Page 1

User Manual

TR 210 Tracker

071-0114-01

Page 2

Copyright © T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., PO Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Huntron and Tracker are registered trademarks of Huntron, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and

workmanship for a period of one (1) year from the date of purchase from an authorized T ektronix distributor. If

any such product proves defective during this warranty period, T ektronix, at its option, either will repair the

defective product without charge for parts and labor, or will provide a replacement in exchange for the defective

product. Batteries are excluded from this warranty.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by T ektronix,

shipping charges prepaid, and with a copy of customer proof of purchase. Tektronix shall pay for the return of the

product to Customer if the shipment is to a location within the country in which the T ektronix service center is

located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any other charges for

products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than T ektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-T ektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE LISTED PRODUCTS IN

LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS

DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANT ABILITY OR FITNESS FOR A

P ARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE

PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR

BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF

WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF

SUCH DAMAGES.

Page 4

Contacting Tektronix

Product

Support

Service

Support

For other

information

To write us Tektronix, Inc.

For application-oriented questions about a Tektronix measurement product, call toll free in North America:

1-800-TEK-WIDE (1-800-835-9433 ext. 2400)

6:00 a.m. – 5:00 p.m. Pacific time

Or contact us by e-mail:

tm_app_supp@tek.com

For product support outside of North America, contact your

local Tektronix distributor or sales office.

Contact your local Tektronix distributor or sales office. Or visit

our web site for a listing of worldwide service locations.

http://www.tek.com

In North America:

1-800-TEK-WIDE (1-800-835-9433)

An operator will direct your call.

P.O. Box 500

Beaverton, OR 97077

Page 5

Contents

General Safety Summary................................................................................ v

Introduction and Specifications ..................................................................1-1

What is Signature Analysis?........................................................................... 1-2

Power Configuration ...................................................................................... 1-3

Signal Fuse Replacement................................................................................1-4

50/60Hz Selector Switch................................................................................ 1-4

Unpacking Your TR 210 ................................................................................ 1-4

Installation......................................................................................................1-5

Operating the TR 210..................................................................................... 1-6

Specifications ................................................................................................. 1-8

Accessories.....................................................................................................1-12

A Quick Tour................................................................................................ 2-1

Front Panel...................................................................................................... 2-2

Back Panel......................................................................................................2-4

Oscilloscope Display......................................................................................2-5

Initial Setups................................................................................................... 2-6

Power On........................................................................................................ 2-6

Range Selection.............................................................................................. 2-6

Frequency Selection ....................................................................................... 2-7

Channel Selection........................................................................................... 2-7

Pulse Generator .............................................................................................. 2-8

Using Your TR 210....................................................................................... 3-1

Basics of ASA - How it Works ...................................................................... 3-2

Horizontal Axis .............................................................................................. 3-3

Vertical Axis................................................................................................... 3-4

Basic Analog Signatures - Open and Short.................................................... 3-5

Four Basic Component Analog Signatures .................................................... 3-7

TR 210 User Manual i

Page 6

Contents

Testing Passive Components........................................................................4-1

Resistors..........................................................................................................4-1

Shorts and Opens, Resistor Faults..................................................................4-4

Review............................................................................................................4-4

Troubleshooting Applications ........................................................................4-5

Capacitors.......................................................................................................4-6

Capacitor Analog Signatures..........................................................................4-7

The Signatures of Different Capacitors in LOW2 Range...............................4-8

Understanding Capacitor Analog Signatures..................................................4-9

Capacitor Failures - Leakage..........................................................................4-10

Review............................................................................................................4-11

Applications....................................................................................................4-11

Inductors.........................................................................................................4-11

Inductor Analog Signatures............................................................................ 4-12

The Signatures of Different Inductors in LOW2 Range.................................4-13

Affect of Frequency F

on Inductor Signatures..............................................4-13

s

Understanding Inductive Signatures...............................................................4-14

Review............................................................................................................4-14

Applications....................................................................................................4-15

Electromechanical Switching Components....................................................4-16

Manually Operated Mechanical Switches......................................................4-16

Review............................................................................................................4-18

Electomechanical Relays................................................................................4-18

Relay Coil Test...............................................................................................4-18

Using the Pulse Generator to Test a 5V Reed Relay......................................4-19

Review............................................................................................................4-20

Testing Discrete Semiconductors................................................................5-1

Diodes.............................................................................................................5-1

Diode Analog Signatures................................................................................5-1

Affects of Frequency (F

) on the Diode Signature .........................................5-3

s

The Composite Diode Signature.....................................................................5-3

Diode Failures.................................................................................................5-4

Internal Resistance Flaw in a Diode...............................................................5-5

Internal Leakage Flaw in a Diode...................................................................5-6

Zener Diodes...................................................................................................5-6

Review............................................................................................................5-8

Applications....................................................................................................5-8

Transistors ......................................................................................................5-9

Bipolar Transistor Signatures.........................................................................5-9

Bipolar Transistor Base-Collector Signatures................................................5-10

Identifying Unknown Transistors...................................................................5-12

Darlington Bipolar Transistor Signatures.......................................................5-14

Using the Pulse Generator to Test Transistor Operation................................ 5-15

Analyzing the Active Characteristics of a Transistor..................................... 5-16

Review............................................................................................................5-17

Applications....................................................................................................5-18

Optical Switches.............................................................................................5-18

Phototransistors ..............................................................................................5-19

ii

TR 210 User Manual

Page 7

Contents

Optocoupler Dynamic Testing........................................................................5-20

Optocoupler Signatures.................................................................................. 5-20

SCRs and Triacs ............................................................................................. 5-22

Silicon Controlled Rectifiers (SCRs)............................................................. 5-22

Active Testing of an SCR............................................................................... 5-24

Triacs.............................................................................................................. 5-25

Active Testing of Triacs................................................................................. 5-26

Review............................................................................................................ 5-27

Applications.................................................................................................... 5-27

Testing Integrated Circuits.......................................................................... 6-1

Digital Integrated Circuits.............................................................................. 6-1

Integrated Circuit Failures..............................................................................6-1

Digital Integrated Circuit Signatures.............................................................. 6-2

Signatures of a Digital IC............................................................................... 6-3

Signatures for Different Logic Chip Families................................................6-4

Comparing Two TTL Families....................................................................... 6-4

CMOS Logic Family...................................................................................... 6-5

CMOS Components and Test Signal Frequency F

........................................ 6-7

s

Troubleshooting Digital Logic ICs................................................................. 6-8

Comparison Testing for Digital ICs............................................................... 6-9

Review............................................................................................................ 6-10

Applications.................................................................................................... 6-10

Analog Circuits............................................................................................... 6-11

Op Amps.........................................................................................................6-11

Op Amp Signatures ........................................................................................ 6-12

Troubleshooting Op Amp Circuits................................................................. 6-13

Linear Voltage Regulators.............................................................................. 6-14

Review............................................................................................................ 6-15

Applications.................................................................................................... 6-15

Low Voltage................................................................................................... 6-16

Review............................................................................................................ 6-18

Applications.................................................................................................... 6-18

TR 210 User Manual

iii

Page 8

Contents

iv

TR 210 User Manual

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or Personal

Injury

Use Proper Power Cord.

Use only the power cord specified for this product and

certified for the country of use.

Use Proper Voltage Setting.

Before applying power, ensure that the line selector is

in the proper position for the power source being used.

Connect and Disconnect Properly.

Do not connect or disconnect probes or test leads

while they are connected to a voltage source.

Ground the Product.

This product is grounded through the grounding conductor of

the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings.

To avoid fire or shock hazard, observe all ratings and

markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers.

Do not operate this product with covers or panels

removed.

Use Proper Fuse.

Avoid Exposed Circuitry.

Use only the fuse type and rating specified for this product.

Do not touch exposed connections and components when

power is present.

Do Not Operate With Suspected Failures.

If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

TR 210 User Manual v

Page 10

General Safety Summary

Symbols and Terms

Terms in this Manual

These terms may appear in this manual:

.

WARNING.

Warning statements identify conditions or practices that could result in

injury or loss of life.

CAUTION.

Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product.

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read

the marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product.

The following symbols may appear on the product:

vi TR 210 User Manual

Page 11

Introduction and Specifications

The Tektronix TR 210 is an accessory to an oscilloscope which allows power off

troubleshooting of electronic circuits by using the technique of Analog Signature

Analysis.

This signature shows the V/I characteristics of an electronic device which when

compared with a known good device, can assist in locating faulty components of

a circuit without applying power to the board under test. This technique of

troubleshooting simply involves the visual comparison of circuit signatures

which can assist in isolating circuit failures due to opens, shorts, device leakage,

ESD damage, power supply over-voltage and transients.

Figure 1-1. TR 210

TR 210 User Manual 1-1

Page 12

Introduction and Specifications

What is Analog Signature Analysis

Analog Signature Analysis or ASA is a unique, power-off troubleshooting

technique. It uses an alternating current (AC) sinewave stimulus to show the

current (I) vs. voltage (V) characteristic of an unpowered component on a CRT.

The IV characteristic is called an analog signature and each pin of a component

can have a unique signature. When components fail, their signatures change so

troubleshooting using ASA is simply a matter of finding the defective

component by analyzing its signature. You can compare signatures of suspect

components to signatures of known-good components.

Test current applied across a component is limited. When used carefully, this

technique is non-destructive and does not damage any components. ASA has

many advantages as a proven, fast, and effective troubleshooting technique.

You can:

Troubleshoot circuitry that cannot be powered up due to a shorted condition.

■

Troubleshoot in a qualitative mode, allowing you to see physical problems

■

with a suspect component.

Compare device characteristics with known types for better matching.

■

?

Eliminate risk of accidental shorting across other points during POWER ON

■

testing which could further damage the component or other components on

the board.

Minimize the risk of shock hazard since the ASA troubleshooting approach

■

requires no power applied to the circuitry.

Perform preventative maintenance by seeing flaws in components that could

■

possibly lead to untimely failures.

Look at replacement components before they are installed in circuitry to

■

reduce the risk of installing defective ones.

1-2 TR 210 User Manual

Page 13

Power Configuration

Introduction and Specifications

The Tektronix TR 210 graphically displays the analog signature when connected

to two terminals of a component for visual interpretation. ASA may be

universally applied to any type of passive component like a resistor, capacitor, or

inductor, or a solid state semiconductor component like a diode, transistor, SCR,

digital, analog, or mixed-signal IC. When troubleshooting a board, the resultant

signature is a composite of various component signatures at a particular node in

the circuitry. By understanding what different signatures mean, you can

determine which components are faulty.

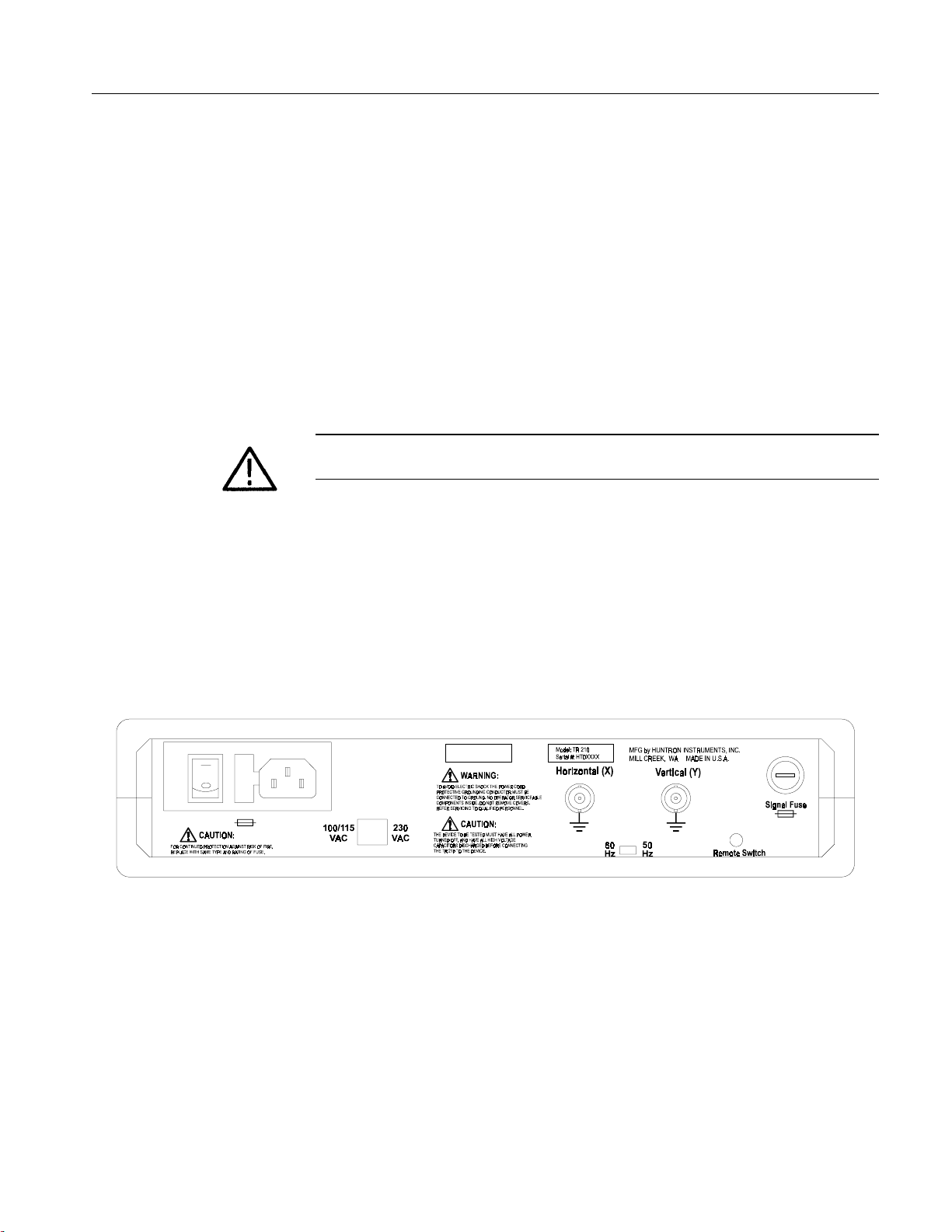

Line Selector Switch

Line Fuse

CAUTION.

position and install the correct fuse before applying line power.

The Line Selector Switch, located on the TR 210’s back panel, selects between

100/115VAC and 230VAC. Slide the switch to the line voltage that you will be

using.

The power entry module on the TR 210 includes the power switch (0 = OFF,

1 = ON), power cord connector, and a removable tray which holds the line fuse

and a spare fuse. Make sure that replacement fuses are of the type and current

rating specified. If necessary, insert the specified line fuse (see line fuse

specification on page 1-9) into the fuse tray.

To avoid product damage, set the line selector switch to the correct

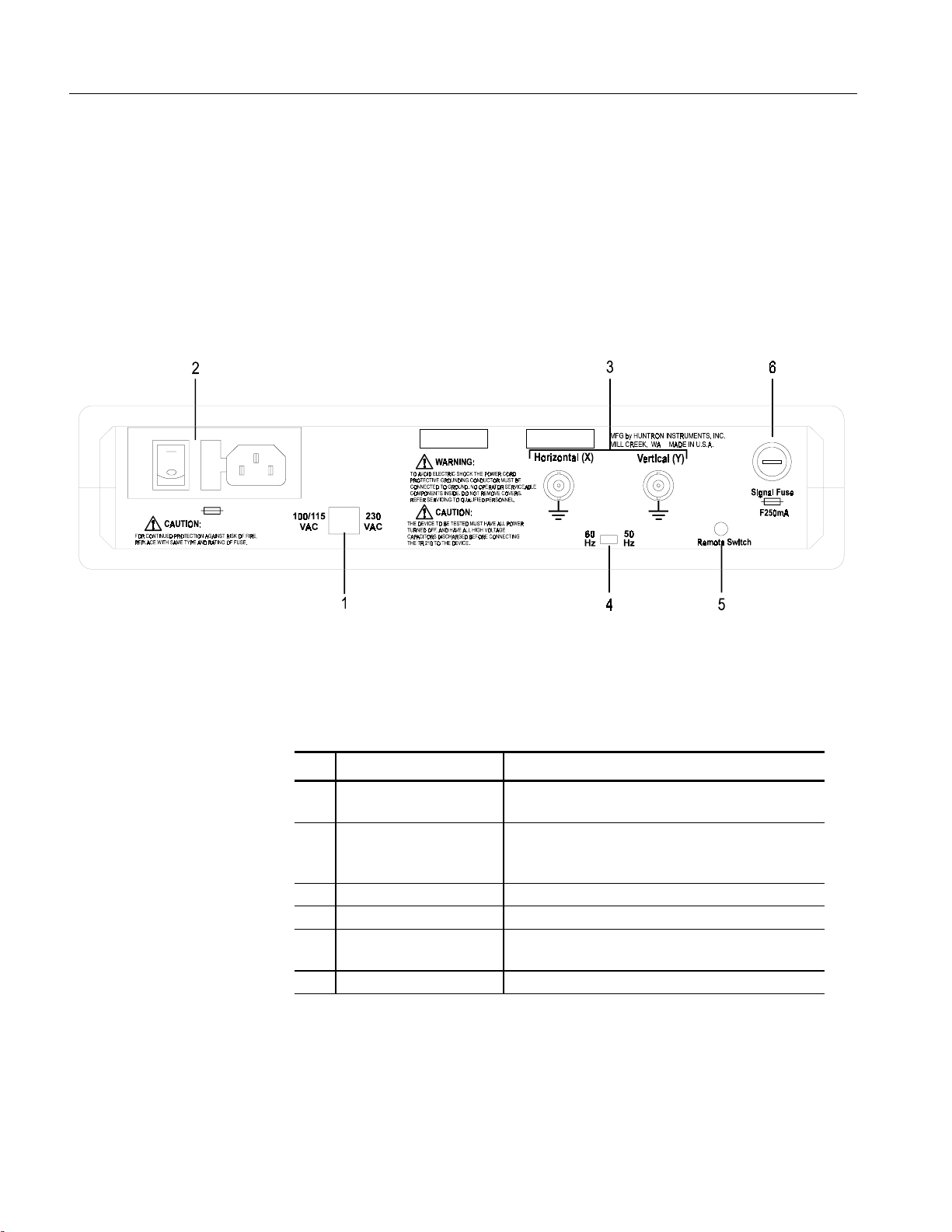

Figure 1-2. Back panel.

The line fuse should only open when there is a failure inside the instrument.

Therefore the problem should always be located and corrected before fuse

replacement. Be sure to always use a fuse with the type and rating specified on

page 1-9.

TR 210 User Manual 1-3

Page 14

Introduction and Specifications

Signal Fuse Replacement

The Signal fuse is located on the back panel of the TR 210 in a panel mounted

fuse holder. If the fuse opens, replace it with another 5 mm x 20 mm, F250 mA

250 V (IEC127-2/II type GDB) fuse.

50/60Hz Selector Switch

The 50/60Hz Selector Switch, located on the TR 210 back panel, is for

indicating to the TR 210 what your line frequency is. Slide the switch to the

setting that matches your line frequency.

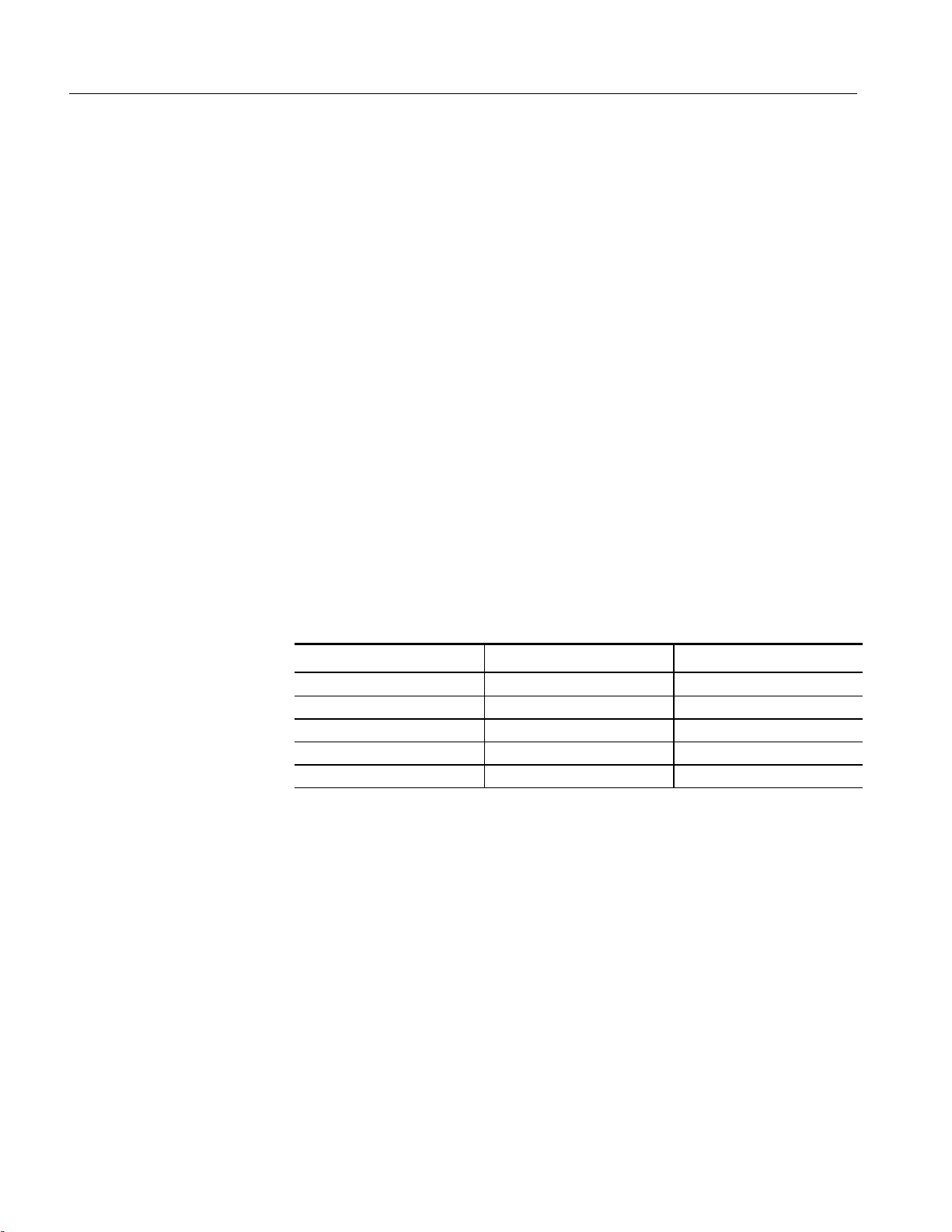

Unpacking Your TR 210

Your instrument was shipped with the following items:

Table 1-2. TR 210 Shipping and Replaceable Parts List

Part Number Description Quantity

ATL25 Tracker Probes 1 pair

98-0043* Black Ground Leads 2

98-0270* Blue Clip Leads 2

161-0230-01 Power Cord (115V)

071-0114-XX TR 210 User Manual

* Replacements available from Huntron, Inc. See page 1-12 for ordering information.

†

Options add international power cords and translated manuals.

†

†

1

1

Check the shipment carefully and contact the place of purchase if anything is

missing. If there is shipping damage, then contact your freight company. If

shipment is necessary, please use the original shipping carton and packing foam.

If these are not available, be sure that the instrument is packed in a box with a

minimum of two inches (5 cm) of cushioning material on all sides.

1-4 TR 210 User Manual

Page 15

Installation

Introduction and Specifications

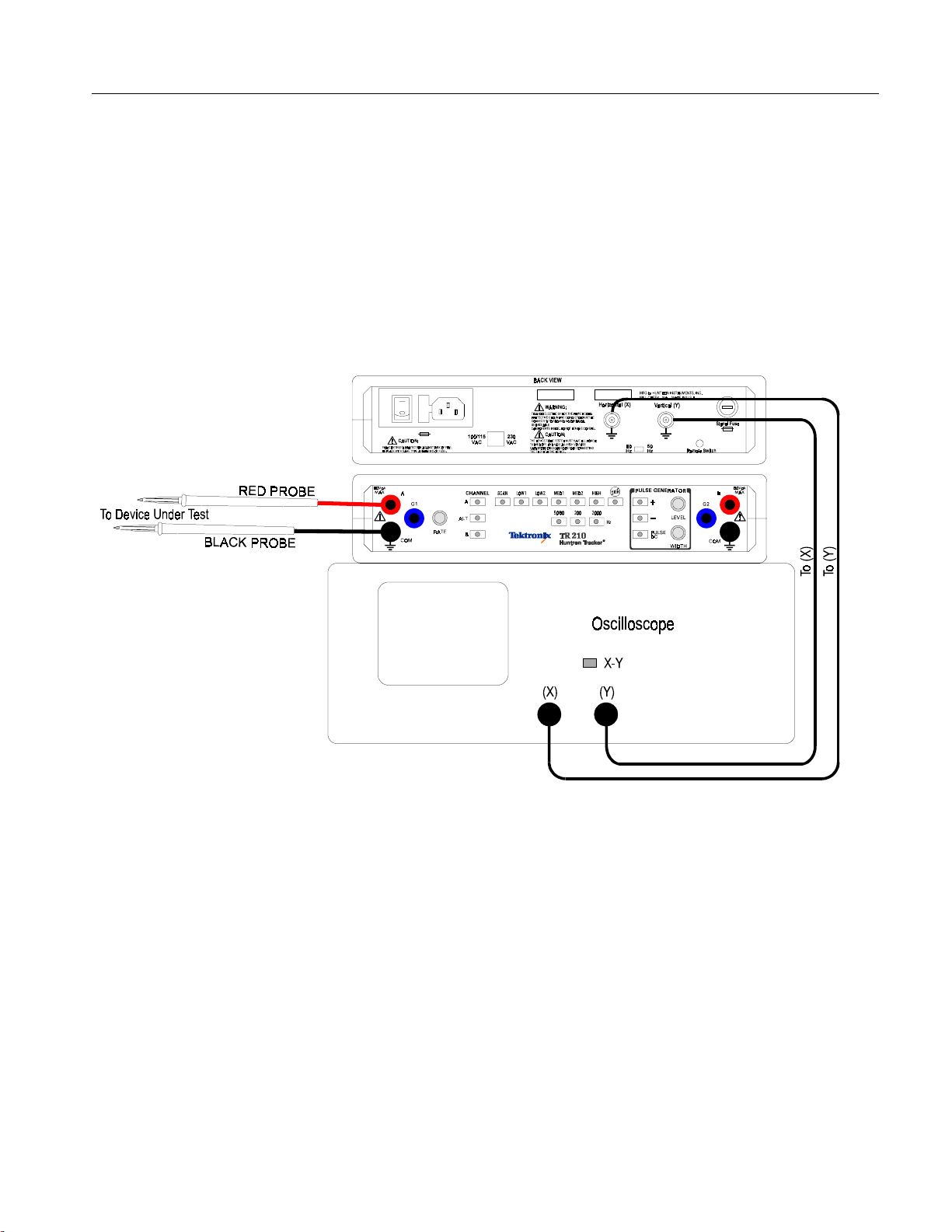

The TR 210 requires a 2 channel Oscilloscope with X/Y capability for

displaying the signature of the device under test.

The figure below shows a typical connection of a TR 210 to an

1.

oscilloscope.

Figure 1-3. Typical TR 210-to-Oscilloscope connection.

Using BNC cables, connect the first oscilloscope channel 1 or X to the

2.

Horizontal (X) channel of the TR 210. Connect the second oscilloscope

channel 2 or Y to the Vertical (Y) channel of the TR 210.

Connect the power cord to the TR 210 and switch the unit on.

3.

TR 210 User Manual 1-5

Page 16

Introduction and Specifications

Operating the TR 210

Setup the oscilloscope as follows:

4.

1 V/div vertical scale on each channel

5 ms/div time base

Trigger on channel 1

X/Y mode

The TR 210 will be in the LOW2 range. Adjust the Horizontal position so

that the open circuit trace which should be a horizontal line is at the

horizontal crosshair of the graticule. Connect the test probes to the front

panel A and COM terminals of the TR 210. Short the test terminals. A

vertical Trace will be displayed. Adjust the vertical position of the trace so

that it is at the vertical crosshair of the graticule.

You are now ready to use the TR 210.

5.

To select a test range, press one of the five range buttons.

1.

To select a test frequency, press one of the three frequency buttons. All test

2.

ranges will then be using the selected frequency.

To compare two devices, connect the test terminal of channel A to the

3.

reference or good device. Plug the banana jack of a second test probe to the

channel B test terminal. See Figure 1-4 for instructions on adjusting the

probe tips. Connect the test probe to the suspect device. Connect the

common lead to one of the COM terminals. Press the ALT button and set the

speed at which channel A and B will switch by turning the RATE knob. The

signature of Channel A will alternate with the signature of channel B for an

easy visual comparison of the two signatures.

1-6 TR 210 User Manual

Page 17

Figure 1-4. Adjusting the Probe Tips.

Introduction and Specifications

To avoid pressing each one of the test ranges, press the SCAN button. This

4.

will scan through all the test ranges one at a time.

The pulse generator is used to test gate fired devices like SCRs and Triacs.

5.

By connecting the G1 terminal to the gate of the device and applying the test

terminal across the anode and cathode of the device, it is possible to actually

turn the device on and look at the V/I characteristics of the device. This is

particularly useful for power supplies where you are unable to turn on

devices because the power supply is faulty on power up.

Refer to later chapters of this manual for details on testing resistors,

6.

capacitors, inductors, diodes, multiple component circuits, integrated

circuits, SCRs and optocouplers.

TR 210 User Manual 1-7

Page 18

Introduction and Specifications

Specifications

The specifications for the TR 210 are listed in Table 1-1.

Table 1-1. TR 210 Specifications

Electrical

Test Signal: Sine wave

Open Circuit Voltage (VS): 60 Vpk HIGH Range

20 Vpk MED 2 Range

15 Vpk MED 1 Range

10 Vpk LOW 2 Range

3 Vpk LOW 1 Range

Source Resistance (RS):

Frequency (FS): 50/60 Hz

Channels:

Number 2

Display modes A, B, Alt

Overload Protection Fuse: 5 mm x 20 mm, F250 mA, 250 V

Overvoltage Category CAT I

Pulse Generator:

Number of Outputs: 2

Level 0 V to +/- 5 V, open circuit

DC Mode +/- DC Level

Pulse Mode +/- or Composite

Frequency Matches selected test signal frequency

Width (pulse mode) 2% to 50% duty cycle

Source resistance

Short circuit current 50 mA max. each output

74 kΩ HIGH Range

27.6 kΩ MED 2 Range

1.24 kΩ MED 1 Range

54 Ω LOW 2 Range

10 kΩ LOW 1 Range

200 Hz

2000 Hz

(IEC 127-2/II, type GDB)

100 Ω each output

1-8 TR 210 User Manual

Page 19

Introduction and Specifications

Table 1-1. TR 210 Specifications (continued)

Electrical (continued):

Power Requirements:

Line Voltage 100/115 VAC or 230 VAC

Frequency 50 Hz to 60 Hz

Power 15 W maximum

Line Fuse 100/115 V: 5 mm x 20 mm, T160 mA, 250 V

(IEC127-2/III, type GDC)

230 V: 5 mm x 20 mm, T160 mA, 250 V

(IEC127-2/III, type GDC)

Mechanical

Dimensions 11.5” W x 2.7” H x 10.2” D

(29.1 cm W x 6.9 cm H x 25.9 cm D)

Weight 4.6 lbs (2.1 kg)

Shipping Weight approx. 7 lbs (3.0 kg)

Environmental

Indoor Use

Altitude <2000m (<6560')

Temperature

Operating 0°C to +40°C (32°F to 104°F)

Storage -50°C to +60°C (-58°F to 140°F)

Relative Humidity < 80% up to 31°C,

derated linearly to 50% at 40°C

TR 210 User Manual 1-9

Page 20

Introduction and Specifications

Table 1-1. TR 210 Specifications (continued)

Certifications and Compliances

EC Declaration of Conformity - EMC Directive Meets the intent of Directive 89/336/EC for

Electromagnetic Compatibility. Compliance

was demonstrated to the following

specifications as listed in the Official Journal of

the European Communities:

EN 50081-1 Emissions:

EN 55011 Class B Radiated and

Conducted Emissions

EN 50082-1 Immunity:

IEC1000-4-2Electrostatic Discharge

IEC1000-4-3RF Electromagnetic

Field

IEC1000-4-4Electrical Fast Transient/

Burst

IEC1000-4-5Power Line Surge

EC Declaration of Conformity - Low Voltage

Directive

Compliance was demonstrated to the following

specification as listed in the Official Journal of

the European Communities:

Low Voltage Directive 73/23/EEC, as

ammended by 93/68/EEC

EN 61010-1:1993

Safety requirements for electrical

equipment for measurement,

control, and laboratory use

1-10 TR 210 User Manual

Page 21

Introduction and Specifications

Table 1-1. TR 210 Specifications (continued)

Certifications and Compliances (continued)

Approvals UL3111-1 Standard for electrical measuring

and test equipment

CAN/CSA C22.2 No. 1010.1 Safety

requirements for electrical equipment for

measurement, control, and laboratory use

Installation Category Descriptions Terminals on this product may have different

category designations. The installation

categories are:

CAT III - Distribution-level mains (usually

permanently connected). Equipment at this

level is typically in a fixed industrial location.

CAT II - Local-level mains (wall sockets).

Equipment at this level includes appliances,

portable tools, and similar products. Equipment

is usually cord connected.

CAT I - Secondary (signal level) or battery

operated circuits of electronic equipment.

Pollution Degree 2

NOTE. Tektronix does not offer a Certificate of Traceable Calibration for the

TR 210. The TR 210 is a troubleshooting tool and is not intended for use in

calibration or conformance-testing applications.

TR 210 User Manual 1-11

Page 22

Introduction and Specifications

Accessories

You can order a foot switch (part number 98-0314) and other replacement parts

from Huntron, Inc., at the address below:

Huntron, Inc.

15720 Mill Creek Blvd.

Mill Creek, WA 98012 U.S.A.

phone: 425-743-3171, or 1-800-426-9265 in the U.S.A.

The foot switch connects to the back panel of the TR 210. When the switch is

depressed, the next test range is automatically selected. Using the foot switch is a

convenient way of avoiding having to manually select the test range on the

TR 210 front panel.

1-12 TR 210 User Manual

Page 23

A Quick Tour

The Tektronix TR 210 is a versatile troubleshooting tool having the following

features:

Four test ranges and an additional low voltage (3 Volt) range for Low Power

■

Surface Mounted devices.

Two-channel pulse generator allowing the testing of gate fired devices.

■

Three test frequencies to expand the range capability for testing capacitors

■

and inductors.

Two-channel compairson mode allowing the automatic switching between

■

the reference signature and the suspect signature.

Easy hookup to an oscilloscope with X/Y capability for displaying the

■

signatures.

The TR 210 tests components using a two terminal system (three terminal

system when the built-in pulse generator is used) where two leads are placed on

the leads of the component under test. The TR 210 tests components in-circuit,

even when there are several components in parallel.

All voltage sources in boards and systems must be in a power-off condition when

using the TR 210. Electronic protection is a signal fuse connected in series with

the channel A and B test terminals. Accidental contact of the test leads to active

voltage sources, for example, line voltage, powered-up boards or systems,

charged high voltage capacitors, etc., may cause the signal fuse to open. An

open signal fuse is indicated by channel A and B showing a short-circuit

signature at all times regardless if anything is connected across the probes.

When this condition occurs, follow the directions in Signal Fuse Replacement on

page 1-4 for replacing the signal fuse.

CAUTION.

The device to be tested must have all power turned off, and have all

high voltage capacitors discharged before connecting the TR 210 to the device.

TR 210 User Manual 2-1

Page 24

A Quick Tour

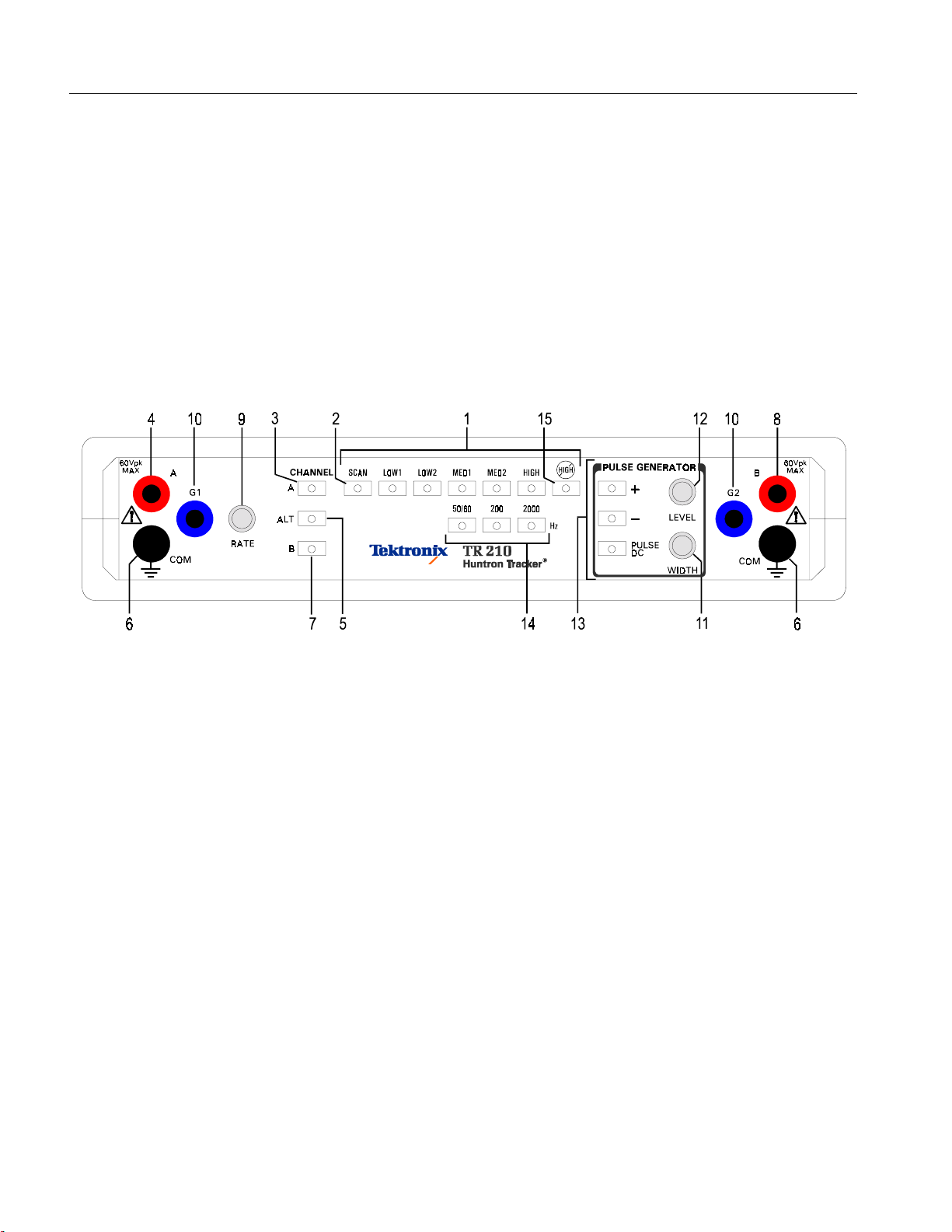

Front Panel

Before you begin to use the TR 210, please take a few minutes to familiarize

yourself with the instrument. All of the externally accessible features are

discussed in the following sections.

The front panel of the TR 210 is designed to ease access to its many features.

All buttons are momentary action type and most have adjacent LED indicators to

show which functions are active. Refer to Figure 2-1 and Table 2-1 for a

detailed description of each item on the front panel.

Figure 2-1. TR 210 Front Panel With Callouts.

2-2 TR 210 User Manual

Page 25

A Quick Tour

Table 2-1. Front Panel Controls And Connections.

Name Function

1 Range Selectors Push buttons that select one of five impedance

ranges: LOW1, LOW2, MED1, MED2 and HIGH

2 Scan Switch Push button that initiates automatic scanning of the

five ranges from LOW1 to HIGH. The scanning

speed is determined by the RATE control (see item

#9).

3 Channel A Switch Selects channel A for display on the oscilloscope.

4 Channel A Test Terminal Safety shrouded banana jack for channel A test

signal.

5 ALT Switch Causes the TR 210 to alternate between channel A

and channel B at a speed determined by the RATE

control (see item #9).

6 COM Test Terminal Safety shrouded banana jack that is the instrument

common and the common reference point for both

channel A and channel B.

7 Channel B Switch Selects channel B for display on the oscilloscope.

8 Channel B Test Terminal Safety shrouded banana jack for channel B test

signal.

9 RATE Control Controls the speed of channel alternation and/or

range scanning.

10 G1 & G2 Terminals Pulse Generator dual outputs.

11 WIDTH Control Controls the duty cycle of the pulse generator output.

12 LEVEL Control Controls the amplitude of the pulse generator output.

13 Pulse Generator Selectors Push buttons that select various output modes of the

pulse generator: Positive(+), Negative (-) and

PULSE/DC.

14 Frequency Selectors Push buttons that select one of the three signal

frequencies: 50/60 Hz, 200 Hz and 2000 Hz.

15 NO HIGH range Switch Push button that activates a mode where it is not

possible to enter the HIGH range either by manual or

scan range selection.

TR 210 User Manual 2-3

Page 26

A Quick Tour

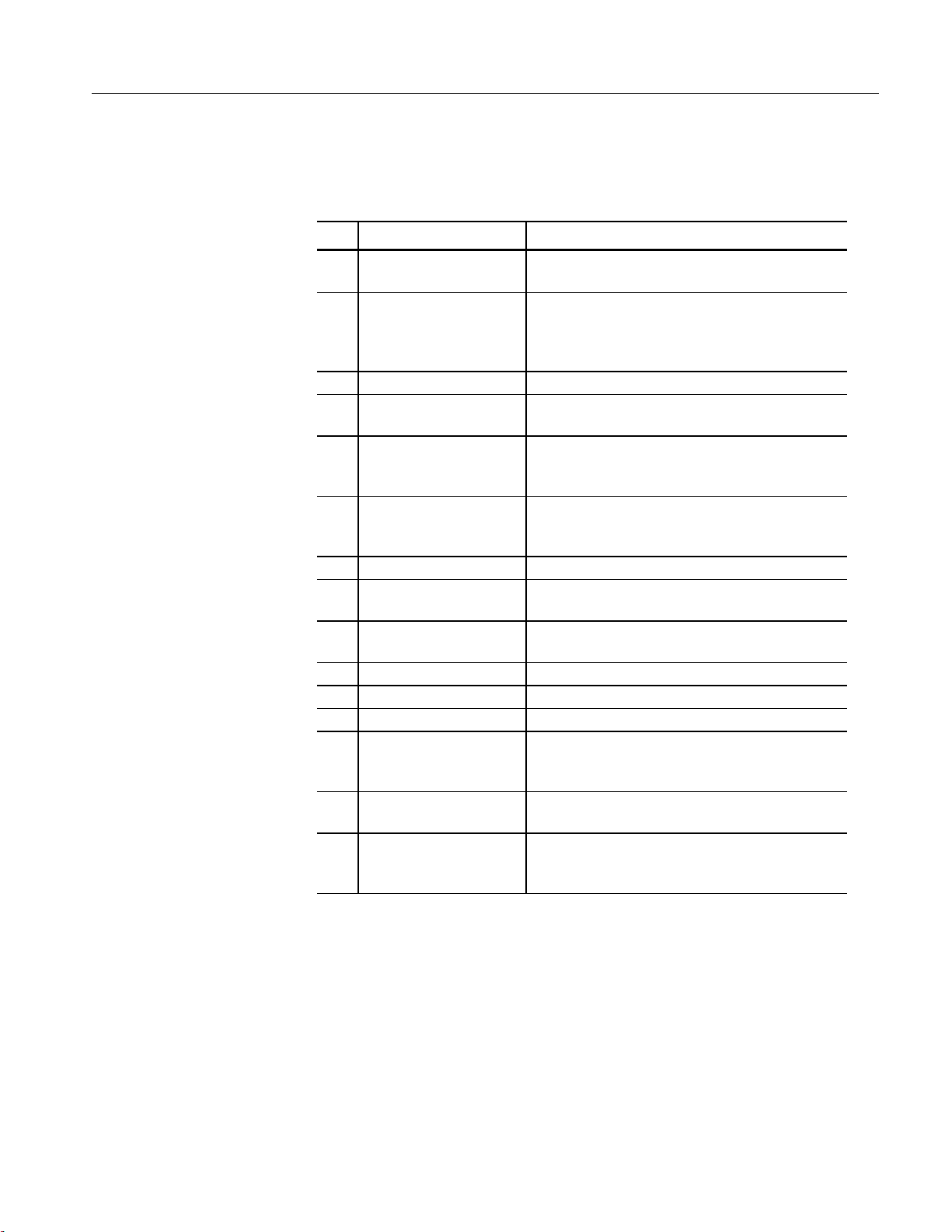

Back Panel

Secondary controls and connectors are on the back panel. Refer to Figure 2-2

and Table 2-2 for a detailed description of each item on the back panel

Figure 2-2. TR 210 Back Panel.

Table 2-2. Back Panel Connections.

Name

1 Input Voltage Selector Select between 100/115 VAC and 230 VAC input

2 Power cord connector

Power fuse holder

Power switch

3 X & Y output X & Y outputs connects to oscilloscope.

4 Input Hz selector Select between 50 or 60 Hz input frequency

5 Remote Switch Using the Foot Switch accessory, you can change to

6 Signal Fuse 250 mA fuse.

Function

voltage.

IEC standard connector that mates with any CDD-22

power cord. Power fuse holder and Power switch.

the next range in the scan sequence.

2-4 TR 210 User Manual

Page 27

Oscilloscope Display

A Quick Tour

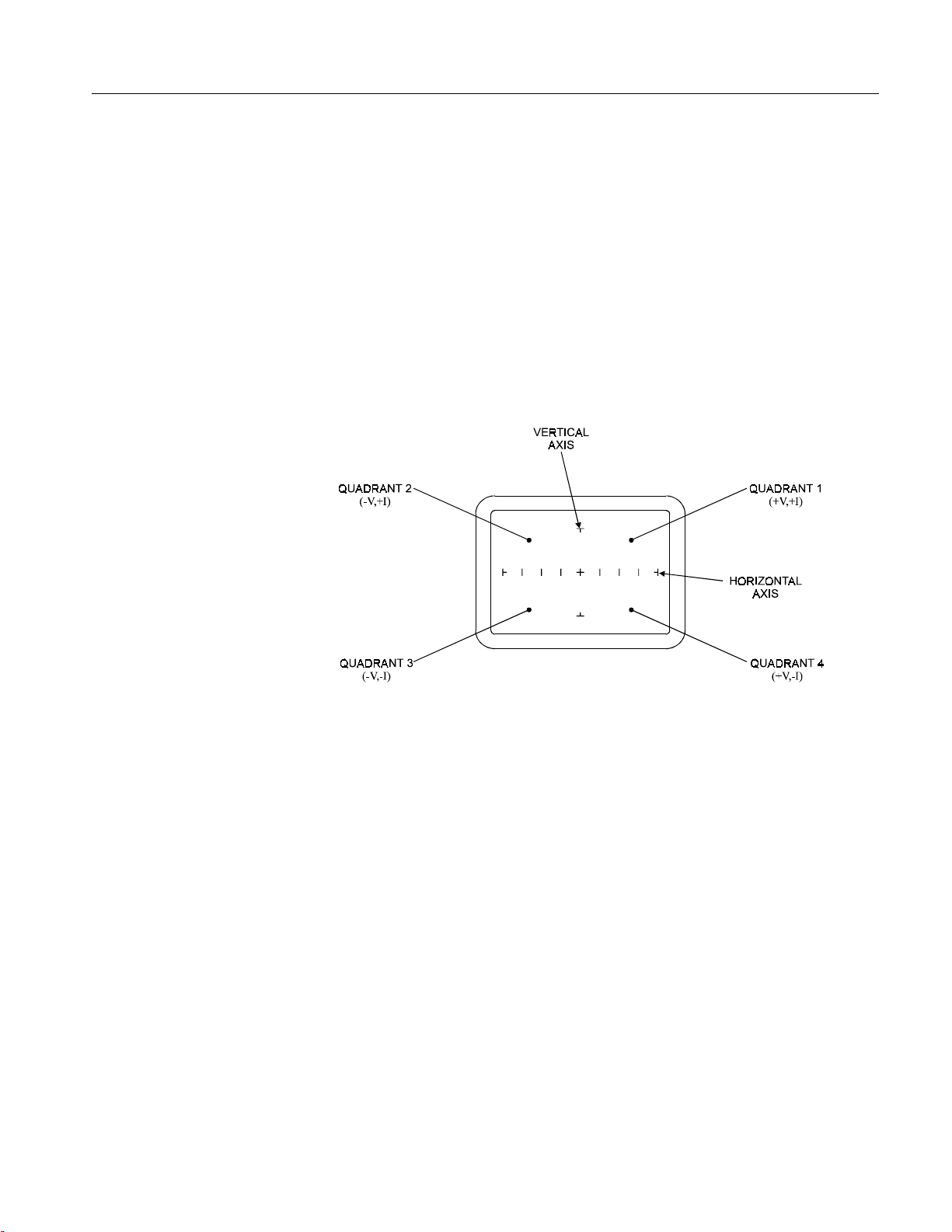

The TR 210 uses the display of any oscilloscope that is capable of displaying an

untriggered XY waveform. The oscilloscope display can be divided into four

quadrants. Each quadrant displays different portions of the signatures. Quadrant

1 displays positive voltage (+V) and positive current (+I), quadrant 2 displays

negative voltage (-V) and positive current (+I), quadrant 3 displays negative

voltage (-V) and negative current (-I), and quadrant 4 displays positive voltage

(+V) and negative current (-I).

Figure 2-3. Oscilloscope Display.

TR 210 User Manual 2-5

Page 28

A Quick Tour

Initial Setups

Power On

The following setups assume that the TR 210 has been connected to an

oscilloscope and the TR 210s power cord has been plugged into an appropriate

wall socket.

Turn the power on to your TR 210 using the power switch located on the rear

panel. The TR 210 should come on with the LEDs for channel A, 50/60 Hz,

LOW2 range and Pulse/DC illuminated.

Range Selection

The TR 210 is designed with five impedance ranges (LOW1, LOW2, MED1,

MED2 and HIGH). These ranges are selected by pressing the appropriate button

on the front panel. It is best to start with one of the medium ranges (i.e. MED1

or MED2). If the signature on the oscilloscope display is close to an open

(horizontal trace), go to the next higher range for a more descriptive signature. If

the signature is close to a short (vertical trace), go to the next lower range.

NOTE

In HIGH range, up to 60 V

:

When using the HIGH range, be careful not to touch probe tips or any circuits

connected to the A or B test terminals.

The NO HIGH lock feature, when activated, prevents the instrument from

entering the HIGH range in either the manual or scan mode.

The scan feature scans through the five ranges (four with the NO HIGH lock

activated) at a speed set by the RATE control This feature allows the user to see

the signature of a component in different ranges while keeping hands free to hold

the test leads.

is present on the A and B test terminals.

pk

2-6 TR 210 User Manual

Page 29

Frequency Selection

A Quick Tour

Three test frequencies can be selected by pressing the appropriate button on the

front panel.

The 50/60 Hz button selects either 50 or 60 Hz depending on the position of the

rear-panel switch. Set this switch to match the local power line frequency in use.

In most cases this selection is the best one to use for general troubleshooting.

The 200 Hz button selects 200 Hz as the test signal frequency. This frequency

also allows you to see smaller values of capacitance. The 2000 Hz button selects

2000 Hz as the test signal frequency. This frequency allows you to see even

smaller values of capacitance.

The 200 Hz or 2000 Hz frequency selections may require you to adjust the

oscilloscope time base to optimize the display.

Channel Selection

There are two test signal channels in the TR 210, Channel A and Channel B.

There are three buttons,

the oscilloscope.

Before you view an analog signature on the TR 210, make sure that the analog

signature is displayed in the correct quadrants on the display by following this

procedure. When using a single channel, plug the red test probe into the

corresponding channel test terminal and plug the black test probe into the

common test terminal. When testing solid state or polarity sensitive

components, place the red test probe to its positive terminal (i.e., anode, +V,

etc.) and place the black probe to its negative terminal (i.e. cathode, -V, ground,

etc.).

Push the corresponding channel button, A or B to view a single analog signature.

Push the

mode provides an automatic alternating display of channel A and channel B. It's

easy to make a visual comparison of analog signatures for two of the same

components or the same node points on two identical circuit boards when in Alt

mode. Alternate display mode is one of the most useful features for comparing a

known good device with a unknown device of the same type. The alternation

frequency is varied by the RATE control. Refer to Figure 2-4 for an example on

how to connect your test leads for comparison testing.

button to enable the Alternate display mode of the TR 210. This

Alt

Alt, A

and B to select what channel will be displayed on

TR 210 User Manual 2-7

Page 30

A Quick Tour

Pulse Generator

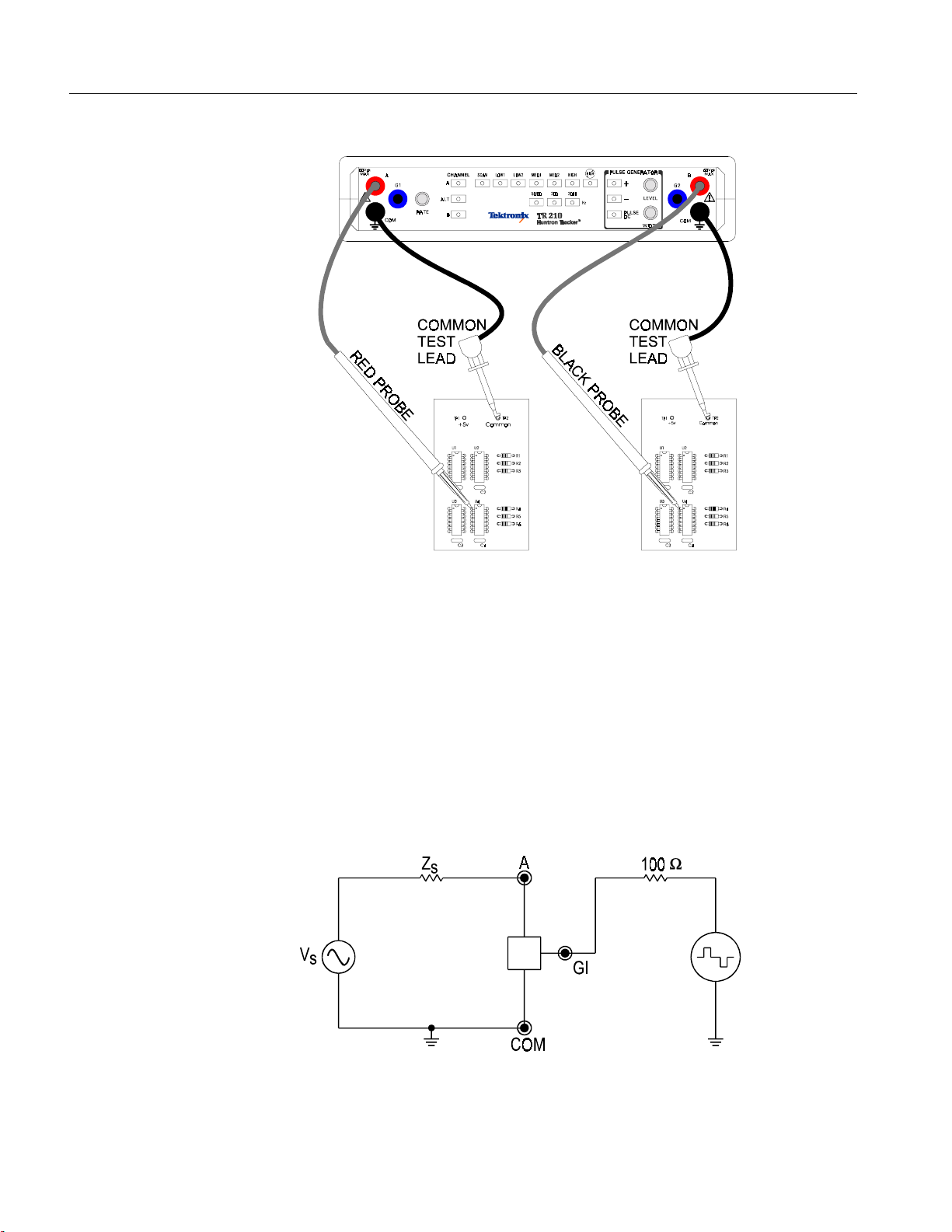

Figure 2-4. Comparison Testing with Alternate Display Mode.

The pulse generator is used to drive the control input of a device under test

which provides a dynamic test for certain types of devices. The normal two

terminal mode of using the TR 210 can be thought of as a static test since

devices with three or more terminals are not tested in their active state.

However, with the pulse generator, an in-circuit active test of a device is

possible. Figure 2-5 shows the equivalent circuit of the pulse generator and the

signal section with the display connections remove for clarity.

Figure 2-5. Pulse Generator/Signal section Equivalent Circuit.

2-8 TR 210 User Manual

Page 31

A Quick Tour

In pulse mode, this circuit uses the zero crossing of the test signal to trigger the

start of a pulse. When positive (+) is enabled, a positive-going zero crossing

triggers a positive pulse. When negative (-) is enabled, a negative-going zero

crossing triggers a negative pulse. If both polarities are enabled, then both

positive and negative pulses are produced on alternate zero crossings (composite

pulses). Once triggered, the duration of a pulse is set by the width control.

Figure 2-6 shows the waveforms for the three pulse polarity types at various

settings of the width control.

Figure 2-6. Pulse Generator Waveforms.

The LEVEL control adjusts the peak of each pulse from zero to 5 Volts is

absolute magnitude with the polarity dependent on the pulse polarity type

selected. The maximum open circuit outputs are, therefore, 5 Volts peak-to-peak

with either positive or negative enabled, and 10 Volts peak-to-peak when the

composite pulse is activated.

When DC mode is selected, a zero to 5 Volt DC level is produced at G1 and G2.

The polarity is again controlled by the positive and negative buttons. Pressing

the positive button enables a positive DC output and disables the negative

button. The negative button enables a negative DC output only when positive is

off. Using this configuration, it is easy to change polarities with only one

button: first press the negative button (which is remembered by the control

logic) then press the positive button which switches the output polarity to

positive. The next time the positive button is pressed, the positive output is

turned off which re-enables the negative output. Therefore, each time the

positive button is pressed the output polarity will toggle back and forth between

positive and negative. The Width control has no effect in DC modes.

TR 210 User Manual 2-9

Page 32

A Quick Tour

A variety of output waveforms is available using the pulse generator selector

buttons as shown in Figure 2-7. First select the Pulse mode or the DC mode

using the PULSE/DC button. In Pulse mode, the LED flashes at a slow rate,

while in DC mode, the LED is continuously on. Then select the polarity of

output desired using the positive (+) and negative (-) buttons. All three buttons

function in a “push-on/push-off” mode and only interact with each other to avoid

the NOT ALLOWED state.

Figure 2-7. Pulse Generator Selector Chart.

Once the specific output type is selected, the exact output is set using the

LEVEL and WIDTH controls. The LEVEL control varies the magnitude of the

output amplitude from zero to 5 Volts (peak or DC). During Pulse mode, the

WIDTH control adjusts the duty cycle of the pulse output from a low duty cycle

to 50% maximum (square wave). The start of a pulse is triggered by the

appropriate zero crossing of the test signal which results in the pulse frequency

being equal to the selected test signal frequency. The end of a pulse is

determined by the Width control setting which selects the duty cycle. The

WIDTH control has no effect when DC mode is selected.

The pulse generator of the TR 210 has dual tracking outputs (G1 and G2) so that

you can visually compare the analog signatures of two of these three or more

terminal components by using the Alt mode. The following figure illustrates

how to connect the TR 210 when using the pulse generator in ALT mode.

2-10 TR 210 User Manual

Page 33

A Quick Tour

Figure 2-8. Comparison Testing with the Pulse Generator.

TR 210 User Manual 2-11

Page 34

A Quick Tour

Notes:

2-12 TR 210 User Manual

Page 35

Using Your TR 210

Electronic troubleshooting is a skilled art, based largely on logical deduction,

experience and intuition. The Tektronix TR 210 uses Analog Signature Analysis

or ASA to take full advantage of a technician's skills. ASA is the examination of

the current verses voltage characteristic of a component under power-off

conditions for the purpose of troubleshooting. The component's analog signature

is displayed for visual analysis and indicates its relative health and condition.

For solid state components, ASA enables you to visualize component leakage

and substrate damage that is difficult to find with conventional test methods.

With ASA, you can troubleshoot components without applying power, saving

circuits from possible further damage. By comparing the signatures of a

questionable component with those of a known-good component, you can

quickly locate failed and marginal components in most cases. You can

troubleshoot and quickly find problems on circuit boards even if there is no

schematic.

Figure 3-1. TR 210 with Test Probes.

TR 210 User Manual 3-1

Page 36

Using Your TR 210

Basics of ASA - How it Works

Here's how ASA and power-off testing works:

The TR 210 outputs a precision current-limited AC sine wave signal to a

component and displays the resulting current flow, voltage drop and any phase

shift on the oscilloscope X-Y display. The current flow causes a vertical trace

deflection on the display, while the voltage across the component causes a

horizontal trace deflection. This resultant trace on the display is called an analog

signature.

Understanding the TR 210's basic core circuit is the key to understanding how

analog signatures respond to different types of components. Since the induced

current is a function of the impedance of the circuit, the analog signature

displayed can be thought of as a visual representation of Ohm’s Law,

V = IR

where V = voltage, I = current and R = resistance

The next figure shows a simplified diagram of the Tracker core circuit. The sine

wave generator is the test signal source and is connected to a resistor voltage

divider made up of R

component under test. R

impedance R

. Because RS is constant, both the voltage across the component

S

under test and the current through it is a function solely of R

and RL. The load impedance, RL, is the impedance of the

S

is in series with the TR 210's internal or source

L

.

L

3-2 TR 210 User Manual

Page 37

Rs = Source Resistance, Vs = Source Voltage,

= Load Resistance, Fs = Source Frequency.

R

L

Figure 3-2. TR 210 Core Circuit Block Diagram.

Using Your TR 210

Horizontal Axis

Each test signal or range has two parameters: source voltage V

,and resistance R

s

and source frequency Fs. When using ASA for troubleshooting, the objective is

to select the range that will display the most descriptive analog signature

information.

The TR 210 can readily accomplish this by changing the proper range parameter.

The range of the test signal can be used to enhance or disregard semiconductor

switching and avalanche characteristics. The F

or frequency of the test signal

s

source can be used to enhance or disregard the reactive factor (capacitance or

inductance) of a component.

The voltage across the component under test controls the amount of horizontal

trace deflection on the oscilloscope display. When the component under test is

removed, creating an open circuit (e.g., R

= ∞), the voltage at the output

L

terminals is at its maximum and thus the trace on the display is a straight

horizontal line with its maximum width.

When the test signal is positive, this means that the voltage and current are

positive so the signature's trace is on the right hand side of the oscilloscope

display. When the test signal is negative, the voltage and current are negative so

the trace is in the left hand side of the display.

s

Turn on the TR 210 and observe the oscilloscope display. With nothing

connected to its test terminals, the display trace is a horizontal line (that is,

R

=∞).

L

TR210 User Manual 3-3

Page 38

Using Your TR 210

Vertical Axis

Figure 3-3. TR 210 CRT Display with Open Test Terminals.

The amount of vertical trace deflection on the oscilloscope display is controlled

by the voltage dropped across the internal impedance R

R

is in series with the load RL, this voltage will be proportional to the current

s

flowing through R

. This current that flows through the component under test is

L

of the TR 210. Because

s

the vertical part of the analog signature.

When the R

common terminal, there is no voltage dropped across R

is zero ohms (0 Ω) as when you short an output terminal to the

L

, so there is no

L

horizontal component in the analog signature. This short circuit signature is a

vertical line trace on the oscilloscope display.

1. Connect the red microprobe to the output channel A jack on the TR 210 and

the black microprobe to the Common jack.

2. Touch and hold the probes together and observe the analog signature on the

oscilloscope display.

3. You will see a vertical line trace in the middle of the oscilloscope display.

3-4 TR 210 User Manual

Page 39

Figure 3-4. TR 210 Oscilloscope Display with Short Circuit Signature.

Basic Analog Signatures - Open and Short

Using Your TR 210

In ASA, the two most basic analog signatures are the open and the short. The

open signature occurs when an output terminal is not connected to anything. The

short signature occurs when an output terminal is directed connected to the

common terminal. In the following figures, the upper screen represents the

TR 210's oscilloscope X-Y display and the lower screen is a graphical plot of the

sine wave test signal at the output terminal showing its current and voltage

relationship. The current and voltage graphical plots are for illustration only and

cannot be displayed on the display.

Figure 3-5. "OPEN" Analog Signature on Oscilloscope display (Horizontal Line).

TR210 User Manual 3-5

Page 40

Using Your TR 210

Figure 3-6. Test Signal (Open Circuit) with Current and Voltage Waveforms.

Minimum Current and Maximum Voltage

Figure 3-7. "SHORT" Analog Signature on the Oscilloscope Display (Vertical Line).

Figure 3-8. Test Signal (Short Circuit) with Current and Voltage Waveforms.

Maximum Current and Minimum Voltage

3-6 TR 210 User Manual

Page 41

Four Basic Component Analog Signatures

All analog signatures are a composite of one or more of the four basic

component signatures which are: resistance, capacitance, inductance and

semiconductor. Each one of these basic components responds differently to

TR 210's test signal, so recognizing these four basic unique signatures on the

oscilloscope display are one of the keys to successful ASA troubleshooting.

When components are connected together to form a circuit, the signature at each

circuit node is a composite of the basic component signatures in that circuit. For

example, a circuit with both resistance and capacitance will have a signature that

combines the analog signatures of a resistor and capacitor. The signature of a

resistor is always indicated by a straight line at an angle from 0 to 90 degrees.

The signature of a capacitor is always in the form of a circle or ellipse shape.

The signature of an inductor is also a circle or ellipsoid shape, that may also

have internal resistance. Finally, the semiconductor diode signature is always

made up of two or more linear line segments that most of the time form an

approximate right angle.

Using Your TR 210

RESISTOR CAPACITOR INDUCTOR SEMICONDUCTOR

Figure 3-9. Analog Signatures of 4 Basic Components.

TR210 User Manual 3-7

Page 42

Using Your TR 210

Notes:

3-8 TR 210 User Manual

Page 43

Testing Passive Components

Resistors

Exploring how the TR†210 ranges interact with different resistance values is a

good introduction on how basic ASA troubleshooting is applied. This section

will briefly familiarize you with TR†210 basic operation and teach you how

resistor signatures relate to both test range and the resistance of the circuit under

test. After completing this section, you will know how to:

Apply test probes across a resistor

Identify a pure resistive signature

Analyze and predict resistive signatures

As you go through the following section, make a mental note on the relationship

between the TR†210's test range parameters: voltage, resistance and frequency.

Turn power on to your TR†210. Put the red test lead in the A jack, and the black

test lead in the

Common

jack.

Figure 4-1. TR 210 with Test Probe Leads.

To display the analog signature of a resistor:

1. Press the LOW2 range button.

2. The LED will be on indicating that LOW2 range is active.

TR†210 User Manual 4-1

Page 44

Testing Passive Components

3. Place or clip a test lead on the opposite ends of a resistor and observe the

signature on the Oscilloscope CRT display.

Figure 4-2. TR 210 Connected to a Resistor.

4-2 TR†210 User Manual

Page 45

Testing Passive Components

Below are four analog signatures of different resistors, 150, 1.5 k, 15 k and 150 k

ohms in the upper four ranges. Note how the slope or angle of each analog

signature changes with each resistor's value.

150 Ω 1.5 k

150 Ω 1.5 k

150 Ω 1.5 k

Ω

HIGH Range

Ω

MED2 Range

Ω

MED1 Range

15 k

15 k

15 k

Ω

Ω

Ω

150 k

150 k

150 k

Ω

Ω

Ω

150 Ω 1.5 k

Ω

15 k

Ω

150 k

Ω

LOW2 Range

Figure 4-3. Signatures of Resistors in Different Ranges.

TR210 User Manual 4-3

Page 46

Testing Passive Components

Shorts and Opens, Resistor Faults

Two of the most common faults that occur in electronic components and circuits

are shorts and opens. A short circuit is typically a 0 Ω to 10 Ω low resistive path

between two points in a component or circuit that normally would have a higher

resistance between them. An open circuit is a break between two points in a

component or circuit that prevents current from flowing.

Review

Short Open

Figure 4-4. Short and Open Signature.

The signature of a purely resistive circuit is a straight line because the

relationship between voltage and current in a purely resistive circuit is linear.

This straight line signature can vary from

■

ñcompletely horizontal (an open)

ñcompletely vertical ( a short)

As resistance increases

■

ñcurrent decreases

ñthe signature becomes more horizontal

As the range increases

■

ñthe volts per division of the horizontal axis increases

ñthe internal resistance increases

ñthe signature becomes more vertical

4-4 TR†210 User Manual

Page 47

Troubleshooting Applications

The TR†210 is a fast and efficient continuity tester, providing real time

■

information.

The TR†210 will quickly locate resistor defects, shorts, opens and

■

degradation that other testers cannot find.

A majority of component failures are resistive in nature. This is important to

■

remember; a component fault may only appear in one range because of the

resistive nature of the fault.

The TR†210ís ability to determine the approximate fault resistance value

■

greatly enhances the troubleshooting capability if the correct value is known.

The Oscilloscopeís CRT is a real time display and using the TR†210 for

■

testing noisy or dirty potentiometer (variable resistors) is an excellent

application. Connect TR†210's test terminals to one fixed pot lead and the

other to the pot's wiper lead. Simply monitor the wiper signature while

rotating the pot back and forth. A flawed pot would have the telltale

intermittent angular signature.

Testing Passive Components

Figure 4-5. Using TR 210 to Test a Potentiometer.

TR210 User Manual 4-5

Page 48

Testing Passive Components

The TR†210 can be used to adjust a potentiometer in circuit to an approximate

operational setting. This application requires a known good board. Adjust each

potentiometer on the board under repair to match the settings on a known good

operational board. In most cases, the board under repair can now be powered up

to an operational state where it can be adjusted to true specifications.

Figure 4-6. Using TR 210 to Compare Two Potentiometers.

Capacitors

With a capacitor connected to the TR†210, the test signal across it responds

quite differently than a resistor. The typical analog signature of a capacitor is an

elliptical circular pattern and this is due to the fact that relationship between the

test signal's current and voltage are non linear. The current's waveform is 90

degrees out of phase with respect to the voltage. The diagram below illustrates

this basic principle for capacitors.

Figure 4-7. Capacitor Circuit with Test Signal's Current and Voltage Waveforms.

4-6 TR†210 User Manual

Page 49

As the test signal's voltage crosses zero volts and becomes more positive, the

current flowing in the circuit is at its maximum and becoming smaller. By the

time the voltage has reached its maximum value, the current in the circuit has

ceased flowing. As the voltage begins decreasing toward zero, the current

begins increasing toward maximum. When the voltage reaches zero, the current

is at its maximum value. Similarly, this same pattern follows as the voltage goes

negative.

Because the current is at its maximum value when the voltage is at zero, the

current leads the voltage. This is called phase shift and in a purely capacitive

circuit, this phase shift equals 90°. This analog signature appears as a circular or

elliptical waveform.

Capacitor Analog Signatures

The goal of this part is to explore some capacitive signatures and to help you

understand how capacitor signatures are related to:

Testing Passive Components

The capacitance (µf) of the circuit under test

The frequency (F

The current range of the TR†210.

Turn power on to your TR†210. Plug the red test microprobe in the A jack, and

the black test clip lead in the Common jack.

CAUTION.

high voltage capacitors discharged before connecting the TR†210 to the device.

Do the following to display the analog signature of a capacitor:

1. Press the LOW2 range button.

2. The buttonís LED will be on indicating that the LOW2 range is active.

3. Place or clip a test lead on the opposite ends of a resistor and observe the

The device to be tested must have all power turned off, and have all

signature on the Oscilloscopeís display.

) of the test signal

s

TR210 User Manual 4-7

Page 50

Testing Passive Components

Figure 4-8. TR 210 with Test Probes Connected to a Capacitor.

The Signatures of Different Capacitors in LOW2 Range

The figure below shows analog signatures for four different value capacitors,

1000 µf, 100 µf, 10 µf and 1µf. The TR†210 LOW2 range is selected.

1000 µF 100 µF 10 µF 1 µF

Figure 4-9. Signatures Of 4 Capacitors In the LOW2 Range.

Note that as the capacitance values decrease, each signature changes from a

vertical elliptical pattern to a horizontal elliptical pattern. In ASA, a large value

capacitor has a signature that looks similar to a short circuit. And likewise, a

small value capacitor has a signature that's similar to an open circuit.

4-8 TR†210 User Manual

Page 51

Understanding Capacitor Analog Signatures

Figure 4-10. TR 210 Core Circuit Block Diagram With A Capacitor.

The Oscilloscopes CRT displays as a response to the test signal, an analog

signature that represents the relationship between voltage, current and resistance

of a component. For circuits that contain capacitors, the effective resistance is

called capacitive reactance, X

Testing Passive Components

. The mathematical formula is:

C

Xc =

2π fC

XC is inversely related to both capacitance and frequency. So to review and

summarize capacitive analog signatures up to this point:

Changing capacitance: As the capacitance of a circuit increases, the

■

1

capacitive reactance X

increases, the amount of current in the component or circuit will increase.

On the TR†210, the elliptical signature will become increasingly vertical

that implies more current flow.

Changing frequency FS: As the frequency of the test signal increases, the

■

capacitive reactance X

will increase. On the TR†210, the elliptical signature will become

increasingly vertical that implies more current flow.

Changing the range from LOW1 to HIGH the following occurs:

■

X

of the capacitor is not affected

C

V

increases so current decreases proportionately

S

The elliptical signature becomes increasingly vertical

decreases. This means that when capacitance

C

will decrease and the amount of current in the circuit

C

TR210 User Manual 4-9

Page 52

Testing Passive Components

Capacitor Failures - Leakage

One common physical failure in capacitors is dielectric leakage. The dielectric

or insulator in a capacitor normally acts as a non conductor between the

capacitor's two plates. A flawed capacitor develops a conductive or leakage path

between its two plates. This can be thought of as a resistance in parallel with the

capacitance when observing its analog signature. The following examples show

what some capacitor leakage problems may look like on the TR†210 display.

Normal Capacitor Leaky Capacitor

Figure 4-11. Signatures of a 100 µF Capacitor with Dielectric Leakage. LOW2

Range, F

= 60 Hz

S

This example only simulates the leakage flaw by adding a 100 Ω resistor in

parallel to a 100 µF capacitor. It shows the signature change from a normal

circular ellipse pattern to a sloped and depressed vertical pattern. The signature

of a real capacitive leakage would be quite similar to this example.

Another example of capacitive leakage is shown for a 10 µF capacitor.

Normal Capacitor Leaky Capacitor

Figure 4-12. Signatures of a 10 µF Capacitor with Dielectric Leakage. LOW2

Range, F

= 60 Hz

S

Again, this example only simulates the leakage flaw by adding a 68 Ω resistor in

parallel to a 10 µF capacitor. It shows the signature change from a normal

circular ellipse pattern to a sloped and depressed vertical pattern. The signature

of a real capacitive leakage would be quite similar to this example.

4-10 TR†210 User Manual

Page 53

Review

Testing Passive Components

As you can see from the two previous examples, adding resistance in parallel to

a capacitor distorts the normal signature with a diagonal bend to it. This is our

first look at a composite signature, the kind of signature the TR†210 displays

when there are several components connected together in a circuit.

Capacitors have circular or elliptical signatures due to the current and

■

voltage phase shift.

As the test signal's frequency increases, the capacitor's signature becomes

■

more vertical due to decreasing X

Capacitors with leakage flaws have their ellipses tilted diagonally due to an

■

of the component.

C

internal resistance in parallel with the capacitance.

Applications

Inductors

The TR†210 can locate defective capacitors in or out of circuit. The ranges

■

cover 10 pF to 20,000 µF.

When analyzing a capacitor's signature, adjust the TR†210's ranges and

■

frequencies for the most pronounced ellipse.

The test signal frequency FS can be changed to enhance a composite

■

signature by emphasizing or de-emphasizing the capacitance.

Besides resistance, faulty capacitor signatures often exhibit other

■

irregularities such as non-symmetry, broken or distorted ellipse and sawtoothed shapes that can be seen in on the CRT display.

Inductors, like capacitors, have elliptical analog signatures. Also like capacitors,

an inductor's reactance (resistance to an AC test signal) is dependent on the test

signal's frequency. Because of the way they are constructed using wire which

some amount of resistance in it, it is hard to find a pure inductance. An

inductor's analog signature will usually be an elliptical pattern with a some slope

or tilt to it due to the resistance of the coil wire.

TR210 User Manual 4-11

Page 54

Testing Passive Components

Inductor Analog Signatures

The goal of this part is to explore some inductive signatures and to help you

understand how inductor signatures are related to:

The inductance (L in µH) of the circuit under test

The frequency (F

The active range of the TR†210

Turn power on to your TR†210. Plug the red test microprobe in the A jack, and

the black test clip lead in the

Do the following to display the analog signature of an inductor:

1. Press the LOW2 range button.

2. The LED will be on to indicate that the LOW2 range is activae.

3. Place or clip each test lead on the opposite ends of an inductor and observe

the signature on the Oscilloscope CRT display.

in Hz) of the test signal

S

Common

jack.

Figure 4-13. TR 210 with Probes to an Inductor.

4-12 TR†210 User Manual

Page 55

The Signatures of Different Inductors in LOW2 Range

The figure below shows analog signatures for four different value inductors,

12,000 µH, 1200 µH, 120 µH and 12 µH in LOW2 range.

12000 µH 1200 µH 120 µH 12 µH

Figure 4-14. Signatures of 4 Inductors in LOW2 Range. 2000 Hz

Testing Passive Components

Note that as the inductance values decrease, each signature changes from a

horizontal elliptical pattern to a vertical elliptical pattern. In ASA, a large value

inductor has a signature that looks similar to an open circuit. And likewise, a

small value inductor has a signature that's similar to a short circuit.

Affect of Frequency FS on Inductor Signatures

FS = 50/60 Hz FS = 200 Hz FS = 2000 Hz

Figure 4-15. Affect of Varying F

on Inductor Signatures in LOW2

S

Note that the signature changes from a vertical position to a horizontal position

as the frequency increases. This means the resistance of an inductor increases as

frequency increases.

TR210 User Manual 4-13

Page 56

Testing Passive Components

Understanding Inductive Signatures

Figure 4-16. TR 210 Core Circuit Block Diagram with an Inductor.

Review

The TR†210's block diagram shows an inductor between the test terminals. The

current is represented by the vertical axis and is derived as a series current that

flows through TR†210ís internal resistance, R

The voltage is represented by

S.

the horizontal axis and is derived as a voltage across the inductor.

The formula for the reactance X

As the test signal frequency increases, the inductive reactance X

of an inductor is:

L

= 2πfL

X

L

becomes

L

larger. As a result, the inductorís analog signature will change from a rounder

elliptical to a flatter resistive type pattern. The size and shape of the ellipse

depend on the inductor value, test signal frequency, and the selected ranges

internal resistance R

.

S

Since inductors in reality are not pure inductors, the elliptical signatures they

form on the oscilloscopes display are sometimes distorted. Inductors constructed

with a ferrite core makes the inductive characteristics different from those

constructed without. The TR†210 responds with a unique analog signature for

each inductor type.

Inductors display elliptical signatures similar to capacitors. Since the

■

inductor also exhibits resistance, due to its construction, the ellipse may be

tilted.

As the TR†210 test signalís frequency is increased, the ellipse signature

■

becomes flatter. This response is opposite to that of a capacitor.

4-14 TR†210 User Manual

Page 57

Applications

Testing Passive Components

As the TR†210 range increases, an inductor's signature becomes more

■

vertical (like the capacitor signature).

When an inductor has a ferrite core, its signature distorts from a non ferrite

■

inductorís ellipse.

The TR†210 is excellent for troubleshooting inductors. It can reveal shorted

■

or open windings in large variety of inductive components.

Components that are inductors or have inductive characteristics can be found

■

in many real world applications. For example, some of these are power

transformers, relays, solenoids, flybacks, speakers, magnetic sensors,

stepping motors and motor windings.

The best technique for testing inductors is the comparison of a known good

■

component's signature to a suspect component. For example, a motor

armature has typically numerous windings so every winding should have a

similar analog signature. This fact is true whether it's from an elevator or a

tape deck. The armature of a DC motor can be tested by simply connecting

to the motor brush leads and then adjusting the test range for the most

pronounced or descriptive signature. Slowly turn the armature. Observe the

TR†210ís CRT display. This test will check continuity, the inductance, and

the condition of each brush contact without disassembling the motor.

A computer switching power supply contains inductors. For example, a

■

computer is reported ìdead." To make a quick diagnosis of the possible

problem first make sure the computer is disconnected from AC power. Then

connect the red and black test probes across the prongs on the AC line cord

going to the computer. Turn the computer power switch to the On position.

If there is a response on the ProTrack display, adjust the test range for the

most pronounced inductive signature. Flick the power switch off and on and

watch for noisy switch contacts. If there is no response, start by checking

each component up to the primary winding of the transformer. With this

technique, we have just verified the AC cord, the AC noise filter, the fuse,

the power switch and the primary winding of the transformer, without

removing the cover of the computer.

Another simple test for a speaker or microphone is to apply the TR†210

■

signal in LOW2 range to the device input leads and listen for the 60 Hz tone

or audible hum.

To test solenoids, connect the test probes to the coil leads and manually

■

move the plunger or activator in and out while observing if its signature

changes.

TR210 User Manual 4-15

Page 58

Testing Passive Components

Electromechanical Switching Component s

Switches are electrical devices that either stop or allow current to flow in a

circuit. They are either in an on or off state. Switching devices come in all types

and sizes. There are simple mechanical switches, relays, optical switches, and

many kinds of semiconductor switches. They are different because each uses a

different kind of stimulus to turn them on or off. Because there are so many

kinds of switching devices, there is no single testing procedure that will test

them all completely. With the TR†210, the test signal can be setup so that the

switch's analog signature will verify its switching function. The goal of this

section is to develop a test strategy using ASA to test the switching function.

This is not a complete test, but it will be enough to determine whether or not the

device is functioning as a switch.

Manually Operated Mechanical Switches

A mechanical switch has two states: it is either open or closed. When open, no

current can flow; when closed, it acts as a short and allows current to flow. The

TR†210 can test the switching function of mechanically activated switches

easily. Unlike the DVM that samples and gives a continuity measurement, the

TR†210 displays real time activity so if a switch has noisy or intermittent

operation, its analog signature on TR†210's display will reflect these conditions.

Turn power on to your TR†210. Plug the red test microprobe in the A jack, and

the black test clip lead in the Common jack.

Do the following to display the analog signature of a mechanical switch:

1. Press the LOW2 range button.

2. The LED will be on indicating that the LOW2 range is activated.