Page 1

Instructions

TDSXF05

TDS Series Digitizing Oscilloscopes

Video Trigger Upgrade Kit (Option 05)

070-9636-02

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

Page 2

Copyright T ektronix, Inc., All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

Kit Description

This kit includes parts and instructions to upgrade a standard TDS Series

instrument with Option 05, Video Trigger.

The TDSXF05 Video Trigger kit gives you a variety of tools for investigating

events that occur when a video signal generates a horizontal or vertical sync

pulse. The tools allow you to investigate a range of NTSC, PAL, SECAM and

high definition TV signals. To make one of these kits work, you must have the

Video Trigger hardware (provided in the kit) installed in a TDS Series oscilloscope.

Instruments

TDS500A and later, all serial numbers

TDS600A and later, all serial numbers

TDS700A and later, all serial numbers

Minimum Tools and Equipment List

Tool Part number

Torxdriv driver & T-15, T -20 tip n/a

Torque driver n/a

3/16 inch nut driver n/a

Video Trigger Upgrade Kit (Option 05)

1

Page 4

Kit Description

Kit Parts List

Compt no. Quantity Part number Description

1 ea 01 1-0055-01 Term, coaxial:75 ,1 W, bnc (Video trigger accessory)

1 ea 013-0278-00

070-8762-xx

1 ea 070-8748-xx Manual tech: Instruction, TDS Option 05

1 ea 070-9636-xx Manual Tech: Instructions, TDSXF05, field kit

1 ea 174-0655-00 Cable assy, rf: Video trigger, 50 , coax, sma to petola, 22.4 length. 9-2

2 ea 174-2574-00 Ca assy , sp: Ribbon, 28 awg, 4.875 inches length

1 ea 174-3728-00 Ca assy , sp: Ribbon, 40-pin, 28 awg, 5.15 inches length

1 ea 174-3729-00 Ca assy , sp: Ribbon, 50-pin, 28 awg, 6.0 inches length

1 ea 174-3340-00 Ca assy , sp: Ribbon, 40-pin, 28 awg, 6.4 inches length

Video clamp: Display, back porch clamp (Video trigger accessory)

Manual tech: User,Video Clamp

(Cable for TDS 500A and TDS 600A series except the TDS 684A)

(Cable for the TDS 500B, TDS 600B, TDS 700A and later series and

TDS 684A)

(Cable for the TDS 500B, TDS 600B, TDS 700A and later series and

TDS 684A)

(Cable for the TDS 500A and TDS 600A series except the TDS 684A)

2 ea 214-2270-00 Contact, elec: Clip, attenuators to cabinet

2 ea 210-0409-00 Nut, plain, hex: 8-32 x 0.312 brass, cd plate

2 ea 21 1-0720-00 Screw, assembly, washer: 6-32 x 0.500, pnh, T-15

A27 1 ea 671-4095-00 Circuit board assy: Option connector

A29 1 ea 671-2476-04 Circuit board assy: TV trigger

A14 1 ea 671-2770-00 Circuit board assy: D1-BUS

(For TDS 500A and TDS 600A except TDS 684A)

A14 1 ea 671-2848-00 Circuit board assy: D1-BUS

(For TDS 500B, TDS 600B, TDS 700 and later series and the TDS 684A )

2

Video Trigger Upgrade Kit (Option 05)

Page 5

Service Safety Summary

WARNING. The servicing instructions are for use by qualified personnel only. To

avoid personal injury, do not perform any servicing unless you are qualified to

do so. Refer to the General Safety Summary in the appropriate TDS Series

service manual before performing any service.

Kit Description

Do Not Service Alone

Avoid Exposed Circuitry

Use Care When Servicing

With Power On

Do not perform internal service on this product unless another person capable of

rendering first aid and resuscitation is present.

To avoid injury, remove jewelry such as rings, watches, and other metallic

objects. Do not touch exposed connections and components when power is

present.

Dangerous voltages or currents may exist in this product. Disconnect the power,

remove the battery (if applicable), and disconnect test leads before removing

protective panels, soldering, or replacing components.

Video Trigger Upgrade Kit (Option 05)

3

Page 6

Installation Instructions

These instructions assume a certain familiarity with the instrument. If further

details are required for disassembly or assembly, refer to the appropriate

TDS Series service manual. For assistance to install this kit, please call your

nearest Tektronix, Inc., Service Center or Tektronix Inc., Factory Service.

CAUTION. To prevent static discharge damage, service the instrument only in a

static-free environment. Observe standard handling precautions for static-sensitive devices while installing this kit. Always wear a grounded wrist and foot

strap while installing this kit.

Rear Cover and Cabinet Removal

Equipment required One screwdriver with a size T-20 Torx tip.

1. Install the front cover. Set the oscilloscope face down with the front cover on

the work surface and the bottom facing up (see Figure 1).

2. Unplug the power cord from its receptacle at the rear panel.

3. Using the screwdriver with size T-20 Torx

securing the rear cover to the oscilloscope. Lift off the rear cover.

4. Grasp the left and right edges of the cabinet at the rear. Pull upward to slide

the cabinet off the oscilloscope. Do not bind or snag the cabinet on the

oscilloscope internal cabling of the oscilloscope as you remove it.

tip, remove the four screws

4

Video Trigger Upgrade Kit (Option 05)

Page 7

T-20 screws (4)

Rear cover

Cabinet

Installation Instructions

Figure 1: Rear cover and cabinet removal

Video Trigger Upgrade Kit (Option 05)

5

Page 8

Installation Instructions

TV T rigger Circuit Board Addition

Equipment required One screwdriver with a size T-15 Torx tip.

1. The A23 SerPar circuit board (RS-232 Centronics) assembly must be

removed to allow the TV Trigger circuit board to be installed onto the

mounting posts, then locked in place by the rear SerPar circuit board

brackets. See Figures 2 and 6.

a. Using a screwdriver with size T-15 Torx

tip, remove the two screws

securing the rear plate of the A23 SerPar circuit board assembly.

b. Disconnect P37, the SerPar 26 pin ribbon cable connector, from J37 on

the Processor circuit board A11. Pull the cable and SerPar circuit board

assembly out of the instrument.

SerPar circuit board brackets (2)

SerPar cable connector P37

SerPar circuit board assembly

(Centronics RS-232)

T-15 screws (2)

Figure 2: Pull out A23 SerPar circuit board assembly

6

Video Trigger Upgrade Kit (Option 05)

Page 9

50 Coaxial cable

assembly, T ektronix part

number 174-0655-xx

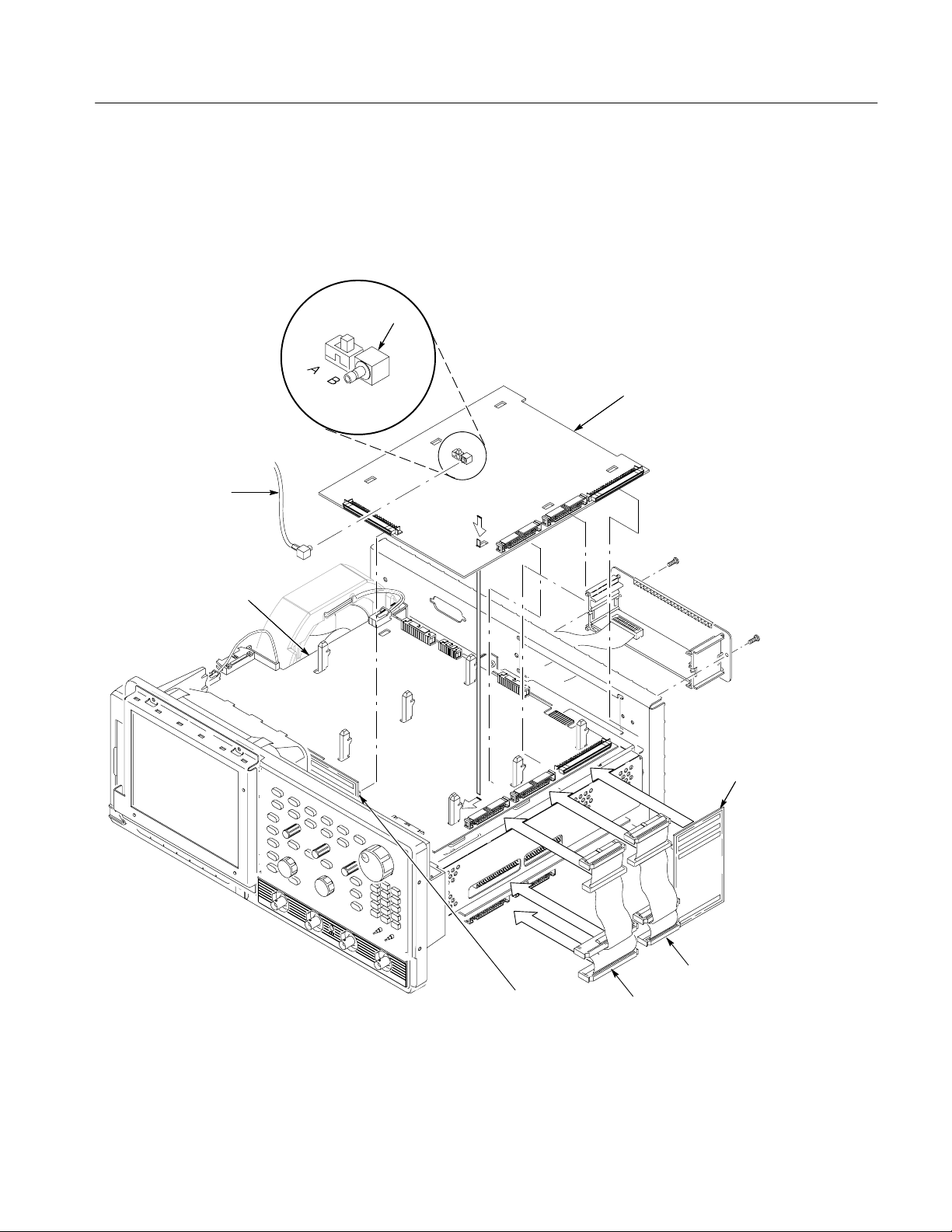

Installation Instructions

2. Install the TV Trigger circuit board A29 (provided in this kit) into the

instrument. Push down and slide the TV Trigger circuit board onto the board

mounts (see Figure 3). Refer to the Removal and Installation Procedures in

the TDS Series service manual for more detailed installation procedures.

J6

TV Trigger circuit board

J1

Processor circuit board

Option connector

circuit board

D1-BUS

Circuit board

Ribbon cable

Ribbon cable

Figure 3: Circuit board insertion

Video Trigger Upgrade Kit (Option 05)

7

Page 10

Installation Instructions

3. Connect the appropriate power ribbon cables (provided in this kit). The two

(2) ribbon cables interconnect to the analog power and digital power to the

Acquisition circuit board, Processor circuit board, and TV Trigger circuit

board.

4. Install the appropriate A14 D1-BUS board (provided in this kit).

NOTE. When plugging in the D1-BUS boards (see figure 3) make sure that they

remain plugged in on both ends after the kit is installed.

5. Install the Option Connector circuit board A27 (provided in this kit).

Carefully connect the bottom of the Option Connector circuit board to J39

on the Processor circuit board. Then connect the top of the Option Connector

to J1 on the TV Trigger circuit board.

6. Plug the sma connector of the 50 coaxial video cable (provided in this kit)

to J6 on the TV Trigger circuit board A29. Connect the petola end of the

cable to J1500 on the Acquisition circuit board. See Figure 4 for the

appropriate video cable routing.

7. Set the slide switch located on the TV Trigger circuit board to the following

position (see Figure 3):

a. Position A (BTL trigger IC) TDS 500B, TDS 684A, TDS 600B, and

TDS 700A and later instruments.

b. Position B (CTL trigger IC) TDS 500A and TDS 600A, except the

TDS 684A.

8

Video Trigger Upgrade Kit (Option 05)

Page 11

Installation Instructions

Route video cable

underneath the processor

circuit board.

Top view

Bottom view

TDS520A

TDS524A

J6

J1500

Route video cable

underneath the processor

circuit board.

Top view

Bottom view

TDS540A

TDS544A

J6

J1500

Top view

Bottom view

TDS620A

TDS640A

J6

TDS644A

TDS500B

TDS600B

TDS684A

TDS700A

and later

J1500

Top view

Bottom view

J6

J1500

Figure 4: Video cable routing (Acquisition to Processor)

Video Trigger Upgrade Kit (Option 05)

9

Page 12

Installation Instructions

Attenuator Electrical Contacts Installation

Equipment required One screwdriver with a size T-15 Torx tip.

TDS 500A and TDS 600A instruments (except TDS 684A) require electrical

contacts to be installed on the Attenuator circuit board.

NOTE. Examine the attenuator section located towards the front panel on the

bottom side of the oscilloscope. If the attenuators are located on a separate

circuit board assembly, perform the following procedure (see Figure 5).

1. Remove and discard the second and fourth screw and washer assemblies

from the Attenuator Circuit board using a T-15 Torxdriver. The screws and

washer assemblies are located nearest to the Acquisition circuit board.

2. Using the 8-32 nuts (provided in this kit) as spacers, place the nuts on

mounting holes just vacated by the T-15 screws just removed. The 8-32 nuts

are used as spacers.

CAUTION. To ensure proper operation of the new video trigger upgrade the

electrical contact clip must be in contact with the the cabinet when reassembled.

Make sure the electrical contact clip is position correctly. The small tab near the

mounting clip hole should be facing up and towards the Acquisition circuit

board.

3. Place the electrical contacts, clips (provided in this kit) on top of the nuts.

Secure the clips to the Attenuator circuit board by using the 6-32 x

0.500 inch panhead T-15 screws (provided in this kit).

10

Video Trigger Upgrade Kit (Option 05)

Page 13

T-15 6-32 0.500 (2)

Electrical contact clips (2)

8-32 Nuts (2)

Electrical contact

Installation Instructions

clip assembly

Figure 5: Partial view, attenuator electrical contacts installation

Video Trigger Upgrade Kit (Option 05)

11

Page 14

Installation Instructions

Replace A23 Circuit Board

Equipment required One torque driver

NOTE. When reinstalling the four screws at the rear panel, use the torque driver

to tighten the screws to 8 inch-lbs torque.

1. Do in reverse order, steps a to b of the TV Trigger Circuit board Addition

2. Make sure the A23 SerPar circuit board brackets slide over the TV Trigger

SerPar circuit board

procedure starting on page 6.

circuit board. This will lock the TV Trigger circuit board A29 into place. See

Figure 6.

bracket

Video Trigger board

12

Figure 6: TV Trigger and SerPar circuit board detail

Video Trigger Upgrade Kit (Option 05)

Page 15

Replace Cabinet and Rear Cover

Equipment required One screwdriver with a size T-20 Torx tip.

1. Do step 1 of the Rear Cover and Cabinet Removal procedure on

page 4.

2. Do in reverse order steps 2 through 4 of the Rear Cover and Cabinet

Removal procedure starting on page 4.

NOTE. When reinstalling the four screws at the rear panel, use the torque driver

to tighten the screws to 16 inch-lbs torque.

Installation Instructions

One torque driver.

Execute Diagnostics

Executing Extended

Diagnostics Routine

To ensure the Video Trigger is working correctly, perform the Diagnostics

procedure.

Prerequisites: Power on the oscilloscope and allow a 20 minute warm-up before

doing this procedure.

1. Press SHIFT UTILITY

Execute (main) ➞ OK Confirm Run Test (side).

2. The internal diagnostics routine checks oscilloscope functions. When

finished, the oscilloscope displays an on-screen report of any failed modules,

features, or interfaces.

3. If the video trigger feature fails diagnostics, verify that all cables are securely

seated and are not damaged.

4. If the video trigger feature continues to fail diagnostics, call the nearest

Tektronix, Inc., field office for assistance.

g End of document g

➞ System (main) ➞ Diag/Err (pop-up) ➞

Video Trigger Upgrade Kit (Option 05)

13

Page 16

Installation Instructions

14

Video Trigger Upgrade Kit (Option 05)

Page 17

Page 18

Loading...

Loading...