www.keithley.com

Model 2000 Digital Multimeter

Quick Start Guide

2000-903-01 Rev. C / October 2007

A GREATER MEASURE OF CONFIDENCE

Model 2000 Digital Multimeter

Quick Start Guide

©2007, Keithley Instruments, Inc.

Document Number:

All rights reserved.

Cleveland, Ohio, U.S.A.

2000-903-01 Rev. C / October 2007

Manual Print History Model 2000 Digital Multimeter Quick Start Guide

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this

manual. The Revision Level letter increases alphabetically as the manual undergoes subsequent

updates. Addenda, which are released between Revisions, contain important change information that

the user should incorporate immediately into the man ual. Addenda are numbered sequ entially. When a

new Revision is created, all Addenda associated with the previous Revision of the manual are

incorporated into the new Revision of the manual. Each new Revision includes a revised copy of this

print history page.

Revision A (Document Number 2000-903-01)..........................................................April 1995

Revision B (Document Number 2000-903-01)..................................................Feburary 2000

Revision C (Document Number 2000-903-01) ....................................................October 2007

All Keithley Instruments product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand names are trademarks or registered trademarks of their respective holders.

2000-903-01 Rev. C / October 2007

The following safety precautions should be observed before using this product an d any associated instrumentation. Although some

instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions may

be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required

to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the product. Refer

to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the instrument.

They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line voltage or

replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures explicitly state if the

operator may perform them. Otherwise, they should be performed only by service personnel.

Safety Precautions

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained service

personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are rate d Measurement Category I and Measurement

Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most measurement, control, and

data I/O signals are Measurement Category I and must not be directly connected to mains voltage or to voltage sources with high transient

over-voltages. Measurement Category II connections require protection for high transient over-voltages often associated with local AC

mains connections. Assume all measurement, control, and data I/O connections are for connection to Category I sources unless otherwise

marked or described in the user documentation.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than 30V RMS, 42.4V peak,

or 60VDC are present. A good safety practice is to expect that hazardous voltage is present in any unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators are

prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential human contact.

Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If the circuit is capable of

operating at or above 1000V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited sources. NEVER

connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current

and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

08/07

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input power

!

disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under test.

AL W AYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting cables or jumpers,

installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions, or the safety of the

equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information,

and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a lid

interlock.

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

The symbol on an instrument indicates that the user should refer to the operating instructions located in the user documentation.

The symbol on an instrument shows that it can source or measure 1000V or more, including the combined effect of normal and

common mode voltages. Use standard safety precautions to avoid personal contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be properly

disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains dangers that might result in personal injury or death. Always read the

associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains hazards that could damage the instrument. Such damage may invalidate the

warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

T o maintain protection from electric shock and fire, replacement components in mains circuits - including the power transformer, test leads,

and input jacks - must be purchased from Keithley Instruments. Standard fuses with applicable national safety approvals may be used if

the rating and type are the same. Other components that are not safety-related may be purchased from other suppliers as long as they

are equivalent to the original component (note that selected parts should be purchased only through Keithley Instruments to maintain

accuracy and functionality of the product). If you are unsure about the applicability of a replacement component, call a Keithley Instruments

office for information.

To clean an instrument, use a damp cloth or mild, water-based cleaner. Clean the exterior of the instrument only. Do not apply cleaner

directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with no case or chassis

(e.g., a data acquisition board for installation into a computer) should never require cleaning if handled according to instructions. If the

board becomes contaminated and operation is affected, the board should be returned to the factory for proper cleaning/servicing.

Table of Contents

Section T opic Page

1 Introduction................................................................................................. 1-2

Operation Summary.................................................................................... 1-2

Power-on defaults................................................................................ 1-2

Remote Operation Summary ............................................................. 1-13

Table of Contents Model 2000 Digital Multimeter Quick Start Guide

This page left blank intentionally.

2 2000-903-01 Rev. C / October 2007

List of Figures

Section Figure Title Page

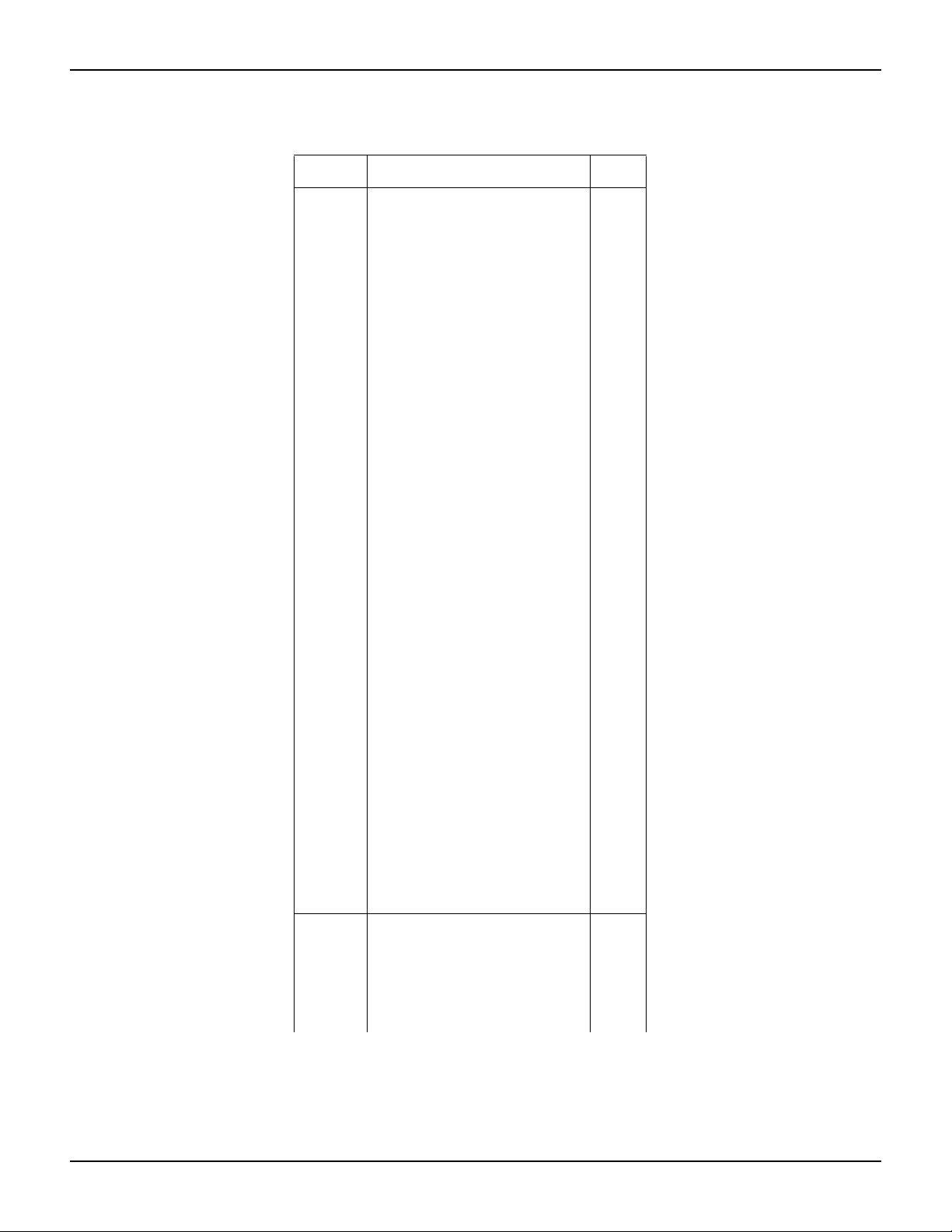

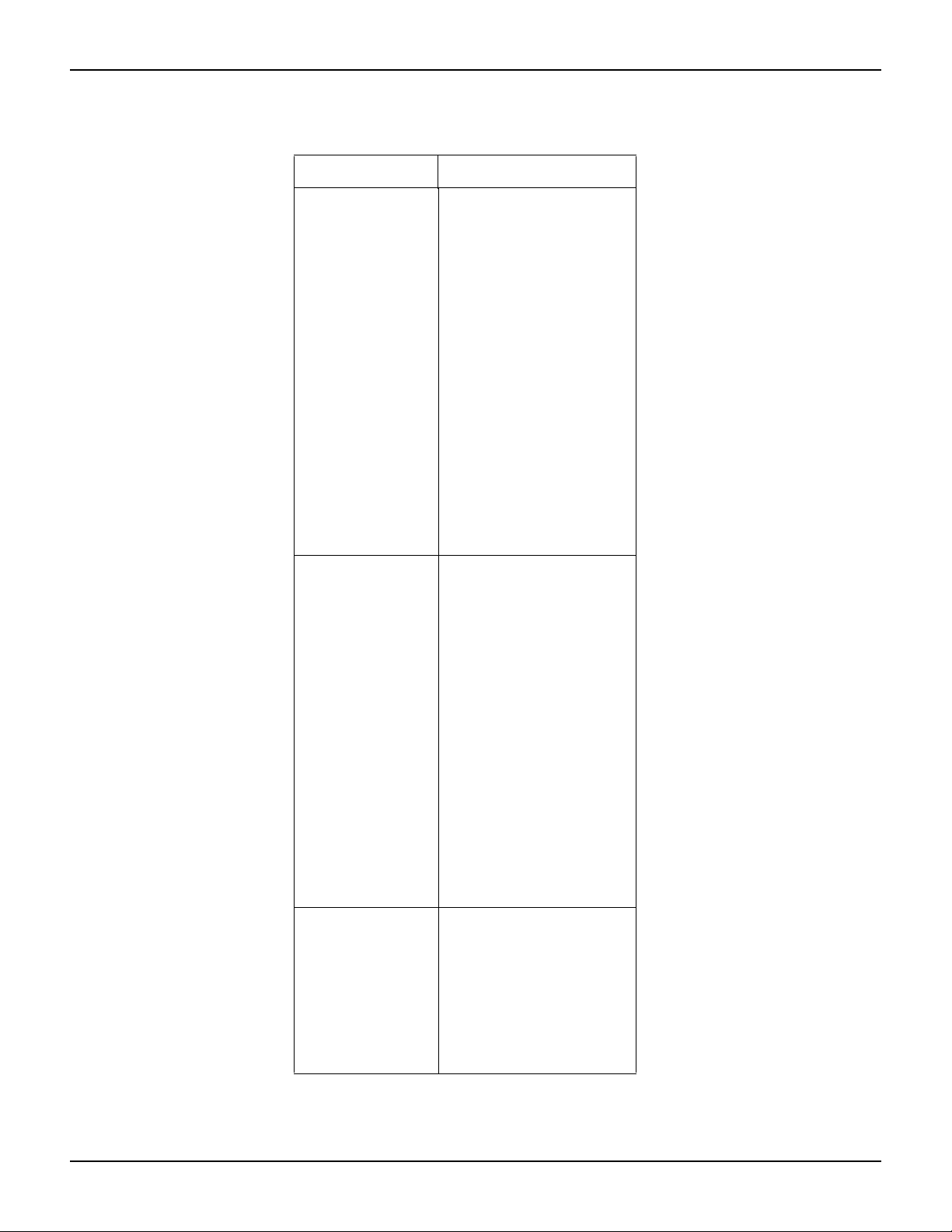

1 Figure 1-1 Basic measurement connections................................................... 1-3

Figure 1-2 Standard event status.................................................................. 1-13

Figure 1-3 Operation event status................................................................. 1-14

Figure 1-4 Measurement event status .......................................................... 1-14

Figure 1-5 Questionable event status ........................................................... 1-15

Figure 1-6 Status byte and service request (SRQ) ....................................... 1-15

List of Figures Model 2000 Digital Multimeter Quick Start Guide

This page left blank intentionally.

4 2000-903-01 Rev. C / October 2007

List of Tables

Section Figure Title Page

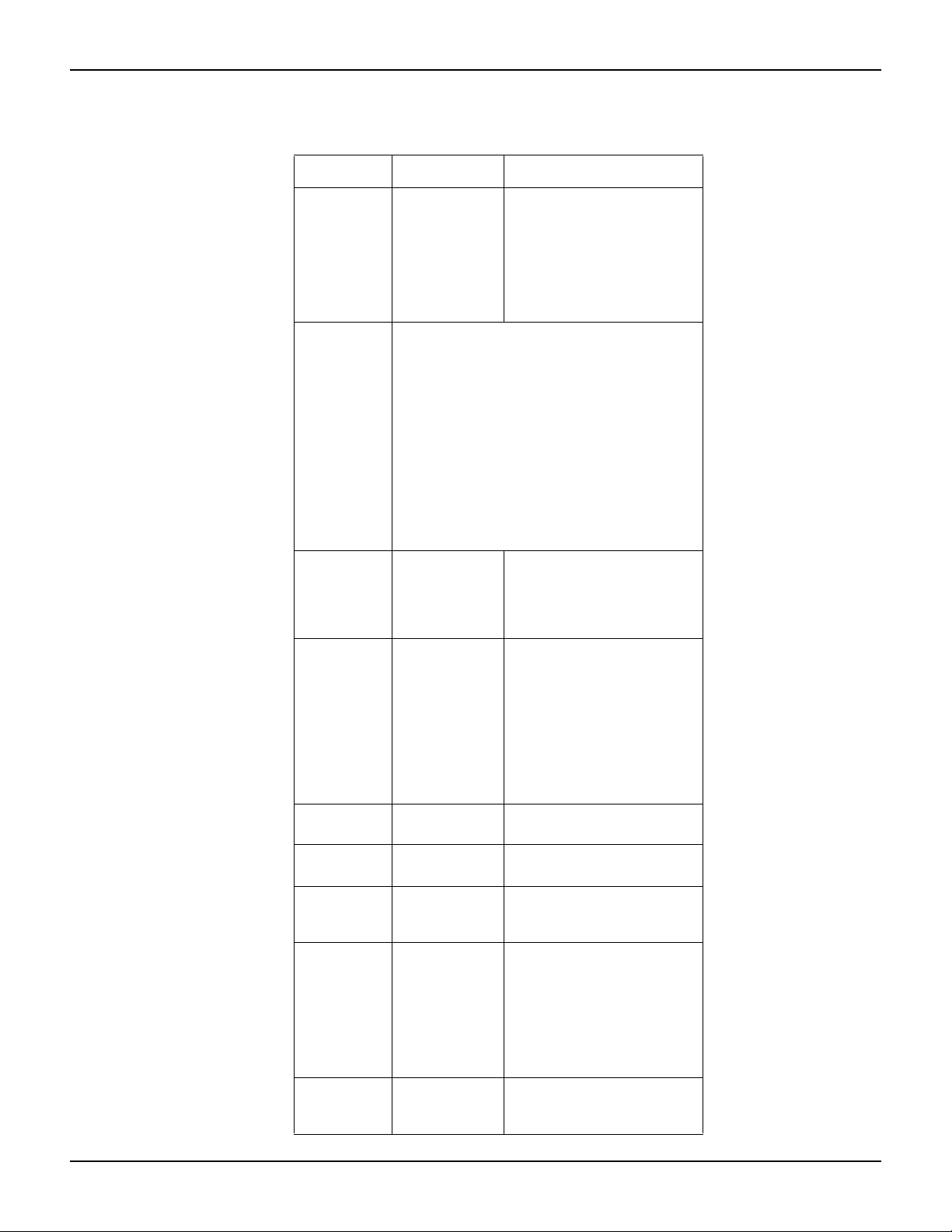

1 Table 1-1 Commands to select sense mode ................................................. 1-3

Table 1-2 Factory defaults ............................................................................. 1-7

Table 1-3 Error and status messages............................................................ 1-9

Table 1-4 IEEE-488.2 common commands and queries............................. 1-16

Table 1-5 Signal oriented measurement commands ................................... 1-17

Table 1-6 CALCulate command summary................................................... 1-18

Table 1-7 DISPlay command summary....................................................... 1-19

Table 1-8 FORMat command summary....................................................... 1-19

Table 1-9 ROUTe command summary........................................................ 1-20

Table 1-10 SENSe command summary ........................................................ 1-20

Table 1-11 STATus command summary........................................................ 1-28

Table 1-12 SYSTem command summary...................................................... 1-29

Table 1-13 TRACe command summary ........................................................ 1-29

Table 1-14 Trigger command summary......................................................... 1-30

Table 1-15 TEMPerature command summary............................................... 1-31

Table 1-16 Models 196/199 device-dependent command summary............. 1-32

Table 1-17 Models 8840A/8842A device-dependent comma nd summary.... 1-36

List of Tables Series 2600 System SourceMeter® Instruments User’s Manual

This page left blank intentionally.

4 2600S-900-01 Rev. B / September 2007

In this section:

Topic Page

Introduction................................................................................1-1

Operation Summary.................................................................1-2

Section 1

Introduction

Power-on defaults..............................................................1-2

Remote Operation Summary.........................................1-13

Section 1: Introduction Model 2000 Digital Multimeter Quick Start Guide

Introduction

This quick reference guide includes summary information on front panel and remote operation for

the Model 2000 Multimeter. For detailed operating information, consult the Model 2000 User’s

Manual.Front Panel

Operation Summary

Power-on defaults

Power-on defaults are those settings the instrument assumes when it is turned on. The Model

2000 offers two choices for the settings: user or factory. With user, the instrument will power-on to

the last configuration that you saved. With factory, the instrument will power on to the factory

default settings.

To store a user configuration in memory:

1. Configure the instrument as desired for USER default.

2. Press SHIFT and then SAVE.

3. Use the ▲ and ▼ keys to select YES or NO. Note: Select NO if you do not wish to change

the last configuration that you saved.

4. Press ENTER.

To restore factory or user settings:

1. Press SHIFT and then SETUP.

2. Use the ▲ and ▼ keys to select FACTory or USER.

3. Press ENTER.

NOTE Factory default settings are listed in Table 2.

Instrument connections

Basic connections for Model 2000 measurements are shown in Figure 1. Th ese drawings show

connections to the front panel terminals (INPUTS switch in the FRONT position). If using the rear

panel terminals, place the INPUTS switch in the REAR position. Note that current (DCI and ACI)

measurements cannot be made from the rear panel terminals.

1-2 Return to Section Topics 2000-903-01 Rev. C / October 2007

Model 2000 Digital Multimeter Quick Start Guide Section 1: Introduction

!

F

500V

PEAK

FRONT/REAR

2A 250V

AMPS

HI

INPUT

LO

SENSE

Ω 4 WIRE

INPUTS

350V

PEAK

1100V

PEAK

R

Model 2000

Measure DCV, ACV,

Ω2, FREQ (PERIOD)

or TEMP *

* Temperature measurements are typically

performed through a thermocouple

scanner card, such as the Model 2001-TCSCAN.

See the User's Manual for details.

!

F

500V

PEAK

FRONT/REAR

2A 250V

AMPS

HI

INPUT

LO

SENSE

Ω 4 WIRE

INPUTS

350V

PEAK

1100V

PEAK

R

Model 2000

Measure

DCI or ACI

!

F

500V

PEAK

FRONT/REAR

2A 250V

AMPS

HI

INPUT

LO

SENSE

Ω 4 WIRE

INPUTS

350V

PEAK

1100V

PEAK

R

Model 2000

Measure

Ω4

R

Figure 1-1

Basic measurement connections

For resistance measurements (¾2 and ¾4) greater than 100k¾, more stable readings can be

achieved by using shielding. Place the resistance in a shielded enclosure and connect the shield

to INPUT LO. Shielded cable should be used such that the shield (INPUT LO) encircles the other

cable conductor(s).

Maximum inputs for the Model 2000 are summarized in Table 1.

Table 1-1

Commands to select sense mode

Function Maximum input

DCV 1000V peak

ACV 750V rms, 1000V peak, 8×107V•Hz

DCI 3A dc, 250V

ACI 3A rms, 250V

FREQ (PERIOD) 1000V peak, 8× 107V•Hz

Basic measurement procedure

1. Connect the instrument as explained in “Instrument connection”.

2. From the function keys, select the desired measurement function.

3. Use the RANGE keys to select autoranging or a manual range. Pressing the AUTO range

key toggles autoranging. You can select a different range with the ▲ and ▼ RANGE keys.

4. Take a reading from the display.

2000-903-01 Rev. C / October 2007 Return to Section T opics 1-3

Section 1: Introduction Model 2000 Digital Multimeter Quick Start Guide

Storing readings (2 to 1024)

1. Set up the instrument for the desired configuration.

2. Press the STORE key.

3. Use the , , ▲ and ▼ keys to select the number of readings to stor e in th e bu ffer.

4. Press ENTER to start the storage process. The asterisk (*) annunciator turns on to indi cate

a data storage operation. It turns off when the storage is finished.

Recalling readings

1. Press the RECALL key. The BUFFER annunciator indicates that stored readings are being

displayed. The arrow annunciator indicates that more dat a can be viewed with the , , ▲

and ▼ keys.

2. Use the , , ▲ and ▼ keys to navigate through the reading numbe rs, reading values, and

statistics. For any of the buffer st atistics ( maximum, minim um, average, st and ard devia tion)

the STA T annunciator is on.

3. Use the EXIT key to return to the normal display.

Changing speed, resolution and filter

RATE — Measurement speed (reading RATE) can be changed for any measurement function

except frequency, period, continuity and diode test. Use the RATE key to select FAST, MEDium or

SLOW. Use FAST (0.1 PLC) if speed is of primary importance (at the expense of increased noise

and fewer usable digits of resolution). SLOW (10 PLC) provides better noise performance at the

expense of speed. MEDium (1 PLC) provides a compromise between noise and speed.

DIGITS — Display resolution can be changed for any measurement function. Use the DIGITS key

to select the desired number of digits (3 to 6 ).

FILTER — Filter state (on/off) and configuration can be changed for any measurement function,

except frequency, period, continuity and diode test. The FILTER key toggles between filter on

(FILT annunciator on) and filter off. After pressing FILTER to enable the filter, you can then enter

the filter count (1 to 100), and select the filter type (moving or repeating). (If the FILT annunciator is

already on, press FILTER twice before entering the filter count.)

Changing temperature measurement configuration

Press SHIFT and then TCOUPL. Three choices are available using the ▲ and ▼ keys:

• UNITS — C, K or F. Specify units.

• TYPE — J, K or T. Specify thermocouple type.

• JUNC — SIM or CH1. Simulate a reference junction temperature (for direct thermocouple

connection to the INPUT), or use the reference junction (channel 1) provided on a switching

card. In order to keep the reference calculations update d and accurate, Channel 1 needs to

be read periodically.

To assign a value to a parameter, use the ▲ and ▼ keys to scroll to the desired parameter. Select

the

key, and use the ▲ and ▼ keys to scroll through and choose the p referred value. Select the

ENTER key to save any changes.

Relative (rel)

Rel can be used to null offsets or subtract a baseline reading from present and future read ings.

When rel is enabled by pressing REL (REL annunciator on), the instrument uses the present

reading as the relative value. Subsequent readings will be the difference between the actual input

value and the rel value. You can define a rel value for each function. Pressing REL a second time

disables rel.

1-4 Return to Section Topics 2000-903-01 Rev. C / October 2007

Model 2000 Digital Multimeter Quick Start Guide Section 1: Introduction

Percent

Input - Reference

Input

--------------------------------------------- - 100%¥=

dBm 10 log

V

2

IN

Z

REF

§

⎝⎠

⎛⎞

1mW

---------------------------------- -=

V

IN

V

REF

----------------=

Math

To enable and configure a math oper ation, press SHIFT and then the desir ed math key (MX+B, %,

dBm or dB). Use the

, , ▲ and ▼ keys to configure the math operation and press ENTER

when done. Pressing SHIFT and then the related math key a second time disables the math

operation.

MX+B

Y = mX + b

Where: X is the normal display reading.

m and b are the user entered constants.

Y is the displayed result.

Percent (%)

Where: Input is the normal display reading.

Reference is the user entered constant.

Percent is the displayed result.

dBm

Where: VIN is the DC or AC input signal.

Z

is the specified reference impedance.

REF

dB

Where:VIN is the DC or AC input signal.

V

is the specified voltage reference impedance.

REF

Measuring continuity

With this feature, the instrument alerts you with a beep when a resist ance re ading is below the set

level. To measure continuity, press SHIFT and then CONT. Use the

, , ▲ and ▼ keys to set the

resistance threshold level, and press ENTER. Connect the test leads to INPUT HI and LO.

T esting diodes

With this feature, the instrument measures the forward voltage drop of general-purpose diodes

and the zener voltage of zener diodes. To test diodes, press SHIFT and then (

▼ keys to select the test current.

). Use the ▲ and

Limit operations

With this feature, you can check to see of readings are within (“IN” displayed), below (“LO”

displayed) or above (“HI” displayed) specified low and high reading limits. You can also set the

instrument to beep when readings are inside or outside of the limit range.

2000-903-01 Rev. C / October 2007 Return to Section T opics 1-5

Section 1: Introduction Model 2000 Digital Multimeter Quick Start Guide

Setting limits — To set limits (absolute values), press SHIFT and then LIMITS to display the high

limit. Use the

limit value and again press ENTER.

Enabling limits — Press SHIFT and then ON/OFF to display the beeper status. Use the ▲ and ▼

keys to change the beeper status (NEVER, OUTSIDE or INSIDE) and press ENTER to enable

limits. Pressing SHIFT and then ON/OFF a second time disables limit operations.

, , ▲ and ▼ keys to enter the desired value, and press ENTER. Enter the low

Reading hold

With this feature, an audible beep is sounded when a valid, settled reading is acquired. A valid

reading is determined by the specified window and count.

1. Press SHIFT and then HOLD. Select a window percentage and enter a count.

2. Apply the test probes to the signal and wait for the beeper to sound to indicate a valid reading.

3. Remove the hold condition by lifting the probe s.

Pressing SHIFT and then HOLD a second time disables Hold.

Triggers

Factory defaults place the instrument in a continuous (immediate) measurement mode. The

instrument can be placed in an external trigger mode where a programmed event is required to

cause a measurement (device action).

The instrument is placed in the external trigger mode by pressing th e EXT TRIG key. In this mode,

a device action (measurement) will occur when the TRIG key is pressed, a bus trigger (*TRG or

GET) is received, or an input trigger via the TRIGGER LINK connector is received. After the device

action (measurement), an output trigger occurs and is available at the TRIGGER LINK connector.

Refer to the User’s Manual for details on using the trigger link. Pressing EXT TRIG a second time

returns the instrument to continuous operation.

Delay — A programmable delay before the device action (measureme nt) occurs is available. It

can be set manually or an auto delay can be used. To set a delay, press SHIFT and then DELAY.

Use the ▲ and ▼ keys to select AUTO or MANual. If MANual is chosen, enter the duration of the

delay and press ENTER. The AUTO delay times are listed in Table 3-2 of the User’s Manual.

Scan operations

The Model 2000 can be used with an internal scanner car d (Model 2000 SCAN or 2001-TCSCAN),

or with external scanner cards installed in a switching main frame (i.e. Model 7001 and 7002).

Step/Scan configuration — A “walk-thr ough” menu is provided to configure stepp ing or scanning.

The main menu is accessed by pressing SHIFT and then CONFIG. Use the

ENTER keys to select scan type (INTernal or EXTernal), first channel in the scan (MINimum

CHANnel), last channel in the scan (MAXimum CHANnel), time between scans, and reading co unt

(RDG CNT).

and keys — These keys can be used to manually scan through channels on the internal

scanner card. Press to manually increment channels or to manually decrement channels.

Hold down either key to scan continuously.

, , ▲, ▼ and

OPEN and CLOSE keys — Use these keys to open and close channels on the internal scanner

card. After pressing CLOSE, use the

and press ENTER. Selecting a different channel will cause the previously closed channel to open.

For the ¾4 function, CLOSE will close the selected channel and the paired channel. Paired

channels for the Model 2000 SCAN are 1&6, 2&7, 3&8, 4&9, and 5&10. Channel pairs are similar

for the Model 2001-TCSCAN except that channels 1&6 are not paired.

1-6 Return to Section Topics 2000-903-01 Rev. C / October 2007

, , ▲ and ▼ keys to display the desired channel (1 to 10)

Model 2000 Digital Multimeter Quick Start Guide Section 1: Introduction

STEP key — Pressing this key starts a stepping operation of consecutive channels, where output

triggers are sent after every channel closure.

SCAN key — Pressing this key starts a scanning operation of consecutive channels, wh ere an

output trigger is sent at the end of the scan list.

HALT — Pressing SHIFT and then HALT stops stepping or scanning.

Factory default conditions

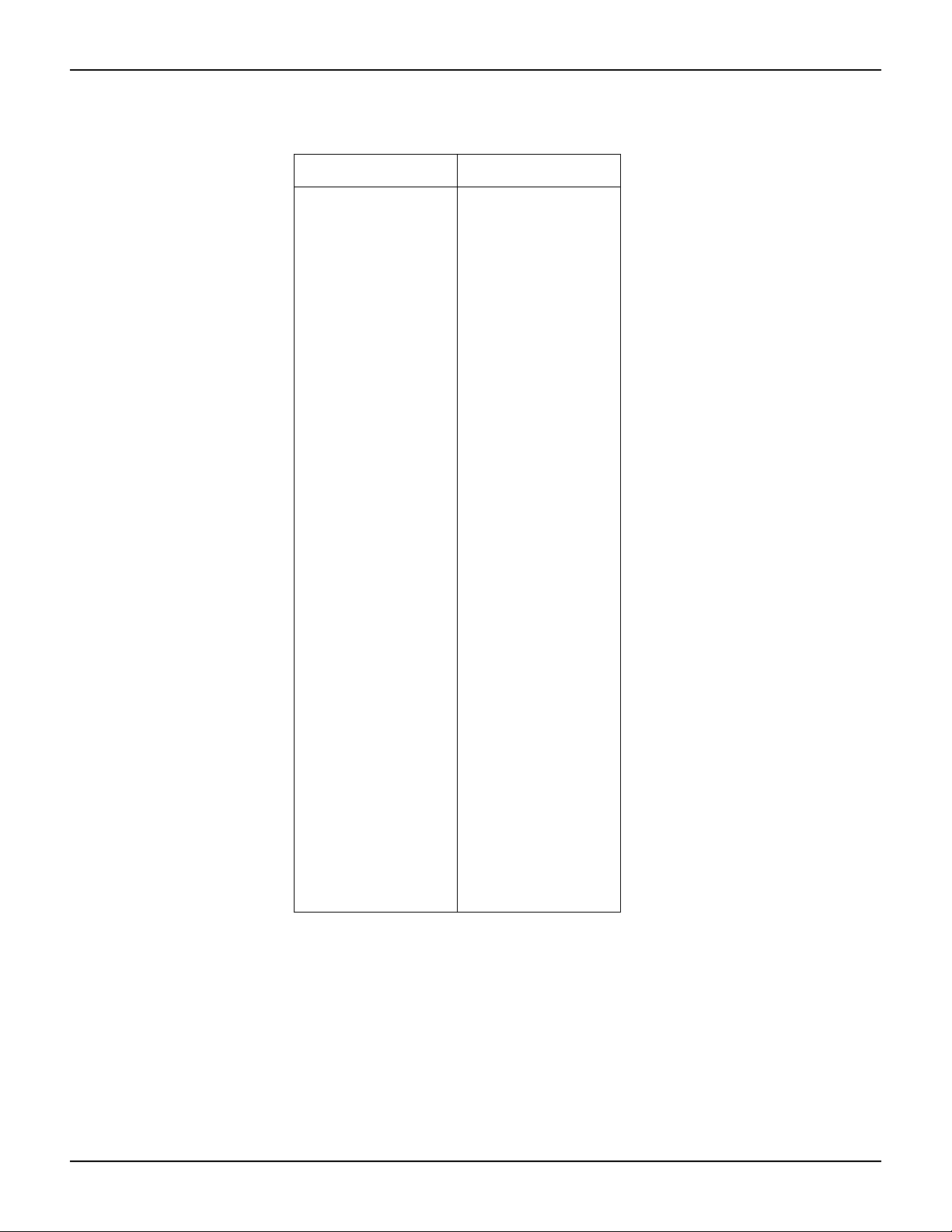

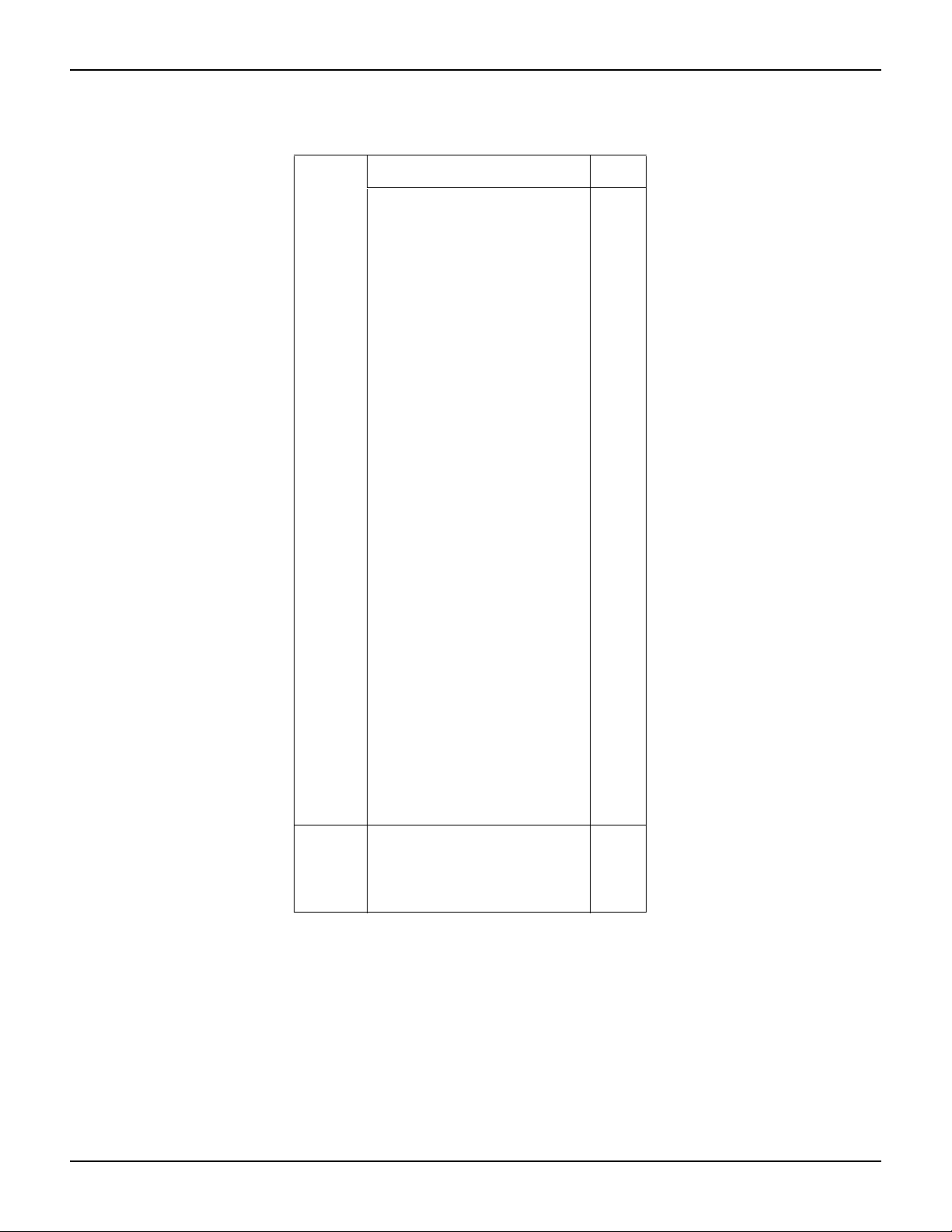

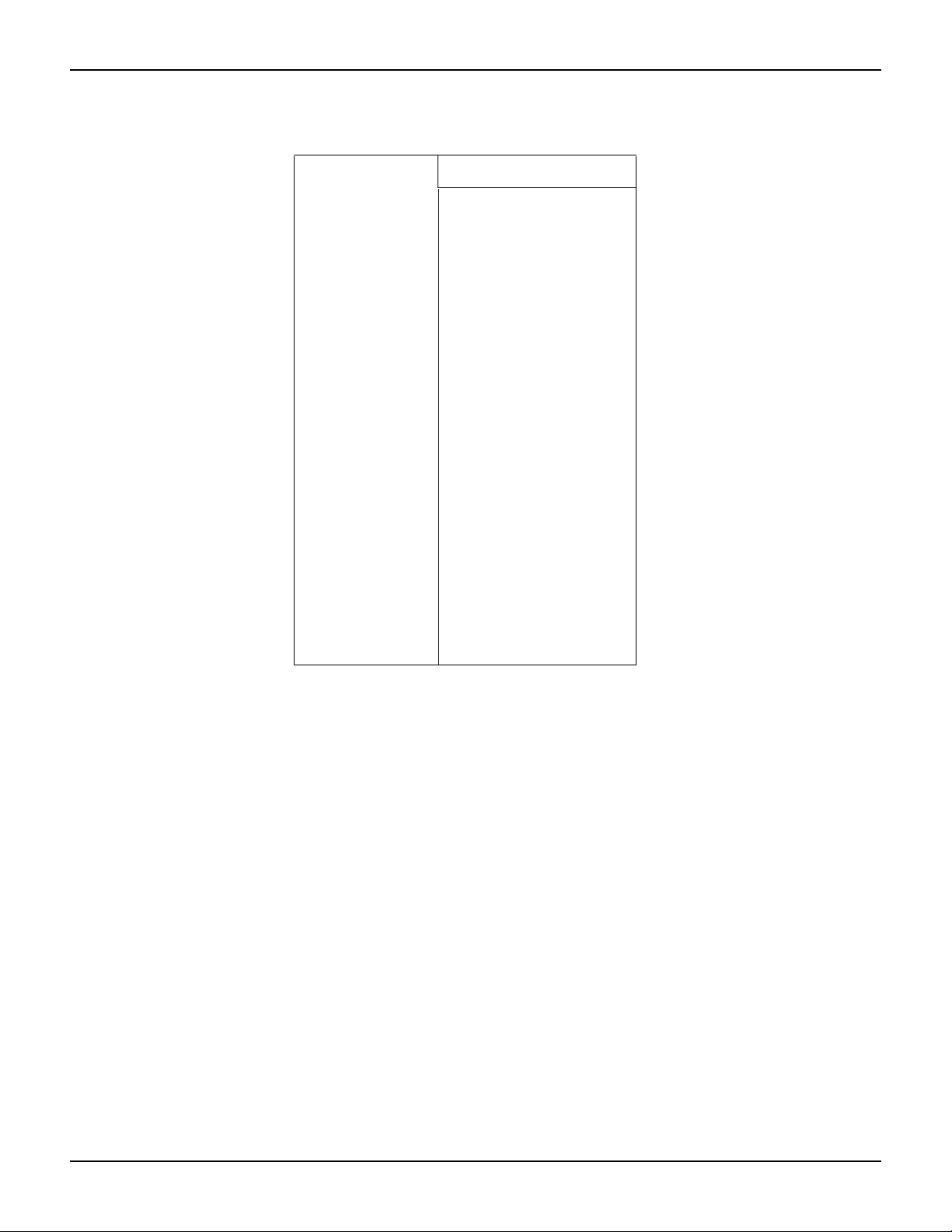

Table 1-2

Factory defaults

Setting Factory default

Autozero

Buffer

Continuity

Beeper

Digits

Rate

Threshold

Current (AC and DC)

Digits (AC)

Digits (DC)

Filter

Count

Mode

Range

Relative

Value

Rate (AC)

Rate (DC)

Diode test

Digits

Range

Rate

Frequency and Period

Digits

Range

Relative

Value

Rate

Function

GPIB

Address

Language

Limits

Beeper

High limit

Low limit

mX+b

Scale factor

Offset

Percent

References

On

No effect

On

4

Fast (0.1 PLC)

10¾

5

6

On

10

Moving average

Auto

Off

0.0

Medium*

Medium (1 PLC)

6

1mA

Medium (1 PLC)

6

10V

Off

0.0

Slow (1 sec)

DCV

No effect

(16 at factory)

(SCPI at factory)

Off

Never

+1

-1

Off

1.0

0.0

Off

1.0

2000-903-01 Rev. C / October 2007 Return to Section T opics 1-7

Section 1: Introduction Model 2000 Digital Multimeter Quick Start Guide

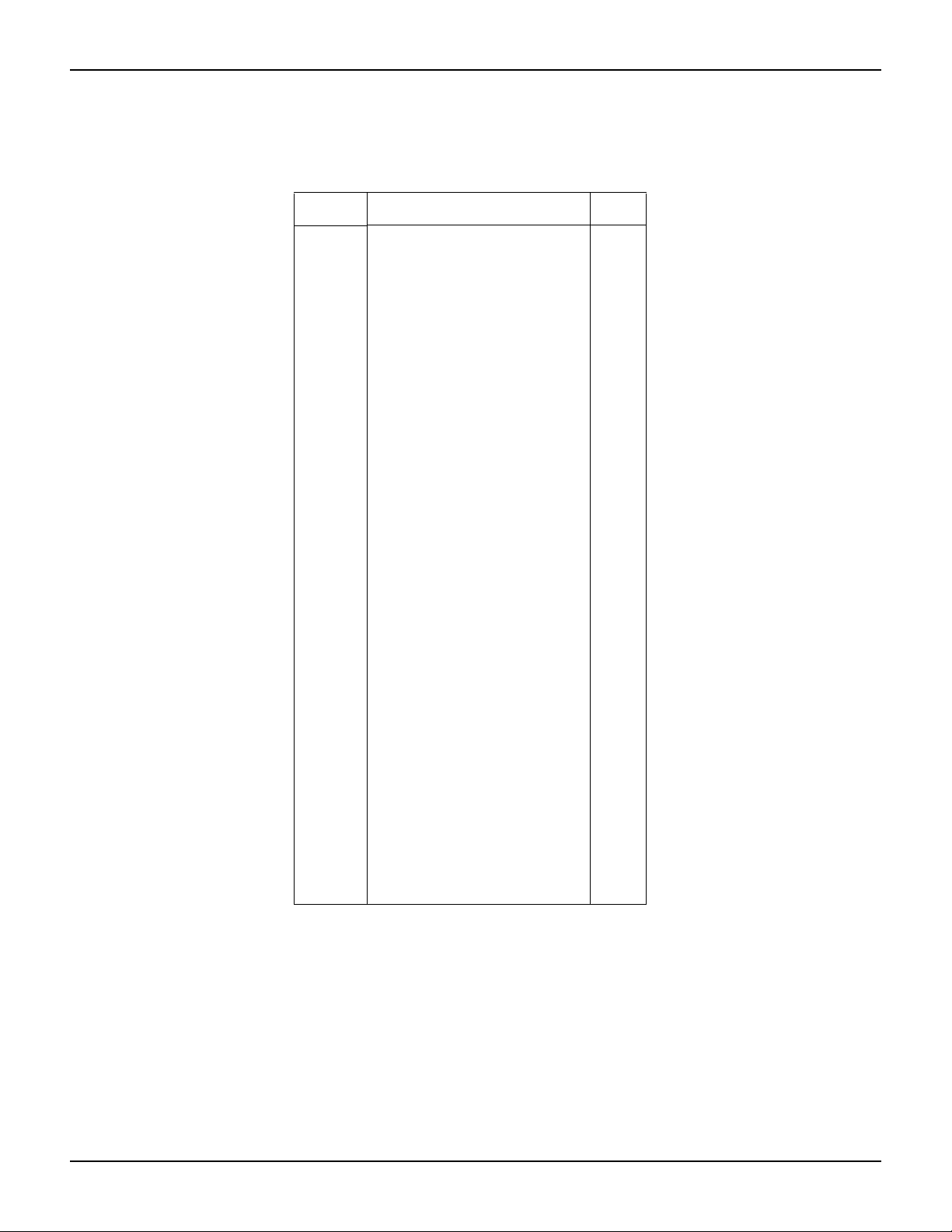

Table 1-2

Factory defaults (cont.)

Setting Factory default

Resistance (2-wire and

4-wire)

Digits

Filter

Count

Mode

Range

Relative

Value

Rate

RS-232

Baud

Flow

Tx term

Scanning

Channels

6

On

10

Moving average

Auto

Off

0.0

Medium (1 PLC)

Off

No effect

No effect

No effect

Off

1-10

Internal

Mode

Temperature

Digits

Filter

Count

Mode

Junction

Temperature

Relative

Value

Rate

Thermocouple

5

On

10

Moving average

Simulated

23°C

Off

0.0

Medium (1 PLC)

J

°C

Units

Triggers

Continuous

Delay

On

Auto

Immediate

Source

Voltage (AC and DC)

dB reference

dBm reference

Digits (AC)

Digits (DC)

Filter

Count

Mode

Range

Relative

Value

Rate (AC)

No effect

75¾

5

6

On

10

Moving average

Auto

Off

0.0

Medium*

Medium (1 PLC)

Rate (DC)

*DETector:BANDwidth 30

1-8 Return to Section Topics 2000-903-01 Rev. C / October 2007

Model 2000 Digital Multimeter Quick Start Guide Section 1: Introduction

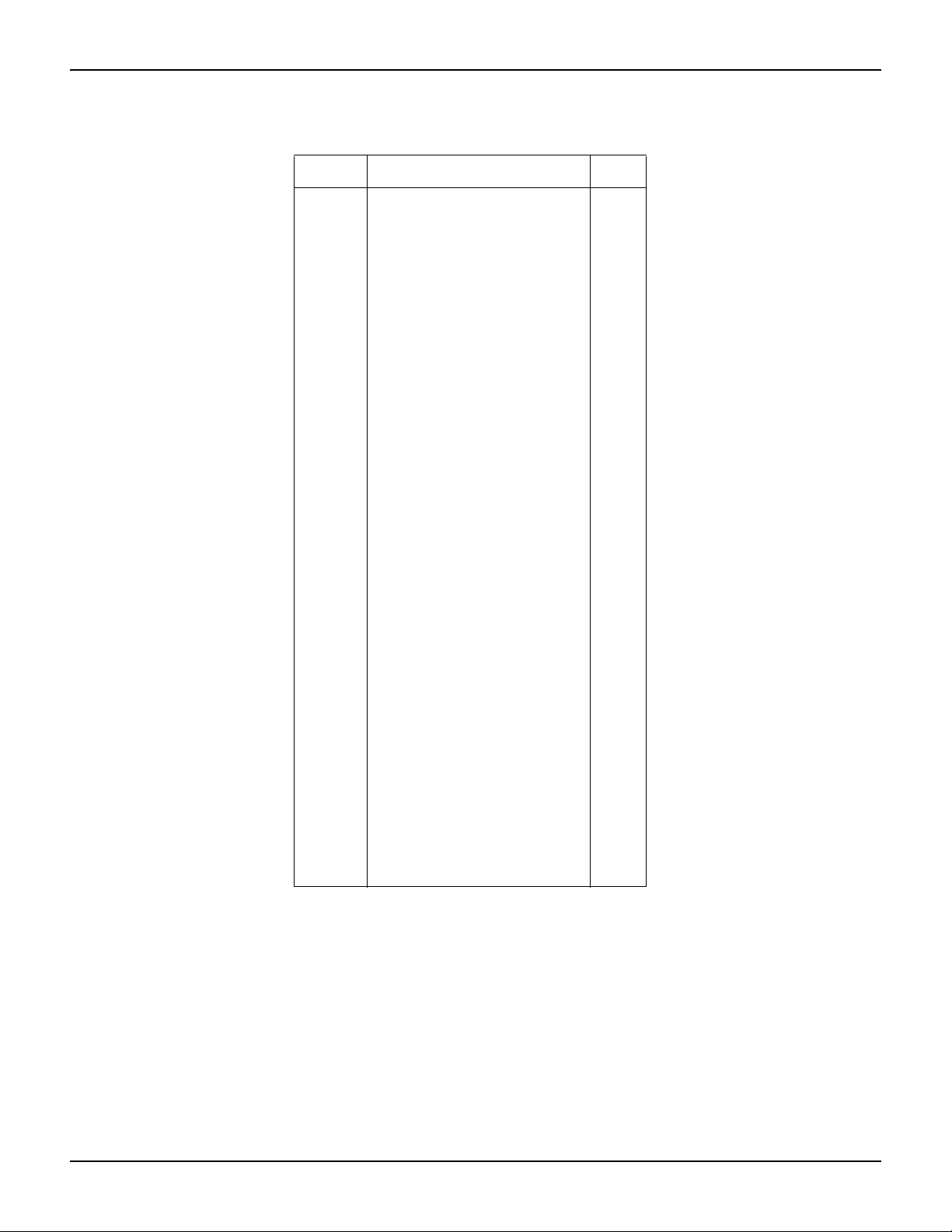

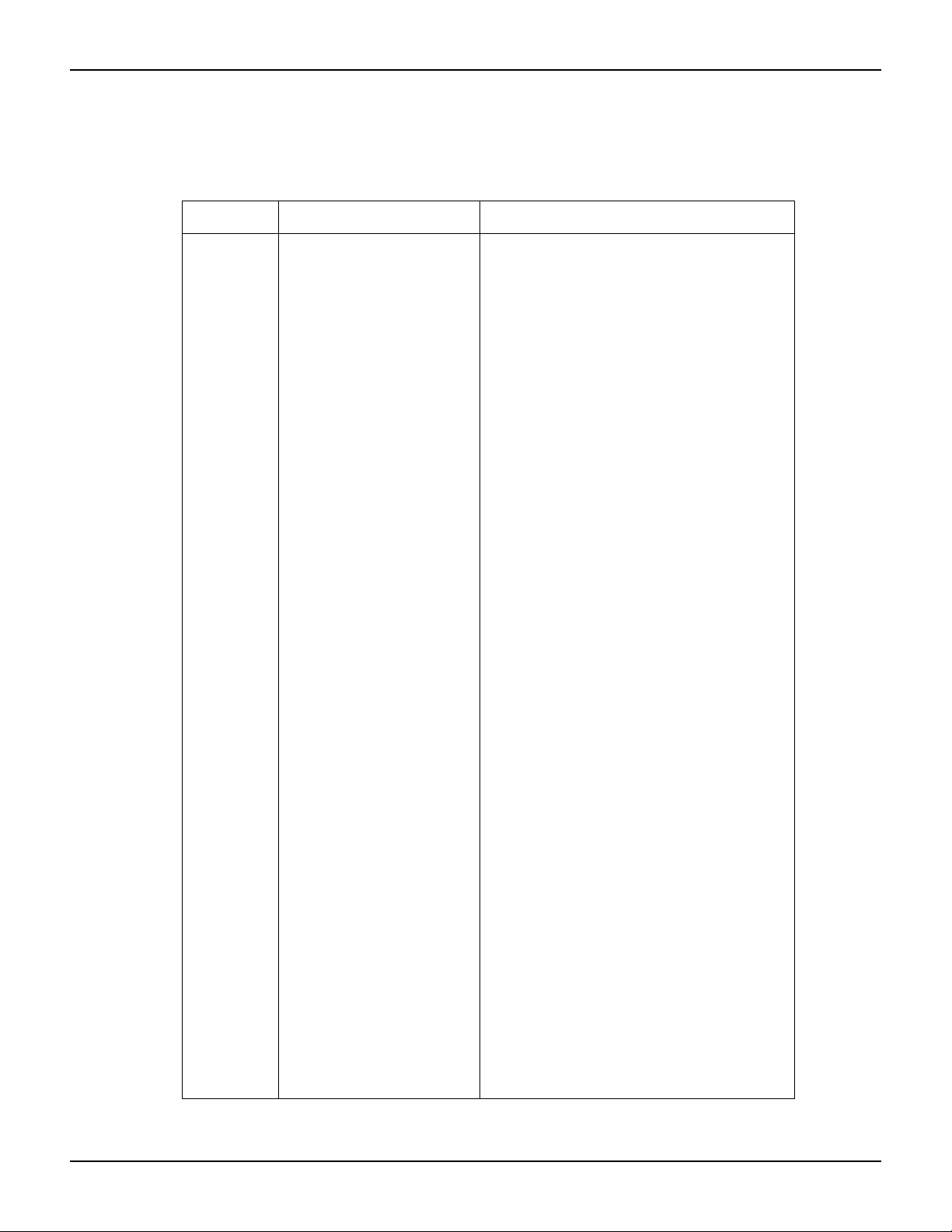

Error and status messages

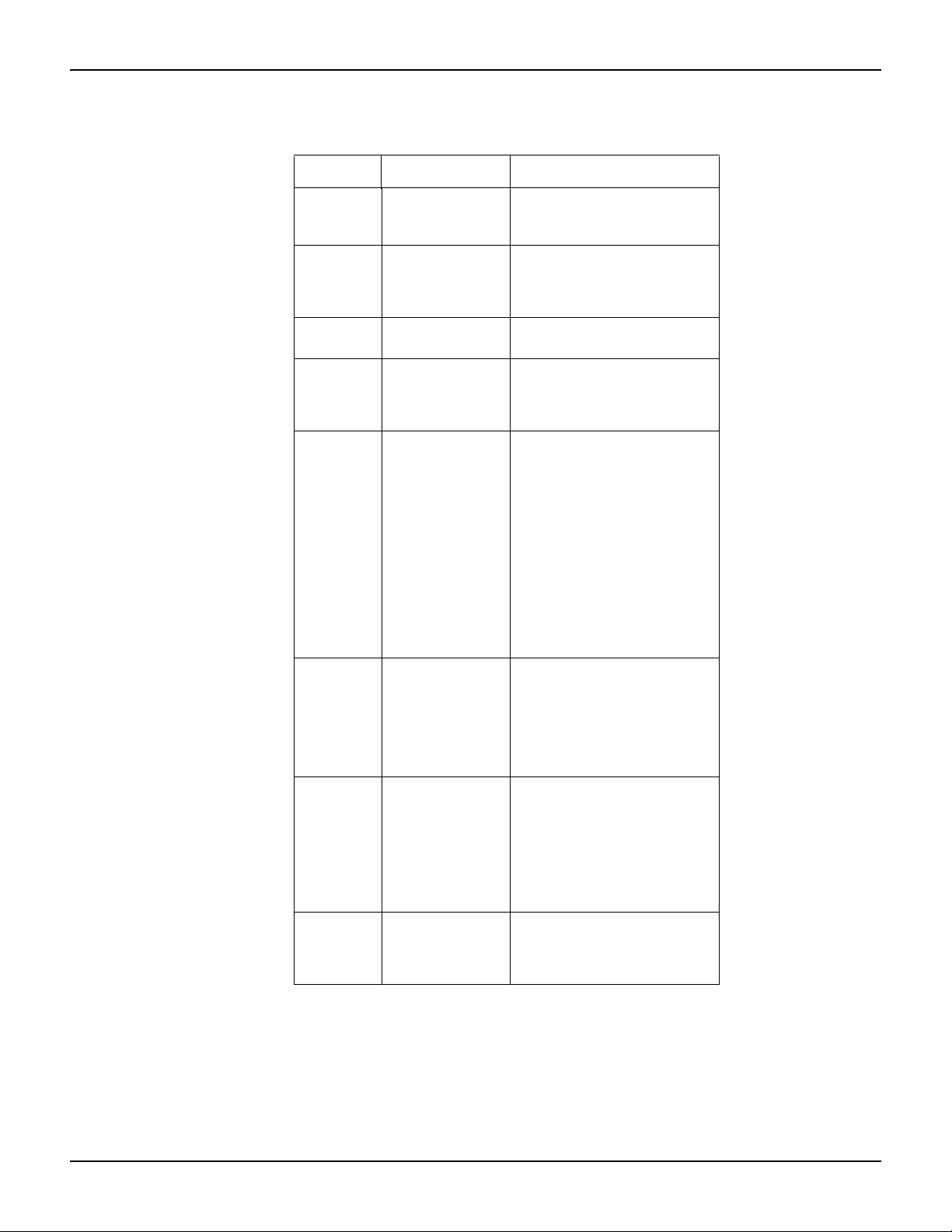

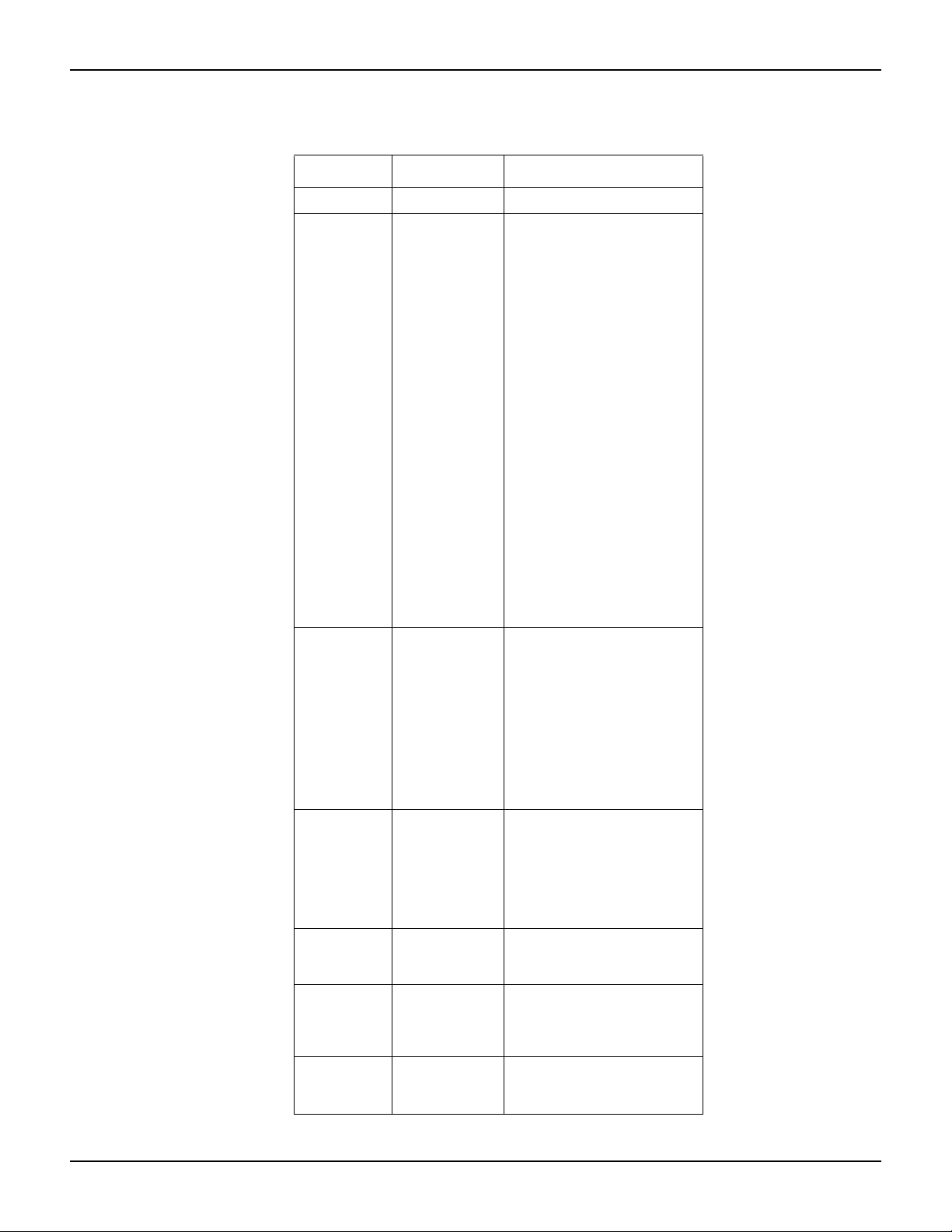

Table 1-3

Error and status messages

Number Description Event

-440

-430

-420

-410

-363

-350

-330

-314

-315

-285

-284

-282

-281

-260

-241

-230

-225

-224

-223

-222

-221

-220

-215

-214

-213

-212

-211

-210

-202

-201

-200

-178

-171

-170

-168

-161

-160

-158

-154

-151

-150

-148

Query unterminated after

indefinite response

Query deadlocked

Query unterminated

Query interrupted

Input buffer overrun

Queue overflow

Self-test failed

Save/recall memory lost

Configuration memory lost

Program syntax error

Program currently running

Illegal program name

Cannot create program

Expression error

Hardware missing

Data corrupt or stale

Out of memory

Illegal parameter value

Too much data

Parameter data out of range

Settings conflict

Parameter error

Arm deadlock

Trigger deadlock

Init ignored

Arm ignored

Trigger ignored

Trigger error

Settings lost due to rtl

Invalid while in local

Execution error

Expression data not allowed

Invalid expression

Expression error

Block data not allowed

Invalid block data

Block data error

String data not allowed

String too long

Invalid string data

String data error

Character data not allowed

EE

EE

EE

EE

SYS

SYS

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

2000-903-01 Rev. C / October 2007 Return to Section T opics 1-9

Section 1: Introduction Model 2000 Digital Multimeter Quick Start Guide

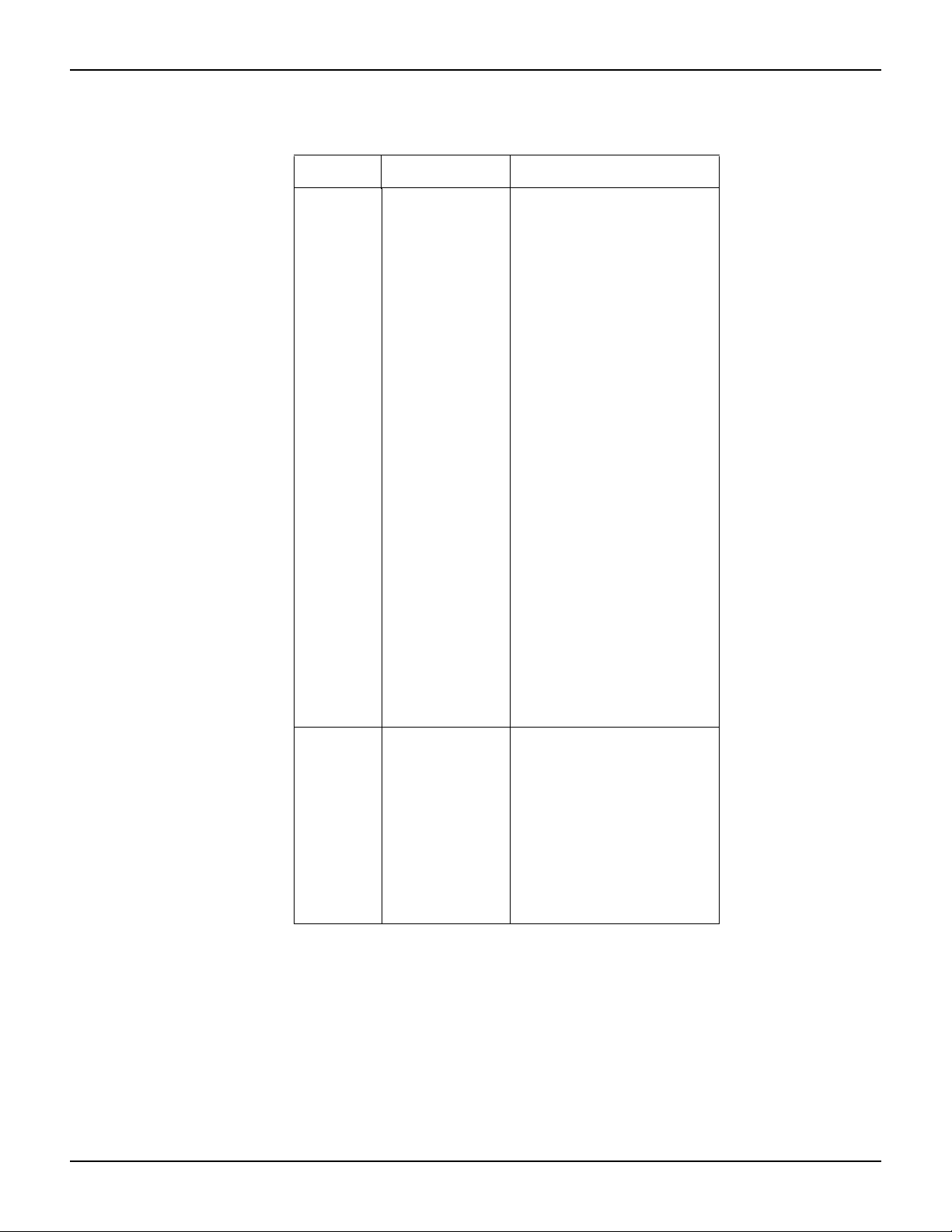

Table 1-3

Error and status messages (cont.)

Number Description Event

-144

-141

-140

-128

-124

-123

-121

-120

-114

-113

-112

-111

-110

-109

-108

-105

-104

-103

-102

-101

-100

Character data too long

Invalid character data

Character data error

Numeric data not allowed

Too many digits

Exponent too large

Invalid character in number

Numeric data error

Header suffix out of range

Undefined header

Program mnemonic too long

Header separator error

Command header error

Missing parameter

Parameter not allowed

GET not allowed

Data type error

Invalid separator

Syntax error

Invalid character

Command error

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

+000 No error SE

+101

+121

+122

+123

+124

+125

+126

+161

+171

+174

+301

+302

+303

+304

+305

+306

+307

+308

+309

+310

+311

Operation complete

Device calibrating

Device settling

Device ranging

Device sweeping

Device measuring

Device calculating

Program running

Waiting in trigger layer

Re-entering the idle layer

Reading overflow

Low limit 1 event

High limit 1 event

Low limit 2 event

High limit 2 event

Reading available

Voltmeter complete

Buffer available

Buffer half full

Buffer full

Buffer overflow

SE

SE

SE

SE

SE

SE

SE

SE

SE

SE

SE

SE

SE

SE

SE

SE

SE

SE

SE

SE

SE

1-10 Return to Section Topics 2000-903-01 Rev. C / October 2007

Model 2000 Digital Multimeter Quick Start Guide Section 1: Introduction

Table 1-3

Error and status messages (cont.)

Number Description Event

+400

+401

+402

+403

+404

+405

+406

+407

+408

+409

+410

+411

+412

+413

+414

+415

+416

+417

+418

+419

+420

+421

+422

+423

+424

+425

+438

+439

+450

+451

+452

+453

+454

+455

+456

+457

+458

+459

+460

+461

+462

+463

+464

+465

+466

+467

+468

+469

+470

+471

+472

+473

Calibration messages:

10 vdc zero error

100 vdc zero error

10 vdc full scale error

-10 vdc full scale error

100 vdc full scale error

-100 vdc full scale error

1k 2-w zero error

10k 2-w zero error

100k 2-w zero error

10M 2-w zero error

10M 2-w full scale error

10M 2-w open error

1k 4-w zero error

10k 4-w zero error

100k 4-w zero error

10M 4-w sense lo zero error

1k 4-w full scale error

10k 4-w full scale error

100k 4-w full scale error

1M 4-w full scale error

10M 4-w full scale error

10m adc zero error

100m adc zero error

10m adc full scale error

100m adc full scale error

1 adc full scale error

Date of calibration not set

Next date of calibration not set

100m vac dac error

1 vac dac error

10 vac dac error

100 vac dac error

100m vac zero error

100m vac full scale error

1 vac zero error

1 vac full scale error

1 vac noise error

10 vac zero error

10 vac full scale error

10 vac noise error

100 vac zero error

100 vac full scale error

750 vac zero error

750 vac full scale error

750 vac noise error

Post filter offset error

1 aac zero error

1 aac full scale error

3 aac zero error

3 aac full scale error

Input time constant error

Frequency gain error

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

2000-903-01 Rev. C / October 2007 Return to Section T opics 1-11

Section 1: Introduction Model 2000 Digital Multimeter Quick Start Guide

Table 1-3

Error and status messages (cont.)

Number Description Event

+500

+510

+511

+512

+513

+514

+515

+522

+610

+611

+800

+802

+803

+805

+806

+807

+808

+900

Calibration data invalid

Reading buffer data lost

GPIB address lost

Power-on state lost

AC calibration data lost

DC calibration data lost

Calibration dates lost

GPIB communication language

lost

Questionable Calibration

Questionable Temperature

RS-232 Framing Error detected

RS-232 Overrun detected

RS-232 Break detected

Invalid system communication

RS-232 Settings Lost

RS-232 OFLO: Characters Lost

ASCII only with RS-232

Internal System Error

DDC Status Model:

+950

+951

+952

+953

+954

+955

+956

+957

+958

+959

+960

+961

DDC Trigger Overrun Error

DDC Interval Overrun Error

DDC Big String Error

DDC Uncalibrated Error

DDC No Scanner Error

DDC Maximum Channel is 4

DDC Maximum Channel is 8

DDC Calibration Locked

DDC Conflict Error

DDC No Remote Error

DDC Mode IDDC Error

DDC Mode IDDCO Error

Keithley 199 Serial Poll Byte

+962

+963

+964

+965

+966

Events:

DDC Ready

DDC Reading Done

DDC Buffer Half Full

DDC Buffer Full

DDC Reading overflow

Fluke 8842 serial poll byte

+970

+971

+972

events:

Fluke Error

Data Available

Overrange

EE = error event

SE = status event

SYS = system error event

EE

EE

EE

EE

EE

EE

EE

EE

SE

SE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

EE

SE

SE

SE

SE

SE

SE

SE

SE

1-12 Return to Section Topics 2000-903-01 Rev. C / October 2007

Model 2000 Digital Multimeter Quick Start Guide Section 1: Introduction

* ESR ?

PON

(B7)

URQ

(B6)

CME

(B5)

EXE

(B4)

DDE

(B3)

QYE

(B2) (B1) (B0)

OR

Standard Event

Status Register

Standard Event

Status Enable

Register

PON = Power On

URQ = User Request

CME = Command Error

EXE = Execution Error

DDE = Device-Dependent Error

QYE = Query Error

OPC = Operation Complete

& = Logical AND

OR = Logical OR

&

&

&

&

&

OPC

&

&

PON

(B7)

URQ

(B6)

CME

(B5)

EXE

(B4)

DDE

(B3)

QYE

(B2) (B1) (B0)

OPC

* ESE

* ESE ?

To Event

Summary

Bit (ESB) of

Status Byte

Register (See

Figure 6).

(B15 - B8)

(B15 - B8)

Remote Operation Summary

At the factory, the instrument is set for GPIB bus operation at primary address 16 using the SCPI

programming language.

GPIB bus — Use the GPIB bus configuration menu to enable or disable GPIB bus operation (ON

or OFF), and to check and/or change the primary address (0 to 30) and language (SCPI, 199, or

8842). The configuration menu is accessed by pressing SHIFT and then GPIB. Commands for the

SCPI language are provided in Tables 4 through 15. The DDC commands for the 199 and 8842

languages are provided in Tables 16 and 17.

RS-232 interface — Use the RS-232 interface menu to enable or disable RS-2 32 interface

operation (ON or OFF), and to check and/or change the baud rate (300 to 19.2k), flow control

(NONE or XonXoFF) and terminator (LF, CR or LFCR). Note that only the SCPI language

commands can be used over the RS-232 interface.

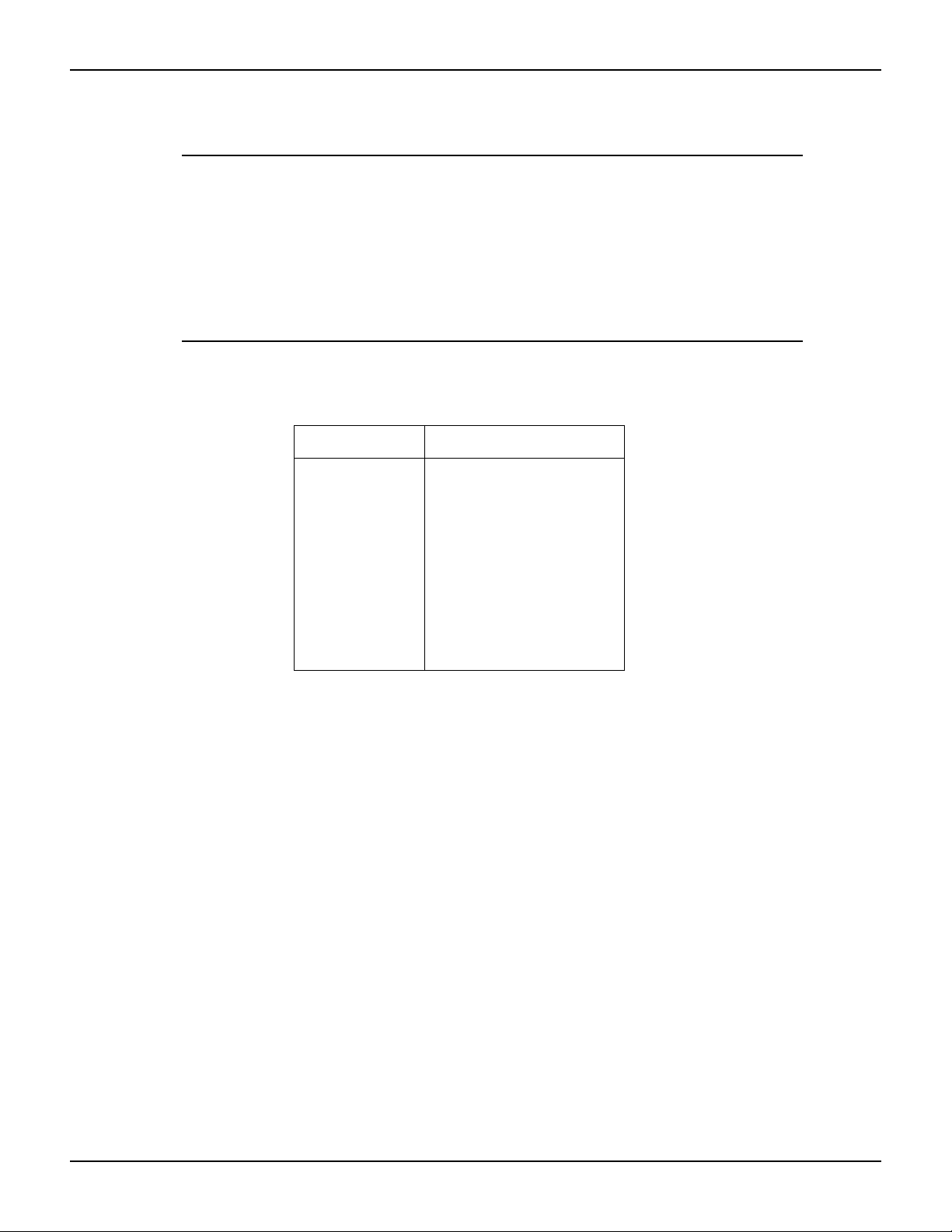

Status structure

Figure 1-2

Standard event status

2000-903-01 Rev. C / October 2007 Return to Section T opics 1-13

Section 1: Introduction Model 2000 Digital Multimeter Quick Start Guide

OR

Idle = Idle state of the 2000

Trig = Triggering

Meas = Measuring

& = Logical AND

OR = Logical OR

(B15 - B11)

Idle

(B10) (B9) (B8) (B7) (B6)

Trig

(B5)

Meas

(B4) (B3) (B2) (B1) (B0)

Operation Event

Register

(B15 - B11)

Idle

(B10) (B9) (B8) (B7) (B6)

Trig

(B5)

Meas

(B4) (B3) (B2) (B1) (B0)

Operation Event

Enable Register

&

To Operation

Summary Bit

(OSB) of Status

Byte Register.

(See Figure 6).

&

&

(B15 - B11)

Idle

(B10) (B9) (B8) (B7) (B6)

Trig

(B5)

Meas

(B4) (B3) (B2) (B1) (B0)

Operation

Condition Register

OR

BFL = Buffer Full

BHF = Buffer Half Full

BAV = Buffer Available

& = Logical AND

OR = Logical OR

(B15 - B12) (B10) (B9)

BHF

(B8)

BAV

(B7) (B6)

RAV

(B5) (B4) (B3)

(B2)

LL

(B1) (B0)

Measurement Event

Register

(B15 - B12)

Measurement Event

Enable

Register

To Measurement

Summary Bit

(MSB) of Status

Byte Register.

(See Figure 6).

&

&

(B15 - B12) (B10) (B9) (B8) (B7) (B6)

RAV

(B5) (B4) (B3)

(B2)

LL

(B1) (B0)

Measurement

Condition Register

BFL

HL

ROF

BFL

ROF

&

&

&

BHF BAV

HL

&

&

(B10) (B9)

BHF

(B8)

BAV

(B7) (B6)

RAV

(B5)

(B4) (B3)

(B2)

LL

(B1) (B0)

BFL ROFHL

RAV = Reading Available

HL = High Limit

LL = Low Limit

ROF = Reading Overflow

(B11)

(B11)

(B11)

Figure 1-3

Operation event status

Figure 1-4

Measurement event status

1-14 Return to Section Topics 2000-903-01 Rev. C / October 2007

Model 2000 Digital Multimeter Quick Start Guide Section 1: Introduction

(B13 - B9)(B14) (B8)(B15)

OR

Questionable

Condition Register

Questionable Event

Enable Register

Warn = Command Warning

Cal = Calibration Summary

Temp = Temperature Summary

& = Logical AND

OR = Logical OR

&

&

&

0

(B13 - B9)(B14)

(B8)

(B15)

0

Warn Cal

Questionable Event

Register

(B13 - B9)(B14) (B8)(B15)

To Questionable

Summary Bit (QSB)

of Status

Byte Register

(See Figure 6).

(B7 - B5)

(B7 - B5)

(B7 - B5)

Warn Cal

0

Warn Cal

(B4)

Temp

(B4)

Temp

(B3 - B0)

(B3 - B0)

(B3 - B0)(B4)

Temp

&

Status Summary Messages

* STB?

Serial Poll

OSB

(B7)

RQS

(B6)

MSS

ESB

(B5)

MAV

(B4)

QSB

(B3)

EAV

(B2)

(B1) (B0)

OR

* SRE

* SRE?

Status Byte

Register

Service

Request

Enable

Register

OSB = Operation Summary Bit

MSS = Master Summary Status

RQS = Request for Service

ESB = Event Summary Bit

MAV = Message Available

QSB = Questionable Summary Bit

EAV = Error Available

MSB = Measurement Summary Bit

& = Logical AND

OR = Logical OR

OSB

(B7) (B6)

ESB

(B5)

MAV

(B4)

QSB

(B3)

EAV

(B2)

(B1) (B0)

&

&

&

&

&

MSB

MSB

&

Service

Request

Generation

Read by Serial Poll

Read by *STB?

Figure 1-5

Questionable event status

Figure 1-6

Status byte and service request (SRQ)

2000-903-01 Rev. C / October 2007 Return to Section T opics 1-15

Section 1: Introduction Model 2000 Digital Multimeter Quick Start Guide

IEEE-488.2 common commands and queries

Table 1-4

IEEE-488.2 common commands and queries

Mnemonic Name Description

*CLS

*ESE <NRf>

*ESE?

*ESR?

*IDN?

*OPC

*OPC?

*OPT?

Clear status

Event enable command

Event enable query

Event status register query

Identification query

Operation complete

command

Operation complete query

Option identification query

Clears all event registers and Error Queue.

Program the Standard Event Enable Register.

Read the Standard Event Enable Register.

Read the Standard Event Enable Register and

clear it.

Returns the manufacturer, model number,

serial number and firmware revision levels of

the unit.

Set the Operation Complete bit in the Standard

Event Status Register after all pending

commands have been executed.

Places an ASCII “1” into the output queue

when all pending selected device operations

have been completed.

Returns an ID code that indicates which

memory option is installed and whether or not

the optional scanner card is installed.

*RCL <NRf>

*RST

*SAV <NRf>

*SRE <NRf>

*SRE?

*STB?

*TRG

*TST?

*WAI

1-16 Return to Section Topics 2000-903-01 Rev. C / October 2007

Recall command

Reset command

Save command

Service request enable

command

Service request enable query

Read status byte query

Trigger command

Self-test query

Wait-to-continue command

Returns the Model 2000 to the setup

configuration stored in the specified memory

location.

Returns the Model 2000 to the *RST default

conditions.

Saves the current setup to the specified

memory location.

Programs the Service Request Enable

Register.

Reads the Service Request Enable Register.

Reads the Status Byte Register.

Sends a bus trigger to the 2000.

Performs a checksum test on ROM and returns

the result.

Wait until all previous commands are executed.

Model 2000 Digital Multimeter Quick Start Guide Section 1: Introduction

SCPI command subsystems

NOTE 1. Brackets ([]) are used to denote optional character sets. These

optional characters do not have to be included in the program

message. Do not use brackets in the program message.

2. Angle brackets (<>) are used to indicate parameter type. Do not

use angle brackets in the program message.

3. Upper case characters indicate the short-from version for each

command word.

Table 1-5

Signal oriented measurement commands

Command Description

:CONFigure:<funct

ion>

:FETCh?

:READ?

MEASure[:<functio

n>]?

Places the Model 2000 in a

“one-shot” measurement

mode for the specified

function.

Requests the latest reading.

Performs an :ABORt,

:INITiate, and a :FETCh?.

Performs an :ABORt,

:CONFigure:<function>, and

a :READ?.

2000-903-01 Rev. C / October 2007 Return to Section T opics 1-17

Section 1: Introduction Model 2000 Digital Multimeter Quick Start Guide

Table 1-6

CALCulate command summary

Command Description

:CALCulate[1]

:FORMat <name>

:FORMat?

:KMATh

:MMFactor <NRf>

:MMFactor?

:MBFactor <NRf>

:MBFactor?

:MUNits <name>

:MUNits?

:PERCent <NRf>

:ACQuire

:PERCent?

:ST ATe <b>

:STATe?

:DATA?

:CALCulate2

:FORMat <name>

:FORMat?

:STATe <b>

:STATe?

:IMMediate

:IMMediate?

:DATA?

:CALCulate3

:LIMit[1]

:UPPer

[:DATA] <n>

[:DATA]?

:LOWer

[:DATA] <n>

[:DATA]?

:STATe <b>

:STATe?

:FAIL?

:CLEAR

[:IMMediate]

:AUTO <b>

:AUTO?

:IMMediate

Subsystem to control CALC 1:

Select math format (NONE, MXB,

PERCent).

Query math format.

Path to configure math calculations:

Set “m” factor for mx+b (-100e6 to

100e6).

Query “m” factor.

Set “b” factor for mx+b (-100e6 to

100e6).

Query “b” factor.

Specify units for mx+b reading

(three characters ‘A’ through ‘Z’).

Query “mx+b” units.

Set target value for PERCent

calculation (-100e6 to 100e6).

Use input signal as target value.

Query percent.

Enable or disable kmath calculation.

Query state of kmath function.

Read result of kmath calculation.

Subsystem to control CALC 2:

Select math format: (MEAN,

SDEViation, MAXimum, MINimum,

or NONE).

Query math format.

Enable or disable calculation.

Query state of math function.

Recalculate raw input data in buffer.

Perform calculation and read result.

Read math result of CALC 2.

Subsystem to control CALC 3 (limit

test):

Path to control LIMIT 1 test:

Path to configure upper limit:

Set upper limit (-100e6 to 100e6).

Query upper limit.

Path to configure lower limit:

Set lower limit (-100e6 to 100e6).

Query lower limit.

Enable or disable limit test.

Query state of limit test.

Query test result (1 = pass, 0 = fail).

Path to clear failed test:

Clear failed test indication.

Enable or disable auto clear.

Query auto clear.

Re-perform limit tests.

1-18 Return to Section Topics 2000-903-01 Rev. C / October 2007

Model 2000 Digital Multimeter Quick Start Guide Section 1: Introduction

Table 1-7

DISPlay command summary

Command Description

:DISPlay

[:WINDow[1]]

:TEXT

:DATA <a>

:DATA?

:STATe <b>

:STATe?

:ENABle <b>

:ENABle?

Path to control user text

messages.

Define ASCII message “a” (up to

12 characters).

Query text message.

Enable or disable message

mode.

Query text message state.

Enable or disable the front panel

display.

Query state of the display.

Table 1-8

FORMat command summary

Command Description

:FORMat

[:DATA]

<type>[,<length>]

[:DATA]?

:ELEMents <item list>

:ELEMents?

:BORDer <name>

:BORDer?

Select data format: (ASCii,

SREal or DREal).

Query data format.

Specify data elements:

(READing, CHANnel, and

UNITs).

Query data elements.

Select binary byte order:

(NORMal or SWAPped).

Query byte order.

2000-903-01 Rev. C / October 2007 Return to Section T opics 1-19

Section 1: Introduction Model 2000 Digital Multimeter Quick Start Guide

Table 1-9

ROUTe command summary

Command Description

:ROUTe

:CLOSe <chan

num>

:STATe?

:OPEN:ALL

:MULTiple

:CLOSe <list>

:STATe?

:OPEN <list>

:SCAN

[:INTernal] <list>

[:INTernal]?

:EXTernal <list>

:EXTernal?

:LSELect <name>

:LSELect?

Table 1-10

SENSe command summary

Commands to control scanner

card:

Close specified channel (1 to

10) or channel pair (1 to 5).

Query closed channel (or

channel pair).

Open all input channels

(1 through 10).

Path to close and open

multiple channels:

Close specified channels (1 to

11).

Query closed channel.

Open specified channels (1 to

11).

Path to scan channels.

Specify internal scan list (2 to

10 channels).

Query internal scan list.

Specify external scan list (2 to

800 channels).

Query external scan list.

Select scan operation

(INTernal, EXTernal, or

NONE).

Query scan operation.

Command Description

[:SENSe[1]]

:FUNCtion <name>

:FUNCtion?

:DATA?

:FRESh?

:HOLD

:WINDow <NRf>

:WINDow?

:COUNt <NRf>

:COUNt?

:ST ATe <NRf>

:STATe?

Select measurement

function: ‘VOLTage:AC’,

VOLTage :DC’, RESistance’,

‘FRESistance’,

‘CURRent:AC’, ‘CURRent:

DC’ ,

‘FREQuency’,‘TEMPerature’,

‘PERiod’, ‘DIODe’,

“CONTinuity’.

Query function.

Return the last instrument

reading.

Returns a new (fresh)

reading.

Path to control Hold feature:

Set Hold window (%); 0.01 to

20.

Query Hold window.

Set Hold count; 2 to 100.

Query Hold count.

Enable or disable Hold.

Query state of Hold.

1-20 Return to Section Topics 2000-903-01 Rev. C / October 2007

Model 2000 Digital Multimeter Quick Start Guide Section 1: Introduction

Table 1-10

SENSe command summary (cont.)

Command Description

:CURRent:AC

:NPLCycles <n>

:NPLCycles?

:RANGe

[:UPPer] <n>

[:UPPer]?

:AUTO <b>

:AUTO?

:REFerence <n>

:STATe <b>

:STATe?

:ACQuire

:REFerence?

:DIGits <n>

:DIGits?

:AVERage

:TCONtrol <name>

:TCONtrol?

:COUNt <n>

:COUNt?

:STATe <b>

:STATe?

:CURRent:AC

:DETector

:BANDwidth <NRf>

:BANDwidth?

Path to configure AC current.

Set integration rate (line

cycles; 0.01 to 10).

Query line cycle integration

rate.

Path to configure

measurement range:

Select range (0 to 3.1).

Query range.

Enable or disable auto range.

Query auto range.

Specify reference (-3.1 to

3.1).

Enable or disable reference.

Query state of reference.

Use input signal as

reference.

Query reference value.

Specify measurement

resolution (4 to 7).

Query resolution.

Path to configure and control

the filter.

Select filter type: (MOVing or

REPeat).

Query filter type.

Specify filter count (1 to 100).

Query filter count.

Enable or disable filter.

Query state of digital filter.

Path to configure bandwidth:

Specify bandwidth (3 to

300e3).

Query bandwidth.

2000-903-01 Rev. C / October 2007 Return to Section T opics 1-21

Section 1: Introduction Model 2000 Digital Multimeter Quick Start Guide

Table 1-10

SENSe command summary (cont.)

Command Description

:CURRent:DC

:NPLCycles <n>

:NPLCycles?

:RANGe

[:UPPer] <n>

[:UPPer]?

:AUTO <b>

:AUTO?

:REFerence <n>

:STATe <b>

:STATe?

:ACQuire

:REFerence?

:DIGits <n>

:DIGits?

:AVERage

:TCONtrol <name>

:TCONtrol?

:COUNt <n>

:COUNt?

:STATe <b>

:STATe?

:VOLTage:AC

:NPLCycles <n>

:NPLCycles?

:RANGe

[:UPPer] <n>

[:UPPer]?

:AUTO <b>

:AUTO?

:REFerence <n>

Path to configure DC current.

Set integration rate (line

cycles; 0.01 to 10).

Query line cycle integration

rate.

Path to configure

measurement range:

Select range (0 to 3.1).

Query range.

Enable or disable auto range.

Query auto range.

Specify reference (-3.1 to

3.1).

Enable or disable reference.

Query state of reference.

Use input signal as

reference.

Query reference value.

Specify measurement

resolution (4 to 7).

Query resolution.

Path to configure and control

the filter.

Select filter type: (MOVing or

REPeat).

Query filter type.

Specify filter count (1 to 100).

Query filter count.

Enable or disable filter.

Query state of digital filter.

Path to configure AC voltage.

Set integration rate (line

cycles; 0.01 to 10).

Query line cycle integration

rate.

Path to configure

measurement range:

Select range (0 to 757.5).

Query range.

Enable or disable auto range.

Query auto range.

Specify reference (-757.5 to

757.5).

1-22 Return to Section Topics 2000-903-01 Rev. C / October 2007

Model 2000 Digital Multimeter Quick Start Guide Section 1: Introduction

Table 1-10

SENSe command summary (cont.)

Command Description

:VOLTage:AC

:REFerence <n>

:STATe <b>

:STATe?

:ACQuire

:REFerence?

:DIGits <n>

Enable or disable reference.

Query state of reference.

Use input signal as

reference.

Query reference value.

Specify measurement

:DIGits?

:AVERage

resolution (4 to 7).

Query resolution.

Path to configure and control

:TCONtrol <name>

the filter.

Select filter type: (MOVing or

:TCONtrol?

:COUNt <n>

:COUNt?

:STATe <b>

:STATe?

:DETector

:BANDwidth <NRf>

REPeat).

Query filter type.

Specify filter count (1 to 100).

Query filter count.

Enable or disable filter.

Query state of digital filter.

Path to configure bandwidth:

Specify bandwidth (3 to

:BANDwidth?

300e3).

Query bandwidth.

:VOLTage:DC

:NPLCycles <n>

Path to configure DC voltage:

Set integration rate (line

cycles; (0.01 to 10).

:NPLCycles?

:RANGe

Query line cycle integration

rate.

Path to configure

[:UPPer] <n>

[:UPPer]?

:AUTO <b>

:AUTO?

:REFerence <n>

measurement range:

Select range (0 to 1010).

Query range.

Enable or disable auto range.

Query auto range.

Specify reference (-1010 to

:STATe <b>

:STATe?

+1010).

Enable or disable reference.

Query state of reference (0 or

:ACQuire

:REFerence?

:DIGits <n>

1).

Use input signal as

reference.

Query reference value.

:DIGits?

Specify measurement

resolution (4 to 7).

Query resolution.

:VOLTage:DC

:AVERage

Path to configure and control

the filter.

:TCONtrol <name>

Select filter type: (MOVing or

REPeat).

:TCONtrol?

:COUNt <n>

:COUNt?

:STATe <b>

:STATe?

Query filter type.

Specify filter count (1 to 100).

Query filter count.

Enable or disable filter.

Query state of digital filter.

2000-903-01 Rev. C / October 2007 Return to Section T opics 1-23

Section 1: Introduction Model 2000 Digital Multimeter Quick Start Guide

Table 1-10

SENSe command summary (cont.)

Command Description

:RESistance

:NPLCycles <n>

:NPLCycles?

:RANGe

[:UPPer] <n>

[:UPPer]?

:AUTO <b>

:AUTO?

:REFerence <n>

:STATe <b>

:STATe?

:ACQuire

:REFerence?

:DIGits <n>

:DIGits?

:AVERage

:TCONtrol <name>

:TCONtrol?

:COUNt <n>

:COUNt?

:STATe <b>

:STATe?

Path to configure resistance:

Set integration rate (line

cycles; 0.01 to 10).

Query line cycle integration

rate.

Path to configure

measurement range:

Select range (0 to 120e6).

Query range.

Enable or disable auto range.

Query auto range.

Specify reference (0 to

120e6).

Enable or disable reference.

Query state of reference.

Use input signal as

reference.

Query reference value.

Specify measurement

resolution (4 to 7).

Query resolution.

Path to configure and control

filter.

Select filter type: (MOVing or

REPeat).

Query filter type.

Specify filter count (1 to 100).

Query filter count.

Enable or disable filter.

Query state of digital filter.

1-24 Return to Section Topics 2000-903-01 Rev. C / October 2007

Model 2000 Digital Multimeter Quick Start Guide Section 1: Introduction

Table 1-10

SENSe command summary (cont.)

Command Description

:FRESistance

:NPLCycles <n>

:NPLCycles?

:RANGe

[:UPPer] <n>

[:UPPer]?

:AUTO <b>

:AUTO?

:REFerence <n>

:STATe <b>

:STATe?

:ACQuire

:REFerence?

:DIGits <n>

:DIGits?

:AVERage

:TCONtrol <name>

:TCONtrol?

:COUNt <n>

:COUNt?

:STATe <b>

:STATe?

:TEMPerature

:NPLCycles <n>

:NPLCycles?

:REFerence <n>

:STATe <b>

:STATe?

:ACQuire

:REFerence?

:DIGits <n>

:DIGits?

:AVERage

Path to configure four-wire

resistance:

Set integration rate (line

cycles; 0.01 to 10).

Query line cycle integration

rate.

Path to configure

measurement range:

Select range (0 to 101e6).

Query range.

Enable or disable auto range.

Query auto range.

Specify reference (0 to

+101e6).

Enable or disable reference.

Query state of reference.

Use input signal as

reference.

Query reference value.

Specify measurement

resolution (4 to 7).

Query resolution.

Path to configure and control

filter.

Select filter type: (MOVing or

REPeat).

Query filter type.

Specify filter count (1 to 100).

Query filter count.

Enable or disable filter.

Query state of digital filter.

Path to configure

temperature:

Set integration rate (line

cycles; 0.01 to 10).

Query line cycle integration

rate.

Specify reference; -200 to

1372.

Enable or disable reference.

Query state of reference.

Use input signal as

reference.

Query reference value.

Specify measurement

resolution (4 to 7).

Query resolution.

Path to configure and control

the filter.

2000-903-01 Rev. C / October 2007 Return to Section T opics 1-25

Section 1: Introduction Model 2000 Digital Multimeter Quick Start Guide

Table 1-10

SENSe command summary (cont.)

Command Description

:TEMPerature

:AVERage

:TCONtrol <name>

Select filter type: (MOVing or

REPeat).

:TCONtrol?

:COUNt <n>

:COUNt?

:STATe <b>

:STATe?

:TCouple

:TYPE <name>

Query filter type.

Specify filter count (1 to 100).

Query filter count.

Enable or disable filter.

Query state of digital filter.

Path to configure

thermocouple:

Select thermocouple type (J,

:TYPE?

:RJUNction

K, or T).

Query thermocouple type.

Path to configure reference

:RSELect <name>

junction:

Select reference type

:RSELect?

:SIMulated <n>

(SIMulated or REAL).

Query reference type.

Specify simulated

:SIMulated?

temperature in °C (0 to 50).

Query simulated

:REAL

temperature.

Path to configure real

:TCOefficient <n>

reference junction:

Specify temp coefficient

:TCOefficient?

:OFFSET <n>

(-0.09999 to 0.09999).

Query temp coefficient.

Specify voltage offset at 0°C

(-0.09999 to 0.09999).

:OFFSet?

:FREQuency

:APERture

Query voltage offset.

Path to configure frequency.

Sets gate time for period

measurements (0.01-1.0s).

:APERture?

:THReshold

Query period gate time.

Path to select the threshold

voltage range:

:VOLTage

:RANGe <n>

Select threshold range (0 to

1010).

:RANGe?

:REFerence <n>

:ST ATe <b>

:STATe?

:ACQuire

:REFerence?

:DIGits <n>

Query threshold range.

Specify reference (0 to

1.5e7)

Enable or disable reference.

Query state of reference.

Use input signal as

reference.

Query reference value.

:DIGits?

Specify measurement

resolution (4 to 7).

Query resolution.

1-26 Return to Section Topics 2000-903-01 Rev. C / October 2007

Model 2000 Digital Multimeter Quick Start Guide Section 1: Introduction

Table 1-10

SENSe command summary (cont.)

Command Description

:PERiod

:APERture

:APERture?

:THReshold

:VOLTage

:RANGe <n>

:RANGe?

:REFerence <n>

:ST ATe <b>

:STATe?

:ACQuire

:REFerence?

:DIGits <n>

:DIGits?

:DIODe

:CURRent

:RANGe

[:UPPer] <NRf>

[:UPPer]?

:CONTinuity

:THReshold <NRf>

:THReshold?

Path to configure period.

Sets gate time for period

measurements (0.01-1.0s).

Query period gate time.

Path to select the threshold

voltage range:

Select threshold range (0 to

1010).

Query threshold range.

Specify reference (0 to 1).

Enable or disable reference.

Query state of reference.

Use input signal as

reference.

Query reference value.

Specify measurement

resolution (4 to 7).

Query resolution.

Paths to configure diode test:

Path to select range.

Select range (0 to 1e-3)

Query range.

Path to configure continuity

test:

Set threshold resistance (1 to

1000).

Query threshold resistance.

2000-903-01 Rev. C / October 2007 Return to Section T opics 1-27

Section 1: Introduction Model 2000 Digital Multimeter Quick Start Guide

Table 1-11

STATus command summary

Command Description

:STATus

:MEASurement

Path to control measurement

event registers:

[:EVENt]?

:ENABle <NRf>

:ENABle?

:CONDition?

:OPERation

Read the event register.

Program the enable register.

Read the enable register.

Read the condition register.

Path to control operation status

registers:

[:EVENt]?

:ENABle <NRf>

:ENABle?

:CONDition?

:QUEStionable

Read the event register.

Program the enable register.

Read the enable register.

Read the condition register.

Path to control questionable

status registers:

[:EVENt]?

:ENABle <NRf>

:ENABle?

:CONDition?

:PRESet

:QUEue

[:NEXT]?

:ENABle <list>

Read the event register.

Program the enable register.

Read the enable register.

Read the condition register.

Return status registers to

default states.

Path to access error queue:

Read the most recent error

message.

:ENABle?

:DISable <list>

Specify error and status

messages for queue.

Read the enabled messages.

:DISable?

:CLEar

Specify messages not to be

placed in queue.

Read the disabled messages.

Clears all messages from Error

Queue.

1-28 Return to Section Topics 2000-903-01 Rev. C / October 2007

Model 2000 Digital Multimeter Quick Start Guide Section 1: Introduction

Table 1-12

SYSTem command summary

Command Description

:SYSTem

:PRESet

:POSetup

<name>

:POSetup?

:FRSWitch?

:VERSion?

:ERRor?

:AZERo

:STATe <b>

:STATe?

:KEY <NRf>

:KEY?

:CLEar

:BEEPer

[:STATe] <b>

[:STATe]?

:LOCal

:REMote

:RWLock

:KCLick <b>

:KCLick

:LFRequency?

Return to :SYST:PRES

defaults.

Select power-on setup: (RST,

PRESet or SAV0).

Query power-on setup.

Query INPUTS switch (0=rear,

1=front).

Query rev level of SCPI

standard.

Query (read) Error Queue.

Path to set up autozero.

Enable or disable autozero.

Query autozero.

Simulate key-press (1 to 31;

see Figure 5-10 of the User’s

Manual).

Query the last “pressed” key.

Clears messages from the

Error Queue.

Path to control beeper.

Enable or disable beeper.

Query state of beeper.

Take 2000 out of remote and

restore operation of front panel

controls (RS-232 only).

Place 2000 in remote (RS-232

only).

Lockout front panel controls

(RS-232 only).

Turn the keyclick on/off.

Query the keyclick status.

Query power line frequency.

Table 1-13

TRACe command summary

Command Description

:TRACe|:DATA

:CLEar

:FREE?

:POINts <NRf>

:POINts?

:FEED <name>

:CONTrol <name>

:CONTrol?

:FEED?

:DATA?

2000-903-01 Rev. C / October 2007 Return to Section T opics 1-29

Use :TRACe or :DATA as

root command.

Clear readings from buffer.

Query bytes available and

bytes in use.

Specify size of buffer (2 to

1024).

Query buffer size.

Select source of readings

(SENSe[1], CALCulate[1],

NONE.

Select buffer control mode

(NEVer or NEXT)

Query buffer control mode.

Query source of readings for

buffer.

Read all readings in the

buffer.

Section 1: Introduction Model 2000 Digital Multimeter Quick Start Guide

Table 1-14

Trigger command summary

Command Description

:INITiate

[:IMMediate]

:CONTinuous <b>

:CONTinuous?

:ABORt

:TRIGger[:SEQuen

ce[1]]

:COUNt <n>

:COUNt?

:DELay <n>

:AUTO <b>

:AUTO?

:DELay?

:SOURce

<name>

:SOURce?

:TIMer <n>

:TIMer?

:SIGNal

:SAMPle

:COUNt <NRf>

:COUNt?

Subsystem command path:

Initiate one trigger cycle.

Enable or disable continuous

initiation.

Query continuous initiation.

Reset trigger system.

Path to program Trigger

Layer:

Set measure count (1 to

9999, or INF).

Query measure count.

Set delay (0 to 999999.999

sec)

Enable or disable auto delay.

Query state of delay.

Query delay.

Select control source

(IMMediate, TIMer, MANual,

BUS, or EXTernal).

Query control source.

Set timer interval (0 to

999999.999 sec).

Request the programmed

timer interval.

Loop around control source.

Specify sample count (1 to

1024).

Query sample count.

1-30 Return to Section Topics 2000-903-01 Rev. C / October 2007

Model 2000 Digital Multimeter Quick Start Guide Section 1: Introduction

Table 1-15

TEMPerature command summary

Command Description

:UNIT

:TEMPerature

<name>

Select temperature

measurement units (C, F, or

K).

:TEMPerature?

:VOLTage

:AC <name>

Query temperature units.

Path to configure voltage

units.

Select ACV measurement

:DB

units (V, DB or DBM).

Path to set DB reference

:REFerence <n>

:REFerence?

:DBM

voltage.

Specify reference in volts

-7

to 1000).

(1e

Query DB reference.

Path to set DBM reference

:IMPedance <n>

impedance.

Specify reference

:IMPedance?

impedance (1 to 9999).

Query DBM reference

:AC?

[:DC] <name>

impedance.

Query ACV units.

Select DCV measurement

:DB

units (V, DB, or DBM)

Path to set DB reference

:REFerence <n>

voltage:

Specify reference in volts (0

:REFerence?

:DBM

to 1000).

Query reference.

Path to set DBM refernece

:IMPedance <n>

:IMPedance?

:DC?

impedance:

Specify reference

impedance (1e

-7

to 9999).

Query reference impedance.

Query DCV units.

2000-903-01 Rev. C / October 2007 Return to Section T opics 1-31

Section 1: Introduction Model 2000 Digital Multimeter Quick Start Guide

Models 196/199 and 8840A/8842A commands

Table 1-16

Models 196/199 device-dependent command summary

Mode Command Description

Execute X Execute other device-

dependent commands.

Function F0

Range

R0

R1

R2

R3

R4

R5

R6

R7

Zero (rel) Z0

Filter P0

Rate S0

Trigger

mode

F1

F2

F3

F4

F5

F6

F7

F8

F9

DCV ACV DCA ACA Ohms* ACV dB Freq

Auto Auto Auto Auto Auto Auto —

1V 1V 100mA 1A 1k¾ 1V 0.1V

10V 10V 3A 3A 10k¾ 10V 1V

100V 100V 3A 3A 100k¾ 100V 10V

1000V 750V 3A 3A 1M¾ 750V 100V

1000V 750V 3A 3A 10M¾ 750V 750V

1000V 750V 3A 3A 100M¾ 750V —

1000V 750V 3A 3A 100M¾ 750V —

*2-wire and 4-wire ohms

Z1

Z2

P1

P2

S1

S2

T0

T1

T2

T3

T4

T5

T6

DC volts

AC volts

2-wire ohms

DC current

AC current

ACV dB

Not valid

Frequency

Temperature

4-wire ohms

Zero disabled

Zero enabled

Zero enabled using a zero

value (V)

Filter disabled

Moving filter (count = 10)

Repeat filter (count = 10)

0.1 PLC integration

Line cycle integration

(16.67msec, 60Hz; 20msec,

50Hz)

10 PLC (166.67msec

integration, 60Hz;

200msec integration, 50Hz)

Continuous on Talk

One-shot on Talk

Continuous on GET

One-shot on GET

Continuous on X

One-shot on X

Continuous on External Trigger

T7

Reading

mode

1-32 Return to Section Topics 2000-903-01 Rev. C / October 2007

B0

B1

B2

One-shot on External Trigger

Readings from A/D converter

Individual readings from data

store

All readings from data store

(buffer dump)

Model 2000 Digital Multimeter Quick Start Guide Section 1: Introduction

Table 1-16

Models 196/199 device-dependent command summary (cont.)

Mode Command Description

Data store

size

I0

In

Interval Q0

Qn

Value V±nn.nnnn or

V±n.nnnnnnE+n

Default

L0

conditions

L1

Data format G0

G1

G2

G3

G4

G5

G6

G7

SRQ M0

M1

M2

M4

M8

M16

M32

EOI and bus

K0

hold-off

K1

K2

K3

Terminator Y0

Y1

Y2

Y3

Disable data store

Data store of n (n=1 to 500), fill

and stop

Default interval, 175msec

(SELECT OFF)

n=interval in milliseconds

(15msec to 999999msec)

Zero value, simulated

reference junction temperature

Restore factory default

conditions and save (L1)

Save present machine states

as default conditions

Reading with prefix.

Reading without prefix.

Reading and buffer location

with prefix.

Reading and buffer location

without prefix.

Reading and channel with

prefix.

Reading and channel without

prefix.

Reading, buffer location, and

channel with prefix.

Reading, buffer location, and

channel without prefix.

Disable

Reading overflow

Data store full

Data store half full

Reading done

Ready

Error

Enable EOI and bus hold-off

on X

Disable EOI, enable bus holdoff on X

Enable EOI, disable bus holdoff on X

Disable both EOI and bus holdoff on X

CR LF

LF CR

CR

LF

2000-903-01 Rev. C / October 2007 Return to Section T opics 1-33