Page 1

Instruction Manual

TMSSY2

mPGA479 Socket Support

(Includes TMSMPH4 mPGA479

probe head installation instructions)

071-1899-00

www.tektronix.com

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or

suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered tra demarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

H In North America, call 1-800-833-9200.

H Worldwide, visit www.tektronix.com to find contacts in your area.

Page 3

WARRANTY 2

Tektronix warrants that the products that it manufactures and sells will be free from defec ts in materials and

workmanship for a period of one (1) year from the date of shipment. If a product proves defective during this

warranty period, Tektronix, at its option, either will repair the defective product without charge for parts and labor,

or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by Tektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the Tektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than Tektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR

THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

WARRANTY 9b

Tektronix warrants that the media on which this software product is furnished and the encoding of the programs on

the media will be free from defects in materials and workmanship for a period of three (3) months from the date of

shipment. If a medium or encoding proves defective during the warranty period, Tektronix will provide a

replacement in exchange for the defective medium. Except as to the media on which this software product is

furnished, this software product is provided “as is” without warranty of any kind, either express or implied.

Tektronix does not warrant that the functions contained in this software product will meet Customer’s

requirements or that the operation of the programs will be uninterrupted or error-free.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period. If Tektronix is unable to provide a replacement that is free from defects in materials and

workmanship within a reasonable time thereafter, Customer may terminate the license for this software product

and return this software product and any associated materials for credit or refund.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPLACE DEFECTIVE MEDIA OR REFUND CUSTOMER’S PAYMENT IS

THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS

WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT,

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER

TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 5

Table of Contents

General Safety Summary iii...................................

Service Safety Summary v....................................

Environmental Considerations vii...............................

Preface ix...................................................

Getting Started 1............................................

Logic Analyzer Configuration 2......................................

Connect the P6960 Probes and TMSCAB1 Cables 3.......................

Connect the Logic Analyzer to a SUT 5................................

Replaceable Parts List 9.............................................

Logic Analyzer Software Compatibility 10...............................

Installing the Software 10............................................

Support Package Setup 10............................................

Maintenance and Shipping 11..................................

Care and Maintenance 11.............................................

Shipping the Probe Adapter 15........................................

Specifications 17............................................

Circuit Description 17...............................................

Loading Diagrams 18................................................

Specifications 20...................................................

Certifications and Compliances 23.....................................

Appendix 29.................................................

Accessories 29.....................................................

Apply TMSCAB1 Labels 30..........................................

Probe Adapter Notes 31..............................................

TMSSY2 mPGA479 Socket Hardware Support

i

Page 6

Table of Contents

List of Figures

Figure 1: Master and Slave module configuration 2...............

Figure 2: Module configuration 3..............................

Figure 3: Probe, cable and preprocessor unit 4...................

Figure4:ProbeheadinstallationusingChipcool1&2heatsink

hardware 7.............................................

Figure 5: Install heat sink (Chipcool 1 & 2) 8....................

Figure 6: Preprocessor unit in static-shielding bags 13.............

Figure 7: Folded cables 13.....................................

Figure 8: Probe head storage case 14............................

Figure 9: Probe adapter load model for typical signals 18...........

Figure 10: Preprocessor load model for typical signals 18...........

Figure 11: Receiver topology A 19..............................

Figure 12: Receiver topology B 19..............................

Figure 13: Receiver topology C 19..............................

Figure 14: Eye diagram 21.....................................

Figure 15: Dimensions of the probe head 26......................

Figure 16: Dimensions of the preprocessor unit 27.................

Figure 17: Apply TMSCAB1 labels 30...........................

List of Tables

Table 1: Preprocessor airflow clearance 5.......................

Table 2: Replaceable parts list 9...............................

Table 3: Electrical specifications for the SUT 20..................

Table 4: Electrical specifications for the AC input to the

preprocessor unit 21......................................

Table 5: BCLK timing and electrical specifications at 25 5C 21.....

Table 6: Environmental specifications 21........................

ii

TMSSY2 mPGA479 Socket Hardware Support

Page 7

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions related to operating the system.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

The inputs are not rated for connection to mains or Category II, III, or IV

circuits.

Connect the probe reference lead to earth ground only.

Power Disconnect. The power switch disconnects the product from the power

source. See instructions for the location. Do not block the power switch; it must

remain accessible to the user at all times.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

TMSSY2 mPGA479 Socket Hardware Support

iii

Page 8

General Safety Summary

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

Terms in this Manual

Symbols and Terms

on the Product

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

H DANGER indicates an injury hazard immediately accessible as you read the

marking.

H WARNING indicates an injury hazard not immediately accessible as you

read the marking.

H CAUTION indicates a hazard to property including the product.

The following symbol(s) may appear on the product:

CAUTION

Refer to Manual

WARNING

High Voltage

iv

Protective Ground

(Earth) Terminal

Mains Disconnected

OFF (Power)

Mains Connected

ON (Power)

TMSSY2 mPGA479 Socket Hardware Support

Page 9

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

TMSSY2 mPGA479 Socket Hardware Support

v

Page 10

Service Safety Summary

vi

TMSSY2 mPGA479 Socket Hardware Support

Page 11

Environmental Considerations

This section provides information about the environmental impact of the

product.

Product End-of-Life

Handling

Observe the following guidelines when recycling an instrument or component:

Equipment Recycling. Production of this equipment required the extraction and

use of natural resources. The equipment may contain substances that could be

harmful to the environment or human health if improperly handled at the

product’s end of life. In order to avoid release of such substances into the

environment and to reduce the use of natural resources, we encourage you to

recycle this product in an appropriate system that will ensure that most of the

materials are reused or recycled appropriately.

The symbol shown to the left indicates that this product

complies with the European Union’s requirements

according to Directive 2002/96/EC on waste electrical and

electronic equipment (WEEE). For information about

recycling options, check the Support/Service section of the

Tektronix Web site (www.tektronix.com).

Battery Recycling. This product may contain a Nickel Cadmium (NiCd) or

lithium ion (Li--ion) rechargeable battery, which must be recycled or disposed of

properly. Please properly dispose of or recycle the battery according to local

government regulations.

Restriction of Hazardous

Substances

TMSSY2 mPGA479 Socket Hardware Support

This product has been classified as Monitoring and Control equipment, and is

outside the scope of the 2002/95/EC RoHS Directive. This product complies

with the RoHS Directive requirements except for the presence of hexavalent

chromium in the surface coating of the aluminum chassis parts, assembly

hardware, and 63/37 tin/lead solder used in the fabrication of the circuit boards.

vii

Page 12

Environmental Considerations

viii

TMSSY2 mPGA479 Socket Hardware Support

Page 13

Preface

This manual contains specific information about the TMSSY2 preprocessor unit

and the TMSMPH4 probe head that combine to make a probe adapter. This

manual is part of a set of information on how to operate this product on

compatible Tektronix Logic Analyzers.

If you are familiar with operating microprocessor support probe adapters with the

logic analyzer, you need only this manual to set up and run the probe adapter.

TMSSY2 mPGA479 Socket Hardware Support

ix

Page 14

Preface

x

TMSSY2 mPGA479 Socket Hardware Support

Page 15

Getting Started

The TMSSY2 support product (preprocessor unit) is an interposer design that

allows the logic analyzer to acquire data from a microprocessor in the operating

environment with little affect on the SUT.

To accomplish this, the probe adapter (preprocessor unit and probe head) is

connected to the SUT, and then the microprocessor is connected to the probe

adapter. Signals from the microprocessor-based system flow through the probe

adapter cables to the logic analyzer where the loaded support software disassembles data acquired from the SUT.

The TMSSY2 support product includes:

H TMSSY2 preprocessor unit

H CD-ROM with PUB32G15 support software and instruction manual

NOTE. To acquire signals from the SUT you also need compatible cables, probes,

and probe head to complete the connection between the logic analyzer and the

SUT. Contact your Tektronix sales representative for information about these

other products.

For optional and standard accessories for this product, see Accessories on

page 29.

TMSSY2 mPGA479 Socket Hardware Support

1

Page 16

Getting Started

Logic Analyzer Configuration

To use the probe adapter to acquire state signals, you need a Tektronix Logic

Analyzer equipped with four, merged 235 MHz, TLA7Ax4 logic analyzer

modules.

The modules must be configured and merged as shown in Figure 1. The memory

depth is automatically based on the shallowest memory depth of the modules.

The term Master module refers to the second module of a 4-wide module

configuration. (See Figure 1). The term Slave module refers to the modules to

the left or right of the Master module.

S

L

A

V

E

2

Figure 1: Master and Slave module configuration

All signals are acquired through probes connected to the logic analyzer. Use the

logic analyzer modules and the P6960 probes to connect to the probe adapter.

The probes should already be labeled; if you need to apply labels, refer to the

instructions that came with your probe documentation.

CAUTION. To prevent damage to the P6960 connectors on the preprocessor unit,

Tektronix recommends that you use the strain relief method that is described in

the P69XX Series Instruction Manual, Tektronix part number 071-1528-XX, after

connecting the P6960 probes.

M

A

S

T

E

R

S

L

A

V

E

1

S

L

A

V

E

3

You can access the P69XX Series Instruction Manual from the Tektronix.com

Web site.

2

TMSSY2 mPGA479 Socket Hardware Support

Page 17

Connect the P6960 Probes and TMSCAB1 Cables

Use the P6960 probes and the TMSCAB1 cables to connect to the TLA7Ax4

logic analyzer modules to the preprocessor unit.

NOTE. If you need to attach labels to TMSCAB1 cables, refer to Appendix 30.

Getting Started

TMSCAB1

Modules

4 5(M,S1,S2) 6(M,S3) Does not acquire auxiliary

cables

P6960 probes (2)

S

L

A

V

E

2

TMSCAB1 cables (5)

M

A

S

T

E

R

P6960

probes

S

L

A

V

E

1

S

L

A

V

E

3

P6960 probes (4)

Description

common clock signals

Support

Software

PUB32G15

Figure 2: Module configuration

TMSCAB1 Cables

TMSSY2 mPGA479 Socket Hardware Support

1. From the Master module, match the label on the TMSCAB1 cable with the

corresponding connector label on the preprocessor unit and connect the

cable. The TMSCAB1 cable connector is keyed for correct alignment to the

preprocessor unit.

2. Use care to evenly tighten both screws on the module end of the probes or

cables until they are snug. First slightly tighten both screws, then snug each

screw to 4 in-lbs (max).

3. Repeat step 1 to attach the TMSCAB1 cables with the Slave1 and Slave2

modules.

3

Page 18

Getting Started

CAUTION. To prevent damage to the probe and preprocessor unit, always

position the probes perpendicular to the footprint on the circuit board. Incorrect

handling of the probe while connecting to or disconnecting from the preprocessor unit can damage the probe.

When attaching the probe head, use care to evenly tighten the probe head screws

until they are snug. First, tighten both screws until the nut bar makes contact

with the board surface, and then snug each screw to 1 in-lbs (max). Under-tightening the screws can result in intermittence. Over-tightening can result in

damage to the elastomer holder and stripped screws.

P6960 Probes

4. Match the A, D, C, and E probes from the Slave3 and Master module with

the corresponding D3/D2 and A3/A2, D1/D0 and A1/A0, C1/C0 and C3/C2,

and E3/E2 and E1/E0 connector labels on the preprocessor unit. The P6960

probe connector is keyed for correct alignment to the preprocessor unit.

NOTE. To prevent faulty connections and loss of data, check that the probe board

connections are clean and free of debris.

P6960

Single-ended probe

TMSCAB1 cable

Figure 3: Probe, cable and preprocessor unit

4

TMSSY2 mPGA479 Socket Hardware Support

Page 19

Connect the Logic Analyzer to a SUT

CAUTION. To prevent static damage to the microprocessor, the probe adapters,

the probes, and the module, handle components only in a static-free environment.

Always wear a grounding wrist strap, heel strap, or similar device while

handling the microprocessor and probe adapter.

WARNING. To prevent harm to yourself or damage to the preprocessor unit, do

not open the preprocessor unit. There are no operator serviceable parts inside

the preprocessor unit. Refer servicing of internal parts in the preprocessor unit

to Tektronix authorized personnel only. External parts may be replaced by

qualified service personnel.

Getting Started

Airflow Clearance

Tools

Table 1 lists airflow clearances for the preprocessor unit.

Table 1: Preprocessor airflow clearance

Characteristic Description

Required airflow clearances for the

preprocessor

Front, top, left side 5.08 cm (2 in)

Back 7.60 cm (3 in)

Bottom, right side 0.635 cm (0.250 in)

Following is a list of tools:

H Required. Use a flatbladed screwdriver (0.1-in tip width) to lock the ZIF

socket.

H Required. Phillips (P1) screwdriver to tighten the screws that attach the

heatsink brackets.

H Optional. A torque wrench helps to ensure reliable connections to meet the

nominal torque values that may be listed in these instructions. When

attaching screws to the probe head use 2 in-lbs (0.226 Newton meters) of

torque, unless stated otherwise.

NOTE. For storage and shipping, retain the cardboard cartons and packing

material that are shipped with the probe adapter.

For a list of replaceable parts, see page 9.

TMSSY2 mPGA479 Socket Hardware Support

5

Page 20

Getting Started

Read the following instructions before removing or installing parts.

Connect the Logic

Analyzer

Use the following steps to connect the logic analyzer to the SUT:

1. Power off the SUT. It is not necessary to power off the logic analyzer.

2. Power off any preprocessor units that may be attached to your SUT.

NOTE. T o dischar ge static electricity , touch the ground connector located on the

logic analyzer.

3. Remove the heat sink and any retention brackets from the SUT.

CAUTION. To prevent damage to the probe head and pins, you must always

handle the probe head carefully and use care to properly align the probe head

pins to the ZIF socket on the SUT. Also, reinstall the pin protector on the bottom

of the probe head when the probe head is not in use.

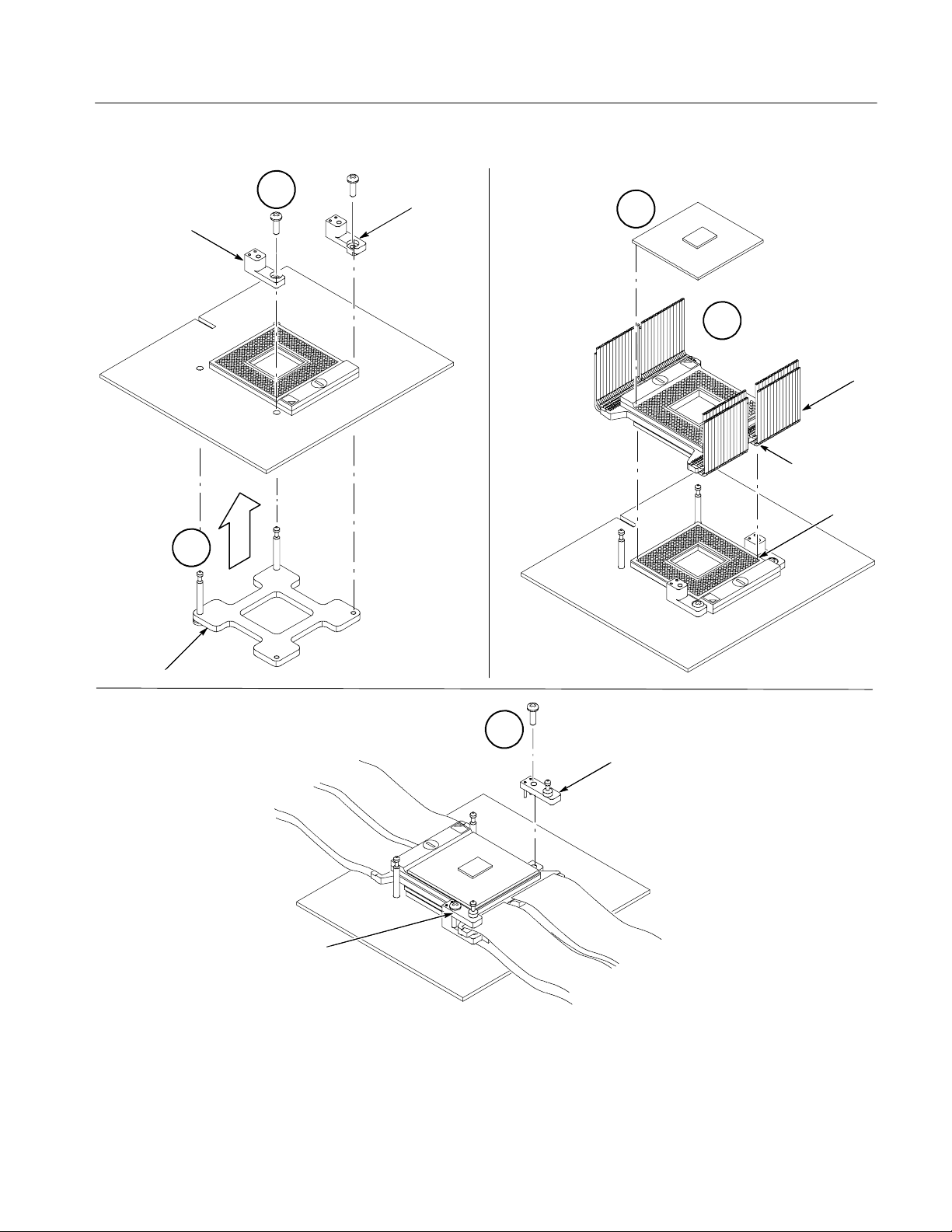

4. Attach the TMSMPH4 probe head.

To attach the probe head to the SUT use the Chipcool 1&2 heat sink

attachment kit (020-2616-XX) and follow the steps shown in Figures 4 & 5

startingonpage7.

6

TMSSY2 mPGA479 Socket Hardware Support

Page 21

Getting Started

Heat sink attaching hardware:

Using the supplied screws, attach

the two bottom brackets as shown.

Bottom bracket

(blue)

SUT

Insert bottom

plate as shown.

1

2

Bottom

bracket

(black)

the socket and lock

the ZIF socket on the

Install the

microprocessor in

probe head.

SUT

3

Connect the probe head

to the SUT and lock the

4

ZIF socket on the SUT.

Probe head

Remove pin

protector

Pin 1

Bottom plate

Heat sink attaching hardware:

Using the supplied screws, attach

the two top brackets to the SUT.

Top bracket

(blue)

5

Figure 4: Probe head installation using Chipcool 1 & 2 heat sink hardware

Top bracket

(black)

SUT

TMSSY2 mPGA479 Socket Hardware Support

7

Page 22

Getting Started

Place the heat sink on the

probe head with the four

bottom-plate posts inserted

into the heat-sink holes.

Post

Slide the heat sink

housing all the way

over to the post

Figure 5: Install heat sink (Chipcool 1 & 2)

6

SUT

Probe Head Removal

Applying and Removing

Power

Follow these steps to remove the probe head from the SUT:

1. Power off the SUT, and unplug the AC power cord on the preprocessor unit.

The power switch is located on the back of the preprocessor unit. It is not

necessary to power off the logic analyzer mainframe.

2. ReversethestepsinFigures4and5onpages7and8toremovetheprobe

head.

3. Store the probe head in the original packing material.

To apply power to the probe adapter and SUT, follow these steps:

1. Make sure the power switch on the preprocessor unit is in the off position. If

powered off, the zero (0) is visible on the power switch.

2. Plug the AC power cord into the IEC connector on the back of the preproces-

sor unit.

3. Plug the AC power cord into an electrical outlet.

4. Power on the preprocessor unit using the switch on the back of the prepro-

cessor unit. A green, power-on LED lights on the front of the preprocessor

unit, indicating that the preprocessor unit is active.

5. Power on the SUT.

To remove power from the SUT and the preprocessor unit, reverse the preceding

steps.

8

TMSSY2 mPGA479 Socket Hardware Support

Page 23

Replaceable Parts List

Getting Started

Refer to Table 2 to reorder replaceable parts for the probe head and preprocessor

unit.

NOTE. For a list of standard and optional accessories, refer to Appendix 2.

Table 2: Replaceable parts list

Fig.

number

&page

number

3--4 TMSSY2 1 CIRCUIT BOARD ASSY; PROBE HEAD BOARD

4--7 TMSMPH4

8--14 016-1941-XX 1 CASE, STORAGE: PLASTIC, W/FOAM,

1

Part number Quantity Description

W/CABLES & PADDLE BOARD;TESTED

1

1 MICRO SUPPORT; PROBE HEAD; M--479 PIN

MPGA FOR USE WITH TMSSY2

12.4X8.9X2.9;FLEX CABLE ASSEMBLY

To replace the heat sink attaching hardware, refer to the Appendix under

Standard Accessories on page 29 for heat-sink kit part number.

TMSSY2 mPGA479 Socket Hardware Support

9

Page 24

Getting Started

Logic Analyzer Software Compatibility

Refer to the label on the software support CD for the current compatible version

of the Tektronix Logic Analyzer system software.

Installing the Software

NOTE. Before you install any software, verify that the microprocessor support

software is compatible with the logic analyzer software. Compare the version

number on the CD to the Tektronix logic analyzer system software.

To install the PUB32G15 software on the Tektronix logic analyzer, follow these

steps:

1. Insert the CD in the CD drive.

2. Follow the on-screen instructions to install the software.

Support Package Setup

To remove or uninstall software, use the Add or Remove Programs utility in the

Windows Control Panel. Close all windows before you uninstall any software.

The PUB32G15 support software installs one setup file. After installing the

software, you need to load the PUB32G15 setup file. Follow these steps:

1. Open a logic analyzer system window and select File, Load Support

Package.

2. In the Load Support Package dialog box, select the support and click load.

3. Follow the on-screen instructions.

10

TMSSY2 mPGA479 Socket Hardware Support

Page 25

Maintenance and Shipping

Care and Maintenance

Before cleaning this product, read the following information:

CAUTION. To prevent static damage to the microprocessor, the probe adapter, the

probes, and the module, handle components only in a static-free environment.

Always wear a grounding wrist strap, heel strap, or similar device while

handling the microprocessor and probe adapter.

The probe adapter, consisting of the probe head and preprocessor unit, does not

require scheduled or periodic maintenance. However, to keep good electrical

contact and efficient heat dissipation, keep the probe adapter free of dirt, dust,

and contaminants. When not in use, store the probe adapter in the original

shipping bags and cardboard carton.

External Cleaning Only

Fuses

Clean dirt and dust with a soft bristle brush. For more extensive cleaning, use

only a damp cloth moistened with deionized water; do not use any chemical

cleaning agents.

WARNING. To prevent harm to yourself or damage to the preprocessor unit, do

not open the preprocessor unit for cleaning and do not allow any moisture inside

the preprocessor unit. There are no operator serviceable parts inside the

preprocessor unit. Refer servicing of internal parts in the preprocessor unit to

Tektronix authorized personnel only. External parts may be replaced by qualified

service personnel.

There are no user-replaceable fuses in the preprocessor unit.

If the probe adapter is not functioning correctly, contact your Tektronix sales

representative.

TMSSY2 mPGA479 Socket Hardware Support

11

Page 26

Maintenance and Shipping

Short-Term Storage

Follow steps 1 through 4 for short-term storage of the probe head:

CAUTION. To prevent static damage to the microprocessor, the probe adapter, the

probes, and the module, handle components only in a static-free environment.

Always wear a grounding wrist strap, heel strap, or similar device while

handling the microprocessor and probe adapter.

1. Power off the SUT and unplug the AC power cord on the preprocessor unit.

It is not necessary to power off the logic analyzer.

2. To remove the probe head, reverse the probe installation instructions

(starting on page 7) that apply to your heat sink attachment hardware.

CAUTION. To prevent damage to the sensitive probe head cables, you must

position the cables so that they are not pinched or contacting any sharp objects.

When you fold the cables, use a minimum radius of 0.25 (0.64 cm) at the fold.

3. Using antistatic nongenerating tape, tape the pin-protector board onto the pin

header on the bottom of the probe head.

4. Store the probe head in an antistatic bag.

12

TMSSY2 mPGA479 Socket Hardware Support

Page 27

Maintenance and Shipping

Long-Term Storage

Follow these steps using the existing cardboard carton and packaging:

1. Disconnect the preprocessor unit from the logic analyzer by removing the

probes and TMSCAB1 cables from the top of the preprocessor unit.

2. Place the preprocessor unit and cables in static-shielding bags.

Figure 6: Preprocessor unit in static-shielding bags

3. Place the foam in the bottom of the cardboard carton.

4. Place the foam end caps on both sides of the preprocessor unit.

5. Place the preprocessor unit in the cardboard carton.

Figure 7: Folded cables

6. Place the preprocessor cables carefully over the preprocessor unit.

7. Place foam on top of the preprocessor unit and lay the preprocessor cables on

top of the foam.

TMSSY2 mPGA479 Socket Hardware Support

13

Page 28

Maintenance and Shipping

8. Place the accessory tray in the cardboard carton.

9. Place the probe head in the black plastic storage case.

10. Place the storage case in the accessory tray.

Figure 8: Probe head storage case

11. Close and tape the cardboard carton.

To ship the probe adapter, refer to Shipping the Probe Adapter.

14

TMSSY2 mPGA479 Socket Hardware Support

Page 29

Shipping the Probe Adapter

To commercially transport the probe adapter, package as follows:

1. Use the existing cardboard shipping carton and cushioning material to ship

the probe adapter. See Long-Term Storage for repackaging instructions.

If the existing shipping carton is not available, use a double-walled,

corrugated cardboard shipping carton that allows a 3 inch (7.62 cm)

minimum on all sides of the product.

2. If you are shipping a probe adapter to a Tektronix service center for Warranty

service, attach a tag to the probe adapter showing the following:

H Owner’s name and address

H Name of a person who can be contacted

H Probe adapter type and serial number

H Description of the problem

Maintenance and Shipping

TMSSY2 mPGA479 Socket Hardware Support

15

Page 30

Maintenance and Shipping

16

TMSSY2 mPGA479 Socket Hardware Support

Page 31

Specifications

Circuit Description

The probe adapter hardware uses a custom ASIC to preprocess the 4x (Quad

Pumped) Signals before the signals are captured by the logic analyzer. The

custom ASIC performs the following functions:

H Latches signals within a narrow valid window

H Demultiplexes double-pumped, source-synchronous signals

H Deterministically synchronizes source-synchronous signals to BCLK

All other signals are buffered and amplified in the probe adapter hardware before

being captured by the logic analyzer.

Latched Operation

Signal Probing

Bus Tracking Logic

The microprocessor signals are processed in the probe adapter according to their

type. Following is a description of each type:

4x Quad-Pumped Signals. These signals include D[63:00]# and DBI[3:0]#. The

ASIC latches these signals using their dedicated strobes, STBP[3:0] and

STBN[3:0], and then performs four-way demultiplexing on these signals. The

ASIC also inverts the appropriate signals when the DBI[3:0] signals are active.

2x Double-Pumped Signals. These signals include A[39:03]# and REQ[4:0]#. The

logic analyzer latches these signals using their dedicated strobes, ASTB[1:0],

and then performs two-way demultiplexing on these signals.

1x Common-Clock Signals. These signals include all of the remaining front-side bus

signals. The logic analyzer latches these signals using the rising edge of BCLK.

The probe adapters use passive series isolation to acquire data.

The probe adapter uses a bus tracking PAL to aid the disassembly software in

linking various bus phases.

TMSSY2 mPGA479 Socket Hardware Support

17

Page 32

Specifications

Loading Diagrams

Processor and

mated PGA socket

Preprocessor

Model

Preprocessor

Model

Preprocessor

Model

VSS

75 Ω

4 inches

477 ps

--0.4 dB

75 Ω

4 inches

477 ps

--0.4 dB

75 Ω

4 inches

477 ps

--0.4 dB

Out 1

Out 2

Out 3

75 Ω

1300 mils

213 ps

0.7 pF 0.7 pF

0.7 pF 0.7 pF

75 Ω

1300 mils

213 ps

75 Ω

1300 mils

213 ps

200 Ω+/−1%

200 Ω+/−1%

200 Ω+/−1%

75 Ω

25 mils

4.6 ps

75 Ω

25 mils

4.6 ps

75 Ω

25 mils

4.6 ps

Node 6

Node 5

Node 8

Motherboard socket

mated with LAI pin

header and LAI PCB

VSS

Node 1

Node 4

Node 9

0.7 pF 0.7 pF

Figure 9: Probe adapter load model for typical signals

10 m Ω

0.5 pF

0.7 pF 0.5 pF

0.7 pF

Figure 10: Preprocessor load model for typical signals

18

75 Ω

44 inches

4.18 ns

--1.58 dB

75 Ω

25 mils

4.6 ps

0.4 pF

Receiver topology

A, B, or C

TMSSY2 mPGA479 Socket Hardware Support

Page 33

Specifications

75 Ω

83 ps

225 fF

Figure 11: Receiver topology A

150 nH

75 Ω

750 Ω

+

0.53 V

--

Figure 12: Receiver topology B

0.2 Ω

150 nH

750 Ω

100 Ω

5ps

75 k Ω

450 fF

75 Ω

+

0.8 V

--

150 nH

750 Ω

Figure 13: Receiver topology C

150 nH

750 Ω

75 k Ω

TMSSY2 mPGA479 Socket Hardware Support

19

Page 34

Specifications

Specifications

These specifications are for a probe adapter connected between a compatible

Tektronix logic analyzer and a SUT. Signal voltage swing in your SUT must be

at least 200 mV

around the GTL+ reference voltage.

p-p

Table 3 lists the electrical requirements of the SUT. Table 4 on page 21 lists the

electrical requirements for the power supply that provides power to the probe

adapter. Table 5 on page 21 lists the BCLK timing and electrical specifications.

Table 6 on page 21 lists the environmental specifications.

Table 3: Electrical specifications for the SUT

Characteristics Requirements (typical)

DC power requirements

Voltage, V

cc

Current, GLT

REF

1.05 V ᐔ5%

I maximum <15 nA, I typical <3 nA at 25 °C

Common clock rate Maximum 200 MHz

Common clock capture

Typical - - Vcc=1.05V,V

=0.7V,VIH=V

REF

+100 mV, VIL=V

REF,

Window 900 ps

T

su

T

hd

900 ps

0ps

2x Source-Synchronous capture

Window 750 ps

T

su

T

hd

375 ps

375 ps

4x Source-Synchronous capture

(DBI disabled)

Window 500 ps

T

su

T

hd

200 ps

300 ps

--100mV,at25°C

REF

20

TMSSY2 mPGA479 Socket Hardware Support

Page 35

Specifications

In Figure 14, the

ᐔ100 mV must be centered around GTLREF and the ringback

cannot come within 60 mV of GTLREF after the initial 100 mV requirement to

detect the initial transition.

40 ps

100 mV

100 mV

DSTRB, ADSTRB

su hd

Composite LAI

time/voltage eye

60 mV

60 mV

Figure 14: Eye diagram

Table 4: Electrical specifications for the AC input to the preprocessor unit

Characteristic Description

Input Voltage rating 100 -- 240 VAC ᐔ10% CAT II

Input Frequency rating 50 -- 60 Hz

Input Current rating 6 A maximum

Table 5: BCLK timing and electrical specifications at 25 °C

Characteristics Minimum Maximum Units Notes

Vin(lo) min -- V

Vin(hi) max V

+100 mV -- V

REF

--100 mV V

REF

Duty Cycle 45 55 %

Table 6: Environmental specifications

Characteristic

Temperature

Maximum operating +50 °C (+122 °F)

1

Description

2

TMSSY2 mPGA479 Socket Hardware Support

21

Page 36

Specifications

Table 6: Environmental specifications (cont.)

Characteristic

1

Description

Minimum operating 0 °C(+32°F)

Nonoperating -- 5 5 °Cto+75°C(--67°F to +167 °F)

Humidity 10 to 95% relative humidity, noncondensing

Altitude

Operating 3 km (10,000 ft) maximum

Nonoperating 15 km (50,000 ft) maximum

Electrostatic immunity The probe adapter is static sensitive

1

Designed to meet Tektronix standard 062-2847-00 class 5.

2

Not to exceed microprocessor thermal considerations. Customer supplied cooling

might be required across the CPU.

22

TMSSY2 mPGA479 Socket Hardware Support

Page 37

Certifications and Compliances

Specifications

EC Declaration of

Conformity - EMC

Australia / New Zealand

Declaration of Conformity

-EMC

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility.

Compliance was demonstrated to the following specifications as listed in the

Official Journal of the European Communities:

EN 61326. EMC requirements for Class A electrical equipment for measurement,

control, and laboratory use (conducted emissions). Annex D.

H IEC 61000--4--2. Electrostatic discharge immunity

H IEC 61000--4--3. RF electromagnetic field immunity

H IEC 61000--4--4. Electrical fast transient / burst immunity

H IEC 61000--4--5. Power line surge immunity

H IEC 61000--4--6. Conducted RF Immunity

H IEC 61000--4--11. Voltage dips and interruptions immunity

EN 61000- 3- 2. AC power line harmonic emissions

EN 61000- 3- 3. Voltage changes, fluctuations, and flicker

Complies with EMC provision of Radiocommunications Act per these standard(s):

H AS/NZS 2064.1/2. Industrial, Scientific, and Medical Equipment: 1992

H AS/NZS 3548. Information Technology Equipment: 1995

EMC Compliance

FCC Compliance

Russian Federation

Peoples Republic of China

TMSSY2 mPGA479 Socket Hardware Support

Meets the intent of Directive 89/336/EEC for Electromagnetic Compatibility

when it is used with the product(s) stated in the specifications table. Refer to the

EMC specification published for the stated products. May not meet the intent of

the directive if used with other products.

Emissions comply with FCC 47 CFR, Part 15, Subpart B for Class A equipment.

This product was certified by the GOST ministry of Russia to be in compliance

with all applicable EMC regulations.

This product has received the Chinese Metrology Certification. (CMC).

23

Page 38

Specifications

EC Declaration of

Conformity - Low Voltage

U.S. Nationally

Recognized Testing

Laboratory Listing

Canadian Certification

Additional Compliance

Equipment Type

Safety Class

Compliance was demonstrated to the following specification as listed in the

Official Journal of the European Communities:

Low Voltage Directive 73/23/EEC, amended by 93/68/EEC.

H EN 61010-1:2001. Safety requirements for electrical equipment for

measurement control and laboratory use.

H UL 61010B--1:2003. Standard for electrical measuring and test equipment.

H CAN/CSA C22.2 No. 1010.1:1997. Particular requirements for electrical

equipment for measurement, control, and laboratory use. Part 1.

H IEC 61010--1:2001. Safety requirements for electrical equipment for

measurement, control, and laboratory use.

Test and measuring equipment

Class 1 -- grounded product

Pollution Degree

Descriptions

Pollution Degree

A measure of the contaminates that could occur in the environment around and

within a product. Typically the internal environment inside a product is

considered to be the same as the external. Products should be used only in the

environment for which they are rated.

H Pollution Degree 1. No pollution or only dry, nonconductive pollution

occurs. Products in this category are generally encapsulated, hermetically

sealed, or located in clean rooms.

H Pollution Degree 2. Normally only dry, nonconductive pollution occurs.

Occasionally a temporary conductivity that is caused by condensation must

be expected. This location is a typical office/home environment. Temporary

condensation occurs only when the product is out of service.

H Pollution Degree 3. Conductive pollution, or dry, nonconductive pollution

that becomes conductive due to condensation. These are sheltered locations

where neither temperature nor humidity is controlled. The area is protected

from direct sunshine, rain, or direct wind.

H Pollution Degree 4. Pollution that generates persistent conductivity through

conductive dust, rain, or snow. Typical outdoor locations.

Pollution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor use only.

24

TMSSY2 mPGA479 Socket Hardware Support

Page 39

Specifications

Installation (Overvoltage)

Category Descriptions

Overvoltage Category

Terminals on this product may have different installation (overvoltage) category

designations. The installation categories are:

H Measurement Category IV. For measurements performed at the source of

low-voltage installation.

H Measurement Category III. For measurements performed in the building

installation.

H Measurement Category II. For measurements performed on circuits directly

connected to the low-voltage installation.

H Measurement Category I. For measurements performed on circuits not

directly connected to MAINS.

Overvoltage Category II (as defined in IEC 61010-1), for power input only.

TMSSY2 mPGA479 Socket Hardware Support

25

Page 40

Specifications

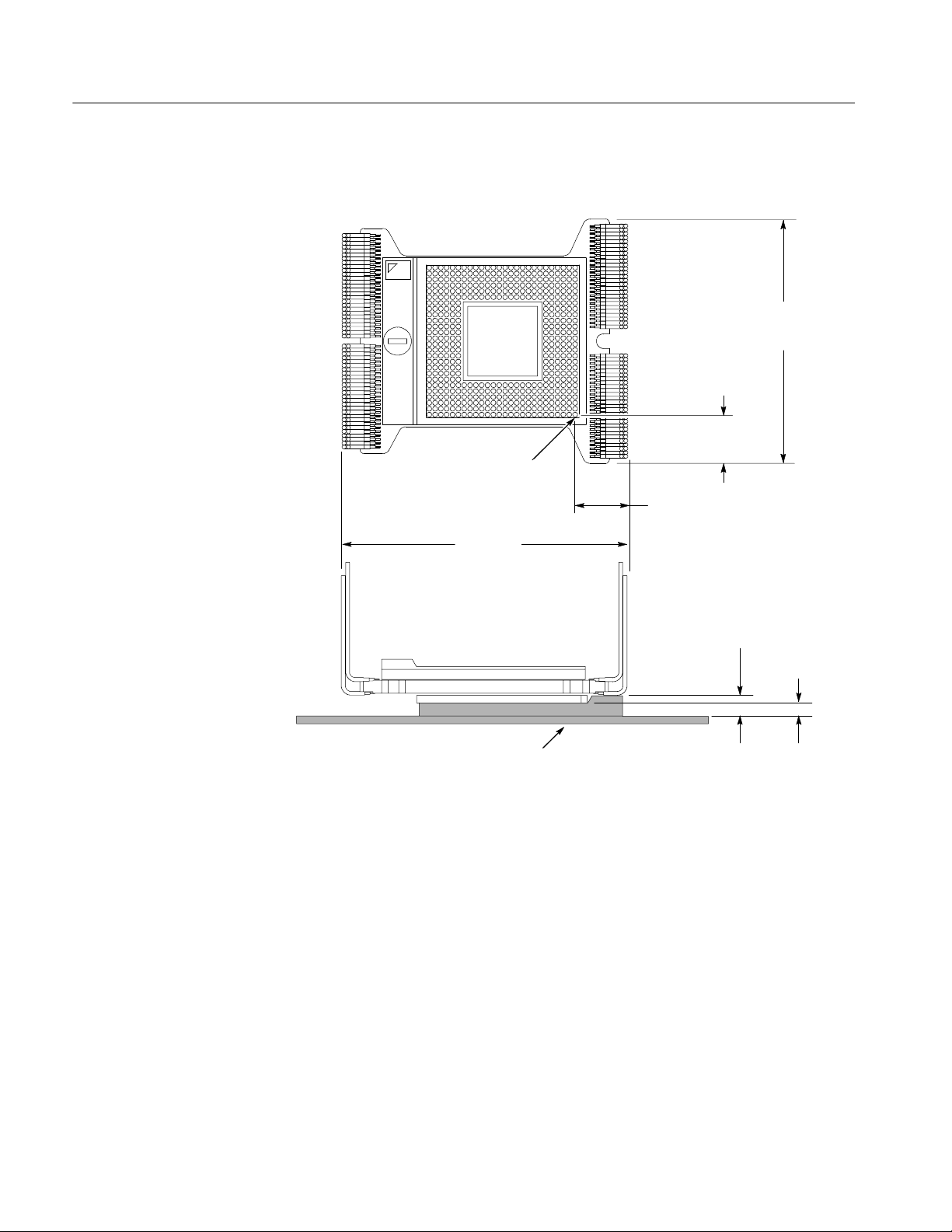

Dimensions

Figure 15 shows the dimensions of the probe head.

52.78 mm

(2.078 in)

10.52 mm

(0.414 in)

Pin 1

11.30 mm

(0.445 in)

63.14 mm

(2.486 in)

4.55 mm

(0.179 in)

3.66 mm

(0.144 in)

26

Platform and socket

Figure 15: Dimensions of the probe head

TMSSY2 mPGA479 Socket Hardware Support

Page 41

Specifications

Figure 16 shows the dimensions of the preprocessor unit.

CAUTION. To prevent damage to the circuitry in the prepr ocessor unit, you must

observe the required clearances in T able 1 on page 5 (clearances are not shown in

Figure 16).

474.32 mm

(18.674 in)

425.45 mm

(16.750 in)

420.37 mm

(16.550 in)

139.70 mm

(5.500 in)

Figure 16: Dimensions of the preprocessor unit

160.27 mm

(6.310 in)

TMSSY2 mPGA479 Socket Hardware Support

27

Page 42

Specifications

28

TMSSY2 mPGA479 Socket Hardware Support

Page 43

Appendix

Accessories

Standard Accessory

Optional Accessories

The following standard accessories are shipped with these products, as noted by

a check mark.

TMSSY2 TMSMPH4 Quantity Description Part number

n

-- -- -- n 1 ACCESSORY KIT; CHIPCOOL 1 & 2

-- -- -- 1 SOFTWARE PKG; W/INSTRUCTIONS MANUAL, TMSSY2

PUB32G15

HEATSINK,JEWEL CASE & HEAT

SINK PARTS; TMSMPH4

063-3983-XX

020-2719-XX

The following optional accessories are available for the probe adapter.

Option Description Part number

--

-- PREPROCESSOR CABLE ASSEMBLY W/

-- TMS131 MICRO SUPPORT; IA32G15 SOFTWARE

LOGIC ANALYZER PROBE:SINGLE ENDED

34--CH HIGH--DENSITY

LABELS

W/HW & SW MANUALS; MICROPROCESSOR

SUPPORT, RUL *2

1

P6960

TMSCAB1

063-3927-XX

2

3

A0 US POWER CORD. (STANDARD ACCESSORY) 161-0104-00

A1 UNIVERSAL EURO POWER CORD 161-0104-06

A2 UNITED KINGDOM POWER CORD 161-0104-07

A3 AUSTRALIA POWER CORD 161-0166-13

A5 SWITZERLAND POWER CORD 161-0167-00

A6 JAPAN POWER CORD 161-0298-00

A10 CHINA POWER CORD 161-0304-00

1

Requires six probes

2

Requires five cables

3

This support software is available only to customers with a valid, restricted, and

secret nondisclosure agreement (RS-NDA) with Intel and Tektronix.

TMSSY2 mPGA479 Socket Hardware Support

29

Page 44

Appendix

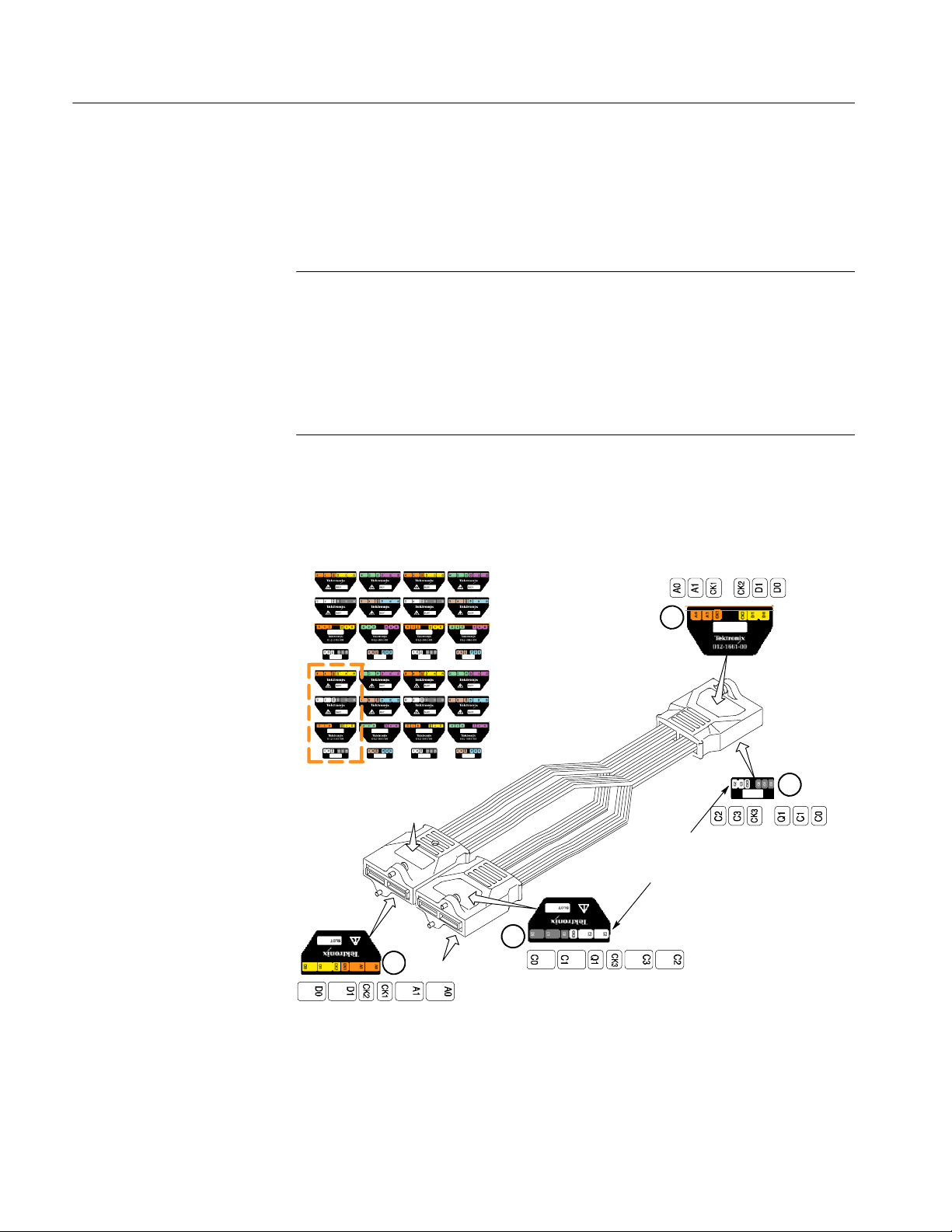

Apply TMSCAB1 Labels

To attach labels to the module- and preprocessor ends of the TMSCAB1 cables,

use the following instructions.

NOTE. Always use flat-nosed tweezers to remove the labels from the sheet of

labels. Never peel labels with your fingers. The labels are made of soft vinyl and

can stretch and distort easily. To avoid stretching the label, always grasp it from

the top right corner while removing it from the sheet of labels.

The adhesive on the vinyl labels is extremely strong. Carefully align the label to

the indented outline on the module end and preprocessor unit end. Once labels

are placed on the TMSCAB1 cables, they are difficult to remove.

1. Determine which channel groups you plan to use and identify the matching

labels.

2. Follow the steps in Figure 17 while attaching the labels.

Blank

Module end

4

Blank

Figure 17: Apply TMSCAB1 labels

Align and place the labels

in the label indents.

Repeat for all steps.

TMSCAB1 Cable

3

1

Preprocessor-unit

end

2

Match the

color and the

channel name.

30

TMSSY2 mPGA479 Socket Hardware Support

Page 45

Probe Adapter Notes

Appendix

System Clock Rate

Acquisition before Reset

Data Bus

Address Bus

Disabling the Cache

(disassembly)

The TMSSY2 hardware support can acquire data from the microprocessor

operating at speeds of up to 200 MHz.

Contact your Tektronix sales representative for current information on the fastest

devices supported.

If data is acquired before a processor Reset signal is observed by the preprocessor unit, the data acquired by the logic analyzer will be inaccurate.

The TMSSY2 product supports only a quad-pumped data bus.

The TMSSY2 product supports only a double-pumped address bus.

The cache bus is not observable; therefore, disassembly requires that the cache

must be disabled. Disabling the cache makes all instruction prefetches visible on

the bus so that they are acquired, displayed and correctly disassembled.

TMSSY2 mPGA479 Socket Hardware Support

31

Page 46

Appendix

32

TMSSY2 mPGA479 Socket Hardware Support

Page 47

Index

A

About this manual set, ix

Address bus, 31

Airflow clearance, preprocessor, 5

Application, logic analyzer configuration, 2

C

Care and maintenance, external, 11

Circuit description, 17

Clock rate, 31

Connections

P6960, 2

TMSCAB1 cable, 30

TMSCAB1 cables, 3

to SUT, 6

D

Data bus, 31

Dimensions

preprocessor unit, 27

probe head, 26

Disabling the cache, 31

Disassembler, logic analyzer configuration, 2

E

I

Installing support software, 10

L

Loading diagrams, 18

Logic analyzer

configuration for disassembler, 2

configuration for the application, 2

M

Maintenance, fuses, 11

Manual, how to use the set, ix

Modules connections, 3, 30

O

Optional accessory, 29

P

P6960, 2

Power, applying, 8

Probe adpater review

clock rate, 31

reset, 31

Electrical specifications, 17

AC adapter, 21

BCKL timing, 21

clock rate, 20

power requirements, 20

setup time, 20

source synchronous capture, disabled, 20

Environmental specifications, 21

altitude, 22

electrostatic immunity, 22

humidity, 22

temperature, 21

F

Fuses, maintenance, 11

TMSSY2 mPGA479 Socket Hardware Support

R

Removing hardware, from SUT, 8, 12

Replaceable parts list, 9

Reset, 31

Restrictions

address bus, 31

data bus, 31

disabling the cache, 31

33

Page 48

Index

S

Shipping, probe adapter, assembled, 15

Specifications, 17

airflow clearance, 5

electrical, 17

environmental, 21

mechanical (dimensions), 26, 27

Standard accessory, 29

Storage, long--term, 13

Support package setup, software, 10

T

TLA7AX4, probes, measurements, 2

TLA7AX4 module, measurements, 3, 30

TMSCAB1 cable, connections, 3, 30

TMSCAB1 Cables, appling lables, 3

34

TMSSY2 mPGA479 Socket Hardware Support

Loading...

Loading...