Page 1

Service Manual

TLA 704

Color Portable Mainframe

070-9777-02

This document applies to TLA 700 application

software version 1.00 and above.

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

Page 2

Copyright © T ektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its suppliers and

are protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in T echnical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software – Restricted Rights clause at F AR 52.227-19, as applicable.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Windows and Windows 95 are trademarks of Microsoft Corporation.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of shipment. If a product proves defective during this warranty period, T ektronix,

at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

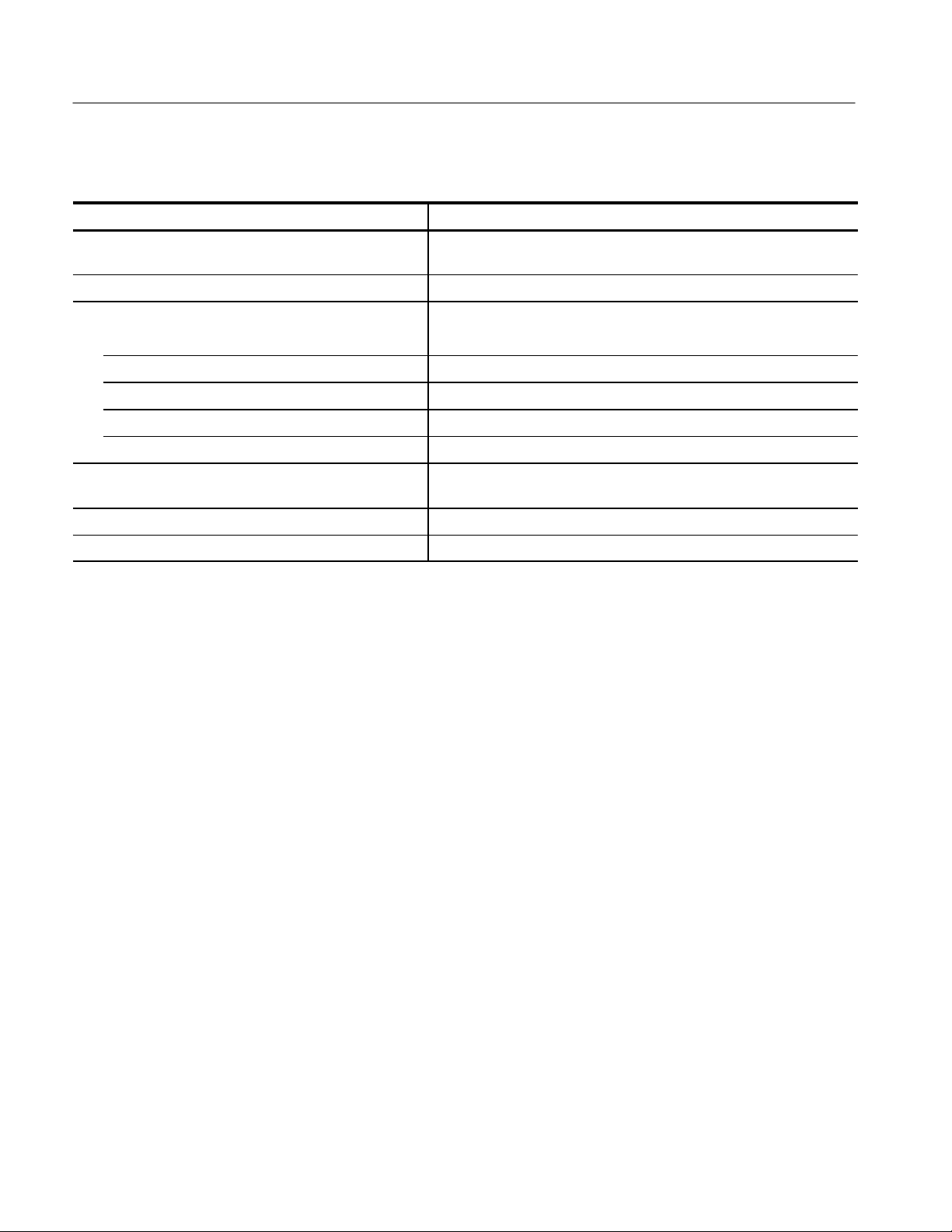

TEKTRONIX SERVICE OPTIONS

T ektronix offers the following service options. These options are modular, flexible, and easy to order with your instrument. Designed to ease installation and start up, to support tracking of calibration to requirements of ISO9000, and

to provide for extended repair coverage, these options help fix your long-term maintenance costs and eliminate unplanned expenditures. And these options can be converted from service at T ektronix service depots to service on-site

(see Option S3), which helps keep downtime to a minimum.

Product installation service

1

Option IN Provides initial installation of the product and

familiarizes new users with some of its operation features

Three years of calibration services Option C3 Provides initial Certification on delivery, plus

two more annual calibrations from your

service center

Test data Option D3 Provides test data on delivery and when cal-

ibration services are provided (three

total, order with Option C3)

Three years repair coverage Option R3 Provides three years of repair coverage for the

instrument, including displays and accessories

sold with the instrument

One year uplift to on–site service

1,2

Option S1 Converts the standard one year, “return to

depot” warranty to provide service on site for

one year

Three year uplift to on-site service

1,2

Option S3 Converts any C3, D3, and R3 options pur-

chased to on-site services for three years

Tektronix Service Options are available at the time you order your instrument. Contact your local Tektronix Sales

Office for more information.

1

Availability of installation and on-site services depends on the type of product and may vary by geography.

2

Uplift options are ordered with the mainframe products and cover individual modules.

Page 5

Table of Contents

Specifications

Operating Information

General Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Structure ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Conventions x. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Manuals xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment and Certification Interval xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strategy for Servicing xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Offerings xiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting T ektronix xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Characteristics T ables 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O and Memory Hardware 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating System and Application Interface 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theory of Operation

Portable Mainframe 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification

Performance Verification 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedures

Adjustment Procedures 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance

Preparation 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventing ESD 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Cleaning 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation Procedures 6–5. . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation — Please Read 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedures for External Parts 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Cover and Trim Ring 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Control Assembly 6–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flat Panel Display Assembly 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Knobs 6–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TLA 704 Color Portable Mainframe Service Manual

i

Page 6

Table of Contents

Bottom Cover 6–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T op Cover 6–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Left Side Cover 6–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Right Side Cover 6–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Cord and Line Fuse 6–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply 6–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Chassis Fan Tray 6–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Individual Fans 6–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flip Stands and Rear Feet 6–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cord-Wrap Feet 6–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handle 6–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedures for Internal Parts 6–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller Board 6–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RAM SIMMs 6–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backplane Board 6–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Floppy Disk Drive 6–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hard Disk Drive 6–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface Board 6–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Control Board 6–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glidepoint Assembly 6–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Elastomeric Keypad 6–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 6–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check for Common Problems 6–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Eliminate Other Problem Sources 6–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshoot the TLA 704 Portable Mainframe 6–42. . . . . . . . . . . . . . . . . . . . . . . . .

BIOS Setup Error Messages 6–51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Update the BIOS Version 6–53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment After Repair 6–56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repackaging Instructions 6–57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options

Electrical Parts List

Diagrams

Replaceable Parts List

Options and Upgrade Kits 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Parts List 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Accessories 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Accessories 10–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 10–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common Replaceable Parts 10–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Parts List 10–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

TLA 704 Color Portable Mainframe Service Manual

Page 7

List of Figures

Table of Contents

Figure 1–1: Front and side views of TLA 704 Color Portable

Mainframe 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–1: TLA 704 Color Portable Mainframe front panel 2–2. . . . . .

Figure 2–2: TLA 704 Color Portable Mainframe rear panel 2–3. . . . . . .

Figure 2–3: Typical System window 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–1: TLA 704 Color Portable Mainframe major components

block diagram 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–1: External parts 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–2: Front cover and trim ring removal 6–10. . . . . . . . . . . . . . . . . .

Figure 6–3: Front-panel control assembly removal 6–11. . . . . . . . . . . . . . .

Figure 6–4: Flat panel display assembly removal 6–13. . . . . . . . . . . . . . . .

Figure 6–5: Top and side cover removal 6–16. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–6: Line cord and line fuse removal 6–19. . . . . . . . . . . . . . . . . . . .

Figure 6–7: Power supply removal 6–20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–8: Rear chassis fan tray removal 6–22. . . . . . . . . . . . . . . . . . . . . .

Figure 6–9: Individual fan removal 6–24. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–10: Flip stand and rear feet removal 6–25. . . . . . . . . . . . . . . . . . .

Figure 6–11: Cord-wrap feet removal 6–26. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–12: Handle removal 6–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–13: Internal parts 6–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–14: Front panel control assembly parts locations 6–35. . . . . . . . .

Figure 6–15: Primary troubleshooting tree 6–43. . . . . . . . . . . . . . . . . . . . . .

Figure 6–16: Jumper locations for bypassing front panel control

assembly 6–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–17: Location of J1 and J2 pins within the portable

mainframe 6–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–18: ResMan32 program output 6–50. . . . . . . . . . . . . . . . . . . . . . .

Figure 6–19: BIOS jumper location 6–54. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–1: Interconnection diagram 9–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–2: Block diagram 9–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–1: External parts 10–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–2: Front panel display and control assemblies 10–11. . . . . . . . . .

Figure 10–3: Floppy disk drive, hard disk drive, front panel interface

board, and related cables 10–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–4: Controller board, interface board, and EMI shield 10–15. . .

Figure 10–5: Power supply, handle, and fan 10–17. . . . . . . . . . . . . . . . . . . . .

TLA 704 Color Portable Mainframe Service Manual

iii

Page 8

Table of Contents

List of Tables

Table 1–1: Internal controller 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–2: Display system 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–3: Backplane interface 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–4: Front panel interface 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–5: Rear panel interface 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–6: AC power source 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–7: Secondary power 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–8: Certifications and compliances:

TLA 704 Color Portable Mainframe 1–10. . . . . . . . . . . . . . . . . . . . . . .

Table 1–9: Cooling 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–10: Environmental 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–11: Mechanical 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–1: SVGA OUT pin assignments 2–4. . . . . . . . . . . . . . . . . . . . . . .

Table 2–2: COM (serial interface) pin assignments 2–5. . . . . . . . . . . . . .

Table 2–3: LPT (parallel interface) pin assignments 2–5. . . . . . . . . . . . .

Table 6–1: Tools required for part removal 6–6. . . . . . . . . . . . . . . . . . . . .

Table 6–2: Failure symptoms and possible causes 6–40. . . . . . . . . . . . . . . .

Table 6–3: TLA 700 Power-on diagnostic tests 6–44. . . . . . . . . . . . . . . . . .

Table 6–4: Power supply voltages and backplane connector pins 6–47. . .

Table 6–5: Command line options for ResMan32 6–49. . . . . . . . . . . . . . . .

Table 6–6: BIOS error codes and explanations 6–51. . . . . . . . . . . . . . . . . .

Table 7–1: TLA 704 Color Portable Mainframe options and

upgrade kits 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10–1: Standard accessories 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10–2: Power cord identification 10–2. . . . . . . . . . . . . . . . . . . . . . . . .

Table 10–3: Optional accessories 10–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10–4: Common replaceable parts 10–5. . . . . . . . . . . . . . . . . . . . . . . .

Table 10–5: Parts lists column descriptions 10–6. . . . . . . . . . . . . . . . . . . . .

iv

TLA 704 Color Portable Mainframe Service Manual

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly . Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and marking on the product. Consult the product manual for further ratings

information before making connections to the product.

The common terminal is at ground potential. Do not connect the common

terminal to elevated voltages.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry .

TLA 704 Color Portable Mainframe Service Manual

v

Page 10

General Safety Summary

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

Symbols and Terms

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

WARNING

High Voltage

vi

Protective Ground

(Earth) T erminal

TLA 704 Color Portable Mainframe Service Manual

CAUTION

Refer to Manual

Double

Insulated

Page 11

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the main power by means

of the power cord or, if provided, the power switch.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

TLA 704 Color Portable Mainframe Service Manual

vii

Page 12

Service Safety

viii

TLA 704 Color Portable Mainframe Service Manual

Page 13

Preface

Manual Structure

This is the service manual for the TLA 704 Color Portable Mainframe. Read this

preface to learn how this manual is structured, what conventions it uses, and

where you can find other information related to servicing this product. Read the

Introduction following this preface for safety and other important background

information needed before using this manual for servicing this product.

The TLA 704 Color Portable Mainframe Service Manual is divided into chapters,

which are made up of related subordinate topics. These topics can be cross

referenced as sections.

Be sure to read the introductions to all procedures. These introductions provide

important information needed to do the service correctly, safely, and efficiently.

A brief description of each chapter follows:

H Specifications contains a product description of the portable mainframe and

tables of the characteristics and descriptions that apply to it.

H Operating Information includes basic installation and operating instructions

at the level needed to safely operate and service the portable mainframe. For

complete installation and configuration procedures, refer to the TLA 700

Series Installation Manual.

H Theory of Operation contains circuit descriptions that support general service

to the circuit board or replacement part level.

H Performance Verification refers you to the TLA 700 Series Performance

Verification and Adjustment Manual that contains the performance verifica-

tion procedures for the portable mainframe and for other major components

in TLA 700 Series Logic Analyzers.

H Adjustment Procedures notes that the portable mainframe requires no

adjustment.

H Maintenance contains information and procedures for doing preventive and

corrective maintenance on the portable mainframe. Included are instructions

for cleaning, for removal and installation of replaceable parts, and for

troubleshooting product failures. Instructions for shipping the module are

also found in this chapter.

H Options contains information on the factory-installed options that may be

available for the portable mainframe.

TLA 704 Color Portable Mainframe Service Manual

ix

Page 14

Preface

Manual Conventions

H Diagrams contains a block diagram and an interconnection diagram useful

for isolating failed circuit boards or assemblies.

H Mechanical Parts List includes a table of all replaceable parts, their

descriptions, and their Tektronix part numbers.

This manual uses certain conventions that you should become familiar with

before attempting service.

Modules

Replaceable Parts

Safety

Throughout this manual, the term module refers to a TLA 700 Series Logic

Analyzer or DSO unit that mounts inside a TLA 700 Series Portable or Benchtop

Mainframe. A module is composed of circuit cards, interconnecting cables, and a

user-accessible front panel.

This manual refers to any field-replaceable assembly or mechanical part

specifically by its name or generically as a replaceable part. In general, a

replaceable part is any circuit board or assembly, such as the hard disk drive, or a

mechanical part, such as the I/O port connectors, that is listed in the replaceable

parts list of Chapter 10. Also, see Strategy for Servicing on page xiii.

Symbols and terms related to safety appear in the Service Safety Summary found

at the beginning of this manual.

x

TLA 704 Color Portable Mainframe Service Manual

Page 15

Related Manuals

The following manuals are available as part of the TLA 700 Series Logic

Analyzer documentation set. (See Standard Accessories and Optional

Accessories on pages 10–1 and 10–3 for manual part numbers.)

The procedures and information in this manual assumes that service personnel

have access to all manuals listed in the following table.

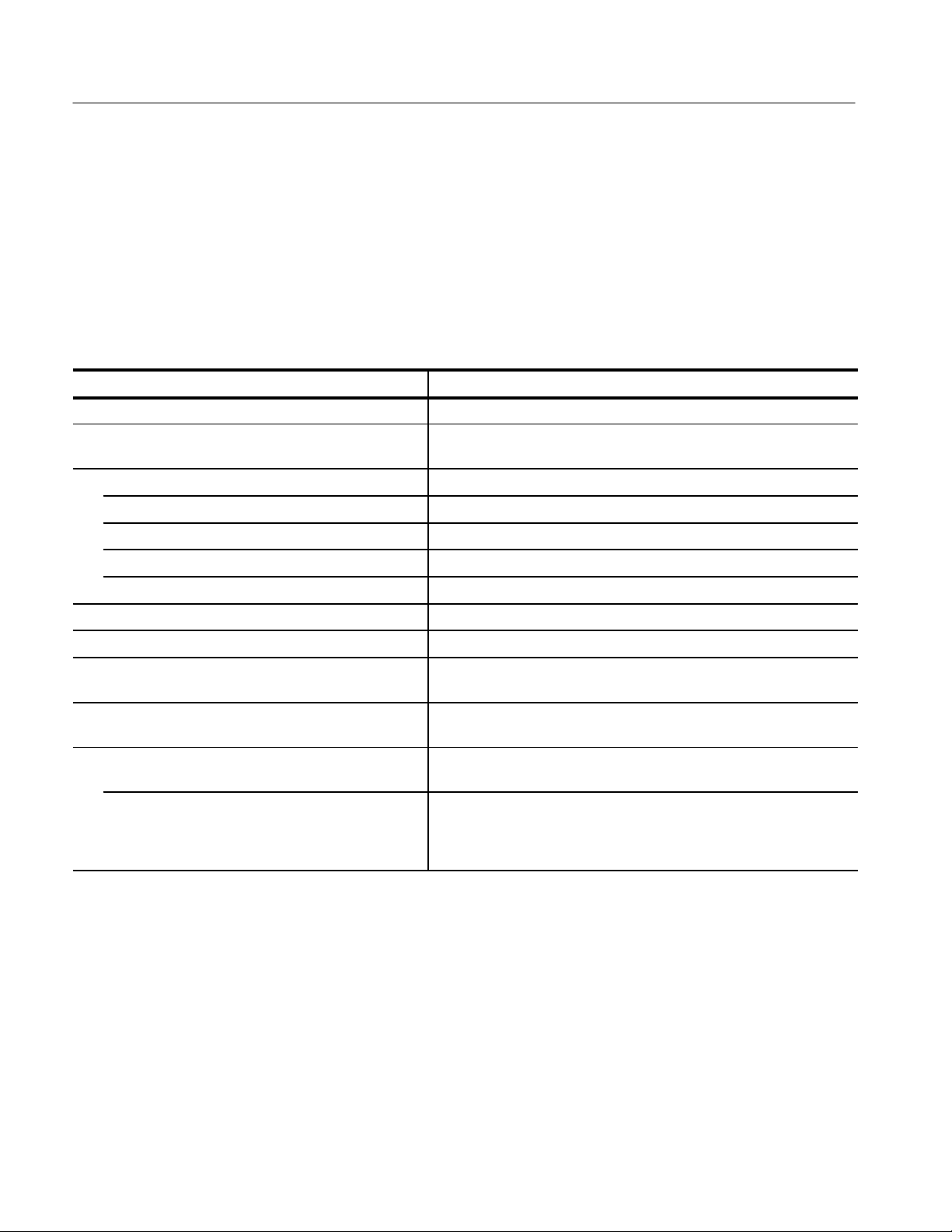

Manual Name Description Service Use

Preface

The TLA 700 Series Installation Manual Provides the basic installation instructions

for the TLA 700 Series Logic Analyzer.

The TLA 700 Series Performance Verifica-

tion and Adjustment T echnical Reference

Manual

The TLA 700 Series Logic Analyzer User

Manual and TLA 700 Online Help

The TLA 711 Color Benchtop Chassis

Service Manual

The TLA 711 Color Benchtop Controller

Service Manual

The TLA 7Lx/TLA 7Mx Logic Analyzer

Service Manual

Provides performance verification, certification, and adjustment procedures for the

TLA 700 Series Logic Analyzer

Provides operating information on the

TLA 700 Series Logic Analyzer

Provides service information for the

benchtop chassis

Provides service information for the slot 0

controller in the benchtop mainframe

Provides service information for the logic

analyzer modules

Installation and removal of DSO, Logic

Analyzer, and Benchtop-Controller Modules

Reinstallation of Windows 95 and TLA 700

software and firmware

Replacing individual podlet cables in the

logic analyzer probes

Reformatting hard disk

Performing periodic or after-repair functional

or performance verifications, calibrations, or

certifications

Performing periodic or after-repair adjustment

Augments operating information found in

chapter 2 of this manual

Isolating and correcting failures in the

benchtop chassis

Isolating and correcting failures in the

benchtop controller

Isolating and correcting failures in the Logic

Analyzer module

The TLA 7Dx/TLA 7Ex Digitizing Oscillo-

scope Service Manual

Provides service information for the

digitizing oscilloscope modules

TLA 704 Color Portable Mainframe Service Manual

Isolating and correcting failures in the

Digitizing Signal Oscilloscope module

xi

Page 16

Preface

xii

TLA 704 Color Portable Mainframe Service Manual

Page 17

Introduction

This manual contains information needed to properly service the TLA 704 Color

Portable Mainframe. This introduction contains information critical to safe and

effective servicing.

To prevent personal injury or damage to the portable mainframe, consider the

following requirements before attempting service:

H The procedures in this manual should be performed only by a qualified

service person.

H Read the General Safety Summary and Service Safety Summary found at the

beginning of this manual.

H Read the Preface beginning on page ix.

H Read Operating Information beginning on page 2–1.

When using this manual for servicing, be sure to follow all warnings, cautions,

and notes.

Adjustment and Certification Interval

Strategy for Servicing

Generally, you should perform the adjustments and certification (calibration)

described in the TLA 700 Series Performance Verification and Adjustment

Technical Reference Manual once per year or following repairs that affect

adjustment or calibration.

This manual supports and contains information needed for periodic maintenance

of the portable mainframe.

This manual also supports and contains information for corrective maintenance

of this product:

H supports isolation of faults to the failed circuit board or assembly level

shown in the replaceable parts list of Chapter 10

H supports removal and replacement of those boards or assemblies

H supports removal and replacement of fuse, knobs, chassis, and other

mechanical parts listed in the replaceable parts list

This manual does not support component-level fault isolation and replacement.

TLA 704 Color Portable Mainframe Service Manual

xiii

Page 18

Introduction

Service Offerings

Tektronix provides service to cover repair under warranty as well as other

services that are designed to meet your specific service needs.

Whether providing warranty repair service or any of the other services listed

below, Tektronix service technicians are well equipped to service the TLA 704

Color Portable Mainframe. Tektronix technicians train on Tektronix products;

they have access to the latest information on improvements to the TLA 704

Color Portable Mainframe as well as the latest new product upgrades. Services

are provided at Tektronix Services Centers and on-site at your facility, depending

on your location.

Warranty Repair Service

Calibration and Repair

Service

Tektronix warrants this product for one year from date of purchase. (The

warranty appears behind the title page in this manual.) Tektronix technicians

provide warranty service at most Tektronix service locations worldwide. The

Tektronix product catalog lists all service locations worldwide or you can visit us

on our Customer Services World Center web site at http://www.tek.com/Mea-

surement/Service. See our latest service offerings and contact us by email.

In addition to warranty repair, Tektronix Service offers calibration and other

services which provide cost-effective solutions to your service needs and qualitystandards compliance requirements. Our instruments are supported worldwide by

the leading-edge design, manufacturing, and service resources of Tektronix to

provide the best possible service.

The following services can be tailored to fit your requirements for calibration

and/or repair of the TLA 704 Color Portable Mainframe.

Service Options. Tektronix Service Options can be selected at the time you

purchase your instrument. You select these options to provide the services that

best meet your service needs. These service options are listed on the Tektronix

Service Options page following the title page of this manual.

xiv

Service Agreements. If service options are not added to the instrument purchase,

then service agreements are available on an annual basis to provide calibration

services or post-warranty repair coverage for the TLA 704 Color Portable

Mainframe. Service agreements may be customized to meet special turn-around

time and/or on-site requirements.

Service on Demand. Tektronix also offers calibration and repair services on a

“per-incident” basis that is available with standard prices for many products.

TLA 704 Color Portable Mainframe Service Manual

Page 19

Contacting Tektronix

Introduction

Self Service. Tektronix supports repair to the replaceable-part level by providing

for circuit board exchange.

Use this service to reduce down-time for repair by exchanging circuit boards for

remanufactured ones. Tektronix ships updated and tested exchange boards. Each

board comes with a 90-day service warranty.

For More Information. Contact your local Tektronix service center or sales

engineer for more information on any of the Calibration and Repair Services just

described.

Product

Support

Service

Support

For other

information

To write us Tektronix, Inc.

For application-oriented questions about a Tektronix measurement product, call toll free in North America:

1-800-TEK-WIDE (1-800-835-9433 ext. 2400)

6:00 a.m. – 5:00 p.m. Pacific time

Or contact us by e-mail:

tm_app_supp@tek.com

For product support outside of North America, contact your

local Tektronix distributor or sales office.

Contact your local Tektronix distributor or sales office. Or visit

our web site for a listing of worldwide service locations.

http://www.tek.com

In North America:

1-800-TEK-WIDE (1-800-835-9433)

An operator will direct your call.

P.O. Box 1000

Wilsonville, OR 97070-1000

TLA 704 Color Portable Mainframe Service Manual

xv

Page 20

Introduction

xvi

TLA 704 Color Portable Mainframe Service Manual

Page 21

Page 22

Specifications

Product Description

This chapter provides a brief product description and lists the warranted

characteristics, nominal traits, and typical characteristics of the TLA 704 Color

Portable Mainframe.

The TLA 704 Color Portable Mainframe is the base component of a customerconfigurable portable instrument. It can function as a logic analyzer, a digital

storage oscilloscope, or both, depending on the module cards installed in its

slots. The mainframe has the following features:

H Microsoft Windows 95 operating system

H Standard PC I/O ports, two PC card slots, and a PC-based processor

architecture provides automatic connectivity to numerous off-the-shelf I/O

devices (Ethernet, modem, printers, etc.)

H Display system provides internal color flat-panel LCD display (10.4-inch

active-matrix TFT) and an external SVGA port capable of driving large,

high-resolution external monitors

H Four backplane slots provide compatibility with TLA 700 Series instrument

modules

H Easy user configurability

H Precision clock, bus trigger line, and event signaling between the mainframe

and instrument modules supports real-time triggering, sequencing, and time

correlation of events

H Easy service access to field-replaceable parts

H Mainframe compatible with international power standards, certified to

international safety and EMC requirements, and tested to rugged environmental standards

TLA 704 Color Portable Mainframe Service Manual

1–1

Page 23

Specifications

Characteristics Tables

This section contains the complete specifications for the portable mainframe. All

specifications are warranted unless noted “typical.” Typical characteristics

describe typical or average performance and provide useful reference information. Specifications marked with the n symbol are checked in the TLA 700

Series Performance Verification and Adjustment Technical Reference Manual.

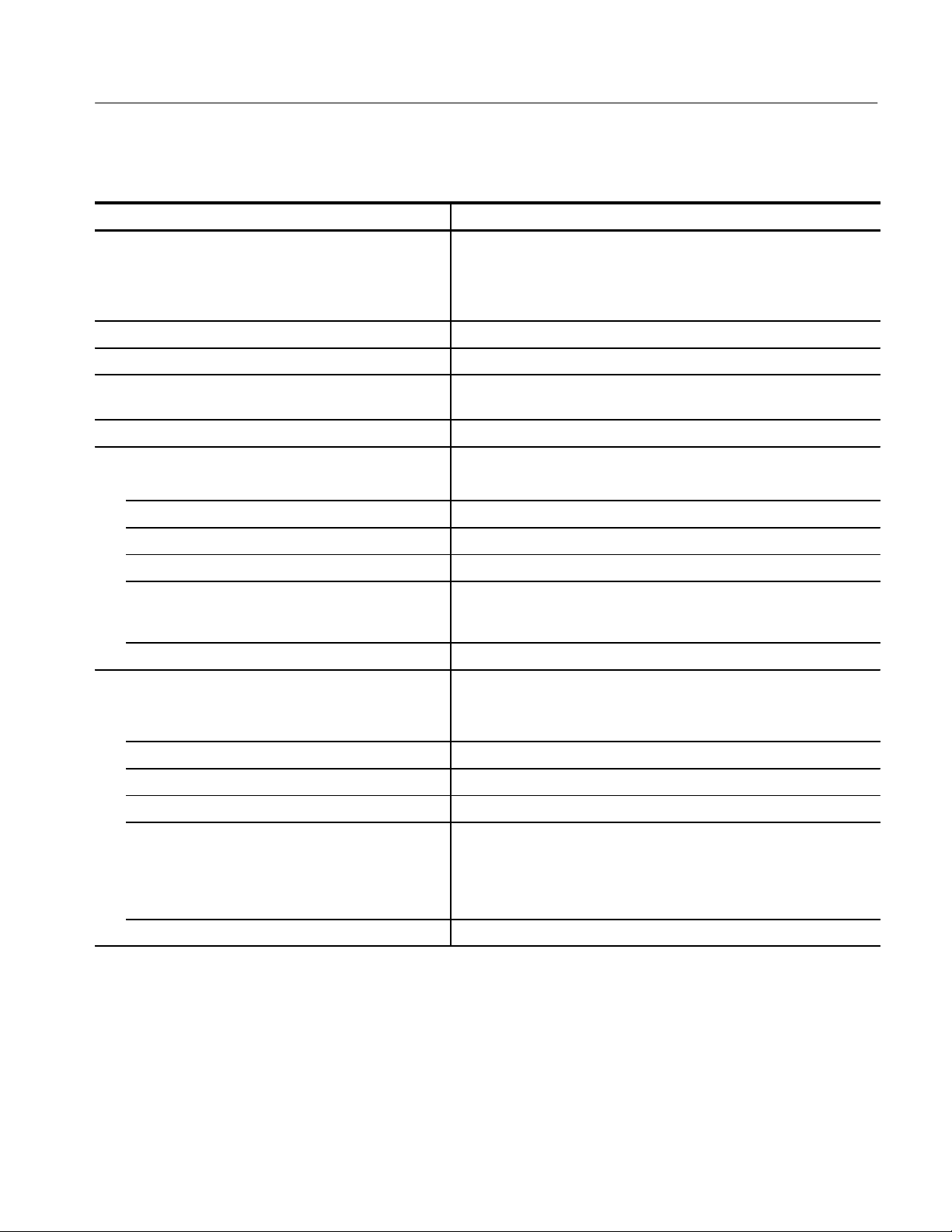

T able 1–1: Internal controller

Characteristic Description

Classification Microsoft Windows 95 compliant

Processor Intel 133 MHz Pentium PC-AT configuration, with an Intel 82430HX

(Triton II) chip set

Main Memory EDO DRAM

Style Two 72-pin SIMMs, gold-plated

Loading Symmetric, 2-SIMM minimum (64 bits)

Speed 60ns

Installed Configurations 16 MByte minimum, 32 MByte maximum

Cache Memory 256 KByte Level 2 (L2) write-back cache

Flash BIOS 512 KByte

Real-Time Clock and CMOS Setups NVRAM Real-Time clock/calendar, with typical 10-year life. Standard and

advanced PC CMOS setups; see BIOS specification.

Floppy Disk Drive Standard 3.5 inch 1.44-MByte PC compatible high-density, double-sided

floppy disk drive.

Hard Disk Drive Standard PC compatible ATA/Enhanced Integration Device Electronics

(EIDE) hard disk drive.

Size MIN configuration: 840 MByte

MAX configuration: 2.16 GByte

Subject to change; these are the storage capacities valid at product

introduction.

1–2

TLA 704 Color Portable Mainframe Service Manual

Page 24

Specifications

T able 1–2: Display system

Characteristic Description

Classification Standard PC graphics-accelerator technology (bitBLT-based); capable of

supporting both internal color LCD display and external color SVGA/XGA

monitor

Display Memory DRAM-based frame-buffer memory

Size 1 MByte

Width 32-bit

Display Selection Hardware sense of external SVGA monitor during BIOS boot sequence;

defaults to internal color LCD display; automatically switches to external

SVGA monitor, if attached.

Dual (simultaneous) display of external SVGA monitor and internal color

LCD is possible via special CMOS “simulscan” setup, as long as internal

and external displays operate at same resolution (limited to 640x480 on

current TFT LCD) and display rates.

Dynamic Display Configuration 1 (DDC1) support for external SVGA

monitor is provided.

External Display Drive 1 SVGA/XGA-compatible analog output port

Display Size Resolution (Pixels) Colors DDC1?

640x480 256 yes

640x480 64K yes

640x480 16.8M no

800x600 256 yes

800x600 64K yes

1024x768 256 yes

Internal Display

Classification Thin Film Transistor (TFT) 10.4” active-matrix color LCD display , CCFL

backlight, intensity controllable via software.

Resolution 640 pixels horizontal by 480 pixels

Color Scale 262,144 colors (6-bit RGB)

T able 1–3: Backplane interface

Characteristic Description

Slots 4 C-size, compliant with VXIBus System Spec Rev. 1.4, except as

follows:

MODID driver not capable of sinking 48 mA as required for 3-state

lines (meets standard design practices for VXI); and

TLA 704 Color Portable Mainframe Service Manual

TTL TRG* may not be unasserted after SYSRESET*, as ADG332

does not use SYSRESET* (accommodated via local controller

reset)

1–3

Page 25

Specifications

T able 1–3: Backplane interface (Cont.)

Characteristic Description

n CLK10 Frequency 10 MHz ±100 PPM

System-Level Relative Time

Correlation Error

1,2

LA to LA “MagniVu” data 2 ns

LA to LA “normal” data utilizing an internal clock

3

LA to LA “normal” data utilizing an external clock 2 ns

LA “MagniVu” to DSO data 3 ns

LA to DSO “normal” data utilizing an internal clock

LA to DSO “normal” data utilizing an external clock

DSO to DSO

4

System Trigger and External Signal Input Latencies

External System Trigger Input to LA Probe Tip

External Signal Input to LA Probe Tip via Signal 3, 4

External Signal Input to LA Probe Tip via Signal 1, 2

External System Trigger Input to DSO Probe Tip

System Trigger and External Signal Output Latencies

LA Probe Tip to External System Trigger Out

LA Probe Tip to External Signal Out via Signal 3, 4

3,4

4

5,6

7

8

8,9

7

6

9

9

OR function 371 ns + Smpl

All measurements typical.

1 LA Sample – 0.5 ns

1 LA sample + 1 ns

3 ns

3 ns

All measurements typical.

–271 ns

–212 ns + Clk

–208 ns + Clk

–27 ns

All measurements typical.

380 ns + Smpl

AND function 383 ns + Smpl

LA Probe Tip to External Signal Out via Signal 1, 2

6,9

normal function 381 ns + Smpl

inverted logic on backplane 384 ns + Smpl

DSO Probe Tip to External System Trigger Out 70 ns

DSO Probe Tip to External Signal Out via Signal 3, 4

OR function 68 ns

AND function 78 ns

DSO Probe Tip to External Signal Out via Signal 1, 2

9

normal function 71 ns

inverted logic on backplane 71 ns

1–4

TLA 704 Color Portable Mainframe Service Manual

Page 26

Specifications

T able 1–3: Backplane interface (Cont.)

Characteristic Description

Inter-Module Latencies

LA to DSO Inter-Module System Trigger

LA to LA Inter-Module System Trigger

LA to DSO Inter-Module ARM

LA to LA Inter-Module ARM

LA to LA Inter-Module via Signal 1, 2

LA to LA Inter-Module via Signal 3, 4

DSO to DSO Inter-Module System Trigger

DSO to LA Inter-Module System Trigger

DSO to LA Inter-Module ARM

DSO to DSO Inter-Module ARM 59 ns

DSO to LA Inter-Module via Signal 1, 2

DSO to LA Inter-Module via Signal 3, 4

1

Includes typical jitter, slot-to-slot skew, and probe-to-probe variations to provide a “typical” number for the measurement.

Assumes standard accessory probes are utilized.

2

For time intervals longer than 1 ms between modules, add 0.01% of the difference between the absolute time measurements to the relative time correlation error to account for the inaccuracy of the CLK10 source.

3

“Smpl” represents the time from the event at the probe tip inputs to the next valid data sample of the logic analyzer. In

the normal internal clock mode, this represents the delta time to the next sample clock. In MagniVu internal clock mode,

this represents 500 ps or less. In external clock mode, this represents the time to the next master clock generated by the

setup of the clocking state machine and the supplied SUT clocks and qualification data.

4

DSO modules time correlation measured at maximum sample rate on channel one only.

5

All system trigger and external signal input latencies were measured from a falling-edge transition (active/true low) with

signals measured in the “wired-or” configuration.

6

Latencies are based on typical portable mainframe configurations consisting of two LA modules or an LA module plus a

DSO module. Latencies are system-configuration-dependent and may vary slightly with module loading.

7

In the Waveform window , triggers are always marked immediately except when delayed to the first sample. In the Listing

window, triggers are always marked on the next sample period following their occurrence.

8

“+Clk” represents the time to the next “master” clock at the destination logic analyzer. In the “asynchronous” or

“internal” clock mode, this represents the delta time to the next sample clock beyond the minimum async rate of 4 ns. In

the “synchronous” or “external” clock mode, this represents the time to the next master clock generated by the setup of

the clocking state machine and the supplied SUT clocks and qualification data.

9

Signals 1 and 2 (ECLTRG0, 1) are limited to a “broadcast” mode of operation, where only one source is allowed to drive

the signal node at any one time. That single source may be utilized to drive any combination of destinations.

6

3,7

3,7

3

3,8

3,8,9

3,8

7

7

8

8, 9

8

All measurements typical.

358 ns + Smpl

68 ns + Smpl

360 ns + Smpl

108 ns + Smpl + Clk

120 ns + Smpl + Clk

116 ns + Smpl + Clk

50 ns

–236 ns

–192 ns + Clk

–179 ns + Clk

–184 ns + Clk

TLA 704 Color Portable Mainframe Service Manual

1–5

Page 27

Specifications

T able 1–4: Front panel interface

Characteristic Description

QWERTY Keypad 31-key ASCII keypad to support naming of files, traces, and keyboard

equivalents of pointing device inputs for menus

HEX Keypad 25-key HEX keypad supporting standard DSO and LA entry functions

Special Function Knobs

Multi-Function Knob Various increment/decrement functions

Vertical Position Scrolling and positioning dependent on display type

Vertical Scale Scales waveform displays only

Horizontal Position Scrolling and positioning dependent on display type

Horizontal Scale Scales waveform displays only

Integrated Pointing Device Vertically mounted glidepoint touchpad with three keypad control buttons

(DRAG, SELECT, and MENU)

Mouse Port PS/2 compatible mouse port utilizing a mini-DIN connector

Keyboard Port PS/2 compatible keyboard port utilizing a mini-DIN connector

1–6

TLA 704 Color Portable Mainframe Service Manual

Page 28

Specifications

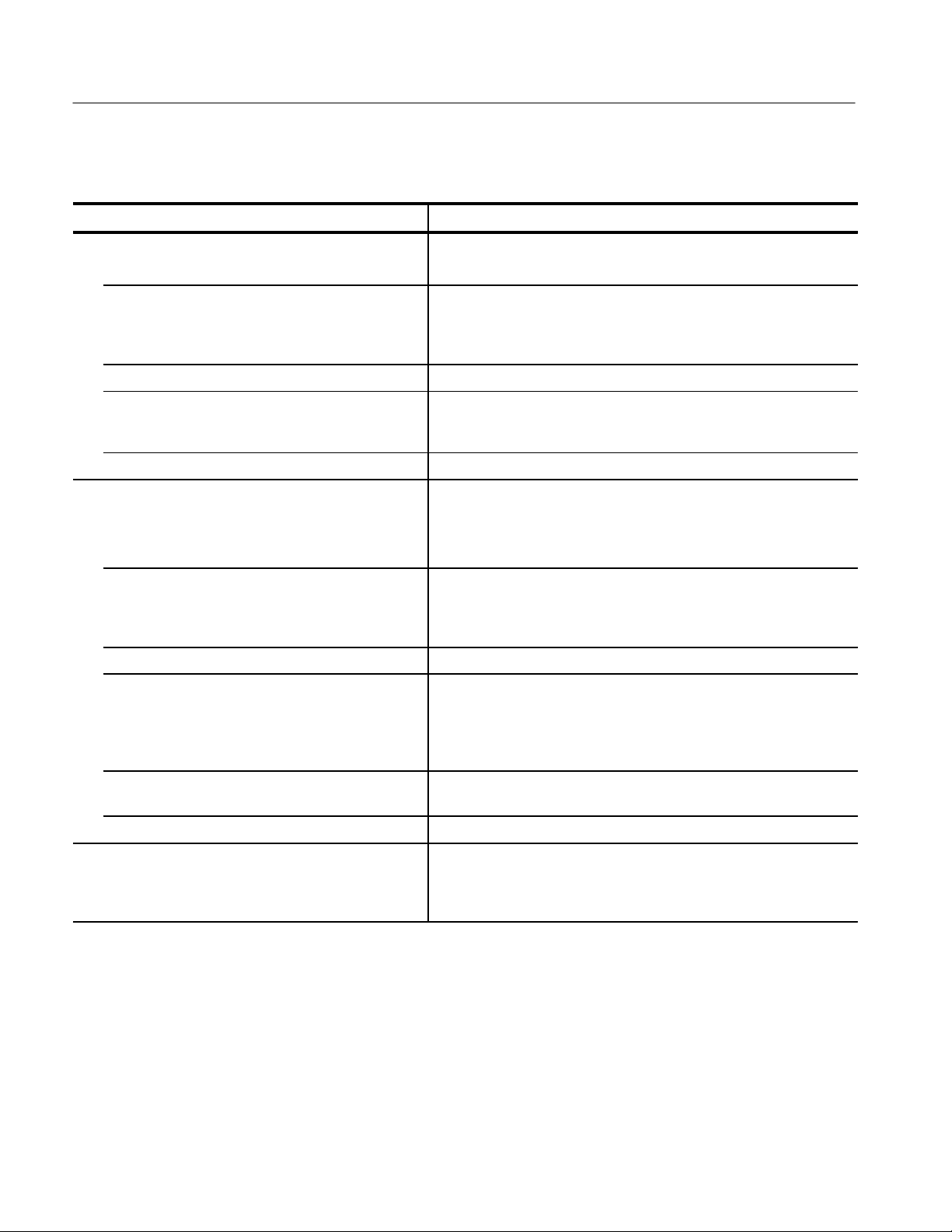

T able 1–5: Rear panel interface

Characteristic Description

LPT (Parallel Interface) Port 36-pin high-density connector supports standard Centronics mode,

Enhanced Parallel Port (EPP), or Microsoft high-speed mode (ECP)

Complies with IEEE P1284-C/D2 for bi-directional Parallel Peripheral

Interface for Personal Computers (draft) style 1284-C

COM (Serial Interface) Port 9-pin male sub-D connector to support RS-232 serial port.

SVGA Output Port 15-pin sub-D SVGA connector.

Type I and II PC Card Port Standard Type I and II PC-compatible PC card slot. Complies with

PCMCIA 2.1 and JEIDA 4.1

Type I, II, and III PC Card Port Standard Type I, II, and III PC-compatible PC card slot

System Trigger Input TTL-compatible inputs via rear-panel BNC connectors

Input Destination System trigger (TTLTRG7)

Input Levels VIH ≥2.0V; VIL ≤ 0.8V (TTL-compatible input)

Input Mode Falling edge sensitive, latched (active low)

Minimum Pulse Width 12 ns

Active Period Accepts system triggers during valid acquisition periods via real-time

gating; resets system trigger input latch between valid acquisition

periods.

Maximum Input Voltage 0 to +5V peak

External Signal Input TTL-compatible inputs via rear-panel BNC connectors

Input Destinations Signal 1, 2 (ECLTRG0, 1)

Signal 3, 4 (TTLTRG0, 1)

Input Levels VIH ≥2.0V; VIL ≤ 0.8V (TTL-compatible input)

Maximum Input Voltage 0 to +5V peak

Input Mode Active (true) low, level sensitive

Input Bandwidth Signal 1, 2: 50 MHz square wave minimum;

Signal 3, 4: 10 MHz square wave minimum.

Input bandwidth only applies to signals to the modules, not round-trip

signals into the external signal input and back out the external signal

output.

Active Period Accepts signals during valid acquisition periods via real-time gating

TLA 704 Color Portable Mainframe Service Manual

1–7

Page 29

Specifications

T able 1–5: Rear panel interface (Cont.)

Characteristic Description

System Trigger Output TTL-compatible outputs via rear-panel BNC connectors

Source Selection System trigger (TTLTRG7)

Output Levels 50-W back-terminated TTL output

VOH ≥ 4 V into open circuit

VOH ≥ 2 V into 50 W to ground

VOL ≤ 0.7 V sinking 10 mA

Source Mode Falling edge sensitive

Active Period Outputs system trigger state during valid acquisition period; resets

system trigger output to false state and resets output latch between valid

acquisitions via software

Output Protection Short-circuit protected (to ground)

External Signal Output TTL-compatible outputs via rear-panel BNC connectors

Source Selection Signal 1, 2 (ECL TRG0, 1)

Signal 3, 4 (TTLTRG0, 1)

10 MHz clock (CLK10)

Output Levels 50-W back-terminated TTL output

VOH ≥ 4 V into open circuit

VOH ≥ 2 V into 50 W to ground

VOL ≤ 0.7 V sinking 10 mA

Output Modes User-definable: active (true) low or active (true) high

Output Bandwidth Signal 1, 2: 50 MHz square wave minimum

Signal 3, 4: 10 MHz square wave minimum.

The output bandwidth only applies to signals from the modules, not

round-trip signals into the External Signal Input and back out the

External Signal Output.

Active Period Outputs signals during valid acquisition periods; resets signals to false

state between valid acquisitions via software

Output Protection Short-circuit protected (to ground)

Intermodule Signal Line Bandwidth Minimum bandwidth over which the intermodule signals are specified to

operate correctly:

Signal 1,2 (ECLTRG0,1): 50 MHz square wave minimum

Signals 3,4 (TTLTRG0,1): 10 MHz square wave minimum

;

1–8

TLA 704 Color Portable Mainframe Service Manual

Page 30

T able 1–6: AC power source

Characteristic Description

Source Voltage and Frequency 90 V

100 V

Fuse Rating

RMS

RMS

to 250 V

to 132 V

, 45 Hz to 66 Hz, continuous range CAT II;

RMS

, 360 Hz to 440 Hz, continuous range CAT II

RMS

Specifications

90 V - 250 V Operation

(159–0046–00)

90 V - 250 V Operation

(159–0381–00)

UL198/CSA C22.2

0.25 in × 1.25 in, Fast Blow, 8 A, 250 V

IEC 127/Sheet 1

5 mm × 20 mm, Fast Blow, 6.3 A, 250 V

Maximum Power Consumption 600 W line power maximum

Steady-State Input Current 6 A

maximum

RMS

Inrush Surge Current 70 A maximum

Power Factor Correction Yes

On/Standby Switch and Indicator Front Panel On/Standby switch, with LED indicator located next to

switch.

The power cord provides main power disconnect.

T able 1–7: Secondary power

Characteristic Description

DC Voltage Regulation Voltage Vmin Vnom Vmax

+24 V 23.28 V 24.24 V 25.20 V

+12 V 11.64 V 12.12 V 12.60 V

TLA 704 Color Portable Mainframe Service Manual

+5 V 4.875 V 5.063 V 5.250 V

–2 V –2.10 V –2.00 V –1.90 V

–5.2 V –5.460 V –5.252 V –5.044 V

–12 V –12.60 V –12.12 V –11.64 V

–24 V –25.20 V –24.24 V –23.28 V

1–9

Page 31

Specifications

T able 1–8: Certifications and compliances: TLA 704 Color Portable Mainframe

EC Declaration of Conformity –

EMC

EC Declaration of Conformity –

Low Voltage

Approvals UL31 11-1 – Standard for electrical measuring and test equipment

Installation Category Descriptions Terminals on this product may have different installation category designations. The installation

Conditions of Approval Safety Certifications/Compliances are made for the following conditions:

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility. Compliance was

demonstrated to the following specifications as listed in the Official Journal of the European

Communities:

EN 55011 Class A Radiated and Conducted Emissions

EN 50081-1 Emissions:

EN 60555-2 AC Power Line Harmonic Emissions

EN 50082-1 Immunity:

IEC 801-2 Electrostatic Discharge Immunity

IEC 801-3 RF Electromagnetic Field Immunity

IEC 801-4 Electrical Fast Transient/Burst Immunity

IEC 801-5 Power Line Surge Immunity

Tektronix, Inc. claims compliance to EMC Directive 89/336/EEC for the following products when

used with the above named mainframes:

TLA 700 Series Logic Analyzer Modules (TLA 7L1, TLA 7L2, TLA 7L3, TLA 7L4, TLA 7M1,

TLA 7M2, TLA 7M3, TLA 7M4)

TLA 700 Series Digitizing Oscilloscope Modules (TLA 7D1, TLA 7D2, TLA 7E1, TLA 7E2)

Compliance was demonstrated to the following specification as listed in the Official Journal of the

European Communities:

Low Voltage Directive 73/23/EEC

EN 61010-1:/A2 1995 Safety requirements for electrical equipment for measurement,

control, and laboratory use

CAN/CSA C22.2 No. 1010.1 – Safety requirements for electrical equipment for measurement,

control and laboratory use

categories are:

CA T III Distribution-level mains (usually permanently connected). Equipment at this level is

typically in a fixed industrial location

CA T II Local-level mains (wall sockets). Equipment at this level includes appliances, portable

tools, and similar products. Equipment is usually cord-connected

CA T I Secondary (signal level) or battery operated circuits of electronic equipment

Temperature (operation): +5_C to +40_C

Altitude (maximum operation): 2000 meters

IEC Characteristics Equipment type:

Test and Measuring

Installation Category II

Pollution Degree 2

Safety Class I

1–10

TLA 704 Color Portable Mainframe Service Manual

Page 32

Specifications

T able 1–9: Cooling

Characteristic Description

Cooling System Forced air circulation (negative pressurization) utilizing six fans operating

in parallel

Cooling Clearance 2 inches (51 mm), sides and rear; unit should be operated on a flat,

unobstructed surface

T able 1–10: Environmental

Characteristic Description

Atmospherics

Temperature (no media in floppy drive)

Operating +5° C to +50° C, 15° C/hr maximum gradient, non-condensing. Derated

1° C per 1000 feet (305 m) above 5000 feet (1524 m) altitude.

Nonoperating –20° C to +60° C, 15° C/hr maximum gradient, non-condensing

Relative Humidity (no media in floppy drive)

Operating 20% to 80% relative humidity, non-condensing. Maximum wet bulb

temperature: +29° C (derates relative humidity to ~22% at +50° C)

Nonoperating 8% to 80% relative humidity, non-condensing. Maximum wet bulb

temperature: 29° C (derates relative humidity to ~22% at +50° C)

Altitude

Operating To 10,000 ft. (3040 m). Derated 1° C/1000 ft. (305 m) above 5000 ft.

(1524 m) altitude

Nonoperating To 40,000 ft. (12,190 m)

Dynamics

Random Vibration Three axis, 30 minutes total, 10 minutes per axis; without VXI instrument

modules installed, or with instrument modules installed but not

exceeding 5 lbs/slot

Operating 0.27 g

Nonoperating 2.28 g

Mechanical Shock

Operating

Half sine, 30 g, 11 ms duration, three drops each side, 18 shocks total,

no media in floppy drive, without instrument modules installed or with

total from 5 Hz to 500 Hz

RMS

total from 5 Hz to 500 Hz

RMS

instrument modules installed but not exceeding 5 lbs/slot. Meets

functional shock requirements of MIL-T-28800E, Type-III, Class 5

TLA 704 Color Portable Mainframe Service Manual

1–11

Page 33

Specifications

T able 1–11: Mechanical

Characteristic Description

Overall Dimensions (See Figure 1–1 for overall chassis dimensions)

Height (with feet) 9.25 in (23.5 cm)

Width 17 in (43.18 cm)

Depth 17.5 in (44.45 cm)

Weight 30 lbs 12 oz (13.9 kg) with no modules installed, two dual-wide slot

covers, and empty pouch

Shipping Configuration 60 lbs 13 oz (27.58 kg) minimum configuration (no modules), with all

standard accessories

86 lbs 9 oz (39.26 kg) full configuration, with two TLA 7M4 modules and

standard accessories (including probes)

17 in

(43.18 cm)

9.25 in

(23.5 cm)

Figure 1–1: Front and side views of TLA 704 Color Portable Mainframe

17.5 in

(44.45 cm)

1–12

TLA 704 Color Portable Mainframe Service Manual

Page 34

Page 35

Operating Information

This chapter contains information about operating the TLA 704 Color Portable

Mainframe.

Installation

Refer to the TLA 700 Series Logic Analyzer Installation Manual for complete

information on how to install and configure the portable mainframe.

I/O and Memory Hardware

This section describes the I/O and memory hardware on the portable mainframe,

including:

H Color LCD display

H Front-panel keypad and knobs

H Glidepoint point device

H Mouse and keyboard connectors

H External I/O BNCs

H PCMCIA PC card ports

H Rear-panel I/O ports

H Floppy disk drive

H Hard disk drive

H Memory SIMMs

Figure 2–1 on page 2–2 shows the front panel of the portable mainframe and

indicates the location of the external I/O hardware. Figure 2–2 on page 2–3

shows the rear panel of the portable mainframe.

TLA 704 Color Portable Mainframe Service Manual

2–1

Page 36

Operating Information

Knobs

Glidepoint

Floppy drive

Color LCD Display

Front Panel Keypad,

Knobs

Keyboard

Mouse

Color flat panel

display

Figure 2–1: TLA 704 Color Portable Mainframe front panel

The portable mainframe features a 10.4-inch diagonal, flat-panel LCD active-matrix Thin-Film-Transistor (TFT) color display.

The front panel of the portable mainframe includes a QWERTY keyboard, a

hexadecimal numeric keypad, and five front panel knobs. The keypads are active

simultaneously with the standard external keyboard.

QWERTY Keypad. The QWERTY keypad is useful for file naming and other

operations where a complete alphabetic character set is needed.

Front panel

keyboard

Glidepoint Point Device

2–2

Hexadecimal Numeric Keypad. The hexadecimal numeric keypad is useful for

numeric entry of data.

Front Panel Knobs. The front panel knobs include a large multi-function knob and

four smaller positioning/scale knobs. The multi-function knob is used primarily

for incrementing and decrementing values in selected menu boxes. The positioning and scale knobs (Vertical Position, Horizontal Position, Vertical Scale, and

Horizontal Scale) provide necessary control of DSO applications, as well as the

scrolling of logic analyzer displays.

The glidepoint device, vertically mounted on the front panel, can be used instead

of the external mouse when limited bench space is available. The glidepoint

device and the standard external mouse are active simultaneously.

TLA 704 Color Portable Mainframe Service Manual

Page 37

Operating Information

Mouse and Keyboard

Connectors

External I/O BNCs

The portable mainframe has two six-pin PS/2 compliant DIN connectors. One

connector supports an external mouse; the other connector supports an external

keyboard. Descriptions of the two ports follow.

MOUSE Connector. The mouse connector is a standard six-pin, PS/2-compliant

DIN connector. The mouse port can be connected to an external, standard

PS/2-compliant three-button mouse.

KEYBOARD Connector. The keyboard connector is a standard six-pin PS/2-compliant DIN connector. The keyboard port can be connected to an external,

standard PS/2-compliant keyboard.

The portable mainframe has four test I/O BNC connectors on the rear panel (see

Figure 2–2): SYSTEM TRIG IN, SYSTEM TRIG OUT, EXTERNAL SIGNAL

IN, and EXTERNAL SIGNAL OUT.

PCMCIA

PC cards (2)

SYSTEM TRIG IN

SYSTEM TRIG OUT

EXTERNAL SIGNAL IN

EXTERNAL SIGNAL OUT

SVGA OUT port

COM port

LPT port

Figure 2–2: TLA 704 Color Portable Mainframe rear panel

SYSTEM TRIG IN Connector. The System Trigger Input is a TTL-compatible

signal input that is user definable in software. The System Trigger Input utilizes a

BNC connector. Refer to the

TLA 700 Series Logic Analyzer User Manual for

additional information.

SYSTEM TRIG OUT Connector. The System Trigger Output is a TTL-compatible

output signal that is user definable in software. The System Trigger Output

utilizes a BNC connector. Refer to the

TLA 700 Series Logic Analyzer User Manual

for additional information.

TLA 704 Color Portable Mainframe Service Manual

2–3

Page 38

Operating Information

EXTERNAL SIGNAL IN Connector. The External Signal Input is a TTL-compatible

input signal that is user definable in software. The External Signal Input utilizes a

BNC connector. Refer to the

TLA 700 Series Logic Analyzer User Manual for

additional information.

EXTERNAL SIGNAL OUT Connector. The External Signal Output is a TTL-compatible output signal that is user definable in software. The System Trigger

Output utilizes a BNC connector. Refer to the

Manual for additional information.

TLA 700 Series Logic Analyzer User

PCMCIA PC Card Port

I/O Ports

The portable mainframe includes one slot that supports an industry standard

Type I or Type II PC card, and another that supports a Type I, II, or III PC card.

The portable mainframe has three (3) I/O Ports: an SVGA OUT port, a COM

port, and an LPT port. Descriptions of the three ports follow.

SVGA OUT Port. The SVGA OUT port supports an industry standard SVGA color

monitor. The connector is a 15-pin, sub-D SVGA-compliant connector. See

Table 2–1 for pin assignments.

T able 2–1: SVGA OUT pin assignments

Pin number Pin function Pin number Pin function

1 RED 2 GRN

3 BLU 4 DDC DB2

5 GND 6 GND

7 GND 8 GND

9 (KEY) 10 GND

11 DDC DB0 12 DDC DB1

2–4

13 HSYNC 14 VSYNC

15 DDC DB3

COM Port. The COM port is an RS232 serial port. The connector is a 9-pin male,

sub-D plug. See Table 2–2 for pin assignments.

TLA 704 Color Portable Mainframe Service Manual

Page 39

Operating Information

T able 2–2: COM (serial interface) pin assignments

Pin number Pin function Pin number Pin function

1 DCD 2 RXD

3 TXD 4 DTR

5 GND 6 DSR

7 RTS 8 CTS

9 Ring Indicator

LPT Port. The LPT port is a parallel printer port. This parallel printer port

supports standard Centronics mode, Enhanced Parallel Port (EPP), or Microsoft

high-speed mode (ECP) and utilizes a 36-pin high density Centronics-compliant

connector. See Table 2–3 for pin assignments.

T able 2–3: LPT (parallel interface) pin assignments

Pin number Pin function Pin number Pin function

1 BUSY 19 GND

2 SLCT 20 GND

3 ACK* 21 GND

4 ERR* 22 GND

5 PE 23 GND

6 D0 24 GND

7 D1 25 GND

8 D2 26 GND

9 D3 27 GND

10 D4 28 GND

11 D5 29 GND

12 D6 30 GND

13 D7 31 GND

14 INIT* 32 GND

15 STB* 33 GND

16 SLIN* 34 GND

17 AFD* 35 GND

18 HI? 36 GND

See IEEE specification P1284-C for pin connection definitions for other modes

TLA 704 Color Portable Mainframe Service Manual

2–5

Page 40

Operating Information

Floppy Disk Drive (FDD)

Hard Disk Drive (HDD)

Memory SIMMs

The TLA 704 Color Portable Mainframe has one standard 1/2 inch drive that

supports 3.5 inch, 1.44 MByte, high-density/double-sided floppy disk media.

The TLA 704 Color Portable Mainframe has one standard 2.5 inch IDE drive that

interfaces directly to the controller via an Enhanced Integrated Device Electronics (IDE) interface. The Hard Disk Drive (HDD) is available in two configurations: the 840 MByte (minimum) configuration and the 2.16 GByte

configuration. Configurations offered are subject to change; this manual lists

configurations available at the time the product was introduced.

The TLA 704 Color Portable Mainframe utilizes two (2) 72-pin EDO DRAM

memory SIMMs (Single Inline Memory Module). The SIMMs must have gold

pins and must be loaded symmetrically (in pairs). The SIMM speed requirement

is 60 ns minimum.

Memory requirements are the 16 MByte minimum configuration or the

32 MByte maximum configuration.

Operating System and Application Interface

The portable mainframe comes with the Windows 95 operating system factoryinstalled. Operations and capabilities when running on the portable mainframe

are the same as with Windows 95 running on a high-performance personal

computer. Windows Help is available from the Start menu of the Windows 95

Task Bar. The Windows 95 software is included with the product. See the

software and the

Windows 95 application.

TLA 700 Series Installation Manual if you need to reinstall the

2–6

The portable mainframe also comes with the TLA 700 application software

configured at the factory to launch after the logic analyzer boots up and

Windows 95 is running. The TLA 700 application software controls data

acquisition and processing by the logic analyzer. The TLA 700 application

software is included with the product. Refer to the

Manual

if you need to reinstall the TLA 700 application software.

TLA 704 Color Portable Mainframe Service Manual

TLA 700 Series Installation

Page 41

Operating Information

The topics that follow provide a brief overview of the TLA 700 application

software.

System Window

This window provides an overview of the entire logic analyzer. Use this window

to navigate through the logic analyzer. Figure 2–3 shows an example of the

System window.

Figure 2–3: Typical System window

The center of the System window displays icons that represent hardware modules

installed in the portable mainframe. The icons are links to the other windows in

the instrument.

Trigger Window

Listing Window

Waveform Window

TLA 704 Color Portable Mainframe Service Manual

The Trigger window provides access to the logic-analyzer trigger hardware. You

can specify the data patterns you want to acquire and how much data to acquire

by defining the trigger setups in menus and dialogs.

The Listing window displays acquired data as tabular text. Each column of data

represents one group of data or other logical data information, such as timestamps. Each row of data represents a different time that the data was acquired;

newer samples of data display below older samples.

The Waveform window displays acquired data as graphical waveforms. All

defined channel groups display as busforms for the logic analyzer and as

individual channels for the digitizing oscilloscope.

2–7

Page 42

Operating Information

Setup Window

Diagnostics

Online Help

A setup window exists for each module in the instrument. It contains the setup

information for each installed module, such as clocking, memory depth,

threshold information, and channel information. Menus and dialogs contain

information to set up the window as needed. Most of the changes that you make

in menus or dialogs take effect at the end of the acquisition; however, probe

threshold changes take effect immediately.

Most of the user information for operating the portable mainframe is available

through online help.

Refer to the TLA 700 online help for more information on the individual menus,

icons, and fields within each window. You may also want to refer to the TLA 700

Series Logic Analyzer User Manual for additional information.

Refer to your Microsoft Windows documentation for additional information on

using Windows help.

The TLA 704 Portable Mainframe contains the following diagnostics:

H BIOS diagnostic tests (automatic)

H TLA 700 Series application software (automatic and manual)

H TLA 700 Series mainframe diagnostics (manual)

H QAPlus/Win (manual)

All diagnostics (both automatic and manually executed tests) are useful for

troubleshooting purposes.

The portable mainframe performs BIOS and TLA 700 Series application

diagnostics for the mainframe and all installed modules every time you power on.

The diagnostics window displays when any of the diagnostic tests fail. To access

the diagnostics tests in the TLA 700 Series application software, use the System

pull-down menu.

In addition to Power-on Diagnostics, the TLA 704 Portable Mainframe also

contains mainframe diagnostics and QAPlus/Win diagnostics for the PC

hardware.

For more information about diagnostics, refer to the Maintenance chapter.

2–8

TLA 704 Color Portable Mainframe Service Manual

Page 43

Page 44

Theory of Operation

This section provides a brief overview of the theory of operation for the portable

mainframe. Figure 3–1 shows a functional block diagram of the major components.

Controller Board

PCI to backplane

bridge ASIC

Backplane

PC Cards, SVGA, COM, LPT

& trigger/signal ports

VTC Trig

ASIC

Fans

TLA 700 Series Module # 1

TLA 700 Series Module # 2

PC Controller

display and I/O

Hard disk

drive

Power supply

Color flat

panel display

Front panel

keypads & knobs

Front panel interface

Floppy disk

Figure 3–1: TLA 704 Color Portable Mainframe major components block diagram

drive

Glide point

pointing device

External mouse

& keyboard

Portable Mainframe

The portable mainframe contains the following major components:

H Power supply

H Backplane

H Controller Board

H Front Panel Interface Board

H Front Panel Controls Board

H Color Flat Panel Display

TLA 704 Color Portable Mainframe Service Manual

3–1

Page 45

Theory of Operation

H Front Panel Keypads and Knobs

H Glidepoint Pointing Device

H Hard Disk Drive

H Floppy Disk Drive

H Mechanical Chassis

Power Supply

Backplane

Controller Board

The power supply provides all voltages and currents to the portable mainframe.

The power supply connects to the backplane at P400 and P401.

The backplane supports up to four “C” sized TLA 700 slots for support of

instrument modules. The backplane also connects the power supply secondary to

the remainder of the system, including the fans, distributes the precision 10-MHz

(CLK10) system clock, and supports all communication to, from, and between

the instrument modules.

The Controller Board provides the portable mainframe with a high-performance

PC-based controller architecture, including graphics and I/O, and interfaces to

the backplane bus and front panel. The Controller Board mounts vertically on the

left side of the instrument and connects to the back of the backplane via a P1/P2

interconnect. The Controller Board also provides I/O to the rear panel and is the

source of the 10-MHz (CLK10) system clock.

The PC controller features a Pentium 133-MHz processor with either 16 or

32 MBytes of EDO DRAM, 256 KBytes of L2 cache, and 512 KBytes of

flash-based BIOS.

A Cirrus Logic PCI-to-PCMCIA/PC CARD Host Adapter ASIC controls the two

PC card slots.

3–2

A Cirrus Logic Viking display controller with 1 MByte of DRAM supports the

flat-panel display and an external SVGA port.

One ECP/EPP Centronics-compatible parallel port and two 16550-based serial

RS-232 COM ports (one external) support standard PC-based I/O peripherals.

A Tektronix-designed ADG343 CMOS ASIC manages the PCI-to-backplane

interface, supporting DMA transfers with FIFO, IRQ management, programmable byte swapping, address space management/windowing, bus arbitration,

and MODID control lines.

A Tektronix-designed ASIC manages the trigger lines, cross-connecting any of

the 10 backplane trigger lines (ECL and TTL) to any of the four BNC ports on

the rear I/O panel of the mainframe. The VTC ASIC supports several standard

TLA 704 Color Portable Mainframe Service Manual

Page 46

Theory of Operation

trigger protocols and several custom features, including time interpolation to

support individual module applications.

Front Panel

Interface Board

Front Panel Controls

Board

Mechanical Chassis

The Interface Board interconnects the Controller Board, the flat-panel display,

the floppy disk drive, the front-panel keypad and glidepoint, and the external

mouse and keyboard ports. Dual 50-pin cables connect the Front Panel Interface

Board to the Controller Board. The Interface Board also supplies the PC speaker.

The Front Panel Controls Board combines signals from the front-panel hex

keypad, the front-panel QWERTY keypad, and an external keyboard to generate

or receive standard keyboard scan-codes from the Controller Board. Keys are

controlled via a 6805C processor. A second 6805C processor controls the five

front-panel knobs and the glidepoint.

The Mechanical Chassis provides the mechanical support structure for the

instrument, and includes the cooling system, the modular-card cage, the EMI

shielding system, and all the subsystems previously listed.

TLA 704 Color Portable Mainframe Service Manual

3–3

Page 47

Theory of Operation

3–4

TLA 704 Color Portable Mainframe Service Manual

Page 48

Page 49

Performance Verification

Refer to the TLA 700 Series Performance Verification and Adjustment Technical

Reference Manual for complete performance verification and calibration

(certification) procedures for the TLA 704 Color Portable Mainframe.

TLA 704 Color Portable Mainframe Service Manual

4–1

Page 50

Performance Verification

4–2

TLA 704 Color Portable Mainframe Service Manual

Page 51

Page 52

Adjustment Procedures

There are no adjustment procedures specific to the TLA 704 Color Portable

Mainframe.

TLA 704 Color Portable Mainframe Service Manual

5–1

Page 53

Adjustment Procedures

5–2

TLA 704 Color Portable Mainframe Service Manual

Page 54

Page 55

Maintenance

Preparation

Preventing ESD

This chapter provides procedures for inspecting and cleaning the portable

mainframe, removing and replacing internal chassis components, and isolating

problems to the board or replacement part level.

To repair, you must exchange or replace the failed part; this manual does not

provide component-level procedures for isolating components on the failed part.

The information in this chapter is designed for use by qualified service personnel. Read the Safety Summary at the front of this manual before attempting any