Page 1

Service Manual

TLA 720

Color Benchtop Chassis and

TLA 7XM

Expansion Chassis

071-0699-00

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

Page 2

Copyright © T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

T ektronix, Inc., 14200 SW Karl Braun Drive, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

HARDWARE WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of shipment. If a product proves defective during this warranty period, T ektronix,

at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

SOFTWARE WARRANTY

T ektronix warrants that the media on which this software product is furnished and the encoding of the programs on the

media will be free from defects in materials and workmanship for a period of three (3) months from the date of shipment.

If a medium or encoding proves defective during the warranty period, T ektronix will provide a replacement in exchange

for the defective medium. Except as to the media on which this software product is furnished, this software product is

provided “as is” without warranty of any kind, either express or implied. T ektronix does not warrant that the functions

contained in this software product will meet Customer’s requirements or that the operation of the programs will be

uninterrupted or error-free.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period. If T ektronix is unable to provide a replacement that is free from defects in materials and workmanship

within a reasonable time thereafter, Customer may terminate the license for this software product and return this software

product and any associated materials for credit or refund.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REPLACE DEFECTIVE MEDIA OR REFUND CUSTOMER’S PAYMENT IS THE SOLE AND EXCLUSIVE

REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS

VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF

THE POSSIBILITY OF SUCH DAMAGES.

Page 5

Table of Contents

Specifications

Operating Information

General Safety Summary ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Structure xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Conventions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting T ektronix xiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Interval xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strategy for Servicing xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Offerings xvi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Benchtop Chassis Specifications 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Characteristics T ables 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expansion Chassis Specifications 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Characteristics T ables 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting the Correct Power Cord and Fuse 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Passive Monitor Connector 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enhanced Monitor RS-232 Connector 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backplane Connectors 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enhanced Monitor 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Syntax 2–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCPI 2–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Syntax 2–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entering Commands 2–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Groups 2–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Commands 2–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Commands 2–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T est Commands 2–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST Subsystem 2–67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST? 2–68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST:NUMBer? 2–69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST:RESults? 2–70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST:RESults:VERBose? 2–71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

i

Page 6

Table of Contents

Theory of Operation

Maintenance

IEEE 488.2 Common Commands 2–73. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*CLS 2–74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*ESE? 2–75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*ESR? 2–76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*IDN? 2–77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*OPC? 2–78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*PSC? 2–79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*RST 2–80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*SRE? 2–81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*STB? 2–82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*TST? 2–83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*WAI 2–84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Benchtop Chassis 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventing ESD 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Cleaning 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation Procedures 4–3. . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ools Required 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Empty Slot Panel Fillers 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Removal and Replacement 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Blower Assembly 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Enhanced Monitor Board 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Power Supply 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Mainframe Cover 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Card Guides 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Nut Rails 4–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the T emperature Sense Board 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the EMI DIN Shields 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Backplane 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Configuration Options 4–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Jumper Settings 4–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backplane Jumpers 4–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enhanced Monitor Board Jumpers 4–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enhanced Monitor Board Flash Jumper 4–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enhanced Monitor Board Logical Address Switch Settings 4–25. . . . . . . . . . . . . . . .

Hardware Troubleshooting 4–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Level 4–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check for Common Problems 4–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshoot the Benchtop Chassis 4–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview of Procedures 4–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mainframe Troubleshooting 4–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics 4–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Problems 4–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Problems 4–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 7

Check for Common Problems 4–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TLA 700 Startup Sequence 4–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Isolating System Problems 4–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expansion Mainframe Troubleshooting 4–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repackaging Instructions 4–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Packaging 4–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shipping to the Service Center 4–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options

Service Options 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams

Replaceable Mechanical Parts

Standard Accessories 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Accessories 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Parts List 7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Index

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

iii

Page 8

Table of Contents

List of Figures

Figure 1–1: Front and side view of the benchtop chassis 1–7. . . . . . . . . .

Figure 1–2: Front and side view of the expansion chassis 1–14. . . . . . . . . .

Figure 2–1: Front view of the benchtop chassis with a

benchtop controller 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–2: Front view of the expansion chassis 2–2. . . . . . . . . . . . . . . . .

Figure 2–3: Rear view of the benchtop chassis 2–2. . . . . . . . . . . . . . . . . . .

Figure 2–4: Rear view of the enhanced monitor 2–4. . . . . . . . . . . . . . . . .

Figure 2–5: Power cord identification chart 2–5. . . . . . . . . . . . . . . . . . . . .

Figure 2–6: Passive monitor connector 2–8. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–7: RS-232 connector pinout 2–11. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–8: Tree hierarchy 2–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–9: Command header 2–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–10: Command header with parameter 2–20. . . . . . . . . . . . . . . . .

Figure 2–11: TEST subsystem hierarchy 2–67. . . . . . . . . . . . . . . . . . . . . . .

Figure 4–1: Installing the empty slot panel fillers 4–4. . . . . . . . . . . . . . . .

Figure 4–2: Location of blower assembly screws 4–6. . . . . . . . . . . . . . . . .

Figure 4–3: Removing the blower assembly 4–7. . . . . . . . . . . . . . . . . . . . .

Figure 4–4: Removing the blower 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–5: Removing the enhanced monitor board 4–8. . . . . . . . . . . . . .

Figure 4–6: Removing the power supply 4–9. . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–7: Removing the mainframe cover 4–10. . . . . . . . . . . . . . . . . . . .

Figure 4–8: Removing the top and bottom card guides 4–12. . . . . . . . . . . .

Figure 4–9: Replacing the top and bottom nut rails 4–13. . . . . . . . . . . . . .

Figure 4–10: Removing the temperature sense board 4–14. . . . . . . . . . . . .

Figure 4–11: Removing the backplane EMI DIN shields 4–15. . . . . . . . . .

Figure 4–12: Removing the backplane 4–17. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–13: Power switch connectors 4–19. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–14: Soft power down jumper setting 4–22. . . . . . . . . . . . . . . . . . .

Figure 4–15: Enhanced monitor board jumpers 4–23. . . . . . . . . . . . . . . . .

Figure 4–16: Enhanced monitor board flash jumper 4–24. . . . . . . . . . . . .

Figure 4–17: Logical address switches 4–25. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–18: Rear-panel connector diagram 4–29. . . . . . . . . . . . . . . . . . . .

Figure 4–19: Primary troubleshooting procedure 4–31. . . . . . . . . . . . . . . .

Figure 4–20: TLA 700 startup sequence 4–32. . . . . . . . . . . . . . . . . . . . . . . .

iv

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 9

Table of Contents

Figure 4–21: TLA 700 startup sequence 4–41. . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–22: ResMan32 program output 4–43. . . . . . . . . . . . . . . . . . . . . . .

Figure 6–1: Interconnection block diagram 6–1. . . . . . . . . . . . . . . . . . . . .

Figure 6–2: Benchtop chassis block diagram 6–2. . . . . . . . . . . . . . . . . . .

Figure 7–1: Cabinet and chassis assembly 7–7. . . . . . . . . . . . . . . . . . . . . .

Figure 7–2: Circuit boards and chassis parts 7–10. . . . . . . . . . . . . . . . . . . .

Figure 7–3: Power supply, monitor, and fan assembly 7–13. . . . . . . . . . . .

Figure 7–4: Rackmount assembly 7–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

v

Page 10

Table of Contents

List of Tables

Table 1–1: AC power source 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–2: Secondary power 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–3: Cooling 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–4: Certifications and compliances 1–5. . . . . . . . . . . . . . . . . . . . . .

Table 1–5: Environmental 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–6: Mechanical 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–7: AC power source 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–8: Secondary power 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–9: Cooling 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–10: Certifications and compliances 1–11. . . . . . . . . . . . . . . . . . . . .

Table 1–11: Environmental 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–12: Mechanical 1–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–1: Passive monitor connector pinouts 2–9. . . . . . . . . . . . . . . . . .

Table 2–2: RS-232 pin connector 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–3: P1 connector pinouts 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–4: P2 connector pinouts for slots 1 – 12 2–14. . . . . . . . . . . . . . . . .

Table 2–5: P2 connector pinouts for slot 0 2–15. . . . . . . . . . . . . . . . . . . . . .

Table 2–6: Messages 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–7: Parameter types for syntax descriptions 2–21. . . . . . . . . . . . . .

Table 2–8: Status commands 2–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–9: System commands 2–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–10: Test commands 2–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–11: Mainframe self test 2–67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–12: IEEE 488.2 common commands 2–73. . . . . . . . . . . . . . . . . . . .

Table 4–1: Chassis backplane jumpers 4–21. . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–2: Enhanced monitor board jumpers 4–24. . . . . . . . . . . . . . . . . . .

Table 4–3: Failure symptoms and possible causes 4–28. . . . . . . . . . . . . . . .

Table 4–4: T r oubleshooting overview 4–30. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–5: Failure symptoms and possible causes 4–37. . . . . . . . . . . . . . . .

Table 4–6: Command line options for ResMan32 4–42. . . . . . . . . . . . . . . .

Table 5–1: Options 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 11

Table of Contents

Table 7–1: Standard accessories 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7–2: Standard accessories 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

vii

Page 12

Table of Contents

viii

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 13

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly . Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and marking on the product. Consult the product manual for further ratings

information before making connections to the product.

The common terminal is at ground potential. Do not connect the common

terminal to elevated voltages.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry .

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

ix

Page 14

General Safety Summary

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

Symbols and Terms

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

WARNING

High Voltage

x

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Protective Ground

(Earth) T erminal

CAUTION

Refer to Manual

Double

Insulated

Page 15

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the main power by means

of the power cord or, if provided, the power switch.

Use Caution When Servicing the CRT. To avoid electric shock or injury, use

extreme caution when handling the CRT. Only qualified personnel familiar with

CRT servicing procedures and precautions should remove or install the CRT.

CRTs retain hazardous voltages for long periods of time after power is turned off.

Before attempting any servicing, discharge the CRT by shorting the anode to

chassis ground. When discharging the CRT, connect the discharge path to ground

and then the anode. Rough handling may cause the CRT to implode. Do not nick

or scratch the glass or subject it to undue pressure when removing or installing it.

When handling the CRT, wear safety goggles and heavy gloves for protection.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

X-Radiation. To avoid x-radiation exposure, do not modify or otherwise alter the

high-voltage circuitry or the CRT enclosure. X-ray emissions generated within

this product have been sufficiently shielded.

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

xi

Page 16

Service Safety Summary

xii

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 17

Preface

Manual Structure

Manual Conventions

Read this preface to learn how this manual is structured, what conventions are

used, and where you can find other information related to servicing this product.

Read the Introduction, which follows this preface for safety and other important

background information before using this manual for servicing this product.

This manual is divided into chapters, which are made up of related subordinate

topics. These topics can be cross referenced as sections.

Read the introductions to all procedures. These introductions provide important

information needed to do the service correctly, safely, and efficiently.

This manual uses certain conventions and terminology that you should become

familiar with before attempting service.

Benchtop Chassis

Benchtop Mainframe

Expansion Chassis

Expansion Mainframe

Modules

Safety

A benchtop chassis is a benchtop mainframe without a benchtop controller

installed.

A benchtop mainframe is a benchtop chassis with a benchtop controller installed.

An expansion chassis is an expansion mainframe without an expansion module

installed.

An expansion mainframe is an expansion chassis with an expansion module

installed.

Throughout this manual, the term module refers to an LA module or a DSO

module that plugs into a portable mainframe, benchtop mainframe, or expansion

mainframe. A module is composed of circuit cards, interconnecting cables, and a

user-accessible front panel.

Symbols and terms related to safety appear in the Service Safety Summary found

at the beginning of this manual.

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

xiii

Page 18

Preface

Replaceable Parts

Contacting Tektronix

This manual refers to any field-replaceable assembly or mechanical part

specifically by its name or generically as a replaceable part. In general, a

replaceable part is any circuit board or assembly that is listed in the replaceable

parts list of Chapter 10.

Product

Support

Service

Support

For questions about using Tektronix measurement products, call

toll free in North America:

1-800-TEK-WIDE (1-800-835-9433 ext. 2400)

6:00 a.m. – 5:00 p.m. Pacific time

Or contact us by e-mail:

tm_app_supp@tek.com

For product support outside of North America, contact your

local Tektronix distributor or sales office.

Tektronix offers extended warranty and calibration programs as

options on many products. Contact your local Tektronix

distributor or sales office.

For a listing of worldwide service centers, visit our web site.

For other

information

To write us

Website

In North America:

1-800-TEK-WIDE (1-800-835-9433)

An operator will direct your call.

Tektronix, Inc.

14200 SW Karl Braun Drive

Beaverton, OR 97077

USA

Tektronix.com

xiv

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 19

Introduction

This manual contains information needed to properly service the benchtop

chassis and the expansion chassis. This introduction contains information critical

to safe and effective servicing.

To prevent personal injury or damage to the benchtop chassis or expansion

chassis, consider the following requirements before attempting service:

H The procedures in this manual should be performed only by a qualified

service person.

H Read the General Safety Summary and Service Safety Summary found at the

beginning of this manual.

H Read the Preface beginning on page xiii.

H Read Operating Information beginning on page 2–1.

When using this manual for servicing, be sure to follow all warnings, cautions,

and notes.

Adjustment Interval

Strategy for Servicing

There are no adjustments or certifiable parameters for the benchtop chassis or

expansion chassis.

This manual supports and contains all the information needed for periodic

maintenance of the benchtop chassis and expansion chassis. Examples of such

information are procedures for fault isolation of a failed circuit board or

assembly and for removal and replacement of the failed boards or assemblies.

This manual also:

H Supports isolation of faults to the failed circuit board or assembly level

shown in the replaceable parts list.

H Supports removal and replacement of those boards or assemblies.

H Supports removal and replacement of fuses, knobs, chassis, and other

mechanical parts listed in the replaceable parts list.

This manual does not support component-level fault isolation and replacement.

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

xv

Page 20

Introduction

Service Offerings

Tektronix provides service to cover repair under warranty as well as other

services that are designed to meet your specific service needs.

Whether providing warranty repair service or any of the other services listed

below, Tektronix service technicians are equipped to service the benchtop chassis

and the expansion chassis. Services are provided at Tektronix Services Centers

and on-site at your facility, depending on your location.

Warranty Repair Service

Calibration and Repair

Service

Tektronix warrants this product for one year from date of purchase. The warranty

appears behind the title page in this manual. Tektronix technicians provide

warranty service at most Tektronix service locations worldwide. The Tektronix

product catalog lists all service locations worldwide.

In addition to warranty repair, Tektronix Service offers calibration and other

services which provide cost-effective solutions to your service needs and qualitystandards compliance requirements. Our instruments are supported worldwide by

the leading-edge design, manufacturing, and service resources of Tektronix to

provide the best possible service.

The following services can be tailored to fit your requirements for calibration

and/or repair of the benchtop chassis or expansion chassis.

Service Options. Tektronix Service Options can be selected at the time you

purchase your instrument. You select these options to provide the services that

best meet your service needs. These service options are listed on the Tektronix

Service Options page following the title page of this manual.

Service Agreements. If service options are not added to the instrument purchase,

then service agreements are available on an annual basis to provide calibration

services or post-warranty repair coverage for the benchtop chassis. Service

agreements may be customized to meet special turn-around time and/or on-site

requirements.

xvi

Service on Demand. Tektronix also offers calibration and repair services on a

per-incident basis that is available with standard prices for many products.

Self Service. Tektronix supports repair to the replaceable-part level by providing

for circuit board exchange.

Use this service to reduce down-time for repair by exchanging circuit boards for

remanufactured ones. Tektronix ships updated and tested exchange boards. Each

board comes with a 90-day service warranty.

For More Information. Contact your local Tektronix service center or sales

engineer for more information on any of the calibration and repair services just

described.

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 21

Specifications

Page 22

Page 23

Benchtop Chassis Specifications

This chapter provides a general description of the benchtop chassis. A selected

list of specification tables beginning on page 1–3 that will aid you in servicing.

Product Description

The benchtop chassis is designed to be used as part of the TLA 700 Series Logic

Analyzer family. The benchtop chassis is an intelligent 13-slot chassis, with

intelligent cooling for installed modules, and a high quality auto-configurable

backplane.

Power Supply

Intelligent Cooling

The power supply input line capacity is 1450 Watts, with 872 Watts usable by

the TLA 700 Series instrument modules at any given time.

The power supply plugs directly into the rear of the chassis and has no cables to

disconnect. Because of this design, you can replace the power supply in a short

amount of time. The power supply automatically accommodates for the

appropriate input voltage and frequency; therefore, their is no mechanical switch

required to select the correct line voltage and frequency.

The benchtop chassis accommodates both exclusively digital applications (using

the logic analyzer module), and exclusively analog applications (using the DSO

module), as well as combinations of both digital and analog.

The benchtop chassis provides optimal cooling for all installed modules. The

chassis uses an intelligent, adaptive cooling scheme to efficiently remove heat

while maintaining quiet operation. When you set the blower to variable speed

(default), the chassis automatically adjusts the blower speed to keep the

temperature rise above the modules to approximately 10° C or less. Using a rear

panel switch, you can set the blower to full speed to provide maximum cooling

at all times.

Air is exhausted at the sides of the chassis allowing you to stack the expansion

chassis with the benchtop chassis or other rackmount equipment. You do not

have to to worry about restricting any airflow out of the top of the chassis or

creating a chimney effect.

Card guides and airflow shutters automatically direct air to only those slots

containing modules and empty slots are shut off. The chassis directs airflow

across each installed module from the bottom to the top of each slot. Baffles

balance the airflow from the front to back and across occupied slots in the

chassis.

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

1–1

Page 24

Benchtop Chassis Specifications

Backplane

The benchtop chassis has an autoconfigurable, solid-state backplane that uses

electronic jumpering of the IACK and BUS GRANT signal lines.

Full differential distribution of the CLK10 signals provide a clean timing source

for the instrument.

1–2

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 25

Characteristics Tables

This section lists only the specifications that are useful for servicing. All

specifications listed here should be considered “typical”. Typical characteristics

describe typical or average performance and provide useful reference information.

Refer to Appendix A in the User manual for a complete listing of all specifications.

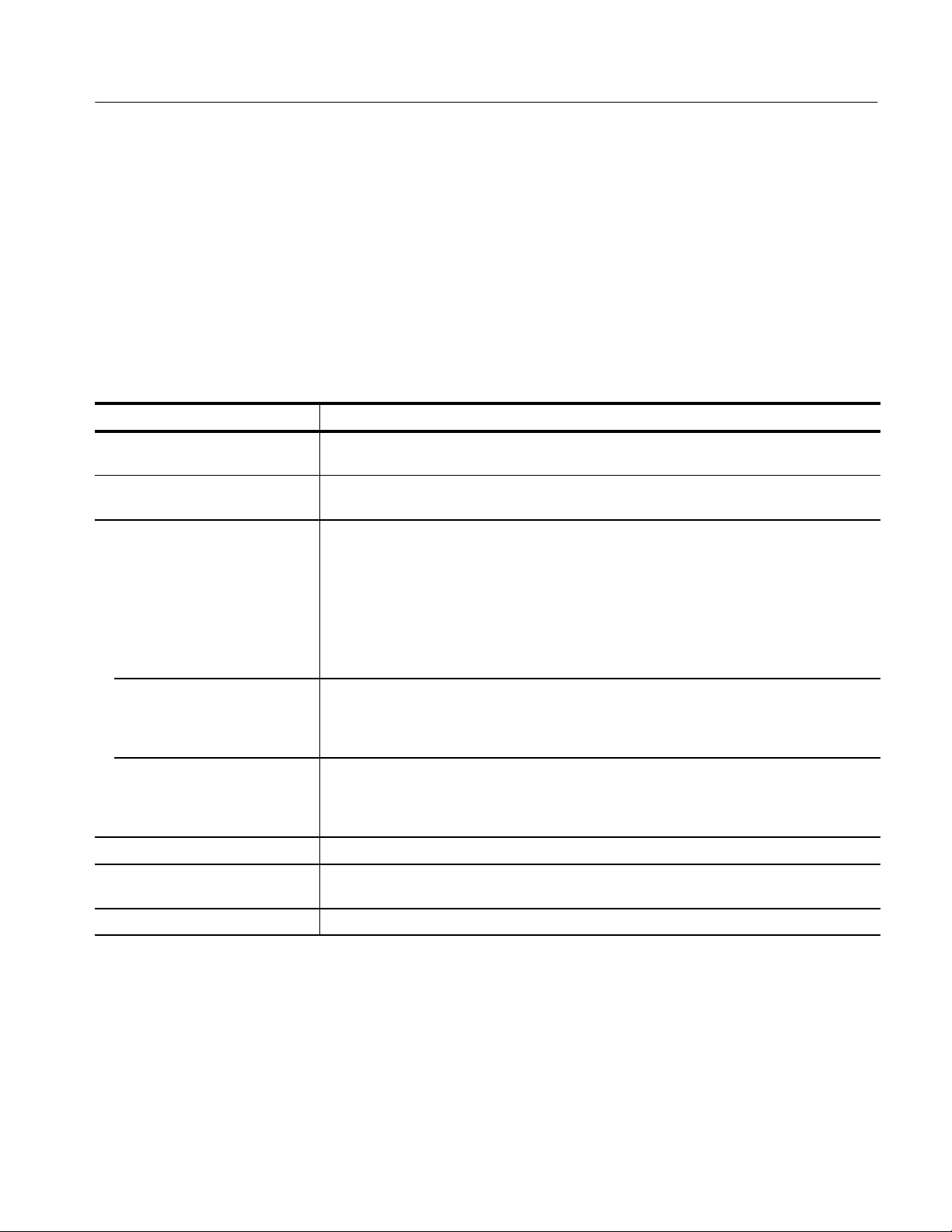

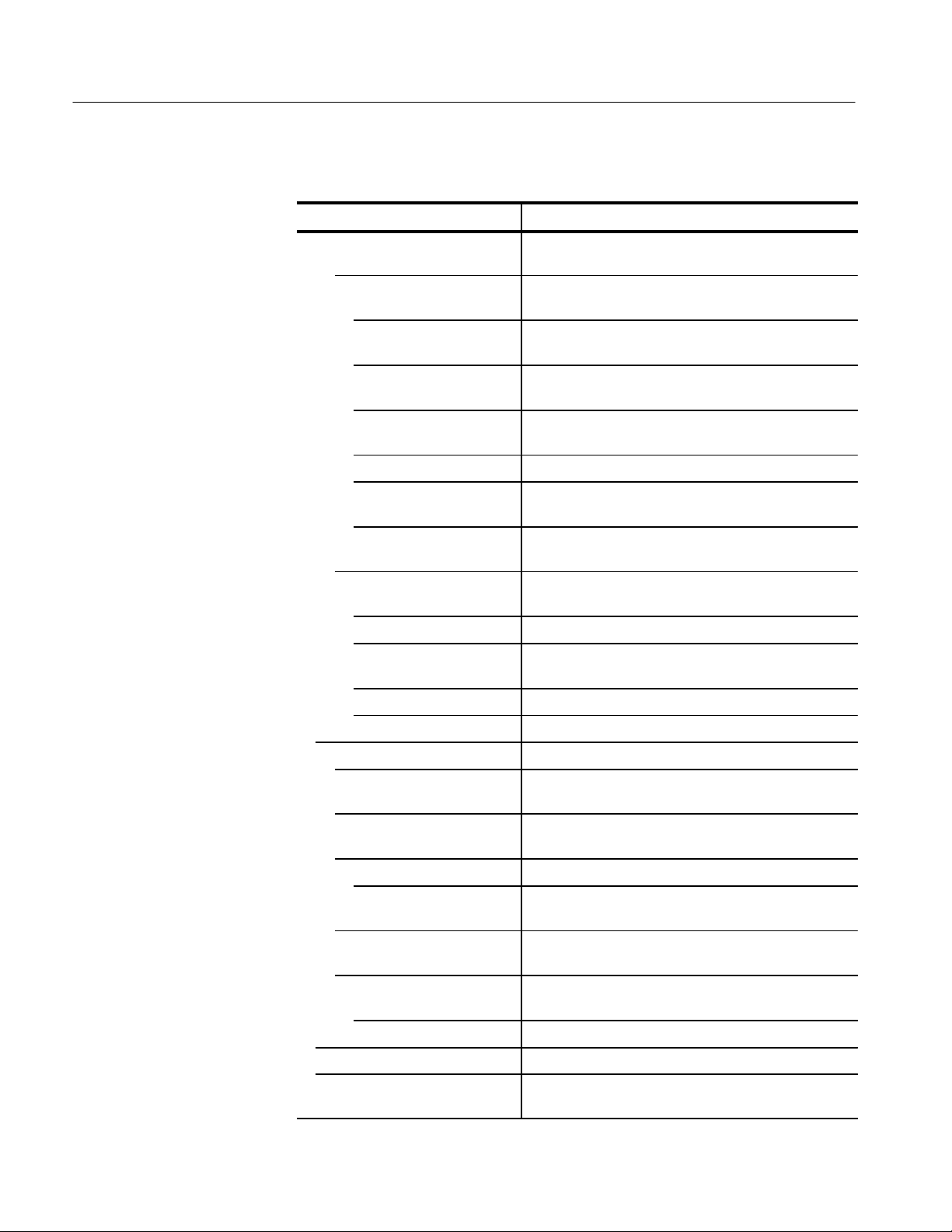

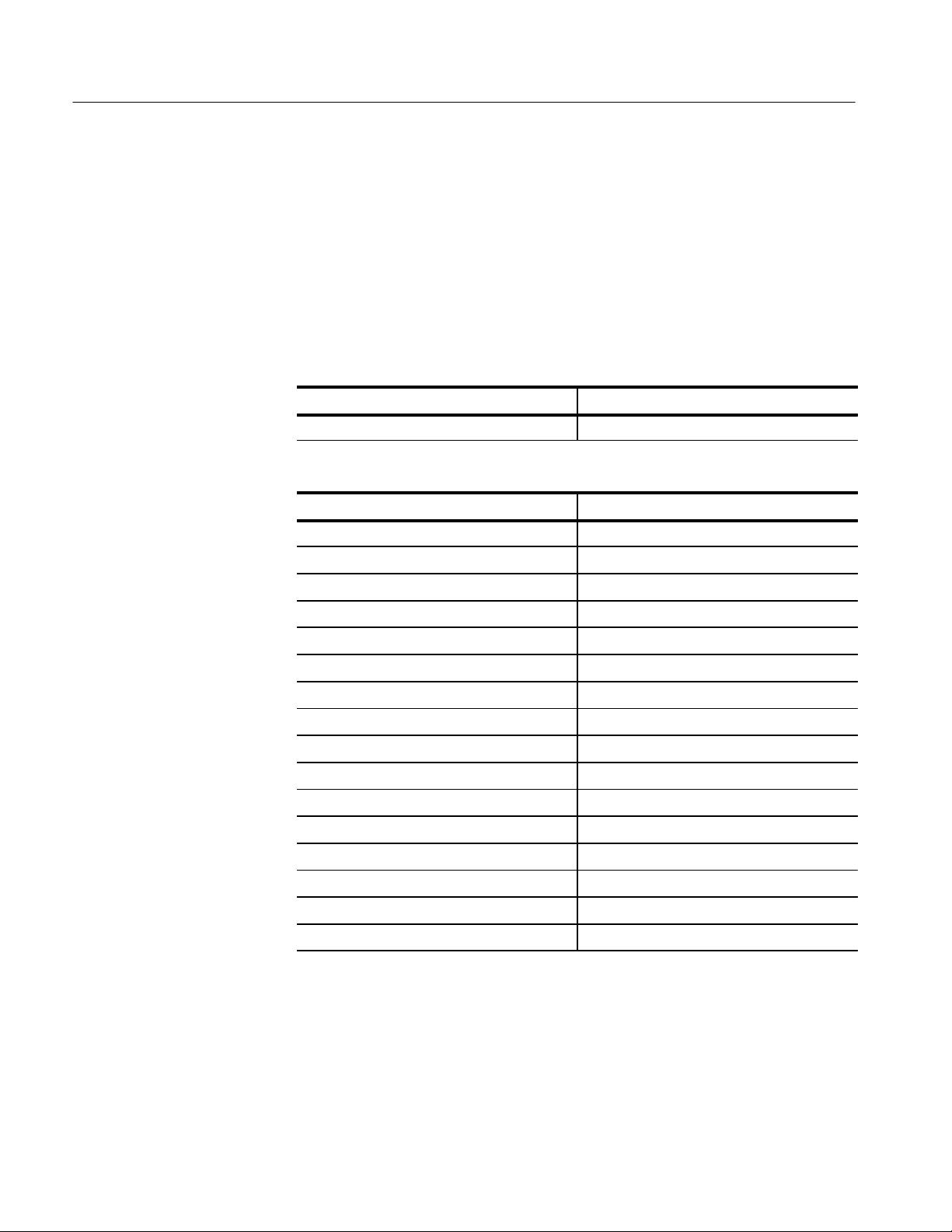

T able 1–1: AC power source

Characteristic Description

Source Voltage 90–250 V

100–132 V

Maximum Power Consumption 1450 W line power

(The maximum power consumed by a fully loaded 13-slot instrument)

45–66 Hertz, continuous range CA T II

RMS,

360–440 Hertz, continuous range CAT II

RMS,

Benchtop Chassis Specifications

Fuse Rating

(Current and voltage ratings and type

of fuse used to fuse the source line

voltage)

90 V – 132 VAC

(High-power/Low Line

(159-0379-00)

Operation

RMS

Safety: UL198G

Size: 0.25 in × 1.25 in,

Style: Slow acting,

Rating: 20 A/250 V

103 V – 250 VAC

(159-0256-00)

Operation

RMS

Safety: UL198G

Size: 0.25 in × 1.25 in,

Style: No. 59/Fast acting,

Rating: 15 A/250 V

207 V – 250 VAC

(159-0381-00)

Operation

RMS

Safety: IEC 127/sheet 1

Size: 5 mm × 20 mm,

Style: Sheet 1, Fast acting “F”, high-breaking capacity,

Rating: 6.3 A/250 V

Inrush Surge Current 70 A maximum

Steady State Input Current 16.5 A RMS maximum at 90 VAC

6.3 Amps RMS maximum at 207 VAC

Power Factor Correction Yes

RMS

RMS

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

1–3

Page 26

Benchtop Chassis Specifications

T able 1–2: Secondary power

Characteristic Description

DC Voltage Regulation

(Combined System, voltage

available at each slot) Voltage V

+24 V 23.28 V 24.24 V 25.20 V

+12 V 11.64 V 12.12 V 12.60 V

min

V

nom

V

max

+5 V

–2 V

–5.2 V

4.875 V 5.063 V 5.25 V

–2.1 V –2.000 V –1.9 V

–5.46 V –5.252 V –5.044 V

–12 V –12.60 V –12.12 V –11.64 V

–24 V –25.20 V –24.24 V –23.28 V

T able 1–3: Cooling

Characteristic Description

Cooling System Positive pressurization forced air circulation system utilizing a single low-noise squirrel cage

centripetal blower configuration with no removable filters.

Blower Speed Control Rear panel switch selects between full speed and variable speed. Slot exhaust temperature and

ambient air temperature are monitored so that a constant delta temperature is maintained

across the module with the highest exit air temperature at the minimum operational blower

speed.

Slot Activation Installing a module activates the cooling for the corresponding occupied slots by opening the air flow

shutter mechanism.

1–4

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 27

Benchtop Chassis Specifications

T able 1–4: Certifications and compliances

EC Declaration of Conformity – EMC Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility . Compliance was

demonstrated to the following specifications as listed in the Official Journal of the European

Communities:

EN 61326–1 EMC requirements for Class A electrical equipment

for measurement, control and laboratory use.

IEC 1000–4–2 Electrostatic Discharge Immunity

(Performance Criterion B)

IEC 1000–4–3 RF Electromagnetic Field Immunity

(Performance Criterion A)

IEC 1000–4–4 Electrical Fast Transient / Burst Immunity

(Performance Criterion B)

IEC 1000–4–5 Power Line Surge Immunity

(Performance Criterion B)

IEC 1000–4–6 Conducted RF Immunity

(Performance Criterion A)

IEC 1000–4–11 Power Line Dips and Interruptions Immunity

(Performance Criterion B)

EN 61000–3–2 AC Power Line Harmonic Emissions

T able 1–5: Environmental

Characteristic Description

Classification

Atmospherics

Temperature

Operating +5° C to 50° C, 15 ° C/hr max gradient, non-condensing (derated 1° C per 1000 ft. above

5000 ft. altitude

Nonoperating –20° C to 60° C, 15° C/hr max gradient, non-condensing

Relative Humidity

Operating 20% to 80% relative humidity, non-condensing.

Max wet bulb temperature: +29°C

(derates relative humidity to approximately 22% @ 50°C).

Nonoperating 8% to 80% relative humidity, non-condensing.

Max wet bulb temperature: +29° C

(derates relative humidity to ~55% @ 50°C).

Altitude

Operating To 9,144 ft. (3,000 m)

(derated 1° C/1000 ft. (305m) above 5000 ft. (1524m) altitude)

Nonoperating 39,376 ft. (12,000 m)

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

1–5

Page 28

Benchtop Chassis Specifications

T able 1–6: Mechanical

Characteristic Description

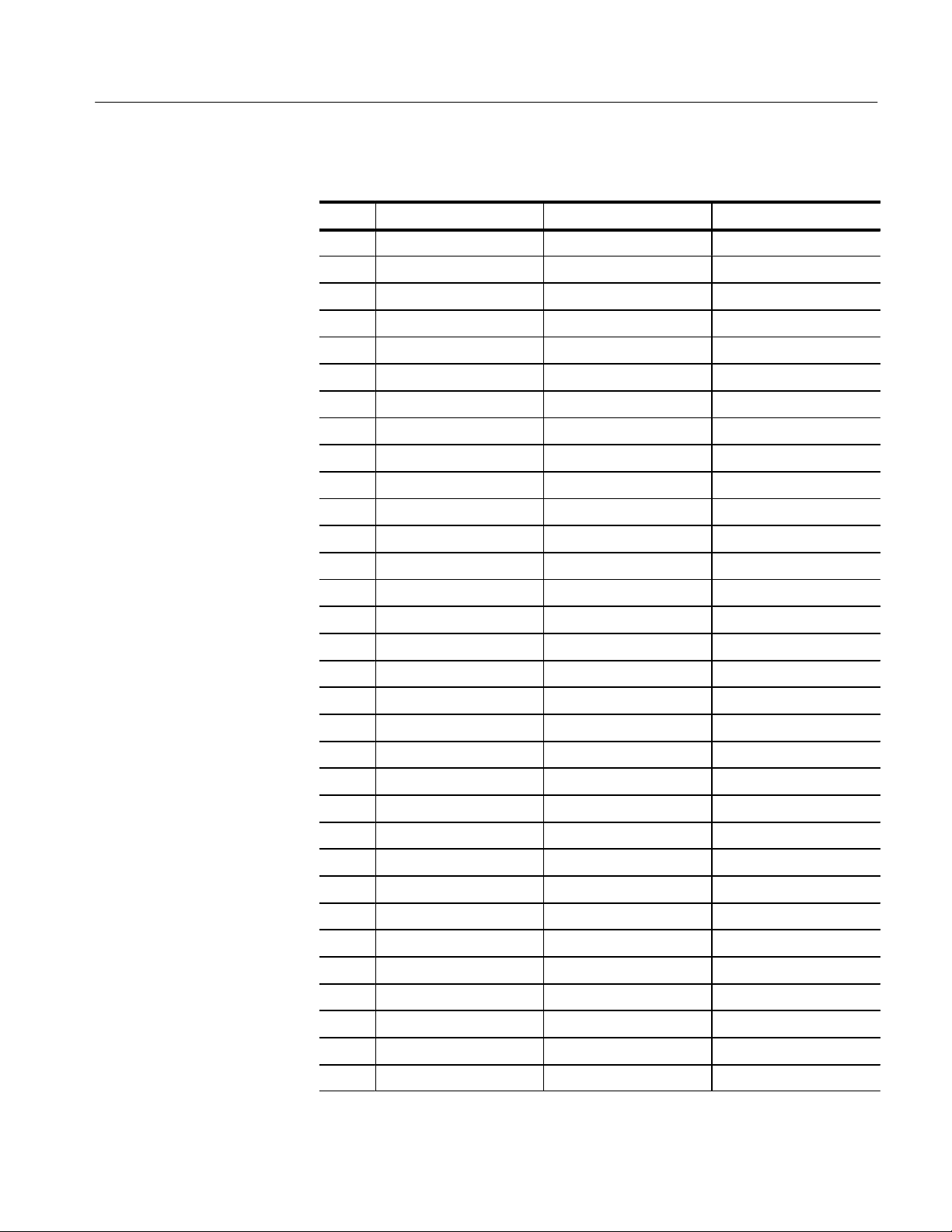

Overall Dimensions (See Figure 1–1 for overall chassis dimensions)

Standard Chassis

Height (with feet) 13.65 in (362.0 mm)

Width 17.6 in (425.5 mm)

Depth 26.5 in (673.1 mm)

Chassis with Rackmount

Height 13.25 in (355.6 mm)

Width 18.9 in (480.1 mm)

Depth 28.9 in (746.7 mm) min to 33.9 in (873.8 mm) max

Weight

Minimum mainframe configuration with benchtop controller and slot filler

panels installed

(5 dual wide and 1 single wide)

Typical configuration: same as as minimum above with the addition of

two TLA 7x4 LA’s and

one TLA 7x2 DSO at 5 lbs 10 oz each, and removal of 3 slot filler panels

Shipping weight: minimum configuration with benchtop controller module

(only) and all mainframe standard accessories (2 manuals, 5 dual wide,

1 single slot filler panels, power cord, empty pouch, front cover,

keyboard, software, and cables

Shipping weight: fully configured instrument. Same as minimum above

with the addition of 3 LA modules (TLA 7N4, TLA 7P2, and TLA 7P4)

and 2 DSO’s (TLA 7D1 and TLA 7E1), and all module standard

accessories (probes, clips)

Rackmount kit adder 20 lbs (9.07 kg)

Module Size 13 plug-in slots

48.5 lbs (22.1 kg)

63.7 lbs (28.9 kg)

104 lb (47.2 kg)

161 lb (73 kg)

1–6

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 29

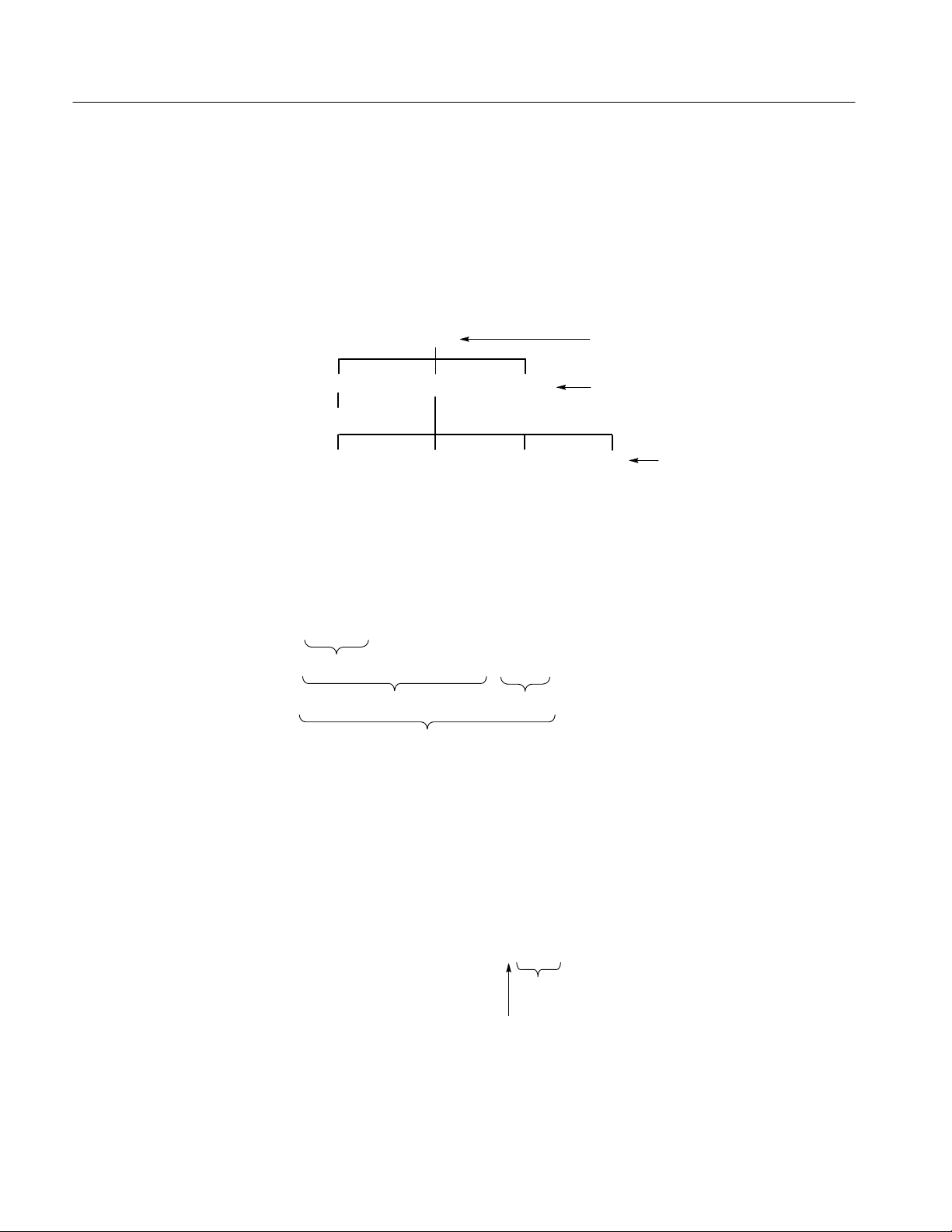

Benchtop Chassis Specifications

16.7 in

(42.55 cm)

13.65 in

(35.00 cm)

13.25 in

(33.6 cm)

Figure 1–1: Front and side view of the benchtop chassis

26.5 in

(69.99 cm)

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

1–7

Page 30

Benchtop Chassis Specifications

1–8

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 31

Expansion Chassis Specifications

This chapter provides a general description of the expansion chassis. A selected

list of specification tables beginning on page 1–3 that will aid you in servicing.

Product Description

The expansion chassis is designed to be used as part of the TLA 700 Series

Logic Analyzer family. The expansion chassis is an intelligent 13-slot chassis,

with intelligent cooling for installed modules, and a high quality auto-configurable backplane.

Power Supply

Intelligent Cooling

The power supply input line capacity is 1450 Watts, with 872 Watts usable by

the TLA 700 Series instrument modules at any given time.

The power supply plugs directly into the rear of the chassis and has no cables to

disconnect. Because of this design, you can replace the power supply in a short

amount of time. The power supply automatically accommodates for the

appropriate input voltage and frequency; therefore, their is no mechanical switch

required to select the correct line voltage and frequency.

The chassis accommodates both exclusively digital applications (using the logic

analyzer module), and exclusively analog applications (using the DSO module),

as well as combinations of both digital and analog.

The expansion chassis provides optimal cooling for all installed modules. The

chassis uses an intelligent, adaptive cooling scheme to efficiently remove heat

while maintaining quiet operation. When you set the blower to variable speed

(default), the chassis automatically adjusts the blower speed to keep the

temperature rise above the modules to approximately 10° C or less. Using a rear

panel switch, you can set the blower to full speed to provide maximum cooling

at all times.

Air is exhausted at the sides of the chassis allowing you to stack the expansion

chassis with the benchtop chassis or other rackmount equipment. You do not

have to to worry about restricting any airflow out of the top of the chassis or

creating a chimney effect.

Card guides and airflow shutters automatically direct air to only those slots

containing modules and empty slots are shut off. The chassis directs airflow

across each installed module from the bottom to the top of each slot. Baffles

balance the airflow from the front to back and across occupied slots in the

chassis.

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

1–9

Page 32

Expansion Chassis Specifications

Backplane

The expansion chassis has an autoconfigurable, solid-state backplane that uses

electronic jumpering of the IACK and BUS GRANT signal lines.

Full differential distribution of the CLK10 signals provide a clean timing source

for the instrument.

Characteristics Tables

This section lists only the specifications that are useful for servicing. All

specifications listed here should be considered “typical”. Typical characteristics

describe typical or average performance and provide useful reference information.

Refer to Appendix A in the User manual for a complete listing of all specifications.

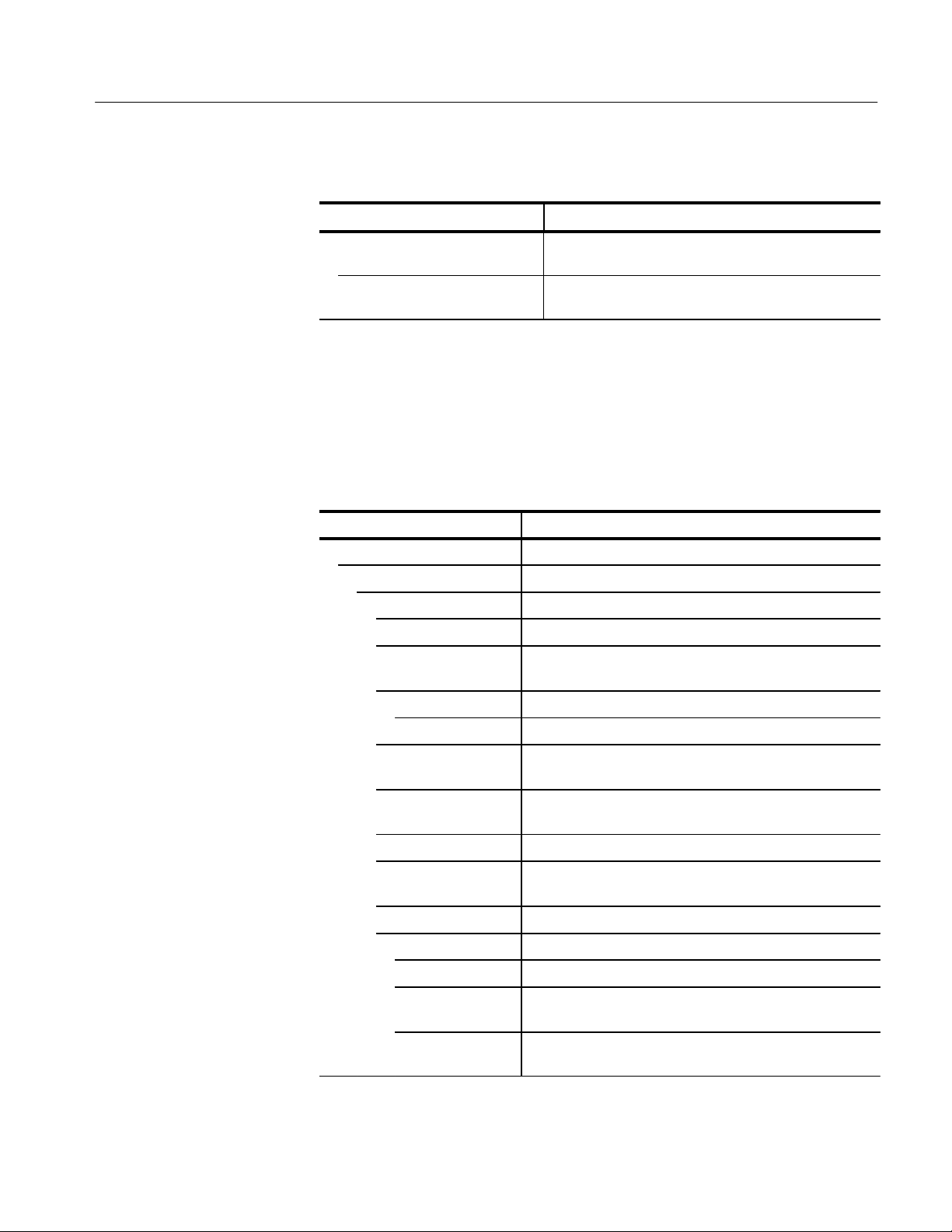

T able 1–7: AC power source

Characteristic Description

Source Voltage 90–250 V

100–132 V

Maximum Power Consumption 1450 W line power

(The maximum power consumed by a fully loaded 13-slot instrument)

45–66 Hertz, continuous range CA T II

RMS,

360–440 Hertz, continuous range CAT II

RMS,

Fuse Rating

(Current and voltage ratings and type

of fuse used to fuse the source line

voltage)

90 V – 132 VAC

(High-power/Low Line

(159-0379-00)

103 V – 250 VAC

(159-0256-00)

207 V – 250 VAC

(159-0381-00)

Inrush Surge Current 70 A maximum

Steady State Input Current 16.5 A RMS maximum at 90 VAC

Power Factor Correction Yes

Operation

RMS

RMS

RMS

Operation

Operation

Safety: UL198G

Size: 0.25 in × 1.25 in,

Style: Slow acting,

Rating: 20 A/250 V

Safety: UL198G

Size: 0.25 in × 1.25 in,

Style: No. 59/Fast acting,

Rating: 15 A/250 V

Safety: IEC 127/sheet 1

Size: 5 mm × 20 mm,

Style: Sheet 1, Fast acting “F”, high-breaking capacity,

Rating: 6.3 A/250 V

6.3 Amps RMS maximum at 207 VAC

RMS

RMS

1–10

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 33

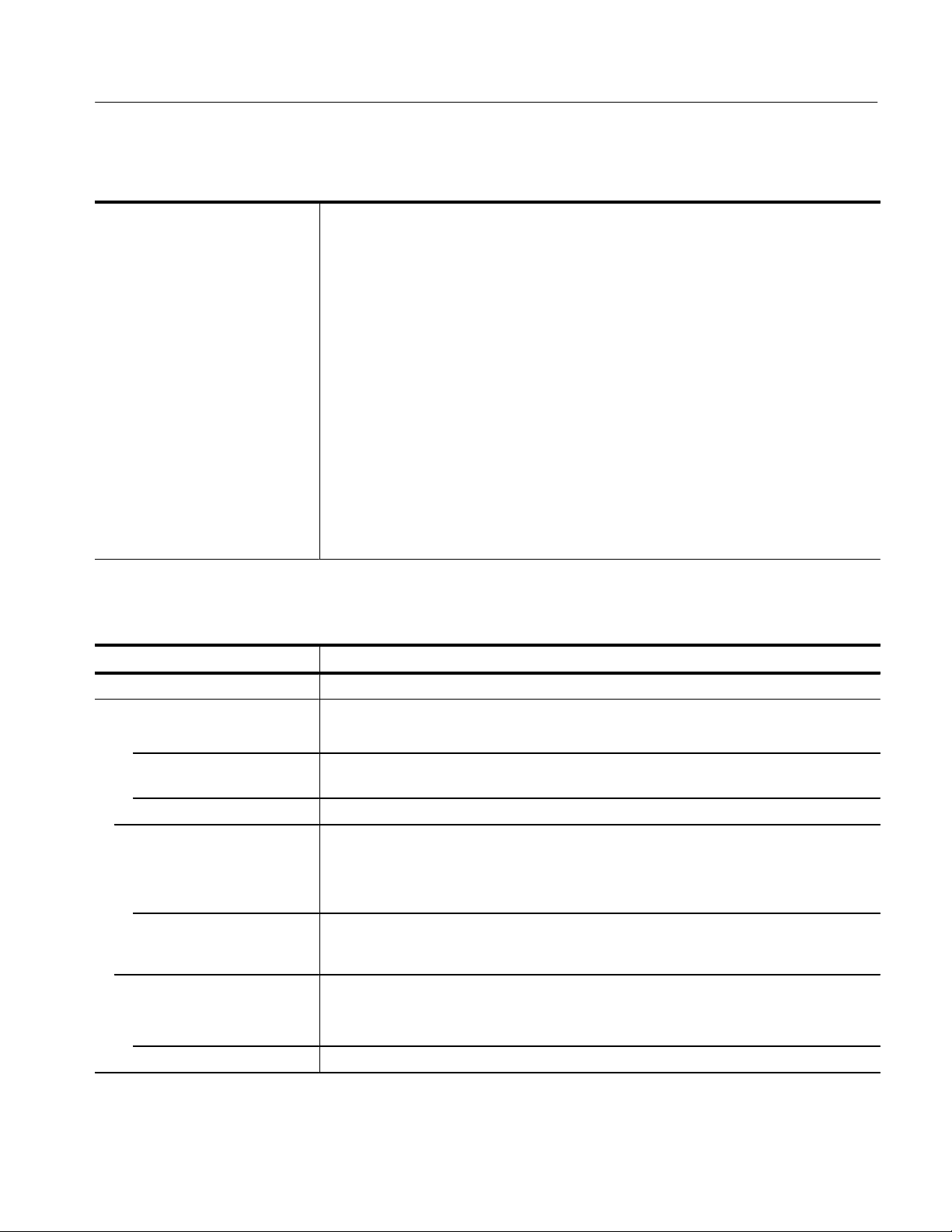

T able 1–8: Secondary power

Characteristic Description

DC Voltage Regulation

(Combined System, voltage

available at each slot) Voltage V

+24 V 23.28 V 24.24 V 25.20 V

+12 V 11.64 V 12.12 V 12.60 V

min

Expansion Chassis Specifications

V

nom

V

max

+5 V

–2 V

–5.2 V

4.875 V 5.063 V 5.25 V

–2.1 V –2.000 V –1.9 V

–5.46 V –5.252 V –5.044 V

–12 V –12.60 V –12.12 V –11.64 V

–24 V –25.20 V –24.24 V –23.28 V

T able 1–9: Cooling

Characteristic Description

Cooling System Positive pressurization forced air circulation system utilizing a single low-noise squirrel cage

centripetal blower configuration with no removable filters.

Blower Speed Control Rear panel switch selects between full speed and variable speed. Slot exhaust temperature and

ambient air temperature are monitored so that a constant delta temperature is maintained

across the module with the highest exit air temperature at the minimum operational blower

speed.

Slot Activation Installing a module activates the cooling for the corresponding occupied slots by opening the air flow

shutter mechanism.

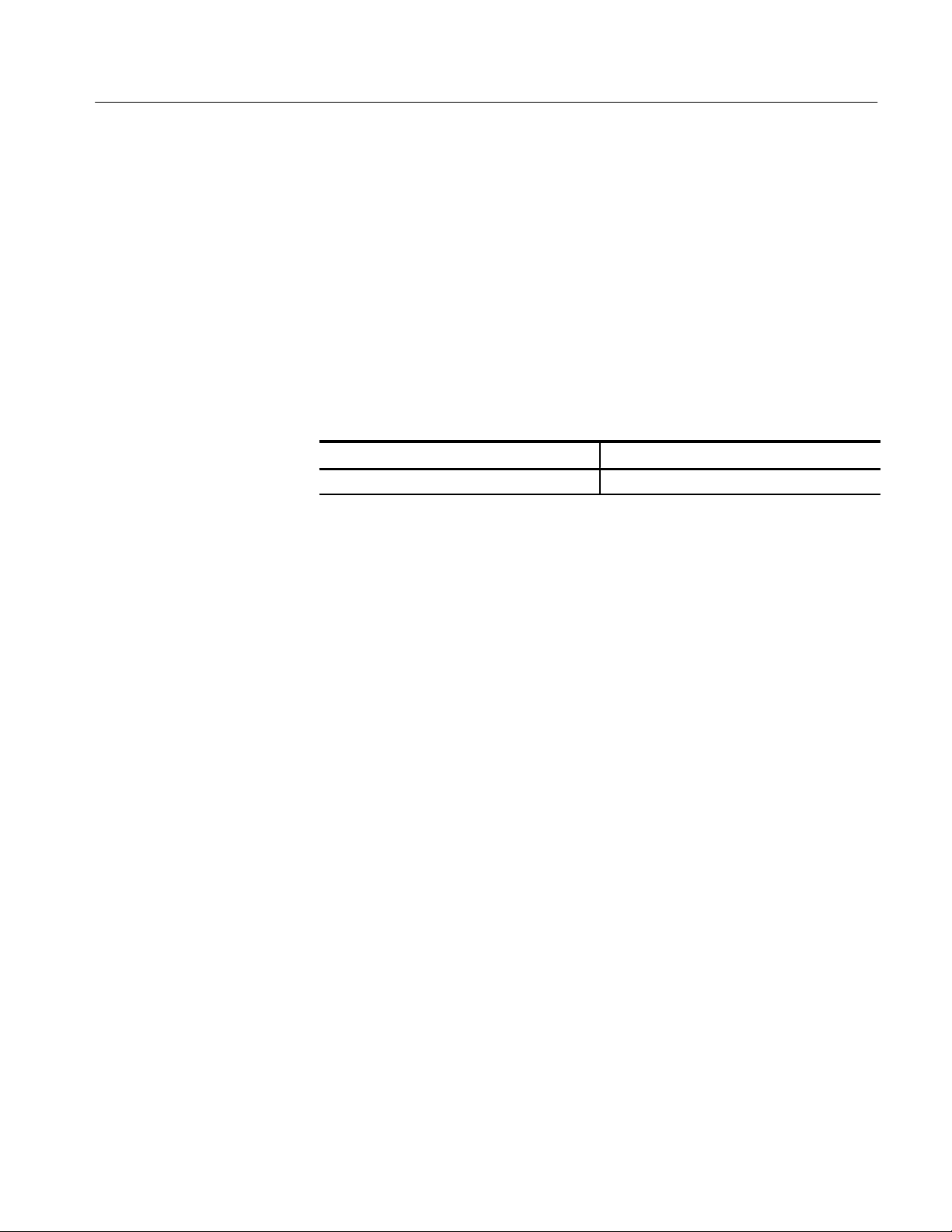

T able 1–10: Certifications and compliances

Category Standards or description

EC Declaration of Conformity – EMC Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility when used with the

TLA 720 Benchtop Chassis.

Refer to the EMC published for the TLA 720 Benchtop Chassis.

Australia/New Zealand Declaration

of Conformity –

Complies with EMC provision of Radiocommunications Act when used with the

TLA 720 Benchtop Chassis.

EMC

Refer to the EMC published for the TLA 720 Benchtop Chassis.

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

1–11

Page 34

Expansion Chassis Specifications

T able 1–10: Certifications and compliances (Cont.)

Category Standards or description

U.S. Nationally Recognized Testing

Laboratory Listing

Canadian Certification CAN/CSA C22.2 No. 1010.1 Safety requirements for electrical equipment for measurement,

Installation (Overvoltage) Category Terminals on this product may have different installation (overvoltage) category designations.

Pollution Degree A measure of the contaminates that could occur in the environment around and within a

Safety Certification Compliance

Altitude (maximum operating) 2000 meters

Equipment Type Test and measuring

Safety Class Class 1 (as defined in IEC 1010-1, Annex H) – grounded product

Pollution Degree Pollution Degree 2 (as defined in IEC 1010-1). Note: Rated for indoor use only.

UL31 11-1 Standard for electrical measuring and test equipment.

control, and laboratory use.

The installation categories are:

CA T III Distribution-level mains (usually permanently connected). Equipment at this level is

typically in a fixed industrial location.

CA T II Local-level mains (wall sockets). Equipment at this level includes appliances, portable

tools, and similar products. Equipment is usually cord-connected.

CA T I Secondary (signal level) or battery operated circuits of electronic equipment.

product. Typically the internal environment inside a product is considered to be the same as the

external. Products should be used only in the environment for which they are rated.

Pollution Degree 2 Normally only dry, nonconductive pollution occurs. Occasionally a

temporary conductivity that is caused by condensation must be

expected. This location is a typical office/home environment.

Temporary condensation occurs only when the product is out of

service.

T able 1–11: Environmental

Characteristic Description

Classification

Atmospherics

Temperature

Operating +5° C to 50° C, 15 ° C/hr max gradient, non-condensing (derated 1° C per 1000 ft. above

5000 ft. altitude

Nonoperating –20° C to 60° C, 15° C/hr max gradient, non-condensing

Relative Humidity

Operating 20% to 80% relative humidity, non-condensing.

Max wet bulb temperature: +29°C

(derates relative humidity to approximately 22% @ 50°C).

1–12

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 35

Expansion Chassis Specifications

T able 1–11: Environmental (Cont.)

Characteristic Description

Nonoperating 8% to 80% relative humidity , non-condensing.

Max wet bulb temperature: +29° C

(derates relative humidity to ~55% @ 50°C).

Altitude

Operating To 9,144 ft. (3,000 m)

(derated 1° C/1000 ft. (305m) above 5000 ft. (1524m) altitude)

Nonoperating 39,376 ft. (12,000 m)

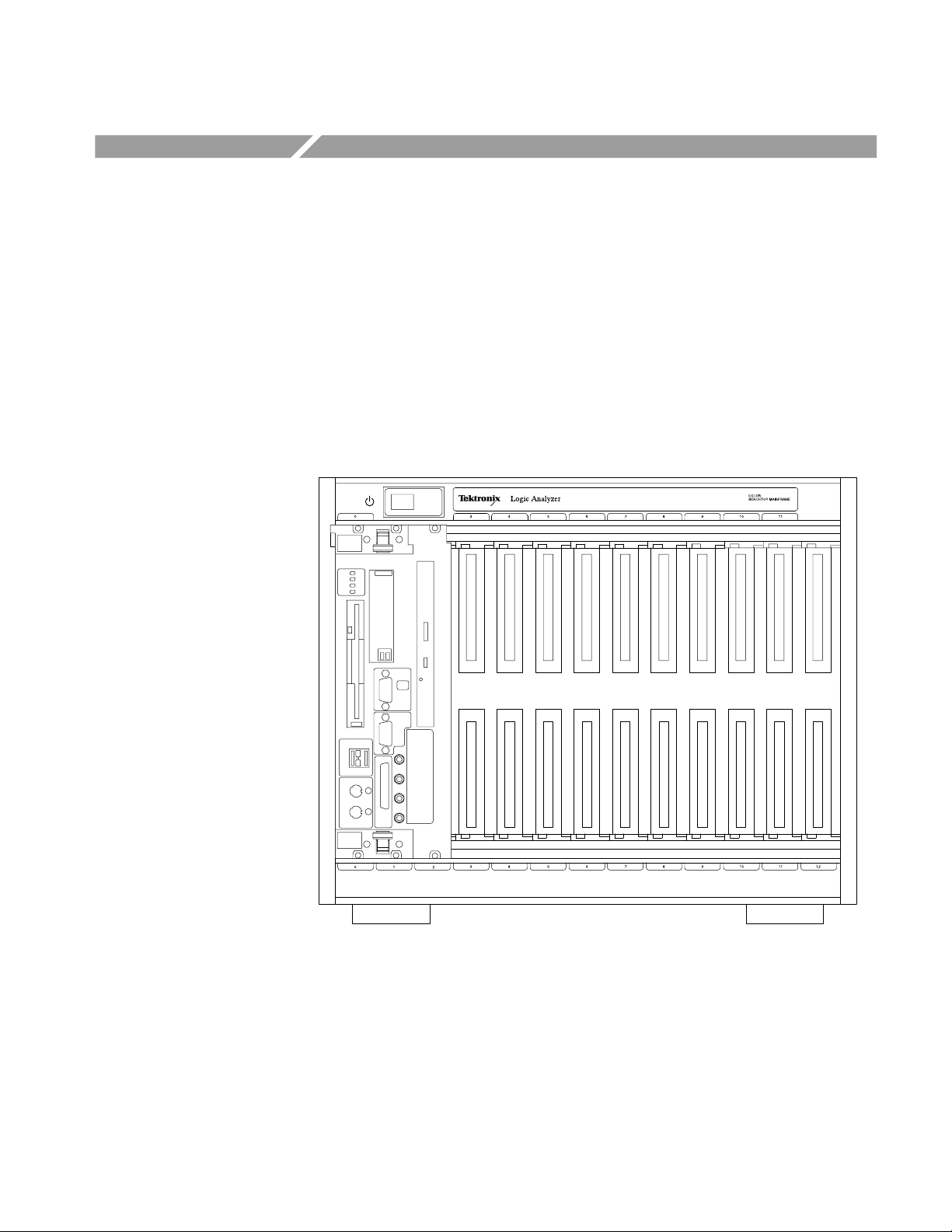

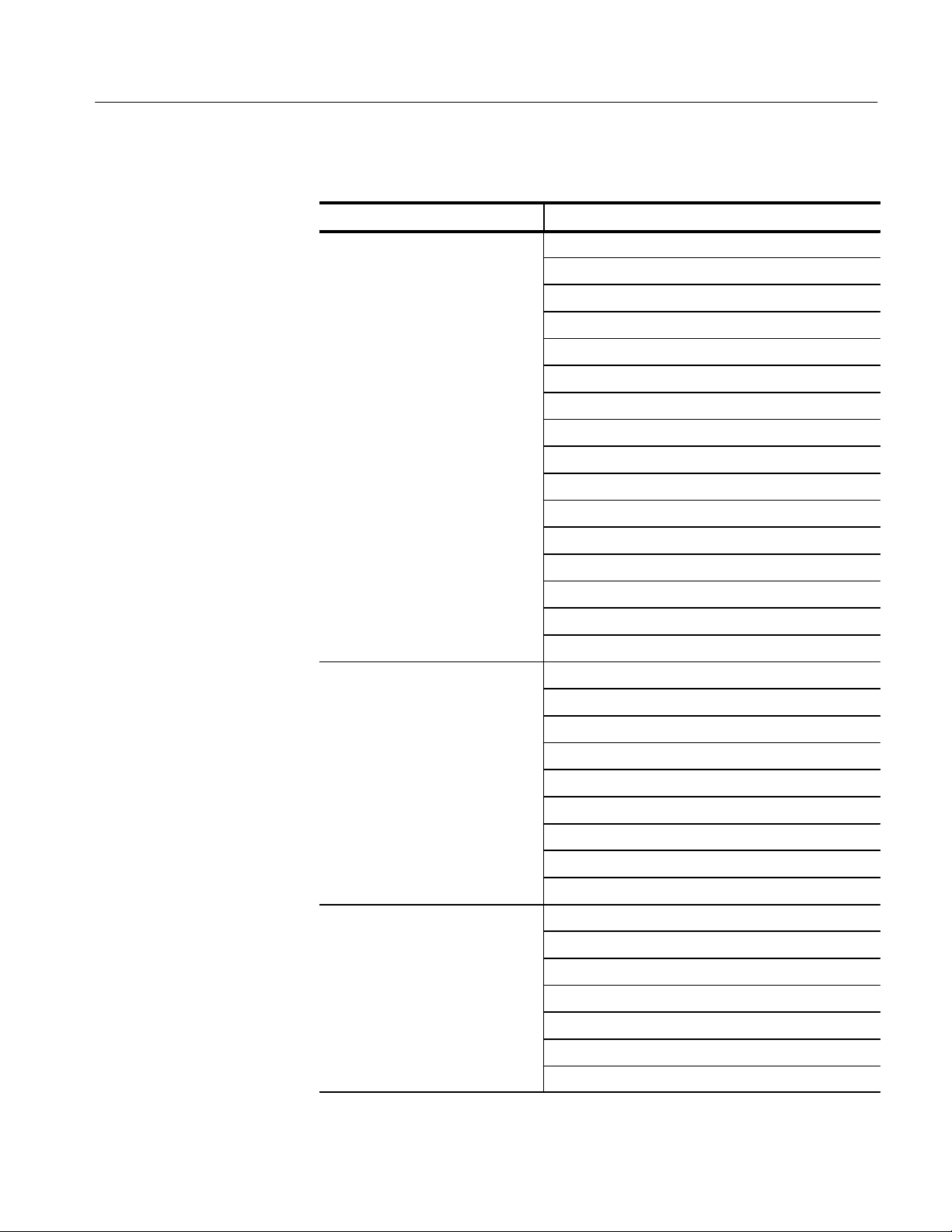

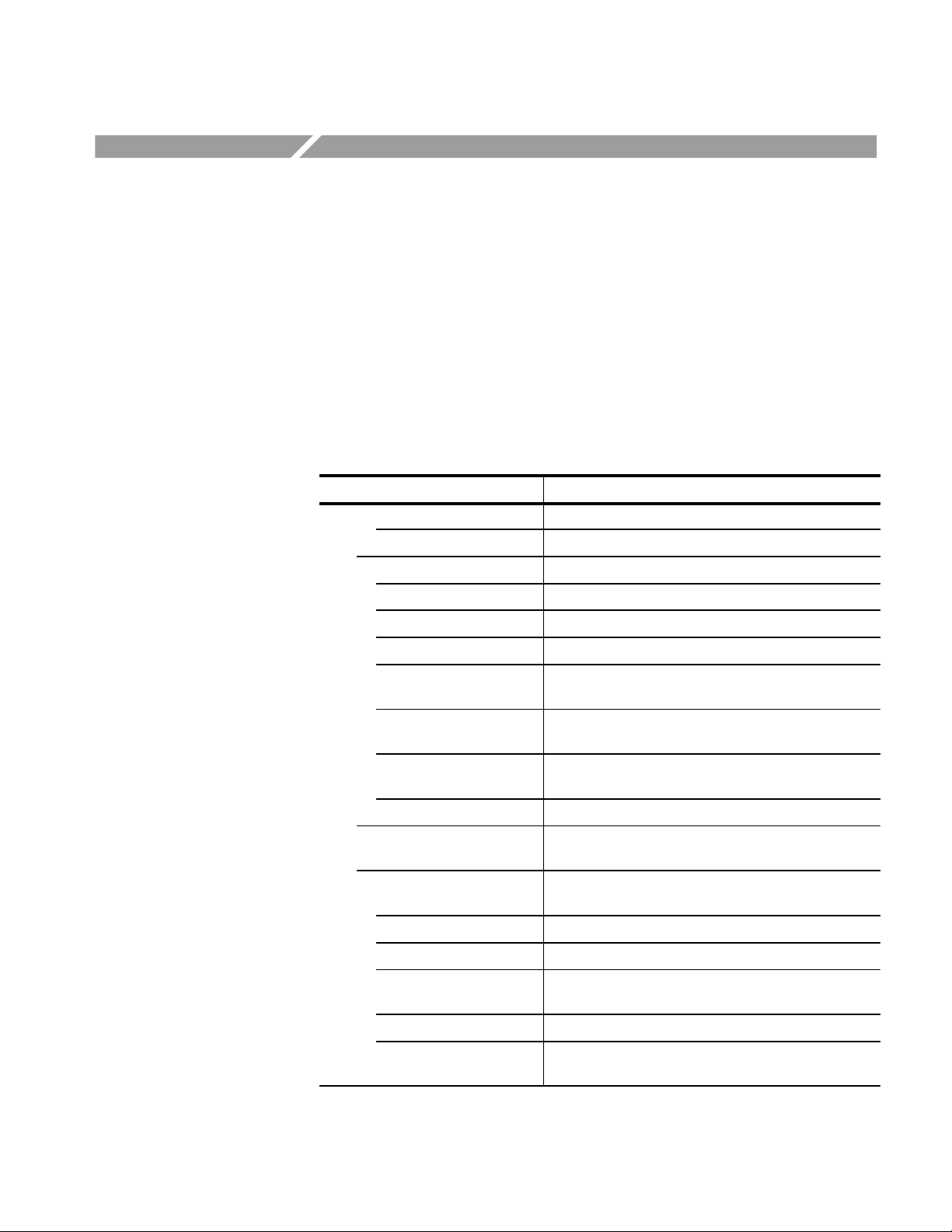

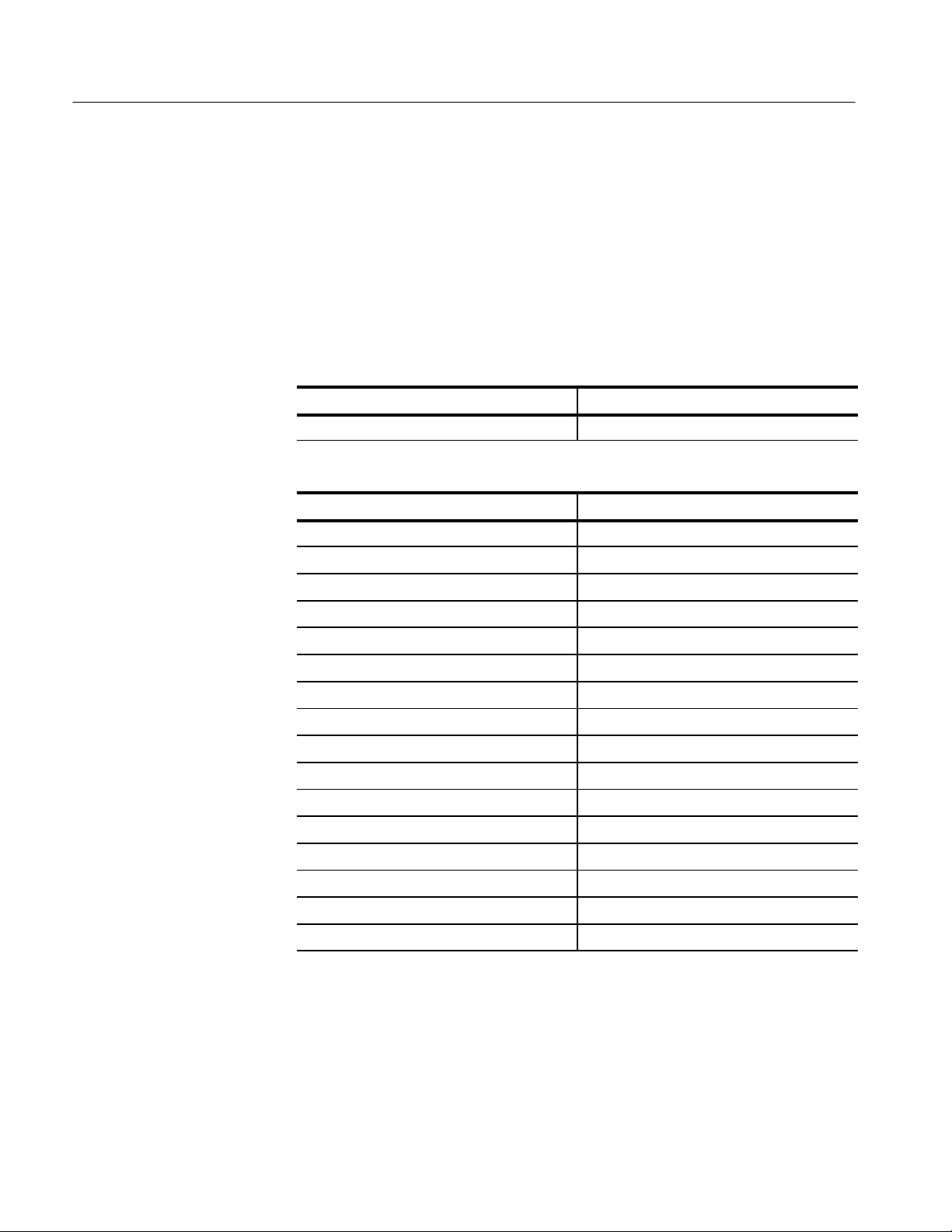

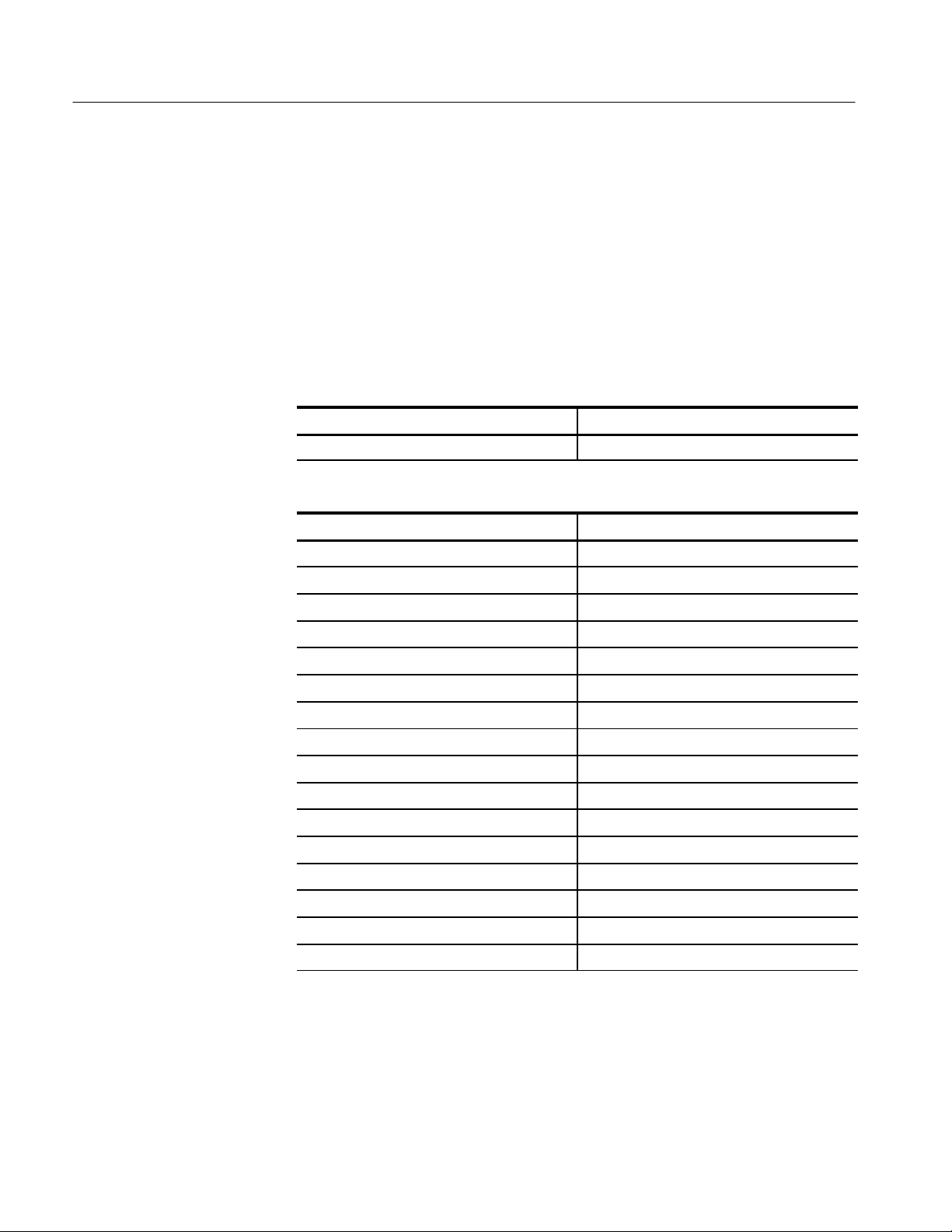

T able 1–12: Mechanical

Characteristic Description

Overall Dimensions (See Figure 1–1 for overall chassis dimensions)

Standard Chassis

Height (with feet) 13.65 in (362.0 mm)

Width 17.6 in (425.5 mm)

Depth 26.5 in (673.1 mm)

Chassis with Rackmount

Height 13.25 in (355.6 mm)

Width 18.9 in (480.1 mm)

Depth 28.9 in (746.7 mm) min to 33.9 in (873.8 mm) max

Weight

Minimum mainframe configuration with expansion module and slot filler

panels installed.

Typical configuration: same as as minimum above with the addition of

two TLA 7x4 LA’s and

one TLA 7x2 DSO at 5 lbs 10 oz each, and removal of 3 slot filler panels

Shipping weight: minimum configuration with expansion module module

(only) and all mainframe standard accessories (2 manuals, 5 dual wide,

1 single slot filler panels, power cord, empty pouch, front cover,

keyboard, software, and cables

Shipping weight: fully configured instrument. Same as minimum above

with the addition of 3 LA modules (TLA 7N4, TLA 7P2, and TLA 7P4)

and 2 DSO’s (TLA 7D1 and TLA 7E1), and all module standard

accessories (probes, clips)

48.5 lbs (22.1 kg)

63.7 lbs (28.9 kg)

104 lb (47.2 kg)

161 lb (73 kg)

Rackmount kit adder 20 lbs (9.07 kg)

Module Size 13 plug-in slots

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

1–13

Page 36

Expansion Chassis Specifications

16.7 in

(42.55 cm)

13.65 in

(35.00 cm)

13.25 in

(33.6 cm)

Figure 1–2: Front and side view of the expansion chassis

26.5 in

(69.99 cm)

1–14

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 37

Operating Information

Page 38

Page 39

Operating Information

This chapter contains information about operating the benchtop chassis. Refer to

the TLA 700 Series Installation Manual for information on how to install and

configure the benchtop chassis. For more detailed operating information, refer to

the TLA 700 Series Logic Analyzer User Manual and in the online help.

Figure 2–1 shows the front view of the benchtop chassis with a benchtop

controller installed. Figure 2–3 shows the rear view of the benchtop chassis.

Chassis slots 3 through 11 are labeled on the top and bottom of the chassis.

Slots 0, 1 and 2 are reserved for the three slot-wide controller, all other slots are

available for any other TLA 700 Series module.

Figure 2–1: Front view of the benchtop chassis with a benchtop controller

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

2–1

Page 40

Operating Information

Fuse

AC Power

Figure 2–2: Front view of the expansion chassis (with out expansion module)

25-Pin PASSIVE

MONITOR connector

Fan speed switch

Figure 2–3: Rear view of the benchtop chassis

2–2

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 41

Operating Information

When you install a module, shutters on the bottom of each slot automatically

open to provide cooling.

On/Standby Switch

AC Power Connector

Chassis Ground Screw

Fan Speed Switch

The On/Standby switch on the top-left corner of the front panel applies DC

voltages to the chassis. The switch is a momentary contact switch. The switch is

lighted when DC voltages are applied to the benchtop chassis. The benchtop

chassis can also be remotely controlled.

You can configure the benchtop chassis to bypass the On/Standby switch. (Refer

to Remote Power Switch Configuration on page 4–18 of the Maintenance

chapter for information on configuring the power switch.) In this configuration,

the On/Standby switch remains lighted while power is applied, but the switch

itself no longer controls the benchtop chassis.

The AC power connector is located on the rear bottom left side of the benchtop

chassis. The AC fuse holder is located just above the power connector.

The chassis ground screw can be used to connect more than one benchtop chassis

to a common ground point.

The fan speed switch controls the speed of the blower. When the switch is set to

the VAR (variable) position, the mainframe automatically controls the speed of

the blower depending on the air temperature and amount of cooling required by

the modules. When the switch is in the FULL position, the blower operates at

full speed.

Enhanced Monitor

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

The enhanced monitor, in addition to the DB25-pin connector and the fan switch,

includes an industry standard 9-pin RS-232 serial port, logical address switches, a

jumper for slot-1 or slot-12 MODID selection, an auxiliary power connection, a slot

for adding programming FLASH jumper, and status lights. Refer to Figure 2–4.

2–3

Page 42

Operating Information

RS-232C connector

MONITOR BACKUP

POWER SUPPLY

LOGICAL ADDRESS switches

READY light

ACCESSED light

MODID Jumper Selection

Figure 2–4: Rear view of the enhanced monitor

The logical address switches select the logical addresses for the enhanced

monitor. The top switch sets the most-significant digit, the bottom switch sets

the least-significant digit.

The green READY indicator lights after the power-on diagnostics are complete

and there are no failures. During normal operation, the light flashes if there is a

pending error message. Once all error messages have been retrieved, the READY

indicator stops flashing and remains on.

The amber ACCESSED indicator lights when the MODID line is accessed by

the slot 0 device. Refer to Enhanced Monitor Board Jumpers on page 4–23 for

information on the jumper MODID jumper positions.

An auxiliary power connector (MONITOR BACKUP POWER SUPPLY) allows

you to apply +5 V to the enhanced monitor board to provide RS-232 communication with the enhanced monitor while the mainframe is not powered on. The

jumper located just above the power connector determines whether you source

the +5 V standby voltage from the monitor backup power supply connector or

from the 25-pin connector.

For additional information on the enhanced monitor board jumpers, refer to the

Enhanced Monitor Board Jumpers section on page 4–23.

2–4

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 43

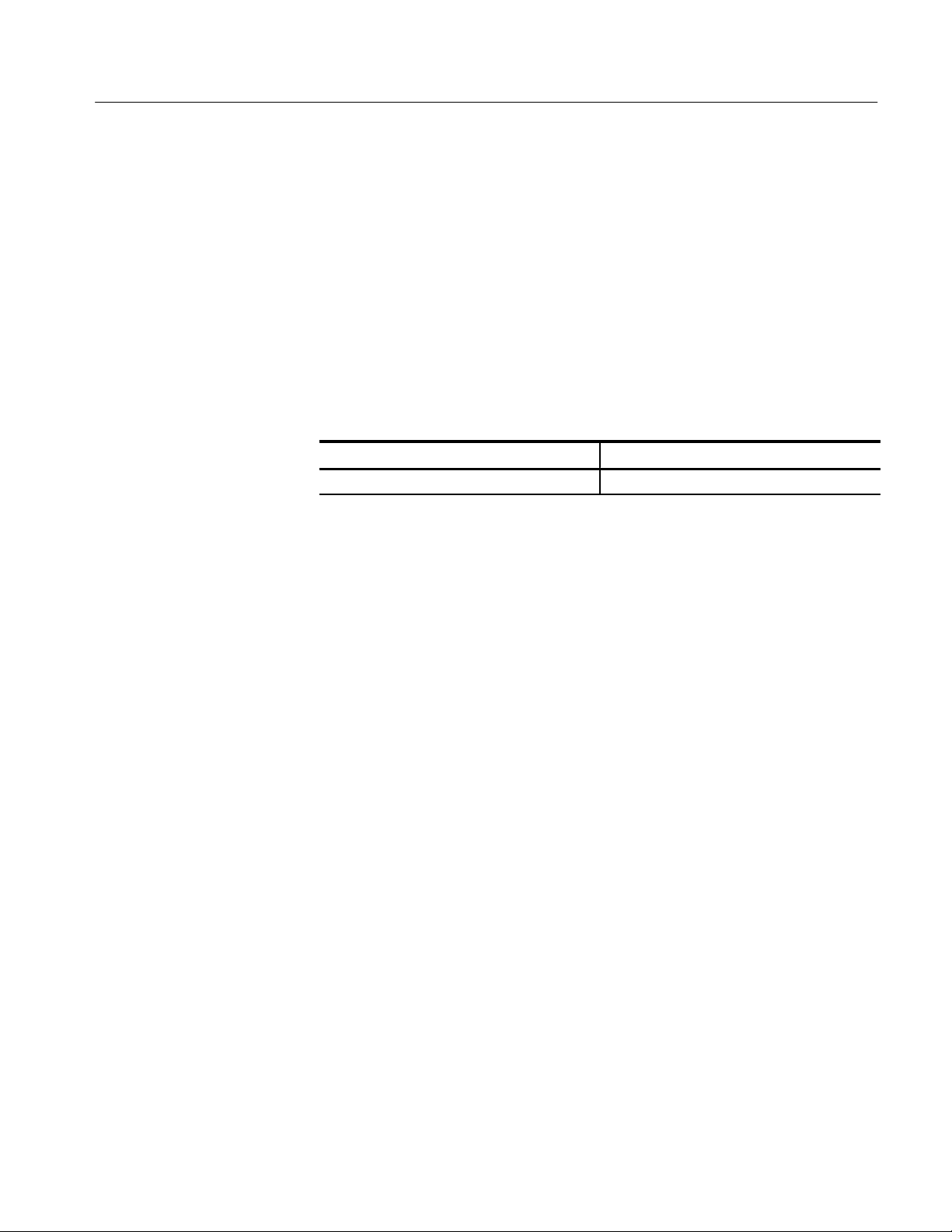

Selecting the Correct Power Cord and Fuse

The benchtop chassis comes standard with two power cords and three fuses.

Before installing the chassis you must determine the correct fuse and power cord

for your application. Use the following information to determine the appropriate

power cord and line fuse. This information is important to avoid overloading the

power distribution system and to comply with the National Electrical Code.

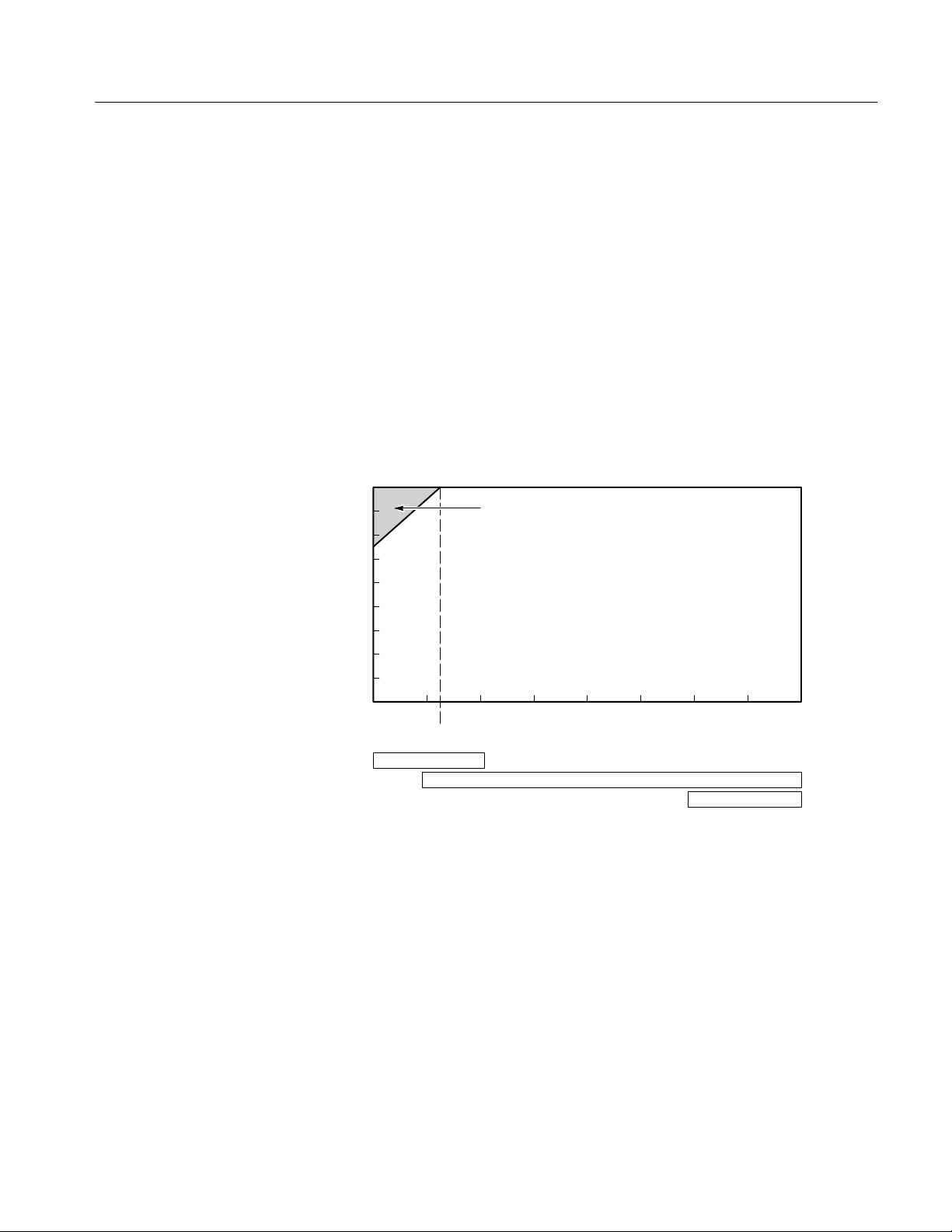

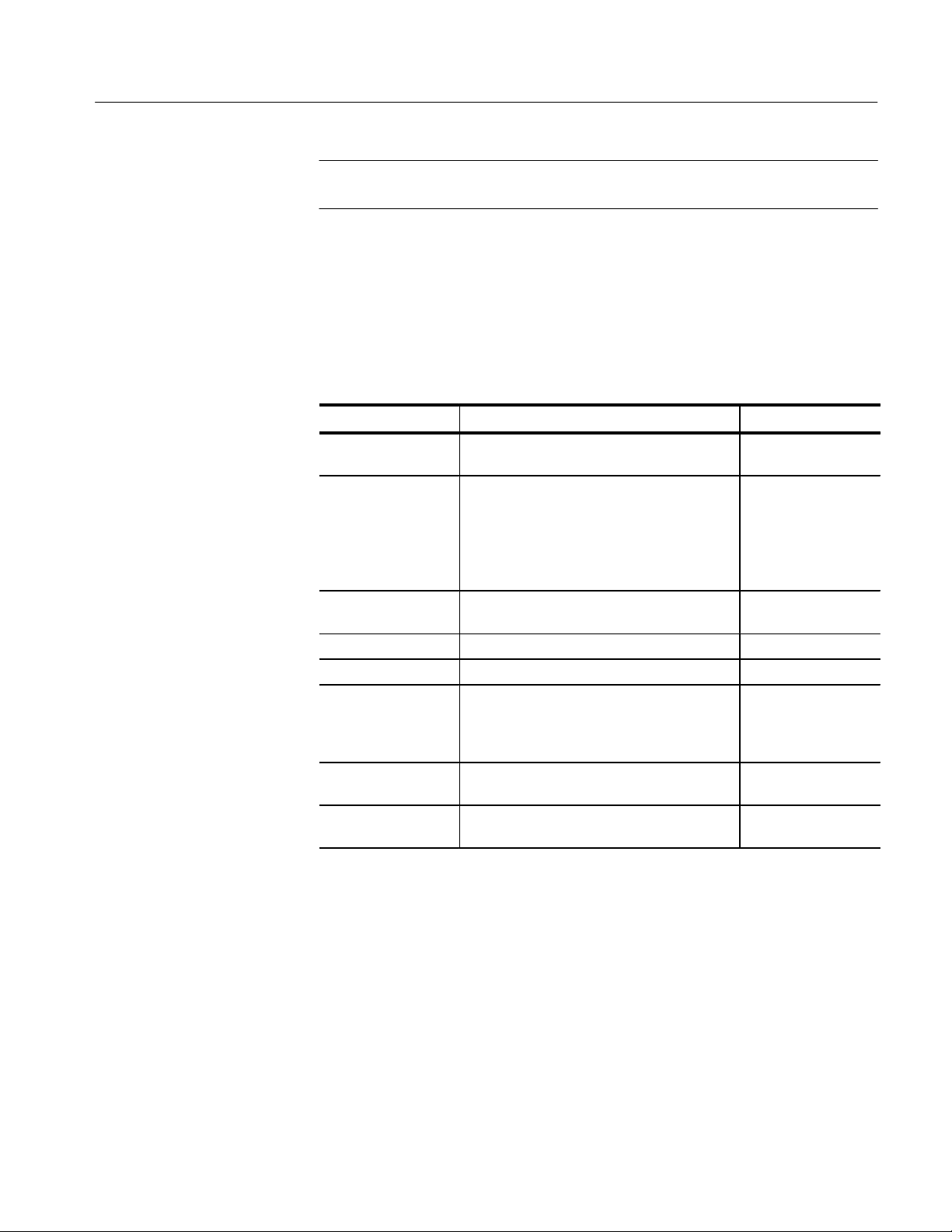

For card cage loads in the nonshaded region of Figure 2–5, use the power cord

with the 15 A plug (Tektronix part number 161-0213-XX) or the power cord

with the 20 A plug (Tektronix part number 161-0218-XX). For high card cage

loads combined with low input line voltages (shaded region), use only the power

cord with the 20 A plug.

Select the proper fuse based on the ranges shown in Figure 2–5.

Operating Information

Power Cord with 20A plug (NEMA 5–20P) ONLY!

Power Cord with 15A plug (NEMA 5–15P)

Power Cord with 20A plug (NEMA 5–20P)

130 150 170 190 210 230 250

Input Line Voltage (Volts AC)

Card Cage Power Consumption (Watts)

800

700

600

500

400

300

200

100

0

90 110

20AT Fuse

115

15AF Fuse

Figure 2–5: Power cord identification chart

6.3AF Fuse

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

2–5

Page 44

Operating Information

2–6

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 45

Reference

This chapter provides reference information on the mainframe and its connectors.

A description of the command set and information related to the Enhanced

Monitor makes up the remainder of this chapter.

Passive Monitor Connector

The 25-pin Sub-D connector lets you monitor the power supply voltages, fan

speed, and the maximum slot temperature rise within the mainframe.

The connector also provides remote on and off capability and access to the

SYSRESET* and ACFAIL* signals.

Figure 2–6 shows the location of the Passive Monitor Connector. Table 2–1 lists

the pin out of the Passive Monitor Connector and its function.

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

2–7

Page 46

Reference

Pin 1

Pin 25

Figure 2–6: Passive monitor connector

2–8

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 47

Reference

T able 2–1: Passive monitor connector pinouts

Pin Function Description

1 +5 VM +5 V for voltage monitoring

To monitor, only use a probe with greater than 1 MW impedance.

2 –12 VM –12 V for voltage monitoring

To monitor, only use a probe with greater than 1 MW impedance.

3 –24 VM –24 V for voltage monitoring

To monitor, only use a probe with greater than 1 MW impedance.

4 –2 VM –2 V for voltage monitoring

To monitor, only use a probe with greater than 1 MW impedance.

5 ON/ST Remote On/Standby Power Switch.

6 +5 VC +5 V output for charging batteries, running external TTL circuitry,

1 A maximum

7 +12 VC +12 V output for charging batteries, running external TTL circuitry,

1 A maximum

1

8 +5 VB Input for +5 V standby voltage (for example, from an external

battery). Maximum of 1 A total (pins 8 and 21 combined)

9 GND Logic Ground

10 SYSRESET* Backplane SYSRESET* signal (input or output). If you use this pin,

do not violate VXIbus electrical specifications (keep the extender

cable as short as possible).

11 ∆T An analog output signal proportional to the maximum temperature

rise of the 13 modules (100 mV/°C) 0V=0°C

12 TACH1 A square wave output signal whose period is proporitinal to the

speed of fan number 1

13 TACH2 A square wave output signal whose period is proporitinal to the

speed of fan number 2 when a second fan is used. In the current

mainframe only a single fan is used.

14 +12 VM +12 V for voltage monitoring

To monitor, only use a probe with greater than 1 MW impedance.

15 +24 VM +24 V for voltage monitoring

To monitor, only use a probe with greater than 1 MW impedance.

16 –5.2 VM –5.2 V for voltage monitoring

To monitor, only use a probe with greater than 1 MW impedance.

17 GND Logic Ground

18 GND Logic Ground

2

19 GND Logic Ground

20 GND Logic Ground

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

2–9

Page 48

Reference

T able 2–1: Passive monitor connector pinouts (Cont.)

Pin DescriptionFunction

21 +5 VB Input for +5 V standby voltage (for example, from an external

battery). Maximum of 1 A total (pins 8 and 21 combined)

22 GND Logic Ground

23 ACFAIL* Backplane ACFAIL* signal output. If you use this pin, do not violate

the VXIbus electrical specifications (keep the extender cable as

short as possible).

Refer to VMEbus Specification Manual for details on using the

ACFAIL* and SYSRESET* signals.

24 GND Logic Ground

25 RSV Request Service signal

1

By momentarily grounding this line, the mainframe will toggle from on to off (or vice

3

versa). The state changes on the falling edge of the signal. Hold the signal low for at

least 500 ms before releasing. Attach only a momentary switch or an open collector

device to drive this line. The line is pulled up to 1 V internally.

2

If you use pins 8 and 21 (+5 VB) to supply +5 V Standby to the backplane, make sure

that the rear panel jumper is in the correct position (refer to Enhanced Monitor Board

Jumpers on page 4–23).

3

The RSV signal is equivalent to the IEEE 488.1 SRQ signal. The signal is asserted (0)

when an enable event is generated; the signal is unasserted(1) when the event is

cleared by reading the event register. This line is an open collector output. The

signal can be stand-alone or multiple mainframes can be tied together. If you tie

multiple mainframes together , each mainframe must be polled to determine the

source of the service request.

2

2–10

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 49

Enhanced Monitor RS-232 Connector

The Enhanced Monitor includes a 9-pin RS-232 connector that allows connection to a RS-232 host. Figure 2–7 shows the pinouts of the 9-pin RS-232

connector; Table 2–2 describes the pin assignments.

Reference

Pin 1

Pin 9

Figure 2–7: RS-232 connector pinout

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

2–11

Page 50

Reference

T able 2–2: RS-232 pin connector

Pin Description

Shield Protective Ground

1 No Connection

2 Receive Data (RxD)

3 Transmit Data (TxD)

4 Data Terminal Ready (DTR)

5 Signal Ground (GND)

6 No Connection

7 Request to Send (RTS)

8 Clear to Send (CTS)

9 No Connection

Backplane Connectors

Table 2–3 shows the P1 connector pinouts for all slots in themainframe.

Table 2–4 shows the P2 connector pinouts for slots 1 to 12 and Table 2–5 shows

the pinouts for the Slot 0 P2 connector.

2–12

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 51

T able 2–3: P1 connector pinouts

Pin Row A Row B Row C

1 D00 BBSY* D08

2 D01 BCLR* D09

3 D02 ACFAIL* D10

4 D03 BG0IN* D11

5 D04 BG0OUT* D12

6 D05 BG1IN* D13

7 D06 BG1OUT* D14

8 D07 BG2IN* D15

9 GND BG2OUT* GND

10 SYSCLK BG3IN* SYSFAIL*

11 GND BG3OUT* BERR*

12 DS1* BR0* SYSRESET*

Reference

13 DS0* BR1* LWORD*

14 WRITE* BR2* AM5

15 GND BR3* A23

16 DTACK* AM0 A22

17 GND AM1 A21

18 AS* AM2 A20

19 GND AM3 A19

20 IACK* GND A18

21 IACKIN* SERCLK A17

22 IACKOUT* SERDAT* A16

23 AM4 GND A15

24 A07 IRQ7* A14

25 A06 IRQ6* A13

26 A05 IRQ5* A12

27 A04 IRQ4* A11

28 A03 IRQ3* A10

29 A02 IRQ2* A09

30 A01 IRQ1* A08

31 –12 V +5 V STDBY +12 V

32 +5 V +5 V +5 V

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

2–13

Page 52

Reference

T able 2–4: P2 connector pinouts for slots 1 – 12

Pin Row A Row B Row C

1 ECLTRG0 +5 V CLK10+

2 –2 V GND CLK10–

3 ECLTRG1 RSV1 GND

4 GND A24 –5.2 V

5 LBUSA00 A25 LBUSC00

6 LBUSA01 A26 LBUSC01

7 –5.2 V A27 GND

8 LBUSA02 A28 LBUSC02

9 LBUSA03 A29 LBUSC03

10 GND A30 GND

11 LBUSA04 A31 LBUSC04

12 LBUSA05 GND LBUSC05

13 –5.2 V +5 V –2 V

14 LBUSA06 D16 LBUSC06

15 LBUSA07 D17 LBUSC07

16 GND D18 GND

17 LBUSA08 D19 LBUSC08

18 LBUSA09 D20 LBUSC09

19 –5.2 V D21 –5.2 V

20 LBUSA10 D22 LBUSC10

21 LBUSA11 D23 LBUSC11

22 GND GND GND

23 TTLTRG0* D24 TTLTRG1*

24 TTLTRG2* D25 TTLTRG3*

25 +5 V D26 GND

26 TTLTRG4* D27 TTLTRG5*

27 TTLTRG6* D28 TTLTRG7*

28 GND D29 GND

29 RSV2 D30 RSV3

2–14

30 MODID D31 GND

31 GND GND +24 V

32 SUMBUS +5 V –24 V

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 53

T able 2–5: P2 connector pinouts for slot 0

Pin Row A Row B Row C

1 ECLTRG0 +5 V CLK10+

2 –2 V GND CLK10–

3 ECLTRG1 RSV1 GND

4 GND A24 –5.2 V

5 MODID12 A25 LBUSC00

6 MODID11 A26 LBUSC01

7 –5.2 V A27 GND

8 MODID10 A28 LBUSC02

9 MODID09 A29 LBUSC03

10 GND A30 GND

11 MODID08 A31 LBUSC04

12 MODID07 GND LBUSC05

Reference

13 –5.2 V +5 V –2 V

14 MODID06 D16 LBUSC06

15 MODID05 D17 LBUSC07

16 GND D18 GND

17 MODID04 D19 LBUSC08

18 MODID03 D20 LBUSC09

19 –5.2 V D21 –5.2 V

20 MODID02 D22 LBUSC10

21 MODID01 D23 LBUSC11

22 GND GND GND

23 TTLTRG0* D24 TTLTRG1*

24 TTLTRG2* D25 TTLTRG3*

25 +5 V D26 GND

26 TTLTRG4* D27 TTLTRG5*

27 TTLTRG6* D28 TTLTRG7*

28 GND D29 GND

29 RSV2 D30 RSV3

30 MODID00 D31 GND

31 GND GND +24 V

32 SUMBUS +5 V –24 V

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

2–15

Page 54

Reference

Enhanced Monitor

The Enhanced Monitor provides the mainframe with the following additional

capabilities via the RS-232 interface:

H Power supply voltage readouts

H Power supply current readouts

H Power supply wattage readout

H Ambient (input) air temperature readout

H Exhaust temperature readout for each slot

H Fan speed readout

H User-selectable maximum temperature rise

Use defined messages with the DISPlay:TEXT command.

T able 2–6: Messages

Category Message

Power Supply Voltage Messages FAIL:+24V@XX.XX

FAIL:+12V@XX.XX

FAIL:+5V@X.XX

FAIL:+5V STBY@XX.XX

FAIL:+5V EXT@XX.XX

FAIL:–2V@X.XX

FAIL:–5.2V@X.XX

FAIL:–12V@XX.XX

FAIL:–24V@XX.XX

Power Supply Current Average

Messages

FAIL:+24I@XX.XXA

FAIL:+12I@XX.XXA

FAIL:+5I@XX.XXA

FAIL:–2I@XX.XXA

FAIL:–5.2I@XX.XXA

FAIL:–12I@XX.XXA

2–16

FAIL:–24I@XX.XXA

Power Supply message FAIL: Total W@XX.XW

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 55

T able 2–6: Messages (Cont.)

Category Message

Slot Temperature messages FAIL:S0 ∆Τ@XX°C

FAIL:S1 ∆Τ@XX°C

FAIL:S2 ∆Τ@XX°C

FAIL:S3 ∆Τ@XX°C

FAIL:S4 ∆Τ@XX°C

FAIL:S5 ∆Τ@XX°C

FAIL:S6 ∆Τ@XX°C

FAIL:S7 ∆Τ@XX°C

FAIL:S8 ∆Τ@XX°C

FAIL:S9 ∆Τ@XX°C

FAIL:S10 ∆Τ@XX°C

FAIL:S11 ∆Τ@XX°C

Reference

FAIL:S12 ∆Τ@XX°C

FAIL:Ambient Τ@XX°C

FAIL:Fan1 XXXXRPM

FAIL:Fan2 XXXXRPM (VX1410A only)

Power Supply Voltage Messages +24 Volts:XX.XXV

+12 Volts:XX.XXV

+5 Volts:X.XXV

+5V Stby:X.XXV

+5V External:X.XXV

–2 Volts:X.XXV

–5.2 Volts:X.XXV

–12 Volts:XX.XXV

–24 Volts:XX.XXV

Power Supply Current Amperage

Messages

+24V Amps:XX.XXA

+12V Amps:XX.XXA

+5V Amps:XX.XXA

–2V Amps:XX.XXA

–5.2V Amps:XX.XXA

–12V Amps:XX.XXA

–24V Amps:XX.XXA

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

2–17

Page 56

Reference

T able 2–6: Messages (Cont.)

Category Message

Power Supply Power Messages Total Power:XXX.XW

T emperature Status Messages Ambient T:XX°C

∆Τ S0,S1:XX,XX°C

∆Τ S2,S3:XX,XX°C

∆Τ S4,S5:XX,XX°C

∆Τ S6,S7:XX,XX°C

∆Τ S8,S9:XX,XX°C

∆Τ S10,S11:XX,XX °C

∆Τ S12:XX°C

Fan Status Messages Fan 1 RPM: XXXX

Fan 2 RPM: XXXX (VX1410A only)

Miscellaneous Messages Time On:HHHHHH:MM

Hr of Oper:HHHHHH

Date and Time Message Year–Mon–XX XX:XX

SYSTEM OFF

SYSTEM OK

1

After power on a prompt will appear in the display. Press the PREV and NEXT

buttons to set the date and time. Pressing the PREV or NEXT will cycle through the

values, while pressing both buttons simultaneously moves the cursor to the next

field.

1

2–18

TLA 720 Benchtop Chassis and TLA 7XM Expansion Chassis Service Manual

Page 57

Syntax

SCPI

This section provides an overview of the commands for the mainframe and

includes the following topics:

H A brief introduction to SCPI

H A description of the command syntax

H Instructions on how to enter commands

The commands for the mainframe are compatible with IEEE-488.1, IEEE-488.2,

and SCPI-1995.0 standards.

SCPI (Standard Commands for Programmable Instruments) is a standard created

by an international consortium of the major manufacturers of test and measurement equipment. SCPI uses IEEE-488.2 syntax to provide common commands

for the same functions of various programmable instruments.

The standard simplifies the task of programming a group of instruments that use

SCPI. Instead of having to learn different commands for every instrument, the

programmer may use the same commands for the same functions of each

instrument.

Command Syntax

The controller sends instructions to the instrument in the form of commands or

queries.