Page 1

User Manual

TFP2A FiberMaster

Optical Time-Domain Reflectometer

070-9189-03

This document applies to firmware version T1.2E

and above. Earlier instruments may not include all

featuresdescribedinthismanual.Refertoappendix

E.

First Printing : November1998

Page 2

Copyright 1998 Tektronix, Inc. All rights reserved. Contents of this publication may not be

reproduced in any form without the written permission of Tektronix, Inc.

Products of Tektronix,Inc. andits subsidiaries are coveredby U.S.and foreignpatents and/

or pending patents.

TEKTRONIX, TEK, and FiberMaster are registered trademarks of Tektronix, Inc.

Printed in U.S.A. Specification and price change privileges are reserved.

Tektronix, Inc.

P.O. Box 1000

Wilsonville, OR 97070-1000

Page 3

WARNING

This equipment generates, uses, and can radiate radio-frequency energy, and if not installed and

used in accordance with the instructions manual, may cause interference to radio communications. It has been tested and found to comply with the limits for a Class A computing device pursuant to Subpart J of Part 15 of FCC Rules, which are designated to provide reasonable

protection against such interference when operated in a commercial environment. Operation of

this equipment in a residential area is likely to cause interference, in which case, the user, at his

or her own expense, will be required to take whatever measures may be required to correct the

interference.

EC Declaration of Conformity

We

Tektronix Holland N.V.

Marktweg 73A

8444 AB Heerenveen

The Netherlands

declare under sole responsibility that the

TFP2A FiberMaster

meets the intent of Directive 89/336/EEC for Electromagnetic Compatibility. Compliance was demonstrated to the following specifications as listed in the official Journal of the European Communities:

EN 50081-1 Emissions

EN 55022 Radiated, Class B

IEC 1000-3-2 Mains Current Harmonics

EN 50082-1 Immunity:

IEC 1000-4-2 Electrostatic Discharge

IEC 1000-4-3 RF Radiated

IEC 1000-4-4 Fast Transients

IEC 1000-4-5 Surge

IEC 1000-4-11 Dropout

Australia / New Zealand Declaration of Conformity

EMC Complies with EMC provision of Radiocommunications per the following standard(s):

AN/NZS 2064. 1/2 Industrial, Scientific, and Medical Equipment: 1992

Page 4

Page 5

TFP2A FiberMaster User Manual

Table of Contents

Safety Information .......................................................................... xvii

1 Introduction: the FiberMaster OTDR...................................... 1-1

Product Description......................................................................................1-1

General Waveform Analysis.........................................................................1-4

Overview of FiberMaster Operation.............................................................1-6

The Acquisition Screen.............................................................................1-8

About this Manual .......................................................................................1-12

Conventions Used in this Manual ...........................................................1-13

Change and History Information.............................................................1-13

Unpacking and Preparation for Use ..........................................................1-14

Preparation for Use.................................................................................1-14

Repacking for Shipment..........................................................................1-20

Specifications..............................................................................................1-21

Electrical Characteristics.........................................................................1-21

Operational Characteristics.....................................................................1-24

Physical Characteristics..........................................................................1-24

Environmental Characteristics ................................................................1-25

FS1300 Singlemode Optical Module ......................................................1-27

FS1500 Singlemode Optical Module ......................................................1-28

FS1315 Singlemode Optical Module ......................................................1-29

FG1300 Singlemode Optical Module......................................................1-30

FG1315 Singlemode Optical Module......................................................1-31

FL1300 Singlemode Optical Module.......................................................1-32

FL1500 Singlemode Optical Module.......................................................1-33

FL1315 Singlemode Optical Module.......................................................1-34

FM8500 Multimode Optical Module ........................................................1-35

FM1300 Multimode Optical Module ........................................................1-36

FM8513 Multimode Optical Module ........................................................1-37

Inspection, Cleaning, and Maintenance....................................................1-38

Exterior Inspection..................................................................................1-38

Exterior Cleaning ....................................................................................1-39

Optical-Fiber Cleaning............................................................................1-39

Fuses, Filters, and Batteries...................................................................1-41

2 Controls, Indicators, and Connectors ................................... 2-1

General Controls, Indicators, and Connectors...........................................2-2

Optical Output Controls................................................................................2-4

Cursor Controls.............................................................................................2-6

Window Controls and Indicators .................................................................2-8

Waveform Controls and Indicators............................................................2-10

TFP2A FiberMaster User Manual v

Page 6

Table of Contents

3 Getting Started.........................................................................3-1

Power-On Defaults ........................................................................................3-4

Using FiberMaster’s Online Help.................................................................3-6

Setting up the System...................................................................................3-7

Selecting Waveform Settings....................................................................3-9

Entering Operator Settings .....................................................................3-32

Selecting System Settings......................................................................3-34

Setting User Defaults..............................................................................3-56

Remote Menu .........................................................................................3-59

4 Making Optical Fiber Measurements ..................................... 4-1

Preview Mode.................................................................................................4-3

Front Panel Controls - Preview Mode.......................................................4-4

Preview Mode Measurements—Examples...............................................4-7

Two Point Mode.............................................................................................4-9

Front-Panel Controls—Two Point Mode .................................................4-12

Two Point Measurements—Examples....................................................4-16

Splice Loss Mode........................................................................................4-22

Front Panel Controls – Splice Loss Mode...............................................4-24

Splice-Loss Measurements—Examples .................................................4-27

Link Return Loss Mode...............................................................................4-29

Front-Panel Controls—Link Return Loss Mode ......................................4-32

Link Return-Loss Measurements—Examples.........................................4-35

Event Return Loss Mode ............................................................................4-38

Front Panel Controls – Event Return Loss Mode ...................................4-41

Event Return-Loss Measurements—Examples......................................4-44

5 Event Marking .......................................................................... 5-1

Overview.........................................................................................................5-2

Turning on Event Marking............................................................................5-5

The Event Table.............................................................................................5-7

Reverting to Automatic Measurements...................................................5-10

Printing the Event Table..........................................................................5-10

Event Notes..................................................................................................5-11

Entering and Editing Event Notes...........................................................5-12

Manual Event Marking.................................................................................5-14

Entering the Place Event Markers Screen..............................................5-15

Placing Event Markers............................................................................5-15

Examples................................................................................................5-17

Automatic Measurements with Manually Placed Markers ......................5-17

Storing and Retrieving Event Markers ......................................................5-18

Operational Details of Automatic Event Marking.....................................5-19

Event-Marking Examples............................................................................5-23

vi TFP2A FiberMaster User Manual

Page 7

Table of Contents

6 Advanced Operating Functions ............................................. 6-1

The Expansion Window................................................................................6-2

Vertical SIZE Knob....................................................................................6-3

Horizontal SIZE Knob ...............................................................................6-5

Distance CURSOR Knob..........................................................................6-5

CURSOR SELECT Button........................................................................6-6

Extending the Acquisition Range................................................................6-7

High-Density Data Acquisition.....................................................................6-9

Parameter Settings and High-Density Data Acquisition..........................6-10

Storing High-Density Data ......................................................................6-10

Dual-Trace Mode..........................................................................................6-11

Aligning Waveform Scales......................................................................6-12

Changing Instrument Settings.................................................................6-12

The Expansion Window..........................................................................6-12

High-Density Data Acquisition ................................................................6-13

Real-Time Acquisition.................................................................................6-14

Setting Manual Masks.................................................................................6-15

Entering the Place Manual Masks Screen..............................................6-16

Adjusting Masks......................................................................................6-17

Implementing Manual Masks ..................................................................6-19

Clearing and Replacing Manual Masks ..................................................6-19

Exiting the Place Manual Masks Screen.................................................6-20

7 Mass Storage ........................................................................... 7-1

Load from Disk ..............................................................................................7-3

Selecting a File to Load ............................................................................7-3

Loading a Waveform File..........................................................................7-4

Loading a Settings File .............................................................................7-5

Quick Load................................................................................................7-5

Exiting the Load from Disk Menu..............................................................7-6

Save to Disk...................................................................................................7-7

File Format................................................................................................7-7

File Specifications.....................................................................................7-7

Saving the File........................................................................................7-11

Quick Save..............................................................................................7-11

Exiting the Save to Disk Menu................................................................7-12

Format ..........................................................................................................7-13

Selecting the Drive..................................................................................7-14

Exiting the Format Menu.........................................................................7-14

Delete............................................................................................................7-15

Selecting a File to Delete........................................................................7-15

Exiting the Delete Menu..........................................................................7-16

Copy..............................................................................................................7-17

Quick Copy .............................................................................................7-18

Batch Copy .............................................................................................7-18

Exiting the Copy Menu............................................................................7-18

TFP2A FiberMaster User Manual vii

Page 8

Table of Contents

8 Remote Control........................................................................8-1

GPIB System..................................................................................................8-1

GPIB Signal Lines.....................................................................................8-2

GPIB Interface Functions..........................................................................8-3

GPIB Addressing ......................................................................................8-4

GPIB Communications..............................................................................8-5

GPIB Status Reporting and Error Handling ............................................8-11

GPIB System Errors, Events, and Warnings ..........................................8-19

GPIB Message-Exchange Protocol ........................................................8-22

GPIB Controller and Instrument Synchronization ...................................8-23

GPIB Device Initialization........................................................................8-25

RS-232 System.............................................................................................8-27

RS-232 Signal Lines...............................................................................8-28

RS-232 System Setup ............................................................................8-29

RS-232 Communications........................................................................8-36

RS-232 Status Reporting and Error Handling.........................................8-39

RS-232 System Errors, Events, and Warnings.......................................8-43

RS-232 Controller and Instrument Synchronization................................8-46

RS-232 Device Initialization....................................................................8-47

Similarities and Differences between GPIB and

RS-232 Remote Control ..............................................................................8-49

Differences between GPIB and RS-232 Remote Control .......................8-49

RS-232 Emulation of IEEE 488.1 Interface Messages ...........................8-53

Remote Control Data Formats....................................................................8-56

Commands and Queries.............................................................................8-62

GPIB-Only and RS-232-Only Commands and Queries..........................8-62

Remote/Local Commands and Queries..................................................8-73

Module-Independent Settings Commands..............................................8-75

Module-Independent Settings Queries ...................................................8-79

Module-Dependent Settings Commands................................................8-82

Module-Dependent Settings Queries......................................................8-85

Module Information Queries....................................................................8-88

Serial-Port Settings Commands and Queries.........................................8-91

RS-232 Remote-Control Command........................................................8-93

Acquisition Commands...........................................................................8-94

Cursor Command and Query..................................................................8-97

Expansion Commands and Queries .......................................................8-98

Measurement Command and Queries..................................................8-101

Event Marking and Event Table Commands and Queries....................8-106

Event Marker Commands and Queries.................................................8-111

Waveform Selection and Storage Commands and Queries .................8-114

Waveform Data Command and Queries...............................................8-116

Response Formatting Commands ........................................................8-121

Response Formatting Queries..............................................................8-122

Waveform Transfer Commands and Queries .......................................8-123

Mass-Storage Commands ....................................................................8-132

Mass-Storage Queries..........................................................................8-137

Hardcopy Commands and Queries.......................................................8-141

Display-Related Commands and Query ...............................................8-146

viii TFP2A FiberMaster User Manual

Page 9

Table of Contents

Identification Query...............................................................................8-149

Learn Settings Queries.........................................................................8-150

Reset and Stop Commands..................................................................8-152

Status and Error-Reporting Commands................................................8-153

Status and Error-Reporting Queries .....................................................8-154

Device Synchronization Commands and Query ...................................8-156

Selftest Queries ....................................................................................8-157

GPIB Programming Example....................................................................8-158

RS-232 Programming Example................................................................8-161

Remote Control Event Codes and Messages.........................................8-164

Queue Status Codes.............................................................................8-164

Command Errors...................................................................................8-164

Execution Errors ...................................................................................8-166

Internal Errors.......................................................................................8-172

System Events......................................................................................8-172

Execution Warnings..............................................................................8-173

Internal Warnings..................................................................................8-173

A Accessories and Options........................................................A-1

Mainframes..............................................................................................A-1

Accessories.............................................................................................. A-1

Options..................................................................................................... A-3

B Keyboard Definitions...............................................................B-1

C FiberMaster Data Format ........................................................C-1

D Diagnostics Menus..................................................................D-1

E Firmware Features...................................................................E-1

F Error Codes..............................................................................F-1

TFP2A FiberMaster User Manual ix

Page 10

List of Illustrations

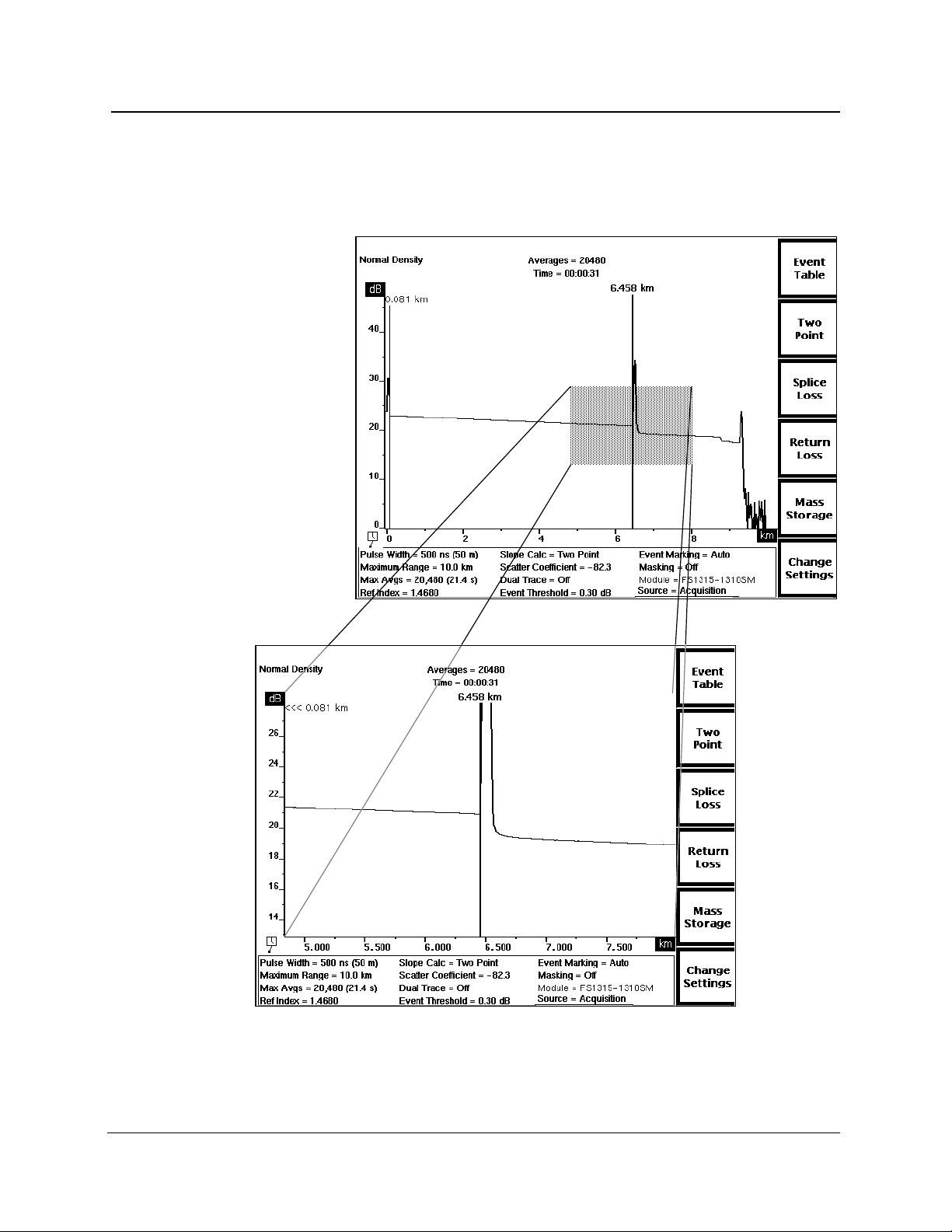

Figure 1-1. General Waveform Analysis .............................................................1-5

Figure 1-2. Features on the Acquisition Screen.................................................1-8

Figure 1-3. Acquisition Screen Expansion—Overview (top),

Figure 1-4. Installing Optical Modules ..............................................................1-15

Figure 1-5. Interconnect Circuit Board Connectors.........................................1-16

Figure 1-6. Installing the Module Spacer:

Figure 1-7. Front-Panel Option Covers .............................................................1-18

Figure 1-8. Loading Paper into the Internal Printer .........................................1-19

Figure 1-9. Cleaning and Changing the Universal Connector ........................1-40

Figure 2-1. FiberMaster Front-Panel Controls, Indicators,

Figure 2-2. FiberMaster Rear-Panel Connectors..............................................2-12

Figure 3-1. FiberMaster Start-Up Screen ............................................................3-2

Figure 3-2. Sample Help Screen ..........................................................................3-6

Figure 3-3. Pulse Width Pop-Up Selection Window,

Figure 3-4. Maximum Range Pop-Up Selection Window,

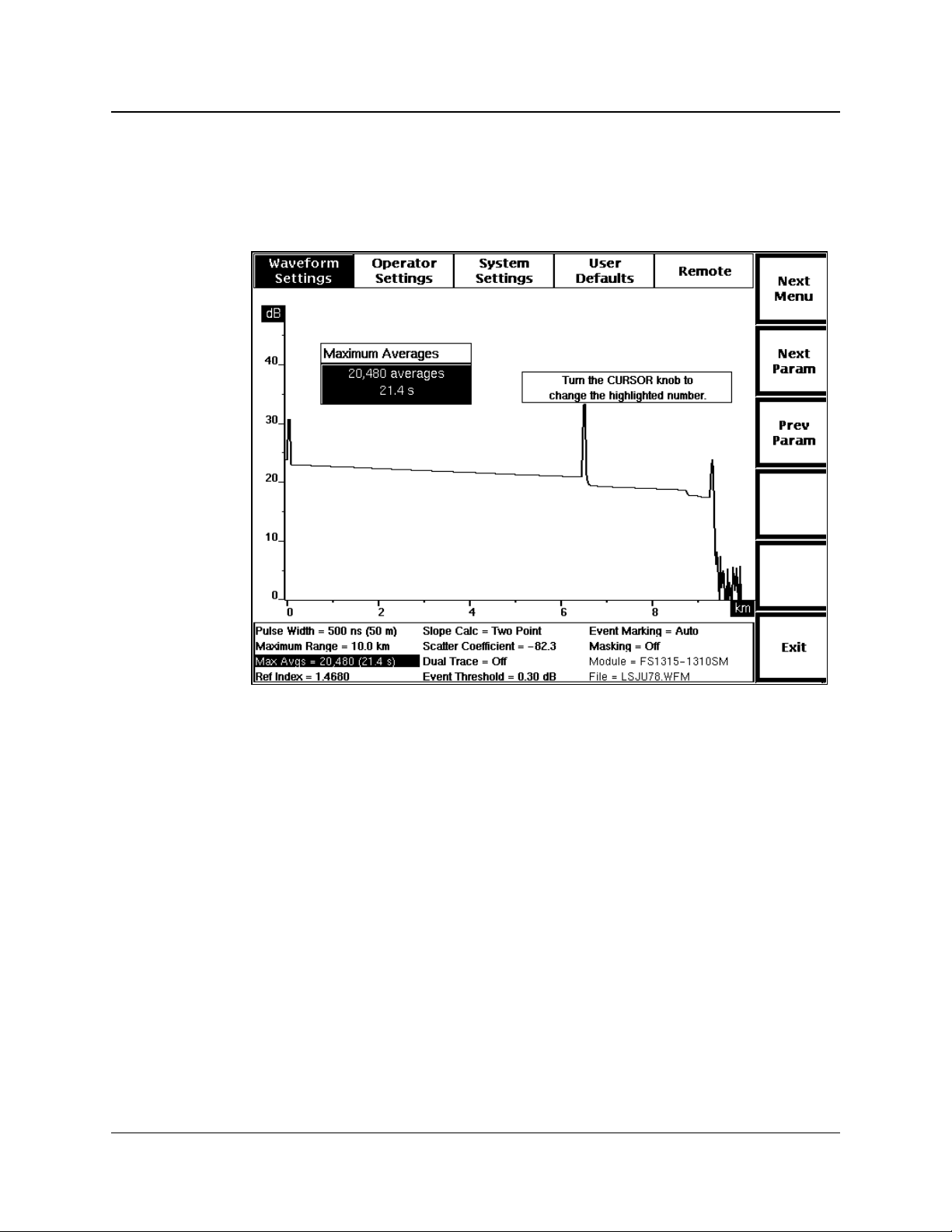

Figure 3-5. Maximum Averages Pop-Up Selection Window,

Figure 3-6. Refractive Index Pop-Up Selection Window,

Figure 3-7. Slope Calculation Pop-Up Selection Window,

Figure 3-8. Scattering Coefficient Pop-Up Selection Window,

Figure 3-9. Dual Trace Pop-Up Selection Window,

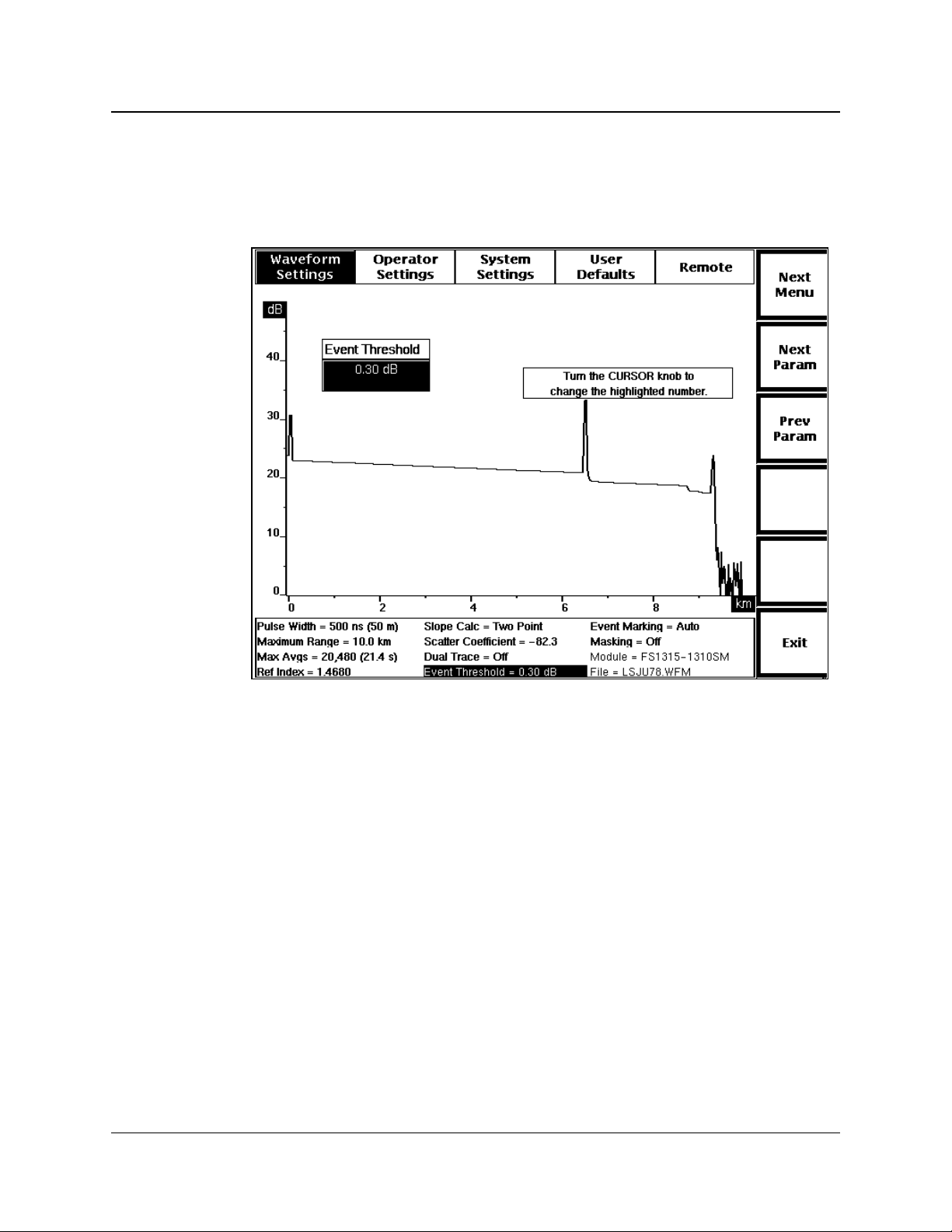

Figure 3-10. Event Threshold Pop-Up Selection Window,

Figure 3-11. Event Marking Pop-Up Selection Window,

Figure 3-12. Masking Type Pop-Up Selection Window,

Figure 3-13. Unmasked Reflection ....................................................................3-28

Figure 3-14. QuickMask......................................................................................3-28

Figure 3-15. AccuMask .......................................................................................3-29

and Expanded View (bottom)....................................................1-9

Two-Module Configuration......................................................1-17

and Connectors..........................................................................2-1

Waveform Settings Menu........................................................3-10

Waveform Settings Menu........................................................3-12

Waveform Settings Menu........................................................3-14

Waveform Settings Menu........................................................3-16

Waveform Settings Menu........................................................3-18

Waveform Settings Menu.......................................................3-20

Waveform Settings Menu........................................................3-22

Waveform Settings Menu.......................................................3-23

Waveform Settings Menu.......................................................3-25

Waveform Settings Menu.......................................................3-27

x TFP2A FiberMaster User Manual

Page 11

List of Illustrations

Figure 3-16. Filtering Pop-Up Selection Window,

Waveform Settings Menu........................................................3-30

Figure 3-17. Operator Settings Menu ................................................................3-32

Figure 3-18. Language Pop-Up Selection Window,

System Settings Menu.............................................................3-35

Figure 3-19. Display Intensity Pop-Up Selection Window,

System Settings Menu.............................................................3-37

Figure 3-20. Display Color Pop-Up Selection Window,

System Settings Menu............................................................3-38

Figure 3-21. Sound Pop-Up Selection Window,

System Settings Menu.............................................................3-39

Figure 3-22. System Time Pop-Up Selection Window,

System Settings Menu.............................................................3-40

Figure 3-23. System Date Pop-Up Selection Window,

System Settings Menu.............................................................3-41

Figure 3-24. Date Format Pop-Up Selection Window,

System Settings Menu.............................................................3-42

Figure 3-25. Units Pop-Up Selection Window,

System Settings Menu.............................................................3-43

Figure 3-26. Keyboard Translation Pop-Up Selection Window,

System Settings Menu.............................................................3-44

Figure 3-27. File Format Pop-Up Selection Window,

System Settings Menu.............................................................3-45

Figure 3-28. Hardcopy Device Pop-Up Selection Window,

System Settings Menu.............................................................3-47

Figure 3-29. GPIB Status Pop-Up Selection Window,

System Settings Menu.............................................................3-49

Figure 3-30. GPIB Address Pop-Up Selection Window,

System Settings Menu.............................................................3-50

Figure 3-31. RS232 Baud Rate Pop-Up Selection Window,

System Settings Menu.............................................................3-51

Figure 3-32. RS232 Parity Pop-Up Selection Window,

System Settings Menu.............................................................3-52

Figure 3-33. RS232 Stop Bits Pop-Up Selection Window,

System Settings Menu.............................................................3-53

Figure 3-34. RS232 Data Bits Pop-Up Selection Window,

System Settings Menu.............................................................3-54

Figure 3-35. RS232 Flow Control Pop-Up Selection Window,

System Settings Menu.............................................................3-55

Figure 3-36. User Defaults Menu, Page 1..........................................................3-56

Figure 3-37. User Defaults Menu, Page 2..........................................................3-57

Figure 3-38. Remote Menu .................................................................................3-59

Figure 4-1. Preview Mode, Overview (top) and

Expanded View (bottom)...........................................................4-3

TFP2A FiberMaster User Manual xi

Page 12

List of Illustrations

Figure 4-2. Preview Mode, Measuring Distance to End of Fiber.......................4-7

Figure 4-3. Preview Mode, Measuring Distance to Fusion Splice ....................4-8

Figure 4-4. Two Point Mode (Two-Point Slope Calculation) .............................4-9

Figure 4-5. Two Point Mode (LSA Slope Calculation)......................................4-10

Figure 4-6. Automatic Two-Point Measurement—Positioning the

First Distance Cursor...............................................................4-16

Figure 4-7. Automatic Two-Point Measurement—Positioning the

Second Distance Cursor .........................................................4-17

Figure 4-8. User-Adjusted Two-Point Measurement—Adjusting the

Active Loss Cursor..................................................................4-18

Figure 4-9. User-Adjusted Two-Point Measurement—Adjusting the

Loss Cursor in Expanded View ..............................................4-19

Figure 4-10. User-Adjusted Two-Point Measurement......................................4-19

Figure 4-11. Automatic Fiber Loss Measurement—Placing the

First Cursor...............................................................................4-20

Figure 4-12. Automatic Fiber-Loss Measurement—Placing the

Second Cursor .........................................................................4-21

Figure 4-13. Splice Loss Mode...........................................................................4-22

Figure 4-14. Automatic Splice-Loss Measurement..........................................4-27

Figure 4-15. User-Adjusted Splice-Loss Measurement...................................4-28

Figure 4-16. Link Return Loss Mode .................................................................4-30

Figure 4-17. Automatic Link Return-Loss Measurement—Placing the

First Cursor at the Start of the Link........................................4-35

Figure 4-18. Automatic Link Return-Loss Measurement—Placing the

Second Cursor at the End of the Link....................................4-36

Figure 4-19. User-Adjusted Link Return-Loss Measurement..........................4-37

Figure 4-20. Event Return Loss Mode...............................................................4-39

Figure 4-21. Automatic Event Return-Loss Measurement ..............................4-44

Figure 4-22. User-Adjusted Event Return-Loss Measurement .......................4-45

Figure 5-1. Event Marking ....................................................................................5-2

Figure 5-2. Event Table (above) and Event Notes (below) ................................5-3

Figure 5-3. Turning on Event Marking.................................................................5-5

Figure 5-4. The Event Table .................................................................................5-7

Figure 5-5. Event Notes ......................................................................................5-11

Figure 5-6. Editing Event Notes.........................................................................5-12

Figure 5-7. The Place Event Markers Screen

(Cursor on Event Marker)........................................................5-14

Figure 5-8. The Place Event Markers Screen

(Cursor off Event Marker)........................................................5-16

Figure 5-9. The Place Event Markers Screen (Moving Event Marker)............5-16

Figure 5-10. Event Marking and Grouped Reflective Events ..........................5-19

Figure 5-11. Event Marking and Grouped Non-Reflective Events..................5-20

xii TFP2A FiberMaster User Manual

Page 13

List of Illustrations

Figure 5-12. Event Marking and Unmasked Grouped Events.........................5-21

Figure 5-13. Event Marking and Masked Grouped Events..............................5-21

Figure 5-14. Event Marking and Nonreflective Gain

Produced by Waveform Reconstruction................................5-22

Figure 5-15. Event Marking and Incorrect Mask Placement............................5-22

Figure 5-16. Unmarked Fusion Splice...............................................................5-23

Figure 5-17. Manually Marked Fusion Splice....................................................5-23

Figure 5-18. Automatically Marked Fusion Splice ...........................................5-24

Figure 5-19. Fusion Splice Undetected in Noise..............................................5-24

Figure 5-20. Fusion Splice Automatically Detected in Noise..........................5-25

Figure 6-1. The Expansion Window.....................................................................6-2

Figure 6-2. Moving the Expansion Window........................................................6-4

Figure 6-3. Short Acquisition Range...................................................................6-7

Figure 6-4. Cursor Past Acquisition Range and Resulting Prompt..................6-8

Figure 6-5. Extended Acquisition ........................................................................6-8

Figure 6-6. Dual Waveform Display...................................................................6-11

Figure 6-7. Place Manual Masks Screen ...........................................................6-15

Figure 7-1. Load from Disk Menu: Single-Drive Instrument..............................7-3

Figure 7-2. Load Menu: Dual-Drive Instrument ..................................................7-4

Figure 7-3. Quick Load .........................................................................................7-6

Figure 7-4. Save Menu: Dual-Drive Instrument ..................................................7-8

Figure 7-5. Save Menu: Single-Drive Instrument ...............................................7-9

Figure 7-6. Format Menu: Single-Drive Instrument..........................................7-13

Figure 7-7. Format Menu: Dual-Drive Instrument.............................................7-14

Figure 7-8. Delete Menu: Single-Drive Instrument...........................................7-15

Figure 7-9. Delete Menu: Dual-Drive Instrument..............................................7-16

Figure 7-10. Copy Menu: Dual-Drive Instrument..............................................7-17

Figure 8-1. Standard and Linear Bus Configurations........................................8-1

Figure 8-2. Sample GPIB IEEE 488 System ........................................................8-2

Figure 8-3. GPIB Status Reporting and Error Handling...................................8-13

Figure 8-4. RS-232 Direct Connection and Connection over

Telephone Line.........................................................................8-27

Figure 8-5. RS-232 Status Reporting and Error Handling ...............................8-39

Figure A-1. Connector Options...........................................................................A-4

Figure D-1. Run Diagnostics Menu.....................................................................D-1

Figure D-2. Set Options Menu.............................................................................D-2

Figure E-1. Firmware Version Number on the Start-Up Screen.......................E-1

TFP2A FiberMaster User Manual xiii

Page 14

List of Tables

Table 1-1. Display Range—Vertical System .....................................................1-21

Table 1-2. Display Range—Horizontal System.................................................1-22

Table 1-3. Display................................................................................................1-22

Table 1-4. Keyboard............................................................................................1-22

Table 1-5. Hardcopy............................................................................................1-23

Table 1-6. Mass Storage .....................................................................................1-23

Table 1-7. Operational Characteristics..............................................................1-24

Table 1-8. Physical Characteristics...................................................................1-24

Table 1-9. Environmental Characteristics.........................................................1-25

Table 1-10. FS1300 Singlemode Optical Module..............................................1-27

Table 1-11. FS1500 Singlemode Optical Module..............................................1-28

Table 1-12. FS1315 Singlemode Optical Module..............................................1-29

Table 1-13. FG1300 Singlemode Optical Module .............................................1-30

Table 1-14. FG1315 Singlemode Optical Module .............................................1-31

Table 1-15. FL1300 Singlemode Optical Module..............................................1-32

Table 1-16. FL1500 Singlemode Optical Module..............................................1-33

Table 1-17. FL1315 Singlemode Optical Module..............................................1-34

Table 1-18. FM8500 Multimode Optical Module................................................1-35

Table 1-19. FM1300 Multimode Optical Module................................................1-36

Table 1-20. FM8513 Multimode Optical Module................................................1-37

Table 1-21. External Inspection Checklist ........................................................1-38

Table 8-1. FiberMaster GPIB Interface Functions ..............................................8-3

Table 8-2. Uniline Interface Messages ................................................................8-5

Table 8-3. Multiline Universal Interface Messages.............................................8-6

Table 8-4. Multiline Addressed Interface Messages .........................................8-6

Table 8-5. Multiline Address Interface Messages ..............................................8-6

Table 8-6. GPIB Status Register Summary.......................................................8-11

Table 8-7. GPIB Event Code Categories ...........................................................8-19

Table 8-8. RS-232 Signal Lines ..........................................................................8-28

Table 8-9. FiberMaster-to-DTE Wiring...............................................................8-29

Table 8-10. FiberMaster-to-DCE Wiring.............................................................8-30

Table 8-11. FiberMaster-to-DTE Wiring.............................................................8-30

Table 8-12. Hayes Accura Modem Settings for FiberMaster

Table 8-13. RS-232 Status Register Summary..................................................8-39

Table 8-14. RS-232 Event Code Categories......................................................8-43

Table 8-15. Remote/Local Commands and Queries.........................................8-64

Remote Control...............................................................................8-32

xiv TFP2A FiberMaster User Manual

Page 15

List of Tables

Table 8-16. Module-Independent Settings Commands and Queries.............8-64

Table 8-17. Module-Dependent Settings Commands and Queries.................8-65

Table 8-18. Module Information Queries...........................................................8-65

Table 8-19. Serial Port Settings Commands and Queries...............................8-65

Table 8-20. RS-232 Remote-Control Command................................................8-66

Table 8-21. Acquisition Commands ..................................................................8-66

Table 8-22. Cursor Movement Command and Query.......................................8-66

Table 8-23. Expansion Commands and Queries..............................................8-66

Table 8-24. Measurement Command and Queries...........................................8-67

Table 8-25. Event Marking and Event Table Commands and Queries...........8-67

Table 8-26. Event Marker Commands and Queries..........................................8-68

Table 8-27. Waveform Selection and Storage Commands and Queries........8-68

Table 8-28. Waveform Data Command and Queries........................................8-68

Table 8-29. Response Formatting Commands and Queries ...........................8-69

Table 8-30. Waveform Transfer Commands and Queries ...............................8-69

Table 8-31. Mass-Storage Commands and Queries.........................................8-70

Table 8-32. Hardcopy Commands and Queries................................................8-71

Table 8-33. Display-Related Commands and Query ........................................8-71

Table 8-34. Identification Query.........................................................................8-71

Table 8-35. Learn Settings Queries ...................................................................8-71

Table 8-36. Reset and Stop Commands............................................................8-72

Table 8-37. Status and Error Reporting Commands and Queries..................8-72

Table 8-38. Device Synchronization Commands and Query...........................8-72

Table 8-39. Selftest Queries ...............................................................................8-72

Table A-1. Mainframe Options ............................................................................A-1

Table A-2. Standard Accessories .......................................................................A-1

Table A-3. Optional Accessories ........................................................................A-2

Table A-4. System Options..................................................................................A-2

Table A-5. System Multimode Options...............................................................A-2

Table A-6. System Singlemode Options ............................................................A-3

Table A-7. Option Accessories ...........................................................................A-3

Table B-1. Global Keyboard Functions..............................................................B-1

Table B-2. Menu-System Keyboard Functions..................................................B-2

Table B-3. Menu-System Numeric-Parameter Keyboard Functions................B-2

Table B-4. Menu-System Alphanumeric-Parameter

Keyboard Functions........................................................................B-3

Table B-5. Mass-Storage Keyboard Functions..................................................B-3

Table B-6. Acquisition-Screen Keyboard Functions ........................................B-4

Table E-1. Firmware Versions and Features...................................................... E-2

TFP2A FiberMaster User Manual xv

Page 16

List of Tables

Table F-1. File System Error Codes ................................................................... F-1

Table F-2. Flash Memory Error Codes .............................................................. F-3

Table F-3. LED Error Codes ............................................................................... F-4

Table F-4. Phase 1 Error Codes ......................................................................... F-5

Table F-6. Phase 2 Error Codes ......................................................................... F-5

xvi TFP2A FiberMaster User Manual

Page 17

Safety Information

The general safety information in these pages is for both operating and servicing

personnel. In addition, specific warnings and cautions appear throughout the manual

where they apply.

Definition of Terms and Symbols

In this manual, a CAUTION flag identifies a potential for equipment or other property

damage.

A WARNING flag identifies a potential for personal injury or property damage.

A DANGER flag identifies an immediate hazard to personal safety or property.

Symbols that may be marked on the equipment indicate the following:

DANGER—High Voltage

!

Power Source

This product is designed to operate from a power source that will not apply more than

250 volts RMS between the supply conductors or between the supply conductor and

ground. A protective ground connection by way of the grounding conductor in the

power cord is essential for safe operation.

Grounding the Instrument

The instrument is grounded through the grounding conductor of the power cord. To

avoid electric shock, plug the power cord into a properly wired receptacle before

connecting to the product input or output terminals.

ATTENTION—refer to manual

Protective ground (earth) terminal

TFP2A FiberMaster User Manual xvii

Page 18

User Safety Summary

Danger Arising from Loss of Ground

If you lose the protective ground connection, all accessible conductive parts (including

knobs and controls that appear to be insulating) can render an electric shock.

Use the Proper Power Cord

Use only the power cord and connector specified for your product. Use only a power

cord in good condition. Refer cord and connector changes to qualified service

personnel.

Use the Proper Fuse

To avoid fire hazard, use only a fuse of the correct type, voltage rating, and current

rating as specified in theparts list for yourproduct. Refer fuse replacement to qualified

service personnel.

Do Not Operate in Explosive Atmospheres

To avoid explosion, do not operate this product in an explosive atmosphere unless it

has been specifically certified for such operation.

Do Not Remove Covers or Panels

To avoid personal injury, do not remove the product covers or panels. Donot operate

the product without the covers or panel properly installed.

Laser Radiation

Avoid eye exposure to the laser output and open-ended fibers by covering the end or

directing the output at a non-reflective surface.

Class 1 laser product under the Radiation Control and Health Safety Act of 1968.

Repair

Refer all repair problems to qualified service personnel.

FiberMaster has been classified as a

xviii TFP2A FiberMaster User Manual

Page 19

Page 20

1 Introduction:

the FiberMaster OTDR

ATTENTION!

Read the Safety Information section located at the front of this manual before

operating FiberMaster.

This manual applies to the TFP2A firmware shown on the title page of this

manual. For a list of firmware releases and major features, refer to appendix E.

The information in this appendix will help you use this manual with earlier TFP2

firmware versions.

If you have questions about using FiberMaster, or have special application

problems, in the U.S. and Canada call our toll-free help line,

1-800-TEK-WIDE ext. 24

Product Description

The TEKTRONIX TFP2A FiberMaster Optical Time-Domain Reflectometer (OTDR) is

an optical-fiber test instrument capable of measuring loss characteristics and

displaying faults, splices, and other fiber events in singlemode and multimode optical

fibers.

FiberMaster applies pulses of light to the fiber under test via the optical output

connector. As the pulses travel through the fiber, some light is reflected back to the

instrument. These reflections are processed to display a visual representation of the

fiber on FiberMaster’s cathode ray tube (CRT), where you can make distance and

loss measurements on the fiber under test.

, or contact your local Tektronix representative.

The CRT display is a time plot, read from left to right. The trace starts with the

outgoing pulse, and the time difference is converted to distance in the measurement

process. When you view a typical fiber display, events that are further down the fiber

appear to the right (later in time). Loss is measured on the CRT’s vertical scale.

NOTE

TFP2A FiberMaster User Manual 1-1

This manual explains how to use the TFP2A FiberMaster product line, which

includes mainframe models TFP2A (color monitor) and TFP2AM (monochrome

monitor), configured with various options. (Refer to appendix A,

Options

“FiberMaster” or “TFP2A,” to refer to both the TFP2A and TFP2AM models.

With the exception of a parameter on the System Settings menu used to set the

color on color monitors, the operation of the two mainframes is identical.

This manual is also compatible with TFP2/TFP2M instruments. Refer to appendix

E for a list of the firmware features that apply to earlier FiberMaster models.

.) In this manual, the instrument is referred to generically as

Accessories and

Page 21

Chapter 1: Introduction

Modular, Plug-In Laser Sources

❏ The FiberMaster OTDR was designed using a modular approach that allows you

to choose options that answer your specific test and measurement applications.

You can easily upgrade your instrument configuration as your system

requirements change. FiberMaster can accommodate 850-nanometer (nm)

multimode, 1300-nm multimode, 1310-nm singlemode, and 1550-nm singlemode

laser sources in one or two plug-in modules. The modules can contain either two

singlemode or two multimode lasers, or any single laser, allowing the instrument

to be configured with from one to all four wavelengths.

❏ Temperature-controlled laser light sources ensure stable wavelength and optical

output for highly accurate measurements.

Accurate, High-Speed Data Acquisition and Measurement

❏ The internal 32-bit microprocessor performs up to 16 million high-speed

averages per acquisition, maximizing the signal-to-noise ratio, giving a clear

display of fiber events.

❏ FiberMaster measures a specific fiber feature, with single-keystroke

convenience. In addition, manual adjustments provide extended flexibility in

interpreting the fiber data.

❏ An expand function allows you to magnify any portion or feature on the displayed

fiber acquisition.

❏ FiberMaster’s high-density acquisition capability offers extended expansion

capacity and highly accurate measurements.

❏ A masking function can be performed automatically, or you can set manual

masks to eliminate detector saturation caused by large Fresnel reflections,

improving measurement linearity.

Automatic and Manual Event Marking

❏ The instrument’s event-marking function automatically locates and measures

events on the fiber under test that have splice losses above a user-specified

threshold, or you can also mark events manually.

❏ An event table is compiled displaying the measurements for each marked event.

You can edit and print out this table, plus enter notes and mapping information

about each event.

1-2 TFP2A FiberMaster User Manual

Page 22

Extended Memory and Storage Capacity

❏ FiberMaster offers both a current memory, containing the current data

acquisition, and a reference memory, for previously acquired fiber waveform

data. A dual-trace mode makes it possible to display the contents of both current

and reference memory simultaneously, allowing you to compare a current

optical-fiber acquisition to historical data.

❏ Mass-storage devices (the standard floppy-disk drive and optional internal RAM)

permit unlimited storage of waveform and settings data on both removable and

internal media.

Hardcopy Options

❏ You can choose the optional high-speed internal thermal printer, or use

FiberMaster with either an IEEE 488 general-purpose interface bus (GPIB)

external plotter or printer, or an RS232 external plotter or printer. One press of a

button on the instrument’s front panel provides a 15-second hard copy of the

displayed waveform and instrument settings on the internal printer.

Chapter 1: Introduction

Remote Control Capability

❏ The FiberMaster OTDR can be operated under the remote control of an

instrument controller or a computer with a GPIB interface, using an IEEE 488

general-purpose interface bus, or via the RS-232 serial interface.

Additional Features

❏ An easy-to-use menu system simplifies setting instrument measurement

parameters.

❏ You can upload and download waveform and settings data using the RS232

interface and XModem protocol.

❏ The 7-inch diagonal, high-resolution color or monochrome CRT provides a

comprehensive on-screen readout of waveform and measurement data, and

instrument settings.

❏ Online help displays context-sensitive operator assistance at the press of a

button.

❏ Rugged, portable construction is also lightweight—under 35 pounds (15

kilograms).

TFP2A FiberMaster User Manual 1-3

Page 23

Chapter 1: Introduction

General Waveform Analysis

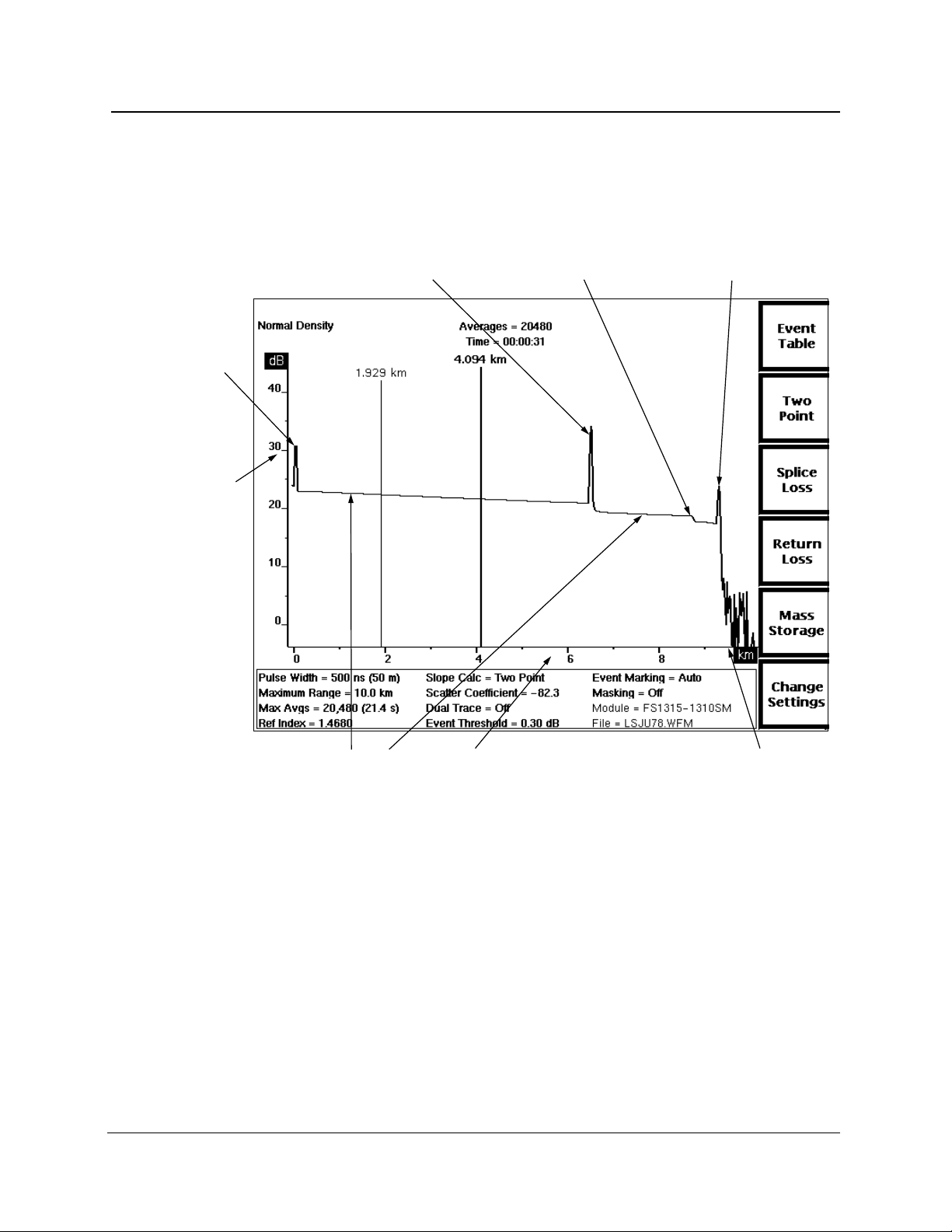

Figure 1-1 shows an optical fiber waveform acquisition typical of the data you might

see on the FiberMaster CRT. The horizontal axis shows the distance from

FiberMaster’s front-panel connector to points along the fiber under test. The vertical

axis measures reflected light detected by the OTDR, and represents transmission

loss along the fiber length.

The leftmost spike is a reflection caused by the front-panel connector. The sloping

waveform is backscattered light (light reflected back towards its source) that shows

fiber characteristics. The slope of the waveform represents the optical fiber loss. A

low-loss, homogeneous fiber will show a gradually sloping waveform.

Any breaks or connections along the fiber appear on the display as either reflective or

nonreflective discontinuities in the waveform, as shown in figure 1-1. These

discontinuities, or “events,” indicate locations along the fiber where you might find a

splice, connector, bend, break, or other anomaly in the cable.

1-4 TFP2A FiberMaster User Manual

Page 24

Chapter 1: Introduction

Use the data displayed on the OTDR’s screen to determine the physical locations of

these types of optical-fiber faults, to help analyze their probable causes, and to

measure cable transmission loss.

Reflection

at front-panel

connector

Loss

scale

(dB)

Reflective loss

at connector or

mechanical splice

Nonreflective loss,

i.e. a fusion splice

or a bend in the cable

Reflective break at

the end of the fiber

(the end of the fiber

can also be nonreflective)

Backscattered

light

Distance scale (meters or feet)

Noise

floor

Figure 1-1. General Waveform Analysis

TFP2A FiberMaster User Manual 1-5

Page 25

Chapter 1: Introduction

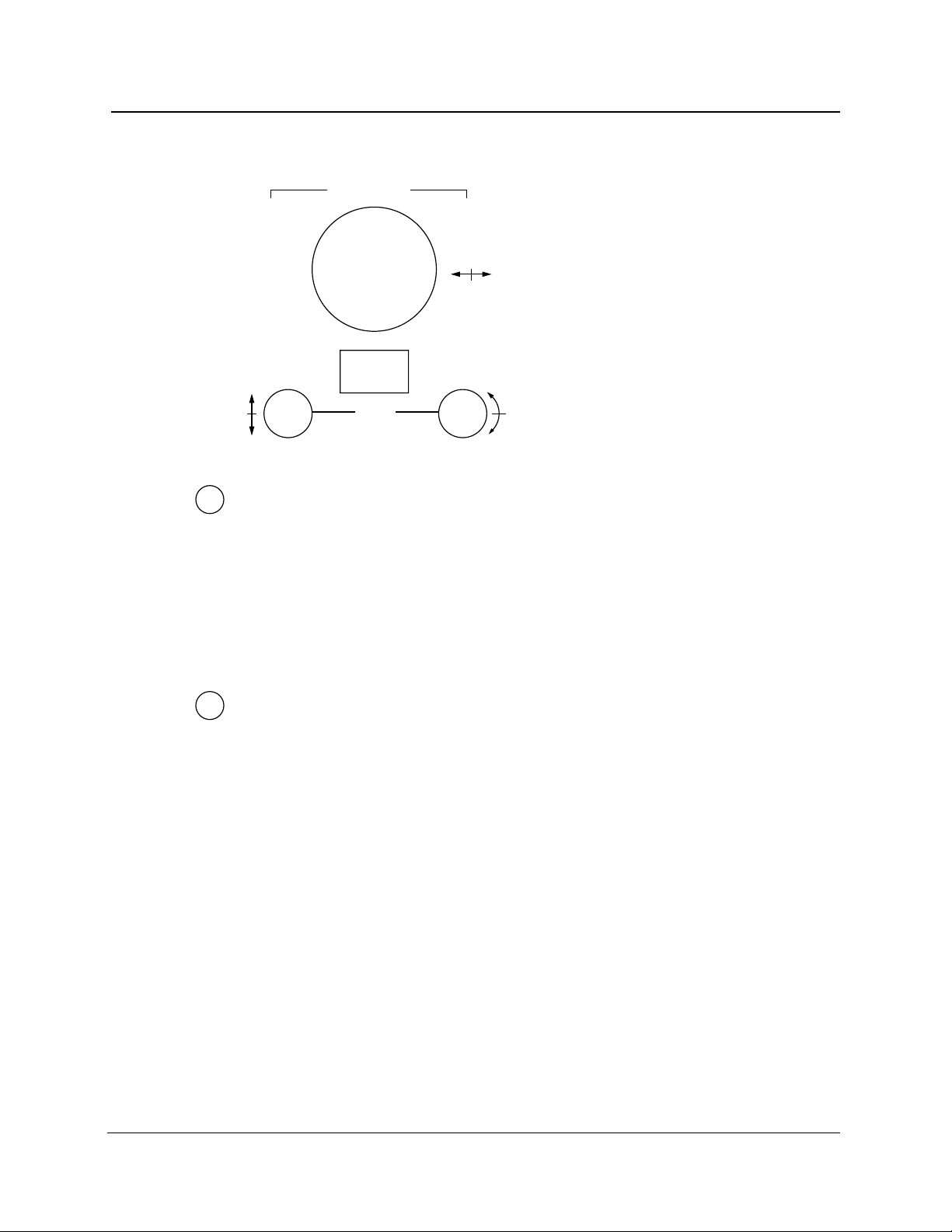

Overview of FiberMaster Operation

Start data acquisition on a fiber-optic cable under test by simply connecting the cable

to the appropriate front-panel connector, and pressing the START/STOP button. An

averaged waveform appears on the screen, and you can make measurements

immediately.

The FiberMaster OTDR provides five measurement modes for viewing faults and

measuring transmission loss, fusion-splice loss, connection loss, return loss, and

other characteristics of fiber-optic cable. These are Preview, Two Point, Splice Loss,

and two Return Loss modes.

❏ Preview mode gives a clear overview of the fiber. Scan fiber features and

measure distances in Preview mode.

❏ Two Point mode allows you to measure loss between any two points on the fiber.

❏ Splice Loss mode gives loss measurements at splice points along the fiber.

❏ Link Return Loss mode lets you measure the return loss of a fiber link.

❏ Event Return Loss shows the return loss for a particular event on the fiber.

Enter each measurement mode by pressing a front-panel softkey. Two-point, splice-

loss, and return-loss measurements can be made automatically. Front-panel controls

permit manual adjustment to automatic measurements.

Automatic and manual event-marking modes locate and perform measurements on

all events on the fiber under test. An online table is compiled that contains two-point,

splice-loss, return-loss, and distance measurements for each event. You can adjust

measurement values on the table, and enter and edit notes for each event.

A general-purpose interface bus (GPIB) and the RS-232 serial interface allow remote

control of the instrument.

Advanced Functions

FiberMaster’s automatic measurements provide adequate data for many applications.

If you require more in-depth fiber analysis, however, the instrument’s advanced

functions offer extended flexibility in acquiring and interpreting fiber data. These

functions include:

❏ High-density data acquisition

❏ A dual-waveform display, for comparing two waveforms

❏ Manipulation of the expansion window

❏ Real-time acquisition

❏ Manual-masking capabilities

1-6 TFP2A FiberMaster User Manual

Page 26

Instrument Configuration

Instrument configuration and measurement settings are set through a menu system,

accessed by pressing a front-panel softkey. You can set parameters using various

front-panel controls to enter the data, or you can connect an optional IBM-ATcompatible keyboard to FiberMaster for data entry.

Mass Storage

The mass-storage system is also entered through a front-panel softkey, for storing

waveform and settings data on floppy disks or an optional internal RAM. Data is

saved in MS-DOS-compatible files.

Chapter 1: Introduction

TFP2A FiberMaster User Manual 1-7

Page 27

Chapter 1: Introduction

The Acquisition Screen

The acquisition screen displays fiber test data and measurement information, and is

used for all fiber-evaluation activity. Other than instrument setup, event marking, and

mass-storage operations, most of your work with FiberMaster will be on the

acquisition screen.

The acquisition screen displays either data acquisition in progress or a completed

acquisition, including all measurements on the fiber under test. Distance and loss

cursors display on this screen, depending on the measurement mode, and can be

manipulated to perform manual measurements on the fiber.

The acquisition screen includes:

❏ A horizontal distance scale and a vertical loss scale.

❏ One or two distance cursors, and one or two loss cursors, depending on the

measurement mode.

Vertical

scale (dB)

Inactive

distance

cursor

Waveform

settings

Expansion

window

Active

distance

cursor

Loss

cursors

Horizontal scale

(kilometers or kilofeet)

Softkey labels

Figure 1-2. Features on the Acquisition Screen

1-8 TFP2A FiberMaster User Manual

Page 28

Chapter 1: Introduction

❏ An expansion window. Pressing the EXPAND button on the front panel switches

between expanded view and overview. In expanded view, the area within the

expansion window is magnified to fill the display, allowing closer examination of

the fiber. See figure 1-3.

Figure 1-3. Acquisition Screen Expansion—Overview (top),

and Expanded View (bottom)

TFP2A FiberMaster User Manual 1-9

Page 29

Chapter 1: Introduction

❏ Waveform and measurement data. Distance and loss measurements are

displayed on the screen near the waveform. In Two Point mode and both returnloss modes, the slope calculation and return loss, respectively, appears in the

upper right-hand corner of the screen. The message User Adjusted

Measurement displays in the upper left-hand corner of the screen for all

manually adjusted measurements. The actual number of averages that were

performed on the waveform, and the actual elapsed averaging time are shown in

the upper center screen. If an acquisition is in progress, the number of averages

and the time elapsed are seen increasing.

During an acquisition, the display also contains an acquisition-active indicator in

the lower-left corner of the waveform area. This indicator provides a quick way to

check whether an acquisition is still in progress. When data acquisition is

complete, and calculations are still in progress, the indicator changes to show a

clock with a swinging pendulum.

When event-marking mode is turned on, events on the fiber are marked and

numbered at the bottom of the acquisition screen. In addition, when the active

distance cursor is on an event marker, a field below the horizontal distance scale

displays measurements for that event.

❏ On color monitors, the waveform area of the acquisition screen is color coded for

easier interpretation of data and measurements. Waveform data, including the

active waveform (except for high-density data), the number of averages, elapsed

time, and the Normal Density or High Density message, is green. The useradjustable elements—distance and loss cursors, and the User Adjusted

Measurement message—are displayed in red. Measurement values such as the

two-point distance and loss, splice loss, fiber loss, and return loss figures are

shown in yellow. Event markers are also displayed in yellow.

1-10 TFP2A FiberMaster User Manual

Page 30

Chapter 1: Introduction

❏ All waveform settings used for the acquisition are displayed at the bottom of the

screen. These user-defined settings are selected on the Waveform Settings

menu, reached by pressing the Change Settings softkey on the acquisition

screen. Refer to chapter 3,

Getting Started

, for information on configuring your

instrument and setting parameters.

A Module parameter in the list of settings indicates which laser source is

currently selected. The type of module is shown, plus the currently selected

wavelength. For example, FS1315-1310SM indicates that the 1310-nm

wavelength of a dual-wavelength singlemode FS-type optical module is currently

selected. If the active module is different from the one that was used to acquire

the current waveform, the module parameter is highlighted.

The module parameter may include alphabetical characters to indicate the

modification level of the module, and whether the module has an internal fiber

with a non-standard core diameter. This information is appended to the

wavelength. Lower-case letters indicate the modification level of the module, and

upper-case letters stand for a non-standard core diameter. For example:

FS1315-1310SM — standard module with standard core diameter

FS1315-1310SMaA — modified module with non-standard core diameter

FS1315-1310SMA — standard module with non-standard core diameter

FS1315-1310SMa — modified module with standard core diameter

For more information on module modifications and internal fiber core diameters,

in the U.S. and Canada, call 1-800-833-9200, or contact your local Tektronix

representative.

The Source parameter shows where the current waveform data originated. The

data could be the result of an acquisition, a data transfer, or from a mass-storage

file. For an acquisition, the parameter displays as Source = Acquisition. If the

waveform was loaded from mass storage, the parameter reads File =

<FILE_NAME> where <FILE_NAME> is the name of the mass-storage file. If the

waveform data was received via an XModem data transfer, the parameter reads

Source = XModem.

❏ Softkey labels display along the right-hand edge of the screen. On the acquisition

screen, the softkeys allow you to switch measurement modes, view the event

table, enter the menu system, and access mass-storage functions.

TFP2A FiberMaster User Manual 1-11

Page 31

Chapter 1: Introduction

About this Manual

The FiberMaster User Manual consists of seven chapters and six appendices,

containing the following information:

❏ Chapter 1,

unpacking and repacking instructions, instrument specifications, and user

maintenance.

❏ Chapter 2,

of the front- and rear-panel controls and connectors.

❏ Chapter 3,

settings defaults, and describes the menu system used to configure the

instrument and set measurement parameters.

❏ Chapter 4,

measurement modes—Preview, Two Point, Splice Loss, Link Return Loss, and

Event Return Loss—and how to make automatic and manual measurements on

a fiber in these modes.

❏ Chapter 5,

documenting events on the fiber under test. Events can be marked either

automatically or manually. An event table of measurements is compiled, based

on the locations of the event markers.

❏ Chapter 6,

FiberMaster’s features, including details on the expansion window, high-density

data acquisition, dual waveform operation, and real-time mode.

❏ Chapter 7,

(floppy disk drive, internal RAM) to store and retrieve waveform and settings

data.

Introduction

, provides a description of the FiberMaster OTDR,

Controls, Indicators, and Connectors

Getting Started

, explains how to use the online help function, lists

Making Optical Fiber Measurements

Event Marking,

Advanced Operating Functions

Mass Storage

explains the process of locating, measuring, and

, outlines advanced aspects of some of

, explains how to use the mass-storage device(s)

, describes the functions of each

, describes each of the

❏ Chapter 8,

instructions on how to use the instrument under remote control via GPIB and RS-

232.

❏ Appendices contain information that applies to general operation of the

instrument. They include a list of options and accessories available for use with

the FiberMaster OTDR, a description of the instrument’s data output, a list of

keyboard sequences recognized by the instrument, how to run the instrument’s

diagnostic self tests, a list of firmware versions, a list of start-up error codes, and

instructions on how to upgrade software via floppy disk.

1-12 TFP2A FiberMaster User Manual

Remote Control

, contains the remote-control command set and

Page 32

Conventions Used

in this Manual

In the text of this manual, references to front-panel controls and softkeys appear in

boldface type, for example:

Press the START/STOP button.

Change instrument settings by pressing the Change Settings softkey.

Remote-control commands and messages as sent and received by the instrument

are shown indented and in upper-case, boldface type:

ACQUIRE 10.0,START,NORMAL;*OPC?

Change and History Information

Change information that involves manual corrections and additional data is located at

the back of this manual in the

the updated data is integrated into the text or diagrams when a page is updated.

Change Information

Chapter 1: Introduction

section. History information with

TFP2A FiberMaster User Manual 1-13

Page 33

Chapter 1: Introduction

Unpacking and Preparation for Use

Before unpacking FiberMaster from its shipping container or carton, inspect for signs

of external damage. If the carton is damaged, notify the carrier. The shipping carton

contains the instrument and its standard and optional accessories.

If the contents of the shipping container are incomplete, if there is mechanical

damage or defects, or if the instrument does not meet operational check

requirements, contact your local Tektronix Field Office or representative. If the

shipping container is damaged, notify the carrier as well as Tektronix.

The instrument was inspected both mechanically and electrically before shipment. It

should be free of mechanical damage and meet or exceed all electrical

specifications. Functional and operational self tests are performed at power-on. If

your instrument fails to perform satisfactorily, contact your Tektronix representative

immediately, or in the U.S. and Canada, telephone toll free 1-800-TEK-WIDE ext.

2400.

Preparation for Use

Use FiberMaster’s front cover to protect the front panel when storing and transporting

the instrument. Remove the cover by pulling out on the sides and lifting off. Replace

the cover by pressing it over the front panel until the cover snaps in place. The

instrument’s accessories are stored in the soft carrying case.

You can position FiberMaster’s handle to serve as a tilt stand, or you can move it to

the front of the instrument, so the instrument can be stacked or carried. To position

the handle, press in at both pivot points and rotate to the desired position.

Power Source and Power Requirements

FiberMaster is intended to be operated from a power source that does not apply more

than 250V RMS between the supply conductors, or between either supply conductor

and ground. A protective ground connection by way of the grounding conductor in the

power cord is essential for safe operation.

The AC power connector is a three-wide, polarized plug with the ground (earth) lead

connected directly to the instrument frame to provide electrical shock protection. If

the unit is connected to any other power source, the unit frame must be connected to

an earth ground.

CAUTION

To avoid electric shock, the power cord protective grounding conductor must be

connected to ground.

1-14 TFP2A FiberMaster User Manual

Page 34

Power and voltage requirements are printed on the back panel. With the DC power

option (option 17), FiberMaster can be operated from 11 to 16 VDC, or from 90 to

250 VAC nominal line voltage at 47 to 73 Hz. AC-only instruments can be operated

from 90 to 250 VAC, 47 to 73 Hz.; or from 90 to 130 VAC, 47 to 440 Hz. In AC-only

instruments, power-source selection is made automatically when the unit is plugged

in.

Installing the Optical Module(s)

Your TFP2A mainframe may be shipped with optical module(s) installed. If you order

modules separately, you may have to install them at your site. Install one or two

optical modules into the mainframe as follows:

1. Detach the left-hand side of the mainframe back panel by unscrewing four black

quick-release screws in each corner of the back-panel assembly (see figure 1-4).

Pull the back-panel assembly off the mainframe using the handle provided,

disconnecting the control and module support boardsfrom the interconnectboard,

which is attached to the inside of the back panel.

Backpanel

quick-release screws

Chapter 1: Introduction

Module

quick-release screws

Backpanel

quick-release screws

Figure 1-4. Installing Optical Modules

TFP2A FiberMaster User Manual 1-15

Page 35

Chapter 1: Introduction

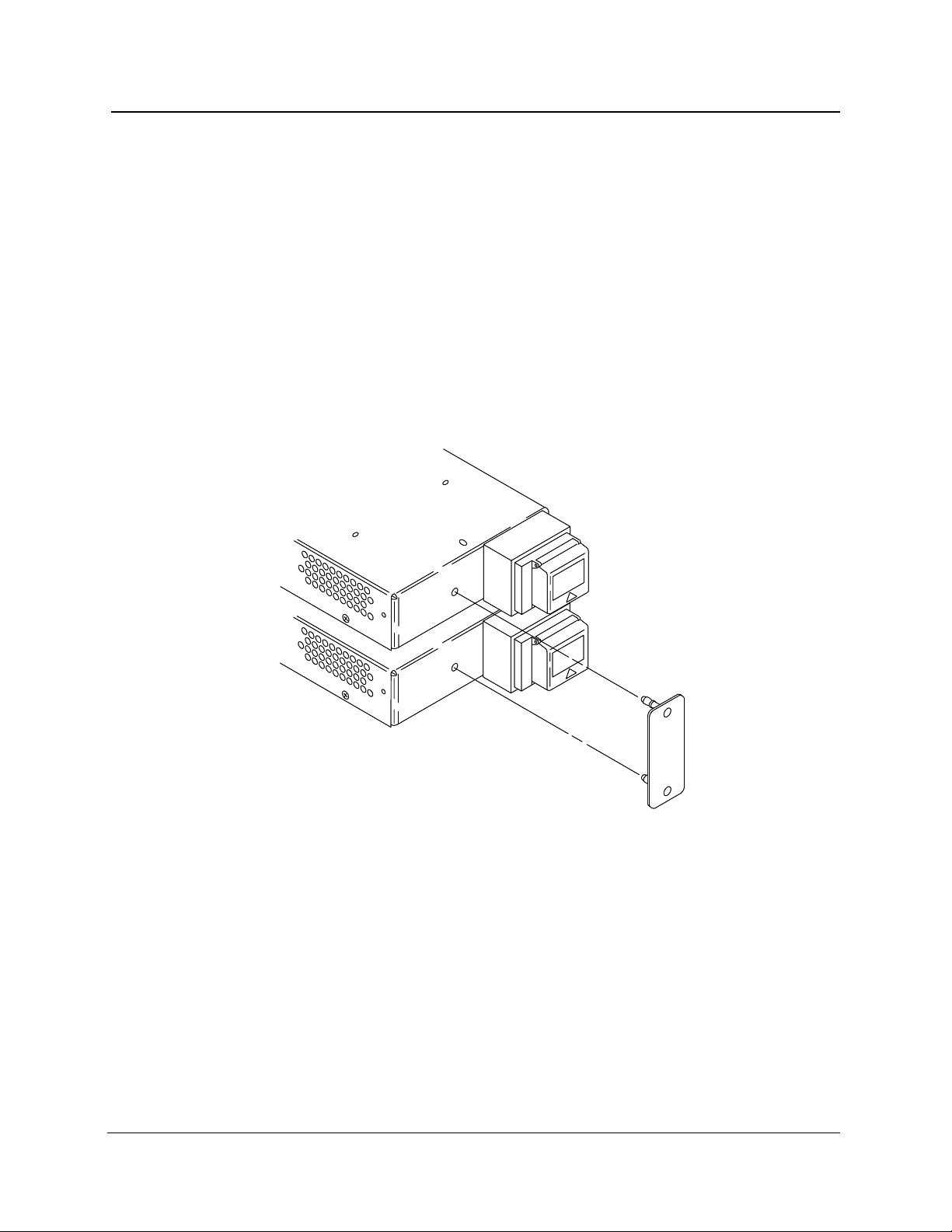

(use for second module)

2. Plug one module into the bottom set of module connectors on the interconnect

board, inserting the module’s screwholes through the back-panel assembly. (See

figure 1-5.)

3. Secure the module to the back-panel assembly by tightening the two back-panel

quick-release screws into the module’s screwholes.

4. If you have a second module, plug it into the top set of module connectors on the

interconnect board.

Module support

board connectors

Module connectors

Module connectors

(use for single module)

Control board

connector

Figure 1-5. Interconnect Circuit Board Connectors

5. Secure the secondmodule to the back-panelassemblyby tightening the twoquick-

release screws into the module’s screwholes.

1-16 TFP2A FiberMaster User Manual

Page 36

Chapter 1: Introduction

6. If you are installing two modules, snap the spacer between the modules as shown

in figure 1-6, into the holes provided .

7. Place the modules inside the mainframe, lining up the fiber connectors with the

openings in the front panel, and reconnecting the control and module support

boards to the interconnect board.

NOTE

Align the connectors on the interconnect board correctly to ensure complete

connections with the module support board, optical module(s), and control board.

If connections are not made properly, the instrument will not work.

8. Reattach the back-panel assembly to the mainframe by tightening the four black

quick-release screws. All the screws in the back-panel assembly can be tightened

further using a screwdriver, if necessary.

To take the modules out of the TFP2A mainframe, reverse this procedure.

Figure 1-6. Installing the Module Spacer:

Two-Module Configuration

TFP2A FiberMaster User Manual 1-17

Page 37

Chapter 1: Introduction

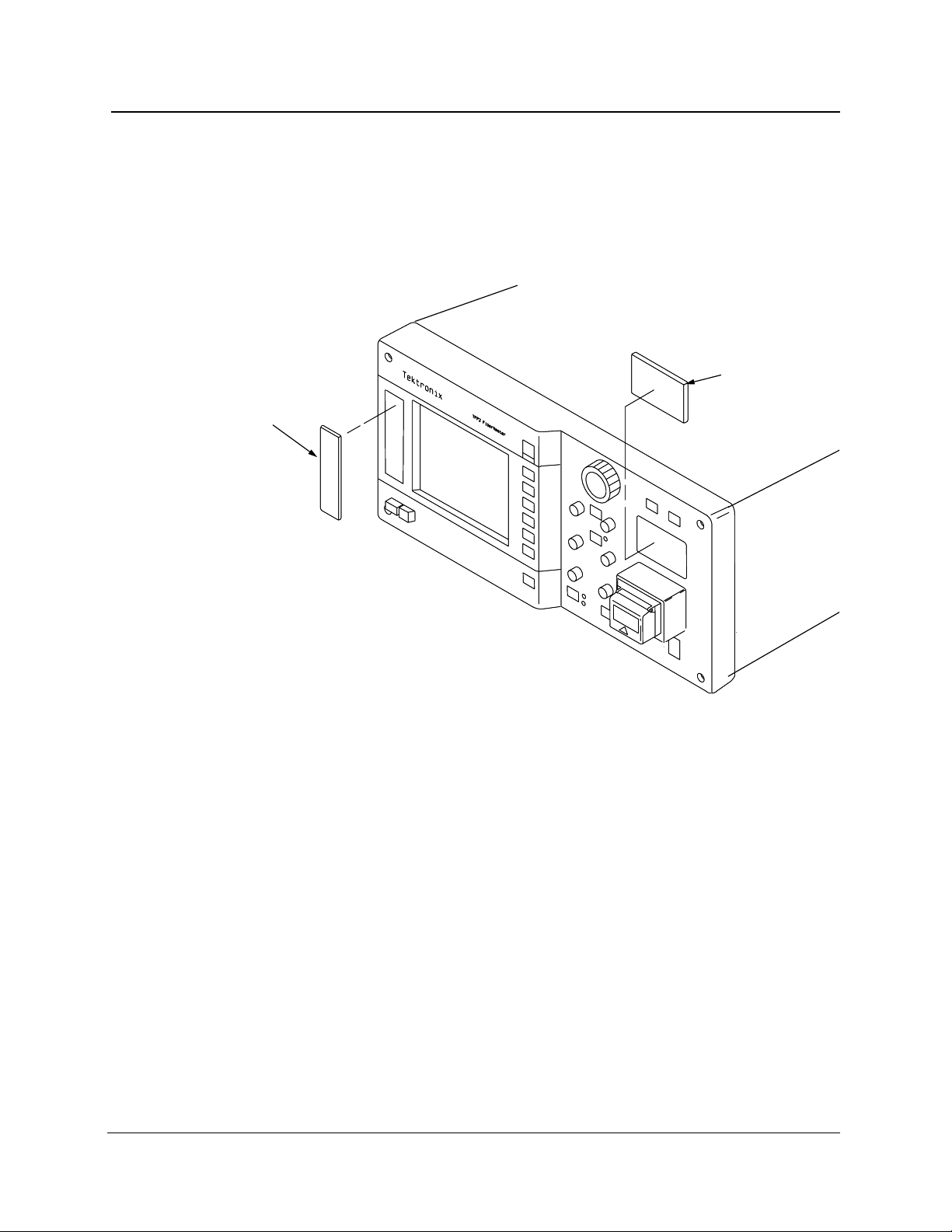

Front-Panel Covers

If your instrument includes one optical module, the top module slot on the front panel

is unused. If your instrument is not configured with a floppy-disk drive, the drive slot is

unused. Unused option slots are covered before the instrument is shipped from the

factory. If you change your instrument’s configuration, however, you may need to

remove or install these covers, as shown in figure 1-7.

Disk-drive

cover

Option-port

cover

Figure 1-7. Front-Panel Option Covers

1-18 TFP2A FiberMaster User Manual

Page 38

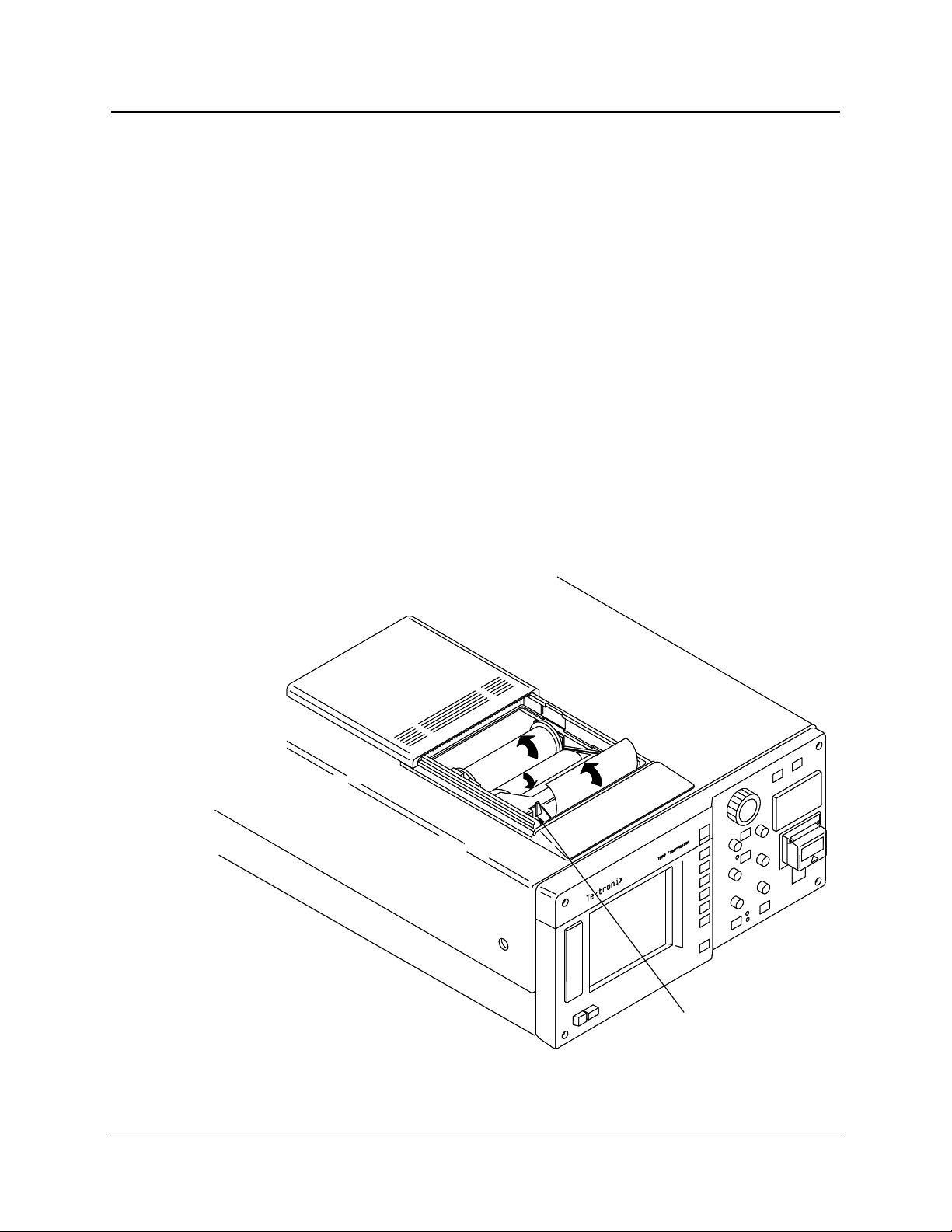

Loading Paper into the Internal Printer

To load paper into the internal thermal printer, follow these steps:

1. Slide the printer cover back.

2. Lift out the old paper roll and remove the black disks from either end.

3. Insert the disks into the ends of the new paper roll.

4. Place the new roll into the printer, with the end of the paper coming out from under

the roll towards the front of the instrument.

5. Push the paper tension lever down, and hold it down for step 6.

6. Feed the paper into the slot in the paper guide, until it comes out in front of the

aluminum paper guide. See figure 1-8. The arrows indicate the direction in which

to feed the paper.

7. Release the tension lever.

When the printer is in use, slide the printer cover closed until it reaches the stops

provided for the paper opening. Use the serrated edge of the cover as a guide to tear

the paper off. After printing, tear off any remaining paper and slide the cover

completely closed over the printer.

Chapter 1: Introduction

Paper tension

lever

Figure 1-8. Loading Paper into the Internal Printer

TFP2A FiberMaster User Manual 1-19

Page 39

Chapter 1: Introduction

Laser Output

FiberMaster is equipped with low-energy lasers and does not output continuous

energy unless you have started data acquisition (by pressing the START/STOP button).

WARNING

The TFP2A FiberMaster has been classified as a Class 1 laser product under the

Radiation Control and Health Safety Act of 1968.

Although output from a Class 1 laser is not considered hazardous, it is good

practice not to allow eye exposure from direct or reflected laser light. This can be

avoided by covering the end of the fiber or directing the output at a non-reflective

surface.