Page 1

xx

TCPA300/400 Amplifiers &

ZZZ

TCP300A/400 Series AC/DC Current Probes

User Manual

*P077118301*

077-1183-01

Page 2

Page 3

xx

TCPA300/400 Amplifiers &

ZZZ

TCP300A/400 Series AC/DC Current Probes

User Manual

This document applies for firmware version 1.0 and above.

www.tektronix.com

077-1183-01

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty p rovisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Additional trademark statements can be added here.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O . B ox 5 0 0

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worl d wid e, v i si t www.tektronix.com to find contacts in your area.

Page 5

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty

work may be n

the property of Tektronix.

ew or reconditioned to like new performance. All replaced parts, modules and products become

In order to o

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, with shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused b y improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

result

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

TEK

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ing from attempts by personnel other than Tektronix representatives to install, repair or service the product;

Page 6

Page 7

Table of Contents

General safety summary ...... .................................. ................................ ................... v

Compliance Information......................................................................................... vii

EMC Compliance (Applies to TCPA300 & TCPA400 Amplifiers Only) .... ......................... vii

Safety Compliance Information....................... ................................ ..................... viii

Environmental Considerations .......... ................................ ................................ ..... x

Preface .............................................................................................................. xi

Manual Conventions............................................ ................................ .............. xi

Getting Started .. .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. 1

System Configuration ......................................................................................... 1

Options.......................................................................................................... 3

Standard Accessories.......................................................................................... 4

Optional Accessories .......................................................................................... 4

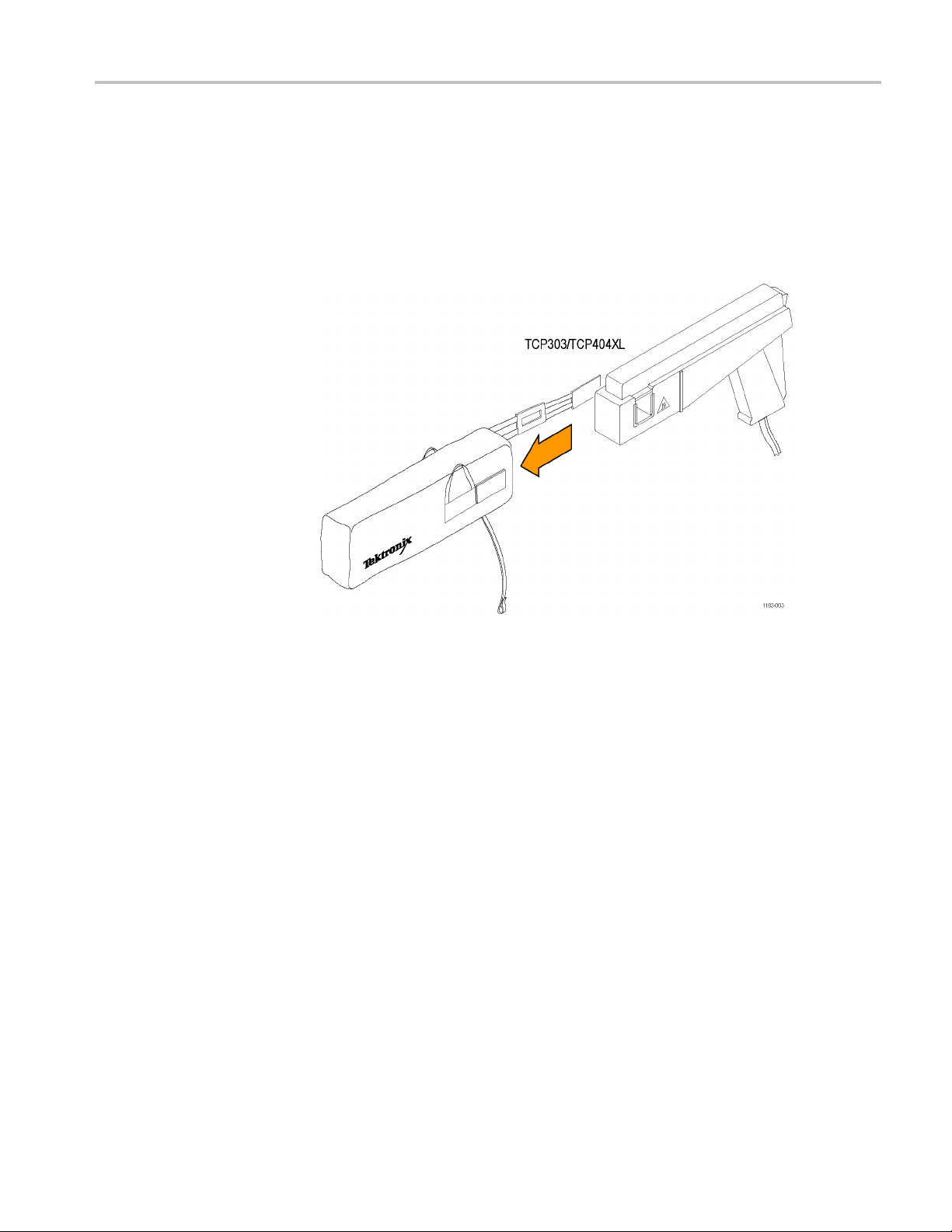

Probe Cover ..... ................................ ................................ ............................... 5

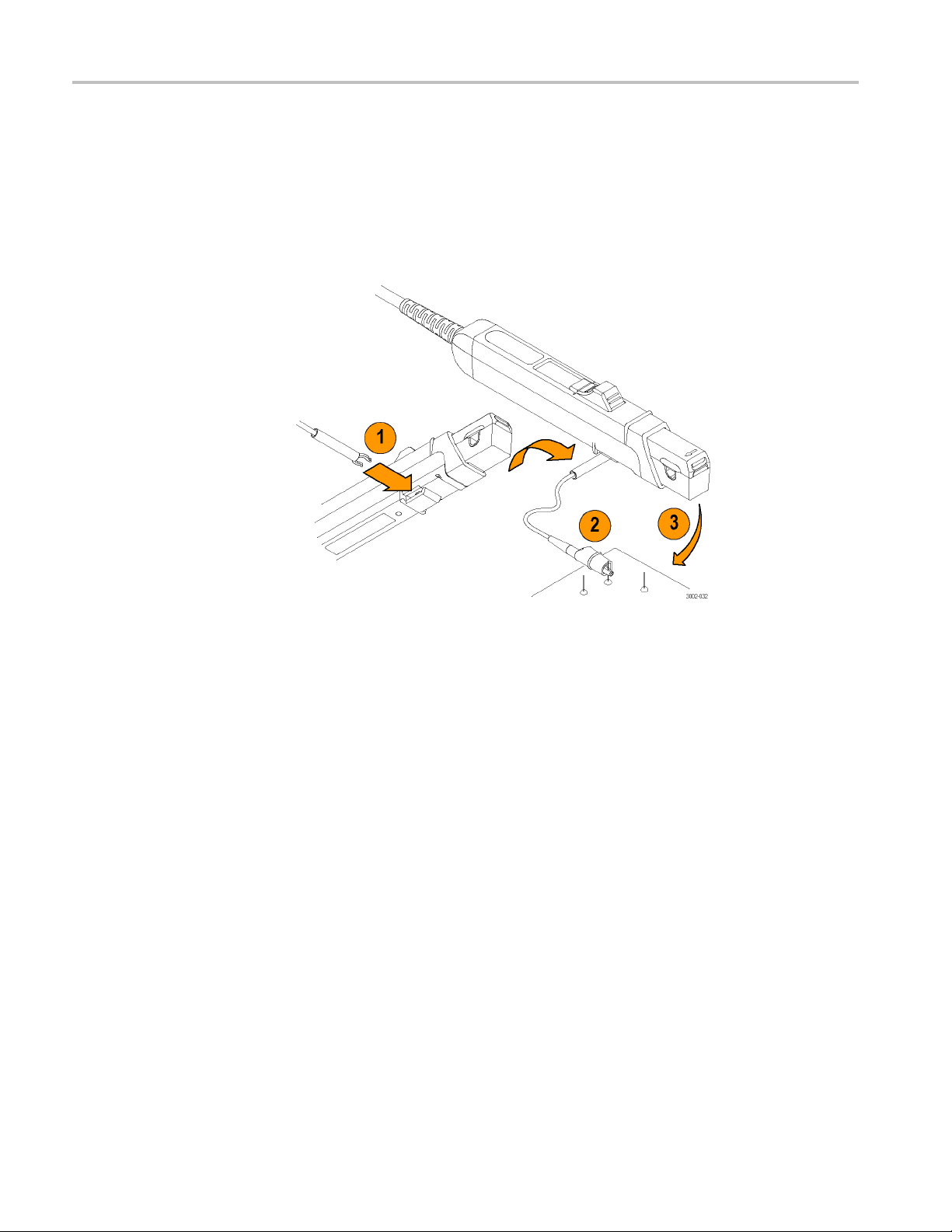

Ground Lead ...................... .................................. ................................ ........... 6

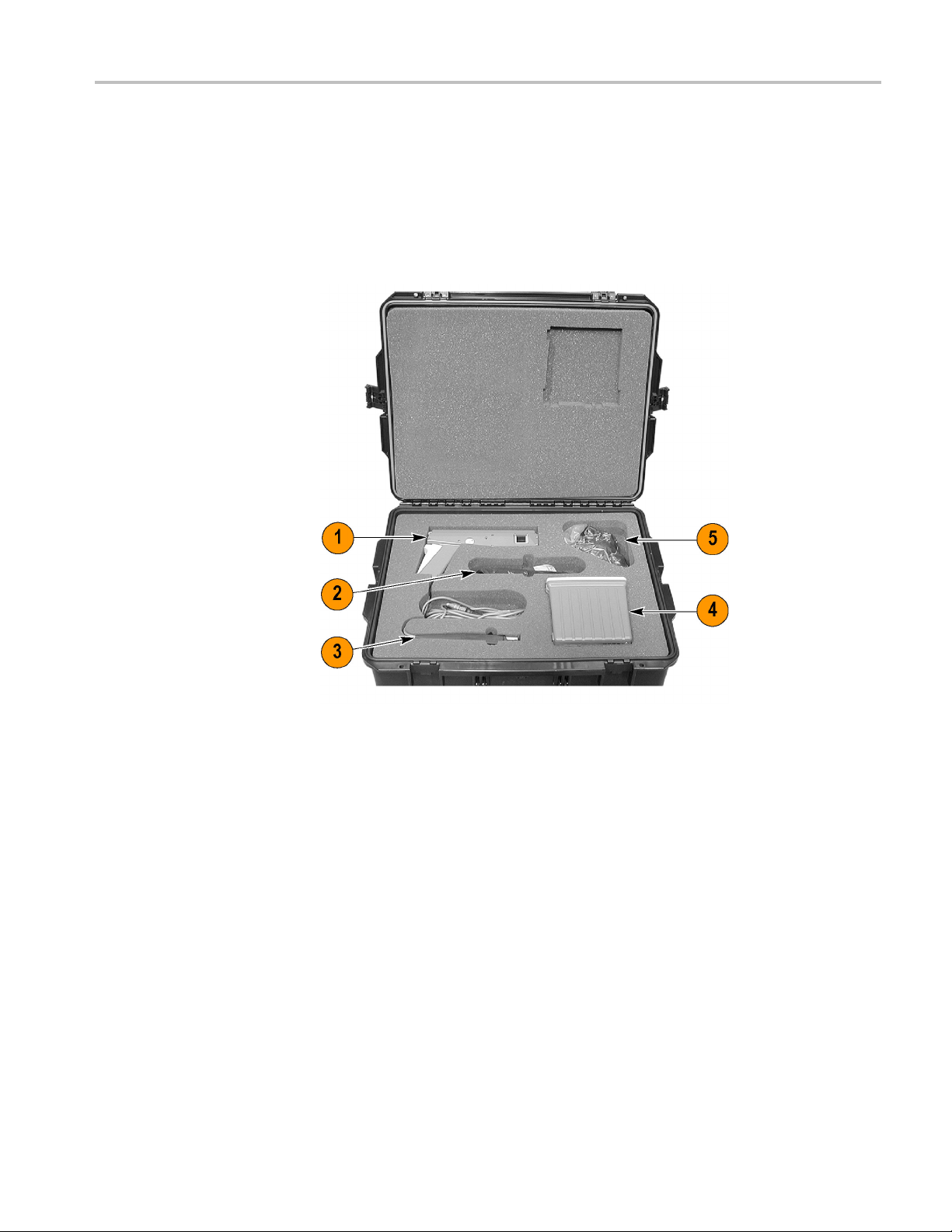

Travel Case .......................... ................................ ................................ ........... 7

Connecting the Amplifier to an Oscilloscope.. . .. .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. . .. .. .. .. . .. .. . .. .. .. .. . .. .. 8

Power on the Amplifier ............ ................................ .................................. ......... 8

nnecting a Current Probe to the Amplifier...................... .................................. ....... 9

Co

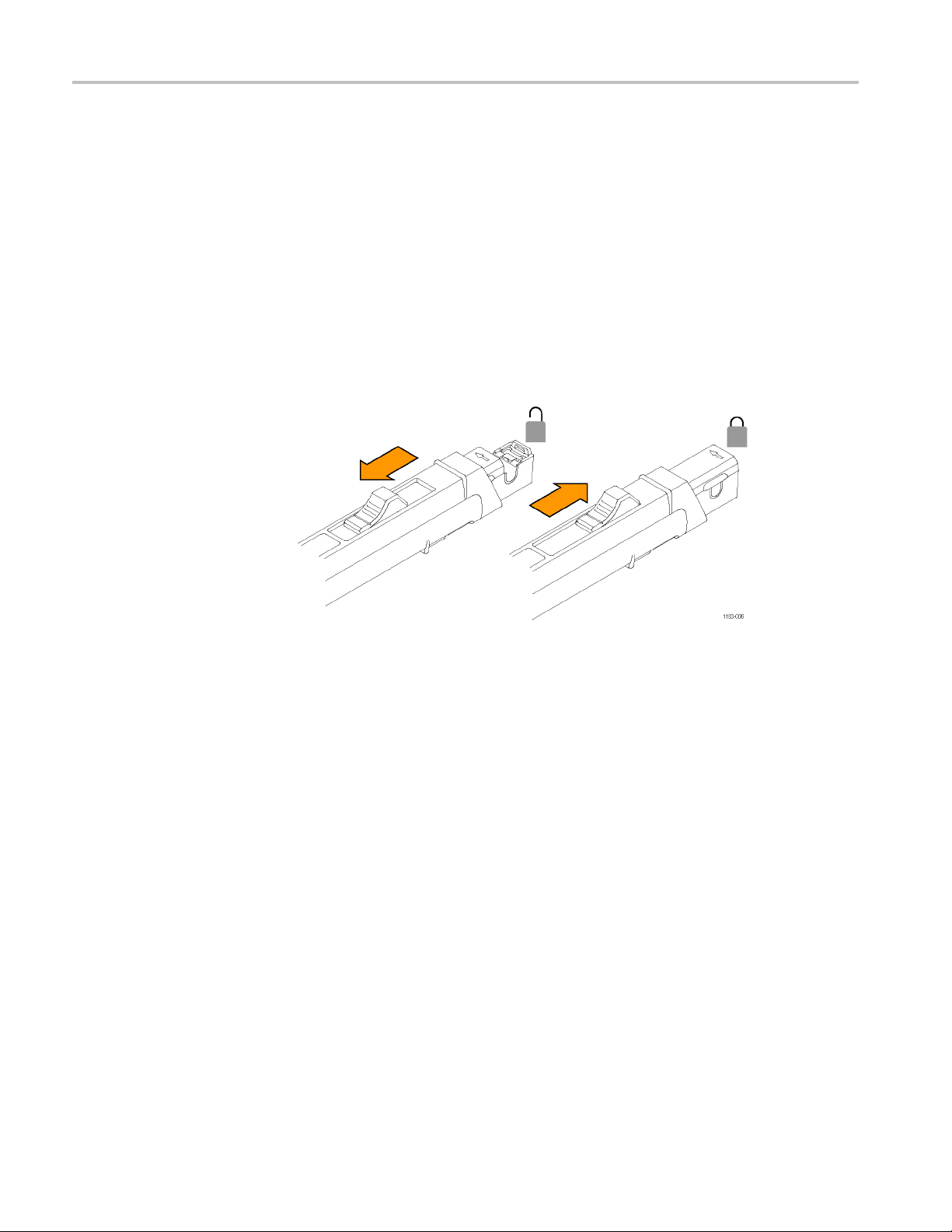

Operating the Current Probe Slide.......................................................................... 10

Degaussing and Autobalancing the Current Probe........................................................ 12

DC Measurements ............................................................................................ 13

AC Measurements ............................................................................................ 15

Control Summary...................... .................................. ................................ .......... 17

TCPA300 and TCPA400 Controls .......................................................................... 18

Reference Notes ................................................................................................... 23

Degaussing a Probe with an Unpowered Conductor in the Jaws ........................................ 23

Measuring Differential Current ............................................................................. 24

AC and DC Coupling......................... .................................. .............................. 26

Maximum Current Limits.............. .................................. ................................ .... 27

Measuring Noncontinuous Current with the TCP404XL Probe......................................... 30

Extending Current Range.................................................................................... 32

Increasing Sensitivity. .. .. .. . .. .. .. . .. .. .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. .. .. . .. .. .. . .. .. .. . .. .. .. . 34

Application Notes ................................................................................................. 35

Automobile Charging Systems .............................................................................. 35

Inductance Measurements . ................................ .................................. ................ 37

Continuity Test of Multiple-Conductor Cable .. . .. .. .. . .. .. .. . .. .. .. . .. .. .. . .. .. .. .. . .. .. .. . .. .. .. . .. .. .. . 39

Measuring Inductor Turns Count . ................................ .................................. ........ 40

Power Measurement and Analysis Software......................... .................................. .... 41

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual i

Page 8

Table of Contents

Troubleshooti

Displaying Error Codes with the Probe Degauss Autobalance Button ........... ...................... 45

Correcting the Cause of an Error Code........... ................................ .......................... 47

Shutdown Error . ................................ ................................ .............................. 47

Specifications .......... ................................ ................................ ............................ 49

Warranted Specifications..................................................................................... 49

Nominal and

Mechanical Characteristics .................................................................................. 51

Environmental Characteristics .............................................................................. 53

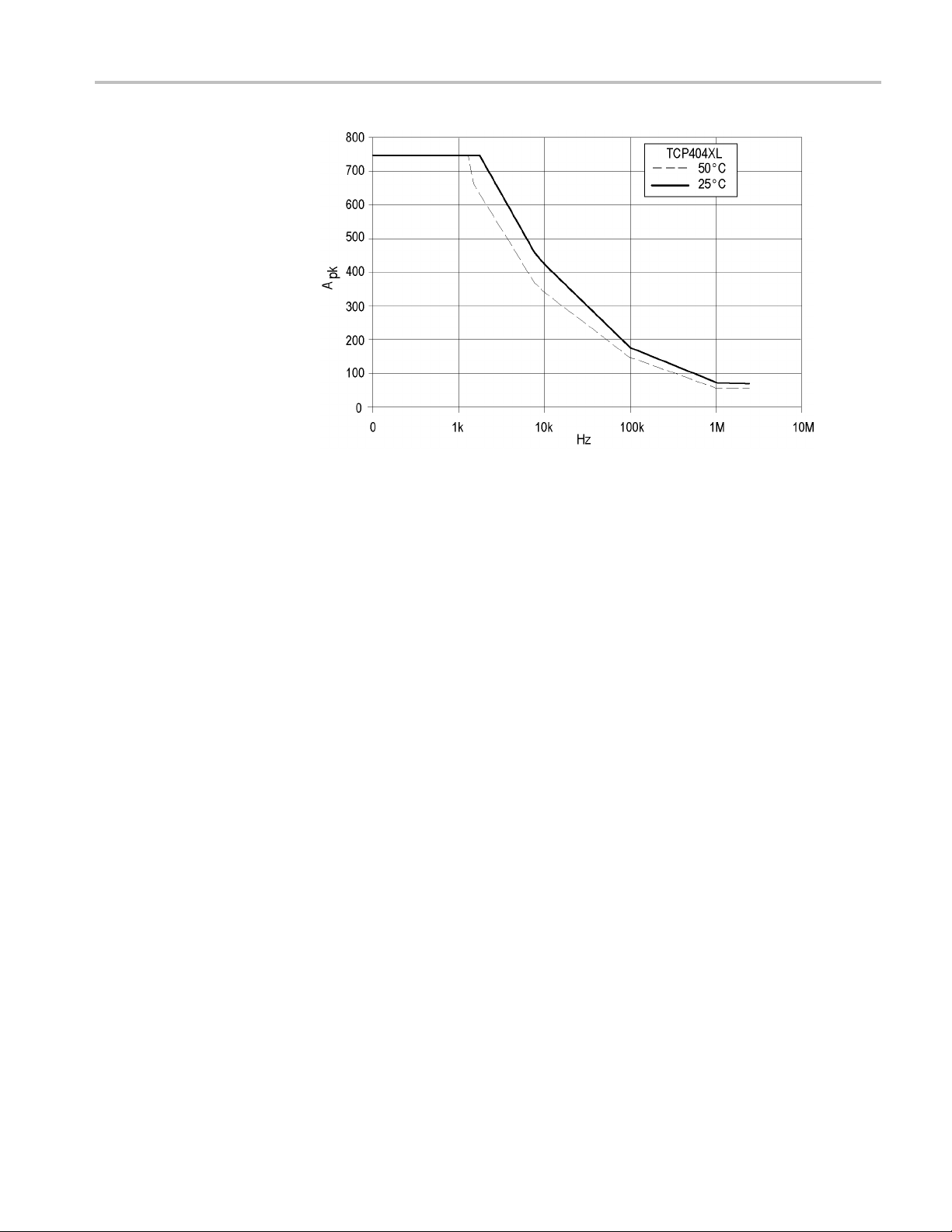

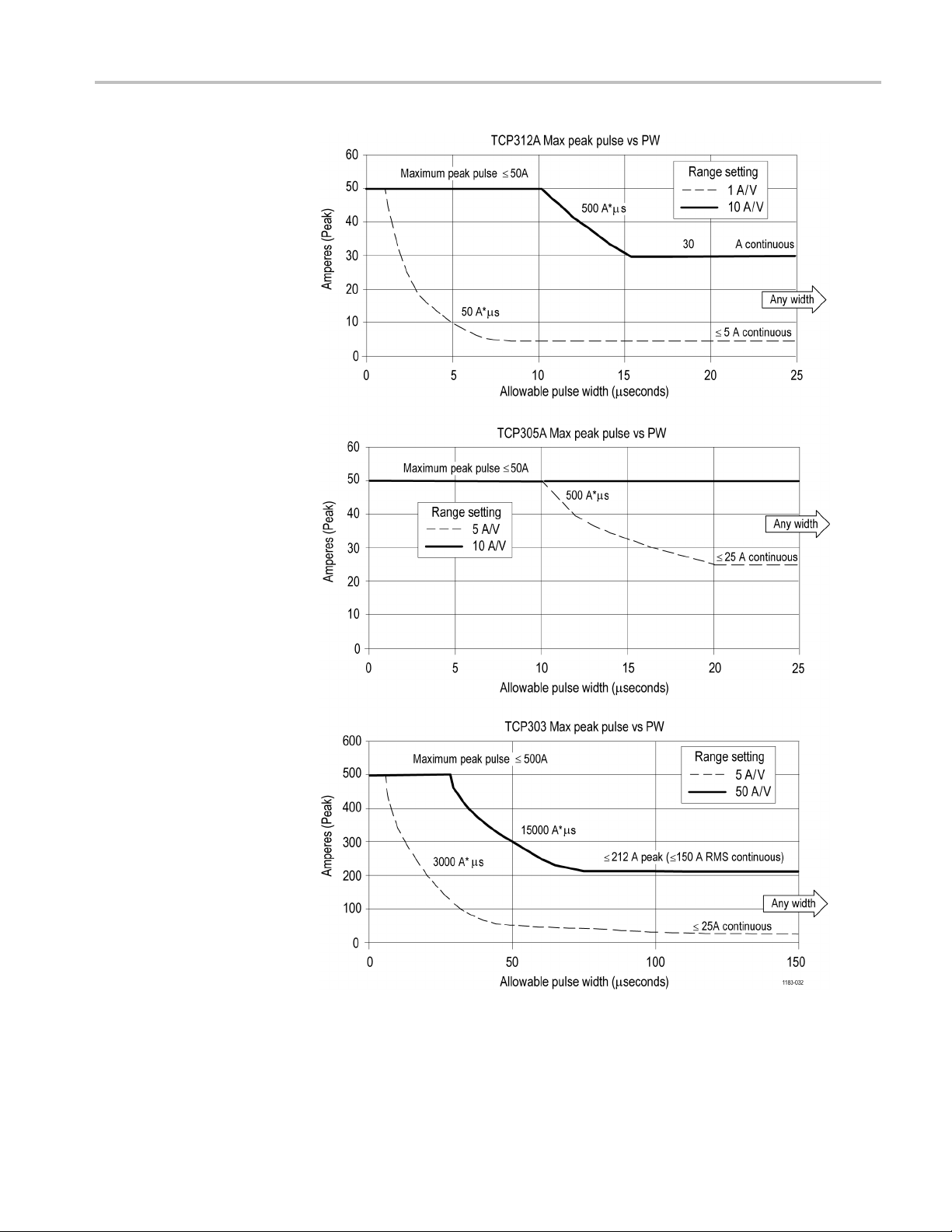

Performance Graphs .............................. .................................. .......................... 54

TCP404XL Maximum Measurement Times..................................... .......................... 58

Glossary

Index

ng and Error Codes.......................... ................................ ...................... 42

Typical Characteristics ..... ................................ .................................. 50

ii TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 9

List of Figures

Figure 1: Typical TCPA300/400 current measurement system............................... ................. 1

Figure 2: Using the probe cover ................. ................................ ................................. 5

Figure 3: Connecting the ground lead ................ .................................. ......................... 6

Figure 4: Equipment locations in the travel case ............................................................... 7

Figure 5: Connecting and disconnecting a current probe to the amplifier.................................... 9

Figure 6: TCP312A and TCP305A slide operation...................... .................................. .... 10

Figure 7: Unlock and open the TCP303 and TCP404XL ................... ................................ .. 11

Figure 8: Close and lock the TCP303 and TCP404XL........................................................ 11

Figure 9: Arrow on current probe indicates conventional current flow ..................................... 14

Figure 10: The TCPA300 front panel ................. ................................ .......................... 17

Figure 11: Measuring two conductors........................................................................... 24

Figure 12: Measuring differential current and nulls ........................................................... 25

Figure 13: Effect of AC or DC coupling on low-frequency signals .. .. . .. .. .. . . . .. .. . .. .. .. .. . .. .. .. . .. .. .. 26

Figure 14: Applying the amp-second product rule .. .................................. ........................ 28

Figure 15: Duty cycle calculation ............. .................................. ................................ 30

Figure 16: Adding a second conductor............................ ................................ .............. 33

Figure 17: Adding multiple turns................................................................................ 33

Figure 18: Increasing probe sensitivity .. .. .. . .. .. .. .. . .. .. . . . .. .. .. . .. .. .. . .. .. .. .. . .. .. . . . .. .. .. . .. .. .. . .. .. .. 34

Figure 19: Setup for measuring charging current................ ................................ .............. 36

Figure 20: Charge current waveforms..... ................................ .................................. .... 36

Figure 21: Measuring inductance with a low-impedance source............................................. 37

Figure 22: Linear current vs. time ramp ........................................................................ 38

Figure 23: High-impedance source current ramp .............. ................................ ................ 39

Figure 24: Measuring the number of turns in a coil ..... ................................ ...................... 40

Figure 25: Turns measurement using reference coil........................................................... 40

Figure 26: Error code d

Figure 27: Interpreting the error code display................ ................................ .................. 46

Figure 28: Probe jaw dimensions (nominal).... ................................ ................................ 52

Figure 29: Frequency derating-TCP312A ...................................................................... 54

Figure 30: Frequency derating-TCP305A ...................................................................... 54

Figure 31: Frequency derating-TCP303 ................ .................................. ...................... 54

Figure 32: Frequency derating-TCP404XL .... .................................. .............................. 55

Figure 33: Insertion impedance versus frequency ............................................................. 56

Figure 34: Specified operating area of the probes ............................................................. 57

Figure 35: Measuring 750A noncontinuous at 50 °C ambient temperature................................. 58

Figure 36: Measuring 600A noncontinuous at 50 °C ambient temperature................................. 58

Figure 37: Measuring 750A noncontinuous at 23 °C ambient temperature................................. 59

isplay .... .................................. ................................ .............. 45

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual iii

Page 10

Table of Contents

List of Tables

Table 1: Safety compliance information ....................................................................... viii

Table 2: Amp

Table 3: Service options ................ .................................. ................................ ......... 3

Table 4: Unpowered circuit degauss limits ..................................................................... 23

Table 5: Automobile charging systems test setup............ ................................ .................. 35

Table 6: Troubleshooting ............. ................................ .................................. .......... 42

Table 7: Amplifier error codes ....... .................................. ................................ .......... 46

Table 8: W

Table 9: Nominal and typical amplifier characteristics........................................................ 50

Table 10: TCPA300 and TCPA400 mechanical characteristics ............ ................................ .. 51

Table 11: Probe mechanical characteristics......................... ................................ ............ 52

Table 12: Shipping weights and dimensions ................................................................... 52

Table 13: Environmental characteristics ........................................................................ 53

lifier options...................... .................................. ................................ . 3

arranted TCPA300 and TCPA400 specifications................................ .................. 49

iv TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 11

General safety summary

General safet

To avoid fire or personal

injury

y summary

Review the fo

this product or any products connected to it.

To avoid pot

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions r

Use proper power cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and disconnect properly. Do not connect or d isconnect probes or test

leads while they are connected to a voltage source.

Connect and disconnect properly. Connect the probe output to the measurement

instrument before connecting the probe to the circuit under test. Connect the

probe reference lead to the circuit under test before connecting the probe input.

Disconnect the probe input and the probe reference lead from the circuit under test

before disconnecting the probe from the measurement instrument.

llowing safety precautions to avoid injury and prevent damage to

ential hazards, u se this product only as specified.

elated to operating the system.

Ground the product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

nected to earth ground. Before making connections to the input or output

con

terminals of the product, ensure that the product is properly grounded.

erve all terminal ratings. To avoid fire or shock hazard, observe all ratings

Obs

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Connect the probe reference lead to earth ground only.

o not connect a current probe to any wire that carries voltages above the current

D

probe voltage rating.

Do not operate without covers. Do not operate this product with covers or panels

removed.

Do not operate with suspected failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Avoid exposed circuitry. Do not touch exposed connections and components when

power is present.

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual v

Page 12

General safety summary

Termsinthismanual

Symbols and terms on the

product

Do not operate i

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

Provide prop

on installing the product so it has proper ventilation.

These terms may appear in this manual:

WARNING.

in injury or loss of life.

CAUTION

damage to this product or other property.

These t

erms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read

the ma

n wet/damp conditions.

er ventilation. Refer to the manual's installation instructions for details

Warning statements identify conditions or practices that could result

. Caution statements identify conditions or practices that could result in

rking.

WARNING indicates an injury hazard not immediately accessible as you

the marking.

read

CAUTION indicates a hazard to property including the product.

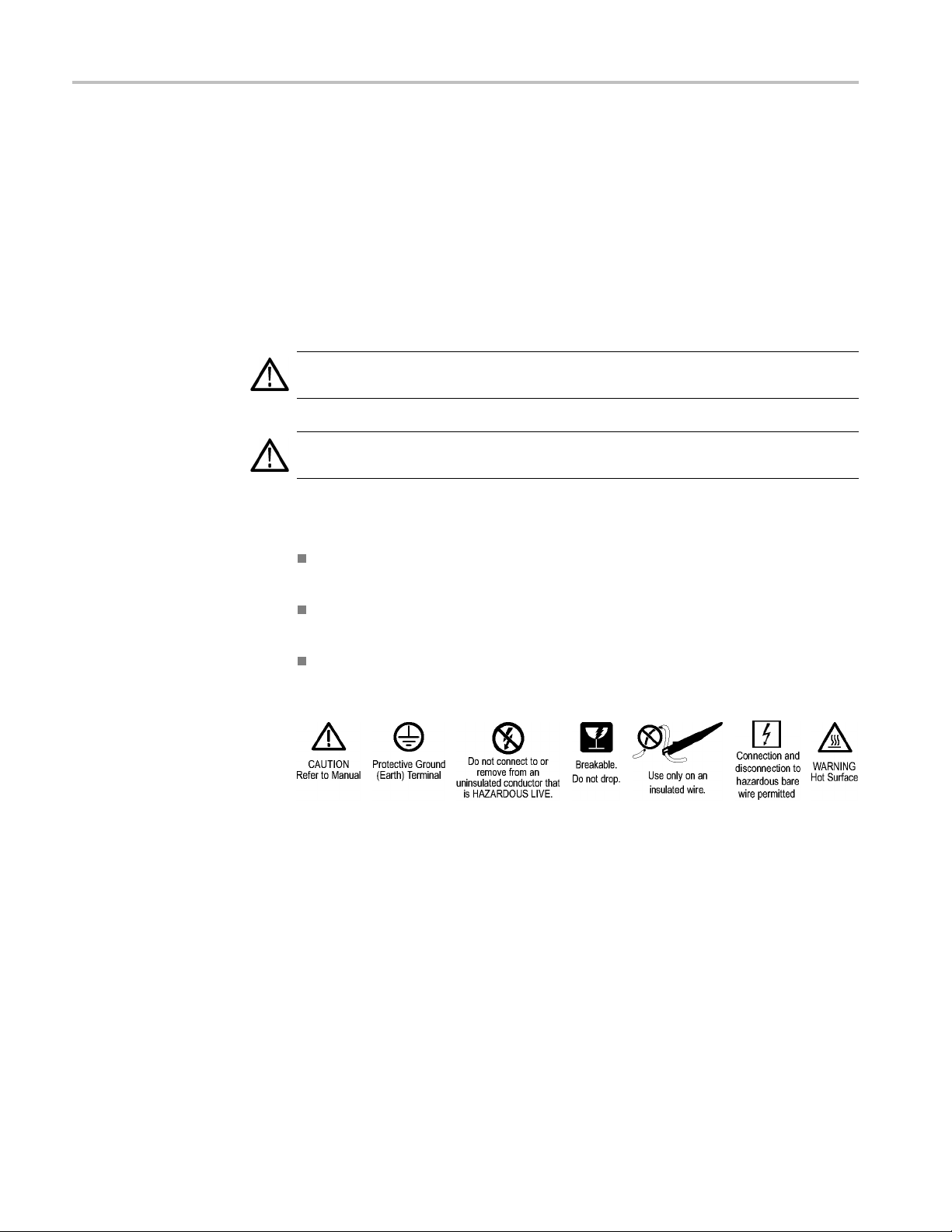

The following symbol(s) may appear on the product:

vi TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 13

Compliance Information

This section lists the EMC (electromagnetic compliance) and environmental

standards with which the instrument complies.

EMC Compliance (Applies to TCPA300 & TCPA400 Amplifiers Only)

EC Declaration o f

Conformity

–EMC

Meets intent of Directive 2004/108/EC for Electromagnetic Compatibility.

Complianc

e was demonstrated to the following specifications as listed in the

Official Journal of the European Communities:

EN 61326-1:2006, EN 61326-2-1:2006. EMC requirements for electrical equipment

for measurement, control, and laboratory use.

123

CISPR 11:2003. Radiated and conducted emissions, Group 1, Class A

IEC 61000-4-2:2001. Electrostatic discharge immunity

IEC 61000-4-3:2002. RF electromagnetic field immunity

IEC 610

00-4-4:2004. Electrical fast transient/burst immunity

IEC 61000-4-5:2001. Power line surge immunity

IEC 61000-4-6:2003. Conducted RF immunity

IEC 61000-4-11:2004. Voltage dips and interruptions immunity

4

EN 61000-3-2:2006. AC power line harmonic emissions

EN 61000-3-3:1995. Voltage changes, fluctuations, and flicker

European Contact.

Tektronix UK, Ltd.

Western Peninsula

estern Road

W

Bracknell, RG12 1RF

United Kingdom

1

This product is intended for use in nonresidential areas only. Use in residential areas may cause electromagnetic

interference.

2

Emissions which exceed the levels required by this standard may occur when this equipment is connected to a

test object.

3

To ensure compliance with the EMC standards listed here, high quality shielded interface cables should be used.

4

Performance Criterion C applied at the 70%/25 cycle Voltage-Dip and the 0%/250 cycle Voltage-Interruption test

levels (IEC 61000-4-11).

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual vii

Page 14

Compliance Information

Australia / New Zealand

Declaration of

Conformity – EMC

Complies with t

following standard.

CISPR 11:2003

he EMC provision of the Radiocommunications Act per the

. Radiated and Conducted Emissions, Group 1, Class A, in

accordance with EN 61326-1:2006 and EN 61326-2-1:2006.

FCC–EMC

Emissions are within the limits of FCC 47 CFR, Part 15, Subpart B for Class A

equipment.

Safety Compliance Information

Table 1: S

Category Standards or description

EC Declaration o f Conformity – Low

Voltage

U.S. Nationally Recognized Testing

Laboratory Listing

Cana

Add

stallation (Overvoltage) Category

In

Descriptions

afety compliance information

1

dian Certification

itional Compliance

Compliance was demonstrated to the following specification as listed in the Official Journal

of the European Communities:

Low Volt

EN 61010-1/A2:1995. Safety requirements for electrical equipment for measurement

control and laboratory use.

EN 6101

measurement and test equipment.

UL3111-1. Standard for electrical measuring and test equipment.

UL3111-2-032. Hand-held probe assemblies for electrical measurement and test.

UL610

laboratory use.

UL61010B-2-032: Particular requirements for hand-held current clamps for electrical

measu

CAN/

measurement, control, and laboratory use.

CAN/CSA C22.2 No. 61010.2.032:1996. Particular requirements for hand-held probe

ass

IEC

measurement and test.

IEC 61010-1:2001. Safety requirements for electrical equipment for measurement control

an

Te

designations. The installation categories are:

CAT III. Distribution-level mains (usually permanently connected). Equipment at this level is

t

CAT II. Local-level mains (wall sockets). Equipment at this level includes appliances,

portable tools, and similar products. Equipment is usually cord-connected.

C

age Directive 73/23/EEC, amended by 93/68/EEC.

0-2-032:1995. Particular requirements for hand-held current clamps for electrical

10-1. Safety requirements for electrical equipment for measurement, control, and

rement and test.

CSA C22.2 No. 61010.1. Safety requirements for electrical equipment for

emblies for electrical measurement and test equipment.

61010-2-032:1995. Particular requirements for hand-held current clamps for electrical

d laboratory use.

rminals on this product may have different installation (overvoltage) category

ypically in a fixed industrial location.

AT I. Secondary (signal level) or battery operated circuits of electronic equipment.

viii TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 15

Compliance Information

Table 1: Safety compliance information (cont.)

Category Standards or description

Pollution Degree Descriptions

Equipment Type Test and measuring

Safety Class Class 1 (as defined in IEC 61010-1, Annex H) – grounded product

Overvoltage Category Overvoltage Category II (as defined in IEC 61010-1, Annex J)

Pollution Degree

1

The TCP305A and TCP312A Current Probes are exempt from the Low Voltage Directive and are not third-party listed. However, they have been evaluated to

applicable safety standards.

A measure of the contaminates that could occur in the environment around and within a

product. Typically the internal environment inside a product is considered to be the same

as the external. Products should be used only in the environment for which they are rated.

Pollution Degree 1. No pollution or only dry, nonconductive pollution occurs. Products in

this category are generally encapsulated, hermetically sealed, or located in clean rooms.

Pollution Degree 2. Normally only dry, nonconductive pollution occurs. Occasionally a

temporary conductivity that is caused by condensation must be expected. This location

is a typical office/home environment. Temporary condensation occurs only when the

product is out of service.

Pollution Degree 3. Conductive pollution, or dry, nonconductive pollution that becomes

conductive due to condensation. These are sheltered locations where neither temperature

nor humidity is controlled. The area is protected from direct sunshine, rain, or direct wind.

Pollution Degree 4. Pollution that generates persistent conductivity through conductive

dust, rain, or snow. Typical outdoor locations.

Pollution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor use only.

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual ix

Page 16

Compliance Information

Environmenta

l Considerations

Product End-of-Life

Handling

Restriction of Hazardous

Substances

This section provides information about the environmental impact of the product.

Observe the following guidelines when recycling an instrument or component:

Equipment Recycling. Production of this equipment required the extraction and

use of natural resources. The equipment may contain substances that could be

harmful to

end of life. In order to avoid release of such substances into the environment and

to reduce the use of natural resources, we encourage you to recycle this product

in an appropriate system that will ensure that most of the materials are reused or

recycled appropriately.

This product is classified as an industrial monitoring and control instrument

accessory, and is not required to comply with the substance restrictions of the

recast RoHS Directive 2011/65/EU until July 22, 2017.

the environment or human health if improperly handled at the product’s

This sym

Union requirements according to Directives 2002/96/EC and 2006/66/EC

on waste electrical and electronic equipment (WEEE) and batteries. For

informa

Tektronix Web site (www.tektronix.com).

bol indicates that this product complies with the applicable European

tion about recycling options, check the Support/Service section of the

x TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 17

Preface

This User Manual supports the operation and basic maintenance of the TCPA300

and TCPA400 Current Probe Amplifiers, and the TCP300/400 Series AC/DC

current prob

manual are listed below:

es that mate with the amplifiers. The current probes covered in this

Service Manual

TCP312A (30

TCP305A (50 A, 50 MHz, compatible with TCPA300)

TCP303 (150 A, 15 MHz, compatible with TCPA300)

TCP404XL (500 A*, 2 MHz, compatible with TCPA400) *750 A DC derated

with duty cycle

If you are not familiar with these products, please refer to the Getting Started and

Operating Basics chapters of this manual for basic operating information.

If you are an advanced user, the Reference section contains information on

advanced applications as well as user diagnostic and troubleshooting information.

The Glossary and Index are provided as quick reference locators for important

information.

The Performance Verification and Adjustment procedures are located in the

Service Manual and support the qualification and calibration of the probes when

used with either amplifier.

The Maintenance section is also located in the Service Manual and supports the

routine maintenance and repair of mechanical parts associated with the amplifiers.

A, 100 MHz, compatible with TCPA300)

nual Conventions

Ma

The term "amplifier" is used to refer to either the TCPA300 or TCPA400 when

referring to common attributes. If a subject is unique to either amplifier, the

mplifier will be referred to directly by model.

a

The terms "current probe" and "probe" are used to refer to any of the TCP300A/400

Series current probes when referring to common attributes. If a subject is unique

to a particular probe, the probe will be referred to directly by model.

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual xi

Page 18

Preface

xii TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 19

Getting Started

The TCPA300 and TCPA400 current probe amplifiers let you use one probe to

simultaneously measure AC and DC current. The amplifiers convert the sensed

current into

oscilloscope.

a p roportional voltage signal that you can measure directly with an

em Configuration

Syst

The TCPA300

than other current measurement systems because of a current feedback process

used with the probe. DC measurement capability and high bandwidth allow the

amplifiers to accurately represent square waves and fast-rise signals.

The TCPA300 and TCPA400 amplifiers and associated probes provide these

features:

Simultaneous DC and AC current measurements up to 750 A peak

High sensitivity

One-bu

No adjustments needed to match a current probe to an individual amplifier

AC or DC coupling of signal

Direct scaling and unit readout on compatible TEKPROBE level II

oscilloscopes

A complete current measurement system consists o f a current probe amplifier, a

compatible current probe, and an appropriate oscilloscope. (See Figure 1.)

and TCPA400 current probe amplifiers provide better linearity

tton autobalancing and probe degaussing

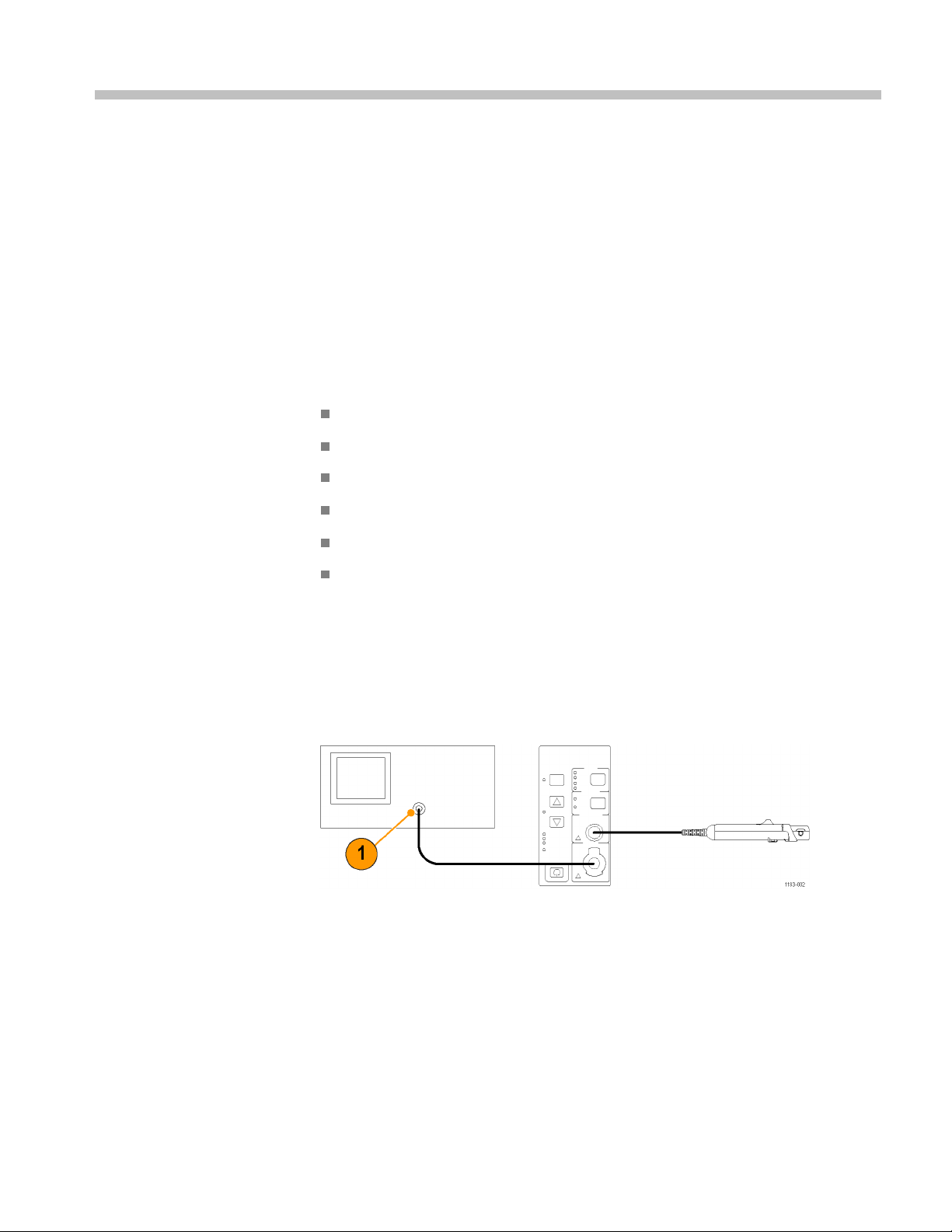

Figure 1: Typical TCPA300/400 current measurement system

1. 50 Ω oscilloscope input — use the TEKPROBE Interface Cable or use a

50 Ω cable. (Add a 50 Ω termination here if the oscilloscope only has a

high-impedance input).

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual 1

Page 20

Getting Started

TCPA300 and TCPA400

Current Probe Amplifiers

Current P robes

Oscilloscope

The amplifier am

plifies the current sensed by the probe and converts the current

to a proportional voltage that is displayed on an oscilloscope or other similar

measuring device.

The followin

g Tektronix current probes are compatible with the

TCPA300 Amplifier:

TCP312A (30

A, 100 MHz)

TCP305A (50 A, 50 MHz)

TCP303 (150 A, 15 MHz)

The following Tektronix current probes are compatible with the

TCPA400 Amplifier:

TCP404XL (750 A1,2MHz)

1

500 A continuous, 750 A DC derated with duty cycle

An osci

lloscope displays the output from the current measuring system. A 50 Ω

cable is included to connect the amplifier to the oscilloscope input channel. A

TEKPROBE-to-TEKPROBE interface cable is also included for connecting to

TEKPROBE level II oscilloscopes.

If the oscilloscope does not have an input that can be set to 50 Ω impedance, you

need a feedthrough 50 Ω termination. This termination is included as a standard

accessory with your TCPA300 and TCPA400 Current Probe Amplifiers.

2 TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 21

Options

Getting Started

Table 1-1 lists options that are available for the TCPA300 and TCPA400

amplifiers.

Tabl e 2: Amp

Option Description

A1 Universal E

A2 United Kingdom power cord

A3 Australia power cord

A5

A6 Japan pow

AC China po

A99 No power cord

lifier options

uro power cord

Switzerland power cord

er cord

wer cord

Tektronix service options that you can order for your amplifiers and probes are

in this section. (See Table 3.) Designed to support tracking of calibration

listed

to requirements of ISO9000 a nd to provide for extended repair coverage, these

options help fix your long-term maintenance costs and eliminate unplanned

expenditures. Tektronix Service Options are available at the time you order your

instrument. Contact your local Tektronix Sales Office for more information.

Table 3: Service options

Option Description

D1

C3 Provides factory calibration certification on delivery, plus two more years of calibration coverage. Throughout the

D3

R3

C5 Provides factory calibration certification on delivery, plus four more years of calibration coverage. Throughout the

D5

R5

SILV400 Standard warranty extended to 5 years (TCP305A, TCP312A, TCPA300 and TCPA400)

SILV600 Standard warranty extended to 5 years (TCP303 and TCP404XL)

Provides the initial Test Data Report from the factory o n delivery.

coverage period, the instrument will be calibrated according to its Recommended Calibration Interval.

Provides test data on delivery plus a Test Data Report for every calibration performed during three years of coverage

(requires Option C3).

Extends product repair warranty to a total of three years.

coverage period, the instrument will be calibrated according to its Recommended Calibration Interval.

Provides test data on delivery plus a Test Data Report for every calibration performed during five years of coverage

(requires Option C5).

Extends product repair warranty to a total of five years.

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual 3

Page 22

Getting Started

Standard Acce

Amplifiers

ssories

Probes

The following accessories are shipped with the amplifiers and probes.

The following accessories are shipped with the TCPA300 and TCPA400

amplifiers.

Power Cord (customer-chosen option)

BNC Cable

Terminat i

TEKPROBE Interconnect Cable

Documentation CD (Includes User Manual–English, Japanese, and Russian

languages, and Service Manual–English only)

Certificate of Traceable Calibration

When you order a current probe, you will receive these accessories:

Probe cover (TCP303 and TCP404XL only)

Probe

on, 50 Ω 2W

ground lead, 6 inch length (TCP305A and TCP312A only)

ional Accessories

Opt

Instruction Sheet

Certificate of Traceable Calibration

You can order the following optional accessories for the amplifiers and probes.

One-turn 50 Ω HF current loop. Two versions are available; one for ea ch

style of probe. The current loops are used in the performance verification

procedures for checking the performance of the TCPA300 Amplifier and

he compatible probes.

t

TCPA Calibration Adapter. Use the TCPA Calibration Adapter to verify the

amplifier(s) p erformance independent of the current probes.

Travel Case. The travel case includes room to store one amplifier and two

current probes, along with related cables and adapters.

Deskew Fixture. This fixture converts the PROBE COMPENSATION output

or TRIGGER OUTPUT of the TDS5000 or TDS7000 into a set of test point

connections that allow you a convenient way to compensate for timing

differences between voltage and current probes.

4 TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 23

Probe Cover

Getting Started

The TCP400 Series Current Probes come with a probe cover that stores the probe

when not in use. Use the probe cover to hold your probe in a convenient place at

your bench or

cover to the side of the bench to keep the probe off of your work surface. (See

Figure 2.)

workstation when you are not using it. You can attach the probe

Figure 2: Using the probe cover

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual 5

Page 24

Getting Started

Ground Lead

The TCP305A and TCP312A probes include a 6-inch ground lead. The ground

lead grounds the shield around the probe transformer at the probe end of the

cable. This a

measuring, thereby improving high frequency shielding. The ground lead clips

onto the ground connector on the bottom of the probe.

llows you to move the ground connection closer to the circuit you are

Figure 3: Connecting the ground lead

The ground lead on the current probes is intended to be used in high dV/dt

environments. The probes have a grounded shield between the conductor under

test and the current sense transformer. Any capacitively-coupled current will then

flow in the ground instead of the transformer windings.

When you take high frequency measurements, connect the probe ground lead to

the probe ground connector and attach the alligator clip directly to RF ground to

improve EMI rejection at high frequencies (2 MHz and above). This will reduce

nging and help bypass capacitively-coupled RF currents which can flow into

ri

the probe cable. In some cases, it may be helpful to move the ground lead or

reposition the probe away from noise sources in the circuit under test.

6 TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 25

Travel Case

Getting Started

The travel case is a recommended accessory for the TCPA300/400 Amplifiers.

The travel case includes room to store one amplifier and two TCP300A/400 Series

Current Prob

a TCP303 probe.) A compartment is included to store associated cables and

terminations. (See Figure 4.)

es, one of each size. (For example, you can store a TCP305A and

re 4: Equipment locations in the travel case

Figu

1. Larg

2. Probe holders

3. Small current probe

4. Amplifier

5. Cables and terminations

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual 7

e current probe

Page 26

Getting Started

Connecting th

eAmplifier to an Oscilloscope

You will need an oscilloscope to display the TCPA300 and TCPA400 measurement

output. To use the full dynamic range of the probe/amplifier combination, the

oscilloscop

1 V/div.

If you are us

TEKPROBE-to-TEKPROBE interface cable. Otherwise, use the supplied

50 Ω BNC cable to connect the amplifier OUTPUT connector to your oscilloscope.

(SeeFigure1onpage1.)

The input impedance of the oscilloscope channel must be 50 Ω, or you will

encounter slowed pulse response, increased aberrations, or incorrect DC

measurement amplitudes. If your oscilloscope provides only 1 M Ω inputs, you

need to attach a 50 Ω feed-through termination between the oscilloscope input

and the B

BNC cable.

To util

attached current probe, the oscilloscope bandwidth must be approximately five

times that of the current probe. For example, when using a TCP312A Current

Probe, the oscilloscope bandwidth must be at least 500 MHz. When using a

TCP305A Current Probe, the oscilloscope bandwidth must be at least 250 MHz.

e must be capable of displaying a vertical scale factor of 1 mV/div to

ing a TEKPROBE II-compatible oscilloscope, use the

NC cable. Do not install this termination at the amplifier end of the

ize the full bandwidth capability of the TCPA300 and TCPA400 and

er on the Amplifier

Pow

After you have connected the amplifier to the oscilloscope, allow the equipment

to warm up to a stable temperature; usually 20 minutes is required.

Connect the power cord to the power input connector on the rear of the amplifier,

and then connect the power cord to your local mains supply (100 VAC to

40 VAC, 50 Hz to 400 Hz). To allow for proper ventilation, place the rear panel

2

of the amplifier at least 2 inches away from any obstructions. Set the a mplifier on

the bottom rubber feet, and keep papers and other items away from the bottom of

the amplifier which could restrict airflow and cause overheating.

Power on the amplifier by pressing the ON/STANDBY button at the lower-left

corner of the front panel. The amplifier goes through a self-test and cycles the

front-panel LEDs.

NOTE. The amplifier stores the power state it is in when the power cord is

unplugged. If you do not put the amplifier into STANDBY m ode before unplugging

it, the amplifier will power on immediately w hen you plug it in again.

When you connect a probe to the amplifier, the amplifier uses detection circuitry

to indicate probe conditions such as noncompatible probe type and probe open.

8 TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 27

Getting Started

Connecting a C

urrent Probe to the Amplifier

To connect a current probe to the amplifier input connector, do the following and

refer to the illustration. (See Figure 5.)

1. To connect the probe, align the red dots.

2. Push the probe connector in. Do not twist the connector.

3. To disconnect the probe, pull back the collar.

4. Pull out the connector.

Figure 5: Connecting and disconnecting a current probe to the amplifier

CAUTION. Handle current probes with care. Do not drop a probe or subject it to

ct, or the core may crack.

impa

Do not connect or disconnect a current probe while the probe is clamped around a

ve conductor, or the probe may suffer electrical damage.

li

If you connect a probe to the wrong amplifier, (for example, a TCP312A to a

PA400), the NONCOMPATIBLE PROBE TYPE LED illuminates. Disconnect

TC

the probe and use the correct amplifier. The TCPA400 amplifier accepts

TCP3XXA probes, but will only operate properly with TCP4XX probes.

Each current probe is calibrated before it is shipped, and should not require

further adjustment. If a probe requires adjustment, information is available in the

service manual. The adjustment procedure must be performed only by qualified

service personnel. Contact your nearest Tektronix Service Center if you need

more assistance.

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual 9

Page 28

Getting Started

Operating the

Current Probe Slide

The current probes each ha ve a slide mechanism that opens and closes the probe

jaw. This allows you to clamp the probe around a conductor under test. The slide

must be locke

probe is unlocked, the PROBE OPEN indicator on the amplifier will light.

The current

the circuit must be de-energized when connecting or removing the current probe.

The slide o

the following illustration. (See Figure 6.) To open the probe, pull the slide back

until the jaw is open. To lock the probe, push the slide forward until the detent

snaps into place.

d closed to accurately measure current or to degauss the probe. If a

probes can be used to measure current on uninsulated wires. However,

peration of the TCP305A and TCP312A current probes is shown in

Figure 6: TCP312A and TCP305A s lide operation

10 TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 29

Getting Started

The slide opera

following illustrations. To open the probe:

1. Press the bott

2. Squeeze the handle until the core is open.

3. Place the probe core around the conductor.

tion of the TCP303 and TCP404XL current probes is shown in the

om of the lock button.

Figure 7: Unlock and open the TCP303 and TCP404XL

4. To lock the probe, release the squeeze handle.

5. Press the top of the lock button.

Figure 8: Close and lock the TCP303 and TCP404XL

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual 11

Page 30

Getting Started

Degaussing an

d Autobalancing the Current Probe

Degaussing the probe removes any residual magnetization from the probe core.

Such residual magnetization can induce measurement error. Autobalancing

removes unwa

probe is a leading cause of measurement errors. The DEGAUSS LED flashes

until you degauss the probe.

To degauss the probe, disconnect the probe from the test circuit, or ensure that

the conductor under test has no power, close and lock the slide, and then press

the amplifier PROBE DEGAUSS AUTOBALANCE button on the front panel of

the amplifier. To maintain measurement accuracy, degauss your probe in each of

these cases:

After you turn on the amplifier and allow a 20-minute warm-up period.

Before you connect the probe to a conductor.

Whenever a current or thermal overload condition occurs.

Whenever you connect a new probe.

Whene

Periodically during normal use.

To degauss and autobalance a current probe, perform these steps:

nted DC offsets in the amplifier circuitry. Failure to degauss the

ver you subject the probe to a strong external magnetic field.

1. Verify that the current probe is connected to the amplifier.

2. Remove the current probe from the conductor under test.

3. Lock the probe slide closed. (See Figure 6.) (See Figure 7.)

ess the amplifier PROBE DEGAUSS AUTOBALANCE button.

4. Pr

5. Wait about five seconds for the degauss procedure to complete.

The PROBE DEGAUSS AUTOBALANCE LED glows green when the

operation has successfully completed. If the LED is blinking orange, the degauss

peration is still in progress. If the LED is red, the operation failed, and the cause

o

of the failure needs to be found and fixed. (See page 18, PROBE DEGAUSS

AUTOBALANCE Button and Indicator.)

NOTE. The degauss procedure will fail if the amplifier is not properly connected

to an oscilloscope having 50 Ω input impedance. If this occurs, the NOT

TERMINATED INTO 50 Ω LED lights on the amplifier front panel.

After you have completed the oscilloscope adjustments and the amplifier

degauss/autobalance procedure, your system is ready to measure current.

12 TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 31

Getting Started

DC Measuremen

ts

To measure DC current, first degauss the probe:

1. Verify that the a mplifi er and the oscilloscope input coupling are set to DC,

and the input impedance is set to 50 Ω.

2. Lock the probe closed without a conductor passing through it.

3. Adjust the ground reference of the oscilloscope to move the trace to the

desired graticule line.

4. Press the amplifier PROBE DEGAUSS AUTOBALANCE button.

The NOT TERMINATED INTO 50 Ω LED is lighted if impedance is not

50 Ω. If this is the case, make necessary changes. (For example, use a 50 Ω

termination.)

5. After the degauss/autobalance routine completes, adjust the ground reference

(if necessary) using the amplifier MANUAL BALANCE controls.

WAR N I NG. The current probes can be u sed to measure current on uninsulated

wires. However, the circuit must be de-energized when connecting or removing

rrent probe.

the cu

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual 13

Page 32

Getting Started

The current pro

Notice that the probe arrow points toward the negative terminal of the power

supplytoconf

To measure DC current, perform these steps:

1. Open the pro

then lock the slide.

2. For correct

the direction of conventional (positive to negative) current flow. Reversing

the flow will display the current waveform upside-down on the oscilloscope.

3. Adjust the oscilloscope time base, trigger, and gain as needed.

be is shown connected to a power supply line. (See Figure 9.)

orm to the conventional current flow of positive (+) to negative (-).

be slide, place the probe around the conductor under test, and

measurement polarity, make sure the probe arrow is pointing in

Figure 9: Arrow on current probe indicates conventional current flow

14 TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 33

Getting Started

AC Measuremen

ts

To measure AC current only, and remove the DC component of the current being

measured, follow the instructions below. These are identical to the instructions for

DC current me

1. Verify that the oscilloscope input coupling is set to DC, and the input

impedance i

amplifier is lit if impedance is not 50 Ω.)

2. Verify tha

3. Adjust the ground reference of the oscilloscope to move the trace to the

desired g

4. Lock the probe closed without a conductor passing through it, and then press

the ampl

WAR N I NG. The current probes can be u sed to measure current on uninsulated

wires. However, the circuit must be de-energized when connecting or removing

the current probe.

5. Open the probe slide, place the probe around the conductor under test, and

then lock the slide. For correct measurement polarity, make sure the probe

arrow is pointing in the direction of conventional (positive to negative)

current flow. Reversing the flow will invert the displayed current waveform

on the oscilloscope.

asurements except that the amplifiercouplinginstep2issettoAC.

ssetto50Ω. (The NOT TERMINATED INTO 50 Ω LED on the

t the amplifier input coupling is AC.

raticule line.

ifier PROBE DEGAUSS AUTOBALANCE button.

E. Even when making AC current measurements, leave the oscilloscope

NOT

coupling on DC. Change only the amplifier coupling to AC. Using the oscilloscope

AC coupling may cause the amplifier to exceed its output dynamic range.

6. Adjust the oscilloscope time base and trigger as needed.

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual 15

Page 34

Getting Started

16 TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 35

Control Summary

This section describes the function of each TCPA300 and TCPA400 front panel

control and connector. The overview shows most functions and is followed by a

detailed des

Some seldom-used functions do not appear in the illustration. These functions are

completely

cription. (See Figure 10.)

discussed in the detailed d escriptions that follow this illustration.

Figure 10: The TCPA300 front panel

1. The PROBE DEGAUSS AUTOBALANCE button removes residual

magnetism from the attached current probe. A m ulti-color LED indicates the

status of the degauss circuit.

2. The MANUAL BALANCE buttons allow you to fine-adjust DC offset from

the amplifier. The adjacent LED lights when one of the buttons has been

pressed.

3. The four probe error lights indicate the following faults: PROBE OPEN,

OVERLOAD (current or temperature), N OT TERMINATED INTO 50 Ω and

NONCOMPATIBLE PROBE TYPE.

4. The ON/STANDBY button turns on power to the amplifier.

5. The TCPA300 and TCPA400 output appears at the OUTPUT connector.

Connect this to a 50 Ω input of your oscilloscope.

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual 17

Page 36

Control Summary

6. The current pro

INPUT connector.

7. The COUPLING b

the LEDs.

8. The RANGE bu

for the attached probe (TCPA300 only). LEDs indicate the selected range.

TCPA300 and TCPA400 Controls

These front panel controls and indicators are common to both the TCPA300 and

TCPA400 current probe amplifiers, unless otherwise indicated.

PROBE DEGAUSS

AUTOBALANCE Button

and Indicator

When pres

accuracy. First, the amplifier generates a degauss signal to remove any residual

magnetism from the attached current probe. Second, the amplifier initiates an

operation to remove any undesired DC offsets from the circuitry. During the

degauss p rocess, the amplifier is busy and cannot be used to measure current.

The indicator light next to the PROBE DEGAUSS AUTOBALANCE button

blinks red whenever the amplifier detects that the current probe needs degaussing.

The amplifier cannot detect all circumstances that require probe degaussing,

so yo

AUTOBALANCE light is not blinking red. The red blinking light serves as a

reminder to degauss the current probe when one o f the following conditions

occurs:

sed, this button performs two functions that maximize measurement

u may need to degauss the probe at times when the PROBE DEGAUSS

bes connect to the TCPA300 and TCPA400 at the PROBE

utton selects AC or DC probe coupling, as indicated by

tton toggles between the two scale factors that are available

The amplifier has just been turned on with a current probe connected.

The current probe has been changed.

overload was detected.

An

To perform the probe degauss/autobalance function, remove the probe from

ll conductors (or ensure that the conductor under test has no power), make

a

sure the probe is locked closed, and then press the PROBE DEGAUSS

AUTOBALANCE button. The probe degauss/autobalance routine will not pass

if the current probe is disconnected from the amplifier input, or if it is unlocked

(the PROBE OPEN LED is on).

The indicator blinks orange during the time the amplifier is busy performing

the probe degauss functions. When the degauss and autobalance procedure is

complete, the indicator light turns green.

18 TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 37

Control Summary

The PROBE DEGAU

the MANUAL BALANCE buttons have been pressed after a degauss has been

successfully completed. This indicates that the DC offset value has been manually

changed from the original value set during the degauss routine. Depending on

the amount of offset (balance) you have entered with the MANUAL BALANCE

buttons, another degauss operation may be necessary to ensure accurate

measuremen

you should de-energize the circuit under test and perform another degauss routine.

Then, reenergize the circuit and take your meas ure ments.

If the degauss operation has failed, and the AC and DC COUPLING LEDs are

alternately flashing, this indicates the amplifier is displaying an error code with

the four status LEDs on the lower-left front panel.

(See page 45, Displaying Error Codes with the Probe Degauss Autobalance

Button.)

NOTE. The NOT TERMINATED INTO 50 Ω LED is on when the amplifier

output is not properly terminated into a 50 Ω load. Makesureyouramplifier

OUTPU

that the oscilloscope input is set to 50 Ω impedance. Proper cabling is shown.

(SeeFigure1onpage1.)

ts. Generally, if you change the DC offset by more than 5 divisions,

T is connected to an oscilloscope input using a 50 Ω BNC cable, and

SS AUTOBALANCE indicator light will be orange if

MANUAL BALANCE

Buttons a nd Indicator

PROBE OPEN Indicator

OVERLOAD Indicator

If your oscilloscope does n ot have 50 Ω impedance settings for inputs, you can

place a 50 Ω feed-through termination on the oscilloscope input and connect

the amplifier output cable to the termination. Do not place the feed-through

termination at the amplifier end of the BNC connecting cable.

The MANUAL BALANCE buttons allow you to fine-adjust the DC offset that

appears at the amplifier OUTPUT connector. The manual balance adjustment

only functions when the amplifier is set to DC coupling, and the MANUAL

ALANCE indicator is only lighted after you press one of the MANUAL

B

BALANCE buttons in DC coupling mode.

When lit, this indicator informs you that the current probe is unlocked. You must

have the probe slide locked to degauss the p robe or to accurately measure current.

When this LED is red, it informs you that the measurement you are taking exceeds

the continuous current limit of the probe or amplifier.

When this LED is orange, it indicates that the safe operating temperature of the

probe, and possibly the amplifier, has been exceeded. Disconnect the probe from

the current source and allow time for the probe head and amplifier to cool.

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual 19

Page 38

Control Summary

NOT TERMINATED

NONCOM

PATIBLE

When this LED bl

temperature of the probe and the current limit have been exceeded.

WARNING. To avoid personal injury or equipment damage, do not exceed the

specified electrical limits of the TCPA300 and TCPA400 or any applicable

accessories.

When lit, th

cable from the OUTPUT of the amplifier is not connected to a 50 Ω input on the

oscilloscope. You need to switch the termination setting on the oscilloscope to

50 Ω,orusea50Ω termination on the oscilloscope input.

NOTE. NOT TERMINATED INTO 50 Ω is only detected during the DEGAUSS

AUTOBALANCE operation.

When lit, this indicator informs you that the probe that is connected to the

amplifier is not designed to work with the amplifier. TCP3XXA probes only

work with the TCPA300 Amplifier, and the TCP404XL probe only works with

the TC

PA400 Amplifier.

inks red and orange, it indicates that both the safe operating

is indicator informs you that the TEKPROBE interface cable or BNC

ON/STANDBY Button

RANGE Button

COUPLING Button and

Indicators

Use this button to power on the amplifier. When the amplifier is in STANDBY

mode, the amplifier is in a limited-power mode. Most of the secondary circuitry is

abled, but the line voltage remains connected to the amplifier power supply.

dis

Press the RANGE button to toggle between the scale factors (sensitivity settings)

of the probe attached to the TCPA300. If no RANGE LEDs are lit, this indicates a

obe is not connected to the amplifier.

pr

The COUPLING button determines the coupling between the TCPA300/TCPA400

and the oscilloscope. Press the COUPLING button to toggle between AC and

C coupling. To couple the amplifierforDCplusACmeasurements,useDC

D

coupling. For AC measurements only, use AC coupling. When the amplifier is set

to AC coupling, the Manual Balance adjustment is disabled since the DC offset

component is not visible on the output waveform.

NOTE. Even when making AC current measurements, leave the oscilloscope

coupling on DC. Change only the amplifier coupling to AC. Using the oscilloscope

AC coupling may cause the amplifier to exceed its output dynamic range.

20 TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 39

Control Summary

PROBE INPUT Connector

OUTPUT Co

nnector

Under normal op

mode of the amplifier. If they alternately flash after a degauss operation, this

indicates the amplifier is displaying an error code with the four status LEDs on

the lower-left front panel. (See page 45, Displaying Error Codes with the Probe

Degauss Autobalance Button.)

All current probes compatible with the TCPA300 and TCPA400 attach at the

PROBE INPUT connector, which is a multi-pin female connector. Information

about connecting a probe is available. (See page 9, Connecting a Current Probe

to the A mplifier.)

The amplifier current measurement output is accessed at the OUTPUT connector,

which s hould be connected to the oscilloscope input. Attach one end of a 50 Ω

BNC cable to this connector and the other end to a 50 Ω vertical input of your

scope. The output impedance of the amplifier is 50 Ω.

oscillo

To get a direct readout of current on your Tektronix oscilloscope, use the

TEKPRO

NOTE. To obtain accurate measurements, the input impedance of your

oscilloscope must be 50 Ω. Make sure your amplifier OUTPUT is connected to an

oscilloscope input using a 50 Ω BNC cable, and that the oscilloscope input is set

to 50 Ω impedance. The proper cabling is shown. (See Figure 1 on page 1.)

BE interface cable to connect the amplifier to your oscilloscope.

eration, the AC and DC COUPLING LEDs indicate the coupling

Probe DC Gain Adjust

ocated on probes)

(l

If your oscilloscope does not have 50 Ω impedance settings for inputs, you can

place a 50 Ω feedthrough termination on the oscilloscope input and connect

the amplifier output cable to the termination. Do not place the feedthrough

mination at the amplifier end of the BNC connecting cable.

ter

After the PROBE DEGAUSS AUTOBALANCE routine has been run, the probe

nd amplifier system will meet all published specifications. However, if you want

a

to improve the tolerance of the system accuracy, or to intentionally offset the

accuracy to make up for total system errors, you can manually adjust the gain of

the probe. See the service manual for adjustment procedures and locations.

NOTE. You should be careful to note the existing position of the DC Gain

Adjustment before you alter it, so that you may return it to the initial, calibrated

position. By altering the DC Gain Adjustment, you may cause the probe to not

meet the warranted DC Accuracy specification.

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual 21

Page 40

Control Summary

GPIB Operation

For example, th

1%. If you want to measure a 3 Ap-p, 1 kHz square wave and need increased

accuracy (better than 0.25% is attainable), first adjust the TCP312A on the 1 A/V

range setting using a calibrated 3 Ap-p, 1 kHz square wave source. Then, attach

the probe to your circuit and take your measurement. Remember, altering the DC

Gain Adjustment may cause the probe to not meet the warranted DC Accuracy

specificati

The TCPA300 and TCPA400 Current Probe Amplifiers do not have direct GPIB

connections. However, you can use a computer to control the oscilloscope that the

amplifier

your current measurements over the oscilloscope GPIB bus.

Refer to

your oscilloscope manual for instructions on using the GPIB bus.

e typical accuracy of the TCP312A probe on the 1 A/V range is

on.

is connected to, enabling you to change the time and scale factors of

22 TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 41

Reference Notes

These notes are provided to help you utilize the full potential o f the TCPA300

and TCPA400 current probe systems.

Degaussing a Probe with an Unpowered Conductor in the Jaws

Under almost all conditions, you can degauss your current probe while a conductor

of an unpow

with an unpowered circuit is that any offset from stray DC magnetic fields are

compensated. In an automated environment, degaussing with the conductor in the

probe jaws eliminates the need to manually remove the probe.

NOTE. Be certain that the conductor in the probe jaws is completely unpowered.

Any current flowing through the conductor will cause a residual offset in the

current

If the impedance of your circuit is higher than that shown, the degauss procedure

eds because the amplifier is able to saturate the probe core. (See Figure 12

succe

on page 25.) While degauss occurs, the probe induces a voltage in the unpowered

circuit as shown. (See Figure 12 on page 25.) Your circuit must be able to absorb

this induced voltage. With low impedance circuits, several amperes may be

induced in the circuit being measured. This may be of concern when you are

using very small conductors.

ered circuit is clamped in the jaws. The advantage of degaussing

probe, and the amplifier may report an inaccurate result.

le 4: Unpowered circuit degauss limits

Tab

imum circuit

Min

Probe type

TCP312A 10 mΩ

TCP305A 5 mΩ

TCP303 5 mΩ

TCP404XL 1 mΩ

resistance Maximum induced voltage

mV at 200 Hz

40

mV at 200 Hz

40

0 mV at 200 Hz

3

5 mV at 100 Hz

1

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual 23

Page 42

Reference Notes

Measuring Dif

ferential Current

You can place two conductors in a current probe to provide differential or null

current measurement. (See Figure 11.) This avoids the necessity of using two

current meas

Figure 1

WARNING. To avoid injury or loss of life from shock or fire, do not put more than

one uninsulated conductor at a time in the probes.

1: Measuring two conductors

urement systems with a differential oscilloscope.

An insulated conductor is defined as any conductor that is surrounded by an

insulating material that is capable of isolating the voltage present on the conductor.

Note that lacquer coatings like those typically found on transformer windings do

not provide sufficient, reliable insulation for use with current probes. The lacquer

coating can be easily nicked or damaged, compromising the insulating capabilities

e lacquer coating.

of th

Do not force the slide closed. Damage to the probe may result. If you cannot close

slide around the conductor(s), either reduce the number of conductors you are

the

measuring, or, if possible, take your measurement on a smaller conductor.

ient the two conductors under test so that the polarities oppose each other.

1. Or

2. Clamp the current probe around the two conductors as shown. Be careful not

o pinch a conductor in the probe jaws.

t

24 TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 43

Reference Notes

Figure 12: Measuring differential current and nulls

3. Measure the current. A waveform above the baseline indicates the conductor

with the conventional current flow (I

, in the direction of the probe arrow),

1

is carrying the greater current. Conventional current flows from positive to

negative.

4. To adjust for a current null, adjust the current in one of the conductors until

the displayed measurement is zero.

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual 25

Page 44

Reference Notes

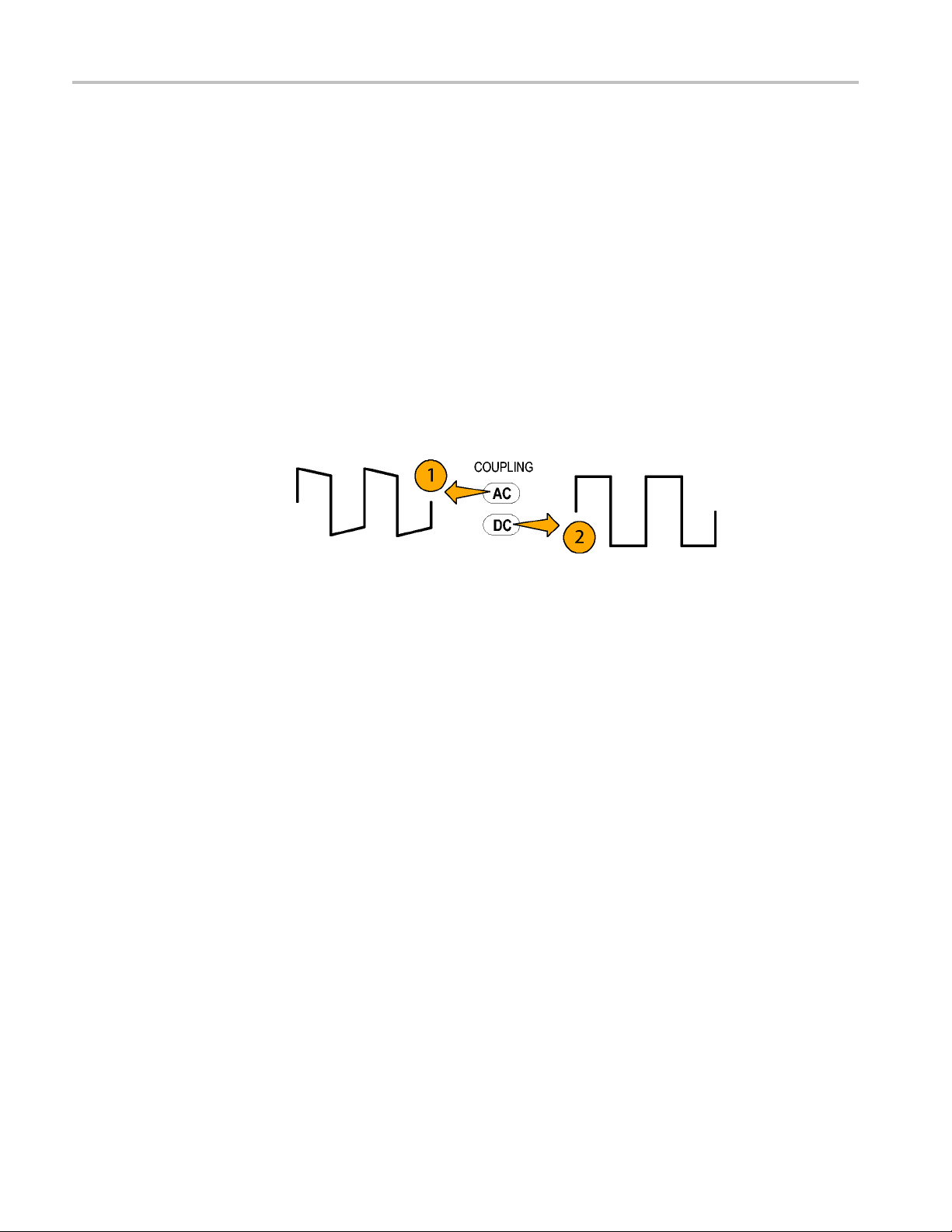

AC and DC Coupl

ing

You can couple the signal input to the TCPA300 and TCPA400 with either DC

or AC coupling. DC coupling shows the DC and AC measurement components

while AC coup

you use AC coupling, make sure that the input DC current does not exceed the

probe specifications.

AC coupling will affect waveforms at frequencies higher than the AC Coupling

Low-Frequency Bandwidth. For example, pulsed currents may exhibit rolloff or

decreased amplitude. (See Figure 13.)

1. A low-frequency square wave using AC coupling. The signal exhibits

low-frequency rolloff.

2. By changing the amplifier coupling to DC, the pulse is displayed as truly

square, as shown.

e 13: Effect of AC or DC coupling on low-frequency signals

Figur

ling removes the DC component from the displayed signal. When

u are trying to examine a low-frequency signal that is superimposed on a

If yo

comparatively large DC component, you can resolve the signal by p erforming

these steps:

1. Select the range setting that will display the maximum detail without

exceeding the dynamic range of the signal.

2. Adjust the oscilloscope V/div sensitivity (A/div if using the TEKPROBE

interface), to display maximum signal detail.

26 TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 45

Reference Notes

Maximum Curre

nt Limits

Current probes have three maximum current ratings: continuous, pulsed, and

Ampere-second p roduct. Exceeding any of these ratings can saturate the probe

core, magnet

NOTE. Always degauss the probe after measuring a current that exceeds the

maximum continuous current, maximum pulsed current, or Ampere-second

product rating of the probe. Exceeding these ratings can magnetize the probe

and cause measurement errors.

izing the core and causing measurement errors.

Maximum Continuous Current refers to the maximum current that can be

continuous

Specifications.) The maximum continuous current value is derated with

frequency; as the frequency increases, the maximum continuous current

rating decreases.

Maximum Pulsed Current refers to the maximum peak value of pulsed current

the probe can accurately measure, regardless of how short (within bandwidth

limitations) the pulse duration is.

Ampere-Second Product defines the maximum width of pulsed current

that you can measure when the pulse amplitude is between the maximum

continuous and maximum pulsed current specifications. The maximum

contin

ly measured at DC or at a specified AC frequency. (See page 49,

uous specification itself varies by frequency.

etermine if your measurement exceeds the Ampere-second product, perform

To d

either Procedure A (Maximum Allowable Pulse Width), or Procedure B

(Maximum Allowable Pulse Amplitude).

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual 27

Page 46

Reference Notes

Procedure A: Maximum

Allowable Pulse Width

To determine th

e maximum allowable pulse width do the following:

1. Measure the peak current of the pulse.

2. Divide the Ampere-second (or Ampere-microsecond) specification for the

range setting of the probe by the measured peak current of the pulse. The

quotient is

the maximum allowable pulse width (PW

max

).

For example, the TCP312A Current Probe has a maximum Ampere-second

product of 500 A-μs in the 10 A/V range setting. If a pulse measured with a

TCP312A has a peak current of 40 A, the maximum allowable pulse width

would be 500 A-μs divided by 40 A, or 12.5 μs.

3. Check that the pulse width at the 50% point of the measured signal is less than

the calculated m aximum allowable pulse width (PW

max

).

Figure 14: Applying the amp-second product rule

28 TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 47

Reference Notes

Procedure B: Maximum

Allowable Pulse Amplitude

To determine th

1. Measure the pulse width at the 50% points.

2. Divide the Ampere-second (or Ampere-microsecond) specification for the

range setting of the probe by the pulse width. The quotient is the maximum

allowable p

be less than this value.

For example

product of 500 A-μs in the 10 A/V range setting. If a pulse measured with a

TCP312A probe has a width of 15 μs, the maximum allowable peak current

would be 500 A-μs divided by 15 μs, or 33.3 A.

e maximum allowable pulse amplitude do the following:

ulse amplitude; the peak amplitude of the measured pulse must

, the TCP312A Current Probe has a maximum Ampere-second

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual 29

Page 48

Reference Notes

Measuring Non

continuous Current with the TCP404XL Probe

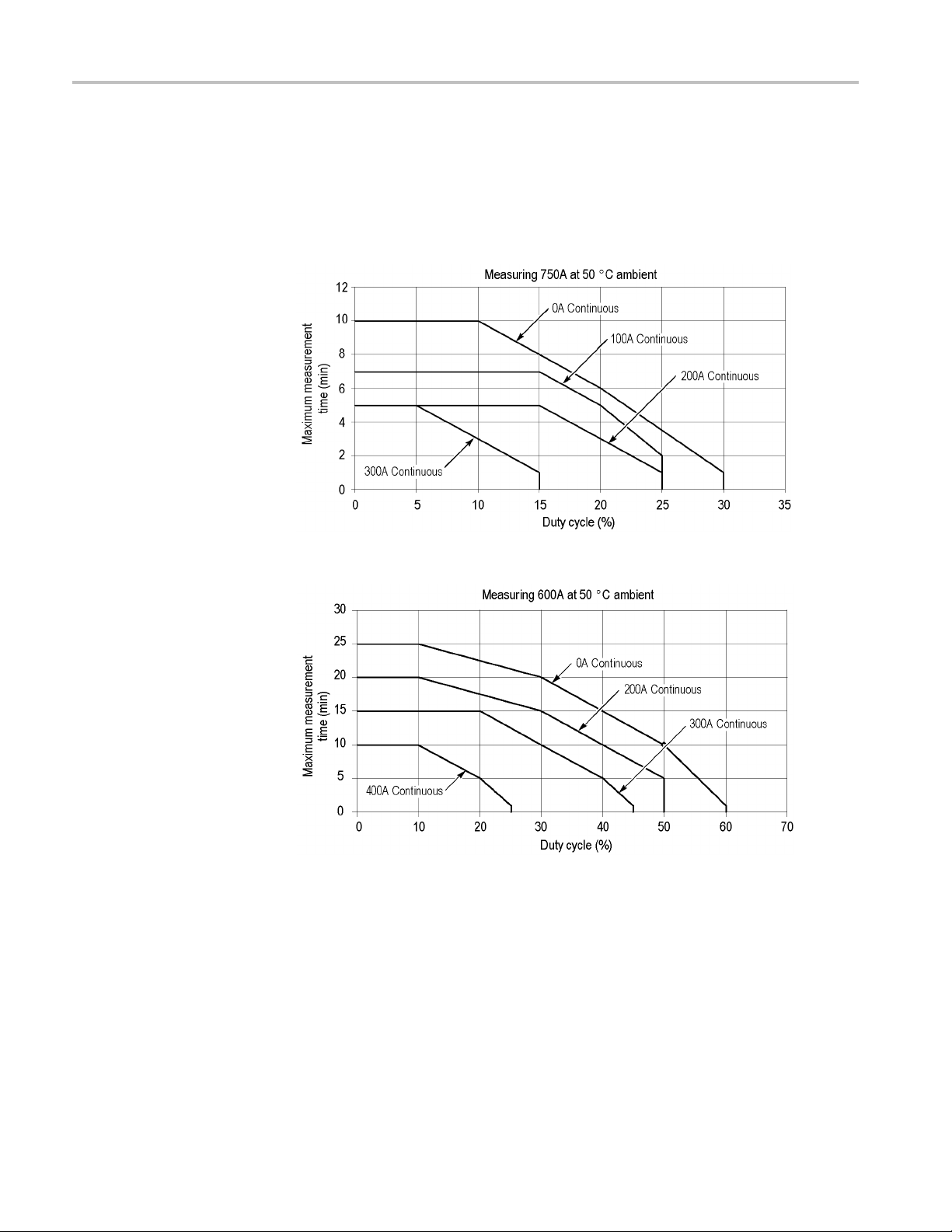

When you measure a noncontinuous current with the TCP404XL probe, you

need to take into consideration several factors to ensure that you make accurate

measurement

and duty cycle of the continuous and noncontinuous current, and the ambient

temperature, all affect the maximum amount of time allowed for the measurement,

which defines the safe operating area of the probe.

You can calculate the duty cycle of the continuous and noncontinuous

current when you know the duration of the noncontinuous current (defined as

measurement time) and the measurement period. A continuous and noncontinuous

current is shown and how to calculate the duty cycle. (See Figure 15.)

s and do not trip the thermal overload circuit. The amplitude

ure 15: Duty cycle calculation

Fig

er you calculate the duty cycle of the noncontinuous current you are measuring,

Aft

you can use the other factors (continuous and noncontinuous current amplitude,

etc.) to compare your measurement to those shown. (See Figure 35 on page 58.)

(See Figure 37 on page 59.)

You can see how duty cycle affects the measurement time by looking at any of

thethreegraphs. (SeeFigure35onpage58.)(SeeFigure37onpage59.) Asthe

duty cycle increases on the x-axis, the measurement time (of the noncontinuous

current) on the y-axis decreases.

30 TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual

Page 49

Reference Notes

The effect of me

and 600 A respectively, with varying duty cycles and levels of continuous current

is illustrated. (See Figure 35 on page 58.) (See Figure 36 on page 58.) The

ambient temperature in these two examples is kept constant at 50 °C.

WAR N I NG. To prevent injury, keep your hands away from the probe head until it

has had time to cool after disconnecting the probe from the circuit. Because when

using the pr

for extended lengths of time, the probe head surface can become hot to the touch.

To see how

the curves for measurements of 200 A continuous between the two graphs. (See

Figure 35 on page 58.) (See Figure 36 on page 58.) Compare the maximum

measurement time allowed for a duty cycle of 20%: At 750 A, you have 3 minutes

of safe measurement time, versus 17 minutes for a smaller noncontinuous-current

amplitude of 600 A.

By looking at any of the three graphs, you can also see that when you measure

a noncontinuous current having the same amplitude and duty cycle, the

rement time decreases as the continuous-current amplitude increases.

measu

Finally, compare the two graphs. (See Figure 35 on page 58.) (See Figure 37

ge 59.) Here, the effect of ambient temperature on measurement time is

on pa

illustrated. Given a continuous current of 200 A with a noncontinuous current

of 750 A, and having a 20% duty cycle, a 27 °C increase in temperature yields a

12 minute decrease in maximum measurement time.

asuring two different noncontinuous current amplitudes, 750 A

obe near the upper current limit and maximum ambient temperature

noncontinuous current amplitude affects measurement time, look at

Keep these factors into account when taking measurements to ensure accuracy

and to protect both yourself from injury and the equipment from damage.

TCPA300/400 Amplifiers and TCP300A/400 Series Current Probes User Manual 31

Page 50

Reference Notes

Extending Cur

Extending DC Range

rent Range

You may encounter situations where your measurement exceeds the maximum

current rating of the connected probe. This section discusses methods for

extending AC

WARNING. To avoid personal injury or loss of life due to shock or fire, do

not exceed the specified electrical limits of the TCPA300 and TCPA400 or any

applicable accessories. When using multiple conductors, do not exceed current

limits on either conductor.

If you wan