Tektronix The PCF-20 Guide to Driver Software for the DAS-20 24893A (UNSUPPORTED) User manual

Page 1

PCF-20

Keithley MetraByte Corporation

Page 2

*****

Page 3

The

PCF-20

Guide to Using

PASCAL, C, & FORTRAN

Callable Driver Software

for the

DAS-20

Revision A, - 1987

Copyright @ Kelthley MetraByte Corp. 1987

Part Number: 24893

KEITHLEY METRABYTE CORPORATION

440 MYLES STANDISH BLVD., Taunton, MA 02780

TEL. f&8/880-3000. FAX 5W880-0179

. . .

- 111 -

Page 4

Warranty Information

All products manufactured by Keithley MetraByte are warranted against defective materials

and worksmanship for a period of one year from the date of delivery to the original

purchaser, Any product that is found to be defective within the warranty period will. at the

option of Keithley MetraByte. be repaired or replaced. This warranty does not apply to

products damaged by improper use.

Warning

Keithley MetraByte assumes no liability for damages

consequent to the use of this product. This product is not

designed with components of a level of reliability suitable

for use in life support or critical applications.

Disclaimer

Information furnished by Keithley MetraByte is believed to be accurate and reliable.

However, the Keithley MetraByte Corporation assumes no responsibility for the use of such

information nor for any infringements of patents or other rights of third parties that may

result from its use. No license is granted by implication or otherwise under any patent

rights of Keithley MetraByte Corporation.

Notes

Keithley MetraByte/Asyst/DAC is also referred to here-in as Keithley MefraByte.

BasicTM is a trademark of Dartmouth College.

IBM@ is a registered trademark of International Business Machines Corporation.

PC, XT, AT, PS/2, and Micro Channel Architecture@ (MCA) are trademarks of

International Business Machines Corporation.

Microsoft@ is a registered trademark of Microsoft Corporation.

Turbo C@ is a registered trademark of Borland International.

- iv -

Page 5

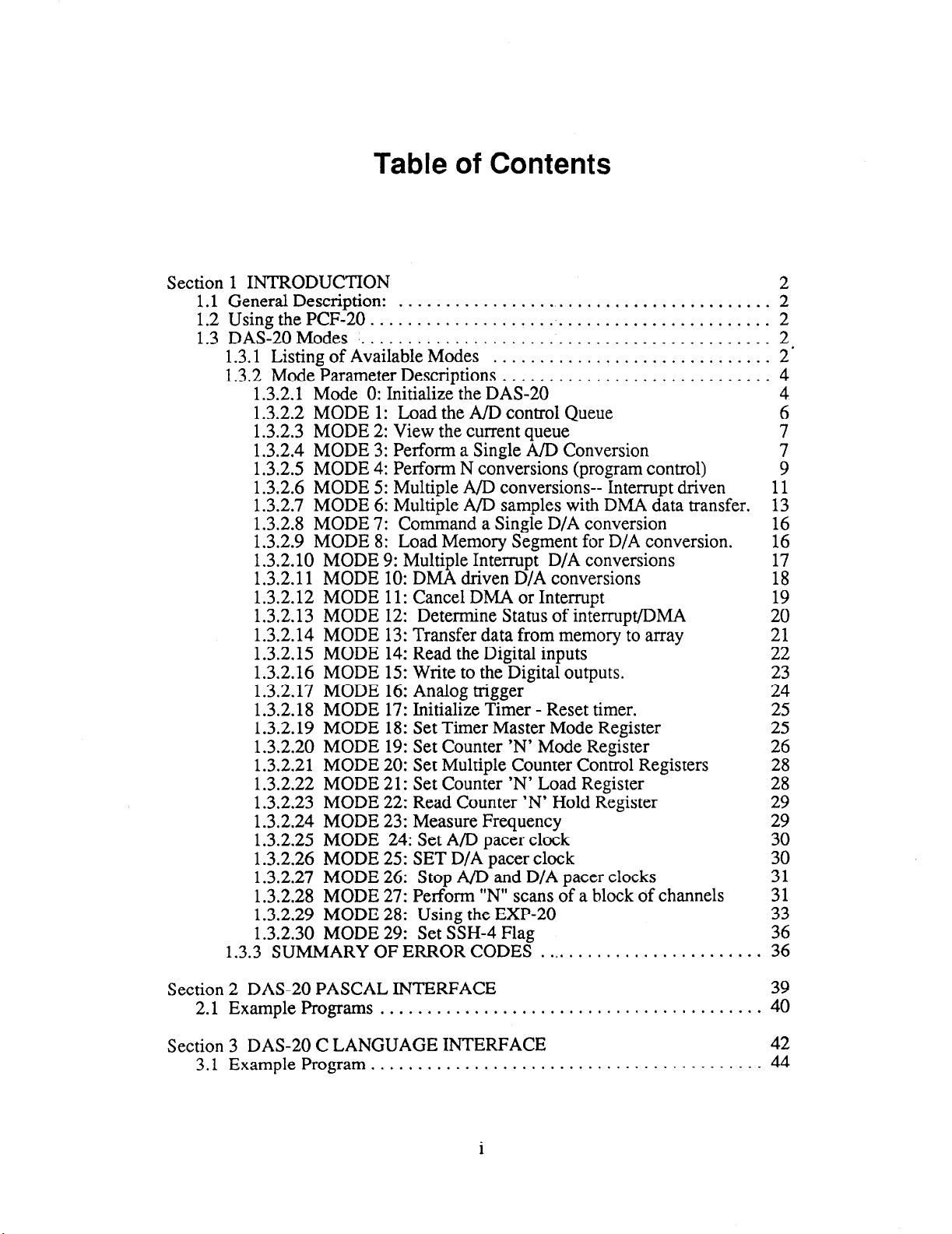

Table of Contents

Section 1 INTRODUCTION 2

1.1 General Description:

1.2 Using the PCF-20

1.3 DAS-20Modes

1.3.1 Listing of Available Modes ..............................

1.3.2 Mode Parameter Descriptions .............................

1.3.2.1 Mode 0: Initialize the DAS-20

1.3.2.2 MODE 1: Load the A/D control Queue

1.3.2.3 MODE 2: View the current queue

1.3.2.4 MODE 3: Perform a Single A/D Conversion

1.3.2.5 MODE 4: Perform N conversions (program control)

1.3.2.6 MODE 5: Multiple A/D conversions-- Interrupt driven

1.3.2.7 MODE 6: Multiple A/D samples with DMA data transfer.

1.3.2.8 MODE 7: Command a Single D/A conversion

1.3.2.9 MODE 8: Load Memory Segment for D/A conversion.

1.3.2.10 MODE 9: Multiple Interrupt D/A conversions

1.3.2.11 MODE 10: DMA driven D/A conversions

1.3.2.12 MODE 11: Cancel DMA or Interrupt

1.3.2.13 MODE 12: Determine Status of interrupt/DMA

1.3.2.14 MODE 13: Transfer data from memory to array

1.3.2.15 MODE 14: Read the Digital inputs

1.3.2.16 MODE 15: Write to the Digital outputs.

1.3.2.17 MODE 16: Analog trigger

1.3.2.18 MODE 17: Initialize Timer - Reset timer.

1.3.2.19 MODE 18: Set Timer Master Mode Register

1.3.2.20 MODE 19: Set Counter ‘N’ Mode Register

1.3.2.21 MODE 20: Set Multiple Counter Control Registers

1.3.2.22 MODE 21: Set Counter ‘N’ Load Register

1.3.2.23 MODE 22: Read Counter ‘N’ Hold Register

1.3.2.24 MODE 23: Measure Frequency

1.3.2.25 MODE 24: Set A/D pacer clock

1.3.2.26 MODE 25: SET D/A pacer clock

1.3.2.27 MODE 26: Stop A/D and D/A pacer clocks

1.3.2.28 MODE 27: Perform “N” scans of a block of channels

1.3.2.29 MODE 28: Using the EXP-20

1.3.2.30 MODE 29: Set SSH-4 Flag

1.3.3 SUMMARY OF ERROR CODES . .,. . . . . . . . . . . . . . . . . . . . . . 36

........................................

...........................................

............................................

11

13

16

16

:;:

19

20

2

;i

25

25

26

28

28

29

i;

;‘:

31

33

36

2

2

2

2’

4

4

7”

7

9

Section 2 DAS-20 PASCAL INTERFACE

2.1 Example Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Section 3 DAS-20 C LANGUAGE INTERFACE

3.1 Example Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

39

42

Page 6

Section 4 DAS-20 FORTRAN INTERFACE

4.1 Example Program.. . . . . . . . . . . . . . . . . . . . . . , . . . . . . . . . . . . . . . . . . 46

45

Page 7

Section 1

INTRODUCTION

1 .I General Description:

The PCF-20 software package has been developed for Pascal, C, and Fortran

programmers wishing to write data acquisition and control software for MetraByte DAS-20,

EXP-20 and SSH-4 boards. The PCF-20 is supplied on three disks (one for each language). In

addition to the assembly level driver, each disk contains a number of example programs, and a

simple graphics package that may prove helpful in writing display routines.

1.2 Using the PCF-20

Each of the three software drivers supplied in the PCF package are virtually identical

to the standard BASIC driver rouitines provided with the DAS-20. The only difference is in the

way data and computer control are passed back and forth between the user program and the

assembly driver.

Currently there are 30 modes (numbered 0 to 29), and each performs a specific function. Rather

than write four redundant descriptions of each mode for each language, this manual refers to the

DAS-20 manual, and specifically Chapter four on programming to describe the funcion of each

of the modes. This manual simply describes the syntax and conventions required to excecute one

of the 30 modes from Pascal, C, and Fortran. However, as a quick reference guied the modes,

and a brief description of the applicable excecution parameters are listed in the next section.

Different functions of the assembly driver are selected by selecting a Mode.

1.3 DAS-20 Modes

1.3.1 Listing of Available Modes

The following DAS-20 functions are supported by the DAS20.BIN driver:

MODE DESCRIPTION~OF~FUNCTION

0

1

2

Initialize the DAS-20, (Base Address, Interrupt

level, and DMA level).

Load the Channel/Gain queuing RAM

View the current Channel/Gain Queuing RAM

-2-

Page 8

3

Perform a single A/D conversion and load the

data into a BASICA variable

4

5

6

7

8

9

10

Perform an “N” conversion scan and store the

data in a BASICA array, Sample rate is set by

pacer clock or external trigger. and maximum

sample rate is about 4000 samples per second.

Perform an “N” conversion scan, and store the

data in memory under interrupt control. Maximum

conversion rate = 4000 samples/set.

Perform an “N” conversion scan under DMA

control. Conversion rate is set by on board

pacer clock or by external trigger, Maximum

conversion rate = 100,000 Khz

Command a single D/A conversion

: Load memory with D/A conversion data for Modes 9

and 10.

Perform “N” D/A conversions under interrupt

control.

Perform “N” D/A conversions, DMA data transfers.

Conversion timing from pacer clock or external

trigger. Up to 260,000 Conversions per second.

11

12

13

14

15

16

17

18

19

Cancel DMA or interrupt driven operations.

Return control completely to program software.

Return current status of DMA or Interrupt

driven data transfers.

Transfer data from memory into BASICA arrays.

This mode is necessary since interrupt and DMA

driven conversions write and read directly from

memory locations without regard

variables.

Read the 8 digital input Bits

Write to the 8 digital output bits.

Set Analog trigger mode. This mode can cause

any other mode to wait until a certain specified

input condition is met before proceeding.

Initialize the Counter/Timer chip

Set the 95 13 counter’s master mode register

Set counter “N” mode register

to BASICA

-3-

Page 9

20

Set Multiple counter control register

21

22

23

24

25

26

27

28

29

Set Counter “N” load register

Read counter “N” hold register

Measure Frequency with counter timer

Set D/A pacer clock

Set A/D pacer clock

Stop A/D & D/A pacer clocks

Perform “N” scans of a block of analog input

channels

Sample Data from EXP-20 board

Set Flag for using SSH-4 accesory board

1.3.2 Mode Parameter Descriptions

The following section provides a much more detailed description of the functions and uses

of each of these modes. Arguments marked with

marked with ‘<-’ are return values. Any arguments which are not specified, or are marked with

the value ‘X’ are don’t care arguments.

‘->’ are values passed to the driver. Those

1.3.2.1 Mode 0: Initialize the DAS-20

Mode 0 sets the DAS-20’s Base Address, DMA channel, and interrupt level. Mode 0 also resets

the A/D and sample control queue, sets the input gain to 1X, Bipolar, selects input channel

0, and resets the timer (see initialize timer function).

performed before any other “calls” are made to the DAS-20 driver. Trying to execute any other

call before executing a Mode 0 call will generate FLAG% =l, Driver not initialized error.

example of using Mode 0 is shown in example program EXO.BAS which has been included on

the DAS-20 software disk.

On entry the following parameters should be assigned:

MD% -> 0

DIO%(O) -> BASE ADDRESS

DIO%( 1) -> Interrupt Level

DI0%(2) -> DMA channel

FLAG% <-

Error checking flag, the value

before the call does not matter

‘Mode 0

‘usually &H300

‘2 through 7

‘1 or3

A mode 0 initialization call must be

An

-4-

Page 10

The following error codes apply to mode O:-

FLAG% = 0

Error #l will occur if you have specified an I/O address that is less than 512 (Hex 200) or

greater than 1008 (Hex 3FO). I/O addresses below Hex 200 are used internally by devices

on the IBM P.C. system board and would always cause an address conflict and I/O addresses

above Hex 3FF are not decoded on the IBM P.C. Error #2 will occur if you have

specified a non-valid interrupt level.

correspond to 2 thru 7. Certain of these levels may be in use by other peripheral devices

(especially level 6 used by floppy disk drive). A,list of the standard IBM interrupt assignments

is:-

Level 2 Level 3 Level 4 Level 5 Level 6 Level 7 -

If you do not have a particular device installed, it is safe to assume that that level is available

for use by DAS-20. The lower the level number, the higher the interrupt priority. Note that

the interrupt will not be enabled unless you enter a mode which requires interrupts for

operation. If you are not going to make use of interrupts any level can be chosen e.g. DIO%( 1)

= 2.

=-

1 (mode number out of range, <O or >29)

=

=:.

=3

=

-3 (Board not present, I/O address wrong)

Reserved (but not used) by Color Graphics adapter

Serial I/O - used if COM2: installed.

Serial I/O - used if COMl: installed.

Printer - may be used by LPT2: if installed.

Always in use by disk drives

Printer - may be used by LPTl: if installed.

(no error, o.k.)

(base address out of range 412 or >1008)

(interrupt level <2 or >7)

(DMA level not 1 or 3)

The available levels on the P.C. expansion bus

Error #3 is obtained if you specify a DMA level other than 1 or 3. There are 4 DMA levels

available on the IBM P.C. (see Appendix E of the DAS-20 Manual), the highest priority is

internally used for dynamic memory refresh and is not accessible to the user. The other

levels 1 thru 3 are available on the expansion bus, but level 2 is always used by the floppy disk

drive(s) and cannot be shared. In hard disk (XT) computers, level 3 may be used by the hard

disk, but depending on the design of the disk controller hardware and fixed disk BIOS, may in

some cases be available. To determine whether your computer’s hard disk uses level 3, run

LEV3.EXE from DOS. In any case level 1 is usually available so if level 3 is used by the hard

disk set DI0%(2) = 1. In floppy disk only machines DI0%(2) can be 1 or 3. Also, note that

DMA requests and the 8237 controller are not enabled until you enter modes 6 or 10. If you are

not using modes 6 or 10, it is irrelevant whether you set DI0%(2) = 1 or 3.

Mode 0 performs several other initializing functions. The Queing RAM sequncer is

cleared. The DAS-20 control and timer counter enable registers are cleared, disabling all

interrupt,DMA and external trigger functions.

as a check on the function and presence of the DAS-20 hardware. If you obtain error -2, it is

either indicative of a hardware fault in the DAS-20 or more commonly a discrepancy between

the base address specified in DIO%(O) and the actual switch setting on the board.

Mode 0 also performs a simple read/write test

-5-

Page 11

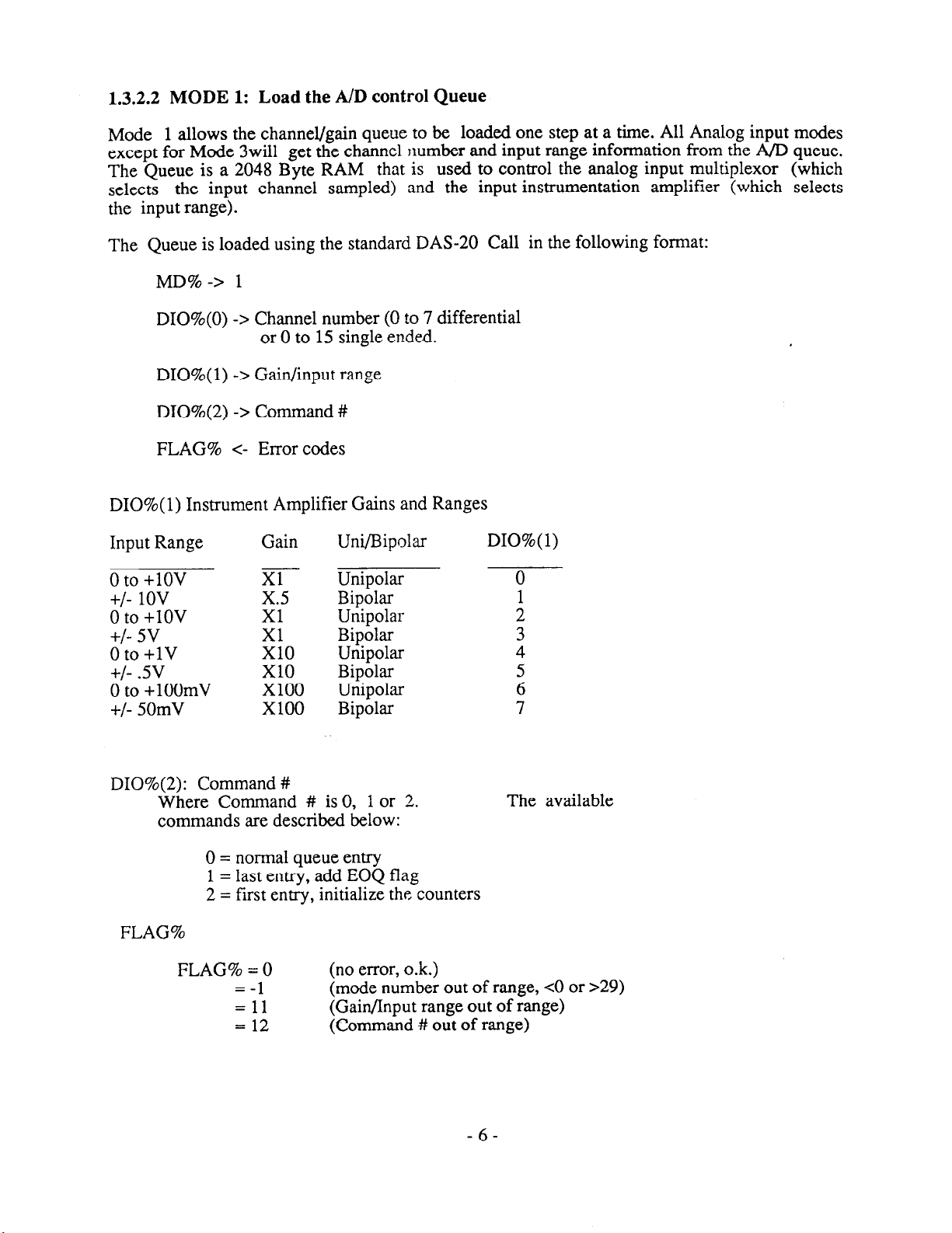

1.3.2.2 MODE 1: Load the A/D control Queue

Mode 1 allows the channel/gain queue to be loaded one step at a time. All Analog input modes

except for Mode 3will get the channel number and input range information from the AfD queue.

The Queue is a 2048 Byte RAM that is used to control the analog input multiplexor (which

selects the input channel sampled) and the input instrumentation amplifier (which selects

the input range).

The Queue is loaded using the standard DAS-20 Call in the following format:

MD%-> 1

DIO%(O) -> Channel number (0 to 7 differential

or 0 to 15 single ended.

DIO%( 1) -7 Gain/input range

DI0%(2) -7 Command #

FLAG% c- Error codes

DIO%( 1) Instrument Amplifier Gains and Ranges

Input Range Gain

0 to

+lOV

+/- 1ov

0

to +lOV

+/- 5v

0 to

+lV

+/- .5v

0

to +lOOmV

+/- 50mV

DI0%(2): Command #

Where Command # is 0, 1 or 2.

commands are described below:

0 = normal queue entry

1 = last entry, add EOQ flag

2 = first entry, initialize the counters

FLAG%

FLAG% = 0

=-

1

= 11

= 12

Xl

x.5

Xl

Xl

x10

x10

Xl00

x100

Urn/Bipolar DIO%( 1)

Unipolar

Bipolar

Unipolar

Bipolar

Unipolar

Bipolar

Unipolar

Bipolar

The available

(no error, o.k.)

(mode number out of range, <O or 729)

(Gain/Input range out of range)

(Command # out of range)

-6-

Page 12

The first entry (when DI0%(2) is 2) automatically re-initializes the DAS-20 counters, The

second and subsequent (DI0%(2)

entry (DI0%(2)

and reading the sampling

= 1) automatically inserts an EOQ (End Of Queue) bit. An example of loading

Queue has been provided on the DAS-20 software disk.

= 0) entries simply load the queuing RAM, while the final

1.3.2.3 MODE 2: View the current queue

Mode 2 allows the current RAM Queue to be read. When DIO%(2) is 0, the Queue pointer is

automatically incremented after the read so that the next read will be of the next Queue location.

To reset the Queue pointer to 0, issue the same call with DI0%(2) = 1. An exampleof loading

and reading the Queue has been provided in the EXl.BAS program included on the DAS-20

disk.

Arguments:

MD% -7 2

DIO%(O) <- channel number

DIO%(l) c- Gain

DI0%(2) -7 Command #

DI0%(2) <- EOQ condition

Where “Command #” operates as follows:

0 = get next queue command

2 = reset and return to first command in the

queue

On Return, DI0%(2) will be:

,O -- End of Queue bit not set

--

1

End of Queue bit set

FLAG% <- Errors

0 = (No Error)

-1 = (Mode # out of Range)

1 = (Gain out of range)

2 = (Command # out of range)

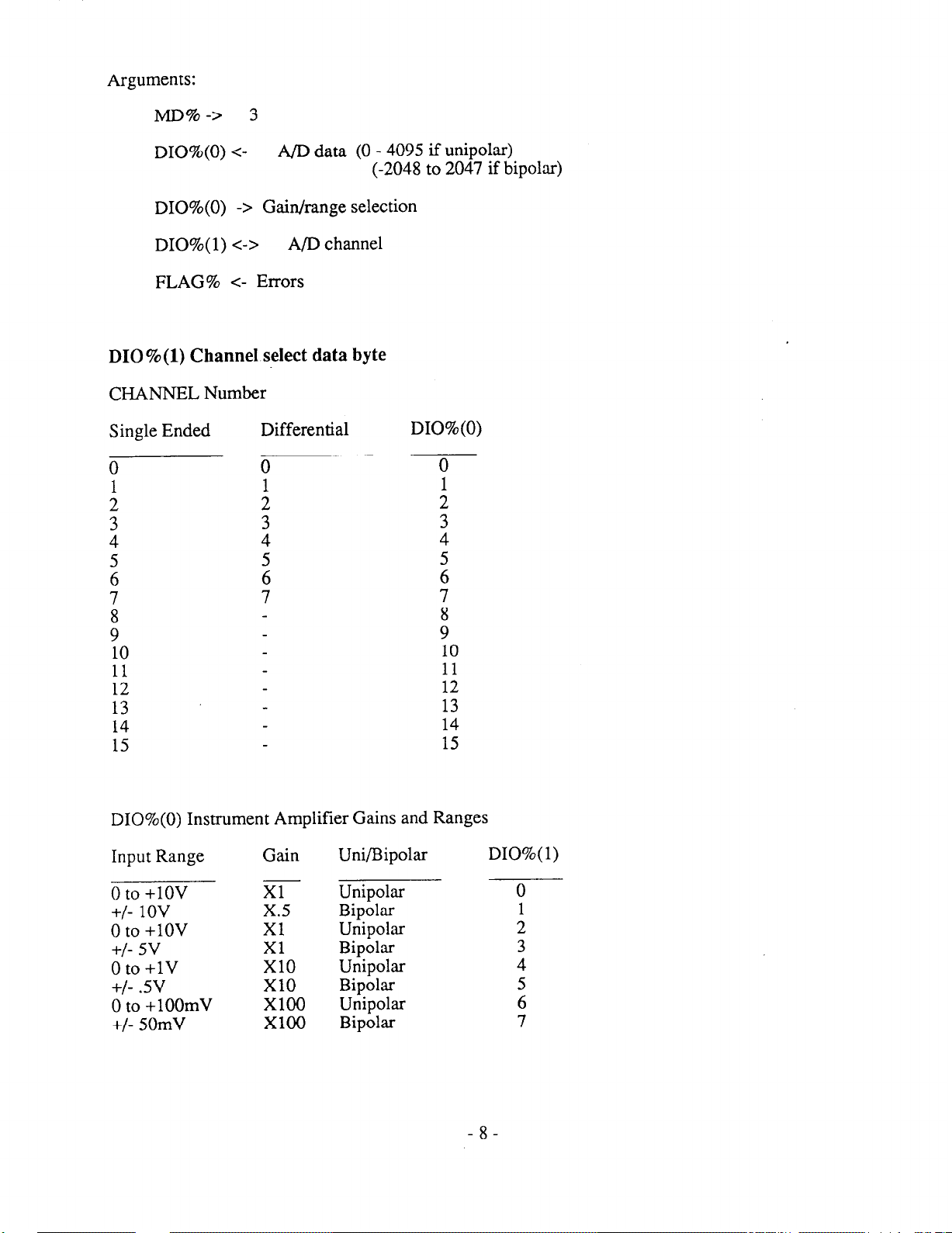

1.3.2.4 MODE 3: Perform a Single A/D Conversion

Initialize the A/D converter, set the channel and input range desired, wait for completion, and

return data. Note that this is the only mode that does not perform conversions based on the

Queuing RAM.

- 7 -

Page 13

Arguments:

MD%-7 3

DIO%(O) <-

DIO%(O) -7 Gain/range selection

DIO%( 1) c-7 A/D channel

FLAG% <- Errors

A/D data (0 - 4095 if unipolar)

(-2048 to 2047 if bipolar)

010%(l) ChanneI select data byte

CHANNEL Number

Single Ended

0

1

;

Differential

0

4

5

6

7

t

10

DIO%(O)

0

1

i

4

z

7

8

9

10

::.

13

14

15

DIO%(O) Instrument Amplifier Gains and Ranges

Input Range

0 to +lOV

+/- 1ov

0 to +lOV

+/- 5v

0 to +lV

+/- .5v

0 to +lOOmV

+/- 50mV

Gain

Xl

x.5

Xl

EO

x10

x100

x100

Uni/Bipolar DIO%( 1)

Unipolar 0

Bipolar

Unipolar

Bipolar

Unipolar

Bipolar

Unipolar

Bipolar

-8-

1

2

3

4

5

6

7

Page 14

FLAG% <- Errors (if any)

=

=

-! Hardware error

=,311

= 32

No Errors

Mode # out of range

Gain/input range out of range

Chnnel # out of range (note that if a channel

# between 8 and 15 is entered, and the board

is set to 8 channel Diff operation this error

will result

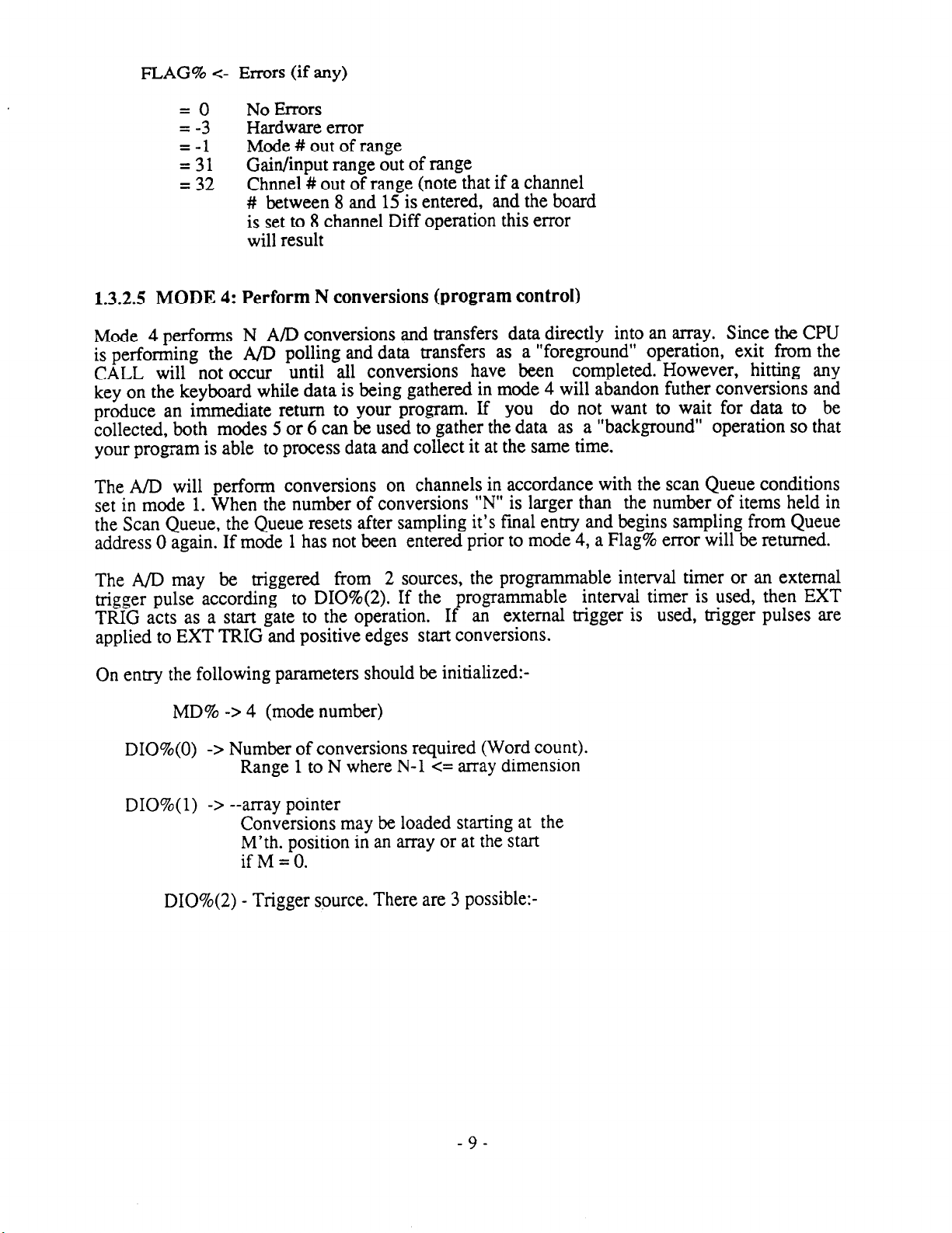

1.3.2.5 MODE 4: Perform N conversions (program control)

Mode 4 performs N A/D conversions and transfers data directly into an array. Since the CPU

is performing the A/D polling and data transfers as a “foreground” operation, exit from the

CALL will not occur until all conversions have been completed. However, hitting any

key on the keyboard while data is being gathered in mode 4 will abandon futher conversions and

produce an immediate return to your program. If you do not want to wait for data to be

collected, both modes 5 or 6 can be used to gather the data as a “background” operation so that

your program is able to process data and collect it at the same time.

The A/D will perform conversions on channels in accordance with the scan Queue conditions

set in mode 1. When the number of conversions “N” is larger than the number of items held in

the Scan Queue, the Queue resets after sampling it’s final entry and begins sampling from Queue

address 0 again. If mode 1 has not been entered prior to mode 4, a Flag% error will be returned.

The A/D may be triggered from 2 sources, the programmable interval timer or an external

trigger pulse according to DI0%(2). If the programmable interval timer is used, then EXT

TRIG acts as a start gate to the operation.

If an external trigger is used, trigger pulses are

applied to EXT TRIG and positive edges start conversions.

On entry the following parameters should be initialized:-

MD% -> 4 (mode number)

DIO%(O) -7 Number of conversions required (Word count).

Range 1 to N where N-l c= array dimension

DIO%( 1) -7 --array pointer

Conversions may be loaded starting at the

M’th. position in an array or at the start

if M = 0.

DI0%(2) - Trigger source. There are 3 possible:-

-9-

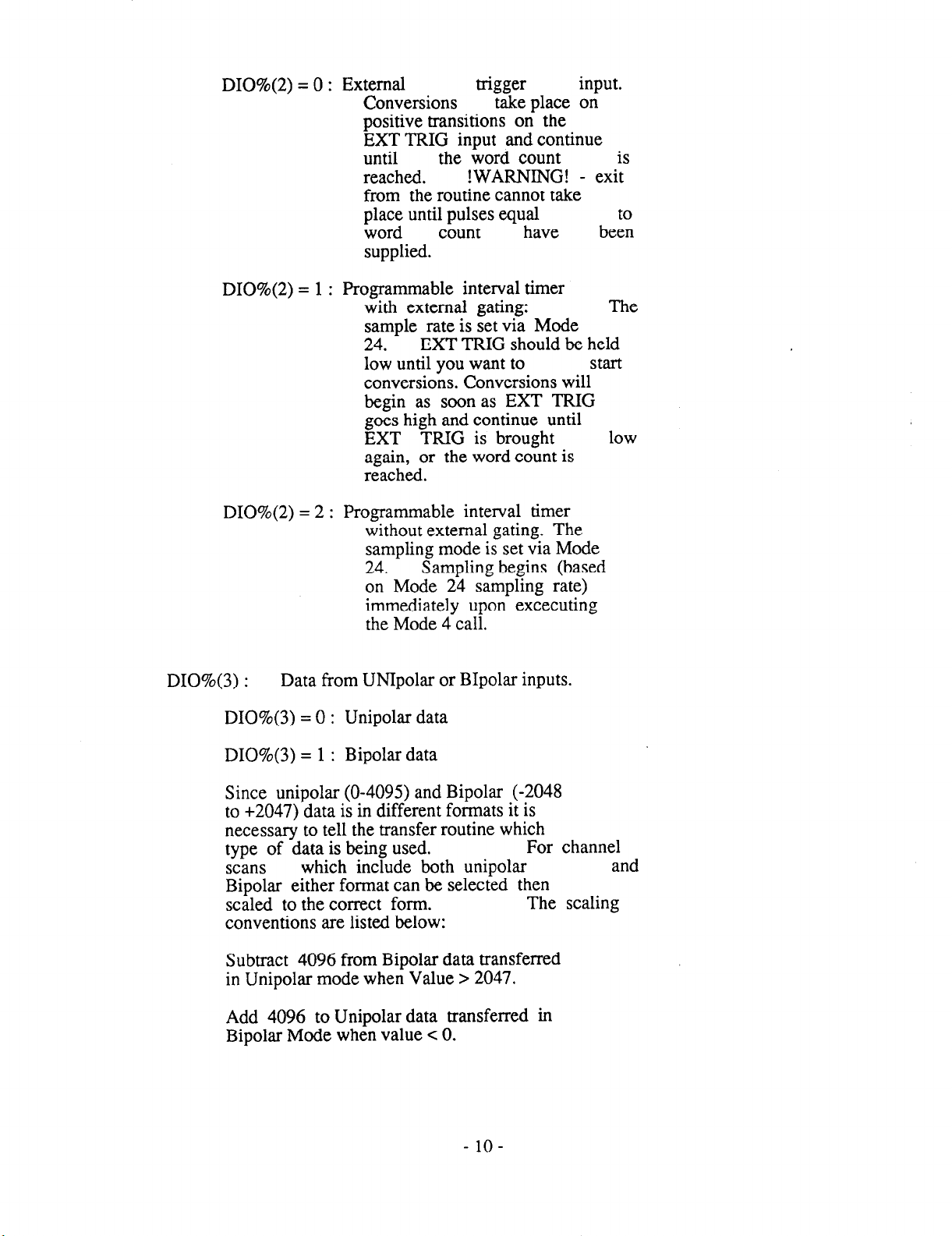

Page 15

DI0%(2) = 0 : External

Conversions

positive transitions on the

EXT TRIG input and continue

until

reached.

from the routine cannot take

place until pulses equal

word count

supplied.

DI0%(2) = 1 : Programmable interval timer

with external gating:

sample rate is set via Mode

24.

low until you want to

conversions. Conversions will

begin as soon as EXT TRIG

goes high and continue until

EXT TRIG is brought

again, or the word count is

reached.

DI0%(2) = 2 : Programmable interval timer

without external gating. The

sampling mode is set via Mode

24.

on Mode 24 sampling rate)

immediately upon excecuting

the Mode 4 call.

EXT TRIG should be held

Sampling begins (based

trigger

take place on

the word count *

!WARNING! - ex?

have

input.

be:

The

start

low

DI0%(3) :

DI0%(3) = 0 : Unipolar data

DI0%(3) = 1 : Bipolar data

Since unipolar (o-4095) and Bipolar (-2048

to +2047) data is in different formats it is

necessary to tell the transfer routine which

type of data is being used.

scans

Bipolar either format can be selected then

scaled to the correct form.

conventions are listed below:

Subtract 4096 from Bipolar data transferred

in Unipolar mode when Value 7 2047.

Add 4096 to Unipolar data transferred in

Bipolar Mode when value < 0.

Data from UNIpolar or Bipolar inputs.

For channel

which include both unipolar

The scaling

and

- lo-

Page 16

The following error codes apply to mode 4:-

FLAG% = 0 (no error, o.k.)

=

-2 (driver not initialized)

=

-1 (mode number out of range, <O or 729)

= 41

= 43 (trigger mode not 0 or 1)

(number of conversions 0 or negative)

1.3.2.6 MODE 5: Multiple A/D conversions-- Interrupt driven

Mode 5 performs N A/D conversions triggered either externally or by the programmable

timer. At the end of each conversion, an interrupt is generated that invokes an interrupt handler

routine installed by this mode. This routine transfers the data from each conversion to a

specified segment of memory and keeps track of the total number of conversions performed.

When the number reaches N, as specified by DIO%(O), interrupts are disabled if in the nonrecycle mode (DI0%(3)=0), or the process is repeated continuously to the same segment of

memory if DI0%(3) specifies the recycle mode. Note that once mode 5 has enabled interrupts,

conversions continue regardless of what other programs the user may be running (although

they should not interfere either with the location of the DAS20.BIN driver or the A/D data

area). For this reason it is termed a background operation and in most respects is

functionally similar to mode 6 (D.M.A.) although much slower. About 3000 samples/set. are

possible in mode 5.

The A/D will perform conversions on channels in accordance with the scan Queue that must

be set by mode

1. When the number of conversions “N” is larger than the number of items held in the Scan

Queue, the Queue resets after sampling it’s final entry and begins sampling from Queue address

0 again.

The A/D may be triggered from 2 sources, the programmable interval timer or an external

trigger pulse according to DI0%(2). If the programmable interval timer is used, then EXT

TRIG acts as a start gate to the operation. If an external trigger is used, trigger pulses are

applied to EXT TRIG, positive edges start conversions.

On entry the following parameters should be initialized:-

MD% -7 5 (mode number)

DIO%(O) = Number of conversions required (Word count).

Range 1 to N, where N can range from 1 to

32766.

items in the sample Queue,

automatically resets the Queue pointer, and

continues sampling.

DIO%( 1) = Segment of

When N is larger than the number of

the program

memory to

receive

data.

- ll-

Page 17

DI0%(2) - Trigger source. There are 3 possible:-

DI0%(2) = 0 : External

Conversions take place

positive transitions on the

EXT TRIG input and continue

until

reached.

DI0%(2) = 1 : Programmable interval timer

with external gating:

sample rate is set via Mode

24.

low until you want to

conversions. Conversions will

begin as soon as EXT TRIG

goes high and continue until

EXT TRIG is brought

again, or the word count is

reached.

DI0%(2) = 2 : Programmable interval timer

without external gating. The

sampling mode is set via Mode

24.

on Mode 24 sampling rate)

immediately upon excecuting

the Mode 5 call.

EXT TRIG should be held

Sampling begins (based

trigger

the word count is

input.

on

The

start

low

Since Mode 5 is a background task, the foreground program may stop the A/D collection

at any time by executing a Mode 11 call. If the Mode 5 operation is being internally paced,

Mode 26 (stop A/D clock) should also be called.

DI0%(3) - Single cycle/Re-cycle operation:-

DI0%(3) = 0 : Re-cycle. In this case data

is continuously written to

DIO%(O)

stopped by

the

DI0%(3) = 1 : One cycle. After completion

DI0%(4) = X

FLAG% = X

the same memory.

corresponds to the memory

“buffer” length. The status

of the operation is 1 =

active

mode 11.

of the number of conversions

specified,

disabled,

operation status to zero.

(value does not matter)

(value does not matter)

until

interrupts are

setting

- 12-

Page 18

The following error codes apply to mode 5:-

FLAG% = 0

=

-2

=

-1 (mode number out of range, CO or 729)

= 50 (Interrupt or D.M.A. already active)

=51 (number of conversions 0 or negative)

= 53 (Trigger input out of range)

=54

(no error, o.k.)

(driver not initialized)

(Recycle flag not 0 or 1)

1.3.2.7 MODE 6: Multiple A/D samples with DMA data transfer.

Mode 6 performs “N” A/D conversions triggered either externally or by the programmable

timer, and at the end of each conversion, a direct memory transfer from the A/D to memory is

performed under the control of the IBM P.C. 8237 D.M.A. controller. This device transfers

the data from each conversion to a specified segment of memory and keeps track of the total

number of conversions performed without involving the 8088 CPU. When the number reaches

N, as specified by DIO%(O), D.M.A. transfers cease and a terminal interrupt is generated if in

the non-recycle mode (DI0%(3), or D.M.A. transfers are repeated continuously to the same

segment of memory if DI0%(3) specifies the re-cycle (auto-initialize) mode. Note that once

mode 6 has enabled D.M.A., conversions continue regardless of what other programs the user

may be running.

background operation and is extremely fast. Throughput is limited by the speed of the A/D

converter and settling of the sample hold. Using the Harris HI-774 A/D converter, the DAS-20

can sustain a throughput slightly in excess of 100,ooO samples/set. A technical description of

the IBM P.C. D.M.A. arrangements is contained in Appendix E of the DAS-20 Manual.

D.M.A. is performed purely by the system and DAS-20 hardware, is a

The A/D will perform conversions on channels in accordance with the scan Queue set in mode

1. When the number of conversions “N” is larger than the number of items held in the Scan

Queue,

address 0 again. If mode 1 has not been entered prior to mode 6, a FLAG% error will be

generated and no conversions will be performed.

the Queue resets after sampling it’s final entry and begins sampling from Queue

NOTE: The DAS-20’s input instrumentation amplifier has been designed for low noise,

high gain, and high speed performance.

However, in order to minimize noise at high

gains, the input bandwidth has been reduced. To assure accurate readings the following

maximum sample rates at higher gains should be observed.

Input Range

Oto 1ov

-t/- 10 v

+/- 5 v

o-1 v

+/- 0.5 v

Oto 1OOmV

+/-50 mV

Maximum Recommended

sample rate

100,000 samples/set

100,000 samples/set

100,000 samples/set

80,000 samples/set

80,000 samples/set

40,000 samples/set

40,000 samples/set

- 13-

Page 19

On entry the following parameters should be initialized:-

MD% -7 6 (modenumber)

DIO%(O) -7 Number of conversions required (Word count).

Range 1 to N, where N can range from 1 to

32766. When N is larger than the number of

items in the sample Queue, the program

automatically resets the Queue pointer, and

continues sampling.

DIO%( 1) -7 Segment of memory to receive data.

DI0%(2) -7 Trigger source. There are 3 possible:-

DI0%(2) = 0 : External trigger input.

Conversions take place on

positive transitions on the

EXT TRIG input and continue

until the word count is

reached.

DI0%(2) = 1 : Programmable interval timer

with external gating: The

sample rate is set via Mode

24.

EXT TRIG should be held

low until you want to start

conversions. Conversions will

begin as soon as EXT TRIG

goes high and continue until

EXT TRIG is brought low

again, or the .word count is

reached.

DI0%(2) = 2 : Programmable interval timer

without external gating. The

sampling mode is set via Mode

24.

Sampling begins (based

on Mode 24 sampling rate)

immediately upon excecuting

the Mode 6 call.

Since Mode 6 is a background task, the foreground program may stop the A/D collection at

any time by executing a Mode 11 call. If the Mode 5 operation is being internally paced, Mode

26 (stop A/D clock) should also be cal.led.

- 14-

Page 20

DI0%(3) -7 Single cycle/Recycle operation:-

DI0%(3) = 0 : Re-cycle. In this case data

is continuously written to

the same memory.

corresponds to the memory

“buffer”

corresponds

auto-initialize

To end the acquisition, mode

11 must be run.

DI0%(3) = 1 : One cycle. After completion

of the number of conversions

specified, DMA ceases, an

interrupt is generated and

DMA is disabled, setting the

DMA status to zero.

length.

to

DIO%(O)

This

a D.M.A.

operation.

DI0%(4) = X

The following error codes apply to mode 6:-

FLAG% = 0

=

1

==6;

= 61

= 63

Several details apply to the reliable use of mode 6. First, you cannot re-run mode 6 if a mode 5

interrupt or a previous mode 6 D.M.A. operation is still active. Error #60 will result. If you

request the recycle mode which generates continuous D.M.A. transfers, then mode 11 which

disables D.M.A. and interrupts must be run before you can succesfully run mode 6 again. If you

are in non-recycle mode, then it must have reached the word count which automatically disables

D.M.A. before mode 6 can be run again.

D.M.A. request (DRQ) drivers of the DAS-20 are placed in the high impedance state. This

allows more than one hardware device, or multiple DAS-20’s to use the same D.M.A. level as

long as they do so sequentially.

Second, since the D.M.A. page registers

maximum data area available is 64K (a page) for 32,767 conversions. Be sure that your data

area is not in use by your program or altered by subsequent operations. Also be careful that

your word count added to your segment will not cross a page boundary. This condition

which would otherwise cause a wrap round to the beginning of the page is detected by the

driver and produces error #67. To avoid this, a conservative rule is to use a segment that is also

a page boundary e.g. &HlOOO, &H2000 etc. Data may be retrieved using mode 13 during or

after the operation of mode 6 and mode 13 will not alter the memory.

(no error, o.k.)

(driver not initialized)

(mode number out of range, <O or 729)

(Interrupt or D.M.A. already active)

(number of conversions 0 or negative)

(Trigger out of range)

(value does not matter)

On completion of a D.M.A. operation, the n-i-state

cannot be incremented by the controller, the

Note that once DMA operation is initiated, it may well continue during or following execution

of the program. This

is a “background” operation.

- 15-

Strange effects can occur if you

Page 21

inadvertently transfer data into your program area,

be sure to use a free area of memory for

your DMA buffer. DEBUG can help you locate free areas, they are usually loaded with zeroes

on boot-up.

If you require to transfer more data than can be held in one 64K data segment, MetraByte is

currently in development of an optional data streamer software (STREAM-16) which has

been specially devised to perform continuous transfer through a D.M.A. buffer to hard disk.

With this software it is possible to continuosly stream “gapless” data to your hard disk at more

than 5OKHz on a PC/AT (somewhat slower on an XT). A standard 20 Megabyte hard disk will

hold about 3 minutes of data at 5OKHz. The maximum speeds attainable are dependent on the

type of your disk controller and manufacturer of your hard disk - contact MetraByte for

further information. Call MetraByte for availablility information on the STREAM- 16 package.

1.3.2.8 MODE 7: Command a Single D/A conversion

Mode 7 performs a write to one of the D/A converters.

MD% -7 7

DIO%(O) -7 D/A channel (0 or 1)

DIO%( 1) -7 D/A data (0 - 4095 for unipolar)

(-2048 to 2047 for Bipolar)

FLAG% = 0 (no error, o.k.)

=

=-

=71

1

1

(driver not initialized)

(mode number out of range, <O or 729)

(D/A channel # not 0 or 1)

= 72 (D/A data out of range, <O or >4095)

1.3.2.9 MODE 8: Load Memory Segment for D/A conversion.

Mode 8 has been developed to allow the user to load a segment of memory in preparation

for writing the data out to the DAS-20 D/A converters. Each conversion requires two bytes

of memory to be stored. This allows up to 32,768 conversions (single D/A), or 16,384

conversions (both D/A’s) to be loaded into a 64 KiloByte page of memory.

Arguments:

MD%-7 8

DIO%(O) ->

DIO%(l) -7

Number of Data words (conversions)

to transfer.

Memory Segment Address for raw data

- 16-

Page 22

DI0%(2) -7

Starting offset for entering data

into the raw data buffer. DI0%(2)

will usually be 0, and the first

data word will be written into the

first buffer location.

some instances, when data is being

taken from more than one array, it

is necessary to load one array into

memory,

immediately following the first.

then load another array

However, in

DI0%(3) ->

FLAG% <- Errors

FLAG% = 0

Pointer to array containing

the data to write to the D/As.

may be found by executing

(no error, o.k.)

(driver not initialized)

(mode number out of range, ~0 or 729)

(Word count zero or >32766)

(Segment address out of range)

(Start offset out of range)

(Data pointer out of range)

=

=-

=8;

=81

1;;

pointer

the following instructions:

1

The

1.3.2.10 MODE 9: Multiple Interrupt D/A conversions

Mode 9 performs “N” D/A conversions based on interrupt control. Data is read directly

from memory (loaded by Mode 8) and written to the D/A converters. If Mode 8 was set to

load data for both D/A’s than Mode 9 must also select two channel operation. However, if Mode

8 only loaded data for one D/A channel,

update rate for D/A conversions can be set with Mode 25, or by an external signal.

Mode 9’s channel select can select either D/A. The

The following variables are defined by Mode 9:

MD% -> 9

DIO%(O) -7 Number of conversions

DIO%( 1) -7 Segment address of buffer

- 17-

Page 23

DI0%(2) -> Trigger source:

DI0%(2) = 0

DI0%(2) = 1

DI0%(2) = 2

DI0%(3) -7 Recycle flag

0 = restart on Nth conversion

X = terminate on X* cycle of

N conversions.

DI0%(4) -7 Channel select

0 = channel 0

1 = channel 1

2 = both channels

External trigger.

conversion is started on each

rising edge of the DAC TRIG

pin. (pin 29)

Internal Trigger w/ external

gating.

initiated based on the clock

rate set in Mode 25, and

gated by the EXT GATE pin.

Internal

external

conversion is initiated based

on the Mode 25 clock rate.

A D/A

A conversion is

Trigger without

gating.

A

FLAG% <- Error Codes

FLAG% = 0

=

1

.

=

=&

=91

=92

= 93

= 94

= 95

(no error, o.k.)

(driver not initialized)

(mode number out of range, <O or 729)

(Interrupt already active)

(Word count zero or 732767)

(Buffer address out of range)

(Trigger source not 0, 1, or 2)

(Recycle flag out of range)

(D/A channel not 0,l or 2)

1.3.2.11 MODE 10: DMA driven D/A conversions

Mode 10 performs

directlv from memory (loaded by Mode 8) and written to the D/A converters. If Mode 8 was set

to load data for both D/A’s than Mode 10 must also select two channel operation. However,

if Mode 8 only loaded data for one D/A channel,

select either channel 0 or 1.

The update rate of the D/A conversions can be set by the internal pacer clock (and Mode 25) or

can be synchronized to an external trigger.

“N” D/A conversions based on DMA data transfers. Data is read

Mode 10’s channel select control can

- 18-

Page 24

The following variables are defined by Mode 10:

MD% -> 10

DIO%(O) -> Number of conversions

DIO%( 1) -> Segment address of buffer

DI0%(2) -> Trigger source:

DI0%(2) = 0

DI0%(2) = 1

DI0%(2) = 2

DI0%(3) -> Recycle flag

0 = restart on Nth conversion

X = terminate on P cycle of

N conversions.

DI0%(4) -> Channel select

0 = channel 0

1 = channel 1

2 = both channels

External trigger. A D/A

conversion is started on each

rising edge of the DAC TRIG

pin. (pin 29)

Internal Trigger w/ external

gating. A conversion

initiated based on the clock

rate set in Mode 25, and

gated by the EXT GATE pin.

Internal Trigger without

external gating. A

conversion is initiated based

on the Mode 25 clock rate.

is

FLAG% c- Error Codes

FLAG% = 0

=

1

== lb0

=

101

= 102

= 103

= 104

= 105

(no error, o.k.)

(driver not initialized)

(mode number out of range, <O or >20)

(Interrupt already active)

(Word count zero or >32767)

(Buffer address out of range)

(Trigger source not 0, 1, or 2)

(Recycle flag out of range)

(D/A channel not 0,l or 2)

- 19-

Page 25

1.3.2.12 MODE 11: Cancel DMA or Interrupt

Mode 11 causes an immediate disable of any rurl.ling interrupt or D.M.A. operation

initiated by modes 5,6,9 or 10. The operation will be abandoned at the time mode 11 executes.

On entry the following parameters should be initialized:-

MD%-> 11

DIO%(O) -> X (where X = any value)

FLAG% <- Errors (if any)

The following error codes apply to mode 11:

FLAG% = 0

=-

1

(no error, o.kJ

(mode number out of range, ~0 or >29)

1.3.2.13 MODE 12: Determine Status of interrupt/DMA

Mode 12 allows you to monitor the status of a background operation initiated by modes

5, 6,9 or 10.

Arguments:

MD% -> 12

DIO%(O) c- operation type in progress

0 - none

l-DMA,

2 - interrupt,

DIO%( 1) <- status of operation

0 - Done (finished)

1 - Active

DI0%(2) <- current word count

Number of conversions so far

The following. error codes apply to mode 12:-

FLAG% = 0

=

=-

-2

(no error)

(driver not initialized)

(mode number out of range, ~0 or >27)

1

- 20 -

Page 26

1.3.2.14 MODE 13: Transfer data from memory to array

Mode 13 transfers data from any segment of memory to integer array variables. Data in

memory derived from modes 5, 6 and 27 is in packed form consisting a word (2 bytes) of A/D

data + channel number.

Note how mode 13 functions. The number of words (or conversions) that you wish to transfer

to the data and channel arrays is set into DIO%(O). The segment of memory that you wish to

transfer data from is set into DIO%(l). Data can be transferred from the beginning of this

segment (DI0%(2) = 0) or any other point. A/D data is transferred to a dimensioned integer

array. The transfer will start at the pointer set into DI0%(3).

A/D data is shifted and also the MSB complimented if the DAS-20 is operating in bipolar mode.

In unipolar mode data ranges from 0 to 4095, in bipolar -2048 to +2047. The channel data is

masked out and ranges from 0 - 15.

Note that you must be careful about the transfer parameters. In particular:-

1: Do not transfer more words than an array will hold

or overun the end of the array. No checking is

performed to detect this condition which will

corrupt BASIC workspace and cause strange effects.

2: There is nothing to prevent you transferring

garbage from a source segment that does not

contain A/D data or from overrunning the end of

A/D data. No checking is performed to detect this

condition.

3: Due to the reformatting of data that this mode

performs, it is not a general purpose block move

utility.

On entry the following parameters should be assigned:-

MD% = 13 (mode number)

DIO%(O) -> Number of words to transfer (1 - 32767)

(Number of Scans if DI0%(5) > 0)

DIO%( 1) -> Buffer segment in memory (0 - 65536)

DI0%(2) -> Starting conversion number (0 - 32767)

(Starting Scan # if DI0%(5) > 0)

DI0%(3) -> Array Pointer (data)

DI0%(4) -> Array Pointer (channel)

(set = 0 if no channel data required)

DI0%(5) -> Unipolar/Bipolar Flag.

-2l-

Page 27

= 0 (transfer unipolar data)

= 1 (transfer Bipolar data)

Since unipolar (o-4095) and Bipolar (2048 to +2047) data is in different

formats it is necessary to tell the

transfer routine which type of data is

being used.

include both unipolar and Bipolar either

format can be selected then scaled to the

correct form.

are listed below:

For channel scans which

The scaling conventions

Subtract 4096 from

transferred in Unipolar mode for data > 2047.

Add 4096 to Unipolar data transferred in

Bipolar Mode when value < 0.

DI0%(6) -> SSH-4,Flag. If the input data has been

acquired using the SSH-4, set DI0%(5) to

the number of channels in each scan.

This removes the Dummy first converseion

in each SSH-4 scan. Otherwise, DIO%(O) =

0.

FLAG% = X (value does not matter)

The following error codes apply to mode 13:-

FLAG% = 0

=

-2

== 131 (word count, DIO%(O), zero or negative)

= 132 (buffer Segment out of range)

= 133 (start conversion number, DI0%(2), negative)

= 134 (DI0%(3) out of range)

= 135 (DIO%(4) out of range)

= 136 (SSH-4 Flag out of range)

(no error)

(driver not initialized)

(mode number out of range, CO or >29)

1

Bipolar

data

Once data acquisition has been set up as a constant background operation using the recycle

options of mode 5 or 6, a foreground program can be processing the data as it is acquired using

mode 13 to retrieve the data. This is excellent for graphic and “digital oscilloscope”

applications.

- 22 -

Page 28

1.X2.15 MODE 14: Read the Digital inputs

Mode 14 allows you to read the state of digital inputs DIN0 through DIN7. Data returned

can range between 0 and 255 corresponding to all combinations of the 8 input bits.

On entry the following parameters should be initiaiized:-

MD%=14

DIO%(O thru 4) - value does not matter

FLAG%=X -

On return:

DIO%(O) contains input data (range 0 - 255)

DIO%(l thru 4) - unchanged

The following error codes apply to mode 14:-

FLAG% = 0

=

-2

=

-1

value does not matter

(no error, o.k.)

(driver not initialized)

(mode number out of range, <O or >29)

1.3.2.16 MODE 15: Write to the Digital outputs.

Mode 15 is used to write digital data to the 8 bit output port, DOUTO through DOUT7.

Output data is checked to be in the range 0 - 255 and if not an error exit (error # 151) occurs.

On entry the following parameters shouid be assigned:-

MD%=15

DIO%(O)

DIO%(l thru 4) - value does not matter

The following error codes apply to mode 15:-

FLAG% = 0

=

-2

=

-1

=

151

(no error, o.k.)

(driver not initialized)

(mode number out of range, CO or >29)

(output data ~0 or >255)

- output data (range O-255)

- 23 -

Page 29

1.3.2.17 MODE 16: Analog trigger

Mode 16 provides an analog trigger function similar to an oscilloscope trigger. It is

sometimes useful to wait for a voltage to reach a certain level before starting to ga’&er data

and mode 16 provides this capability. Any of the analog input channels may be designated as a

trigger channel, and you may set the level and slope for triggering. The input range for the

analog triggering mode is always set at _+lO Volts, full scale.

The main use for mode 16 is in front of any of the other data acquisition modes as a gating or

wait loop until the specified analog trigger conditions are met. Since it is possible to get stuck

in the wait loop indefinitely if the trigger conditions are not fulfilled, you can also exit mode 16

by hitting any key which will return you to the calling program.

Parameters DIO%(O) thru DI0%(2) control the triggering and select the trigger channel number,

the trigger level and the

number. It may be one of the scanned channels i.e. within the scan limits and carrying one of the

measured signals,

triggering. The voltage level at which triggering occurs is set by DIO%(l) in bits, ranges of

-2048 to +2047 bits corresponding to bipolar input ranges. The direction of triggering or

slope is controlled by DI0%(2), for instance if DIO%(l) = 1024 on the +/-1Ov range the trigger

level will be +5.OOV and if DI0%(2)

signal exceeds +5.OOV, alternatively if DI0%(2)

place when the trigger signal becomes less than +5.0 Volt.

or a separate channel outside

trigger direction (slope). DIO%(O) specifies the trigger channel

the scanned channels used only for

= 0 (positive slope) triggering will take place when the

= 1 (negative slope) triggering would take

On entry the following variables should be initialized:-

MD%=16

DIO%(O) = Channel number (0- 15)

DIO%( 1) = Trigger level

(-2048 to +2047 bits)

DI0%(2) = Slope (0 = positive, 1 = negative)

DI0%(3) thru DI0%(4) - value irrelevant

The following error codes apply to mode 16:

FLAG% = 0

=

-2

=-

1

= 160

= 161

= 162 (trigger data out of range

= 163

(no error, o.k.)

(driver not initialized)

(mode number out of range, <O or >24)

(Trigger aborted by Keyboard)

(trigger channel out of range)

~2048 or >2047

(slope data not 0 or 1)

- 24 -

Page 30

1.3.2.18 MODE 17: Initialize Timer - Reset timer.

Set counters 3, 4 & 5 to ADC time delays. The AMD9513 counter timer operation are

discussed in much greater detail in chapter 7, and Appendix F of the DAS-20 manual.

Arguments:

MD% -> 17

DIO%(O) -> Don’t Care

FLAG% <-

=o

= -1 (Mode # out of range)

Errors (if any)

(No errors)

1.3.2.19 MODE 18: Set Timer Master Mode Register

Mode 18 sets the AMD9513 to a user specified configuration. Data bus width set to 8

bits, Data pointer

operation are discussed in much greater detail in chapter 7, and Appendix F of the DAS-20

manual.

Arguments:

MD% -> 18

DIO%(O) -> Fout divider ratio (1 - 16)

DIO%(l) -> Fout source

auto increment enabled, Binary division. The AMD9513 counter timer

O=Fl

1 = Source 1

2 = Source 2

3 = Source 3 I

4 = Source 4 I No Connection

5 = Source 5 I

6 = Gate 1

7 = Gate 2

8 = Gate 3 I

9 = Gate 4 I No Connection

10 = Gate 5 I

11 =Fl

12=F2

13=F3

14 = F4

15 =F5

- 25 -

Page 31

DI0%(2) -> Compare 2 disable/enable (O/l)

DI0%(3) -> Compare 1 disable/enable (O/l)

DI0%(4) -> time of day mode control

0 = TOD disabled

1 = TOD Enabled /5 input

2 = TOD Enabled /6 input

3 = TOD Enabled /lO input

FLAG% <- Errors

=o

= -2 (Driver not initialized)

= -1

=

= 182 (DIO%( 1) out of range)

= 183 (DI0%(2) not 0 or 1)

= 184 (DI0%(3) not 0 or 1)

= 185 (DI0%(4) out of range <O or >3)

(No error)

(Mode out or range CO or >29)

18 1 (DIO%(O) out of range)

1.3.2.20 MODE 19: Set Counter ‘N’ Mode Register

Mode 19 sets counter N to to user specified value. The AMD9513 counter timer operation

are discussed in much greater detail in chapter 7, and Appendix F of the DAS-20 manual.

Arguments:

MD% -> 19

DIO%(O) -> Counter Number (1 - 5)

DIO%(l) -> Gating Control (0 - 7)

0 = No gating

1 = Active high level TCN-1

2 = Active high level Gate N+l

3 = Active high level Gate N-l

4 = Active high level Gate N

5 = Active low level Gate N

6 = Active high edge Gate N

7 = Active low edge Gate N

DIO%(2) -> Count Edge positive/negative (O/l)

- 26 -

Page 32

DI0%(3) -> Count Source Selection (0 - 15)

O=TCN-1

1 = Source 1

2 = Source 2

3 = Source 3 I

4 = Source 4 I No Connection

5=Source51

6 = Gate 1

7 = Gate 2

8 = Gate 3 I

9 = Gate 4 I No Connection

10 = Gate 5 I

11 =Fl

12=F2

13=F3

14=F4

15=F5

DI0%(4) -> Disable/Enable special gate (O/l)

DI0%(5) -> Reload from Load/ReIoad from Load

or Hold (O/l)

DI0%(6) -> Count once/Count repetitively (O/l)

DI0%(7) -> Binary counVI3.C.D. count (O/l)

DI0%(8) -> Count down/Count up (O/l)

DI0%(9) -> Output control (0 - 5, except 3)

0 = Inactive

1 = Active high terminal count pulse

2 = Terminal count toggled

3 = *** Illegal ***

4 = Inactive, output high impedence

5 = Active low terminal count pulse

FLAG% c- Errors

FLAG% <- Errors

=

= -2 (Driver not initialized)

= -1

=

= 182 (DIO%(l) out of range CO or >7)

= 183 (DI0%(2) not 0,or 1)

= 184 (DI0%(3) out of range <O or >15)

= 185

= 186

= 187

= 188

= 189

= 180

(No error)

0

(Mode out or range CO or >29)

181 (DIO%(O) out of range cl or >5)

(DI0%(4) not 0 or 1)

(DI0%(5) not 0 or 1)

(DIO%(6) not 0 or 1)

(DI0%(7) not 0 or 1)

(DI0%(8) not 0 or 1)

(DI0%(9) not 0, 1,2,4

or 5)

- 27 -

Page 33

1.3.2.21 MODE 20: Set Multiple Counter Control Registers

- To user specified value. The AMD9513 counter timer operation are discussed in much

greater detail in chapter 7, and Appendix F of the DAS-20 manual.

Arguments:

MD% -> 20

DIO%(O) -> Command (1 - 6)

1 = Arm selected counter

2 = Load source to counter

3 = Load and arm counter

4 = Disarm and save counter

5 = Latch counter to hold register

6 = Disarm counter

DIO%(l) -> Select Counter 1 (O/l)

DI0%(2) -> Select Counter 2 (O/l)

DI0%(3) -> Select Counter 3 (O/l)

DI0%(4) -> Select Counter 4 (O/l)

DI0%(5) -> Select Counter 5 (O/l)

FLAG% <- Errors (if any)

=o (No errors)

= -2 (Driver not initialized)

= -1 (Mode out of range <O or >29)

= 201 (Command # out of range)

= 202 (Select Counter 1 not

= 203 (Select Counter 2

= 204 (Select Counter 3

= 205 (Select Counter 4

= 206 (Select Counter 5

0 or 1)

not 0 or 1)

not 0 or 1)

not 0 or 1)

not 0 or 1)

1.3.2.22 MODE 21: Set Counter ‘N’ Load Register

- To user specified value. The AMD9513 counter timer operation are discussed in much

greater detail in chapter 7, and Appendix F of the DAS-20 manual.

Arguments:

MD% -> 21

DIO%(O) -> 16 bit value

DIO%(l) -> Counter # (1 - 5)

- 28 -

Page 34

FLtGo% <- errors (if any)

(No errors)

= -2 (Driver not initialized)

= -1 (Mode out of range CO or >29)

= 211 (DIO%(O) out of range)

= 212 (counter out of range <l or >5)

1.3.2.23 MODE 22: Read Counter ‘N’ Hold Register

The AMD9513 counter timer operation are discussed in, much greater detail in chapter 7, and

Appendix F of the DAS-20 manual.

Arguments:

MD% -> 22

DIO%(O) <- 16 bit value

DIO%( 1) -> Counter ‘N’ (1 - 5)

FLAG% <- Errors (if any)

=o (No errors)

= -2 (Driver not initialized)

= -1 (Mode out of range <O or >29)

= 221 (DIO%(O) out of range)

= 222 (counter out of range <l or >5)

1.3.2.24 MODE 23: Measure Frequency

Mode 23 returns frequency expressed as cycles per gating interval. The AMD9513

counter timer operation are discussed in much greater detail in chapter 7, and Appendix F of the

DAS-20 manual. The output of CIT # 1, must be physically jumpered to the Gate of C/T # 2 for

proper operation.

Arguments:

MD% -> 23

DIO%(O) -> Gating interval in mS (0 - 32767)

DIO%( 1) -> Select source input signal (1 - 3)

1 = Source 1

2 = Source .2

3 = Gate 1

DI0%(2) <- Count accumulated during gating interval.

- 29 -

Page 35

FLAGo% c- Errors (if any)

=

= -2 (Driver not initialized)

= -1 (Mode out of range <O or >29)

= 231 (DIO%(O) out of range)

= 232 (Input source out of range <I or >4)

(No errors)

1.3.2.25 MODE 24: Set A/D pacer clock

The A/D timer allows the analog outputs to be updated based on the DAS-20’s onboard 5 Mhz clock. The A/D pacer clock uses the AMD-9513 counter chip to divide the 5 Mhz

clock. The board uses 2 of the AMD-9513’s 16 bit counters allowing the 5 Mhz clock to be

divide by any value from 50 to 4.29 E9 (100 Khz to .00116 hz respectivley). The actual

divisor number will be DIVISOR 1, (DIO%(O)) multiplyed by DIVISOR 2, (DIO%(I). To

obtain an update rate of 100 Khz (5 Mhz divided by fifty), enter a divisor of 10 in

DIO%(O) and 5 in DIO%(l), or ( 5 in DIO%(O) and 10 in DIO%( 1)). For 25 Khz use

DIO%(O) = 4, and DIO%(l) = 50 etc. Note that DIO%(O) may be set zero or one if only one

divisor is required.

Arguments:

MD% -> 24

DIO%(O) -> Divisor 1 (50 - 65536)

DIO%(l) -> Divisor 2 (set = to 0)

FLAG% <- Error Codes

=

0 (no errors)

=

-2 (Driver not initialized)

=-

1 (Mode out of range <O or >29)

= 241 (Divisor 1 out of range)

= 242 (Divisor 2 out or range)

1.3.2.26 MODE 25: SET D/A pacer clock

The D/A timer allows the analog outputs to be updated based on the DAS-20’s on-board 5

Mhz clock. The D/A pacer clock uses the AMD-95 13 counter chip to divide the 5 Mhz clock by

any value from 20 to 232 (250 Khz to Once every 14 minutes). Note that Mode 25 is also used

to set the scan rate for Mode 27. The actual divisor is transfered in DIO%(O) and DIO%(l). If

the total divisor is less than 65536 then 010%(l) can be set to 0. The AMD-9513’s counter 2

is set to divide the 5 Mhz by Divisor # 1.

counter 1 is automatically connected to counter 2, and the total division ratio is the 5 Mhz

divided by Divisor 1 multiplied by Divisor 2. To obtain an update rate of 100 Khz, set Divisor #

1 equal to 50, and Divisor # 2 equal to 0. Alternatively you could set Divisor # 1 to 10, and

Divisor # 2 to 5 and obtain the same result. Note that mode 25 uses AMD-9513 channel 2

If Divisor # 2 is not zero, then AMD-95 13

(and channel 1 if Divisor # 2 is not zero). Counter 2 (and 1 if non-zero Divisor # 2) cannot

- 30 -

Page 36

be used for other timing/counting applications while Mode 25 is being used to pace D/A

conversions

Arguments:

MD% -> 25

DIO%(O) -> Divisor # 1 (1 to 65536)

DIO%(l) -> Divisor # 2 (set to = 0)

FLAG% C- Errors (if any)

The following error codes apply to mode 25:

FLAG% = 0

=

-2 (driver not initialized)

=

-1

= 251 (Divisor # 1 out of range)

= 252 (Divisor # 2 out of range)

(no error)

(Mode out or range ~0 or >29)

1.3.2.27 MODE 26: Stop A/D and D/A pacer clocks

Mode 26 can be used to stop either the A/D or D/A pacer clocks. Modes 24 or 25 will

can then be executed to restart the timers.

MD% -> 26

DIO%(O) -> A/D or D/A clock

DIO%(O) = 0, Stop A/D timer

= 1, Stop D/A timer

=2, Both

FLAG% c- Errors

FLAG% = 0 (no error)

=

-2

== 261 @IO%(O)

(driver not initialized)

1 (Mode out or range ~0 or >29)

not 0, 1, or 2)

1.3.2.28 MODE 27: Perform, “N” scans of a block of channels

Mode 27 performs a block scan of channels. On an input trigger (either from the pacer

clock or an external trigger), the entire Sampling Queue is scanned at the DAS-20’s maximum

sample rate, and the input data is transfered to memory via DMA. The board then waits for the

next trigger and repeats the process. The channels sampled must have been previously set with

a Mode 1 call of a Flag% error will result. This function is very useful in applications where it

is important to have all channels sampled at the same time,

-3l-

but when the overall sample rate

Page 37

need not be extremely high. Note that the same memory limitations apply to Mode 27 as to

Mode 6. The memory used by mode 27 is limited to one Page (64 KiloBytes).

In the block mode counters 3, 4, and 5 are used to control the speed of the A/D

conversions once the command to perform a full scan of the Queue has been given. The

counters are loaded such that the A/D conversions occur as rapidly as possible while still

allowing the input circuitry adequete time to settle.

The start of Scan can be synchronized to the Counter # 2 pacer clock (using Mode 25),

or to an external trigger. At all times within a scan. Note that for proper operation the block

scan time (# of conversions times the internal sample rate) must be less than the period of the

input trigger (the block scan must be completed once before another scan can be performed

again).

Mode 27 is ideally suited for use with the SSH-4 simultaneous sample & hold board. See

Appendix H, for further details on using the SSH-4.

MD% -> 27

DIO%(O) -> Total # of “block” scans

DIO%( 1) -> Segment Address of Buffer

DI0%(2) -> Trigger source. There are 2 possible:-

DI0%(2) = 0 : External interrupt input.

Conversions take place on

positive transitions on the

CTR2 Gate/EXT INT input and

continue until the word

count is reached.

DI0%(2) = 1 : Programmable interval timer

with external gating: The

sample rate is set via Mode

24. CTR2 Gate/EXT TRIG

should be held low until you

want to start

Conversions will begin as

soon as EXT INT goes high and

continue until EXT INT is

brought low again, or the

word count is reached.

DI0%(2) = 2 : Programmable interval timer

without external gating. The

sampling mode is set via Mode

24. Sampling begins (based

on Mode 24 sampling rate)

immediately upon excecuting

the Mode 27 call.

conversions.

- 32 -

Page 38

DIO%(3) -> Single cycle/Re-cycle operation:-

DI0%(3) = N : N cycles. After completion

of the number of scans

specified, DMA ceases, an

interrupt is generated and

DMA is disabled, setting the

DMA status to zero.

DI0%(3) = 0 : Re-cycle. In this case data

is continuously written to

the same memory. DIO%(O)

corresponds to the memory

“buffer” length. This

corresponds to a D.M.A.

auto-initialize

To end the acquisition, mode

11 must be run.

operation.

DI0%(4) = X

DI0%(5) = X

DI0%(6) <--

FLAG% = X

FLAG% = 0

Returns number of channels in

block scan queue, if SSH-4

flag is set, otherwise returns

a 0.

Errors, if any

(no error)

=

-2

== 271 (# of scans out of range)

= 272 (Buffer segment out of range)

= 273 (Trigger source out of range)

= 274 (recycle flag not 0 or 1)

(driver not initialized)

(Mode out or range ~0 or >29)

1

(value does not matter)

(Value does not matter)

1.3.2.29 MODE 28: Using the EXP-20

Use of the EXP-20 with the DAS-20 is greatly simplified by using the mode 28 call.

Mode 28 allows a complete or partial scan of an EXP-20 by combining A/D input control

with Digital output control. Mode 28 allows the user to scan from 1 to 256 EXP-20 channels.

When the number of channels to scan is larger than 16, Mode 28 assumes that there are more

than one EXP-20 installed. As more EXP-20’s are cascaded it is important to note that the

first EXP-20 must be connected to DAS-20 channel # 0, the second to DAS-20 channel # 1,

and soon.

- 33 -

Page 39

The Mode 28 arguments are:

MD% -> 28

DIO%(O) -> DAS-20 Gain/Range

Input Range Gain

0 to

+lOV

+/- 1ov

0 to

+lOV

Xl

x.5

Xl

+/- 5v

0 to

+lV

+/- .5v

0 to

+lOOmV

+/- 50mV

20

x10

Xl00

Xl00

DIO%( 1) -> “N”, the total number of channels

DI0%(2) -> --the array pointer

to the array the data will be loaded

into.

Uni/Bipolar

Unipolar

Bipolar

Unipolar

Bipolar

Unipolar

Bipolar

Unipolar

Bipolar

DIO%( 1)

- 34 -

Page 40

The data returned is of the form 0 to 4095 for

unipolar inputs, and -2048 to +2047 for Bipolar inputs.

The table below shows the scan sequence/assignments for

MODE 28:

DATA DAS -20

Variable Channel

ARRAY%(O)

ARRAY%(l) :

ARRAY%(2) 0

ARRAY%(3)

ARRAY %(4) :

ARRAY %(5)

ARRAY %(6)

ARRAY %(7)

ARRAY%(8) i

AmAYs(g) ii ARRAY%(lO)

ARRAY%(l 1) 0

ARRAY%(12) 0

ARRAY%(13)

ARRAY%(14) i

ARRAY%(lS) 0

ARRAY%(16) 1

ARRAY%(17) 1

ARRAY%(18) 1

ARRAY%(19) 1

ARRAY%(20) 1

ARRAY%(21) 1

ARRAY%(22) 1

. .

i

EXP-20

Channel

A

:

D

E

fi

H

I

J

K

L

M

s

P

A

B

C

D

E

E Two

EXP-20

NUMBER

ONE

EXP-20

NUMBER

ARRAY%(N-1) N/16

*

The last EXP-20 channel scanned will be channel P

only if the total number of channels is evenly divisable

by 16.

FLAG% <- Errors

FLAG% = 0 (no error)

=

-2 (driver not initialized)

=-

1 (Mode out or range CO or >29)

= 281 (DIO%(O) not 0 through 7)

= 282 (Number of channels out of range)

i)*

- 35 -

Page 41

1.3.2.30 MODE 29: Set SSH-4 Flag

Mode 29 sets a flag that is very helpful in applications which utilize the SSH-4

simultaneous sample & hold accesory board. The fast A/D sample in a standard SSH-4 scan

routine is a dummy conversion, and contains no useful data. Setting the SSH-4 flag in mode

29 causes that dummy conversion to be ignored in a Mode 13 transfer of data from Memory into

your program.

Arguments:

MD% -> 29

DIO%(O) -> SSH-4 Flag

= 0 (normal operation)

= 1 (Set SSH-4 Flag)

FLAG% <- Errors

FLAG% = 0 (no error)

=

-2

=

-1 (Mode out or range <O or >29)

(driver not initialized)

= 291 (DIO%(O) not 0 or 1)

1.3.3 SUMMARY OF ERROR CODES

If for any reason the FLAG% variable is returned non-zero, then an error has occurred in the

input of data to the CALL routine.

will be taken if an error condition exists. An immediate return will take place with the error

specified in the FLAG% variable. The only exception to this rule is error type -3 (hardware

failure or installation error), where an attempt will be made to initialize the hardware even if

there appears to be a problem so that other modes may possibly be run to diagnose the

problem.

All positive error FLAG%‘s are returned with the mode number, trailed by an error code. For

example, a FLAG% returned of 61, would signify a type “1” error, found while calling a

Mode 6. Similarly a 143 error would signify a type 3 error in a Mode 14 call.

The following table lists the standard error types. In addition to these errors, some modes

have other applicable error flags.

description

Checking of data occurs first in the routine and no action

For special error codes, please refer to the specific mode

- 36 -

Page 42

Following is a list of standard error codes:-

ERROR TYPE

-3”

-2

-1

FAULT

No error

Hardware Error

Driver Not Initialized before

non-Mode 0 call

Mode number out of range <O or

>29

DIO%(O) out of range

DIO%( 1) out of range

DI0%(2) out of range

DI0%(3) out of range

DI0%(4) out of range

DIO%(S) out of range

DI0%(6) out of range

DI0%(7) out of range

DI0%(8) out of range

DI0%(9) out of range or Special

Mode dependant error.

- 38 -

Page 43

Section 2

DAS-20 PASCAL INTERFACE

The DAS-20 BASIC Interface has been converted to a PASCAL callable Library:

DAS20p.LIB. This was accomplished by removing the BASIC specific despatcher code to a

separate INCLUDE file, DAS20b.ASM and INCLUDing instead the file DAS20p.ASM in

DAS20.ASM. DAS20p.LIB consist of the single OBJ file DAS20.0BJ, which also contains the

routines: SEGADR, OFFADR and ALLOC. SEGADR and OFFADR return the segment and

offset values of a memory buffer. This is very useful in calls to DAS20 from PASCAL. Be sure

todeclare each of these functions as INTEGER*2 in your program. Modes 6 and 7, for example,

require the segment value and assume the offset to be 0, mode 4, 8, 13 etc require the offset

value and assume thesegment to be the same as that of DIO%(). ALLOC(#) allocates a buffer of

# of 16-bit words and returns a far pointer to it. It guarantees paragraph alignment and enough

room for # conversions. i.e.OFFADR(ALLOC(#)) will always = 0 and SEGADR(ALLOC(#)) +

#/16 < O-FFFh.

maximumnumber of conversions in mode 6 or 27.

The PDRAW.LIB Graphics Library has also been included on this disk. It contains the

non-DAS-20

COLOR(i,r,g,b),POINT(x,y) and LINE(xO,yO,xl,y2). “A”n parameters are 16 bit integers. Mode is

the IBM BIOS crt-mode. Intensity, red, green, blue, if non-zero, turn on those color planes when

16 colors are available for that mode. x, y, x0, y0, xl, yl are 16 bit signed integers and represent

screen coordinates in center = (0,O) format. The y values are scaled by the aspect ratio for the

given mode so that n pixels in the vertical direction are roughly the same distance as n pixels in

the horizon.tal direction. The graphic library may eventually do more, but for now is offered as is.

If you do not have an EGA display system, you must change the value of mode in the demos to

CGA mode 4,5 or 6.

Thus ALLOC(32766) returns a segment suitable for DMAing the

Graphics

routines,

such SETUP(mode), CLEAR(i,r,g,b),

To re-LINK any of the example programs, use DAS20P+PDRAW at the libraries prompt.

The MAKEDEMO.BAT utility is provided for this purpose (see MAKEDEMO.DOC).

The example programs, D20MO-6.PAS, D20M27.PAS, D20M7-lO.PAS, D20M16.PAS

and D20M23.PAS test various modes (the numbers or range of numbers after the M). These

programs contain other commented options and can be used as a starting point to develop

specialized user programs in PASCAL. D20MO-6 gives the user an on-line way of testing and

comparing the various analog to digital conversion modes. Be sure not to exceed the maximum

rate for the given mode. D20M27 tests block scan mode. D20M7-10 tests the DAC output

modes. D20M16 test the analog trigger function and D20M23 test the frequency measurement

routine.

Most of the DAS-20 Manual (for BASIC) applies to the PASCAL package. The format of

the BASIC call is:

CALL DAS20 (MD%,DIO%(O),FLAG%)

- 39 -

Page 44

This becomes a function routine reference in PASCAL:

FLAG% = DAS20(MD%,DIO%( 1))

The FLAG% returned value (16-bit) can be ignored if zero.

The MD% value (16-bit) is the BASIC MODE (0 - 29).

DIO% is a 16-bit array which contains up to 5 other parameters,

which are either input or output from the DAS20 routines.

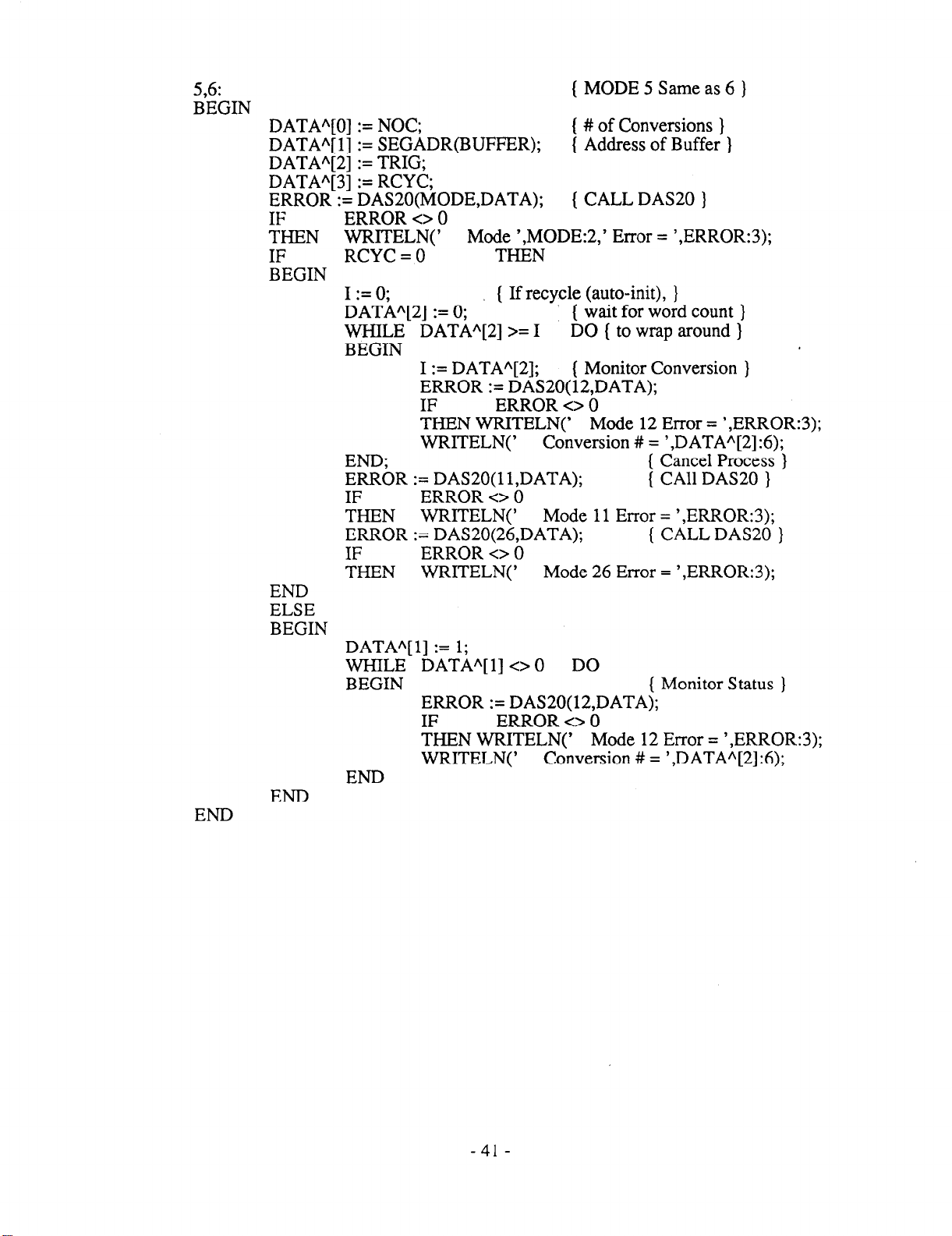

2.1 Example Programs

A number of example pograms have been included on the PCF-20 disks. However as a quick

example, we have included the following example program print-out. An excerpt from the

D20MO-6.PAS demo follows:

- 40 -

Page 45

5,6:

BEGIN

END

DATA”[O] := NOC;

DATA”[ l] := SEGADR(BUFFER);

DATAA[2] := TRIG;

DATA*[3] := RCYC;

ERROR := DAS20(MODE,DATA);

IF

THEN

IF

BEGIN

END

ELSE

BEGIN

END

ERROR 0 0

WRIT.ELN( ’

RCYC = 0

I := 0;

DATA”[2] := 0;

WHILE DATA”[2] >= I DO ( to wrap around )

BEGIN

I := DATAA[2]; ( Monitor Conversion }

THEN WRITELN(’ Mode 12 Error = ‘,ERROR:3

%R := DAS20( 11 DATA);

&EN WRITELN(’ Mode 11 Error = ‘,ERROR:3);

ERROR := DAS20(26,DATA); ( CALL DAS20 }

FHEN WRrrELN(’

DATA”[l] := 1;

WHILE DATAA[l] <> 0 DO

BEGIN

END

Mode ‘,MODE:2,’ Error = ‘,ERROR:3);

THEN

( If recycle (auto-init), }

ERROR := DAS20(12,DATA);

IF ERROR <> 0

WRITELN(’ Conversion # = ‘,DATA*[2]:6);

ERROR <> b

ERROR <> 0

ERROR := DAS20(12,DATA);

IF ERROR <> 0

THEN WRITELN(’ Mode 12 Error = ‘,ERROR:3);

WRITELN(’

MODE 5 Same as 6 )

# of Conversions }

Address of Buffer )

CALL DAS20 )

( wait for word count )

3;

( Cancel Process }

{ CA11 DAS20 }

Mode 26 Error = ‘,ERROR:3);

( Monitor Status ]

Conversion # = ‘,DATAA[2]:6);

-41-

Page 46

Section 3

DAS-20 C LANGUAGE INTERFACE

The DAS-20 BASIC Interface has been converted to a Clanguage callable Library:

DAS20c.LIB. This was accomplished by removing the BASIC specific despatcher code to a

separate INCLUDE file, DAS20b.ASM and INCLUDing instead the file DAS20cASM in

DAS20.ASM. DAS2OcLIB consist of the single OBJ file DAS20.0BJ, which also contains the

routines: SEGADR, OFFADR and ALLOC.SEGADR and OFFADR return the segment and

offset values of amemory buffer. This is very useful in calls to DAS20 from C.Modes 5 and 6,

for example, require the segment value and assume the offset to be 0, modes 4, 8, 13 etc. require

the offset value and assume the segment to be the same as that of DIO%(). ALLOC(#) allocates a

buffer of # of 16-bit words and returns a far pointer to it. It guarantees paragraph alignment and

enough room for # conversions. i.e. OFFADR(ALLOC(#)) will always = 0 and

SEGADR(ALLOC(#)) + #/16 c O-FFFh. Thus ALLOC(32766) returns a segment suitable for

DMAing the maximum number of conversions in mode 6 or 27.

The CxDRAW.LIB graphics libraries have also been included on this disk [x =

S(mall),M(edium),C(ompact) or L(arge)]. It contains the non-DAS-20 Graphics routines, such as

SETUP(mode),CLEAR(i,r,g,b) COLOR(i,r,g,b),POINT(x,y) and LINE(xO,yO,xl,y2). All

parameters are 16 bit integers. Mode is the IBM BIOS crt-mode. Intensity, red, green, blue, if

non-zero, turn on those color planes when 16 colors are available for that mode. x, y, x0, y0, xl,

yl are 16 bit signed integers and represent screen coordinates in center = (0,O) format. The y

values are scaled by the aspect ratio for the given mode so that n pixels in the vertical direction

are roughly the same distance as n pixels in the horizontal direction. The graphics libraries may

eventually do more, but for now are offered as is. If you do not have an EGA display system, you

must change the value of mode in the demos to CGA mode 4,5 or 6.

To re-LINK any of the example programs, use DAS2Ocl+clDRAW at the libraries

prompt. If you recompile with MSC, be sure to specify the correct memory model with /Ax (x =

S,M,C or L). The MAKEDEMO.BAT utility is provided for this purpose (see

MAKEDEMO.DOC).

The example programs, D20MO-6.C, D20M27.C, D20M7-lO.C, D20M16.C and

D20M23.C test various modes (the numbers or range of numbers after the M). These programs

contain other commented options and can be used as a starting point to develop specialized user

programs in C. D20MO-6 gives the user an on-line way of testing and comparing the various

analog to digital conversion modes. Be sure not to exceed the maximum rate for the given mode.

D20M27 tests block scan mode. D20M7-10 tests the DAC output modes. D20M16 test the

analog trigger function and D20M23 test the frequency measurement routine.

- 42 -

Page 47

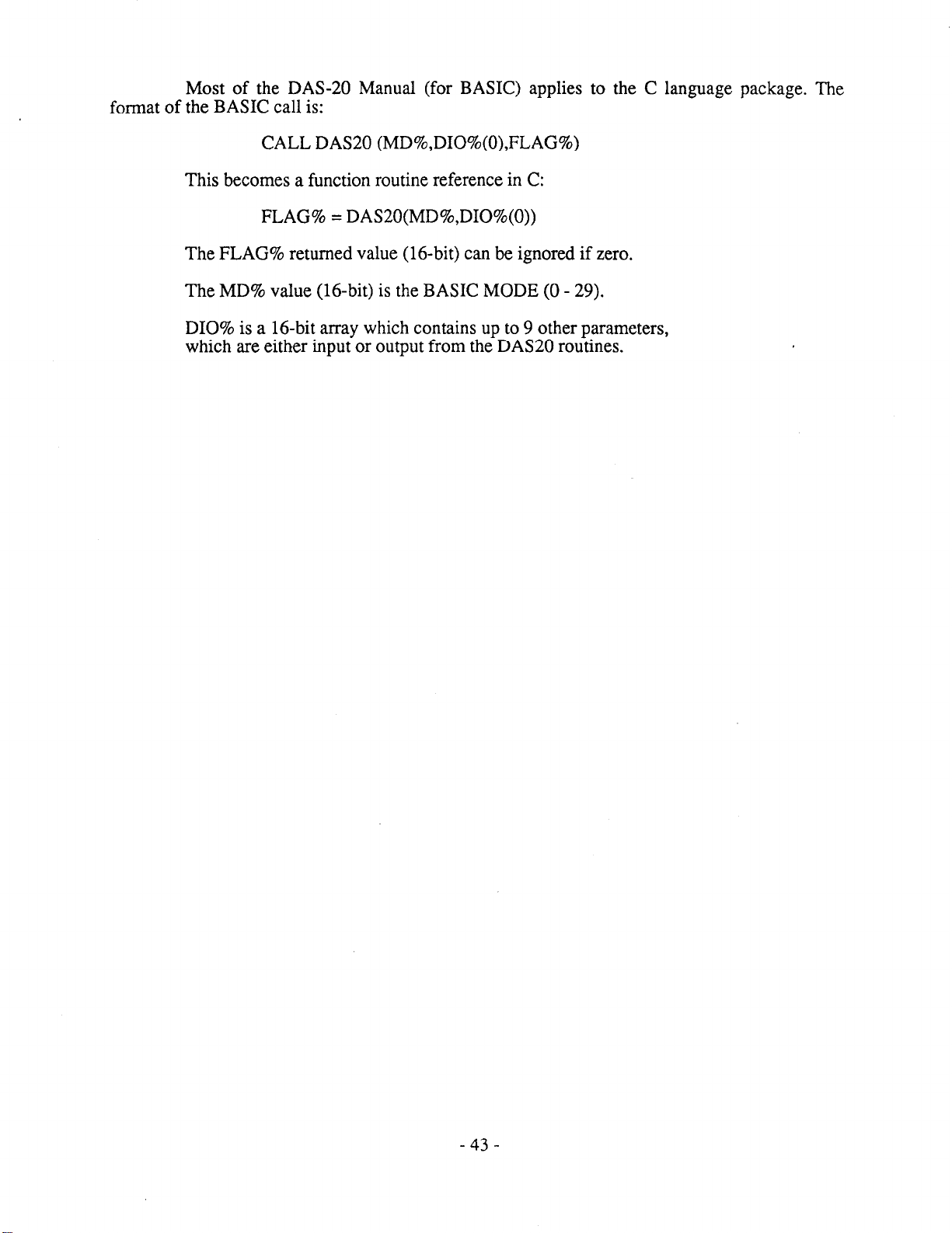

Most of the DAS-20 Manual (for BASIC) applies to the C language package. The

format of the BASIC call is:

CALL DAS20 (MD%,DIO%(O),FLAG%)

This becomes a function routine reference in C:

FLAG% = DAS2O(MD%,DIO%(O))

The FLAG% returned value (16-bit) can be ignored if zero.

The MD% value (16-bit) is the BASIC MODE (0 - 29).

DIO% is a 16-bit array which contains up to 9 other parameters,

which are either input or output from the DAS20 routines.

-43 -

Page 48

3.1 Example Program

A number of sample and example programs have been included on the PCF-20 disks, however as

a quick example a printout of one of the programs has been included. An excerpt from the

D20MO-6.C demo follows:

case 6:

/* MODE 6 */

data[O] = not;

data[ l] = segadr(buffer); /* Paragraph Address of Buffer */

data[2] = trig;

data[3] = rcyc;

if

if

t

1

else

1

) break;

((error = das20(mode,data)) != 0) /* CALL DAS20 */

printf( ‘In Mode %u Error = %d”,mode,error);

== 0)

WC

i = 0; /* Lf recycle (auto-init), */

data[2] = 0;

while (data[2] >= i) /* to wrap around */

{

1

if ((error = das20( 11,data)) != 0) /* CALL DAS20 */

if ((error = das20(26,data)) != 0) /* CALL DAS20 */

data[l] = 1;

while (data[ l] != 0)

{

1

i = data[2];

if ((error = das20(12,data)) != 0)

printf( ‘Yn

printf( “n

printf( ‘Yn

printf(‘ln Mode 26 Error = %d”,error);

if ((error = das20( 12,data)) != 0)