Page 1

Online Help

TDSVNM CAN and LIN Timing and Protocol

Decode Software

077-0017-00

www.tektronix.com

Page 2

Page 3

Copyright

Copyright © Tektronix, Inc. All rights reserved. Licensed software products

are owned by Tektronix or its suppliers and are protected by United States

copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and

pending. Information in this publication supercedes that in all previously

published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

TDSVNM CAN and LIN Timing and Protocol Decode Software Online Help

Version 3.0.0, 076-0048-00.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive or P.O. Box 500

Beaverton, OR 97077 USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

Page 4

Page 5

Table of Contents

Copyright ......................................................................................................................................... 1

Contacting Tektronix ............................................................................................................... 1

Table of Contents.............................................................................................................................. i

General Safety Summary ................................................................................................................. v

Introduction...................................................................................................................................... 1

About TDSVNM CAN and LIN Timing and Protocol Decode Software ............................... 1

Using Online Help ................................................................................................................... 2

Application Description ........................................................................................................... 2

Applications................................................................................................................... 2

Features.......................................................................................................................... 3

Easy System Integration ................................................................................................ 3

Network Management ................................................................................................... 4

Monitoring Multiple Protocols ...................................................................................... 5

Protocol Decoding ......................................................................................................... 5

About the ATM-1 Automotive Trigger Module ...................................................................... 6

Application Environment .............................................................................................. 6

Trigger Module Connections......................................................................................... 6

Buses and Bus Connections........................................................................................... 7

Printing from the Online Help ................................................................................................. 8

Conventions ............................................................................................................................. 8

Updates from the Web Site ...................................................................................................... 8

Feedback ............................................................................................................................... 9

Getting Started ............................................................................................................................... 11

Compatibility ......................................................................................................................... 11

Recommended Accessories.................................................................................................... 11

Starting the Application ......................................................................................................... 11

Requirements and Restrictions............................................................................................... 12

Maximizing and Minimizing the Application........................................................................ 12

Returning to the Application.................................................................................................. 13

Exiting the Application .......................................................................................................... 13

Application Directories and Usage ........................................................................................ 13

Operating Basics ............................................................................................................................ 15

Protocol Decoding and Timing Analysis Tests...................................................................... 15

TDSVNM Application View ................................................................................................. 16

Menus ............................................................................................................................. 16

File Menu..................................................................................................................... 16

Tests Menu .................................................................................................................. 17

Results Menu ............................................................................................................... 17

TDSVNM Timing and Protocol Decode Software i

Page 6

Table of Contents

Utilities Menu.............................................................................................................. 18

Help Menu ................................................................................................................... 18

Selection Panel....................................................................................................................... 18

Control Panel ......................................................................................................................... 19

Status Bar ............................................................................................................................. 20

Setting Preferences................................................................................................................. 20

Virtual Keyboard.................................................................................................................... 21

How to ........................................................................................................................................... 25

Select ............................................................................................................................. 25

Protocol and Timing Analysis Tests............................................................................ 25

Configure ............................................................................................................................. 26

Configure Protocol ...................................................................................................... 26

Configure CAN Protocol ............................................................................................. 28

Configure LIN Protocol............................................................................................... 30

Configure CAN and LIN Protocol............................................................................... 32

Timing Analysis Tests................................................................................................. 34

Configure Oscillator Tolerance ................................................................................... 36

Configure Eye Diagram............................................................................................... 37

Configure Bus Traffic.................................................................................................. 39

Configure Data Rate .................................................................................................... 40

Configure Wakeup Time ............................................................................................. 41

Configure Propagation Delay ...................................................................................... 42

Set up Trigger ........................................................................................................................ 43

Set up Trigger .............................................................................................................. 43

Trigger CAN and CAN/LIN Protocol ......................................................................... 47

Trigger LIN Protocol ................................................................................................... 49

Trigger for Oscillator Tolerance, Eye Diagram, and Data Rate .................................. 49

Trigger Bus Traffic...................................................................................................... 51

Trigger Wakeup Time ................................................................................................. 53

Trigger Propagation Delay .......................................................................................... 54

Define Elementary Trigger Events .............................................................................. 54

Define Logical Trigger Events .................................................................................... 58

Define Advanced Trigger Events ................................................................................ 61

Connect ............................................................................................................................. 65

Connections for Protocol and Timing Tests ................................................................ 65

Connections for CAN Dual Wire ................................................................................ 66

Connections for CAN and LIN Protocols.................................................................... 75

View Results .......................................................................................................................... 76

Results Window........................................................................................................... 76

Protocol Analysis Window.......................................................................................... 77

Results for CAN Protocol............................................................................................ 85

Results for LIN Protocol.............................................................................................. 87

ii TDSVNM Timing and Protocol Decode Software

Page 7

Table of Contents

Results for CAN and LIN Protocols............................................................................ 88

Results for Eye Diagram.............................................................................................. 89

Eye Diagram Plot......................................................................................................... 91

Results for Oscillator Tolerance .................................................................................. 92

Results for Data Rate................................................................................................... 93

Results > Details.......................................................................................................... 93

Results for Bus Traffic ................................................................................................ 94

Results for Wakeup Time ............................................................................................ 95

Results for Propagation Delay..................................................................................... 96

Install ATM-1 License ...........................................................................................................97

ATM-1 License Installation......................................................................................... 97

References...................................................................................................................................... 99

Shortcut Keys......................................................................................................................... 99

Error Messages..................................................................................................................... 100

Default Settings Part I .......................................................................................................... 103

Default Settings Part II......................................................................................................... 106

Measurement Algorithms..................................................................................................... 108

CAN Protocol ............................................................................................................ 108

LIN Protocol.............................................................................................................. 109

Oscillator Tolerance .................................................................................................. 110

Eye Diagram.............................................................................................................. 111

Data Rate ................................................................................................................... 111

Bus Traffic................................................................................................................. 112

Wakeup Time ............................................................................................................ 113

Propagation Delay ..................................................................................................... 113

Index ........................................................................................................................................ 115

TDSVNM Timing and Protocol Decode Software iii

Page 8

Table of Contents

iv TDSVNM Timing and Protocol Decode Software

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage

to the measurement instrument or any products connected to it. To avoid

potential hazards, use the software and measurement instrument only as

specified.

While using this software, you may need to access other parts of the system.

Read the General Safety Summary and specification sections in other

equipment manuals for warnings, cautions, and ratings related to operating

the system with this software.

To avoid Fire and Personal Injury

Connect and Disconnect Properly. Connect the probe output to the

measurement instrument before connecting the probe to the circuit under test.

Disconnect the probe input and the probe ground from the circuit under test

before disconnecting the probe from the measurement instrument.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all

ratings and markings on the measurement instrument and other equipment

used with this software. Consult the individual product manuals for further

ratings information before making connections to the circuit under test.

Do Not Operate With Suspected Failures. If you suspect there is damage to

the measurement instrument or other equipment being used with this

software, have it inspected by qualified service personnel.

Terms in this Manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could

result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could

result in damage to the measurement instrument or other property.

TDSVNM Timing and Protocol Decode Software v

Page 10

General Safety Summary

vi TDSVNM Timing and Protocol Decode Software

Page 11

Introduction

About TDSVNM CAN and LIN Timing and Protocol

Decode Software

The TDSVNM CAN and LIN Timing and Protocol Decode Software is a low

speed serial bus test software program for CAN and LIN buses that run on

Tektronix oscilloscopes. The software helps to decode CAN and LIN

protocol messages simultaneously, set trigger conditions based on the CAN

bus message, capture data for specific conditions of the in-vehicle network,

decode and display the captured CAN and LIN messages, and analyze the

displayed frames. TDSVNM offers timing analysis tests that help

characterize CAN node performance.

The TDSVNM CAN and LIN Timing and Protocol Decode Software offers

the following:

Protocol Decoding

CAN bus

LIN bus

CAN & LIN buses

CAN Timing Tests

Eye Diagram

Oscillator Tolerance

Data Rate

Bus Traffic

Wakeup Time

Propagation Delay

TDSVNM Timing and Protocol Decode Software 1

Page 12

Introduction

Using Online Help

The TDSVNM CAN and LIN Timing and Protocol Decode Software online

help serves as a reference for using the TDSVNM CAN and LIN Timing and

Protocol Decode Software.

Contents: The Contents tab displays books and pages that represent the

categories of information in the online Help system.

Index: The Index tab displays a multi-level list of keywords and keyword

phrases. These terms are associated with topics in the Help system and direct

you to specific topics.

Search: The Search tab enables you to search for keywords in the Help

system and to locate topics containing those words. When the search is

completed, a list of topics is displayed so you can select a specific topic to

view.

Back and Forward: The Back and Forward buttons allow you to browse

through topics.

To print a topic: Select the Print button from the Help Topics menu bar.

Application Description

Applications

Some typical applications while developing, integrating, operating, and

updating the CAN and LIN network are as follows:

Easy System Integration: Adding new features to existing in-vehicle

networks often results in adding new CAN nodes (devices). While integrating

a new CAN node, there is a need to ensure that the CAN node is

synchronized for seamless network operation. The oscillator tolerance and

propagation delay measurements help to locate any network synchronization

problems.

CAN/LIN network management: An in-vehicle network in a car enables

communication between auto body parts such as doors, seats, dashboard,

airbag, and engine parts such as the engine, steering, and gear box. A tool that

helps to monitor the communications between different segments of the

vehicle network is needed.

Protocol Decoding: The performance of an existing in-vehicle network is

improved by enhancing the software in upper layers of the OSI model. This

involves updating the existing vehicle firmware and testing its performance.

Monitor multiple protocols: An in-vehicle network is heterogeneous. Based

on the cost and performance of a node, automotive manufacturers use

different networks and integrate them using gateways.

2 TDSVNM Timing and Protocol Decode Software

Page 13

Introduction

Features

TDSVNM CAN and LIN Timing and Protocol Decode Software offers the

following features and benefits:

Oscillator Tolerance and Propagation Delay measurements help in

addressing network synchronization issues

Simultaneous protocol decoding of CAN and LIN messages helps in

ensuring communication accuracy and acceptable latency between the

two segments of the network

Ability to link decoded and time-stamped CAN messages to its timing

waveform to clearly visualize bus functions

Integrated search functions help to efficiently debug network problems

in the data link layer

CAN Eye diagram analysis quickly locates noise in the CAN message

caused by jitter, amplitude aberration, spikes and glitches

Bus Traffic measurement helps in optimizing network performance and

bus utilization for different CAN message frames

Support for various CAN configurations: CAN single wire, CAN Dual

wire, CAN fault tolerant makes TDSVNM useful for a wide range of

CAN signaling types

Speedy network debug by setting trigger conditions based on CAN

message content such as ID, DATA and DLC

Setting trigger conditions to detect overload, passive error, active error

and remote frames helps to quickly identify CAN network

communication errors

Powerful conditional triggers such as if-then-else enable users to

monitor the CAN network and efficiently capture intermittent or

occasional events

Characterize long duration network timing performance by triggering on

the nth occurrence of a specific CAN message or triggering only after a

user specified time has elapsed

Ability to generate ACK Bit removes the need for a receiving CAN node

while testing a single CAN node

Capability to use the DPO-CAN Bus Trigger feature

Easy System Integration

CAN and LIN nodes are connected to form an in-vehicle network. CAN is a

serial, asynchronous, and multi-master communication network. The data is

transmitted from one CAN node to another CAN node with overhead and

payload. The receiving node samples the incoming data using the internal

TDSVNM Timing and Protocol Decode Software 3

Page 14

Introduction

clock. The oscillator, which resides in each CAN node, generates the internal

clock. The sample point is programmed at an appropriate bit interval such

that data from a distant node is interpreted accurately. The sample point can

be programmed anywhere between 20% and 90% of the bit time. The sample

point position depends on the following:

Oscillator tolerance of the receiving CAN node

Propagation delay from the transmitting node to the receiving node

If the sample point is set at 50% of the bit time, you may be limited to using

short cables for the network. If the sample point is set at 80% of the bit time,

you may be able to use longer cables. This requires a very high tolerance

oscillator, which generates the sampling clock. A low tolerance oscillator

may cause sampling beyond the bit time and wrong interpretation of the data

by the CAN node.

It is apparent that a low tolerance oscillator is not compatible with long cable

length. Oscillator tolerance also varies with the operating temperature and

age of the CAN network.

New nodes are added to the existing network to add more features to the

vehicle. During system integration, you need a tool that allows you to

synchronize the new CAN node by setting an appropriate sample point

location in the bit time, based on the oscillator tolerance of the CAN nodes

and propagation delay of the network.

TDSVNM is a tool that helps in characterizing the oscillator tolerance and

propagation delay of the CAN network. TDSVNM helps to easily integrate

an in-vehicle network and add new CAN nodes to the existing network.

Network Management

CAN and LIN network enables the communication between doors, seats,

dashboard, airbag, and engine parts. The communication needs to be efficient

and timely between the CAN and LIN nodes. To measure the effectiveness of

the communication, you need to capture the physical layer activity using an

oscilloscope. This data will be in the YT format, which is difficult to

interpret. Analyzing a YT waveform is time consuming and prone to errors.

You might want to view the YT data in hexadecimal, binary, or decimal

format.

Each CAN node expects to communicate in a timely manner. This

requirement becomes critical for the safety bus, since it controls the airbag

and ABS. To characterize this part of the communication, you need a tool

that allows you to measure the time difference between the communication of

the node that provides input and the nodes that respond to the input.

An in-vehicle network manages combustion, emission, safety and comfort

needs of the vehicle by continuous communication. For reliable operation of

the CAN and LIN, network traffic needs to be monitored for a long time.

4 TDSVNM Timing and Protocol Decode Software

Page 15

Introduction

Monitoring Multiple Protocols

An in-vehicle network is heterogeneous. Based on performance requirements

and the cost of a node, automotive manufacturers use different networks and

integrate those using gateways. Two dominant networks are CAN and LIN.

In a CAN network, different data speeds are used based on the application of

that segment of the network. In many cases there could be communication

across the two-segment networks through a gateway. You need to ensure that

communication across the gateway is accurate and timely. To characterize

this, you need tools that would provide simultaneous decoding of the data for

each segment of the network.

A typical example for a CAN-LIN network is as shown in Figure 1-1:

Figure 1-1: Example of a CAN-LIN network

In this application, design engineers and system integration engineers would

need to monitor the LIN and CAN protocol across the gateway. In the

picture, the gateway is an ECU that converts LIN to CAN protocol and vice

versa. Engineers need to monitor the delays in the two-way communication

between the CAN and LIN network. This is because each of the segments of

the network operates at different speeds. The delay between the CAN and

LIN gateway would affect the movement of the gears that control the

headlight position.

Protocol Decoding

The performance of an automotive, medical electronics or industrial

automation network is improved by enhancing the software in upper layers of

the OSI model. This involves updating the existing vehicle firmware and

testing its performance. During firmware update, you need to monitor the

physical layer activity of the CAN in hexadecimal, binary or decimal format,

and then optimize the performance of the network.

TDSVNM Timing and Protocol Decode Software 5

Page 16

Introduction

About the ATM-1 Automotive Trigger Module

The ATM-1 Automotive Trigger Module monitors the CAN bus protocol and

provides an output signal to trigger a Tektronix oscilloscope when a userspecified bus condition occurs.

The ATM-1 automotive trigger module is manufactured by Crescent Heart

Software (CHS). Refer to www.c-h-s.com for contact information.

The ATM-1 monitors the behavior of the bus to which it is connected, and

can also send signals to the bus in specific situations (for example, to

optionally signal an acknowledge on the CAN bus).

The ATM-1 functions as an addition to an oscilloscope, enabling the

oscilloscope to be triggered when a complex signaling situation occurs on the

bus. The ATM-1 can track and produce a trigger signal as a result of

signaling conditions that are too complex for the oscilloscope to trigger on.

Such complex signaling conditions occur as a result of the multiple levels of

signaling protocol implemented on the CAN bus.

The ATM-1 is packaged in an aluminum metal case with front and rear-panel

signal input and output connectors.

Application Environment

An oscilloscope uses standard probes to monitor the electrical activity of the

bus signal(s). For single wire buses, the signal voltage is determined relative

to the system ground. For dual wire buses, which use differential signaling,

the differential voltage is determined using either a differential probe or two

conventional (non differential) probes with the algebraic voltage difference

mathematically computed by the oscilloscope.

The ATM-1 also connects to the bus signal(s), allowing the module to

monitor the logical behavior of the bus.

Trigger Module Connections

A D-SUB 25-pin male connector on the front panel of the ATM-1 accepts the

bus signals to be monitored. Connecting the bus signals to the ATM-1

requires wiring the 25-pin female mating connector provided with the unit, or

using the optional companion cable assembly.

The ATM-1 produces a TTL-compatible 50-Ω back-terminated trigger output

through a BNC connector on the rear panel of the unit; use the standard 50-Ω

BNC cable provided with the ATM-1 to connect the ATM-1 trigger output to

a trigger input on the oscilloscope. The trigger state machine of the ATM-1

creates an output signal on the trigger output according to user-specified

trigger events.

6 TDSVNM Timing and Protocol Decode Software

Page 17

Introduction

The ATM-1 can be connected to the oscilloscope using the USB port on the

rear panel of the unit. Through this connection, the application software

running on the oscilloscope can set up trigger conditions, control, and

monitor the trigger module.

The bicolor (yellow/green) LED on the ATM-1 front panel indicates the

presence of power, the status of the USB connection, and certain error

conditions.

Buses and Bus Connections

The current version of the ATM-1 firmware supports following versions of

CAN bus:

CANH, CANL: High- or medium-speed CAN bus differential signals,

In/Out

FTCANH, FTCANL: Fault-tolerant low-speed CAN bus differential

signals, In/Out

SWCAN: Single-wire CAN bus signal, In/Out

TDSVNM Timing and Protocol Decode Software 7

Page 18

Introduction

Printing from the Online Help

While using the online help, you can print topics and information from the

HTML Help viewer.

To print a single topic:

1. Find the topic in the Contents pane.

2. Click Print.

3. Click Print the selected topic and click OK.

To print all topics in a selected TOC book:

4. Find the TOC book in the Contents pane.

5. Click Print.

6. Click Print the selected heading and all subtopics and click OK.

Some online help topics have color in the examples of the displayed

application. If you want to print this type of topic on a monochrome printer,

some colors may not print. To avoid this problem, print the topic from the

PDF file that corresponds to the online help. You can find this file in the

Documents directory on the Optional Applications Software on WindowsBased Oscilloscopes CD-ROM. The application menus in the PDF file are

gray scale and all the information can be printed.

Conventions

Online help uses the following conventions:

When steps require a sequence of selections using the application

interface, the ">" delimiter marks each transition between a menu and an

option. For example, File > Minimize.

DUT refers to the transmitter of the signal to be tested.

Updates from the Web Site

You can find information about this and other applications at the Tektronix

Inc. Web site, www.tektronix.com. Check this site for firmware updates and

other information about our application.

8 TDSVNM Timing and Protocol Decode Software

Page 19

Feedback

Introduction

Tektronix values your feedback on our products. To help us serve you better,

please send us your suggestions, ideas, or comments on the application.

Direct your feedback using email to techsupport@tektronix.com or tdsvnmfeedback@tek.com. You can also send feedback by FAX to (503) 627-5695.

Please include the following information and be as specific as possible.

General information:

Instrument model number and hardware options if any, with serial

number

Probes used

Your name, company, mailing address, phone number, FAX number,

email address

Please indicate if you would like to be contacted by Tektronix about

your suggestion or comments

Application specific information:

Software version number

Description of the problem such that technical support can duplicate the

problem

The setup file of the oscilloscope and the application is also required to

identify the problem

If possible, save the waveform on which you are performing the

measurement as a .wfm file

Note: To find the Software version number, click Help > About in the

application.

Once you have gathered this information, you can contact technical support

by fax or through email. If using email, be sure to enter "TDSVNM Software

Problem" in the subject line, and attach the .wfm files.

You can then attach the file to your email (depending on the capabilities of

your email editor).

TDSVNM Timing and Protocol Decode Software 9

Page 20

Introduction

10 TDSVNM Timing and Protocol Decode Software

Page 21

Getting Started

Compatibility

For information on oscilloscope Compatibility, refer to the Optional

Applications Software on Windows-Based Oscilloscopes Installation Manual,

Tektronix part number 071-1888-00. The manual is also available as a PDF

file.

Recommended Accessories

The following probes are supported by the application:

P5205

P5200

P6246

P6247

P6248

ADA400A

TCA-1MEG, probe adapter for use with supported oscilloscopes

TPA-BNC, TEKPROBE™ BNC adapter for use with supported

oscilloscopes

Starting the Application

Depending on the type of oscilloscope that you have, you can start the

software in the following way:

1. To start the application, do one of the following:

• Select File > Run Application > in the oscilloscope menu bar. Then

select CAN and LIN Timing and Protocol Decode Software

• Select App > CAN and LIN Timing and Protocol Decode Software

• Select Analyze > CAN and LIN Timing and Protocol Decode

Software

2. A splash screen indicates that the software loading is in progress.

3. The oscilloscope display resizes to fit in the upper part of the screen.

The lower part of the oscilloscope screen displays the TDSVNM CAN

and LIN Timing and Protocol Decode Software.

TDSVNM Timing and Protocol Decode Software 11

Page 22

Getting Started

4. The software is automatically set to its default settings.

5. If you gain access to the oscilloscope functions, then the oscilloscope

display appears full screen and the TDSVNM CAN and LIN Timing and

Protocol Decode Software recedes to the background.

6. To return to the TDSVNM CAN and LIN Timing and Protocol Decode

Software, do one of the following:

• Select App on the top right of the oscilloscope display

• Select App > Restore Application

• Select Analyze > Restore Application

Requirements and Restrictions

Requirements

DPO-CAN Bus trigger is required:

To define Elementary Trigger

To carry out the Oscillator Tolerance, Eye Diagram, and Data Rate

tests

The ATM-1 Automotive Trigger Module is required:

To specify trigger conditions and perform elementary, logical or

advanced triggering during protocol decoding

To carry out the Oscillator Tolerance, Eye Diagram, and Data Rate

tests

The ATM-1 Automotive Trigger Module can be ordered from Crescent Heart

Software (www.c-h-s.com). Contact a Tektronix representative for more

details.

Restrictions

It is recommended that you do not connect more than one ATM-1 module to

an oscilloscope.

Maximizing and Minimizing the Application

The software appears even when you minimize the oscilloscope display.

To minimize the software, click File > Minimize. The TDSVNM CAN

and LIN Timing and Protocol Decode Software window minimizes to

the Windows taskbar. The upper part of the screen has the oscilloscope

display and the lower part of the screen has the desktop.

To restore the minimized window to its previous size, click its taskbar

button.

12 TDSVNM Timing and Protocol Decode Software

Page 23

To hide the window, click on the top-right of the software

window.

Returning to the Application

When you gain access to the oscilloscope functions, the oscilloscope fills the

display. You can access the oscilloscope functions in the following ways:

Choose either the menu bar or the toolbar mode on the oscilloscope, and

then gain access to the menus.

Click App > Restore Application or click APP on the top right of the

oscilloscope display to return to the software.

Exiting the Application

To exit the software:

Getting Started

1. On the menu bar, click File > Exit or click

2. The Exit dialog box appears.

3. Click either Yes, No, or Cancel. Yes is selected by default. When the

software runs, it automatically changes some oscilloscope settings.

When you quit the software, you can choose whether to retain these

settings or restore the previous settings.

Application Directories and Usage

The TDSVNM CAN and LIN Timing and Protocol Decode Software uses

directories to save and recall setup files and uses file name extensions to

identify the file type. Table 2-1 lists the default directory names.

Table 2-1: Directory names and their use

Default directory names* Directory use

C:\TekApplications\TDSVNM TDSVNM application home location

\Images Plot files

\Reports Results of protocol decoding

\Setup Setup files for TDSVNM

\Temp Temporary files

*All subdirectories are located in the C:\TekApplications\TDSVNM directory.

.

TDSVNM Timing and Protocol Decode Software 13

Page 24

Getting Started

14 TDSVNM Timing and Protocol Decode Software

Page 25

Operating Basics

Protocol Decoding and Timing Analysis Tests

The TDSVNM CAN and LIN Timing and Protocol Decode Software offers

the tests as shown in Table 3-1:

Table 3-1: Descriptions of protocols and tests

Protocol or Test Description

CAN bus (Controller Area

Network)

LIN Bus (Local Interconnect

Network)

CAN and LIN Decodes and displays the waveform acquired simultaneously on CAN and LIN buses.

Eye Diagram Represents the overlaying of the individual NRZ bits of a CAN message. This allows

Oscillator Tolerance Measures the deviation of the oscillator deduced from the transmitted data. This

Data Rate Extracts the data rate of the selected node based on the ID from the acquired CAN

Bus Traffic Determines the load of the CAN message on the CAN bus network expressed as

Wakeup Time Measures the time difference between time of the ignition signal to the first CAN

Propagation Delay Measures the time taken for a message to travel from one end of the network to the

Converts the waveform acquired by the oscilloscope from the Controller Area Network

into a bit stream and decodes it to display CAN protocol messages in the protocol

analysis window.

The application supports CAN Dual Wire, CAN Single Wire and CAN Fault Tolerant

buses.

Converts the waveform acquired on the Local Interconnect Network into a bit stream

and decodes it to display LIN protocol messages in the protocol analysis window.

you to find electrical noise in the CAN message such as amplitude aberration, jitter,

spikes and glitches. The ability to view Eye diagram with Ack and without Ack bit allows

you to realize the impact of propagation delay on the bit time and adjust the sample

point accordingly.

enables you to program the segments and to operate the node synchronously with

other nodes. Oscillator tolerance is measured in percentage.

frame signal. Data rate is measured in Kbps.

percentage of bus occupancy. Determines the details of the message that occupies the

bus of the selected node. It also gives the number of CAN messages and frame types

on the network. Bus traffic is measured in percentage.

message during network start up. Wakeup time is measured in seconds.

other end. This is measured for the signal transition on the start frame of the message.

Propagation delay is measured in seconds.

TDSVNM Timing and Protocol Decode Software 15

Page 26

Operating Basics

TDSVNM Application View

Figure 3-1 shows the default application view and its areas.

Figure 3-1: Application view and its areas

Menus

The menu bar of TDSVNM software consists of the following menus (as

shown in Figure 3-2):

Figure 3-2: Application Menu

File Menu

Figure 3-3: File Menu

16 TDSVNM Timing and Protocol Decode Software

Page 27

Table 3-2: File Menu selections and their descriptions

Menu selection Description

Recall Default Click File > Recall Default to recall the default settings for both the software and the

oscilloscope.

Recall Click File > Recall to recall the previously saved settings for the software from an .ini

file.

Save Click File > Save to save the software settings to an .ini file.

Recall Recent Click File > Recall Recent to select among the recently saved and recalled setups.

Preferences Click File > Preferences to set preferences.

Minimize Click File > Minimize to minimize the software window.

Exit Click File > Exit to quit the software.

Tests Menu

Operating Basics

Figure 3-4: Tests Menu

Table 3-3: Tests Menu selections and their descriptions

Menu selection Description

Select Click Tests > Select to display or modify the protocol or test selection.

Configure Click Tests > Configure to display or modify the configuration parameters for the

selected protocol or test.

Trigger Setup Click Tests > Trigger Setup to display or modify the trigger parameters and trigger

type for the selected protocol or timing test.

Connect Click Tests > Connect to display the connection instructions for the selected

protocol or test.

Results Menu

Figure 3-5: Results Menu

Click Results > Details to display the detailed results of the last test that was

conducted.

TDSVNM Timing and Protocol Decode Software 17

Page 28

Operating Basics

Utilities Menu

Figure 3-6: Utilities Menu

Click Utilities > ATM-1 License Installation to install or upgrade ATM-1

automotive trigger module license key information.

Help Menu

Figure 3-7: Help Menu

Table 3-4: Help Menu selection and their descriptions

Menu selection Description

Help Topics Click Help > Help Topics to display the help file for the TDSVNM CAN and LIN

Timing and Protocol Decode Software.

About TDSVNM Click Help > About TDSVNM to display a dialog box with information about the

current TDSVNM CAN and LIN Timing and Protocol Decode Software.

About ATM-1 Click Help > About ATM-1 to display a dialog box with information about the current

ATM-1 automotive trigger module.

Selection Panel

The selection panel appears at the far left of every screen. It allows you to

navigate through the TDSVNM application.

Figure 3-8: Select panel

18 TDSVNM Timing and Protocol Decode Software

Page 29

Operating Basics

Table 3-5 shows the buttons and their descriptions:

Table 3-5: Select panel buttons and their descriptions

Button Description

Select Click Select to display the protocols and timing tests to select from.

Configure Click Configure to display the configuration parameters for the selected protocol or

timing test.

Trigger Setup Click Trigger Setup to display the trigger parameters and trigger type for the selected

protocol or timing test.

Connect Click Connect to display the connection instructions for the selected protocol or timing

test.

After you select and configure a protocol or test, you can either set up the

trigger conditions or make equipment connections for the selected protocol or

test.

Control Panel

The control panel appears at the far right of every screen. It controls all of the

application’s operations.

Figure 3-9: Control panel

Table 3-6 shows the buttons and their descriptions:

Table 3-6: Control panel buttons and their descriptions

Button Description

Run Executes the protocol decoding or test selected. The Run button changes to Stop when the

test is running. You can stop the test by clicking the Stop button.

Results Displays the respective Result details panel for the protocol or the test that is configured.

Clear Clears the results displayed on the results screen.

Sequence Mode

Single Run

Free Run

No Acq

Same as the “Single” button on the oscilloscope front panel.

Runs continuously until you press Stop.

Conducts the test without acquiring the waveform.

TDSVNM Timing and Protocol Decode Software 19

Page 30

Operating Basics

Note: When Ref sources are selected in configuration panel, only the No Acq

sequencer mode is available.

Status Bar

The status bar at the bottom of the application screen dynamically updates

according to your selection. The status bar shows the selected Protocol or

Test, Configuration parameters, Hints, and Sequence state.

Figure 3-10: Status bar

Setting Preferences

File > Preferences

Figure 3-11 shows the preferences that you can set.

Figure 3-11: Setting preferences

Math Destination is applicable only when:

The probe type is single-ended

20 TDSVNM Timing and Protocol Decode Software

Page 31

Operating Basics

The bus type is CAN-DW-HL, CAN-DW-LH, CAN-Fault-T-HL, or

CAN-Fault-T-LH

However, Reference Level is used for all bus sources.

Table 3-7 shows the preferences and their descriptions.

Table 3-7: Preferences options and their descriptions

Options Description

Math Destination

Bus1 Source Select the Bus1 source from Math1, Math2, Math3, Math4.

Bus2 Source Select the Bus2 source from Math1, Math2, Math3, Math4.

CAN Node Sensor Source Select the CAN Node Sensor source from Math1, Math2, Math3, Math4.

Reference Level for Bus1 Source, Bus2 Source, and CAN Node Source

Slope* Set the slope to Rise or Fall.

Units Select the units from Percentage and Absolute.

Mid Set the Mid range value in the units specified.

Hysteresis Set the Hysteresis range value in the units specified.

Do Autoset Every Time Select this option to perform autoset every time you click Run whether any parameters in

the Config panel have changed or not.

When this selection is cleared, autoset is performed only when the Bus Type or Bus

Source changes in the Config panel.

* Slope is applicable only for CAN Node Sensor Source.

Note: For Timing Analysis tests, Bus2 preferences are disabled because the

tests are performed for the bus that is configured.

Virtual Keyboard

Virtual Keyboard - Numeric

1. Click any number box to display the icon for the numeric keyboard.

2. Click the icon to display the numeric keyboard.

TDSVNM Timing and Protocol Decode Software 21

Page 32

Operating Basics

Figure 3-12 shows the numeric keyboard.

Figure 3-12: Virtual keyboard - numeric

3. Click the number keys to enter the desired value.

4. Select a unit of measure.

5. Click Enter to confirm your entry. Selections are not effective until you

click Enter.

Virtual Keyboard - Binary

1. In the Trigger Settings window, set Format to Binary.

2. Click the number box next to the ID, DLC, or Data fields to display the

icon for the binary keyboard.

Figure 3-13 shows the binary keyboard.

Figure 3-13: Virtual keyboard - binary

22 TDSVNM Timing and Protocol Decode Software

Page 33

Operating Basics

3. Click the number keys (X, 1, 0) to enter the desired value. X represents a

'Don't Care' value.

Note: If a value has already been entered, click Clear to clear the entry

before entering a new value.

4. Click Apply to confirm your entry. Selections are not effective until you

click Apply.

Virtual Keyboard - Hexadecimal

1. In the Trigger Settings window, set Format to Hex.

2. Click the number box next to the ID, DLC, or Data fields to display the

icon for the hexadecimal keyboard.

Figure 3-14 shows the hexadecimal keyboard.

Figure 3-14: Virtual keyboard - hexadecimal

3. Click the number keys (0 through 9, A through F, and X) to enter the

desired value. X represents a 'Don't Care' value.

Note: If a value has already been entered, click Clear to clear the entry

before entering a new value.

4. Click Apply to confirm your entry. Selections are not effective until you

click Apply.

TDSVNM Timing and Protocol Decode Software 23

Page 34

Operating Basics

24 TDSVNM Timing and Protocol Decode Software

Page 35

How to ...

Select

Protocol and Timing Analysis Tests

Figure 4-1 shows the protocols and timing analysis tests.

Figure 4-1: Selecting a protocol or test

Table 4-1 shows how to select the protocol to decode:

Table 4-1: Selecting a protocol

Test Type How to select

Protocol Click Tests > Select from the menu to view the tests.

CAN In the CAN and LIN Protocol Decoding area, click CAN.

LIN In the CAN and LIN Protocol Decoding area, click LIN.

CAN & LIN In the CAN and LIN Protocol Decoding area, click CAN & LIN to select both the

protocols to decode.

TDSVNM Timing and Protocol Decode Software 25

Page 36

How to…

Table 4-2 shows how to select the timing analysis tests:

Table 4-2: Selecting a timing test

Test Type How to select

Timing Analysis Tests Click Tests > Select from the menu to view the tests.

Oscillator Tolerance In the Timing Analysis Tests area, click Oscillator Tolerance.

Eye Diagram In the Timing Analysis Tests area, click Eye Diagram.

Bus Traffic In the Timing Analysis Tests area, click Bus Traffic.

Data Rate In the Timing Analysis Tests area, click Data Rate.

Wakeup Time In the Timing Analysis Tests area, click Wakeup Time.

Propagation Delay In the Timing Analysis Tests area, click Propagation Delay.

Configure

Configure Protocol

On the menu bar, click Tests > Configure to configure the parameters for the

selected protocol. Figure 4-2 shows the configuration parameters for

protocols.

Figure 4-2: Configuring a protocol or test

In the configure pane, you will see the factory default configuration for the

test you selected. For most tests, you can use the factory default

configuration. However, you can change the values by using the virtual

keyboard or the general purpose knob on the oscilloscope front panel. Using

the File menu, you can also restore the factory defaults or save and recall

your own configuration settings.

26 TDSVNM Timing and Protocol Decode Software

Page 37

How to ...

The following table shows the parameters that you can configure for protocol

decoding.

Note: When Ref sources are selected in configuration panel, only the No Acq

sequencer mode is available.

For two-channel oscilloscopes, source selections Ref3, Ref4, Ch1-Ch3, and

Ch1-Ch4 are not available.

In the Configure Panel, an option input Trigger Using is available to use the

internal trigger feature of the instrument in the application. Trigger Using has

three selections: DPO-CAN, ATM-1, and Standard.

TDSVNM Timing and Protocol Decode Software 27

Page 38

How to…

DPO-CAN: This selection is available only on a DPO-series

oscilloscope when CB:CAN Bus Trigger option is installed. When

Trigger Using is set to DPO-CAN, the application supports the

following standard date rates:

10 Kbps, 20 Kbps, 33.3 Kbps, 50 Kbps, 62.5 Kbps, 83.3 Kbps, 100

Kbps, 125 Kbps, 250 Kbps, 500 Kbps, 800 Kbps, and 1 Mbps.

ATM-1: This selection is available to use ATM-1 trigger module

Standard: This selection is available only for CAN and LIN protocol

decoding and not applicable to CAN-Timing Analysis Tests. In this

selection, you need to configure the required trigger settings in the

Trigger panel of the oscilloscope to standard triggers such as Edge,

Width, Glitch.

Note: Trigger Using selection is not applicable to Wakeup time and

Propagation delay measurements.

After you select and configure a protocol or test, you can either set up the

trigger conditions or make equipment connections for the selected protocol or

test.

Configure CAN Protocol

Figure 4-3 shows the configuration parameters for the CAN protocol.

Figure 4-3: Configuring a CAN protocol

Follow these steps to configure the CAN bus.

1. On the menu bar, click Tests > Configure to configure the parameters for

the selected protocol.

28 TDSVNM Timing and Protocol Decode Software

Page 39

Table 4-3 shows the parameters that you can configure for CAN

protocol decoding. You can decode two CAN buses simultaneously.

Table 4-3: CAN protocol configuration parameters

Parameter Description

Trigger Using

DPO-CAN Sets the trigger to use to DPO-CAN

ATM-1 Sets the trigger to use to ATM-1

Standard Sets the trigger to use to Standard

Probe Type

Single-ended Sets the probe type to single-ended.

Differential Sets the probe type to differential.

Bus1 (Trigger Source)

Source Select the channel source for Bus1. The source selections for a single-ended

probe type are: Ch1-Ch2, Ch1-Ch3, Ch1-Ch4, Ref1, Ref2, Ref3, Ref4.*

The source selections for a differential probe type are: Ch1, Ch2, Ch3, Ch4,

Ref1, Ref2, Ref3, Ref4.*

Bus Type Select the bus type. The bus type selections are: CAN-DW-LH, CAN-DW-HL,

CAN-SW**, CAN-Fault-T-HL, CAN-Fault-T-LH.

If you use a differential probe, and the positive terminal is connected to a CAN

High signal and the negative terminal to CAN Low, use the CAN-H-L (High-Low)

configuration. If the polarity is reversed, use the CAN-L-H configuration.

If you use a single-ended probe and if Ch1 is connected to a CAN High signal

and Ch2 is connected to a CAN Low signal, use the CAN-H-L (High-Low)

configuration. If you connect Ch1 to a CAN Low signal and Ch2 to a CAN High

signal, use the CAN-L-H (High-Low) configuration.

Bit Rate Set the bit rate of the selected bus type.

Bus2

Source Select the channel source for Bus2. If you do not have a second bus, set this

option to None.

Bus Type Select the bus type, if applicable.

Bit Rate Set the bit rate for the selected bus type, if applicable.

CAN Node Sensor

Source Sets the CAN node sensor source. For a differential probe, the source

selections are: Ch1, Ch2, Ch3, Ch4, Ref1, Ref2, Ref3, Ref4, None.

For a single-ended probe, the source selections are: Ch1-Ch2, Ch3-Ch4, Ch1-

Ch3, Ch2-Ch4, Ref1, Ref2, Ref3, Ref4, None.

ID Enter or type the ID for which the messages are analyzed.

Analysis Select the type of analysis to perform on the data— Timing or Data. Use Data

for protocol decoding.

* For Ref sources, Timing/Data Analysis is not available.

** For the CAN-SW Bus Type and Single-ended Probe Type, the source channel selection is always Ch1, Ch2, Ch3,

Ch4, Ref1, Ref2, Ref3, Ref4.

How to ...

TDSVNM Timing and Protocol Decode Software 29

Page 40

How to…

2. Select the probe type.

3. Select the parameters for Bus1 (Source, Bus Type, and Bit Rate). The

selected Bus Type and Data Rate are used to set the Bus Type and Data

Rate of the ATM-1 automotive trigger module.

4. If you have a second bus, select the parameters for Bus2 (Source, Bus

Type, and Bit Rate). If you do not have a second bus, set the Source and

Bus Type to None.

5. Set the CAN Node Sensor Source and ID. If you set the sensor source to

None, the ID field is disabled.

6. Select the type of analysis to perform on the data—Timing or Data. Use

Data to decode a protocol.

Note: Usually, timing analysis is used to detect anomalies in the acquired

signal. Data analysis is used for protocol decoding.

7. Click Tests > Trigger Setup to configure the trigger parameters or click

Tests > Connect to make connections to the device under test.

Configure LIN Protocol

Figure 4-4 shows the configuration parameters for the LIN protocol.

Figure 4-4: Configuring a LIN protocol

Follow these steps to configure the LIN bus.

1. On the menu bar, click Tests > Configure to configure the parameters for

the selected protocol.

Note: Trigger Using is not applicable to LIN.

30 TDSVNM Timing and Protocol Decode Software

Page 41

How to ...

Table 4-4 shows the parameters that you can configure for LIN protocol

decoding. You can decode two LIN buses simultaneously.

Table 4-4: LIN protocol configuration parameters

Parameter Description

Probe Type

Single-ended Sets the probe type to single-ended.

Differential Sets the probe type to differential.

Bus1 (Trigger Source)

Source Select the channel source for Bus1. The source selections for single-ended and

differential probe types are: Ch1, Ch2, Ch3, Ch4, Ref1, Ref2, Ref3, Ref4.*

Bus Type Set the bus type to LIN.

Bit Rate Set the bit rate for the selected bus type.

Bus2

Source Select the channel source for Bus2. If you do not have a second bus, set this option to

None.

Bus Type Select the bus type to LIN, if applicable.

Bit Rate Set the bit rate of the selected bus type, if applicable.

Analysis Select the type of analysis to perform on the data— Timing or Data. Use Data for protocol

decoding.

* For Ref sources, Timing/Data Analysis is not available.

2. Select the probe type.

3. Select the parameters for Bus1 (Source, Bus Type, and Bit Rate).

4. If you have a second bus, select the parameters for Bus2 (Source, Bus

Type, and Bit Rate). If you do not have a second bus, set the Source and

Bus Type to None.

5. Select the type of analysis to perform on the data (Timing or Data). Use

Data to decode a protocol.

Note: Usually, timing analysis is used to detect anomalies in the acquired

signal. Data analysis is used for protocol decoding.

6. Click Tests > Connect to connect to the device under test.

TDSVNM Timing and Protocol Decode Software 31

Page 42

How to…

Configure CAN and LIN Protocol

Figure 4-5 shows the configuration parameters for the CAN & LIN protocols.

Figure 4-5: Configuring CAN and LIN protocols

Follow these steps to configure the CAN and LIN bus.

1. On the menu bar, click Tests > Configure to configure the parameters for

the selected protocols.

Table 4-5 shows the parameters that you can configure for CAN and

LIN protocol decoding. You can decode the two buses simultaneously.

Table 4-5: CAN and LIN protocol configuration parameters

Parameter Description

Trigger Using

DPO-CAN Sets the trigger to use to DPO-CAN

ATM-1 Sels the trigger to use to ATM-1

Standard Sets the trigger to use to Standard

Probe Type

Single-ended Sets the probe type to single-ended.

Differential Sets the probe type to differential.

Bus1 (Trigger Source)

Source Select the channel source for Bus1. The source selections for a single-ended

probe type are: Ch1-Ch2, Ch1-Ch3, Ch1-Ch4, Ref1, Ref2, Ref3, Ref4.*

The source selections for a differential probe type are: Ch1, Ch2, Ch3, Ch4,

Ref1, Ref2, Ref3, Ref4.*

32 TDSVNM Timing and Protocol Decode Software

Page 43

Table 4-5: CAN and LIN protocol configuration parameters (cont.)

Parameter Description

Bus Type Select the bus type. The bus type selections are: CAN-DW-LH, CAN-DW-

HL, CAN-SW**, CAN-Fault-T-HL, CAN-Fault-T-LH.

If you use a differential probe, and the positive terminal is connected to a

CAN High signal and the negative terminal to CAN Low, use the CAN-H-L

(High-Low) configuration. If the polarity is reversed, use the CAN-L-H

configuration.

If you use a single-ended probe and if Ch1 is connected to a CAN High

signal and Ch2 is connected to a CAN Low signal, use the CAN-H-L (HighLow) configuration. If you connect Ch1 to a CAN Low signal and Ch2 to a

CAN High signal, use the CAN-L-H (High-Low) configuration.

Bit Rate Set the bit rate of the selected bus type.

Bus2

Source Select the channel source for Bus2.

The source selections available for single-ended and differential probe types

are: Ch1, Ch2, Ch3, Ch4, Ref1, Ref2, Ref3, Ref4, None.

Bus Type Set the bus type to the default (LIN).

Bit Rate Set the bit rate for the selected bus type.

CAN Node Sensor

Source Sets the CAN node sensor source. For a differential probe, the source

selections are: Ch1, Ch2, Ch3, Ch4, Ref1, Ref2, Ref3, Ref4, None.

For a single-ended probe, the source selections are: Ch1-Ch2, Ch3-Ch4,

Ch1-Ch3, Ch2-Ch4, Ref1, Ref2, Ref3, Ref4, None.

ID Enter or type the ID for which the messages are analyzed.

Analysis Select the type of analysis to perform on the data— Timing or Data. Use

Data for protocol decoding.

Figure 4-ï For Ref sources, Timing/Data Analysis is not available.

**For the CAN-SW Bus Type and Single-ended Probe Type, the source channel selection is always Ch1, Ch2, Ch3,

Ch4, Ref1, Ref2, Ref3, Ref4.

2. Select the probe type.

How to ...

3. Select the parameters for Bus1 (Source, Bus Type, and Bit Rate). Bus1

is always the CAN bus. The selected Bus Type and Data Rate selected

are used to set the Bus Type and Data Rate of the ATM-1 automotive

trigger module.

4. Select the parameters for Bus2 (Source, Bus Type, and Bit Rate). Bus2

is always the LIN bus.

5. Set the CAN Node Sensor Source and ID. If you set the sensor source to

None, the ID field is disabled.

6. Select the type of analysis to perform on the data (Timing or Data). Use

Data to decode a protocol.

Note: Usually, timing analysis is used to detect anomalies in the acquired

signal. Data analysis is used for protocol decoding.

TDSVNM Timing and Protocol Decode Software 33

Page 44

How to…

7. Click Tests > Trigger Setup to configure the trigger parameters or click

Tests > Connect to make connections to the device under test.

Timing Analysis Tests

On the menu bar, click Tests > Configure to configure the parameters for the

selected timing analysis test. Figure 4-6 shows the configuration parameters

for the timing analysis tests.

Figure 4-6: Configuration parameters for timing analysis tests

In the configure pane, you will see the factory default configuration for the

test you selected. For most tests, you can use the factory default

configuration. However, you can change the values by using the virtual

keyboard or the general purpose knob on the oscilloscope front panel. Using

the File menu, you can also restore the factory defaults or save and recall

your own configuration settings.

The following table shows the parameters that you can configure for timing

analysis tests.

34 TDSVNM Timing and Protocol Decode Software

Page 45

How to ...

Note: When Ref sources are selected in configuration panel, only the No Acq

sequencer mode is available.

For the Wakeup Time test, only the Single and No Acq sequencer modes are

available.

Standard is not available for timing analysis tests

For two-channel oscilloscopes, source selections Ref3, Ref4, Ch1-Ch3, and

Ch1-Ch4 are not available.

TDSVNM Timing and Protocol Decode Software 35

Page 46

How to…

When Trigger Using is set to DPO-CAN, the application supports the

following standard date rates:

10 Kbps, 20 Kbps, 33.3 Kbps, 50 Kbps, 62.5 Kbps, 83.3 Kbps, 100 Kbps,

125 Kbps, 250 Kbps, 500 Kbps, 800 Kbps, and 1 Mbps.

After you select and configure a protocol or test, you can either set up the

trigger conditions or make equipment connections for the selected protocol or

test.

Configure Oscillator Tolerance

Figure 4-7 shows the configuration parameters for the Oscillator Tolerance

test.

Figure 4-7: Configuration parameters for oscillator tolerance test

Follow these steps to configure the Oscillator Tolerance test.

1. On the menu bar, click Tests > Configure to configure the parameters for

the Oscillator Tolerance test. Table 4-6 shows the parameters that you

can configure for the Oscillator Tolerance test.

2. Select the Trigger Using for the DPO oscilloscope.

Table 4-6: Oscillator tolerance configuration parameters

Parameter Description

Trigger Using

DPO-CAN Sets the trigger to use to DPO-CAN

ATM-1 Sets the trigger to use to ATM-1

Probe Type

Single-ended Sets the probe type to single-ended.

Differential Sets the probe type to differential.

36 TDSVNM Timing and Protocol Decode Software

Page 47

Table 4-6: Oscillator tolerance configuration parameters (cont.)

Parameter Description

Bus (Trigger Source)

Source Select the channel source for the bus. The source selections for a

single-ended probe type are: Ch1-Ch2, Ch1-Ch3, Ch1-Ch4, Ref1, Ref2,

Ref3, Ref4.

The source selections for a differential probe type are: Ch1, Ch2, Ch3,

Ch4, Ref1, Ref2, Ref3, Ref4.

Bus Type Select the bus type. The bus type selections are: CAN-DW-LH, CAN-

DW-HL, CAN-SW*, CAN-Fault-T-HL, CAN-Fault-T-LH.

Bit Rate Set the bit rate of the selected bus type.

* For the CAN-SW Bus Type the source channel selection is always Ch1, Ch2, Ch3, Ch4, Ref1, Ref2, Ref3, Ref4.

3. Select the probe type.

How to ...

4. Select the parameters–Source, Bus Type, and Bit Rate.

5. Click Tests > Trigger Setup to configure the trigger parameters or click

Tests > Connect to make connections to the device under test.

Configure Eye Diagram

Figure 4-8 shows the configuration parameters for the Eye Diagram test.

Figure 4-8: Configuration parameters for eye diagram test

Follow these steps to configure the Eye Diagram test.

1. On the menu bar, click Tests > Configure to configure the parameters for

the Eye Diagram test.

2. Select the Trigger Using for the DPO oscilloscope.

TDSVNM Timing and Protocol Decode Software 37

Page 48

How to…

Table 4-7 shows the parameters that you can configure for the Eye

Diagram test.

Table 4-7: Eye diagram configuration parameters

Parameter Description

Trigger Using

DPO-CAN Sets the trigger to use to DPO-CAN

ATM-1 Sets the trigger to use to ATM-1

Probe Type

Single-ended Sets the probe type to single-ended.

Differential Sets the probe type to differential.

Bus (Trigger Source)

Source Select the channel source for the bus. The source selections for a

single-ended probe type are: Ch1-Ch2, Ch1-Ch3, Ch1-Ch4, Ref1, Ref2,

Ref3, Ref4.

The source selections for a differential probe type are: Ch1, Ch2, Ch3,

Ch4, Ref1, Ref2, Ref3, Ref4.

Bus Type Select the bus type. The bus type selections are: CAN-DW-LH, CAN-

DW-HL, CAN-SW*, CAN-Fault-T-HL, CAN-Fault-T-LH.

Bit Rate Set the bit rate for the selected bus type.

* For the CAN-SW Bus Type the source channel selection is always Ch1, Ch2, Ch3, Ch4, Ref1, Ref2, Ref3, Ref4.

3. Select the probe type.

4. Select the parameters–Source, Bus Type, and Bit Rate.

5. Click Tests > Trigger Setup to configure the trigger parameters or click

Tests > Connect to make connections to the device under test.

38 TDSVNM Timing and Protocol Decode Software

Page 49

Configure Bus Traffic

Figure 4-9 shows the configuration parameters for the Bus Traffic test.

Figure 4-9: Configuration parameters for bus traffic test

How to ...

Follow these steps to configure the Bus Traffic Trigger Using selection.

1. On the menu bar, click Tests > Configure to configure the parameters for

the Bus Traffic test. Table 4-8 shows the parameters that you can

configure for the Bus Traffic test.

Table 4-8: Bus traffic configuration parameters

Parameter Description

Trigger Using

DPO-CAN Sets the trigger to use to DPO-CAN

ATM-1 Sets the trigger to use to ATM-1

Probe Type

Single-ended Sets the probe type to single-ended.

Differential Sets the probe type to differential.

Bus (Trigger Source)

Source Select the channel source for the bus. The source selections for a

single-ended probe type are: Ch1-Ch2, Ch1-Ch3, Ch1-Ch4, Ref1, Ref2,

Ref3, Ref4.

The source selections for a differential probe type are: Ch1, Ch2, Ch3,

Ch4, Ref1, Ref2, Ref3, Ref4.

Bus Type Select the bus type. The bus type selections are: CAN-DW-LH, CAN-

DW-HL, CAN-SW*, CAN-Fault-T-HL, CAN-Fault-T-LH.

Bit Rate Set the bit rate for the selected bus type.

* For the CAN-SW Bus Type the source channel selection is always Ch1, Ch2, Ch3, Ch4, Ref1, Ref2, Ref3, Ref4.

2. Select the probe type.

3. Select the parameters–Source, Bus Type, and Bit Rate.

TDSVNM Timing and Protocol Decode Software 39

Page 50

How to…

4. Click Tests > Trigger Setup to configure the trigger parameters or click

Tests > Connect to connect to the device under test.

Configure Data Rate

Figure 4-10 shows the configuration parameters for the Data Rate test.

Figure 4-10: Configuration parameters for data rate test

Follow these steps to configure the Data Rate test.

1. On the menu bar, click Tests > Configure to configure the parameters for

the Data Rate test.

2. Select the Trigger Using for the DPO oscilloscope. Table 4-9 shows the

parameters that you can configure for the Data Rate test.

Table 4-9: Data rate configuration parameters

Parameter Description

Trigger Using

DPO-CAN Sets the trigger to use to DPO-CAN

ATM-1 Sets the trigger to use to ATM-1

Probe Type

Single-ended Sets the probe type to single-ended.

Differential Sets the probe type to differential.

Bus (Trigger Source)

Source Select the channel source for the bus. The source selections for a

single-ended probe type are: Ch1-Ch2, Ch1-Ch3, Ch1-Ch4, Ref1, Ref2,

Ref3, Ref4.

The source selections for a differential probe type are: Ch1, Ch2, Ch3,

Ch4, Ref1, Ref2, Ref3, Ref4.

Bus Type Select the bus type. The bus type selections are: CAN-DW-LH, CAN-

DW-HL, CAN-SW*, CAN-Fault-T-HL, CAN-Fault-T-LH.

Bit Rate Set the bit rate for the selected bus type.

* For the CAN-SW Bus Type the source channel selection is always Ch1, Ch2, Ch3, Ch4, Ref1, Ref2, Ref3, Ref4.

40 TDSVNM Timing and Protocol Decode Software

Page 51

How to ...

3. Select the probe type.

4. Select the parameters–Source, Bus Type, and Bit Rate.

5. Click Tests > Trigger Setup to configure the trigger parameters or click

Tests > Connect to make connections to the device under test.

Configure Wakeup Time

Figure 4-11 shows the configuration parameters for the Wakeup Time test.

Figure 4-11: Configuration parameters for wakeup time test

Follow these steps to configure the Wakeup Time test.

1. On the menu bar, click Tests > Configure to configure the parameters for

the Wakeup Time test. Table 4-10 shows the parameters that you can

configure for the Wakeup Time test.

Table 4-10: Wakeup time configuration parameters

Parameter Description

Probe Type

Single-ended Sets the probe type to single-ended.

Differential Sets the probe type to differential.

Bus (Trigger Source)

Source Select the channel source for the bus. The source selections for a

single-ended probe type are: Ch1-Ch2, Ch1-Ch3, Ch1-Ch4, Ref1, Ref2,

Ref3, Ref4.

The source selections for a differential probe type are: Ch1, Ch2, Ch3,

Ch4, Ref1, Ref2, Ref3, Ref4.

Bus Type Select the bus type. The bus type selections are: CAN-DW-LH, CAN-

DW-HL, CAN-SW*, CAN-Fault-T-HL, CAN-Fault-T-LH.

Bit Rate Set the bit rate for the selected bus type.

* For the CAN-SW Bus Type the source channel selection is always Ch1, Ch2, Ch3, Ch4, Ref1, Ref2, Ref3, Ref4.

TDSVNM Timing and Protocol Decode Software 41

Page 52

How to…

2. Select the probe type.

3. Select the parameters–Source, Bus Type, and Bit Rate.

4. Click Tests > Trigger Setup to configure the trigger parameters or click

Tests > Connect to make connections to the device under test.

Note: Trigger Using is not available for the Wakeup Time measurement

Configure Propagation Delay

Figure 4-12 shows the configuration parameters for the Propagation Delay

test.

Figure 4-12: Configuration parameters for propagation delay test

Follow these steps to configure the Propagation Delay test.

1. On the menu bar, click Tests > Configure to configure the parameters for

the Propagation Delay test. Table 4-11 shows the parameters that you

can configure for the Propagation Delay test.

Table 4-11: Propagation delay configuration parameters

Parameter Description

Probe Type

Single-ended Sets the probe type to single-ended.

Differential Sets the probe type to differential.

Bus (Trigger Source)

From Source

To Source

Select the From and To channel sources for the bus. The source

selections for a single-ended probe type are: Ch1-Ch2, Ch3-Ch4, Ch1Ch3, Ch2-Ch4, Ref1, Ref2, Ref3, Ref4.

The source selections for a differential probe type are: Ch1, Ch2, Ch3,

Ch4, Ref1, Ref2, Ref3, Ref4.

42 TDSVNM Timing and Protocol Decode Software

Page 53

Table 4-11: Propagation delay configuration parameters (cont.)

Parameter Description

Bus Type Select the bus type. The bus type selections are: CAN-DW-LH, CAN-

DW-HL, CAN-SW*, CAN-Fault-T-HL, CAN-Fault-T-LH.

Bit Rate Set the bit rate for the selected bus type.

* For the CAN-SW Bus Type the source channel selection is always Ch1, Ch2, Ch3, Ch4, Ref1, Ref2, Ref3, Ref4.

2. Select the probe type.

3. Select the parameters–From Source, To Source, Bus Type, and Bit Rate.

4. Click Tests > Connect to connect to the device under test.

Note: Trigger Using is not available for Propagation Delay test

How to ...

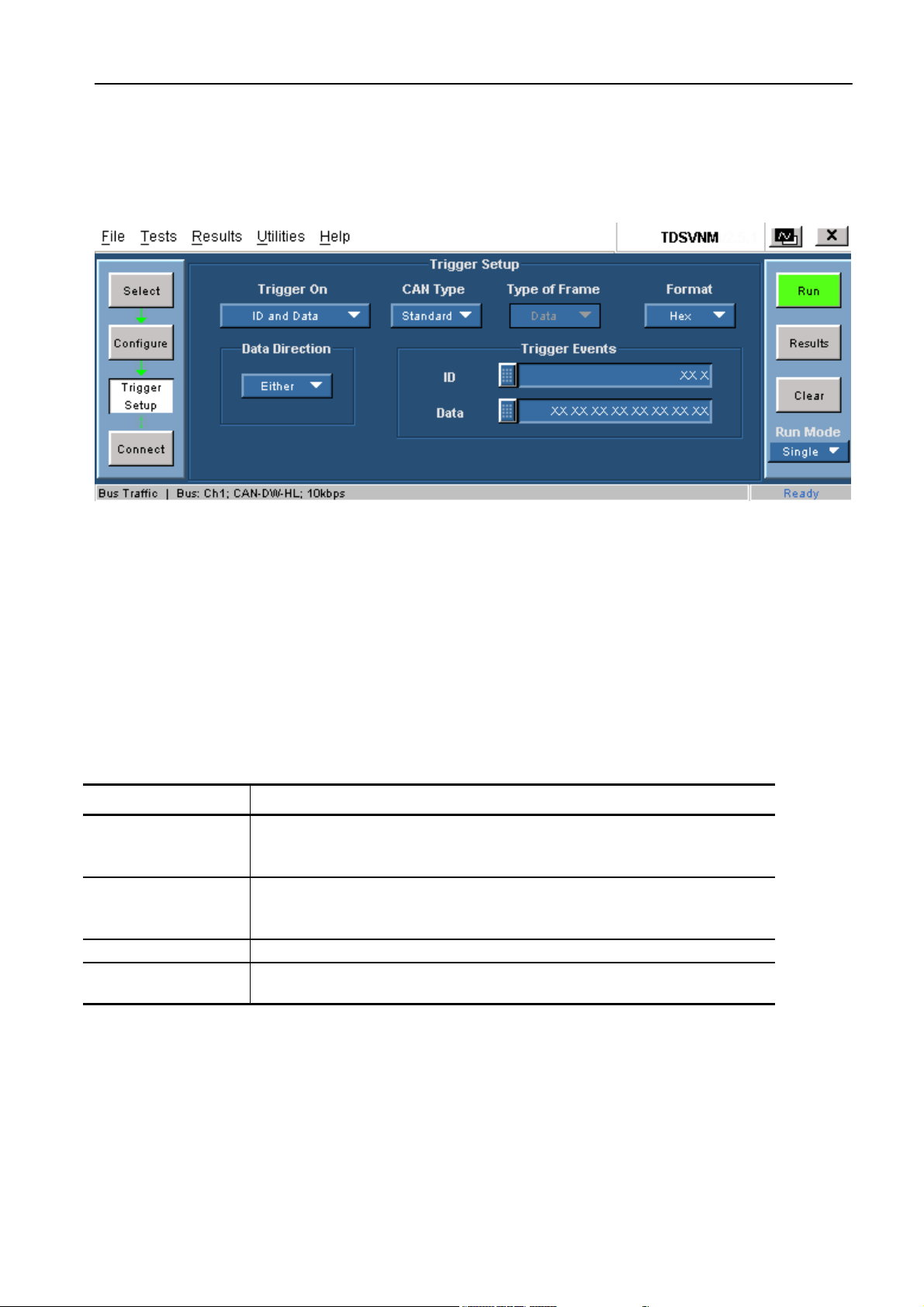

Set up Trigger

Set up Trigger

On the menu bar, click Tests > Trigger Setup to set up the trigger parameters

and conditions for the selected test. You can configure the trigger setup for

the ATM-1 automotive trigger module in the trigger panel.

You can force a trigger by pressing the Single button on the front panel.

Forced trigger is used to observe the sequence of events manually. Click Run

to decode the acquired data in the Single No Acq mode.

Figure 4-13 shows the trigger setup parameters for protocol decoding when

Trigger Using is set to ATM-1.

Figure 4-13: Trigger setup parameters for protocol decoding (ATM-1)

TDSVNM Timing and Protocol Decode Software 43

Page 54

How to…

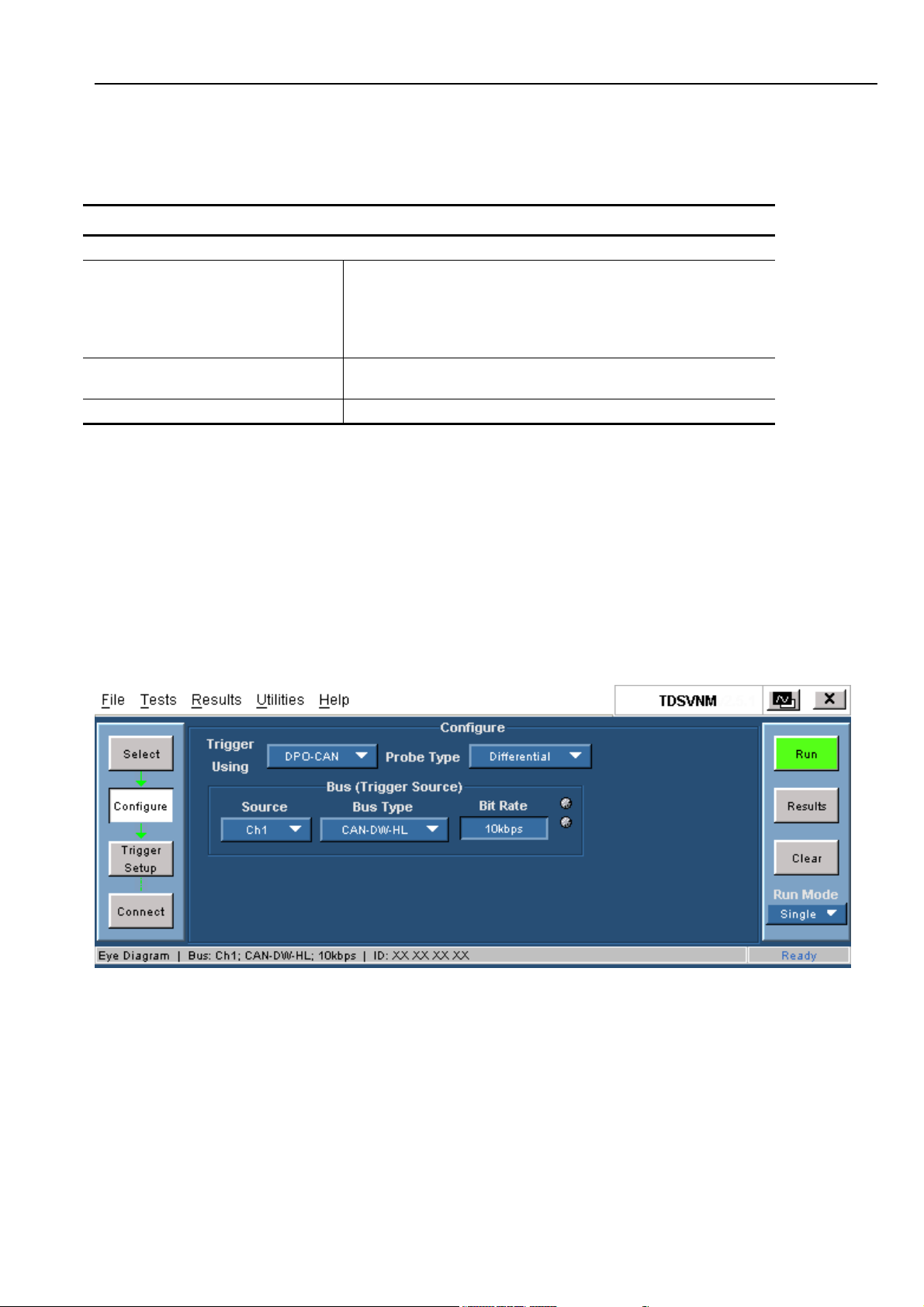

Figure 4-14 shows the trigger setup parameters when Trigger Using is set to

DPO-CAN.

Figure 4-14: Trigger setup parameters for protocol decoding (DPO-CAN)

Figure 4-15 shows the trigger setup parameters when Trigger Using is set to

Standard.

Figure 4-15: Trigger setup parameters for protocol decoding (Standard)

44 TDSVNM Timing and Protocol Decode Software

Page 55

How to ...