Page 1

TECHNICAL MANUAL

OPERATOR’S, ORGANIZATIONAL, DIRECT

SUPPORT, AND GENERAL SUPPORT

MAINTENANCE MANUAL INCLUDING

REPAIR PARTS AND SPECIAL TOOLS LISTS

SPECTRUM ANALYZER PL-1391/U

(TEKTRONIX MODEL 7L5)

(NSN 6625-01-015-6587)

TM 11-6625-2759-14 & P

HEADQUARTERS, DEPARTMENT OF THE ARMY

DECEMBER 1978

Page 2

WARNING

DANGEROUS VOLTAGES

exist in this equipment. Be extremely careful when working on the power supply circuit or the AC line connections during

line power operation. Serious injury or DEATH may result from contact with these points.

DON’T TAKE CHANCES!

Page 3

TM 11-6625-2759-14 & P

This manual contains copywrite material reproduced by permission of the Tektronix Company.

TECHNICAL MANUAL HEADQUARTERS

DEPARTMENT OF THE ARMY

NO. 11-6625-2759-14 & P WASHINGTON, DC,

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT,

AND GENERAL SUPPORT MAINTENANCE MANUAL

INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

You can improve this manual by recommending improvem ents using DA Form 2028-2 located in the back of the

manual. Simply tear out the self- addressed form, fill it out as shown on the sam ple, f old it where shown, and drop it in the

mail.

If there are no blank DA Forms 2028-2 in the back of the manual, use the standard DA Form 2028 (Recommended

Changes to Publications and Blank Forms) and forward to the Comm ander, US Army Communications and Electronics

Materiel Readiness Command, ATTN: DRSEL-ME-MQ, Fort Monmouth, NJ 07703.

In either case a reply will be furnished direct to you.

6December 1978

SPECTRUM ANALYZER PL-1391/U

(TEKTRONIX MODEL 7L5)

(NSN 6625-01-015-6587)

REPORTING OF ERRORS

NOTE

This manual is an authentication of the manufacturer’s commercial literature which, through usage, has been found to

cover the data required to operate and maintain this equipment. Since the manual was not prepared in ac cordance with

military specifications and AR 310-3, the format has not been structured to consider levels of maintenance.

i

Page 4

PART I TM 11-6625-2759-14 & P

TABLE OF CONTENTS

PAGE

Section 0 INTRODUCTION 0-1

Section 1 General Information

Introduction 1-1

Description 1-1

Specification 1-1

Frequency Characteristics 1-1

Input Characteristics 1-2

Amplitude Characteristics 1-2

Sweep Characteristics 1-3

Output Connectors 1-3

Environmental Characteristics 1-4

Physical Characteristics 1-4

Accessories and Options 1-4

Section 2 Installation

Initial Inspection 2-1

Installation 2-1

Repackaging 2-1

Section 3 Operating Instructions

Introduction 3-1

Functional Block Description 3-1

Front Panel Controls and Connectors 3-3

Calibrating the 7L5 to the Oscilloscope Mainframe 3-7

Operational Checkout 3-8

Preliminary Preparation 3-8

Operational Check of Readout Characters 3-8

Dynamic Range Accuracy 3-10

Reference Level Accuracy 3-11

Input Buffer 3-12

Residual (Incidental) FM 3-12

Residual Response 3-12

Sensitivity Check 3-13

Resolution Bandwidth Accuracy, Amplitude Deviation and Shape Factor 3-13

Using the Analyzer 3-14

Impedance Matching 3-14

Signal Application 3-14

Edge Noise 3-14

Frequency Measurement Technique 3-15

Max Span Operation 3-15

Resolution and Resolution Bandwidth 3-15

Digital Storage 3-15

Applications for Spectrum Analyzers 3-15

Page 5

INTRODUCTION

0-1. SCOPE

This manual describes Spectrum Analyzer PL1391/U and provides instructions for operation (Part I)

and maintenance (Part II). T hroughout this manual the

PL-1391/U is referred to as the Tekronix Model 7L5.

SECTION 0

(SF 361).

Report (DISREP) (SF 361) as prescribed in AR 5538/NAVSUPINST 4610.33B/AFR 75-18/MCO P4610.19C

and DLAR 4500.15.

TM 11-6625-2759-14 & P

c. Discrepancy in Shipment Report (DISREP)

Fill out and forward Discrepancy in Shipm ent

0-2. INDEXES OF PUBLICATIONS

a.

DA Pam 310-4. Refer to the latest issue of

DA Pam 310-4 to determine whether there are new

editions, changes, or additional publications pertaining to

the equipment.

b

. DA Pam 310-7. Refer to the DA Pam 310-7

to determine whether there are modif ication work orders

(MWO’s) pertaining to the equipment.

0-3. FORMS AND RECORDS

a. Reports of Maintenance and Unsatisfactory

Equipment.

which are to be used by maintenance personnel at all

maintenance levels are listed in and prescribed by TM

38-750.

Maintenance forms, records, and reports

b. Report of Packaging and Handling

Deficiencies.

Improvement Report) as prescribed in AR 70058/NAVSUPINST 4030.29/AFR 71-13Imco P4030.29A

and DLAR 4145.8.

Fill out and forward DD Form 6 (Pack aging

0-4. REPORTING EQUIPMENT IMPROVEMENT

RECOMMENDATIONS (EIR)

EIR’s will be prepared using SF Form 368,

Quality Deficiency Report. Instructions for preparing

EIR’s are provided in TM 38-750, The Army Maintenance

Management System. EIR’s should be mailed direct to

Commander, US Army Comm unications and Electronics

Materiel Readiness Command, ATTN: DRSEL-ME-MQ,

Fort Monmouth, NJ 07703. A reply will be furnished

direct to you.

0-5. ADMINISTRATIVE STORAGE

For information concerning storage, refer to section 2.

0-6. DESTRUCTION OF ARMY ELECTRONICS

MATERIEL

Destruction of Army electronics materiel to prevent

enemy use shall be in accordance with TM 750-244-2.

0-1

Page 6

TM 11-6625-2759-14 & P

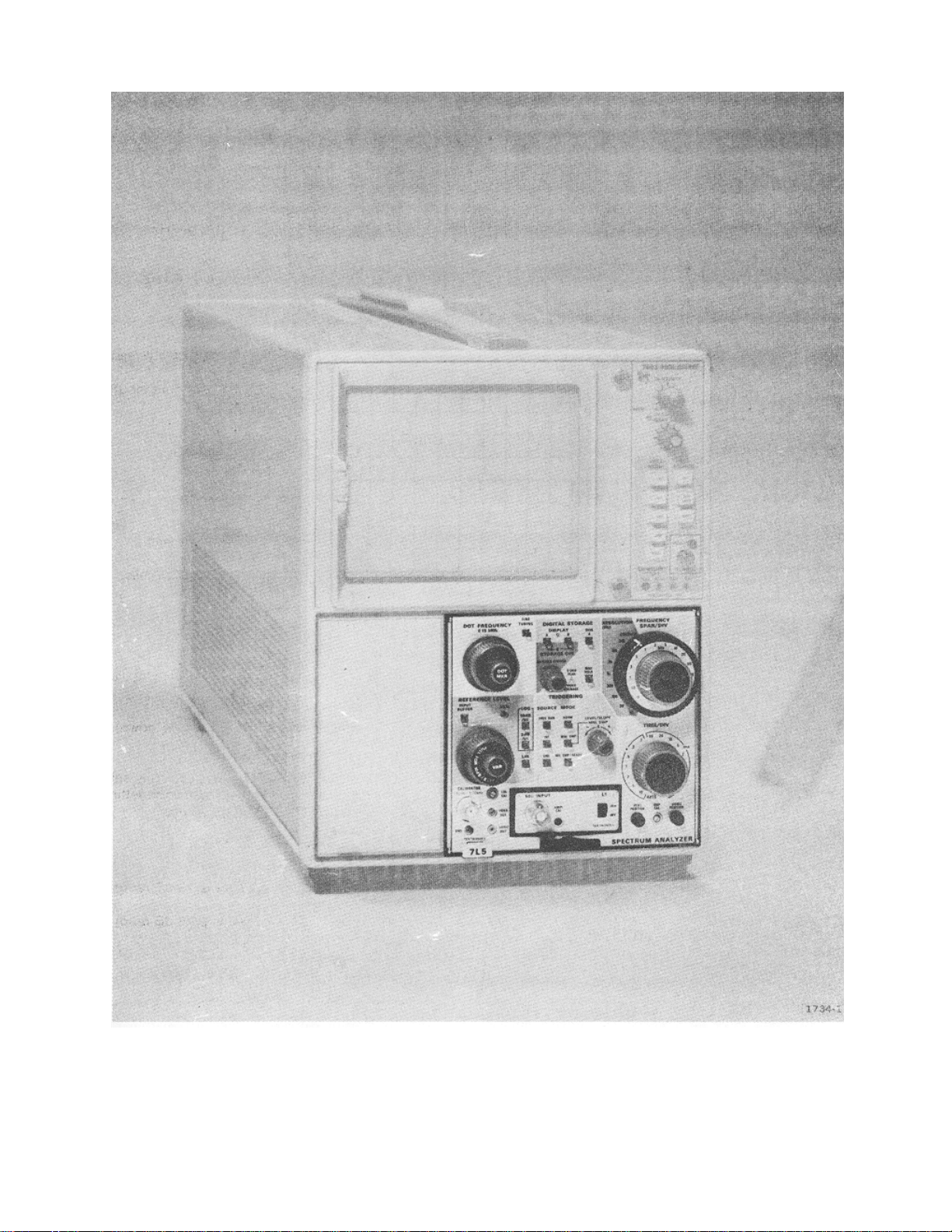

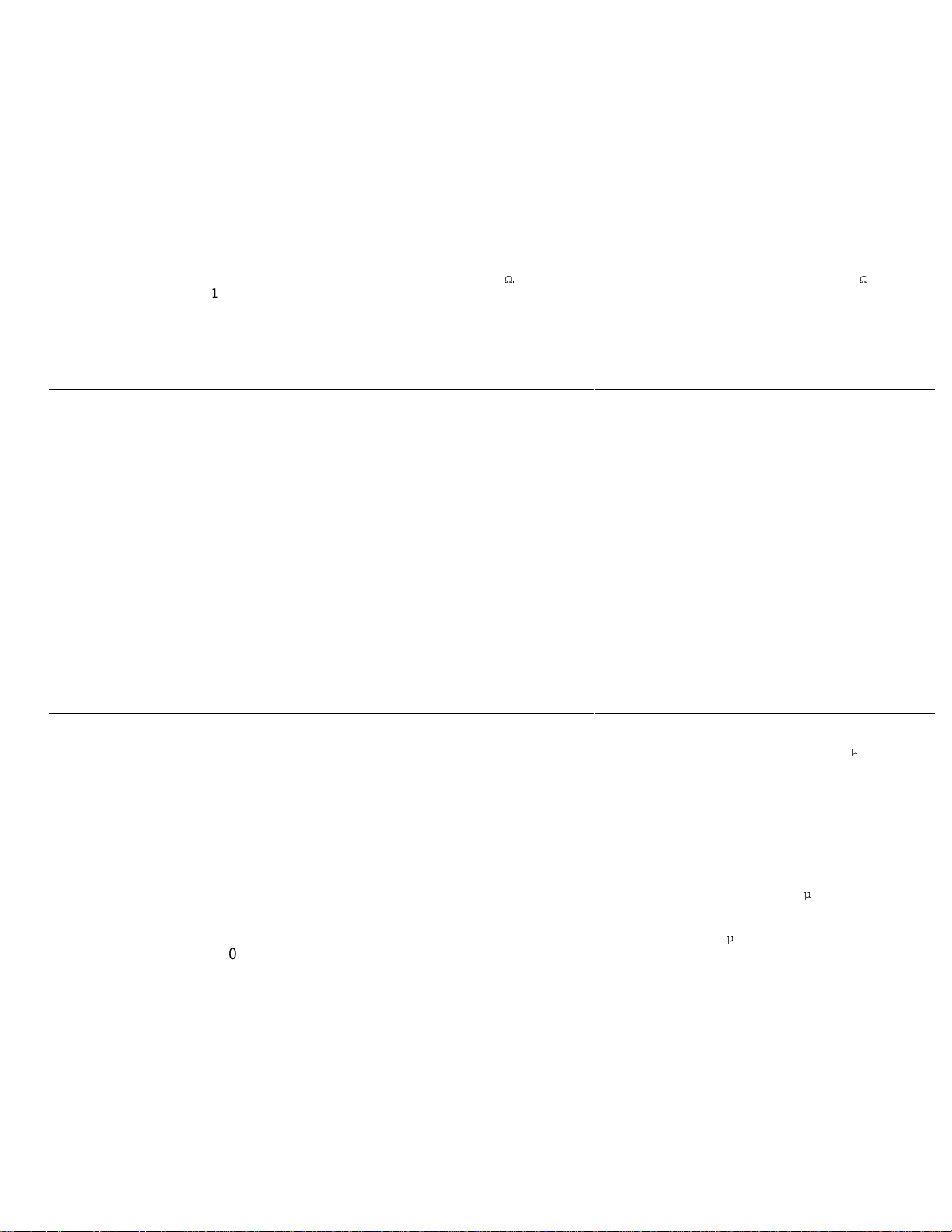

Fig. 1-1. 7L5 Spectrum Analyzer.

1-0

Page 7

SECTION 1. SPECIFICATION

Introduction

To effectively use the 7L5 Spectrum Analyzer,

the operation and capabilities of the instrument must be

known This instruction manual covers general operating

information about the instrument. Service information,

such as circuit description and c alibration are contained

in the Service manual.

TM 11-6625-2759-14 & P

Frequency Characteristics

Range

Input Frequency: 10 Hz through 5 0 MHz.

Dot Frequency: 0 Hz through 4999.75 kHz.

Description

The 7L5 is a 5 MHz spectrum analyzer with

digital storage. Frequency stability is within 5 Hz/hr and

center frequency (dot) can be read with six digit acc uracy

immediately after turn-on. There is no need to fine tune

the display Complex measurements and analysis can be

made with relative ease. Built-in micro-processing

circuits decode control settings, process frequency and

reference level information, and optimize sweep time and

resolution for the selected frequency span.

The 7L5 with 80 dB or more of spurious free

dynamic range, provides the ability to measure wide

relative amplitudes. Nanovolt sensitivity provides very

low-level signal and noise measurements.

The 7L5 display is fully calibrated in dBm, dBV,

or volts/div The reference level can be acc ur ately s et to 1

dB increments. A front panel input buffer control

increases front-end immunity to intermodulation distortion

while maintaining a constant reference level. To

accommodate a wide variety of impedance sources, the

7L5 uses quick disconnect plug-in input impedance

modules of 50 Ò, 75 Ò, 600 Ò, 1 MÒ/28 pF and

customized units to meet special requirements.

Digital storage allows any 7000-Series

mainframe, with crt readout, to present clean, easy to

photograph, displays. A smooth integrated display

provides an accurate analysis of most displays. Two

complete displays can be held in memory for comparis on

Two modes select either the conventional peak display or

a digitally averaged display.

ELECTRICAL CHARACTERISTICS

Accuracy

20àC to 30°C: +(5 Hz + 2 x 10

readout).

0°C to 50°C: ±(20 Hz + 10

readout).

Drift

5 Hz/hour or less.

Residual (Incidental) FM

50 Hz/div to 2 kHz/div: 1 Hz (p-p) or less.

5 kHz/div to 500 kHz/div. 40 Hz (p-p) or less.

Resolution Bandwidth

Accuracy

30 kHz--30 Hz: Within 20% of selected

resolution (6 dB down).

10 Hz: Within 100 Hz ±20 Hz (70 dB down).

The COUPLED setting electronically selects

the best resolution bandwidth for each setting of

the FREQUENCY SPAN/DIV control.

Shape Factor

30 kHz-3 kHz 5:1 or better (60:6 dB ratio).

1 kHz-10 Hz: 10:1 or better (60:6 dB ratio).

Amplitude Deviation

30 kHz-100 Hz: 0.5 dB or less.

-5

of dot

-6

of dot

The following electrical characteristics apply

when the 7L5 Spectrum Analyzer, in combination with a

Plug-In Module, are normally installed in a 7000-Series

oscilloscope and after a warm-up of ten minutes or more.

30 kHz-10 Hz: 2.0 dB or less.

1-1

Page 8

TM 11-6625-2759-14 & P

Input Characteristics

CAUTION

The application of a dc voltage to the INPUT of the L1 or

L2 Plug-In Modules may cause permanent damage to the

mixer circuit.

Input Impedance (Nominal):

L1 50Ò

L2 75Ò

L3 Selectable (50Ò, 600Ò, and 1 MÒ/28 pF).

Input Power (maximum Input level for refer ence

levels of 0 dBm or greater):

L1 21 dBm or 2.5 V rms

L2 21 dBm or 3.07 V rms

L3 21 dBm-input terminated 50Ò or 600Ò; 100

V (peak ac + dc) Input 1 MÒ/28 pF.

Input Power (maximum input level for reference

levels below 0 dBm):

L1 +10 dBm

L2 +10 dBm

L3 +10 dBm--input terminated 50Ò or 600Ò,

and 100 V (peak ac + dc) with input of 1 MÒ3/28 pF.

Equivalent Input Noise

Resolution (equal to or better than)

Bandwidth L1 L2 L3

10 Hz -135 dBm -135 dBm -148 dBV

30 Hz -133 dBm -133 dBm -146 dBV

100 Hz -130 dBm -130 dBm -143 dBV

300 Hz -125 dBm -125 dBm -138 dBV

1 kHz -120 dBm -120 dBm -133 dBV

3 kHz -115 dBm -115 dBm -128 dBV

10 kHz -110 dBm -110 dBm -123 dBV

30 kHz -105 dBm -105 dBm -118 dBV

NOTE

Sensitivity is degraded an additional 8 dB when the

INPUT BUFFER is on; e.g., at 3 kHz, the equivalent input

noise would be -107 dBm instead of -115 dBm. Noise

level will increase by approximately 10 dB when

operation Is In video peak mode,.

Intermodulation Distortion

Intermodulation products from two on-screen

signals, within any frequency span are >75 dB down for

third order products and at least 72 dB down for second

order products.

Second and third order intermodulation products

from two on-screen -53 dBV or less signals within any

frequency span are at least 80 dB down.

Amplitude Characteristics

NOTE

If digital storage is used, an additional quantization err or

of 0.5% of full screen should be added to the amplitude

characteristics.

Residual Response

Internally generated spurious signals are -130

dBm or less referred to the input (harmonics of the

calibrator are -125 dB) with L1 or L2 plug-in module and 143 dBV with the L3 plug-in module.

Sensitivity

The following tabulation of equivalent input noise for each

resolution bandwidth is measured with; the INPUT

BUFFER off, the VIDEO PEAK/AVG at m ax cw, and the

TIME/DIV set to 10 seconds.

With the INPUT BUFFER switch on, the second

and third order intermodulation products, for any two

onscreen signals, within any frequency span, are at least

80 dB down.

Display Flatness

Peak to peak deviation, over any selected

frequency span: Quantization error must be added (see

Note under Amplitude Characteristics ) if digital st orage is

used.

L1 0.5 dB;

L2 0.5 dB;

L3 0.5 dB

Reference Level

Refers to top graticule line in Log mode.

Calibrated in 1 dB and 10 dB steps for the L1 and L2

modules and 1 dB/2 dB and 10 dB for L3 plug-in m odule.

1-2

Page 9

TM 11-6625-2759-14 & P

Range L1 L2 L3

Log -128 dBm -128 dBm/ -128 dBm to

2 dB/Div to +21 dBm 139 dBV to +21 dBm (50Ò),

+21 dBm/ -139 dBm to

+10 dBV +10dBm (600Ò),

-141 dBV to

+8 dBV (Hi Z)

Log -70 dBm -70 dBm/ -70 dBm to

10 dB/Div

to +21 dBm

Incremental Accuracy

When calibrated at -40 dBV in Log mode.

L1, L2 and L3: Within 0.2 dB/dB with cumulative

error of 0.25 dB/10 dB.

Lin Mode Range: 20 nV/Div to 200 mV/Div within

5% in 1-2-5 sequence.

-81 dBV to +21 dBm (50Ò),

+21 dBm/ -81 dBm to

+10 dBV +10 dBm (600 Ò),

-83 dBV to

+8 dBV (Hi Z)

NOTE

A >sign is displayed adjacent to the reference level

readout when the reference level is not calibrated due to

an incompatible selection of controls.

Display Dynamic Range/Accuracy

Log 10 dB/DIV Mode: Dynamic window is 80 dB.

Accuracy is within 0.05 dB/dB to 2 dB maximum.

Log 2 dB/DIV Mode: Dynamic window is 16 dB.

Accuracy is within 0.1 dB/dB to 1 d,B maximum.

Sweep Characteristics

Frequency Span

Provides calibrated frequency spans from

50 Hz/div to max (500 kHz/div), within 4%, in 1-2-5

sequence.

Horizontal linearity is within 4% over the

entire 10 div display.

A 0-Hz/Div position is provided for time

domain operation.

Time per div is selectable from 10 s/Div to 0.1

ms/Div in 1-2-5 sequence. An AUTO position permits

automatic selection of optim um time/div for the selected

resolution and span/div settings.

Sweep rate accuracy is within 5% of the rate

selected.

Triggering

Provides two triggering sources, INT (internal)

and LINE, in addition to a FREE-RUN position.

When INT is selected, ac coupled signal

components from the mainframe T rigger Source (left or

right vertical amplifiers) are used.

When LINE is selected, ac coupled sample of

mainframe line voltage is used.

Three triggering modes are; NORM (normal),

SGL SWP/READY (single sweep), and MNL SWEEP

(manual sweep).

Trigger level is >1.0 div of internal signal for both

NORM and SGL SWP modes over the approximate

frequency range of 30 Hz to 500 kHz.

Output Connectors

Video Out

Front-panel pin jack connector s upplies the video

(vertical) output signal at an amplitude of 50 mV/div +5%

(about the crt vertical center) with source im pedanc e of 1

kÒ.

Horiz Out

A front-panel pin jack connectorsupplies

horizontal output signal (negative-going sawtooth that

varies from 0.0 V dc to approximately -6 V dc with a

source impedance of 5 kÒ.

Calibrator

Front panel BNC connector supplies a calibrated

500 kHz squarewave output signal (derived from the

analyzer’s time base). Output amplitude is within +0.15

dB of -40 dBV into impedance of the plug-in module.

Sweep Rate

1-3

Page 10

TM 11-6625-2759-14 & P

ENVIRONMENTAL CHARACTERISTICS

The 7L5 Spectrum Analyzer will meet the

foregoing electrical characteristics within the

environmental limits of a 7000-Series oscilloscope.

Complete details on environmental test procedures

including failure criteria etc., can be obtained from a local

Tektronix Field Office or representative.

PHYSICAL CHARACTERISTICS

Net weight (instrument only), 8 pounds, 12

ounces.

ACCESSORIES AND OPTIONS

Standard Accessories Tektronix Part No.

Graticule, Spectrum

Analyzer 377-1159-02 (7000-Series)

Filter, light amber 378-0684-00

Manual, Operating 070-1734-00

Manual, Service 070-2184-00

Optional Accessories

Plug-in Module,

50 ohm L1

Plug-in Module,

75 ohm L2

Plug-in Module

50 Ò 600Ò &

1 MÒ/28 pF L3

Probe (10X) P6105 (see L3 Manual)

Attenuator, step.

50 ohm 2701

Attenuator, step,

75 ohm 2703

OPTIONS

7L5 Option 21 -(Log Display)

7L5 Option 25--(Tracking Generator)

7L5 Option 28--(Readout)

7L5 Option 30-(Option 21/25)

7L5 Option 31 -(Option 21/28)

7L5 Option 32-(Option 25/28)

7L5 Option 33--(Options 21/25/28)

1-4

Page 11

SECTION 2. INSTALLATION

TM 11-6625-2759-14 & P

Initial Inspection

This instrument was inspected both mechanic ally

and electrically before shipment. It should be free of

mars or scratches and electric ally meet or exceed all

specifications. Inspect the instrument for physical

damage and check the electrical performance by the

Operational Check procedure provided within these

instructions. This procedure will verify that the

instrument is operating correctly and it will satisfy most

receiving or incoming inspection requirements. If all

instrument specifications are to be verified, refer to the

Service Instructions for the 7L5.

If there is physical damage or performance

deficiency, contact your local Tektronix Field Office or

representative

Installation

To install the 7L5, align the upper and lower

guide rails with those in the receiving compartments of

the mainframe. Slide the instrument along the rails into

the mainframe When the electrical connectors at the rear

of the 7L5 make contact, apply firm, steady pressure to

the front panel until the rear connectors are engaged and

the front panel is approximately flush with the

oscilloscope front panel. To remove the 7L5, pull the

release latch labeled 7L5, at the lower left of the front

panel, and remove the instrument.

REPACKAGING FOR SHIPMENT

Include complete instrument serial number and

description of the service required.

Save and re-use the container your instrument

was shipped in. If the original packaging is not available

or is unfit for use, repackage as follows:

1. Obtain a shipping container of heavy

corrugated cardboard or wood with inside dimensions six

inches or greater than the instrument dimensions. This

will allow room for cushioning. Refer to Table 2-1 for

carton test strength requirements.

2. Wrap the instrument in heavy paper or

polyethylene sheeting to protect the instrument finish.

Protect the front panel with urethane foam or cardboard

strips.

3 Cushion the instrument on all sides by

packing dunnage or urethane foam between the carton

and the instrument, allowing three inches on all sides.

4. Seal the shipping carton with shipping tape

or an industrial stapler.

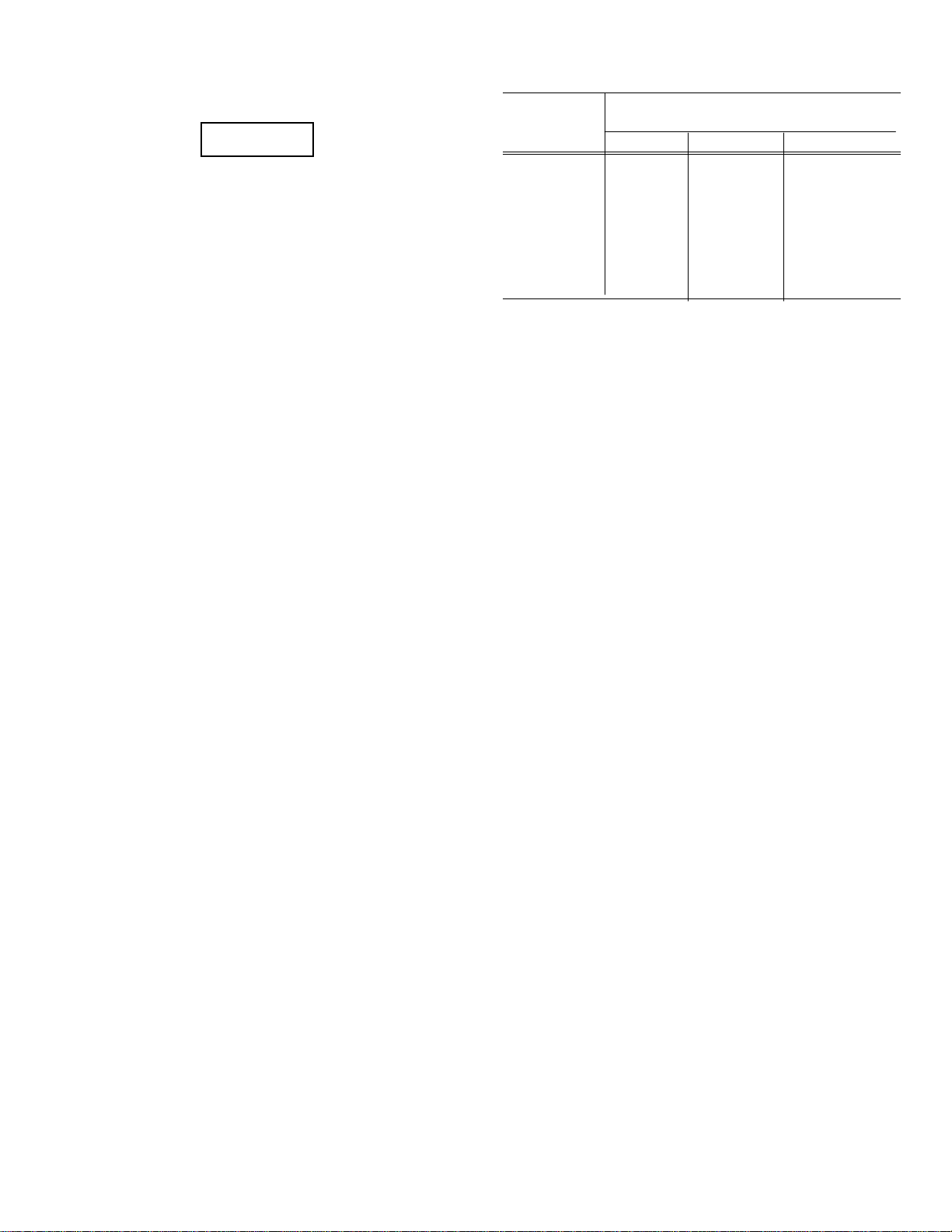

TABLE 2-1

Gross Weight (lb) Carton Test Strength (lb)

0-10 200

10-30 275

30-120 375

120-140 500

140-160 600

If your Tektronix instrument is to be shipped to a

Tektronix Service Center for service or replacement,

attach a tag showing; owner (with address) and the name

of an individual, at your firm, that can be contacted.

If you have any questions, contact your local

Tektronix Field Office or representative.

2-1

Page 12

SECTION 3. OPERATING INSTRUCTIONS

Introduction

This section contains; a simplified block diagram

description, function of the front panel controls and

connectors, an operational check-out and familiarization

procedure, and a section devoted to the use and

application of the instrument. Service information is

contained in the Service Instruction manual.

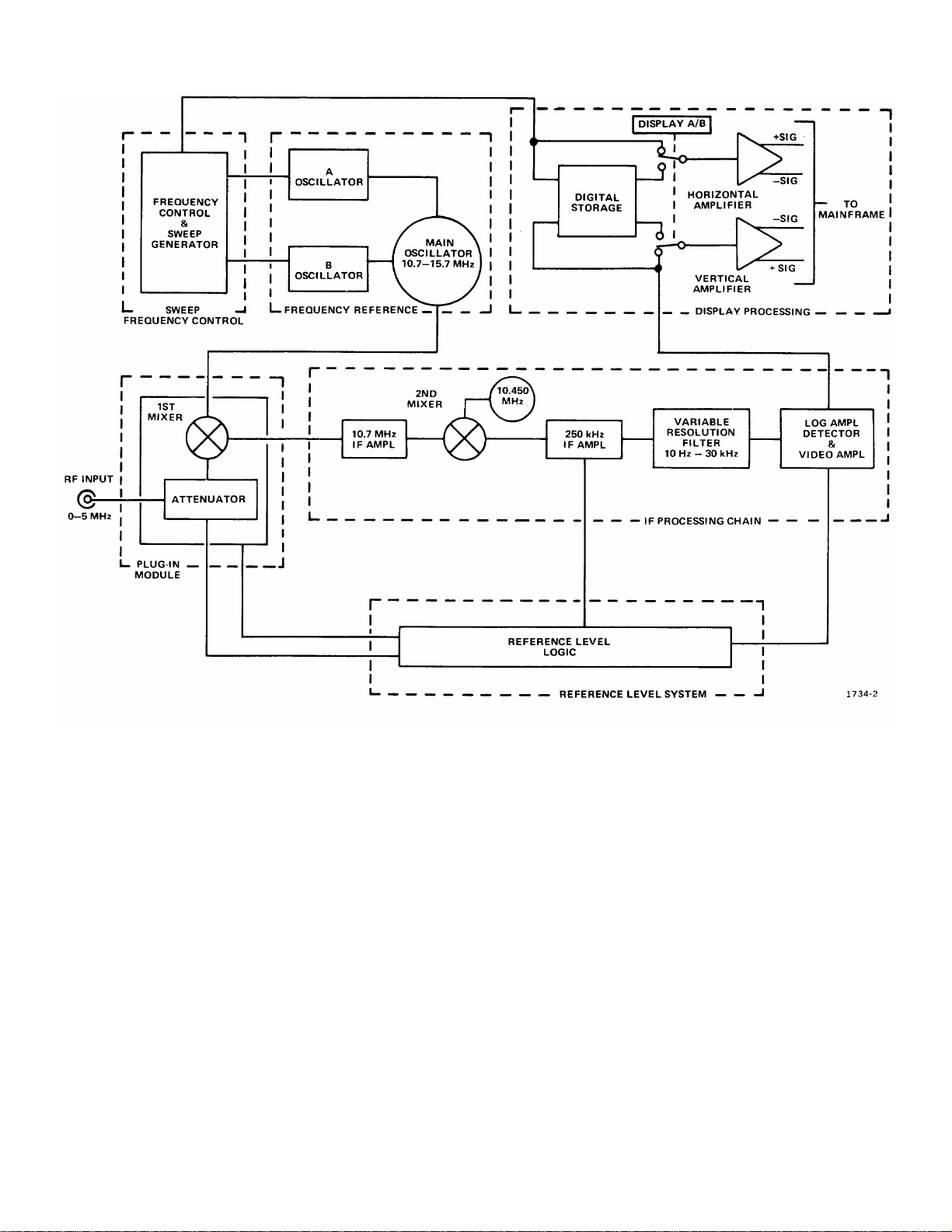

FUNCTIONAL BLOCK DESCRIPTION

Functional Block Description

The 7L5 is a swept front end spectrum analyzer

with selectable front-end plug-in modules that permit the

user to obtain calibrated display for a number of different

Impedances (i.e., 50 ohm, 600 ohm, etc.). The plug-in

module contains; selectable attenuation, the first mixer,

and an Input buffer selector that trades attenuation for IF

gain. Signal attenuation in the plug-in and gain of the IF

processing chain are controlled by a r eference level logic

circuit in the 7L5 which provides calibrated settings in 1

dB or 10 dB steps over a range of approximately 146 dB

(depending on the plug-in module). A simplified block

diagram is shown in Fig. 3-1.

The input signal to the 7L5 is mixed with the

frequency of the main oscillator and the IF of 10. 7 MHz is

fed to and amplified by the 10.7 MHz IF amplifier. Since

the 7L5 input frequency range is O to 5 MHz, the main

oscillator is tuned and swept from 10.7 to 15.7 MHz. The

frequency of the main oscillator is controlled by two

secondary (A and B) oscillators that use a synthesizer

technique to tune and phase lock their frequencies. The

sweep frequency control circuit drives the oscillators

TM 11-6625-2759-14 & P

according to the settings of front panel DOT

FREQUENCY and FREQUENCY SPAN/DIV controls.

The 10 7 MHz IF is processed through bandpass

filters and amplifiers and then mixed with the output from

a 10.450 oscillator, to down-convert the 10.7 MHz to an

IF of 250 kHz Gain of the 250 kHz amplifier is c ontrolled

by the reference level logic circuit which establishes the

amount of attenuation in the plug-in module and gain for

the 250 kHz IF and Log amplifiers. The reference level is

selectable in 1 dB and 10 dB steps.

The 250 kHz IF signal is processed through the

variable resolution filter circuits for bandwidth selec tions

of 10 Hz to 30 kHz. The signal is again amplified,

detected, and the video is sent through amplifier circuits

that provide the 10 dB/dlv, 2 dB/dlv, and linear gain

characteristics.

The video signal is then fed to the display

processing circuits where the signal is either stored and

displayed, or, if the storage mode is not selected, the

signal is passed directly through the vertical output

amplifier to the mainframe circuit. If either or both the

DISPLAY A or DISPLAY B latches are enabled, the

signal is converted to digital data, stored in A or B

memory, then converted back to analog data and

processed through the output amplifiers to the mainframe

The vertical information is digitized and stored at 512

horizontal address locations across the screen.

Therefore, the horizontal sweep information is converted

to digital data for storage, then converted back to an

analog signal for display The horizontal sweep ramp is

processed the same as the vertical s ignal. The vertical

(video) information can be averaged or peak detected.

3-1

Page 13

TM 11-6625-2759-14 & P

Fig. 3-1. Functional block diagram.

3-2

Page 14

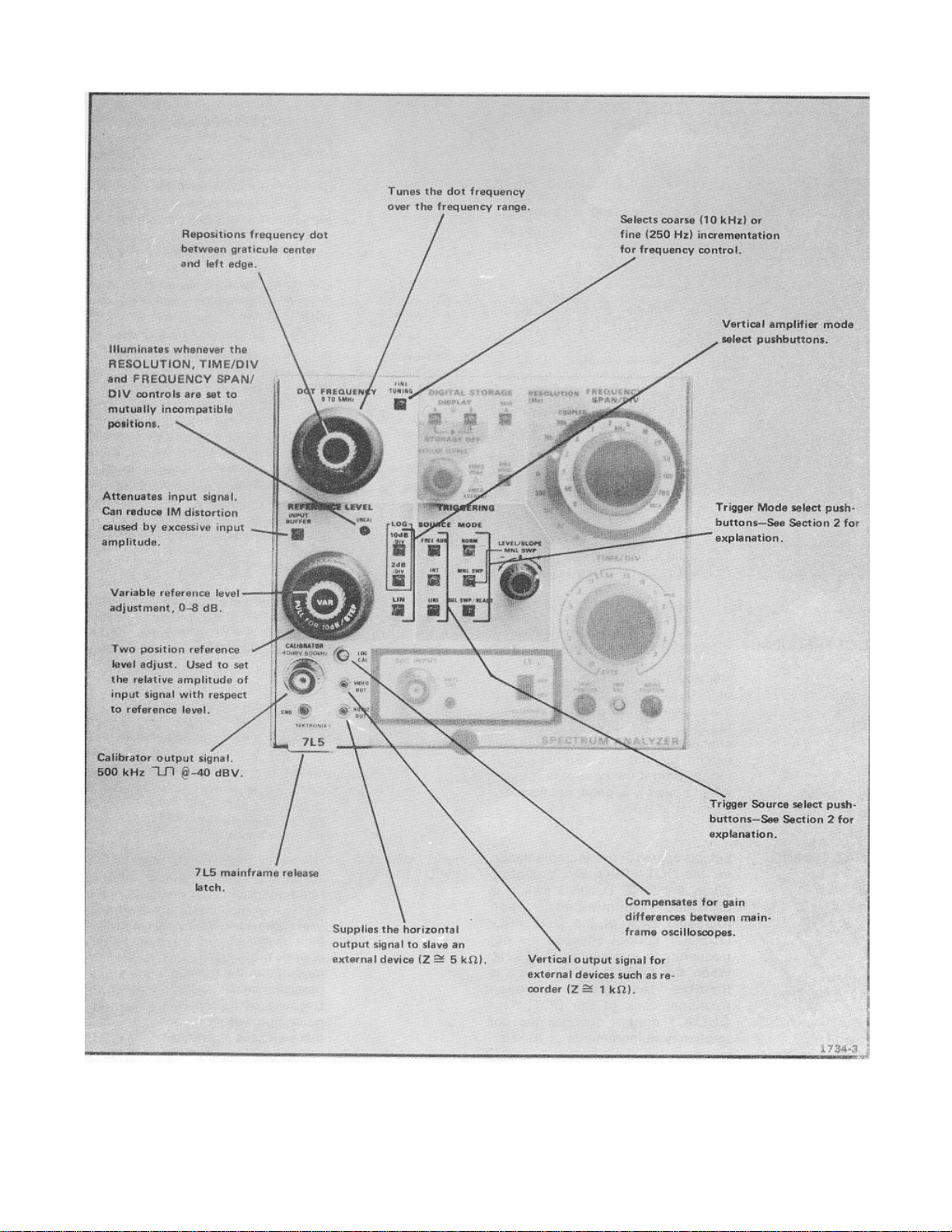

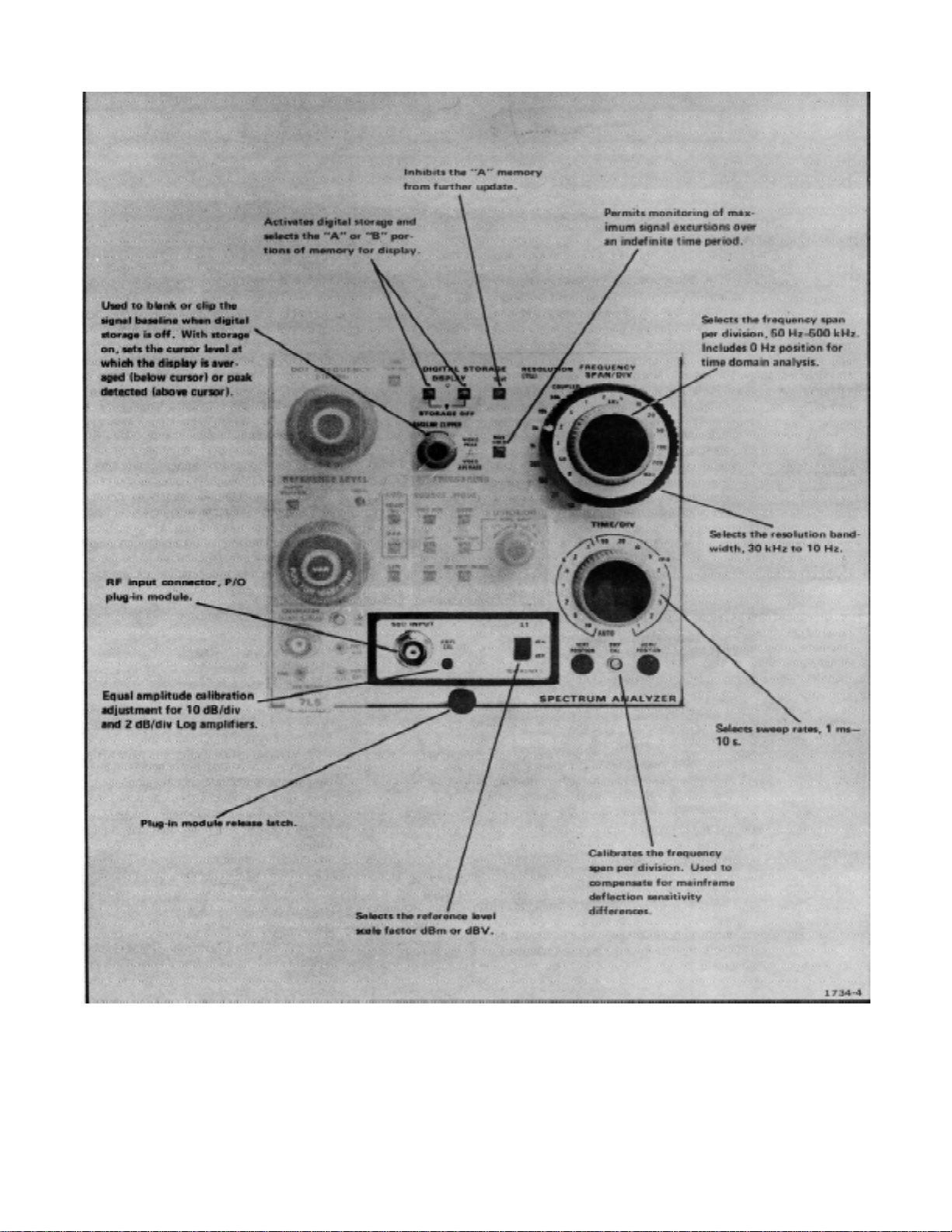

FRONT PANEL CONTROLS AND

CONNECTORS

Pushing any front panel pushbutton switch

activates a bistable electronic circuit to c hange its output

state. When in the active state, the plastic pus hbutton is

illuminated. Pressing the pushbutton a second time

changes the output of the circuit to the inactive state and

extinguishes the illuminated button.

Front panel controls also include two special

photo-optic switch assemblies, the FREQUENCY

SPAN/’DIV-RESOLUTION switch and the TIME/DIV

switch. Designed especially for the 7L5, each assem bly

is a mechanical/photo-electric, digital switch, that

provides a TTL compatible five-bit binary output. The

reliability of these switches has been demonstrated and

with normal use they should last the life of the

instrument. Dism antling or field repair of these switches

is discouraged since their proper operation requires

precision alignment of their internal components. If either

switch assembly is damaged or suspected of

malfunction, it should be replaced as an assembly.

The following describes the function of the front

panel selectors for the 7L5. A layout of the front panel is

shown in Fig. 3-2.

DOT FREQUENCY Changes the dot (marker)

frequency in coarse (10 kHz) or

fine (250 Hz) steps over the input

frequency range of 0 Hz to 5 MHz.

The frequency of the dot mark er is

displayed on the crt readout in the

upper right set of character s. Dot

frequency will not extend beyond

the 7L5 frequency range, even if

the control is rotated. When power

is applied, dot frequency starts at

0.000.

FINE TUNING Selects coarse or fine

incrementation for the DOT

FREQUENCY control. When the

FINE TUNING switch is activated

(illuminated), each rotational click

of the DOT FREQUENCY control

changes the dot frequency in

increments of 250 Hz. When the

FINE TUNING switch is inactive

(extinguished), each rotational

click of the DOT FREQUENCY

control changes the dot frequency

in increments of 10 kHz.

TM 11-6625-2759-14 & P

DOT MKR Used to horizontally position the

frequency dot. The displayed

frequency readout characters

enumerate the actual frequency of the

dot. When the DOT MKR control is in

its detent position (fully ccw), the

frequency dot and the selected

frequency are on the vertical center

line of the graticule. The 7L5 can be

operated in a start sweep mode when

the frequency dot is positioned to the

left vertical graticule line. The DOT

MKR control is disabled when the

FREQUENCY SPAN/DIV switch is at

MAX.

REFERENCE Sets the full screen signal amplitude

LEVEL level (dBm, dBV) required at the

INPUT to the plug-in module. This

level is relevant to the input impedance

of the plug-in module. Ref erence level

is associated to the top graticule line of

the display area and signal level is

relative to this reference. The

reference level range depends on the

plug-in module, however, in the 2

dB/Div mode it covers 149 dB, in the

10 dB/Div mode the range is 90 dB

and in the Lin mode 20 nV/div to 200

mV/div. The control has two speeds or

stepping increments; pulled out, each

increment is 10 dB, pushed in each

increment is 1 dB or in some cases

(dependent on the plug-in module) 2

dB.

VAR The VAR (variable) control provides 8

dB or more gain adjustment

between each calibrated reference

level step. A<symbol is displayed on

the crt, preceding the reference level

readout, whenever the reference level

is not calibrated (VAR is not in its

detent position).

INPUT BUFFER The active (illuminated) state of this

pushbutton switch inserts 8 dB of

signal attenuation at the input of the

first mixer and adds 8 dB of vertical

gain (after the variable resolution

filters). When used, it reduces

intermodulation distortion caused by

excessive input signal amplitude.

Because of its increased gain, the

noise figure is increased 8 dB when

this switch is activated.

3-3

Page 15

TM 11-6625-2759-14 & P

Fig. 3-2.A. 7L5 front panel controls and connectors.

3-4

Page 16

TM 11-6625-2759-14&P

Fig. 3-2B. 7LS-L1 plug-in front panel control and connectors.

@ 3-5

Page 17

TM 11-6625-2759-14&P

LOG 10 dB/DIV The illuminated condition of this

pushbutton selects a logarithmic

display of 10 dB/div with a dynamic

range of 80 dB.

LOG 2 dB/DIV The illuminated condition of this

pushbutton selects a logarithmic

display of 2 dB/div with a dynamic

range of 16 dB

LIN The illuminated condition of this

pushbutton selects a linear display.

Signal amplitude is a linear function of

input level.

FREQUENCY Selects frequency spans from

SPAN/DIV 50 Hz/div to 500 kHz/div (MAX

position). A 0 Hz position provides

time domain display with a bandpass

dependent on the setting of the

RESOLUTION selector. In the 0 Hz

position the frequency dot is not

displayed and when in the MAX

position the frequency dot position is

controlled by the DOT FREQUENCY

control.

RESOLUTION Selects resolution bandwidths of 10

Hz to 30 kHz in a 1-3 sequence. A

COUPLED position electronically

selects the best compatible resolution

bandwidth setting for the

FREQUENCY SPAN/DIV selection.

TIME/DIV Selects the analyzer’s sweep rate.

Sweep rates are 10 s/div to 0.1

ms/div in a 5-2-1 sequence. An AUTO

position electronically programs sweep

rate so the display remains calibrated

for the selected frequency span and

resolution bandwidth settings.

UNCAL When the display is uncalibrated

because the FREQUENCY

SPAN/DIV, RESOLUTION, and

TIME/DIV switch settings are

incompatible, this indicator lights and a

> symbol is displayed on the crt as a

prefix to the reference level readout

characters.

TRIGGERING Two trigger sources (Line and Internal)

plus a Free Run mode can be

selected. In the Free Run mode

(FREE RUN button activated) the

sweep free runs and will not sync with

any trigger signal. When the LINE

pushbutton is activated (illuminated)

the sweep is triggered by the line

voltage to the mainframe. The INT

pushbutton selects ac coupled signal

components from the mainframe

Trigger Source (left or right vertical).

Three trigger modes are provided:

NORM (normal), SGL SWP/READY

(single sweep/ready) and MNL

SWEEP (manually controlled sweep).

When the NORM button is activated,

the sweep is triggered from the s our ce

selected; or, if the trigger is not

present, the sweep automatically runs

in about 10-second intervals to provide

a baseline display. When the SGL

SWP/READY button is activated, the,

sweep runs with the next trigger or in

about 10 seconds if trigger is not

present. In time domain operation

(FREQ SPAN/DIV at 0 Hz) pushing

the button activates the sweep ready

state. The button lights to indicate the

trigger circuit is arm ed and ready. The

sweep will run with the arrival of a

trigger. The button remains

illuminated until the sweep has

completed its run. This provides a

ready indication of the sweep state

when photographing a display.

LEVEL/SLOPE- A dual function control. As a level

MNL SWP slope/control, it adjusts the level of the

trigger threshold on either a positive or

negative slope. As a manual sweep

control, it positions the crt beam

anywhere along the X- axis.

Maximum cc w corresponds to a beam

location at the left graticule edge.

DIGITAL SAVE A: Activating the SAVE A

STORAGE pushbutton dedicates one half of the

digital storage mem ory to preserve the

binary equivalent of the existing

waveform amplitude at 256 X-axis

locations. The A memory is inhibited

from further update until SAVE A is

deactivated (extinguished).

@ 3-6

Page 18

TM 11-6625-2759-14&P

DISPLAY A/B: When DISPLAY A or

DISPLAY B is selected, the

corresponding pushbutton switch is

illuminated and the contents of

memory A or memory B is displayed.

With SAVE A of f, all m e m ory locations

are displayed contiguously. With

SAVE A on, DISPLAY A and DISPLAY

B are selected. The con- tents of both

memories are interlaced and

displayed.

PEAK AVERAGE/BASELINE

CLIPPER: A dual function control.

When digital storage is of f, this c ontrol

operates as a conventional baseline

clipper, i.e., as the control is rotated

ccw, more of the vertical display is

progressively blanked or clipped over

the last 1/3 turn of the control. W hen

digital storage is on, the PEAK

AVERAGE control sets the level at

which the vertical display is either

peak detected or digitally averaged.

Video signals above the level set by

the PEAK AVERAGE control (and

denoted by a horizontal cursor) are

peak detected and stored. Video

signals below the level set by the

PEAK AVERAGE control are digitally

averaged and stored.

MAX HOLD: Enables the digital

storage memory to store the

maximum signal levels within the

period the circuit is active (button

illuminated). This maximum signal

can then be saved and com pared with

future signals for drift or amplitude

variations.

SWP CAL Adjusted during the operational check

to calibrate the sweep. This

adjustment compensates for

differences in deflection sensitivity

between mainframe oscilloscopes.

The SWP CAL control should be

adjusted or checked for pr oper setting

each time the 7L5 is installed in an

oscilloscope.

LOG CAL Adjusted during the operational

check to calibrate the 2 dB/div and the

10 dB/div displays. This adjustm ent is

used to compensate for differences in

vertical gain between mainframe

oscilloscopes. The LOG CAL control

should be adjusted or checked for

proper setting each time the 7L5 is

installed in an oscilloscope.

AMPL CAL (L1 The AMPL CAL control is adjusted

Plug-In Module) during the initial calibration to

calibrate the full screen reference

level. This control is used to

compensate for gain dif ferences in the

RF and IF portions of the instrument.

The AMPL CAL control should be

adjusted or checked for pr oper setting

each time a plug-in m odule is installed

in the 7L5.

HORIZ POS Positions the display or baseline on

the crt X-axis.

VERT POS Positions the display or baseline on

the crt Y-axis.

dBm/dBV Located on the plug-in module front

panel, the dBm/dBV control selects

the reference level scale factor;

decibels with respect to one milliwatt

or decibels with respect to one volt.

Calibrating the 7L5 to the Oscilloscope Mainframe

1. Install or verify the presence of a plug-in

module (see Optional Accessories, Section 1)

2. Select oscilloscope Vertical Mode,

Horizontal Mode and Trigger Source (Right or Left)

corresponding with plug-in compartments occupied by

the spectrum analyzer. Turn on the mainframe power

and allow a 10 minute warm-up period.

3. Set the front panel controls as follows:

DOT MKR max ccw (detent position)

FREQUENCY

SPAN/DIV MAX (500 kHz)

RESOLUTION COUPLED

VAR max ccw (detent position)

BASELINE

CLIPPER max cw

LOG 10 dB/DIV on

REFERENCE LEVEL -40 dBV

INPUT BUFFER off

FREE RUN on

NORM on

SAVE A off

MAX HOLD off

dBm/dBV dBV (plug-in module

switch)

TIME/DIV AUTO

@ 3-7

Page 19

TM 11-6625-2759-14&P

4. Connect the CALIBRATOR signal to the

INPUT connector on the plug-in module with a short

length of coaxial cable. Adjust the SW P CAL and the

HORIZ POSITION controls to align the s econd and tenth

vertical signals with the second and tenth vertical

graticule lines counting from the left edge.

5. Set the FREQUENCY SPAN/DIV to 2 kHz,

Display Mode 2 dB/div, and DISPLAY A and B on.

Adjust the VERT POSIT ION control to place the display

baseline on the bottom horizontal graticule line.

6. Set RESOLUTION control to 3 kHz and

DOT FREQUENCY to 500.00 kHz.

7. Select the LOG 10 dB/DIV pushbutton and

adjust the LOG CAL control fo r a full screen (8 division)

display.

8. Select the LOG 2 dB/DIV pushbutton and

adjust the AMPL CAL (on plug-in module) for a full

screen display.

9. Repeat steps 7 and 8 until the displayed

waveforms are 8 vertical divisions in both log amplifier

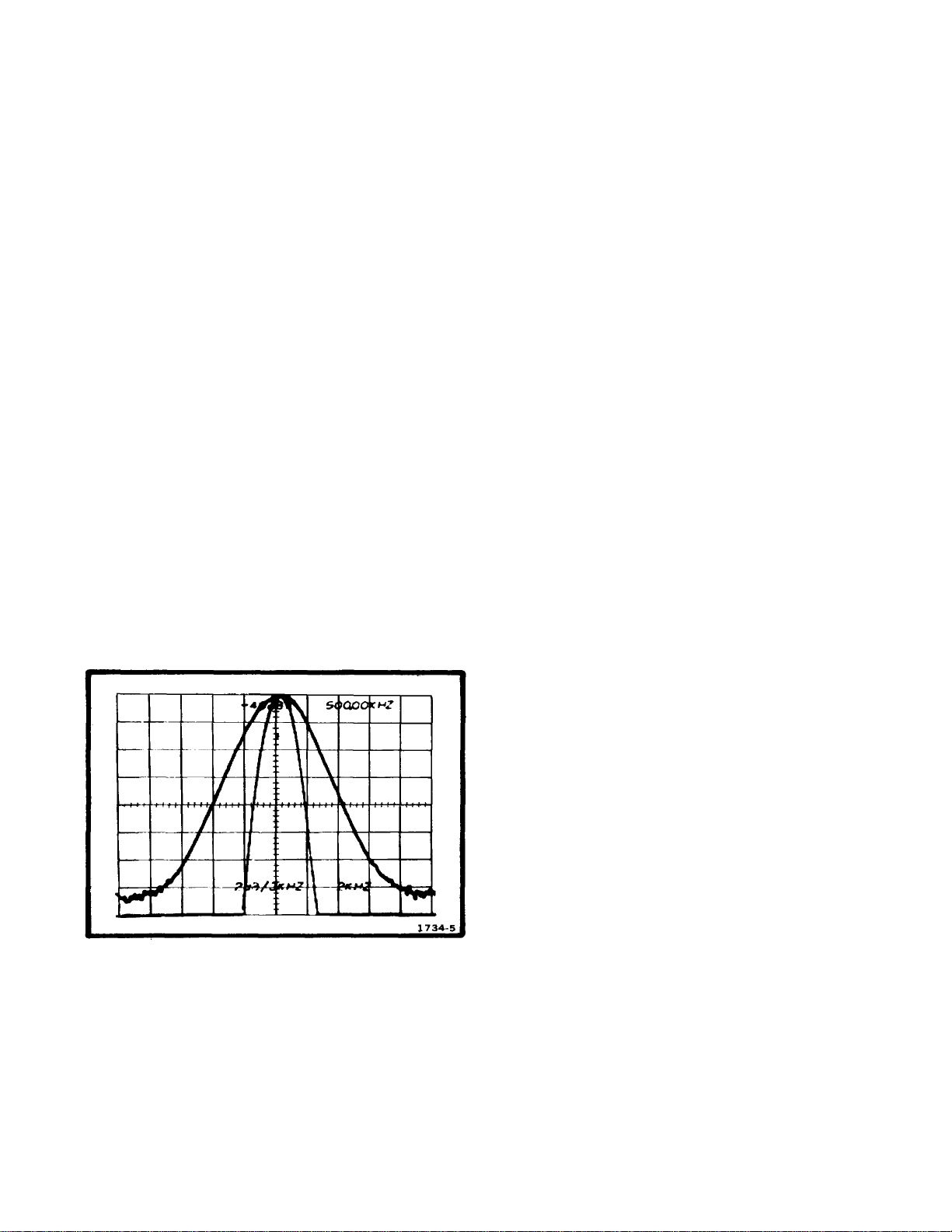

settings. (Refer to Fig. 3-3, Log Amplifier Calibration

Composite W aveform.) If desired, check linearity of the

10 dB/div display by increasing the REFERENCE LEVEL

in 10 dB steps. Adjust LOG CAL slightly to correct any

non- linearity.

OPERATIONAL CHECKOUT

Introduction

This is an operational checkout procedure

intended to satisfy most custom er’s receiving inspection

requirements and to provide instrument familiarization for

the new user We recommend using this checkout as part

of the users routine maintenance program and a

preliminary check before performing the Performance

Check portion of the Service Instruction manual.

The front panel CALIBRATOR output is an

accurate signal source and is used in the following

procedures to verify operational status of the instrum ent.

Calibrator frequency accuracy may be verified by

applying it to an accurate digital counter.

Some procedures require a s tep attenuator and

two short lengths of coaxial cable. To verif y the absolute

reference level specifications, the attenuator accuracy

must be calibrated or verified at some specific frequency,

to within 0.03 dB/dB with a cumulative error not to

exceed 0.1 dB for any change up to 10 dB. Incremental

accuracy can be verified and a good indication of the

absolute reference level accuracy can be obtained by

using two Tektronix Step Attenuators, such as the 2701

(see Optional Accessories, Section 1). These

attenuators provide a good indication of oper ation even

though their accuracy specifications are not within the

limits described.

Fig. 3-3. Log amplifier calibration composite waveform.

1. Preliminary Preparation

Preset the front panel controls and selectors as

described under Calibrating the 7L5 to the Osc illoscope

Mainframe and perform the calibration procedure as

previously described.

2. Operational Check of Readout Characters

With the 7L5 installed and operating in a 7000Series mainfram e, perform the following steps to c heck

the readout operation.

Dot Frequency Readout

a. Verify that the dot frequency readout is 0.00

kHz after initial turn-on. (Readout characters f or the dot

frequency are located near the top edge of the crt and

can be identified by the suffix characters kHz).

b. With the FINE TUNING pushbutton not

illuminated (inactive), verify that the DOT FREQUENCY

control changes the value of the readout characters in 10

kHz increments.

@ 3-8

Page 20

TM 11-6625-2759-14&P

c. Rotating DOT FREQUENCY control cw

should increase the readout and ccw rotation should

decrease the readout.

d. Activate the FINE TUNING pushbutton and

verify that the DOT FREQUENCY control changes the

value of the readout characters in 250 Hz increments.

e. Verify that continuous cw rotation of the

DOT FREQUENCY control causes no change of the

readout characters after an indicated 4999.75 kHz.

NOTE

Following a change of the DOT FREQUENCY

control, the first click in the opposite direc tion will

have no effect.

Reference Level Readout (L1 Plug-In Module)

f. Select the LOG 2 dB/DIV mode and set the

dBm/dBV switch (on the plug-in m odule) to dBm. Verify

that the indicated value of the reference level changes by

13 dB (e.g., -40 dBV = -27 dBm). Reference level

readout characters are located near the top edge of the

crt and can be identified by the suffix charac ters dBm or

dBV.

g. With the UNCAL light off, rotate the VAR

(variable) control and verify that a < symbol (not

calibrated) prefixes the refer ence level readout. Rotate

the VAR control to its maximum ccw (detent) position

and verify that the < symbol is no longer displayed.

h. Pull the REFERENCE LEVEL control out to

its coarse position and verify that the value of the

reference level readout changes in 10 dB steps. Push

the REFERENCE LEVEL control in to its fine position

and verify that the value of the reference level readout

changes in 1 dB steps.

i. Verify, that rotation of the REFERENCE

LEVEL control beyond the reference level limits of ; -128

dBm (-141 dBV), In the 1 dB/step position, or; -70 dBm (83 dBV) in the 10 dB/step position-for the one extrem eand +21 dBm (8 dBV) for the other extreme remains

constant. (These extrem es are applicable only for 50 Ò

plug-in modules.)

J. With the REFERENCE LEVEL control at

max ccw position, select the LIN mode and verify that the

readout changes to 200 mV.

k. Rotate the REFERENCE LEVEL cw and

verify that the readout changes from m V to ÎV to nV in a

2-1-5 sequence. Verify that continuous cw rotation of the

REFERENCE LEVEL control causes no change of the

corresponding readout characters beyond 20 nV.

Time/Div Readout

I. Set the FREQUECNY SPAN/DIV switch to

0. Rotate the TIME/DIV control to each of its positions

and verify that its front panel designations corres pond to

the crt readout characters. (Readout c haracters for the

sweep time per division are located near the bottom r ight

edge of the crt and can be identified by the suffix

character S when the FREQUENCY SPAN/DIV is set to

0.)

Frequency Span/Div Readout

m. Set TIME/DIV control to AUTO and the

RESOLUTION control to COUPLED. Rotate the FREQUENCY SPAN/DIV control to each of Its positions and

verify that the readout characters correspond with the

front panel designations and change In accordanc e with

the readout listed in Table 3-1. (Readout characters f or

frequency span per division setting occupy the sam e crt

position as the time per division readout characters.

They are located near the bottom edge of the crt and

except for the 0 span setting, can be identified by the

suffix characters Hz.)

TABLE 3-1

FREQUENCY SPAN/DIV FREQUENCY

SPAN/DIV

control settings readout

0 10 ms

50 (Hz) 50 Hz

1 kHz 100 Hz

.2 kHz 200 Hz

.5 kHz 500 Hz

1 kHz 1 kHz

2 kHz 2 kHz

5 kHz 5 kHz

10 kHz 10 kHz

20 kHz 20 kHz

50 kHz 50 kHz

.1 MHz 100 kHz

.2 MHz 200 kHz

MAX 500 kHz

Resolution Readout

n. Rotate the RESOLUTION control to eac h of

its: positions and verify that the readout characters

correspond with the front panel designations. ( Readout

characters for the resolution function are located near

the bottom edge of the crt and can be identified by the

suffix characters Hz.)

@ 3-9

Page 21

TM 11-6625-2759-14&P

o. With the RESOLUTION control in the

COUPLED position, rotate the FREQUENCY SPAN/DIV

to each of its positions and verify that the RESOLUTION

readout characters change in accord with Table 3-2.

TABLE 3-2

FREQUENCY

SPAN/DIV

control settings readout

MAX (500 kHz) 30 kHz

200 kHz 30 kHz

100 kHz 30 kHz

50 kHz 10 kHz

20 kHz 3 kHz

10 kHz 3 kHz

5 kHz 1 kHz

2 kHz 300 Hz

1 kHz 300 Hz

.5 kHz 100 Hz

2 kHz 30 Hz

.1 kHz 30 Hz

50 (Hz) 10 Hz

0 30 kHz

RESOLUTION

NOTE

The full dynamic range of the Log 10

dB/div and the Log 2 dB/div is not

measured in the following paragraphs. If

the log amplifiers include a negative

error, full range verification would

require signal level measurem ent below

the display baseline. Since this is not

possible, the following steps verify 78 of

the 80 dB range and 15 dB of the 16 dB

range for the two log amplifier

selections.

LOG 10 dB/DIV (Dynamic window is 80 dB,

accuracy is ±0.05 dB/dB to 2 dB maximum)

a. Set the 7L5 controls as follows:

DOT FREQUENCY 500.00 kHz

RESOLUTION COUPLED

FREQUENCY SPAN/DIV 0.1 kHz

TIME/DIV AUTO

REFERENCE LEVEL -40 dBV

dBm/dBV (L1 Plug-in) dBV

Vertical Amplifier Mode Readout

p. Select the 10 dB/DIV pushbutton switch and

verify that the readout characters for the vertic al amplifier

mode indicate 10 dB/ Readout characters for the vertical

amplifier mode are loc ated near the lower edge of the c rt

and for the log positions, can be identified by the suffix

symbol /.

q. Select the 2 dB/DIV mode and verify that

the readout characters indicate 2 dB/.

r. Push the LIN pushbutton and verify an

absense of readout characters for vertical amplifier

mode.

Uncalibrated Readout

s. Set the RESOLUTION control to COUPLED

and the FREQUENCY SPAN/DIV control to MAX.

Rotate the TIME/DIV cw until the UNCAL light is

illuminated. Verify that a > symbol prefixes the

referenced level readout characters. Rotate the

TIME/DIV ccw until the UNCAL light is extinguished

Verify that the > symbol is no longer displayed

b. Apply the CALIBRATOR signal through

external attenuator(s), such as Tektronix, 2701 (for 50

Ò)-see Optional Accessories in Section 1-to the INPUT

connector. Select the LOG 10 dB/DIV pushbutton.

c. Increase external attenuation in 10 dB steps

to 70 dB and verify that each step decreases the

displayed f signal level 10 dB ±0.5 dB.

d. Increase external attenuation by 8 dB (for a

total of 78 dB) and verify that the total overall decrease in

signal amplitude is 78 dB ±2 0 dB.

LOG 2 dB/DIV (Dynamic window is 16 dB,

accuracy is ±0.01 dB/dB to ±1 dB maximum)

e. Set the external attenuators to 0 dB. Set

the FRE- QUENCY SPAN/DIV to 50 Hz, RESOLUTION

to 30 Hz and select the 2 dB/DIV pushbutton.

f. Add 15 dB attenuation, with the external 1

dB step attenuator, in 2 dB and 1 dB increments. Verify

that the signal level change, is within 0.1 dB/dB of added

attenuation to a maximum of 1.0 dB deviation over the

15 dB range.

3. Dynamic Range

LIN Linearity

g. Select the LIN pushbutton and adjust

the REFERENCE LEVEL control for a crt readout of 500

pV/ (per division).

@ 3-10

Page 22

h. Add 10 dB of external attenuation. Adjust

the VAR control for a signal display amplitude of 8

divisions.

i. Add 6 dB of external attenuation. Verify

that the signal amplitude decreases to 4.0 ±0.2 division

(±5%) or half amplitude.

j. Add an additional 6 dB of external

attenuation and verify that the display amplitude

decreases to 2.0 ±0.1 division.

VARiable Control Range

k. Inser t 10 dB of external attenuation. Select

the 2 dB/DIV pushbutton and rotate the VAR control fully

cw. Adjust the REFERENCE LEVEL to set the displayed

signal amplitude to a vertical reference point near full

screen.

I. Rotate the VAR control fully ccw (detent

position). Verify that the signal amplitude decreases at

least 4.0 divisions. Decrease external attenuation to

return the signal amplitude to the reference point and

verify that the required change was 8 dB or more.

4. Reference Level Accuracy (within 0.2 dB/dB

with a cumulative error not to exceed 0.25 dB for any

change up to 10 dB)

The external attenuator accuracy requirements

to perform this step, have been described in the

Introduction to this Operational Check procedure.

Reference level increments are 1 dB and 10 dB steps.

Circuitry of the 7L5 provides 1, 2, 4, 8, and 16 dB gain

steps. These steps, or combinations of the steps,

provide the reference level range. This procedure

checks the accuracy of each gain cell and thus the

overall accuracy. The accuracy of the V/Div mode will be

within that specified if the Log mode reference level is

within limits. A few check points may be perform ed as

listed in Table 3-4 to spot check Lin mode operation.

TM 11-6625-2759-14&P

c. Change the REFERENCE LEVEL control to

-30 dBm. Increase the exter nal attenuation 1 dB (3 dB

total) and verify that the signal peak is within 0.2 dB of

the reference point established in step b.

d. Rotate the REFERENCE LEVEL control to 31 dBm. Increase the external attenuation another 1 dB

(4 dB total) and verify that the signal peak is within 0.25

dB of the reference point.

e. Readjust the VERT POSITION control, as

required, to establish a new graticule reference point for

the signal peak.

f. Pull the REFERENCE LEVEL control out to

the 10 dB/step position and set it for a crt readout of -41

dBm. Increase the external attenuation 10 dB (14 dB

total) and verify that the signal level is within 0.25 dB of

the reference point established in step e.

g. Check the Reference Level accurac y for the

remaining range by following the settings listed in Table

3-3 and noting the error.

TABLE 3-3

Reference Level External Attenuation Allowable

Limits

(dBm) (dB) (dB)

-41 14 0.25

-51 24 0.50

-61 34 0 75

-71 44 1.00

-81 54 1.25

-91 64 1.50

-101 74 1.75

-111 84 2.00

-121 94 2.25

LIN Accuracy

This procedure uses a 50 0 plug-in module (L1):

a. Switch the dBm/dBV selector (on the plug-

in module) to dBm and set the 7L5 controls as follows:

REFERENCE LEVEL -29 dBm

RESOLUTION 3 kHz

FREQEUNCY SPAN/DIV 1 kHz

TIME/DIV AUTO

b. Set the external attenuation to 2 dB and

adjust the REFERENCE LEVEL for a readout of -29

dBm. Adjust the VERT POSITION control slightly, as

required to establish a graticule reference point for the

signal peak.

g. Set the external attenuator to 0 dB. Select

the LIN pushbutton and adjust the REFERENCE LEVEL

control for a crt readout of 10 mV.

h. Set the external attenuator and the

REFERENCE LEVEL control to the positions listed in

Table 3-4. Check that the measured s ignal amplitudes

are in accordance with those listed in Table 3-4.

@ 3-11

Page 23

TM 11-6625-2759-14&P

TABLE 3-4

Reference Signal

Attenuator Voltage Level Amplitude

Setting (dB) Input Volts/DIV

0 10 mV 2 mV 5

20 1 mV 0.2 mV 5

40 100 ÎV 20 ÎV5

60 10 ÎV2 ÎV5

80 1.0 ÎV 200 nV 5

5. Input Buffer (Operational check only)

a. Apply the CALIBRATOR signal to the

INPUT on the plug-in module. Set the 7L5 front panel

controls as follows:

DOT FREQUENCY 500.00 kHz

RESOLUTION 3 kHz

FREQUENCY SPAN/DIV 1 kHz

TIME/DIV AUTO

INPUT BUFFER Off

LOG 2 dB/DIV On

b. Establish a signal amplitude of 7 divisions

with the REFERENCE LEVEL control

c. Switch the INPUT BUFFER on and verify

that the display amplitude does not change more than 1

dB (.05 div).

d. Change the RESOLUTION to 10 kHz and

check amplitude change of the calibr ator signal with the

INPUT BUFFER on and off.

6. Residual (Incidental) FM (Incidental FM is <1

Hz, 50 Hz/div to 2 Hz/div and <40 kHz, 5 kHz/div to 500

kHz/div)

a. With the CALIBRATOR signal applied to the

INPUT of the plug-in module, set the 7L5 front panel

controls as follows:

DOT FREQUENCY 500.00 kHz

REFERENCE LEVEL -57 dBM

RESOLUTION COUPLED

FREQUENCY SPAN/DIV 50 (Hz)

TIME/DIV AUTO

LOG 2 dB/DIV On

INPUT BUFFER Off

DIGITAL STORAGE Off

b. Select the MNL SWP pushbutton and

adjust the MNL SWP control to place the trace dot

halfway up one side of the displayed 10 Hz filter

waveform, near center screen. Verify that incidental FM

(short term, peak to peak movem ent of trace dot) is less

than 1.0 vertical division (1 Hz).

in Div’s ±5%

c. Set the RESOLUTION control to 300 Hz,

the FREQUENCY SPAN/DIV to 5 kHz, and the

REFERENCE LEVEL to -62 dBm. Adjust the MNL

control to place the trace dot halfway up one side of the

displayed 300 Hz filter waveform, near center screen.

Verify that maximum vertical jitter of the trace dot does

not exceed 1.2 division (40 Hz)

7. Residual Response (Plug-in module

dependent. Internally generated spurious signals are

down 130 dB or more with the L1 Plug-In Module)

NOTE

Each 7L5 Spectrum Analyzer is

carefully tested at the factory to ensure

that all internally generated spurious

responses are below-130 dBm.

Thorough verification of this

specification would take several days.

A procedure to check the f ull frequency

range (to - 110 dBm) and to spot check

100 kHz of the total frequency range, to

-130 dBm is given in the following

steps. The 100 kHz frequency range

chosen is 300 through 400 kHz. The

procedure can also be used to spot

check any 200 kHz span within the 0-5

MHz capability of the instrument.

a. Terminate the input connector with a

resistive load that equals the characteristic input

impedance of the plug- in module. Set the 7L5 front

panel controls as follows:

DOT FREQUENCY 500.00 kHz

RESOLUTION 300 Hz

FREQUENCY SPAN/DIV 100 kHz

TIME/DIV AUTO

LOG 10 dB/DIV On

REFERENCE LEVEL -70 dBm

INPUT BUFFER. Off

BASELINE CLIPPER max cw

DIGITAL STORAGE DISPLAY A/B

SAVE A Off

MAX HOLD Off

b. Press the SGL SWP pushbutton twice to

initiate a sweep. (Additional sweeps are initialiated each

time the SGL SWP pus hbutton is pressed.) Obser ve the

display for spurious response (spurs ). Ver if y that, except

for the O Hz response, the amplitude of any observed

spur is -110 dBm (40 dB below -70 dBm).

c. Sequentially reset the DOT FREQUENCY

control to 1500 00 kHz, 2500.00 kHz, 3500.00 kHz, and

4500.00 kHz and repeat step b at each frequency

setting.

d. Set the DOT FREQUENCY control to

305.00 kHz, the RESOLUTION to 30 Hz, and the

FREQUENCY SPAN/DIV to 1 kHz.

@ 3-12

Page 24

e. With TRIGGER SOURCE in FREE RUN,

select the SGL SWP pushbutton and observe the dis play

for spurs. Verify that the amplitude of any observed

spurious response is at least 130 dB below 0 dBm.

(Press SGL SWP again as required for observation.)

f. Increase the dot frequency in 10 kHz

increments and repeat step e until the display is scanned

from 305.00 kHz to a dot frequency of 395.00 kHz.

NOTE

TM 11-6625-2759-14&P

c. Measure the average noise level by

adjusting the AVERAGE LEVEL cursor above the noise

peaks and noting the noise level.

d. Check the average noise level for each

resolution bandwidth listed as per Table 3-5.

TABLE 3-5

To measure the amplitude of a spur,

carefully reset DO T FREQUENCY to

place and keep the spur within one

division of center screen. Continue to

reduce the frequency span per division

with each sweep until maximum

amplitude of the spur has been

determined.

8. Sensitivity Check (Sensitivity is plug-in module

dependent)

NOTE

The sensitivity for the 7L5 Spectrum

Analyzer is specified with an L1 or L2

Plug-In Module using the equivalent

input noise method. Sensitivity

specifications and test procedures for

other plug-in modules are described in

the Instruction manual for the res pective

plug-in module.

The 7L5’s internal reference level, as

indicated by the display readout, is used

as the reference in the following

procedure. The accuracy of the

reference level readout may be verified

using external test equipment and the

procedure provided in the Service

Instructions.

a. Set the front panel controls as follows:

DOT FREQUENCY 1000.00 kHz

RESOLUTION 30 kHz

FREQUENCY SPAN/DIV.1 kHz

TIME/DIV 10 s

LOG 10 dB/DIV On

REFERENCE LEVEL -70 dBm

INPUT BUFFER Off

DIGITAL STORAGE DISPLAY A/DISPLAY

B

TRIGGERING FREE RUN and NORM

b. Terminate the INPUT in its characteristic

impedance (50 0 for the L1) to prevent outside noise

from entering and cluttering the display.

RESOLUTION Average Noise Level

30 kHz -105 dBm or less (35 dB below reference)

10 kHz -110dBm or less (40 dB below reference)

3 kHz -115 dBm or less (45 dB below reference)

1 kHz -120 dBm or less (50 dB below reference)

300 Hz -125 dBm or less (55dB below reference)

100 Hz -130 dBm or less (60dB below reference)

30 Hz -133 dBm or less (63 dB below reference)

10 Hz -135 dBm or less (65 dB below reference)

e. Remove the termination from the INPUT

connector.

9. Resolution Bandwidth Accuracy, Amplitude

Deviation, and Shape Factor

Bandwidth accuracy; within 20% except 10 Hz

position which is 100 Hz ±20 Hz, 70 dB down. Shape

factor; 5:1 or better (30 kHz-3 k Hz) and 10’1 or better (1

kHz-10 Hz). Amplitude deviation; less than 0 5 dB (30

kHz-100 kHz) and less than 2.0 dB (30 kHz-10 Hz).

a. Apply the CALIBRATOR signal to the

INPUT on the plug-in module and set the front panel

controls as follows:

DOT FREQUENCY 500.00 kHz

RESOLUTION 30 kHz

TIME/DIV AUTO

DIGITAL STORAGE DISPLAY A/DISPLAY B

DISPLAY MODE LOG 2 dB/DIV

b. Adjust the REFERENCE LEVEL and

FREQUENCY SPAN/DIV controls to establish a signal

response that is 7 divisions high and about3 divisions

wide at half amplitude.

c. Switch the RESOLUTION from 30 kHz to

100 Hz and reset the FREQUENCY SPAN/DIV as

required so the signal amplitude deviation over the 30

kHz to 100 Hz resolution range can be observed.

d. Total deviation over the range should not

exceed 0.5 dB.

@ 3-13

Page 25

TM 11-6625-2759-14&P

e. Switch the RESOLUTION through the 30

kHz to 10 Ht range and check that the amplitude

deviation does not exceed 2 0 dB

f. Return the RESOLUTION selector to 30

kHz, the FREQUENCY SPAN/DIV control to 10 kHz, and

adjust the REFERENCE LEVEL control for a signal

amplitude of 7 divisions

g. Measure the bandwidth at the 6 dB down

point by using the DOT FREQUENCY control to shift the

signal across a graticule reference line and noting the

frequency difference from one side to the other.

h. Bandwidth must equal the RESOLUTION

setting ±20 percent or 30 kHz ±6 kHz.

i. Repeat this procedure to check the -6 dB

bandwidth of each RESOLUTION setting from 30 kHz

through 3 kHz Verify that the bandwidth of each pos ition

is within 20 percent Note these measur ements f or futur e

use when measuring the shape factor.

j. Set the RESOLUTION selector to 1 kHz,

the FREQUENCY SPAN/DIV to 1 kHz or less, and adjust

the REFERENCE LEVEL for a signal amplitude of 7

divisions.

k. Use the DOT MKR to adjust the signal

position so the -6 dB bandwidth can be measured in

graticule divisions. Convert the number of divisions to

frequency by noting the setting of the FREQUENCY

SPAN/DIV selector Resolution bandwidth must equal the

RESOLUTION setting ±20 percent.

I. Repeat this procedure to check the

resolution bandwidth for RESOLUTION settings from 1

kHz through 30 Hz Bandwidth must equal the

RESOLUTION setting ±20 percent.

m. Switch to the 10 dB/DIV display mode Set

the RESOLUTION selector to 10 Hz, the FREQUENCY

SPAN/DIV to 50 Hz, and adjust the REFERENCE LEVEL

for a signal amplitude of 8 divisions.

n. Measure the bandwidth 70 dB down by

using the DOT MKR to position the display across a

reference point as previously described Bandwidth must

equal 100 Hz ±20 Hz (70 dB down) q

o. Return the RESOLUTION selector to 30

kHz, the FREQUENCY SPAN/DIV to 10 kHz and

measure the bandwidth 60 dB down using the procedure

previously described.

p. Check the shape factor (60.6 dB ratio) by

measuring the 60 dB bandwidth for all RESOLUTION

settings and compare this with the previous -6 dB

bandwidth readings noted in steps g though I. Shape

factor for RESOLUTION setting from 30 kHz to 3 kHz

must equal 5:1 or better Shape factor for RESOLUTION

settings from 1 kHz to 10 Hz must equal 10:1 or better.

USING THE ANALYZER

Impedance Matching

Input impedance of the 7L5 Spectrum Analyzer

is determined by the plug-in module (L1, L2, L3, etc.).

Impedance mismatch between a signal source and the

module's input connector caus es reflections or standing

waves in the interconnecting transmission line and

results in signal amplitude errors of the display and an

overall degraded performance of the analyzer To

minimize the probability of an impedance m ismatch, the

signal source and transmission lines, fastened to the

Input connector, should have the same impedance as

the plug-in module. Use cables of minimum length, and

good quality. Amplitude error due to plug-in swr will be

improved by turning on the 7L5's INPUT BUFFER

Signal Application

High amplitude signals (above +21 dBm or 2.5 V

rms) will overload and damage the mixer circuit and

should not be applied to the input connector (See the

plug-in instruction manual for maximum allowable input

power ) Signals of unknown amplitude should be routed

through a attenuator If spurious or multitone

intermodulation signals are present on the display, or, if

saturation of the mixer is suspected, the 7L5 INPUT

BUFFER will add 8 dB of attenuation in series with the

input signal. If the displayed signals show little or no

change with the buffer on, the intermodulation or

spurious signals are not generated by the spectrum

analyzer.

@ 3-14

Page 26

TM 11-6625-2759-14&P

Edge Noise

When using the digital storage mode, some

applications may leave display remnants at the edges of

the crt. This condition is an unavoidable result of the

storage memory being wider than the crt screen and not

a malfunction. Edge noise is removed as follows: 1)

Disconnect any signal from the INPUT connector. 2)

With digital storage on the FREQUENCY SPAN/DIV set

to other than MAX, rotate DOT MKR control to max cw

position 3) After one sweep has occ urred, to extend the

baseline, rotate the DOT MKR control max ccw to the

detent position. 4) Wait one sweep to clear the left edge

then apply the input signal.

Frequency Measurement Technique

Frequency measurement should be made on the

second or subsequent sweeps after the DOT

FREQUENCY has been changed. (Oscillator

stabilization time is 1 second or less.)

Following a change of the DOT FREQUENCY

control, the first click in the opposite direction will have

no effect. This is due to the electronic coupling within the

DOT FREQUENCY control assembly.

Bandwidth determines both the noise level and

resolution capability of the analyzer. As bandwidth

decreases, both sensitivity and signal-to-noise ratio

improve. Maximum sensitivity is obtained when

resoltuion bandwidth is narrow (10-30 Hz).

For most applications, the analyzer should be

used with the RESOLUTION control set to COUPLED

and the TIME/DIV switch set to AUTO. These autoranged positions provide the best sweep rate and

resolution bandwidth for each setting of the

FREQUENCY SPAN/DIV switch. When the analyzer is

used to make amplitude measurements, especially in

digital storage mode, the COUPLED and AUTO positions

of these controls ensures maximum accuracy.

Digital Storage Use

When using digital storage, the best

measurement accuracy is obtained by setting the

following controls as follows; (see Fig. 3-2, Front Panel

Controls.)

1. VIDEO Adjust to place the cursor at a point

PEAK/VIDEO midway between maximum signal

AVERAGE: amplitude and baseline noise.

Max Span Operation

When the 7L5 is operated with the

FREQUENCY SPAN/DIV control set to MAX (500 k Hz),

optimum instrument performance will be ensured by

setting the RESOLUTION to 30 kHz or COUPLED

position. The COUPLED position will m aintain a desired

ratio of 20:1 or less between the frequency span per

division and the resolution bandwidth.

Resolution, Resolution Bandwidth

The, term resolution represents an instrument’s

ability to display adjacent signal responses discretely. A

measure of resolution is the frequency separation in

hertz of responses which merge with a 3 dB notch.

Displayed resolution is a function of spectrum analyzer

bandwidth, horizontal sweep rate and frequency span.

Resolution is also affected by incidental (residual) FM.

Resolution bandwidth, as defined for the 7L5, is

the width in hertz between 6 dB down image points, on

the curve of the analyzer’s displayed response, to a cw

input signal.

2. DISPLAY A/ Press both pushbuttons to activate

DISPLAY B storage operation

3. RESOLUTION Set to COUPLED position.

4. TIME/DIV Set to AUTO position or a position

that is compatible with the setting of

FREQUENCY SPAN/DIV control

(UNCAL light not illuminated).

Applications for Spectrum Analyzers

Applications for spectrum analyzers such as the

7L5 include; measuring intermodulation products,

radiation interference, modulation percentage, absolute

and relative signal level measurements, bandpass

characteristics, etc. Numerous application notes on

spectrum analyzer measurements are available from

your local Tektronix Field Office or representative,

including assistance for specific measurement

applications you may desire.

@ 3-15

Page 27

Section 1 GENERAL INFORMATION

Introduction and Description.......................................................................................... 1-1

Manual Organization...................................................................................................... 1-2

Electrical Characteristics................................................................................................ 1-2

Frequency............................................................................................................... 1-2

Input........................................................................................................................ 1-3

Amplitude................................................................................................................ 1-3

Sweep..................................................................................................................... 1-4

Output Connectors.................................................................................................. 1-4

Environmental Characteristics....................................................................................... 1-5

Physical Characteristics................................................................................................. 1-5

Accessories and Options............................................................................................... 1-5

Installation...................................................................................................................... 1-5

Repackaging for Shipment............................................................................................. 1-6

Section 2 CIRCUIT DESCRIPTION

Block Diagrams.............................................................................................................. 2-1

IF Processing Chain............................................................................................... 2-1

Sweep Control and Frequency Reference.............................................................. 2-2

Frequency Control Circuits .................................................................................... 2-3

Readout.................................................................................................................. 2-5

Display Processing................................................................................................. 2-6

Detailed Circuit Description............................................................................................ 2-7

Sweep Control........................................................................................................ 2-7

Trigger Logic and Sweep Control........................................................................... 2-11

Frequency Span and Readout................................................................................ 2-13

Tune Reference- N Loops....................................................................................... 2-13

A&B Oscillator and Control..................................................................................... 2-14

1st LO/1st LO Lock........................................................................................................ 2-15

Reference Level, Readout, and Timeslot................................................................ 2-15

Readout and Timeslot Decode............................................................................... 2-18

IF Processing Chain............................................................................................... 2-19

Variable Resolution................................................................................................. 2-20

10 kHz & 30 kHz Filters and Post VR Amplifier...................................................... 2-22

Log/Lin Amplifier..................................................................................................... 2-22

Detector and Video Amplifier.................................................................................. 2-22

Display Processing........................................................................................................ 2-23

Horizontal and Vertical Display Processing............................................................ 2-23

Average Calculator................................................................................................. 2-24

Digital Storage........................................................................................................ 2-25

TM 11-6625-2759-14&P

PART II

TABLE OF CONTENTS

Page

Section 3 PERFORMANCE CHECK

Introduction.................................................................................................................... 3-1

Equipment Required or Recommended......................................................................... 3-1

1. Sweep Triggering............................................................................................... 3-2

2. Dot Frequency Range and Accuracy................................................................. 3-2

3. Display Flatness................................................................................................ 3-3

4. Frequency Span Accuracy & Linearity............................................................... 3-4

5. Sweep Rate Accuracy........................................................................................ 3-5

6. Intermodulation Distortion.................................................................................. 3-6

7. Display Frequency Stability................................................................................ 3-7

Section 4 CALIBRATION PROCEDURE

Complete or Partial Calibration...................................................................................... 4-1

History Information......................................................................................................... 4-1

Interaction...................................................................................................................... 4-1

Equipment Required...................................................................................................... 4-2

Short Form Procedure and Record................................................................................ 4-2

Preliminary Procedure................................................................................................... 4-3

1. Check/Adjust the Reference Oscillator Frequency................................................... 4 -6

2. Check/Adjust the Calibrator Output Level................................................................. 4-6

Page 28

3. Frequency Span/Div Calibration ........................................................................ 4-7

4. Sweep Timing.................................................................................................... 4-9

5. 1st LO and 1st LO Phase Lock Calibration........................................................ 4-10

6. Function IF Calibration....................................................................................... 4-11

7. Calibrate the 250 kHz, 2nd Mixer, and 10.7 MHz Input Filter ............................ 4-12

8. Variable Resolution Calibration ......................................................................... 4-13

9. Digital Storage Calibration ................................................................................. 4-16

Calibration Test Equipment Replacement Chart..................................................... 4-19

Section 5 MAINTENANCE

Introduction .................................................................................................................... 5-1

Preventive Maintenance................................................................................................. 5-1

Cleaning......................................................................................................................... 5-1

Lubrication ..................................................................................................................... 5-2

Visual Inspection............................................................................................................ 5-2

Transistor and Integrated Circuit Checks....................................................................... 5-2

Troubleshooting ............................................................................................................. 5-2

Troubleshooting Aids .............................................................................................. 5-2

Finding Faulty Semiconductors .............................................................................. 5-3

General Troubleshooting Techniques............................................................................ 5-5

Corrective Maintenance ................................................................................................. 5-5

Disassembly of the 7L5 and Replacing Assemblies ...................................................... 5-7

Removing the Front Panel ............................................................................................. 5-7

Removing the IF Module Assembly ............................................................................... 5-7

Removing the Sweep Board .......................................................................................... 5-8

Removing the RF Module .............................................................................................. 5-9

Reassembling the 7L5 .......................................................................................................... 5-9

TM 11-6625-27S9-14&P

Page

Section 6 OPTION INFORMATION

Section 7 REPLACEABLE ELECTRICAL PARTS ......................................................................... 7-1

Part Number-NSN Index ................................................................................................ 7-42

Section 8 DIAGRAMS AND CIRCUIT BOARD ILLUSTRATIONS

Section 9 REPLACEMENT MECHANICAL PARTS AND EXPLODED DRAWINGS

Section 10 DIFFERENCE DATA SHEETS ...................................................................................... 10-1

Appendix A. References..................................................................................................................... A-1

Appendix B. Operator’s, Organizational, Direct Support, and General Support