Page 1

Instruction Manual

TCPA300/400 Amplifiers &

TCP300/400 Series AC/DC Current Probes

071-1183-03

This document applies for firmware version 1.0

and above.

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or

suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

H In North America, call 1-800-833-9200.

H Worldwide, visit www.tektronix.com to find contacts in your area.

Page 3

Warranty 2

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty work

may be new or reconditioned to like new performance. All replaced parts, modules and products become the

property of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by Tektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the Tektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than Tektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A P ARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

Getting Started

Operating Basics

Preface xv........................................................

System Configuration 1--1.............................................

Options 1--3........................................................

Standard Accessories 1--4.............................................

Optional Accessories 1--5.............................................

Probe Covers 1--6....................................................

Travel Case 1--7.....................................................

Connecting the Amplifier to an Oscilloscope 1--8..........................

Power on the Amplifier 1--8...........................................

Connecting a Current Probe to the Amplifier 1-- 9..........................

Operating the Current Probe Slide 1--10...................................

Degaussing and Autobalancing the Current Probe 1--11......................

DC Measurements 1--12...............................................

AC Measurements 1--14...............................................

Control Summary 2--1.........................................

TCPA300 and TCPA400 Controls 2--2...................................

PROBE DEGAUSS AUTOBALANCE Button and Indicator 2--2..........

MANUAL BALANCE Buttons and Indicator 2--3......................

PROBE OPEN Indicator 2--3.......................................

OVERLOAD Indicator 2--3........................................

NOT TERMINATED INTO 50 Ω Indicator 2--4........................

NONCOMPATIBLE PROBE TYPE Indicator 2--4......................

ON/STANDBY Button 2--4........................................

RANGE Button (TCPA300 only) 2--4................................

COUPLING Button and Indicators 2--4...............................

PROBE INPUT Connector 2--5.....................................

OUTPUT Connector 2--5..........................................

Probe DC Gain Adjust (located on probes) 2--5.........................

GPIB Operation 2--6..............................................

Reference

Reference Notes 3--1...........................................

Degaussing a Probe with an Unpowered Conductor in the Jaws 3--1............

Measuring Differential Current 3--2.....................................

AC and DC Coupling 3--3.............................................

Maximum Current Limits 3--4..........................................

Measuring Noncontinuous Current with the TCP404XL Probe 3--6............

Extending Current Range 3--8..........................................

Increasing Sensitivity 3--10.............................................

Application Notes 3--11..........................................

Automobile Charging Systems 3--11......................................

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

i

Page 6

Table of Contents

Inductance Measurements 3--13.........................................

Continuity Test of Multiple-Conductor Cable 3--15..........................

Measuring Inductor Turns Count 3--16....................................

Power Measurement and Analysis Software 3--17...........................

Troubleshooting and Error Codes 3--19............................

Displaying Error Codes with the Probe Degauss Autobalance Button 3--22.......

Correcting the Cause of an Error Code 3--24...............................

Shutdown Error 3--24..................................................

Specifications

Warranted Specifications 4 --1..........................................

Nominal and Typical Characteristics 4--2.................................

Mechanical Characteristics 4--3........................................

Environmental Characteristics 4--5......................................

TCP404XL Maximum Measurement Times 4--12...........................

Performance Verification

Performance V erification Overview 5--1...........................

Performance Verification and Functional Checks 5--1.......................

Test Procedure Conditions 5--2.........................................

Equipment Preparation 5--2............................................

TCPA300 and TCPA400 Performance Verification 5--3..............

Equipment Required 5--3..............................................

Making DC Current Loops 5--4.........................................

Front-Panel Display 5--5..............................................

DC Gain Accuracy 5--6...............................................

Bandwidth 5--9......................................................

AC Coupling 5--12....................................................

Degauss 5--13........................................................

Current Overload Test 5--14............................................

TCPA300 Amplifier Test Record 5--16....................................

TCPA400 Amplifier Test Record 5--17....................................

TCP305 and TCP312 Performance Verification 5--19.................

Required Test Equipment 5--20..........................................

DC Gain Accuracy 5--21...............................................

Rise Time 5--24......................................................

Bandwidth 5--26......................................................

TCP305 Current Probe Test Record 5--29..................................

TCP312 Current Probe Test Record 5--30..................................

TCP303 and TCP404XL Performance Verification 5--31..............

Equipment Required 5--32..............................................

DC Gain Accuracy 5--33...............................................

Rise Time 5--36......................................................

Bandwidth (TCP303) 5--39.............................................

Bandwidth (TCP404XL) 5--41..........................................

TCP303 Current Probe Test Record 5--42..................................

TCP404XL Current Probe Test Record 5--43...............................

ii

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 7

Adjustment Procedures

Maintenance

Table of Contents

Adjustment Procedures Overview 6--1............................

TCPA300 and TCPA400 Amplifier Adjustments 6--3................

Required Test Equipment 6--3..........................................

Accessing the Adjustments 6--3.........................................

TCPA300 Amplifier 6--4..............................................

TCPA400 Amplifier 6--5..............................................

TCP305 and TCP312 Adjustments 6--7...........................

Required Test Equipment 6--7..........................................

Accessing the Adjustments 6--7.........................................

TCP305 and TCP312 DC Gain Adjustment 6--8............................

TCP303 and TCP404XL Adjustments 6--11........................

Required Test Equipment 6--11..........................................

Adjustment Locations 6--12.............................................

TCP303 and TCP404XL Transient Response and Coarse Gain Adjustment 6--13..

DC Gain Adjustment 6--18.............................................

Replaceable Parts

Customer Maintenance 7--1.....................................

Service Strategy 7--1.................................................

Preventive Maintenance 7--1...........................................

Disassembly 7--3..............................................

Amplifiers 7--3......................................................

Equipment Required 7--3..............................................

Removing the Outer Case and Internal Covers 7--4.........................

Replacing the Front Panel Assembly 7--7.................................

Replacing the Amplifier Board 7 --8.....................................

Replacing the Power Supply 7--10.......................................

Replacing the Fan 7--11................................................

Probes 7--13.........................................................

Equipment Required 7--13..............................................

TCP305 and TCP312 7--14.............................................

TCP303 and TCP404XL 7--18..........................................

Isolating Hardware Faults 7--21..................................

Determining the Amplifier Firmware Version Number 7--22...................

Replaceable Parts 8--1..........................................

Parts Ordering Information 8--1.........................................

Using the Replaceable Parts List 8--1....................................

Amplifier Replaceable Parts 8--3.................................

Current Probes Replaceable Parts 8--9............................

Glossary and Index

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

iii

Page 8

Table of Contents

iv

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 9

List of Figures

Table of Contents

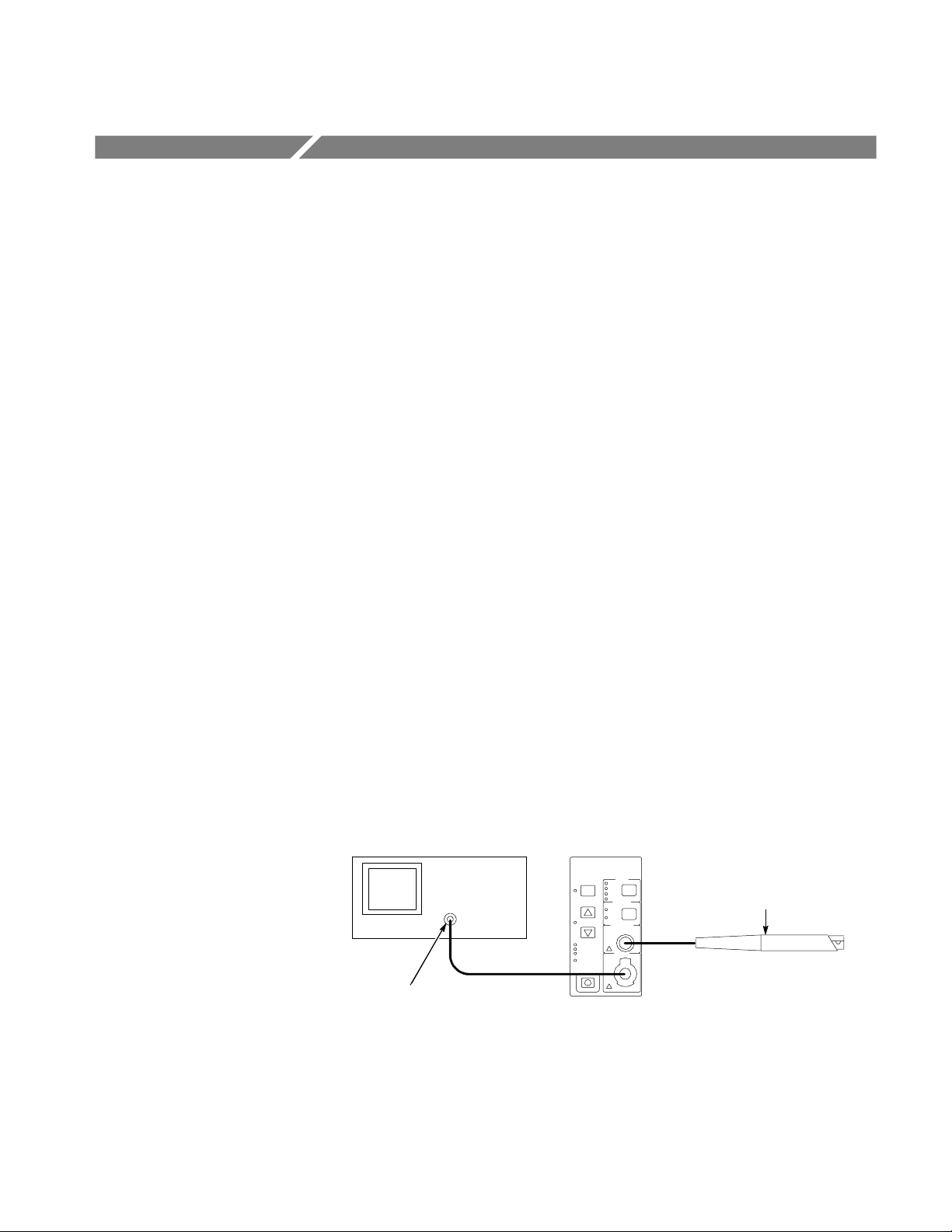

Figure 1--1: Typical TCPA300/400 current measurement system 1--1...

Figure 1--2: Using the probe holders 1--6..........................

Figure 1--3: Equipment locations in the travel case 1--7..............

Figure 1--4: Connecting and disconnecting a current probe

to the amplifier 1--9........................................

Figure 1--5: TCP312 and TCP305 slide operation 1--10...............

Figure 1--6: TCP303 and TCP404XL slide operation 1--11............

Figure 1--7: Current probe polarity 1--13...........................

Figure 2--1: The TCPA300 front panel 2--1........................

Figure 3--1: Measuring differential current and nulls 3--3............

Figure 3--2: Effect of AC or DC coupling on low-frequency signals 3--3.

Figure 3--3: Applying the amp-second product rule 3--5..............

Figure 3--4: Duty cycle calculation 3--6............................

Figure 3--5: Increasing the DC measurement range 3--9..............

Figure 3--6: Increasing probe sensitivity 3--10.......................

Figure 3--7: Setup for measuring charging current 3--12..............

Figure 3--8: Charge Current Waveforms 3--12.......................

Figure 3--9: Measuring inductance with a low-impedance source 3--13..

Figure 3--10: Linear current vs. time ramp 3--14.....................

Figure 3--11: Measuring inductance with a high-impedance source 3--15.

Figure 3--12: High-impedance source current ramp 3--15.............

Figure 3--13: Measuring the number of turns in a coil 3--16...........

Figure 3--14: Turns measurement using reference coil 3--17............

Figure 3--15: Error code display 3--22..............................

Figure 3--16: Interpreting the error code display 3--23................

Figure 4--1: Probe jaw dimensions (nominal) 4--4...................

Figure 4--2: Frequency derating--TCP312 4--8......................

Figure 4--3: Frequency derating--TCP305 4--8......................

Figure 4--4: Frequency derating--TCP303 4--9......................

Figure 4--5: Frequency derating--TCP404XL 4--9...................

Figure 4--6: Insertion impedance graphs for the current probes 4--10...

Figure 4--7: Specified operating area of the probes 4--11..............

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

v

Page 10

Table of Contents

Figure 4--8: Measuring 750A noncontinuous at 50 °C

ambient temperature 4--12....................................

Figure 4--9: Measuring 600A noncontinuous at 50 °C

ambient temperature 4--12....................................

Figure 4--10: Measuring 750A noncontinuous at 23 °C

ambient temperature 4--13....................................

Figure 5--1: Check LED functionality 5--5.........................

Figure 5--2: Equipment setup for DC gain accuracy test 5--6..........

Figure 5--3: Bandwidth test setup 5--9.............................

Figure 5--4: AC coupling test setup 5--12...........................

Figure 5--5: Setup for degaussing the current probe 5 -- 13.............

Figure 5--6: Overload test setup 5--14..............................

Figure 5--7: DC gain accuracy test setup for TCP305 and TCP312 5--21.

Figure 5--8: Rise time test setup for the TCP305 and TCP312 5--24.....

Figure 5--9: Bandwidth test setup for TCP305 and TCP312 5--26.......

Figure 5--10: DC gain accuracy test setup for the

TCP303 and TCP404XL 5--33.................................

Figure 5--11: Rise time test setup for the TCP303 and TCP404XL 5--36.

Figure 5--12: Bandwidth test setup for TCP303 5--39.................

Figure 6--1: Amplifier adjustments 6--4...........................

Figure 6--2: Gain adjustment locations 6--5........................

Figure 6--3: TCP305 and TCP312 DC gain adjustment location 6--7...

Figure 6--4: DC gain adjustment setup for TCP305 and TCP312 6--9..

Figure 6--5: TCP303 and TCP404XL adjustment locations 6--12.......

Figure 6--6: TCP303 and TCP404XL transient response and

coarse gain adjustment setup 6--14.............................

Figure 6--7: DC gain accuracy adjustment setup 6--18................

Figure 7--1: Removing the case from the amplifier 7--4...............

Figure 7--2: Removing the right-side inner panel 7--5................

Figure 7--3: Removing the left-side inner panel 7--6.................

Figure 7--4: Disconnecting the front panel assembly 7--7.............

Figure 7--5: Removing the three heat sink clips 7--8.................

Figure 7--6: Removing the amplifier board 7--9.....................

Figure 7--7: Replacing the power supply 7--10.......................

Figure 7--8: Removing the AC power connector 7--11.................

Figure 7--9: Removing the fan 7--12...............................

vi

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 11

Table of Contents

Figure 7--10: Removing the strain relief boot 7--14...................

Figure 7--11: Removing the top half of the probe 7--15................

Figure 7--12: Removing the probe slide 7--15........................

Figure 7--13: Removing the current transformer 7--16................

Figure 7--14: Removing the circuit board and cable assembly 7--17.....

Figure 7--15: Removing the handle 7--18...........................

Figure 7--16: Removing the current transformer 7--19................

Figure 7--17: Removing the circuit board and cable 7--20.............

Figure 7--18: Displaying the amplifier firmware version number 7--22..

Figure 8--1: TCPA300 and TCPA400 replaceable parts 8--3...........

Figure 8--2: TCPA300 and TCPA400 standard accessories 8--6........

Figure 8--3: TCPA300 and TCPA400 optional accessories 8--7........

Figure 8--4: TCP305 and TCP312 replaceable parts 8--9.............

Figure 8--5: TCP303 replaceable parts 8--11........................

Figure 8--5: TCP404XL replaceable parts 8--13......................

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

vii

Page 12

Table of Contents

viii

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 13

List of Tables

Table of Contents

Table 1--1: Amplifier options 1--3................................

Table 1--2: Service options 1--3..................................

Table 3--1: Unpowered circuit degauss limits 3--1...................

T able 3--2: Automobile charging systems test setup 3--11.............

Table 3--3: Troubleshooting 3--19.................................

Table 3--4: Amplifier error codes 3--23.............................

Table 4--1: Warranted TCPA300 and TCPA400 specifications 4--1....

Table 4--2: Nominal and typical amplifier characteristics 4--2........

Table 4--3: TCPA300 and TCPA400 mechanical characteristics 4--3...

Table 4--4: Probe mechanical characteristics 4--4...................

Table 4--5: Shipping weights and dimensions 4--4...................

T able 4--6: Environmental characteristics 4--5.....................

Table 4--7: Certifications and compliances 4--6.....................

Table 5--1: Amplifier checks 5--1.................................

T able 5--2: Probe performance verification checks 5--1..............

Table 5--3: Required test equipment 5--3.........................

Table 5--4: Equipment settings 5--7..............................

Table 5--5: DC gain accuracy test for the TCPA300 and TCPA400 5--7.

Table 5--6: Equipment settings for bandwidth check 5--9............

Table 5--7: TCPA300 bandwidth measurements 5 -- 11................

Table 5--8: TCPA400 bandwidth measurements 5 -- 11................

Table 5--9: TCPA300 AC coupling measurements 5--13...............

Table 5--10: Maximum current ratings for

TCPA300-compatible probes 5--15............................

Table 5--11: Required test equipment 5--20.........................

T able 5--12: Equipment settings for DC gain accuracy 5--21...........

Table 5--13: DC gain accuracy test for the TCP305 and TCP312 5--23..

Table 5--14: Equipment settings for rise time 5--25..................

Table 5--15: Equipment settings for bandwidth 5--27.................

Table 5--16: Bandwidth test for the TCP305 and TCP312 5--28........

Table 5--17: Required test equipment 5 -- 32.........................

T able 5--18: Equipment settings for DC gain accuracy 5--33...........

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

ix

Page 14

Table of Contents

T able 5--19: DC gain accuracy test worksheet for the TCP303 and

TCP404XL 5--35...........................................

Table 5--20: Equipment settings for rise time 5--37..................

Table 5--21: Equipment settings for bandwidth 5--40.................

Table 5--22: Bandwidth test for the TCP303 5--41...................

Table 6--1: Amplifier and probe adjustments 6--1...................

Table 6--2: Required test equipment 6--3..........................

Table 6--3: TCPA300 gain adjustments 6--4........................

Table 6--4: TCPA400 gain adjustments 6--5........................

Table 6--5: Required test equipment 6--7..........................

Table 6--6: Settings for DC gain adjustment 6--8...................

Table 6--7: DC gain accuracy adjustments for the

TCP305 and TCP312 6--9...................................

Table 6--8: Required test equipment 6--11..........................

Table 6--9: Settings for transient response and

preliminary gain adjustments 6--14............................

T able 6--10: Equipment settings for DC gain accuracy 6--19...........

Table 6--11: DC gain accuracy adjustments for the

TCP303 and TCP404XL 6--19................................

Table 7--1: Equipment required 7--3.............................

Table 7--2: Equipment required 7--13.............................

Table 7--3: Amplifier hardware faults 7--21.........................

Table 7--4: Probe hardware faults 7--22............................

Table 8--1: Power cord identification 8--5.........................

x

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 15

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Connect and Disconnect Properly. Connect the probe output to the measurement

instrument before connecting the probe to the circuit under test. Disconnect the

probe input and the probe ground from the circuit under test before disconnecting

the probe from the measurement instrument.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Connect the ground lead of the probe to earth ground only.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

xi

Page 16

General Safety Summary

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

Do not connect to or

remove from an

uninsulated conductor that

is HAZARDOUS LIVE.

Protective Ground

(Earth) Terminal

Breakable.

Do not drop.

Do not connect

to or discon-

nect from unin-

sulated Haz-

ardous Live

conductors.

WARNING

Hot Surface

Use only on an

insulated wire.

xii

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 17

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

xiii

Page 18

Service Safety Summary

xiv

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 19

Preface

This Instruction Manual supports the operation and basic maintenance of the

TCPA300 and TCPA400 Current Probe Amplifiers, and the TCP300/400 Series

AC/DC current probes that mate with the amplifiers. The current probes covered

in this manual are listed below:

H TCP312 (30 amps, 100 MHz, compatible with TCPA300)

H TCP305 (50 amps, 50 MHz, compatible with TCPA300)

H TCP303 (150 amps, 15 MHz, compatible with TCPA300)

H TCP404XL (500 amps*, 2 MHz, compatible with TCPA400)

*750 amps DC derated with duty cycle

If you are not familiar with these products, please refer to the Getting Started and

Operating Basics chapters of this manual for basic operating information.

If you are an advanced user, the Reference section contains information on

advanced applications as well as user diagnostic and troubleshooting information.

The Performance Verification and Adjustment Procedure sections support the

qualification and calibration of the probes when used with either amplifier.

Manual Conventions

The Maintenance section supports the routine maintenance and repair of

mechanical parts associated with the amplifiers.

The Glossary and Index are provided as quick reference locators for important

information.

The term “amplifier” is used to refer to either the TCPA300 or TCPA400 when

referring to common attributes. If a subject is unique to either amplifier, the

amplifier will be referred to directly by model.

The terms “current probe” and “probe” are used to refer to any of the

TCP300/400 Series current probes when referring to common attributes. If a

subject is unique to a particular probe, the probe will be referred to directly by

model.

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

xv

Page 20

Preface

xvi

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 21

Getting Started

Page 22

Page 23

Getting Started

The TCPA300 and TCPA400 current probe amplifiers let you use one probe to

simultaneously measure AC and DC current. The amplifiers convert the sensed

current into a proportional voltage signal that you can measure directly with an

oscilloscope.

The TCPA300 and TCPA400 current probe amplifiers provide better linearity

than other current measurement systems because of a current feedback process

used with the probe. DC measurement capability and high bandwidth allow the

amplifiers to accurately represent square waves and fast-rise signals.

The TCPA300 and TCPA400 and associated probes provide these features:

H Simultaneous DC and AC current measurements up to 750 A peak

H High sensitivity

H One-button autobalancing and probe degaussing

H No adjustments needed to match a current probe to an individual amplifier

H AC or DC coupling of signal

System Configuration

H Direct scaling and unit readout on compatible TEKPROBE level II

oscilloscopes

A complete current measurement system consists of a current probe amplifier, a

compatible current probe, and an appropriate oscilloscope. Refer to Figure 1--1.

AmplifierTest oscilloscope

Current probe

Input

Output

50 Ω oscilloscope input -- use the

TEKPROBE Interface Cable or use a 50 Ω

cable. (Add 50 Ω termination here if

oscilloscope has only high-impedance input.)

Figure 1- 1: Typical TCPA300/400 current measurement system

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

1- 1

Page 24

Getting Started

TCPA300 and TCPA400

Current Probe Amplifiers

Current Probes

The amplifier amplifies the current sensed by the probe and converts the current

to a proportional voltage that is displayed on an oscilloscope or other similar

measuring device.

The following Tektronix current probes are compatible with the TCPA300

Amplifier:

H TCP312 (30 amps, 100 MHz)

H TCP305 (50 amps, 50 MHz)

H TCP303 (150 amps, 15 MHz)

The following Tektronix current probes are compatible with the TCPA400

Amplifier:

H TCP404XL (750 amps*, 2 MHz)

* 500 amps continuous, 750 amps DC derated with duty cycle

You can also use the CT-4 High-Current Transformer with the TCP305 and

TCP312 current probes to extend the AC current measurement range to

20,000 peak amps.

Oscilloscope

An oscilloscope displays the output from the current measuring system. A 50 Ω

cable is included to connect the amplifier to the oscilloscope input channel. A

TEKPROBE-to-TEKPROBE interface cable is also included for connecting to

TEKPROBE level II oscilloscopes.

If the oscilloscope does not have an input that can be set to 50 Ω impedance, you

need a feedthrough 50 Ω termination. This termination is included as a standard

accessory with your TCPA300 and TCPA400 Current Probe Amplifiers.

1- 2

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 25

Options

Getting Started

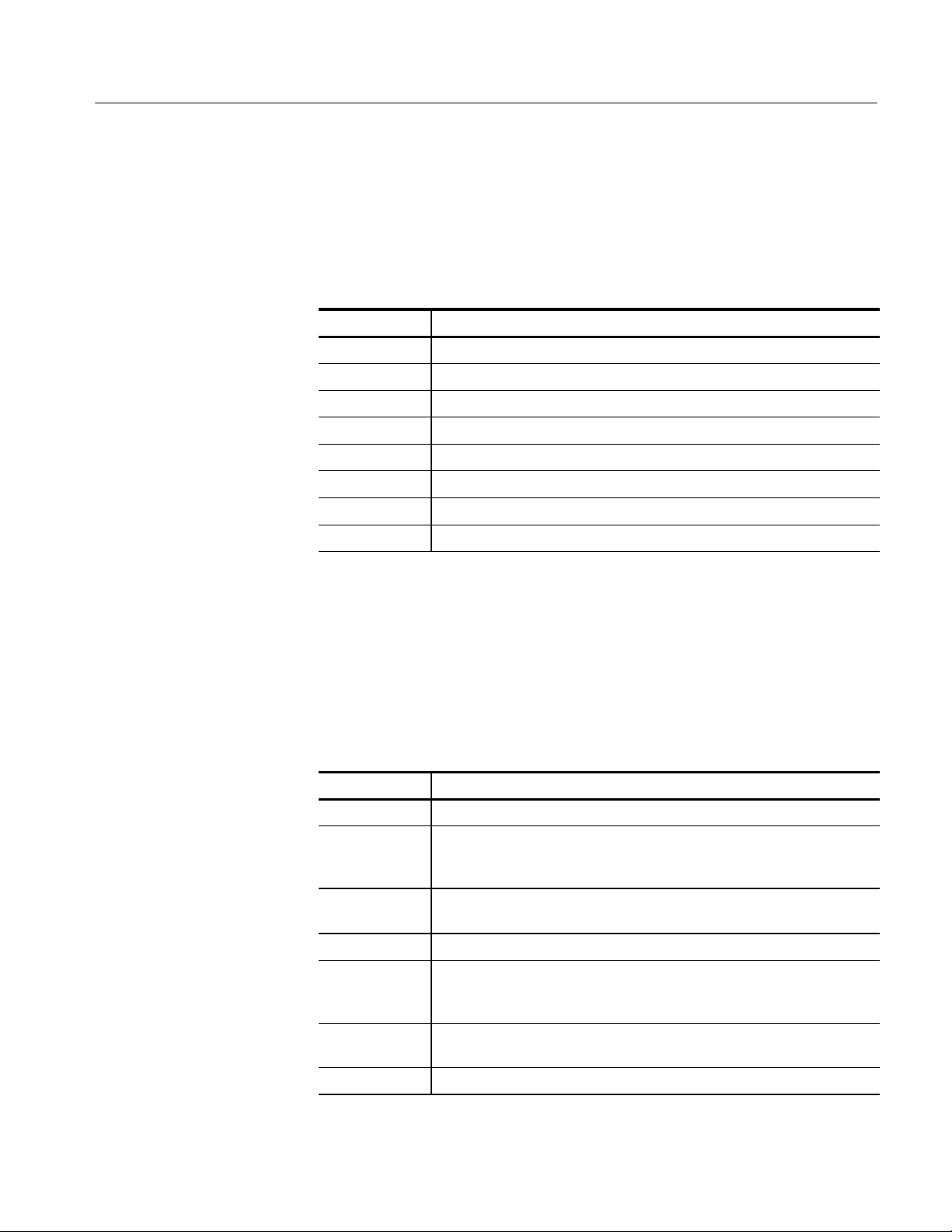

Table 1--1 lists options that are available for the TCPA300 and TCPA400

amplifiers.

Table 1- 1: Amplifier options

Option Description

A1 Universal Euro power cord

A2 United Kingdom power cord

A3 Australia power cord

A5 Switzerland power cord

A6 Japan power cord

AC China power cord

A99 No power cord

L5 Japanese Instruction Manual

Table 1--2 lists the Tektronix service options you can order for your amplifiers

and probes. Designed to support tracking of calibration to requirements of

ISO9000 and to provide for extended repair coverage, these options help fix your

long-term maintenance costs and eliminate unplanned expenditures. Tektronix

Service Options are available at the time you order your instrument. Contact

your local Tektronix Sales Office for more information.

Table 1- 2: Service options

Option Description

D1 Provides the initial Test Data Report from the factory on delivery.

C3 Provides factory calibration certification on delivery, plus two more years of

calibration coverage. Throughout the coverage period, the instrument will be

calibrated according to its Recommended Calibration Interval.

D3 Provides test data on delivery plus a Test Data Report for every calibration

performed during three years of coverage (requires Option C3).

R3 Extends product repair warranty to a total of three years.

C5 Provides factory calibration certification on delivery, plus four more years of

calibration coverage. Throughout the coverage period, the instrument will be

calibrated according to its Recommended Calibration Interval.

D5 Provides test data on delivery plus a Test Data Report for every calibration

performed during five years of coverage (requires Option C5).

R5 Extends product repair warranty to a total of five years.

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

1- 3

Page 26

Getting Started

Standard Accessories

The following accessories are shipped with the amplifiers and probes. Refer to

the Replaceable Parts List beginning on page 8--1 for Tektronix part numbers to

use in ordering accessories.

Amplifiers

Probes

The following accessories are shipped with the TCPA300 and TCPA400

amplifiers.

H Power Cord (customer-chosen option)

H BNC Cable

H Termination, 50 Ω, 2W

H TEKPROBE Interconnect Cable

H Instruction Manual (English or Japanese; customer-chosen language option)

H Certificate of Traceable Calibration

When you order a current probe, you will receive these accessories:

H Probe cover

H Probe ground lead, 6 inch length (TCP305 and TCP312 only)

H Instruction Sheet

H Certificate of Traceable Calibration

1- 4

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 27

Optional Accessories

Getting Started

You can order the following optional accessories for the amplifiers and probes.

Refer to the Replaceable Parts List beginning on page 8--1 for Tektronix part

numbers to use in ordering accessories.

H One-turn 50 Ω current loop. The current loop is used in the performance

verification procedure for checking the performance of the TCPA300

Amplifier and the compatible probes.

H CT-4 High-Current Transformer. If you need to measure high-amplitude AC

currents, consider using the CT-4 with the TCP303 and TCP312 probes. The

CT-4 provides step-down ratios of 20:1 or 1000:1. For more information

about the CT-4, consult your Tektronix sales representative.

H TCPA Calibration Adapter. Use the TCPA Calibration Adapter to verify the

amplifier(s) performance independent of the current probes.

H Travel Case. The travel case includes room to store one amplifier and two

current probes, along with related cables and adapters.

H Deskew Fixture. This fixture converts the PROBE COMPENSATION output

or TRIGGER OUTPUT of the TDS5000 or TDS7000 into a set of test point

connections that allow you a convenient way to compensate for timing

differences between voltage and current probes.

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

1- 5

Page 28

Getting Started

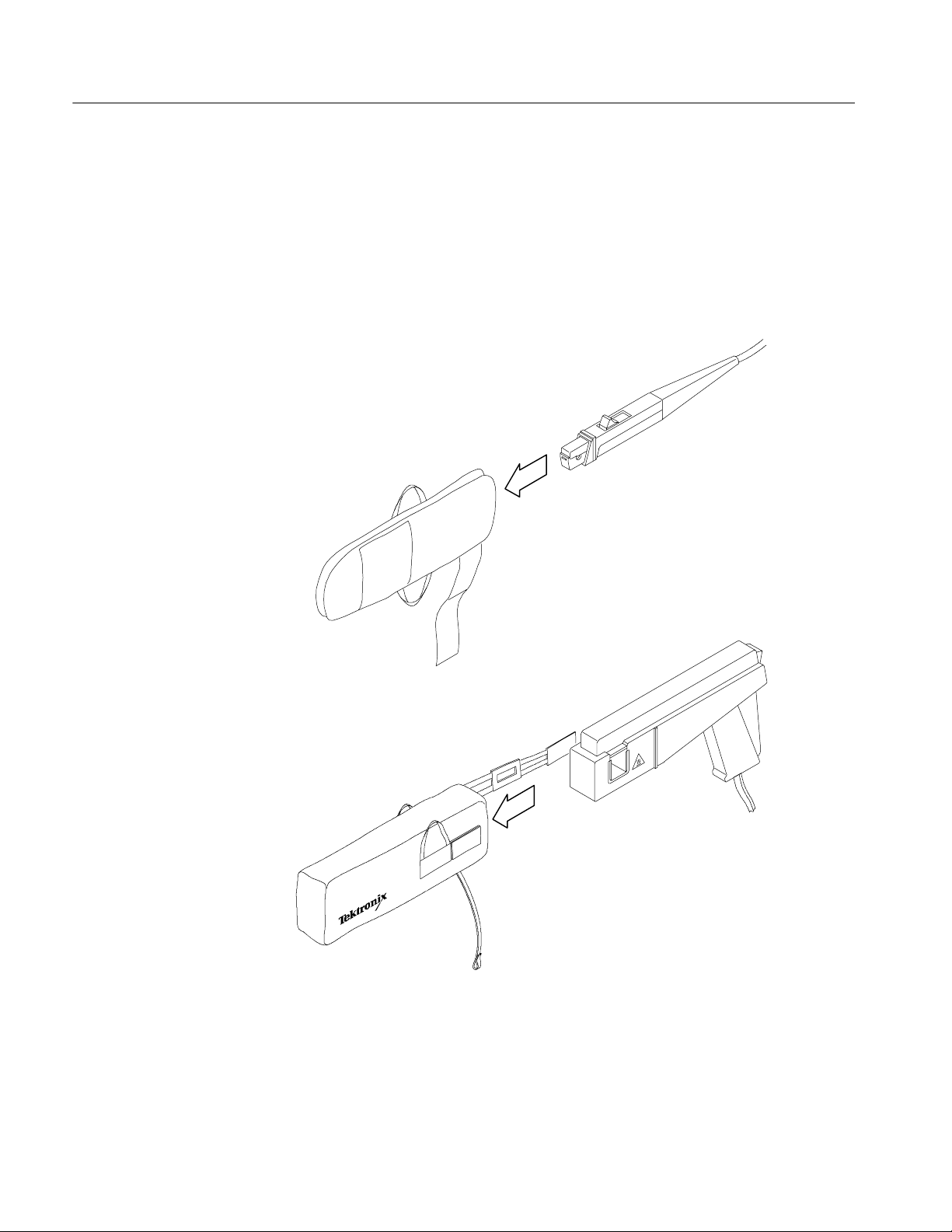

Probe Covers

The TCP300/400 Series Current Probes come with a probe cover that stores the

probe when not in use. Use the probe cover to hold your probe in a convenient

place at your bench or workstation when you are not using it. You can attach the

probe cover to the side of the bench to keep the probe off of your work surface.

See Figure 1--2.

TCP305/312

TCP303/TCP404XL

Figure 1- 2: Using the probe covers

1- 6

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 29

Travel Case

Getting Started

The travel case is a recommended accessory for the TCP A300/400 Amplifiers.

The travel case includes room to store one amplifier and two TCP300/400 Series

Current Probes, one of each size. (For example, you can store a TCP305 and a

TCP303 probe.) A compartment is included to store associated cables and

terminations. See Figure 1--3 for the proper location of the equipment.

Instruction

manual

Large current

probe

Probe holders

Small current

probe

Figure 1- 3: Equipment locations in the travel case

Cables &

terminations

Amplifier

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

1- 7

Page 30

Getting Started

Connecting the Amplifier to an Oscilloscope

You will need an oscilloscope to display the TCPA300 and TCPA400 measurement output. To use the full dynamic range of the probe/amplifier combination,

the oscilloscope must be capable of displaying a vertical scale factor of 1 mV/div

to 1V/div.

If you are using a TEKPROBE II-compatible oscilloscope, use the TEKPROBEto-TEKPROBE interface cable. Otherwise, use the supplied 50 Ω BNC cable to

connect the amplifier OUTPUT connector to your oscilloscope (see Figure 1--1

on page 1--1).

The input impedance of the oscilloscope channel must be 50 Ω, or you will

encounter slowed pulse response, increased aberrations, or incorrect DC

measurement amplitudes. If your oscilloscope provides only 1 MΩ inputs, you

need to attach a 50 Ω feed-through termination between the oscilloscope input

and the BNC cable. Do not install this termination at the amplifier end of the

BNC cable.

To utilize the full bandwidth capability of the TCPA300 and TCPA400 and

attached current probe, the oscilloscope bandwidth must be approximately five

times that of the current probe. For example, when using a TCP312 Current

Probe, the oscilloscope bandwidth must be at least 500 MHz. When using a

TCP305 Current Probe, the oscilloscope bandwidth must be at least 250 MHz.

Power on the Amplifier

After you have connected the amplifier to the oscilloscope, allow the equipment

to warm up to a stable temperature; usually 20 minutes is required.

Connect the power cord to the power input connector on the rear of the amplifier,

and then connect the power cord to your local mains supply (100 VAC to 240

VAC, 50 Hz to 400 Hz). To allow for proper ventilation, place the rear panel of

the amplifier at least 2 inches away from any obstructions. Set the amplifier on

the bottom rubber feet, and keep papers and other items away from the bottom of

the amplifier which could restrict airflow and cause overheating.

Power on the amplifier by pressing the ON/STANDBY button at the lower-left

corner of the front panel. The amplifier goes through a self-test and cycles the

front-panel LEDs.

NOTE. The amplifier stores the power state it is in when the power cord is

unplugged. If you do not put the amplifier into STANDBY mode before unplugging it, the amplifier will power on immediately when you plug it in again.

When you connect a probe to the amplifier, the amplifier uses detection circuitry

to indicate probe conditions such as noncompatible probe type and probe open.

1- 8

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 31

Connecting a Current Probe to the Amplifier

To connect a current probe to the amplifier input connector, align the red dot on

the probe connector with the red dot on the amplifier front panel, as shown in

Figure 1--4. Push the probe connector in to lock the connector. Do not twist the

connector. The connector locks into place when you push it all the way into the

front panel.

If you connect a probe to the wrong amplifier, (for example, a TCP312 to a

TCPA400), the NONCOMPATIBLE PROBE TYPE LED illuminates. Disconnect the probe and use the correct amplifier. The TCPA400 amplifier accepts

TCP3XX probes, but will only operate properly with TCP4XX probes.

To disconnect the probe from the amplifier, pull back on the connector housing

and pull the connector straight off the front panel.

CAUTION. Handle current probes with care. Do not drop a probe or subject it to

impact, or the core may crack.

Getting Started

Do not connect or disconnect a current probe while the probe is clamped around

a live conductor, or the probe may suffer electrical damage.

Align the red dots

Pull back collar,

then pull out connector

Connecting Disconnecting

Figure 1- 4: Connecting and disconnecting a current probe to the am plifier

Each current probe is calibrated before it is shipped, and should not require

further adjustment. If a probe requires adjustment, refer to the Adjustment

Procedure Overview on page 6--1 or contact your nearest Tektronix Service

Center. The adjustment procedure must be performed only by qualified service

personnel.

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

1- 9

Page 32

Getting Started

Operating the Current Probe Slide

The current probes each have a slide mechanism that opens and closes the probe

jaw. This allows you to clamp the probe around a conductor under test. The slide

must be locked closed to accurately measure current or to degauss the probe. If a

probe is unlocked, the PROBE OPEN indicator on the amplifier will light.

WARNING. Do not clamp the TCP305 or TCP312 current probes around

uninsulated wires. Damage to the probe or personal injury may result. Only use

the TCP305 or TCP312 current probes on INSULATED wires.

The TCP303 and TCP404XL current probes can be used to measure current on

uninsulated wires. However , the circuit must be de-energized when connecting or

removing the current probe.

Figure 1--5 illustrates the slide operation of the TCP305 and TCP312 current

probes. To open the probe, pull the slide back until the jaw is open. To lock the

probe, push the slide forward until the detent snaps into place.

Probe open Probe locked

Figure 1- 5: TCP312 and TCP305 slide operation

Figure 1--6 on page 1--11 illustrates the slide operation of the TCP303 and

TCP404XL current probes. To open the probe, press the bottom of the lock

button and squeeze the handle until the core is open. To lock the probe, release

the squeeze handle and press the top of the lock button.

1- 10

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 33

(1) Unlock the probe

(2) Squeeze

the handle

(a) Opening the probe

Getting Started

(2) Lock the probe

(1) Release the handle

(b) Closing and locking the probe

Figure 1- 6: TCP303 and TCP404XL slide operation

Degaussing and Autobalancing the Current Probe

Degaussing the probe removes any residual magnetization from the probe core.

Such residual magnetization can induce measurement error. Autobalancing

removes unwanted DC offsets in the amplifier circuitry. Failure to degauss the

probe is a leading cause of measurement errors. The DEGAUSS LED flashes

until you degauss the probe.

To degauss the probe, disconnect the probe from the test circuit, or ensure that

the conductor under test has no power, close and lock the slide, and then press

the amplifier PROBE DEGAUSS AUTOBALANCE button on the front panel of

the amplifier. To maintain measurement accuracy, degauss your probe in each of

these cases:

H After you turn on the amplifier and allow a 20-minute warm-up period.

H Before you connect the probe to a conductor.

H Whenever a current or thermal overload condition occurs.

H Whenever you connect a new probe.

H Whenever you subject the probe to a strong external magnetic field.

H Periodically during normal use.

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

1- 11

Page 34

Getting Started

To degauss and autobalance a current probe, perform these steps:

1. Verify that the current probe is connected to the amplifier.

2. Remove the current probe from the conductor under test.

3. Lock the probe slide closed (see Figures 1--5 and 1--6).

4. Press the amplifier PROBE DEGAUSS AUTOBALANCE button.

5. Wait about five seconds for the degauss procedure to complete.

The PROBE DEGAUSS AUTOBALANCE LED glows green when the

operation has successfully completed. If the LED is blinking orange, the degauss

operation is still in progress. If the LED is red, the operation failed, and the

cause of the failure needs to be found and fixed. For more information, refer to

the PROBE DEGAUSS AUTOBALANCE button discussion on page 2--2.

NOTE. The degauss procedure will fail if the amplifier is not properly connected

to an oscilloscope having 50 Ω input impedance. If this occurs, the NOT

TERMINATED INTO 50 Ω LED lights on the amplifier front panel.

DC Measurements

After you have completed the oscilloscope adjustments and the amplifier

degauss/autobalance procedure, your system is ready to measure current.

To measure DC current, perform these steps:

1. Verify that the amplifier and the oscilloscope input coupling are set to DC,

and the input impedance is set to 50 Ω.

2. Lock the probe closed without a conductor passing through it.

3. Adjust the ground reference of the oscilloscope to move the trace to the

desired graticule line.

4. Press the amplifier PROBE DEGAUSS AUTOBALANCE button.

The NOT TERMINATED INTO 50 Ω LED is lighted if impedance is not 50 Ω.

If this is the case, make necessary changes. (For example, use a 50 Ω termination.)

5. After the degauss/autobalance routine completes, adjust the ground reference

(if necessary) using the amplifier MANUAL BALANCE controls.

1- 12

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 35

Getting Started

WARNING. Do not clamp the TCP305 or TCP312 current probes around

uninsulated wires. Damage to the probe or personal injury may result. Only use

the TCP305 or TCP312 current probes on INSULATED wires.

The TCP303 and TCP404XL current probes can be used to measure current on

uninsulated wires. However , the circuit must be de-energized when connecting or

removing the current probe.

6. Open the probe slide, place the probe around the conductor under test, and

then lock the slide. For correct measurement polarity, make sure the probe

arrow is pointing in the direction of conventional (positive to negative)

current flow. Reversing the flow will display the current waveform upsidedown on the oscilloscope.

7. Adjust the oscilloscope time base, trigger, and gain as needed.

Figure 1--7 shows a current probe connected to a power supply line. Notice that

the probe arrow points toward the negative terminal of the power supply to

conform to the conventional current flow of positive (+) to negative (--).

Current probe

Conventional current arrow

Figure 1- 7: Current probe polarity

Power supply

Load

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

1- 13

Page 36

Getting Started

AC Measurements

To measure AC current only, and remove the DC component of the current being

measured, follow the instructions below. These are identical to the instructions

for DC current measurements except that the amplifier coupling in step 2 is set to

AC.

1. Verify that the oscilloscope input coupling is set to DC.

2. Verify that the amplifier input coupling is AC, and the input impedance is set

to 50 Ω. (The NOT TERMINATED INTO 50 Ω LED is on if impedance is

not 50 Ω.)

3. Adjust the ground reference of the oscilloscope to move the trace to the

desired graticule line.

4. Lock the probe closed without a conductor passing through it, and then press

the amplifier PROBE DEGAUSS AUTOBALANCE button.

WARNING. Do not clamp the TCP305 or TCP312 current probes around

uninsulated wires. Damage to the probe or personal injury may result. Only use

the TCP305 or TCP312 current probes on INSULATED wires.

The TCP303 and TCP404XL current probes can be used to measure current on

uninsulated wires. However , the circuit must be de-energized when connecting or

removing the current probe.

5. Open the probe slide, place the probe around the conductor under test, and

then lock the slide. For correct measurement polarity, make sure the probe

arrow is pointing in the direction of conventional (positive to negative)

current flow. Reversing the flow will invert the displayed current waveform

on the oscilloscope.

NOTE. Even when making AC current measurements, leave the oscilloscope

coupling on DC. Change only the amplifier coupling to AC. Using the oscilloscope AC coupling may cause the amplifier to exceed its output dynamic range.

6. Adjust the oscilloscope time base and trigger as needed.

1- 14

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 37

Operating Basics

Page 38

Page 39

Control Summary

This section describes the function of each TCP A300 and TCPA400 front panel

control and connector. The overview in Figure 2--1 is followed by a detailed

description.

Some seldom-used functions do not appear in Figure 2--1. These functions are

completely discussed in the detailed descriptions that follow Figure 2--1.

The PROBE DEGAUSS AUTOBALANCE button

removes residual magnetism from the attached

current probe. A multi-color LED indicates the

status of the degauss circuit.

The MANUAL BALANCE buttons allow you to

fine-adjust DC offset from the amplifier. The

adjacent LED lights when one of the buttons

has been pressed.

The four probe error lights indicate the following

faults: PROBE OPEN, OVERLOAD (current or

temperature), NOT TERMINATED INTO 50 Ω

and NONCOMPATIBLE PROBE TYPE.

The ON/STANDBY button turns on power to

the amplifier.

Figure 2- 1: The TCPA300 front panel

The RANGE button toggles between the two

scale factors that are available for the attached

probe (TCPA300 only). LEDs indicate the

selected range.

The COUPLING button selects AC or DC probe

coupling, as indicated by the LEDs.

The current probes connect to the TCPA300 and

TCPA400 at the PROBE INPUT connector.

The TCPA300 and TCPA400 output appears at

the OUTPUT connector. Connect this to a 50 Ω

input of your oscilloscope.

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

2- 1

Page 40

Control Summary

TCPA300 and TCPA400 Controls

These front panel controls and indicators are common to both the TCPA300 and

TCPA400 current probe amplifiers, unless otherwise indicated.

PROBE DEGAUSS

AUTOBALANCE Button

and Indicator

When pressed, this button performs two functions that maximize measurement

accuracy. First, the amplifier generates a degauss signal to remove any residual

magnetism from the attached current probe. Second, the amplifier initiates an

operation to remove any undesired DC offsets from the circuitry. During the

degauss process, the amplifier is busy and cannot be used to measure current.

The indicator light next to the PROBE DEGAUSS AUTOBALANCE button

blinks red whenever the amplifier detects that the current probe needs degaussing. The amplifier cannot detect all circumstances that require probe degaussing, so you may need to degauss the probe at times when the PROBE

DEGAUSS AUTOBALANCE light is not blinking red. The red blinking light

serves as a reminder to degauss the current probe when one of the following

conditions occurs:

H The amplifier has just been turned on with a current probe connected.

H The current probe has been changed.

H An overload was detected.

To perform the probe degauss/autobalance function, remove the probe from all

conductors (or ensure that the conductor under test has no power), make sure the

probe is locked closed, and then press the PROBE DEGAUSS AUTOBALANCE button. The probe degauss/autobalance routine will not pass if the

current probe is disconnected from the amplifier input, or if it is unlocked (the

PROBE OPEN LED is on).

2- 2

The indicator blinks orange during the time the amplifier is busy performing the

probe degauss functions. When the degauss and autobalance procedure is

complete, the indicator light turns green.

The PROBE DEGAUSS AUTOBALANCE indicator light will be orange if the

MANUAL BALANCE buttons have been pressed after a degauss has been

successfully completed. This indicates that the DC offset value has been

manually changed from the original value set during the degauss routine.

Depending on the amount of offset (balance) you have entered with the

MANUAL BALANCE buttons, another degauss operation may be necessary to

ensure accurate measurements. Generally, if you change the DC offset by more

than 5 divisions, you should de-energize the circuit under test and perform

another degauss routine. Then, re-energize the circuit and take your measurements.

If the degauss operation has failed, and the AC and DC COUPLING LEDs are

alternately flashing, this indicates the amplifier is displaying an error code with

the four status LEDs on the lower-left front panel. If this occurs, refer to

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 41

Control Summary

Displaying Error Codes with the Probe Degauss Autobalance Button on

page 3--22.

NOTE. The NOT TERMINATED INTO 50 Ω LED is on when the amplifier output

is not properly terminated into a 50 Ω load. Make sure your amplifier OUTPUT

is connected to an oscilloscope input using a 50 Ω BNC cable, and that the

oscilloscope input is set to 50 Ω impedance. See Figure 1--1 on page 1--1 for

proper cabling.

If your oscilloscope does not have 50 Ω impedance settings for inputs, you can

place a 50 Ω feed-through termination on the oscilloscope input and connect the

amplifier output cable to the termination. Do not place the feed-through

termination at the amplifier end of the BNC connecting cable.

MANUAL BALANCE

Buttons and Indicator

PROBE OPEN Indicator

OVERLOAD Indicator

The MANUAL BALANCE buttons allow you to fine-adjust the DC offset that

appears at the amplifier OUTPUT connector. The manual balance adjustment

only functions when the amplifier is set to DC coupling, and the MANUAL

BALANCE indicator is only lighted after you press one of the MANUAL

BALANCE buttons in DC coupling mode.

When lit, this indicator informs you that the current probe is unlocked. You must

have the probe slide locked to degauss the probe or to accurately measure

current.

When this LED is red, it informs you that the measurement you are taking

exceeds the continuous amplitude limit of the TCPA300 and TCPA400. The

detection circuits detect only low frequency and DC overloads. Since overloads

can magnetize the probe, always degauss the probe after an overload. When the

OVERLOAD indicator flashes red, it indicates the pulsed waveform is exceeding

the amplitude limit of the amplifier.

When this LED is orange, it indicates that the safe operating temperature of the

probe, and possibly the amplifier, has been exceeded. Disconnect the probe from

the current source and allow time for the probe head and amplifier to cool.

When this LED blinks red and orange, it indicates that both the safe operating

temperature of the probe and the current limit have been exceeded.

WARNING. To avoid personal injury or equipment damage, do not exceed the

specified electrical limits of the TCPA300 and TCPA400 or any applicable

accessories.

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

2- 3

Page 42

Control Summary

NOT TERMINATED

INTO 50 Ω Indicator

NONCOMPATIBLE

PROBE TYPE Indicator

ON/STANDBY Button

RANGE Button

(TCPA300 only)

When lit, this indicator informs you that the TEKPROBE interface cable or BNC

cable from the OUTPUT of the amplifier is not connected to a 50 ohm input on

the oscilloscope. You need to switch the termination setting on the oscilloscope

to 50 Ω,orusea50Ω termination on the oscilloscope input.

NOTE. NOT TERMINATED INTO 50 Ω is only detected during the DEGAUSS

AUTOBALANCE operation.

When lit, this indicator informs you that the probe that is connected to the

amplifier is not designed to work with the amplifier. TCP3XX probes only work

with the TCPA300 Amplifier, and the TCP404XL probe only works with the

TCPA400 Amplifier.

Use this button to power on the amplifier. When the amplifier is in STANDBY

mode, the amplifier is in a limited-power mode. Most of the secondary circuitry

is disabled, but the line voltage remains connected to the amplifier power supply.

Press the RANGE button to toggle between the scale factors (sensitivity settings)

of the probe attached to the TCPA300. If no RANGE LEDs are lit, this indicates

a probe is not connected to the amplifier.

COUPLING Button and

Indicators

The COUPLING button determines the coupling between the

TCPA300/TCPA400 and the oscilloscope. Press the COUPLING button to

toggle between AC and DC coupling. To couple the amplifier for DC plus AC

measurements, use DC coupling. For AC measurements only, use AC coupling.

When the amplifier is set to AC coupling, the Manual Balance adjustment is

disabled since the DC offset component is not visible on the output waveform.

NOTE. Even when making AC current measurements, leave the oscilloscope

coupling on DC. Change only the amplifier coupling to AC. Using the oscilloscope AC coupling may cause the amplifier to exceed its output dynamic range.

Under normal operation, the AC and DC COUPLING LEDs indicate the

coupling mode of the amplifier. If they alternately flash after a degauss operation, this indicates the amplifier is displaying an error code with the four status

LEDs on the lower-left front panel. If this occurs, refer to Displaying Error

Codes with the Probe Degauss Autobalance Button on page 3--22.

2- 4

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 43

Control Summary

PROBE INPUT Connector

OUTPUT Connector

All current probes compatible with the TCPA300 and TCPA400 attach at the

PROBE INPUT connector, which is a multi-pin female connector. For information about connecting a probe, see Connecting a Current Probe to the Amplifier

on page 1--9.

The amplifier current measurement output is accessed at the OUTPUT connector,

which should be connected to the oscilloscope input. Attach one end of a 50 Ω

BNC cable to this connector and the other end to a 50 Ω vertical input of your

oscilloscope. The output impedance of the amplifier is 50 Ω.

To get a direct readout of current on your Tektronix oscilloscope, use the

TEKPROBE interface cable to connect the amplifier to your oscilloscope.

NOTE. To obtain accurate measurements, the input impedance of your oscilloscope must be 50 Ω. Make sure your amplifier OUTPUT is connected to an

oscilloscope input using a 50 Ω BNC cable, and that the oscilloscope input is set

to 50 Ω impedance. See Figure 1--1 on page 1--1 for proper cabling.

If your oscilloscope does not have 50 Ω impedance settings for inputs, you can

place a 50 Ω feedthrough termination on the oscilloscope input and connect the

amplifier output cable to the termination. Do not place the feedthrough

termination at the amplifier end of the BNC connecting cable.

Probe DC Gain Adjust

(located on probes)

After the PROBE DEGAUSS AUTOBALANCE routine has been run, the probe

and amplifier system will meet all published specifications. However, if you

want to improve the tolerance of the system accuracy, or to intentionally offset

the accuracy to make up for total system errors, you can manually adjust the gain

of the probe. Refer to Figures 6--3 and 6--5 on pages 6--7 and 6--12 for the

adjustment locations.

NOTE. You should be careful to note the existing position of the DC Gain

Adjustment before you alter it, so that you may return it to the initial, calibrated

position. By altering the DC Gain Adjustment, you may cause the probe to not

meet the warranted DC Accuracy specification.

For example, the typical accuracy of the TCP312 probe on the 1A/V range is

1%. If you want to measure a 3A p-p, 1kHz square wave and need increased

accuracy (better than 0.25% is attainable), first adjust the TCP312 on the 1A/V

range setting using a calibrated 3A p-p, 1kHz square wave source. Then, attach

the probe to your circuit and take your measurement. Remember, altering the DC

Gain Adjustment may cause the probe to not meet the warranted DC Accuracy

specification.

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

2- 5

Page 44

Control Summary

GPIB Operation

The TCPA300 and TCPA400 Current Probe Amplifiers do not have direct GPIB

connections. However, you can use a computer to control the oscilloscope that

the amplifier is connected to, enabling you to change the time and scale factors

of your current measurements over the oscilloscope GPIB bus.

Refer to your oscilloscope manual for instructions on using the GPIB bus.

2- 6

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 45

Reference

Page 46

Page 47

Reference Notes

These notes are provided to help you utilize the full potential of the TCPA300

and TCPA400 current probe systems.

Degaussing a Probe with an Unpowered Conductor in the Jaws

Under almost all conditions, you can degauss your current probe while a

conductor of an unpowered circuit is clamped in the jaws. The advantage of

degaussing with an unpowered circuit is that any offset from stray DC magnetic

fields are compensated. In an automated environment, degaussing with the

conductor in the probe jaws eliminates the need to manually remove the probe.

NOTE. Be certain that the conductor in the probe jaws is completely unpowered.

Any current flowing through the conductor will cause a residual offset in the

current probe, and the amplifier may report an inaccurate result.

If the impedance of your circuit is higher than that shown in Table 3--1, the

degauss procedure will succeed because the amplifier will be able to saturate the

probe core. While degauss occurs, the probe will induce a voltage in the

unpowered circuit. This also appears in Table 3--1. Your circuit must be able to

absorb this induced voltage. With low impedance circuits, several amperes may

be induced in the circuit being measured. This may be of concern when you are

using very small conductors.

Table 3- 1: Unpowered circuit degauss limits

Probe type Minimum circuit resistance Maximum induced voltage

TCP312 10 mΩ 40 mV at 200 Hz

TCP305 5mΩ 40 mV at 200 Hz

TCP303 5mΩ 30 mV at 200 Hz

TCP404XL 1mΩ 15 mV at 100 Hz

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

3- 1

Page 48

Reference Notes

Measuring Differential Current

You can place two conductors in a current probe to provide differential or null

current measurement. This avoids the necessity of using two current measurement systems with a differential oscilloscope.

WARNING. Do not put more than one uninsulated conductor at a time in the

TCP303 or TCP404XL probes. Do not put any uninsulated conductors in the

TCP305 or TCP312 probes. An uninsulated conductor is defined as any

conductor without insulation or without insulation rated for the voltage present

on the conductor under test.

An insulated conductor is defined as any conductor that is surrounded by an

insulating material that is capable of isolating the voltage present on the

conductor. Note that lacquer coatings like those typically found on transformer

windings do not provide sufficient, reliable insulation for use with current

probes. The lacquer coating can be easily nicked or damaged, compromising the

insulating capabilities of the lacquer coating.

Do not force the slide closed. Damage to the probe may result. If you cannot

close the slide around the conductor(s), either reduce the number of conductors

you are measuring, or, if possible, take your measurement on a smaller

conductor.

1. Orient the two conductors under test so that the polarities oppose each other.

Clamp the current probe around the two conductors as shown in Figure 3--1.

Be careful not to pinch a conductor in the probe jaws.

2. Measure the current. A waveform above the baseline indicates the conductor

with the conventional current flow in the direction of the probe arrow is

carrying the greater current. Conventional current flows from positive to

negative.

3. To adjust for a current null, adjust the current in one of the conductors until

the displayed measurement is zero.

3- 2

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 49

AC and DC Coupling

Reference Notes

Conductor #2

Conductor #1

Current

Current

Current probe

Figure 3- 1: Measuring differential current and nulls

You can couple the signal input to the TCPA300 and TCPA400 with either DC or

AC coupling. DC coupling shows the DC and AC measurement components

while AC coupling removes the DC component from the displayed signal. When

you use AC coupling, make sure that the input DC current does not exceed the

probe specifications.

AC coupling will affect waveforms at frequencies higher than the AC Coupling

Low-Frequency Bandwidth. For example, pulsed currents may exhibit rolloff or

decreased amplitude. Figure 3--2(a) shows a low-frequency square wave using

AC coupling. The signal exhibits low-frequency rolloff. By changing the

amplifier coupling to DC, the pulse is displayed as truly square, as shown in

Figure 3--2(b).

(a) AC-Coupled signal

(b) DC-Coupled signal

Figure 3- 2: Effect of AC or DC coupling on low-fr equency signals

If you are trying to examine a low-frequency signal that is superimposed on a

comparatively large DC component, you can resolve the signal by performing

these steps:

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

3- 3

Page 50

Reference Notes

1. Select the range setting that will display the maximum detail without

2. Adjust the oscilloscope V/div sensitivity (A/div if using the TEKPROBE

Maximum Current Limits

Current probes have three maximum current ratings: continuous, pulsed, and

Ampere-second product. Exceeding any of these ratings can saturate the probe

core, magnetizing the core and causing measurement errors. See Specifications

beginning on page 4--1 for the maximum current ratings of compatible probes.

H Maximum Continuous Current refers to the maximum current that can be

H Maximum Pulsed Current refers to the maximum peak value of pulsed

exceeding the dynamic range of the signal.

interface), to display maximum signal detail.

continuously measured at DC or at a specified AC frequency. The maximum

continuous current value is derated with frequency; as the frequency

increases, the maximum continuous current rating decreases.

current the probe can accurately measure, regardless of how short (within

bandwidth limitations) the pulse duration is.

Procedure A

H Ampere-Second Product defines the maximum width of pulsed current that

you can measure when the pulse amplitude is between the maximum

continuous and maximum pulsed current specifications. The maximum

continuous specification itself varies by frequency.

NOTE. Always degauss the probe after measuring a current that exceeds the

maximum continuous current, maximum pulsed current, or Ampere-second

product rating of the probe. Exceeding these ratings can magnetize the probe

and cause measurement errors.

To determine if your measurement exceeds the Ampere-second product, perform

either Procedure A or Procedure B.

To determine the maximum allowable pulse width, measure the peak current of

the pulse (see Figure 3--3a). Divide the Ampere-second (or Ampere-microsecond) specification of your probe by the measured peak current of the pulse. The

quotient is the maximum allowable pulse width; the pulse width at the 50% point

of the measured signal must be less than this value.

For example, the TCP312 Current Probe has a maximum Ampere-second

product of 500 A⋅s in the 10 A/V range setting. If a pulse measured with a

TCP312 has a peak current of 40 A, the maximum allowable pulse width would

be 500 A⋅s divided by 40 A, or 12.5 s.

3- 4

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 51

Reference Notes

I

max

p

Pulse width

at 50%

50%

I

max

c

0A

(a) Maximum allowable pulse width (b) Maximum allowable pulse amplitude

Figure 3- 3: Applying the amp-second product rule

Do Not Exceed

Pulse width

at 50%

50%

Maximum

pulsed

current

Maximum

continuous

current

Procedure B

To determine the maximum allowable pulse amplitude, measure the pulse width

at the 50% points (see Figure 3--3b). Divide the Ampere-second (or Amperemicrosecond) specification of your probe by the pulse width. The quotient is the

maximum allowable current; the peak amplitude of the measured pulse must be

less than this value.

For example, the TCP312 Current Probe has a maximum Ampere-second

product of 500 A⋅s in the 10 A/V range setting. If a pulse measured with a

TCP312 probe has a width of 15 s, the maximum allowable peak current would

be 500 A⋅s divided by 15 s, or 33.3 A.

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

3- 5

Page 52

Reference Notes

Measuring Noncontinuous Current with the TCP404XL Probe

When you measure a noncontinuous current with the TCP404XL probe, you

need to take into consideration several factors to ensure that you make accurate

measurements and do not trip the thermal overload circuit. The amplitude and

duty cycle of the continuous and noncontinuous current, and the ambient

temperature, all affect the maximum amount of time allowed for the measurement, which defines the safe operating area of the probe.

You can calculate the duty cycle of the continuous and noncontinuous current

when you know the duration of the noncontinuous current (defined in Figure 3--4

as measurement time) and the measurement period. Figure 3--4 illustrates a

continuous and noncontinuous current and how to calculate the duty cycle.

Measured

current (A)

Noncontinuous

current level (A)

Continuous

current level (A)

Measurement

time (min)

Measurement

period (min)

Duty cycle (%) = 100x

Measurement time

Measurement period

Time (min)

Figure 3- 4: Duty cycle calculation

After you calculate the duty cycle of the noncontinuous current you are

measuring, you can use the other factors (continuous and noncontinuous current

amplitude, etc.) to compare your measurement to those shown in Figures 4--8

through 4--10 in the Specifications section.

You can see how duty cycle affects the measurement time by looking at any of

the three graphs in Figures 4--8 through 4--10. As the duty cycle increases on the

x-axis, the measurement time (of the noncontinuous current) on the y-axis

decreases.

Figures 4--8 and 4--9 on page 4--12 illustrate the effect of measuring two different

noncontinuous current amplitudes, 750 amps and 600 amps respectively, with

3- 6

TCPA300/400 Amplifiers and TCP300/400 Series Current Probes Instruction Manual

Page 53

Reference Notes

varying duty cycles and levels of continuous current. The ambient temperature in

these two examples is kept constant at 50 °C.

WARNING. When using the probe near the upper current limit and maximum

ambient temperature for extended lengths of time, the probe head surface can

become hot to the touch. To prevent injury, keep your hands away from the probe

head until it has had time to cool after disconnecting the probe from the circuit.

To see how noncontinuous current amplitude affects measurement time, look at

the curves for measurements of 200 amps continuous between the two graphs in

Figures 4--8 and 4--9 on page 4--12. Compare the maximum measurement time

allowed for a duty cycle of 20%: At 750 amps, you have 3 minutes of safe

measurement time, versus 17 minutes for a smaller noncontinuous-current

amplitude of 600 amps.

By looking at any of the three graphs, you can also see that when you measure a

noncontinuous current having the same amplitude and duty cycle, the measurement time decreases as the continuous-current amplitude increases.