Page 1

x

TPR1000 and TPR4000

Active Power Rail Probes

ZZZ

User Manual

*P077154200*

077-1542-00

Page 2

Page 3

xx

TPR1000 and TPR4000

Active Power Rail Probes

ZZZ

User Manual

www.tek.com

077-1542-00

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or suppliers, and are

protected by na

tional copyright laws and international treaty provisions.

Tektronix pro

previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

TekVPI is a trademark of Tektronix, Inc.

ducts are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tek.com to find contacts in your area.

Page 5

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year from the date of

shipment. If any such product proves defective during this warranty period, Tektronix, at its option, either will repair the defective

product without charge for parts and labor, or will provide a replacement in exchange for the defective product. Parts, modules and

replacement products used by Tektronix for warranty work may be new or reconditioned to like new performance. All replaced

parts, modules and products become the property of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the warranty period

and make suitable arrangements for the performance of service. Customer shall be responsible for packaging and shipping the

defective product to the service center designated by Tektronix, with shipping charges prepaid. Tektronix shall pay for the return of the

product to Customer if the shipment is to a location within the country in which the Tektronix service center is located. Customer shall

be responsible for paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate maintenance and

care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting from attempts by personnel

other than Tektronix representatives to install, repair or service the product; b) to repair damage resulting from improper use or

connection to incompatible equipment; c) to repair any damage or malfunction caused by the use of non-Tektronix supplies; or

d) to service a product that has been modified or integrated with other products when the effect of such modification or integration

increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEK TR ON IX WITH RESPECT TO THE PRODUCT IN LIEU O F ANY OTHER WARRANTIES,

EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS

IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IRRESPECTIVE OF WHE THER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

[W2 – 15AUG04]

Page 6

Page 7

Table of Contents

Important Safety information .......................................................................................................... iii

General safety summary... . .. . . .. . . .. . ... . .. . . .. . . .. . ... . ... . ... . .. . . .. . . .. . ... . .. . . .. . . .. . . .. . ... . .. . . .. . . .. . ... . ... . ... . .. . . .. iii

Service safety summary ......................................................................................................... iii

Terms in this manual .. . . .. . ... . .. . . ... . .. . . .. . . .. . ... . ... . .. . . .. . . .. . . .. . . .. . ... . .. . . .. . . .. . . .. . ... . ... . ... . .. . . .. . . .. . ... . ... . .. iv

Symbols and terms on the product . ... . .. . . .. . . .. . ... . ... . ... . .. . . .. . . .. . ... . ... . .. . . .. . . .. . ... . ... . ... . .. . . .. . . .. . ... . ... . .. . . . iv

Compliance information ............................................................................................................... v

Environmental considerations ................................................................................................... v

Preface................................................................................................................................. vi

Documentation ...................................................................................................................vi

Conventions used in this manual. . . .. . ... . .. . . .. . . .. . ... . ... . ... . .. . . .. . . .. . ... . .. . . .. . . .. . ... . ... . .. . . .. . . .. . ... . .. . . .. . . .. . . .. vi

Returning the probe for servicing................................................................................................ vi

Why use a power-rail probe? ... . ... . .. . . ... . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . ... . . .. . . .. . ... . . .. . ... . ... . ... . ... . ... . .. . . v

Theory of operation . . ... . ... . ... . .. . . .. . . .. . ... . .. . . .. . . .. . . .. . ... . .. . . .. . . .. . ... . ... . ... . .. . . .. . . .. . ... . .. . . .. . . .. . ... . ... . .. . . vii

Key features.................................................................................................................... viii

Installation.............................................................................................................................. 1

Operating considerations........................................................................................................ 1

Connecting to the host instrument. . ... . .. . . .. . . .. . ... . .. . . .. . . .. . ... . .. . . .. . ... . .. . . .. . . .. . ... . .. . . .. . . .. . ... . .. . . .. . ... . .. . . .. . 2

Probe controls and indicators.................................................................................................... 2

Functional check. .. . ... . ... . .. . . .. . . .. . ... . . .. . ... . ... . .. . . .. . . .. . ... . . .. . ... . ... . .. . . .. . . .. . ... . . .. . ... . .. . . .. . . .. . . .. . ... . . .. . ....... 4

Required equipment ... . .. . . .. . . .. . . .. . ... . . .. . ... . ... . .. . . ... . .. . . .. . . .. . . .. . ... . . .. . ... . ... . .. . . ... . .. . . .. . . .. . . .. . ... . . .. . ... . 4

Basic operation . . ... . .. . . .. . . .. . .. . . .. . ... . .. . . .. . ... . .. . . .. . . .. . .. . . .. . ... . .. . . .. . ... . .. . . .. . . .. . .. . . .. . ... . .. . . .. . ... . .. . . .. . . ....... 6

Required oscilloscope software versions . . .. . ... . .. . . .. . . .. . ... . .. . . .. . . .. . ... . .. . . .. . . .. . ... . .. . . .. . . .. . ... . ... . .. . . .. . ... . ... 6

Probe input . .. . ... . ... . .. . . ... . .. . . .. . . .. . . .. . ... . ... . ... . .. . . .. . . .. . . .. . ... . . .. . ... . ... . .. . . .. . . .. . . .. . . .. . ... . ... . .. . . ... . .. . . .. 6

Probe offset....................................................................................................................... 7

Connect MMCX accessories ... . ... . ... . ... . ... . .. . . ... . .. . . .. . . .. . . .. . . .. . . .. . . .. . ... . . .. . ... . ... . ... . ... . ... . .. . . ... . .. . . .. . . . 7

Connect solder-in accessories .. . . .. . . .. . ... . .. . . .. . . .. . . .. . . .. . ... . ... . .. . . .. . . .. . ... . . .. . ... . .. . . .. . . .. . . .. . ... . ... . ... . .. . . .. 7

Using the solder-pin installation tool............................................................................................. 8

Using the tripod ..................................................................................................................9

Using the optional browser . . .. . . .. . ... . ... . ... . .. . . .. . . .. . . .. . ... . ... . ... . .. . . .. . . .. . . .. . ... . ... . ... . .. . . .. . . .. . . .. . ... . ... . ... . 9

Accessories and options ............................................................................................................. 11

Standard accessories . .. . . .. . . .. . . .. . . .. . ... . ... . .. . . .. . . .. . ... . ... . ... . .. . . .. . . .. . . .. . ... . .. . . .. . . .. . . .. . . .. . ... . ... . .. . . .. . . .. 11

Optional accessories.. . . .. . ... . .. . . .. . . .. . ... . .. . . .. . . .. . ... . ... . .. . . .. . . .. . ... . ... . .. . . .. . . .. . ... . .. . . .. . . .. . ... . .. . . .. . . .. . ... 12

Options .......................................................................................................................... 14

Probing principles..................................................................................................................... 15

Ground lead length. .. . . .. . ... . ... . .. . . .. . . .. . ... . ... . ... . .. . . .. . . .. . . .. . ... . .. . . ... . .. . . .. . . .. . ... . ... . .. . . .. . . .. . ... . . .. . ... . .. 15

Ground lead inductance . .. . . .. . ... . ... . .. . . .. . . .. . ... . ... . ... . .. . . .. . . .. . . .. . ... . .. . . ... . .. . . .. . . .. . ... . ... . .. . . .. . . .. . ... . . .. . ... ... 16

Specifications .........................................................................................................................17

Warranted characteristics....................................................................................................... 17

Typical characteristics........................................................................................................... 18

Nominal characteristics ......................................................................................................... 21

Accessory characteristics....................................................................................................... 21

Table of Content

s

ii

TPR1000 and TPR4000 User Manual i

Page 8

Table of Content

Performance verification.............................................................................................................. 26

Maintenance ... . .. . . .. . . .. . ... . .. . . .. . ... . .. . . .. . . .. . ... . .. . . .. . . .. . ... . .. . . .. . . .. . ... . .. . ... . .. . . .. . . .. . ... . .. . . .. . . .. . ... . .. . . ...... 35

Index

s

Equipment requ

Equipment setup ................................................................................................................ 27

Check the DCgain accuracy ................................................................................................... 29

Check the DC in

Check the input offset range and scale accuracy.. . . .. . . .. . . .. . . .. . ... . ... . ... . ... . .. . . .. . . .. . . .. . . .. . . .. . ... . ... . ... . ... . .. . . 32

Check the analog bandwidth ... . ... . . .. . ... . .. . . .. . . .. . . .. . ... . . .. . ... . .. . . .. . . .. . . .. . ... . ... . ... . .. . . .. . . .. . . .. . ... . ... . ... . .. 33

Test record....................................................................................................................... 3

Error c ondition . ... . .. . . .. . . .. . . .. . ... . .. . . .. . . .. . ... . ... . ... . .. . . .. . . .. . ... . .. . . .. . . .. . ... . ... . .. . . .. . . .. . ... . .. . . .. . . .. . . .. . . . .. 35

Replacemen

Cleaning . . .. . ... . ... . ... . .. . . .. . . .. . ... . ... . .. . . .. . . .. . ... . ... . ... . .. . . .. . . .. . ... . ... . .. . . .. . . .. . ... . ... . ... . .. . . .. . . .. . ... . ... .. 35

ired ............................................................................................................. 26

put dynamic range ... . .. . . .. . . .. . . .. . . .. . ... . ... . ... . ... . .. . . .. . . .. . . .. . ... . ... . ... . .. . . .. . . .. . . .. . . .. . . .. . ... 31

t parts.............................................................................................................. 35

4

ii TPR1000 and TPR4000 User Manual

Page 9

Important Safet

y information

Important Saf

This manual contains information and warnings that must be followed by the user for safe operation and to keep the

product in a safe condition.

To safely perform service on this product, additional information is provided at the end of this section in the Service safety

summary.

ety information

General safety summary

Use the prod

or any products connected to it. Carefully read all instructions. Retain these instructions for future reference.

Probes and test leads

Before connecting probes or test leads, connect the power cord from the power connector to a properly grounded power

outlet.

Inspect the probe and accessories.

defects in the probe body, accessories, or cable jacket). Do not use if damaged.

High tem

uct only as specified. Review the following safety precautions to avoid injury and prevent damage to this product

perature probe tips

Before each use, inspect probe and accessories for damage (cuts, tears, or

WARNING. To prevent a burn injury, when using a solder micro-coax or flex tip in a high temperature application, be

sure to allow the tip to cool down before handling the tip.

Servicesafetysummary

The Service safety summary section contains additional information required to safely perform service on the product. Only

qualified personnel should perform service procedures. Read this Service safety summary and the General safety summary

before performing any service procedures.

Do not service alone.

rendering fi

rst aid and resuscitation is present.

Do not perform internal service or adjustments of this product unless another person capable of

TPR1000 and TPR4000 User Manual iii

Page 10

Important Safet

y information

Terms in this manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in damage to this product or other property.

Symbols and terms on the product

When this symbol is marked on the product, be sure to consult the manual to find out the nature of the

potential hazards and any actions which have to be taken to avoid them. (This symbol may also be used to

refer the user to ratings in the manual.)

The following symbol(s) may appear on the product:

iv TPR1000 and TPR4000 User Manual

Page 11

Compliance info

rmation

Compliance in

This product is intended for use by professionals and trained personnel only; it is not designed for use in households or

by children.

Questions about the following compliance information may be directed to the following address:

Te ktronix, Inc.

PO Box 500, MS 19-045

Beaverton, OR 97077, USA

www.tek.com

formation

Environmental considerations

This section provides information about the environmental impact of the product.

Restrict

Complies with RoHS2 Directive 2011/65/EU.

Product end-of-life handling

Observe

ion of hazardous substances

the following guidelines when recycling an instrument or component:

Equipment recycling.

may contain substances that could b e harmful to the environment or human health if improperly handled at the product’s

end of life. To avoid release of such substances into the environment and to reduce the use of natural resources, we

encourage you to recycle this product in an appropriate system that will ensure that most of the materials are reused

or recycled appropriately.

This symbol indicates that this product complies with the applicable European Union requirements according

to Directives 2012/19/EU and 2006/66/EC on waste electrical and electronic equipment (WEEE) and batteries.

For information about recycling options, check the Tektronix Web site (www.tek.com/productrecycling).

Production of this equipment required the extraction and use of natural resources. The equipment

TPR1000 and TPR4000 User Manual v

Page 12

Preface

Preface

This manual describes the installation and operation of the TPR1000 and TPR4000 active power rail probes. Basic probe

operations and concepts are presented in this manual. The 6 Series MSO oscilloscope and the TPR4000 probe is used

in all illustrations in this manual, unless noted otherwise. You can access this document and other related information

from the Tektronix website (www.tek.com).

Documentation

To read about Use these documents

TPR1000 and TPR4000 Probes: First Time Operation, Functional Check,

Operating Basics, Specifications, Performance Verification

Conventions used in this manual

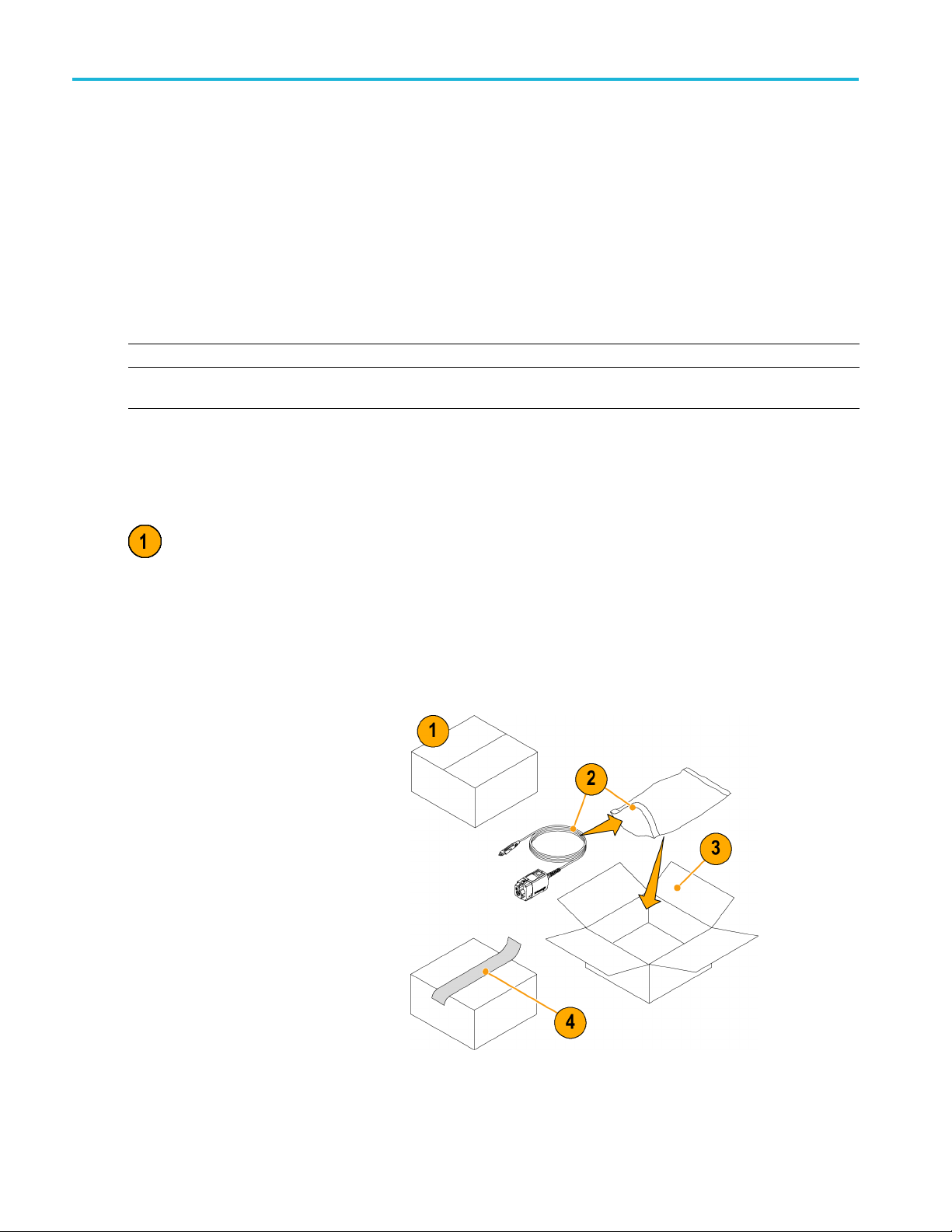

The following icon is used throughout this manual to indicate a step sequence.

Returning the probe for servicing

If your probe requires servicing, you must return the probe to Tektronix. If the original packaging is un fit for use or not

available, use the following packaging guidelines:

Preparation for shipment

1. Use a corrugated cardboard shipping

carton having inside dimensions at

least one inch greater than the probe

dimensions. The box should have a

carton test strength of at least 200

pounds.

Read this Instruction Manual.

2. Put the probe into an antistatic bag or

wrap it to protect it from dampness.

3. Place the probe into the box and stabilize

it with light packing material.

4. Seal the carton with shipping tape.

5. Refer to Contacting Tektronix at the

beginning of this manual for the shipping

address.

vi TPR1000 and TPR4000 User Manual

Page 13

Whyuseapower-railprobe?

The added functionality, higher density, and faster switching speeds of modern electronic products drive the need for lower

supply voltages. Designers need to zoom-in on power rails to look for high-frequency intruder signals, measure ripple and

analyze coupling effects with tighter tolerances. Oscilloscopes often do not have enough offset to shift the noise and ripple

on DC rails to the center of the screen to make the needed measurements.

The TPR1000 and TPR4000 probes provide a low-noise measurement solution (oscilloscope and probe), which is critical to

not confuse the noise of the oscilloscope and probe with the noise and ripple of the DC supply being measured. The higher

input impedance in the probes minimize the oscilloscope loading effect on DC rails (50 kΩ at DC). The probes provide higher

bandwidth to see more signal content (harmonics, faster ripples, e tc.) on DC rails that could affect data signals, clocks, etc.

The TPR1000 and TPR4000 provide a best-in-class solution for power integrity and validation engineers in the high speed

(μP), low power (mobile) and switched-mode power supply markets. The probes are designed to offer the lowest noise

with high bandwidth at 60 V offset, flexible connectivity options to cover customers challenges, and software packages to

cover the digital power management market.

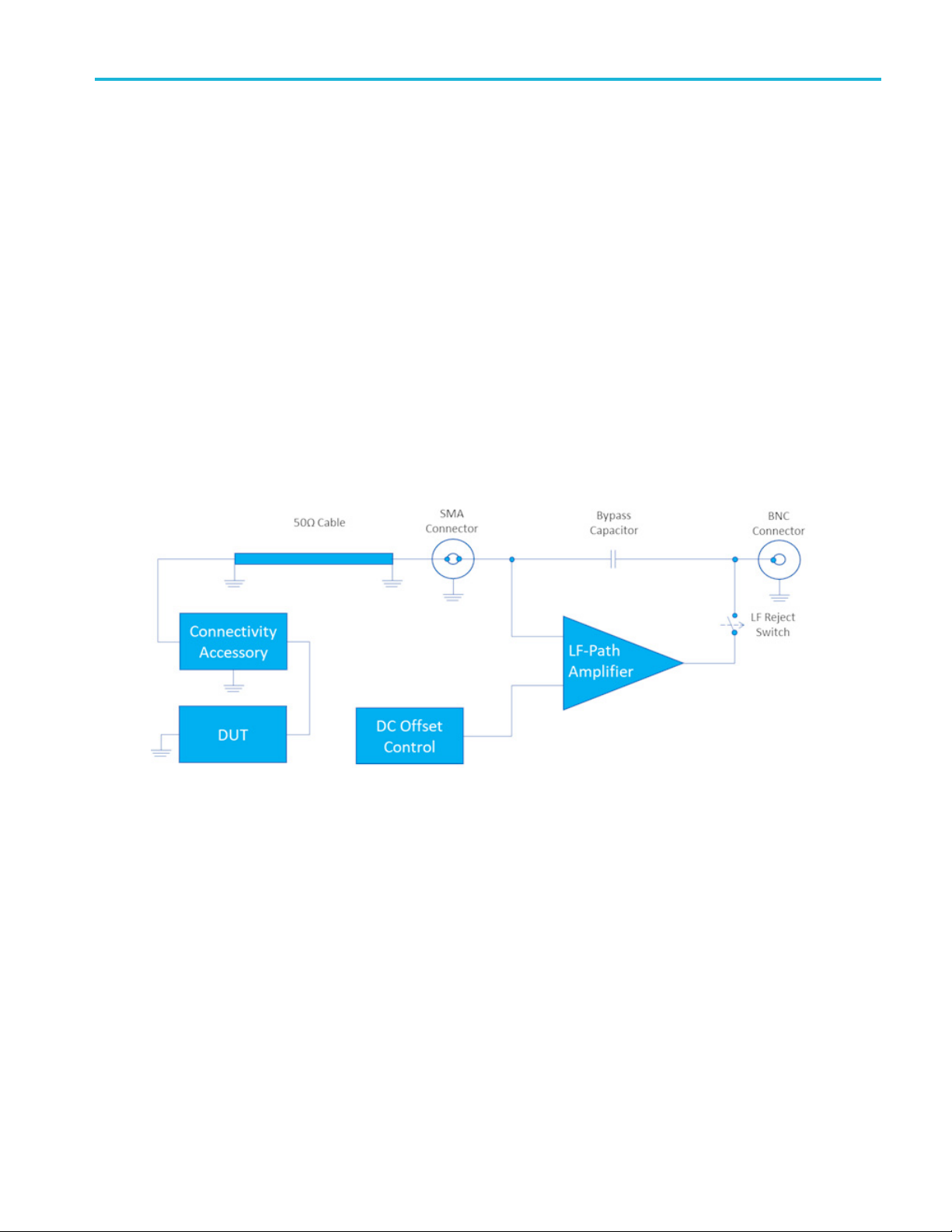

Theory of operation

The block diagram shows the major circuit blocks or modules in the TPR1000 and TPR4000 probes.

Preface

Figure i: TPR1000 and TPR4000 clock diagram

The TPR1000 and TPR4000 function by extending the oscilloscopes offset capability while maintaining a low noise signal

path into the instrument. The linear dynamic range can be moved around the offset voltage operating window using the

DC offset control into the LF amplifier. The LF amplifier can be disconnected when DC offset is not needed by setting the

coupling mode to DC reject in the instrument vertical menu. The bypass capacitor acts as a low impedance path for high

frequency components while blocking low frequency components. Because the TPR1000 and TPR4000 are designed for

measuring the low source impedances of power distribution planes it is not recommended to measure devices with source

impedances >1 Ω as it may cause distortion of the waveform.

TPR1000 and TPR4000 User Manual vii

Page 14

Preface

Key features

The TPR1000 and TPR4000 probes provide a low noise, large offset range solution for measurement of ripple on DC power

rails ranging from –60 to +60 VDC. Tektronix’s power rail probes offer industry leading low noise and high offset range

required to measure AC ripple between 200 μVp-p and 1 Vp-p at up to 4 GHz. Key features include:

Oscilloscope compatibility

6 series MSO, 5 series MSO, 4 series MSO, 3 series

MDO, MDO3000

DPO7000C, and DPO70000C/DX/SX

Bandwidth (DC coupling mode)

1

, MDO4000C1, MSO/DPO5000B,

2

34

TPR1000: DC to 1 GHz

Noise

<200 μVp-p noise on 6 Series MSO (20 MHz BW Limit)

<1 mVp-p noise on 6 Series MSO (Full Bandwidth)

Input impedance

50 kΩ DC to 10 Hz

50 Ω AC > 100 kHz

TPR4000: DC to 4 GHz

6

Bandwidth (DC reject mode)

TPR1000: 10 kHz to 1 GHz

34

Temperature range at tip

–40 to +85 °C (standard accessories)

–40 to +155 °C (high temperature cable option)

TPR4000: 10 kHz to 4 GHz

Offset

Linear dynamic range

Up to 60 V DC, 1 Vp-p to bandwidth

Attenuation: 1.25x

3

Measurement accuracy

5

±60 V offset range

Offset setting error

Max: ±(2% of setting value + 2.5 mV)

Typical: ±(0.1% + 2.5 mV) after SPC and Probe Zero

DC linearity: <0.1%

Step response long-term aberrations: <±1%

1

Due to software incompatibilities between the TPR1000 and TPR4000 probes and the MDO3000 and MDO4000C oscilloscopes, the accuracy

of probe measurements is reduced when these oscilloscopes are used in vertical scale settings less than 2 mV/division. For all other vertical

scale settings, the specified accuracy of the probe is maintained.

2

DPO70000 oscilloscopes require the optional TCA-VPI50 adapter.

3

Frequency response optimized for <1 Ω source impedance.

4

Through SMA-to-SMA cable or Solder Micro-Coax tip.

5

Max AC RMS of 1 V.

6

The comp box and oscilloscope temperature range is limited to the oscilloscope operating conditions. Please refer to the oscilloscope specifications.

viii TPR1000 and TPR4000 User Manual

Page 15

Installation

Operating considerations

TPR1000 and TPR4000 power rail probe operating considerations.

Table 1 : Environmental characteristics

Characteristic Description

Temperature (comp box) Operating: 0 to +50 °C (+32 to +122 °F)

Temperature (standard accessories)

Temperature (optional high temperature

accessories)

Humidity (operating and nonoperating) 5-95% RH, tested up to +40 °C (+104 °F)

Altitude

Dynamics (random vibration) Operating: 5 to 500 Hz, 2.66 gRMS

1

Operation temperature when using the standard accessory kit (TPR4KIT).

2

Operation temperature when using the optional high temperature accessory kit (TPR4KITHT).

2

Nonoperating: -20 to +85 °C (-4 to +185 °F)

1

Operating: -40 to +125 °C (-40 to +257 °F)

Operating: -55 to +155 °C (-67 to +311 °F)

5-85% RH, tested above +40 °C (+104 °F)

Operating: Up to 3000 meters (9,843 feet),

Nonoperating: Up to 12,000 meters (39,370 feet)

Nonoperating: 5 to 500 Hz, 3.48 gRMS

Installation

TPR1000 and TPR4000 User Manual 1

Page 16

Installation

Connecting to the host instrument

1. Slide the probe body into the FlexChannel

or VPI receptacle. The probe clicks into

place when fully engaged.

When the probe is connected, the host

instrument reads information from the

probe and identifies the device.

NOTE. Allow the probe to warm up for at

least 20 minutes to achieve guaranteed

specifications.

2. Attach one of the following probe cables

to the SMA connector on the probe body.

Limit SMA nut torque to 8 in-lbs for either

attachment or removal:

SMA-to-SMA standard cable (standard

accessory)

SMA-to-MMCX standard cable (standard

accessory)

SMA-to-MMCX high-temperature cable

(optional accessory)

1 GHz browser probe cable (optional

accessory)

3. To disconnect, press the latch release

button and pull away from the instrument.

Probe controls and indicators

Status LED

When the probe is powered on, the multicolor

Status LED:

A solid green LED indicates t

probe has initialized and is in the normal

operating mode.

A flashing green LED indicates that

the probe is connected, but

initialized.

hat the

has not

A red LED in any state indicates an error

condition exists. (See page 35, Error

condition.)

2 TPR1000 and TPR4000 User Manual

Page 17

Menu button

1. Press the probe Menu button to display

the Probe Control screen on the

oscilloscope.

2. Use the touch-screen buttons on the

instrument to set the probe parameters.

3. Press the probe Menu button again to

close the Probe Control screen.

AutoZero

We recommend that you run the probe

AutoZero r

outine:

Installation

After the

When the o

probe changes by ±5 °C

1. Press the probe Menu button to display

the Probe Control screen on the

oscillo

2. Short th

3. Press th

instrument to execute the AutoZero

routine.

20 minute warm-up period

perating temperature of the

scope.

e probe tip to ground.

e AutoZero buttononthe

TPR1000 and TPR4000 User Manual 3

Page 18

Functional chec

k

Functional check

Use the following procedure to check that your probe is functioning properly. To verify that your probe meets the warranted

specifications, refer to the Performance Verification procedures. (See page 26.)

Required equipment

Description and quantity Performance requirement Recommended example

Oscilloscope TekVP I Interface Tektronix DPO7000 Series

SMA cable 1.3 m cable, SMA male-to-SMA male,

Sine wave generator

50 Ω

Frequency: 10 Mhz

Amplitude: 1 Vpp, Offset 1 Vpp

Tektronix 3 Series MDO

Tektronix 4 Series MSO

Tektronix 5 Series MSO

Tektronix 6 Series MSO

Cable included in standard accessory

kit (TPR4KIT)

Figure 1: Functional check connection diagram

1. Connect the probe to the oscilloscope and a function generator as detailed in the connection diagram. (See Figure 1.)

2. If the function generator allows load impedance scaling, set the load impedance to high-Z. Otherwise, place a 50 Ω feed

through terminator between the SMA cable and the probe.

4 TPR1000 and TPR4000 User Manual

Page 19

3. Set the probes offset to 1 V and the vertical scale to 200 mV/div.

4. Set the function generator to 1 Vpp amplitude 1 V offset and the function to a 10 MHz sine wave.

5. The instrument should show a 1 Vpp sine wave on the screen centered around 1 V.

6. Open the vertical channel menu and change the coupling mode to DC reject.

7. Set the vertical offset to 0 V.

8. Confirm that the signal is centered around 0 V.

Functional chec

k

TPR1000 and TPR4000 User Manual 5

Page 20

Basic operation

Basic operation

Follow these operating guidelines to get the best performance from your probe.

Required oscilloscope software versions

Oscilloscope Required software version

3 series MDO, 4 Series MSO, 5 Series MSO and 6 Series

MSO

MDO3000

MDO4000C

MSO/DPO5000B

DPO7000C

DPO70000C/DX/SX

1

The probe may operate with older versions of oscilloscope software. However, older software versions than those listed are not guaranteed to

provide full probe functionality.

Probe input

The probe is electrically protected against static voltage. However, applying voltages above its design limits may damage the

probe tip amplifier. (See Figure 2 on page 6.)

Input Linear Dynamic Range

The probe head amplifier used by the probe has a limited linear operating range. To keep the input linearity error within

specification, you m ust limit the signal input voltage to ±1 V.

1

1.12.5

1.27462

1.09354

10.8.3.3

10.8.3.3

10.9.1

Figure 2: Dynamic and Offset Limitations

6 TPR1000 and TPR4000 User Manual

Page 21

Probe offset

The probe offset is adjustable for operation within the linear range of the probe, and to increase the sensitivity of the probe at

higher DC measurement voltages. Using the offset to cancel DC signal components enables optimal probe performance.

(See Figure 2 on page 6.)

NOTE. See your oscilloscope manual for specific instructions on using the offset control.

To set the probe offset, follow these steps:

1. Set the probe offset equal to the expected nominal DC value of the source you are connecting to.

2. Set the vertical scale to 500 mV/div.

3. Connect the probe to the circuit.

4. Change the volts/div setting to the desired range, adjusting the offset as needed to keep the signal in the center of

the screen.

The probe has a ±60 V offset range. The linear operating r ange is ±1 V. (See Figure 2 on page 6.) When you adjust the

probe offset with no signal applied to the probe input, the output range is ±1 V, (the linear operating range of the probe),

not the ±60 V offset range of the probe. However, when you apply up to ±60 V to the probe input, the probe offset control

canzerothisoffset.

Basic operation

NOTE. If the signal on the screen displays an offset that is either 1 Volt higher or lower than expected, check to make sure

the DUT is connected and operating. This is a result of the input to the LF amplifier being clamped at one extreme of

the dynamic range when no input is present.

Connect MMCX accessories

Gently insert the MMCX end of the cable into one of the following accessories: micro-coax tip, solder flex tip, u.fl adapter or

MMCX to square pin Y-lead adapter, until you feel the connector engage. To remove an accessory, gently pull from the

MMCX connection point, being careful to only grip the knurled metal area of the connector.

Connect solder-in accessories

Micro-coax tip.

soldered to the test point. You can reuse a tip by removing the tip from the solder joint and then trimming the wire insulation

back to expose the center pin and ground shield on the tip cable.

For convenient first-time use, the solder micro-coax tips are shipped pre-trimmed and ready to be

TPR1000 and TPR4000 User Manual 7

Page 22

Basic operation

Flex tip.

point. Feed the

attach the wire to the tip.

To attach the solder flex tip, first solder the enameled self-fluxing copper wire (standard accessory) to the test

wire through the vias on the end of the flex tip, and then apply a small amount of solder to the vias to

Using the solder-pin installation tool

The supplied set of solder pins are intended to be installed on DUT circuit boards and used with the supplied

MMCX-to-square-pin adapter. To install the solder pins, use the supplied soldering-aide tool as described below

NOTE. The solder pins are extremely small and can be challenging to handle. It is recommended to use tweezers and

a magnifying tool when installing pins on a circuit board.

1. Carefully insert the solder pins into the soldering aide tool as shown below.

2. Use the soldering aide tool to hold the solder pins in place while soldering the pins to the circuit board.

3. If necessary, apply a small amount of adhesive to further strengthen the connection to the circuit board. However, keep

the height of the adhesive to a minimum to provide good electrical contact for the adapter.

8 TPR1000 and TPR4000 User Manual

Page 23

Using the tripod

The tripod probe support adds stability to square-pin mounted test points. For m ore stability, use glue to attach the tripod legs

to the DUT circuit board.

Using the optional browser

Basic operation

The optional browser kit contains the following parts: up to 1 GHz browser probe, square pin Y-lead adapter, micro-SMD clip,

three ground leads (alligator, blade, spring), and four replacement probe-tip pins (two rigid, two spring loaded).

WARNING. To prevent injury to the operator or damage to the probe, oscilloscope and device under test, do not touch the

probe ground to any point that is not at the same potential as the chassis ground of the oscilloscope. The probe ground must

be connected to the same potential as the chassis ground of the oscilloscope.

Installing ground leads.

measurements. It is recommended that you use the shortest ground lead that will function in your electrical application. The

following illustration shows the browser probe tip, the tip cover and the three types of grounds leads supplied with the browser.

To install the ground leads:

To obtain accurate m easurements, always attach a ground lead to the probe tip before making

Spring: Slide the ground lead over the probe tip until it seats around the metal part of the probe-tip housing.

Alligator: Slide the ground lead prongs over the exposed metal between the plastic probe-tip sections.

Blade: Locate the slot in the probe-tip housing as shown below. Slide the ground lead over the probe tip until the

blade slides into the slot.

TPR1000 and TPR4000 User Manual 9

Page 24

Basic operation

Connecting the Y-lead adapter and micro-SMD clip.

clip that co

Replacing browser-tip pins.

housi

use pliers to gently insert the pin into the browser-tip housing until you feel the pin press against the bottom of the housing.

nnect as shown below. The Y-lead adapter can also connect to square pins.

To remove the browser-tip pin, use pliers to grasp the pin and gently pull it out of the tip

ng. To install a new browser-tip pin, select between a solid (silver colored) or spring-loaded (gold colored) pin, and then

The browser kit includes a Y-lead adapter and a micro-SMD

10 TPR1000 and TPR4000 User Manual

Page 25

Accessories and options

This section lists the standard accessories and provides information on how to use the accessories. Specifications are

provided where appropriate so that you can choose the accessory that best fits your needs. In some cases, reorder kit

quantities differ from the actual number of accessories included with the probe.

Standard accessories

Each probe is shipped with one TPR4KIT accessory kit containing the following items:

Item

1.3 m cable, SMA male-to-MMCX male, 50 Ω

1.3 m cable, SMA male-to-SMA male, 50 Ω

Accessories and

options

Y-lead adapter, MMCX female-to-0.8 mm sockets

Adapter cable, MMCX female-to-U.FL female, 50 Ω

Adapter, MMCX female-to-square pin (0.062 centers)

DUT interface solder pins, set of 20

Soldering aide tool, 0.062 solder pins over SMT

TPR1000 and TPR4000 User Manual 11

Page 26

Accessories and

Item

Solder-in c able adapter, MMCX female-to-solder micro-coax tip, 50 Ω, set of 3

Solder-in c able adapter, MMCX female-to-solder flex-paddle tip, 50 Ω, set of 3

Wire card, solderable enameled self-fluxing copper wire (for use with the solder-in tips)

Probe tip tripod support (with living hinge)

options

Marker ban

ds, set of 5 (for probe identification)

Optional accessories

This section lists the optional accessories that you can purchase to help you with your probing tasks.

onal TPR4KITHT high-temperature accessory kit i ncludes the following items:

The opti

Item

2 m high

Solder-in c able adapter, MMCX female-to-solder micro-coax tip, 50 Ω, set of 3

Solder-in c able adapter, MMCX female-to-solder flex-paddle tip, 50 Ω, set of 3

-temperature cable, SMA male-to-MMCX male, 50 Ω

12 TPR1000 and TPR4000 User Manual

Page 27

The optional TPRBRWSR1G browser accessory kit includes the following items:

Item

Browser

Ground leads (blade, 0.5 mm spring, 15 cm alligator)

Y-lead adapter, browser tip-to-0.8 mm sockets

Micro-SMD clip

Accessories and

options

Replacem

ent 0.5 mm browser tips (2 solid tips, 2 spring tips)

The optional TPR4SIACOAX accessory kit includes the following items:

Item

Solder-in cable adapter, MMCX female-to-solder micro-coax tip, 50 Ω, set of 3

The optional TPR4SIAFLEX accessory kit includes the following items:

Item

Solder-in cable adapter, MMCX female-to-solder flex-paddle tip, 50 Ω, set of 3

TPR1000 and TPR4000 User Manual 13

Page 28

Accessories and

Options

Service Options

Option CA1. Provides coverage for a single Calibration Event

Option C3. Calibration Service 3 years

Option C5. Calibration Service 5 years

Option D1. Calibration Data Report

Option D3. Calibration Data Report, 3 years (with Option C3)

Option D5. Calibration Data Report, 5 years (with Option C5)

Option R3. Repair Service 3 years

Option R5. Repair Service 5 years

options

Manual Op

Option L0. English language Instruction Manual

Option L5. Japanese language Instruction Manual

Option L7. Simplified Chinese language Instruction Manual

tions

14 TPR1000 and TPR4000 User Manual

Page 29

Probing principles

Follow these helpful hints to make probing easier and noise free.

Ground lead length

When you are probing a circuit, you should

always use as short a ground lead as

possible between the probe head and circuit

ground. (See the illustration for the effects of

lead length on waveform distortion.)

The series inductance added by the probe

tip and ground lead can result in a resonant

circuit; this circuit may cause parasitic ringing

within the bandwidth of your oscilloscope.

Probing princip

les

TPR1000 and TPR4000 User Manual 15

Page 30

Ground lead indu

ctance

Ground lead in

When you touch your probe tip to a circuit element, you are introducing a new resistance, capacitance, and inductance

into the circuit.

You can determine if ground lead effects may

be a problem in your application if you know

the self-inductance (L) and capacitance (C)

of your probe and ground lead. Calculate the

approximate resonant frequency (f

this parasitic circuit will resonate with the

following formula:

The equation shows that reducing the ground

lead inductance will raise the resonant

frequency. If your measurements are

affected by ringing, your goal is to lower

the inductance of your ground path until the

resulting resonant frequency is well above

the frequency of your measurements.

The low-inductance ground contacts

described in Accessories can help you

reduce the effects of ground lead inductance

on your measurements.

ductance

)atwhich

0

16 TPR1000 and TPR4000 User Manual

Page 31

Specifications

Specification

The specifications are valid under the following conditions:

The probe has been calibrated at an ambient temperature of 23 °C ±5 °C.

The probe is connected to a host instrument with an input impedance of 50 Ω.

The probe and oscilloscope must have a warm-up period of at least 20 minutes and be in an environment that does not

exceed the limits described. (See Table 1.)

The Signal Path Compensation (SPC) has been run on the oscilloscope before testing the probe specifications.

Specifications for the TPR1000 and TPR4000 power rail probes fall into three categories: warranted, typical, and nominal

characteristics. The warranted, typical, and mechanical characteristics apply to the TPR1000 and TPR4000 probes unless

noted otherwise. Environmental characteristics are in the Operating considerations section. (See Table 1.)

s

Warranted characteristics

Warranted characteristics describe guaranteed performance within tolerance limits or certain type-tested requirements.

Warranted characteristics that have checks in the Performance Verification section are marked with the

Table 2: Warranted electrical characteristics

Characteristic Description

DC attenuation

DC attenuation accuracy

Analog b

configuration)

DC input dynamic range

Offset scale accuracy

andwidth (SMA

symbol.

1.25x

<±1% within 80% of DC dynamic range

1 GHz (TPR1000)

4 GHz (TPR4000)

>±1 V

±(2% of setting value + 2.5 mV max)

Typical value is ±(0.1% + 2.5 mV) after SPC and Probe Zero

TPR1000 and TPR4000 User Manual 17

Page 32

Specifications

Typical characteristics

Typical characteristics describe typical but not guaranteed performance.

Table 3: Typical electrical characteristics

Characteristic Description

DC input resistance 50 kΩ

Return loss

DC to AC impedance crossover

frequency

DC to AC gain matching ±1%

Risetime (small signal, 20% to 80%) 282 pS (TPR1000)

Risetime (small signal, 10% to 90%) 408 pS (TPR1000)

Step Response Long Term Aberrations <1% of final value after 50 μS

Delay time (comp box only) 565 ps ±20% (TPR1000)

Delay time for each accessory 6.19 ns ±10% (1.3 m MMCX cable)

Delay time (default configuration)

Maximum: -12 dB between 10 MHz and 1 GHz (TPR1000)

Maximum: -12 dB between 10 MHz and 4 GHz (TPR4000)

300 Hz

88 pS (TPR4000)

128 pS (TPR4000)

475 ps ±20% (TPR4000)

9.47 ns ±10% (2 m MMCX cable)

494 pS ±20% (10 cm blue coax solder-in)

500 pS ±20% (10 cm Flex Paddle Adapter)

484 pS ±20% (U.FL to MMCX Adapter)

5.2 nS ±10% (Browser)

7.12 nS

1

1

NOTE. Base configuration consists of

1.3 m SMA to MMCX cable + MMCX

micro coax tip (TRPSIACOAX)

Noise

Noise (probe only, DC to 20 MHz )

Typical: <25% RMS additive to oscilloscope at full bandwidth

Maximum: 220 μVp-p

Typical: 165 μV p-p into 6-series MS O

Input common mode rejection -20 dB 20 Hz up to probe bandwidth

1

50 Ω reference impedance

18 TPR1000 and TPR4000 User Manual

Page 33

Figure 3: TPR1000 frequency response

Specifications

e 4: TPR4000 frequency response

Figur

TPR1000 and TPR4000 User Manual 19

Page 34

Specifications

Figure 5: TPR1000 and TPR4000 input impedance and phase versus frequency

Table 4: Probe typical mechanical characteristics

Characteristic Description

Dimensions, compensation box

Packaged weight

85.1 mm × 40.6 mm × 30.5 mm (3.4 in × 1.6 i n × 1.2 in)

1.24 kg (2.7 lbs)

20 TPR1000 and TPR4000 User Manual

Page 35

Nominal characteristics

Nominal characteristics describe guaranteed traits, but the traits do not have tolerance limits.

Table 5: Nominal electrical characteristics

Characteristic Description

Compatibility Oscilloscopes equipped with the TekVPI interface

Instrument coupling

Input offset requestable range

Non-destructive input voltage range (AC

frequency above 10 kHz)

Specifications

DC, LF‐Reject

±60 V

2.5 VRMS, with peaks ≤±20 V (DF 6.25%)

Input connector on Comp box SMA-female jack

Output connector on cable SMA-male plug

DUT connector on standard cable

DUT connector on optional cable

Insulation voltage rating

Accessory characteristics

Specifications for the TPR1000 and TPR4000 accessories fall into two categories: warranted and typical characteristics.

Table 6: Accessory electrical characteristics

Characteristic Description

TPR4SIAFLEX and TPRSIACOAX

(typical)

SMA to SMA cable (warranted) 1 GHz (TPR1000)

MMCX to U.FL adapter (typical) 1 GHz (TPR1000)

MMCX to square pin adapter (typical) 1 GHz (TPR1000)

MMCX-male plug

SMA-male plug

SMP-female jack

±30 V RMS (AC)

±42 V Peak (pk-pk)

±60 V DC (DC)

1 GHz (TPR1000)

>3.5 GHz (TPR4000)

4 GHz (TPR4000)

>2 GHz(TPR4000)

1 GHz (TPR4000)

TPR1000 and TPR4000 User Manual 21

Page 36

Specifications

Table 6: Accessory electrical characteristics (cont.)

Characteristic Description

2 M high temperature SMA to MMCX

cable (typical)

TPR4BRWSR1G (typical)

TPR4BRWSR1G (typical) 1 GHz with barrel adapter

Table 7: Accessory typical mechanical characteristics

Item number Dimensions

Rigid Browser

Tip

Pogo Browser

Tip

1 GHz (TPR1000)

>2 GHz (TPR4000)

>350 MHz with short ground

Browser

Browser

Spring Ground

22 TPR1000 and TPR4000 User Manual

Page 37

Table 7: Accessory typical mechanical characteristics (cont.)

Item number Dimensions

Browser Blade

Ground

Browser

Alligator

Ground

TPRSIACOAX

Specifications

TPRSIAFLEX

MMCX to U.FL

adapter

TPR1000 and TPR4000 User Manual 23

Page 38

Specifications

Table 7: Accessory typical mechanical characteristics (cont.)

Item number Dimensions

1.3 m SMA to

MMCX Cable

1.3 m SMA to

SMA Cable

2mSMAto

Cable

MMCX

Browser to

Square-pin

adapter

24 TPR1000 and TPR4000 User Manual

Page 39

Table 7: Accessory typical mechanical characteristics (cont.)

Item number Dimensions

MMCX to

Square-pin

adapter

SMT

Component

Clip

Specifications

TPR1000 and TPR4000 User Manual 25

Page 40

Performance ver

ification

Performance v

The procedures that follow verify the warranted specifications of the probe. The recommended calibration interval is one

year. Perform the verification procedures in the order listed.

erification

Equipment required

The following equipment is required for the performance verification procedures.

Table 8: Test equipment

Description and quantity Performance requirement Recommended example

Oscilloscope TekVP I Interface Tektronix 6 Series MSO

DC calibr

Digital m

Network Analyzer Tektronix VNA TTR506A

TekVPI Calibration Verification adapter TekVP I Interface

SMA to BNC adapter SMA male to BNC female

SMA to BNC adapter SMA female to BNC male

SMA to SMA adapter SMA male to SMA male

BNC-to-dual banana adapter (2)

BNC cable (2) 50 Ω, 0.76 m (30 in) length

Fee

SMA cable for network analyzer N to SMA-M 5 foot cable

SMA adapter for network analyzer Type-N male to Type-SMA female

SMA torque wrench 5/16-in, 7 in-lb.

SMA adapter wrench 7/32-in

1

ation source

ultimeter (DMM)

d-thru termination

Nine-digit part numbers (xxx-xxxx-xx) are Tektronix part numbers.

Resistan

50 Ω,1GHz,±0.5Ω

ce, 0.1% accuracy

8 Hz bandwi

Keithley

Keithley 2700 DMM

067-170

BN533828

015-05

015-0

015-0

103-

012-

-0049-XX

011

-1774-XX

012

3-0406-XX

01

dth option

2400 SMU

1-XX with Calibration kit

54-XX

572-XX

551-XX

0090-XX

0117-XX

1

26 TPR1000 and TPR4000 User Manual

Page 41

Equipment setup

Use the following procedures to set up and warm up the equipment to test the probe.

DC setup connection diagram

Use the DC setup diagram for the following performance checks.

DC gain accuracy (See page 29.)

DC input dynamic range (See page 31.)

Input offset range and scale accuracy (See page 32.)

Performance ver

ification

Figure 6: DC setup connection diagram

TPR1000 and TPR4000 User Manual 27

Page 42

Performance ver

Analyzer setup connection diagram

Use the analyzer setup diagram for the analog bandwidth performance check. (See page 33.)

ification

Figure 7: Analyzer setup connection diagram

28 TPR1000 and TPR4000 User Manual

Page 43

Warm up the test equipment

1. Turn on the TekVPI oscilloscope.

2. Connect the TekVPI Calibration/Verification adapter to the oscilloscope.

3. Connect the probe to the TekVPI Calibration Verification adapter and verify that the Status LED on the probe turns green.

4. Turn on the remaining test equipment.

5. Allow 20 m inutes for the equipment to warm up.

6. Use the test record template to record the test results.(S ee page 34, Te st r e co r d .)

Check the DC gain accuracy

Use the following test to check the DC gain accuracy of the probe.

1. Connect the test equipment as shown in the DC setup diagram. (See Figure 6.)

2. Before attaching the probe to the TekVPI Calibration Verification adapter, measure the resistance of the feed-thru

termination with the DMM.

3. Record its value. If it is out of specification, replace the precision terminator before continuing the test.

Performance ver

ification

4. Attach the probe to the TekVPI Calibration Verification adapter.

5. Ensure the probe offset is set to 0 V.

6. Set the digital multimeter (DMM) to the following settings.

DC Volts auto ranging

Filter mode on

Measurement rate slow

7. Set the DC source current limit to 3 mA.

8. Set the DC source to the first voltage level listed below. ( See Table 9.)

NOTE. When using the DMM function in a Keithley S MU, turn on FILTER to reduce transient output values.

9. On the DMM measure the probe response and record the level in the Vout (measured) column in the following table.

Table 9: DC source voltage levels

Index DC source voltage Vout (measured) Vout (linear fit)

–2 –640 mV –512 mV

–1 –320 mV –256 mV

00mV 0mV

1 320 mV 256 mV

2 640 mV 512 mV

10. Repeat steps 8 and 9 for each voltage level listed in the table. (See page 30, DC gain measurement example.)

TPR1000 and TPR4000 User Manual 29

Page 44

Performance ver

11. Perform a linear fit of the measured data points in the preceding table and record the linear fit values in the table.

12. Divide the measured linear fit slope by the slope of the DC source voltage points. (See page 30, DC gain measurement

example.)

ification

13. Record the Mea

sured Gain value in the test record. (See page 34.)

DC gain measurement example

1. The following table lists example measured values.

Table 1 0: Example DC gain measurements

Index DC source voltage Vout (measured) Vout (linear fit)

–2 –640 mV –513 mV –514 mV

–1 –320 mV –256 mV –257 mV

0 0 mV 0.0009 mV 0 mV

1 320 mV 258 mV 257 mV

2 640 mV 515 mV 514 mV

2. The graph below show the plotted example values.

Figure 8: Example plot of measured values

The gain slope can either be obtained by using a spreadsheet to calculate the linear regression of the points, or graphically

by hand. To obtain the gain slope graphically, carefully plot each measurement point on a rectangular coordinate system,

the X axis is the DC source voltage and the Y axis is the measured DC output value. Using a straight edge, draw a line

through the points, minimizing the error between the line and each point. The gain slope is taken by the slope of the

drawn line (rise in Y divided by run in X), and the zero point error taken at the point at which the line crosses the Y axis.

The DC output value can be predicted by the following equation:

3. The following table shows the measured gain as calculated from the slopes of the plotted measured values.

30 TPR1000 and TPR4000 User Manual

Page 45

Table 11: Example calculation of measured gain

Performance ver

ification

Vout (linear fit

)slope

Vin slope Measured gain

0.257 0.320 0.803125

Check the D C input dynamic range

Use the following test to check the DC input dynamic range of the probe.

1. Connect the test equipment as shown in the DC setup diagram. (See Figure 6.)

2. Before attaching the probe to the TekVPI Calibration Verification adapter, measure the resistance of the feed-thru

termination with the DMM.

3. Record its value. If it is out of specification, replace it before continuing the test.

4. Attach the probe to the TekVPI Calibration Verification adapter.

5. Ensure the probe offset is set to 0 V.

6. Set the DMM to DC Volts autoranging.

NOTE. When using the DMM function in a Keithley SMU, turn on FILTER to reduce transient output values.

7. Set the DC source current limit to 3 mA.

8. Set the source measure unit (SMU) to +1 V and record the output voltage on the D MM.

9. Set the source measure unit (SMU) to –1 V and record the output voltage on the DMM.

10. Using the readings taken in steps 8 and 9, apply the following equation to calculate the gain of the probe:

Gain

probe=Vsource÷Vmeasured

11. Verify that the gain is at l east 90% of the nominal gain range for each input by dividing it by the nominal expected gain

and multiplying by 100:

100 x Gain

measured

÷Gain

nominal

12. If the value is >90%, then that limit of the dynamic range is verified.

13. Record results in test record.

14. Switch the probe to DC Reject mode.

15. While measuring the output, apply +1 V and –1 V to the input of the probe.

16. Ensure that output does not shift by more than 0.01 V during the test. Result is reported as Pass or Fail.

17. Return the probe to DC Coupling mode.

18. Record the result in the test record. (See page 34.)

TPR1000 and TPR4000 User Manual 31

Page 46

Performance ver

ification

Check the input offset range and scale accuracy

Use the following test to check the input offset range and scale accuracy of the probe.

1. Connect the test equipment as shown in the DC setup diagram. (See F igure 6.)

2. Before attaching the probe to the TekVPI Calibration Verification adapter, measure the resistance of the feed-thru

termination with the DMM.

3. Record its value. If it is out of specification, replace it before c ontinuing the test.

4. Attach the probe to the TekVPI Calibration Verification adapter.

5. Set the DMM to DC Volts autoranging.

6. Set the DC source current limit to 3 mA.

7. Sweep the DC source through the discrete points listed in the following table and set the probe offset range to the same

set point using the Probe Setup window on the oscilloscope. Measure the probe response at each point with the D MM.

DC source voltage Probe vertical offset setting

+12 V +12 V

+1 V +1 V

–1 V –1 V

–12 V –12 V

8. Record the result of each setting in the test record. (See page 34.)

32 TPR1000 and TPR4000 User Manual

Page 47

Check the analog bandwidth

Use the following test to check the analog bandwidth of the probe.

1. Connect the test equipment as shown in the Analyzer setup diagram. (See Figure 7.)

2. Set the network analyzer to measure insertion loss (S21) in dB. Set the network analyzer to the following settings:

Power Level: –10 dBm

IF Bandwidth: 1 kHz

Sweep Type: Linear

Start Frequency: 300 kHz

Stop Frequency: 6 GHz

Number of points: 201

Set scale factor: 1 dB

For more information on setting up a network analyzer, use the following links:

tek.com/how/making-basic-2-port-measurements-using-ttr500-vna

tek.com/how/how-calibrate-ttr500-vector-network-analyzer

Performance ver

ification

3. Set up the network analyzer with a fresh 2-port SOLT calibration to the reference planes of the SMA side of network

analyzer cable (port 2) and the SMA side of the SMA-to-N adapter (port 1).

4. Place a marker on the S21 trace at the start frequency (300 kHz).

5. Place a marker on the S21 trace at the probe bandwidth (1 GHz for TPR1000 or 4 GHz for TPR4000).

6. Verify that the amplitude is greater than -3.97 dB (subtracting the 0.97 dB of probe attenuation range from the 3.97 dB

target value yields the 3 dB limit).

7. Record the result in the test record. (See page 34.)

TPR1000 and TPR4000 User Manual 33

Page 48

Performance ver

ification

Test record

Probe Model/Serial Number: _____________________ Certificate Number: __________________________

Temperature: _________________________________ RH %: ____________________________________

Date of Calibration: ____________________________ Technician: ________________________________

Performanc

DC gain a ccu

DC input dy

DC reject function Pass/Fail

Input offset range and scale accuracy

+12 V offset

+1 V offs

–1 V offset

–12 V offset

Analog

TPR1000

TPR4000

e test

racy

namic range

et

bandwidth

Minimum Measured / c

0.792 0.808

–1 V NA

NA +1 V

-194 mV 194 mV

-18mV 18mV

-194 mV 194 mV

-18mV 18mV

-3 dB NA

-3 dB NA

alculated

Maximum

34 TPR1000 and TPR4000 User Manual

Page 49

Maintenance

This section contains maintenance information for your probe.

Error condition

The TPR1000 and TPR4000 power rail probes are designed to work with all TekVPI-interface oscilloscopes and adapters.

However, the

re may be some cases where all of the probe features may not work properly.

Maintenance

If the Statu

and reconnect the probe to restart the power-on diagnostic s equence. If the Status LED continues to be red or fl ashing

for more than 30 seconds when the oscilloscope application is running, the probe is defective and must be returned to

Tektronix f

s LED is red or flashing during or after probe power on, an internal probe diagnostic fault exists. Disconnect

or repair.

Replacement parts

There are no user replaceable parts within the probe. Refer to Accessories for a list of replaceable accessories for your probe.

Cleaning

Protect the probe from adverse weather conditions. T he probe is not waterproof.

CAUTION. To prevent damage to the probe, do not expose it to sprays, liquids, or solvents. Avoid getting moisture inside

the prob

Do not use chemical cleaning agents; they may damage the probe. Avoid using chemicals that contain benzine, benzene,

toluene, xylene, acetone, or similar solvents.

Clean the exterior surfaces of the probe with a dry, lint-free cloth or a soft-bristle brush. If dirt remains, use a soft cloth or

swab dampened

enough solution to dampen the swab or c loth. Do not use abrasive compounds on any part of the probe.

e during exterior cleaning.

with a 75% isopropyl alcohol solution. A swab is useful for cleaning narrow spaces on the probe, use only

TPR1000 and TPR4000 User Manual 35

Page 50

Maintenance

36 TPR1000 and TPR4000 User Manual

Page 51

Index

Index

A

Accessories

connect MMCX accessories, 7

connect solder-in

accessories

optional, 12

standard, 11

using the op

browse, 9

using the solder-pin installation

tool, 8

using the tripod, 9

Analog bandwidth

performan

AutoZero, 3

,7

tional 1 GHz

ce check, 33

C

Cleaning the probe, 35

Connecti

ng the probe, 2

D

DC gain accuracy

performance check, 29

t dynamic range

DC inpu

performance check, 31

Documentation, vi

E

condition, 35

Error

F

Features, vii

Functional check, 4

i

G

Ground lead

inductance

selecting length, 15

,16

I

Indicators, 2

Input offs

et range and scale accuracy

performance check, 32

L

LED

Status,

2

M

Maintenance, 35

Menu Button, 3

O

t, 7

Offse

Operating considerations, 1

Options, 14

P

Performance v

equipment required, 26

equipment setup, 27

Probe contro

erification, 26

ls and indicators, 2

R

Related documentation, vi

Replacement parts, 35

S

Specificat

Status LED, 2, 35

ions, 17

accessories, 21

nominal, 21

18

typical,

warranted, 17

T

TekVPI,

Test record, 34

2

TPR1000 and TPR4000 User Manual 37

Loading...

Loading...