Page 1

TIVM Series

xx

ZZZ

IsoVu™ Measurement System

User Manual

*P071349501*

071-3495-01

Page 2

Page 3

xx

TIVM Series

ZZZ

IsoVu™ Measurement System

User Manual

Register now!

Click the following link to protect your product.

► www.tek.com/register

www.tek.com

071-3495-01

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

ISOVU is a trademark of Tektronix Inc.

TEKVPI is a registered trademark of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. B o x 5 0 0

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tek.com to find contacts in your area.

Page 5

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty

work may be n

the property of Tektronix.

ew or reconditioned to like new performance. All replaced parts, modules and products become

In order to o

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, with shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

result

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has b een modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF A NY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

TEK

AND EXCLUSIVE REMEDY PR OVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ing from attempts by personnel other than Tektronix representatives to install, repair or service the product;

Page 6

Page 7

Table of Contents

Important safety information ........... ................................ ................................ ........... v

General safety summary ...................................................................................... v

Service safety summary ............................ ................................ ......................... vii

Terms in this manual ..................... ................................ ................................ ... viii

Symbols and terms on the product......................................................................... viii

Preface .............................................................................................................. ix

Key features ........................... .................................. ................................ ...... ix

Laser certification................. ................................ .................................. .......... ix

Product description ..... ................................ .................................. ..................... x

Models ......................................................................................................... xi

Supported oscilloscopes...................................................................................... xi

Operating information... .................................. ................................ ......................... 1

Accessories..................................................................................................... 1

Operating considerations...................................................................................... 2

Controls and indicators............................... ................................ ......................... 7

Connecting to a circuit ....... ................................ ................................ ................ 10

Self calibration ................................................................................................ 12

AutoZero....................................................................................................... 14

Menu button ............................. ................................ ................................ ...... 14

Offset correction .............................................................................................. 15

1X/2X Range.................... ................................ ................................ .............. 17

Auto Range.................................................................................................... 18

Selecting a sensor tip cable .................................................................................. 19

Output clamping .......... ................................ .................................. .................. 20

Sensor tip loading............................................................................................. 20

Probe compensation .......................................................................................... 21

Deskew......................................................................................................... 21

Input offset ...... .................................. ................................ ............................ 21

Application examples ............... ................................ ................................ .............. 23

Example 1: High-side V

Example 2: High-side drain current measurement ............................ ............................ 25

Example 3: ESD troubleshooting ............................... .................................. .......... 26

Reference information ............................................................................................ 29

Specifications...................................... ................................ ............................ 29

Dimensional drawings........................................................................................ 33

IsoVu measurement system block diagram ................ .................................. .............. 36

Tripods........... ................................ ................................ .............................. 37

Installing the probe tip adapters . .... . ..... . ..... . ..... . ..... . ... . . ..... . ..... . ..... . ..... . ... . . . .... . ..... . . 39

Installing the square pins on the circuit board . ..... . .... . . .... . ..... . ..... . ..... . .... . ..... . ..... . ..... . .. 42

measurement................................................................... 23

GS

TIVM Series Measurement System User Manual i

Page 8

Table of Contents

User service .......... ................................ .................................. ............................ 45

Service offerings ................ .................................. ................................ ............ 45

Preventive maintenance.................. ................................ .................................. .. 45

Performance verification procedures ....................................................................... 46

Propagation delay............................................................................................. 47

Troubleshooting and error conditions .................. .................................. .................. 50

Repack the m

Test record ..................................................................................................... 53

Appendix A: Remote programming ............................................................................. 55

CH<n>:PRObe?............................................................................................... 55

CH<n>:PRObe:AUTOZero EXECute ..................................................................... 55

CH<n>:PRObe:COMMAND “CLAMP”, {“ON” | “OFF”}......................... .................... 55

CH<n>:P

CH<n>:PRObe:FORCEDRange <NR3> .................................................................. 56

CH<n>:PRObe:GAIN? .... ................................ ................................ .................. 56

CH<n>:PRObe:ID {:SERnumber | :TYPe}? ........ ................................ ...................... 56

CH<n>:PRObe:PROPDELay?............ ................................ ................................ .. 57

CH<n>:PRObe:RECDESkew?.............................................................................. 57

CH<n

CH<n>:PRObe:UNIts?........................... .................................. .......................... 57

CH<n>:PROBECOntrol {AUTO | MAN}................................................................. 57

CH<n>:PROBEFunc:EXTAtten <NR3>................................................................... 57

CH<n>:PROBEFunc:EXTDBatten? ....................................................................... 57

CH<n>:PROBEFunc:EXTUnits {“UU” | “None”}... .................................. .................. 58

pendix B: Compliance information .......................................................................... 59

Ap

Safety compliance ............................................................................................ 59

Environmental considerations............................................................................... 61

Index

easurement system for shipment ............................................................ 52

RObe:SET {“CLAMP ON” | “CLAMP OFF”}................................................ 55

>:PRObe:RESistance? ................................................................................ 57

ii TIVM Series Measurement System User Manual

Page 9

List of Figures

Figure i: TIVM Series IsoVu Measurement System............................................................ x

Figure 1: Maximum safe handling limits for common mode voltages between the sensor head and earth

ground........................................................................................................... 5

Figure 2: RF burn hazard zone around the sensor head............. ................................ ........... 6

Figure 3: Controller indicators and buttons...................................................................... 7

Figure 4: Labels on the sensor head .............................................................................. 9

Figure 5: Sensor tip cable top and botto

Figure 6: Connect the Comp box to the oscilloscope.. . . ..... . ..... . .... . ..... . ..... . .... . ..... . ... . . . .... . ... 11

Figure 7: Connecting the sensor tip cable to the sensor head................................................. 11

Figure 8: Connect the s ensor head to the flexible tripod ...... .................................. .............. 12

Figure 9: Probe Setup menu...................................................................................... 14

Figure 10: Digital filter aliasing ................................................................................. 15

Figure 11: Digital filter aberrations (about 2.5% of V

Figure 12: Digital filter aberrations after disabling offset correction........................................ 17

Figure 13: Top sensor tip labels.................................. ................................ ................ 17

Figure 14: Bottom sensor tip labels ............................................................................. 20

Figure 15: Half-bridge circuit showing the gate, source, and drain of the high-side FET.. . .... . ..... . ... 23

Figure 16: High-side turn-on characteristics . ................................ ................................ .. 24

Figure 17: High side current shunt .............................................................................. 25

Figure 18: SMT resistor model .................................................................................. 26

Figure 19: ESD discharge test example....................... .................................. ................ 27

Figure 20: Sensor head dimensions with probe tip cover ................... .................................. 33

Figure 21: Sensor head dimensions without probe tip cover ....... ................................ .......... 34

Figure 22: Controller dimensions................................................................................ 34

Figure 23: Comp box dimensions ............................................................................... 35

Figure 24: Probe tip adapter dimensions.................................... .................................. .. 35

Figure 25: Block diagram .................... .................................. ................................ .. 36

Figure 26: Installing the flexible tripod under the DUT. ...................................................... 37

Figure 27: Connecting the sensor head to the top of the DUT with the flexible tripod. ................... 37

Figure 28: Connecting to an adapter on the circuit board with the probe tip tripod ....................... 38

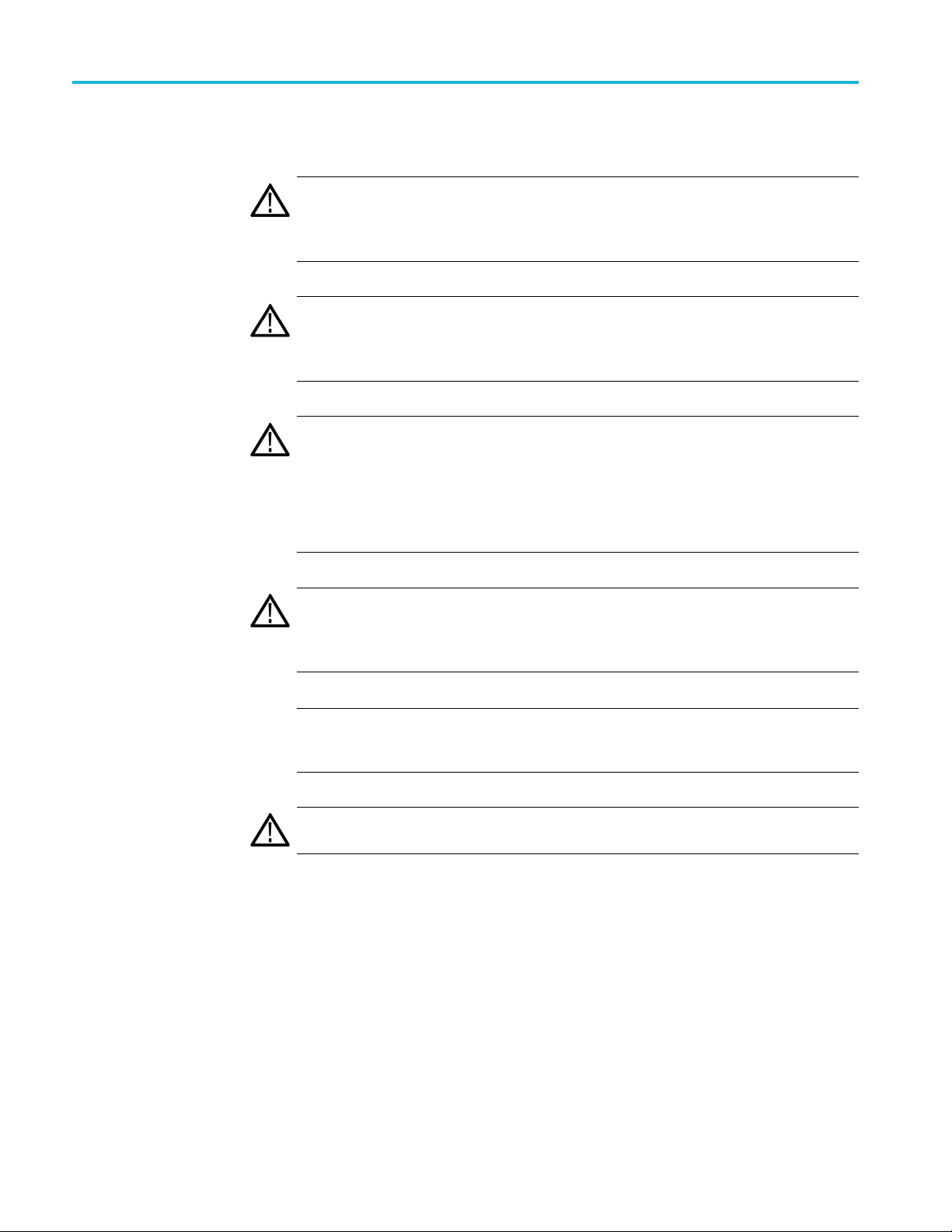

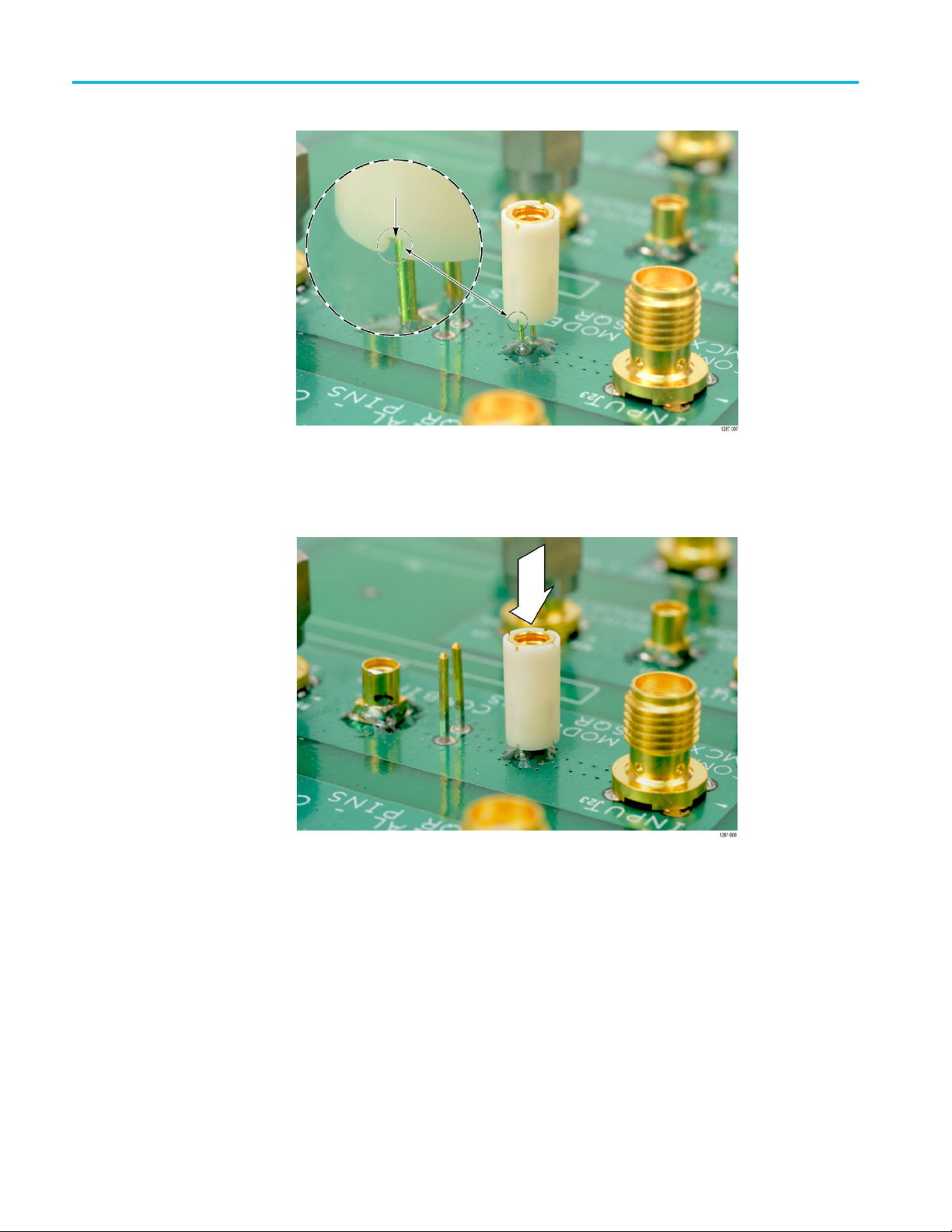

Figure 29: Lining up the MMCX-to-0.1-inch (2.54 mm) adapter on the circuit board.................... 39

Figure 30: Lining up the MMCX-to-0.062-inch (1.57 mm) adapter on the circuit board .... . ..... . .... . . 4 0

Figure 31: Pushing the MMCX-to-0.062-inch (1.57 mm) adapter in place................................. 40

Figure 32: Pushing the MMCX-to-0.1-inch (2.54 mm) adapter in place............................ ........ 41

Figure 33: Adapter clearance requirements ...................... ................................ .............. 42

Figure 34: Removing the header from square pins on the circuit board..................................... 43

Figure 35: Using the soldering aide to install the square pins on the circuit board ........................ 44

Figure 36: Propagation delay measurement .................................................................... 50

m labels ............................................................... 9

) ... ................................ .................. 16

p-p

TIVM Series Measurement System User Manual iii

Page 10

Table of Contents

List of Tables

Table 1: Standard accessories ...... .................................. ................................ ............. 1

Table 2: Opt

Table 3: Input specifications...................... .................................. ............................... 3

Table 4: Environmental considerations .......................................................................... 3

Table 5: Controller indicators and buttons.................. ................................ ..................... 7

Table 6: Sensor tip selection table ............................................................................... 19

Table 7: Input offset............................................................................................... 21

Table 8: W

Table 9: Electrical specifications .............. ................................ .................................. 29

Table 10: Physical specifications ........ .................................. ................................ ...... 33

Table 11: Required equipment for performance verification ................................................. 46

Table 12: Problems and possible solutions ..................................................................... 50

Table 13: Test record........................ .................................. ................................ .... 53

Table

ional accessories ..................................................................................... 2

arranted specifications.................................. ................................ .............. 29

14: Sensor tip cables and dynamic ranges ......................... .................................. .... 56

iv TIVM Series Me asurement System User Manual

Page 11

Important safety information

This manual contains information and warnings that must be followed by the user

for safe operation and to keep the product in a safe condition.

To safely perform service on this product, additional information is provided at

the end of this section. (See page vii, Service safety summary.)

General safety summary

Use the product only as specified. Review the following safety precautions to

avoid injury and prevent damage to this product or any products connected to it.

Carefully read all instructions. Retain these instructions for future reference.

Comply with local and national safety codes.

For correct and safe operation of the product, it is essential that you follow

generally accepted safety procedures in addition to the safety precautions specified

in this manual.

The product is designed to be used by trained personnel only.

To avoid fire or personal

injury

Only qualified perso

the cover for repair, maintenance, or adjustment.

Before use, always check the product with a known source to be sure it is

operating correctly.

This product is not intended for detection of hazardous voltages.

Use personal protective equipment to prevent shock and arc blast injury where

hazardous live conductors are exposed.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions related to operating the system.

When incorporating this equipment into a system, the safety of that system is the

responsibility of the assembler of the system.

Connect and disconnect properly. Do not connect or disconnect sensor tip cables,

test leads, or accessories while they are connected to a voltage source. Use only

test leads and accessorie

to be suitable for the product.

Observe all terminal ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product. Do not exceed the

Measurement Category (CAT) rating and voltage or current rating of the lowest

rated individual component of a product or accessory.

nnel who are aware of the hazards involved should remove

s supplied w ith the product, or indicated by Tektronix

TIVM Series Measurement System User Manual v

Page 12

Important safety information

Do not apply a po

Do not operate without covers. Do not operate this product with covers or panels

removed, or with the case open. Hazardous voltage exposure is possible.

Avoid exposed circuitry. Do not touch exposed connections and components

when power is present.

Do not operate with suspected failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Disable the product if it is damaged. Do not use the product if it is damaged

or operates incorrectly. If in doubt about safety of the product, turn it off and

disconnect it from the instrument. Clearly mark the product to prevent its further

operation.

Before use, inspect accessories for mechanical damage and replace when

damaged. Do not use them if they are damaged, or if there is exposed metal.

Examine the exterior of the product before you use it. Look for cracks or missing

pieces.

Use only specified replacement parts.

Do not operate in wet/damp conditions. Be aware that condensation may occur if

a unit is moved from a cold to a warm environment.

tential that exceeds the m aximum rating.

Sensor tip cables

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry. Remove the input signals before you clean

the product.

Provide a safe working environment. Always place the product in a location

convenient for viewing the display and indicators.

Be sure your work area meets applicable ergonomic standards. Consult with an

ergonomics professional to avoid stress injuries.

Maintain safe clearance from the sensor head and sensor tip cable while connected

to the energized circuit as recommended in this manual.

Remove the sensor tip cable and adapters from the test circuit when not in use.

Leave the sensor tip cable connected to the sensor head when not in use.

Use only correct Measurement Category (CAT), voltage, temperature, altitude,

and amperage rated sensor tip cables and accessories for any measurement.

Beware of high voltages. Understand the voltage ratings for the product you are

using and do not exceed those ratings. It is important to know and understand the

maximum measurement voltage rating of the product. The voltage rating depends

vi TIVM Series Measurement System User Manual

Page 13

Important safety information

on the me asurem

Specifications section of the manual for more information.

WAR NI NG . To prevent electrical shock, do not exceed the maximum measurement

or maximum voltage category.

Connect and disconnect properly.

CAUTION. To avoid damage to the equipment, de-energize the test circuit before

connecting or disconnecting the sensor tip cable.

Servicesafetysummary

The Serv

safely perform service on the p roduct. Only qualified personnel should perform

service procedures. Read this Service safety summary and the General safety

summary before performing any service procedures.

To avoid electric shock. Do not touch exposed connections.

ent category, the instrument, and your application. Refer to the

icesafetysummarysection contains additional information required to

Do not service alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect power. To avoid electric shock, switch off the product power and

connect the power cord from the mains power before removing any covers or

dis

panels, or opening the case for servicing.

Use care when servicing with power on. Dangerous voltages or currents may exist

in this product. Disconnect power, remove battery (if applicable), and disconnect

test leads before removing protective panels, soldering, or replacing components.

Verify safety after repair. Always recheck ground continuity and mains dielectric

strength after performing a repair.

TIVM Series Measurement System User Manual vii

Page 14

Important safety information

Termsinthismanual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Isolated, electrically floating. The terms isolated, electrically floating,and

galvanically isolated are used in this document to indicate a measurement where

there is no direct conduction path to earth ground.

Symbols and terms on the product

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read

the marking.

WARNING indicates an injury hazard not immediately acc essible as you

read the marking.

CAUTION indicates a hazard to property including the product.

this symbol is marked on the product, be sure to consult the manual

When

to find out the nature of the potential hazards and any actions which have to

betakentoavoidthem. (Thissymbolmayalsobeusedtorefertheuserto

ings in the manual.)

rat

The following symbol(s) may appear on the product:

viii TIVM Series Measurement System User Manual

Page 15

Preface

Preface

Key features

Laser certification

This documen

Series IsoVu Mea surement System. The measurement system offers a galvanically

isolated measurement solution for accurately resolving high bandwidth, low

voltage differential signals up to ±50 Vpk in the presence of large common

mode voltages with the best in class common mode rejection p erformance across

its bandwidth.

New IsoVu technology - galvanically isolated, floating, measurement system

Differential voltages up to ±50 Vpk (depending on sensor tip)

Large common mode voltage range up to 60 kV peak

t provides information for installing and using the Tektronix TIVM

Bandwidth from DC to 1 GHz

> 120 dB (1 million to 1 common mode rejection ratio) from DC to

100 MHz and 80 dB (10,000 to 1) at 1 GHz

This product complies with 21 CFR 1040.10 and 1040.11 except for deviations

suant to Laser Notice No. 50, dated June 24, 2007.

pur

CAUTION. Useofcontrolsoradjustmentsforperformanceofproceduresother

than those specified herein may result in hazardous radiation exposure.

TIVM Series Measurement System User Manual ix

Page 16

Preface

Product description

The Tektronix TIVM Series IsoVu Measurement System offers a completely

galvanically isolated (optical isolation) system. The system consists of a sensor

tip cable, a sensor head, a controller, and a TekVPI interface as shown in the

following figure. Hazardous voltages in the sensor head are completely isolated

from the con

troller and oscilloscope by optical fiber cables.

Figure i: TIVM Series IsoVu Measurement System

Comp box

Controller

x TIVM Series Measurement System User Manual

The TekVPI compensation box (Comp box) connects the measurement system

to one of the input channels on the oscilloscope. Power is supplied to the

asurement system through the TekVPI interface of the oscilloscope.

me

The controller connects to the oscilloscope through a coaxial cable and the Comp

box. Buttons and indicators on the controller provide a means for controlling the

easurement system and indicating the overall status.

m

Page 17

Preface

Models

Sensor head

Sensor tip cables

The sensor head

the controller. It contains an electro-optic converter that converts the electrical

signal from the sensor tip cables to an optical signal sent to the controller.

Different se

the DUT. The sensor tip cable consists of an SMA connector that connects to the

sensor head; two screws to secure the sensor tip cable to the sensor head; the other

end of the sensor tip cable connects to the DUT through an MMCX connector

and optional adapters.

The TIVM Series IsoVu Measurement System includes the following models:

TIVM1. Tektronix IsoVu 1 GHz Medium Voltage with 3 m cable

TIVM1L. Tektronix IsoVu 1 GHz Medium Voltage with 10 m cable

TIVM05. Tektronix IsoVu 500 MHz Medium Voltage with 3 m cable

TIVM05

TIVM02. Tektronix IsoVu 200 MHz Medium Voltage with 3 m cable

provides an interface between the device-under-test (DUT) and

nsor tip cables are available to connect the measurement system to

L. Tektronix IsoVu 500 MHz Medium Voltage with 10 m cable

Supp

orted oscilloscopes

The measurement system can be used with the following Tektronix oscilloscopes.

For oscilloscopes not included in this list, contact your local Tektronix

rep

In addition to the above oscilloscopes, the measurement system can also be used

with the following oscilloscopes with a TCA-VPI50 adapter.

TIVM02L. Tektronix IsoVu 200 MHz Medium Voltage with 10 m cable

resentative.

MDO3000 series

MSO/DPO4000B serie s

MDO4000B/C series

MSO/DPO5000B serie s

DPO7000C series

MSO/DPO70000C series

MSO/DPO70000DX series

DPO70000SX series

TIVM Series Measurement System User Manual xi

Page 18

Preface

xii TIVM Series Measurement System User Manual

Page 19

Operating information

Accessories

This section lists the standard and optional accessories available for the

measurement s ystem.

Standard ac

cessories

Table 1: Standard accessories

Tektronix

Accessory

IsoVu product carrying case, soft case

IsoVu accessories carrying case, soft case

Solder aid for 0.062-inch (1.57 mm) pitch square pins (0.016 - 0.018-inch

(0.4 - 0.46 mm) square pin installation tool)

5X Sensor tip cable

25X Sensor tip cable

5/16-inch SMA wrench/driver tool

Probe tip adapter (blue), MMCX to 0.1-inch (2.54 mm) square pin

(0.025-inch (0.635 mm) square pins)

Probe tip adapter (white), MMCX to 0.062-inch (1.57 mm) square pin (0.016

- 0 .018-inch (0.4 - 0.46 mm) square pins)

DUT Interface pin kit with (qty. 20) 0.018-inch (0.46 mm) round solder-in

pins

Flexible tripod with quick release 352-1171-xx

Flexible tripod feet, 3 each

Probe tip tripod support with living h inge, 2 each 352-1170-xx

Certificate of traceable calibration

Data calibration report

part number

016-2108-xx

016-2110-xx

003-1946-xx

IVTIP5X

IVTIP25X

003-1947-xx

131-9717-xx

131-9677-xx

020-3169-xx

344-0693-xx

—

—

TIVM Series Measurement System User Manual 1

Page 20

Operating information

Optional accessories

Additional acc

following table lists the optional accessories.

Table 2: Optional accessories

Accessory

1X Sensor tip cable

10X Sensor tip cable

50X Sensor tip cable

Operating considerations

Read this

operating requirements and clearance requirements including possible hazardous

areas when the measurement system is connected to the DUT.

Measurement system

handling best practices

The mea

to avoid damage or degrading the performance due to mishandling. Consider the

following precautions when handling the fiber-optic cables and sensor tip cables:

essories, such as other sensor tip cables are available. The

Tektronix

part number

IVTIP1X

IVTIP10X

IVTIP50X

section before i nstalling your measurement system to be aware of the

surement system consists of quality parts and should be tre ated with care

Do not crush, crimp, or sharply bend the fiber-optic cable. Avoid making

loops in the fiber-optic cable smaller than 5 inches (12.7 cm).

Do not twist the fiber-optic cable; twisting the cable will stress the optical

fibers.

Do not allow kinks or knots to develop in the fiber-optic cable.

id putting tension on the fiber-optic cable.

Avo

Do not pull or jerk the fiber-optic cable, especially when kinks or knots are

esent.

pr

Do not drop the sensor head or controller assembly since damage and

isalignment of the internal optical components can result.

m

Avoid over-bending the sensor tip cables; do not exceed the minimum bend

radius of 2.0 inches (5.1 cm).

Avoid crushing the cables by accidentally running over the cable with a chair

wheel or by dropping a heavy object onto the cable.

Never support the weight of the sensor head or controller by the fiber-optic

cable.

Store the measurement system in the supplied carrying case when not in use.

2 TIVM Series Measurement System User Manual

Page 21

Operating information

Environmental

requirements

The following t

ables describe specifications and maximum operating

environmental ratings for the measurement system when connected to a DUT

and a Tektronix oscilloscope.

Table 3: Input specifications

Feature Description

Common mode

Differential mode Sensor tip cable dependent (See the Sensor tip cable voltage

1

This product is designed to be used in the circuit with expected transient overvoltage up to 5000 V peak.

60 kV peak

rating below.)

1

Table 4: Environmental considerations

Feature Description

Temperature

Controller

Operating 0 °C to 40 °C (32 °F to 104 °F)

Non-operating

Sensor head

Operating 0 °C to 70 °C (32 °F to 158 °F)

Non-operating

Sensor tip cables/adapters

Operating and

non-operating

Humidity

Controller

Operating 5% to 85% RH (Relative H umidity), at up to 40 °C (104 °F),

Non operating

Sensor head

Operating 5% to 80% RH (Relative Humidity), at up to 40 °C (104 °F)

Non operating

-40°Cto70°C(-40°Fto158°F)

-40°Cto70°C(-40°Fto158°F)

-40°Cto85°C(-40°Fto185°F)

non-condensing

5% to 85% RH (Relative Humidity), at up to 40 °C (104 °F)

5% to 45 % RH above 40 °C (104 °F) up to 70 °C (158 °F),

non-condensing

5% to 45 % RH above 40 °C (104 °F) up to 70 °C (158 °F),

non-condensing

5% to 85% RH (Relative Humidity), at up to 40 °C (104 °F)

5% to 45 % RH above 40 °C (104 °F) up to 70 °C (158 °F),

non-condensing

TIVM Series Measurement System User Manual 3

Page 22

Operating information

Table 4: Environmental considerations (cont.)

Feature Description

Sensor tip cables/adapters

Operating 5% to 80% RH (Relative Humidity), at up to 40 ° C (104 °F)

5% to 45 % RH above 40 °C (104 °F) up to 85°C (185 °F),

non-condensing

Non operating

Altitude

Operating 3000 m (9843 ft.)

Non operating

5% to 85% RH (Relative Humidity), at up to 40 °C (104 °F)

5% to 45 % RH above 40 °C (104 °F) up to 70 °C (158 °F),

non-condensing

12,000 m (39370 ft.)

Cleara

nce requirements

The unique common mode voltage range of the measurement system allows it to

be used in the presence of high frequency/high voltage common mode signals. It

is important to observe all precautions while using this product.

ING. RF burns can occur while using this measurement system. The system

WARN

is intended to isolate the operator from hazardous input voltages (common

voltages);the plastic case of the sensor head and the shield on the sensor tip cable

do not supply safe isolation.

Maintain the safe clearance from the sensor head and sensor tip cable while the

measurement system is connected to the energized circuit as recommended in this

document. (See Figure 2 on page 6.) Do not access the RF Burn Hazard Zone

while taking measurements on a live circuit.

WARNING. RF burns can occur while using this measurement system. Anyone

making measurements that might come within the RF burn regions indicated in

the following figure should be familiar with the hazards of working with signals in

these regions and take appropriate action, such as RF shielding for the DUT.

4 TIVM Series Measurement System User Manual

Page 23

Operating information

While measurin

RF burns. Refer to the following derating curve to identify the danger areas.

Measuring common mode signals within the light gray area can result in RF burns

while directly contacting the sensor head. Measuring common mode signals

within the dark gray shaded area can result in RF burns when within 1 m (40 in.)

of the sensor head.

Figure 1: Maximum safe handling limits for common mode voltages between the

sensor head and earth ground.

g high frequency common mode signals, there is a risk of

TIVM Series Measurement System User Manual 5

Page 24

Operating information

The following fi

potential RF burn area when working with hazardous voltages.

gure shows the components of the measurement system and the

Figure 2: RF burn hazard zone around the sensor head

6 TIVM Series Measurement System User Manual

Page 25

Operating information

Controls and i

Controller

ndicators

The following figure shows the indicators and buttons on the controller; their

functions are described in the following table.

Figure 3: Controller indicators and buttons

Table 5: Controller indicators and buttons

Item Description

1

2

3

OVERRANGE Indicator. This red LED indicates if the DC/low frequency

differential voltage applied to the sensor head or attached sensor tip cable

has exceeded the maximum speci fied input voltage levels.

RANGE indicator. The two LEDs indicate the differential input range

setting.

RANGE button. Push this button to toggle between one of two differential

input voltage ranges.

MENU button. Push this button to view the Probe Control menu on the

oscilloscope display.

TIVM Series Measurement System User Manual 7

Page 26

Operating information

Table 5: C ontroller indicators and buttons (cont.)

Item Description

4

5

6

CLAMPING indicator. This LED indicates whether the output clamping

is enabled.

CLAMPING button. Push this button to enable or disable the output

clamping feature.

SELF CAL indicator. This LED indicates the self calibration status.

Solid green. The self calibration has passed.

Flashing orange. The self calibration is in progress.

Solid red. The self calibration has failed.

Solid Orange. The self calibration has not been run or is questionable.

SELF CAL button. Push this button to start the self calibration routine.

STATUS indicator. This LED indicates the status of the measurement

system:

Solid green. The unit has powered on and passed the power-on self

tests and is in normal operation.

Flashing green. The unit has not completed the power-up sequence.

This is typically due to a communication fault between the host

oscilloscope and the IsoVu unit. Disconnect the TekVPI comp box

and then reattach the comp box.

Solid or flashing red. Error condition that requires the unit to be sent to

Tektronix for service.

Flashing red/yellow. The unit has failed the power on self tests.

Cycle the power; if the problem persists, the unit needs to be sent to

Tektronix for service.

8 TIVM Series Measurement System User Manual

Page 27

Operating information

Sensor head

Sensor tip cables

Labels on the se

the DUT. They also provide reminders of the potential RF burn hazards while

connected to the DUT.

Figure 4: Labels on the sensor head

Each sensor tip cable has a set of labels on the top and bottom. The top labels

provide reminders of the maximum differential input voltage range for each tip

cable. The bottom labels include the name of the tip cable and the differential

input resistance and capacitance for the tip cable (differential loading).

nsor head provide h igh-level specifications for connecting to

Figure 5: Sensor tip cable top and bottom labels

TIVM Series Measurement System User Manual 9

Page 28

Operating information

Connecting to

a circuit

WARNING. This measurement system contains laser sources; exposing these

laser sources may cause laser exposure. Except for the sensor tip cables on the

sensor head, do not remove any plastic or metallic covers from the sensor head

or controller or attempt to disassemble the product.

WARNING. Do not connect the measurement system to an energized circuit to

avoid the risk of shock. Always de-energize the circuit-under-test before installing

or removing the tip cable from the circuit-under-test. The plastic case of the

sensor head and the shield tip of the sensor cable do not supply the isolation.

WARNING. To avoid the risk of electrical shock or RF burns while the DUT

is energized, do not touch the sensor head or sensor tip cable while taking

measur

the measurement. (See Figure 2 on page 6.)

Be sure

the RF burn hazard zone. (See Figure 1 on page 5.)

ements.Alwayskeepa1m(40in.) clearancefromthesensorheadduring

to check the maximum ratings and derating curve for more information on

ION. To avoid possible damage to the equipment, do not connect the coaxial

CAUT

(common) shield of the sensor tip cable or SMA input to the high impedance

portion of a circuit. The additional capacitance can cause circuit damage.

Connect the coaxial (common) shield to the low impedance section of the circuit.

NOTE. Touching the sensor head or sensor tip cable when measuring a high

frequency, high voltage common mode signal increases the capacitive coupling

and can degrade the common mode loading on the circuit-under-test.

WARNING. To prevent the arc flash caused by a different potential, do not place

the sensor head or sensor tip cable on the circuit that has the different voltage.

10 TIVM Series Measurement System User Manual

Page 29

Operating information

The following s

between a Tektronix oscilloscope and the DUT.

1. Verify the DUT

2. Connect the Comp box to one of the channels on the oscilloscope.

Figure 6: Connect the Comp box to the oscilloscope

3. Refer to the following figure and install the sensor tip cable to the sensor head.

a. Line up the sensor tip cable with the sensor head.

teps describe the process for connecting the measurement system

is not connected to an energized circuit.

Take care to avoid bending or twisting the sensor tip cable assembly

during this process.

b. Connect the SMA connector of the sensor tip cable to the sensor head.

Use the accessories wrench to tighten the SMA cable to 4 to 5-in lbs.

Use the adjustment tool that was shipped with your system.

c. Pres

s the sensor tip cable housing against the sensor head and then tighten

the two screws to 3 to 5-in lbs.

the adjustment tool that was shipped with your system.

Use

Figure 7: Connecting the sensor tip cable to the sensor head

TIVM Series Measurement System User Manual 11

Page 30

Operating information

4. Connect the sen

This support keeps the sensor head steady reducing the potential mechanical

stresses at the electrical connection point of the DUT. The support also keeps

the sensor head away from surrounding circuits and conductive objects to

minimize the parasitic capacitive coupling to these surroundings.

NOTE. Thematingthreadinthese

support, make s ure that mating thread is UNC¼-20.

Figure 8: Connect the sensor head to the flexible tripod

sor head to the flexible tripod or a similar support.

nsor head is UNC¼-20. If you use a different

Self calibration

NOTE. To obtain the most accurate measurement, allow the measurement system

to warm up for 20 minutes. Then perform the se

the tip cable to the DUT and taking the measurement.

5. Connect the MMCX end, of the sensor tip cabl

the DUT or to a square pin adapter on the DUT. The adapters connect to

square pins with either 0.100-inch (2.54 mm) spacing or 0.062-inch (1.57 mm)

spacing. (See Figure 28 on page 38.)

6. Set up the controls on the oscilloscope.

7. Apply power to the DUT to take the measurement.

Press the SELF CAL button on the controller to adjust the operating point of the

measurement system for the current range and clamp setting. (This function is not

available in the Probe Setup menu of the oscilloscope.)

NOTE. Make sure there is no differential voltage present at the sensor tip cable

when performing the self calibration.

lf calibration before connecting

e to an MMCX connector on

12 TIVM Series Measurement System User Manual

Page 31

Operating information

Programming

When you power o

the controller is orange, indicating that the operating point of the measurement

system has not been optimized. As a result, the accuracy of the measurement

system might be degraded. The SELF CAL sequence should always be run

on the system after it is first powered on and has warmed up for 20 minutes.

After pushing the SELF CAL button, the indicator blinks orange during the self

calibratio

red when the operation fails.

There are s

status indicator turns orange to indicate when this is necessary:

Users wanting to initiate the self calibration through the programmatic interface

must configure the measurement system to perform a self calibration every time

it receives the AutoZero command. To link these functions, hold the MENU

button down and momentarily press the SELF CAL button. The OVERRANGE

indicator should blink red twice. This mode is non-volatile, and it also changes

the

Restore the original operation by repeating the MENU-SELF CAL button pushes.

In this case the OVERRANGE indicator will blink once.

n process; it turns solid green when the operation completes or solid

ituations when further self calibration is required. The SELF CAL

The measu

Changes are made to the range (1X|2X) or clamp (ON|OFF) setting.

The temperature in the sensor head changes more than 10 °C.

The internal compensation adjustments have shifted outside their normal

operating ranges.

The sensor tip cable is changed.

operation of the AutoZero button in the Probe Setup menu of the oscilloscope.

n the measurement system, the SELF CAL status indicator on

rement system is first attached to the oscilloscope.

TIVM Series Measurement System User Manual 13

Page 32

Operating information

AutoZero

Menu button

When the displayed waveform is not centered correctly (for example, due to a

small DC offset error), you might need to press the AutoZero button in the Probe

Setup menu of the oscilloscope. This might be necessary for the first time after

the self calibration operation has completed. Make sure there is no differential

signal pres

ent at the sensor tip cable.

Press the M

oscilloscope, similar to the following figure.

Figure 9: Probe Setup menu

ENU button on the controller to view the Probe Setup menu on the

Use the buttons on the oscilloscope to change the probe setups. Some of the

functions are the same as pushing the buttons on the controller, such as turning

clamping on or off, or setting the input ranges.

14 TIVM Series Measurement System User Manual

Page 33

Operating information

Offset correc

tion

The measurement system uses state-of-the-art technology that allows the DUT

to be totally isolated from the oscilloscope. This results in a very large common

mode rejecti

be obscured by the h igh common mode interference.

The TIVM Ser

any drift in the system due to changes in temperature or fiber movement. The

offset correction algorithm maintains a constant DC level for the displayed

on-screen signal.

One of the components used for offset correction is a digital low-pass filter.

Normally, the frequency of the signal is high enough that the operation of the

filter is transparent. However, at low frequencies special care must be taken to

prevent aberrations from being introduced.

When attempting to capture a signal that has a frequency near 43.5 Hz, 87.0 Hz, or

130.5 Hz, the display might show aliasing. If you cannot avoid these frequencies,

the off

selected to not alias at 50 Hz or 60 Hz.

on ratio (CMRR) and lets you see small signals that would otherwise

ies products implement a n offset correction algorithm to minimize

set correction should be disabled. The sample rate of the digital filter was

Figure 10: Digital filter aliasing

To disable the offset correction algorithm, hold down the MENU button on the

controller and momentarily press the CLAMPING button. The OVERRANGE

indicator on the controller should blink two times. To re-enable the correction,

repeat the operation; the OVERRANGE indicator should blink once. Turning off

the correction is temporary; when the measurement system is removed/re-attached,

the offset correction is re-enabled.

TIVM Series Measurement System User Manual 15

Page 34

Operating information

Another source

of aberrations is introduced when the signal is below the cutoff

frequency of the digital filter (5.0 Hz). The following figure shows a close-up

view of the front edge of a 0.1 Hz 800 mV

square wave. These aberrations are

p-p

also created by the digital filter.

Figure 11: Digital filter aberrations (about 2.5% of V

p-p

)

The following figure shows the aberrations after the offset correction has been

disabled. When the offset correction is disabled, the system no longer corrects for

long-term drift due to temperature change and fiber movement.

16 TIVM Series Measurement System User Manual

Page 35

Operating information

1X/2X Range

Figure 12

The top label of each sensor tip cable (IVTIP1X, IVTIP5X, IVTIP10X,

IVTIP25X, IVTIP50X) shows the dynamic range in peak-to-peak volts as shown

in the following figure.

Figure 13: Top s ensor tip labels

: Digital filter aberrations after disabling offset correction

TIVM Series Measurement System User Manual 17

Page 36

Operating information

Auto Rang

For example, th

e IVTIP5X tip has a dynamic range of 5 V

when the 1X Range

p-p

is selected. This means that you can display a signal with a ±2.5 V differential

voltage. When the 2X Range is selected, the dynamic range increases from 5 V

to 10 V

(±5.0 V). Refer to the Linear differential input voltage range in the

p-p

p-p

specifications table for more information.

CAUTION. To avoid damaging the probe, do NOT exceed either the RMS OR

Peak Voltag

e ratings. The Maximum Non-Destruct Voltage limits (RMS and Peak

Vo ltage) do not increase when the 2X Range is selected. For the IVTIP5X, the

12 V

and ±21.5 Vpklimits are the same for the 1X or 2X Range.

rms

e

By default, the MSO/DPO5000, DPO7000, and MSO/DPO70000 Series

Oscilloscopes select the 1X or 2X Range automatically when you change the

V/div se

However, there are combinations of Range and V/div settings that cannot be

reached when Auto Range is selected. For these situations, select Manual Range

when full flexibility is desired.

tting. This hides the complexity of selecting the range from casual users.

18 TIVM Series Measurement System User Manual

Page 37

Operating information

Selecting a se

nsor tip cable

CAUTION. Avoid over-voltage conditions that can damage or degrade the sensor

head input termination by selecting the wrong sensor tip cable. The sensor head

SMA input is a 50 Ω terminated input. Selecting the correct sensor tip cable

attenuation factor is crucial to ensure that the sensor head input termination is not

degraded or damaged by an over-voltage condition. Select the sensor tip cable

that will p

This also provides the highest differential impedance to the circuit-under-test.

When sele

following questions:

What is t

(for example, under a fault condition)?

What is

can tolerate?

How la

What sensitivity do I need (for example, the minimum V/div setting)?

The following table will help you select the correct sensor tip. Start at the top of

the table and work down. Choose the first tip that meets all of your criteria.

rovide the highest attenuation possible for the signal being measured.

cting a sensor tip cable for a particular application, consider the

he maximum RMS/Peak Voltage at the test point being measured

the minimum differential loading (input resistance) that my circuit

rge of a signal do I want to display at one time on the oscilloscope?

le 6: Sensor tip selection table

Tab

Most sensitive

Sensor tip

IVTIP50X

IVTIP25X

IVTIP10X

IVTIP5X

IVTIP1X

1

On 1X range

2

On 2X range

V/div setting

50 mV/div ±50 V (100 V

25mV/div ±25V(50V

10mV/div ±10V(20V

5 m V/div ±5 V (10 V

1 mV/div ±1 V (2 V

Differential input specifications

imum

Max

)

non-destruct

voltage (RMS)

35 V

rms

25 V

rms

16 V

rms

12 V

rms

3V

rms

1

range

2

p-p

)

p-p

)

p-p

)

p-p

)

p-p

Linear voltage

imum

Max

non-destruct

voltage (Peak)

200 Vpk

107.5 Vpk

43 Vpk

21.5 Vpk

4.3 Vpk

Differential input

resistance

2.5 k

1.25 k

500

250

50

TIVM Series Measurement System User Manual 19

Page 38

Operating information

Output clampi

ng

Sensor tip loading

The measurement system has a selectable output clamping feature. Push the

button on the controller to enable or disable the output clamping feature. When

enabled (ind

the measurement system into the oscilloscope input. It allows you to increase the

vertical sensitivity without over-driving or saturating the oscilloscope input.

Each of the sensor tip cables (IVTIP1X, IVTIP5X, IVTIP10X, IVTIP25X,

IVTIP50X) has a differential input resistance listed on the bottom labels as shown

in the following figure.

icator is on), the output clamping limits the output voltage swing of

Figure 14: Bottom sensor tip labels

It is important to understand the impact of the tip loading on the DUT. For

mple, the IVTIP5X tip has a differential input resistance of 250 Ω.Ifyou

exa

choose the IVTIP25X tip, the differential input resistance increases to 1.25 kΩ.

Refer to the Input resistance/capacitance section in the specifications table for

more information. The sensor tip cables are specially designed to act as a common

mode choke that helps reduce the common mode loading.

NOTE. The coaxial (common) shield of the sensor tip cable should always be

onnected to the lowest impedance point (usually a circuit common or power

c

supply rail) in the circuit-under-test (relative to the sensor tip cable/center

conductor) to obtain the most accurate waveform.

20 TIVM Series Measurement System User Manual

Page 39

Probe compensation

Deskew

Operating information

The DPO7000 and MSO/DPO70000 Series oscilloscopes have a Compensate

Probe feature accessible from the Probe Setup window. Pressing this button

always results in a failure because the input resistance of the TIVM sensor tips is

too low and cannot be driven by the calibrator output of the oscilloscope. The

accuracy of

though the Compensate Probe feature fails.

Each oscilloscope family has a unique way of allowing you to adjust the timing

relationship between signals acquired between different probes. Consult the user

manual or online help o f the oscilloscope for specific directions needed to deskew

the probe. The 3 m and 10 m measurement systems have a propagation delay of

approximately 35 ns and 68 ns respectively. The actual propagation delay is

measur

the TIVM system is still guaranteed on these oscilloscopes even

ed on each measurement system and is stored within each unit.

Input offset

The me

This allows you to view a portion of the signal that is off-screen. One of the

controls on the oscilloscope can be assigned this function.

The minimum/maximum offset is different for each sensor tip cable. It is the same

when the 1X or 2X Range is selected; it is also the same for all V/div settings.

Refer the following input offset table.

Table 7: Input offset

Se

IVTIP1X ±2 V

IVTIP5X ±10 V

VTIP10X

I

IVTIP25X ±50 V

IVTIP50X ±100 V

asurement system provides a user-adjustable, input referred offset voltage.

nsor tip cable

put offset voltage

In

20 V

±

TIVM Series Measurement System User Manual 21

Page 40

Operating information

22 TIVM Series Measurement System User Manual

Page 41

Application examples

The following examples are provided to help you become familiar with the TIVM

Series IsoVu measurement system and to achieve the best performance for your

application.

Example 1: H

igh-side V

measurement

GS

Advancements in the components used in switching power supplies have made

characterizing the performance of these power supplies increasingly difficult and

challengi

V

GS

good CMRR is required from the test system. The following figure shows an

example of this circuit.

Figure 15: Half-bridge circuit showing the gate, source, and drain of the high-side

FET

ng. A particularly challenging measurement is measuring the high-side

in a half bridge. To accurately make this measurement, an exceptionally

In this type of circuit, the gate-source voltage is of interest because the rate at

which the device switches is determined by the gate drive characteristics. The

reference node for this measurement is the high-side source node, which switches

tween the input supply voltage and the local PCB ground during operation. In a

be

measurement system without sufficient CMRR, this rapidly changing common

mode voltage results in interference which obscures the measurement. It is

important to note that the CMRR for all measurement systems is frequency

dependent; however, the frequency that is critical for this measurement is not

the switching frequency, but the frequency corresponding to the edge rate. For

example, to accurately characteriz e a power supply with a switching frequency

of 100 kHz and an edge rate of 1 ns, a system with good CMRR at 350 Mhz is

necessary because of the edge speed.

TIVM Series Measurement System User Manual 23

Page 42

Application examples

In this example

, the gate drive voltage could be about 5 V but usually has some

ringing and overshoot which are important to characterize. For this measurement,

it is appropriate to use a 10X tip with a 10 V

input (on the 1X range) so that

p-p

the signal is fully resolved and is within the dynamic range of the measurement

system.

To get the best CMRR from your TIVM Series IsoVu measurement system, pay

careful attention when connecting the measurement system to the DUT. This

connection should preserve the signal fidelity and shield the signal from unwanted

interfere

nce. To achieve the best performance from the measurement system, use

an MMCX connector as close to the test point as possible. The MMCX connectors

are available from a number of vendors and are relatively inexpensive. The key

attributes of these connectors, which make them excel for this application, are

their compact footprint and solid metal body. The solid metal body and gold

contacts provide a w ell-shielded signal path.

The IsoVu input provides a floating differential measurement with differential

input resistance from 50 Ω to 2.5 kΩ, depending on the tip attenuation. In the

VGS mea

surement example the 10X tip with a 500 Ω input impedance is used.

The common mode resistance is extremely high, greater than G Ω, in parallel

with a small capacitance from the tip cable shield to ground, typically 2 pF or

less. Keep these impedances in mind when determining how to connect the

measurement system to the DUT. The source node in the h alf bridge circuit is a

very low impedance point, and is the point that should be used to drive the tip

e shield capacitance. The gate driver output, which is also a low impedance

cabl

node (but not as low impedance as the source), should be used to drive the center

contact of the sensor tip cable. The input impedance of the sensor tip cable for the

10X tip is 500 Ω relative to the shield – not to ground.

An example of a measurement that is possible with IsoVu is measuring the

high-side turn-on characteristics shown in the following figure.

Figure 16: High-side turn-on characteristics

24 TIVM Series Measurement System User Manual

Page 43

Application examples

Exampl

In general ther

e a re three characteristic regions of interest of the turn-on waveform

(See Figure 16.):

The first regio

nistheC

charge time.

GS

The second region is the Miller Plateau (the time required to charge the

gate-drain

increases as V

The third re

Miller capacitance (C

increases.

DS

gion occurs when the channel is in conduction and the gate

chargesuptoitsfinal value.

Due to the r

apid rise of the voltage on the switch node during the high side

turn-on, there can be very high frequency and high amplitude common mode

voltage changes during the transition. If this common mode voltage transient is

not rejected, then the measurement of the high-side V

not possible.

e 2: High-side drain current measurement

Current sensing is a critical measurement in many applications. Using the half

bridge circuit again as an example, measuring the high-side drain current, I

y challenging particularly during startup. At startup, there can be common

be ver

mode voltage transients due to parasitic inductance in the supply leads in addition

to large current swings. Inserting a conventional current probe into the circuit at

this point would require adding excessive inductance, which might limit circuit

performance. Using a small value resistor as a current shunt makes it possible

to take very high frequency current measurements with minimal additional

edance in the drain connection. (See Figure 17.)

imp

), and is VDSdependent. The charge time

GD

during the transition is

GS

,can

D

Figure 17: High side current shunt

TIVM Series Measurement System User Manual 25

Page 44

Application examples

In a typical app

current of 1 A, resulting in a voltage swing of 0.25 V, which can be measured with

the measurement system using a 1X or 5X tip. A typical surface mount resistor

can have a series inductance of less than 0.2 nH and series capacitance of less than

0.04 pF, resulting in much lower impedance at high frequency than could be

obtained with a conventional current probe.

Figure 18: SMT resistor model

Go to http://www.vishay.com/docs/60107/freqresp.pdf for models of different

types o

In general, surface mount resistors have fairly low power ratings; care must

be take

Several vendors make very high power parts that can be used when high

power dissipation is required. For example, the RP0402CB-R500FN-2Q from

Barry Industries (http://www.barryind.com/)isa1.0W,0.5Ω 0402 resistor

on an AIN substrate, or the RP0402CB-R500FN-2Q from US Microwaves

(http://www.usmicrowaves.com/)isa1.5W,1Ω resistor on a BeO substrate.

f surface mount resistors.

n not to exceed these ratings when using them as current shunts.

lication, a 0.25 Ω resistor might be used to measure a transient

Example 3: ESD troubleshooting

Many devices and systems can be negatively affected by ESD discharges.

oubleshooting problems that occur during an ESD discharge can be very

Tr

difficult. A piece of test equipment connected to a device undergoing ESD testing

has to not only withstand the ESD discharge, but it also has to reject interference

caused by the rapid changes in potential on the DUT during an ESD discharge test.

For example, consider using the standard human body model of 100 pF and

1500 Ω. If the DUT is being tested to 4 kV and has a capacitance of 50 pF, the

test equipment will be exposed to a voltage change of more than 1 kV in tens

of nanoseconds.

26 TIVM Series Measurement System User Manual

Page 45

Application examples

Figure 19: ESD discharge test example

In this example, if it is suspected that there is a glitch on the communication bus

betwee

the signals on the bus and to inspect them during the discharge. Because the

measurement system uses Galvanic isolation, it rejects any interference from the

ESD transient and tolerates the high common mode voltage during the discharge;

the communication bus can be monitored throughout the ESD discharge and any

irregularities can be investigated without interference from the ESD discharge.

n two devices during the ESD discharge, then it is helpful to connect to

TIVM Series Measurement System User Manual 27

Page 46

Application examples

28 TIVM Series Measurement System User Manual

Page 47

Reference information

Specification

Table 8: Warranted specifications

Characteristic Description

Propagation delay (Warranted) 3 m fiber length: 35 ns ±5 ns (actual propagation delay is measured and stored within each unit)

s

The following tables list the specifications for the measurement system. The

specifications are guaranteed unless otherwise indicated.

The performance limits in this specification are valid with these conditions:

The instrument must be in an environment with temperature, altitude, and

humidity within the operating limits described in these specifications.

The instrument must have had a warm-up period of at least 20 minutes.

The measurement system is powered from a TekVPI compatible oscilloscope.

Warranted specifications describe guaranteed performance with tolerance limits or

certain type-tested requirements.

The performance verification procedures for the Propagation delay are listed later

in this document. (See page 47, Propagation delay.)

10 m fiber length: 68 ns ±7 ns (actual propagation delay is measured and stored within each

unit)

le 9: Electrical specifications

Tab

Characteristic Description

Controller output

termination

Controller output coupling DC coupled

Range attenuation

Terminate the controller output into 50

Sensor tip cable/adapter

Sensor head input SMA 1X (÷1) 2X (÷2)

IVTIP1X, 1X Sensor tip cable 1X (÷1) 2X (÷2)

IVTIP5X, 5X Sensor tip cable 5X (÷5) 10X (÷10)

IVTIP10X, 10X Sensor tip cable 10X (÷10) 20X (÷20)

IVTIP25X, 25X Sensor tip cable 25X (÷25) 50X (÷50)

IVTIP50X, 50X Sensor tip cable 50X (÷50) 100X (÷100)

1X range 2X range

TIVM Series Measurement System User Manual 29

Page 48

Reference information

Table 9: Electrical specifications (cont.)

Characteristic Description

Input

resistance/capacitance

(attached to sensor head,

50 termination), (Ty pical)

Maximum non-destructive

differential input voltage

range, (Typical)

CAUTION. To avoid

damaging the measurement

system, be aware of the

input voltage limits; this

specification applies to

both the 1X Range and 2X

Range.

Linear differential input

voltage range, (Typical)

Output clamping range

(Input referred)

(Typ ical)

Output clamping overdrive

recovery (Typical)

Sensor tip cable/adapter

Sensor head input SMA 50 ±2%

IVTIP1X, 1X Sensor tip cable 50

IVTIP5X, 5X Sensor tip cable 250

IVTIP10X, 10X Sensor tip cable 500

IVTIP25X, 25X Sensor tip cable 1.25 k

IVTIP50X, 50X Sensor tip cable 2.5 k

Sensor tip cable/adapter

Sensor head input SMA

IVTIP1X, 1X Sensor tip cable

IVTIP5X, 5X Sensor tip cable

IVTIP10X, 10X Sensor tip cable

IVTIP25X, 25X Sensor tip cable

IVTIP50X, 50X Sensor tip cable

Sensor tip cable/adapter

Sensor head input SMA

IVTIP1X, 1X Sensor tip cable

IVTIP5X, 5X Sensor tip cable

IVTIP10X, 10X Sensor tip cable

IVTIP25X, 25X Sensor tip cable

IVTIP50X, 50X Sensor tip cable

Sensor tip cable/adapter Clamping on,

Sensor head input SMA

IVTIP1X, 1X Sensor tip cable

IVTIP5X, 5X Sensor tip cable

IVTIP10X, 10X Sensor tip cable

IVTIP25X, 25X Sensor tip cable

IVTIP50X, 50X Sensor tip cable

<20ns

Resistance

V

rms

3 V 4.3 Vpk

3 V 4.3 Vpk

12 V 21.5 Vpk

16 V 43 Vpk

25 V 107.5 Vpk

35 V 200 Vpk

Clamping Off,

1X Range

±V peak

(DC + peak AC)

±0.5 V ±1 V

±0.5 V ±1 V

±2.5 V ±5 V

±5 V ±10 V

±12.5 V ±25 V

±25 V ±50 V

1X Range

± 100 mV ± 200 mV

± 100 mV ± 200 mV

± 500 mV ± 1 V

±1V ±2V

±2.5V ±5V

±5V ±10V

Capacitance

NA

NA

< 1pF

< 1pF

< 1pF

< 1pF

V peak

Clamping Off,

2X Range

±V peak

(DC + peak AC)

Clamping on,

2X Range

30 TIVM Series Measurement System User Manual

Page 49

Table 9: Electrical specifications (cont.)

Characteristic Description

System noise

(Typ ical)

DC gain accuracy1, (Input referred) (Typical)

Differential DC gain

accuracy

80% to 100% of full

scale in 2X Range:

DC offset error voltage

2

(Input referred)

(Typ ical)

Input offset voltage range

(Typ ical)

Input offset voltage

accuracy (Typical)

Small signal rise time (10%

to 90%) (Typical)

(SMA input and with sensor

tip cables)

Small signal frequency

response

(Typ ical)

(SMA input and with sensor

tip cables)

1 GHz system noise (input referred)

Sensor tip cable/adapter

Sensor head input SMA

IVTIP1X, 1X Sensor tip cable

IVTIP5X, 5X Sensor tip cable

IVTIP10X, 10X Sensor tip cable

IVTIP25X, 25X Sensor tip cable

IVTIP50X, 50X Sensor tip cable

±3% ± DC offset error voltage ± input offset accuracy error

±5% ± DC offset error voltage ± input offset accuracy error

Sensor tip cable/adapter

Sensor head input SMA

IVTIP1X, 1X Sensor tip cable

IVTIP5X, 5X Sensor tip cable

IVTIP10X, 10X Sensor tip cable

IVTIP25X, 25X Sensor tip cable

IVTIP50X, 50X Sensor tip cable

Sensor tip cable/adapter Input offset voltage range

Sensor head input SMA

IVTIP1X, 1X Sensor tip cable

IVTIP5X, 5X Sensor tip cable

IVTIP10X, 10X Sensor tip cable

IVTIP25X, 25X Sensor tip cable

IVTIP50X, 50X Sensor tip cable

±5%

TIVM1/TIVM1L

TIVM05/TIVM05L

TIVM02/TIVM02L

TIVM1/TIVM1L DC to 1GHz

TIVM05/TIVM05L DC to 500 MHz

TIVM02/TIVM02L DC to 200 MHz

1X Range 2X Range

<0.8mV

<0.8mV

<4mV

rms

<8mV

rms

<20mV

<40mV

rms

rms

rms

rms

<1.6mV

<1.6mV

<8mV

rms

<16mV

<40mV

<80mV

1X Range 2X Range

±2 mV ±4 mV

±2 mV ±4 mV

±10 m V ±20 mV

±20 m V ±40 mV

±50 m V ±100 mV

±100 mV ±200 mV

±2 V

±2 V

±10 V

±20 V

±50 V

±100 V

Rise time

350 ps

700 ps

1.8 ns

-3 dB bandwidth

Reference information

rms

rms

rms

rms

rms

TIVM Series Measurement System User Manual 31

Page 50

Reference information

Table 9: Electrical specifications (cont.)

Characteristic Description

Common mode rejection ratio (Typical)

Sensor tip cable/adapter DC

IVTIP1X, 1X Sensor tip

> 120 dB 120 dB 110 dB 100 dB 90 dB

cable

IVTIP5X, 5X Sensor tip

> 120 dB 120 dB 110 dB 100 dB 90 dB

cable

IVTIP10X, 10X Sensor

> 120 dB 120 dB 110 dB 100 dB 90 dB

tip cable

IVTIP25X, 25X Sensor

> 120 dB 110 dB 100 dB 100 dB 90 dB

tip cable

IVTIP50X, 50X Sensor

> 120 dB 100 dB 90 dB 90 dB 80 dB

tip cable

MMCX-to 0.1 in

> 120 dB 70 dB 60 dB 40 dB 30 dB

(2.54 mm) square pin

adapter with sensor tip

cable.

MMCX-to 0.062 in

> 120 dB 70 dB 60 dB 40 dB 30 dB

(1.57 mm) square pin

adapter with sensor tip

cable.

Common mode voltage

60 kV peak

3

range

Common mode resistance

N.A. due to Galvanically isolation (fiber optic connection)

(Typ ical)

Common mode

capacitance

4

~2 pF

(Typ ical)

Overload indicator range

(Typ ical)

Sensor tip cable/adapter Overload indicator On

Sensor head input SMA

IVTIP1X, 1X Sensor tip cable

IVTIP5X, 5X Sensor tip cable

IVTIP10X, 10X Sensor tip cable

IVTIP25X, 25X Sensor tip cable

IVTIP50X, 50X Sensor tip cable

1

The difference between the measured DC gain and the nominal DC gain, divided by the nominal DC gain and expressed as a percent.

2

The input referred offset error voltage when the input is shorted and the probe input offset is set to 0 volts

3

This product is designed to be used in the circuit with expected transient overvoltage up to 5000 V peak.

4

The capacitance between the sensor head and a reference plane. The sensor head is placed six inches (15.25 cm) above the reference plane.

100 MHz 200 MHz 500 MHz

<-3VorVin>+3V

V

in

<-3VorVin>+3V

V

in

<-12VorVin>+12V

V

in

<-16VorVin>+16V

V

in

<-25VorVin>+25V

V

in

V

<-35VorVin>+35V

in

1GHz

32 TIVM Series Measurement System User Manual

Page 51

Reference information

Table 10: Physi

Characteristic Description

Net weight

Sensor tip cables 0.025 kg (0.055 lb)

Sensor head 0.363 kg (0.8 lb)

Controller box 0.816 kg (1.8 lb)

TekVPI Comp box 0.57 kg (0.125 lb)

Sensor tip cable length 15.24 cm (6.0 in)

Fiber cab

TekVPI cable length

Overal

le length

TIVM1, TIVM02, TIVM05

TIVM1L, TIVM02L, TIVM05L

l length and tolerances

Comp b

Controller to sensor head

(TIVM1, TIVM02, TIVM05)

Controller to sensor head

VM1L, TIVM02L, TIVM05L)

(TI

cal specifications

ox to controller

(Weight does not include accessories and packaging.)

3m(9.84

10 m (32.

55.88 c

0.558

length.

2.9718 m ±10.2 cm (117 in ±4 in)

9.982 m ±10.2 cm (393 in ±4 in)

ft)

81 ft)

m(22in)