Page 1

User Manual

TDSDDM1

Disk Drive Measurement Application

071-0174-02

This document supports software version 1.0.26

and above.

Page 2

Copyright © T ektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its suppliers and

are protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in T echnical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software – Restricted Rights clause at F AR 52.227-19, as applicable.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the media on which this software product is furnished and the encoding of the programs on the

media will be free from defects in materials and workmanship for a period of three (3) months from the date of shipment.

If a medium or encoding proves defective during the warranty period, T ektronix will provide a replacement in exchange

for the defective medium. Except as to the media on which this software product is furnished, this software product is

provided “as is” without warranty of any kind, either express or implied. T ektronix does not warrant that the functions

contained in this software product will meet Customer’s requirements or that the operation of the programs will be

uninterrupted or error-free.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period. If T ektronix is unable to provide a replacement that is free from defects in materials and workmanship

within a reasonable time thereafter, Customer may terminate the license for this software product and return this software

product and any associated materials for credit or refund.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PAR TICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REPLACE DEFECTIVE MEDIA OR REFUND CUSTOMER’S PAYMENT IS THE SOLE AND EXCLUSIVE

REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS

VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF

THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

Getting Started

Preface vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Documentation vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting T ektronix viii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compatibility 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements and Restrictions 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Updates 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Application 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Updates Through a Web Browser 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disk Drive Connection 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Up the Oscilloscope Trigger 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Up the Application Trigger 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hysteresis 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Input Channels 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Basics

Reference

Functional Overview 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting the Application 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Leaving the Application 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting the Measurement 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing the Waveform 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Local Help 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tutorial 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 1: Measuring the Track Average Amplitude 2–7. . . . . . . . . . . . . . . . . . . . .

Example 2: Measuring the Pulse Width at 50% 2–8. . . . . . . . . . . . . . . . . . . . . . . . . .

Example 3: Creating and Viewing Track Profiles 2–10. . . . . . . . . . . . . . . . . . . . . . . .

Example 4: Saving a Setup and Exiting the Application 2–11. . . . . . . . . . . . . . . . . . .

Example 5: Recalling a Setup 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Structure 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Summary 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Structure 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TDSDDM1 Disk Drive Measurement Application User Manual

i

Page 6

Table of Contents

Setup Parameters 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving and Recalling Setups 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Over a Range of Sectors 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cursor Gating 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Localizing Measurements: an Alternate Method 3–9. . . . . . . . . . . . . . . . . . . . . . . . .

Adding Pass/Fail Results to Measurement Data 3–9. . . . . . . . . . . . . . . . . . . . . . . . .

Measurement Descriptions 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measurement Features 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

W arning Messages 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Track Average Amplitude, TAA 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Track Average Amplitude (Plus), TAA+

Track Average Amplitude (Minus), TAA– 3–16. . . . . . . . . . . . . . . . . . . . . . . . .

Pulse Width at 50%, PW50 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50% Pulse Width (Positive), PW50+

50% Pulse Width (Negative), PW50– 3–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Nonlinear Transition Shift, NLTS 3–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal-to-Noise Ratio, SNR 3–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overwrite 3–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resolution 3–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Asperity 3–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Snapshot Measurements 3–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Snapshot Measurement Definitions 3–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Track Profiles 3–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Track Profiles 3–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About the Track Profile Reference Memory 3–48. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

Index

Appendix A: Specifications A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

TDSDDM1 Disk Drive Measurement Application User Manual

Page 7

List of Figures

Table of Contents

Figure 1–1: TDSDDM1 Disk Drive Measurement Application 1–1. . . . .

Figure 1–2: Primary setup connections 1–5. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–3: Secondary setup connections 1–6. . . . . . . . . . . . . . . . . . . . . . .

Figure 1–4: Selecting the sectors to measure 1–9. . . . . . . . . . . . . . . . . . . .

Figure 1–5: Using hysteresis to avoid false identification of peaks 1–10. . .

Figure 1–6: Hysteresis menu 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–7: The Input Channels menu 1–12. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–1: Starting the application 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–2: Disk Drive Measurement Application initial display 2–3. . .

Figure 2–3: Returning to the application 2–3. . . . . . . . . . . . . . . . . . . . . . .

Figure 2–4: Selecting a measurement from the Measure menu 2–4. . . . .

Figure 2–5: The Control menu 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–6: Track average amplitude (TAA) measurement 2–8. . . . . . . .

Figure 2–7: Pulse width at 50% (PW50) measurement with cursor

gating 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–8: Track profile measurement 2–11. . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–1: Selecting menus 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–2: Save Setup and Recall Setup selections in the Utility

menu 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–3: Selecting the sectors to measure 3–7. . . . . . . . . . . . . . . . . . . .

Figure 3–4: Localizing a measurement using cursor gating 3–8. . . . . . . .

Figure 3–5: Limit Test results 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–6: Setting pass/fail limits 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–7: Standard measurement, snapshot measurement, and

track profile 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–8: Track average amplitude measurement 3–13. . . . . . . . . . . . . .

Figure 3–9: TAA measurement 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–10: TAA– measurement 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–11: TAA+ and TAA– measurements 3–17. . . . . . . . . . . . . . . . . . .

Figure 3–12: PW50 measurement 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–13: Parameters for PW50 disk drive measurements 3–20. . . . . .

Figure 3–14: PW50+ measurement 3–21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–15: Parameters for PW50+ and PW50– disk drive

measurements 3–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TDSDDM1 Disk Drive Measurement Application User Manual

iii

Page 8

Table of Contents

Figure 3–16: NLTS measurement 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–17: Selecting an NLTS measurement 3–26. . . . . . . . . . . . . . . . . . .

Figure 3–18: Specifying the NLTS polynomial 3–28. . . . . . . . . . . . . . . . . . .

Figure 3–19: SNR measurement 3–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–20: Specifying the SNR parameters 3–31. . . . . . . . . . . . . . . . . . . .

Figure 3–21: Overwrite measurement 3–34. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–22: Resolution measurement 3–36. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–23: Asperity measurement 3–39. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–24: Snapshot measurement data 3–41. . . . . . . . . . . . . . . . . . . . . .

Figure 3–25: Time PT and Time TP measurements 3–43. . . . . . . . . . . . . .

Figure 3–26: Track profile waveform 3–45. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–27: Specifying the track profile parameters 3–47. . . . . . . . . . . . .

Figure 3–28: Track profile reference memory 3–48. . . . . . . . . . . . . . . . . . .

iv

TDSDDM1 Disk Drive Measurement Application User Manual

Page 9

List of Tables

Table of Contents

Table 1–1: Primary setup channel assignments 1–5. . . . . . . . . . . . . . . . . .

Table 1–2: Default input channel assignments 1–11. . . . . . . . . . . . . . . . . .

Table A–1: TDSDDM1 Disk Drive Measurement Application

measurements A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TDSDDM1 Disk Drive Measurement Application User Manual

v

Page 10

Table of Contents

vi

TDSDDM1 Disk Drive Measurement Application User Manual

Page 11

Preface

Related Documentation

This manual contains operating information for the TDSDDM1 Disk Drive

Measurement Application. The manual consists of the following chapters:

H The chapter Getting Started briefly describes the TDSDDM1 Disk Drive

Measurement Application and provides installation instructions.

H The chapter Operating Basics covers basic operating principles of the

application.

H The chapter Reference describes how to perform specific tasks.

H The Appendices provide a list of specifications.

The following documents are related to the use of this product:

H The TDS 500D, TDS 600B, & TDS 700D Digitizing Oscilloscope User

Manual (Tektronix part number 071-0130-XX) provides operating instruc-

tions for general oscilloscope features.

Conventions

H The International Disk Drive Equipment and Materials Association

(IDEMA) 1995 Standards Binder, section T for Test Methods, is the source

document for test criteria used by the TDSDDM1 Disk Drive Measurement

Application.

This manual uses the following conventions:

H For brevity, this manual generally refers to the TDSDDM1 Disk Drive

Measurement Application as the Disk Drive Measurement Application or

simply as the application.

H When steps require that you make a sequence of selections using front panel

controls and menu buttons, an arrow ( ➞

front panel button and a menu, or between menus. Also, whether a name is a

main menu or side menu item is clearly indicated: Press VERTICAL

MENU ➞ Coupling (main) ➞ DC (side) ➞ Bandwidth (main) ➞ 250 MHz

(side).

) marks each transition between a

TDSDDM1 Disk Drive Measurement Application User Manual

vii

Page 12

Preface

Contacting Tektronix

Product

Support

Service

Support

For other

information

To write us Tektronix, Inc.

For application-oriented questions about a Tektronix measurement product, call toll free in North America:

1-800-TEK-WIDE (1-800-835-9433 ext. 2400)

6:00 a.m. – 5:00 p.m. Pacific time

Or contact us by e-mail:

tm_app_supp@tek.com

For product support outside of North America, contact your

local Tektronix distributor or sales office.

Contact your local Tektronix distributor or sales office. Or visit

our web site for a listing of worldwide service locations.

http://www.tek.com

In North America:

1-800-TEK-WIDE (1-800-835-9433)

An operator will direct your call.

P.O. Box 1000

Wilsonville, OR 97070-1000

viii

TDSDDM1 Disk Drive Measurement Application User Manual

Page 13

Getting Started

Page 14

Page 15

Product Description

The TDSDDM1 Disk Drive Measurement Application is a software package that

adds disk drive measurement and analysis capability to a Tektronix oscilloscope.

With this application you can quickly and easily set up, acquire, and analyze

signals from your disk drives, in accordance with IDEMA (International Disk

Drive Equipment and Materials Association) standards.

Compatibility

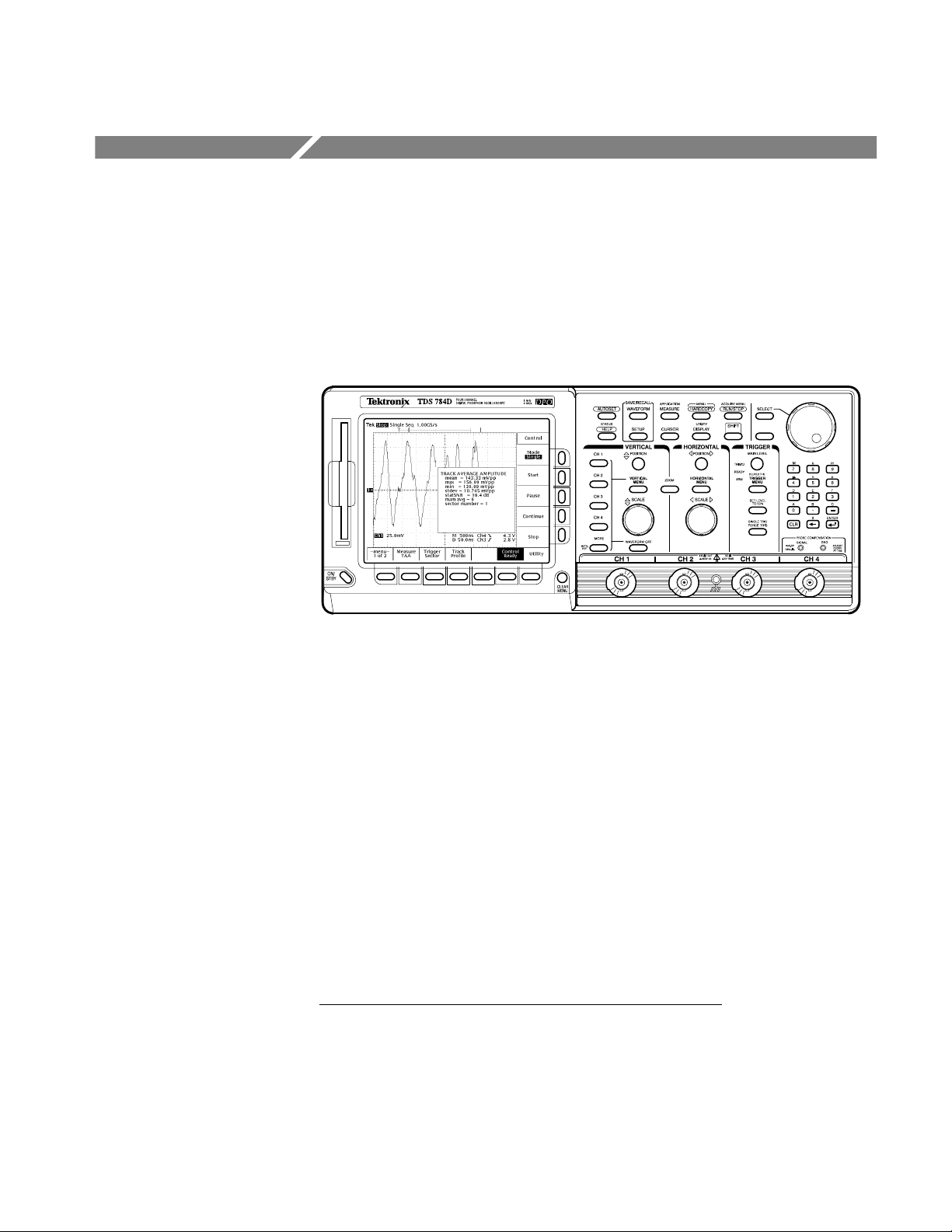

Figure 1–1: TDSDDM1 Disk Drive Measurement Application

The Disk Drive Measurement Application is compatible with the following

Tektronix oscilloscopes:

H All TDS 500D and 700D Digital Phosphor Oscilloscopes with Option HD

(hard disk drive) or Option 2M (hard disk drive plus 8 MB record length)

H TDS 600C Digitizing Oscilloscopes with an Option HD (hard disk drive)

H TDS 700C Color Digitizing Oscilloscopes serial number B020100 and up,

with Option HD (hard disk drive) or Option 2M (hard disk drive plus 8 MB

record length), and with firmware version 5.2e and up

For a current list of compatible oscilloscopes, check the Tektronix, Inc. web site,

http://www.tektronix.com/Measurement/scopes/index.html

Drivers category.

in the Software and

TDSDDM1 Disk Drive Measurement Application User Manual

1–1

Page 16

Product Description

Requirements and Restrictions

The TDS Run-Time Environment V1.1 software or above must be installed on

the oscilloscope to operate the Disk Drive Measurement Application.

The application does not support control by external GPIB commands.

Updates

You can find information about this and other applications at the Tektronix, Inc.

web site, http://www.tektronix.com/Measurement/scopes/index.html

Software and Drivers category. Check this site for application updates that you

can download and for free applications.

For instructions, see Updates Through a Web Browser on page 1–4.

Accessories

in the

There are no standard accessories for this product.

The P6246 and P6247 Differential Probes are recommended for connecting to

Read channel signals.

1–2

TDSDDM1 Disk Drive Measurement Application User Manual

Page 17

Installation

This application resides on a floppy disk. You can download updates, if any,

from the Tektronix ftp site through a web browser.

NOTE. To operate the Disk Drive Measurement Application, the TDS Run-Time

Environment V1.1 or above must be installed on your oscilloscope.

Installing the Application

To install the application from the floppy disk to your oscilloscope, follow these

steps:

1. Create a backup copy of the floppy disks. You can now store the original

NOTE. Additional information about the product or installation, if any, is located

in a Readme.txt file on the floppy disk. You should insert the floppy disk into a

DOS-based personal computer and read the file before you continue.

disks and work from the backup copies.

If you are updating the application, the Readme.txt file on the Tektronix ftp site

supercedes the Readme.txt file on the floppy disk.

2. Power off the oscilloscope.

3. Insert the floppy disk in the floppy disk drive and power on the oscilloscope.

NOTE. To verify that the TDS Run-Time Environment V1.1 or above is installed,

watch for the name to appear at the top of the display when you power on the

oscilloscope. If it does not appear, contact your local Tektronix sales office.

After performing the power-up self-test, the oscilloscope automatically

begins the installation procedure.

As the application loads from the disk, the oscilloscope displays a clock icon

to indicate that it is busy. Also, the floppy disk drive LED is on, indicating

activity. If the clock icon continues to display after the floppy disk LED has

gone out, a problem has occurred with the installation. Repeat this proce-

dure. If the problem persists, contact your Tektronix representative.

TDSDDM1 Disk Drive Measurement Application User Manual

1–3

Page 18

Installation

When the installation is complete, an Installation Complete message

displays.

4. Remove the floppy disk and cycle power to the oscilloscope.

Updates Through a Web Browser

If there is an update for this application, it will be available from the Tektronix

ftp site. To install an application update, you will need to download it from the

ftp site to a hard disk, copy it to a blank DOS-formatted floppy disk, and then

install it on your oscilloscope.

NOTE. More information about changes to the application or installation is in a

Readme.txt file on the ftp site. You should read it before you continue.

To copy the application from a web browser, follow these steps:

Disk Drive Connection

1. Access the ftp site at ftp://ftp.tek.com/mbd/support/00–index.html#1

2. Scroll through the files to the TDSJIT1 application, select the file, and

download it to your hard disk drive. If necessary, unzip the file.

3. Copy the application from the hard disk to a blank DOS-formatted floppy

disk.

4. Follow the Installing the Application procedure on page 1–3.

For best signal fidelity, we recommend you use a differential probe and two

standard probes. For connection to the Read channel signal, use a differential

probe, such as the Tektronix P6247 probe. For connection to the Index and

Sector signals, use standard oscilloscope probes, such as the Tektronix P6139A

passive probe or P6243 active probe.

There are two connection configurations, primary and secondary.

.

1–4

TDSDDM1 Disk Drive Measurement Application User Manual

Page 19

Installation

Primary Setup

Use the primary setup if you want the oscilloscope to control the disk measurements. The primary setup is used for most configurations.

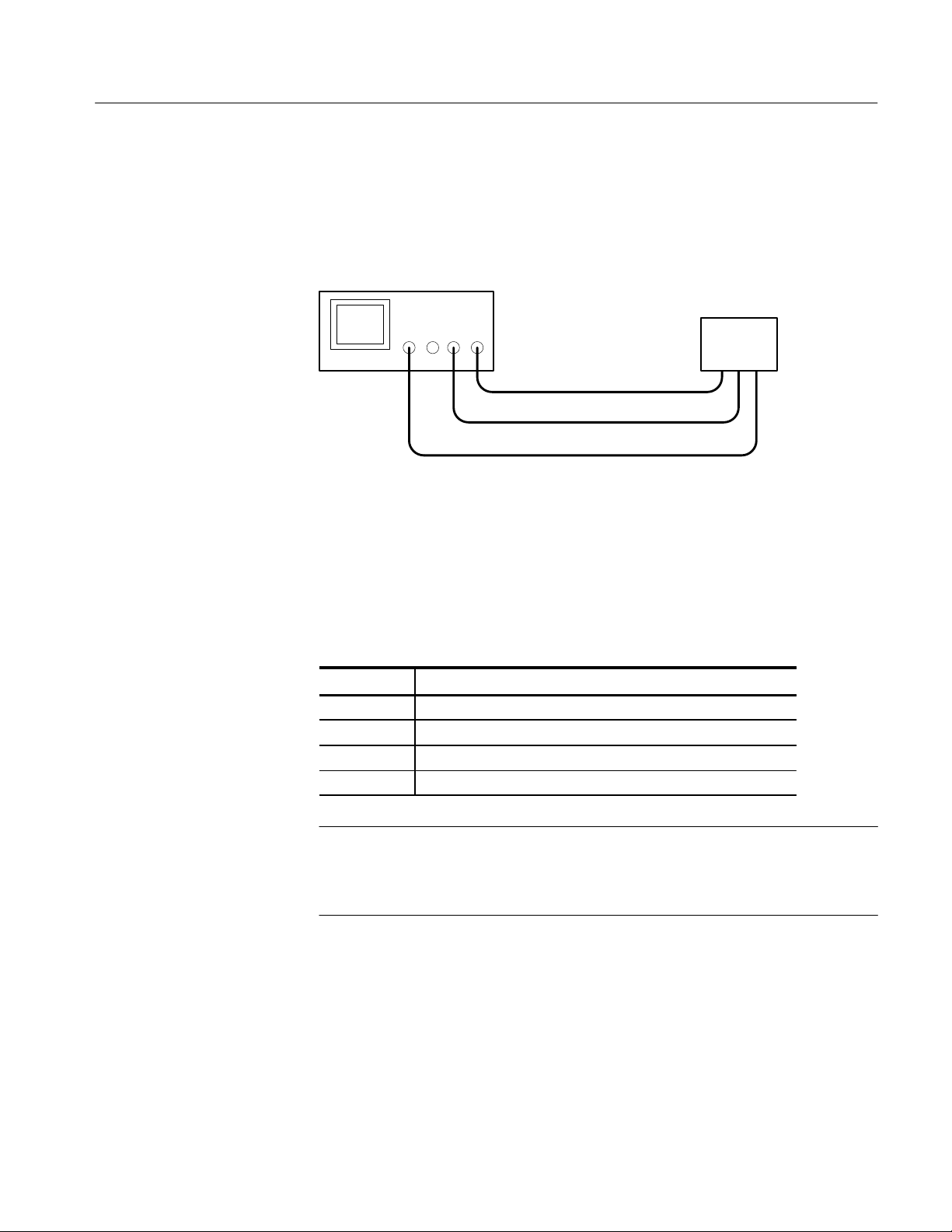

Connect the disk drive to the oscilloscope as shown in Figure 1–2.

Test oscilloscope

Disk drive

CH 1 CH 4

CH 3

Index signal (standard probe)

Sector signal (standard probe)

Read signal (differential probe)

Figure 1–2: Primary setup connections

Table 1–1 shows the default channel-to-signal assignments. You can change the

channel assignments to match your configuration. See Configuring the Input

Channels on page 1–11 for more information.

T able 1–1: Primary setup channel assignments

Channel Description

Ch 1 Read signal from the preamp channel

Ch 2 Read Gate signal (optional)

Ch 3 Sector pulse, marking the beginning of the sector on the track

Ch 4 Index pulse, marking the beginning of the track

NOTE. Some disk drives mark the beginning of a track by the absence of a sector

pulse. For this case, a timeout trigger setup is needed to identify the beginning

of the track. The Disk Drive Measurement Application does not support this

configuration.

TDSDDM1 Disk Drive Measurement Application User Manual

1–5

Page 20

Installation

Secondary Setup

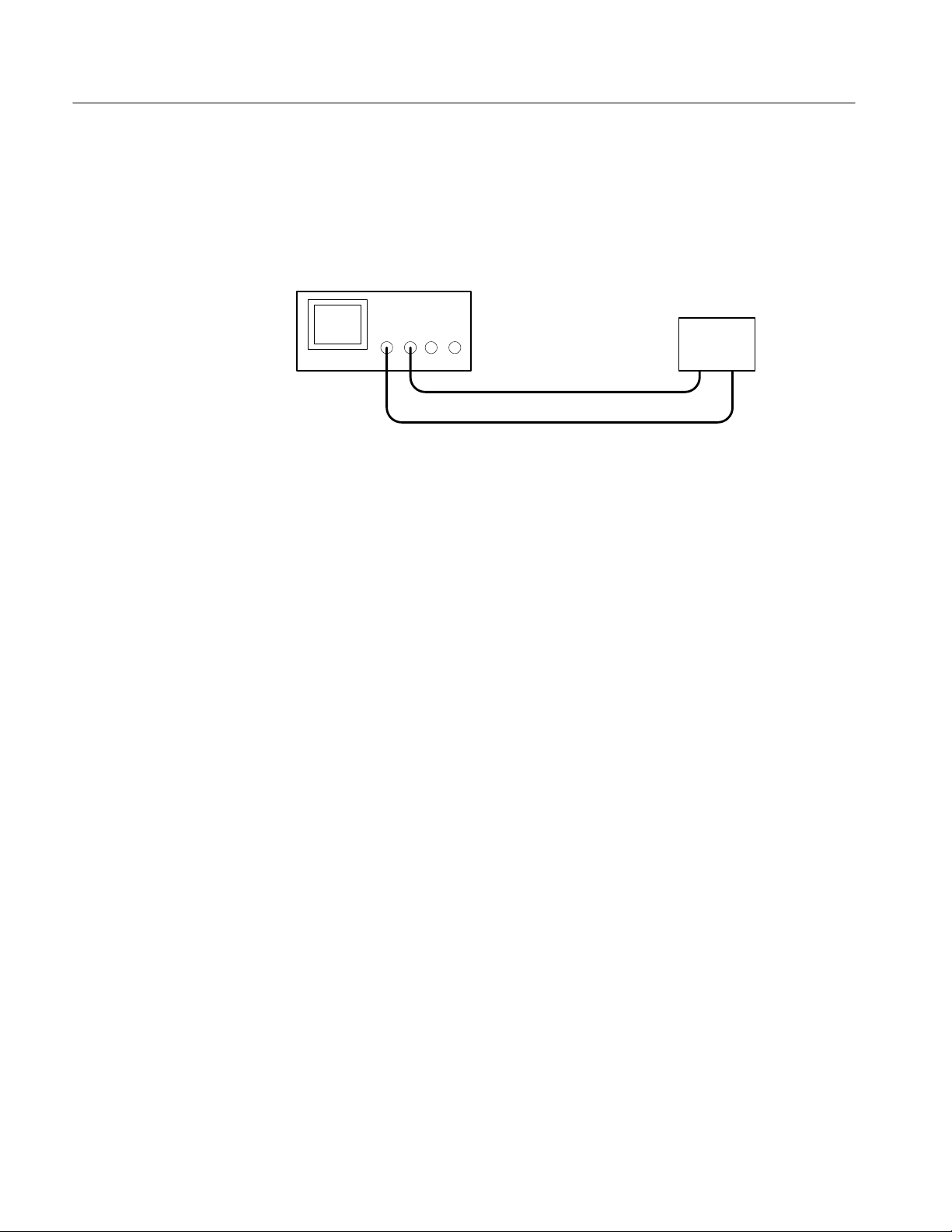

When using the secondary setup, you must specifically program the test

measurement control sequences.

Connect the disk drive to the oscilloscope as shown in Figure 1–3.

Test oscilloscope

Disk drive

CH 1 CH 2

Read Gate signal (standard probe)

Read signal (differential probe)

Figure 1–3: Secondary setup connections

1–6

TDSDDM1 Disk Drive Measurement Application User Manual

Page 21

Configuration

This section describes configuration tasks that you should perform before you

start taking measurements. For the most part, these tasks configure the oscilloscope and Disk Drive Measurement Application to correctly acquire the signals

from the disk drive under test. Additional setup parameters, concerned more with

configuring specific measurements, are located in the Setup Parameters section

beginning on page 3–5.

Setting Up the Oscilloscope Trigger

Before starting measurements, you must manually set up the trigger, as described

in the following procedure:

1. Connect the Index, Sector, and Read signals to channels 4, 3, and 1

respectively.

2. Set the oscilloscope to the desired sample rate using the horizontal SCALE

knob. (The sample rate is usually 500 MS/s, or 1, 2, or 4 GS/s.)

3. Set the time interval:

a. Fit the waveform to the screen by pressing HORIZONTAL MENU ➞

Record Length (main) ➞ Fit to Screen (side). Select ON.

b. In the same menu, select a record length appropriate to the signal under

test.

4. Set up the trigger:

a. Set the trigger coupling to DC by pressing Coupling (main) ➞ DC

(side).

b. Set the slope by pressing Slope (main) and then selecting positive or

negative slope (side). (Select the slope appropriate to your disk drive

signal.)

c. Set the mode to Normal by pressing Mode & Holdoff (main) ➞ Normal

(side).

d. Set the level by pressing Level (main) and then selecting a level

appropriate to your signal.

TDSDDM1 Disk Drive Measurement Application User Manual

1–7

Page 22

Configuration

Setting Up the Application Trigger

Before you begin taking measurements, you should specify the following trigger

parameters:

H Trigger Mode, which selects the input trigger signal

H Start/Stop Sector (used with the Sector Trigger Mode only), which specifies

the range of sectors to be measured

H Preamble Duration (used with the Sector Trigger Mode only), which the

application uses to automatically remove the preamble from the measurement calculations

Set up the trigger parameters as follows:

1. If you have not already done so, start the application as follows:

a. Press SETUP ➞ Select Application (main).

b. Using the general purpose knob, select hd0, and then press SELECT.

(Depending on previous actions, you might not need to do this step.)

c. Using the general purpose knob, select TDSDDM1.APP.

d. Press Activate Application (side).

2. Press Trigger (main) ➞ Mode (side). See Figure 1–4. Select one of the

following:

Sector Select Sector if you want to perform a measurement over a

range of sectors rather than over the entire track. The oscilloscope uses the main trigger to trigger on the Index pulse.

The delayed trigger is used to monitor sectors as follows:

Delayed trigger—triggerable after Events/Time

Delay Edge Source—Sector signal

Delay Count—sequences through sector numbers

Delay Time—preamble duration

Sector is the default Trigger Mode selection.

Read Gate Select Read Gate if you want to trigger on the Read Gate

signal. The delay trigger is not used with this selection.

User Select User if you want to use your own custom trigger set-

up. When you select User, the application does not alter the

trigger settings.

Index Select Index if you want to trigger on the Index signal. The

delay trigger is not used with this selection.

1–8

3. If you selected the Sector mode, set the Start and Stop Sectors now using the

side menu selections.

TDSDDM1 Disk Drive Measurement Application User Manual

Page 23

Configuration

4. Set the Preamble Duration. Using the general-purpose knob, select a value

that is greater than the actual signal preamble duration. This ensures that

none of the preamble is acquired and that the preamble is not included in the

measurement.

Figure 1–4: Selecting the sectors to measure

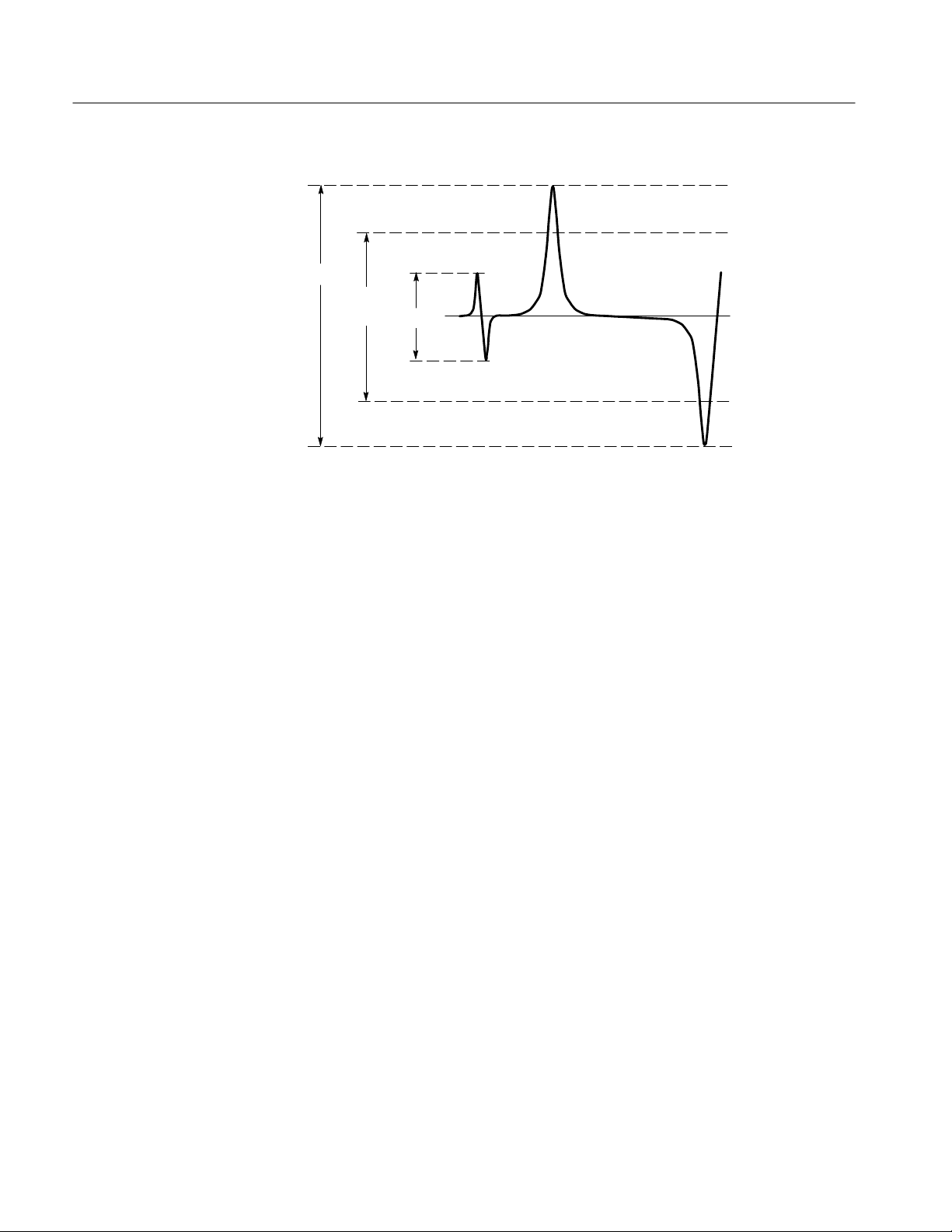

Hysteresis

Many of the measurements require a search for a local event called a peak and

trough pair. Set the hysteresis level so that noise will not cause false identification of peaks in the Read channel waveform. For a peak or trough to be found,

the signal must be greater than the hysteresis level.

Hysteresis is a global setting that is used by measurements such as TAA, PW50,

time asymmetry, and time between peaks.

TDSDDM1 Disk Drive Measurement Application User Manual

1–9

Page 24

Configuration

Peak

Signal

Hysteresis

setting

Noise

Trough

Figure 1–5: Using hysteresis to avoid false identification of peaks

Set the hysteresis levels as follows:

1. Press –menu– (main) to display the second page of menu selections.

2. Press Hysteresis (main) ➞ Hysteresis (side). See Figure 1–6.

3. Specify the hysteresis value.

The units for hysteresis are in divisions. The value you enter is used for the

positive hysteresis level and its negative is used for the negative level. For

example, if you enter a value of 2 divisions, the hysteresis levels are at +2

divisions and –2 divisions.

1–10

TDSDDM1 Disk Drive Measurement Application User Manual

Page 25

Configuration

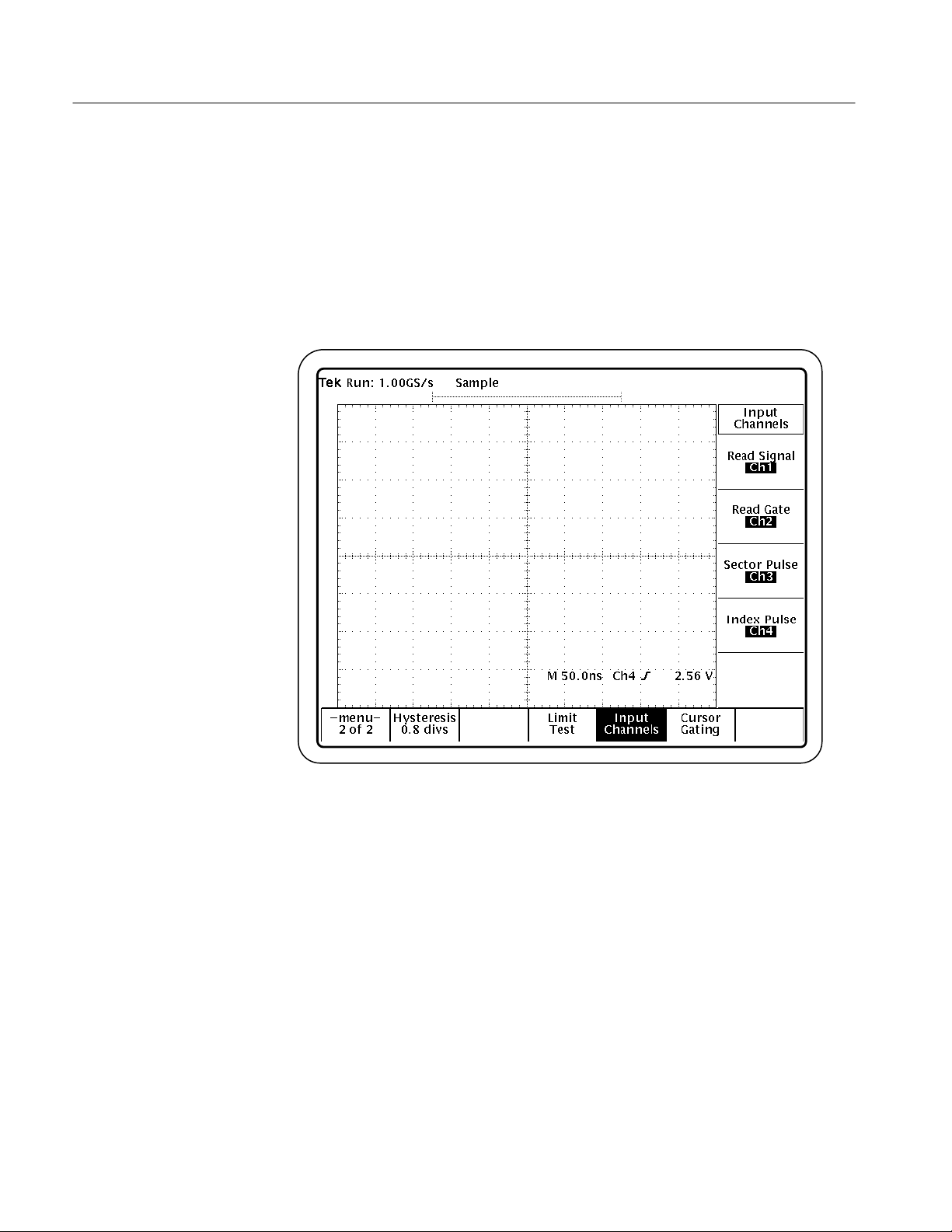

Figure 1–6: Hysteresis menu

Configuring the Input Channels

If you are using the default channel configuration, this topic does not apply to

you.

In some cases, your configuration might not match the channel assignments used

by this Disk Drive Measurement Application. Table 1–2 lists the default input

channel assignments.

T able 1–2: Default input channel assignments

Channel Description

Ch 1 Read signal from the preamp channel

Ch 2 Read Gate signal (optional)

Ch 3 Sector pulse, marking the beginning of the sector on the track

Ch 4 Index pulse, marking the beginning of the track

1

This signal is used for triggering only when the Trigger/Mode/Read

Gate menu item has been selected.

2

This signal is used for triggering only when the Trigger/Mode/Sector

menu item has been selected.

1

2

2

TDSDDM1 Disk Drive Measurement Application User Manual

1–11

Page 26

Configuration

If necessary, you can reconfigure the input channels to match your configuration

using the Input Channels menu, as follows:

1. From the application display, go to the Input Channels menu by pressing

–menu– (main) ➞ Input Channels (side). See Figure 1–7.

2. Using the side menu buttons, assign the disk drive signals to the appropriate

channels.

1–12

Figure 1–7: The Input Channels menu

TDSDDM1 Disk Drive Measurement Application User Manual

Page 27

Operating Basics

Page 28

Page 29

Functional Overview

This section describes how to use the basic functions of the Disk Drive

Measurement Application. Further details about the basic functions and

descriptions of more advanced features are included in the Reference section.

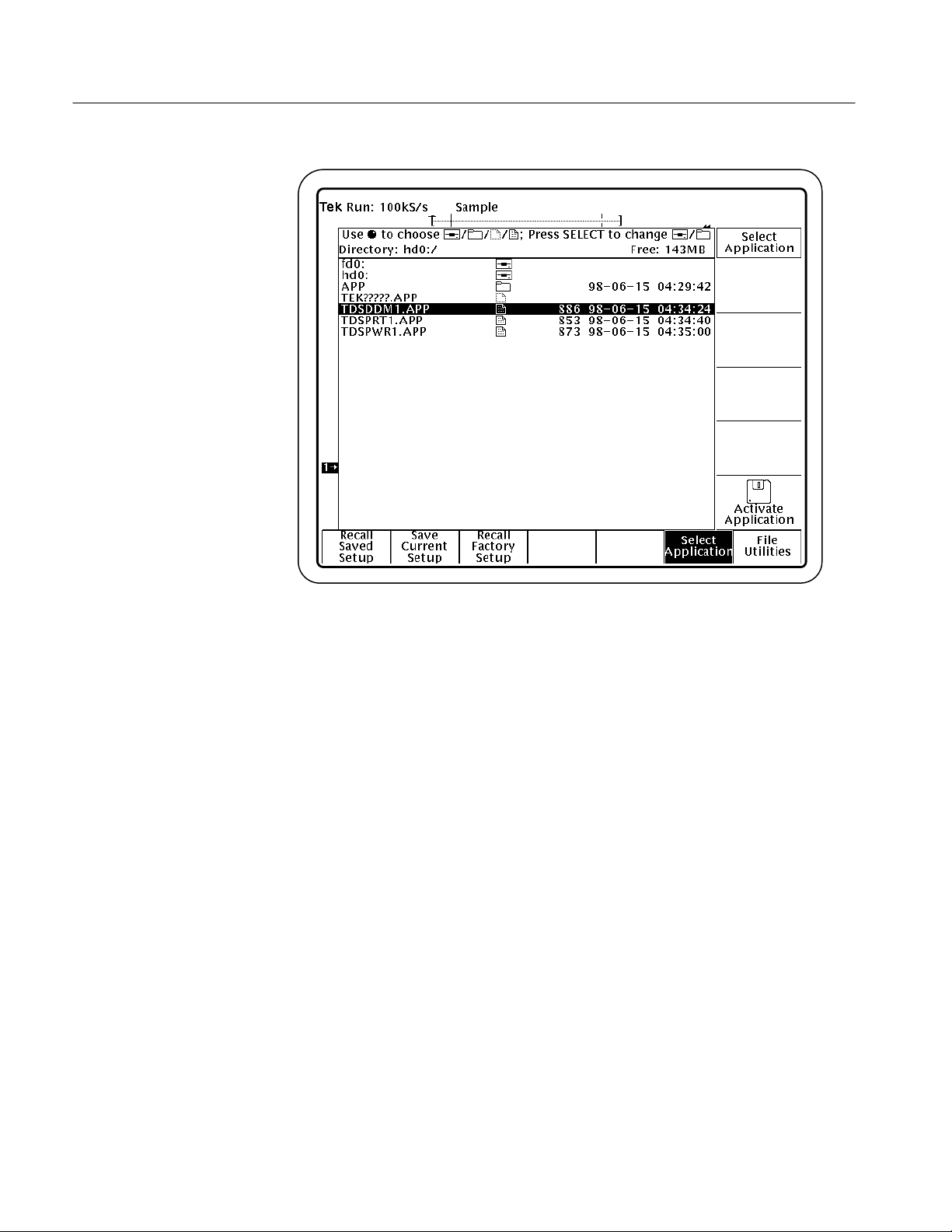

Starting the Application

After the Disk Drive Measurement Application has been installed in the

oscilloscope, start the application as follows:

1. Press SETUP ➞ Select Application (main). See Figure 2–1.

2. Using the general purpose knob, select hd0, and then press SELECT.

(Depending on previous actions, you might not need to do this step.)

3. Using the general purpose knob, select TDSDDM1.APP.

4. Press Activate Application (side).

The application starts up and displays as shown in Figure 2–2.

TDSDDM1 Disk Drive Measurement Application User Manual

2–1

Page 30

Functional Overview

Figure 2–1: Starting the application

2–2

TDSDDM1 Disk Drive Measurement Application User Manual

Page 31

Functional Overview

Leaving the Application

Figure 2–2: Disk Drive Measurement Application initial display

You can switch between the Disk Drive Measurement Application and other

oscilloscope functions. To access primary oscilloscope functions, press the

desired front panel control. To return to the application, push the SHIFT and

APPLICATION front-panel menu buttons as shown in Figure 2–3.

To exit the application, press Utility (main) ➞ Exit (side).

Push the SHIFT and APPLICATION buttons to return to the application.

Figure 2–3: Returning to the application

TDSDDM1 Disk Drive Measurement Application User Manual

2–3

Page 32

Functional Overview

Starting the Measurement

Start the measurement as follows:

1. Select the type of measurement to execute, as follows:

a. Display the Measure menu by pressing Measure (main). See Figure 2–4.

If the measurement you want is not shown, press –more– (side).

b. Select a measurement.

c. Make any further selections required by the measurement. (See

Measurement Descriptions on page 3–11 for information about

individual measurements.)

2–4

Press –menu– for next

menu page

Figure 2–4: Selecting a measurement from the Measure menu

TDSDDM1 Disk Drive Measurement Application User Manual

Page 33

Functional Overview

2. If you want to change trigger settings or localize the measurement, do so

now. The application defaults to the settings specified in the Trigger menu.

For further information, see Setting Up the Application Trigger on page 1–8,

Measuring Over a Range of Sectors on page 3–6, and Cursor Gating on

page 3–7.

3. Press Control (main).

4. Press Mode (side) to select Single or Free Run acquisition mode.

The Single option performs the measurement and then stops. The Free Run

option performs the measurement continually.

In the event that the measurement requires an external operation to occur

before it may continue, the readout changes to Pause. After fulfilling the

requirements specified in the message box, you must press Continue (side)

to finish the measurement.

Figure 2–5: The Control menu

TDSDDM1 Disk Drive Measurement Application User Manual

2–5

Page 34

Functional Overview

Viewing the W aveform

5. Press Start (side).

6. Wait for the measurement to complete (Single), or push the Stop side menu

button to manually stop the measurement.

In single mode, when the measurement has successfully completed, the screen

displays the updated measurement data. All measurement processing halts, but

the waveform acquisitions continue to update on the screen.

NOTE. Do not change oscilloscope settings while a measurement is being taken.

Doing so can invalidate the measurement.

Do not attempt to execute external GPIB commands to control the oscilloscope

while running the application. Doing so may interrupt the process.

Using the Local Help

To view parts of the waveform that are obscured by the measurement display

readout, push the CLEAR MENU button, located near the lower right of the

display.

To return to the application display, push the SHIFT and APPLICATION

front-panel menu buttons.

The application includes help information, available from within the application

menus. The help included with the application is independent of the main

oscilloscope help, and it operates somewhat differently. The application help

does not identify and explain individual controls; instead, it provides information

about the measurements themselves.

Display the local help as follows:

1. Display the help by pressing Utility (main) ➞ Help (side).

2. Use the side menu buttons to navigate within the help.

2–6

TDSDDM1 Disk Drive Measurement Application User Manual

Page 35

Tutorial

Preparation

This tutorial shows you how to use some basic features of the Disk Drive

Measurement Application. In addition, it teaches you how to exit the application

and how to save and recall setups. Further operating information is located in the

Reference chapter.

To perform the tutorial examples, you must have already installed the Disk Drive

Measurement Application in the oscilloscope, connected the probes to a disk

drive, and performed the configuration tasks appropriate to your disk drive under

test. For information, see Installation on page 1–3 and Configuration on

page 1–7.

If you have not already done so, start the application as follows:

1. Press SETUP ➞ Select Application. See Figure 2–1.

2. Using the general purpose knob, select hd0, and then press SELECT.

3. Using the general purpose knob, select TDSDDM1.APP.

4. Press Activate Application (side).

The application starts up and displays its initial screen.

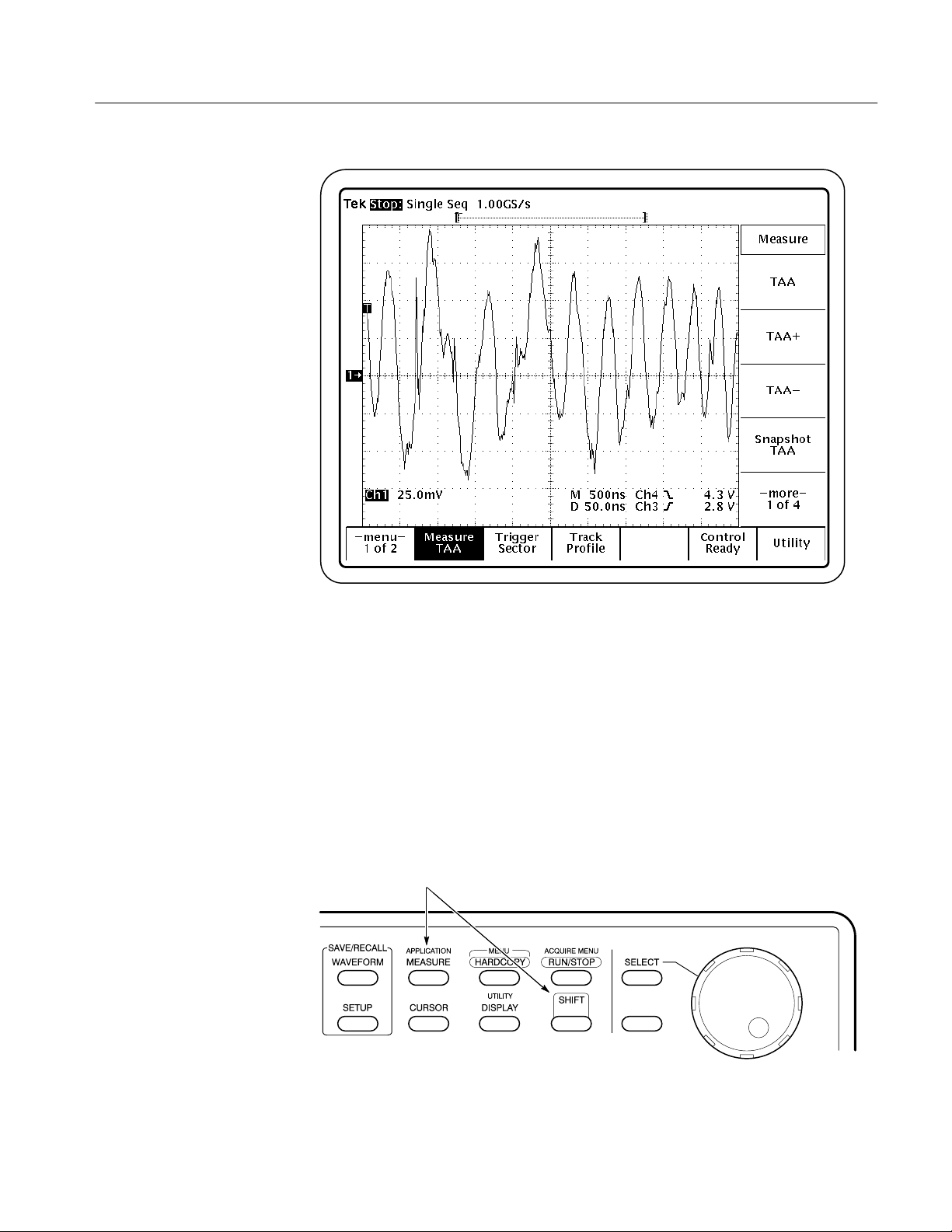

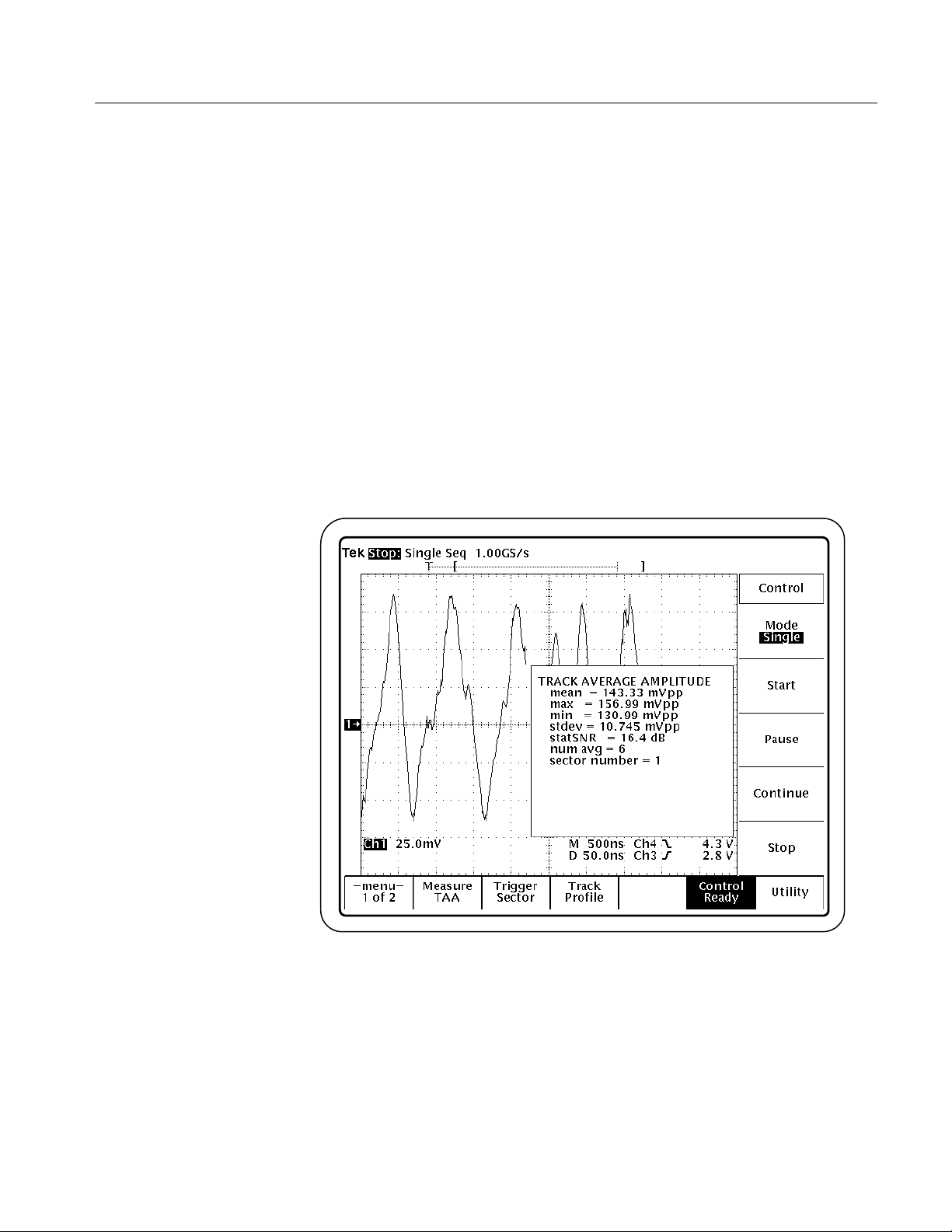

Example 1: Measuring the Track Average Amplitude

In this example, you will measure the track average amplitude (TAA) over a

range of sectors and display the results.

1. Select the TAA measurement by pressing Measure (main) ➞ TAA (side).

2. Specify a range of sectors to measure as follows:

a. Press Trigger (main) ➞ Mode (side). Select Sector.

b. Press Start Sector (side), and set the value to 1.

c. Press Stop Sector (side), and set the value to 10.

3. Set the Preamble Duration. Using the general-purpose knob, select a value

that is greater than the actual signal preamble duration. This ensures that

none of the preamble is acquired and that the preamble is not included in the

measurement.

TDSDDM1 Disk Drive Measurement Application User Manual

2–7

Page 36

Tutorial

4. Start the measurement by pressing Control (main) ➞ Start (side).

5. Wait for the measurement to complete, then view the results as shown in

Figure 2–6.

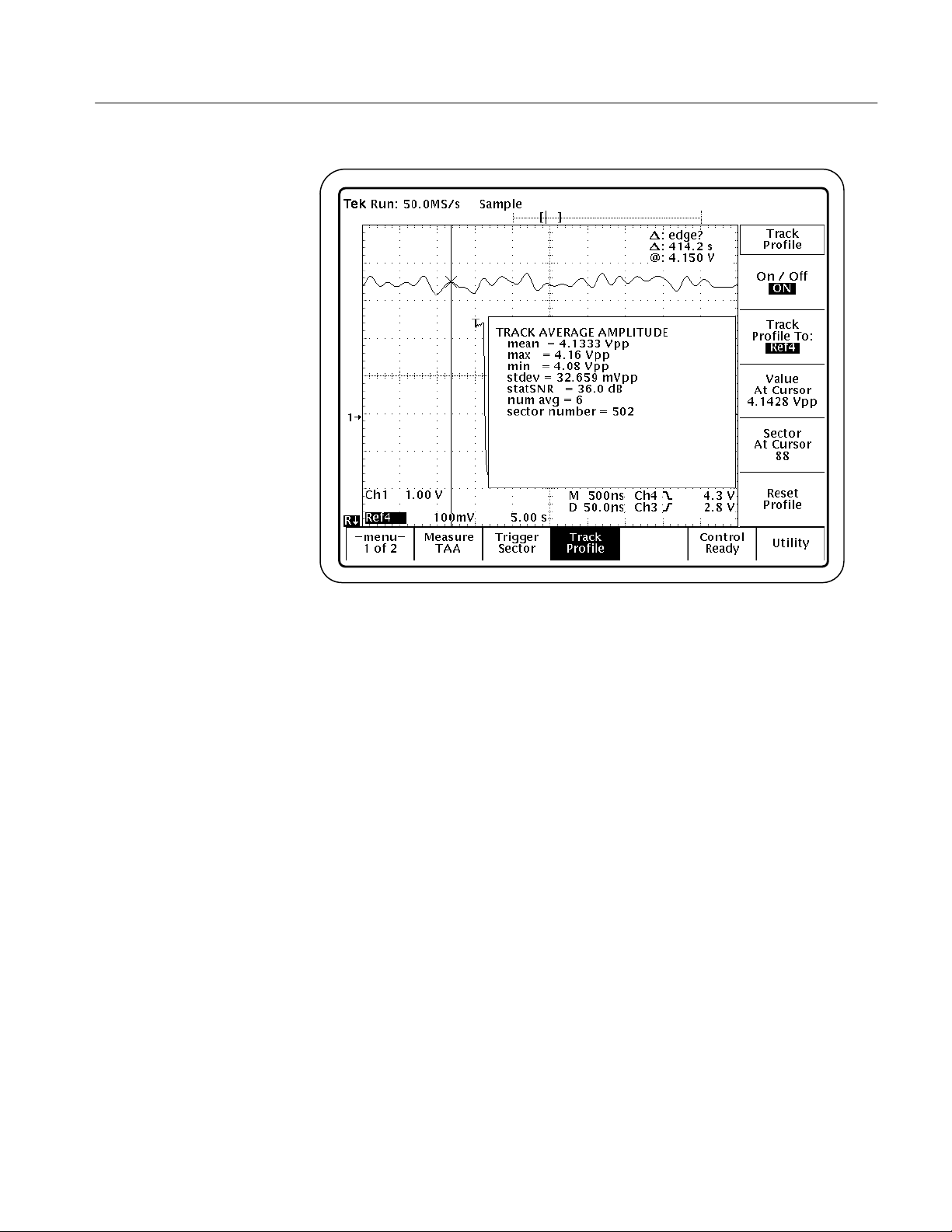

Figure 2–6: Track average amplitude (TAA) measurement

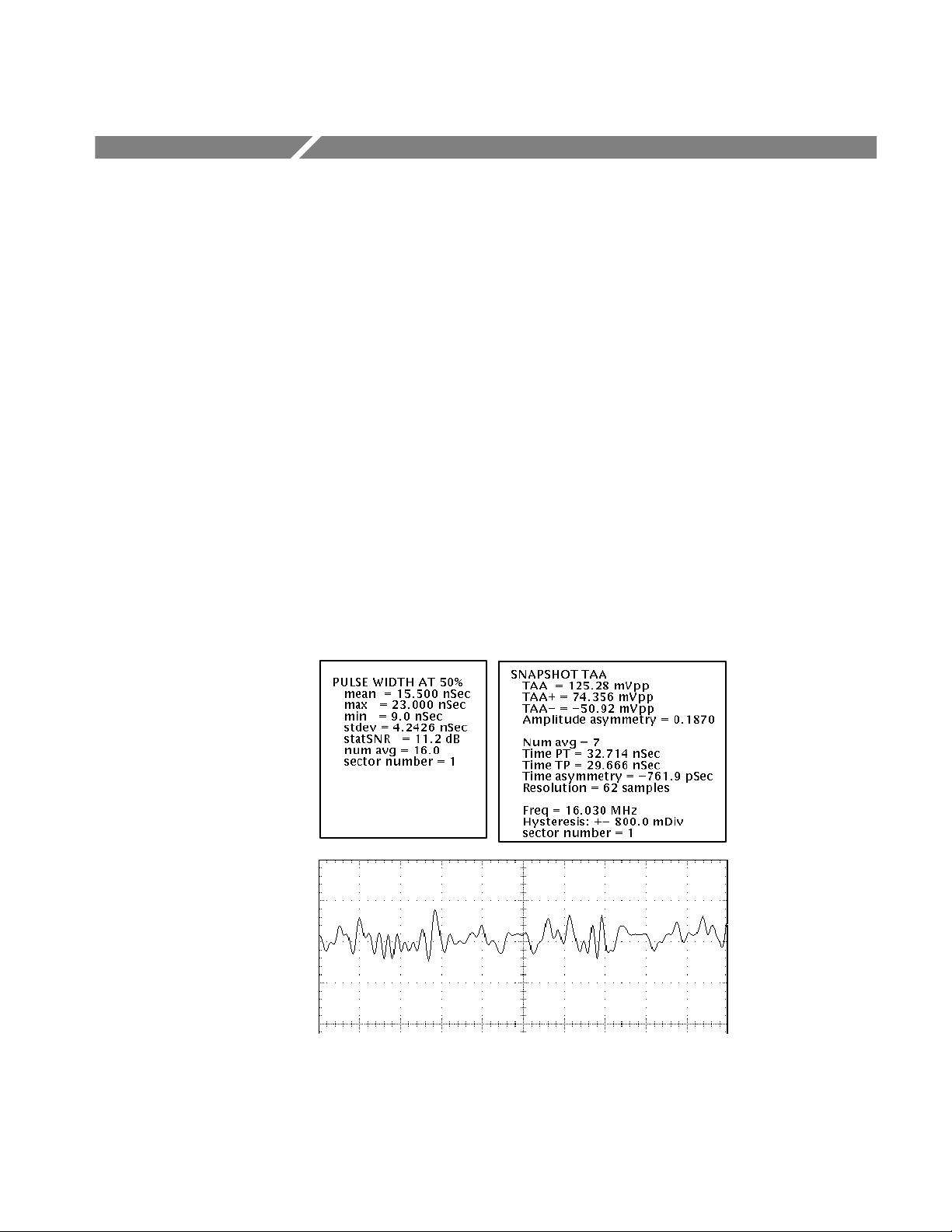

Example 2: Measuring the Pulse Width at 50%

In this example, you will measure the pulse width at 50% (PW50) and use limit

testing to include a pass/fail measurement result. Instead of measuring around

the entire track, you will use cursor gating to localize the measurement. In

addition, you will use the hysteresis feature, to avoid identifying noise as actual

signals.

1. Select the PW50 measurement by pressing Measure (main) ➞ PW50 (side).

2. Select cursor gating by pressing –menu– (main) ➞ Cursor Gating (main) ➞

On/Off (side). Select ON.

3. Place the cursors over the desired segment of the waveform.

2–8

TDSDDM1 Disk Drive Measurement Application User Manual

Page 37

Tutorial

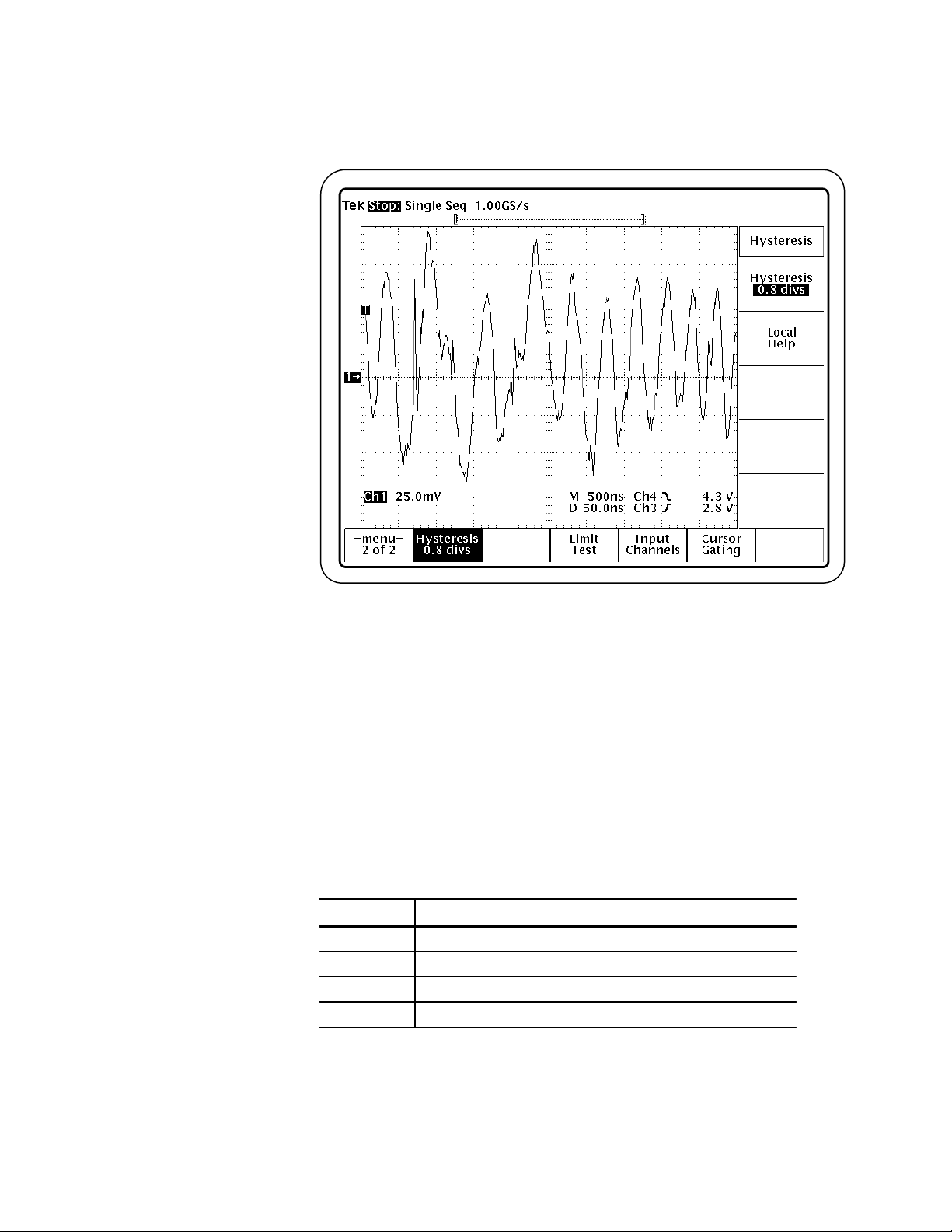

4. Enable hysteresis by pressing Hysteresis (main) ➞ Hysteresis (side). Using

the general purpose knob, set a hysteresis value that is appropriate for your

disk drive signal, such as 1.5 divs.

The hysteresis value, in divisions, is reflected above and below the waveform baseline. For example, if you choose a value of 2.0 divs, the hysteresis

level ranges from –2.0 divs to +2.0 divs.

5. Enable limit testing by pressing Limit Test (main) ➞ On/Off (side). Select

ON.

6. Press Upper Limit (side), and use the general purpose knob to select an

upper limit for this test, such as 100 ms.

7. Press Lower Limit (side), and use the general purpose knob to select a lower

limit for this test, such as 1 ns.

8. Press –menu– (main) ➞ Control (main) ➞ Start (side) to start the test.

9. Wait for the measurement to complete, then view the results as shown in

Figure 2–7.

Figure 2–7: Pulse width at 50% (PW50) measurement with cursor gating

TDSDDM1 Disk Drive Measurement Application User Manual

2–9

Page 38

Tutorial

Example 3: Creating and Viewing Track Profiles

Track profiles are reference memory waveforms that contain a history of

measurement results. You can use track profiles to observe sector-to-sector

variations in measurements and to identify the location of flaws within a track.

In this example, you will take a TAA measurement and view the track profile.

1. Turn the cursor gating feature off by pressing –menu– (main) ➞ Cursor

Gating (main) ➞ On/Off (side). Select OFF. (This feature was set in

Example 2.)

2. Select the track profile feature by pressing Track Profile (main) ➞ On/Off

(side). Select ON.

3. Press Track Profile To (side). Select Ref1.

4. If you did not already specify a range of sectors (in Example 1), do so now.

See step 2 on page 2–7 for information.

5. Select the TAA measurement by pressing Measure (main) ➞ TAA (side).

6. Press Control (main) ➞ Start (side) to start the measurement. The measure-

ment data is displayed. (The data is also stored in the reference memory

Ref1.)

7. Start the measurement by pressing Control (main) ➞ Start (side).Wait for the

results to display.

8. Display the track profile waveform by pressing MORE ➞ Ref1 (main). See

Figure 2–8.

Now you can view the results of each execution of the measurement algorithm

by moving the cursor along the track profile waveform:

9. Return to the Track Profile menu by pressing Track Profile (main).

10. Press CURSOR ➞ Function V Bars (main) ➞ V Bars (side) to display the

vertical bar cursors.

11. Move the cursor to a point of interest on the track profile waveform.

12. Press Value At Cursor (side) or Sector At Cursor (side) to view the measure-

ment results at the current cursor position.

2–10

TDSDDM1 Disk Drive Measurement Application User Manual

Page 39

Tutorial

Figure 2–8: Track profile measurement

Example 4: Saving a Setup and Exiting the Application

You might need to save the oscilloscope setup and the application setup.

To save the oscilloscope setup, refer to the user manual for your oscilloscope.

The procedure varies between models. The setup is always saved in the

APPS/TDSJIT1/TEMP directory on the oscilloscope.

To save the application setup, follow these steps:

1. Press the SHIFT and then the APPLICATION button to return to the

application.

2. Press Utility (main) ➞ Save Setup (side).

3. Press Save to Selected File (side).

4. To exit the application, press Utility (main) ➞ Exit (side). To confirm, press

OK (side).

TDSDDM1 Disk Drive Measurement Application User Manual

2–11

Page 40

Tutorial

Example 5: Recalling a Setup

To return to the tutorial setup, you can recall the saved oscilloscope setup from

the hard disk. You will also need to restart the application.

To recall the oscilloscope setup, refer to the user manual for your oscilloscope.

The procedure varies between models.

To recall the application setup, follow these steps:

1. Start the application as described on page 2–7.

2. Press Utility (main) ➞ Recall Setup (side).

2–12

TDSDDM1 Disk Drive Measurement Application User Manual

Page 41

Reference

Page 42

Page 43

Menu Structure

Menu Summary

This section discusses the menus used in the TDSDDM1 Disk Drive Measurement Application. Included are brief descriptions of the menus and a menu

structure map which shows the relationship between menus.

There are two pages of menu selections in the Disk Drive Measurement

Application. (Press –menu– (main) to access the second page of menus.)

Press –menu– for next

menu page

Figure 3–1: Selecting menus

The following topics briefly summarize the menus.

Measure Menu

TDSDDM1 Disk Drive Measurement Application User Manual

Use the Measure menu to select a disk drive measurement. Measurement

descriptions start on page 3–11.

3–1

Page 44

Menu Structure

Trigger Menu

Track Profile Menu

Control Menu

Utility Menu

Hysteresis Menu

Use the Trigger menu to select the input trigger signal. This menu is important in

specifying setup parameters for the disk drive signals. Using one of the Trigger

menu selections, Sector, you can limit the measurement to a range of sectors. See

Specifying the Trigger on page 1–8 and Measuring Over a Range of Sectors on

page 3–6 for more information.

Use the Track Profile menu if you want to save the measurement data in a track

profile. You can use the track profile to graphically characterize the measurement

data. See Track Profiles on page 3–45 for more information.

Use the Control menu to start and stop measurements. Additional acquisition

control selections are also available, such as pause and acquisition mode control.

See Starting the Measurement on page 2–4 for more information.

Use the Utility menu to save and recall instrument setups. See Saving and

Recalling Setups on page 3–5 for more information.

Use the Hysteresis menu to reduce the effects of noise on measurements. Set

thresholds such that only real peaks and troughs are measured, rather than

measuring noise. See Hysteresis on page 1–9 for more information.

Limit Test Menu

Input Channels Menu

Cursor Gating Menu

Use the Limit Test menu if you want to add a pass/fail result to the measurement.

See Adding Pass/Fail Results to Measurement Data on page 3–9 for more

information.

Use the Input Channels menu if your channel assignment configuration does not

match the default configuration, as described in Configuring Input Channels on

page 1–11.

Use the Cursor Gating menu if you want to localize measurements to a specific

area of the waveform. See Cursor Gating on page 3–7 for more information.

3–2

TDSDDM1 Disk Drive Measurement Application User Manual

Page 45

Menu Structure

The following figure shows the relationship of the application menus.

Menu Structure

Menu 1

Measure

Trigger

TAA

TAA+

TAA–

Snapshot TAA

PW50

PW50+

PW50–

Snapshot PW50

NLTS Initial Mag

NLTS 1st Adjacent

NLTS 2nd Adjacent

NLTS Snapshot

SNR Pattern Duration

Overwrite

Resolution

Asperity

Mode

Start Sector

Stop Sector

Preamble Duration

Pattern Duration

Duration Tolerance

Polynomial Index

Duration Tolerance

Bits per Pattern

Threshold

Reset

Sector

Read Gate

User

Index

Menu 2

Hysteresis Hysteresis

On/Off

Limit Test

Input Channels

Cursor Gating On/Off

Upper LImit

Lower Limit

Read Signal

Read Gate

Sector Pulse

Index Pulse

On/Off

Track Profile To

Track Profile

Control

Utility

Value At Cursor

Sector At Cursor

Reset Profile

Mode

Start

Pause

Continue

Stop

Help

Exit

Save Setup

Recall Setup

Default Setup

Single

Free Run

TDSDDM1 Disk Drive Measurement Application User Manual

3–3

Page 46

Menu Structure

3–4

TDSDDM1 Disk Drive Measurement Application User Manual

Page 47

Setup Parameters

This section describes procedures that change how measurements are taken. For

example, you can localize the area of measurement by specifying a range of

sectors or a segment of the waveform. Additional configuration parameters,

concerned more with hardware and signal setup, are located in the Configuration

section beginning on page 1–7.

Saving and Recalling Setups

To speed up the configuration process, you can save and recall application menu

settings. The save/recall function is controlled from the application Utility menu.

As shown in Figure 3–2, you have the following selections:

H To store the current application settings, press Utility (main) ➞ Save Setup

(side). The settings are stored in the file tdsddm1.ini on the hard disk. Once

you have saved a setup, that setup will be recalled upon starting the Disk

Drive Measurement Application. The tdsddm1.ini file is not updated

automatically; you must use Save Setup to update the file.

NOTE. If you want to save your current configuration, be sure to use the Save

Setup feature to store the current application settings. The settings are not saved

automatically.

You can also manually return to the settings in the file tdsddm1.ini at any

time. To recall the setup, press Utility (main) ➞ Recall Setup (side).

H To recall the factory default menu settings, press Utility (main) ➞ Default

Setup (side).

The Disk Drive Measurement Application Save/Recall function is totally

independent of the primary oscilloscope Save/Recall function, which is stored in

nonvolatile RAM.

TDSDDM1 Disk Drive Measurement Application User Manual

3–5

Page 48

Setup Parameters

Figure 3–2: Save Setup and Recall Setup selections in the Utility menu

Measuring Over a Range of Sectors

To reduce measurement time, or to focus on a specific area of the disk, you can

specify that the measurement take place over a limited range of sectors.

Before starting the measurement, specify the range of sectors to be measured as

follows:

1. Press Trigger (main) ➞ Mode (side). Select Sector. See Figure 3–3.

2. Specify the sector range:

a. Press Start Sector (side).

b. Use the general purpose knob to specify the sector.

c. Repeat for the Stop Sector.

3. If you have not already done so, set the Preamble Duration as described in

step 4 of Setting Up the Application Trigger, on page 1–8.

See also Cursor Gating on page 3–7 for another method of localizing measurements.

3–6

TDSDDM1 Disk Drive Measurement Application User Manual

Page 49

Setup Parameters

NOTE. The Sector Number field displays a ? if the Trigger Mode setting is not

Sector.

Figure 3–3: Selecting the sectors to measure

Cursor Gating

To localize a measurement to a specific area of interest, you can use cursor

gating. With cursor gating, you use the oscilloscope cursors to indicate the area

of interest on the waveform record. See Figure 3–4.

Localizing measurement can speed up processing and eliminate unwanted data

from your analysis.

TDSDDM1 Disk Drive Measurement Application User Manual

3–7

Page 50

Setup Parameters

Figure 3–4: Localizing a measurement using cursor gating

Before starting the measurement, specify the portion of the waveform to be

measured as follows:

1. Press Cursor Gating (main) ➞ On/Off (side). Select ON. See Figure 3–4.

When cursor gating is On, the cursors are turned on and the read channel is

selected.

2. Place the cursors at the beginning and end of the waveform segment of

interest.

When you perform the measurement, only the data between the cursors will be

measured.

When cursor gating is Off, the application measures the full record length.

NOTE. The cursor gating function in this menu applies to the measurements in

the Disk Drive Measurement Application only. It does not apply to measurements in the main Measure menu of the oscilloscope.

3–8

TDSDDM1 Disk Drive Measurement Application User Manual

Page 51

Localizing Measurements: an Alternate Method

There is another way to control the amount of data to measure without using

gated cursors or specifying a range of sectors. You can do this by adjusting the

Preamble Duration in the application Sector menu and the Record Length or

Horizontal Scale in the oscilloscope horizontal menu. By specifying both the

starting point and the total length of the measurement in this way, you can

effectively size the area of interest.

Adding Pass/Fail Results to Measurement Data

You can add a pass/fail test result to the measurement data, based on whether the

data falls within specified limits. See Figure 3–5 for an example.

Setup Parameters

Figure 3–5: Limit Test results

Use the Limit Test menu to set upper and lower limits to be used by the

measurements. See Figure 3–6.

To include Limit Test results, do the following:

1. Select a measurement from the Measure menu (main).

2. Press –menu– (main) ➞ Limit Test (main) ➞ On/Off (side). Select ON. See

Figure 3–6.

3. Set the upper and lower limits for the measurement.

4. Repeat steps 1 and 3 for each measurement.

TDSDDM1 Disk Drive Measurement Application User Manual

3–9

Page 52

Setup Parameters

Figure 3–6: Setting pass/fail limits

3–10

TDSDDM1 Disk Drive Measurement Application User Manual

Page 53

Measurement Descriptions

The following pages describe the measurements you can make with the Disk

Drive Measurement Application package. The descriptions include information

about how to take the measurement and information about the algorithm used to

perform the measurement operation.

Unless specifically stated otherwise, all measurements in the Disk Drive

Measurement Application are conducted in accordance with procedures specified

in the International Disk Drive Equipment and Materials Association (IDEMA)

Disk Drive Standard.

Measurement Features

There are two main groups of measurement types: standard measurements and

snapshot measurements. In addition, you can use track profiles to provide a

history of the track measurements. See Figure 3–7. Standard measurements

provide data associated with a specific measurement. Snapshots list measurement

data for that measurement group. Track profiles collect all the data for each

individual track and display the data graphically.

Figure 3–7: Standard measurement, snapshot measurement, and track profile

TDSDDM1 Disk Drive Measurement Application User Manual

3–11

Page 54

Measurement Descriptions

Warning Messages

Measurements do not continuously update unless you select Free Run mode in

the Control menu before starting the measurement. To take another measurement, press Start (side) again.

Standard measurements (not snapshots) provide a warning if the input conditions

do not support accurate measurements. The application warns you if the number

of samples in the measurement is less than 25. Similarly, the application warns

you of low vertical resolution if the number of digitizing levels is below 50.

3–12

TDSDDM1 Disk Drive Measurement Application User Manual

Page 55

Track Average Amplitude, TAA

The track average amplitude, TAA, is the average peak-to-peak value of the data

on the Read channel signal over the specified range of sectors. IDEMA specifies

the duration to be over one complete track revolution.

Measurement Descriptions

Figure 3–8: Track average amplitude measurement

Definition

TDSDDM1 Disk Drive Measurement Application User Manual

The track average amplitude measurement, TAA, is defined as follows:

N–1

TAA +

Where: N is the number of positive and negative pulse pairs

1

N

i + 0

V

(i)

S

V

pp

is the peak-to-peak voltage

pp

3–13

Page 56

Measurement Descriptions

Procedure

Test Methodology

From the Disk Drive Measurement Application display, follow these steps:

1. Select the TAA measurement by pressing Measure (main) ➞ TAA (side).

2. If you want to change trigger settings or localize the measurement, do so

now. The application defaults to the settings specified in the Trigger menu.

For further information, see Setting Up the Application Trigger on page 1–8,

Measuring Over a Range of Sectors on page 3–6, and Cursor Gating on

page 3–7.

3. Press Control (main) ➞ Start (side) to start the measurement.

4. Wait for the measurement to complete, then view the results as shown in

Figure 3–8.

The application performs the measurement according to the following algorithm:

1. Find all of the peak-to-trough pairs in the data area to be measured.

Find the peak by searching from the first crossing of the signal above the

positive hysteresis level to the crossing of the signal below the negative

hysteresis level. (See Figure 3–9.) Keep the maximum value over this range.

Take one sample on either side of the maximum value and average the three

values to obtain the positive peak value. This is done to remove noise bias

which would otherwise occur.

2. Search the range from the negative hysteresis crossing to the next positive

hysteresis crossing; keep the minimum value. Take one sample on either side

of the minimum value and average the three values to obtain the negative

peak value.

3. Average all measured peak-to-peak values. The result is the TAA value.

3–14

TDSDDM1 Disk Drive Measurement Application User Manual

Page 57

Peak

TAA

Figure 3–9: TAA measurement

Measurement Descriptions

Trough

TDSDDM1 Disk Drive Measurement Application User Manual

3–15

Page 58

Measurement Descriptions

Track Average Amplitude (Plus), TAA+

Track Average Amplitude (Minus), TAA–

The track average amplitude (plus), TAA+, is the average positive peak value of

the data on the read channel signal over the specified range of sectors. IDEMA

specifies the duration to be over one complete track revolution.

The track average amplitude (minus), TAA–, is the average negative peak value

of the data on the read channel signal over the specified range of sectors. IDEMA

specifies the duration to be over one complete track revolution.

3–16

Definition

Figure 3–10: TAA– measurement

The track average amplitude positive or negative measurement is defined as

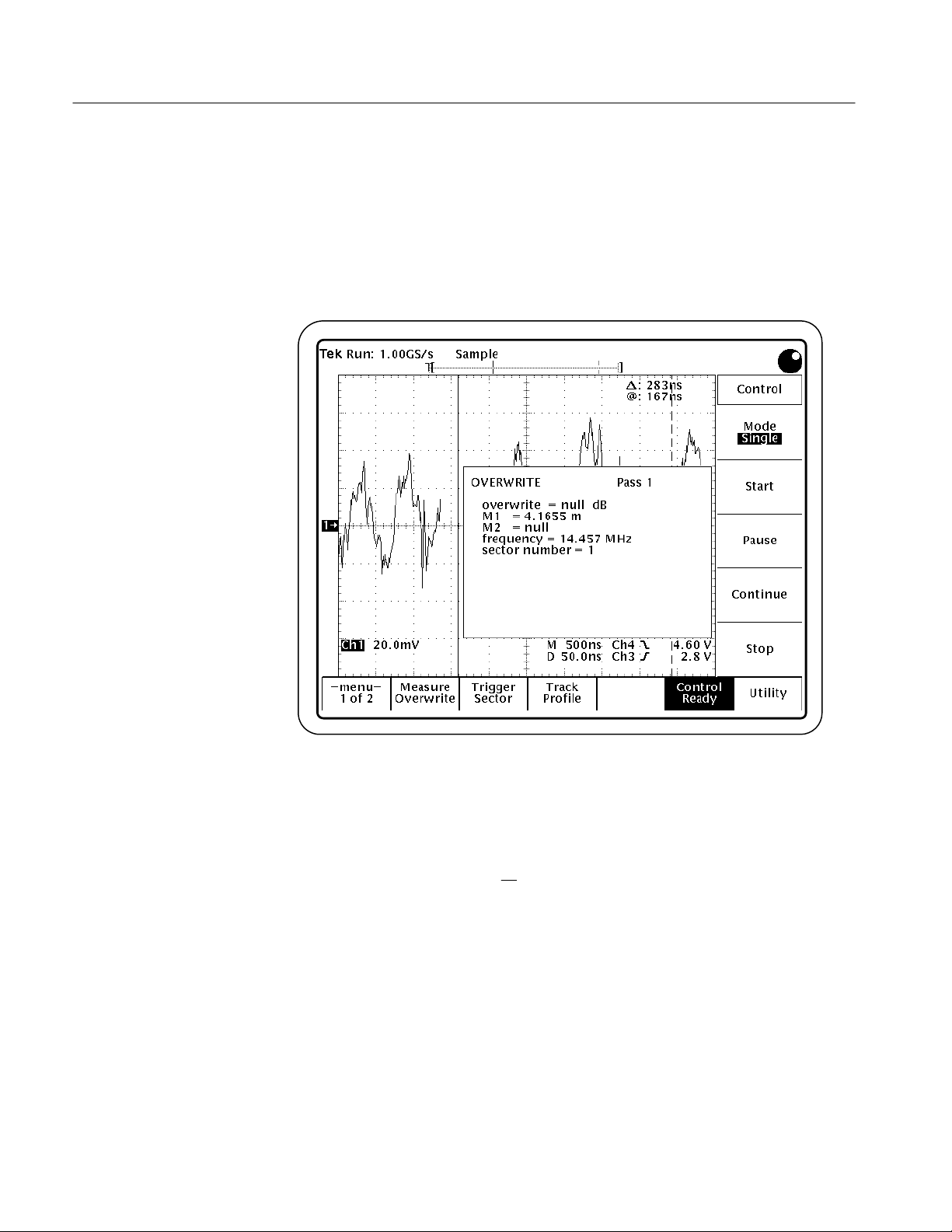

follows:

N–1

TAA "+

1

N

S

i + 0

TDSDDM1 Disk Drive Measurement Application User Manual

(i)

V

p

Page 59

Measurement Descriptions

Where: N is the number of positive or negative pulses

is the peak (positive or negative) voltage

V

p

The application measures enough peak/trough pairs to provide a good statistical

average.

Procedure

Test Methodology

From the Disk Drive Measurement Application menu, follow these steps:

1. Select the TAA+ or TAA– measurement by pressing Measure (main) ➞

TAA+ (side) or TAA– (side).

2. If you want to change trigger settings or localize the measurement, do so

now. The application defaults to the settings specified in the Trigger menu.

For further information, see Setting Up the Application Trigger on page 1–8,

Measuring Over a Range of Sectors on page 3–6, and Cursor Gating on

page 3–7.

3. Press Control (main) ➞ Start (side) to start the measurement.

4. Wait for the measurement to complete, then view the results.

The application performs the measurement according to the same algorithm used

in the TAA measurement, described on page 3–13, with the exception that only

positive pulses are measured for TAA+ and only negative pulses are measured

for TAA–.

Peak

TAA+

TAA

OV

TAA–

Figure 3–11: TAA+ and T AA– measurements

TDSDDM1 Disk Drive Measurement Application User Manual

Trough

3–17

Page 60

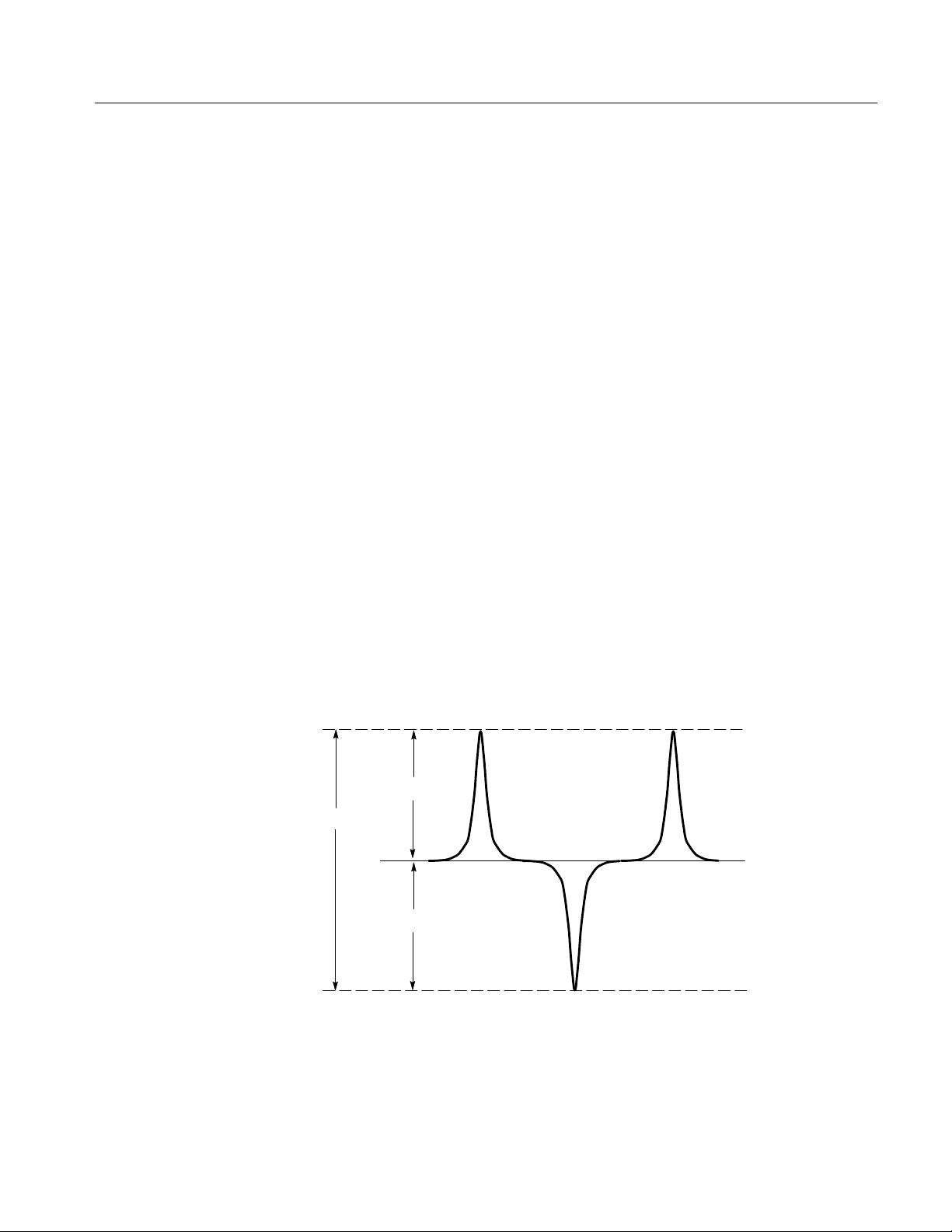

Measurement Descriptions

Pulse Width at 50%, PW50

The pulse width at 50% measurement, PW50, is the average pulse width at 50%

of the pulse peak of a group of both positive and negative pulses.

3–18

Definition

Procedure

Figure 3–12: PW50 measurement

PW50 is defined as the pulse width at 50% of the peak value of the pulse. Both

peaks and troughs are measured. The baseline reference for measuring the peak

or trough is zero volts.

From the Disk Drive Measurement Application display, follow these steps:

1. Select the PW50 measurement by pressing Measure (main) ➞ PW50 (side).

(If necessary, press –more– (side) until the PW50 measurement is shown.)

2. If you want to change trigger settings or localize the measurement, do so

now. The application defaults to the settings specified in the Trigger menu.

For further information, see Setting Up the Application Trigger on page 1–8,

Measuring Over a Range of Sectors on page 3–6, and Cursor Gating on

page 3–7.

3. Press Control (main) ➞ Start (side) to start the measurement.

TDSDDM1 Disk Drive Measurement Application User Manual

Page 61

Measurement Descriptions

4. Wait for the measurement to complete, then view the results as shown in

Figure 3–12.

Test Methodology

The application performs the measurement according to the following algorithm:

1. Set the disk drive to the specified speed.

2. Position the head to the desired gap, radius, and skew angle.

3. Precondition the media service. (See the IDEMA standard, document T3-91,

for information about preconditioning the media service.)

4. Write the specified frequency at the specified current for one revolution of

the disk.

5. Measure the peak-to-peak analog amplitude of the Read signal for one entire

revolution, excluding all non-uniform segments, such as write splices, servo

gaps, and header fields.

The hysteresis setting is used when looking for peaks.

6. Compute the track average amplitude around the entire track by summing up

the peak-to-peak voltages of each plus and minus pulse pair. Divide the

result by the number of pulse pairs.

7. Perform the measurement by acquiring one segment at a time, measuring it,

and combining all the results for the final value. To speed up the measurement process the user can specify a smaller region of each track segment to

measure by using the cursors or by decreasing the record length.

This measurement requires the user to specify the number of segments on the

track to be tested.

8. Use a value of 1/2 of the TAA value as the threshold level at which to

measure the pulse width of each positive and negative pulse. Compute the

average pulse width around the track for all pulses measured.

9. Display the measurement result. (The display also reads out the standard

deviation of the measurement for all pairs used.)

The pulse width at 50% measurement, PW50, is the average width of a group of

positive and negative pulses. The pulses making up the tested group are selected

by the following criteria:

H There must be enough pulses around the recording track to provide an

adequate statistical sample.

H The spacing between pulses must minimize any interaction between the

measured pulses.

TDSDDM1 Disk Drive Measurement Application User Manual

3–19

Page 62

Measurement Descriptions

Peak

PW50+

1/2 peak to baseline

Baseline

PW50 –

Trough

Figure 3–13: Parameters for PW50 disk drive measurements

0 V

3–20

TDSDDM1 Disk Drive Measurement Application User Manual

Page 63

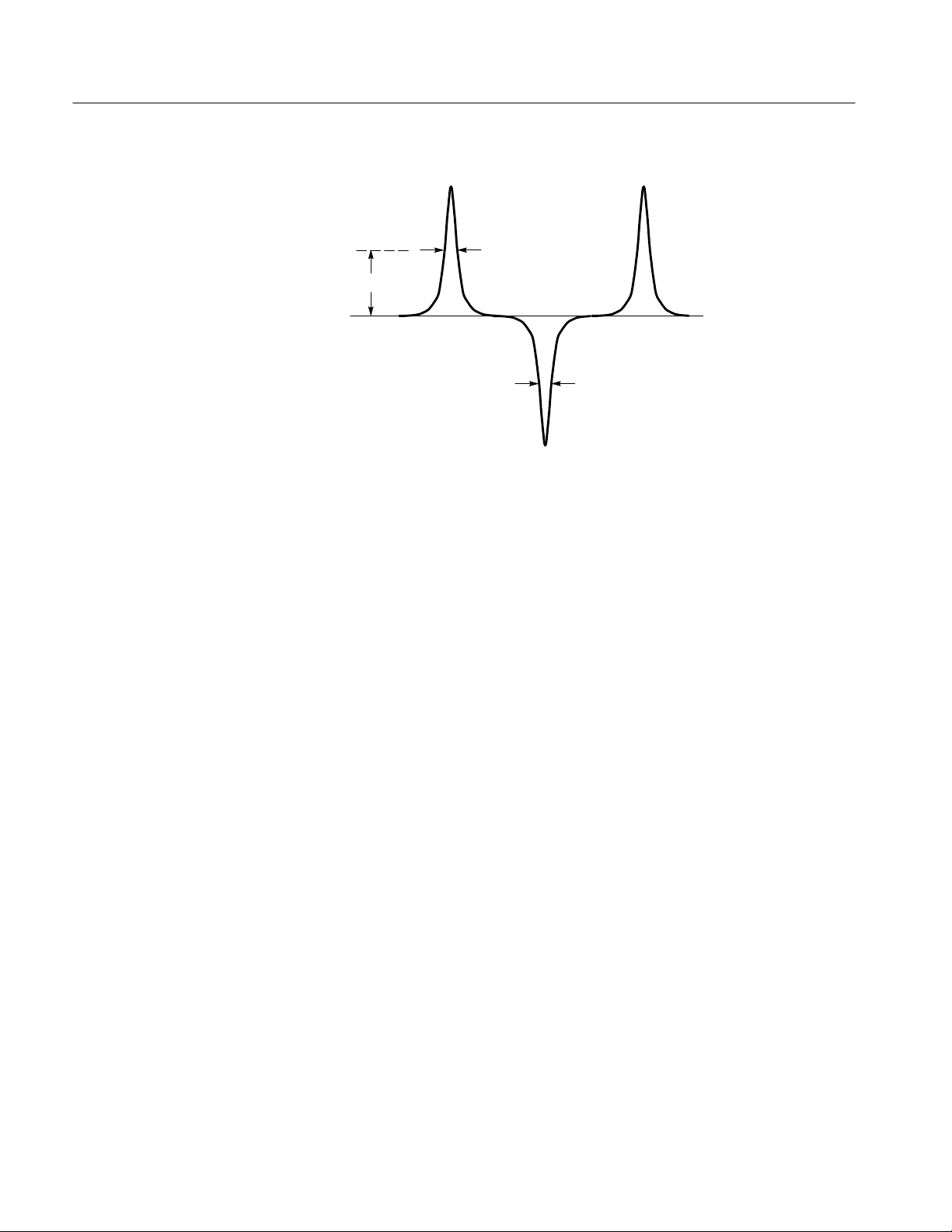

50% Pulse Width (Positive), PW50+

50% Pulse Width (Negative), PW50–

The PW50+ measurement is the average pulse width around a track. It is the

width of the pulse at 50% of TAA+. Only positive pulses are measured.

The PW50– measurement is the average pulse width around a track. It is the

width of the pulse at 50% of TAA–. Only negative pulses are measured.

Measurement Descriptions

Figure 3–14: PW50+ measurement

Definition

Test Methodology

TDSDDM1 Disk Drive Measurement Application User Manual

PW50+ is defined as the pulse width at 50% of the peak value of the pulse. Only

peaks are measured. The baseline reference for measuring the peak is zero volts.

PW50– is defined as the pulse width at 50% of the trough value of the pulse.

Only troughs are measured. The baseline reference for measuring the trough is

zero volts.

The application performs the measurement according to the same algorithm used

in the PW50 measurement, described on page 3–18, with the exception that only

positive pulses are measured for PW50+ and only negative pulses are measured

for PW50–.

3–21

Page 64

Measurement Descriptions

Peak

PW50+

1/2 peak to baseline

Baseline

PW50 –

Trough

0 V

Figure 3–15: Parameters for PW50+ and PW50– disk drive measurements

3–22

TDSDDM1 Disk Drive Measurement Application User Manual

Page 65

Nonlinear T ransition Shift, NLTS

The nonlinear transition shift measurement, NLTS, measures three types of

nonlinear transition shift on the media:

H Initial magnetization (DC erased)

H First adjacent transition

H Second adjacent transition

The initial magnetization of the media can affect the position at which transitions

(reverses in magnetization) are recorded. Initial magnetization is characterized by

a delay in a transition, occurring when the new transition reverses the direction

of the previous magnetization.

The second transition in a series of consecutive transitions is called the adjacent

transition, or first adjacent transition. The first adjacent transition is characterized

as follows: when write data requires transitions on consecutive data bits, the

latter transition is shifted earlier in time. In other words, when one transition in a

series occurs, then the following transition occurs earlier than it should.

Measurement Descriptions

All subsequent transitions in the series of consecutive transitions are grouped

into the category called second adjacent transition. Second adjacent transitions

are similar to first adjacent transitions. The difference is that the transitions are

separated by two bit periods, not one.

When nonlinear transition shift can be characterized, its behavior can be

mitigated with write pre-compensation.

TDSDDM1 Disk Drive Measurement Application User Manual

3–23

Page 66

Measurement Descriptions

Definition

Figure 3–16: NLTS measurement

There is no NLTS specification in the IDEMA standard. The NLTS measurement

is based on a time domain cross-correlation method detailed in the IDEMA Test

and Measurement Committee PRML Working Group Working Paper Nonlinear

Distortion Measurement Techniques, September 1995.

NL TS Initial Magnetization. The NLTS initial magnetization measurement assumes

the following sequence:

1. The medium is initially magnetized in one direction (DC-erased)

2. Transitions that are written by a head field in the opposite direction are

e

shifted later by an amount

.

0

The NLTS initial magnetization measurement assumes the following:

V~(t) [ Vǒt–

Where: V

1

e

2

~

(t) is the playback voltage for a readback channel affected by

e

1

0

Ǔ

–

0

2

T

Vǒt–

1

2

e0)

ǒ

M0–

1

Ǔ

Ǔ

T

2

NLTS initial magnetization

3–24

V(t) is the playback voltage in the absence of nonlinear effects

TDSDDM1 Disk Drive Measurement Application User Manual

Page 67

Measurement Descriptions

T is the bit period

e

is the amount of shift

0

is an integer, whose unique value is determined by the

M

0

polynomial used to generate the recorded pseudo-noise bit

sequence

e

The measurement reports the nonlinear effect as a percentage of T; that is,

0

T

NL TS First Adjacent Transition. The NLTS first adjacent transition is the condition

where the location of a transition is shifted earlier by an amount

e

due to

1

another transition one bit interval earlier.

The NLTS first adjacent transition measurement assumes the following:

V~(t) [ Vǒt )

Where: V

1

e

2

~

(t) is the playback voltage for a readback channel affected by

e

1

1

Ǔ

)

2

Vǒt )

T

1

3

1

e

–

TǓ–

1

2

2

1

2

e

1

Vǒt )

T

1

2

e1)

ǒ

M1–

1

Ǔ

Ǔ

T

2

NLTS first adjacent transition

V(t) is the playback voltage in the absence of nonlinear effects

T is the bit period

e

is the amount of shift

1

is an integer, whose unique value is determined by the

M

1

polynomial used to generate the recorded pseudo-noise bit

sequence

e

The measurement reports the nonlinear effect as a percentage of T; that is,

1

T

NL TS Second Adjacent Transition. The NLTS second adjacent transition is similar

to the NLTS first adjacent transition, with the exception that there are two bit

intervals between the transitions. The amount of shift in this case is

e

. The

2

direction of the shift is determined by the direction of the transitions (earlier if

the transitions are opposite, and later if the transitions are in the same direction).

The NLTS second adjacent transition measurement assumes the following:

V~(t) [ V(t) –

1

2

e

2

T

Vǒt–

3

T

2

Where: V

e

1

)

2

2

T

Ǔ

5

Vǒt–

T

2

~

(t) is the playback voltage for a readback channel affected by

e

1

2

Ǔ

)

2

T

NLTS second adjacent transition

TDSDDM1 Disk Drive Measurement Application User Manual

Vǒt )ǒM1–

1

2

Ǔ

TǓ–

e

1

2

Vǒt )ǒM2–

2

T

1

Ǔ

Ǔ

T

2

3–25

Page 68

Measurement Descriptions

V(t) is the playback voltage in the absence of nonlinear effects

T is the bit period

e

is the amount of shift

2

and M2 are integers, whose unique values are determined by

M

1

the polynomial used to generate the recorded pseudo-noise bit

sequence

The measurement reports the nonlinear effect as a percentage of T; that is,

e

2

T

Procedure

For this measurement you must specify the polynomial used to generate a

pseudo-random data pattern which is written to the disk. You are also responsible

for specifying the cycle repeat time of the data pattern within a known tolerance.

From the Disk Drive Measurement Application display, follow these steps:

1. Access the NLTS measurements by pressing Measure (main). (If necessary,

press –more– (side) until the NLTS measurement is shown.)

2. Select one of the NLTS measurements in the side menu. See Figure 3–17.

3–26

Figure 3–17: Selecting an NL TS measurement

TDSDDM1 Disk Drive Measurement Application User Manual

Page 69

Measurement Descriptions

3. Press Pattern Duration (side). Specify a value.

The pattern duration is the length of time of a pseudo-random data pattern

period in the readback signal. The pattern duration can be an estimate, as

long as the estimate is within the tolerance that you specify in step 4; the

application will determine the exact duration of the pattern. (Due to

variations in revolution speed between disk drives, specifying the pattern

duration is necessarily an estimate.)

4. Press Duration Tolerance (side). Specify the tolerance of your pattern

duration estimate (up to 30%). Using a tighter tolerance reduces measurement time.

NOTE. If you know the exact duration of the data pattern, you can reduce the

measurement time to a minimum by specifying a Duration Tolerance of 0%. The

application will use the Pattern Duration that you specify without attempting to

adjust to the actual duration of the data pattern.

5. Press Polynomial Index (side). Use the general purpose knob to specify the

pseudo-random binary sequence polynomial. This should be the same

polynomial used to generate the data pattern written to the media. See

Figure 3–18.

The NLTS measurement is based on autocorrelation and uses a polynomial

to generate a pseudo-noise sequence. Selecting the polynomial using the

general purpose knob is a simple procedure; all selections provide a valid

pseudo-noise sequence. (The application removes invalid polynomials from

the selection set.) The polynomial index value on the scale is a condensed

notation of the selected polynomial, obtainable by making x=2.

TDSDDM1 Disk Drive Measurement Application User Manual

3–27

Page 70

Measurement Descriptions

NLTS polynomial

Figure 3–18: Specifying the NL TS polynomial

6. If you want to change trigger settings or localize the measurement, do so

now. The application defaults to the settings specified in the Trigger menu.

For further information, see Setting Up the Application Trigger on page 1–8,

Measuring Over a Range of Sectors on page 3–6, and Cursor Gating on

page 3–7.

7. Press Control (main) ➞ Start (side) to start the measurement.

8. Wait for the measurement results to display.

3–28

TDSDDM1 Disk Drive Measurement Application User Manual

Page 71

Measurement Descriptions

Measurement

Requirements

Test Methodology

The NLTS measurement has the following requirements:

H The waveform under test must have at least 1000 samples.

H There must be at least eight samples per bit.

H The oscilloscope must capture at least three periods of the pattern. This

depends on the waveform length, the oscilloscope sample rate specified, the

pattern duration specified, and the number of bits per period. The number of

bits per period for a pseudo-noise sequence depends on the polynomial used.

The NLTS measurement algorithm assumes that the acquired signal consists of a

periodic signal and independent additive noise. The noise is assumed to be

responsible for all the nonperiodic behavior of the acquired waveform.

The NLTS measurement is based on a time domain cross-correlation method, as

detailed in the IDEMA Test and Measurement Committee PRML Working

Group Working Paper Nonlinear Distortion Measurement Techniques, Septem-

ber 1995.

The application performs the measurement according to the following algorithm:

1. Acquire three or more cycles of the waveform.

2. The user specifies the polynomial used to generate the waveform, the

approximate duration of one period of the periodic signal captured in the

waveform, and the tolerance of the approximation.

NOTE. The specified polynomial must generate a pseudo-noise (maximum length)

sequence, or the measurement will not proceed.

3. (This step is not performed if the user specifies a Duration Tolerance of 0%.)

Compute the actual cycle time and delay values. NLTS guarantees that the

real cycle time is determined by the measurement if the initial user estimate

for the cycle time is within the specified tolerance (up to 30%) of its real

value.

The NLTS measurement uses several cycles of the waveform to improve the

accuracy of the measurement, averaging over multiple single-waveformcycle NLTS values.

NLTS values for the auto-correlation method are linearly related to the

autocorrelation of the acquired waveform at different time delays.