Page 1

Service Manual

TR 210 Huntron Tracker

071-0113-00

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

Page 2

Copyright T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Huntron and Tracker are registered trademarks of Huntron, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of shipment. If a product proves defective during this warranty period, T ektronix,

at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Page 5

Table of Contents

Specifications

Operating Basics

General Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Manuals ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting T ektronix ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Specifications 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Specifications 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Specifications 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Certifications and Compliances 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Configuration 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oscilloscope Connection 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front-Panel Controls and Connectors 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational Check Procedure 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theory of Operation

Front Panel Module 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Board Module 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Filter Module 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Panel Module 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification

Equipment Required 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Section 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal Section 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pulse Generator Section 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedures

Equipment Required 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedure 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TR 210 Service Manual

i

Page 6

Table of Contents

Maintenance

Maintenance 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Cleaning 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation Procedures 6–5. . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Fuse 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal Fuse 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Knobs 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T op Cover 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Filter 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Panel Assembly 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Assembly 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Potentiometers and Elastomer 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Board 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options Replaceable Electrical Parts Diagrams Replaceable Mechanical Parts

ii

TR 210 Service Manual

Page 7

List of Figures

Table of Contents

Figure 2–1: TR 210 rear panel 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–2: Connecting the TR 210 Huntron Tracker to an

oscilloscope 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–3: Front panel 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–4: Typical open-circuit signature 2–5. . . . . . . . . . . . . . . . . . . . . .

Figure 2–5: Typical short-circuit signature 2–5. . . . . . . . . . . . . . . . . . . . . .

Figure 3–1: TR 210 block diagram 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–1: Pulse types 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–1: TR 210 adjustment locations and test points 5–3. . . . . . . . . .

Figure 6–1: Accessing the line fuse and spare fuse (159-0414-00) 6–6. . . .

Figure 6–2: Signal fuse (159-0312-00) 6–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–3: Retainer clips 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–4: Line filter 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–1: TR 210 replaceable parts and accessories 10–1. . . . . . . . . . .

TR 210 Service Manual

iii

Page 8

Table of Contents

List of Tables

Table 1–1: Electrical specifications 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–2: Mechanical specifications 1–2. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–3: Environmental specifications 1–2. . . . . . . . . . . . . . . . . . . . . . .

Table 1–4: Certifications and compliances 1–3. . . . . . . . . . . . . . . . . . . . . .

Table 2–1: Front-panel controls and connectors 2–3. . . . . . . . . . . . . . . . .

Table 4–1: Test equipment, fixtures, and supplies 4–1. . . . . . . . . . . . . . . .

Table 5–1: Test equipment, fixtures, and supplies 5–1. . . . . . . . . . . . . . . .

Table 6–1: Internal inspection check list 6–3. . . . . . . . . . . . . . . . . . . . . . .

Table 6–2: Tools required for module removal 6–5. . . . . . . . . . . . . . . . . .

Table 7–1: Power cord identification 7–1. . . . . . . . . . . . . . . . . . . . . . . . . .

iv

TR 210 Service Manual

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Use Proper V oltage Setting. Before applying power, ensure that the line selector is

in the proper position for the power source being used.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

The common terminal is at ground potential. Do not connect the common

terminal to elevated voltages.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Symbols and Terms

TR 210 Service Manual

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

v

Page 10

General Safety Summary

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

WARNING

High Voltage

Protective Ground

(Earth) T erminal

CAUTION

Refer to Manual

Double

Insulated

vi

TR 210 Service Manual

Page 11

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the mains power by means

of the power cord or the power switch.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

TR 210 Service Manual

vii

Page 12

Service Safety Summary

viii

TR 210 Service Manual

Page 13

Preface

Related Manuals

Contacting Tektronix

This manual provides information to troubleshoot and repair the TR 210 Huntron

Tracker to the module level.

Additional documentation for the instrument is contained in the TR 210 Huntron

Tracker User Manual (part number 071-0114-XX).

Product

Support

Service

Support

For other

information

To write us Tektronix, Inc.

For application-oriented questions about a Tektronix measurement product, call toll free in North America:

1-800-TEK-WIDE (1-800-835-9433 ext. 2400)

6:00 a.m. – 5:00 p.m. Pacific time

Or contact us by e-mail:

tm_app_supp@tek.com

For product support outside of North America, contact your

local Tektronix distributor or sales office.

Contact your local Tektronix distributor or sales office. Or visit

our web site for a listing of worldwide service locations.

http://www.tek.com

In North America:

1-800-TEK-WIDE (1-800-835-9433)

An operator will direct your call.

P.O. Box 1000

Wilsonville, OR 97070-1000

TR 210 Service Manual

ix

Page 14

Preface

x

TR 210 Service Manual

Page 15

Page 16

Specifications

This chapter contains the specifications for the TR 210 Huntron Tracker. All

specifications are guaranteed unless noted as “typical.” Typical specifications are

provided for your convenience but are not guaranteed.

Electrical Specifications

Table 1–1 lists the electrical specifications for the TR 210 Huntron Tracker.

T able 1–1: Electrical specifications

Test Signal

Signal Type Sine wave

Ranges

Open Circuit Voltage (Vs), typical Source Resistance (Rs), typical

HIGH

MED 2

MED 1

LOW 2

LOW 1

Frequency 50/60 Hz (switch selectable), 200 Hz, or 2 kHz

Channels 2

Display Modes A, B, or ALT

Signal Fuse (overload protection) 5 mm x 20 mm, F250 mA, 250 V, (IEC127–2/II, type GDB), user replaceable

Overvoltage Category CA T I

Pulse Generator

Outputs 2

Level Range, typical 0 V to ± 5 V

DC Mode ± DC level

Pulse Mode ± or composite

Frequency Matches selected test signal frequency

Width (pulse mode), typical 2% to 50% duty cycle

Source Resistance, typical 100 (each output)

Short Circuit Current 50 mA maximum (each output)

60 V

20 V

15 V

10 V

3 V

pk

pk

pk

pk

pk

74 k

27.6 k

1.24 k

54

10 k

TR 210 Service Manual

1–1

Page 17

Specifications

T able 1–1: Electrical specifications (Cont.)

Power Requirements

Line Voltage 100/1 15 VAC or 230 VAC, selector switch on rear panel

Frequency 50 Hz to 60 Hz

Power 15 W maximum

Line Fuse 100/1 15 V: 5 mm x 20 mm, T125 mA, 250 V,(IEC127-2/III, type GDC), user replaceable

230 V: 5 mm x 20 mm, T125 mA, 250 V,(IEC127-2/III, type GDC), user replaceable

Mechanical Specifications

Table 1–2 lists the mechanical specifications for the TR 210 Huntron Tracker.

T able 1–2: Mechanical specifications

Dimensions (W x H x D) 11.5 in x 2.7 in x 10.2 in (29.1 cm x 6.9 cm x 25.9 cm)

Weight 4.6 lbs. (2.1 kg)

Shipping Weight Approximately 7 lbs. (3 kg)

Environmental Specifications

Table 1–3 lists the environmental specifications for the TR 210 Huntron Tracker.

T able 1–3: Environmental specifications

Application Indoor use

Altitude < 2000 m (< 6560 ft)

Operating Temperature 0 °C to +40 °C (32 °F to 104 °F)

Storage Temperature –50 °C to +60 °C (–58 °F to 140 °F)

Relative Humidity < 80% up to 31 °C, derated linearly to 50% at 40 °C

1–2

TR 210 Service Manual

Page 18

Certifications and Compliances

Table 1–4 lists the certifications and compliances for the TR 210 Huntron

Tracker.

T able 1–4: Certifications and compliances

Characteristic Description

Specifications

EC Declaration of Conformity –

EMC

EC Declaration of Conformity –

Low Voltage

Approvals UL3111-1 – Standard for electrical measuring and test equipment

Installation Category Descriptions Terminals on this product may have different installation category designations. The installation

Pollution Degree 2

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility. Compliance was

demonstrated to the following specifications as listed in the Official Journal of the European

Communities:

EN 50081-1 Emissions:

EN 55011 Class B Radiated and Conducted Emissions

EN 50082-1 Immunity:

IEC 1000-4-2 Electrostatic Discharge Immunity

IEC 1000-4-3 RF Electromagnetic Field Immunity

IEC 1000-4-4 Electrical Fast Transient/Burst Immunity

IEC 1000-4-5 Power Line Surge Immunity

Compliance was demonstrated to the following specification as listed in the Official Journal of the

European Communities:

Low Voltage Directive 73/23/EEC, as amended by 93/68/EEC

EN 61010-1:1993 Safety requirements for electrical equipment for measurement,

control, and laboratory use

CAN/CSA C22.2 No. 1010.1 – Safety requirements for electrical equipment for measurement,

control and laboratory use

categories are:

CA T III Distribution-level mains (usually permanently connected). Equipment at this level is

typically in a fixed industrial location

CA T II Local-level mains (wall sockets). Equipment at this level includes appliances, portable

tools, and similar products. Equipment is usually cord-connected

CA T I Secondary (signal level) or battery operated circuits of electronic equipment

TR 210 Service Manual

1–3

Page 19

Specifications

1–4

TR 210 Service Manual

Page 20

Page 21

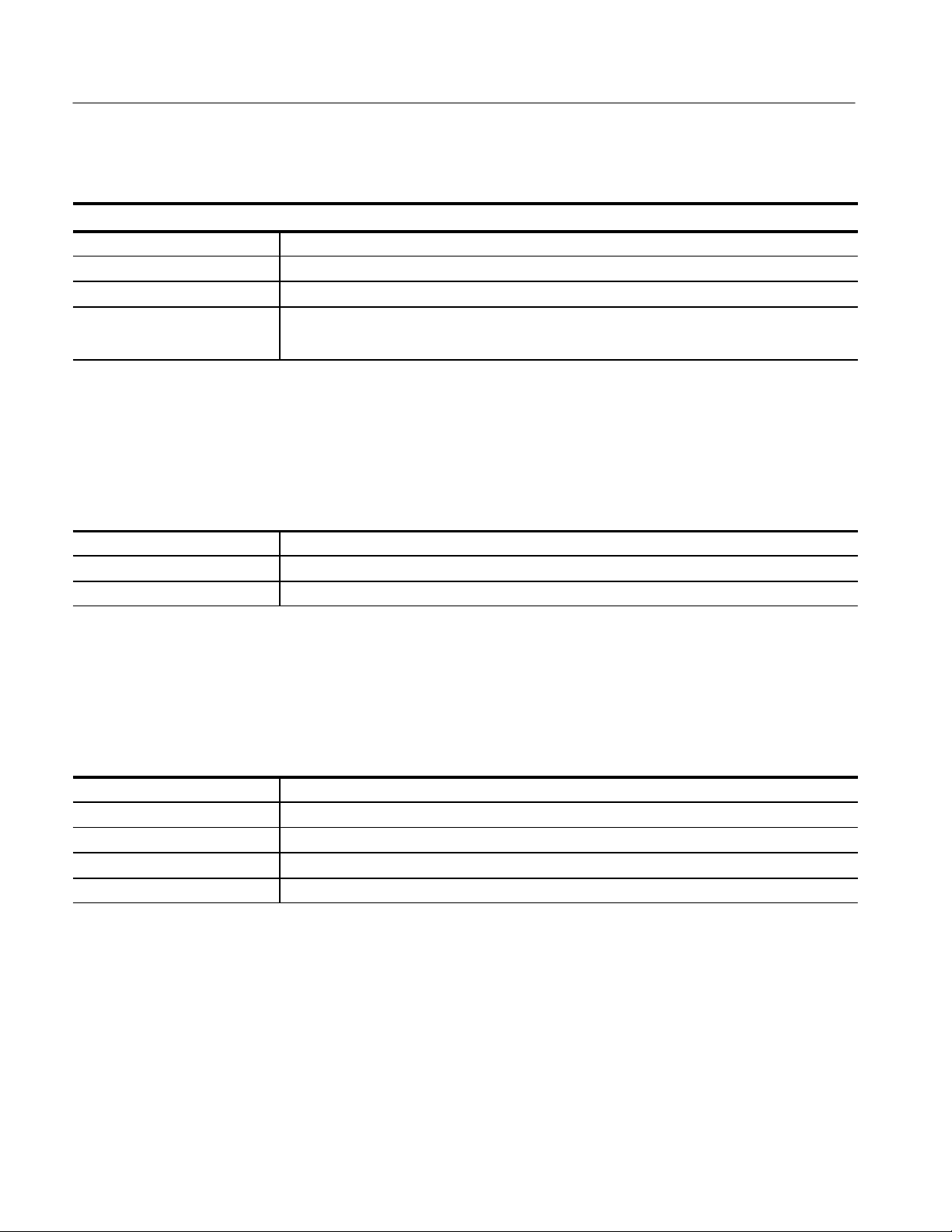

Installation

Power Configuration

This section describes how to configure the TR 210 Huntron Tracker and connect

it to an oscilloscope.

For the following discussion, refer to Figure 2–1 for the location of the rear

panel features.

CAUTION. To avoid product damage, set the line selector switch to the correct

position and install the correct fuse before applying line power.

Line Selector Switch

Line Fuse

50/60 Hz Selector Switch

Line fuse

Set the line selector switch to the correct position for 100/115 V

operation.

The power entry module has a removeable tray that contains the line fuse and a

spare fuse. Install the correct line fuse according to the specification on

page 1–2. To replace the fuse, see Figure 6–1 on page 6–6.

Set the 50/60 Hz selector switch, located on the rear panel, to the setting that

matches your line frequency.

To oscilloscope X and Y inputs

or 230 V

AC

AC

Power switch Line voltage

Figure 2–1: TR 210 rear panel

TR 210 Service Manual

Line frequency

2–1

Page 22

Installation

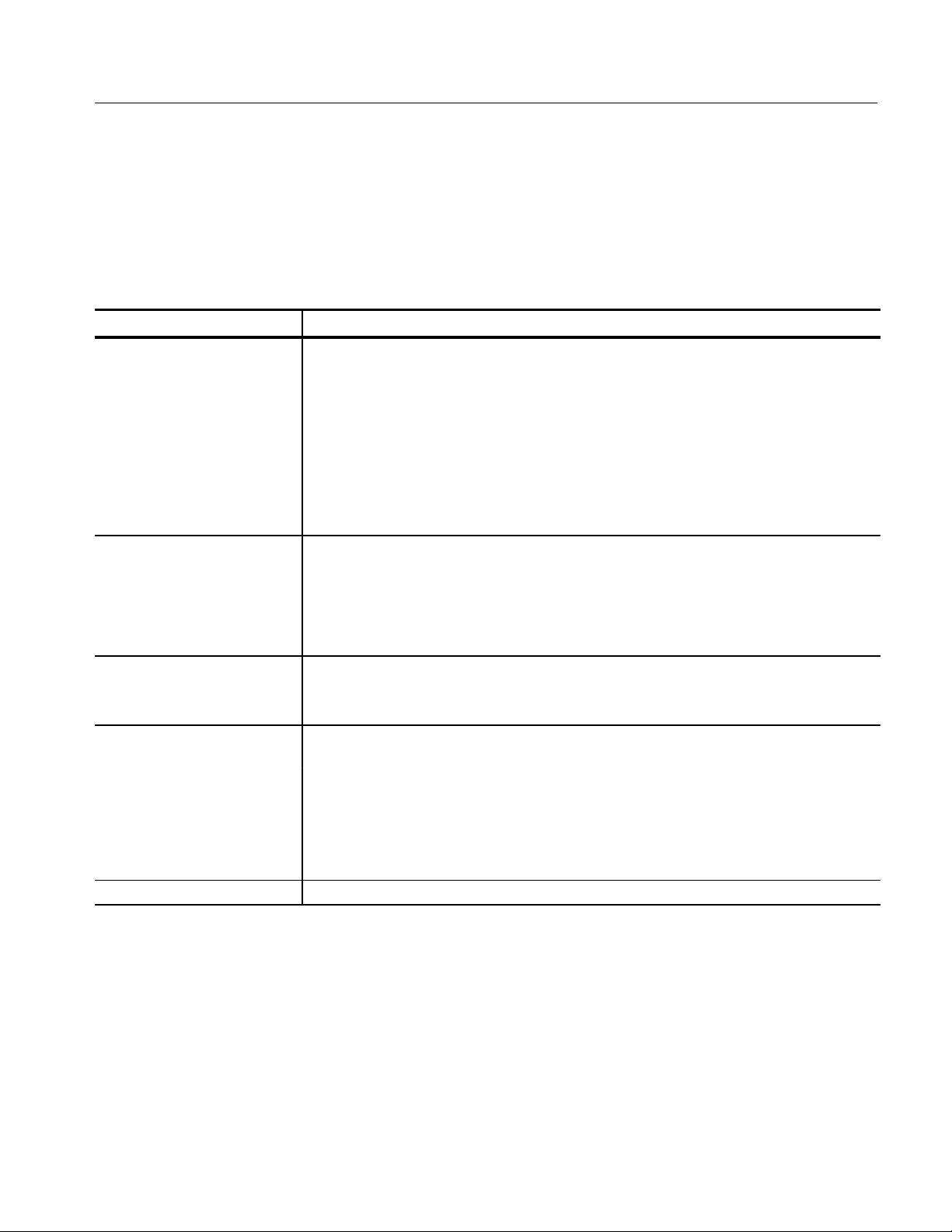

Oscilloscope Connection

The TR 210 Huntron Tracker works with an analog or digital oscilloscope to

display component signatures. The oscilloscope must be capable of displaying an

untriggered XY waveform that is generated by the TR 210 Huntron Tracker.

Connect the TR 210 Huntron Tracker to the oscilloscope as shown in Figure 2–2.

Figure 2–2: Connecting the TR 210 Huntron Tracker to an oscilloscope

Test oscilloscope

TR 210 (rear)

(Y)

(X)

When operating the TR 210 Huntron Tracker, set the oscilloscope to the

following settings:

1. Set the channel 1 and channel 2 vertical scale to 1 V/div.

2. Set the channel 1 and channel 2 vertical positions to center screen.

3. Set the time base to 5 ms/div.

4. Set the trigger source to channel 1.

5. Turn on XY display mode.

2–2

TR 210 Service Manual

Page 23

Operation

This section briefly describes the TR 210 operation. For more information, refer

to the TR 210 User Manual.

Front-Panel Controls and Connectors

Figure 2–3 identifies the front-panel controls and connectors that are described in

Table 2–1.

12 3

Figure 2–3: Front panel

5 67 89104

16

T able 2–1: Front-panel controls and connectors

Name Function

1 Channel A test terminal Safety shrouded banana jack for the channel A test

signal.

2 G1 terminal Pulse generator output for channel A (electrically

connected to G2 terminal).

1112131415

TR 210 Service Manual

3 RATE control Controls the speed of channel alternation or range

scanning.

4 Channel A button Selects channel A for display on the oscilloscope.

5 SCAN button Initiates automatic scanning of the five ranges from

LOW 1 to HIGH. The RATE control determines the

scanning speed.

6 Range selector buttons Select one of the five ranges: LOW 1, LOW 2, MED 1,

MED 2, or HIGH.

2–3

Page 24

Operation

T able 2–1: Front-panel controls and connectors (Cont.)

FunctionName

7 NO HIGH button Prevents entering the HIGH range either manually or

during scanning.

8 LEVEL control Sets the pulse generator output amplitude.

9 G2 terminal Pulse generator output for channel B (electrically

connected to G1 terminal).

10 Channel B terminal Safety shrouded banana jack for the channel B test

signal.

11 COM terminal Safety shrouded banana jack that is the instrument

common.

12 WIDTH terminal Controls the pulse generator duty cycle.

13 Pulse generator buttons Select the output modes for the pulse generator: + pulse,

– pulse, composite + and – pulse, or DC level. The

PULSE/DC button lights steadily when the pulse

generator output is DC. The PULSE/DC button flashes

when the pulse generator output is a pulse.

14 Frequency buttons Select the test signal frequency: 50/60 Hz (depends on

15 AL T button Causes channel A and channel B to alternate in the

16 Channel B button Selects channel B for display on the oscilloscope.

Operational Check Procedure

The following procedure verifies that the TR 210 and the oscilloscope are set up

and connected correctly.

1. Connect the TR 210 and oscilloscope together and set up the oscilloscope as

described in Oscilloscope Connection on page 2–2. Power on both instruments.

2. Verify that a horizontal line is displayed on the oscilloscope screen similar to

that shown in Figure 2–4. This is the open-circuit signature.

3. Fine tune the oscilloscope vertical position controls to center the signature

waveform. The channel 1 vertical position control affects the horizontal

position of the signature. The channel 2 vertical position control affects the

vertical position of the signature.

rear-panel switch setting), 200 Hz, or 2 kHz.

oscilloscope display.

2–4

TR 210 Service Manual

Page 25

Figure 2–4: Typical open-circuit signature

Operation

4. On the TR 210, short the channel A test terminal to the COM test terminal.

5. Verify that a vertical line is now displayed on the oscilloscope screen similar

to that shown in Figure 2–5. This is the short-circuit signature.

Figure 2–5: Typical short-circuit signature

TR 210 Service Manual

This completes the operational check procedure.

2–5

Page 26

Operation

2–6

TR 210 Service Manual

Page 27

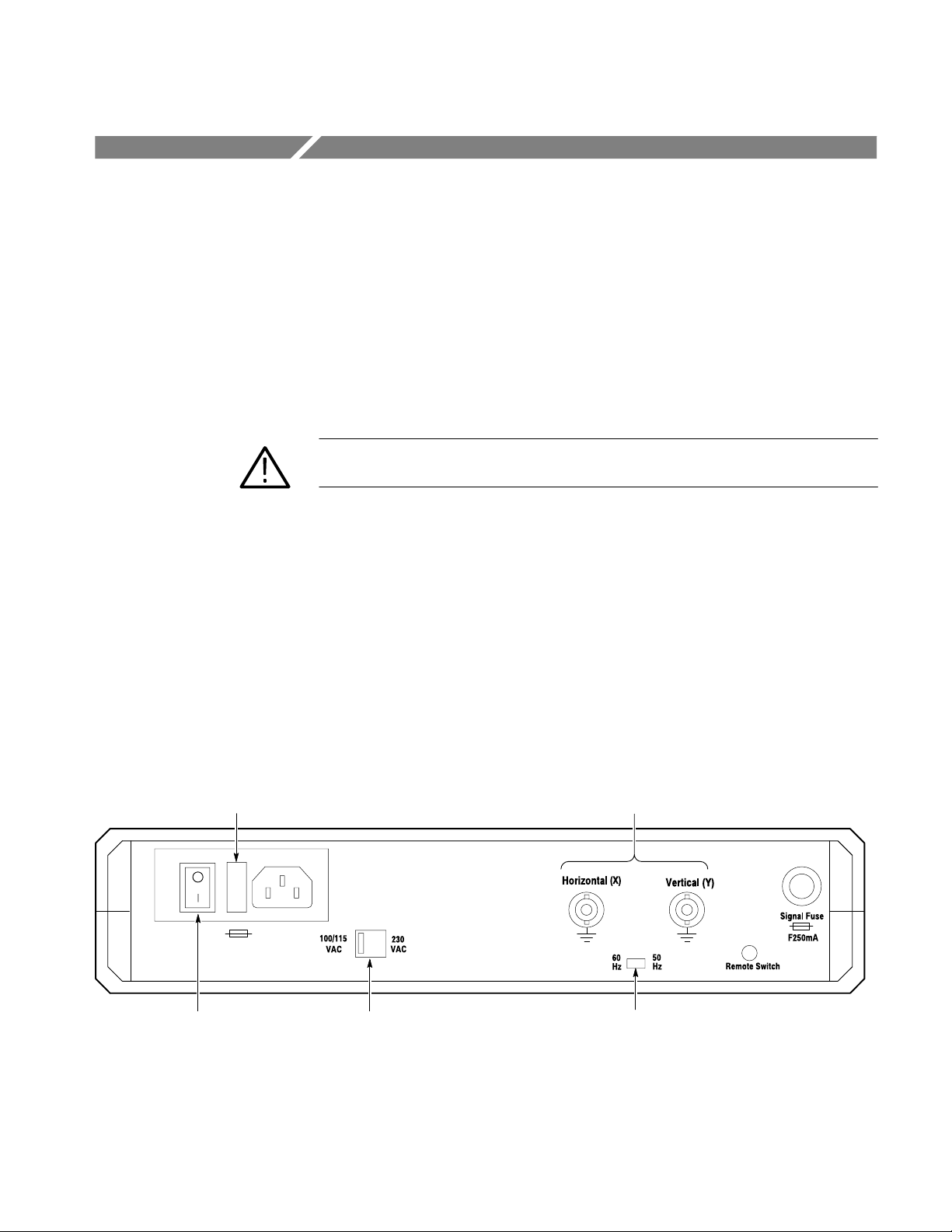

Page 28

Theory of Operation

Figure 3–1 shows a block diagram of the TR 210 Huntron Tracker and replaceable modules.

Front Panel Module Main Board Module

Front panel

controls

G1

G2

Front panel

connectors

A

COM

B

COM

Control logic

Pulse generator

Oscillator

Test signal

Figure 3–1: TR 210 block diagram

+ 15 V

Power supply

– 15 V

Rear Panel

Module

Line Filter Module

Horizontal (X)

Vertical (Y)

To external

oscilloscope

in XY mode

Front Panel Module

Main Board Module

TR 210 Service Manual

The front panel module contains all the probe connections and front panel

controls for the TR 210 Huntron Tracker. Wiring harnesses connect the front

panel controls to the main board.

Control logic circuitry reads the front panel switches and generates the test signal

for Analog Signature Analysis (ASA). An oscillator circuit generates the signal

that alternates the A and B test signals and produces the pulse signals.

To display the signature, the TR 210 Huntron Tracker outputs voltage (V) and

current (I) signals to the horizontal (X) and vertical (Y) inputs of an oscilloscope.

3–1

Page 29

Theory of Operation

Line Filter Module

Rear Panel Module

A line selector switch changes the winding ratio of power transformer. The

power supply circuitry rectifies and filters the transformer output to + and

– 15 VDC.

The line filter module contains the AC input socket, power switch, and line fuse.

The line filter connects to the main board with a 3-wide socket.

The rear panel module contains the rear panel X and Y BNC connectors, signal

fuse, and line filter module.

3–2

TR 210 Service Manual

Page 30

Page 31

Performance Verification

The performance verification procedures in this section verify the basic operation

of the TR 210 Huntron Tracker. Because all specifications are either typical or

guaranteed nominal, no measurement tolerances are given.

Equipment Required

The equipment listed in Table 4–1 is required to verify the performance of the

the TR 210 Huntron Tracker.

T able 4–1: Test equipment, fixtures, and supplies

Item number and description Minimum requirements Example Purpose

1. Multimeter with test leads AC volts, AC current, 50 Hz to

2 kHz frequency

2. One (1) pair shrouded red

and black banana leads

(male-to-male)

3. Oscilloscope with X/Y

display mode

4. Two (2) coaxial cables BNC male-to-male Tektronix part number

5. BNC male to dual binding

post adapter

6. BNC female to dual male

banana

7. Banana plug patch cord As per description Tektronix part number

As per description Tektronix ATL21 Connect DMM to tracker test

As per description and purpose Tektronix TDS 210 Display tracker signals

As per description Tektronix part number

As per description Tektronix part number

Tektronix DMM 916 Measure tracker output voltage,

012-0057-01

103-0035-00

103-0090-00

012-0031-00 or 012-0039-00

frequency, and current

terminals and short tracker test

terminals

Connect tracker signals to

oscilloscope inputs

Adapt female BNC to banana

patch cord

Adapt male BNC to dual

banana connections

Patch connection

TR 210 Service Manual

4–1

Page 32

Performance Verification

Preparation

Prepare the TR 210 Huntron Tracker for the verification as follows:

1. Make sure the line frequency and line voltage switches on the back panel are

set correctly.

2. Plug the TR 210 Huntron Tracker in and turn the power on.

The control indicators of the tracker under test should power up in the following

states:

Control name Indicator status

CHANNEL A On (Channel B and ALT are of f)

LOW 2 On (all other ranges off)

50/60 (Hz) On (all other frequencies off)

PULSE DC On (+ and – off)

Logic Section

3. Turn the RATE control to midrange.

4. Turn the LEVEL and WIDTH controls fully counterclockwise.

1. Check the frequency selection buttons.

a. Press the 200 Hz, 2000 Hz and 50/60 Hz button in that order.

b. Check that each corresponding LED lights when the button is pressed

and that it stays on until another frequency button is pressed.

2. Check the ALT mode.

a. Press the ALT button. Check that the ALT LED lights and the Channel A

and Channel B LEDs alternate.

b. Verify that the alternation rate increases with clockwise rotation of the

RATE control and decreases with counterclockwise rotation of the RATE

control. Return the RATE control to midrange.

c. Press the Channel A button. The ALT LED should go off and the

Channel A LED should stay on.

4–2

d. Press the ALT button again and then press the Channel B button to make

sure it also cancels the ALT function.

TR 210 Service Manual

Page 33

Performance Verification

3. Check the SCAN mode.

a. Press the SCAN button. The SCAN LED should light and the tracker

should scan through the ranges as follows: LOW1, LOW2, MED1,

MED2, HIGH, back to LOW1 and repeat.

b. Verify that the scanning rate increases with clockwise rotation of the

RATE control and decreases with counterclockwise rotation of the RATE

control. Return the RATE control to midrange.

c. Press the LOW1 button. This should cancel the SCAN function and set

the tracker to the LOW1 range.

d. Repeat this procedure for the other 4 ranges (i.e. select SCAN, then

select a range).

4. Check the HIGH lock features

a. Press the HIGH range button. The HIGH range LED should be on.

b. Press the HIGH lock button. The HIGH lock LED should be on and the

HIGH range LED should go off. The MED2 range LED should turn on.

c. Press the SCAN button. The tracker should scan through all the ranges

except the HIGH range.

d. Press the LOW1 button to cancel scanning.

e. Press the HIGH lock button to remove the lock.

5. Check the combined operation of ALT and SCAN.

a. Press the SCAN button. Press the ALT button. The ALT LED should be

on and the Channel A and Channel B LEDs should alternate on and off.

The SCAN LED should be on and all the test ranges should be scanned.

Ranges should change on the B to A transition of the channels.

b. Verify that the scanning and alternation rates increase with clockwise

rotation of the RATE control and decreases with counterclockwise

rotation of the RATE control. Return the RATE control to midrange.

6. Check the PULSE GENERATOR buttons.

a. The PULSE/DC LED should be on.

b. Press the + (positive) button several times. The + LED should toggle

between on an off each time the button is pressed.

c. With the + LED off, repeat the above procedure using the – (negative)

button. The LED should toggle on and off each time the button is

pressed.

TR 210 Service Manual

4–3

Page 34

Performance Verification

Signal Section

d. Turn + on and – off. The PULSE/DC LED should be on and not flashing

which indicates DC mode.

e. Press the PULSE/DC button once. The PULSE/DC LED should flash on

and off to indicate Pulse mode.

f. Press the + and – button so that both the + and – LEDs are on and the

PULSE/DC LED is flashing. Press the PULSE/DC button once so that

the LED is continuously on. The – LED should go off (all three LEDs

cannot be continuously on).

g. Press the + button several times. With each press, the + LED should go

off and the –LED should come on, or visa versa.

Verify the signal voltages on the Channel A and Channel B test terminals and the

X/Y outputs.

Test Terminals

1. Make sure that the HIGH lock LED is off.

2. Select Channel A, HIGH range, and 50/60 Hz.

3. Connect the DMM between the Channel A and COM test terminals with the

red and black banana leads (items 1 and 2 on page 4–1).

4. Measure the RMS sine wave voltage for each range listed below:

DMM range Tracker range selector Measured voltage (typical)

200 VAC HIGH 42.1 VAC

20 VAC MED2 14.1 VAC

20 VAC MED1 10.6 VAC

20 VAC LOW2 7.1 V AC

20 VAC LOW1 2.1 V AC

RMS

RMS

RMS

RMS

RMS

5. Select Channel B and HIGH range.

6. Connect the DMM between the Channel B and COM test terminals. Repeat

the measurements for each range listed.

4–4

7. Remove the connections.

TR 210 Service Manual

Page 35

X/Y Output Signals

Performance Verification

1. Connect the tracker under test to an oscilloscope (item 3) using two BNC

cables (item 4):

a. The Horizontal (X) output connects to the Channel 1 (X) input on the

oscilloscope.

b. The Vertical (Y) output connects to the Channel 2 (Y) input on the

oscilloscope.

2. With Channel B selected, select the HIGH range and 2000 Hz range on the

tracker under test.

3. Make the following oscilloscope settings:

Mode Setting

Time base 100 ms

Channel 1 and 2 1 V/div

Trigger source Channel 1

XY mode On

X and Y position Adjust open circuit trace to center graticule

NOTE. If a horizontal and a diagonal trace is displayed, turn channel 1 off to

eliminate the diagonal trace.

4. Press each test range selector in turn (MED2, MED1, ...). The total

horizontal trace length should be about 8 divisions for opens in any test

range. Select Channel A and repeat the test.

5. With Channel A selected, short the A to COM terminals with a banana lead

(item 2). The total vertical trace length should be about 6 divisions for shorts

in any test range.

6. Remove the short from the A to COM terminals, short the B to COM

terminals, select channel B and repeat the test.

7. Remove the short from the B to COM terminals.

TR 210 Service Manual

4–5

Page 36

Performance Verification

X/Y Output Voltages

1. Connect the Horizontal (X) output to the DMM voltage input with a coax

cable and female BNC to banana adapter (items 4 and 6).

2. Measure the following voltages for each tracker range listed (Channel B):

Measured voltage (X)

DMM range Tracker range (open circuit)

20 VAC HIGH 2.8 V AC

20 VAC MED2 2.8 VAC

20 VAC MED1 2.8 VAC

20 VAC LOW2 2.8 V AC

20 VAC LOW1 2.8 V AC

(typical)

RMS

RMS

RMS

RMS

RMS

3. Select Channel A and repeat the test.

Test Terminal Frequency

4. Connect the Vertical (Y) output to the DMM voltage input with a coax cable

and female BNC to banana adapter (items 4 and 6).

5. Short the Channel A to COM terminals with a banana lead and measure the

following voltages for each tracker range listed:

Measured voltage (Y)

DMM range Tracker range (short circuit)

20 VAC HIGH 2.1 V AC

20 VAC MED2 2.1 VAC

20 VAC MED1 2.1 VAC

20 VAC LOW2 2.1 V AC

20 VAC LOW1 2.1 V AC

(typical)

RMS

RMS

RMS

RMS

RMS

6. Select Channel B, short the Channel B to COM terminals, and repeat the

test.

7. Disconnect the banana lead, coax, and BNC adapter.

4–6

Check the frequency of the test terminal signal.

1. Set the 60/50 Hz switch on the back of the tracker to 60 Hz.

TR 210 Service Manual

Page 37

Performance Verification

2. Select the frequency mode on the DMM and select the 20 VAC range.

3. Select Channel A, LOW2, and 2000 Hz on the tracker.

4. Connect the A and COM terminals of the tracker under test to the frequency

(voltage) inputs of the DMM with the banana leads (item 2).

5. On the front panel of the tracker, select the test signal frequencies listed

below and measure the corresponding frequencies.

Test Terminal Current

DMM range

(frequency mode)

20 VAC 2000 Hz 2000 Hz

20 VAC 200 Hz 200 Hz

20 VAC 50/60 Hz 60 Hz

Selected test signal

frequency

Measured test signal

frequency (typical)

6. Set the 60/50 Hz switch on the back of the tracker to 50 Hz.

7. Verify that the frequency on the output measures 50 Hz nominal.

8. Move the 60/50 Hz switch back to the line frequency.

Measure the RMS value of the test terminal short circuit current in each range.

1. Connect Channel A and COM inputs of the tracker under test to the DMM

200 mA current and common inputs with the banana leads (item 2).

2. Set the DMM to read mA-AC.

3. Verify the following RMS current readings:

TR 210 Service Manual

DMM range

(current mode)

20 mA HIGH 0.57 mA

20 mA MED2 0.53 mA

20 mA MED1 8.2 mA

200 mA LOW2 132 mA

20 mA LOW1 0.21 mA

Tracker range

Measured current

(typical)

4–7

Page 38

Performance Verification

Pulse Generator Section

1. Setup the Oscilloscope for measuring the positive and negative DC levels

(X/Y off).

a. Connect Channel A of the tracker to Channel 1 of the oscilloscope with

the coax cable and BNC female to dual banana adapter (items 4 and 6).

b. Connect G1 (PULSE GENERATOR terminal) of tracker to Channel 2 of

the oscilloscope with a banana patch cord and a male BNC to banana

adapter (items 7 and 5). Connect the patch cord to the red side of the

adapter.

c. Setup the equipment controls as follows:

Tracker control Setting

50/60 Hz On

Channel A On

LOW2 button On

Oscilloscope control Setting

Trigger source Channel 1

Channel 1 5 V/div

Channel 2 2 V/div

Time base 10 ms/div

2. Measure the + DC levels of G1.

a. Press the PULSE/DC button so that it is on continuously.

b. Press the + button so that it is on. Rotate the LEVEL knob clockwise to

its maximum position.

c. Verify that the DC voltage level is approximately 5 volts on Channel 2

of the oscilloscope.

d. Rotate the LEVEL knob counterclockwise and verify that the DC

voltage drops to near zero.

3. Verify that G1 stays at zero.

4–8

a. Press the + and – buttons so that both + and – LEDs are off. Verify that

the voltage level is near zero for this condition.

b. Rotate the LEVEL knob in both directions. The voltage level on

Channel 2 of the oscilloscope should remain near zero.

TR 210 Service Manual

Page 39

Performance Verification

c. Press the PULSE/DC button once so that the PULSE/DC LED is

flashing. The + and – LEDs should still be off.

d. Rotate the LEVEL knob in both directions and verify that the voltage

level remains near zero.

4. Check the width control of G1.

a. Press the + and – buttons. Both + and – LEDs should be on and the

PULSE/DC LED should be flashing.

b. Rotate the LEVEL control knob all the way clockwise.

c. Set the tracker to 50/60 Hz and the oscilloscope time base to 5 ms/div.

d. Vary the Width control and change the + and – settings to display the

waveforms for each of the three pulse types shown in Figure 4–1 on

page 4–10.

e. The rising edge of a positive pulse should always coincide with each

positive going zero-crossing of the sine wave test signal.

f. The falling edge of a negative pulse should always start at each

negative-going zero-crossing of the test signal.

g. Repeat this step for 200 and 2000 Hz. A slight slope in the rising and

falling edges of the pulses is acceptable for 2000 Hz. Set the oscilloscope time base as follows for each frequency range:

Tracker frequency range Oscilloscope time base setting

50/60 Hz 5 ms/div

200 Hz 1 ms/div

2000 Hz 250 ms/div

TR 210 Service Manual

4–9

Page 40

Performance Verification

Pulse

width

settings

Test signal 0

Positive 0

Negative 0

Composite 0

Figure 4–1: Pulse types

(min) (max)

4–10

TR 210 Service Manual

Page 41

Page 42

Adjustment Procedures

This section contains information needed to adjust the TR 210 Huntron Tracker.

NOTE. This procedure is for trained service technicians only

Equipment Required

The equipment listed in Table 5–1 is required to adjust the TR 210 Huntron

Tracker.

T able 5–1: Test equipment, fixtures, and supplies

Item number and description Minimum requirements Example Purpose

1. Multimeter with test leads AC/DC volts Tektronix DMM 916 Measure tracker voltages

2. One (1) pair shrouded red

and black banana leads

(male-to-male)

3. Oscilloscope with X/Y

display mode

4. Two (2) coaxial cables BNC male-to-male Tektronix part number

5. Insulated adjustment tool As per description Electrical adjustments

As per description Tektronix ATL21 Connect DMM to tracker test

terminals

As per description and purpose Tektronix TDS 210 Display tracker signals

Connect tracker signals to

012-0057-01

oscilloscope inputs

Preparation

TR 210 Service Manual

Prepare the TR 210 Huntron Tracker for adjustment as follows:

1. Make sure the line frequency and line voltage switches on the back panel are

set correctly.

2. Refer to the procedure on page 6–7 and remove the top cover.

3. Plug the TR 210 Huntron Tracker in and turn the power on.

5–1

Page 43

Adjustment Procedures

The control indicators of the tracker under test should power up in the following

states:

Control name Indicator status

CHANNEL A On (Channel B and ALT are of f)

LOW 2 On (all other ranges off)

50/60 (Hz) On (all other frequencies off)

PULSE DC On (+ and – off)

4. Turn the RATE control to midrange.

5. Turn the LEVEL and WIDTH controls fully counterclockwise.

5–2

TR 210 Service Manual

Page 44

Adjustment Procedure

Adjustment Procedures

The illustration in Figure 5–1 shows the adjustment locations for the TR 210

Huntron Tracker.

Cathode, D9

Anode, D7

R106

TP1

C123

Figure 5–1: TR 210 adjustment locations and test points

1. Using a DMM (item 1), verify the following voltages with respect to

TP1 (com):

a. Cathode of D9 is between +12 VDC and +18 VDC.

b. Anode of D7 is between –12 VDC and –18 VDC.

2. Make sure that the HIGH lock LED is off.

3. Connect the Channel A and COM test terminals to the voltage inputs of the

DMM with banana leads (items 1 and 2 on page 5–1). Measure the sine

wave voltage.

TR 210 Service Manual

4. Adjust R106 so that the RMS voltage reads between 7.070 and 7.072 V

RMS

.

5–3

Page 45

Adjustment Procedures

5. Connect the tracker under test to an oscilloscope (item 3) using the 2 BNC

cables (item 4):

a. The Horizontal (X) output connects to the Channel 1 (X) input on the

oscilloscope.

b. The Vertical (Y) output connects to the Channel 2 (Y) input on the

oscilloscope.

6. Select the HIGH range and 2000 Hz settings.

7. Make the following oscilloscope settings:

Mode Setting

Time base 100 ms/div

Channel 1 and 2 1 V/div

Trigger source Channel 1

XY mode On

X and Y position Adjust open circuit trace to center graticule

NOTE. If a horizontal and a diagonal trace is displayed, turn channel 1 off to

eliminate the diagonal trace.

8. Adjust the trim cap C123 to eliminate any split trace.

NOTE. Some split trace is normal in all other ranges at 2000 Hz.

5–4

TR 210 Service Manual

Page 46

Page 47

Maintenance

Preparation

This section contains the information needed to do periodic and corrective

maintenance on the TR 210 Huntron Tracker.

Before servicing this product, read the Safety Summary and Introduction at the

front of the manual and the ESD information below.

CAUTION. Static discharge can damage any semiconductor component in this

instrument.

When performing any service which requires internal access to the instrument,

adhere to the following precautions to avoid damaging internal modules and their

components due to electrostatic discharge (ESD).

1. Minimize handling of static-sensitive modules.

2. Transport and store static-sensitive modules in their static protected

containers or on a metal rail. Label any package that contains static-sensitive

modules.

3. Discharge the static voltage from your body by wearing a grounded antistatic

wrist strap while handling these modules. Do service of static-sensitive

modules only at a static-free work station.

4. Nothing capable of generating or holding a static charge should be allowed

on the work station surface.

5. Handle circuit boards by the edges when possible.

6. Do not slide the modules over any surface.

7. Avoid handling modules in areas that have a floor or work-surface covering

capable of generating a static charge.

TR 210 Service Manual

6–1

Page 48

Maintenance

Inspection and Cleaning

How often to do maintenance depends on the severity of the environment in

which the instrument is used. A proper time to perform preventive maintenance

is just before instrument adjustment.

Exterior

Internal

Inspect the outside of the instrument for damage, wear, and missing parts.

Instruments that appear to have been dropped or otherwise abused should be

checked thoroughly to verify correct operation and performance. Immediately

repair defects that could cause personal injury or lead to further damage to the

instrument.

To clean the instrument exterior, do the following steps:

1. Remove loose dust on the outside of the instrument with a lint free cloth.

2. Remove remaining dirt with a lint free cloth dampened in a general purpose

detergent-and-water solution. Do not use abrasive cleaners.

CAUTION. To prevent getting moisture inside the instrument during external

cleaning, use only enough liquid to dampen the cloth or applicator.

To access the inside of the instrument for inspection and repair, refer to the

Removal and Installation Procedures in this section.

No periodic cleaning of internal components is necessary. Cleaning of internal

components should only be necessary after repair. There is no periodic lubrication required for this instrument.

6–2

CAUTION. Avoid the use of chemical cleaning agents which might damage the

plastics used in this instrument. For interior components, use a 75% isopropyl

alcohol solution as a cleaner and rinse with deionized water. Before using any

other type of cleaner, consult your Tektronix Service Center or representative.

Inspect the internal portions of the instrument for damage using Table 6–1 as a

guide. Defects found should be repaired immediately.

TR 210 Service Manual

Page 49

T able 6–1: Internal inspection check list

Item Inspect For Repair Action

Circuit boards Loose, broken, or corroded solder

connections. Burned circuit

boards. Burned, broken, or

cracked circuit-run plating.

Remove failed module and

replace with a fresh module.

Maintenance

Resistors Burned, cracked, broken, blis-

tered condition.

Solder connections Cold solder or rosin joints. Resolder joint and clean with

Capacitors Damaged or leaking cases.

Corroded solder on leads or

terminals.

Wiring and cables Loose plugs or connectors.

Burned, broken, or frayed wiring.

Chassis Dents, deformations, and dam-

aged hardware.

Remove failed module and

replace with a fresh module.

isopropyl alcohol.

Remove damaged module and

replace with a fresh module from

the factory.

Firmly seat connectors. Repair or

replace modules with defective

wires or cables.

Straighten, repair, or replace

defective hardware.

TR 210 Service Manual

6–3

Page 50

Maintenance

6–4

TR 210 Service Manual

Page 51

Removal and Installation Procedures

This section contains procedures for removal and installation of all replaceable

mechanical and electrical parts. For an exploded view and list of these parts, refer

to the Mechanical Parts List on page 10–1.

WARNING. Before doing this or any other procedure in this manual, read the

Safety Summary found at the beginning of this manual. Also, to prevent possible

injury to service personnel or damage to this instrument’s components, read

Installation in Section 2, and Preventing ESD in this section.

Before doing any procedure in this subsection, disconnect the power cord from

the line voltage source. Failure to do so could cause serious injury or death.

Unless indicated otherwise, perform installation in reverse order of removal.

Equipment Required

Refer to Table 6–2 for a list of all equipment required to perform the procedures.

T able 6–2: Tools required for module removal

Item No. Name Description

1 # 1 Phillips screwdriver Standard tool

2 # 1 Pozidrive screwdriver Standard tool

3 Small, flat-blade

screwdriver

4 Angle-Tip Tweezers Standard tool

5 Soldering Iron Standard tool

6 Pliers Standard tool

7 11/32 hex wrench Standard tool

Standard tool

TR 210 Service Manual

6–5

Page 52

Removal and Installation Procedures

Line Fuse

1. Insert a small flat-blade screwdriver into the notch just inside the power cord

2. To access the spare fuse, push out the fuse drawer located inside the fuse

3. Replace the fuse in the fuse holder and snap the fuse holder back into the

socket of the line filter. Use the notch to pull the fuse holder straight out to

remove the fuse.

holder.

lined filter.

Line fuse and spare fuse holder

Line fuse

Spare fuse

Signal Fuse

Release notch

Line filter

Figure 6–1: Accessing the line fuse and spare fuse (159-0414-00)

1. Unscrew the fuse holder located on the right rear panel.

2. Remove and replace the signal fuse from the fuse clip. Use a fuse that has the

same size and rating. The rating for the fuse is listed on the rear panel below

the fuse holder.

6–6

Figure 6–2: Signal fuse (159-0312-00)

TR 210 Service Manual

Page 53

Front Panel Knobs

Top Cover

Removal and Installation Procedures

1. Set the instrument bottom down on the work surface and face the front to

you.

2. Grasp any knob you want to remove and pull it straight out from the front

panel. If the knob is difficult to remove, insert a pair of angle-tip tweezers

between the knob and front panel and carefully pry the knob forward off the

shaft.

3. To reinstall, align the knob to the shaft and push it on.

1. Lay the instrument upside down on the top cover.

2. Use a small flat-blade screwdriver to unsnap the four retainer clips on the

bottom cover that have the rubber feet. See Figure 6–3.

Pry with small screwdriver to unsnap

Retainer clip

Figure 6–3: Retainer clips

3. Use a #1 Phillips screwdriver to unscrew the four cabinet screws.

4. Turn the instrument over and lay it on the bottom cover.

5. Separate the top cover from the front and rear panel assemblies and lift it off

the instrument.

6. To replace the cover, turn the cover so that the tongue and groove features in

the sides of the top cover align with those in the bottom cover and that both

sides fit snugly together. Tighten the screws and reinstall the bottom cover

clips.

TR 210 Service Manual

6–7

Page 54

Removal and Installation Procedures

Line Filter

1. Remove the top cover.

2. Disconnect the wiring harness of the line fuse from the connector receptacle

3. Disconnect the ground wire from the stud on the back chassis using a

4. Use a small flat-blade screwdriver to press in the spring clips on the sides of

on the main board.

inch hex wrench.

the line filter as you pull the line filter out.

Spring clips

11

/

32

Rear Panel Assembly

Line filter

Figure 6–4: Line filter

1. Remove the top cover.

2. Disconnect the rear panel wiring harnesses and from the main circuit board.

3. Disconnect the ground wire on the main board from the stud on the back

11

chassis using a

/32 inch hex wrench.

4. Unscrew the main circuit board from the bottom cover with a #1 Pozidrive

screwdriver.

5. To protect the line frequency switch and remote control socket, keep the rear

of the main board and the rear panel assembly together lifting the back of the

main board only far enough to remove the rear panel assembly.

6–8

6. Remove and replace the rear panel assembly.

7. Reinstall the main circuit board and rear panel assembly in the bottom cover

and tighten the screws so they are just snug (about 2 inch/lbs). Do not

overtighten

TR 210 Service Manual

Page 55

Front Panel Assembly

1. Remove the top cover.

2. Disconnect the ribbon cable from the front panel circuit board.

3. Disconnect the 4-wire and 2-wire harnesses from the main board.

4. Use a #1 Pozidrive screwdriver to disconnect the ground wire from the front

panel assembly.

5. Remove the front panel assembly from the bottom cover.

Front Panel Potentiometers and Elastomer

1. Remove the top cover.

2. Remove the front panel knobs.

Removal and Installation Procedures

Main Board

3. Remove the front panel circuit board.

4. Remove the elastomer for the front panel push buttons.

5. Desolder the potentiometer(s) from the circuit board.

6. Using pliers, untwist the tabs that secure the potentiometer(s) to the circuit

board and remove the potentiometer(s).

1. Remove the top cover.

2. Disconnect the front and rear panel wiring from the main circuit board.

3. Remove the front panel assembly.

4. Unscrew the main circuit board from the bottom cover with a #1 Pozidrive

screwdriver.

5. To protect the line frequency switch and remote control socket, keep the rear

of the main board and the rear panel assembly together as you lift them out

of the bottom cover.

TR 210 Service Manual

6. Reinstall the main circuit board in the bottom cover and tighten the screws so

they are just snug (about 2 inch/lbs). Do not overtighten

6–9

Page 56

Removal and Installation Procedures

6–10

TR 210 Service Manual

Page 57

Page 58

Options

Table 7–1 shows the power cord options available with the TR 210 Huntron

Tracker at the time of purchase. Besides the power cord options, no other options

are available at the time of purchase.

T able 7–1: Power cord identification

Plug configuration Normal usage Option number

North America

125 V/15 A Plug

NEMA 5-15P

Europe

230 V

United Kingdom

230 V

Standard

A1

A2

TR 210 Service Manual

7–1

Page 59

Options

7–2

TR 210 Service Manual

Page 60

Page 61

Replaceable Electrical Parts

For a list of all replaceable parts, refer to the Mechanical Parts List on

page 10–1.

TR 210 Service Manual

8–1

Page 62

Replaceable Electrical Parts

8–2

TR 210 Service Manual

Page 63

Page 64

Diagrams

For an exploded view diagram of the TR 210 Huntron Tracker, refer to the

Mechanical Parts List on page 10–1.

TR 210 Service Manual

9–1

Page 65

Diagrams

9–2

TR 210 Service Manual

Page 66

Page 67

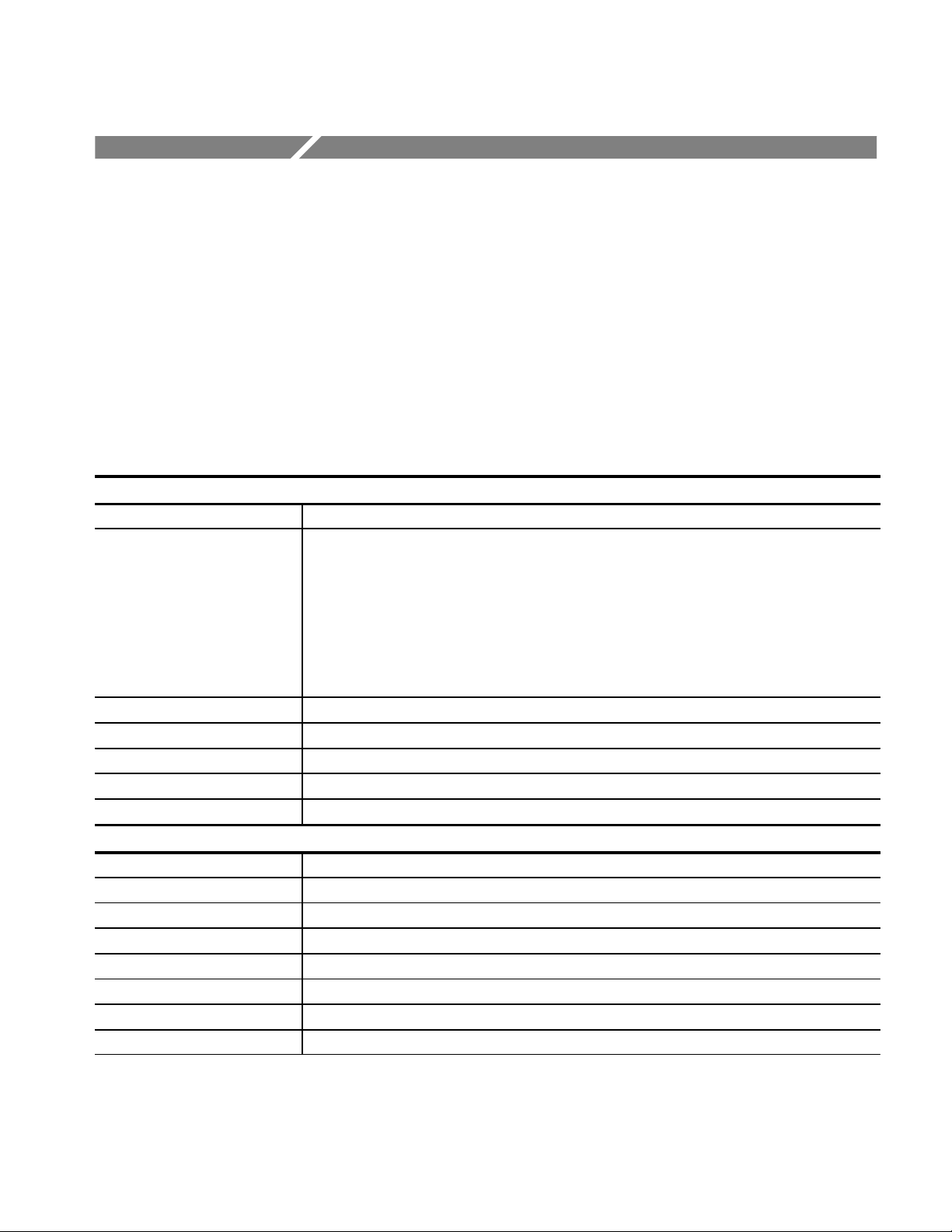

Replaceable Mechanical Parts

14

20

13

19

21

15

16

17

18

1

2

5

4

3

7

8

9

6

12

11

Figure 10–1: TR 210 replaceable parts and accessories

TR 210 Service Manual

10

1

10–1

Page 68

Replaceable Mechanical Parts

Replaceable parts list

Fig. &

index

number

10–1–1 390–1188–00 1 CABINET ASSY:PLASTIC,TOP & BOTTOM

–2 050–3319–00 1 PARTS REPL KIT:SERVICE

–3 650–3815–00 1 PANEL ASSY:REAR,INCLUDES,BNC’S W/WIRING,

–4 159–0312–00 1 FUSE,CARTRIDGE:METRIC,250MA,250V,FAST 57705 02–0022

–5 119–5867–00 1 FILTER,RFI:POWER MODULE 57705 06–2136

–6 159–0414–00 1 FUSE:250V,0.125 A RMS,FAST BLOW,PERIEC125, 57705 02–0023

–7 311–2555–00 1 RES,VAR:CONTROL POT,50K,0.5W,5/8 X 1/8 SHAFT 57705 02–1056

–8 311–2556–00 1 RES,VAR:LIN CONTROL POT,1M,0.5W,5/8 X 1/8

–9 671–4458–00 1 CIRCUIT BD ASSY:MAIN,HUNTRON PN 06–3106 57705 06–3106

–10 342–1040–00 1 INSULATOR:PCB,NOMEX,MAIN BD 57705 01–1242

–11 211–0963–00 12 SCREW:W/O WASHER,MAIN ECB 57705 07–3205

–12 174–3944–00 1 CABLE ASSY:FLAT,MAIN T O FRONT 57705 06–4142

–13 644–0922–00 1 PANEL ASSY:FRONT ,INPUT

–14 366–0801–00 3 KNOB:GREY,W/O INDEX,FRONT PANEL 57705 07–2142

–15 260–2707–00 1 SWITCH:ELASTOMERIC KEY P AD 57705 01–1243

–16 671–4457–00 1 CIRCUIT BD ASSY:PCA CONTROL 57705 06–3105

–17 211–0962–00 6 SCREW:ECB,PCA CNTL,4–40 X 1/4,PH PHI,

–18 311–2557–00 1 RES,VAR:CCW AUD CONTROL POT,1M

–19 ATL25 1 TRACKER PROBES: 1 EA RED AND BLACK 57705 ATL25

–20 –––––––––– 2 Black ground leads 57705 98–0043

–21 –––––––––– 2 Blue Clip Leads 57705 98–0036

Tektronix

part number

161–0230–01 1 CABLE ASSY,PWR:3,18 AWG,92 L,SVT,TAN,60 DEG

071–0113–00 1 MANUAL,TECH:SERVICE,TR210 80009 071–0113–00

071–0114–00 1 MANUAL,TECH:USER,ENGLISH,TR210 80009 071–0114–00

Serial no.

effective

Serial no.

discont’d

Qty Name & description Mfr. code Mfr. part number

CABINET,W/CLIPS & SCREWS

REPLACEMENT,BOTTOM & TOP PLASTIC CLIP

W/FOOT ,8 EA,CASE SCREWS 4 EA

CONNECTORS,FUSE HOLDER & CONNECT,AC

LINE FILTER

SHAFT

JACKS,WIRING&CONNECTORS,ELASTOMERIC

KEY PAD,PCB CONTROL BD W/POTS, CABLE ASSY

FLAT

(Includes Figures 13, 15 & 16)

W/WASHER

OHM,0.5W,5/8 X 1/8 SHAFT

C,MC–6–3C/G X RTANG BME,10A/125V,

57705 01–1241

57705 050–3319–00

57705 06–2135

57705 02–1057

57705 06–2134

57705 07–3050

57705 02–1058

2W733 ORDER BY

DESCRIPTION

10–2

TR 210 Service Manual

Page 69

Replaceable Mechanical Parts

Manufacturers cross index

Mfr.

code

2W733 BELDEN WIRE & CABLE COMPANY 2200 US HWY 27 SOUTH

57705 HUNTRON INC 15720 MILL CREEK BLVD MILL CREEK, WA 98012

80009 TEKTRONIX INC 14150 SW KARL BRAUN DR

TK2280 ESCORT INSTRUMENTS CORP NO. 6, ALLEY 6, LANE 45

Manufacturer Address City, state, zip code

PO BOX 1980

PO BOX 500

PAO–HSIN RD

RICHMOND, IN 47374

BEAVERT ON, OR 97077–0001

HSIN TIEN, TAIPEI, TAIWAN CN

TR 210 Service Manual

10–3

Page 70

Replaceable Mechanical Parts

10–4

TR 210 Service Manual

Page 71

Page 72

Loading...

Loading...