User Manual

TDSRBS1 Rambus Channel Measurements Application

071-0761-00

This document supports software version 1.0.0

and above.

Warning

The servicing instructions are for use by

qualified personnel only. To avoid personal

injury, do not perform any servicing unless you

are qualified to do so. Refer to all safety

summaries prior to performing service.

Copyright © T ektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its suppliers and are protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in T echnical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software – Restricted Rights clause at F AR 52.227-19, as applicable.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

T ektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

T ektronix wishes to recognize and thank the Intel Folsom Desktop Products Group Analog Integrity Engineering team for

their technical contributions in the design of this application.

WARRANTY

T ektronix warrants that the media on which this software product is furnished and the encoding of the programs on the media

will be free from defects in materials and workmanship for a period of three (3) months from the date of shipment. If a

medium or encoding proves defective during the warranty period, T ektronix will provide a replacement in exchange for the

defective medium. Except as to the media on which this software product is furnished, this software product is provided “as

is” without warranty of any kind, either express or implied. T ektronix does not warrant that the functions contained in this

software product will meet Customer’s requirements or that the operation of the programs will be uninterrupted or error-free.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period. If T ektronix is unable to provide a replacement that is free from defects in materials and workmanship

within a reasonable time thereafter, Customer may terminate the license for this software product and return this software

product and any associated materials for credit or refund.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REPLACE DEFECTIVE MEDIA OR REFUND CUSTOMER’S PAYMENT IS THE SOLE AND EXCLUSIVE

REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS

VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF

THE POSSIBILITY OF SUCH DAMAGES.

Table of Contents

Getting Started

Operating Basics

vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Documentation ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions x. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting T ektronix xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compatibility 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements and Restrictions 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Updates Through the Web Site 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Accessories 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Application 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deskewing the Probes and Channels 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting to a System Under T est 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Operations 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Menu Structure 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main and Side Menus 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common Menu Items 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Utility Menus 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Basic Oscilloscope Functions 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Local Help 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Returning to the Application 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

W arning Messages 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Display 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rambus T erms 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Understanding Measurement Points 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Write Pulse Examples 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read Pulse Examples 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Understanding Measurement Patterns 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Up the Application 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measurement Selections 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Measurement 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plot Results Setup 2–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

View Results Setup 2–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T aking Measurements 2–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquiring Waveforms 2–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Localizing Measurements 2–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving the Results and Worst Case Waveforms 2–22. . . . . . . . . . . . . . . . . . . . . . . . . .

Data Log File Format 2–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Importing a Data Log File to a Personal Computer 2–24. . . . . . . . . . . . . . . . . . . . . . .

TDSRBS1 Rambus Channel Measurements Application User Manual

i

Table of Contents

Viewing the Results 2–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Statistics 2–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graphical Formats 2–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clearing Results 2–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving and Recalling Setups 2–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving a Setup 2–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recalling a Setup 2–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exiting the Application 2–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tutorial 2–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Up the Oscilloscope 2–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting the Application 2–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading the Reference Waveform Files 2–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T aking Setup Time and Hold Time Measurements 2–32. . . . . . . . . . . . . . . . . . . . . . .

T aking Measurements from Four Waveforms 2–36. . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving the Results to a Data Log File 2–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing the RESULTS.CSV File (Data Log) 2–41. . . . . . . . . . . . . . . . . . . . . . . . . . .

Stopping the Tutorial 2–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Returning to the Tutorial 2–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPIB Program Example 2–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Guidelines 2–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Example 2–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference

Appendices

Menu Structure 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameters 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measure Menu 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup Menus 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inputs Menu 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deskew Menu 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T est Signal Configuration Menu 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clock Speed Menu 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limits and Limits Edit Menus 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plot Results Menus 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Histogram Menu 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Profiling Menu 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logging Menus 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Results Logging Menu 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Worst Case Wfms Logging Menu 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

View Results Menu 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Menu 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Utility Menus 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A: Measurement Algorithms A–1. . . . . . . . . . . . . . . . . . . . . . . .

Oscilloscope Setup Guidelines A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T est Methodology A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Waveform Analysis Phase A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Computation Phase A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup and Hold Time Measurement A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Quality (Tq) Measurement A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

TDSRBS1 Rambus Channel Measurements Application User Manual

Index

List of Figures

Table of Contents

Channel Error Measurement A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flight Time (Data) Measurement A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flight Time Clock Measurement A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rise Time and Fall T ime Measurements A–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B: GPIB Command Syntax B–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C: Error Codes C–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix D: Deskewing with a Math1 Waveform D–1. . . . . . . . . . . . . . . .

Appendix E: Quick Validation of Setup and Hold Times E–1. . . . . . . . . .

Waveform Display Setup E–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Detailed Procedure E–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Abbreviated Procedure E–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–1: TDSRBS1 Rambus Channel Measurements

Application 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–2: Typical signal path skew 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–3: Accessing the Deskew utility 1–6. . . . . . . . . . . . . . . . . . . . . . .

Figure 1–4: The Deskew menu 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–5: Example of a deskew configuration 1–7. . . . . . . . . . . . . . . . .

Figure 1–6: Deskewing in process 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–7: Deskew complete 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–8: Setting up a Rambus mother board 1–10. . . . . . . . . . . . . . . . .

Figure 1–9: Preparing probes 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–10: Connecting probes to the oscilloscope 1–11. . . . . . . . . . . . . . .

Figure 1–11: Clock signal contact points on RIMM connector,

back of board 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–12: Clock signal contact points on the 82820 MCH

in the BGA area 1–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–13: Probes positioned on a Rambus mother board 1–13. . . . . . .

Figure 1–14: Overall view of the TDSRBS1 setup 1–14. . . . . . . . . . . . . . . .

Figure 1–15: Waveforms from a SUT that is set up and

operating properly 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–1: Returning to the application 2–3. . . . . . . . . . . . . . . . . . . . . . .

Figure 2–2: Write even positive pulse waveforms and

measurement points 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TDSRBS1 Rambus Channel Measurements Application User Manual

iii

Table of Contents

Figure 2–3: Write even negative pulse waveforms and

measurement points 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–4: Read even positive pulse waveforms and

measurement points 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–5: Read even negative pulse waveforms and

measurement points 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–6: How to set reference voltage levels 2–15. . . . . . . . . . . . . . . . . .

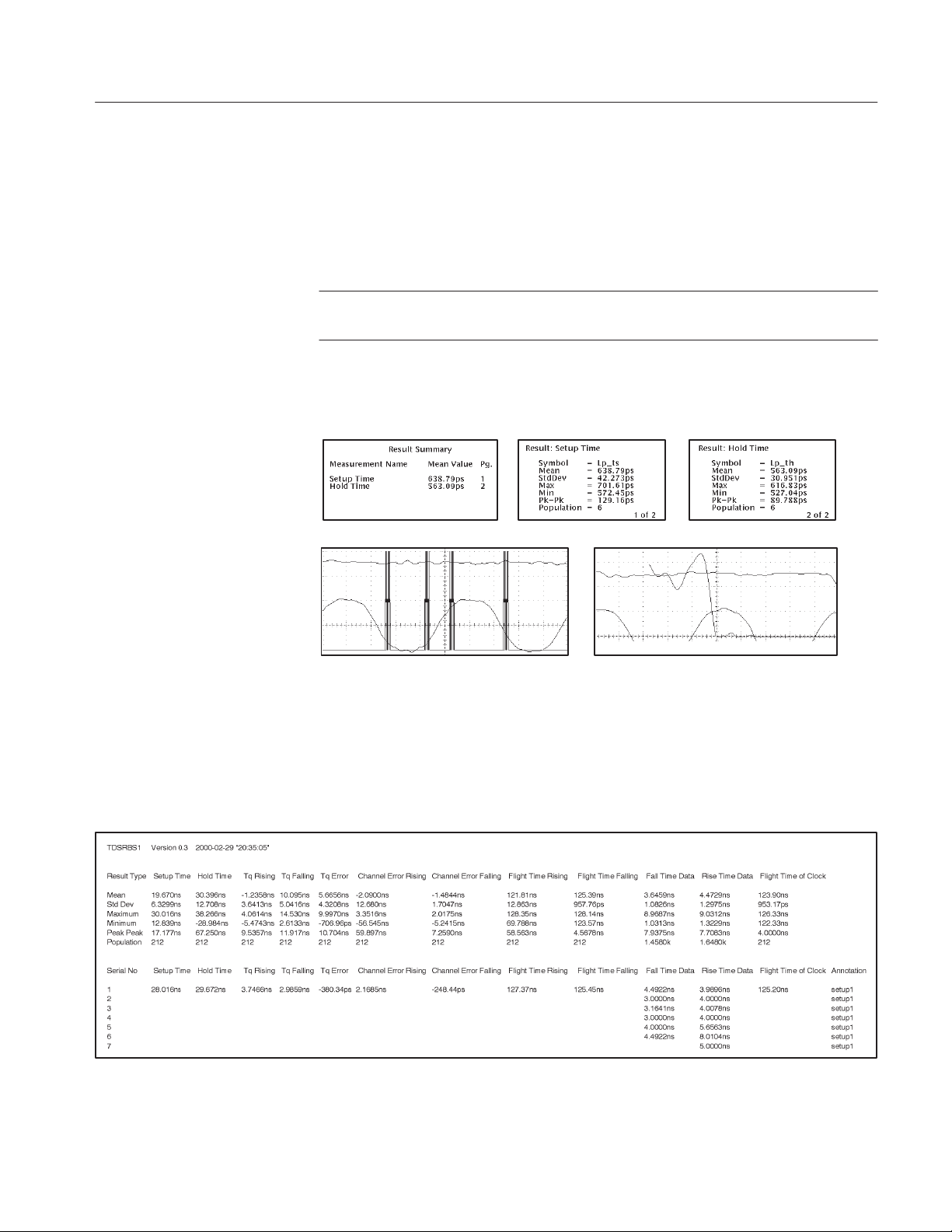

Figure 2–7: Example of the results and display formats 2–25. . . . . . . . . . .

Figure 2–8: Example of data in a RESULTS.CSV file viewed

in a spreadsheet program 2–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–9: Starting the application 2–30. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–10: TDSRBS1 application initial display 2–30. . . . . . . . . . . . . . . .

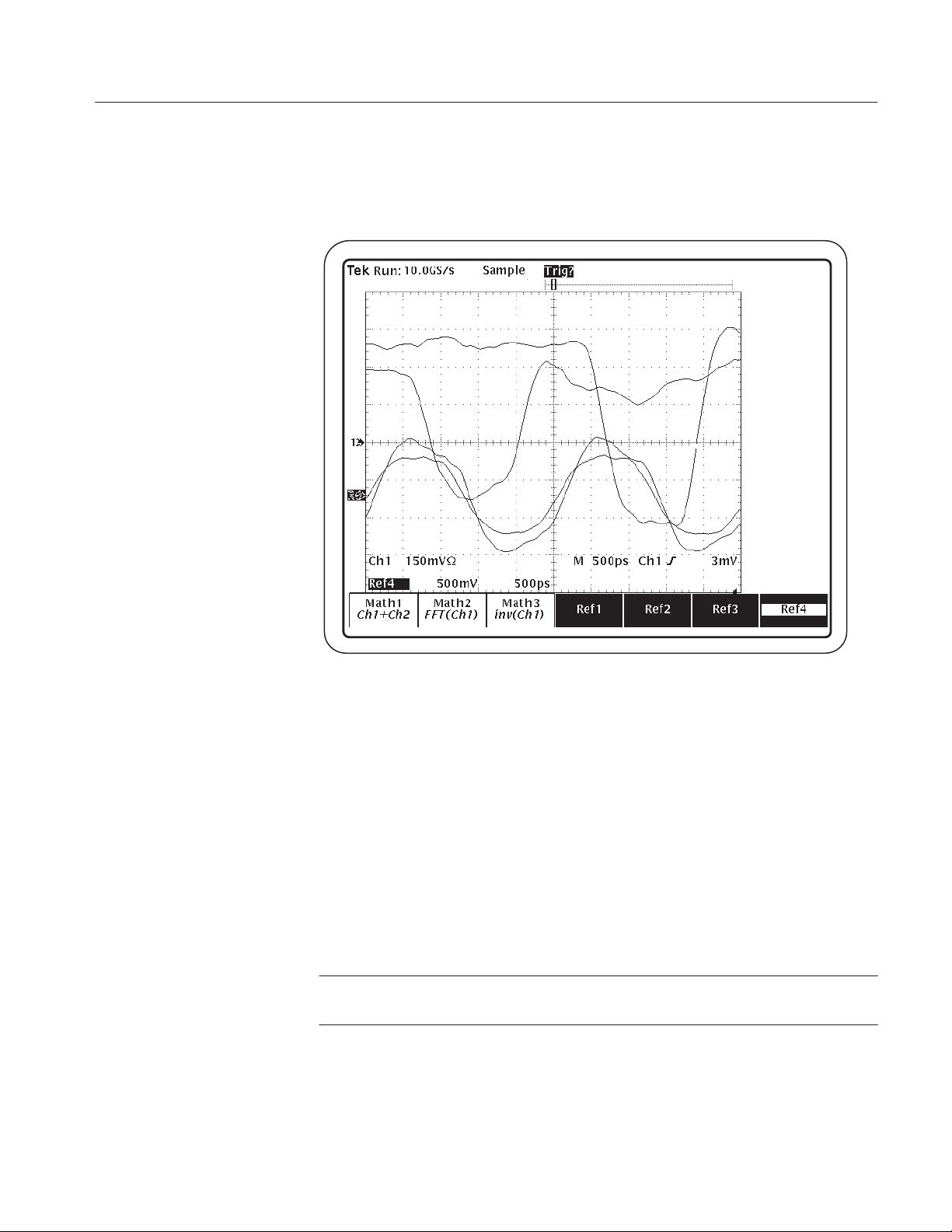

Figure 2–11: Display of the Ref2 and Ref4 waveforms 2–32. . . . . . . . . . . .

Figure 2–12: Inputs menu, Ref4 2–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–13: Clock Speed menu 2–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–14: Test Signal Configuration menu, default selections 2–34. . . .

Figure 2–15: Setup Summary menu; use the GP knob

to scroll the summary 2–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–16: Setup Time and Hold Time lesson: Result

Summary readout 2–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–17: View Details shows the statistical values

for Setup Time 2–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–18: View Details shows the statistical values

for Hold Time 2–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–19: Display of Ref1, Ref2, Ref3, and Ref4 waveforms 2–37. . . . .

Figure 2–20: Channel Error lesson: Result Summary readout 2–38. . . . .

Figure 2–21: View Details shows the statistical values for

Channel Error Falling 2–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–22: Logging menu 2–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

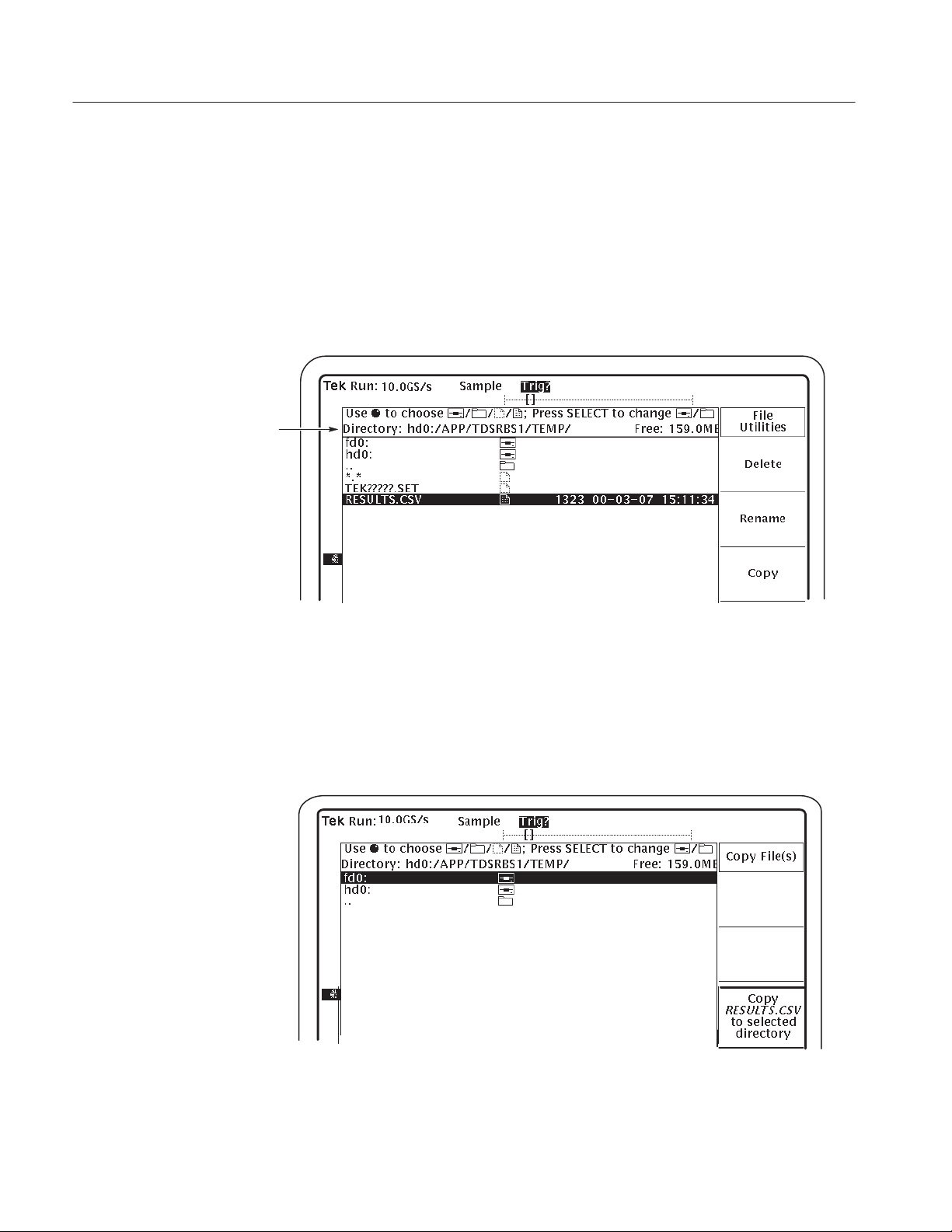

Figure 2–23: Path to the RESULTS.CSV file on the hard drive 2–40. . . . .

Figure 2–24: Copying the RESULTS.CSV file to a floppy disk 2–40. . . . .

Figure 3–1: Measure, Setup, Plot Results, and View Results

menus structures 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–2: Logging, Control, and Utility menus structures 3–2. . . . . . .

Figure D–1: Math1 side menu items D–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure D–2: Change Math Definition side menu items D–2. . . . . . . . . . . .

Figure D–3: Deskew menu: From parameter Math1 selection D–3. . . . . .

Figure D–4: Channel configuration to deskew with a

Math1 waveform D–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

TDSRBS1 Rambus Channel Measurements Application User Manual

List of Tables

Table of Contents

Figure E–1: Rambus clock waveform set up properly example E–2. . . . .

Figure E–2: Statistics set up properly example E–3. . . . . . . . . . . . . . . . . .

Figure E–3: Level Setup set up properly example E–4. . . . . . . . . . . . . . . .

Figure E–4: Statistical results on a Rambus clock signal E–5. . . . . . . . . .

Figure E–5: Statistical results on a Rambus data waveform

(Read cycle) E–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure E–6: Button abbreviations E–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–1: Channel and Rambus signal mapping 1–11. . . . . . . . . . . . . . . .

Table 2–1: Common menu items 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–2: Utility menus 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–3: Display Options menu selections 2–4. . . . . . . . . . . . . . . . . . . .

Table 2–4: Channel or reference memory and Rambus

signal assignments 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–5: Write even positive pulse measurement points 2–5. . . . . . . . .

Table 2–6: Write even positive pulse timing characteristics 2–6. . . . . . . .

Table 2–7: Write even negative pulse measurement points 2–6. . . . . . . .

Table 2–8: Write even negative pulse timing characteristics 2–7. . . . . . .

Table 2–9: Read even positive pulse measurement points 2–8. . . . . . . . .

Table 2–10: Read even positive pulse timing characteristics 2–9. . . . . . .

Table 2–11: Read even negative pulse measurement points 2–10. . . . . . . .

Table 2–12: Read even negative pulse timing characteristics 2–11. . . . . .

Table 2–13: Measurement patterns 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–14: Measure menu selections 2–12. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–15: Setup menu selections 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–16: Inputs menu selections and parameters 2–14. . . . . . . . . . . . .

Table 2–17: Deskew menu selections 2–16. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–18: Test Signal Configuration menu selections 2–16. . . . . . . . . . .

Table 2–19: Clock Speed menu selections 2–17. . . . . . . . . . . . . . . . . . . . . .

Table 2–20: Limits Edit menu selections 2–17. . . . . . . . . . . . . . . . . . . . . . .

Table 2–21: Color of Mean values when using Limits 2–18. . . . . . . . . . . .

Table 2–22: Color of PASS or FAIL when using Limits 2–18. . . . . . . . . . .

Table 2–23: Plot Results menu selections 2–18. . . . . . . . . . . . . . . . . . . . . . .

TDSRBS1 Rambus Channel Measurements Application User Manual

v

Table of Contents

Table 2–24: Histogram menu selections 2–19. . . . . . . . . . . . . . . . . . . . . . . .

Table 2–25: Profiling menu selections 2–20. . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–26: View Results menu selections 2–20. . . . . . . . . . . . . . . . . . . . . .

Table 2–27: Control menu selections 2–21. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–28: Logging menu selections 2–22. . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–29: Results Logging menu selections 2–23. . . . . . . . . . . . . . . . . . .

Table 2–30: Worst Case Wfms Logging menu selections 2–23. . . . . . . . . .

Table 2–31: Reference waveforms and Rambus signal types 2–31. . . . . . .

Table 3–1: Measure menu parameters 3–3. . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–2: Inputs menu parameters 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–3: Deskew menu parameters 3–5. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–4: Test Signal Configuration menu parameters 3–5. . . . . . . . . .

Table 3–5: Clock Speed menu parameters 3–5. . . . . . . . . . . . . . . . . . . . . .

Table 3–6: Limits and Limits Edit menus parameters 3–6. . . . . . . . . . . .

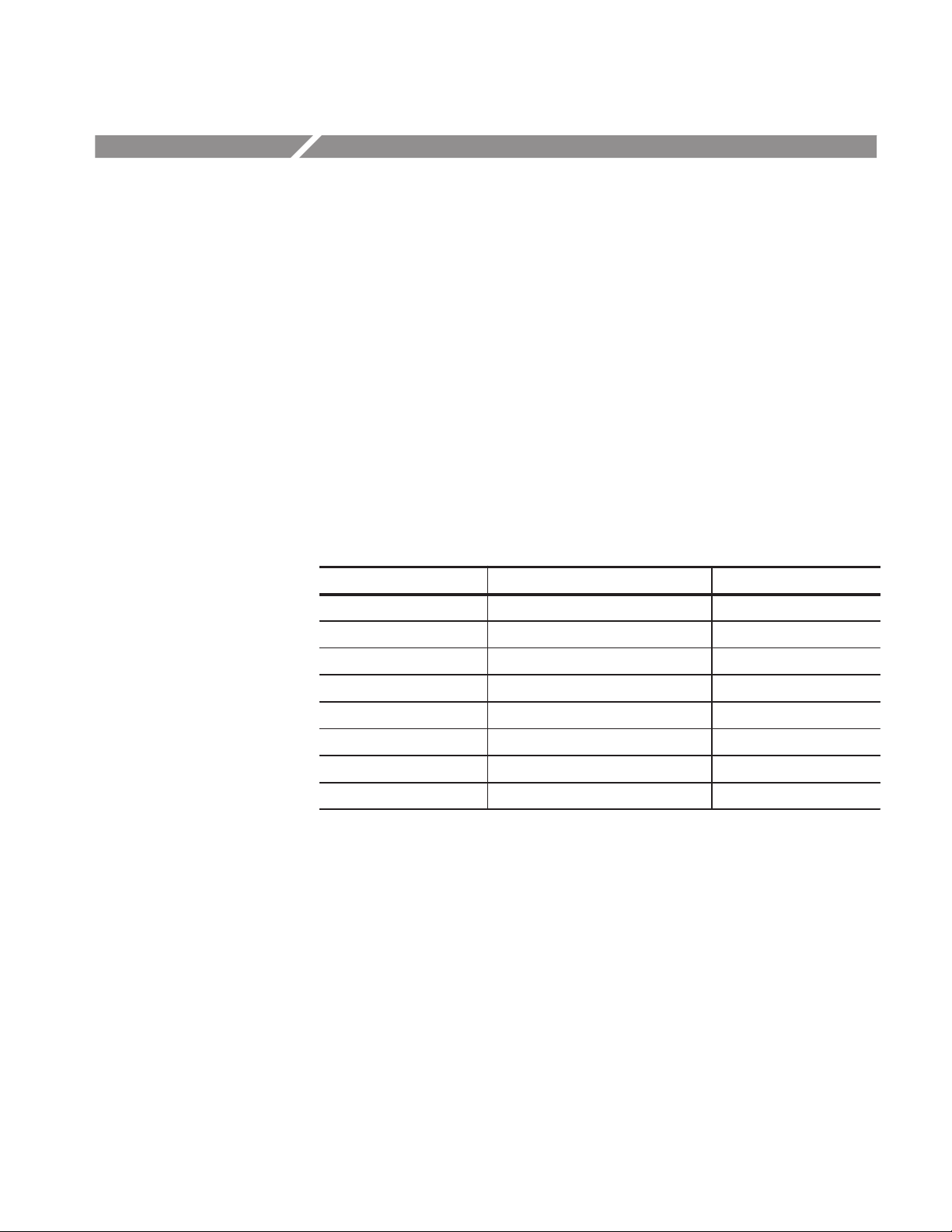

Table 3–7: Measurement number, key, and corresponding

default limits 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–8: Plot Results menu parameters 3–7. . . . . . . . . . . . . . . . . . . . . .

Table 3–9: Histogram menu parameters 3–7. . . . . . . . . . . . . . . . . . . . . . .

Table 3–10: Profile menu parameters 3–7. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–11: Results Logging menu parameters 3–8. . . . . . . . . . . . . . . . . .

Table 3–12: Worst Case Wfms Logging menu parameters 3–8. . . . . . . .

Table 3–13: View Results menu parameters 3–9. . . . . . . . . . . . . . . . . . . .

Table 3–14: Control menu parameters 3–9. . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–15: Utility menus and parameters 3–9. . . . . . . . . . . . . . . . . . . . .

Table B–1: VARIABLE:VALUE TDS COMMAND arguments

and queries B–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table B–2: Measurement, resultFor query, and plotSource

query keys B–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table B–3: Measurement results queries B–7. . . . . . . . . . . . . . . . . . . . . . .

Table C–1: Error codes, descriptions and solutions C–1. . . . . . . . . . . . . .

vi

TDSRBS1 Rambus Channel Measurements Application User Manual

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly . Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry .

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

TDSRBS1 Rambus Channel Measurements Application User Manual

vii

General Safety Summary

Symbols and Terms

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

viii

TDSRBS1 Rambus Channel Measurements Application User Manual

Preface

This manual contains operating information for the TDSRBS1 Rambus Channel

Measurements Application. The manual consists of the following chapters:

H The Getting Started chapter briefly describes the TDSRBS1 Rambus

Channel Measurements Application, lists oscilloscope compatibility, and

provides installation instructions.

H The Operating Basics chapter covers basic operating principles of the

application and includes a tutorial that teaches you how to set up the

application to acquire a waveform, take measurements, and view the results.

To show you how to operate the application using GPIB commands, this

chapter includes a simple GPIB program.

H The Reference chapter includes a diagram of the menu structure and

descriptions of parameters.

H The Measurement Algorithms appendix contains information on measure-

ment guidelines and on how the application takes the measurements.

H The GPIB Command Syntax appendix contains a list of arguments and values

that you can use with the GPIB commands and their associated parameters.

Related Documentation

H The Error Codes appendix contains a list of error codes, descriptions of the

errors, and possible solutions to correct the problem.

H The Deskewing with a Math1 Waveform appendix describes how to deskew

single-ended probes relative to differential probes.

H The Rise Time and Fall Time Analysis appendix contains a procedure on how

to set up the oscilloscope to quickly validate Rise Time and Fall Time

measurements results.

The user manual for your oscilloscope provides general information on how to

operate the oscilloscope.

Programmer information in the online help for your TDS 694C oscilloscope

provides details on how to use GPIB commands to control the oscilloscope. You

can also download the tds6prog.zip file (online help) with examples from the

www.Tektronix.com web site. Refer to Updates Through the Web Site on

page 1–2 for information on how to download the file.

TDSRBS1 Rambus Channel Measurements Application User Manual

ix

Preface

Conventions

To help you use this application, you can also refer to the following materials:

H Rambus® Technology Overview, Rambus, Inc., 1999

H Direct Rambus® Clock Generator, DL-0056, Version 1.0, Rambus, Inc.

H Direct RAC Data Sheet, Rambus Inc., 1998

H Intel® 820 Chipset: 82820 Memory Controller Hub (MCH) Datasheet, Intel

Corp., 1999

This manual uses the following conventions:

H This manual refers to the TDSRBS1 Rambus Channel Measurements

Application as the TDSRBS1 application or as the application.

H When steps require that you make a sequence of selections using front-panel

controls and menu buttons, an arrow ( ➞

front-panel button and a menu, or between menus. Names that are for a main

menu or side menu item are clearly indicated: Press VERTICAL MENU ➞

Coupling (main) ➞ DC (side) ➞ Bandwidth (main) ➞ 250 MHz (side).

) marks each transition between a

x

TDSRBS1 Rambus Channel Measurements Application User Manual

Contacting Tektronix

Preface

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support Email: support@tektronix.com

1-800-833-9200, select option 3*

1-503-627-2400

6:00 a.m. – 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

TDSRBS1 Rambus Channel Measurements Application User Manual

xi

Preface

xii

TDSRBS1 Rambus Channel Measurements Application User Manual

Getting Started

Product Description

The TDSRBS1 Rambus Channel Measurements Application is a Java-based

application that enhances basic capabilities of the TDS 694C oscilloscope.

The application provides Rambus channel timing measurements for the

oscilloscope. Measurements can be performed on Read cycles, Write cycles,

High Data pulses, Low Data pulses, Odd Data fields, and Even Data fields.

Figure 1–1 shows an example of Rambus waveforms and the Results readout.

694C

Figure 1–1: TDSRBS1 Rambus Channel Measurements Application

Compatibility

The Rambus Channel Measurements Application is compatible with the

TDS694C Tektronix oscilloscope with firmware version 6.2 and above.

For information on how to get the current firmware, contact your local Tektronix

distributor or sales office.

For a current list of compatible oscilloscopes, see the Software and Drivers

category in the Tektronix, Inc. web site (www.tektronix.com).

Requirements and Restrictions

The TDS Run-Time Environment V1.2.0 and above must be installed on the

oscilloscope to operate the TDSRBS1 application and use the GPIB commands.

TDSRBS1 Rambus Channel Measurements Application User Manual

1–1

Product Description

Updates Through the Web Site

You can find information about this and other applications at the Tektronix Inc.

web site, www.tektronix.com. Check this site for application updates and for

other free applications.

To install an application update, you will need to download it from the Tektronix

web site to a hard disk, copy it to a blank DOS-formatted floppy disk, and then

install it on your oscilloscope.

NOTE. More information about changes to the application or installation is in a

Readme.txt file on the web site. You should read it before you continue.

To copy an application from the web site, follow these steps:

1. Access www.tek.com/Measurement/Support/scopes/software/index.html.

2. Scroll through the files to the application that you want, select the file, and

download it to your hard disk drive. If necessary, unzip the file.

Optional Accessories

Accessories

3. Copy the application from the hard disk to a blank, DOS-formatted floppy

disk.

4. Follow the Installing the Application procedure on page 1–3.

To take accurate measurements, you need the following accessories:

H Two P6248 Differential Probes

H Two P6249 Active Probes

H Four surface mount device interconnects with articulated arms, such as

Tektronix PPM203Bs

H Probe accessories leadset, Tektronix part number 016-1780-00

There are no standard accessories for this product other than this manual.

1–2

TDSRBS1 Rambus Channel Measurements Application User Manual

Installation

This section contains information on the following tasks:

H Installing the application

H Deskewing probes and channels

H Connecting to a system under test

Installing the Application

The TDSRBS1 floppy disk contains the Rambus Channel Measurements

Application. You can download updates, if any, from the Tektronix ftp site

through a web browser.

NOTE. To operate the TDSRBS1 application, the TDS Run-Time Environment

V1.2.0 or above must be installed on the TDS 694C oscilloscope, and the

oscilloscope must also have firmware version 6.2 or above.

To install the application from the floppy disk to your oscilloscope, follow these

steps:

1. Power off the oscilloscope.

NOTE. Additional information about the application or installation is located in

a Readme.txt file on the floppy disk. You should insert the floppy disk into a

DOS-based personal computer and read the Readme.txt file before you continue.

If you are updating the application, the Readme.txt file on the Tektronix ftp site

supercedes the Readme.txt file on the TDSRBS1 floppy disk.

2. Insert the disk in the floppy disk drive, and power on the oscilloscope.

NOTE. To verify that the TDS Run-Time Environment V1.2.0 or above is

installed, watch for the abbreviated name, RTE, and version number to appear

at the top of the display when you power on the oscilloscope. If they do not

appear, contact your local Tektronix sales office.

After performing the power-on selftest, the oscilloscope automatically begins the

installation procedure.

TDSRBS1 Rambus Channel Measurements Application User Manual

1–3

Installation

As the application loads from the disk, the oscilloscope displays a clock icon to

indicate that it is busy. Also, the floppy disk drive LED is on, indicating activity.

If the clock icon continues to display after the floppy disk LED has gone out, a

problem has occurred with the installation. Repeat the above procedure. If the

problem persists, contact your Tektronix representative.

When the installation is complete, an Installation Complete message displays.

3. Remove the floppy disk, and cycle the power to the oscilloscope.

Deskewing the Probes and Channels

To ensure accurate measurement results, it is important to first deskew the probes

and oscilloscope channels before you take measurements from your Rambus

system under test (SUT). Deskewing is where the oscilloscope adjusts the

relative delay between signals to accurately time correlate the displayed

waveforms.

CAUTION. To prevent erroneous measurement results, retain the probe and

oscilloscope channel combination after deskewing them. When you change the

probe connections, the delay attributes also change. When you move a probe to

another channel, you must perform the deskew procedure again.

NOTE. To produce good deskew results, you should connect the probes to the

fastest clock signals possible, preferably ones with around a 200 pS edge rate.

The application includes an automated deskew utility that you can use to deskew

up to four probes and oscilloscope channels at once. The following procedure

describes how to deskew two channels. Channel 1 (and the probe connected to it)

is the reference point used to deskew channel 2. The steps to deskew the third

and fourth channels are the same.

To deskew a probe and oscilloscope channel, follow these steps:

1. Follow the procedure on page 1–9 to connect similar probes to channels 1

and 2 on the oscilloscope.

2. Connect the probes to a very fast clock signal.

1–4

For optimum results, connect the probes to the output of the Direct Rambus

Clock Generator (DRCG) in the SUT.

TDSRBS1 Rambus Channel Measurements Application User Manual

3. Set up the oscilloscope as follows:

a. Use the Horizontal Scale knob to set the oscilloscope to the fastest

acquisition rate, such as 10 GS/sec.

b. Use the Vertical Scale and Position knobs to adjust the signals to fill the

display (view the full amplitude) without missing any part of the signals.

c. Set the Record Length to 15,000 or 50,000 in the Horizontal menu; this

minimizes the effect of trigger jitter on the resultant deskew values.

Figure 1–2 shows an example of signal path skew found in similar probes.

Installation

Figure 1–2: Typical signal path skew

4. Start the application as described on page 2–29.

5. Press Setup (main) ➞ Inputs (side) ➞ –more– 1 of 2 (side) to access the

Deskew utility. Figure 1–3 shows how to access the Deskew utility.

6. Press Deskew (side). Figure 1–4 shows the Deskew menu.

TDSRBS1 Rambus Channel Measurements Application User Manual

1–5

Installation

Figure 1–3: Accessing the Deskew utility

1–6

Figure 1–4: The Deskew menu

7. Press Channel Config (side) ➞ To (side) and select Ch2.

TDSRBS1 Rambus Channel Measurements Application User Manual

8. Press Done (side).

9. Press Slope (side) and select Falling. See Figure 1–5.

Installation

Figure 1–5: Example of a deskew configuration

10. Press Done (side).

11. To start the deskew utility, press Start Deskew (side).

The utility displays information as it deskews the channels, such as the

number of samples processed and specified. Figure 1–6 shows an example of

the information that displays.

Figure 1–7 shows an example of the utility when it is finished. In this

example, the skew between channels 1 and 2 was reduced to 2.54 ps.

12. Press OK (side) to return to the Deskew menu.

13. Do not change the From channel and deskew channels 3 and 4.

NOTE. For information on one method that you can use to deskew single-ended

probes relative to differential probes, refer to Appendix D: Deskewing with a

Math1 Waveform.

TDSRBS1 Rambus Channel Measurements Application User Manual

1–7

Installation

Figure 1–6: Deskewing in process

1–8

Figure 1–7: Deskew complete

TDSRBS1 Rambus Channel Measurements Application User Manual

14. Press Done (side) to return to the Inputs menu.

15. Press Done (side) to return to the Setup menu.

Connecting to a System Under Test

To connect the oscilloscope and TDSRBS1 application to a SUT, you will need

the following items:

H Two P6248 Differential Probes

H Two P6249 Active Probes

H Four articulated arms, such as Tektronix PPM203Bs

H Probe accessories leadset, Tektronix part number 016-1780-00

H One circuit board mount frame

H Intense light source, such as a halogen lamp

Installation

H Head gear with magnifying lens

You can use other probes, but the P6248 probes and P6249 probes will provide

the most accurate measurements.

To remove and set up the Rambus mother board, follow these steps:

1. Power off your SUT. It is not necessary to power off the oscilloscope.

CAUTION. To prevent static damage, handle these components only in a

static-free environment. Static discharge can damage the Rambus mother board

and the probes.

Always wear a grounding wrist strap, heel strap, or similar device while

handling the Rambus mother board and the probes.

2. To discharge your stored static electricity, touch the Probe Compensation

ground connector located on the front of the oscilloscope. Then, before you

remove the probes from the protective bags they are shipped in, touch the

bag to discharge stored static electricity from each probe.

3. Place the SUT on a horizontal static-free surface and remove the Rambus

mother board.

4. Secure the mother board vertically in a circuit board mount frame on the

horizontal static-free surface, as shown in Figure 1–8.

TDSRBS1 Rambus Channel Measurements Application User Manual

1–9

Installation

Figure 1–8: Setting up a Rambus mother board

5. Connect the power supply to the Rambus mother board.

6. Connect the hard disk drive or floppy disk drive to the mother board.

7. Connect the VGA cable to the mother board.

8. Power on the Rambus SUT, and verify that it operates properly.

9. Power off the SUT.

To connect the P6248 and P6249 probes between the SUT and oscilloscope,

follow these steps:

1. Insert the solid probe tips and pogo ground probe tips from the probe

accessories leadset into the end of the probes as shown in Figure 1–9.

1–10

TDSRBS1 Rambus Channel Measurements Application User Manual

Installation

P6249

Pogo ground

probe tip

Solid probe tip

P6248

Figure 1–9: Preparing probes

2. For each probe, take a matching pair of the colored plastic clips and place the

clip on each end of the probe cable.

3. Connect the probes to the oscilloscope as shown in Figure 1–10.

CH4

CH2

CH3

CH1

P6249

P6249

To the Rambus

mother board

P6248

P6248

Figure 1–10: Connecting probes to the oscilloscope

4. Use an intense light source and magnifying lens to locate the points of

contact to the signals on the back of the mother board. See Table 1–1.

T able 1–1: Channel and Rambus signal mapping

Channel Rambus signal Channel Rambus signal

Ch 1 A data signal at the MCH Ch 3 Clock signal at the MCH

Ch 2 Same data signal at the RIMM Ch 4 Clock signal at the RIMM

5. Position the articulated arms, evenly spaced, around the center of the

memory sockets.

TDSRBS1 Rambus Channel Measurements Application User Manual

1–11

Installation

6. Match the clip colors on the probe cables to the corresponding points of

contact, and secure the probes in the articulated arms.

7. For Write cycle analysis, match the + and – indicators on the P6248 probe

tips to the corresponding indicators on the CFM Clock signals; use the dials

on the articulated arms to firmly position the probe tips on the contact

points.

Figure 1–11 shows the CFM and CTM signal contact points on the RIMM

connectors on the back of a Rambus mother board.

DQA

CTM

0

+–

CFM

+–

2468

1357

DQA

Figure 1–11: Clock signal contact points on RIMM connector, back of board

For Read cycle analysis, remove the P6248 probe tip from the articulated

arms, rotate the probe 180 degrees and match the + and – indicators on the

probe tips to the corresponding indicators on the CTM Clock signals; use the

dials on the articulated arms to firmly position the probe tips on the contact

points.

8. To probe at the RIMM, for each P6249 probe, align the solid probe tips to

the desired data signal and identify the nearest ground run that the pogo

ground tip can easily reach.

CAUTION. To prevent damage to the Rambus mother board, be careful when

removing insulation from any MCH signal path run in the BGA area. Removing

too much insulation can permanently damage the MCH signal paths.

9. To probe at the 82820 MCH, use a sharp tool and gently scrape a little

insulation from the signal path run in the BGA area. Figure 1–12 shows the

location of the CFM clock signals (used for Write cycle analysis) and CTM

clock signals (used for Read cycle analysis) of the 82820 MCH in the BGA

area on the back of the Rambus mother board.

1–12

TDSRBS1 Rambus Channel Measurements Application User Manual

Installation

CFM +

CFM –

CTM –

1011121314

CTM +

9

135

A

B

C

D

E

Pin A1 corner,

back of board

68

7

24

Figure 1–12: Clock signal contact points on the 82820 MCH in the BGA area

10. Realign the solid probe tip to the data signal (see step 8) and the pogo

ground probe tip to the exposed signal run; use the dials on the articulated

arms to firmly position the probe tips on the contact points.

Figure 1–13 shows an example of the probes positioned on a Rambus mother

board.

P6249

P6248

P6248

P6249

Figure 1–13: Probes positioned on a Rambus mother board

Figure 1–14 shows a view of the Rambus SUT set up for the application.

TDSRBS1 Rambus Channel Measurements Application User Manual

1–13

Installation

1–14

Figure 1–14: Overall view of the TDSRBS1 setup

To apply power and acquire data, follow these steps:

1. Power up the SUT.

2. Set the oscilloscope to acquire data at 10 GS/s.

3. Set the record length to 50 K or less.

NOTE. Do not take any TDSRBS1 measurements until you can verify that the

SUT is set up and operating properly.

4. To verify that the Rambus signals are present, select Control (main) ➞ Mode

Free Run (side) and then Start (side). Figure 1–15 shows the display of

waveforms from a SUT that is set up and operating properly.

TDSRBS1 Rambus Channel Measurements Application User Manual

Installation

Figure 1–15: Waveforms from a SUT that is set up and operating properly

5. Press Stop (side).

If the display of Rambus waveforms on your oscilloscope does not appear

similar to that shown in Figure 1–15, try the following solutions:

a. Check all the probe contacts.

b. Verify that channels 1 through 4 are visible on the oscilloscope.

c. On the oscilloscope, set the Trigger mode to AC Line and set the

acquisition mode to Free Run. Gently rock each probe connector on the

contact points until a signal displays.

d. Verify that the SUT is powered on, booted and is operating properly.

e. Ensure that the single-ended probes are well grounded.

After you have verified that your SUT is set up and operating properly, you

should deskew the probes and oscilloscope channels as described in Deskewing

the Probes and Channels on page 1–4, and then set up the application to take

Rambus measurements.

TDSRBS1 Rambus Channel Measurements Application User Manual

1–15

Installation

1–16

TDSRBS1 Rambus Channel Measurements Application User Manual

Operating Basics

Basic Operations

This section contains information on the following topics and tasks:

H Application menu structure

H Using basic oscilloscope functions

H Warning messages

H Configuring the display

H Rambus terms

H Understanding measurement points

H Understanding measurement patterns

H Setting up the application

H Taking measurements

H Storing the results to a data log file

H Importing a data log file into a personal computer

H Viewing the results

H Saving and recalling setups

H Exiting the application

Application Menu Structure

There are two types of menus in the application menu structure: main menus and

side menus. Some side menus contain common items as shown in Table 2–1.

Main and Side Menus

The main menu names appear in the bottom of the display, and the side menu

names appear on the right side of the display. To see the complete application

menu structure, refer to Figure 3–1 on page 3–1.

When you press the front-panel button associated with a main menu, the side

menu changes. In many cases, when you press a side menu, new side menu items

appear. As an example, the next figure shows you how to access the Help

selections through the main Utility menu and the Help side menu.

TDSRBS1 Rambus Channel Measurements Application User Manual

2–1

Basics Operations

Main menu Side menu Side menu item

Utility

Help

First Page

Next Page

Previous Page

Last Page

Quit Help

Common Menu Items

Utility Menus

Table 2–1 lists common side menu items.

T able 2–1: Common menu items

Menu item Description

Cancel Cancels the message being displayed

Done Indicates that you are through making changes to that set of side menus;

the application returns to the previous menu

OK Confirms an action

–more–

x of y

Scrolls to another page of a menu where x is the current page and y is

the total number of pages

Table 2–2 lists the Utility menus.

T able 2–2: Utility menus

Utility name Description

Help Accesses the online help pages and displays useful information on the

application

Exit Exits the application

Display Options Accesses other menus where you can change display settings, such as

Save/Recall Setup Accesses the save and the recall menus for application setups

Using Basic Oscilloscope Functions

You can use the Utility menu to access help information about the application.

You can also use other oscilloscope functions and easily return to the application.

Using Local Help

2–2

The application includes local help information about the measurements modes,

with some explanation of the individual controls.

To display the local help, follow these steps:

1. Press Utility (main) ➞ Help (side).

TDSRBS1 Rambus Channel Measurements Application User Manual

whether the dialog box is opaque or transparent

2. Use the side menu buttons to navigate through the help.

Basics Operations

Returning to the

Application

Warning Messages

You can easily switch between the TDSRBS1 application and other oscilloscope

functions.

To access other oscilloscope functions, press the desired front-panel control. To

return to the application, push the SHIFT and then the APPLICATION frontpanel menu buttons as shown in Figure 2–1.

Push the SHIFT and then the APPLICATION button to return to the application.

Figure 2–1: Returning to the application

All timing measurements provide a warning if the input conditions do not

support accurate measurements. For example, the Channel Error measurement

warns you if you do not have at least a valid Clock signal and a clean 010 or 101

pulse transition.

Refer to Appendix C: Error Codes, for information on specific error codes and

possible solutions.

Configuring the Display

You can change how dialog boxes appear on your oscilloscope, as well as the

color of waveforms. The next figure shows how to access the Display Options

menu, and Table 2–3 lists the options with a brief description of each.

Main menu Side menu Side menu item

Utility Display Options

TDSRBS1 Rambus Channel Measurements Application User Manual

Dialog Box

Box Position

Box Style

Color Theme

Done

2–3

Basics Operations

Rambus Terms

T able 2–3: Display Options menu selections

Option Description

Dialog Box

Box Position Positions the dialog box in the display

Box Style Selects the style of dialog boxes to be Opaque or Transparent

Color Theme Selects a set of colors for waveforms and dialog boxes; the application

Makes dialog boxes visible or invisible

offers seven color themes

This manual contains the following Rambus system terms:

H MCH, an abbreviation for the Memory Controller Hub

H RIMM, an abbreviation for the Rambus Inline Memory Module

H Quiescent Time, the number of inactive clock cycles needed for the

transmission line to be stable (no reflection) enough to take measurements

H Synthetic Clock, an imaginary clock signal whose frequency is double that

of the external clock frequency. It is synchronized with the falling edge of

the external clock and has a 50% duty cycle. All Rambus signals are

synchronized with the falling edge of the synthetic clock.

Understanding Measurement Points

Before you set up the application, you should understand the points (relationships of the waveforms) used by the application to take measurements.

This information is provided as a courtesy by the Intel Desktop Products Group

Analog Integrity Engineering team.

Table 2–4 shows the channel or reference memory to Rambus signal assignments.

T able 2–4: Channel or reference memory and Rambus signal assignments

Channel Reference Rambus signal

Ch 1 Ref 1 Data at the source, MCH

2–4

Ch 2 Ref 2 Data at the destination, RIMM

Ch 3 Ref 3 Clock at the MCH (CFM and CTM signals)

Ch 4 Ref 4 Clock at the RIMM (CFM and CTM signals)

TDSRBS1 Rambus Channel Measurements Application User Manual

Basics Operations

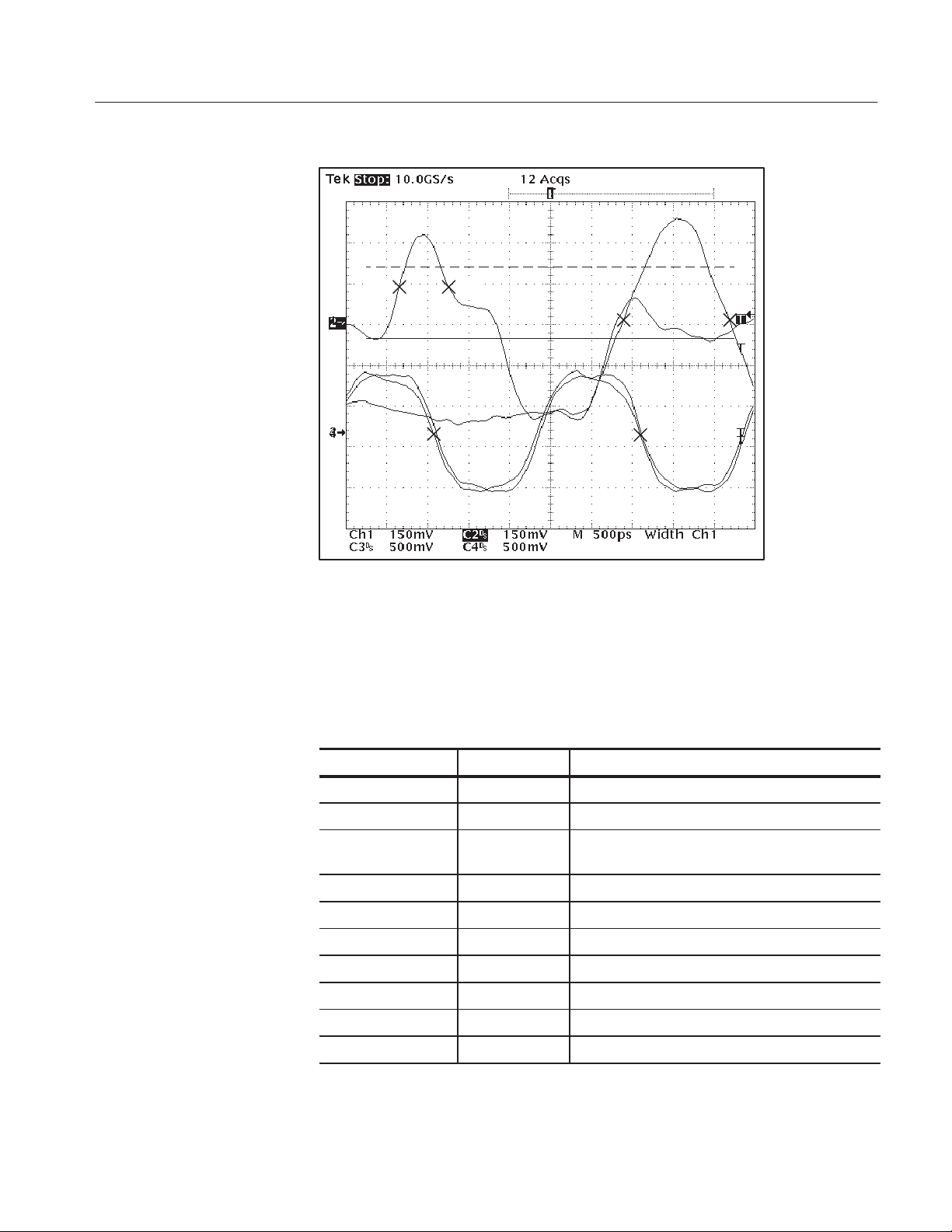

Write Pulse Examples

In these examples, the Write cycle originates at the MCH and the destination is

the RIMM. The application uses six points to determine various timing

characteristics of a write pulse measurement.

High Write Pulse. Table 2–5 lists the measurement points and gives a description

of each for a write even positive pulse measurement. The application looks for a

logical data pattern of 101 for this type of measurement. Figure 2–2 shows the

corresponding measurement points.

T able 2–5: W rite even positive pulse measurement points

Point number Description

T0 Rising edge of the data (1.4 V) at the source, MCH

T1 Falling edge of the clock (crossing) at the source, MCH

T2 Rising edge of the data (1.4 V) at the source, MCH

T3 Rising edge of the data (1.4 V) at the destination, RIMM

T4 Falling edge of the clock (crossing) at the destination, RIMM

T5 Falling edge of the data (1.4 V) at the destination, RIMM

T0

T1 T4

T2

Figure 2–2: Write even positive pulse waveforms and measurement points

TDSRBS1 Rambus Channel Measurements Application User Manual

T5T3

2–5

Basics Operations

Table 2–6 lists the timing characteristic, the Rambus symbol for the characteristic, and the points used to take the measurement.

T able 2–6: W rite even positive pulse timing characteristics

Characteristic Symbol Measurement points used by application

Setup time rising Hp_tsr T4–T3

Hold time falling Hp_thf T5–T4

Tq rising Hp_tqr 625 ps – (T1–T0), where 625 ps is 1/4 of the bus

clock frequency (~400 Mhz)

Tq falling Hp_tqf (T2 – T1) – 625 ps

Tq error Hp_tqerr (Hp_tqr + Hp_tqf) 2

Channel error rising Hp_tcer (T4 – T3) – (T1 – T0)

Channel error falling Hp_tcef (T5 – T4) – (T2 – T1)

Flight time rising Hp_tfr T3 – T0

Flight time falling Hp_tff T5 – T2

Flight time clock edge Hp_tfck T4 – T1

Low Write Pulse. Table 2–7 lists the measurement points and gives a description

of each for a write even negative pulse measurement. The application looks for a

logical data pattern of 010 for this type of measurement. Figure 2–3 shows the

corresponding measurement points.

T able 2–7: W rite even negative pulse measurement points

Point number Description

T0 Falling edge of the data (1.4 V) at the source, MCH

T1 Falling edge of the clock (crossing) at the source, MCH

T2 Rising edge of the data (1.4 V) at the source, MCH

T3 Falling edge of the data (1.4 V) at the destination, RIMM

T4 Falling edge of the clock (crossing) at the destination, RIMM

T5 Rising edge of the data (1.4 V) at the destination, RIMM

2–6

TDSRBS1 Rambus Channel Measurements Application User Manual

Basics Operations

T0

T3T2

T1

T4

T5

Figure 2–3: Write even negative pulse waveforms and measurement points

Table 2–8 lists the timing characteristic, the Rambus symbol for the characteristic, and the points used to take the measurement.

T able 2–8: W rite even negative pulse timing characteristics

Characteristic Symbol Measurement points used by application

Setup time falling Lp_tsf T4–T3

Hold time rising Lp_thr T5–T4

Tq falling Lp_tqf 625 ps – (T1–T0), where 625 ps is 1/4 of the bus

Tq rising Lp_tqr (T2 – T1) – 625 ps

Tq error Lp_tqerr (Lp_tqr + Lp_tqf) 2

Channel error falling Lp_tcef (T4 – T3) – (T1 – T0)

Channel error rising Lp_tcer (T5 – T4) – (T2 – T1)

Flight time falling Lp_tff T3 – T0

Flight time rising Lp_tfr T5 – T2

Flight time clock edge Lp_tfck T4 – T1

TDSRBS1 Rambus Channel Measurements Application User Manual

clock frequency (~400 Mhz)

2–7

Basics Operations

Read Pulse Examples

In these examples, the Read cycle originates at the RIMM and the destination is

the MCH. The application uses six points to determine various timing characteristics of a read pulse measurement.

A Read cycle is like an RDRAM device write cycle except it is initiated at the

mid-transmission line. Write cycles are initiated at the MCH.

A signal injected in the mid-transmission line sees two parallel 27 ohm loads:

one going to the termination and the other going to the MCH. The RDRAM

device views this as a 14 ohm load which causes the Read cycle signal to swing

about 1.6 V instead of the 1.4V swing of a Write cycle.

In addition, it is extremely difficult to generate predictable and detectable pulse

transmissions at the RDRAM devices. Because of this, effective analysis of

timing at the signal source (which is needed for Read Cycle Channel Errors) is

diminished.

Since it is extremely difficult to characterize the source pulse during a Read

cycle, some measurements are not made available through the TDSRBS1 menu

structure. However, the Tq rising, Tq falling, TQ error and Channel error

measurements are still available through remote GPIB commands. Refer to the

GPIB Program Example description on page 2–43 and to Appendix B: GPIB

Command Syntax for more information.

High Read Pulse. Table 2–9 lists the measurement points and gives a description

of each for a read even positive pulse measurement. The application looks for a

logical data pattern of 101 for this type of measurement. Figure 2–4 shows the

corresponding points.

T able 2–9: Read even positive pulse measurement points

Point number Description

T0 Rising edge of the data (1.6 V) at the source, RIMM

T1 Falling edge of the clock (CFM crossing) at the source, RIMM

T2 Falling edge of the data (1.6 V) at the source, RIMM

T3 Rising edge of the data (1.4 V) at the destination, MCH

T4 Falling edge of the clock (CFM crossing) at the destination, MCH

T5 Falling edge of the data (1.4 V) at the destination, MCH

2–8

TDSRBS1 Rambus Channel Measurements Application User Manual

Basics Operations

T0 T2

T1 T4

T3 T5

Figure 2–4: Read even positive pulse waveforms and measurement points

Table 2–10 lists the timing characteristic, the Rambus symbol for the characteristic, and the points used to take the measurement.

T able 2–10: Read even positive pulse timing characteristics

Characteristic Symbol Measurement points used

Setup time rising Hp_tsr T4–T3

Hold time falling Hp_thf T5–T4

Tq rising* Hp_tqr 625 ps – (T1–T0), where 625 ps is 1/4 of the bus

Tq falling* Hp_tqf (T2 – T1) – 625 ps

Tq error* Hp_tqerr (Hp_tqr + Hp_tqf) 2

Channel error falling* Hp_tcef (T4 – T3) – (T1 – T0)

Channel error rising* Hp_tcer (T5 – T4) – (T2 – T1)

Flight time falling Hp_tff T3 – T0

Flight time rising Hp_tfr T5 – T2

Flight time clock edge Hp_tfck T4 – T1

*Only available through remote GPIB execution of the application.

TDSRBS1 Rambus Channel Measurements Application User Manual

clock frequency (~400 Mhz)

2–9

Basics Operations

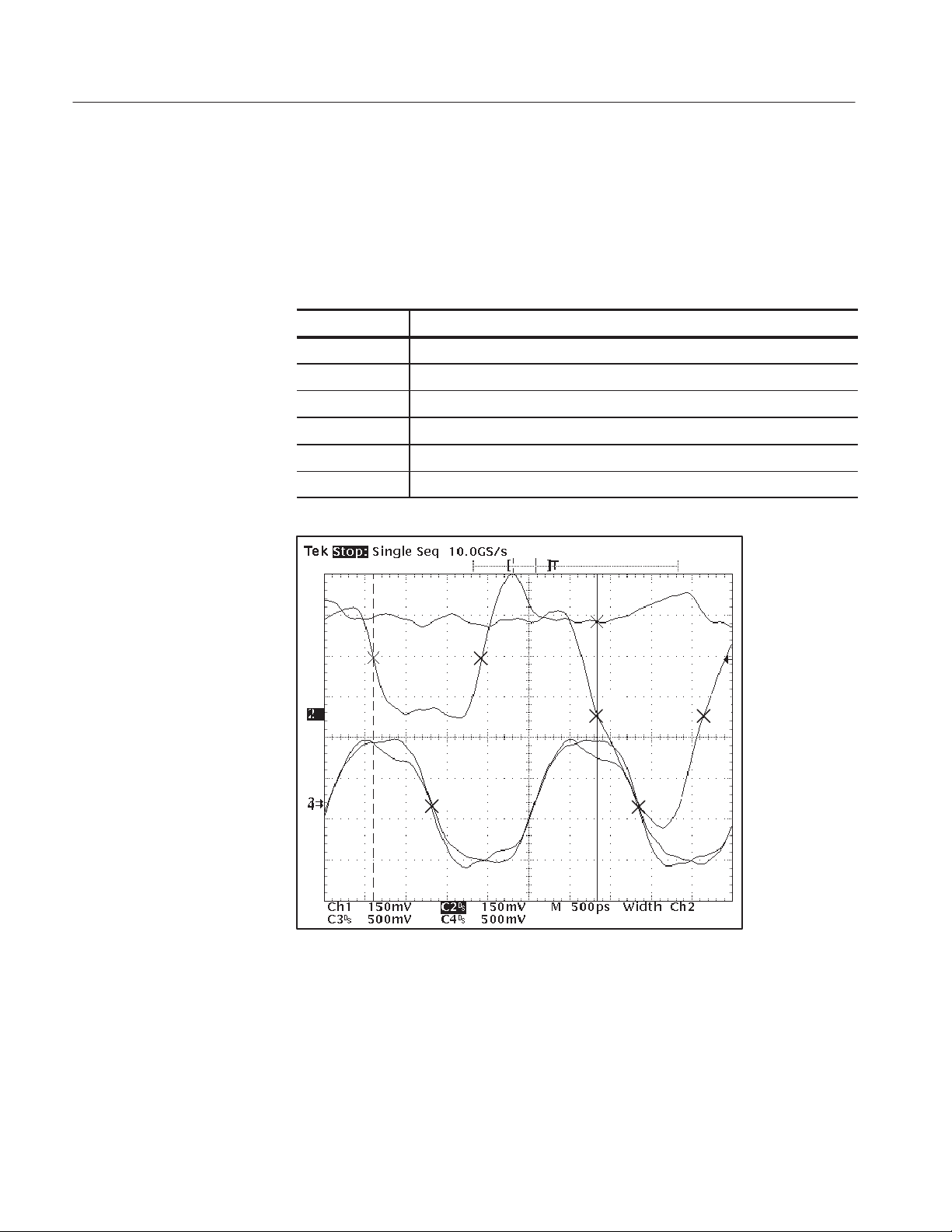

Low Read Pulse. Table 2–11 lists the measurement points and gives a description

of each for a read even negative pulse measurement. The application looks for a

logical data pattern of 010 for this type of measurement. Figure 2–5 shows the

corresponding points.

T able 2–11: Read even negative pulse measurement points

Point number Description

T0 Falling edge of the data (1.6 V) at the source, RIMM

T1 Falling edge of the clock (CTM crossing) at the source, RIMM

T2 Rising edge of the data (1.6 V) at the source, RIMM

T3 Falling edge of the data (1.4 V) at the destination, MCH

T4 Falling edge of the clock (CTM crossing) at the destination, MCH

T5 Rising edge of the data (1.4 V) at the destination, MCH

T0

T1

T2

T3 T5

T4

Figure 2–5: Read even negative pulse waveforms and measurement points

Table 2–12 lists the timing characteristic, the Rambus symbol for the characteristic, and the points used to take the measurement.

2–10

TDSRBS1 Rambus Channel Measurements Application User Manual

Basics Operations

T able 2–12: Read even negative pulse timing characteristics

Characteristic Symbol Measurement points used by application

Setup time falling Lp_tsf T4–T3

Hold time rising Lp_thr T5–T4

Tq falling* Lp_tqf 625 ps – (T1–T0), where 625 ps is 1/4 of the bus

clock frequency (~400 Mhz)

Tq rising* Lp_tqr (T2 – T1) – 625 ps

Tq error* Lp_tqerr (Lp_tqr + Lp_tqf) 2

Channel error falling* Lp_tcef (T4 – T3) – (T1 – T0)

Channel error rising* Lp_tcer (T5 – T4) – (T2 – T1)

Flight time falling Lp_tff T3 – T0

Flight time rising Lp_tfr T5 – T2

Flight time clock edge Lp_tfck T4 – T1

*Only available through remote GPIB execution of the application.

Understanding Measurement Patterns

The application takes measurements after it has located a specific pattern in the

data. Table 2–13 lists these patterns with a brief description of each.

T able 2–13: Measurement patterns

Pattern Description

010 Identifies a read or a write negative pulse

101 Identifies a read or a write positive pulse

Since these patterns occur in a pseudo-random fashion on a Rambus system

operating normally, it can be useful to directly generate the patterns with pattern

generation software. When you run a software generated pattern on the SUT and

trigger the oscilloscope on the pattern, you benefit in two ways.

Triggering on a generated pattern saves time because the application does not

have to wait long for a pattern to occur before taking measurements. If the

pattern generation software can target specific Rambus memory devices (such as

on a single RIMM socket), the application will obtain a narrower standard

deviation which makes the results from the measurements more accurate and

yields much finer timing characterization of individual memory components.

TDSRBS1 Rambus Channel Measurements Application User Manual

2–11

Basics Operations

Setting Up the Application

You can set up the application to take timing measurements from the Rambus

SUT and to display the results or save them to a data log file.

Measurement Selections

The next figure shows how to access the selections in the Measure menu, and

Table 2–14 lists the measurements with a brief description of each.

Main menu Side menu

Setup & Hold

Rise Time

Fall Time

Measure

Flight Clock Edge

Channel Error

Flight Time

Tq

Tq (Error)

T able 2–14: Measure menu selections

Selection Description

Setup and Hold For Setup time, the elapsed time between when a data signal and

its synchronizing clock signal crosses a voltage reference level

followed by the synchronizing clock signal crossing its own voltage

level

For Hold time, the elapsed time between when the clock signal

crosses a voltage reference level followed by an input signal

crossing its own voltage level

2–12

Rise Time Elapsed time from when a rising edge crosses the low reference

voltage level and then the high reference voltage level

Fall Time Elapsed time from when a falling edge crosses the high reference

voltage level and then the low reference voltage level

Flight Clock Edge Propagation delay between the source and destination

Channel Error Difference in Flight time between the clock and data waveforms

Flight Time Propagation delay between the source and destination of the data

signal

Tq Indicates the T iming Quality as how well the data is centered

relative to the synthetic clock

Tq (Error) Average of the TQ Rise Time and TQ Fall Time

TDSRBS1 Rambus Channel Measurements Application User Manual

Basics Operations

NOTE. The application can take many measurements simultaneously and can

display the results in various ways through the View Results menu. You can also

select a specific measurement and graphically plot the results, or log the results

to a file to view later on a personal computer.

Configuring the

Measurement

The next figure shows how to access the parameters in the Setup menu and

Table 2–15 lists the setup parameters with a brief description of each.

Main menu Side menu

Inputs

Setup

Test Signal Configuration

Clock Speed

Limits

Setup Summary

T able 2–15: Setup menu selections

Parameter Description

Input Sets up the waveform edge: source, level, hysteresis, VRefHigh,

and VRefLow

Test Signal Configuration Configures signal parameters: cycle, pulse, or data field

Clock Speed Provides manual or autosense option for the frequency of the clock

Limits Uses the default limits defined by the application or lets you edit the

limits

Setup Summary Displays complete measurement setup information in a scrollable

dialog box

Inputs Menu. After you select a measurement, you must define the waveforms in

the Inputs menu. The application uses these waveforms to take measurements.

NOTE. When you select a channel as an input, the application expects all inputs

to be from channel “live”waveforms. When you select a reference memory as an

input, the application expects all inputs to be from reference memory waveforms.

The application takes Read cycle measurements from the following channel or

reference memory waveforms:

H Rise Time and Fall Time measurements: Ch 1 or Ref 1

H All other measurements: Ch 2, Ch 3, Ch 4, Ref 2, Ref 3, or Ref 4

TDSRBS1 Rambus Channel Measurements Application User Manual

2–13

Basics Operations

The application takes Write cycle measurements from the following channel or

reference memory waveforms:

H Rise Time and Fall Time measurements: Ch 2 or Ref 2

H All other measurements: Ch 1, Ch 3, Ch 4, Ref 1, Ref 3, or Ref 4

The next figure shows how to access the parameters in the Input menu.

Table 2–16 describes the selections in the Inputs menu and lists the input

parameters with a brief description of each.

Side menu

Inputs

* Only required for Rise Time or Fall Time measurements.

Selection

Clock @ MCH

Clock @ RIMM

Data @ MCH

Data @ RIMM

(same name as

selected input)

Side menu items

Source

Level

Hysteresis

VRefHi*

VRefLo*

T able 2–16: Inputs menu selections and parameters

Selection Description

Clock @ MCH Clock waveform at the memory controller (MCH)

Clock @ RIMM Clock waveform at the memory module (RIMM)

Data @ MCH Data waveform at the memory controller (MCH)

Data @ RIMM Data waveform at the memory module (RIMM)

Parameter

Source Selects an active waveform or a reference waveform as the data or

clock source.

Level Selects the level of the waveform on which to start the measurement.

2–14

Hysteresis Selects the threshold margin, in percentage, relative to the reference

level which the voltage must cross to be recognized as changing; the

margin is the voltage reference level plus or minus half the hysteresis

VRefHi* Specifies where on the slope, in Volts, to set the high threshold

VRefLo* Specifies where on the slope, in Volts, to set the low threshold

* Only required for Rise Time or Fall Time measurements; the deskew utility uses these

values when Level Autosense is set to Off.

TDSRBS1 Rambus Channel Measurements Application User Manual

Basics Operations

NOTE. The application detects the minimum and maximum voltage levels of the

waveform. If the reference voltage level plus or minus the hysteresis falls outside

of 2.5% to 97.5% of the waveform peak-to-peak range, no measurement is taken,

and an error message displays.

The Setup and Hold, Flight Clock Edge, Channel Error, Flight Time, Tq, and Tq

(Error) measurements require one voltage reference level to calculate the activity

on the defined waveforms. The Rise Time and Fall Time measurements require

two voltage reference levels. Figure 2–6 shows how to set the voltage reference

levels.

VRefHi

VRef

VRef

VRefLo

Setup and Hold, Flight Clock Edge, Channel

Error, Flight Time, Tq, and Tq (Error)

Rise Time and Fall Time

Figure 2–6: How to set reference voltage levels

Deskew Menu. The next figure shows how to access parameters in the Deskew

menu and Table 2–17 lists the setup parameters with a brief description of each.

Main menu Side menu

Inputs

Deskew

Side menu

Channel Config

Deskew Population

From

To

Slope

Level Autosense

NOTE. To deskew the probes and oscilloscope channels, refer to Deskewing the

Probes and Channels starting on page 1–4.

The deskew utility aligns the signal edges relative to the VRefHi and VRefLo

values specified in the Inputs menu when you set Level Autosense to Off.

TDSRBS1 Rambus Channel Measurements Application User Manual

2–15

Basics Operations

T able 2–17: Deskew menu selections

Parameter Description

Deskew

Population

From Selects the reference point (“live” channels or Math1) to which the remaining

To* Selects the channel to deskew; includes All as a selection

Slope Selects the edge of the signals to be deskewed; the Both selection splits the

Level Autosense Calculates the center point of the signals and uses that value as the voltage

*The All selection allows you to use any channel in the From parameter; otherwise, the

channel in the To parameter is excluded as a selection in the From parameter.

Specifies the number of signal edges sampled by the deskew utility to

determine the deskew value; more samples yield more accurate values, but

also take the utility longer to process

channels (or the one specified) are deskewed; Math1 can be useful when

deskewing single-ended probes relative to differential probes (refer to

Appendix D: Deskewing with a Math1 Waveform)

difference in the middle between the rising and falling edges and then

centers the waveforms relative to each other

reference level; when set to Off, uses the VRefHi and VRefLo values

T est Signal Configuration Menu. The next figure shows how to access the Test

Signal Configuration selections and Table 2–18 describes each selection.

Side menu

Test Signal

Configuration

Side menu item

Cycle Type

Pulse Type

Data Field

Quiescent Time

T able 2–18: Test Signal Configuration menu selections

Selection Description

Cycle Type Specifies a Read or Write type of cycle

Pulse Type Specifies a High (logic 0) or Low (logic 1) type of pulse

Data Field Specifies an Even or Odd type of data field

Quiescent Time Number of inactive clock cycles needed for the transmission line to be

stable enough (free of reflection) to take measurements

Clock Speed Menu. The next figure shows how to access the Clock Speed

selections and Table 2–19 describes each selection.

2–16

TDSRBS1 Rambus Channel Measurements Application User Manual

Basics Operations

Side menu

Clock Speed

Side menu item

Autosense

Clock Speed

T able 2–19: Clock Speed menu selections

Selection Description

Autosense Application automatically senses the clock speed and uses that frequency;

the application responds to a change of 10% or more in the base value of

the clock frequency

Clock Speed Specifies the frequency of the Clock signal; if you use the keypad to enter

the frequency, be sure to also enter the units, such as Shift M for MHz

Limits and Limits Edit Menus. The next figure shows how to access the Limits

menu and Limits Edit menu selections. Table 2–20 describes the editing

selections.

When the Limits menu is enabled (set to On), the application uses the limits to

alert you of a timing condition that is outside the valid limits range, either the

default limits or those specified in the Limits Edit menu.

Side menu

Limits

* Limits must be set to On before you can edit the limits.

Side menu item

On/Off

Edit*

Side menu item

Measurement

Maximum

Minimum

Default

T able 2–20: Limits Edit menu selections

Selection Description

Measurement Selects the measurement for which the values of the limits can be edited

Maximum Specifies the value of the maximum limit for the Rambus Channel signals

used in the selected measurement

Minimum Specifies the value of the minimum limit for the Rambus Channel signals

used in the selected measurement

Default Sets the limits to default maximum and minimum values for the Rambus

Channel signals for each TDSRBS1 measurement; see Table 3–7

TDSRBS1 Rambus Channel Measurements Application User Manual

2–17

Basics Operations

When Limits is enabled (set to On), the Results Summary, accessed through

View Results (main), displays Mean values that are color coded to indicate if the

timing conditions were met. Table 2–21 lists the color code and describes what

each color indicates.

T able 2–21: Color of Mean values when using Limits

Mean values color Indicates

Green Limits test is passing

Y ellow Limits test is passing but the Max or Min values are outside of the range

Red Limits test is not passing

The Results Details, accessed through View Results (main), also displays PASS

or FAIL in color next to the Mean values when Limits is enabled. Table 2–22

shows how the application uses the Mean values to determine what color to use

to display PASS or FAIL.

Plot Results Setup