–5: FCC Composite 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–6: Multiburst 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–7: Multipulse 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–8: NTC7 Combination 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–9: NTC7 Composite 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–10: Red Field 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–11: SIN X/X 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–12: VIRS 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–13: Cable Multiburst 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–14: Cable Sweep 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–1: Inductor and switching transistor switching functions 4–8. .

Figure 5–1: VITS selection DIP switches 5–4. . . . . . . . . . . . . . . . . . . . . . .

Figure 5–2: Measuring VITS on a waveform/ vector monitor 5–6. . . . . .

Figure 5–3: Blanking level at 0 IRE 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–4: Equipment connections for phase matching 5–8. . . . . . . . . .

Figure 5–5: Using the video measurement set to measure waveform

characteristics 5–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–6: Setting up for pulse-to-bar measurement 5–11. . . . . . . . . . . . .

Figure 5–7: Using the video measurement set to compare signals 5–12. . .

Figure 5–8: Measuring hum rejection 5–14. . . . . . . . . . . . . . . . . . . . . . . . . .

VITS100 NTSC VITS Inserter Instruction Manual

iii

Page 10

Table of Contents

Figure 5–9: Connecting the RF bridge to the spectrum

analyzer/tracking generator 5–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–10: The initial frequency response setup 5–20. . . . . . . . . . . . . . . .

Figure 5–11: Frequency response display 5–21. . . . . . . . . . . . . . . . . . . . . . .

Figure 5–12: Measuring frequency response 5–22. . . . . . . . . . . . . . . . . . . .

Figure 6–1: Adjustments and test points 6–4. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–2: A setup for genlock adjustments 6–6. . . . . . . . . . . . . . . . . . . .

Figure 6–3: VITS selection DIP switches 6–7. . . . . . . . . . . . . . . . . . . . . . .

Figure 6–4: Equipment connections for gain adjustments 6–8. . . . . . . . .

Figure 6–5: Equipment for setting gain adjustments 6–8. . . . . . . . . . . . . .

Figure 6–6: Peak-to-peak detector connections 6–10. . . . . . . . . . . . . . . . . .

Figure 6–7: Display for adjusting flatness 6–11. . . . . . . . . . . . . . . . . . . . . .

Figure 6–8: Setting flatness 6–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7–1: Moveable plug jumpers on the inserter circuit board 7–4. . .

Figure 7–2: Mounting hardware for the inserter circuit board 7–10. . . . .

Figure 7–3: Diagnostics switch, S8 7–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–1: A1 VITS Inserter Board (671–2132–05 & Up) 9–1. . . . . . . . .

Figure 9–2: A1A1 Oven Board 9–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–3: A1 VITS Inserter Board (671-2132-00 –04) 9–23. . . . . . . . . . .

Figure 10–1: Exploded view 10–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure A–1: Option 1J Red Field signal A–2. . . . . . . . . . . . . . . . . . . . . . . .

Figure A–2: Option 1J FCC Color Bar signal A–3. . . . . . . . . . . . . . . . . . .

Figure A–3: Option 1J Multipulse signal A–3. . . . . . . . . . . . . . . . . . . . . . .

Figure A–4: Video Measurement Set application for Option 1M A–5. . . .

Figure A–5: Cable Multiburst A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure A–6: Cable Sweep A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

VITS100 NTSC VITS Inserter Instruction Manual

Page 11

List of Tables

Table of Contents

Table 1–1: Factory VITS, Standard and Option 1M 1–4. . . . . . . . . . . . .

Table 1–2: Factory VITS, Option 1J 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–3: Factory VITS, Option 2 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–1: Standard Factory-Programmed Signals 2–5. . . . . . . . . . . . . .

Table 2–2: DIP Switch Settings 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–3: REMOTE Connector Pin Assignments 2–8. . . . . . . . . . . . . . .

Table 3–1: Program channel characteristics 3–1. . . . . . . . . . . . . . . . . . . .

Table 3–2: Test Signal and Black Burst general characteristics 3–2. . . .

Table 3–3: Black and Gray Test Signal characteristics 3–2. . . . . . . . . . . .

Table 3–4: FCC Composite characteristics 3–3. . . . . . . . . . . . . . . . . . . . .

Table 3–5: FCC Color Bars characteristics 3–4. . . . . . . . . . . . . . . . . . . . .

Table 3–6: Multiburst characteristics 3–4. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–7: Multipulse characteristics 3–4. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–8: NTC7 Combination characteristics 3–5. . . . . . . . . . . . . . . . . .

Table 3–9: NTC7 Composite characteristics 3–6. . . . . . . . . . . . . . . . . . . .

Table 3–10: Red Field characteristics 3–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–11: SIN X/X characteristics 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–12: Vertical Interval Reference Signal characteristics 3–7. . . . .

Table 3–13: Cable Multiburst (Option 2) characteristics 3–7. . . . . . . . . .

Table 3–14: Cable Sweep (Option 2) characteristics 3–8. . . . . . . . . . . . . .

Table 3–15: Genlock characteristics 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–16: Power Supply characteristics 3–9. . . . . . . . . . . . . . . . . . . . . .

Table 3–17: Physical characteristics 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–18: Environmental characteristics 3–10. . . . . . . . . . . . . . . . . . . . .

Table 3–19: Certifications and compliances 3–11. . . . . . . . . . . . . . . . . . . . .

Table 5–1: Equipment Required 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–2: DIP Switch Settings 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–3: Spectrum Analyzer Settings 5–19. . . . . . . . . . . . . . . . . . . . . . . .

Table 5–4: Multiburst Controls 5–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–1: Recommended Test Equipment 6–2. . . . . . . . . . . . . . . . . . . . .

Table 6–2: Power Supply Tolerances 6–5. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–3: TSG/SPG Multiburst Settings 6–10. . . . . . . . . . . . . . . . . . . . . .

VITS100 NTSC VITS Inserter Instruction Manual

v

Page 12

Table of Contents

Table 7–1: Mode Selection Jumpers 7–5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7–2: Test Jumpers 7–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7–3: The User Diagnostics 7–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9–1: A1 Component Locator 671–2132–05 & Up 9–2. . . . . . . . . . . .

Table 9–2: A1A1 Component Locator 9–4. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9–3: A1 Component Locator 671–2132–00 through -04 9–24. . . . . .

Table A–1: Option 1J Red Field Characteristics A–2. . . . . . . . . . . . . . . . .

Table A–2: Option 1J Factory Programmed VITS Insertions A–4. . . . . .

Table A–3: Option 1M Factory Programmed VITS Insertions A–5. . . . .

Table A–4: Option 2 DIP Switch Settings A–6. . . . . . . . . . . . . . . . . . . . . .

Table A–5: Cable System Test Signal Characteristics A–6. . . . . . . . . . . . .

Table A–6: Option 2 Factory Programmed VITS Insertions A–8. . . . . . .

vi

VITS100 NTSC VITS Inserter Instruction Manual

Page 13

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Wear Eye Protection. Wear eye protection if exposure to high-intensity rays or

laser radiation exists.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry .

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

Symbols and Terms

VITS100 NTSC VITS Inserter Instruction Manual

T erms in this Manual. These terms may appear in this manual:

vii

Page 14

General Safety Summary

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

WARNING

High Voltage

Double

Insulated

Protective Ground

(Earth) Terminal

Not suitable for

connection to

the public telecom-

munications network

viii

VITS100 NTSC VITS Inserter Instruction Manual

Page 15

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

VITS100 NTSC VITS Inserter Instruction Manual

ix

Page 16

Service Safety Summary

x

VITS100 NTSC VITS Inserter Instruction Manual

Page 17

Getting Started

Page 18

Page 19

Getting Started

VITS Inserter Functions

The Tektronix VITS100 NTSC VITS Inserter is a high quality signal generator

designed to insert VITS (Vertical Interval Test Signals) into program video. It

automatically switches to bypass mode in the event of power failure or loss of

lock to the program video.

See VITS Inserter Functions, below, for a brief explanation of what the VITS

inserter can do. See Functional Check and Installation, on page 1–3, to begin

using your new VITS inserter.

You can program the VITS inserter to generate test signals and a source

identification signal and insert the signal(s) into selected lines of the vertical

interval. You can also use the VITS inserter to overwrite VITS that already exist

in program video; overwriting with a Black signal effectively deletes existing

material.

Test Signals

The VITS inserter uses 12-bit data at an 8F

signal generation. The standard VITS inserter can generate and insert the

following VITS into your choice of lines 17, 18, 19, and 20 in the even or odd

fields of NTSC video:

H NTC7 Combination

H NTC7 Composite

H FCC Multiburst

H 50% Gray

H SIN

H FCC Color Bars

H FCC Composite

H Multipulse

H Vertical Interval Reference Signal (VIRS)

H Red Field

H 0% Black

X/X

data rate to ensure accurate test

SC

H 7.5% Black

VITS100 NTSC VITS Inserter Instruction Manual

1–1

Page 20

Getting Started

Source ID

Auto VIRS

Bypass

The VITS inserter can also insert a one-line source identification code on any of

the available lines in vertical blanking. The Tektronix VM700A Video Measurement Set can then use this code to identify the source of the signal it is measuring.

Another function of the VITS inserter is Auto VIRS. When Auto VIRS is

selected, the VITS inserter checks the specified lines and fields of the incoming

program video for a VIRS signal. If VIRS is detected, the signal is passed with

no processing; if VIRS is not detected, then the VITS inserter inserts the

internally generated VIRS signal on the specified lines and fields.

Maintaining program channel continuity is one of the main considerations in the

VITS inserter. Therefore, the VITS inserter provides rapid response to signal or

equipment failure. If there is a failure, input video is automatically routed to the

program output through circuitry that that adds delay equal to normal inserter

processing delay.

If video is present but the VITS inserter cannot genlock to it (uncorrected-timebase video for example), then the program is passed with no VITS inserted. If

there is no video present, or if the power fails, the VITS inserter switches to the

bypass mode immediately.

When the failure is corrected, the VITS inserter passes program video through as

soon as it is present, and begins VITS insertion as soon as genlock is achieved.

Remote Control

The rear-panel REMOTE connector provides limited remote control of the VITS

inserter. This is a 9-pin ground closure system to permit manual switching

between Bypass and Operate modes. In addition, the interface can drive

indicators to mimic the front-panel POWER, BYPASS, and UNLOCKED LEDs.

Accessories and Options

This instrument is shipped with the following accessories:

H This Instruction Manual

H A power cord appropriate to your local AC supply.

Optional configurations of the VITS inserter are available. See Appendix A: Options for more information.

1–2

VITS100 NTSC VITS Inserter Instruction Manual

Page 21

Functional Check and Installation

It is good practice to perform a functional check of a new instrument before

installing it into your system.

Getting Started

Functional Check

Perform the following functional check to confirm proper operation of your new

VITS inserter and to familiarize yourself with its features.

1. Unpack the instrument. If possible, save all packing materials for later

shipping or storage.

2. Connect the VITS inserter to the local AC power supply with the cord

provided with the instrument. The VITS inserter operates on any 48–62 Hz,

90–250 V supply; no switch or jumper settings are required.

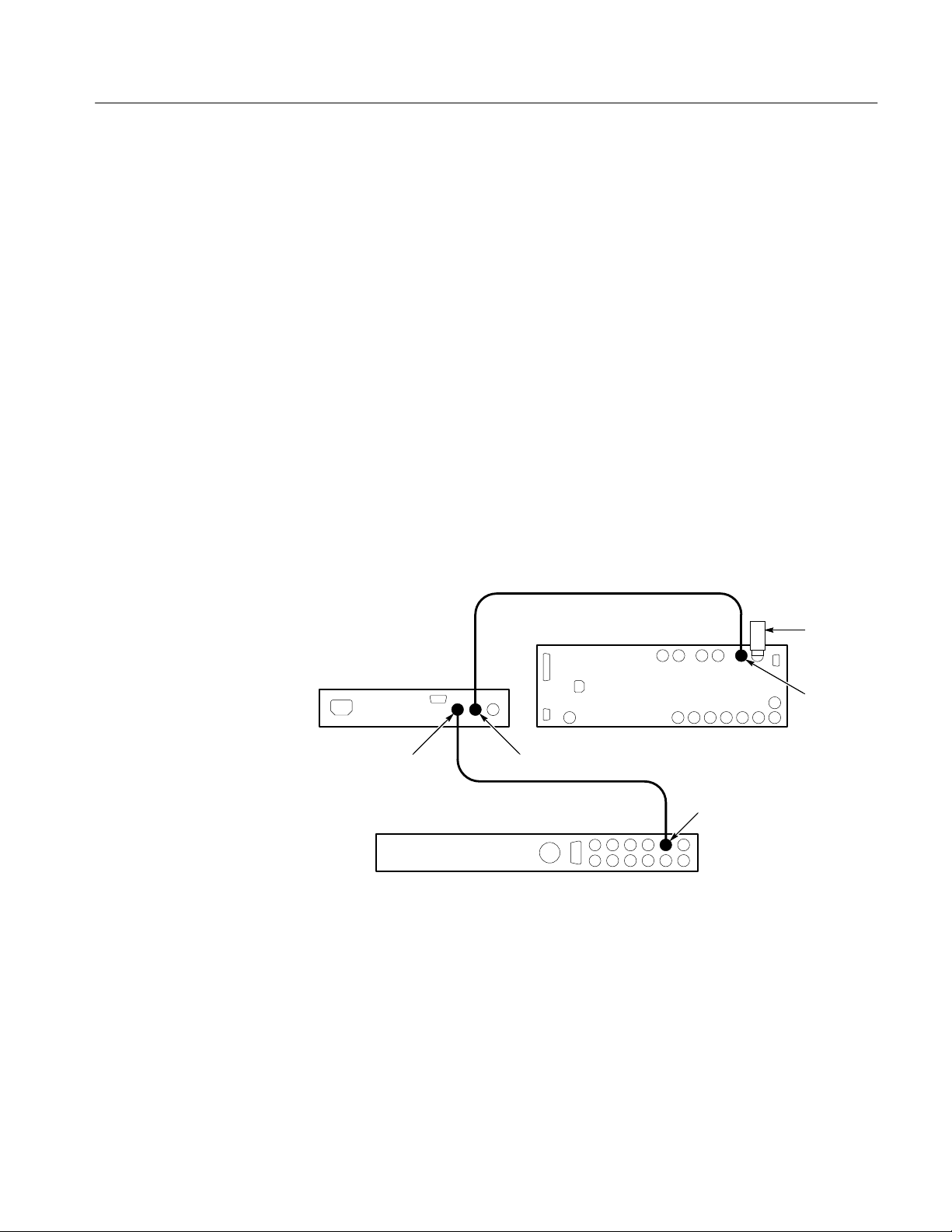

3. Connect the VITS inserter to a test signal generator and waveform monitor

as shown in Figure 1–1.

4. Switch only the VITS inserter on. Confirm that, after approximately one

second, all three front panel LEDs are lit.

Waveform Monitor

VITS 100

NTSC VITS Inserter

75W

Terminator

CH A input

Program In

Figure 1–1: A setup for the functional check

5. Switch the test signal generator on and configure it, if necessary, to output a

signal that does not contain any VITS (if it is available, select Black Burst).

Confirm that the VITS inserter BYPASS and UNLOCKED LEDs are no

longer lit.

6. Switch the waveform monitor on and configure it to display two fields of the

VITS inserter PROGRAM OUT waveform.

VITS100 NTSC VITS Inserter Instruction Manual

Program Out

Test Signal Output

NTSC test signal generator

1–3

Page 22

Getting Started

7. While watching the waveform monitor display, repeatedly press the VITS

inserter BYPASS switch to alternate between bypass and normal operating

modes. Confirm that the appearance of the vertical interval (that is, the “gap”

between the two visible fields) changes in appearance, indicating the

alternating presence and absence of inserted VITS. The change is easiest to

see when the test signal generator is outputting a Black Burst signal.

8. Configure the waveform monitor line-select feature to view one line at a

time. Check lines 17 through 20 of fields 1 and 2 for test signals. Tables 1–1

through 1–3 list the signals generated and inserted by a new VITS100 NTSC

VITS Inserter with the as-manufactured configuration. See the Specifications

Section of this manual or Appendix A: Options for diagrams of the signal

waveforms.

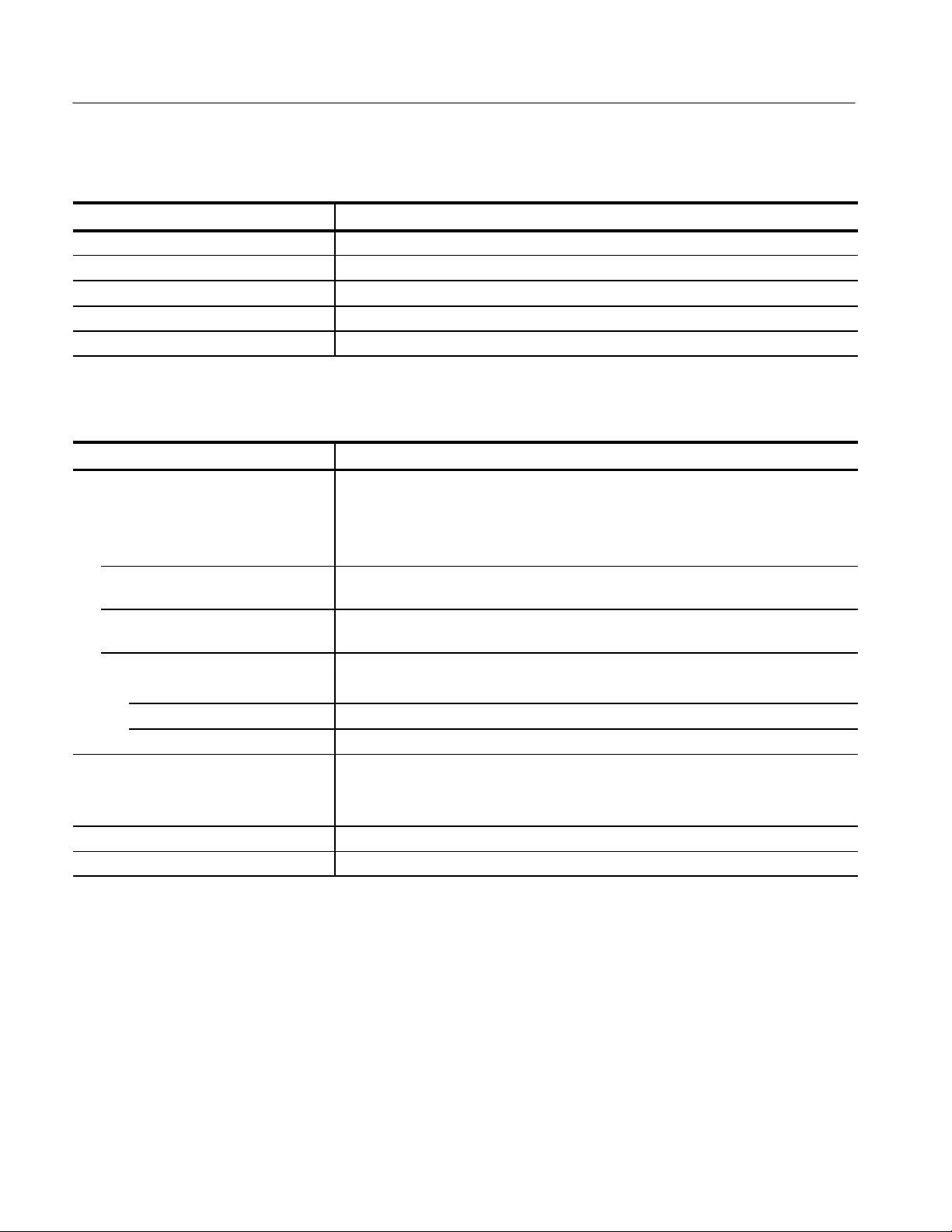

T able 1–1: Factory VITS, Standard and Option 1M

Field Line Signal

1 17 NTC7 Composite

1 19 VIRS

2 17 NTC7 Combination

2 19 VIRS

T able 1–2: Factory VITS, Option 1J

Field Line Signal

1 17 FCC Composite

1 19 Color Bars (No Setup)

1 20 Sin X/X

2 17 Multiburst

2 20 Red Field (modified Luminance and Chrominance)

T able 1–3: Factory VITS, Option 2

Field Line Signal

1 17 Cable Multiburst

1 18 FCC Composite

2 17 Cable Sweep

2 18 Sin X/X

1–4

VITS100 NTSC VITS Inserter Instruction Manual

Page 23

Getting Started

Installation

You can mount the VITS inserter in a standard equipment rack or custom install

it. In custom installations, be sure to provide easy access to the signal-selection

DIP switches through the removeable panel in the top of the instrument. Also be

sure not to block the cooling holes in the top cover. After performing the

functional check, complete installation with the following steps:

1. If you wish, mount the VITS inserter in an existing equipment rack with one

of the following Tektronix generator mounting kits:

H TVGF11A—Single Rack Mount Adapter

H TVGF13—Dual Rack Adapter

H TVGF14—Dual Half-Rack Adapter

Please contact your nearest Tektronix representative or field office for more

information.

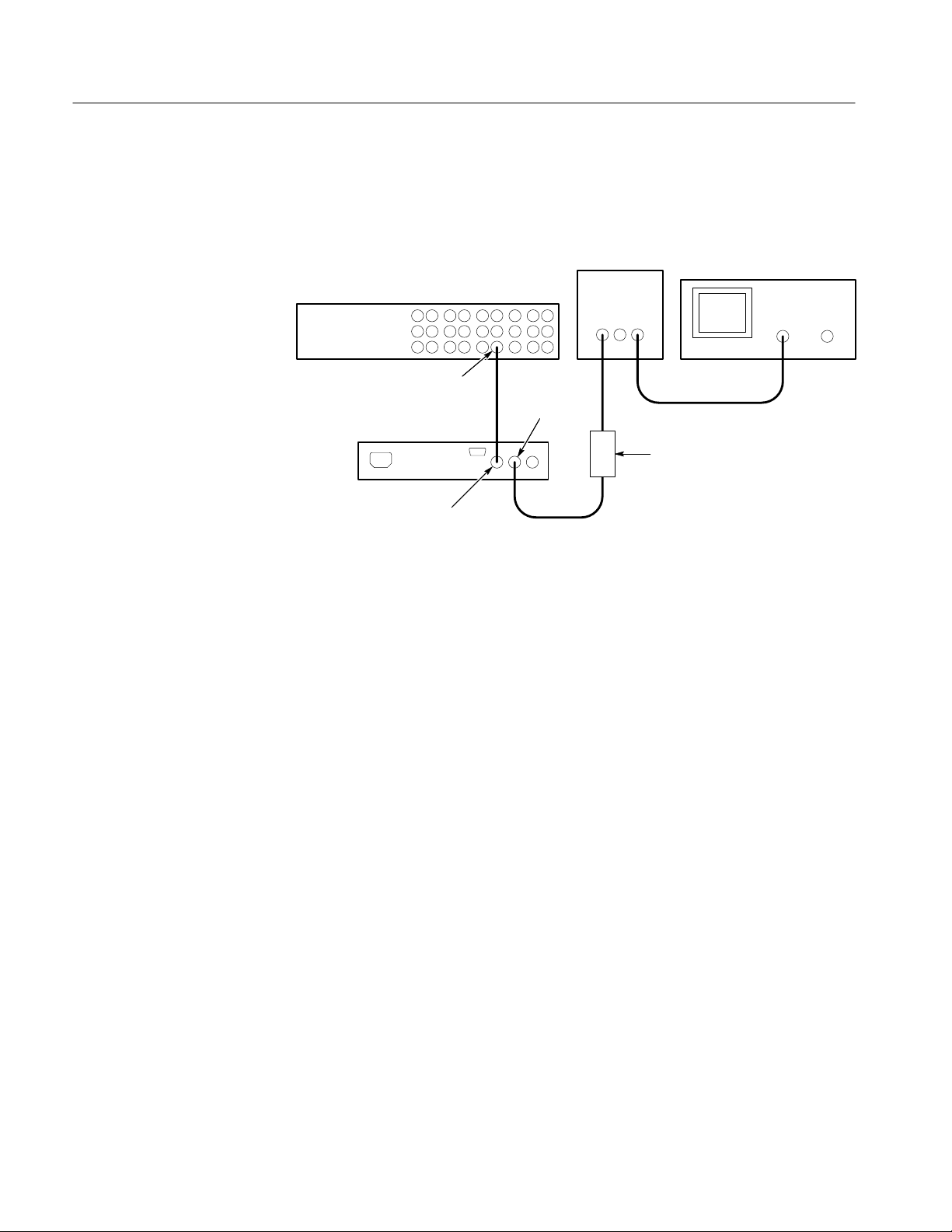

2. Connect the VITS inserter to your system as shown in Figure 1–2.

3. See the Operating Basics section of this manual for more information about

configuring and using the VITS inserter.

Program line IN

Figure 1–2: A typical installation

VITS100 NTSC VITS Inserter Instruction Manual

Waveform monitor or

vector scope (optional)

Program line OUT

1–5

Page 24

Getting Started

1–6

VITS100 NTSC VITS Inserter Instruction Manual

Page 25

Operating Basics

Page 26

Page 27

Operating Basics

Front Panel

The VITS100 NTSC VITS Inserter can generate any one of thirteen test signals

for insertion on lines 17 through 20 in the vertical interval of the video frame. If

power fails or the instrument cannot genlock, the VITS inserter automatically

switches to bypass mode.

VITS signal selection and line assignments are made with four DIP switches that

are accessible through the top of the VITS inserter. See VITS Selection, on page

2–5, for more information.

The VITS inserter has one switch and three indicator LEDs on the front panel, as

shown in Figure 2–1. These features are explained in the following paragraphs.

Figure 2–1: The front panel

BYPASS

Switch and LED

UNLOCKED LED

POWER LED

VITS100 NTSC VITS Inserter Instruction Manual

Press the BYPASS button to place the VITS inserter into Relay Bypass mode. In

this mode, the program input is applied directly to the program output through a

delay line that matches the processing delays that affect the program channel in

normal operation. Press BYPASS a second time to return to the normal operating

mode. The red BYPASS LED is lit whenever the instrument is in bypass mode.

The UNLOCKED indicator is lit when the VITS inserter cannot acquire or

maintain genlock to the program signal. To maintain correct timing, the VITS

inserter must genlock to the input program.

The POWER LED indicates that the VITS inserter is switched on (through the

rear-panel POWER switch). The LED lights when the power supply has

completed its start-up process, approximately one second after you switch the

VITS inserter on.

2–1

Page 28

Operating Basics

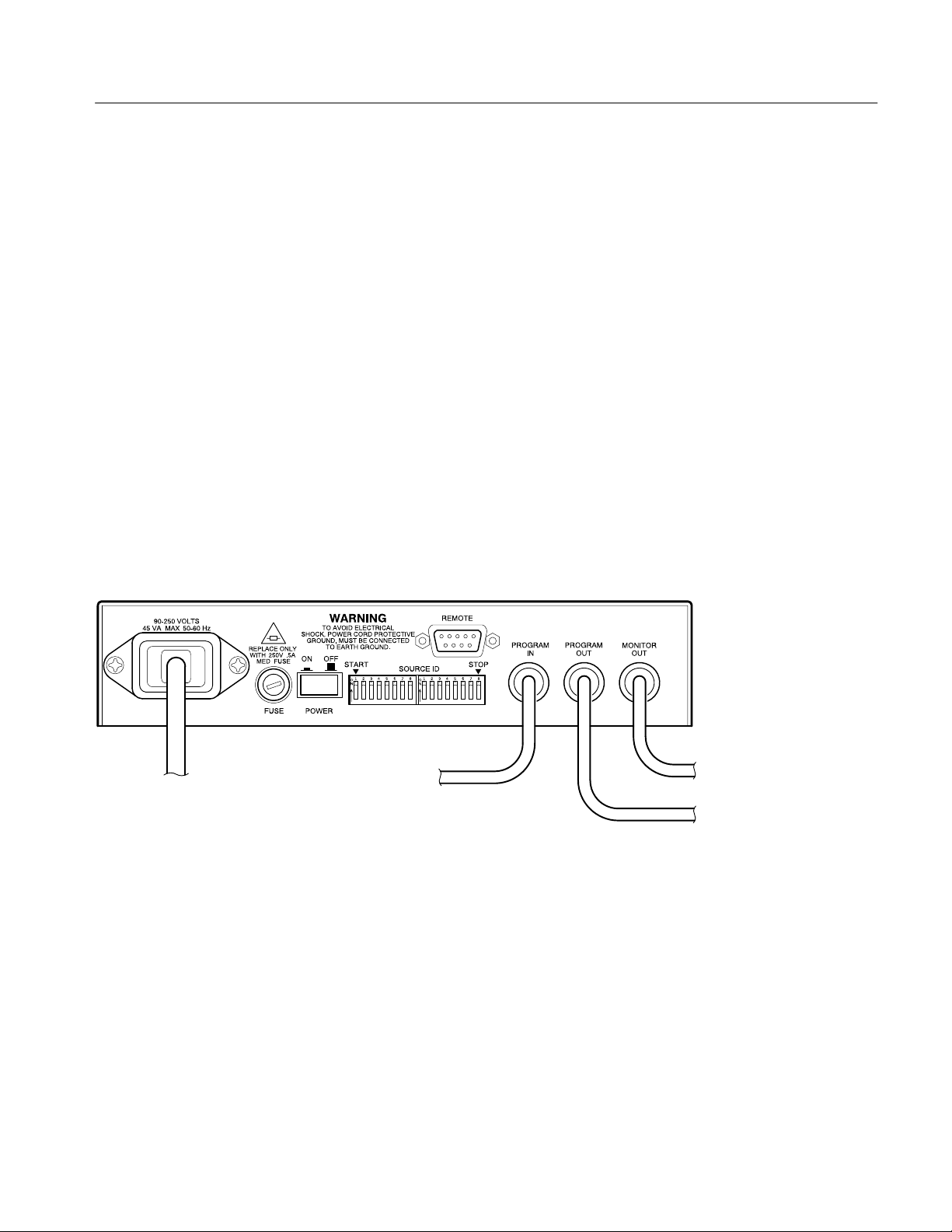

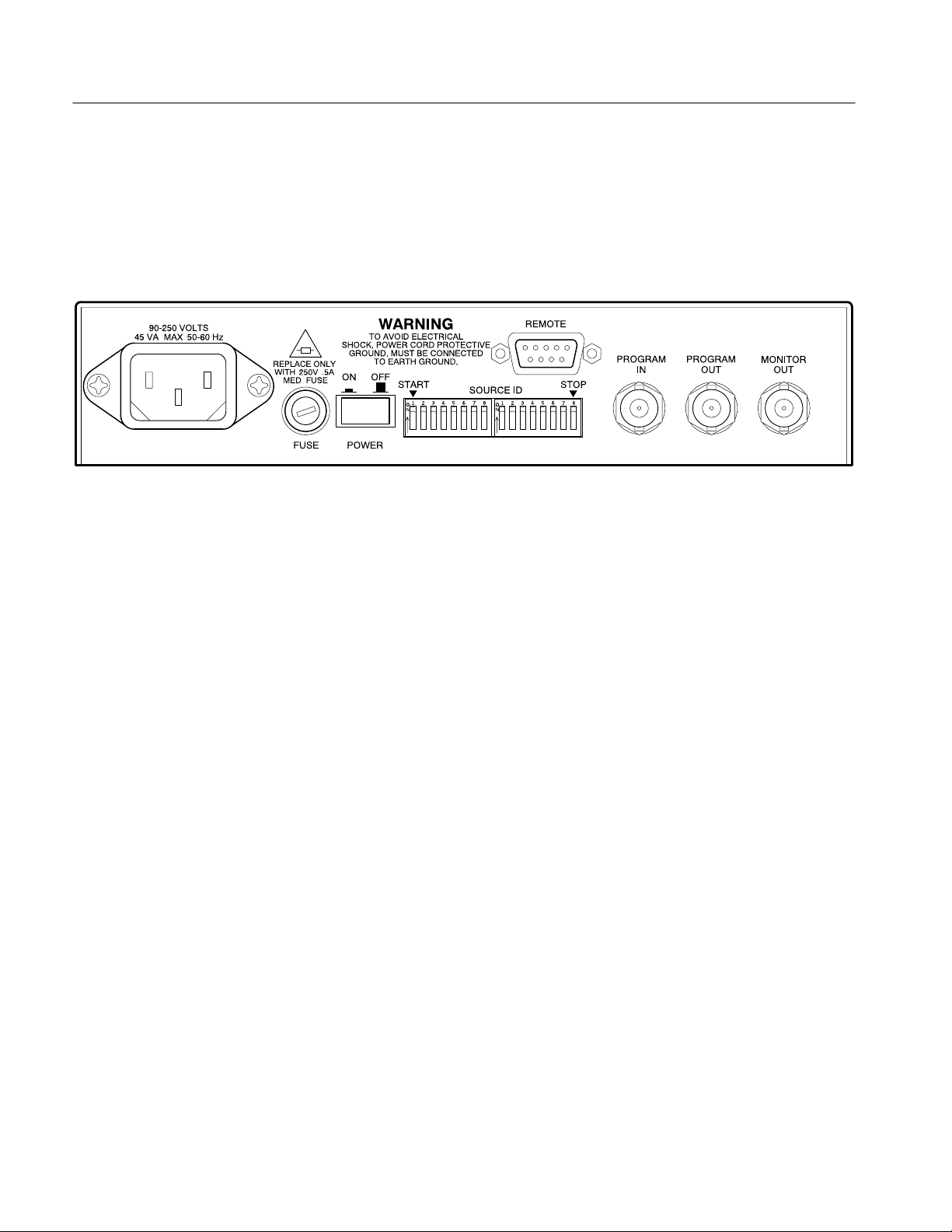

Rear Panel

The VITS100 NTSC VITS Inserter rear panel, shown in Figure 2–2, contains the

mains power input, switch, and fuse; the program input and output connectors;

DIP switches for source identification code selection; and a remote connector.

Figure 2–2: VITS100 NTSC VITS Inserter rear panel

Power

Source ID

The power block consists of the connector, fuse, and power switch. It is located

on the left third of the panel.

Power Connector. This instrument uses a power supply that accepts line voltages

from 90 to 250 VAC without changing voltage ranges or fuses.

Fuse. The fuse holder accepts a standard cartridge fuse. See the rear panel or the

Replaceable Electrical Parts section of this manual for the correct value.

Switch. A push-push, on-off switch; power is on when the switch is latched in the

in position, as indicated by the rear-panel graphic.

This set of two dual in-line package (DIP) switches is used to select a source

identification code. The source ID is a one-line, 16-bit word consisting of a start

and stop bit and any one of 16,384 (2

can be inserted in the vertical interval (lines 17 through 20) to identify the source

of the program signal.

The source ID signal is accepted by other video equipment, such as the Tektronix

VM 700A Video Measurement Set, which can then include the source ID in

reports or printouts to identify the source of the signal being measured.

14

) possible identification codes. The ID

2–2

Program In

The PROGRAM IN connector is the program video input. The input is AC

coupled, clamped to ground, and internally terminated in 75 W.

VITS100 NTSC VITS Inserter Instruction Manual

Page 29

Operating Basics

Program Out

Monitor Out

Remote Connector

Insertion Options

The PROGRAM OUT connector is the program video output. Output video can

have user-selected VITS inserted on selected lines. If the instrument cannot lock

to the program input video signal, or if power fails, the program automatically

bypasses the VITS inserter processing circuitry; the input signal is then routed

through a delay line, with a delay equivalent to the processing delays of the

instrument, to PROGRAM OUT. Matching the delay eliminates timing errors

whenever the VITS inserter must enter bypass mode.

This connector provides the same output as the PROGRAM OUT connector,

except that the MONITOR OUT is not in the bypass signal path. This means

that —during loss of genlock or activation of the bypass mode—the monitor

output will still contain any inserted VITS. There is no output from this

connector if power is lost.

This 9-pin connector enables ground-closure remote control of bypass mode. In

addition, control lines that parallel the three front panel indicators (POWER,

BYPASS, and UNLOCKED) are brought out to this connector.

Inserting Test Signals

You can configure the VITS inserter to insert test signals, pass existing video,

insert or pass VIRS, or insert a source ID on lines 17, 18, 19, and 20 of both the

even and odd fields of NTSC video.

The standard VITS100 NTSC VITS Inserter can insert the following test signals

into the vertical interval:

H FCC Color Bars H FCC Composite

H FCC Multiburst H NTC7 Combination

H NTC7 Composite H VIRS

H 7.5% Black H 0% Black

H Multipulse H SIN X/X

H Red Field H 50% Gray

You can find descriptions of these waveforms in the Specifications section of this

manual. If your instrument contains Option 1J, Option 1M, or Option 2, see

Appendix A: Options for descriptions of the optional signals.

VITS100 NTSC VITS Inserter Instruction Manual

2–3

Page 30

Operating Basics

Passing Program Video

Auto VIRS

Inserting a Source ID

In addition to internally generated test signals, the VITS inserter can pass video

signals that are already in the vertical interval of the program video. This

includes the delete/insert lines, which are lines 17 through 20 in all fields.

When AUTO VIRS is selected, the instrument automatically checks the assigned

line and field of the incoming video for a VIRS signal. If VIRS is detected, the

line is passed with no processing. If VIRS is not detected, the internally

generated VIRS signal is inserted onto the line.

Source identification can be inserted on any of the available vertical interval

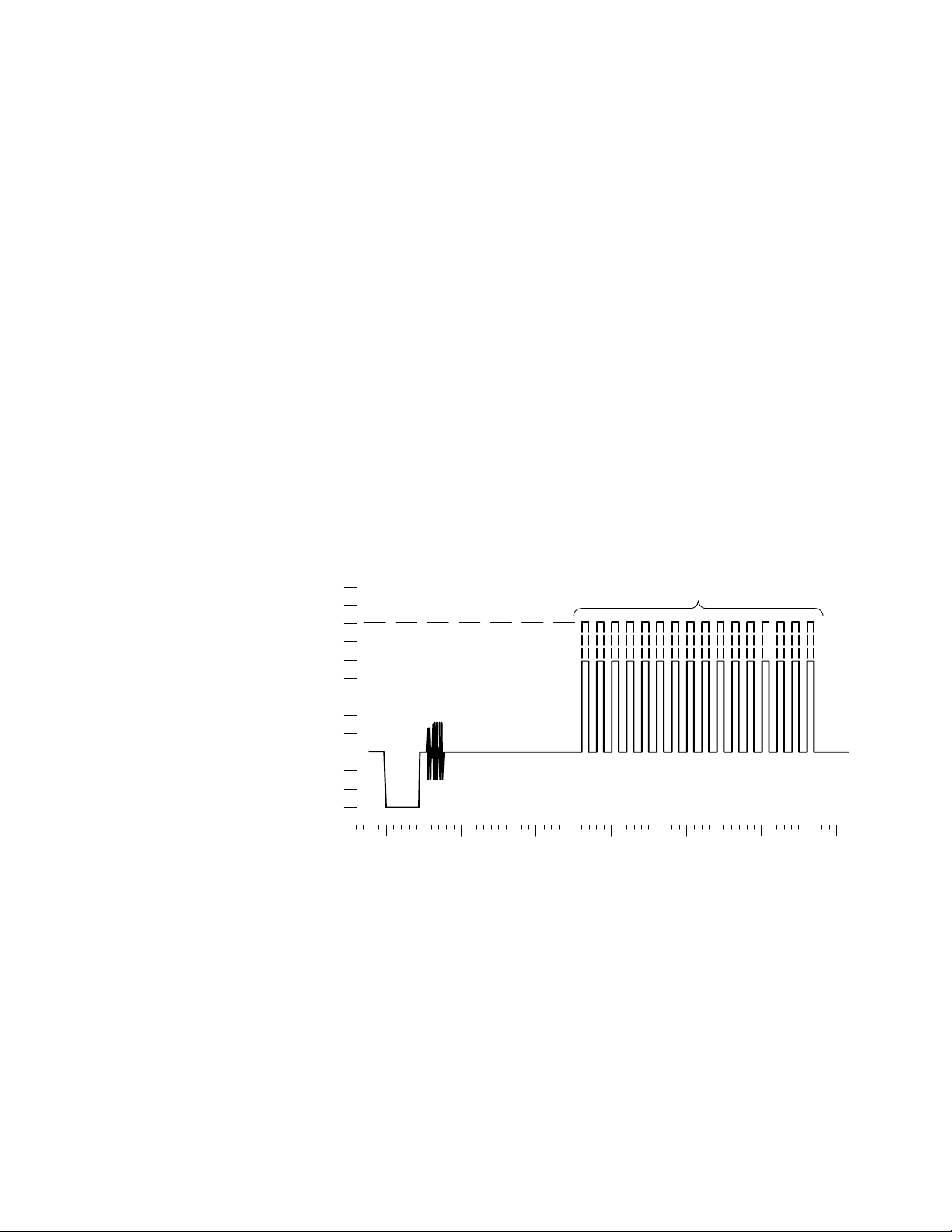

lines. The “Source ID” consists of sixteen equal-duration flags that can be set

high or low with the rear-panel SOURCE ID switches. Source ID is set by the

user to provide a visual identification of the signal path. Some equipment, such

as the Tektronix VM700A Video Measurement Set, can use this signal to

generate an alpha-numeric ID on the screen display or on printed reports. Figure

2–3 shows the waveform of a source identification code that is generated when

all switch segments are set ON.

Source Identification

Switches all on

(S/N 8020244 and below)

0.5

Volts

0.0

(S/N 8020245 and up)

0.0

10.0 20.0 30.0 40.0 50.0 60.0

MicroSeconds

Figure 2–3: VITS100 NTSC VITS Inserter source ID signal

2–4

VITS100 NTSC VITS Inserter Instruction Manual

Page 31

Operating Basics

Factory Configuration

The VITS100 NTSC VITS Inserter is configured during manufacture to insert

the signals listed in Table 2–1. See VITS Selection, below, for instructions on

configuring the VITS inserter to insert the signals that best suit your applications

and facility.

T able 2–1: Standard Factory-Programmed Signals

Field Line Signal

1 17 NTC7 Composite signal

1 18 Pass*

1 19 VIRS

1 20 Pass*

2 17 NTC7 Combination signal

2 18 Pass*

2 19 VIRS

2 20 Pass*

* Passed lines are not deleted or inserted by the VITS 100 NTSC VITS Inserter

VITS Selection

VITS signal selection for the individual vertical interval lines is made with four

DIP switches (S1–S4) mounted on the VITS inserter circuit board. Remove the

small panel from the top cover of the VITS inserter, as shown in Figure 2–4, to

gain access to these switches.

VITS100 NTSC VITS Inserter Instruction Manual

2–5

Page 32

Operating Basics

Screws (2)

Cover

Switch/Line Assignments

Figure 2–4: Location of VITS selection switches

Switches S1 and S2 make the selections for fields 1 and 3, and switches S3 and

S4 make the selections for fields 2 and 4. Each DIP switch selects the test signals

for two of the vertical interval lines, as shown in Figure 2–5.

Program color fields

1 and 3

Line 18Line 17

Line 20Line 19

S1 S2 S3 S4

Program color fields

2 and 4

Line 18Line 17

Line 20Line 19

2–6

Figure 2–5: The VITS selection DIP switches

VITS100 NTSC VITS Inserter Instruction Manual

Page 33

Operating Basics

Switch Settings

The switch settings for signal selection are listed in Table 2–2. When a switch

segment is thrown to the left (as viewed from the front of the VITS inserter), it is

open; when thrown to the right, it is closed. Open positions are denoted in the

table as 1, and closed are denoted as 0.

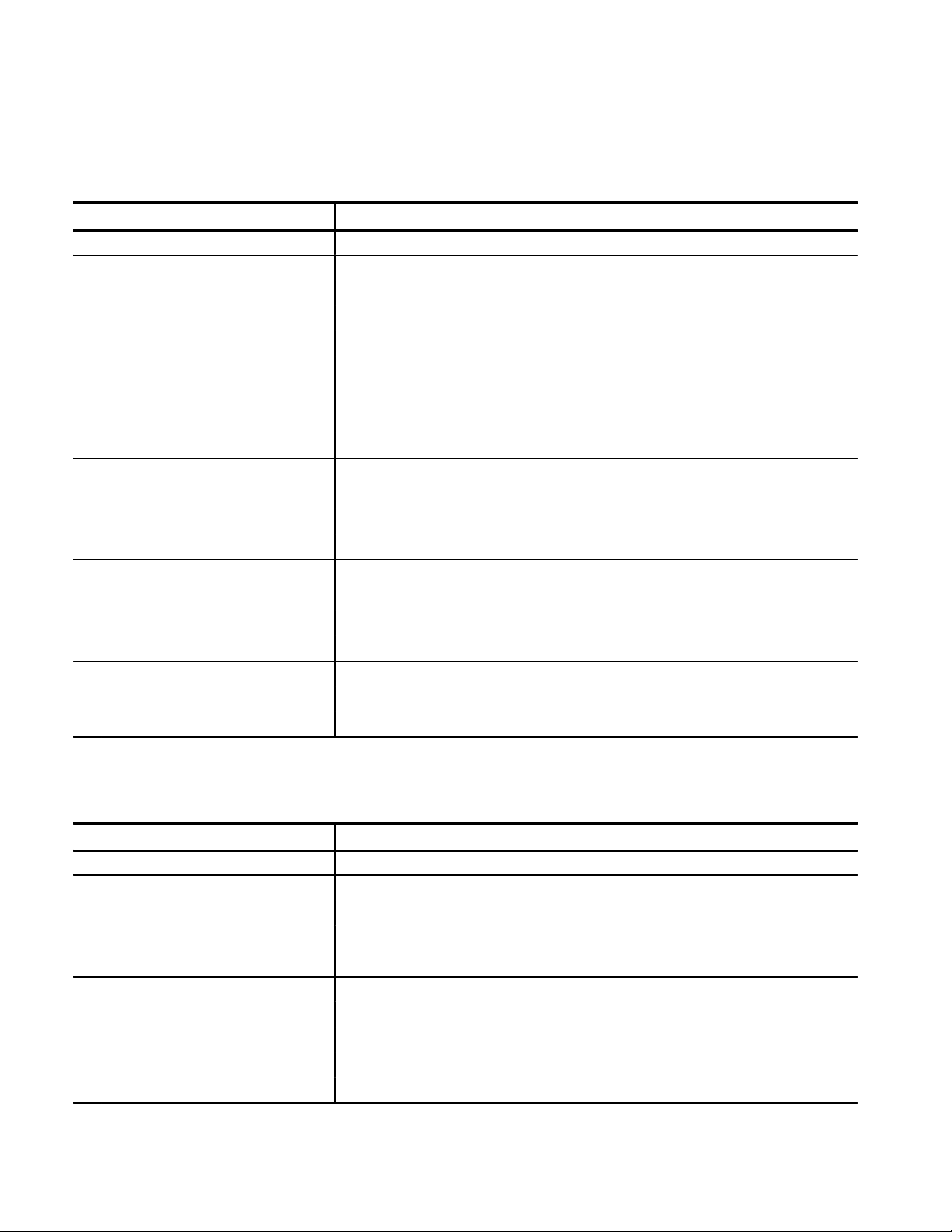

T able 2–2: DIP Switch Settings

VITS inserter Action DIP Segment Settings*

1 (5) 2 (6) 3 (7) 4 (8)

Insert Test Signal:

0% Black (two settings)

7.5% Black 1 1 1 0

50% Gray 1 1 0 1

FCC Color Bars 0 0 0 0

FCC Composite 1 0 0 0

Multiburst 0 1 0 1

Multipulse 0 1 0 0

NTC 7 Composite 1 0 1 0

NTC 7 Combination 0 0 0 1

0 1 1 0

1 0 0 1

Red Field 1 1 0 0

SIN X/X 0 0 1 0

VIRS 1 0 1 1

Pass Program Video 1 1 1 1

Auto VIRS 0 0 1 1

Insert Source ID 0 1 1 1

* 1 signifies an OPEN switch; 0 signifies a closed switch

VITS100 NTSC VITS Inserter Instruction Manual

2–7

Page 34

Operating Basics

Remote Control

Remote control in the standard VITS100 NTSC VITS Inserter is limited to

ground-closure Bypass control and (+5 V) outputs for remote BYPASS,

UNLOCKED, and POWER indicator lights. See Figure 2–6 and Table 2–3 for

the rear-panel REMOTE connector pin assignments.

REMOTE

51

96

VITS Inserter

Figure 2–6: The REMOTE connector

T able 2–3: REMOTE Connector Pin Assignments

Function Pins

Ground 1, 5

Force Bypass 6

BYP ASS Indicator 2

UNLOCKED Indicator 7

POWER Indicator 3

To duplicate the function of the front panel at a remote location, run a cable from

REMOTE pins 1, 2, 3, 5, 6, and 7 to an SPST switch and three indicator LEDs.

H Connect the switch between pins 1 and 6.

H Connect the Bypass indicator between pins 2 and 5.

H Connect the Unlocked indicator between pins 7 and 5.

H Connect the Power indicator between pins 3 and 5.

2–8

Close the switch to force the VITS inserter into bypass mode; the LEDs light

with the corresponding front-panel indicators.

VITS100 NTSC VITS Inserter Instruction Manual

Page 35

Specifications

Page 36

Page 37

Specifications

This section contains tables that list the specifications for the VITS100 NTSC

VITS Inserter. All specifications are guaranteed unless noted “typical.”

The performance limits in this specification are valid with these conditions:

H The VITS inserter must have been calibrated/adjusted at an ambient

temperature between +20

H The VITS inserter must be in an environment with temperature, altitude,

humidity, and vibration within the operating limits described in these

specifications.

H The VITS inserter must have had a warm-up period of at least 20 minutes.

Specification Tables

T able 3–1: Program channel characteristics

Characteristic Information

_ C and +30_ C.

Gain Unity ± 1%

Frequency Response ±1% to 5.5 MHz

±3% to 10 MHz

Chrominance-to-Luminance Gain ±0.5%

Chrominance-to-Luminance Delay ≤5 ns

Diff Phase ≤0.2°

Diff Gain ≤0.2%

Line Tilt ≤0.5%

DC Output Level 0 V ±10 mV

DC Matching of Inserted Test Signal to

Program Signal

Phase Match (Relay Bypass Path to Signal

Processing Path)

Hum Rejection 50 dB (Measured right after burst)

Keyboard (No Noise) Too small to measure on VM700A

Insertion Transients ≤10 mV (Measured on Tektronix 1780R. Typically <5 mV)

Input Impedance 75 W

Return Loss 36 dB to 5 MHz (Program In, Program Out, and Monitor Out)

±3 mV

±1° at F

SC

VITS100 NTSC VITS Inserter Instruction Manual

3–1

Page 38

Specifications

T able 3–1: Program channel characteristics (Cont.)

Characteristic Information

Phase Matching of Inserted Test Signal to

Program Video

Pulse to Bar Ratio 100%±0.5% (Typically within ±0.25%)

Signal to Noise Ratio >70 dB (Unweighted Filter at 5 MHz. Measured 91 dB on VM700A, relative to reference)

±1° (Program Sync and Burst Normal Level)

T able 3–2: Test Signal and Black Burst general characteristics

Characteristic Information

Frequency Response ±1% to 5 MHz

±5% to 10 MHz

Luminance Amplitude Accuracy ±1%

Chrominance-to-Luminance Gain ±0.5%

Chrominance-to-Luminance Delay ≤5 ns

Diff Phase ≤0.3°

Diff Gain ≤0.3%

Line Tilt ±0.5%

Output Impedance 75 W

Signal to Noise Ratio >78 dB (Measured on a VM700A with an unweighted 5 MHz lowpass filter.)

Spurious Signals (5 MHz 50 MHz)

Pulse to Bar Ratio 100% ±0.5%

K Factor (K2T) 0.3% (Typically 0.2%)

Crosstalk ≥60 dB down

DC Offset 0 V DC ±10 mV

SCH Phase Accuracy 0 ±5° (< ±2.5° typical)

Luminance Rise Time 140 ns ±20 ns

Chrominance Rise Time 300 ns ±35 ns

>55 dB down

T able 3–3: Black and Gray Test Signal characteristics

Signal Information

0% Black 0 IRE Luminance with sync and burst; see Figure 3–1.

7.5% Black 7.5 IRE Luminance with sync and burst; see Figure 3–2.

50% Gray 50 IRE Luminance with sync and burst; see Figure 3–3.

3–2

VITS100 NTSC VITS Inserter Instruction Manual

Page 39

T able 3–4: FCC Composite characteristics

Characteristic Information

Timing See Figure 3–5

Modulated 5-step Staircase

Luminance

Amplitude 80.4 IRE ±0.7 IRE

Riser Amplitude 1/5 of 5-step amplitude ±0.5%

Rise Time 250 ns ±25 ns

Chrominance

Phase Same as burst ±0.3°

Envelope Risetime 375 ns ±37.5 ns

2T Pulse

Pulse-to-Bar Ratio 100% ±0.5%

Half Amplitude Duration (HAD) 250 ns ±25 ns

Ringing 1.0 IRE or less

Modulated SIN2 Pulse

Pulse-to-Bar Peak Amplitude 100%

Half Amplitude Duration 1.563 ms ±150 ns

Phase 60.8° ±1°

Bar

Amplitude 100 IRE ±1 IRE

Rise Time 250 ns ±25 ns

Specifications

VITS100 NTSC VITS Inserter Instruction Manual

3–3

Page 40

Specifications

T able 3–5: FCC Color Bars characteristics

Characteristic Information

Timing See Figure 3–4

Luminance Rise Time 250 ns ±25 ns

Bar Characteristics: White Yellow Cyan Green Magenta Red Blue Black

Luminance Amplitude (mV p-p)

Subcarrier Amplitude (mV p-p)

Subcarrier Phase (degrees)

714.3

0.0

0.0

494.3

444.2

167.1

400.7

630.1

283.4

345.7

588.5

240.8

256.0

588.5

60.8

202.1

630.1

103.4

107.8

444.2

347.1

T able 3–6: Multiburst characteristics

Characteristic Information

Timing See Figure 3–6

White Reference Bar Amplitude 100 IRE

Packet Amplitudes 60 IRE p-p

Pedestal 40 IRE

Burst Frequencies 500 kHz, 1.25 MHz, 2.0 MHz, 3.0MHz, 3.58 MHz, 4.1 MHz

Packet Rise Time

500 kHz 140 ns typical (sin2 shaped packets)

Other Packets 400 ns typical (sin2 shaped packets)

53.5

0.0

0.0

T able 3–7: Multipulse characteristics

Characteristic Information

Timing See Figure 3–7

Amplitudes 80 IRE

Frequencies 1.0 MHz, 2.0 MHz, 3.0 MHz, 3.58 MHz, and 4.2 MHz

3–4

VITS100 NTSC VITS Inserter Instruction Manual

Page 41

T able 3–8: NTC7 Combination characteristics

Characteristic Information

Timing See Figure 3–8

White Reference Bar

Amplitude 100 IRE ±0.7 IRE

Rise Time 250 ns ±25 ns

Multiburst Packets

Amplitude 50 IRE ±0.5 IRE p-p

Average Level 50 IRE ±0.5 IRE

Frequencies 500 kHz, 1.0 MHz, 2.0 MHz, 3.0 MHz, 3.58 MHz, 4.2 MHz

Packet Rise Time

500 kHz and 1.0 MHz 140 ns typical (sin2 shaped packets)

Other Frequencies 400 ns typical (sin2 shaped packets)

Modulated Pedestal

Pedestal

Amplitude 50 IRE ±0.5 IRE

Rise Time 250 ns ±25 ns

Chrominance

Amplitude

20 IRE 20.01 IRE ±0.5 IRE

40 IRE 40.02 IRE ±0.5 IRE

80 IRE 80.04 IRE± .5 IRE

Phase relative to burst 90° ±0.5°

Rise Time 400 ns ±40 ns

Specifications

VITS100 NTSC VITS Inserter Instruction Manual

3–5

Page 42

Specifications

T able 3–9: NTC7 Composite characteristics

Characteristic Information

Timing See Figure 3–9

Modulated 5-step Staircase

Luminance

Amplitude 90.2 IRE ±0.7 IRE

Riser Amplitude 1/5 of 5-step amplitude ±0.5%

Rise Time 250 ns ±25 ns

Chrominance

Phase Same as burst ±0.3°

Envelope Risetime 400 ns ±40 ns

2T Pulse

Pulse-to-Bar Ratio 100% ±0.5%

Half Amplitude Duration (HAD) 250 ns ±25 ns

Ringing 1.0 IRE or less

Modulated SIN2 Pulse

Pulse-to-Bar Peak Amplitude 100%

Half Amplitude Duration 1.563 ms ±150 ns

Phase 60.8° ±1°

Bar

Amplitude 100 IRE ±1 IRE

Rise Time 125 ns ±15 ns

T able 3–10: Red Field characteristics

Characteristic Information

Timing See Figure 3–10

Luminance

Amplitude, Standard 202.2 mV ±1%

Amplitude, Option 1J 160.72 mV ±1%

Rise Time 250 ns ±25 ns

Chrominance

Amplitude, Standard 630.1 mV ±1%

Amplitude, Option 1J 681.23 mV ±1%

Phase 103.4° ±0.3°

Rise Time 400 ns ±40 ns

3–6

VITS100 NTSC VITS Inserter Instruction Manual

Page 43

T able 3–11: SIN X/X characteristics

Characteristic Information

Timing See Figure 3–1 1

Bandwidth 4.75 MHz

Pedestal 24 IRE

Peak 90 IRE (Peak amplitude from pedestal )

T able 3–12: Vertical Interval Reference Signal characteristics

Characteristic Information

Timing See Figure 3–12

Chrominance Reference

Amplitude 40 IRE

Phase Same as burst ±0.3°

Envelope Rise Time 1 ms ±100 ns (sin2 shaped)

Average Chrominance Level 70 IRE

Luminance Reference

50 IRE Level 50 IRE

Black Reference 7.5 IRE

Specifications

T able 3–13: Cable Multiburst (Option 2) characteristics

Characteristic Information

Timing See Figure 3–13

White Reference Bar Amplitude 60 IRE

Packet Amplitudes 60 IRE

Pedestal Amplitudes 30 IRE

Burst Frequencies 500 kHz, 1.25 MHz, 2.0 MHz, 3.0 MHz, 3.75 MHz, 4.0 MHz

Packet Rise Time

500 kHz Packet 140 ns typical (sin2 shaped packets)

Other Packets 400 ns typical (sin2 shaped packets)

VITS100 NTSC VITS Inserter Instruction Manual

3–7

Page 44

Specifications

T able 3–14: Cable Sweep (Option 2) characteristics

Characteristic Information

Timing See Figure 3–14

Pedestal Amplitude 50 IRE

Sweep Amplitude 100 IRE

Sweep Start Frequency 0.1 MHz

Sweep End Frequency 4.2 MHz

T able 3–15: Genlock characteristics

Characteristic Information

Burst Lock

Genlock Phase Change with Input

Amplitude

Genlock Phase Change with Input

Signal APL

Genlock Phase Change with Input

Signal Burst Frequency

Lock Range

Frequency , Standard 3.579545 MHz ±20 Hz (NTSC)

Fequency, Option 1M 3.575611 MHz ±20 Hz (PAL-M)

Amplitude +6 dB to –12 dB (Typically to –16 dB NTSC; –14 dB PAL-M)

Genlock Phase Jitter with Input Amplitude

Change

≤2° burst phase change for input sync or burst amplitude range of 287mV ±3 dB

≤4° burst phase change for amplitude range of 287mV ±6dB

(For either composite video or burst amplitude errors)

≤1° burst phase change over 10% to 90% APL

≤1° burst phase change for ±20 Hz change in incoming subcarrier

Typically ≤0.2° peak for input sync or burst amplitude range of 287 mV ±3dB; no noise

on input signal

Typically ≤0.4° peak for input amplitude range of 287 mV ±6 dB; no noise on input signal

Sync Lock Jitter ≤10 ns for input sync amplitude range of 287 mV ±3 dB (No noise on input signal)

Noise Performance Locks to 28 dB S/N Ratio Video

3–8

VITS100 NTSC VITS Inserter Instruction Manual

Page 45

Specifications

T able 3–16: Power Supply characteristics

Characteristic Information

Output Voltages +5 V ±200 mV from 1A to 3 A (voltage adjustable)

–5.2 V ±300 mV from 0.5 A to 1 A

±12 V ±120 mV from 0.05 A to 0.2 A (post regulated from ±14.5 V by linear regulators)

Output Ripple

+5 V ≤50 mV switching ripple,

≤5 mV line frequency ripple

–5.2 V ≤50 mV switching ripple,

≤10 mV line frequency ripple

±12 V ≤10 mV switching ripple,

≤5 mV line frequency ripple

Line Input Range Regulates from 90 to 250 VAC

Minimum Load 10 W minimum load required to operate. However, output voltages other than +5 V may

not meet specifications outside the listed currents. At zero load the power supply cycles

on and off

Power Consumption 40–50 W.

Overvoltage Protection The 5 V output is protected by a crowbar circuit that engages at approximately 5.7 V.

Overvoltage protection causes the power supply to cycle by engaging the primary side

current limit time-out circuit

Power 70 W maximum controlled by primary side current limit circuits. Power supply cycles on

and off when power limit is reached

Short-Circuit Protection All outputs are protected by the primary side current limit and time-out circuits. In

addition, the ±12 V outputs are limited to 1 A by the linear regulators

Efficiency 70% nominal

Fan Drive 15 V to 16.5 V , as determined by supply load

T able 3–17: Physical characteristics

Characteristic Information

Height 1.734 in (4.404 cm)

Width 8.1 in (20.6 cm)

Length 17.2 in (43.7 cm)

Weight

Net 4.7 lbs (2.1 kg)

Shipping 16.7 lbs (7.6 kg)

VITS100 NTSC VITS Inserter Instruction Manual

3–9

Page 46

Specifications

T able 3–18: Environmental characteristics

Characteristic Information

Temperature

Non-Operating –40° to +65° C (–40° to +149° F)

Operating 0° to +50° C (32° to 122° F)

Altitude

Non-Operating To 50,000 ft (15,240 m)

Operating To 15,000 ft (4,572 m)

Vibration (Operating) Fifteen minutes each axis at 0.025 inch, frequency varied from 10-55-10 Hz in 4-minute

cycles with the instrument secured to the vibration platform; ten minutes each axis at any

resonant point, or at 55 Hz.

Shock 50 G, 1/2 sine, 11 ms duration, three guillotine shocks per side

Transportation Qualified under NTSB Test Procedure 1A, Category II (36-inch drop)

3–10

VITS100 NTSC VITS Inserter Instruction Manual

Page 47

T able 3–19: Certifications and compliances

Category Standards or description

Specifications

EC Declaration of Conformity –

EMC

Australia/New Zealand

Declaration of Conformity – EMC

EMC Compliance Meets the intent of Directive 89/336/EEC for Electromagnetic Compatibility when it is used with the

FCC Compliance Emissions comply with FCC Code of Federal Regulations 47, Part 15, Subpart B, Class A Limits.

Installation (Overvoltage)

Category

Pollution Degree A measure of the contaminates that could occur in the environment around and within a product.

Safety Standards

U.S. Nationally Recognized

Testing Laboratory Listing

Canadian Certification CAN/CSA C22.2 No. 231 CSA safety requirements for electrical and electronic measuring and

European Union Compliance Low V oltage Directive 73/23/EEC, amended by 93/69/EEC

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility. Compliance was

demonstrated to the following specifications as listed in the Official Journal of the European Union:

EN 50081-1 Emissions:

EN 55022 Class B Radiated and Conducted Emissions

EN 50082-1 Immunity:

IEC 801-2 Electrostatic Discharge Immunity

IEC 801-3 RF Electromagnetic Field Immunity

IEC 801-4 Electrical Fast Transient/Burst Immunity

Complies with EMC provision of Radiocommunications Act per the following standard(s):

AS/NZS 2064.1/2 Industrial, Scientific, and Medical Equipment: 1992

AS/NZS 3548 Information Technology Equipment: 1995

product(s) stated in the specifications table. Refer to the EMC specification published for the stated

products. May not meet the intent of the directive if used with other products.

Terminals on this product may have different installation (overvoltage) category designations. The

installation categories are:

CA T III Distribution-level mains (usually permanently connected). Equipment at this level is

typically in a fixed industrial location.

CA T II Local-level mains (wall sockets). Equipment at this level includes appliances, portable

tools, and similar products. Equipment is usually cord-connected.

CA T I Secondary (signal level) or battery operated circuits of electronic equipment.

Typically the internal environment inside a product is considered to be the same as the external.

Products should be used only in the environment for which they are rated.

Pollution Degree 2 Normally only dry , nonconductive pollution occurs. Occasionally a

temporary conductivity that is caused by condensation must be

expected. This location is a typical office/home environment.

Temporary condensation occurs only when the product is out of

service.

UL1244 Standard for electrical and electronic measuring and test equipment.

test equipment.

EN 61010-1 Safety requirements for electrical equipment for measurement,

VITS100 NTSC VITS Inserter Instruction Manual

control, and laboratory use.

3–11

Page 48

Specifications

T able 3–19: Certifications and compliances (Cont.)

Category Standards or description

Additional Compliance IEC61010-1 Safety requirements for electrical equipment for measurement,

control, and laboratory use.

Safety Certification Compliance

T emperature, operating +5 to +40_ C

Altitude (maximum

operating)

Equipment Type Test and measuring

Safety Class Class 1 (as defined in IEC 1010-1, Annex H) – grounded product

Overvoltage Category Overvoltage Category II (as defined in IEC 1010-1, Annex J)

Pollution Degree Pollution Degree 2 (as defined in IEC 1010-1). Note: Rated for indoor use only.

2000 meters

Waveform Diagrams

The diagrams in Figures 3–1 through 3–14 contain timing information for the

various test signals generated by the VITS100 NTSC VITS Inserter and

described in Tables 3–3 through 3–14.

Figure 3–1: 0% Black

3–12

VITS100 NTSC VITS Inserter Instruction Manual

Page 49

Figure 3–2: 7.5% Black

Specifications

Figure 3–3: 50% Gray

VITS100 NTSC VITS Inserter Instruction Manual

3–13

Page 50

Specifications

Figure 3–4: FCC Color Bars

3–14

Figure 3–5: FCC Composite

VITS100 NTSC VITS Inserter Instruction Manual

Page 51

Figure 3–6: Multiburst

Specifications

Figure 3–7: Multipulse

VITS100 NTSC VITS Inserter Instruction Manual

3–15

Page 52

Specifications

Figure 3–8: NTC7 Combination

3–16

Figure 3–9: NTC7 Composite

VITS100 NTSC VITS Inserter Instruction Manual

Page 53

Figure 3–10: Red Field

Specifications

Figure 3–11: SIN X/X

VITS100 NTSC VITS Inserter Instruction Manual

3–17

Page 54

Specifications

Figure 3–12: VIRS

3–18

Figure 3–13: Cable Multiburst

VITS100 NTSC VITS Inserter Instruction Manual

Page 55

Figure 3–14: Cable Sweep

Specifications

VITS100 NTSC VITS Inserter Instruction Manual

3–19

Page 56

Specifications

3–20

VITS100 NTSC VITS Inserter Instruction Manual

Page 57

WARNING

The following servicing instructions are for use only by qualified personnel. To

avoid injury, do not perform any servicing other than that stated in the operating

instructions unless you are qualified to do so. Refer to all Safety Summaries before

performing any service.

Page 58

Page 59

Theory of Operation

Page 60

Page 61

Theory of Operation

This section of the manual begins with a functional description of the circuitry.

This brief discussion is followed by a more detailed set of circuit descriptions

that take you to the individual component level of the schematic diagrams.

Functional Description

Program In. The program input is buffered and clamped. The clamped program

video drives the Sync Stripper that strips off composite sync and generates the

backporch timing for the Clamp.

Genlock. The genlock calculates the SCH phase of the incoming video to

determine the correct color framing. A phase-locked loop is used to control a

voltage-controlled oscillator (VCO). When the VITS inserter is genlocked, a

frame reset pulse is generated to align the test signal counters with genlock

counters.

T est Signal Generation. The VITS100 NTSC VITS Inserter can insert four lines

on odd and even fields. Signals are selected with four DIP switches on the main

circuit board. The lines from the switches are multiplexed and form one of the

inputs to the Test Signal Generator.

Test signals are generated by clocking data from PROMs to a digital-to-analog

converter (DAC) at an 8

before driving the VITS Inserter.

Program Out. The VITS inserter video signal output can be from any of three

sources: clamped video through the instrument, VITS signals inserted on one of

the four VITS lines, or the bypassed program line. The bypassed program line

has a built-in delay line to maintain the precise time relationship between the

processed and bypassed video.

Remote Control. Remote control is limited to ground-closure bypass control and

the power, unlocked, and bypass indicator lines.

Power Supply . The power supply, located on the Inserter board, is a current-mode

controlled, discontinuous, flyback, switching power supply. The current output is

distributed among the four supplies.

rate. The output of this DAC is filtered and buffered

FSC

VITS100 NTSC VITS Inserter Instruction Manual

4–1

Page 62

Theory of Operation

Circuit Description

The power inductor is driven by switching the voltage to its primary winding on

and off at a rate of approximately 45 kHz. The power inductor is used as an

energy storage device. Energy is stored in the primary during the first half of the

switching cycle. On the second half of the switching cycle, the stored energy is

transferred to the secondaries.

Regulation is accomplished through feedback from the +5 V supply to the Pulse

Width Modulator that controls the primary voltage. The Pulse Width Modulator

varies the length of time that voltage is applied to the primary changing the

amount of stored energy.

All primary voltages are referenced to a floating ground, not chassis ground. An

isolation transformer or a differential amplifier is therefore required for troubleshooting the circuitry in the primary and the Pulse Width Modulator.

The following circuit description takes you down to the component level.

Because of the arrangement of circuits on the schematic diagrams, most of the

functional headings cover circuits that appear on more than one schematic

diagram.

Test Signal Generation

In this discussion active-low signals are denoted by overbars (like this

names are in lower case and enclosed in quotation marks (“like this”).

The circuitry that generates the test signals for insertion appears on three of the

schematic diagrams located in the Diagrams section of this manual. Key

circuitry is located on diagrams 1 (Test Signal Memory), 3 (H & V Counters,

Source Identification & Bypass Controls), and 7 (Analog Output).

Diagram 3. Test signal generation starts with a 4

Horizontal Counter, U28, to provide 910 counts per line of video. In addition,

this counter decodes the backporch clamp pulse, for the test signal. The output of

the Horizontal Counter drives a Horizontal Decoder PROM, U27, to provide

timing signals for various functions. The Horizontal Counter is reset by the

frame pulse, from the genlock circuitry in order to time the test signals to

program video.

A once-per-line pulse from the Horizontal Decoder PROM (pin 14) enables the

Vertical Counter, U24. This synchronous output of the Vertical Counter drives

the Vertical Decoder PROM, U25. Output of U25 is latched twice per line by

U26, which is clocked by the “vlatch” from U27 (pin 16).

clock that clocks the

FSC

). Signal

4–2

Diagram 1. Test signal data is stored in PROMs U4, U5, and U6. U4 and U5 store

the eight MSBs of alternate data samples. U6 stores the four LSBs for all data

VITS100 NTSC VITS Inserter Instruction Manual

Page 63

Theory of Operation

samples. The outputs of U4 and U5 are multiplexed by U82 and U83 to increase

the data rate from 4

FSC

to 8

. The outputs of U82 and U83 are latched by U1

FSC

before being converted to ECL levels. U9 and U10 are the level converters for

the DAC, U65, which is located on Diagram 7. The four LSBs are latched by U3

and then selected by a multiplexer, U7 before being converted to ECL levels by

U11.

Test signal data is stored in U4, U5, and U6 in blocks of eight. The blocks of

data are addressed by the Block PROM, U13, and two test signal select lines.

When the test signal select circuitry calls for a given test signal, the Block

PROM uses V1 to determine the correct phase of subcarrier, uses “halfline” to

determine when to generate a half line, and uses the seven MSBs of horizontal

count to select the appropriate blocks of data.

Diagram 7. The U65 is a 12-bit DAC that turns the data into analog voltage levels

at an 8

rate. A one-volt reference is generated for the DAC by U84. The

FSC

analog output signal is filtered by a 7-pole filter, L12, L13, and L14, with T2

functioning as a second order group delay correction.

Genlock

The signal is AC coupled to a buffer, U67, and clamped to remove any DC level

change with temperature. This allows the test signal DC level to match the

Program Video DC level very accurately.

This video buffer drives the Channel Switch, U64, which switches between

Program Video and VITS. The output of Channel Switch drives the MONITOR

OUT and the Program Output.

K2 controls the signal to the PROGRAM OUT. It switches the PROGRAM IN

through a delay line, L7, L3, and C52 to the PROGRAM OUT when the power

shuts off or when the front-panel RELAY BYPASS button is pushed. The delay

line in this bypass mode matches the time it takes for the video to travel through

the processing circuitry.

The circuitry that genlocks to the incoming program signal appears on three of

the schematic diagrams in the Diagrams section of this manual. Key circuitry is

located on diagrams 4 (Genlock), 5 (Program Input, Sync Stripper, VIRS

Detection, & Genlock A/D Input), and 6 (Clocks).

Diagram 5. U42 buffers and clamps the program input signal The output of U42

also drives the Sync Stripper, U44. U44 strips off the composite sync and

generates the backporch timing pulse used by the clamps.

Composite sync and the backporch timing are shifted to TTL levels by Q1, Q3,

VR1, and VR2. Their outputs are gated together by U57A and U57B to produce

the clamp pulse for U42.

VITS100 NTSC VITS Inserter Instruction Manual

4–3

Page 64

Theory of Operation

The Input Buffer, U42, also drives the genlock analog-to-digital converter

(ADC), U43. The ADC also has AGC and is clamped with “synctip” and

“backporch” signals, which provide the timing.

The clamped and AGC’d video is then routed through an anti-aliasing filter (L1,

C19, C20, and C21), and then reinput to the ADC where it is digitized. The

digital output is input to a PAL, U41. where it is inverted and latched. The signal

“sis_tm” from the genlock ASIC, on diagram 4, holds the same sample across

the bottom of sync to block Sound-in-Sync pulses from upsetting the genlock

circuitry.

Diagram 4. The output data from the PAL on diagram 3 is input to the Genlock

ASIC, U29, which has RAM, counters, decoders, and the other genlocking

circuitry. Composite sync is routed to the genlock ASIC through a PAL, U70.

The genlock ASIC uses the composite sync to roughly position the horizontal

and vertical counters.

The Genlock Processor, U35, is an 8 MHz Z80 that calculates the SCH of the

incoming video in order to determine the correct color framing. The processor

uses the digitized color subcarrier burst to determine the tangent of the phase

angle between the system clock and the burst. This tangent is used to look up the

arctangent (that is, the angle itself), which is stored in a PROM, U33. The angle

is used as a correction to the system clock, on diagram 6, to form a phase-locked

loop.

Diagram 6. The correction is an 8-bit word which is sent to DAC, U59. The

output of the DAC is integrated by an operational amplifier, U61A and C46. U60

is an analog switch that is used to short the integrator when searching for

genlock and to change the loop characteristics once lock is securely acquired.

The processor also increases loop gain once lock has been acquired and enables

the Genlock ASIC to output a frame reset pulse to align the test signal counters

with the genlock counters.

Y39 is the clock for the genlock processor (NOT the system clock). U31 is a

hardware watchdog that resets the processor if it fails to receive an “awake”

signal from the processor within the right amount of time. U38 latches control

signals “glk/int

” and “acq/hold” for U60, an analog switch, and the signal

“locked” to signify that genlock has been achieved. Counter/Timer U30 is used

to distinguish between even and odd fields of video.

Genlock sub-clock cycle timing can be adjusted up to 90

d

with S7. The VITS

signals are timed to program video input at the factory and should not need

adjustment.

S8 is a diagnostics switch; see the Maintenance section for details.

4–4

VITS100 NTSC VITS Inserter Instruction Manual

Page 65

Theory of Operation

Signal and Switching

Control

The circuitry that controls signal switching appears on three of the schematic

diagrams in the Diagrams section of this manual. Key circuitry is located on

diagrams 1 (Test Signal Memory), 2 (Test Signal Select), and 5 (Program Input,

Sync Stripper, VIRS Detection, & Genlock A/D Input).

Diagram 2. Signal selection is accomplished with four dual in-line package (DIP)

switches, S1, S2, S3, and S4. The lines from the switches are multiplexed by

U18, U19, U20, and U21

to select the appropriate switch segments at the correct time (S1 segments 1

through 4 during line 17 odd fields, for example).

The multiplexing is controlled by two bits from the Vertical Decoder and the

field signal from the Vertical Counters on diagram 3. Two PALs, U16 and U17,

located on diagram 1, decode control signals and latch the signal selections. U16

latches the bits to the test signal PROMs, and decodes when the source ID signal

is requested. Signals “vdrive” and “vsync” force the generation of vertical sync.

Diagram 5. U17, on diagram 1, decodes when Auto VIRS has been requested. It

enables the circuitry that compares program video to the VIRS test signal to

determine if VIRS is present on program video. U46 is an operational amplifier

that subtracts low-pass filtered program video from filtered test signals and

drives U47A and U47B, a window comparator.

Source ID Generation

If the program signal and the test signal match closely enough, the comparator

output remains high and the output of an OR gate, U48A, remains high; a one

shot, U71B, is not triggered. The OR gate can only trigger the one shot when

U17, on diagram 1, determines that Auto VIRS has been requested and drives

“virsamp

and “ccvirs” from U17 is sent to U14 to control insertion.

Diagram 1. U17 also decodes “dvdrive” and “dvsync” which are delayed from

“vdrive” and “vsync” by a half line and therefore are timed with the actual test

signals that are generated.

U14 takes the information from U16 and U17, “chswt” (the insertion timing

signal), and other timing signals; it then determines two control signals for the

program channel switch, “sw0” and “sw1,” and one signal to choose between

source ID generation and test signal generation, “ts/char

The circuitry that controls source ID generation appears on two of the schematic

diagrams in the Diagrams section of this manual. Key circuitry is located on

diagrams 1 (Test Signal Memory) and 3 (H & V Counters, Source Identification

& Bypass Controls).

” low. The signal “virpres” from U71B returns to U17, on diagram 1,

.”

VITS100 NTSC VITS Inserter Instruction Manual

4–5

Page 66

Theory of Operation

Diagram 1. U12 and U15 form a state machine to generate the data for shaped

pulse edges. When U15 sees a low-to-high transition, it counts up to six and

stops. When U15 sees a high-to-low transition it counts back to zero and stops.

This count goes to U12, where it is decoded into the data used to produce rising

and falling shaped edges out of the DAC, U65 on schematic 6.

When source ID pulses are called for, the outputs of the Test Signal Data Latch,

U1, become high impedances, and the outputs of U12 are enabled.

The source identification signal is one line of video with up to sixteen pulses on

it that can be recognized by a Tektronix VM 700A Video Measurement Set. The

VM 700A expects a start and a stop bit, but the other 14 bits (pulses) can be used

to identify up to 16,384 sources.

Diagram 3. The 16 bits can be set or cleared by two sets of DIP switches, S5 and

S6, accessible through the rear panel of the instrument. The 16 bits are loaded

into two shift registers, U22 and U23, once every line by a signal decoded from

the Horizontal Counters. The bits are then shifted out by “idclock,” a clock that

is decoded from the Horizontal Counters.

Remote Control

Power Supply

Diagram 1. The serialized ID bits go to U15 where they are gated with

“idclock” and latched by the 8

clock. If Source ID is chosen for a certain

FSC

line, U16 activates “iden,” which causes the state machine in U15 to be

controlled by the latched ID signal.

The circuitry that controls signal switching appears on one of the schematic

diagrams located in the Diagrams section of this manual. Key circuitry is located

on diagram 3 (H & V Counters, Source Identification & Bypass Controls).

Diagram 3. REMOTE, through J27, is limited to a ground closure bypass control

signal and three indicator lines: “power,” “unlocked,” and “bypass.” U70, a PAL,

gates the remote bypass line, “rembypass,” with the “locked” line from the

genlock circuitry to control the bypass relay.

The power supply circuitry appears on two of the schematic diagrams in the

Diagrams section of this manual. Key circuitry is located on diagram 8 (Power

Supply) and diagram 9 (Regulator & Decoupling Caps).

Diagram 8. The line current passes through line filter LF1, fuse F1, and power

switch S10, and is applied to full-wave bridge rectifier CR12. Two of the diodes

within CR12 conduct on each half cycle of the AC input, causing charge to build

up on C110. The voltage on C110 will vary anywhere from 120 VDC at low-line

(90 VAC) to 350 VDC at high-line, (250 VAC). R157 discharges C110 when

power is turned off.

4–6

VITS100 NTSC VITS Inserter Instruction Manual

Page 67

Theory of Operation

RT1is a thermistor that limits inrush current on power-up. RV1 is metal-oxidevaristor that clips any high voltage spikes on the AC line before they get to the

switching circuits. DS4 is part of a relaxation oscillator that blinks when the