Teknatool Nova Viking Series, Nova 83701, Nova 83700, Nova 83703, Nova 83702 Operation Manual

...

123-0719-018

OPERATION MANUA

L

Viking DVR 16”

Benchtop Drill Press

™

Publication: 123-0719-018

Date: 11 July 2019

Models:

83700 - USA

83701 - NZ/Australia

83702 - Canada

83703 - Europe

83704 - UK

123-0719-018

Contact

Teknatool International Ltd

Phone: (+64) 9 477 5600

Teknatool USA

Phone: 727-954-3433

Customer Solutions

For all worldwide Inquiries, Repairs or Services (issues must be in writing)

Email: Service@Teknatool.com

Or you can contact the retailer where you purchased your NOVA Viking DVR Drill Press, for the contact

details please see our website www.teknatool.com

123-0719-018

Table of Contents

Contact .................................................................................................................................................................................... 2

Table of Contents .................................................................................................................................................................... 3

General Safety Rules ............................................................................................................................................................... 5

Additional Safety Rules for Drill Presses ................................................................................................................................. 6

NOVA DVR Viking Features ..................................................................................................................................................... 1

Drill Press Features ............................................................................................................................................................. 1

Drill Press Specifications ..................................................................................................................................................... 2

Package Contents .................................................................................................................................................................... 3

Assembling the Drill Press ....................................................................................................................................................... 4

Drill Press Body ................................................................................................................................................................... 4

Drill Chuck and Arbor .......................................................................................................................................................... 4

Drill Press Handle ................................................................................................................................................................ 5

Chuck and Arbor Assembly Attachment ............................................................................................................................. 5

Attaching the Drill Press Table ............................................................................................................................................ 6

Tilting the table ............................................................................................................................................................... 6

Attaching the Chuck Guard ................................................................................................................................................. 7

Connecting to Power ............................................................................................................................................................... 8

Ground Fault Interrupters (GFI) ...................................................................................................................................... 9

Setting up your drill press ....................................................................................................................................................... 9

Setting up your workshop environment ............................................................................................................................. 9

Drill Press Interface ............................................................................................................................................................... 10

Keypad Buttons ................................................................................................................................................................. 10

Display Icons ..................................................................................................................................................................... 10

Operating the Drill Press ....................................................................................................................................................... 12

Turning the Drill Press ON ................................................................................................................................................. 12

Basic Drill Press Functions ................................................................................................................................................. 12

Running the drill press .................................................................................................................................................. 12

Stopping the drill press ................................................................................................................................................. 13

Emergency Stop ............................................................................................................................................................ 13

Adjusting the speed ...................................................................................................................................................... 13

Changing the display mode ........................................................................................................................................... 14

Changing the measurement units ................................................................................................................................. 14

Switching between forward and reverse ...................................................................................................................... 15

Zeroing the depth ......................................................................................................................................................... 16

123-0719-018

Using the light and lasers .............................................................................................................................................. 17

Intermediate Functions ..................................................................................................................................................... 18

Using the electronic depth stop function ..................................................................................................................... 18

Quick Set Depth Function ............................................................................................................................................. 19

Electronic Depth Stop Function .................................................................................................................................... 19

Using the Self-Start Function ........................................................................................................................................ 20

Power Spindle Hold Function ........................................................................................................................................ 21

Advanced Functions .......................................................................................................................................................... 22

Performing a Factory Reset ........................................................................................................................................... 22

Turning the sound on or off .......................................................................................................................................... 22

Changing the power bar settings .................................................................................................................................. 23

Calibrating the Height Sensor Drill Press ...................................................................................................................... 24

Unlocking the drill press speed range to 6000rpm ....................................................................................................... 24

Changing the drill press depth stop behaviour ............................................................................................................. 25

Maintaining your Drill Press .................................................................................................................................................. 26

Maintenance after each use ............................................................................................................................................. 26

Monthly maintenance ....................................................................................................................................................... 26

6month Maintenance ....................................................................................................................................................... 26

Speed Chart for Metal Drilling .............................................................................................................................................. 26

Full Speed Chart for General Materials ................................................................................................................................. 27

Firmware Update .................................................................................................................................................................. 28

Checking the firmware version ......................................................................................................................................... 28

USB Mode ......................................................................................................................................................................... 29

Troubleshooting .................................................................................................................................................................... 30

Mechanical Issue ............................................................................................................................................................... 30

Electrical Issues ................................................................................................................................................................. 32

Error Codes ....................................................................................................................................................................... 32

Teknatool Warranty .............................................................................................................................................................. 33

Viking Drill Press Headstock Breakdown .............................................................................................................................. 34

Viking Drill Press Stand and Base .......................................................................................................................................... 35

NOVA Viking Drill Press Parts List ......................................................................................................................................... 36

Chuck Guard .......................................................................................................................................................................... 39

Appendix ............................................................................................................................................................................... 40

NOVA Viking Wiring Diagram ............................................................................................................................................ 40

Using the included accessories ......................................................................................................................................... 41

Chuck Drift..................................................................................................................................................................... 41

123-0719-018

General Safety Rules

WARNING! Failure to follow these rules may result in serious personal injury or death.

IMPORTANT: Before switching the drill press on, ALWAYS check the machine for the correct setting and

speed, as well as ensuring the Chuck Key is removed.

1. FOR YOUR OWN SAFETY, READ THE MANUAL

BEFORE OPERATING THE TOOL. Learn the machine’s

application and limitations, plus the specific hazards

particular to it.

2. ALWAYS USE SAFETY GLASSES (must be ANSI

approved) Everyday eyeglasses usually are only impact

resistant and safety glasses only protect eyes. A full-face

shield will protect the eyes and face. Also use face or dust

mask if cutting operation is dusty.

3. WEAR PROPER APPAREL. Do not wear loose clothing,

gloves, neckties, rings, bracelets or other jewelry which

may get caught in moving parts. Nonslip footwear is

recommended. Wear protective hair covering to contain

long hair.

4. USE EAR PROTECTORS. Use ear muffs for extended

period of operation. Use muffs rated to 103 DBA LEQ (8

hour).

5. DON’T USE IN DANGEROUS ENVIRONMENT. Don’t

use power tools in damp or wet locations, or expose them

to rain. Keep work area well lighted. The NOVA Viking

DVR Drill press is intended for indoor use only. Failure to

do so may void the warranty.

14. KEEP GUARDS IN PLACE and in working order.

15. USE CORRECT TOOLS. Do not use a tool or attachment to

do a job for which it was not designed.

16. USE RECOMMENDED ACCESSORIES. The use of

improper accessories may cause hazards.

17. DON’T FORCE THE TOOL. It will do the job better and be

safer at the rate for which it was designed.

18. MAINTAIN TOOLS IN TOP CONDITION. Keep tools sharp

and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

19. NEVER STAND ON TOOL. Serious injury could occur if the

tool is tipped or if the cutting tool is accidentally contacted.

20. REMOVE ADJUSTING KEYS AND WRENCHES. Form a

habit of checking to see that keys and adjusting wrenches

are removed from tool before turning it on.

21. DON’T OVERREACH. Keep proper footing and balance at

all times.

22. DIRECTION OF FEED. Feed work into a blade or cutter

against the direction of rotation of the blade or cutter only.

23. PAY ATTENTION TO WORK. Concentrate on your work. If

you become tired or frustrated, leave it for a while and rest.

24. SECURE WORK. Use clamps or a vice to hold work when

practical. Severe injury or death can occur if an object comes

free as it can become a dangerous projectile.

25. CHECK DAMAGED PARTS. Before further use of the tool,

any part that is damaged should be carefully checked to

ensure that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of

moving parts, mounting, and any other conditions that may

affect its operation. Any damaged part should be properly

repaired or replaced.

26. DRUGS, ALCOHOL, MEDICATION. Do not operate

machine while under the influence of drugs, alcohol, or any

medication.

27. DUST WARNING. The dust generated by certain woods

and wood products can be harmful to your health. Always

operate machinery in well-ventilated areas and provide

means for proper dust removal. Use wood dust collection

systems whenever possible.

28. DO NOT MODIFY OR USE DRILL PRESS FOR USES

OTHER THAN FOR WHICH IT WAS DESIGNED.

6. KEEP WORK AREA CLEAN. Cluttered areas and benches

invite accidents. Build-up of sawdust is a fire hazard.

7. KEEP CHILDREN AND VISITORS AWAY. The Nova

Viking DVR is not recommended for children and infirm

persons. Such personnel and onlookers should be kept a

safe distance from work area.

8. MAKE WORKSHOP CHILDPROOF with locks, master

switches, or by removing starter keys.

9. GROUND ALL TOOLS. If the tool is equipped with a

three-prong plug, it should be plugged into a three-hole

electrical receptacle. If an adapter is used to

accommodate a two-prong receptacle, the adapter plug

must be attached to a known ground. Never remove the

third prong.

10. MAKE SURE TOOL IS DISCONNECTED FROM POWER

SUPPLY while the motor is being mounted, connected,

or reconnected.

11. DISCONNECT TOOLS FROM WALL SOCKET before

servicing and when changing accessories such as bits,

cutters and fuses etc.

12. AVOID ACCIDENTAL STARTING. Make sure switch is in

the “Off” position before plugging in power cord.

13. NEVER LEAVE MACHINE RUNNING UNATTENDED.

Do not leave machine unless it is turned off and has come

to a complete stop

123-0719-018

Additional Safety Rules for Drill Presses

WARNING! Failure to follow these rules may result in serious personal injury.

1. SEEK INSTRUCTION. If you are not thoroughly familiar

with the operation of drill press, obtain advice from your

supervisor, instructor, or other qualified person.

Instruction from a qualified person is strongly

recommended.

2. DO NOT OPERATE DRILL PRESS until it is completely

assembled and installed. Follow instructions and

recommendations.

3. FOLLOW ELECTRICAL CODES. Make sure wiring codes

and recommended electrical connections are followed

and that the machine is properly grounded.

4. WHEN REPLACING THE FUSE (on relevant models),

completely isolate power when removing the fuse. It is

imperative the plug is removed from the power supply

before the fuse is removed. Replace fuse cap before

reconnecting to power.

5. DO NOT OPEN THE SWITCH AND REAR COVERS.

Components can carry dangerous voltages even when

isolated from mains power.

6. KEEP WORK AREA CLEAN. Do not turn the drill press

on before clearing the drill press of all objects (tools,

scraps of wood, etc.). Keep the nearby area and floor clear

of debris.

7. CHECK SET-UP with spindle off. Examine the set-up

carefully and rotate the work piece by hand to check

clearance and check speed is correctly selected before

turning on spindle.

8. DO NOT MAKE ADJUSTMENTS when the drill press

spindle is turning. Make all adjustments with power OFF.

9. TIGHTEN ALL CLAMP HANDLES on the drill press before

operating drill press.

10. ALWAYS CHECK CORRECT SPEED IS SELECTED

BEFORE SWITCHING ON DRILL PRESS.

11. OPERATE AT RECOMMENDED SPEED. Always operate

the drill press at the recommended speeds. Consult the

built-in speed chart on the drill press for suggested

speeds.

12. DO NOT OPERATE DRILL PRESS IF DAMAGED OR

FAULTY. If any part of your drill press is missing, damaged

or broken, in any way, or any electrical component fails, shut

off the drill press and disconnect the drill press from the

power supply. Replace missing, damaged, or failed parts

before resuming operation.

13. ADDITIONAL SAFETY INFORMATION regarding the safe

and proper operation of this product is available from the

National Safety Council, 444 N. Michigan Avenue, Chicago,

IL 60611 in the Accident Prevention Manual of Industrial

Operations and also in the Safety Data Sheets provided by the

NSC. Also refer to the American National Standards Institute

ANSI 01.1 Safety Requirements for Woodworking Machines

and the U.S Department of Labor OSHA 1910.213 Regulation.

1

123-0719-018

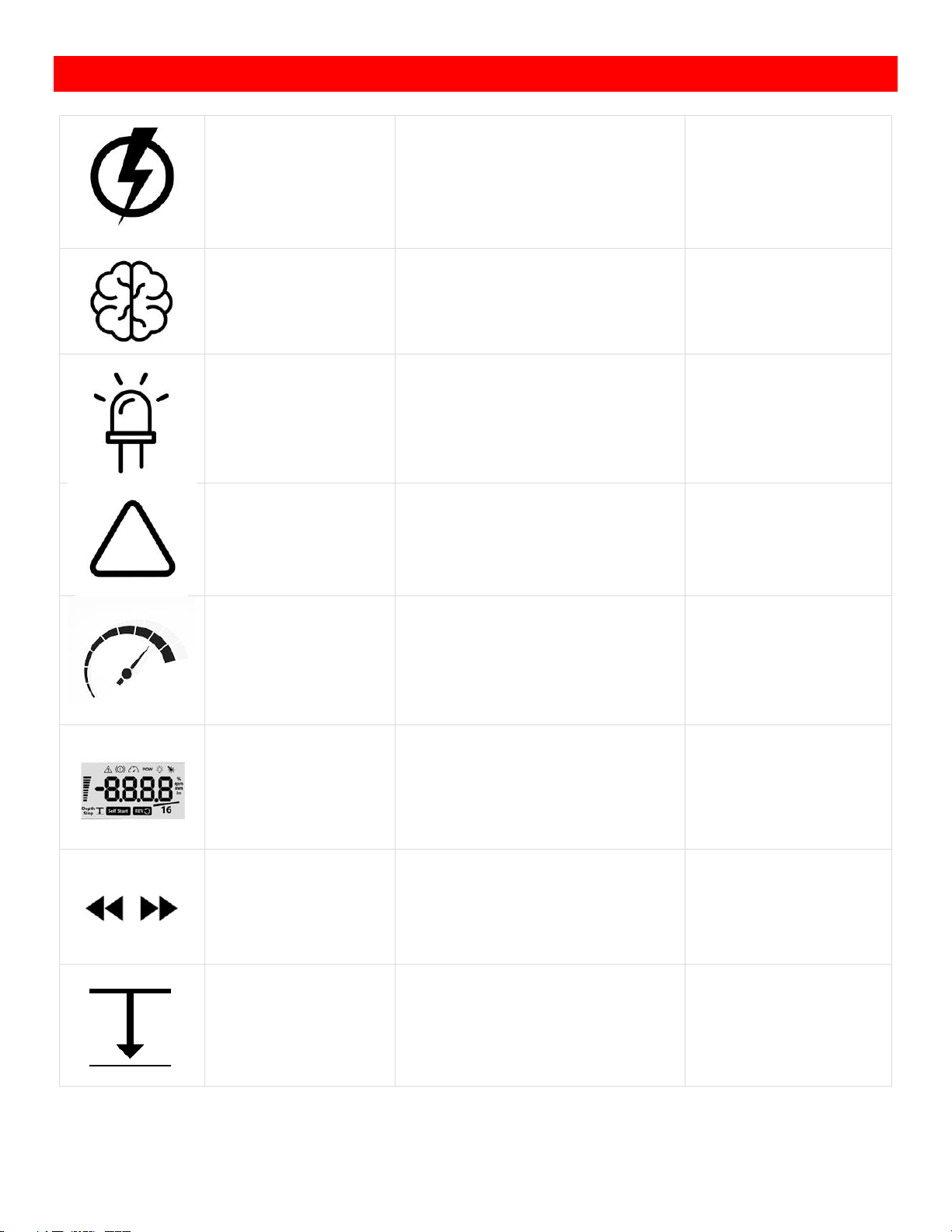

NOVA DVR Viking Features

Drill Press Features

DIRECT DRIVE POWER

AND CONSISTENT

TORQUE

1HP DVR Smart Digital Motor delivers

correct speed, and power to maintain

optimal torque direct to the drill head,

across the entire speed range. No belts

or pulleys to cause vibration or power

loss.

A belt and pulley system

absorb typically 20% of the

motor power before it even

gets to the tool. The DVR

motor delivers constant

torque no matter what the

materials

SMART

DIGITAL

MOTOR

Smart sensors interacting in a

number of ways safety, intelligence

workshop assist, and performance

BUILT IN LASER

AND LIGHT

Quickly locate centre position with

the cross haired laser– laser stays

aligned even when table is moved or

tilted, and the DVR low/no vibration

performance means laser won’t move

in operation. Two powerful LED lights

to keep your project well lit.

CAST IRON

WOODWORKING

TABLE

Maximum flexibility and options for the

user. Solid Cast Iron for maximum

stability. Woodworking design to

provide maximum clamping and

accessory options

12 2/3″ x 12 2/3″ (320mm x

320mm). Tilting and

Rotating

ELECTRONIC

VARIABLE

SPEED

Versatile for a variety of projects – from

large deep hole drilling, mortising,

through to high speed sanding.

DISPLAY

Large, easy to read display with

imperial (fractions or decimal) or metric

provides choice with that the customer

prefers to use.

Easy to switch between modes.

FORWARD

AND REVERSE

For LH drill bits, gives the owner more

flexibility for projects.

ELECTRONIC

DEPTH STOP

Quickly and accurately automatically

stops to the precise depth you program

for your project.

2

123-0719-018

SELF-START

Enables a one-handed drilling

operation by automatically turning on

and off.

SPLIT MOTOR

(EXPOSED)

Easy access to motor. Much easier to

get serviced for both customers and

dealers.

BRAKING

E-stop

Drill Press Specifications

Drill Press Physical Specifications

Swing

16” (406.4mm)

Stroke

4.5” (114.3mm)

Spindle to Table

12 2/3” (321.73mm)

Spindle to Base

22 2/3” (575.73mm)

Drill Chuck

5/8” (2- 15.87mm)

Spindle Taper

2MT

Quill Diameter

60mm

Table Dimension

320 x 320mm

Base Dimension

468.7 x 270 x 55mm

Motor Specifications

Motor Type

DVR Direct Drive Smart Motor

Motor power output

1HP (0.75KW)

Maximum Speed

3000 RPM (6000 RPM when unlocked)

Input voltage

110V ~ 220V

Input Frequency

50/60 Hz

Input Current

15A (max)

3

123-0719-018

Package Contents

Item Number

Description

SKU

1

Viking Drill Press Body

8379001~8379008

2

Drill Press Base

8379025

3

Drill Press Table

8379022

4

Table Insert

8379024

5

Chuck Drift

8379067

6

Chuck Key

8379069

7

Drill Press Chuck

8379068

8

Chuck Arbor

8379019

9

Drill Press Handle (x3)

8379044

10

Table Arm Locking Handle (x2)

8379064

11

Table arm handle

8379028

12

Open end wrench

8379066

13

USB A-A cable

8379059

14

Chuck Guard Assembly

8379009

15

Chuck Key Holder

8379102

16

Allen Key Set

AK3, AK4, AK5

Note: The Chuck Guard Assembly is only included as standard for the EU model

4

123-0719-018

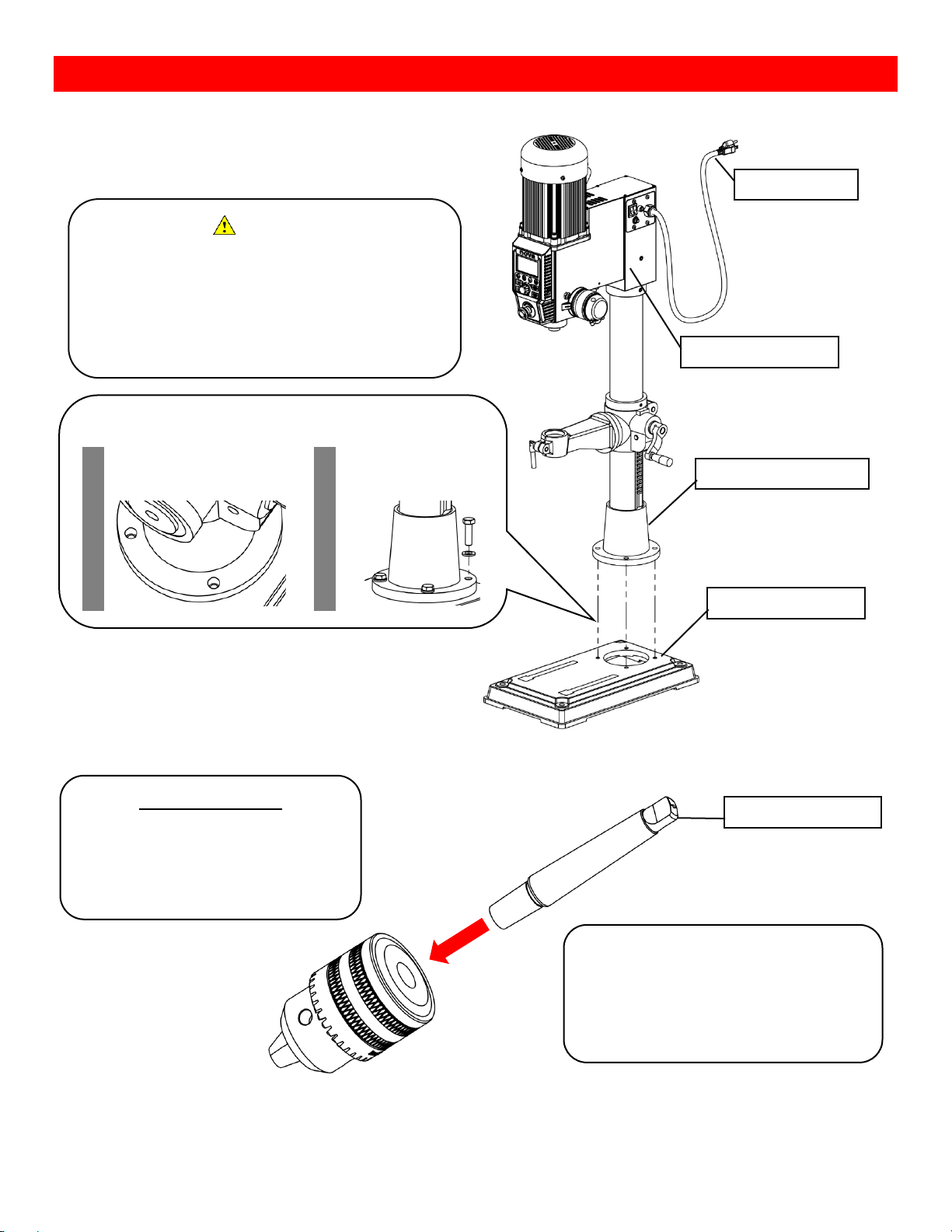

Assembling the Drill Press

Drill Press Body

The NOVA Viking drill press come with its headstock

preassembled with its main column.

Drill Chuck and Arbor

Caution

The headstock assembly can be

heavy and it is a subject to tip over.

It is recommended to have at

least 2 people when assembling

the drill press.

Drill press headstock

Power Cable

Drill press base

Attaching the drill press base

1. Align the thread holes

on the drill press base

and column base

2. Bolt the bases

together with the M10

bolt

Drill press column base

Before assembling

Wipe down all surfaces which makes

contact with other parts free of any dusts

or lubricants.

• Both long and short side of Arbor

• Tapered hole of the chuck

Arbor tongue

Insert the short end of the Arbor into the

drill chuck.

Secure the Arbor into the chuck by lightly

tapping the Arbor tongue with a rubber

mullet.

5

123-0719-018

Drill Press Handle

Chuck and Arbor Assembly Attachment

Screw drill press handles into the drill

press pinion shaft

Insert the arbor into the drill press

quill.

Note:

Make sure the arbor tongue is

facing the correct direction.

If the arbor is installed correctly,

the arbor should stay in the drill

press quill.

Give the chuck a few sharp taps

with a rubber mullet

Few sharp taps

with a rubber

mullet

6

123-0719-018

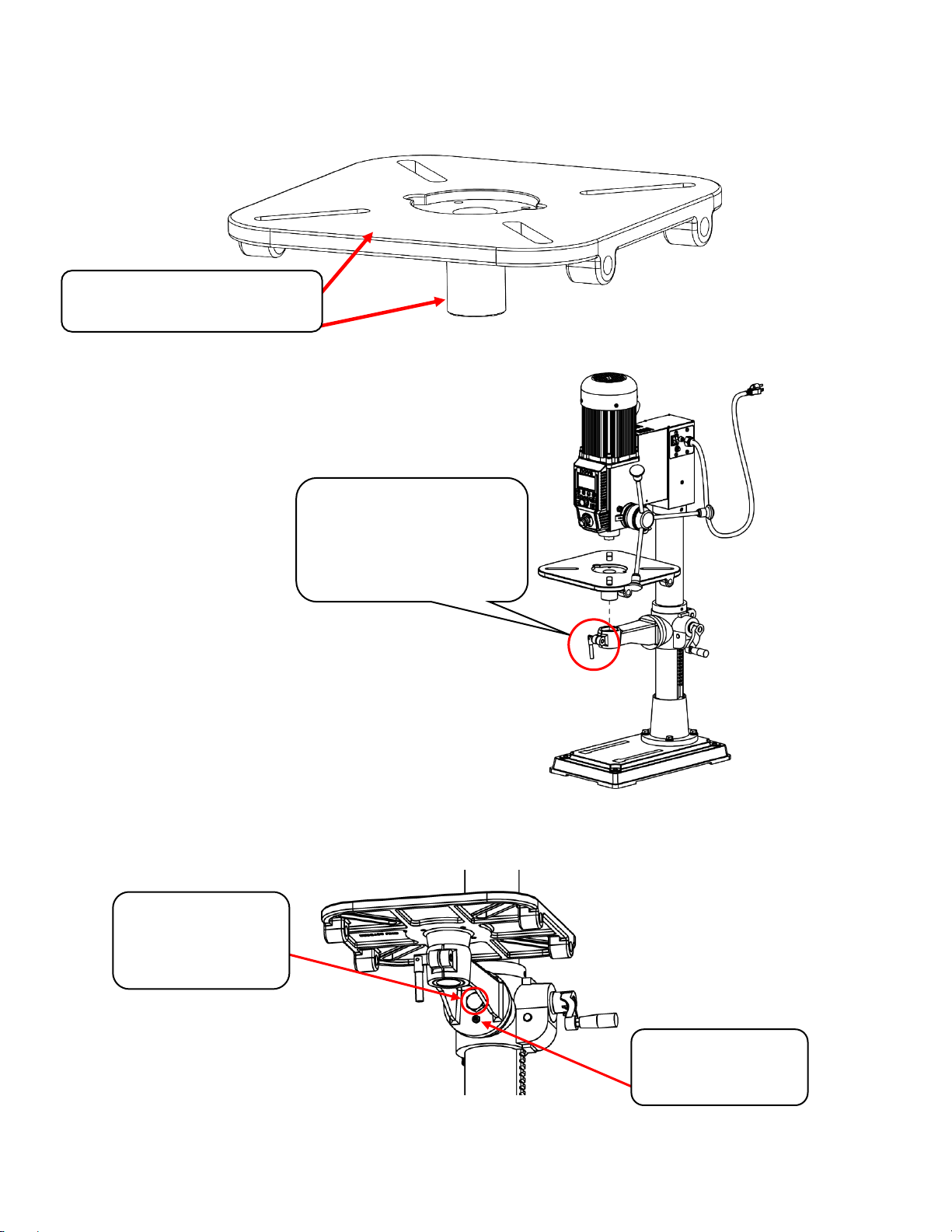

Attaching the Drill Press Table

Take the drill press table out from the packaging and inspect all surfaces for and defects (i.e. Stains, rusts,

fractures, scratches) on the machined cylindrical part of the table.

Insert the drill press table into the table arm.

Loosen the table arm lock if necessary.

Tilting the table

Loosen the main table bolt with a 24mm wrench and loosen the smaller grub screw with <Allen Key>.

Surfaces to check for cracks,

porosities and any defects

This handle is used to lock the

inserted table into place.

Loosen this handle if the table

cannot be inserted easily

1. Main hex bolt to

be loosened with

the included

24mm wrench

2. Grub screw to be

loosened with a

mm Allen key

7

123-0719-018

Lock the main table bolt first and then lock the secondary grub screw to secure the table position.

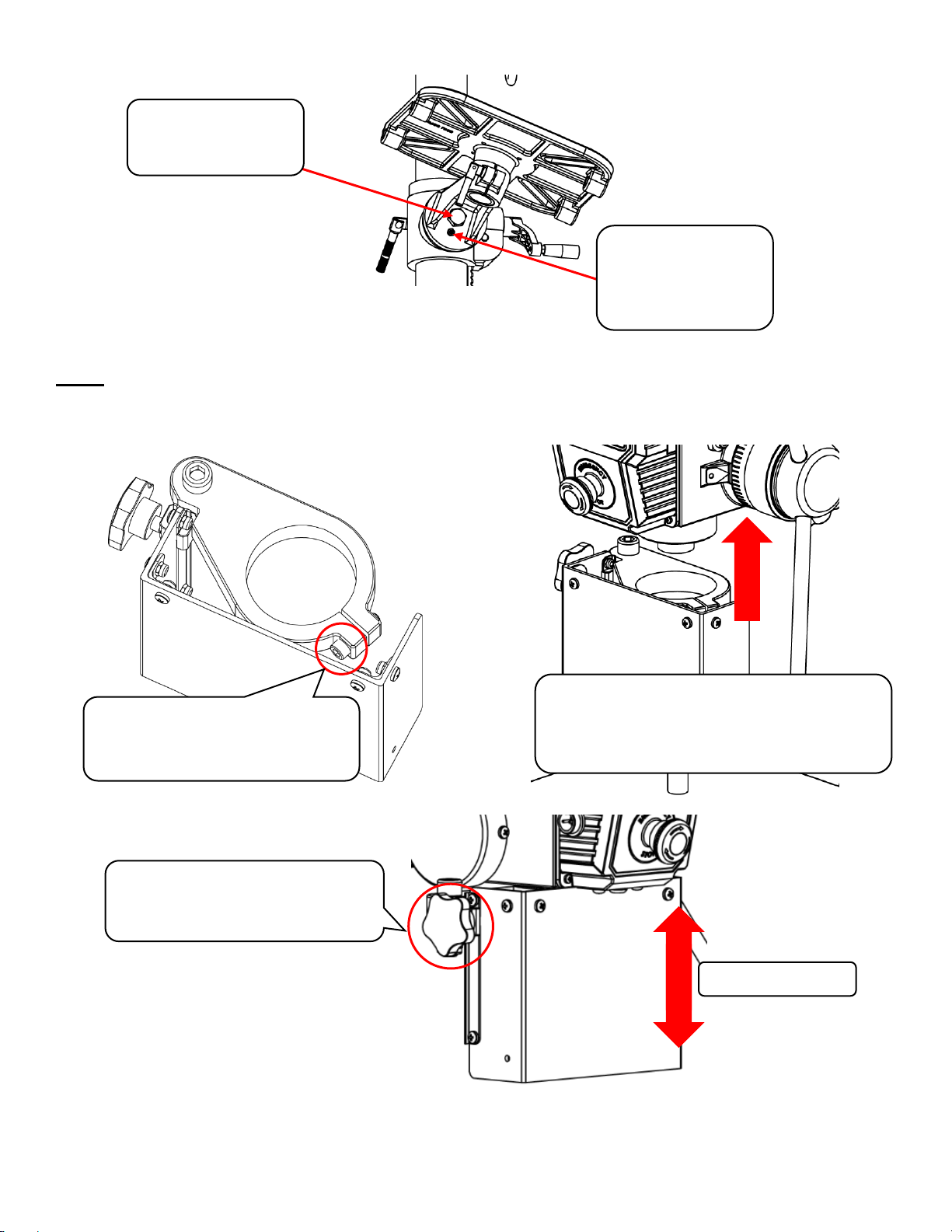

Attaching the Chuck Guard

Note: Only applicable to versions containing the chuck guards at default.

Take the chuck guard out from the packaging and peel off the protective sheet adhered to the guard. Inspect

for any defects on the guard.

Make sure to have the chuck guard covering the entire chuck.

Lock the main bolt

first after the table

angle has been set

Tighten the grub

screw on the bottom

after tightening the

main bolt.

Loosen the guard locking bolt

by hand or use a 5mm Allen

wrench.

Slide the guard over the drill press quill

and lock it into place by tightening the

guard locking bolt by using a 5mm Allen

wrench.

The vertical position of the

guard can be adjusted by

loosening the knob on the side.

Slide up or down

8

123-0719-018

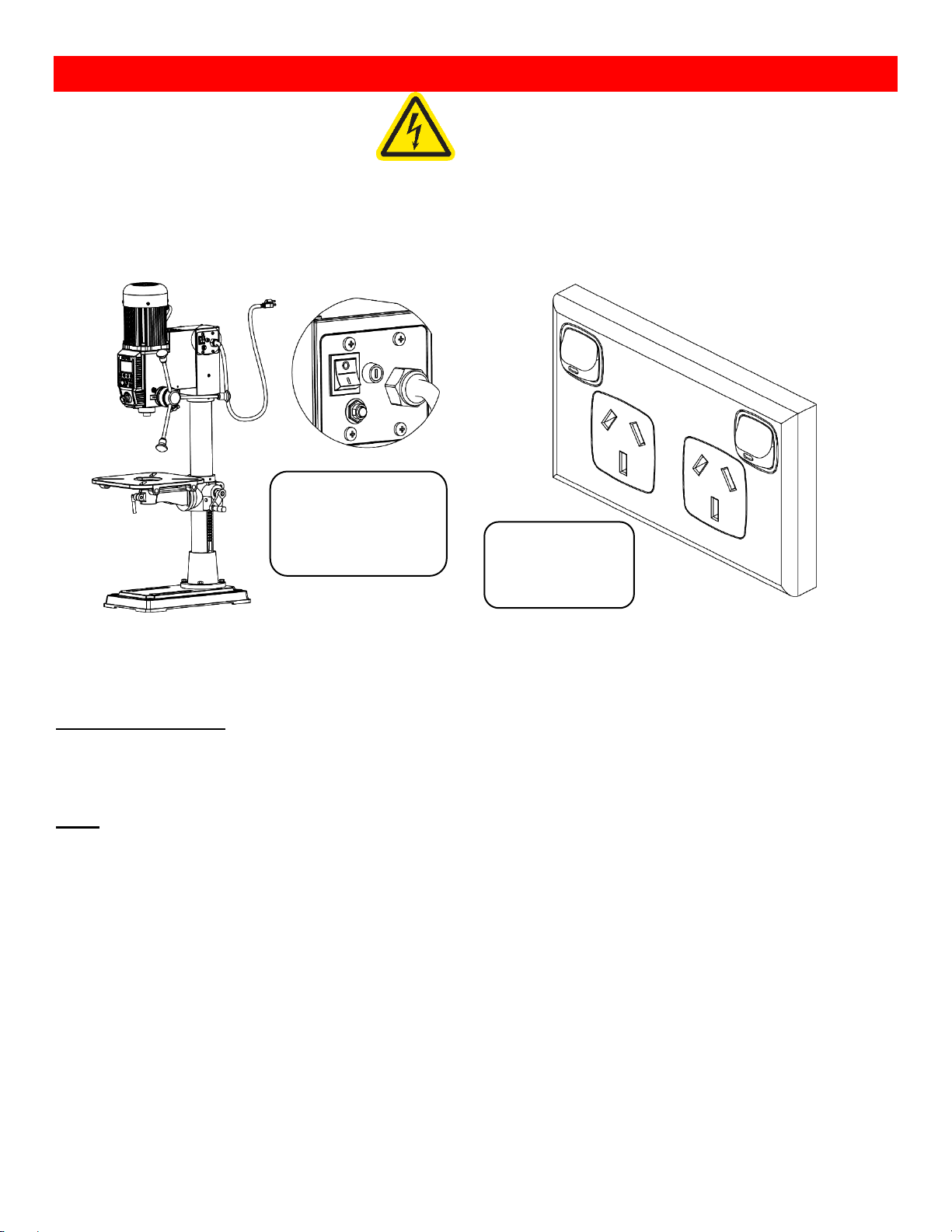

Connecting to Power

Warning!

Improper power connection may result in a risk of electrical hazard.

Make sure of the following before plugging the NOVA Viking drill press into the power source:

1. The main power switch is turned off

2. Power source is switched off

The power cord that is installed on the NOVA Viking drill press will have a three-prong plug which includes a

ground prong. The plug must be connected to a matching outlet that his properly installed and grounded in

accordance with local electrical codes.

For 115V outlet only:

A temporary adapter can be used to plug into a two-pole outlet if a three-prong outlet is unavailable in your

environment. The ground tab on the adapter must be connected to the screw on the outlet for proper

grounding. This adaptor should only be used until a qualified electrician can install a properly grounded outlet.

Note:

If an extension cable is required, make sure to check the following:

1. Extension cable gauge

2. Is the cable properly insulated?

If in any doubt, please contact your local electrician to inspect the cord according to the local electrical

standards before using it.

IMPORTANT:

A surge protection device must be used when using the drill press.

A surge protection device must be rated to at least 15A should be used in countries where 115V are used as a

standard. In countries where 240V is used, a surge protector must be rated to either 10A or 15A.

A surge protector with Joules rating of 3900J will be suitable for DVR motors.

Make sure the “O”

side of the rocker

switch is pressed in

Turn the power

outlet switch to

the “Off” position

9

123-0719-018

Ground Fault Interrupters (GFI)

For a GFI to be compatible with the DVR motor, it must have a leak current threshold rating of 30mA

(0.03A)

Note:

Normal household GFI will typically be rated at 5mA (0.005A) which may trigger during the operation of the

DVR motor. However, frequent tripping of the GFI will not cause any harm to the DVR motor or its control

electronics as it has a built-in protective circuit to prevent damage from frequent switching.

Setting up your drill press

Setting up your workshop environment

Your workshop should set up appropriately for you to effectively use the drill press. The workshop should be

setup with the following factors taken into consideration:

1. Drill press location

o Locate the NOVA Viking drill press close to a power source in an area with good amount of lighting.

Leave enough clearance when the drill press table is swivelled around. Other machines in the

workshop should not interfere with the movement/ operation of the drill press.

2. Lighting

o The work shop should have adequate lighting. There should be enough lighting around the drill

press not to cast shadows upon the workpiece. If possible, locate the drill press near a window. A

portable spotlight might be helpful.

3. Electrical

o The NOVA Viking drill press requires an appropriate power outlet nearby to power the motor. The

outlet wiring must meet the local electrical safety standards. If in any doubt, seek advice from an

electrician. The length of an extension cable should be reduced as must as possible.

4. Ventilation

o Workshop must have an adequate level of ventilation. The level of required ventilation depends on

the size of the workshop and the amount of work that is done within the workshop. The use of dust

collectors and filters will minimize your health risk.

Loading...

Loading...