Page 1

x

TCP0030A

120 MHz, 30 Amp AC/DC Current Probe

ZZZ

Instruction Manual

*P071300600*

071-3006-00

Page 2

Page 3

xx

TCP0030A

120 MHz, 30 Amp AC/DC Current Probe

ZZZ

Instruction Manual

www.tektronix.com

071-3006-00

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or suppliers, and are protected by

national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all previously

published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O . B o x 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

Page 5

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year from the date of shipment. If

any such product proves defective during this warranty period, Tektronix, at its option, either will repair the defective product without charge for parts

and labor, or will provide a replacement in exchange for the defective product. Parts, modules and replacement products used by Tektronix for

warranty work may be new or reconditioned to like new performance. All replaced parts, modules and products become the property of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the warranty period and make

suitable arrangements for the performance of service. Customer shall be responsible for packaging and shipping the defective product to the service

center designated by Tektronix, with shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping charges, duties,

taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate maintenance and care. Tektronix

shall not be obligated to furnish service under this warranty a) to repair damage resulting from attempts by personnel other than Tektronix

representatives to install, repair or service the product; b) to repair damage resulting from improper use or connection to incompatible equipment; c) to

repair any damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or integrated with

other products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. TEKTRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY

PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

Page 6

Page 7

Table of Contents

General safety summary .................................................................................................................... v

Service safety summary................................................................................................................... viii

Compliance Information .................................................................................................................... ix

Safety Compliance.................................................................................................................... ix

Environmental Considerations....................................................................................................... xiii

Preface..................................................................................................................................... xiv

Documentation....................................................................................................................... xiv

Conventions Used in this Manual ................................................................................................... xiv

Returning the Probe for Servicing ...................................................................................................xv

Key Features ............................................................................................................................... 1

Installation .................................................................................................................................. 2

Degauss the Probe ................................................................................................................... 3

Controls and Indicators..................................................................................................................... 5

Probe Slider and Conductor Jaw ..................................................................................................... 5

Control Box............................................................................................................................ 8

Functional Check . ......................................................................................................................... 17

Basic Operation............................................................................................................................ 18

Table of Contents

Application Examples...................................................................................................................... 20

Inductance Measurements . . ........................................................................................................ 21

TCP0030A Current Probe Instruction Manual i

Page 8

Table of Contents

Probing Principles ......................................................................................................................... 26

Accessories and Options.................................................................................................................. 39

Specifications.............................................................................................................................. 45

Performance Verification .................................................................................................................. 53

Measuring Inductor Turns Count .................................................................................................... 24

Degaussing a Probe with an Unpowered Conductor in the Jaws .................................................................. 26

Measuring Differential Current....................................................................................................... 27

Extending Current Range. ........................................................................................................... 29

Increasing Sensitivity ................................................................................................................ 32

Common Mode Noise/Magnetic Field Errors........................................................................................ 33

AC and DC Coupling.................................................................................................................34

Maximum Current Limits............................................................................................................. 35

Optional Accessories ................................................................................................................ 41

Options............................................................................................................................... 44

Warranted Characteristics ........................................................................................................... 45

Typical Characteristics............................................................................................................... 46

Nominal Characteristics ............................................................................................................. 52

Equipment Required................................................................................................................. 54

Making the DC Current Loop ........................................................................................................ 55

Equipment Setup..................................................................................................................... 56

DC Gain Accuracy ................................................................................................................... 57

Rise Time and Bandwidth ........................................................................................................... 61

TestRecord .......................................................................................................................... 63

ii TCP0030A Current Probe Instruction Manual

Page 9

Table of Contents

Adjustments................................................................................................................................ 64

Equipment Required ................................................................................................................. 64

Equipment Setup..................................................................................................................... 64

DC Gain Accuracy ................................................................................................................... 65

High Frequency Response .. ........................................................................................................ 67

Maintenance . . . ............................................................................................................................ 68

Troubleshooting...................................................................................................................... 68

Cleaning.............................................................................................................................. 70

Index

TCP0030A Current Probe Instruction Manual iii

Page 10

Table of Contents

iv TCP0030A Current Probe Instruction Manual

Page 11

General safety summary

Review the following safety precautions to avoid injury and prevent damage to this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

To avoid fire or personal injury

General safety summary

Connect and disconnect properly.

source.

Connect and disconnect properly.

Connect and disconnect properly.

circuit under test. Connect the probe reference lead to the circuit under test before connecting the probe input. Disconnect the probe

input and the probe reference lead from the circuit under test before disconnecting the probe from the measurement instrument.

Observe all terminal ratings.

manual for further ratings information before making connections to the product.

Do not connect a current probe to any wire that carries voltages above the current probe voltage rating.

Do not operate without covers.

Do not operate with suspected failures.

service personnel.

Avoid exposed circuitry.

TCP0030A Current Probe Instruction Manual v

Do not touch exposed connections and components when power is present.

Do not connect or disconnect probes or test leads while they are connected to a voltage

De-energize the circuit under test before connecting or disconnecting the current probe.

Connect the probe output to the measurement instrument before connecting the probe to the

To avoid fire or shock hazard, observe all ratings and markings on the product. Consult the product

Do not operate this product with covers or panels removed.

If you suspect that there is damage to this product, have it inspected by qualified

Page 12

General safety summary

Do not operate in wet/damp conditions.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

Terms in this manual

These terms may appear in this manual:

WARNING.

CAUTION.

Warning statements identify conditions or practices that could result in injury or loss of life.

Caution statements identify conditions or practices that could result in damage to this product or other property.

Symbols and terms on the product

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the marking.

WARNING indicates an injury hazard not immediately accessible as you read the marking.

CAUTION indicates a hazard to property including the product.

vi TCP0030A Current Probe Instruction Manual

Page 13

The following symbol(s) may appear on the product:

General safety summary

TCP0030A Current Probe Instruction Manual vii

Page 14

Service safety summary

Servicesafetysummary

Only qualified personnel should perform service procedures. Read this

before performing any service procedures.

Do not service alone.

first aid and resuscitation is present.

Disconnect power.

power.

Use care when servicing with power on.

battery (if applicable), and disconnect test leads before removing protective panels, soldering, or replacing components.

To avoid electric shock, do not touch exposed connections.

Do not perform internal service or adjustments of this product unless another person capable of rendering

To avoid electric shock, switch off the instrument power, then disconnect the power cord from the mains

Dangerous voltages or currents may exist in this product. Disconnect power, remove

Service safety summary

General safety summary

and the

viii TCP0030A Current Probe Instruction Manual

Page 15

Compliance Information

This section lists the EMC (electromagnetic compliance), safety, and environmental standards with which the instrument complies.

Safety Compliance

EC Declaration of Conformity – Low Voltage

Compliance was demonstrated to the following specification as listed in the Official Journal of the European Communities:

Low Voltage Directive 2006/95/EC.

EN 61010-1: 2001. Safety requirements for electrical equipment for measurement control and laboratory use.

EN 61010-2-032: 2002. Particular requirements for handheld current clamps for electrical measurement and test equipment.

U.S. Nationally Recognized Testing Laboratory Listing

UL 61010-1:2004, 2ndEdition. Standard for electrical measuring and test equipment.

IEC 61010-2-032:2002. Particular requirements for handheld current clamps for electrical measurement and test equipment.

Compliance Information

TCP0030A Current Probe Instruction Manual ix

Page 16

Compliance Information

Canadian Certification

CAN/CSA-C22.2 No. 61010-1:2004. Safety requirements for electrical equipment for measurement, control, and laboratory

use. Part 1.

CAN/CSA-C22.2 No. 61010-2-032-04, 2ndEdition. Particular requirements for handheld and hand-manipulated current

sensors for electrical measurement and test equipment.

Additional Compliances

IEC 61010-1: 2001. Safety requirements for electrical equipment for measurement, control, and laboratory use.

IEC 61010-031: 2002. Particular requirements for handheld probe assemblies for electrical measurement and test equipment.

IEC 61010-2-032: 2002. Particular requirements for handheld current clamps for electrical measurement and test equipment.

Equipment Type

Test and measuring equipment.

x TCP0030A Current Probe Instruction Manual

Page 17

Compliance Information

Pollution Degree Description

A measure of the contaminants that could occur in the environment around and within a product. Typically the internal environment

inside a product is considered to be the same as the external. Products should be used only in the environment for which they

are rated.

Pollution Degree 1. No pollution or only dry, nonconductive pollution occurs. Products in this category are generally

encapsulated, hermetically sealed, or located in clean rooms.

Pollution Degree 2. Normally only dry, nonconductive pollution occurs. Occasionally a temporary conductivity that is caused by

condensation must be expected. This location is a typical office/home environment. Temporary condensation occurs only

when the product is out of service.

Pollution Degree 3. Conductive pollution, or dry, nonconductive pollution that becomes conductive due to condensation. These

are sheltered locations where neither temperature nor humidity is controlled. The area is protected from direct sunshine,

rain, or direct wind.

Pollution Degree 4. Pollution that generates persistent conductivity through conductive dust, rain, or snow. Typical outdoor

locations.

Pollution Degree

Pollution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor use only.

Installation (Overvoltage) Category Descriptions

Terminals on this product may have different installation (overvoltage) category designations. The installation categories are:

TCP0030A Current Probe Instruction Manual xi

Page 18

Compliance Information

Measurement Category IV. For measurements performed at the source of low-voltage installation.

Measurement Category III. For measurements performed in the building installation.

Measurement Category II. For measurements performed on circuits directly connected to the low-voltage installation.

Measurement Category I. For measurements performed on circuits not directly connected to MAINS.

Overvoltage Category

Overvoltage Category II (as defined in IEC 61010-1)

xii TCP0030A Current Probe Instruction Manual

Page 19

Environmental Considerations

This section provides information about the environmental impact of the product.

Product End-of-Life Handling

Observe the following guidelines when recycling an instrument or component:

Compliance Information

Equipment recycling.

contain substances that could be harmful to the environment or human health if improperly handled at the product’s end of life. To

avoid release of such substances into the environment and to reduce the use of natural resources, we encourage you to recycle this

product in an appropriate system that will ensure that most of the materials are reused or recycled appropriately.

This symbol indicates that this product complies with the applicable European Union requirements according to

Directives 2002/96/EC and 2006/66/EC on waste electrical and electronic equipment (WEEE) and batteries.

For information about recycling options, check the Support/Service section of the Tektronix Web site

(www.tektronix.com).

TCP0030A Current Probe Instruction Manual xiii

Production of this equipment required the extraction and use of natural resources. The equipment may

Page 20

Preface

Preface

This manual describes the installation and operation of the TCP0030A current probe. Basic probe operations and concepts are

presented in this manual. You can also access the Tektronix Web site for this document and other related information.

Documentation

To read about Use these documents

TCP0030A Probe: First Time Operation, Functional Check,

Operating Basics, Specifications, Performance Verification

In-depth oscilloscope operation, user interface help, GPIB

commands

*

To access the documentation that is installed on your instrument, click

Read this Instruction Manual.

Access the online help from the Help menu on the host

instrument.

in the taskbar and select

Start

*

Programs > TekApplications

.

Conventions Used in this Manual

The following icon is used throughout this manual to indicate a step sequence.

xiv TCP0030A Current Probe Instruction Manual

Page 21

Returning the Probe for Servicing

If your probe requires servicing, you must return the probe to Tektronix. If the original packaging is unfit for use or not available, use

the following packaging guidelines:

Preparation for Shipment

Use a corrugated cardboard shipping

1.

carton having inside dimensions at

least one inch greater than the probe

dimensions. The box should have a carton

test strength of at least 200 pounds.

Put the probe into an antistatic bag or wrap

2.

it to protect it from dampness.

Place the probe into the box and stabilize it

3.

with light packing material.

Seal the carton with shipping tape.

4.

Preface

Refer to

5.

beginning of this manual for the shipping

address.

TCP0030A Current Probe Instruction Manual xv

Contacting Tektronix

at the

Page 22

Preface

xvi TCP0030A Current Probe Instruction Manual

Page 23

Key Features

You can use the TCP0030A current probe to make accurate measurements from DC to 120 MHz. The probe combines proven

Hall-effect technology with the Tektronix TekVPI oscilloscope interface. Key features include:

>120 MHz bandwidth, <2.92 ns rise time

AC/DC Measurement capability

50 A peak pulse current (pulse widths

<10 μs)

5 A and 30 A range settings

1 mA sensitivity (on TekVPI oscilloscopes

that support the 1 mV/div setting)

1% DC Accuracy (typical)

One-button degauss/autozeroing

Probe control through the TekVPI

oscilloscope menus or remotely through

the oscilloscope

Direct scaling and unit readout on host

instruments

Key Features

AC coupling (on TekVPI oscilloscopes that

support AC coupling)

TCP0030A Current Probe Instruction Manual 1

Page 24

Installation

Installation

CAUTION.

changes in ambient conditions. Do not insert conductors larger than 5.0 mm (0.20 in) diameter into the probe jaw. Damage to

the probe may result.

The probe head is a precision assembly. Do not drop the probe or subject it to physical shock, strain, or sudden

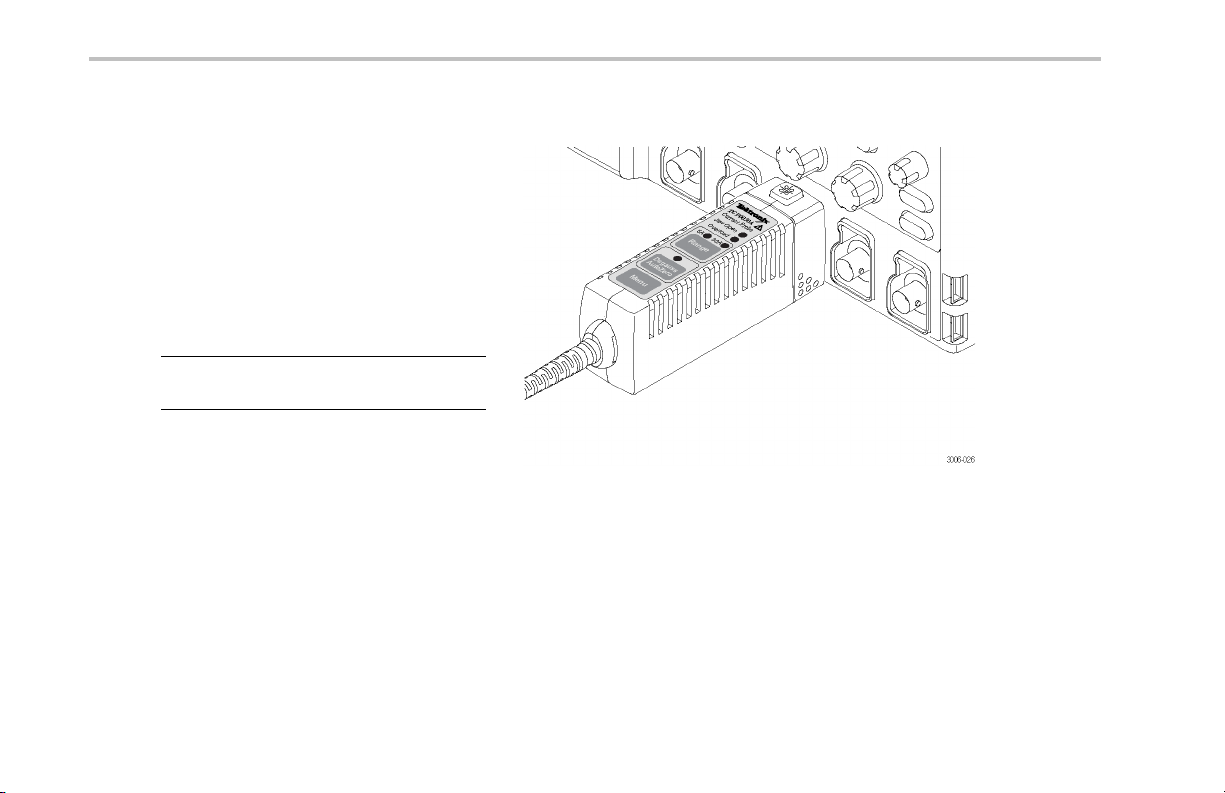

Connect to the Host Instrument

Slide the probe into the TekVPI receptacle.

1.

The probe snaps in when fully engaged.

To disconnect, press the latch button and

2.

pull the probe away from the instrument.

When the probe is connected, the host

instrument reads information from the probe

and identifies the device. All of the probe LEDs

light briefly for a quick visual check.

2 TCP0030A Current Probe Instruction Manual

Page 25

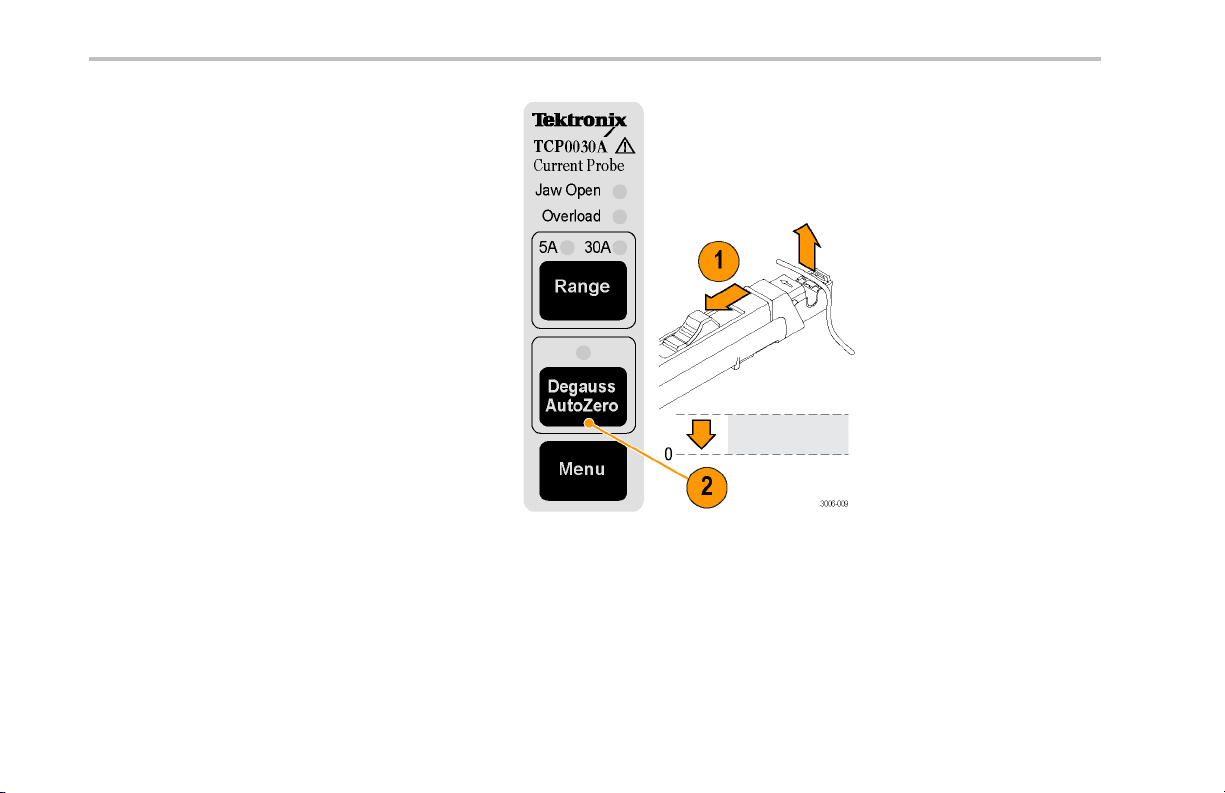

Degauss the Probe

After the probe is identified by the host

1.

instrument, the screen display prompts you

to run a degauss routine.

The multicolor Degauss/AutoZero status

LED on the probe also indicates that a

degauss is needed, by flashing red.

To degauss the probe, firstverifythatthe

2.

probe jaw is closed, and then press the

Degauss/AutoZero

or in the Degauss window on the host

instrument.

The DC gain and offset errors are not

NOTE.

guaranteed when this LED flashes red.

The multicolor Degauss/AutoZero status

3.

LED glows green to indicate a successful

degauss routine was run, and that the

probe is in normal operating mode.

Installation

button on the probe

TCP0030A Current Probe Instruction Manual 3

Page 26

Installation

Quick Tip

To maintain measurement accuracy, degauss

your probe in each of these cases:

After you turn on the measurement system

and allow a 20-minute warm-up period

Before you connect the probe to a

conductor

Whenever a current or thermal overload

condition occurs

Whenever you subject the probe to a

strong external magnetic field

4 TCP0030A Current Probe Instruction Manual

Page 27

Controls and Indicators

Probe Slider and Conductor Jaw

When the slider is in the locked position,

1.

you can degauss the probe and take

measurements.

Move the slider to the unlocked position to

2.

insert and remove conductors to and from

the conductor jaw.

The jaw can accept a 5 mm (0.2 in)

3.

diameter maximum conductor size.

WARNING.

force conductors larger than 5 mm (0.2 in)

diameter into the jaw.

To prevent probe damage, do not

Controls and Indicators

TCP0030A Current Probe Instruction Manual 5

Page 28

Controls and Indicators

Safe handling zone – keep fingers behind

4.

demarcations when taking measurements.

WARNING.

access the area beyond the safe handling zone

(indicated by the shaded area) when you take

measurements.

To avoid electrical shock, do not

WARNING.

To prevent probe damage, do not

drop the probe or subject it to impact.

WARNING.

Do not connect the current probe

to any wire that carries voltages or currents that

exceed the rating of the probes.

6 TCP0030A Current Probe Instruction Manual

Page 29

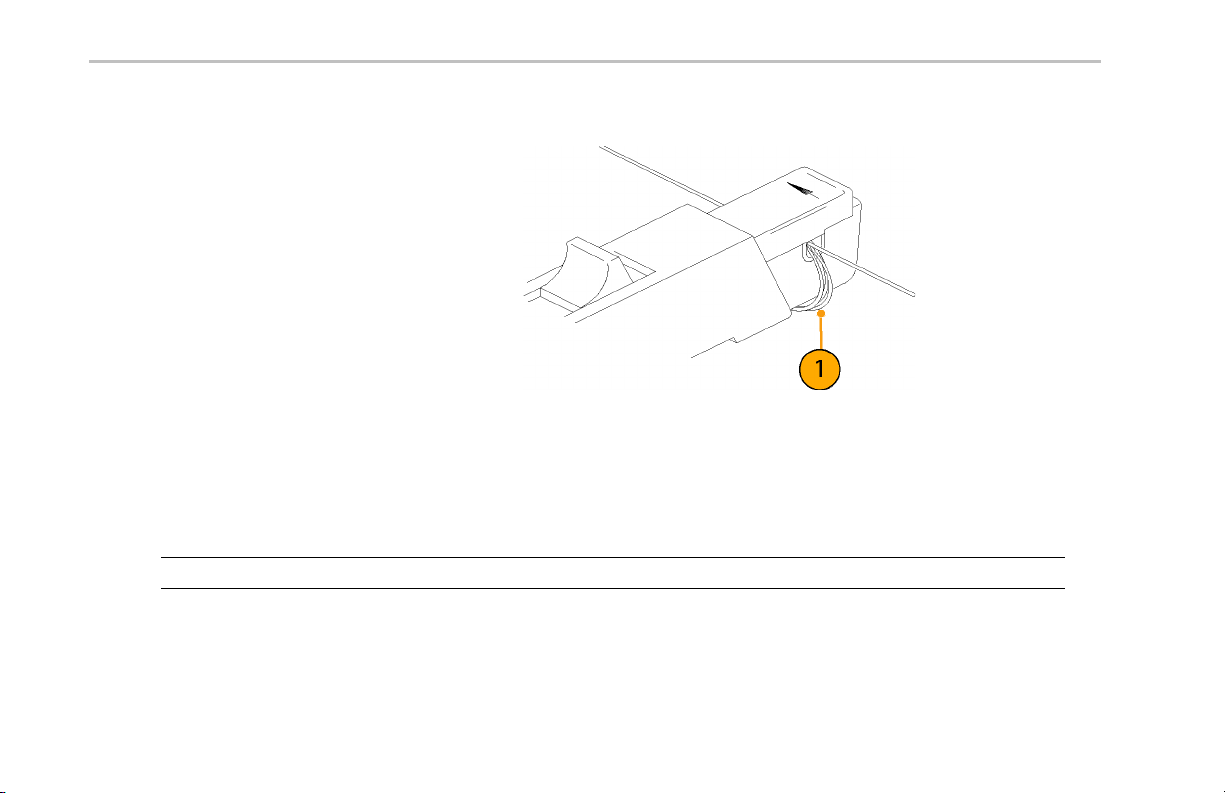

Ground Lead

Use the ground lead to improve EMI rejection at high frequencies.

Clip the ground lead to the ground post at

1.

the bottom of the probe head.

Connect the alligator end of the clip to the

2.

circuit ground.

Clamp the probe around the circuit

3.

conductor.

Controls and Indicators

TCP0030A Current Probe Instruction Manual 7

Page 30

Controls and Indicators

Control Box

The probe function buttons and LED status

indicators are located on the top of the control

box, and are described in the following pages.

When the probe is first plugged in, all of

the indicator LEDs light briefly, and then the

Degauss/AutoZero LED flashes to alert you to

degauss the probe.

One of the Range LEDs remains lit to indicate

the current range selected.

Theprobewillretaintherangestate

NOTE.

and will restore it when it is power cycled.

The Jaw Open LED will also remain lit if the

probe slider is unlocked.

8 TCP0030A Current Probe Instruction Manual

Page 31

Jaw Open LED

If the Jaw Open LED glows, the probe

1.

slider is unlocked.

Close the probe slider to accurately

2.

measure current or to degauss the probe.

CAUTION.

than 5.0 mm (0.20 in) diameter. Damage to the

probe jaws may result.

Do not measure conductors larger

Controls and Indicators

TCP0030A Current Probe Instruction Manual 9

Page 32

Controls and Indicators

Overload LED

The multicolor Overload LED alerts you that

the probe specifications are being exceeded.

When the LED:

Glows red, the maximum input continuous

current limit has been exceeded

Glows orange, the safe operating

temperature of the probe has been

exceeded

Flashes red and orange, both the maximum

input continuous current limit and the safe

operating temperature of the probe have

been exceeded

CAUTION.

conditions that cause the Overload LED to light

for extended periods.

Quick Tip

An input current overload can magnetize

the probe. Always degauss the probe after

an overload.

Do not subject the probe to

10 TCP0030A Current Probe Instruction Manual

Page 33

Range Button

Controls and Indicators

Press the

5 A and 30 A current range settings.

The green LEDs indicate the range selected.

The range and units are also displayed on the

oscilloscope screen.

button to select between the

Range

TCP0030A Current Probe Instruction Manual 11

Page 34

Controls and Indicators

Degauss/AutoZero

When the multicolor Degauss/AutoZero status

LED flashes red, you must degauss the probe.

If the LED flashes orange, you should degauss

the probe. The DC gain and offset errors are

not guaranteed when this LED flashes orange.

The Degauss/AutoZero function also clears

(AutoZeroes) any DC offset in the probe.

To degauss the probe, do the following:

Disconnect the probe from the current

1.

source and then close the slider.

Press the

2.

initiate the degauss routine.

The LED glows green after successfully

completing the Degauss/AutoZero routine.

12 TCP0030A Current Probe Instruction Manual

Degauss/AutoZero

button to

Page 35

Menu Button

Press the Menu button on the TCP0030A probe

to access additional probe functions, such as

probe offset and deskew.

The following menus may appear on the

oscilloscope screen, depending on the model.

An MSO/DPO4000 series oscilloscope is used

in this example.

Controls and Indicators

Press the

1.

The lower-bezel menu appears at

the bottom of the screen, above the

lower-bezel buttons.

Press the

2.

to scroll through the lower-bezel menu.

As each lower-bezel menu item is

3.

highlighted, a side-bezel menu appears

for that function, next to the right-bezel

buttons. The Probe Setup menu is shown

here.

Press the probe

4.

close the menu.

TCP0030A Current Probe Instruction Manual 13

button on the probe.

Menu

button on the oscilloscope

More

button again to

Menu

Page 36

Controls and Indicators

Menu-Driven Probe Functions

The following probe functions are available through menu screens on many Tektronix oscilloscopes. An MSO/DPO4000 series

oscilloscope is used in these examples.

Fine Scale.

adjust the vertical mA/div setting to a custom

scale that is between the fixed 1–2–5 scales

on many oscilloscopes.

For example, to display a 320 mA signal over

exactly 8 vertical divisions (40 mA/div), first

set the fixed scale to 50 mA/div. Next, select

Fine Scale from the lower-bezel menu and

then use the Multipurpose knob to adjust the

Fine Scale down to 40 mA/div, as displayed

on-screen.

Offset and Position.

selections allow you to adjust that parameter

and to return the value to zero by pressing

a side-bezel button.

14 TCP0030A Current Probe Instruction Manual

This feature allows you to

Each of these

Page 37

Controls and Indicators

Probe Setup.

displays probe settings and functional buttons.

Use the side-bezel buttons to initiate routines

such as Degauss and Deskew. The buttons

also display the degauss status of the probe.

The Probe Setup menu

TCP0030A Current Probe Instruction Manual 15

Page 38

Controls and Indicators

Deskew.

other probes, select this function and connect

the probes to the optional deskew fixture. (See

page 43,

The deskew procedure measures the

channel-to-channel delay time, including the

probes, and provides manual and automatic

steps to align the delay (skew). Refer to

your oscilloscope manual or deskew fixture

documentation for instructions.

To deskew the TCP0030A probe to

Deskew/Calibration Fixture

.)

16 TCP0030A Current Probe Instruction Manual

Page 39

Functional Check

The following procedure checks that your probe is functioning properly. To verify that your probe meets the warranted specifications,

refer to the

Performance Verification

Functional Check

procedures. (See page 53.)

CAUTION.

conductors larger than 5 mm (0.20 in) diameter into the probe jaw. Damage to the probe may result.

To check that your probe functions correctly,

do the following:

1.

2.

3.

4.

5.

TCP0030A Current Probe Instruction Manual 17

The probe jaw opening accommodates insulated conductors with a diameter of 5 mm (0.20 in) or less. Do not insert

Connect the probe to any channel of the

oscilloscope.

Set the oscilloscope to display the probe

channel.

Press the Degauss/AutoZero button.

Clamp the probe to your circuit.

Adjust the oscilloscope or use the Autoset

function to display a stable waveform.

When you see a stable waveform, your

probe is functioning correctly.

Page 40

Basic Operation

Basic Operation

CAUTION.

The mating surfaces of the probe head transformer are precision-polished and should be handled with care. Measurements may

be degraded by dirt on the mating surfaces of the probe head transformer. Refer to the Maintenance section of this manual for

information on how to properly clean the probe head transformer surfaces.

1.

2.

3.

Do not force conductors larger than 5.0 mm (0.20 in) diameter into the probe jaws. Damage to the probe may result.

Check the oscilloscope display before

connecting the probe to a conductor.

If there is a DC offset, degauss the probe.

(See page 3,

Close and lock the probe jaw over the

conductor.

For correct polarity reading, connect the

probe so that the current flow, from positive

to negative, is aligned with the arrow on

the probe jaw.

Read the measurement on the oscilloscope

display.

Degauss the Probe

.)

18 TCP0030A Current Probe Instruction Manual

Page 41

Basic Operation

Grounding the Probe

The 6-inch ground lead grounds the shield around the probe transformer at the probe end of the cable. This allows you to move the

ground connection closer to the circuit you are measuring, thereby improving high frequency response.

When you take high frequency measurements,

connect the probe ground lead to the probe

ground connector and attach the alligator clip

directly to RF ground to improve EMI rejection.

In some cases, it may be helpful to move the

ground lead or reposition the probe away from

noise sources in the circuit under test.

Clip the ground lead to the ground post at

1.

the bottom of the probe head.

Connect the alligator end of the clip to the

2.

circuit ground.

Clamp the probe around the circuit

3.

conductor.

TCP0030A Current Probe Instruction Manual 19

Page 42

Application Examples

Application Examples

This section explains ways to use your probe in common troubleshooting tasks and how to extend the use of your measurement

system.

20 TCP0030A Current Probe Instruction Manual

Page 43

Inductance Measurements

You can use the current probe to measure the inductance of coils that have either a low-impedance or high-impedance pulse

source of a known value.

Low-Impedance Pulse Sources

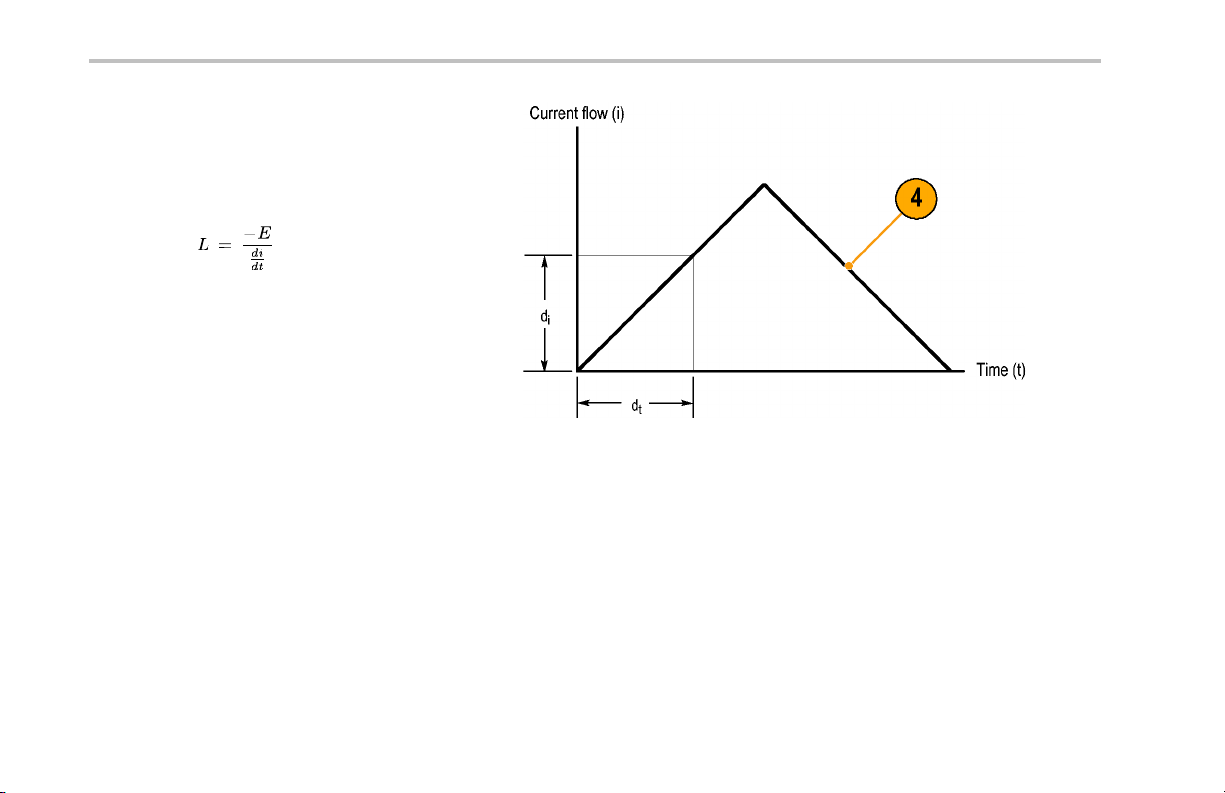

This figure shows a constant-voltage pulse

generator of extremely low output impedance

connected to an inductor that has low

resistance.

Connect the inductor across the output

1.

terminals of the pulse generator.

Maintain a constant voltage across the

2.

inductor.

Clamp the current probe over one of the

3.

source leads.

If the probe impedance is a significant

NOTE.

part of the total circuit inductance, measurement

accuracy will be affected. Refer to the probe

specifications for probe insertion impedance.

Application Examples

TCP0030A Current Probe Instruction Manual 21

Page 44

Application Examples

Measure the current ramp. The inductance

4.

is effectively defined by the slope of the

current ramp shown here.

Calculate the inductance using the

5.

following formula:

where:

L

is the inductance in henries,

E

is the voltage of the pulse generator,

dt

is the change in time, and

di

is the change in current.

22 TCP0030A Current Probe Instruction Manual

Page 45

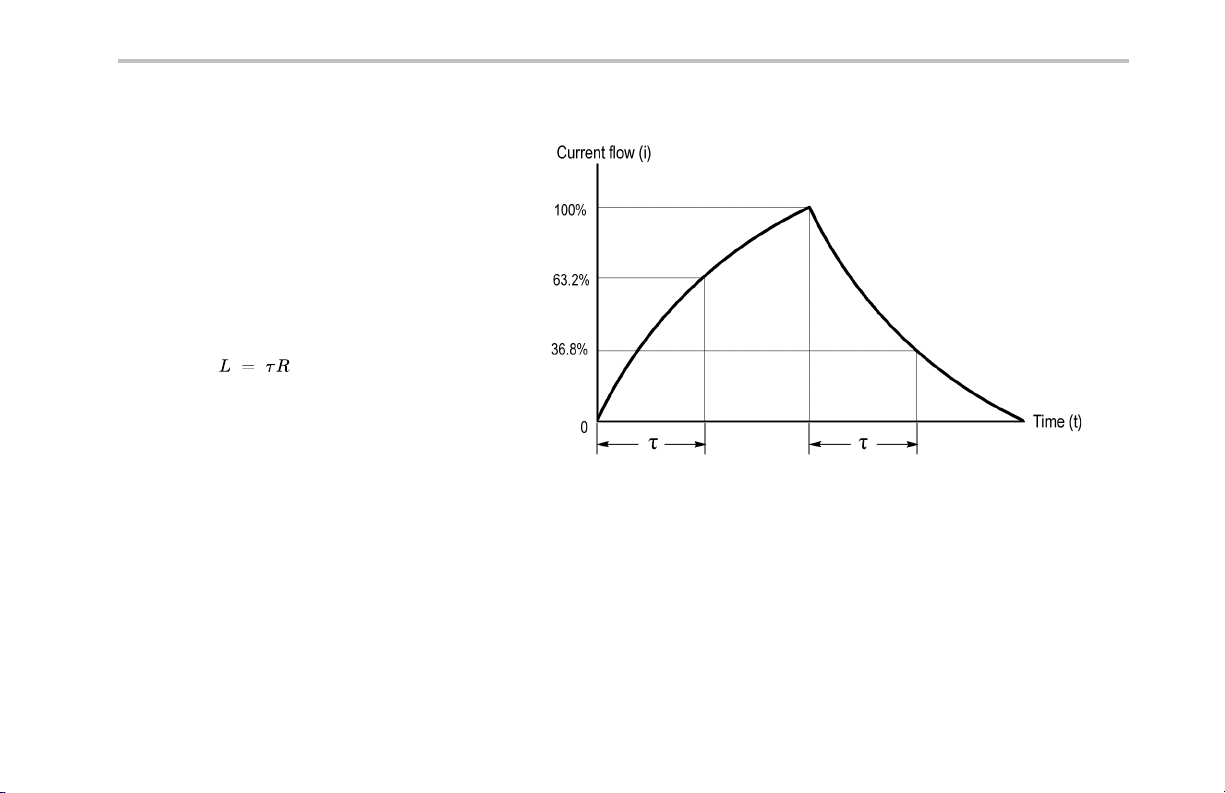

High-Impedance Pulse Sources

If the pulse source has a higher impedance of

known resistance, such that the output voltage

drops as the current increases, the inductance

of a coil can be calculated by the time constant

of the charge curve.

The current ramp shows how the values for the

inductance formula are obtained.

Use this formula to calculate the inductance

based on the current measurement:

where:

L

is the inductance in henries,

τ

is the time required for the current to rise

or fall 63.2% of the total current value, and

R

is the source resistance of the pulse

generator.

Application Examples

TCP0030A Current Probe Instruction Manual 23

Page 46

Application Examples

Measuring Inductor Turns Count

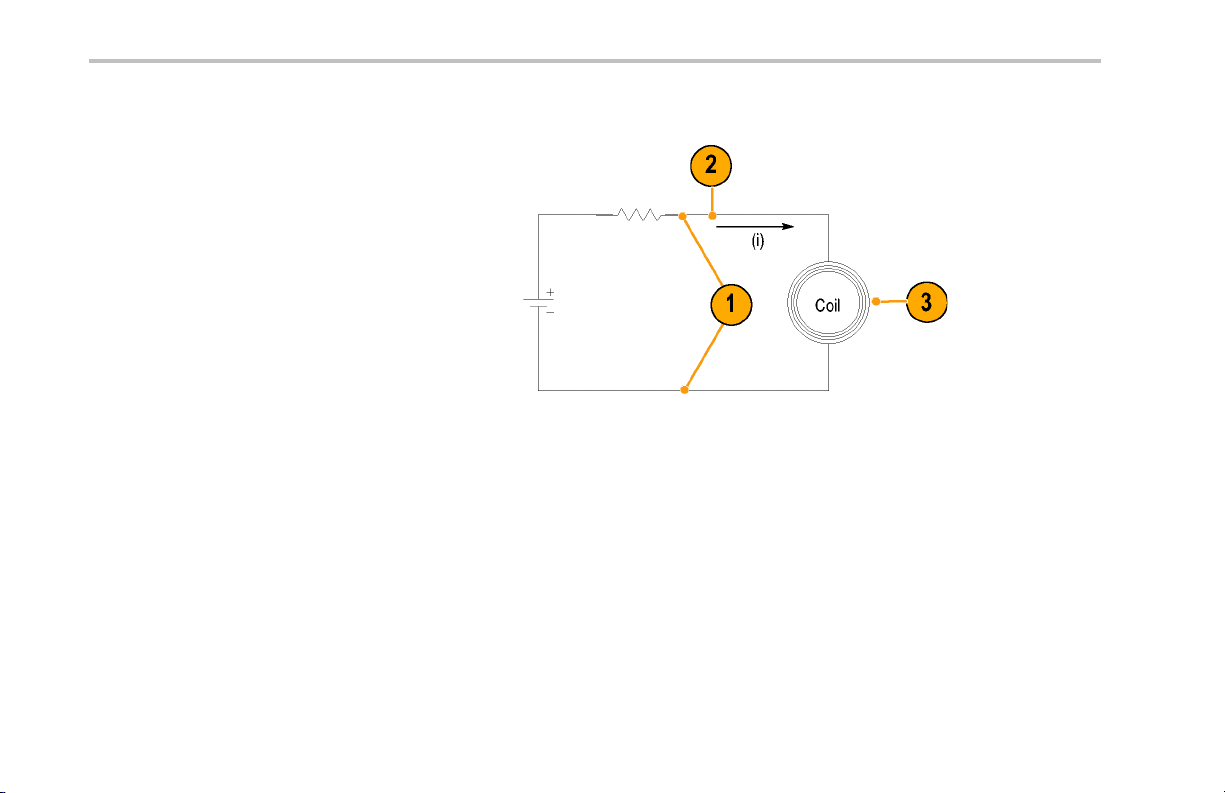

To obtain an approximate turns count of an

inductor, do the following:

Connect the inductor to a current limited

1.

source, as shown.

Measure the input current on one of the

2.

inductor leads.

Clamp the current probe around the

3.

inductor and note the current value.

The number of turns is equal to the ratio of coil

current to input current.

The accuracy of this method is limited by the

current measurement accuracy.

24 TCP0030A Current Probe Instruction Manual

Page 47

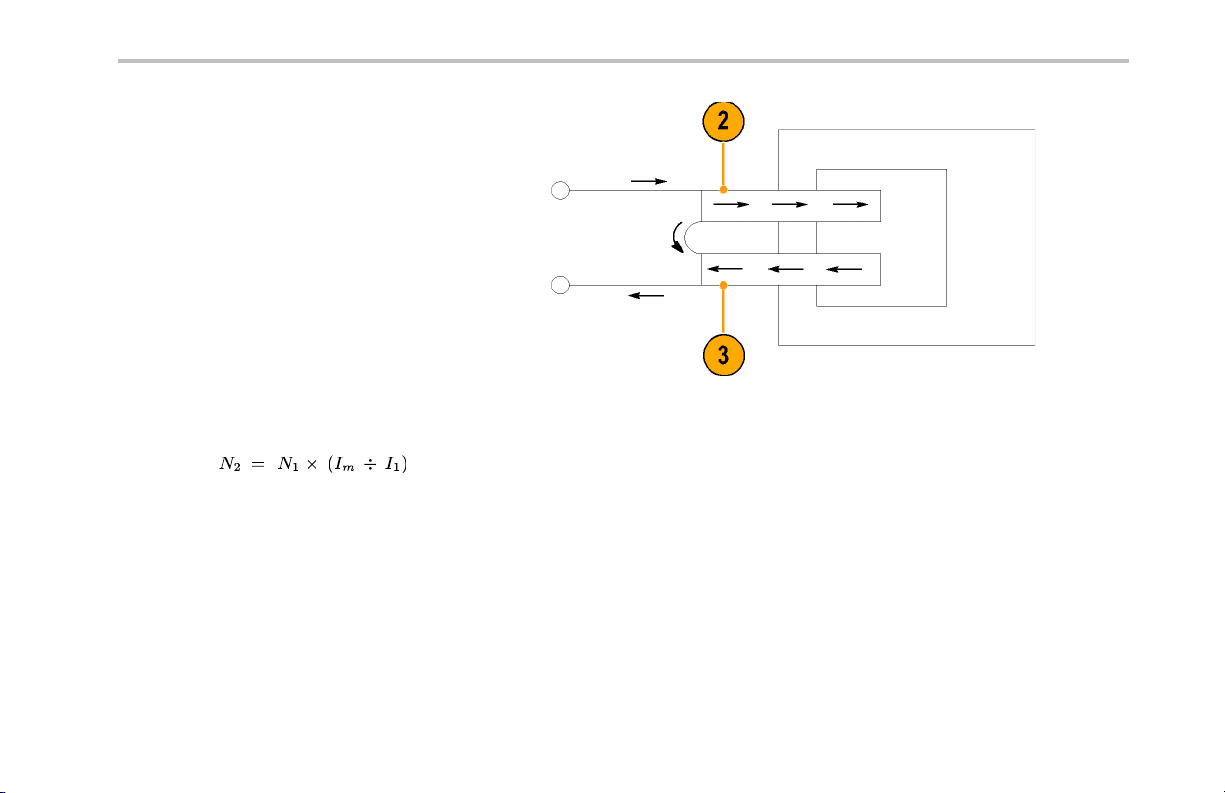

For a more precise turns count, you need a

coil with a known number of turns to use as a

reference. Do the following:

Repeat steps 1 and 2 above and make the

1.

following changes:

Insert the reference coil into the current

2.

probe.

Insert the test coil into the current probe

3.

so that the currents oppose each other

as shown. You must observe the polarity

of coil current to determine whether the

test coil has less or more turns than the

reference coil. The turns are calculated by

using the formula:

where:

N

is the number of turns in the test coil,

2

N

is the number of turns in the reference

1

coil,

I

is the measured coil current, and

m

I

is the input current.

1

Application Examples

TCP0030A Current Probe Instruction Manual 25

Page 48

Probing Principles

Probing Principles

The following information is provided to help you use the full potential of your current probe.

Degaussing a Probe with an Unpowered Conductor in the Jaws

You can degauss your current probe while a conductor of an unpowered circuit is clamped in the jaws. The advantage of

degaussing with an unpowered circuit is that any offset from stray DC magnetic fields is compensated. Degaussing with the

conductor in the probe jaws eliminates the need to manually remove the probe.

Be certain that the conductor in the probe jaws is completely unpowered. Any current flowing through the conductor will

NOTE.

cause a residual offset in the current probe and may cause an inaccurate measurement or an error condition.

The impedance of your circuit must be higher than 10 mΩ for the degauss procedure to work. (The probe core will not saturate with

a circuit impedance of less than 10 mΩ). While degauss occurs, the probe will induce approximately 50 mVp-p, into 50 Ω with a

frequency of 190 Hz. Your circuit must be able to absorb this induced voltage. With low impedance circuits, several amperes may

be induced in the circuit being measured. This may be of concern when you are using very small conductors.

26 TCP0030A Current Probe Instruction Manual

Page 49

Measuring Differential Current

To simplify your differential or null current

measurements, you can place two conductors

in one current probe.

Probing Principles

WARNING.

either reduce the number of conductors you are measuring, or , if possible, take your measurement on a smaller conductor.

TCP0030A Current Probe Instruction Manual 27

Do not force the slide closed. Damage to the probe may result. If you cannot close the slide around the conductor(s),

Page 50

Probing Principles

Orient the two conductors under test so

1.

that the polarities (+ and –) oppose each

other.

Clamp the current probe around the two

2.

conductors. Be careful not to pinch a

conductor in the probe jaws.

Measure the current.

3.

Conventional current flows from positive to

negative. A waveform above the baseline

indicates that the conductor with the

conventional current flow in the direction

of the probe arrow is carrying the greater

current.

28 TCP0030A Current Probe Instruction Manual

Page 51

To adjust for a current null, adjust the

4.

current in one of the conductors until the

displayed measurement is zero.

Extending Current Range

If your measurement exceeds the maximum current rating of the connected probe, you can extend the AC and DC current ranges

without exceeding specified limits by using the following methods.

Probing Principles

WARNING.

applicable accessories. When using multiple conductors, do not exceed current limits on either conductor.

To avoid personal injury or equipment damage, do not exceed the specified electrical limits of the probe or any

Extending DC Range

If you want to measure a low-amplitude AC component that is superimposed on an extremely large steady-state DC component

(such as in a power supply), or if you want to extend the DC current range of your probe, you can add offset (bucking) current with

a second conductor.

TCP0030A Current Probe Instruction Manual 29

Page 52

Probing Principles

WARNING.

Do not put more than one uninsulated conductor at a time in the probe jaws. An uninsulated conductor is any

conductor without insulation or without insulation rated for the voltage present on the conductor under test.

To supply additional bucking current:

Place a second conductor that has a pure

1.

DC component of known value in the probe

jaw with the conductor under test.

Orient the second conductor so that the

2.

bucking current flows in the opposite

direction of the DC flow in the conductor

under test.

To determine measurement values, add

3.

the value of the bucking current to the

displayed measurement.

Adding a second conductor to the probe increases the insertion impedance and reduces the upper bandwidth limit of the

NOTE.

probe. Winding multiple turns further increases the insertion impedance, further reducing the upper bandwidth limit.

30 TCP0030A Current Probe Instruction Manual

Page 53

To increase the value of the bucking current:

Wind multiple turns of the second

1.

conductor around the probe.

The bucking current is equal to the current

flowing in the conductor, multiplied by the

number of turns wound around the probe.

For example, if the second conductor has a

current of 100 mA DC and is wrapped around

the probe five times, the DC bucking current is

100 mA multiplied by 5, or 500 mA DC.

Probing Principles

TCP0030A Current Probe Instruction Manual 31

Page 54

Probing Principles

Increasing Sensitivity

If you are measuring DC or low-frequency

AC signals of very small amplitudes, you can

increase measurement sensitivity of your

current probe by doing the following:

Wind several turns of the conductor under

1.

test around the probe as shown. The

signal is multiplied by the number of turns

around the probe.

To obtain the actual current value, divide

2.

the displayed amplitude by the number of

turns.

For example, if a conductor is wrapped around

the probe three times and the oscilloscope

shows a reading of 3 mA DC, the actual current

flow is 3 mA divided by 3, or 1 mA DC.

Winding more turns around the probe increases the insertion impedance and reduces the upper bandwidth limit of the probe.

NOTE.

32 TCP0030A Current Probe Instruction Manual

Page 55

Common Mode Noise/Magnetic Field Errors

Common-mode noise at high frequencies and

strong magnetic fields on the supply side of

your circuit can cause measurement errors. To

avoid this:

Measure on the low or ground side of your

1.

circuit.

Orient the probe to measure conventional

2.

current flow.

Probing Principles

TCP0030A Current Probe Instruction Manual 33

Page 56

Probing Principles

AC and DC Coupling

You can couple the signal input to the oscilloscope with either DC or AC coupling. DC coupling shows both the DC and AC

measurement components. AC coupling removes the DC component from the displayed signal.

This low-frequency square wave is

1.

displayed using AC coupling. The signal

exhibits low-frequency rolloff.

Press the DC Coupling button to display

2.

the waveform as truly square.

CAUTION.

sure that the input DC current does not exceed

the probe specifications.

When you use AC coupling, make

34 TCP0030A Current Probe Instruction Manual

Page 57

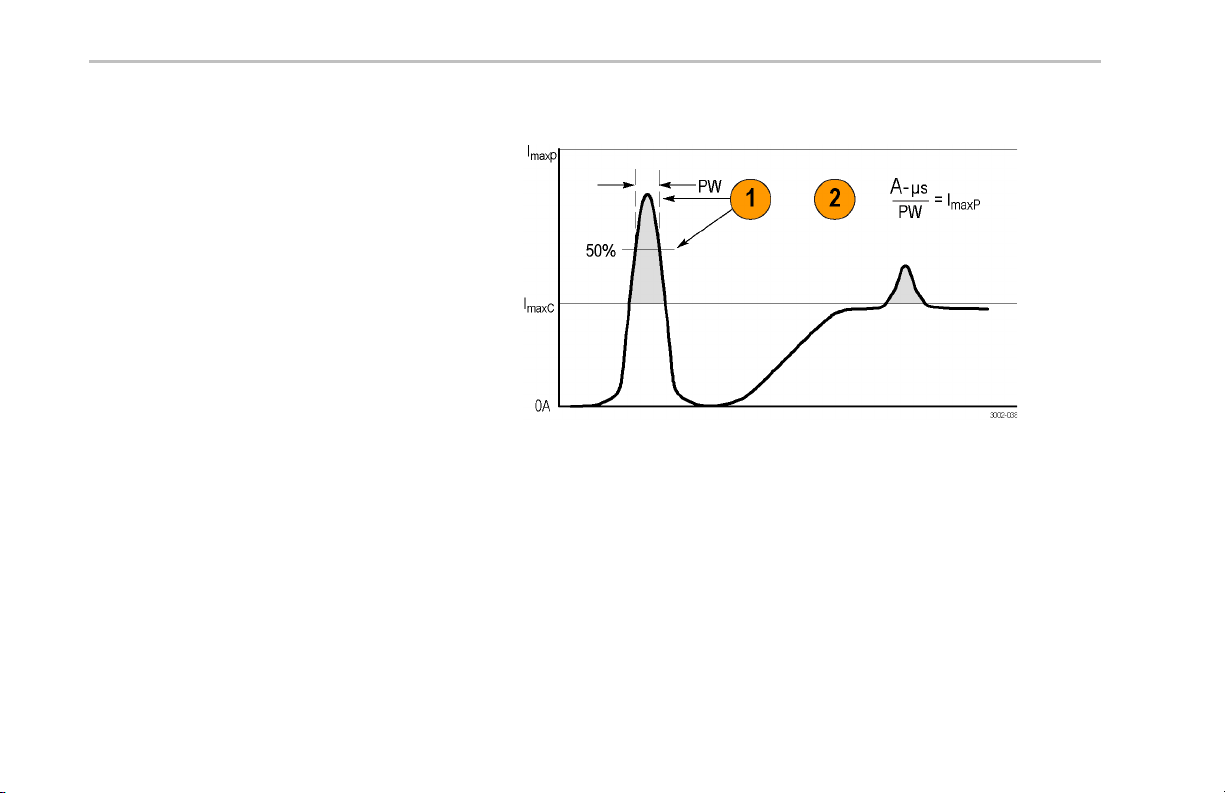

Maximum Current Limits

Current probes have three maximum current ratings: pulsed, continuous, and Ampere-second product. Exceeding any of these

ratings can saturate the probe core, which magnetizes the core and causes measurement errors. Refer to the specifications for the

maximum current ratings of the probe. (See Table 2 on page 46.)

Probing Principles

Maximum Pulsed Current (I

maxP

)isthe

maximum peak value of pulsed current the

probe can accurately measure, regardless

of how short (within bandwidth limitations)

the pulse duration is.

Maximum Continuous Current (I

maxC

)isthe

maximum current that can be continuously

measured at DC or at a specified AC

frequency. The maximum continuous

current value is derated with frequency;

as the frequency increases, the maximum

continuous current rating decreases.

TCP0030A Current Probe Instruction Manual 35

Page 58

Probing Principles

Ampere-Second Product is the maximum

width of pulsed current that you can

measure when the pulse amplitude is

between the maximum continuous and

maximum pulsed current specifications.

The maximum continuous specification

varies by frequency.

To determine if your measurement exceeds

the Ampere-second product, you must first

determine the maximum allowable pulse width

or maximum allowable pulse amplitude, as

described in the following section.

NOTE.

current, or Ampere-second product rating of the probe. Exceeding these ratings can magnetize the probe and cause measurement

errors.

Always degauss the probe after measuring a current that exceeds the maximum continuous current, maximum pulsed

36 TCP0030A Current Probe Instruction Manual

Page 59

Maximum Allowable Pulse Width

To determine the maximum allowable pulse

width do the following:

Measure the peak current of the pulse.

1.

Divide the Ampere-second (or

2.

Ampere-microsecond) specification

for the range setting of the TCP0030A

probe by the measured peak current of the

pulse:

The quotient is the maximum allowable

pulse width (PW

Check that the pulse width at the 50% point

3.

of the measured signal is less than the

calculated maximum allowable pulse width

).

(PW

max

max

).

Probing Principles

TCP0030A Current Probe Instruction Manual 37

Page 60

Probing Principles

Maximum Allowable Pulse Amplitude

To determine the maximum allowable pulse

amplitude do the following:

Measure the pulse width at the 50% points.

1.

Divide the Ampere-second (or

2.

Ampere-microsecond) specification

for the range setting of the TCP0030A

probe by the pulse width.

The quotient is the maximum allowable

pulse amplitude; the peak amplitude of the

measured pulse must be less than this

value.

For example, the TCP0030A probe has a

maximum Ampere-second product of 500 A-μs

in the 30 A range setting. If a pulse measured

with the probe has a width of 11 μs, the

maximum allowable peak current would be

500 A-μs divided by 11 μs, or 45.5 A.

38 TCP0030A Current Probe Instruction Manual

Page 61

Accessories and Options

This section lists the standard accessories and provides information on how to use the accessories. Specifications are provided

where appropriate so that you can choose the accessory that best fits your needs.

Probe Ground Lead

Fasten the small clip to the ground stub on

1.

the probe body.

Clip the alligator clip to your circuit.

2.

Attach the probe to your circuit.

3.

Reorder Tektronix part number 196-3521-xx,

qty. 1.

Accessories and Options

TCP0030A Current Probe Instruction Manual 39

Page 62

Accessories and Options

Instruction Manual

The instruction manual provides operating and

maintenance instructions.

Reorder Tektronix part number: 071-3006-xx

Manuals in the languages listed below are

available for this product. Other languages may

also be available; check the Tektronix Web site

at www.tektronix.com/manuals.

Japanese

Simplified Chinese

40 TCP0030A Current Probe Instruction Manual

Page 63

Optional Accessories

This section lists the optional accessories that are available for the probe.

Current Loop

Use the 1-turn, 50 Ω current loop for the

performance verification procedures. The

BNC connector allows for easy connections to

current sources.

To use the current loop, follow the procedure

for the specific task that you are performing.

Order Tektronix part number: 067-2396-xx

Accessories and Options

TCP0030A Current Probe Instruction Manual 41

Page 64

Accessories and Options

TekVPI Calibration Fixture

This calibration fixture is required to complete

a performance verification and gain accuracy

adjustment procedures on the probe. It

provides power to the probe and routes the

probe output signal out through an SMA

connector on the back of the fixture. The signal

can then be measured with another instrument,

such as a precision DMM, to check and adjust

the gain accuracy of the probe.

Order Tektronix part number 067-1701-xx.

42 TCP0030A Current Probe Instruction Manual

Page 65

Deskew/Calibration Fixture

Connect this fixture to host instruments that

support the probe calibration or deskew

procedures. The deskew procedures

compensate for gain errors and timing

differences between current and voltage

probes. Refer to your oscilloscope manual or

fixture documentation for instructions.

Reorder Tektronix part number: 067-1686-xx

Accessories and Options

TCP0030A Current Probe Instruction Manual 43

Page 66

Accessories and Options

Options

Service Options

Option CA1.

Option C3.

Option C5.

Option D1.

Option D3.

Option D5.

Option R3.

Option R5.

44 TCP0030A Current Probe Instruction Manual

Provides coverage for a single Calibration Event

Calibration Service 3 years

Calibration Service 5 years

Calibration Data Report

Calibration Data Report, 3 years (with Option C3)

Calibration Data Report, 5 years (with Option C5)

Repair Service 3 years

Repair Service 5 years

Page 67

Specifications

The specifications in the tables in this section are valid under the following conditions:

The probe has been calibrated at an ambient temperature of 23 °C ±5 °C.

The probe is connected to a host instrument with an input impedance of 1 MΩ.

The probe must have a warm-up period of at least 20 minutes and be in an environment that does not exceed the limits

described. (See Table 1).

Specifications for the TCP0030A current probe fall into three categories: warranted, typical, and nominal characteristics.

Warranted Characteristics

Warranted characteristics describe guaranteed performance within tolerance limits or certain type-tested requirements. Warranted

characteristics that have checks in the

Table 1: Warranted electrical characteristics

Characteristic Description

DC gain accuracy

Rise time (10% to 90%)

Bandwidth

Performance Verification

<3% (typical <1% at +23 °C, ±5 °C)

≤2.92 ns

DC to 120 MHz

section are marked with the

Specifications

symbol.

TCP0030A Current Probe Instruction Manual 45

Page 68

Specifications

Typical Characteristics

Typical characteristics describe typical but not guaranteed performance.

Table 2: Typical electrical characteristics

Characteristic Description

Maximum continuous current – DC and

low frequency

Maximum peak current

Displayed RMS noise ≤75 μA RMS. (Limit measurement bandwidth to 20 MHz)

Insertion impedance

Signal delay

Maximum voltage on bare wire

Maximum Amp·Second product

5 A Range: 5 A RMS

30 A Range: 30 A RMS (42.4 A peak) (See Figure 3 on page 49.)

50 A maximum peak pulse (See Figure 3 on page 49.)

(See Figure 2 on page 48.)

~14.5 ns

150 V CAT II

5 A range: 50 A·μs

30 A range: 500 A·μs

46 TCP0030A Current Probe Instruction Manual

Page 69

Figure 1: Frequency derating (peak current versus frequency)

Specifications

TCP0030A Current Probe Instruction Manual 47

Page 70

Specifications

Figure 2: Typical input impedance versus frequency

48 TCP0030A Current Probe Instruction Manual

Page 71

Figure 3: Maximum peak pulse versus pulse width

Specifications

TCP0030A Current Probe Instruction Manual 49

Page 72

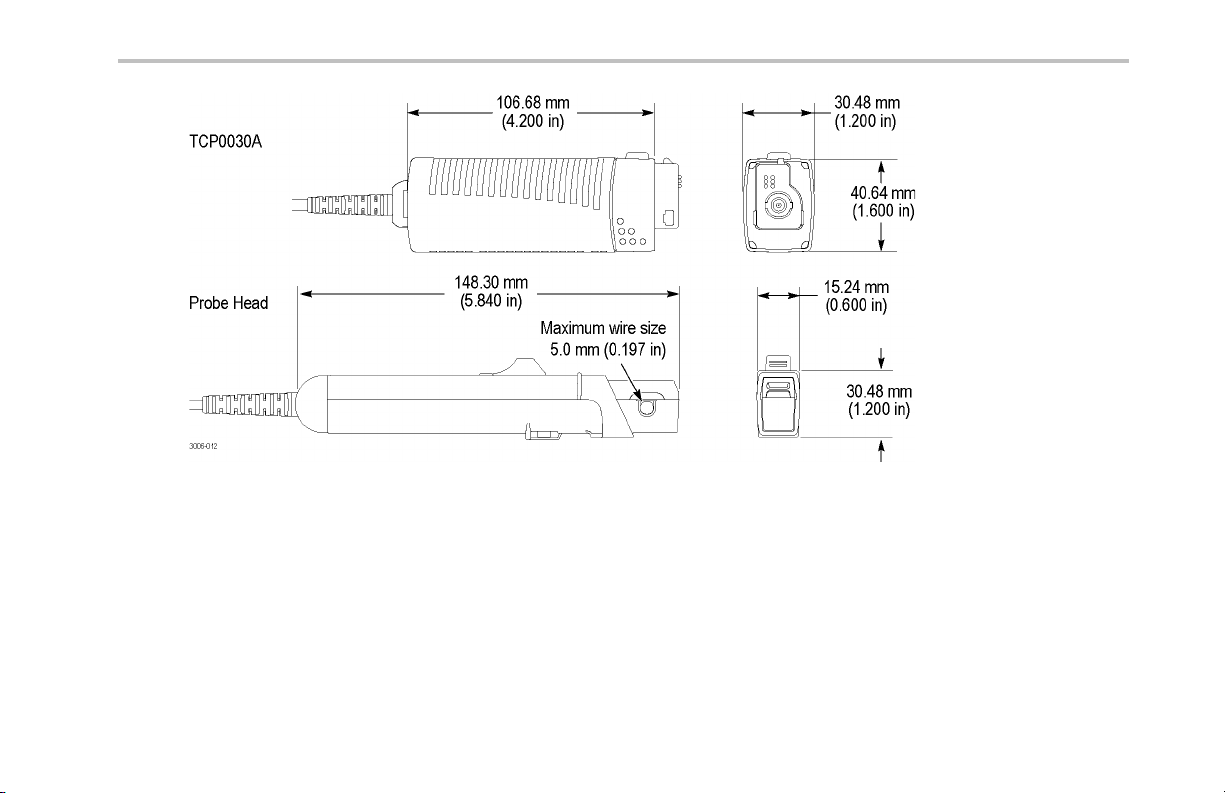

Specifications

Table 3: Environmental characteristics

Characteristic Description

Temperature

Humidity

Altitude

Table 4: Typical mechanical characteristics

Characteristic Description

Dimensions, compensation box

Dimensions, probe head

Dimensions, cable length

Unit weight

Operating: 0 to +50 °C (+32 to +122 °F)

Nonoperating: -40 to +75 °C (-40 to +167 °F)

Operating: 5-95% RH, tested up to +30 °C (+86 °F)

5-85% RH, tested at +30 °C to +50 °C (+86 °F to +122 °F)

Nonoperating: 5-95% RH, tested up to +30 °C (+86 °F)

5-85% RH, tested at +30 °C to +75 °C (+86 °F to +167 °F)

Operating: Up to 3000 meters (10,000 feet)

Nonoperating: Up to 12,192 meters (40,000 feet)

107 mm × 30.5 mm × 41 mm (4.2 in × 1.2 in × 1.6 in)

148.3 mm × 15.2 mm × 30.5 mm (5.8 in × 0.6 in × 1.2 in)

2 m (79 in) (from the probe head to the compensation box)

700 g (1.5 lbs) (probe, accessories, and packaging)

50 TCP0030A Current Probe Instruction Manual

Page 73

Specifications

TCP0030A Current Probe Instruction Manual 51

Page 74

Specifications

Nominal Characteristics

Nominal characteristics describe guaranteed traits, but the traits do not have tolerance limits.

Table 5: Nominal electrical characteristics

Characteristic Description

Input coupling

Current ranges

Termination

Compatibility Oscilloscopes equipped with the TekVPI interface

DC

5 A and 30 A

Terminate output into 1 MΩ

52 TCP0030A Current Probe Instruction Manual

Page 75

Performance Verification

The procedures that follow verify the warranted specifications of the probe, listed below. The recommended calibration interval is

one year.

DC gain accuracy

Rise time

Bandwidth

Perform the following verification procedures in the order listed.

Performance Verification

TCP0030A Current Probe Instruction Manual 53

Page 76

Performance Verification

Equipment Required

The equipment required for the performance verification procedure is listed below. (See Table 6.)

Table 6: Test equipment

Description and quantity Performance requirement Recommended example

Oscilloscope TekVPI interface, 500 MHz or greater bandwidth Tektronix DPO4000

High amplitude pulse generator Risetime <500 ps, pulse width >100 ns, amplitude

Calibrator DCV: 0.2% accuracy, 0 to ±1.5 V, square wave output

DMM

TekVPI Calibration/Verification

adapter

DC current loop 5 turns 18 AWG coated wire on 3 inch form See instructions that follow

HF current loop

Adapter

Adapter

BNC cable 50 Ω, 0.76 m (30 in) length

Test leads (2)

1

Nine-digit part numbers (xxx-xxxx-xx) are Tektronix part numbers.

Picosecond Labs 2600C

>10 Vpp into 50 Ω

Fluke 9100

ACA: 0.25% accuracy, 0 to ±6 A, square wave output

≥2 volt range, ≥1% accuracy

Keithley 2700

TekVPI interface 067-1701-xx (See page 42.)

50 Ω ±0.5%, BNC male

BNC-to-dual banana

SMA male-to-BNC female

067-2396-xx

103-0090-xx

015-1018-xx

012-0117-xx

Banana plug to clip leads Keithley 1681

1

54 TCP0030A Current Probe Instruction Manual

Page 77

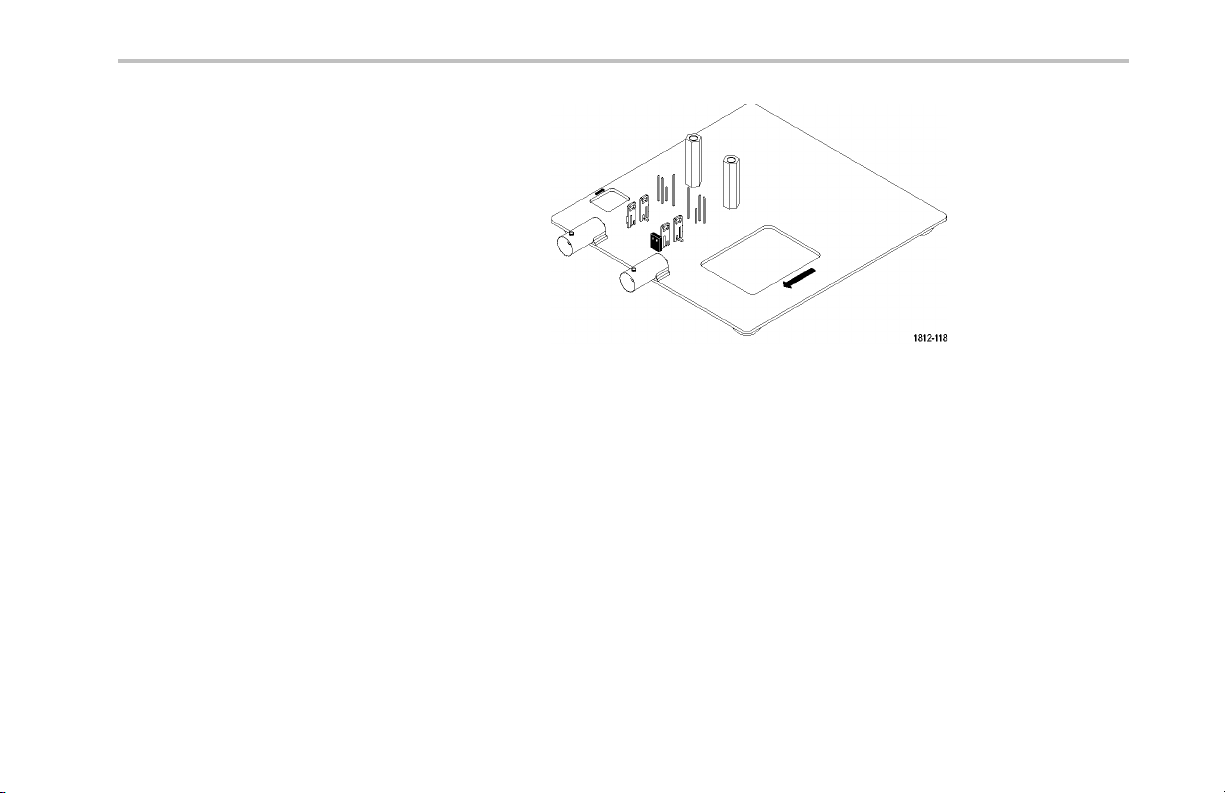

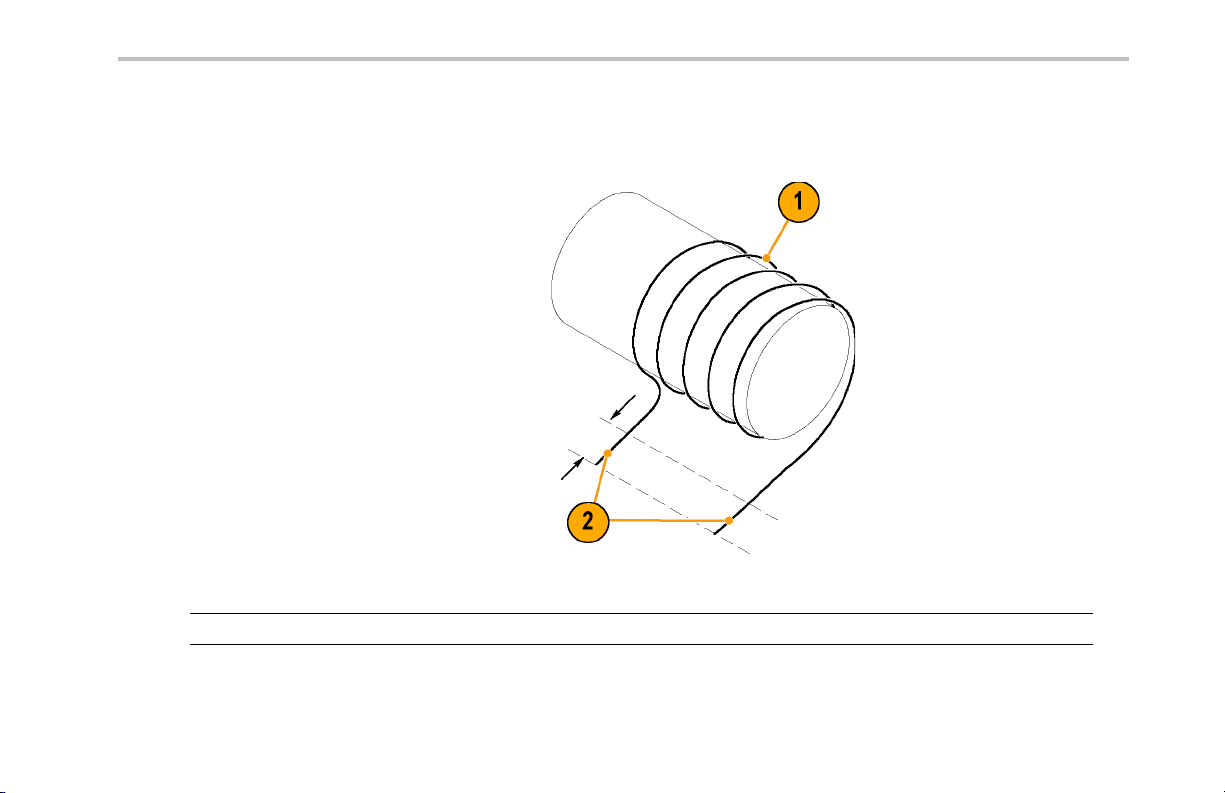

Making the DC Current Loop

Construct the loop using #18 coated wire and a cylindrical form approximately 3 inches in diameter:

exactly

Wind

1.

around the form.

Scrape about a half-inch of coating off of

2.

the ends of the wire.

5 turns of #18 coated wire

Performance Verification

Ensure that the current loop has exactly 5 turns. A significant error will result for each turn variance from 5 turns.

NOTE.

TCP0030A Current Probe Instruction Manual 55

Page 78

Performance Verification

Equipment Setup

Use the following procedure to set up and warm up the equipment to test the probe.

Turn on the oscilloscope.

1.

Connect the probe to any channel (1–4) of

2.

the oscilloscope.

Close the probe slider and then press the

3.

Degauss/AutoZero button.

Set the oscilloscope coupling to DC.

4.

Power on the current source and the pulse

5.

generator.

Allow 20 minutes for the equipment to

6.

warm up.

Photocopy the test record and use it to

7.

record the test results. (See page 63.)

56 TCP0030A Current Probe Instruction Manual

Page 79

DC Gain Accuracy

This test checks the DC gain accuracy of the probe. If the measurements are out of the specified limits in the test record, refer to

Adjustments

the

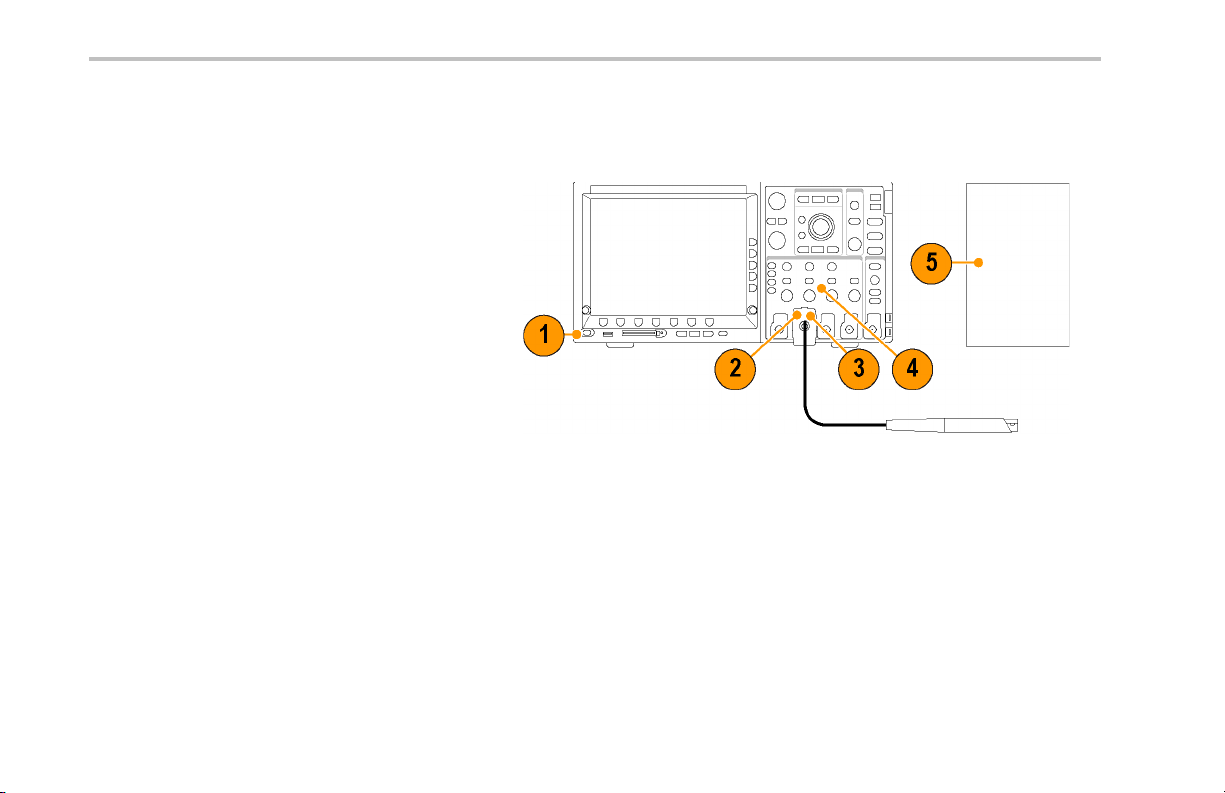

Connect a BNC-to-Dual Banana adapter to

1.

the digital multimeter (DMM) input.

Connect the SMA M-to-BNC F adapter

2.

to the SMA output of the TekVPI

Calibration/Verification adapter.

Connect the BNC cable between

3.

the BNC adapter on the TekVPI

Calibration/Verification adapter and the

BNC adapter attached to the DMM.

Connect the TekVPI Calibration/Verification

4.

adapter to any channel (1–4) of the

oscilloscope.

Connect the probe to the TekVPI

5.

Calibration/Verification adapter.

The adapter is only used to supply

NOTE.

power to the probe; measurements are taken

on the DMM.

section. (See page 64.)

Performance Verification

TCP0030A Current Probe Instruction Manual 57

Page 80

Performance Verification

Do not clamp the current probe around any

6.

conductor, but make sure the jaw is in the

locked position.

Degauss the probe by pressing the

7.

Degauss/AutoZero button.

Connect the 5-turn current loop to the

8.

current source, and then clamp the current

probe around the current loop as shown.

The arrow indicator on the probe should

point away from the (+) terminal of the

current source.

58 TCP0030A Current Probe Instruction Manual

Page 81

5 A Range Test

Set the current source output to +0.50 A

9.

DC.

Set the DMM to measure DC volts, on

10.

≥2 volt range (or use Autoset).

Set the probe to the 5 A range.

11.

Enable the output of the current source.

12.

Performance Verification

Test current = ±2.500 A (±0.50 A source output x 5 coil turns)

Expected output voltage (Ve) = 2.50 V

Record the exact measurement of the

13.

DMM as M1.

Set the current source output to -0.50 A.

14.

Record the exact measurement of the

15.

DMM as M2.

Compute the % Error using the measured

16.

amplitude values and the formula shown.

TCP0030A Current Probe Instruction Manual 59

Example:

Page 82

Performance Verification

30 A Range Test

Set the current source output to +3.00 A.

17.

Set the probe to the 30 A range.

18.

Record the exact measurement of the

19.

DMM as M1.

Set the current source output to -3.00 A.

20.

Record the exact measurement of the

21.

DMM as M2.

Compute the % Error using the measured

22.

amplitude values and the formula shown.

Record the computed %Error values in the

23.

Test Re c or d .

Disable the calibrator output.

24.

Test current = ±15.00 A (±3.00 A source output x 5 coil turns)

Expected output voltage (Ve) = 1.50 V

60 TCP0030A Current Probe Instruction Manual

Page 83

Rise Time and Bandwidth

This procedure verifies that the probe meets the rise time specification on both of the current ranges. The bandwidth of the

probe is then calculated using the measured probe rise time.

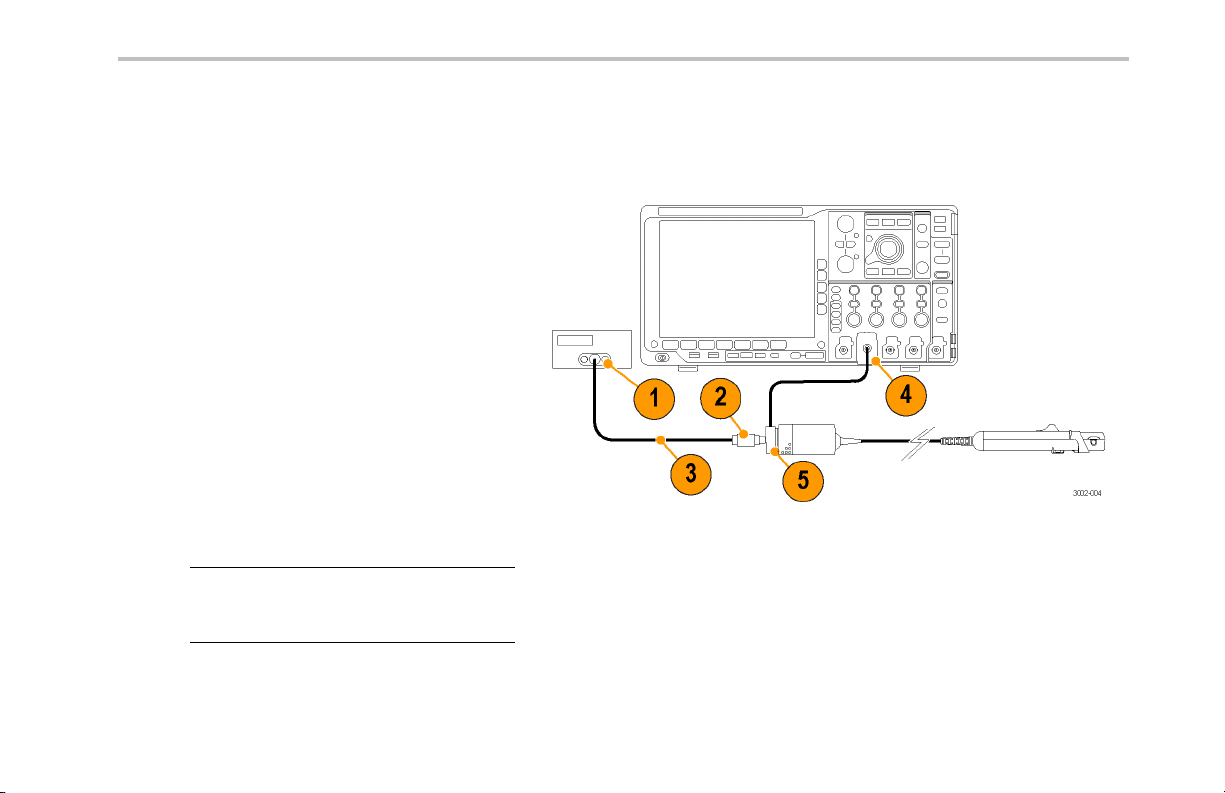

Connect the probe to any channel (1–4).

1.

Connect the BNC cable to the output of

2.

the pulse generator, using a BNC-to-SMA

adapter if necessary.

Connect the other end of the BNC cable to

3.

the HF current loop.

Set the pulse generator output and pulse

4.

width to maximum (0 dB, 100 ns duration).

Set the oscilloscope:

5.

Vertical sensitivity to 200 mA/div

Horizontal to 2 ns/div

Trigger at 50%

Averaging on (32)

Coupling to DC

Performance Verification

To measure Rise Time

TCP0030A Current Probe Instruction Manual 61

Page 84

Performance Verification

Set the probe range to the 5 A setting.

6.

Degauss the probe.

7.

Clamp the current probe around the HF

8.

current loop. Verify that the arrow-shaped

indicator on the probe points away from the

pulse generator.

Record the rise time measurement in the

9.

Test Re c or d .

If the measured rise time is out of

NOTE.

tolerance, you may be able to readjust it. (See

page 64, Adjustments.)

Calculate the probe bandwidth using the

10.

measured rise time in the following formula:

Record the calculated bandwidth value in

11.

the test record.

Set the probe range to the 30 A setting and

12.

set the vertical sensitivity to 200 mA/div.

Remove the probe from the current loop

13.

and then repeat steps 7 through 11.

End of procedures.

62 TCP0030A Current Probe Instruction Manual

Page 85

Test Record

Performance Verification

Probe Model/Serial Number:

Temperature:

Date of Calibration:

Performance

test

DC Gain

Accuracy

Range Test

5 A ±2.5 A ±2.50 V

30 A ±15 A ±1.50 V

5 A ~1 A <2.92 ns NA 2.92 nsRise time

30 A ~1 A <2.92 ns NA 2.92 ns

5 A NA >120 MHz 120 MHz NABandwidth

30 A NA >120 MHz 120 MHz NA

Current

Expected

output

Certificate Number:

RH %:

Technician:

Minimum Incoming

-3% +3%

-3% +3%

Outgoing

Maximum

TCP0030A Current Probe Instruction Manual 63

Page 86

Adjustments

Adjustments

The procedures that follow describe adjustments to the probe to bring the performance within the warranted specifications.

DC gain accuracy

Rise time/aberrations

Equipment Required

Refer to the

tool. The tool is available from Tektronix; order part number 003-1433-00.

Performance Verification

procedure for the equipment required. You also need an insulated, flat-bladed adjustment

Equipment Setup

Refer to the

CAUTION.

handling the probe

64 TCP0030A Current Probe Instruction Manual

Performance Verification

To avoid ESD damage to the probe, use an antistatic wrist strap and work at a static-approved workstation when

procedure for the equipment setup.

Page 87

DC Gain Accuracy

This procedure describes the DC gain accuracy adjustments for the probe. You must first adjust the 5 A range, and then adjust 30 A

range, in that order.

Adjustthe5ARange

Adjustments

Complete the

1.

Performance Verification

DC Gain Accuracy

the test limits, proceed to the next step.

Set the calibrator output to 0.5 A.

2.

Adjust the 5 A DC gain control in the probe head to

3.

display 2.50 V, ±0.075 V on the DMM.

TCP0030A Current Probe Instruction Manual 65

DC Gain Accuracy

procedure. (See page 57,

.) If the measurements fall outside

test in the

Page 88

Adjustments

Adjust the 30 A Range

Set the probe range to 30 A.

4.

Set the calibrator output to 3.0 A.

5.

Adjust the 30 A DC gain control in the probe

6.

compensation box to display 1.50 V, ±0.045 V on the

DMM.

Disconnect the probe from the current source.

7.

66 TCP0030A Current Probe Instruction Manual

Page 89

High Frequency Response

Use this procedure to bring the rise time of the probe to within the warranted specifications. This adjustment also affects the

aberrations on the probe output waveform, so for each current range, you may need to optimize the final adjustment between the

two characteristics.

Adjustments

Complete the

1.

test in the

procedure. If the measurements fall

outside the test limits, proceed to the next

step.

Set the Range to 5 A.

2.

Adjust the H.F. control to optimize the rise

3.

time and aberrations.

Set the Range to 30 A and repeat step 3.

4.

Check that the probe response is optimized

5.

for both ranges.

TCP0030A Current Probe Instruction Manual 67

Rise Time and Bandwidth

Performance Verification

Page 90

Maintenance

Maintenance

This section contains maintenance information for your probe.

Troubleshooting

The TCP0030A current probe is designed to work with all TekVPI-interface oscilloscopes and adapters. The LEDs on the probe

alert you to error or status conditions affecting the probe. If the probe LEDs do not light as expected, or if some of the probe

features do not work properly, an error condition may exist. See the following table.

Table 7: Probe troubleshooting

Symptom

LEDs on the probe flash or remain on:

Jaw Open Continuous red: The conductor jaw is unlocked. Move the slider forward to lock

Overload

Degauss/AutoZero

68 TCP0030A Current Probe Instruction Manual

Possible cause

the jaw closed.

Flashing: An intermittent, repetitive overload is present on the probe. Remove the

probe from the current source. (See page 29,

Continuous red: The measured current exceeds the limit of the probe. Remove the

probe from the current source. (See page 29,

Flashing red: The probe requires degaussing. Degauss the probe.

Flashing red/green: The probe is performing the degauss routine.

Continuous green: The probe is degaussed and ready for use.

Extending Current Range

Extending Current Range

.)

.)

Page 91

Table 7: Probe troubleshooting (cont.)

Maintenance

Symptom

LEDs on the probe do not light The oscilloscope channel may be bad: Try another channel or another oscilloscope.

An error message displays on the

oscilloscope

Possible cause

All LEDs should light briefly and then the Degauss/AutoZero LED should flash.

If the probe functions correctly on another channel or oscilloscope, the contacts on

the input channel that exhibits the problem may need to be cleaned. Refer to your

oscilloscope manual for the proper cleaning procedure.

If the probe does not work on another channel or oscilloscope, the probe is

defective, and must be returned to Tektronix for repair.

The message will describe the cause and solution. For example, if the

degauss needed

message appears, perform the degauss procedure.

Probe

TCP0030A Current Probe Instruction Manual 69

Page 92

Maintenance

Cleaning

Protect the probe from adverse weather conditions. The probe is not waterproof.

CAUTION.

the probe during exterior cleaning.

Do not use chemical cleaning agents; they may damage the probe. Avoid using chemicals that contain benzine, benzene,

toluene, xylene, acetone, or similar solvents.

Clean the exterior surfaces of the probe with a dry, lint-free cloth or a soft-bristle brush. If dirt remains, use a soft cloth or swab

dampened with a 75% isopropyl alcohol solution and rinse with deionized water. A swab is useful for cleaning narrow spaces on the

probe, use only enough solution to dampen the swab or cloth. Do not use abrasive compounds on any part of the probe.

70 TCP0030A Current Probe Instruction Manual

To prevent damage to the probe, do not expose it to sprays, liquids, or solvents. Avoid getting moisture inside

Page 93

Index

Index

A

AC coupling, 34

Accessories

optional, 41

standard, 39

Adjustments, 64

Amp-second product, 36

B

Bucking current, 29

Button

menu, 13

C

Cleaning, 70

Common mode noise, 33

Connect the probe, 2

Coupling modes, 34

Current limitations

amp-second product, 36

maximum continuous, 35

maximum pulsed, 35

Current loop, 55

D

Damage

ESD, 2

DC

coupling, 34

gain accuracy adjustment, 65

gain accuracy check, 57

Degaussing, 3

while connected to a

conductor, 26

Deskew

menu, 16

Differential current, 27

Documentation, xiv

E

Equipment required

performance verification, 54

Equipment setup, 56

ESD damage, 2

Extending the current range of the

probes, 29

F

Features, 1

Fine Scale

menu, 14

Frequency derating, 35

G

Grounding the probe, 19

I

Increasing bucking current, 29

Increasing probe sensitivity, 32

Indicators, 8

J

Jaw, 5

Jaw damage, 17

L

LEDs, flashing, 68

TCP0030A Current Probe Instruction Manual 71

Page 94

Index

M

Magnetic field errors, 33

Maintenance, 68

Maximum

allowable pulse amplitude, 38

allowable pulse width, 37

continuous current rating, 35

pulsed current rating, 35

Measuring current

current nulls, 27

differential current, 27

Menu button, 13

Menu-driven probe functions, 14

N

Null current, 27

O

Offset

menu, 14

Options, 44

P

Performance verification, 53

Position

menu, 14

Probe

controls and indicators, 8

coupling, 34

extending the current range, 29

increasing the current limit, 29

maximum current limits, 35

saturation, 35

setup menu, 15

R

Record, test, 63

Related documentation, xiv

Rise time check, 61

S

Safety Summary, v

Service options, 44

Slider and conductor jaw, 5

Specifications, 45

nominal, 52

typical, 46

warranted, 45

T

TekVPI, 2

Test record, 63

Troubleshooting, 68

72 TCP0030A Current Probe Instruction Manual

Loading...

Loading...