Page 1

Service Manual

TG 2000

Signal Generation Platform

070-9299-01

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

Page 2

Copyright T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Windows and Microsoft are registered trademarks of the Microsoft corporation.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of shipment. If a product proves defective during this warranty period, T ektronix,

at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Service Assurance

If you have not already purchased Service Assurance for this product, you may do so at any time during the product’s

warranty period. Service Assurance provides Repair Protection and Calibration Services to meet your needs.

Repair Protection extends priority repair services beyond the product’s warranty period; you may purchase up to three

years of Repair Protection.

Calibration Services provide annual calibration of your product, standards compliance and required audit documentation,

recall assurance, and reminder notification of scheduled calibration. Coverage begins upon registration; you may purchase

up to five years of Calibration Services.

Service Assurance Advantages

Priced well below the cost of a single repair or calibration

Avoid delays for service by eliminating the need for separate purchase authorizations from your company

Eliminates unexpected service expenses

For Information and Ordering

For more information or to order Service Assurance, contact your T ektronix representative and provide the information

below . Service Assurance may not be available in locations outside the United States of America.

Name VISA or Master Card number and expiration

Company date or purchase order number

Address Repair Protection (1,2, or 3 years)

City , State, Postal code Calibration Services (1,2,3,4, or 5 years)

Country Instrument model and serial number

Phone Instrument purchase date

Page 5

Table of Contents

General Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications

Specifications 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Characteristics T ables 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Information

Installation 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Information 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theory of Operation

Block Level Description 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification

Verification Interval 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T est Equipment Required 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verification Procedures 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedures

Equipment Required 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self Calibration 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedure 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance

Preparation 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Cleaning 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

After Repair Adjustments 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repackaging Instructions 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Replacement 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ools Required 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedures 6–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Procedures 6–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 6–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Troubleshooting Procedures 6–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Symptom T able 6–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Flowcharts 6–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TG 2000 Signal Generation Platform Service Manual

i

Page 6

Contents

Options

Options 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Electrical Parts

Replaceable Electrical Parts 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams

Diagrams 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mainframe Interconnect Diagrams 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modules Interconnect Diagrams 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Mechanical Parts

Replaceable Parts 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Parts List 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index

ii

TG 2000 Signal Generation Platform Service Manual

Page 7

List of Figures

Contents

Figure 2–1: Location of the rear-panel power connector

and configuration 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–2: Location of the CPU configuration switch 2–3. . . . . . . . . . . .

Figure 2–3: Installing the rackmount hardware 2–4. . . . . . . . . . . . . . . . .

Figure 2–4: Installing the TG 2000 Platform mainframe

into the rack 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–5: Instrument front panel 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–6: Browsed and selected display icons 2–9. . . . . . . . . . . . . . . . . .

Figure 2–7: Main display features 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–8: Module and test signal hierarchy 2–12. . . . . . . . . . . . . . . . . . .

Figure 2–9: Selecting the Save Signals to Disk source 2–14. . . . . . . . . . . . .

Figure 2–10: Selecting a Save Signals to Disk destination 2–15. . . . . . . . . .

Figure 2–11: Replacing test signals from disk 2–16. . . . . . . . . . . . . . . . . . .

Figure 2–12: Selecting the source signals to add from disk 2–17. . . . . . . . .

Figure 2–13: Add Signals window with source and destination

selected 2–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–14: Rear-panel connectors 2–19. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–15: RS–232 connector pin descriptions 2–20. . . . . . . . . . . . . . . . .

Figure 3–1: Simplified block diagram 3–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–2: Block diagram of the clocks and frame reset signals 3–4. . . .

Figure 3–3: Comparison of module delay and system delay from

a reference 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–4: Block diagram of module timing delay 3–6. . . . . . . . . . . . . . .

Figure 3–5: Block diagram of the AGL1 Reference timing delay 3–6. . .

Figure 4–1: Save Signals to Disk window 4–3. . . . . . . . . . . . . . . . . . . . . . .

Figure 4–2: New Directory window 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–3: New directory named Test 4–4. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–4: Equipment setup for verifying clock operation 4–9. . . . . . . .

Figure 5–1: Measuring the power supply voltages on the clock board 5–4

Figure 5–2: Locating parts on the clock board 5–5. . . . . . . . . . . . . . . . . . .

Figure 6–1: Placing the module in the protective wrapping 6–5. . . . . . . .

Figure 6–2: Placing the module in the shipping carton 6–6. . . . . . . . . . . .

TG 2000 Signal Generation Platform Service Manual

iii

Page 8

Contents

Figure 6–3: Placing the TG 2000 Platform mainframe in the

shipping carton 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–4: Top cover removal 6–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–5: Removing the front-frame assembly 6–12. . . . . . . . . . . . . . . . .

Figure 6–6: Removing the front-panel board and display

module 6–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–7: Disconnecting the LCD Display module and Front

Panel board 6–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–8: Replacing the knob encoder 6–15. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–9: Replacing the airflow regulator 6–16. . . . . . . . . . . . . . . . . . . . .

Figure 6–10: Removing the floppy drive 6–17. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–11: Installing the floppy drive into the chassis 6–19. . . . . . . . . . .

Figure 6–12: Removing the floppy drive assembly shield 6–20. . . . . . . . . .

Figure 6–13: Location of the Power Supply module grounding strap

(SN B010391 and below only) 6–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–14: Removing the Power Supply module 6–22. . . . . . . . . . . . . . .

Figure 6–15: Removing the Power Supply module attaching

screws 6–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–16: Removing the Power Supply board 6–24. . . . . . . . . . . . . . . . .

Figure 6–17: Removing the Line Filter board 6–25. . . . . . . . . . . . . . . . . . .

Figure 6–18: Installing the fuse holder 6–27. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–19: Removing the CPU module floppy cable 6–28. . . . . . . . . . . .

Figure 6–20: Installing the CPU Memory board 6–29. . . . . . . . . . . . . . . . .

Figure 6–21: Removing the date/time clock from the CPU module 6–30. .

Figure 6–22: Installing the Clock board oscillator 6–32. . . . . . . . . . . . . . . .

Figure 6–23: Removing the Power Supply board fan 6–33. . . . . . . . . . . . .

Figure 6–24: Removing the Clock board fan 6–34. . . . . . . . . . . . . . . . . . . .

Figure 6–25: Removing the Backplane board 6–35. . . . . . . . . . . . . . . . . . .

Figure 6–26: Replacing the battery 6–36. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–27: Instrument does not boot up properly 6–41. . . . . . . . . . . . . .

Figure 6–28: Measuring the power supply voltages on the

clock board 6–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–29: Backlight does not illuminate 6–42. . . . . . . . . . . . . . . . . . . . .

Figure 6–30: Measuring the LCD Display module high voltage 6–43. . . . .

Figure 6–31: Front panel does not function 6–43. . . . . . . . . . . . . . . . . . . . .

Figure 6–32: Locked LED does not illuminate 6–44. . . . . . . . . . . . . . . . . . .

Figure 6–33: Floppy drive does not operate properly 6–44. . . . . . . . . . . . .

Figure 6–34: Instrument is hot or the fans do not operate 6–45. . . . . . . . .

Figure 6–35: Correct time is not stored 6–46. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–36: Signal noise in mainframe slots 9 and 10 6–46. . . . . . . . . . . .

iv

TG 2000 Signal Generation Platform Service Manual

Page 9

Figure 6–37: Instrument loses signal and operating memory during

rear-panel power off 6–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–38: Measuring the battery charging circuit 6–48. . . . . . . . . . . . .

Figure 6–39: Front-panel knob does not function properly 6–48. . . . . . . .

Figure 9–1: Backplane board connections 9–2. . . . . . . . . . . . . . . . . . . . . .

Figure 9–2: CPU, Front Panel board, Power Supply board and

Line Filter connections 9–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–3: Clock connections 9–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–4: AGL1 module connections 9–4. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–5: AVG1 module connections 9–5. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–6: AWVG1 module connections 9–5. . . . . . . . . . . . . . . . . . . . . . .

Figure 9–7: BG1 module connections 9–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–8: GP1 module connections 9–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–9: DVG1 module connections (standard) 9–7. . . . . . . . . . . . . . .

Figure 9–10: DVG1 module connections (with Option S1 installed as

shipped) 9–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

Figure 10–1: Top cover and chassis assembly 10–6. . . . . . . . . . . . . . . . . . . .

Figure 10–2: Front panel, disk drive and display 10–8. . . . . . . . . . . . . . . . .

Figure 10–3: Disk drive assembly 10–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–4: Power Supply module assembly 10–12. . . . . . . . . . . . . . . . . . .

Figure 10–5: CPU assembly 10–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–6: Clock assembly 10–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–7: Accessories 10–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TG 2000 Signal Generation Platform Service Manual

v

Page 10

Contents

List of Tables

Table 1–1: AC Power source 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–2: Physical dimensions 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–3: Environmental characteristics 1–3. . . . . . . . . . . . . . . . . . . . . .

Table 1–4: System clock and frame reset 1–5. . . . . . . . . . . . . . . . . . . . . . .

Table 1–5: Certifications and compliances 1–6. . . . . . . . . . . . . . . . . . . . . .

Table 2–1: AC power fuse requirements 2–2. . . . . . . . . . . . . . . . . . . . . . .

Table 2–2: Keypad definitions 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–1: Test equipment required for verification 4–1. . . . . . . . . . . . . .

Table 5–1: Equipment List for adjustments 5–1. . . . . . . . . . . . . . . . . . . .

Table 6–1: Tools required for module removal 6–9. . . . . . . . . . . . . . . . . .

Table 6–2: Removal and replacement procedure list 6–10. . . . . . . . . . . . .

Table 6–3: Equipment required for troubleshooting 6–37. . . . . . . . . . . . .

Table 6–4: CPU confidence test codes 6–40. . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–5: Fault symptom table 6–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7–1: Power cord identification 7–1. . . . . . . . . . . . . . . . . . . . . . . . . .

vi

TG 2000 Signal Generation Platform Service Manual

Page 11

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

Only qualified personnel should perform service procedures.

To avoid potential hazards, use this product only as specified.

Injury Precautions

Product Damage

Precautions

Use Proper Power Cord. To avoid fire hazard, use only the power cord specified

for this product.

Avoid Electric Overload. To avoid electric shock or fire hazard, do not apply a

voltage to a terminal that is outside the range specified for that terminal.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Do Not Operate Without Covers. To avoid electric shock or fire hazard, do not

operate this product with covers or panels removed.

Use Proper Fuse. To avoid fire hazard, use only the fuse type and rating specified

for this product.

Do Not Operate in Wet/Damp Conditions. To avoid electric shock, do not operate

this product in wet or damp conditions.

Do Not Operate in an Explosive Atmosphere. To avoid injury or fire hazard, do not

operate this product in an explosive atmosphere.

Use Proper Power Source. Do not operate this product from a power source that

applies more than the voltage specified.

Use Proper V oltage Setting. Before applying power, ensure that the line selector is

in the proper position for the power source being used.

Provide Proper Ventilation. To prevent product overheating, provide proper

ventilation.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

TG 2000 Signal Generation Platform Service Manual

vii

Page 12

General Safety Summary

Symbols and Terms

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

Certifications and

Compliances

DANGER

High Voltage

Protective Ground

(Earth) T erminal

ATTENTION

Refer to Manual

Double

Insulated

Refer to the specifications section for a listing of certifications and compliances

that apply to this product.

viii

TG 2000 Signal Generation Platform Service Manual

Page 13

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the mains power by means

of the power cord or the rear-panel power switch.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power cord and test leads before removing

protective panels, soldering, or replacing components.

To avoid electric shock, do not touch exposed connections.

TG 2000 Signal Generation Platform Service Manual

ix

Page 14

Service Safety Summary

x

TG 2000 Signal Generation Platform Service Manual

Page 15

Preface

About This Manual

You have purchased this optional service manual for the TG 2000 Platform

mainframe. You can also purchase service manuals for the modules. Each

module manual begins with a tab so that you can locate it after you add it to the

mainframe manual binder.

The user manuals are set up the same way as the service manuals. You should

receive a user manual with each mainframe or module ordered.

This manual contains information for servicing the TG 2000 Signal Generation

Platform to a module level. The information is designed only for qualified

service technicians, with moderate experience in analog circuits, digital circuits,

and television technology. This manual is composed of the following sections:

Specifications provides a basic product description followed by instrument

specifications tables.

Operating Information is designed to provide just enough operating

information for a service technician to be able to service the product. For

more details, refer to the user manual.

Theory of Operation is an overview of the main components of the platform,

describing general interactions with the modules.

Performance Verification contains procedures necessary to verify that the

mainframe components (Clock, Power Supply, and CPU) are meeting the

requirements listed in the Specifications.

Adjustments contains procedures to adjust the +5V power supply and the

oscillator.

Maintenance contains installation, removal and replacement, and trouble-

shooting instructions.

Options lists all available options for the mainframe.

Replaceable Electrical Parts for the module level are included in the

Replaceable Mechanical Parts list.

Diagrams contains interconnect diagrams showing the connections between

the mainframe and the modules.

Replaceable Mechanical Parts lists the part numbers for replacement parts

that you can order. Exploded view illustrations help you to identify the parts.

TG 2000 Signal Generation Platform Service Manual

xi

Page 16

Preface

Contacting Tektronix

Product

Support

Service

Support

For other

information

To write us Tektronix, Inc.

For application-oriented questions about a Tektronix measurement product, call toll free in North America:

1-800-TEK-WIDE (1-800-835-9433 ext. 2400)

6:00 a.m. – 5:00 p.m. Pacific time

Or contact us by e-mail:

tm_app_supp@tek.com

For product support outside of North America, contact your

local Tektronix distributor or sales office.

Contact your local Tektronix distributor or sales office. Or visit

our web site for a listing of worldwide service locations.

http://www.tek.com

In North America:

1-800-TEK-WIDE (1-800-835-9433)

An operator will direct your call.

P.O. Box 1000

Wilsonville, OR 97070-1000

xii

TG 2000 Signal Generation Platform Service Manual

Page 17

Page 18

Specifications

Product Description

This section contains the Product Description, which describes the product and

accessories, and the Characteristics Tables, which list the product specifications.

The TG 2000 Signal Generation Platform provides multiformat, precision

television test signals for both analog and digital video standards. The physical

configuration is a mainframe with up to nine plug-in modules. Modules either

generate signals or provide special functions, such as genlock capability.

You can use included software (SDP2000 Signal Development Program) to

generate custom test signals, which you can store on a disk or transfer directly

into the memory of a generator module.

The TG 2000 Signal Generation Platform addresses the needs of research and

development, engineering, manufacturing test, and most operational environments.

These are some of the key features of the platform:

Modular architecture with up to nine generators or special function modules

Support of analog and digital environments for most component and

composite video signal formats

Reference generator performance level

Modules genlocked to external reference with the optional AGL1 Genlock

module

Included Microsoft Windows-based SDP2000 software to create new signals

Remote control, using RS-232 interface (or optional GPIB interface) and

SCPI command set

Full support of VM700A video measurement routines

Variable transmission parameters, such as jitter amplitude and frequency, for

serial digital formats using the DVG1 module with option S1

Variable signal parameters for some analog and digital format modules

Circle and text overlays on test signals for some modules

Simultaneous 525/60 and 625/50 signal generation

TG 2000 Signal Generation Platform Service Manual

1–1

Page 19

Specifications

Accessories

Moving signals for compression system testing

Programmable system clocks to support standard and custom formats

Flash EPROM allows easy upgrades to system software

This section describes the key accessories for the TG 2000 Signal Generation

Platform. For a complete list of accessories and their Tektronix part numbers,

refer to the Replaceable Mechanical Parts list at the back of this manual.

BG1 Black Burst

Generator Module

SDP2000 Signal

Development Program

GPIB Card for SDP2000

Communications

The BG1 Generator module is supplied as a standard accessory. There are six

black burst signals to select from; the module provides the selected black burst

signal on the three rear-panel connectors. Additionally, the module can provide

one of the system clocks from its rear-panel clock output.

More than one BG1 Generator module can be added to the mainframe to provide

enough flexibility to meet virtually any system timing requirement. The BG1

Generator module can be removed without affecting system operation.

The SDP2000 Signal Development Program is supplied as a standard accessory.

This program runs under Microsoft

parallel port are compatible with Windows NT. All features are compatible with

Windows 95.

You can use the SDP2000 program to create custom signals for the various

modules. You can use the remote interface or a disk to download the signals to

the module memory. Refer to the SDP2000 Signal Development Program User

Manual for information about using this program.

The Tektronix S3FG210 is a GPIB–PCII/IIA interface card. It provides the type

of interface needed to operate the TG 2000 Signal Generation Platform when

performing GPIB communications with the SDP2000/TGCOMM software.

Windows 3.1 or higher. All features except the

1–2

Accessory Kit

Extender Board

The accessory kit includes a Torx T-10 bit (needed to secure the modules), two

fuses, and a blank panel. The fuses support the two line voltage settings; see

Electrical Installation on page 2–1 for instructions. The blank panel fills the gap

when a module is removed.

The extender board is an optional accessory that you can order to use when

troubleshooting the TG 2000 Signal Generation Platform. The part number can

be found at the end of the Replaceable Mechanical Parts list.

TG 2000 Signal Generation Platform Service Manual

Page 20

Characteristics Tables

Specifications

This section lists the electrical and environmental specifications for the TG 2000

Platform mainframe. For the specifications of a specific module, refer to the user

or service manual for that module.

T able 1–1: AC Power source

Characteristic Performance requirement Reference information

AC Source Voltage

115 V operation 87 V

230 V operation 174 V

RMS

RMS

to 132 V

to 250 V

RMS

RMS

Power Consumption 220 W line power typical

Fuse Rating

115V Operation Slow blow, 6 AT

230 V Operation Slow blow, 3 AT

Nominal Switching Frequency 100 kHz

T able 1–2: Physical dimensions

Characteristic Description

Dimensions Height: 5.25 in (13.34 cm)

Width: 19.0 in (48.26 cm); standard rack width

Depth: 23 in (58.42 cm)

1

Weight

Net Weight: 38 lbs (17.27 kg) typical

Shipping Weight: 52 lbs (23.67 kg) typical

T able 1–3: Environmental characteristics

Characteristic Performance requirement Reference information

T emperature

Operating 32_ F to 104_ F (0_ C to 40_ C)

Nonoperating –4 to +140_ F (–20 to +60_ C)

1

Weight of the TG 2000 will vary depending on the number and type of generator or other modules installed.

2

Battery storage life is specified at 25_ C. At 60_ C, battery discharge accelerates, resulting in self discharge in less than

2

30 days.

TG 2000 Signal Generation Platform Service Manual

1–3

Page 21

Specifications

T able 1–3: Environmental characteristics (cont.)

Characteristic Reference informationPerformance requirement

Altitude

Operating To 15,000 feet (4572 meters)

Nonoperating To 40,000 feet (12,203 meters)

Humidity

Operating ≤ 104_ F (≤ 40_ C ), up to 95% relative

humidity

Nonoperating Up to 95% relative humidity

Heat Dissipation 220 W atts maximum for mainframe with

modules in all slots

Clearance for Cooling For rack installation, allow standard side

cooling and 2 in (5 cm) rear clearance for

cables

For desktop use, allow 2 in (5 cm) side and

rear clearance

Bench Handling 1 drop of 2 inches of each edge for all

significant surfaces

Vibration

Operating 5-100 HZ g2/Hz APSD: 0.00015

100-200 Hz Slope dB/Octave: 0

200-350 HZ g2/Hz APSD: 0.00015

350-500 Hz Slope dB/Octave: –3

500 HZ g2/Hz APSD: 0.000105

GRMS overall: 0.27[0.24]

Time/Axis minutes: 10

Nonoperating 5-100 HZ g2/Hz APSD: 0.0175

100-200 Hz Slope dB/Octave: –3

200-350 HZ g2/Hz APSD: 0.00875

350-500 Hz Slope dB/Octave: –3

500 HZ g2/Hz APSD: 0.006132

GRMS overall: 2.22

Time/Axis minutes: 10

Mechanical Shock, Nonoperating 30 g 1/2 sine, 11 ms duration 3 shocks

per surface (18 total)

1–4

TG 2000 Signal Generation Platform Service Manual

Page 22

Specifications

T able 1–3: Environmental characteristics (cont.)

Characteristic Reference informationPerformance requirement

Transportation Package qualified per Tektronix standard

062–2858–00 Rev. B “Environmental T est

Methods–Dynamics” and MBD Quality

Document ENVL–0060 “Transportation

Package Qualification Test Plan”.

Equipment Type Test and Measuring

Equipment Class Class 5

T able 1–4: System clock and frame reset

Characteristic Performance requirement Reference information

Clock Frequency 27 MHz

DDS Ch 1: 10 MHz to 100 MHz

DDS Ch 2: 10 MHz to 100 MHz

Step Size: 0.1 Hz

Stability ±1 ppm/year, operating at standard oven

temperature

Clock Jitter ≤30 ps RMS

Non-harmonic Clock Spurs –45 dBc or better

Tune Range ± 10 ppm

Frame Reset Two reset channels, 1.7 Hz to 1 kHz

TG 2000 Signal Generation Platform Service Manual

1–5

Page 23

Specifications

eclaration o

ormit

T able 1–5: Certifications and compliances

Category Standard

EC D

Safety

U.S. Nationally Recognized Laboratory

Canadian Certification CAN/CSA C22.2 No. 1010.1 Safety Requirements for Electrical Equipment for

European Union Low Voltage Directive 73/23/EEC, Amended by 93/68/EEC

Additional Compliance UL3111-1 Standard for Electrical Measuring and Test Equipment

Listing

f Conf

y Compliance was demonstrated to the following specifications as listed in the Official

Journal of the European Communities:

EN 50081-1 Emissions:

EN 55022 Class B Radiated and Conducted Emissions

EN 60555-2 AC Power Line Harmonic Emissions

EN 50082-1 Immunity:

IEC 801-2 Electrostatic Discharge Immunity

IEC 801-3 RF Electromagnetic Field Immunity

IEC 801-4 Electrical Fast T ransient/Burst Immunity

IEC 801-5 Power Line Surge Immunity

Low Voltage Directive 73/23/EEC, Amended by 93/68/EEC

EN61010-1 Safety Requirements s for Electrical Equipment for Measurement,

Control, and Laboratory Use

ANSI/ISA S82.01 Safety Standard for Electrical and Electronics Test, Measuring,

Controlling, and Related Equipment, 1994

Measurement, Control, and Laboratory Use

EN61010-1 Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use

Safety Certification Compliance

T emperature, operating 41_ F to 104_ F (+5 to +40_ C)

Altitude (max operating) 6562 feet (2000 meters)

Equipment Type Test and Measuring

Safety Class Class I (as defined in IEC 1010–1, Annex H) – grounded product

Overvoltage Category Installation Category II (as defined in IEC 1010–1, Annex J).

Pollution Degree Pollution Degree 2 (as defined in IEC 1010–1). Rated for indoor use only.

1–6

IEC1010-1 Safety Requirements for Electrical for Measurement, Control, and

Laboratory Use

TG 2000 Signal Generation Platform Service Manual

Page 24

Page 25

Operating Information

This section contains the following information:

Installation instructions

Operating information

All modules that you order are shipped configured and installed in the TG 2000

Platform mainframe. Refer to Options on page 7–1 for information about any

installed options. To install or remove a module, refer to the user or service

manual for that specific module.

Installation

Before you install the TG 2000 Platform mainframe, observe these environmental considerations:

Provide the appropriate operating environment. Refer to Specifications for

temperature, humidity, altitude, and other environmental requirements.

Leave enough space for instrument cooling by ensuring standard side

clearance for rackmount installation or 2 inches (5.1 cm) of side clearance

for countertop use.

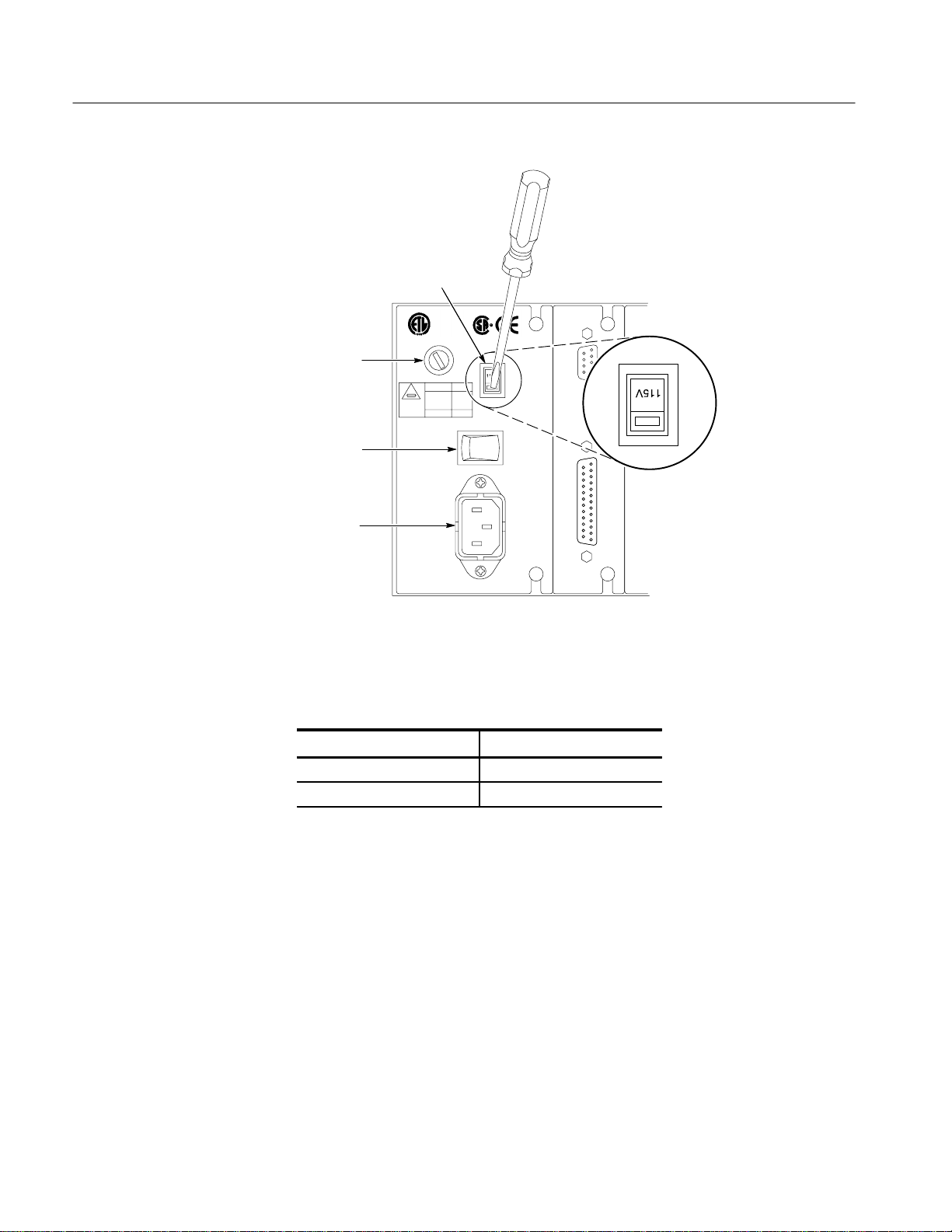

Electrical Installation

Ensure rear clearance of approximately 2 inches (5.1 cm) so that cables are

not damaged by sharp bends.

To install the TG 2000 Platform mainframe, perform these steps:

WARNING. To avoid electrical shock, be sure that the power cord is disconnected

before checking the fuse or changing the setting of the Line Selector switch.

To avoid damaging the TG 2000 Platform mainframe, always use the correct

fuse for the local line voltage. Refer to Table 2–1 on page 2–2 or the fuse chart

located on the rear panel for the proper fuse rating for each line voltage setting.

1. Using the information in Figure 2–1, set the rear-panel Line Selector switch

to the correct position for your local AC power system.

2. Check that the correct line-voltage fuse for your local AC power system is

installed. Refer to Table 2–1 for the fuse ratings.

TG 2000 Signal Generation Platform Service Manual

2–1

Page 26

Operating Information

Line

selector

Fuse

Power

switch

AC line

connecter

Figure 2–1: Location of the rear-panel power connector and configuration

T able 2–1: AC power fuse requirements

Line V oltage Setting Fuse Rating

115 V 250 V, 6 AT

230 V 250 V, 3 AT

3. Check that the CPU configuration switch is in the “0” position. See

Figure 2–2.

4. Check that you are using the correct power cord for the local AC power

system. Refer to Options on page 7–1 for a list of power cords.

5. Connect the power cord from the rear-panel power connector to the AC

power system.

2–2

TG 2000 Signal Generation Platform Service Manual

Page 27

Top view of

instrument

Operating Information

Rackmount Installation

Figure 2–2: Location of the CPU configuration switch (switch set to 0)

To rackmount the TG 2000 Platform mainframe, perform the following steps:

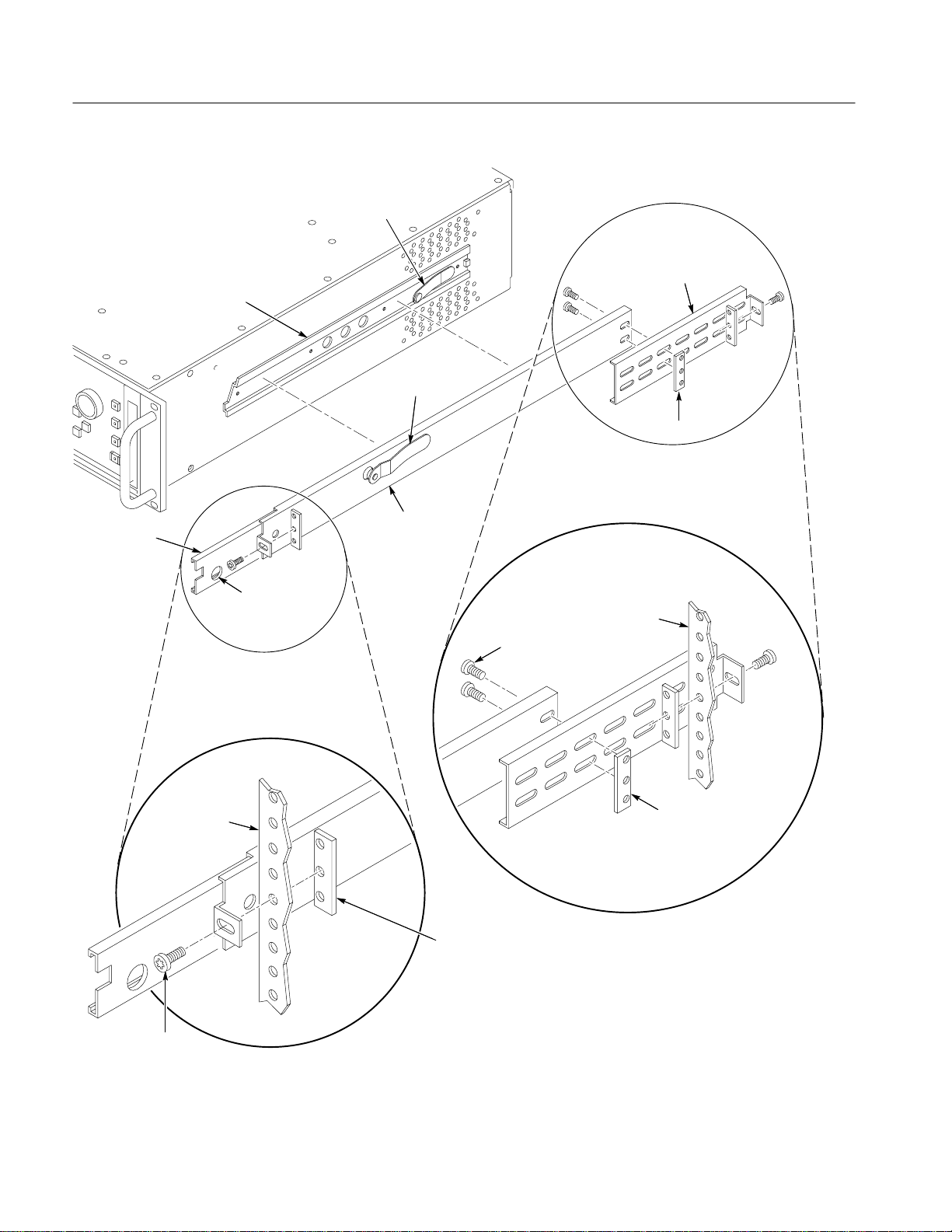

1. Connect the rackmount hardware to the rack, as shown in Figure 2–3.

2. Carefully begin inserting the rack pieces attached to the TG 2000 Platform

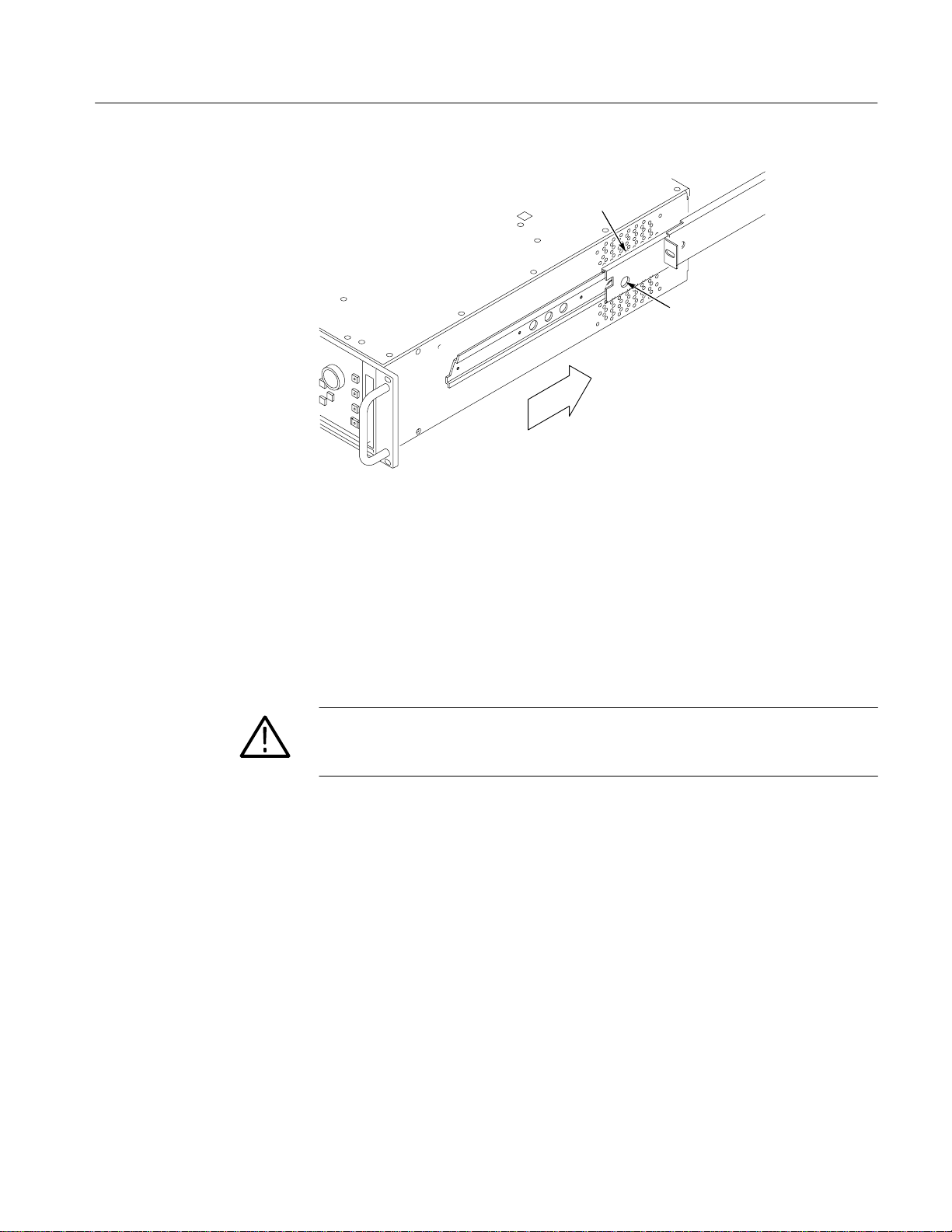

mainframe into the pieces attached to the rack. See Figure 2–4.

WARNING. To prevent the TG 2000 Platform mainframe from falling and causing

injury to yourself and damage to the instrument, be sure that the stop latches

snap into position in the slide-out track on both sides of the instrument. See

Figure 2–4.

3. Support the instrument until the stop latches click into place on both sides.

4. Continue to slide the TG 2000 Platform mainframe completely into the rack.

TG 2000 Signal Generation Platform Service Manual

2–3

Page 28

Operating Information

Chassis section

Intermediate

section

Automatic latches

Rear mounting

bracket

Automatic latches

Flat bar nut

Stationary section

Front rack

10–32 Phs screw

Stop latch

hole

Rear rack

10–32 Phs screws

Flat bar nut

Flat bar nut

(Use if front rail

is not tapped)

Figure 2–3: Installing the rackmount hardware

2–4

TG 2000 Signal Generation Platform Service Manual

Page 29

Operating Information

Side-out track

Stop latch

Figure 2–4: Installing the TG 2000 Platform mainframe into the rack

Rackmount Removal. Perform these steps to remove the TG 2000 Platform

mainframe from the rack:

1. Disconnect the power cord and any attached cables from the rear of the

instrument.

2. Slide the TG 2000 Platform mainframe out until it stops at the catches.

WARNING. To prevent the TG 2000 Platform mainframe from falling and causing

injury to yourself and damage to the instrument, be sure that the stop latches

snap into position in the slide-out track on both sides of the instrument.

3. Support the TG 2000 Platform mainframe while you depress the stop latch

buttons on each side of the instrument. See Figure 2–4.

4. Provide support while you slide the TG 2000 Platform mainframe complete-

ly out of the rack.

TG 2000 Signal Generation Platform Service Manual

2–5

Page 30

Operating Information

Operating Information

This section contains instructions and procedures that will acquaint you with the

basics of operating the TG 2000 Platform mainframe so that you can perform

service on the instrument. Refer to the TG 2000 Signal Generation Platform

User Manual for detailed operating information.

This section includes instructions on the following topics:

Front-panel controls and indicators (page 2–6)

Using the touch screen (page 2–10)

Selecting test signals (page 2–12)

Using the disk drive (page 2–13)

Self Calibration (page 2–18)

Rear-panel connections (page 2–19)

Front-Panel Controls and

Indicators

Power-on procedure (page 2–21)

The primary method to control the TG 2000 Signal Generation Platform is to use

a combination of front-panel button and LCD display touch screen selections to

activate the functions within the instrument.

The secondary method to control the instrument is through the remote ports.

Refer to the user manual for detailed remote instructions.

The front-panel controls (see Figure 2–5) are divided into the following

functional sections:

System function

Keypad

Navigation

Miscellaneous function

After you select an instrument function, the selection may require a few seconds

to implement. A small hourglass icon is displayed in most cases while the

instrument implements your selection. Wait until the hourglass icon disappears

before you make another selection.

2–6

System Function. In most cases, when you push one of the System Function

buttons, a window opens on the LCD display providing touch-screen selections

related to the function of the button. For example, the Modules button displays a

window with selections that represent the installed generator modules.

TG 2000 Signal Generation Platform Service Manual

Page 31

Figure 2–5: Instrument front panel

Operating Information

The following buttons and windows are useful when you have a question about

the operation of the instrument:

Help. Displays a window that explains details about the displayed window.

Status. Displays the following information about all installed modules:

module type, name, slot location, format, and output signal.

The status of an installed AGL1 module is listed at the bottom of the display.

System problems, such as a module failing the power-up self test, are also

displayed in the Status window.

Utilities. Provides access to the following housekeeping functions and

information: date and time, versions of installed modules, front-panel

timeout period, self calibration, clock clients, and frame-reset clients. Refer

to page 2–18 for a self calibration procedure.

The Locked LED (located below the References button) has three states to

indicate the status of the genlock function.

Illuminated. The instrument is locked to the external reference.

Blinking. The instrument is attempting to lock or is unable to lock to the

external reference. Check that the incoming signal matches the type chosen

in the Reference Select window. Also, ensure that the signal line is properly

terminated at the AGL1 loop-through connector or at the distant equipment

connection. The status bar gives the current status.

Off. The instrument reference selector Int/Ext is set to Internal and the AGL1

module is not active, or the AGL1 module is not installed.

TG 2000 Signal Generation Platform Service Manual

2–7

Page 32

Operating Information

Keypad. Use the keypad to enter an exact quantity for a parameter. Use the scale

keys, such as k (kilo) and M (mega), to enter specific values. Table 2–2 shows

the purpose of each key.

T able 2–2: Keypad definitions

Key(s) Function

0–9 Enters numeric values

. Enters a decimal point

+/– Toggles the numeric value between positive and negative

p/T Enters the pico or Tera unit of measure

n/G Enters the nano or Giga unit of measure

m/M Enters the micro or Mega unit of measure

m/k Enters the milli or kilo unit of measure

Escape Exits out of data entry mode without changing the existing data

Back Sp Erases one character

EE Allows exponent entry. When entering a parameter value, enter a

number, press the EE key, and then enter the exponent value. For

example, press 4.2 EE 6 to enter the value 4.2x10

Enter Changes the parameter value to the new value

1

The instrument determines which of the two units is appropriate based on

the parameter being set.

1

1

1

1

6

.

Navigation Controls. The following navigation controls provide an alternative

method to touching onscreen display items to select them:

Arrow Buttons. Use these buttons to navigate through lists and objects on

the display and to move the cursor when entering text.

Knob. Use the knob to scroll through a list or to change a parameter setting.

Turn the knob to browse items in a window and to select characters in a text

entry window. When you have a numeric item selected, the knob will change

the value for the selected parameter. When you change a parameter, the

module output changes immediately.

Select. Use the Select button to confirm an entry or to make a browsed

selection active. Push the Select button repeatedly to sequence through items

within an icon when it contains several selections.

Touching a display item immediately activates the item. You can use the arrow

buttons and knob to move from item to item on the display without activating

them. This technique is known as browsing. To activate a browsed item, push the

Select button or touch the browsed display icon. See Figure 2–6.

2–8

TG 2000 Signal Generation Platform Service Manual

Page 33

Browsed item

Selected item

Operating Information

Figure 2–6: Browsed and selected display icons

Miscellaneous Function Buttons. The four buttons at the right edge of the front

panel provide the following functions:

Front Panel Enable. This button acts like a toggle switch to enable (LED on)

or disable (LED off) the front-panel keys, the knob, and the touch screen.

NOTE. The instrument turns the display off and disables the front-panel controls

when the front panel is not used for the specified timeout period. Push the Front

Panel Enable button to enable the front panel after it has timed out. Push the

Utilities button to access the timeout delay settings.

Remote. Push the Remote button to access control of the remote interfaces

through the Remote window. The following areas of control are available:

Serial Setup. This selection provides control of the serial RS-232

interface.

Parallel Setup. This selection provides control of the parallel interface.

Remote Only. This selection locks out the front-panel controls when

remote-only operation is desired. Touch the Quit icon in the Remote

Only window to return to front-panel operation.

Remote Port. This selection selects an interface port. You must select an

interface port before using it for transferring data or commands. Touch

the Remote Port icon repeatedly to cycle through the selections.

TG 2000 Signal Generation Platform Service Manual

2–9

Page 34

Operating Information

GPIB Setup. This selection lets you set the GPIB configuration. This

selection is only available when the GP1 module is installed.

Screen Contrast. When screen contrast is active (LED on), rotate the knob to

adjust the screen contrast for the best viewing in your environment.

On/Standby. Push the On/Standby button (LED on/LED off respectively), to

turn the instrument off after all critical processes have been completed. This

leaves the instrument in a known state. The On/Standby button is different

than the rear-panel power switch, which immediately shuts off power to the

instrument regardless of any functions that are in process.

When the On/Standby button is set to On, the battery system charges at the

highest rate. When the button is set to Standby and the rear-panel power

switch is on, the battery system charges at a low or trickle rate.

Using the Touch Screen

The LCD display serves as a touch screen that lets you touch display icons to

make functional selections. Touching a display icon either selects the item or

displays additional selections.

The following features appear in the touch-screen windows. See Figure 2–7.

Icons. Icons are display symbols that represent and show the status of test

signals or other selectable items. Touching some display icons repeatedly

cycles through the available selections.

NOTE. Icons of the same function can appear as selections in more than one

window. For convenience, icons appear where they are functionally appropriate.

Status Bar. The Status Bar shows the active signal set and test signal for the

selected module (BG1:2 in Figure 2–7). The status bar also gives the status

of other functions, such as signal transfers.

Window Title. The Window Title shows the window name, which indicates

the selected function.

Slot: #. The slot number identifies the physical location of the selected

module to remind you which module outputs are being controlled. In

Figure 2–7, note that the slot # matches the “2” in the active module name,

BG1:2.

2–10

List box. Touch the List Box to show additional selections that are available

within a display icon, such as a list of test signals. To display the list box

selections, rotate the knob or touch the list box. To select a list box item, use

the cursor keys or the knob to highlight a selection, and then push the Select

button. Touch an open list box to close it without making a selection.

TG 2000 Signal Generation Platform Service Manual

Page 35

Signal set and name

of active signal

Selected item

Selectable items

List box

Operating Information

Location of the selected

Window titleStatus bar

module within the mainframe

Figure 2–7: Main display features

Page or << Page >>. Touch the Page icon to access the previous or following

page of display selections.

Quit/Save. Touch the Quit or the Quit/Save icon to return to a previous

display window. If you have made changes, you will be asked if you want to

save them. If you have changed a test signal, you will be prompted to enter a

signal name. The signal name you enter will always be preceded by an

underscore character to indicate a user-created test signal.

Reset. Touch the Reset icon to return a parameter setting to the value it had

when you entered the window.

Hourglass. A small hourglass icon is displayed in most cases when the

instrument is taking time to implement your selection. Wait until the

hourglass icon disappears before you make another selection.

TG 2000 Signal Generation Platform Service Manual

2–11

Page 36

Operating Information

Selecting Test Signals

The System Function buttons named Module, Signal Sets, and Test Signals

provide access to the output signals. These buttons allow you to select a module,

a signal set within the module, and a particular test signal. After selecting a test

signal, you can set common module parameters and signal parameters for

individual signals. Figure 2–8 shows this test signal hierarchy.

Modules

Signal Sets

Test Signals

Module

Parameters

Signal

Parameters

Figure 2–8: Module and test signal hierarchy

Each module has a Module Parameters selection for parameters that apply to all

appropriate test signals from that module. Each test signal also has unique

parameters controlled through the Signal Parameters icon.

Shared Module Memory. Generator modules of the same type share their onboard

memory spaces to provide larger signal-storage areas. Signals stored on one

module can be loaded and output by other modules of the same type.

When you remove a module, the signals stored on the module are no longer

available to the remaining modules. Before removing a module, copy all signals

for the module type to a floppy disk. After removing the module, you can reload

removed signals from the disk providing there is enough free memory space to

load the signals.

2–12

TG 2000 Signal Generation Platform Service Manual

Page 37

Operating Information

Using the Disk Drive

The disk drive provides a way to load and save signal sets and sequences for a

module. You can also save all current settings, called presets, for the mainframe

and its modules to the disk. The disk drive uses 3.5 inch, 1.44 Mbyte, MS-DOSformatted disks. The disks must be formatted before using them in the drive.

Supported File Types. The disk drive reads and writes several types of files that

support different functions. The following file types are supported:

Signal Sets. These files contain directories of signal groups and, at the

lowest level, test signals. Signal set files have a .dnl suffix and may contain

test signals for more than one type of module. Use the SDP2000 Signal

Development Program software to create signal sets and assign them to a

module type. You can also save signal sets from a module to the disk.

Presets. These settings files are stored in a special binary format that is

unique to each type of module. The settings can be saved to disk and

restored later.

Sequences. These are TCL files stored as ASCII text, which is readable by

any text editor. Sequence files contain a series of SCPI and TCL commands

that are entered using a text editor. Sequence files have a .seq suffix.

To specify a sequence file to run at instrument power on, load a sequence file

named AUTOSTRT into the instrument. At power-on, the instrument checks

the disk drive first and then the internally-stored sequence files for one

named AUTOSTRT. The instrument will automatically execute the contents

of the first AUTOSTRT file it finds.

Saving Signals to Disk. Test signals that can be output from a module can be

saved onto a disk. You should save all signals in a module to a disk before

removing the module. Modules will lose their signal memory after 30 seconds

when you remove them from the mainframe.

To save signals to a disk, follow these steps:

1. Insert a preformatted disk into the drive. Ensure that the disk is not write

protected.

2. Push the Disk button to open the Disk window and then touch the Save

Signals to Disk icon.

3. Touch the Select Source icon to display a window like the one in Figure 2–9.

4. Select a module type (such as AVG1 at the left of the display) by highlight-

ing it with the arrow buttons, and then pushing the Select button. Move right

to select the signals you want to save to a disk file.

TG 2000 Signal Generation Platform Service Manual

2–13

Page 38

Operating Information

Signals are displayed in a hierarchical list with the top of the list shown at

the left under the Signals header. The value Total Tagged: is the combined

size of the selected signals.

If there are more signals than will fit on one disk, use multiple disks and

select a smaller group of signals to save on each disk.

Figure 2–9: Selecting the Save Signals to Disk source

5. Touch Quit/Save when you have selected the signals to save to disk.

6. In the Save Signals to Disk window, touch Select Destination.

7. You can use the New Dir icon to create a directory on the disk. Otherwise,

touch the New File icon and give the output file a name. In Figure 2–10, a

directory named local was created, and then a file named test1 was created.

8. When the source and destination of the test signal are entered, you can save

the signals to disk. Touch the Start Save icon to begin the save process.

Saving signals to disk takes a brief length of time that depends on the

number and size of the signals you are saving.

2–14

TG 2000 Signal Generation Platform Service Manual

Page 39

Operating Information

Figure 2–10: Selecting a Save Signals to Disk destination

Replacing Signals from Disk. You select Replace Signals from the Disk window

to load new signals in place of the currently installed signals for a module type,

such as the AVG1.

CAUTION. To prevent data loss, use caution with the Replace Signals function.

All signal sets currently loaded in the selected module type are DELETED, and

the replacement signals are then loaded into the selected module type. You

should consider saving all the signals in a module type to disk before using the

Replace Signals function.

Follow these steps to replace all signals for a type of generator module, such as

all installed AVG1 modules, with signals from a disk:

1. Insert a disk containing the signal sets into the disk drive.

2. Push the Disk button to open the Disk window, and then touch the Replace

Signals icon.

3. Use the arrow buttons to highlight the signal file you want to load, and then

press the Select button. In Figure 2–11, the file TEST1.DNL is selected.

4. Touch the Quit icon after you have selected the signal file.

5. The signals contained in the signal file (TEST1.DNL in this example) are

displayed in a hierarchical structure. Use the arrow buttons to select the

signals that you want to load. The displayed value Available: indicates the

free module memory remaining after the selected signals are loaded.

6. Touch the Start Replace icon to load the selected signals into the memory of

the compatible modules.

TG 2000 Signal Generation Platform Service Manual

2–15

Page 40

Operating Information

Figure 2–11: Replacing test signals from disk

Adding Signals from Disk. To add signals to a module from the disk drive, follow

these steps:

1. Insert the disk with the test signals into the disk drive, and then push the

Disk button to open the Disk window.

2. Touch the Add Signals icon, and then touch Select Source.

3. Select the signal set file from A: drive and then touch the Quit/Load icon.

4. Select the signals that you want to add from the signal set file. In Fig-

ure 2–12, the Linearity signals under PAL1 are selected. When you have

selected the signals you want to add, touch the Quit/Load icon, and then

touch Quit/Load again to return to the Add Signals window.

2–16

TG 2000 Signal Generation Platform Service Manual

Page 41

Operating Information

Figure 2–12: Selecting the source signals to add from disk

5. Touch the Select Destination icon, and then select the type of destination

module. If you are loading a single test signal, select the destination at the

top of the hierarchy and it will be placed in an appropriate lower folder. You

can also pick a bottom level folder for the destination.

If a mismatch between the source and destination hierarchy occurs, the

following error appears: “This selection is too deep given the source.” Try a

destination at a higher level in the hierarchy and let the TG 2000 Platform

mainframe pick the appropriate level to add the signal.

6. When you have selected the destination for the test signal you are adding,

touch the Quit/Load icon to return to the Add Signals window.

7. In Figure 2–13, the source file SPECIAL is selected from the disk drive. The

destination module type is AVG1, and the point in the hierarchy is PAL 1.

Note that the value Total Tagged: is the size, in kilobytes, of the files to be

loaded. The value Free: is the size, in kilobytes, of the free memory space on

the AVG1 module. If the Tagged value exceeds the Free value, the module

will not have enough memory space to contain the new signals. Reduce the

number of signals being loaded (Select Source) or delete a few signals from

the module (Delete Signals) to free signal space.

8. Touch the Start Load icon to transfer the signals into the destination module.

TG 2000 Signal Generation Platform Service Manual

2–17

Page 42

Operating Information

Figure 2–13: Add Signals window with source and destination selected

Deleting Signals. To delete signals from a module, follow these steps:

Self Calibration

1. Push the Disk button to open the Disk window and then touch the Delete

Signals icon.

2. Select the test signals or signal sets you want to delete. The value Total

Tagged: indicates the memory used by the selected signals.

Note that the custom signal files you create contain only signal-difference

data referenced from an original signal. The custom signals have a .sig suffix

and cannot be deleted without deleting the original signal.

3. Touch the Delete icon to remove the selected signals from the module.

This function performs an auto calibration of the selected modules. Self

calibration does not require any external test equipment, though all output

connections of the modules to be calibrated must be terminated into 75 W.

Perform self calibration on a module anytime it has been replaced to ensure

proper performance of the generator. Refer to the module user manual for

information about any special setup necessary before starting self calibration.

NOTE. All installed modules have their outputs disabled during the calibration of

any module.

2–18

Allow a 20 minute warm-up period before performing self calibration.

TG 2000 Signal Generation Platform Service Manual

Page 43

Operating Information

To calibrate one or more modules, follow these steps:

1. Push the Utilities button and touch the Module Self Cal icon.

2. Touch the module icons that you want to calibrate. Any or all modules may

be selected for calibration.

3. Ensure that all signal outputs for the selected modules are properly termi-

nated into 75 W. (You do not need to terminate the Trigger outputs of any

module and the BG1 module outputs.)

4. Touch the Start Cal icon to begin calibration of the selected modules. The

number of modules selected determines the time required for calibration.

5. Check that no errors are displayed during calibration. Refer to Maintenance

on page 6–37 for troubleshooting information.

Rear-Panel Connections

Figure 2–14 shows the rear-panel connections for the TG 2000 Platform

mainframe. Connections to modules in slots 2 through 10 are discussed in the

appropriate module user manuals.

You must select an interface port before using it. To select the interface port,

push the Remote button, and then touch the Remote Port icon repeatedly to cycle

through the available choices.

AC Power. For important information on the AC power connection, fuse, and

line selector, refer to Electrical Installation on page 2–1.

RS-232

interface

Parallel

interface

0

AC

Power

CPU

Module

Figure 2–14: Rear-panel connectors

TG 2000 Signal Generation Platform Service Manual

1098 7654321

Clock

Module

2–19

Page 44

Operating Information

RS-232 Interface (Serial). This is a standard RS-232 interface for remote control

of the TG 2000 Platform mainframe and all installed modules. The RS-232

connector (on the CPU module) is a 9-pin, subminiature, D-type connector with

male contacts. The pin descriptions are shown in Figure 2–15.

To use the interface, connect the 9-pin serial/RS-232 output of your PC to the

9-pin RS-232 connector on the rear panel of the mainframe, using a 9-pinto-9-pin straight-through cable. If necessary, a 25-pin connector can be used, in

conjunction with a 9-pin-to-25-pin adapter.

Refer to the TG 2000 Signal Generation Platform User Manual for programming information.

Data connection at TG2000

mainframe rear panel

6

9

RS–232

Pin

number

1. Not used

2. RXD (Received Data)

1

5

3. TXD (Transmitted Data)

4. Not used

5. Ground

6. DSR (Data Set Ready)

7. RTS (Request To Send)

8. CTS (Clear To Send)

9. Not used

Figure 2–15: RS-232 connector pin descriptions

Parallel Interface. The parallel interface is a 25 pin D-type connector on the CPU

module. The main purpose of the Centronics-compatible port is for transferring

signal sets from the SDP2000 Signal Development Program software into the

generator modules.

NOTE. For proper operation of the parallel interface, ensure that all 25

connector pins are connected straight through your cable.

2–20

GPIB Interface. The optional GP1 Interface module provides a GPIB interface.

For information on this interface, refer to the GP1 Interface Module User

Manual.

TG 2000 Signal Generation Platform Service Manual

Page 45

Operating Information

Power-on Procedure

The following procedure describes how to check that the TG 2000 Platform

mainframe powers on properly.

1. Before applying power to your TG 2000 Signal Generation Platform, check

the following items:

a. Check for proper installation. Refer to Installation on page 2–1.

b. Check that the power cord is connected to the AC line source.

2. Set the rear-panel Power switch to on.

3. Push the front-panel On/Standby button to apply power.

During power-on, the TG 2000 Platform mainframe performs a self test to

verify functionality. The self test requires a minute or less to complete,

depending on the number of modules installed. The front-panel display will

be on with no displayed errors after the self testing successfully completes.

If your TG 2000 Platform mainframe powers on, but an installed module

fails to appear in the Modules window, refer to Maintenance for troubleshooting instructions.

4. Once the power-on self tests are complete, the TG 2000 Platform mainframe

recalls the settings that were active when the instrument was powered off.

The power-on settings are stored in nonvolatile memory.

5. When you first power on the TG 2000 Platform mainframe after shipment or

long storage, leave the front-panel On/Standby button set to on (LED on) for

12 hours to fully charge the system batteries. The batteries maintain the test

signal data NVRAM when the mains power is disconnected.

NOTE. If backup power is lost, you must reload the test signal data into NVRAM

from the disks supplied with your user manual or through a remote port. After

reloading the test signal data, run a self calibration on all modules.

TG 2000 Signal Generation Platform Service Manual

2–21

Page 46

Operating Information

2–22

TG 2000 Signal Generation Platform Service Manual

Page 47

Page 48

Theory of Operation

This discussion provides an overview of the main components of the TG 2000

Signal Generation Platform. This discussion covers general interactions with the

modules. For information about a specific module, refer to the user manual for

that module.

Block Level Description

Figure 3–1 shows a simplified block diagram of the TG 2000 Signal Generation

Platform

External

Reference

(optional)

With AGL1 Option

Front

Panel

Disk

Drive

Remote

Control

RS-232

Parallel

GPIB

Genlock

Mainframe

CPU

Memory

Clock

CPU

Bus

Clock

Bus

Generator

Module

Signal

Memory

Generator

Module

Signal

Memory

Modules

Black

Burst

Module

Signals

Out

Signals

Out

Nine

Slots

Signals

Out

Figure 3–1: Simplified block diagram

System Control

As shown in Figure 3–1, the mainframe CPU coordinates front panel and remote

interface commands and uses that input to set up the modules, the clock, and the

optional AGL1 Genlock module. The CPU sends data and control messages over

the CPU bus to set up the generator modules to perform a function, such as load

a test signal into module memory or change the output configuration.

TG 2000 Signal Generation Platform Service Manual

3–1

Page 49

Theory of Operation

Power Supply

Disk Drive

Remote Control

Generator Modules

The 220 W power supply has a rear-panel switch to select between 115 V and

230 V operation.

The power supply delivers voltages to the various modules and mainframe

components and to the two cooling fans. The rear-panel switch is a hard power

switch, while the front-panel switch is a soft power switch.

The disk drive provides an easy way to load signal sets, presets, sequences and

other data. It also provides a way to export the same types of data. The drive

supports 1.44 Mbyte, MS-DOS format disks. The complete signal sets for each

module type are shipped with the module on 3.5 inch disks.

Most front-panel control functions can be remotely controlled using the RS-232

or optional GPIB port. A computer or other controller sends SCPI compatible

commands to set up the mainframe or a specific module. Each module must be

individually set up, using its own set of commands. The mainframe and modules

use some of the same commands, but each also has unique commands. The SCPI

command set for each module is described in section 3 of the module user

manual.

There are eleven module slots in the mainframe. The Clock and CPU modules

are required for system operation and permanently occupy two special slots (they

must be installed in these slots). The BG1 Black Burst Generator module is also

a standard component of the mainframe, but it can be moved or replaced with

another module if desired. Without the BG1 Generator module, optional AGL1

Genlock module or optional GP1 Interface module, there is room for nine

generator modules. Any combination of different generator modules and/or

multiples of the same generator module may be used.

3–2

Signal Memory

Battery Backup for

NVRAM

Most generator modules contain NVRAM for storing test signals. The test

signals are initially loaded from the supplied disks or through the parallel or

RS-232 port into NVRAM. The signal that is selected for output is loaded into

fast memory on the module. The loaded signal configures the module to

immediately output the selected signal. The flexible memory architecture allows

one generator module to output signals stored on another module of the same

type. Installing four of the same type of module, such as the AVG1 Generator

module, provides four times the signal storage space. All four modules have

equal access to this expanded memory space.

A central rechargeable battery maintains NVRAM data in the mainframe and

modules when AC power is not connected. The power supply quick charges the

battery while the instrument power is on. When the instrument is turned off

using the front-panel On/Standby switch, the battery is trickle charged. The

battery is not recharged while the rear-panel power switch is off.

TG 2000 Signal Generation Platform Service Manual

Page 50

Theory of Operation

The power drain on the battery is low enough to allow module memory to

remain intact for many months. When you add more modules or modules that

use more power, the length of time that the memory remains intact is shortened.

In the event of memory failure from power loss, reload the signal memory

(NVRAM) from the supplied disks or through a remote port, and then run self

cal on all modules.

NOTE. When you first turn on the mainframe, leave it turned on for at least 12

hours to fully charge the backup battery. Do this also after you replace the

backup battery.

Clocks and Frame Reset

Signals

The 27 MHz master clock synchronizes the clocks and frame reset pulses that

control module timing, as shown in Figure 3–2. The Clock module provides

three high-speed clock signals, one at 27 MHz, and two at rates from 10 MHz to

100 MHz. In addition, there are two frame resets which allow different modules

to operate in separate television standards, such as PAL and NTSC.

The TG 2000 Signal Generation Platform can generate different standards, such

as PAL and NTSC, at the same time, using the 27 MHz or the two adjustable

clocks and the two frame reset pulses. The clocks and frame reset pulses ensure

that all modules driving the same format remain synchronized. The CPU

configures the clock to generate the clock frequencies and frame reset pulses

needed to support the different video formats.

TG 2000 Signal Generation Platform Service Manual

3–3

Page 51

Theory of Operation

CPU Bus

Black Burst In

Black Burst In

Sine Wave

(optional module)

Temperature Controlled

Master Oscillator

(27 MHz)

AGL1

Genlock

Preset

Frame

Counter

Reset

Digital

Frequency

Synthesizer

Frame

Counter

Reset

Digital

Frequency

Synthesizer

Frame Reset 1

Clock 1

Frame Reset 2

Clock 2

27 MHz Clock

Figure 3–2: Block diagram of the clocks and frame reset signals

External Reference

Genlock

An external reference may be used by the optional AGL1 module to lock on one

of several video standards. All modules using the same standard as the AGL1

Genlock module are locked to the external reference. Refer to the AGL1 Genlock

module user manual for a list of the supported formats.

Module Timing Delay

Most generator modules can be separately timed with respect to the system. This

is accomplished by applying a precise, variable delay to the system clocks and